18 minute read

2.2.2.17. WORKING IN A TUNNEL

Tünel gibi zorlu koşullarda çalışan makinelerin periyodik kontrol ve bakım süreleri ve işletilme şartları normal şartlarda çalışan makinelere göre farklılık gösterir.

Tünelde çalıştırılacak makine, uygun donanıma ve ataşmanlara sahip olmalıdır. Tünellerde kullanılacak kırıcı braketi tünel tipi braket olmalıdır ve sadece Hidromek’in onayladığı kırıcı markaları kullanılmalıdır. Tünelde kullanılacak hidrolik kırıcılar tünel dışında kullanılanlardan farklıdır.

Makineye bağlanacak bom, arm, kırıcı, kırıcı braketi vb. ataşmanlar yalnız Hidromek’in onayı alındıktan sonra kullanılabilir. Aksi takdirde, makinede meydana gelebilecek hasar ve arızalardan Hidromek sorumlu tutulamaz

Tünelde kullanılabilecek hidrolik kırıcı modelleri, hidrolik yağ tipi, filtre, bakım periyotları gibi hususlarda detaylı bilgi için Hidromek'e başvurunuz.

Bu Kullanım ve Bakım El Kitabında tavsiye edilen standart Hidrolik yağlar yerine çinkosuz yağ kullanılması önerilir.

Hidrolik Sistemdeki kirliliği azaltmak için Bypass Filtre kullanılabilir.

Hidrolik yağ değişim periyodunun 2000 saatten 1000 saate, hidrolik tank havalandırma elemanı değişim periyodunun ise 1000 saatten 500 saate düşürülmesi gerekir

Hidrolik kırıcı dönüş filtresini (varsa) bu kitapta belirtilenden daha sık değiştirmek gerekebilir.

Filtre ve yağ değişim aralıklarını belirlemek için hidrolik yağı düzenli olarak analiz edin.

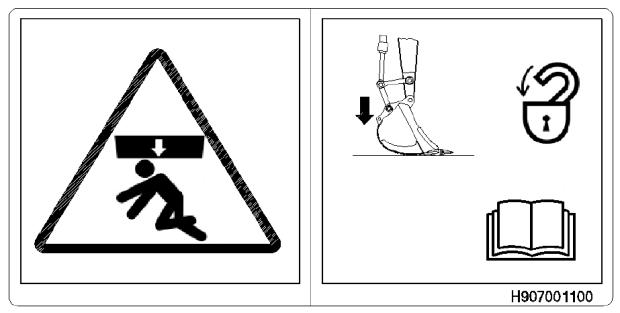

Maden ocakları ve tünellerde çalışırken, Düşen Cisimlere Karşı Muhafaza (FOG) kullanın.

DİKKAT

Hidrolik kırıcı ile, maden ocakları ve tünellerde veya düşen ya da sıçrayan maddelerin olabileceği diğer ortamlarda çalışırken, çalışma koşullarına göre gerekenkoruyucu muhafazaları kullanın. Çalışma ortamına uygun muhafazalar için HİDROMEK yetkili servisleriyle görüşün.

2.2.3. TRANSPORTATION

2.2.3.1. CAUTION WHILE LOADING/UNLOADING

Pay special attention to loading and unloading. Operate the engine at low rpm, and set machine travel speed to low. Choose a firm, level place, and keep adequate distance from the road shoulder. Make sure the strength, width; length and thickness of the planks are safe for loading/unloading. If they bend excessively, support with blocks. Remove grease, oil, mud, ice, etc. from the planks and trailer bed to prevent the machine from slipping sideways.

Never change course on the planks. If it is unavoidable, first descend from the planks and then change course. When swinging on the trailer, operate slowly because the base is unstable. After loading, block each tire and secure the machine with tie downs of adequate load rating so that the machine cannot move.

Cover the exhaust pipe to prevent turbocharger damage. Lock the cab door and lower the antenna.

A: Angle of the slope should be less than 15°

2.2.3.2. CAUTION DURING TRANSPORTATION

When transporting, observe all local, provincial, state regulations governing the weight, width height and length of a load.

Choose a transport route taking into account the overpass clearances, bridge and road load limits, wide load prohibitions and travel hours.

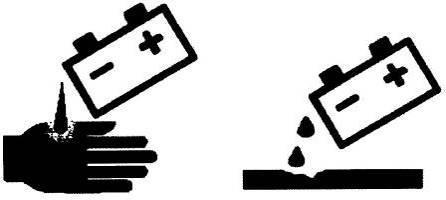

2.2.4.1. CAUTION WORKING WITH USED BATTERIES

Battery electrolyte consists of water and sulphuric acid, so it may be harmful on clothes or skin. If the battery electrolyte is spilled on your clothes or skin, immediately flush with clean water. If battery electrolyte is spattered into the eyes, immediately flush with clean water and consult a medical doctor.

If you accidentally swallow the battery electrolyte, drink a great quantity of water, milk or vegetable oil, or eat a raw egg, and then immediately consult a doctor.

Always wear safety glasses when handling the battery.

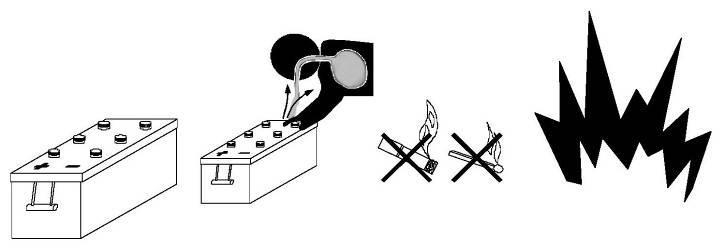

There is a danger of explosion because hydrogen gas is emitted. Never approach with a burning cigarette or fire near the battery, and never do any work which may cause sparks.

When checking or handling the battery, first stop the engine and turn the start key to OFF.

Make sure both poles do not make contact with metals such as tools.

Make sure the terminals are tightened firmly. A loose terminal may cause sparking due to poor contact and cause explosion of accumulated gases.

When installing the cables, make sure which is the (+) terminal and (-) terminal.

Tighten the battery plug securely.

2.2.4.2. STARTING USING BOOSTER CABLES

Wear safety glasses when starting by use of booster cables (jump starting).

When starting by use of another machine, the normal machine and disabled machine must not make physical contact.

When installing the cable, first connect positive terminal, and when detaching it, first disconnect ground terminal (normally, negative terminal). Pay attention that any tool doesn’t cause contact between a terminal and the chassis, as it will cause sparking. Take precautions to prevent such occurrence.

Verify the connection of booster cables. The positive terminal and negative terminal must not make contact.

The cable must be connected to upper frame last. In this case, sparks will occur, so connect it as far from the battery as possible. Start procedure by use of booster cable Refer to 5.5.1. Starting the Engine with Booster Cables (Jump start).

2.2.5. TOWING

Improper towing may cause serious injury.

When towing the machine use wire ropes that are certified, in good condition and are of adequate load rating and length.

Never perform towing on a slope.

Never use a wire rope, which is kinked, twisted or damaged.

Never straddle a cable or wire rope.

When towing the disabled machine, make sure that no one is between the machines. Keep all persons at a safe distance for protection, should the cable break.

Make sure the connection points of disabled unit and towing machine are in a straight line, and then attach the cables.

Insert a protective device between the wire rope and the machine to prevent damage.

Do not tow this machine if the wire rope is attached to the towing eye.

Towing Refer to "Chapter 5.2 Towing Method"

2.2.6.

Lifting Objects

For lifting objects, see 4 16

2.2.6.1. GENERAL PRECAUTIONS

2.2.6.1.1. LIFTING HOLES

When lifting, use holes and eyes provided for lifting only.

When lifting, pay attention to the following: DO NOT hang the wire rope onto a bucket tools to lift objects.

DO NOT wind the wire rope around boom or arm to lift objects.

2.2.6.1.2. CHECK FOR ANY ABNORMALITY

Before lifting, check the followings for a sign of abnormality.

Crack or deformation on connections or welds to the body.

Crack or damage on the lifting holes.

During periodic inspection (monthly and 6 monthly), add a check item for "Abnormality on lifting holes" on the inspection list, and inspect and record the result.

2.2.6.1.3. SELECTING THE WORK PLACE

Before you start to work, examine the ground and the nature of soil, and select a firm and level place to prevent a possibility of roll over. Always make safety around the work-site your priority.

2.2.6.1.4. DO NOT RIDE THE ATTACHMENT

Never allow anyone to ride on the attachment or on the load. This is an extremely dangerous practice and it is strictly forbidden.

2.2.6.1.5. KEEP WORKING AREA CLEAR

Never let anyone enter the working area of the machine.

2.2.6.1.6. DESIGNATE A LEADER

Prior to lifting, designate a signalman, and obey his instructions. Observe the signalman's instructions for the working method and procedure.

2.2.6.1.7. HANDLING OF WIRE ROPES

•Wear protective gloves prior tohandling wire ropes.

• Ensure that the wire rope, hooks and shackles are certified, in good condition and of adequate load rating.

2.2.6.2. CAUTION DURING LIFTING

2.2.6.2.1. OPERATE SLOWLY

Run the engine at low rpm.

Do not operate the levers abruptly. Do not turn, lift or stop unnecessarily fast. Check the limits of height, width and weight, and do not work beyond the limit.

Make the rope length between objects and hook as short as possible so that the object will not swing.

2.2.6.2.2. DO NOT LEAVE OPERATOR’S SEAT

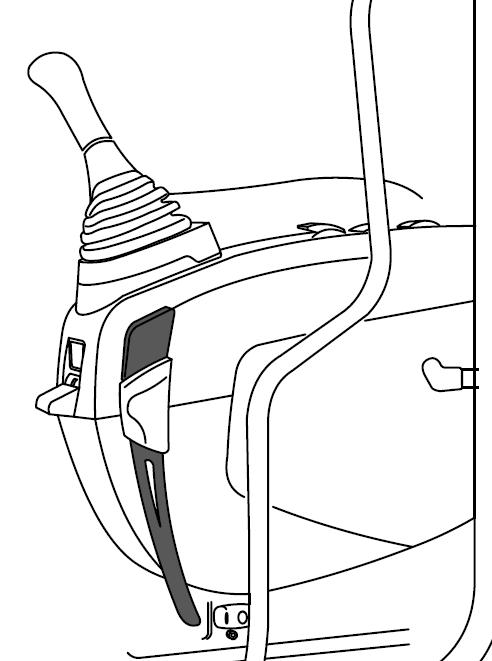

Do not leave operator’s seat with the object suspended. When you leave operator's seat, lower the object to a safe place and engage the safetylocking device.

Safety locking device Refer to 3.17. Safety Locking System

2.2.6.2.3. DO NOT EXCEED CAPACITY

Working beyond the capacity of the machine may cause an accident or breakdown.

Know the weight of the load. The combined weight of the load and lifting devices must be less than the rated lifting capacity of the machine. Do not attempt to lift an overload or exert an impact on a load to move it.

Do not use the swing or arm-in operation to drag a load.

2.2.6.2.4. NEVER TRAVEL WITH A SUSPENDED LOAD

Never travel with the load suspended from the hook.

2.2.6.2.5. LET EVERYBODY BE AWAY FROM THE BOOM CYLINDER

Keep everybodyawayfrom the boom cylinder. While lifting, hoses might burst and can cause serious accidents.

If hoses burst, boom might fall by its gravity and cause accidents.

2.3. CAUTION ON MAINTENANCE

2.3.1. BEFORE MAINTENANCE

2.3.1.1.

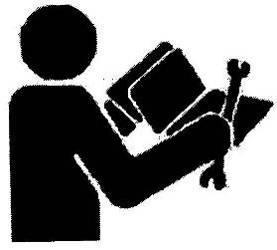

Read Manual

Read and understand operation and maintenance manual before maintenance.

2.3.1.2.

Hang The Warning Tag

If anyone starts the engine or touches the levers by mistake during inspecting or maintaining, serious injury may occur.

Hang a "DO NOT OPERATE” warning tag on the control lever.

If necessary, place signs around the machine.

2.3.1.3.

Use Proper Tools

It is very dangerous to use broken or deteriorated tools, or to use the tools for inappropriate purpose. Use proper tools for maintenance.

2.3.1.4. REPLACE SECURITY PARTS PERIODICALLY

Replace the following parts periodically

Fuel system: Fuel hose, return hose, fuel tube cap

Hydraulic system: Pump outlet hose, flange hose Replace above parts periodically even if they are not damaged.

Immediately replace above parts if they are damaged.

Periodical replacement of main parts Refer to Chapter 6.3.

2.3.1.5. FIRST STOP THE ENGINE

Before you attempt any maintenance operation on the machine carefully read and understand the operation and maintenance manual. When inspecting or maintaining the machine, put it on a firm and level place, and stop the engine. If the engine must be operated for maintenance such as flushing the radiator core, lock the safety-locking lever. This work requires two men. One man shall be sitting on the operator's seat to stop the engine at any time. Take care not to touch any lever by mistake. Use the release knob to release the safetylocking device.

The man performing maintenance must take every precaution that the moving parts do not catch his clothes, objects he is wearing or members of his body.

2.3.1.6. CAUTION ADDING FUEL OR OIL

Add fuel or oil in a well-ventilated area. Before adding fuel, stop the engine, DO NOT smoke, DO NOT approach with flame. Wipe out spilled fuel or oil immediately. Tighten the caps on containers for fuel or oil securely.

2.3.1.7. COOLANT LEVEL

If it is required to add to coolant to the radiator, stop the engine, and wait until the engine and radiator has cooled down.

Before removing the cap, loosen it slowly to release the inner pressure.

2.3.1.8. USAGE OF LIGHT

When inspecting the fuel, oil, coolant or battery electrolyte, use the explosion proof type lights. There is a risk of explosion if a light other than explosion proof type lights is used.

2.3.2. DURING MAINTENANCE

2.3.2.1. OFF-LIMITS TO PERSON OTHER THAN CONCERNED

During maintenance, keep non-essential personnel out of the work area. Pay attention to persons around the work-site.

Pay special attention when grinding, welding or using a large hammer.

2.3.2.2. DETACHED ATTACHMENT

When detaching or installing the attachment, make sure it will not fall.

The attachments must be well stabilized and supported to avoid roll-over.

Do not stand, do not let anybody near the attachment when assembling or disassembling an attachment

2.3.2.3. WORKING UNDER THE MACHINE

Before inspecting or maintaining under the machine, lower the attachment to the ground or to the lowest level possible.

When working under the machine, first put a block strong enough under the tires, and then continue to work.

If the machine is not supported sufficiently, never work under the machine.

2.3.2.4. KEEP THE MACHINE CLEAN

Grease, oil, and mud on the machine cause very slippery and dangerous surfaces. Keep the machine clean at all times. Do not use water or steam to clean inside the operator's cab. Water can cause the electrical systems to malfunction or cause system damage.

Clean the machine thoroughly before performing inspection and maintenance procedures. It is easier and safer to locate problems and to perform maintenance when the machine is clean. The possibility of contamination of the hydraulic system is also reduced. Do not wash the machine while the engine is running. During washing the machine observe the following procedures:

Park the machine on a hard and level ground.

Spray at an angle that will not damage the wick of the doors and windows.

Do not wash the machine with hot water.

Use a soft brush during cleaning.

When rinsing use only water.

Always lubricate the machine after washing.

During high pressure washing observe precautions below:

Warning

Too high pressure and too short distance may cause damage to the paint finish and other surfaces of the machine. Avoid using cleaning agents or chemicals in order to minimize the risk of damage to the paint finish. Clean more frequently under heavy operating conditions or in a dusty environment.

Specification of water

2.3.2.5. PRECAUTIONS FOR HIGH-PRESSURE HOSES

Never bend or hit high-pressure hoses. Never use bent or damaged pipes, tubes or hoses. Tighten loose fittings and replace damaged fuel hoses and hydraulic hoses. Fuel or oil leakage may start fire.

2.3.2.7. WORKING AROUND EXTREMELY HOT AREAS

Hydraulic oil, engine oil and engine coolant are very hot and under pressure immediately after the machine is stopped. In this condition, if you attempt to replace a filter, drain the oil or coolant, or open the cap, hot fluid may cause burning or scalding.

2.3.2.6. PRECAUTIONS FOR HIGH-PRESSURE OIL

The hydraulic circuit is under pressure at all times, regardless of the engine dead or operating. Never add or drain the oil or inspect or maintain hydraulic system until you are sure that the internal pressure is released.

To prevent spouting of hot coolant: Stop the engine. Wait until the temperature is lowered. Turn the cap slowly to release the inner pressure, and then open the cap.

Danger

While operating or immediately after stopping the machine, the engine, manifold, muffler and turbocharger are very hot. Be careful not to touch these components.

To release internal pressure:

Main circuit

Stop the engine, turn the starter switch to operating position (ON) and operate the right / left control levers to forward, reverse, right and left several times.

Hydraulic tank

Stop the engine and release internal pressure through the breather.

Release the pressure in tank Refer to chapter 6.1.29.2. "Releasing pressure in tank".

Diesel / hydraulic oil escaping under pressure can penetrate the skin and eyes causing serious injury. DO NOT use your hands to search for leaks. Check leaks with a piece of cardboard.

Wear safety goggles and gloves. If an accident occurs, immediately consult a physician.

2.3.2.8. CHANGING TIRES

Changing tires or adding air can be a hazardous business. Under pressure, a tire and rim assembly packs the potential explosive power of TNT. Special tools and procedures are required for changing truck.

2.3.2.9. CAUTION AS CHECK TIRE PRESSURE

Maintenance on wheels and tires must be performed by people who trained and qualified in advance. Check tires pressure from a position facing the tread of the tire, not the side.

Use long handled gauge to keep your body away from the trajectory path of rims and wheels. Always use a safety cage in fig to inflate tires or add air after servicing for your safety.

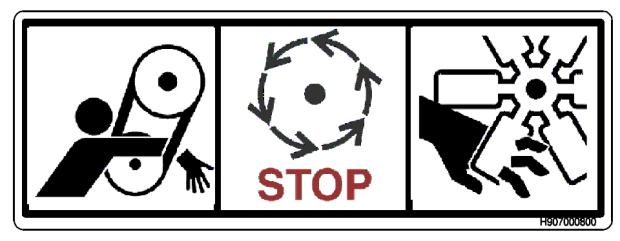

2.3.2.10. ROTATING FAN AND BELT

Tie up long hair, do not wear loose clothing or dangling jewelry or necklaces when you work on the machine. They may be caught by the rotating parts. Do not put your hands or tools near any rotating parts.

If you become entangled, serious injury or death could result.

2.3.2.11. DISPOSAL OF WASTE MATTER

Never discharge waste oil to drains, lakes or rivers. When draining the oil from the machine, drain it into suitable containers.

Never drain oil directly into the ground. Observe all related regulations when disposing of hazardous fluids and materials such as oil, fuel, coolant, filters and batteries.

2.3.2.12. CAUTION FOR WELDING

Ensure that there is good ventilation in welding area. Turn off the starter switch before welding. Disconnect battery terminals and remove batteries. Detach electronic control unit’s cables before welding otherwise serious damage will occur on electronic parts.

When welding, first remove paint around the area to be welded. Heated paint gives off harmful gases. Do not weld near flammable materials such as polymers, elastomers, flammable fluids. Before you weld components which contains flammable materials, remove them from the welding area. Make sure a fire extinguisher exists.

2.3.2.13. WHEN THE ENGINE COOLANT IS HOT

Do not loosen or remove the radiator cap. Doing so would be dangerous because steam and hot air can shoot out.

2.3.2.14. WHEN THE SILENCER AND EXHAUST PIPES ARE HOT

While the engine is running, the urea SCR system is purging, and immediately after operating, the silencer and exhaust piping are extremely hot. Be extremelycareful to avoid mistakenly touching these when performing works nearby. Otherwise, you could get burned.

2.3.2.15. IF THE BATTERY GOES FLAT

When charging the battery from an external power source, remove the battery cables to protect the alternator.

2.3.2.16. DO NOT CLIMB ONTO THE ENGINE

The engine is the vital part of the machine. Do not step on the engine or climb onto it. The head cover and the various connectors may be damaged, leading to an engine failure.

2.3.2.17. MAKE SURE THE ENGINE IS INSPECTED AT REGULAR INTERVALS

Inspections and maintenance enable you to use the engine without any problems. They also provide the engine to have a longer service life.

2.4. ATTACHED POSITIONS SAFETY LABEL

Always keep the safety labels clean. Replace the damaged labels with new ones. Safety labels are also attached on various places as well as the positions indicated below.

2.4.1. ATTACHED POSITIONS

Lifting capacity

Technical Specifications

2.4.2. CONTENTS OF SAFETY DECAL

1. Emergency hammer warning

3. Pressurized hydraulic oil or coolant warning

This decal is located on the rear window of the cab. Use emergency hammer to break through window glass in an emergency situation. The door and the rear window are the emergency exits of the operator's cab. Take the emergency hammer from the pillar at the rear left hand side of the cab and break the window glass.

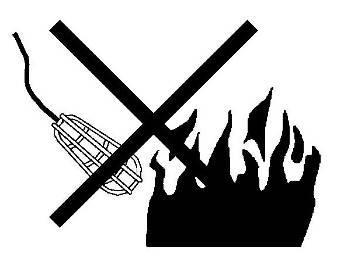

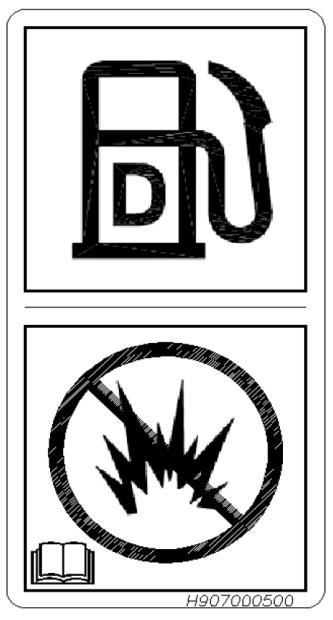

2. Risk of fire when refueling warning

This decal is located on the fuel tank. Stop the engine before refueling. When refueling, do not smoke, keep fire and sparks away.

One of these decals is located on the hydraulic tank and the other is located on the radiator.

Do not open any of the caps if the engine is running.

After stopping the engine wait for the engine to cool down.

Do not remove the cap under high temperature since hydraulic oil may gush out. Open the cap slowly to release the internal pressure. Wear protective gloves. Hold the cap with a piece of thick cloth. Do not screw the drain plug under high temperature.

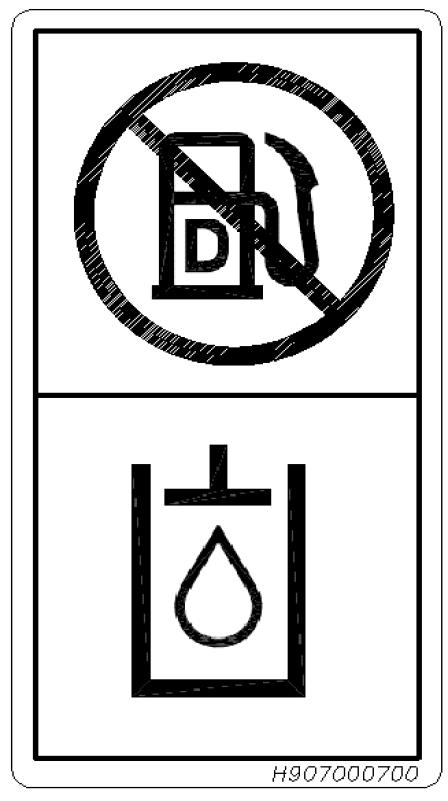

This decal is located on the hydraulic tank. Do not fill fuel in the hydraulic tank. Do not mix different brands of oils. Change oil and filters periodically.

Caution

Move the attachments to correct position. For more information refer to "Hydraulic tank level check".

Check hydraulic oil level by sight gauge. Oil level should be on the center mark of the gauge. If the level is low, open the cover on the tank to add hydraulic oil.

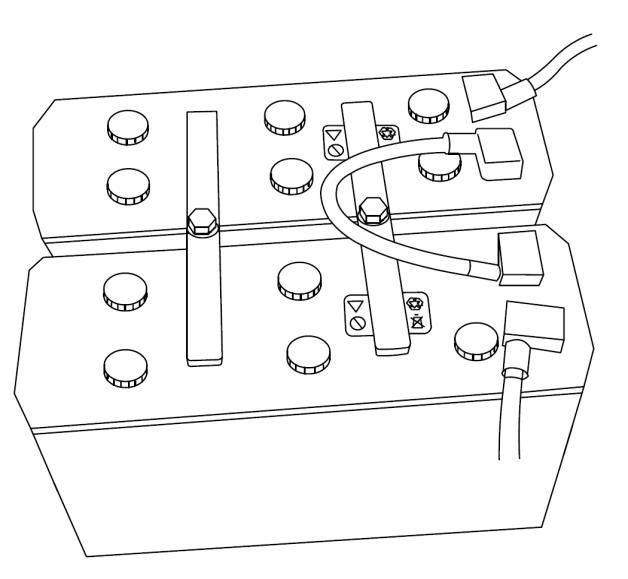

This decal is located on the battery cover.

Carelessness on handling could cause battery to ignite and explode.

The inflammables like the contact of electric lines, sparks and cigarettes are dangerous.

Before repairing (welding etc.) remove the (+) terminal of the battery.

When using booster cables, do handle with care to prevent short-circuit.

Battery fluid may harm your eyes and burn anything it touches.

If the battery acid gets on your skin or clothing, flush with plenty of water immediately. If it gets into your eyes, flush with fresh water and then get medical aid.

Care should be taken to keep away from children.

This decal is located on the right hand side window of the operator's cab.

Objects that hit the operator's cab at front or fall to the top may injure or kill the operator. If there is a risk of object falling in the worksite, install necessary protective guards as defined in the chapter 8.4.

7. General precautions

This decal is located on the right hand side window of the operator's cab.

For operation safety, correct maintenance and maximum efficiency read the operating and maintenance manual.

When arm and boom of the machine is raised, do not stay under the attachments. Before leaving the operator's seat lower the bucket to the ground and stop the engine.

Instrument panel does not show all information about the machine. During daily maintenance, not only the maintenance jobs listed in the instrument panel but also every part of the machine that is listed in the operating and maintenance manual should be checked.

Engine settings are adjusted in the factory and so are all the hydraulic equipment settings. In case of any problem refer to the operating and maintenance manual or contact Hidromek

Authorized Service

8. Hot surfaces

This decal is located on the engine hood.

Do not touch hot surfaces.

Machine components may become very hot after operating or waiting under the sun that they can harm your skin. Wear protective clothing and gloves.

9. General precautions

This is decal located on the right hand side window of the operator's cab.

Never Approach High Voltage Transmission Line

You may receive an electric shock if the machine is too close to a high voltage transmission line. A narrow proximity even without a physical contact will cause electrocution from the power line.

Take extreme caution around high voltage transmission lines. Leave necessary distance between the lines and the machine. To learn about minimum distances and more refer to Chapter 2.2.2.9.

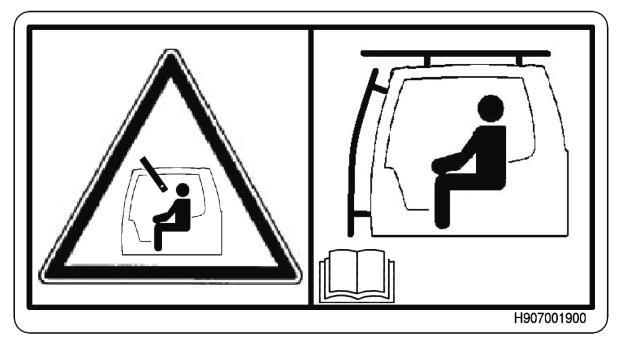

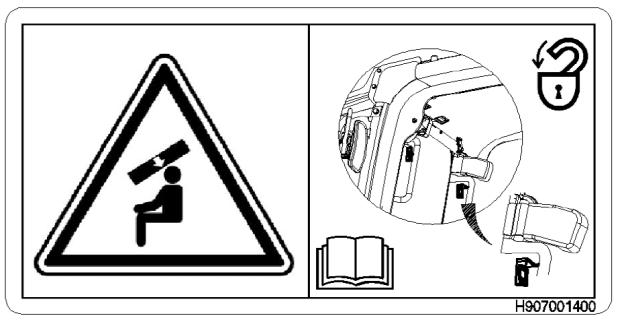

ATTACHMENT MAY HIT TO OPERATOR'S CAB

Careless control of arm and boom may cause attachment to crash into operator's cab or to windshield glass which results in material damage, personnel injury or death.

Precautions Before Maintenance

Before repairing read and understand the operating and maintenance manual.

Before working with the machine or performing maintenance jobs, park the machine on a flat and firm ground.

Stop the engine and take the starter key with you.

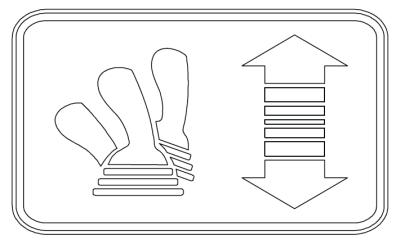

Fasten Your Seat Belt

Fasten your seat belt before starting engine and keep it fastened. Seatbelt is the most necessary part of the ROPS system.

If the machine starts tipping over by a result of an accident, do not remove your seat belt and never try to jump out.

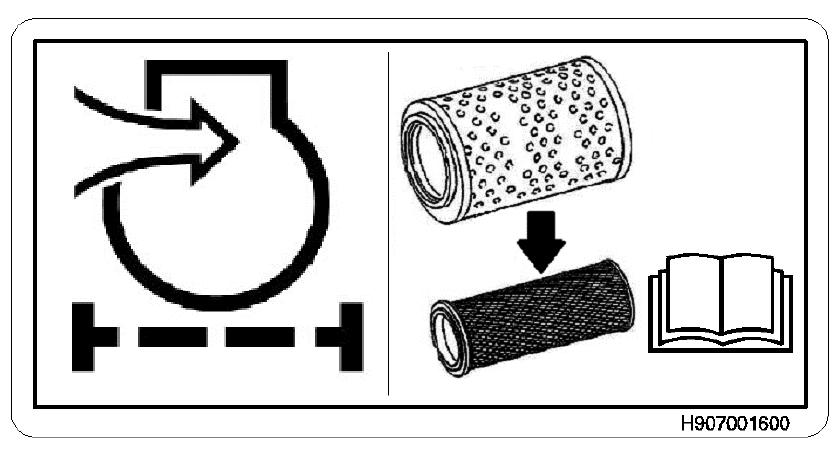

10. Precautions for filter elements

This decal is located on the air filter.

13. Caution for arm

Periodic maintenance, cleaning and replacing of filter elements will increase engine performance and extend its lifetime.

11. Precautions about windshield

This decal is located on the windshield.

After opening the windshield make sure it’s locked from both sides.

12. Electrical circuit caution

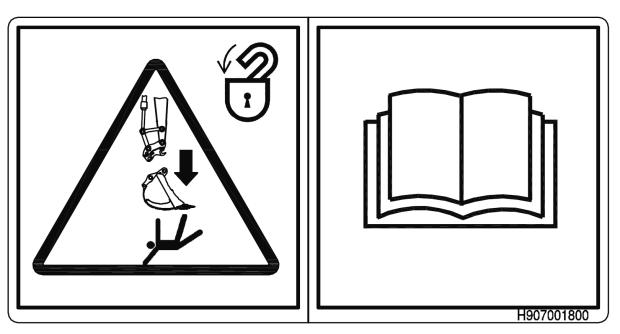

This decal is located on the arm.

When the arm is raised, keep people away. Arm may suddenly fall down and cause injury or death.

14. Do not step on the engine hood warning

To use the machine more effectively and safely read and understand the operating and maintenance manual completely before operating the machine.

Keep this manual in the operators cab at all times. Keep it clean and complete. If lost or damaged, ask your HIDROMEK dealer or service station for a new copy.

If you do not understand any point, or if you feel information contained in this manual is missing or incomplete, or erroneous, consult your service or dealer for appropriate information.

This decal is located on the radiator.

When performing any inspection or maintenance DO NOT wear loose clothing or jewelry as they may be caught in the rotating parts or linkages of the engine. Keep your hands, hair, feet, and clothing away from moving parts. Protective components of the rotating equipment/parts may only be removed after the rotation of the part is completely stopped. Protective components such as engine/motor covers, doors, bonnet and guards must be reattached properly after maintenance or repair work.

19. Falling hazard warning

This decal is located on the right hand side window of the operator's cab.

Overloading the machine can affect the machine's balance and cause it to tip over. Tipping over can cause serious or even fatal damage to the operator. To lift the objects with the machine, overload warning switch must be installed and operating correctly.

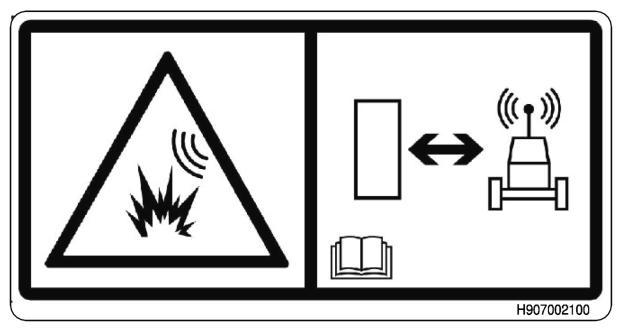

21. GPS warning

This decal is located on the machine at 3 different points.

When you climb the machine for maintenance or control you may fall down. Wear nonslip safety shoes and use equipment suited for work safety. Clean the oil, snow etc. from the machine and let it dry. When climbing the machine always contact at 3 points.

This decal is located on the right hand side window of the operator's cab.

This machine is equipped with Smartlink satellite tracking system. At blasting areas, gas stations, near explosive materials Smartlink system should be deactivated to prevent fire or unexpected explosions.

22. Quick coupling warning

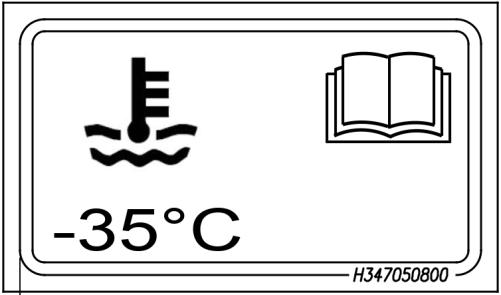

24. Coolant level warning

This decal is located on the reservoir tank.

This decal is located on the right hand side window of the operator's cab.

Make sure the pins on the bucket or other attachments are placed correctly on the quick coupling and locked properly.

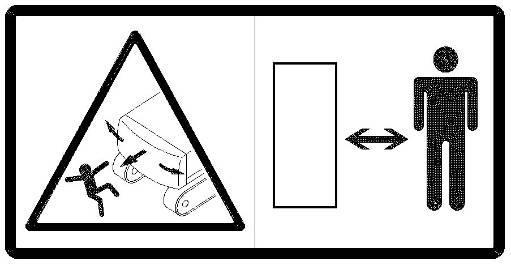

23. Keep away from working area warning

25. Antifreeze warning

This decals are located on the counterweight.

Do not allow people to enter the worksite. Always keep necessary distance with the machine.

This decal is located on the reservoir tank.

Engine coolant is a mixture of antifreeze and water in 50:50 ratio. It protects the engine down to -35 °C. For more information see Chapter 6.2. "Oil, Fuel, Coolant And Diesel Exhaust Fluid".

This decal is located on the inner side of the pump door on the right hand side.

On machines having fuel line cleaning system, refer to chapter "6.10.1. Changing Fuel Filter Elements" for more information about changing fuel filters and cleaning fuel line.

3. DESCRIPTION

3.1.

In this manual, machine direction is determined from the operator seat as illustrated.