International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

Made Suarda1 , I Putu Widiarta2

1Asst. Professor, Mechanical Engineering Study Program, Udayana University, Badung, Bali, Indonesia

2Asst. Professor, Mechanical Engineering Study Program, Udayana University, Badung, Bali, Indonesia

Abstract - Vortexturbinesarewidelydevelopedbecauseof theiradvantagesinbeingabletobeappliedtolowflowheads and their simpler construction, making them suitable for application in mountainous areas. The efficiency of vortex turbines is still relatively low, thus triggering many innovations to be carried out to improve the performance of vortex turbines by conducting research both experimentally andthroughCFDsimulations.Inlowpressurevortexturbines, it is used to create an air core so that a vortex flow can be created. On the other hand, a low-pressure area that is too highintheturbinerunnerareacausestheconversionofvortex flowenergyandturbinetorquetobelessthanoptimal,soitis necessarytoaddaturbineflowcontrolmechanism,namelya draft tube. Adding a divergent draft tube model to the basin outletchannelresultsanincreaseinthepressurevaluearound theturbinerunnerandenhancestheturbinetorqueby22.7%.

Key Words: Vortex turbine, draft tube, flow phenomena, torque,vortexturbine

Energy is a crucial factor in the sustainability and advancement of human civilization. The primary energy sourceisfossilfuels.Thedownsideoffossilfuelsisthatthey arenotenvironmentallyfriendlyandarenon-renewable[1]. These issues have prompted a shift towards more environmentally friendly and renewable energy sources. Severalrenewableenergysources,suchasair,solarenergy, and water, are being utilized as more environmentally friendlyalternativesforgeneratingelectricity.Waterenergy is used to drive turbines, which in turn drive alternators, therebygeneratingelectricalenergy[2].

Waterturbinescangenerallybeclassifiedintotwotypesin termsofflowenergyconversion,namelyimpulseturbines and reaction turbines. Impulse turbines are turbines that utilize flow velocity energy to generate momentum on turbine blades while reaction turbines are turbines that utilize changes in working fluid flow pressure [3], [4]. Nowadays,vortexturbinesarewidelydevelopedbecauseof theiradvantagesthatcanbeappliedtolowflowheadsand simplerconstructionsothattheyaresuitableforapplication inmountainousareas[5].Thewayvortexturbinesworkis byutilizingthevortexflowcreatedintheturbinebasinto drive the turbine runner [6]. The efficiency of vortex turbines is still relatively low so that it triggers many

innovationstoimprovetheperformanceofvortexturbines, oneofwhichisthetorqueontherunner.Effortstoimprove the performance of vortex turbines are carried out both experimentally and through CFD (Computational Fluid Dynamic)simulations.Someofthemainaspectsthatarethe object of research are making modifications to the main components of the turbine such as the notch angle of the turbinechannel,theheightandshapeofthebasinandthe profileoftheturbinebladesandthevortexturbinebasin[7].

Research that has been conducted to improve the performance of vortex turbines such as conical turbine basins produces higher turbine efficiency compared to cylindrical basin models [8]. Increasing the value of the vortex turbine notch angle can increase the flow velocity fromthechannelmovingtowardstheturbinebasinsothat the resulting vortex becomes more optimal [9, 10]. The runner immersion position affects turbine performance whereoptimalvortexturbineefficiencycanbeobtainedata runner immersion position of 65-75% of the basin height [11]. The addition of a booster runner can increase the power of the vortex turbine by 20.4% this is because the vortexenergyatthebottomofthebasinisreusedtorotate theboosterrunner[12].Ontheotherhand,therotationof the turbine runner affects turbine performance where optimalefficiencyisobtainedataturbinerotationof90rpm [13].ResearchconductedbyKim etal.(2021)addedasmalldrafttubeconfigurationatthevortexturbineoutletchannel whichhasaneffectonincreasingrunnertorqueduetothe low-pressureareabeingmaintainedwithadrafttubesothat itcanincreasethepressuredropintheturbinerunnerarea [14]. The function of the draft tube is to convert the flow velocity energy in the outlet channel into flow pressure energyandcancontroltheoutletmassflow.Inlowpressure vortexturbinesareusedtocreateanaircoresothatavortex flowcanbecreated,ontheotherhand,alow-pressurearea that is too high in the turbine runner area causes the conversionofvortexflowenergyandturbinetorquetobe less than optimal because the air core space is too high causing the runner area affected by the vortex flow to be reduced[15].Thus,aflowcontrolmechanismisneededto improve turbine performance, namely the vortex turbine torque.

Basedontheliteraturereviewconducted,furtherresearchis neededontheadditionofadrafttubewithadivergentdraft tubeconfigurationtothevortexturbineoutlet.Thepurpose

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

ofthisstudyistoanalysetheeffectoftheadditionofadraft tubeappliedtothevortexturbinebasinoutletonthevortex turbine flow and torque phenomena. The study was conductedusingCFDsimulationusingAnsysFluentsoftware andtestedatthesamemassflow.

2.1.

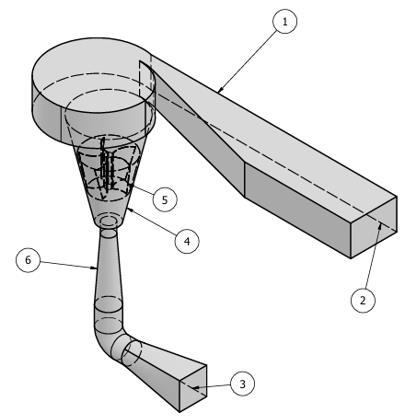

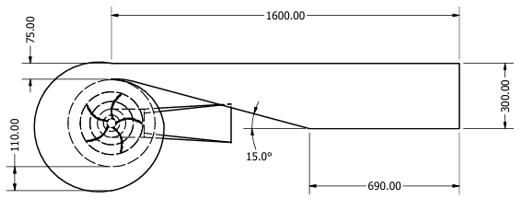

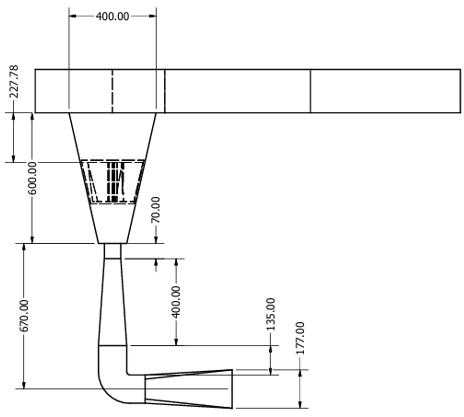

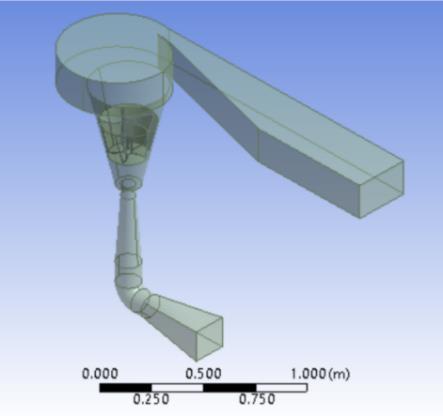

Thegeometryofthestudywascarriedoutbyaddingadraft tubetothevortexturbineoutletchannelasshowninFigure 1. The main components ofthe vortex turbine consist ofa channel(1),Inletofthechannel(2),outletofdrafttube(3), basin(4),runner(5)anddrafttube(6).Thevortexturbine worksbychannelingtheflowcapacityflowinginthechannel to the turbine basin. In the turbine basin, the flow is convertedintoavortexflowandusedtodrivetherunnerso that the turbine runner can produce torque and turbine outputpower.

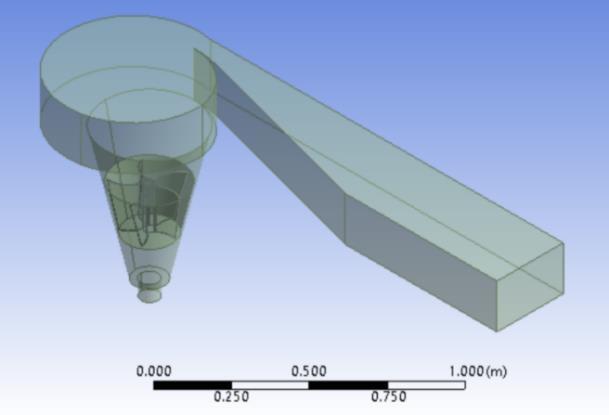

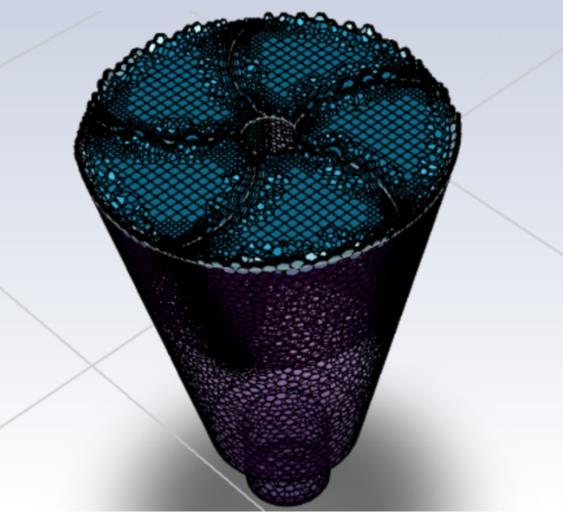

CFDsimulationsgenerallyconsistofthreemainprocesses: pre-processing,solving,andpost-processing.Pre-processing is the stage of creating a rotating fluid domain and a stationaryfluiddomain,aswellasperformingthemeshing process.Themeshtypeusedisthepoly-hexcoretype,which is a combination of a poly and a hexcore mesh. The fluid domainandmeshareshowninFigures2and3.Themesh resultsstatisticsareshowninTable1.

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

Table -1: MeshStatistics

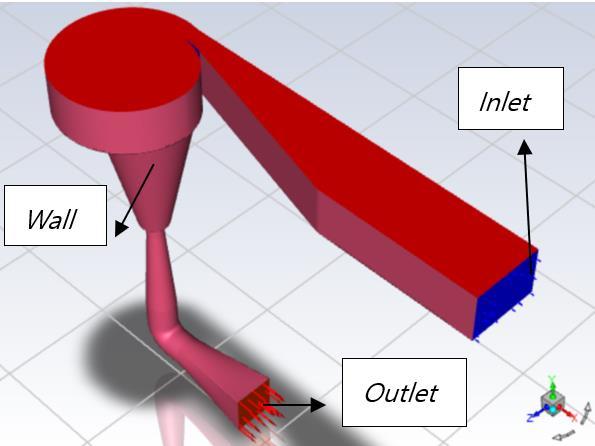

The solver process is the process of determining the simulationboundaryconditionssuchaswall,inlet,andoutlet.

ThesimulationboundaryconditionsareshowninFigure4. Wheretheinletconditionissettomassflowinlet,thewallis set to non-slip condition, and the outlet is pressure outlet. Theoutletpressureinthetestwithoutadrafttubeissetto0 atm(gaugepressure),whileintheoutletconditionwiththe additionofadrafttube,itissetto2970Pa(gaugepressure), wherethisconditionindicatesasubmergeddrafttube(tail race).TheturbulencemodelusedintheCFDsimulationiskomegaSSTwiththeSIMPLE(SemiImplicitPressureLinked Equation) scheme solver, where this solver connects the pressure and velocity values to obtain the mass flow conservationvalue.

3. RESULTS AND DISCUSSION

The residual results of the CFD simulation, namely momentumineachdirectionx,yandz,reachedaresidual valueofe-05,whilekandomegaandcontinuitywereableto reacharesidualvalueofe-04.

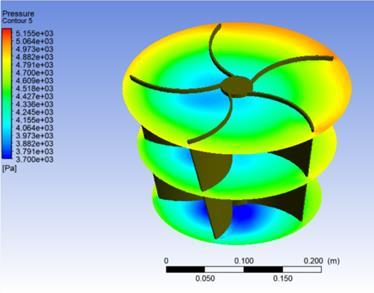

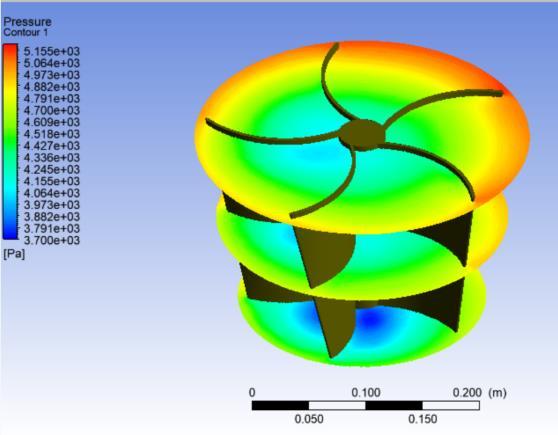

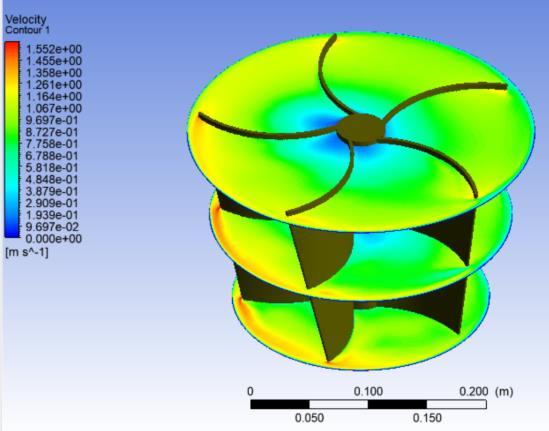

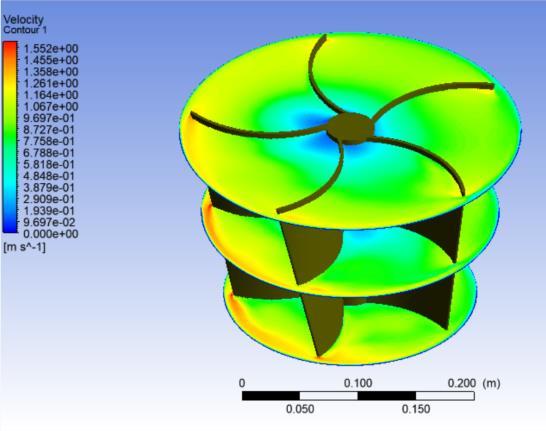

Thefluidpressureandvelocitycontoursaroundtherunner weretakenatthemiddle,top,andbottompositionsofthe runner.Figure5showsthedistributionofpressurecontour results and Figure 6 shows the distribution of velocity contoursaroundtheturbinerunner.Theadditionofadraft tube to the vortex turbine basin outlet channel causes an increase in the flow pressure value around the turbine runner. The increase in flow pressure caused by the lowpressurearea at the basin outletcan be minimized bythe draft tube which causes a change in flow pressure in the turbine basin where the kinetic energy of the flow is converted back into pressure energy by the shape of the draft tube configuration, namely divergent. On the other hand,theadditionofadrafttubecausesthedistributionof lowpressurearoundtherunnerwithoutadrafttubetobe reducedsothattheturbinerunnerismoreevenlyexposed to the vortex flow so that the resulting torque can be increased.

Fig -5:Pressurecontours:(a)withoutdrafttube,(b) equippedwithdrafttube

The flow velocity distribution around the turbine runner tendstoremainunchangedwiththeadditionofadrafttube tothevortexturbinebasinoutletchannelasshowninFigure 6.Thisisbecausetheturbineissimulatedatthesamerunner

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

speedof90rpm,therefore,therunnerrotationiscontrolled and maintained constant. Thus, the velocity distribution aroundtherunnerhasatendencytohavethesamevelocity valueinvariationswithandwithouttheadditionofadraft tube.

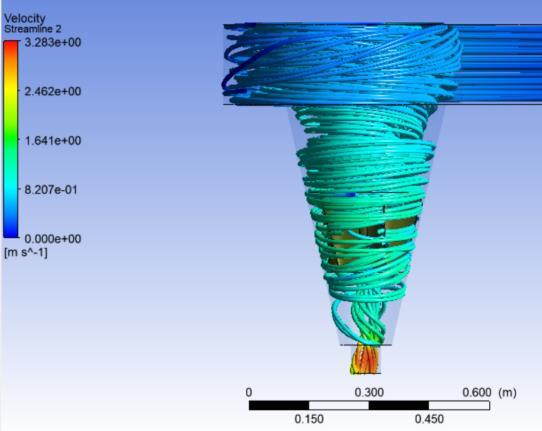

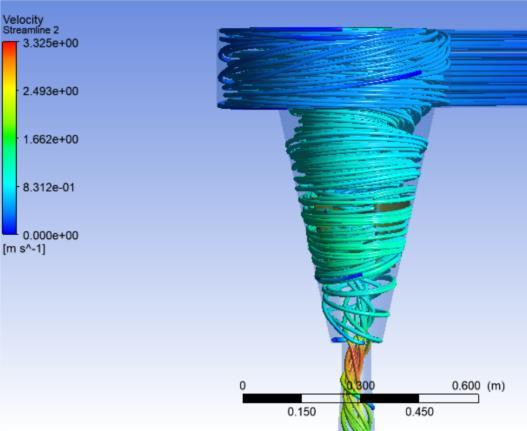

Theflowstreamlinewascreatedwith100trackingpointsto obtaintheflowpath.Figure7showstheflowstreamlineina vortexturbinewithandwithouttheadditionofadrafttube. Theadditionofadrafttubetotheoutletbasinchannelcauses achangeinthepathphenomenonofthevortexflowinthe turbinebasin.Thevortexflowafterhittingthebladesonthe turbine without the addition of a draft tube tends to be directedinanaxialdirectionsothattheflowfallsfreelyand exitstowardstheturbineoutletchannel.Thisphenomenon causestheflowstreamlinetobeunevenlydistributedover thevortexturbinerunnerareaandcanaffecttheresulting torque gain. On the other hand, adding a draft tube to the outletbasinchannelcanchangetheflowphenomenonfrom axial flow near the outlet channel to tangential flow. This phenomenoncanbeobservedfromtheflowstreamline.The changeinflowphenomenonduetotheeffectoftheaddition ofadrafttubecausestheflowstreamlinetobemoreevenly

distributedoverthevortexturbinerunnerareasothatthe flowareathathitstherunnercanbeoptimized.

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page787

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

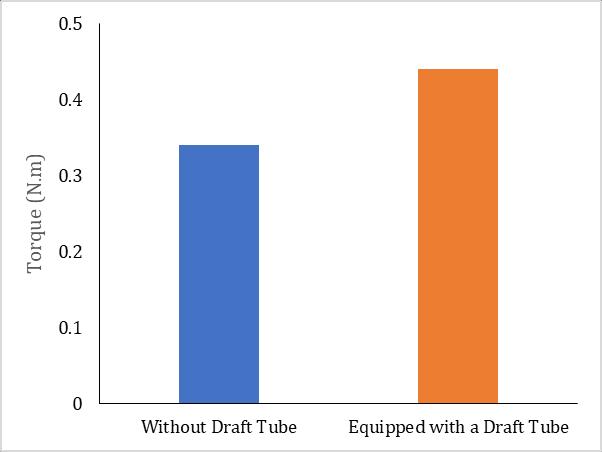

Figure 8 shows the torque of a vortex turbine with and withouttheadditionofadrafttubefromtheCFDsimulation results. The simulation results show that a vortex turbine withtheadditionofadrafttubeattheoutletchannelcauses an increase in the torque value on the turbine runner, a similarfindingwasalsofoundinresearchconductedbyKim etal. (2021).InresearchconductedbyKim etal. (2021)the additionofasmalldrafttubecauseda3%increaseintorque [14].Theincreaseintorquevalueiscausedbyanincreasein the flow pressure value and a more even flow streamline aroundtheturbinerunnerasshowninFigures5(b)and7 (b). A higher flow pressure value produces a higher force whenithitstheturbinebladearea.Thegreatertheforcethat canbegeneratedwiththesamerunnerdiameter,theturbine torque can be increased where the turbine torque is the multiplicationoftheforceandtherunnerradius.Meanwhile, amoreevenstreamlinecausesthewettedareaontherunner tobemoreevenlydistributed.

3. CONCLUSIONS

Theadditionofadrafttubetothevortexturbinebasinoutlet with a divergent configuration can increase the flow pressure around the vortex turbine runner area. The addition of a draft tube also causes the flow streamlines aroundtheturbinerunnertooccurmoreevenlycompared to without the addition of a draft tube. The addition of a divergent draft tube increases runner torque by 22.7%. Suggestions for future research is examining variations of thedrafttubedimensionalconfigurationstoachieveoptimal performance.

The authors would like to express their gratitude to the Mechanical Engineering Study Program, Faculty of Engineering,UdayanaUniversity.

[1] Perera,F.,&Nadeau,K.(2022).ClimateChange,FossilFuel Pollution, and Children’s Health. New England Journal of Medicine, 386(24), 2303–2314. https://doi.org/10.1056/nejmra2117706

[2] Ng,S.K.,Nakayama,A.,&Ng,W.X.(2024).Applicationof Smoothed Particle Hydrodynamics Method for the Analysisofthe FlowPast Vertical Vortex Turbine ofa Micro Hydropower. KSCE Journal of Civil Engineering, 28(3), 1132–1139. https://doi.org/10.1007/s12205024-1732-x

[3] Peng, N., Wang, E., & Wang, W. (2023). Design and analysis of a 1.5 kW single-stage partial-admission impulseturbineforlow-gradeenergyutilization. Energy, 268.https://doi.org/10.1016/j.energy.2023.126631

[4] Karre, R. K., Srinivas, K., Mannan, K., Prashanth, B., & Prasad, C. R. (2022). A review on hydro power plants and turbines. AIP Conference Proceedings, 2418. https://doi.org/10.1063/5.0081709

[5] Dhakal, S., Timilsina, A. B., Dhakal, R., Timilsina, A. B., Dhakal,R.,Fuyal,D.,RatnaBajracharya,T.,&Pandit,H. P. (2014). Effect of Dominant Parameters for Conical Basin: Gravitational Water Vortex Power Plant. Proceeding of IOE Graduate Conference https://doi.org/10.13140/RG.2.1.1455.7843

[6] Rahman,M.M.,Tan,J.H.,Fadzlita,M.T.,&WanKhairul Muzammil,A.R.(2017).AReviewontheDevelopment ofGravitationalWaterVortexPowerPlantasAlternative Renewable Energy Resources. IOP Conference Series: Materials Science and Engineering, 217(1). https://doi.org/10.1088/1757-899X/217/1/012007

[7] Maika,N.,Lin,W.,&Khatamifar,M.(2023).AReviewof GravitationalWaterVortexHydroTurbineSystemsfor HydropowerGeneration. In Energies (Vol. 16, Issue 14). Multidisciplinary Digital Publishing Institute (MDPI) https://doi.org/10.3390/en16145394

[8] Aziz, M. Q. A., Idris, J., & Abdullah, M. F. (2022). Simulation Of the Conical Gravitational Water Vortex Turbine (GWVT) Design in Producing Optimum Force forEnergyProduction. JournalofAdvanced Research in Fluid Mechanics and Thermal Sciences, 89(2), 77–91. https://doi.org/10.37934/arfmts.89.2.99113

[9] Bajracharya, T.R., Timilsina, A. B., Ghimire, R. M., & Timilsina, A. B. (2018). Design And Performance Analysis of Water Vortex Powerplant In Context Of Nepal Comparative Study of Gaseous and Particulate Emissions from Traditional and Modified Charcoal ProductionKilnsViewProjectComputationalmodeling (atomistic, nanoscale and mesoscale simulations) of materials. View project DESIGN AND PERFORMANCE ANALYSIS OF WATER VORTEX POWERPLANT IN CONTEXTOFNEPAL. In 20 th International Seminar on Hydropower Plants. https://www.researchgate.net/publication/330083382

[10] Sukadana,I.G.K.,Suarda,M.,Widiarta,IP.,&Danus,I. (2024).CFD(ComputationalFluidDynamics)Simulation of Hydrodynamic Vortex Turbine Performance: InfluenceofNotchAngleVariationonFlowPatternsand Efficiency. NaturalSciencesEngineeringandTechnology Journal, 4(2), 336–351. https://doi.org/10.37275/nasetjournal.v4i2.56

[11] Bajracharya,T.R,Timilsina,A.B.,Niraula,R.,Timilsina, A. B., Niraula, R., Rasaily, B., Lama, M., & Pathak, P. (2022). Effect Of Stay Vanes in Gravitational Water VortexPowerPlantwithSpiralBasin.21stInternational SeminaronHydropowerPlants-Hydropowerforfuture

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

generations, 09-11 November, Vienna, Austria. https://www.researchgate.net/publication/370301646

[12] Dahal, N., Shrestha, R. K., Sherchan, S., Milapati, S., Shakya,S.R.,&Jha,A.K.(2020).PerformanceAnalysis of Booster based Gravitational Water Vortex Power Plant.JournaloftheInstituteofEngineering,15(3),90–96.https://doi.org/10.3126/jie.v15i3.32026

[13] Gusti Muttaqin, I., Sucipta, M., & Suarda, M. (2022). Computational Fluid Dynamic Simulation on Vortex Turbine Model with Runner Rotation Speed Variation (“Simulasi Computational Fluid Dynamic Pada Model Turbin Vortex Variasi Kecepatan Rotasi Runner”). Sibatik Journal Jurnal Ilmiah Bidang Sosial, Ekonomi, Budaya,Teknologi,DanPendidikan,1(8),1445–1454. https://doi.org/10.54443/sibatik.v1i8.188

[14] Kim,M.S.,Edirisinghe,D.S.,Yang,H.-S.,Gunawardane,S. D.G.S.P.,&Lee,Y.-H.(2021).Effectsofbladenumber anddrafttubeingravitationalwatervortexpowerplant determined using computational fluid dynamics simulations. Journal of Advanced Marine Engineering and Technology, 45(5), 252–262. https://doi.org/10.5916/jamet.2021.45.5.252

[15] Sinaga,D.A.,Septiyanto,M.D.,Arifin,Z.,Rusdiyanto,G., Prasetyo, S. D., & Hadi, S. (2023). The Effect of Blade Distances on the Performance of Double-Stage Gravitational Water Vortex Turbine. Journal of Advanced Research in Fluid Mechanics and Thermal Sciences, 109(1), 196–209. https://doi.org/10.37934/arfmts.109.1.196209