International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

Sajith Francis1 , George K George2

1. Student, Department Of Civil Engineering, KMEA Engineering College, Edathala, Aluva, Kerala, India

2. Assistant Professor, Department Of Civil Engineering, KMEA Engineering College, Edathala, Aluva, Kerala, India

Abstract - This study presents a new method for constructinglightweightlaminatedwallsbycombiningColdFormedSteel(CFS)andRecycledPlasticLumber(RPL).The aim is to create a structural system that leverages CFS's strength and RPL's lightweight, sustainable properties, making it suitable for various applications, from architecturalprojectstomobilestructures.

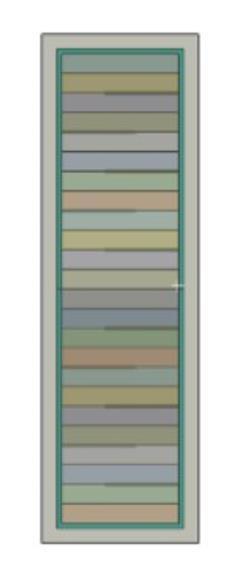

In this system, RPL blocks are strategically arranged and bonded with epoxy, then externally reinforced with CFS sheets to enhance structural integrity. Additionally, CFS componentsareincorporatedinternallyinvariouspatterns tooptimizeperformance.

Theresearchfocusesoninvestigatingtheaxialcompression and bending performance of three wall configurations: externally strengthened, internally strengthened, and a combination of both. The methodology includes a comprehensiveliteraturereviewtoestablishafoundationof existing knowledge. Following this, model validation processes are conducted to ensure the accuracy of computational models developed using ANSYS software. Thesemodelssimulatethebehaviorofthethreewalltypes underdifferentloadingconditions.

Theresultsfromthesesimulationsarethoroughlyanalyzed to identify the most effective configurations in terms of structural performance. This research advances the understanding of how CFS and RPL can be combined to create lightweight yet strong laminated walls. It aims to provide practical guidance for implementing these innovativestructuralsolutionsinreal-worldsettings.

Key Words: Cold-Formed Steel (CFS), Recycled Plastic Lumber(RPL),Axialloading

1. INTRODUCTION ON LIGHTWEIGHT LAMINATED WALL CONCEPT

Alightweightlaminatedwalltypicallyincorporatesmultiple layersofmaterialsstrategicallybondedtogethertooptimize strength and durability while minimizing overall weight. Traditionally,materialssuchasplywood,foam,orcomposite panels are used in such systems to achieve a sturdy yet manageable structure. The integration of CFS and RPL introduces a novel approach by combining the benefits of steelandrecycledplastics

Cold-formedsteelismanufacturedbyshapingsheetsofsteel atroomtemperaturethroughprocesseslikeroll-formingor pressing. Despite being lighter and more cost-effective comparedtohot-rolledsteel,CFSmaintainsrobustnessand dimensional precision suitable for various construction applications.Inthisintegratedsystem,CFScomponentssuch asstuds,joists,andpanelsplayapivotalroleinreinforcing thelaminatedwallstructure.

1.2 Recycled Plastic Lumbers (RPL):

recycled plastic lumber is an environmentally sustainable alternative to traditional wood materials, composed of recycledplasticsthatcontributetoreducingenvironmental pollutionfromplasticwaste.rplexhibitsversatilityinboth nonstructuralandstructuralapplications,offeringdurability and resilience while promoting sustainable construction practices

1.3 Integration and advantages of the laminated wall system

EnhancedStructuralIntegritystrategicallyisachievedby placingCFScomponentswithinthelaminatedstructure both externally laminating with CFS sheets and internally embedding CFS between RPL blocks the wall system achievesenhancedload-bearingcapacityandresistanceto lateralforces.

Environmental Sustainability by Utilizing RPL reduces reliance on virgin materials and minimizes the environmental footprint associated with traditional construction materials. This aligns with global efforts towards sustainable building practices and contributes to LEED (Leadership in Energy and Environmental Design) certificationobjectives.

Thisprovidesaconciseoverviewoftheexistingliteratureon the structural performance of novel CFS-integrated lightweightlaminatedwalls.Thereviewprimarilyexamines currentdevelopmentsandfindingsinthefield,summarizing themintothefollowingmaincategories.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

2.1 Jing Zhong Tong, Chao Qun Yu, Lei Zhang 2021

Thepaperfocusesoninvestigatingthesectionalstrengthof PDSCWs under combined axial and out of plane bending loads It presents a nonlinear finite element (model to simulatethisbehaviour,validatedthroughcomparisonwith independent test results. A numerical parametric study exploresvariousparameters,includingfaceplatethickness, wall depth, faceplate steel strength, infilled concrete strength,andfaceplatetypeInteractioncurves(NMcurves) are derived from extensive modelling with different eccentricities.Additionally,thepaperintroducesasectional analysis model considering the local buckling effect of faceplates to theoretically evaluate the sectional axial and bendingstrengthofPDSCWs.BycomparingthederivedNM interactioncurvewithFEresults,thestudyconcludesthat theproposeddesignformulaseffectivelypredicttheultimate resistance of PDSCWs under combined axial and bending effects.Theseformulasoffervaluableinsightsforpractical designapplications.

2.2 Juan P. Herrera, Daniel Bedoya Ruiz, Jorge

E. Hurtado 2018

This paper outlines a study focused on the utilization of Recycled Plastic Lumber as a material for constructing structural walls in seismic resistant housing systems. The primaryobjectiveistoaddressenvironmentalpollutionby repurposingplasticwastewhilesimultaneouslyaddressing housingdeficiencies,

particularlyinseismicproneregions.Thestudyemploysa comprehensiveexperimentalapproach,testingfullscaleRPL wallsundercyclingloadingconditionstoevaluatevarious structural parameters critical for seismic design and assessment.Theseparametersincludestrength,hysteretic behavior,ductility,energydissipation,equivalentdamping, andcharacteristicfailuremodesofRPLwalls.

To study the effect of axial compression behavior and the bendingperformanceof:

LaminatedwallstrengthenedexternallyusingCFSsheetsin various thickness and finding the appropriate thickness required.

LaminatedwallstrengthenedusingCFSsheetsindifferent typecasingandfindingappropriatecasing.

LaminatedwallstrengthenedusingCFSsheetsindifferent orientationofRPL

TheANSYSWorkbenchplatformwasemployedtoanalyze thewallsystem.TheDesignModelerplatformwithinANSYS Workbenchwasusedformodelingthewallsystem,Element usedformodellingisSOLID186andoveralldimensionsof wall1000x600asspecifiedinbasejournalsistaken(1)and (2).Additionally,theengineeringpropertiesofCold-Formed SteelandRecycledPlasticLumberwerederivedfromthese basejournals,aslistedinthetablebelow.

4.1 Material Properties of Plastic lumber block

Properties Values

Young’sModulus(MPa) 1102.5

Poisson’sratio 0.3

Density(Kg/m3) 872

Bulkmodulus(Pa) 9.1875E+08

Shearmodulus(Pa) 4.2404E+08

Yeildstrength(MPa) 19.32

4.2 Material Properties of Cold form steel

Properties

Values

Young’sModulus(MPa) 2E+05

Poisson’sratio 0.3

Density(Kg/m3) 7850

Bulkmodulus(Pa) 1.6667E+11

Shearmodulus(Pa) 7.6923E+08

Yeildstrength(MPa) 390

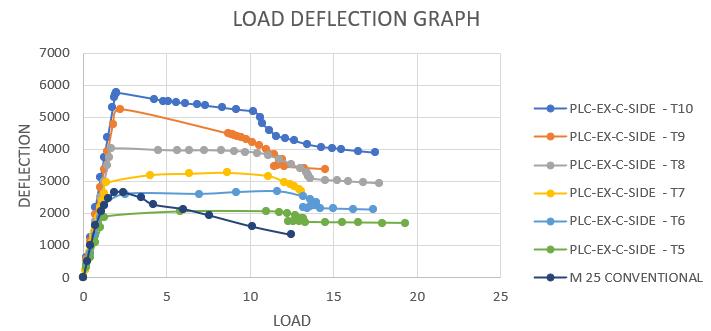

This study has three objectives. The first objective is to comparemodelswithaconventionalwallsystemmadeof M25 concrete, examining the thickness of steel casing needed for equivalent load-bearing capacity. Six versions withthicknessesrangingfrom10mmto5mmweremodeled todeterminetheappropriatethickness.

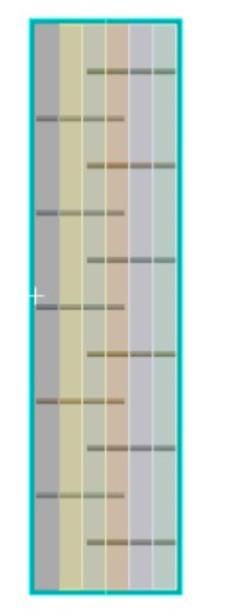

ThesecondobjectiveinvolvesanalyzingvarioustypesofCFS sheet casings using the thickness determined in the first objective.Eightvariationsweremodeled,andtheonewith the highest load-bearing capacity was selected for further study.Thecasingwasarrangedindifferentways:externalC casing from the front and side, internal back-to-back C casing, and internal dual C casing, with plastic lumbers placedbothbondedandlayered.

The final objective is to change the orientation of the recycled plastic lumber blocks to find the model with the highestload-bearingcapacity.Usingthethicknessandcasing selected from the previous objectives, the blocks were arrangedlongitudinally,transversely,andinbothdirections combined,placedaslayeredandbonded,toanalyzewhich modelperformsbest

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

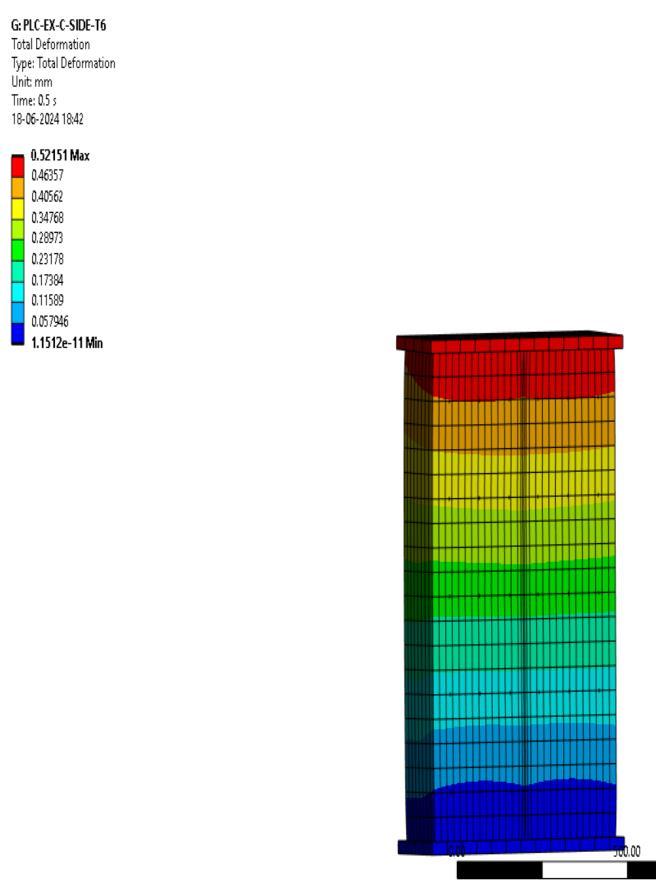

5.1 Analysis Of PLB Wall Exterior C encasement in Side by Varying Thickness

Modelswiththicknessofcasingfrom5-10mmarecreated usingANSYS

5.1.1 Finite Element Meshing

Meshingwasperformedtodividethemodelintoelements and nodes. Hexahedral meshing was applied using ANSYS tools.Theresultswerecalculatedbynumericallysolvingthe relevantgoverningequationsateachnodeofthemesh.The elementtypeSOLID185wasused,witheachelementsized at25mm.

5.1.2 Results for PLB wall exterior – C casing

Thedifferentmodelswithdifferentthicknessareanalyzed and we get the matching result corresponding to the conventionalsystemin6mmthickness.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

5:Load-Deflectioncurve

3

4

7

Table-1:AnalysisresultsofPLBwallexteriorCcasing

5.2 .ANALYSIS OF PLB WALL WITH VARIOUS TYPE OF CASING

PLBwallwithlayeredlumberstypecasing

a) ExteriorCside

b) ExteriorCfront

c) Back-to-backC

d) DualCback

PLBwallwithlayeredlumberstypecasing

a) BoundedPLBExteriorCfront

b) BoundedPLBExteriorCside

c) BoundedPLBback-to-backC

d) BoundedPLBDualCback

6:Load-Deflectioncurve-ofPLBwallwithvarious typeofcasing

Table2AnalysisresultsofPLBwallswithdifferentcasing

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

5.3 ANALYSIS OF PLB WALL WITH VARIOUS TYPE OF ORIENTATION

a) PLBwallbondtransverseexteriorCside

b) PLBwallpartialbondtransverseexterior-C-side

c) PLBwallbondtransverseex-C

d) PLBwallpartialtransverse-ex-C

wall Bounded transverse exterior c side

DifferentmodelswerepreparedandanalyzedusingANSYS, yieldingthefollowingconclusions:

Forthefirstobjective,plasticlumberwallswithexteriorside Ccasinginvariousthicknesseswereanalyzed.Itwasfound that a 6mm casing thickness approximately matched the load-bearingcapacityoftheconventionalM30model.

Using the determined thickness of 6mm for subsequent objectives,variousPLBwallsystemswithdifferentcasings were analyzed. The maximum load-bearing capacity was observedinthebondedPLBwallwithexteriorsideCcasing.

Further analysis of different orientations of the lumber blocks(bothpartiallyandfullybonded)indicatedthatthe bondedtransversePLBwithexteriorsideCcasinghadthe highestload-bearingcapacity.

Thus,thebondedtransversePLBwithexteriorsideCcasing can be used as an alternative to the conventional wall system.

[1] Jing-Zhong Tong, Chao-Qun Yu, Lei Zhang.,(2021) Sectionalstrengthanddesignofdouble-skincomposite wallswithre-entrantprofiledfaceplate”.

[2] JuanP.Herrera,DanielBedoya-Ruiz,JorgeE.Hurtado., (2018) “Seismic behavior of recycled plastic lumber walls:Anexperimentalandanalyticalresearch”

[3] MahaM.S.Ridha.,DandaLi.,Medina,G.CharlesClifton., Xing Ma., (2019) Structural Behavior of Composite Panels Made of Lightly Profiled Steel Skins and Lightweight Concrete under Concentric and Eccentric Loads.

[4] YoujunQi.,HaiFang.,HuiyuanShi.,WeiqingLiu.,YuBai., (2017)BendingperformanceofGFRP-woodsandwich beams with lattice-web reinforcement in flatwise and sidewisedirections.

[5] Yashida Nadir., Praveen Nagarajan., (2014 ) The behaviorofhorizontallygluedlaminatedbeamsusing rubberwood

[6] FernandaA.dosSantos.,LeonardoB.Canto.,AnaLúcia N.daSilva.,LeilaLeaYuanVisconte.,ElenB.A.Vasques Pacheco.,(2018 )Processing and Properties of Plastic Lumber.

[7] Jing-Zhong Tong., Chao-Qun Yu., Lei Zhang., (2020) “Sectionalstrengthanddesignofdouble-skincomposite wallswithre-entrantprofiledfaceplates”.

Table2AnalysisresultsofPLBwallswallwithvarious typeoforientation

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 07 | July 2024 www.irjet.net p-ISSN: 2395-0072

[8] JohanVessby.,BertilEnquist.,HansPetersson.,Tomas Alsmarker., (2009) Experimental study of crosslaminatedtimberwallpanels.

[9] 9. G.J Hancock., J Rondal., J.M Davies., (2016) “Coldformedsteelstructures”

[10] C. Kaleeswaran ., R. Saravanakumar ., D. Vivek ., K.S. Elango ., R. Gopi ., D. Balaji .,( 2021) A study on cold formedsteelcompressionmember.