11 minute read

6.2.2. RECOMMENDED LUBRICATION OIL

• The engine oil has a significant impact on the performance and service life of the engine, and fuel economy, so it is recommended to use the recommended oil specified by Hidromek. Any failure or accident which arises from use of inappropriate engine oil is excluded from the coverage of warranty.

• The engine oil has the following important functions:

- Prevents each part of the engine from wearing.

- Cools down each part of the engine.

- Cleans each part of the engine.

- Maintains airtightness of the combustion chambers and prevents rust generation. Replace the engine oil periodically.

CAUTION

Using fuel other than extra-low-sulfur diesel fuel (with sulfur content of 15 ppm or lower) may have a harmful effect on the engine and the exhaust gas purification device (urea SCR system), possibility resulting in a breakdown. If a wrong type of fuel is filled in, drain it completely. It is dangerous to start the engine with the wrong type of fuel filled in because doing so may cause a fire or engine damage. Open the fuel cap slowly. If the cap is opened quickly, the fuel may spurt out. Engine warranty is not applicable if any fuel except extra low sulfur diesel is used.

CAUTION

Engine oil lubricates and cools the engine interior components. The quality of the oil is degraded and the quantity of oil is reduced by evaporation, exhaust and combustion during the engine's operation. Continually using the same oil without checking the level or without replenishing and changing it could cause seizure or damage to the engine. Add or change the oil when the quality of the oil has degraded or the quantity is reduced, even if that occurs before expiration of the specified intervals in the maintenance schedule, which will differ depending on the conditions of use.

Fuel gradually gets mixed with the engine oil, causing the engine oil to become thin. Make sure to replace the engine oil at the specified intervals.

WARNING

Engine life and engine oil life will be affected by the quality and cleanliness of the fuel used. Make sure you know the quality of the fuel you are buying. If you are not sure, USE MINIMAL INTERVAL for oil change as specified below.

CAUTION

It is the responsibility of the user to monitor the actual condition of the engine oil. Perform maintenance (oil, fuel and air filters) according to the Maintenance Section (6.4) and follow recommendations made therein. It is extremely important to pay attention to type of fuel used and to CLEANLINESS.

6.2.3. RECOMMENDED FUEL

Use correct type of fuel that is recommended in this manual.

CAUTION

• Using fuel other than extra-low-sulfur diesel fuel (with a sulfur content of 10 ppm or lower for Japan and Europe, 15 ppm or lower for America) may have a harmful effect on the engine and the exhaust gas purification device (urea SCR), possibly resulting in a breakdown. If a wrong type of fuel is filled in, drain it completely. It is dangerous to start the engine with the wrong type of fuel filled in because doing so may cause a fire or engine damage.

• Any failure which arises from use of fuel other than extra-low-sulfur diesel fuel is excluded from the coverage of warranty.

• Open the fuel cap slowly. If the cap is opened quickly, the fuel may spurt out.

Caution

• For fuel of diesel engine, the following characteristics are required. Use a type of extra-low-sulfur diesel fuel designated for general diesel vehicles that is compliant with the following standards: Japanese Industrial Standards (JIS) K2204, American Society for Testing and Materials (ASTM) D975 No. 1-D S15 and No. 2-D S15, British Standards (BS) EN590, Deutsche Industrie Normen (DIN) EN590, Canada General Standards Board (CGSB) CGSB-3.517

- No fine dust is contained.

- Appropriate degree of viscosity is provided.

- High in cetane value.

- Good low-temperature fluidity.

- Low sulfur content.

- Low carbon residue.

•Besure touseextra-low-sulfur diesel fuel. Adding of or mixing with inferior fuel, water remover, other fuel additives, gasoline, heating oil, heavy oil or alcoholic fuel for use may cause a sliding failure of the fuel lubricating portions in the fuel filter and injector, and have harmful effects on each part of the engine which may result in an engine failure.

NOTE

• The specifications of diesel fuel vary depending on the season and the region.

WARNING

• Be sure to place the starter switch in the "OFF" position to shut down the engine before refueling the machine because refueling while the engine is running may cause a fire.

• When refueling, putting any flame nearby is strictly prohibited. Do not place a lighted cigarette or something similar nearby which may result in a fire.

• When refueling, take care not to spill the fuel. If any fuel is spilled, carefully wipe it away. Leaving as it is may cause the spilled fuel to be ignited, resulting in a fire.

Also, the cloths, papers, etc. used for wiping are easily ignitable. Dispose of them properly as flammable waste.

• When the fuel cap is not securely closed, the fuel may leak and cause a fire while driving.

Caution

• When dust or water mixes into the fuel, this may lead to an engine failure or accident. When adding the fuel to the fuel tank, take care not to let dust or water enter in the tank. When refilling directly from a drum can out of necessity, particularly be cautious to prevent foreign matters from entering into the tank.

• Add sufficient amount of fuel to the fuel tank, and periodically open the drain plug located at the bottom part of the tank to remove the sediments (dust and moisture) deposited at the bottom.

6.2.4. DIESEL EXHAUST FLUID(DEF/AdBlue®) Use DEF/AdBlue® specified by Hidromek. Use DEF/AdBlue® compliant with the following standards: JIS (Japanese Industrial Standards) K2247 standard defined for AUS 32, ISO (International Organization for Standardization) 22241 standard defined for AUS 32, the API (American Petroleum Institute) standards.

DEF/AdBlue® is a clear, colorless liquid. Do not use if there is color, as the DEF/AdBlue® mayhave deteriorated or been altered.

6.2.5. COOLANT WARNING

Use distilled water in the radiator. Do not use water from a well, river, sea, or brackish and waste water otherwise the cooling system maybe damaged.

If you add coolant to the system, use coolant in the same concentration with the coolant in the system.

When refilling coolant, flush out the system with distilled water.

Never mix different brands and different classes antifreeze. For example never mix standard life ethylene glycol antifreeze with extended life ethylene glycol antifreeze. If they are mixed, the protection level will be reduced.

Replace the engine coolant periodically. When only water is used as coolant, it can cause a serious damage in the cooling system because of lower freezing point, lower boiling point, and unfavorable corrosive properties. Therefore, add antifreeze when preparing coolant.

If it is not possible to have distilled water, the coolant water quality should comply with the following requirements.

The mixing ratio is determined according to the temperature, however to get minimum protection, at least 30% per volume is needed. When mixing antifreeze into coolant, determine the mixing ratio considering the lowest temperature expected. Set the freezing point at 10º C lower than the expected lowest temperature. Check the mixing ratio of antifreeze solution with the Baumé scale.

Values given in the table are water and antifreeze volumes in 1 liter of coolant. Multiply the values with the coolant capacity of your machine to calculate the total amount of water and antifreeze.

Eg: For protection of 39 liters coolant to -24 C. Volume of antifreeze is 39 x 0,4 = 15,6 L and volume of water is 39 x 0,6 = 23,4 L.

6.3. PERIODIC REPLACEMENT OF MAIN PARTS

To assure operational and working safety the user must perform maintenance of the machine and its components periodically as specified in the manual. Main parts and components listed in the following section must be replaced in their specified periods to secure max. safety and performance.

As the characteristics of these material deteriorate or the main parts wear out over time, it is hard to judge their condition just by periodical checks. Therefore, they should be replaced with the new ones at specified intervals, even though there are no apparent extraordinary abnormalities.

However, whenever any abnormality is found, replace them immediately. Also when you are replacing the hoses, if any damage is found on the hose clamps, replace the clamps as well.

Regularly, check hydraulic oil hoses in addition to the periodical replaced pads, if any abnormality is found, tighten or replace them.

When replacing the hoses, also replace O-Rings and gaskets.

For replacement of main parts, contact HİDROMEK dealer service centers.

Check the hydraulic oil hoses and fuel hoses periodically as follows:

Description Checking items

Before working

Monthly checking

Frequently checking

Leakage from connector of fuel, hydraulic oil hoses.

Leakage from connector of fuel, hydraulic oil hoses. Damage of fuel hoses, hydraulic oil hoses (cracks, wear, falling-off).

Leakage from connector of fuel, hydraulic oil hoses. Blistering, twisting, aging, cracking and wear damage of fuel, and oil hoses.

6.4. INSPECTION AND MAINTENANCE LIST

●: Routine inspection and maintenance

■: First inspection and maintenance

: Contact Authorized HIDROMEK Service

(1): See "Chapter 5 Troubleshooting".

(2): Replacement interval may change depending on fuel consumption and fuel quality.

(3): Replacement interval may change depending on engine oil type and fuel quality. See Chapter 6.2. "Oil, Fuel, Coolant And Diesel Exhaust Fluid" for more information.

(4): The use of hydraulic breaker decreases hydraulic oil replacement interval. In this case, replace the hydraulic oil every 1000 hours and hydraulic return filter every 500 hours of operation. For more information about oil and filter life refer to chapter "8.7.3. Hydraulic Breaker".

Replace the hydraulic breaker return filter according to hydraulic breaker operating hours.

(5): Hose assemblies will eventually age, harden, wear and deteriorate under thermal cycling and compression set. Periodically inspect, at intervals not exceeding 4 years, all hose assemblies for damage, crack, flattening, blistering and crushing. Replace if any of the above-mentioned is found.

WARNING

The hydraulic hoses bear extreme pressure. Any minor defect may cause hydraulic oil to eject in streams and cause heavy injury. In such a case, immediately consult your doctor.

(6): If the machine works in water or mud, do not wait for the given periodic maintenance schedule time and refill new grease to the submerged parts in a shorter period of time. Grease attachments like bucket pins and remove the old grease completely.

(7): See Chapter 6.2. "Oil, Fuel, Coolant And Diesel Exhaust Fluid" for coolant properties

(8): Replace the air filter outer element when the "air cleaner clogged" indicator comes on the instrument panel.

(9): Shorten the inspection / cleaning and replacement intervals to 250 hours if the machine is used particularly in a dusty environment.

IMPORTANT

The inspection and maintenance list is provided only for normal operating conditions. It may be necessary to change the inspection and maintenance interval depending on operator and operating conditions including excessive dust, water, humidity and temperature. Please read maintenance suggestions for specific operating conditions given in this manual and consult your Hidromek dealer.

6.5. EVERY 10 HOURS (BEFORE STARTING)

6.5.1. WALK-AROUND INSPECTION (VISUAL INSPECTION)

Before starting the engine, visually check bolts and nuts for tightness, oil, fuel or coolant circuits for leakage, damaged lines, and loose connections, and check attachment or hydraulic system for abnormality.

Warning

Dust around the engine and leakage of oil or fuel may cause fire. Keep the parts clean. Check thoroughly, if any abnormality is found, be sure to repair them. If it is impossible, contact the authorized HIDROMEK dealer.

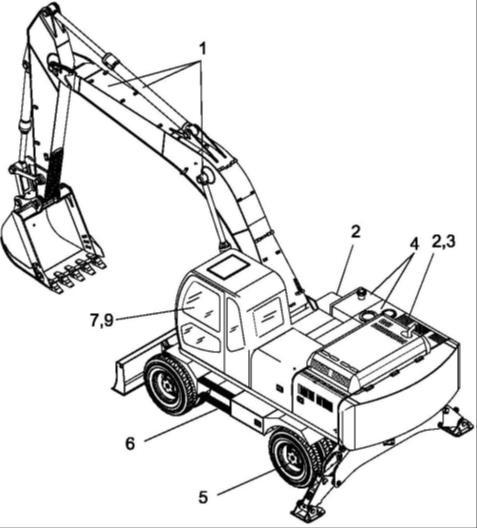

Inspect for the following items before starting the engine every day:

1. Inspect components that showed abnormalities during previous operation.

2. Check battery fluid level. Looseness and corrosion in terminal section of battery.

3. Check engine oil level and contamination.

4. Check coolant level.

5. Remove water from fuel. Drain the water in fuel filter water separators.

6. Inspect of presence or absence of engine failure indication.

7. Check fan belt tension and damage.

8. Check the attachments, cylinders, and hoses for damage, wear and clearance. If any abnormality is found, repair them.

9. Check for dust around the engine and radiator. If any abnormality exists, remove dust from the engine and the radiator.

10. Check for coolant and oil leakages while the engine is running. Repair if any abnormality exists.

11. Check for leakage in the hydraulic system, hydraulic tank and hose connections. If any abnormality exists, repair the parts.

12. Check the undercarriage for damage, wear, looseness of bolts and leakage. If any abnormality exists, repair it. Check pressure of tires and inflate them to proper value.

13. Check the guardrails and steps for damage and bolts for tightness. If there is any damage, repair them and fasten the bolts.

14. Check the gauges and monitor for damage and bolts for tightness. Check the gauges and instrument panel in the operator’s cab for damage, if any abnormality exists, replace it. Keep the surface of them clean.

15. Check rear view mirrors and replace if there is any damage. Keep the surface of the mirrors clean and adjust the angle for the best view.

16. Check for the seat belts and its mounting hardware, replace them if damaged.

6.5.2. INSPECTING ENGINE STARTABILITY AND ABNORMAL NOISE

Operate the starter switch to start the engine. At this time, confirm that the engine is started quickly and also there is no abnormal noise.

6.5.3. INSPECTING CONDITION OF THE ENGINE AT LOW SPEEDS AND DURING ACCELERATION

1. Operate the starter switch to start the engine, and warm up the engine.

2. Confirm that the engine is running smoothly at the idling speed within the range of normal idling speeds.

However, the following condition should be excluded.

When the coolant temperature is low.

3. Confirm that the engine speed increases smoothly and there is no knocking when accelerating gradually by operating the accelerator.

*: Inspection items that should be performed at an appropriate period determined based on the operation hours, driving conditions, etc. are indicated.

6.5.4. COOLANT LEVEL CHECK

Coolant reservoir tank has its own cover on the engine hood. It could be reached by opening the cover with its key.

WARNING

Do not perform any maintenance while the engine is running. Right after operating the engine, the coolant is very hot. Never open the radiator cap immediately after shut-down. Wait until it cools down, and then open the cap slowly to release the internal pressure. Hot vapor or boiling water may burst out and cause a burn. When removing the cap of the radiator or reserve tank, use a thick cloth to cover the cap and loosen it gradually.

Notes

Stop the engine before checking the coolant level and wait until it cools down. Coolant expands with temperature thus when the engine is hot, coolant level seems to be higher.

If the coolant level is abnormally low, there may be a leakage in the system. In this case, contact Hidromek Authorized Service and get checked the cooling system.

Inspect the radiator and radiator hose for a crack, damage and water leakage. Also, check whether a stain of water leakage is left on the ground surface where the machine is set. When a crack, damage or water leakage is found, contact a Hidromek Authorized Service.

WARNING

Use without fixing the water leakage can cause engine seizure.

Use specified amount of antifreeze-water mixture as coolant in all seasons.

Check the coolant level in the reservoir tank after the engine is cooled down. Fill the coolant reservoir tank to the maximum level.

Coolant and water specifications, mixing ratios Refer to Chapter 6.2 "Oil, Fuel, Coolant and Diesel Exhaust Fluid”.

When an overheating problem occurs in your engine, refer to the Chapter "Troubleshooting" before adding coolant to the system.

WARNING

The coolant is toxic and must not be ingested. If the coolant is mistakenly ingested, immediately vomit it and seek prompt medical attention. When the coolant gets in your eyes, rinse it off immediately with a large amount of water for 15 minutes or longer. Also, if still an abnormality such as irritation is felt, seek medical attention. When the coolant gets on your skin, rinse it off using a soap with a large amount of water. Also, if an abnormality is observed, seek medical attention.

The coolant is flammable. Keep flames away from it. Also, the coolant could catch fire if it comes in contact with a hot surface, such as the exhaust manifold. Pay attention to prevent this from happening.