16 minute read

1.11. IDENTIFICATION PLATES

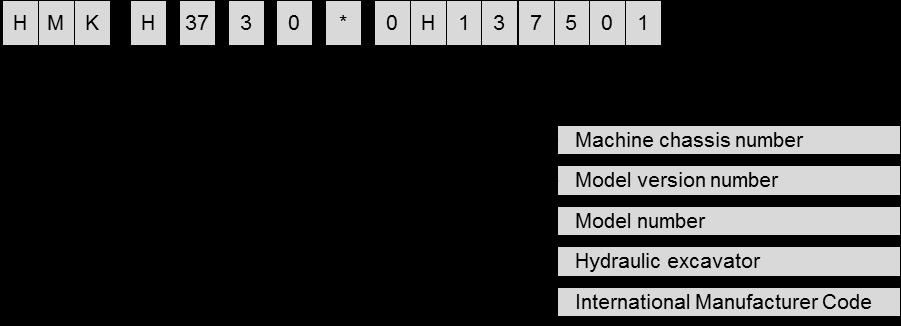

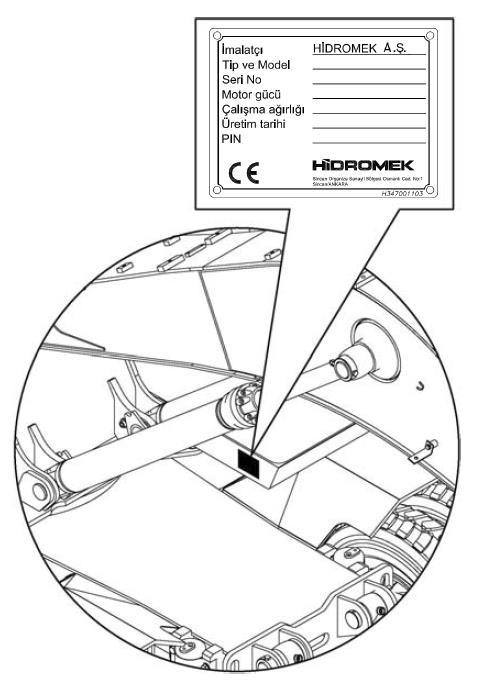

1.11.1. LOCATION OF THE MACHINE ID PLATE

This nameplate is attached on the lower right hand side of the operator’s compartment. The manufacturer’s name, machine type and model information, machine serial number, engine power value, operating weight, manufacturing date and PIN number are given on the nameplate. Do not forget to inform your service about your machine serial number while ordering spare parts.

PIN number is machine identification number. It has 17 alphanumeric characters. For example;

1.11.2. ENGINE IDENTIFICATION PLATES

The engine number is required for engine registration and inspection. Provide your Hidromek Authorized Service with names of the engine manufacturer, type, etc. in addition to the engine number when you are having the machine repaired or are ordering replacement parts, so that the Hidromek Authorized Service can provide service more effectively and efficiently.

Danger

Before checking the engine number, make sure to stop the engine to prevent your body from being caught in the rotating parts and confirm that the engine and Urea SCR system are cooled down. Be careful not to get burned with the heat from the exhaust system, the high temperature coolant or the heat from the engine itself during inspection or maintenance.

1.11.2.1. ENGINE NAME PLATE

ISUZU 4HK1:

It is stamped on the right side bottom part of the cylinder block.

1.11.2.2. ENGINE ID LABEL

It is attached to the cylinder head cover.

1.11.2.3. EMISSION LABEL PLATE

It is attached to the cylinder head cover.

The emission labels on the engine indicate very important instructions and information that you should respect to ensure safe and proper operation of the engine. Be sure to read them before using the engine.

The descriptions in the emission labels are only about the engine unit.

1.12. MAIN COMPONENTS PLATES

Transmission Plate

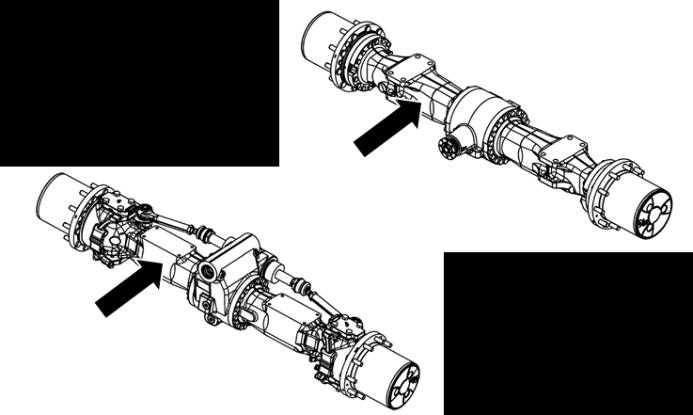

Front & Rear Axle Plates

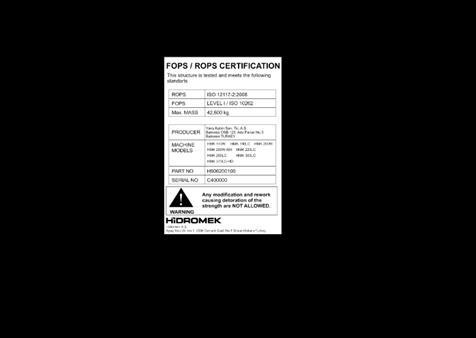

Operator's Cab Plate

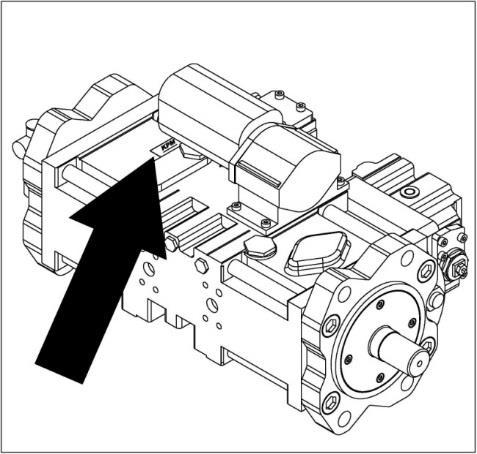

Main Pump Plate

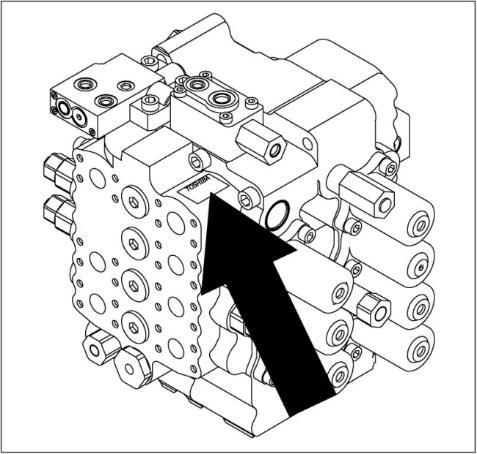

Main Control Valve Plate

Name plate is hanged on the left hand side of the operator's cab.

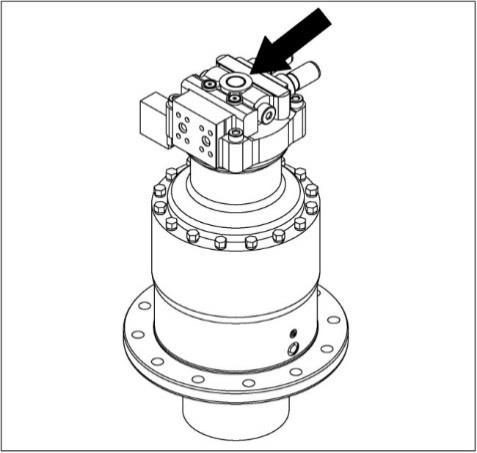

Swing Unit Plate

2. SAFETY

2.1. GENERAL CAUTION

2.1.1. OPERATORS MUST HAVE CERTAIN QUALIFICATIONS

People who use or operate hydraulic excavators must be:

Physically: have a good vision, hearing, coordination, and be capable of performing all functions safelyas required for the operation of the machine.

Mentally: be able to understand and apply established rules, regulations, and safe practices; be alert, using good judgment for his own safety and for safety of the others; be willing to do his/her job in a correct and responsible manner.

Emotionally: be calm and capable of withstanding stress and make judgments concerning his/her own physical and mental conditions.

Trained: Havereadandunderstoodtheoperator’s instructional manual, hand signals chart and warning decals, and be skilled and knowledgeable in all operational and maintenance aspects of the machine.

Licensed: have a legally valid license as required by laws and regulations in effect.

2.1.2. OBSERVE ALL SAFETY RULES ON-SITE

Only certified personnel may operate or maintain this machine.

Observe all rules, cautions and procedures for safety when operating or maintaining the machine. When working with a signalman, work according to the specified signals.

2.1.3. INSTALL ALL GUARDS AND SAFETY DEVICES

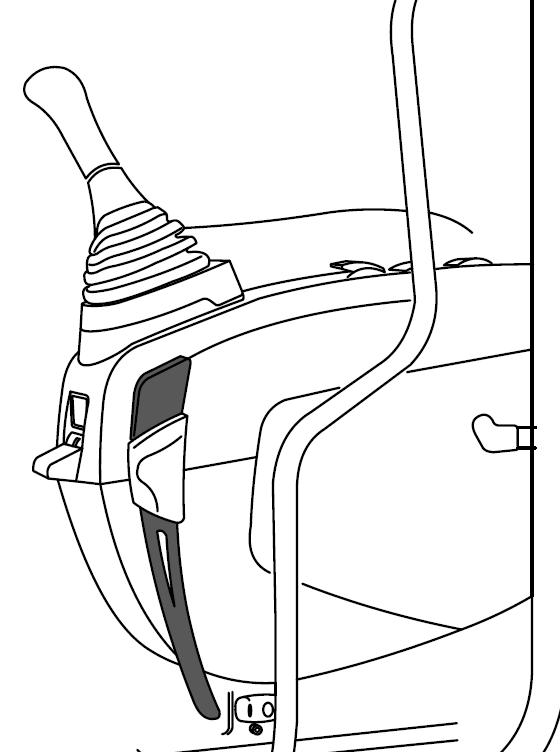

Ensure all of the guards and covers are correctly installed. Repair or replace damaged items. Know the correct usage of safety locking device lever and safety belt, and use as recommended. Safetylocking lever Refer to Chapter 3.17. “Safety Locking Device".

Safety Belt (Seat Belt) Refer to chapter 3.46. “Seat Belt"

Incorrect operation of the safety device may cause serious injury.

2.1.4. WEAR PROTECTIVE CLOTHES AND SAFETY EQUIPMENT

Wear well fitting clothing. Never wear personal items, which may be caught by control lever or components or oiled clothes, which can easily catch fire.

Wear appropriate protective clothing and safety equipment in accordance with working conditions when operating and maintaining the machine. Do not wear radio/cassette headphones while operating the machine.

2.1.5. MODIFICATIONS

Modifications without consent of HIDROMEK may cause safety related problems, and invalidate warranty. If modifications are required, contact HİDROMEK or your local dealer.

HİDROMEK is not responsible for injury or defects due to modifications without permission duly obtained from Hidromek.

2.1.6. BEFORE LEAVING THE MACHINE

Lock the safety-locking lever securely before leaving the operators seat. If a control lever is not locked and activated inadvertently, the machine or attachments may operate suddenly, and cause serious injury or death.

Make sure you lower the attachment to the ground, lock the safety-locking device, stop the engine, and lock the door when leaving the machine. Never forget to remove the starter key.

Safetylocking lever Refer to Chapter 3.17. “Safety Locking Device".

Also lifting the left console is useful which will provide more space when getting into or out of the cab. For more information refer to Chapter 3.21. "Left Console Lifting Lever".

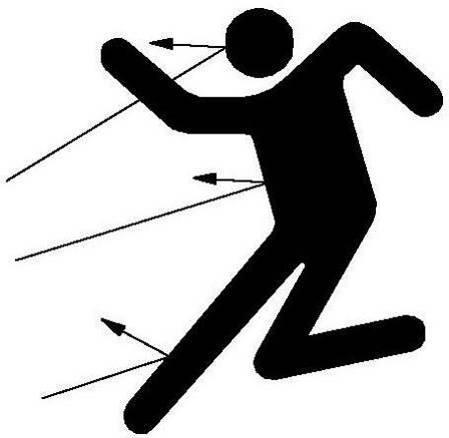

2.1.7. USE HANDRAILS AND FOOTHOLDS TO GET ON/OFF THE MACHINE

Do not jump on/off a machine. Especially, never get on/off a machine while it is moving.

Never grasp the control lever to get on/off.

Make sure to support the body (by maintaining 3 points of contact by use of feet and hands) by use of handrail and foothold.

If your shoes, the handrails or footholds are covered with oil or mud, wipe them off immediately. Especially, clean the windows, rear view mirrors and lights.

When you have to hold onto the door handrail while getting on/off the cabin or moving to the rear of the machine, ensure that the cabin door is locked against the cab wall.

2.1.8. DO NOT ALLOW FIRE NEAR FUEL AND OIL

Antifreeze, fuel and oil are flammable. Keep away from open flame or other fire hazards. Never put a burning cigarette or match near flammables.

Before adding fuel, stop the engine and put out your cigarette.

Wipe up spilled oil immediately.

Tighten the caps on containers for fuel or oil securely.

Keep fuel or oil in a well-ventilated place. Do not use fuel or oil for cleaning. Keep fuel or oil in a protected place designated for this purpose.

2.1.9. HANDLE WITH CARE UNDER HIGH TEMPERATURE

Immediately after stopping the machine, the temperature of the hydraulic oil, engine oil and engine coolant will be very high and pressure will be accumulated. In this condition, while you replace a filter, drain the oil or coolant, or open the cap pay attention as the hot fluid will will eject under trapped pressure and cause burning.

To prevent spouting of the hot coolant:

Stop the engine.

Wait until the temperature is lowered.

Hold the cap with a thick cloth to protect yourself from unintentional hazards.

Turn the cap slowly to release the inner pressure, and then open the cap.

While operating or immediately after stopping the machine, the engine, manifold, muffler and turbocharger are very hot. Take care not to touch these components.

2.1.10. DO NOT INHALE DUST CONTAINING ASBESTOS

If you inhale dust containing asbestos, it may cause a disorder of the respiratory system and can cause cancer.

This machine and its components as delivered to you from the factory does not contain asbestos; however, if you handle any materials that might contain asbestos while you work with the machine, observe the following measures.

Never use compressed air as a cleaning tool.

Avoid brushing or grinding material containing asbestos.

Apply a mist of water on material containing asbestos.

Wear an approved respirator.

2.1.11. PAY ATTENTION TO MOVING PARTS

The area near moving parts (between upper and lower frame, moving parts of attachment, engine compartment, etc.) maycause death or injury. When you perform inspection or maintenance in these areas, lock or secure the moving the parts and pay special attention.

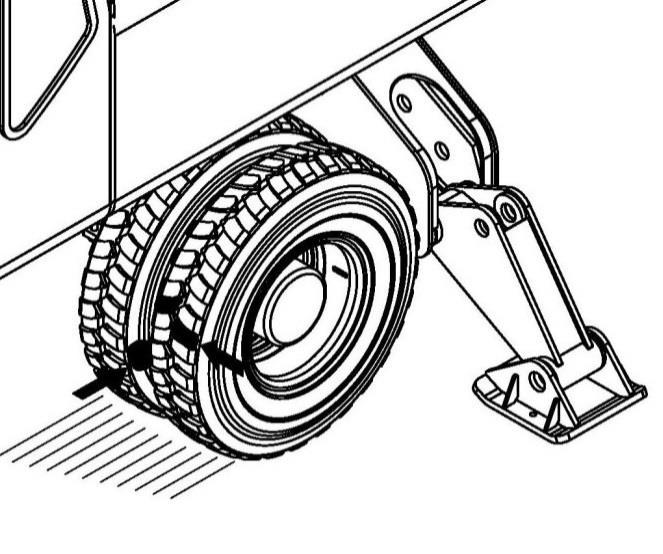

When tires are lifted to maintain the lower frame, support with hardwood blocks. Never support the body with boom or arm alone.

2.1.12. MACHINE FIRE EXTINGUISHER AND FIRST-AID KIT

Make available a fire extinguisher, and read carefully the directions for use.

Make available a first-aid kit and instruction booklet. Display the measures to be taken in case of fire or accident.

Display the names and telephone numbers of personnel to contact in case of an emergency.

2.1.13. PROTECTION FROM FALLING OR FLYING MATERIALS

Install the necessary protection guards according to working conditions while working with breaker, working at quarries and demolition or where falling or flying materials can enter the operator's cab (see 8.4).

Do not operate or travel with the front window open.

Ensure that unauthorized people are kept away at safe distance both from the machine and the source of falling/scattering materials.

2.1.14. BEFORE WORKING IN THE VICINITY OF GAS LINES

Always contact the authorities of the gas lines or the nearest gas utility before beginning to work. Determine jointly what specific precautions must be taken to insure safety. Use a signal person. The sole responsibility of the signal person is to observe and signal the operator. The signal person must be in direct communication with the operator, and the operator must pay close attention to signals.

2.1.15. CAUTION FOR OPTIONAL WORKING ATTACHMENT

Read this manual and the attachment manual before operating with attachments. Do not use an attachment, which is not authorized by HİDROMEK.

Accidents or machine damage from unauthorized attachments shall be considered as user's own responsibilities.

2.1.16. DO NOT REMOVE FRONT ATTACHMENT OR COUNTERWEIGHT

Do not remove front attachment or counterweight, otherwise machine may become unbalanced and serious accidents due to tipping over of the machine may occur with death or injury.

Hidromek is not responsible for such an improper use.

2.1.17. CAUTION FOR POLYMERS AND ELASTOMERS

Some elements of machine are made from polymers and elastomers such as viton sealing rings, teflon rings, piston seals, electric cable insulating materials. These materials contain hazardous fluoro-carbons. When these materials are burnt, they release highly toxic gases and harmful substances for skin and respiratory tracts. When handling a burnt machine observe the following safety procedures.

Do not touch component or surrounding area. Wear thick rubber gloves and protective goggles. Dispose hazardous waste according to the regulations.

Discard gloves and other items that have been in contact with fluoro-carbons.

Wash contaminated area with calcium hydroxide or other suitable alkaline solution.

See a medical doctor, if redness, stinging and swelling appears after contact with fluoro-carbons.

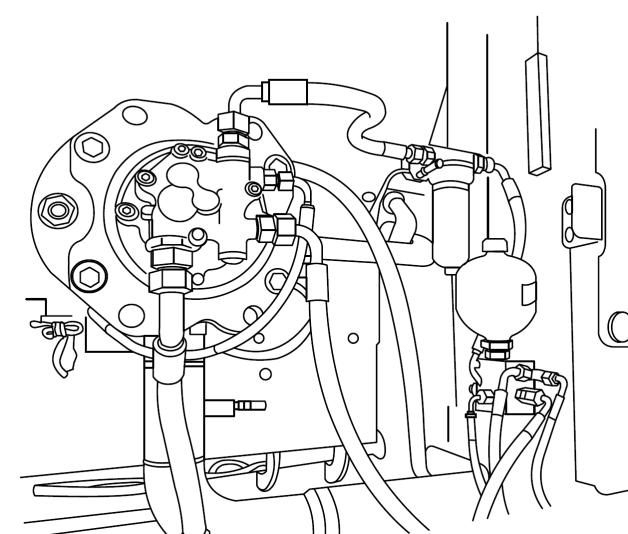

2.1.18. HANDLING OF ACCUMULATOR

WARNING

The accumulator is charged with high-pressure nitrogen gas.

To prevent serious injury or death, handle it with care and observe the following:

Do not hit, drill, or weld the accumulator. Keep away from open flame or any source of heat.

Request the HİDROMEK dealer to discharge the accumulator prior to disposal.

If you operate the boom control lever downward with the engine stopped, the accumulator enables the attachment to move by its own weight. After the attachment is at rest, ensure that the safety locking lever is in LOCKED position.

2.1.18.1. HYDRAULIC ACCUMULATOR

An accumulator is installed on the hydraulic pilot circuit of Attachments and is used to accumulate stand-by hydraulic pressure. If the starter key is turned to start position (ON) when the engine is stopped by turning the start key to the stop position (OFF) and all the operations are stopped, the control circuit of attachment can still be activated by using this accumulated pressure. In this case, put the operation lever at descent position to lower attachments by its own weight.

2.1.18.2. RELEASING THE PRESSURE OF CONTROL CIRCUIT OF ACCUMULATOR

Lower the attachment to the ground completely. After stopping the engine, turn the start switch to operation position (ON).

When the safety locking system is released, remove the pressure of control circuit by moving control levers and pedals of attachment forward/reverse, left/right to each end position.

Turn the start switch to stop position (OFF), and pull the safety-locking lever to operate the safety locking system.

The pressure may not be totally relieved even after performing the above. If you need to remove and replace the hydraulic accumulator then contact Hidromek Authorized Service.

Warning

The SAFETY LOCK LEVER must be pulled in LOCKED position to prevent machine controls from an accidental movement. The operator must lock the safety lever before he leaves the operator’s seat and especially during maintenance and repair work unless it is necessary to operate the machine for this purpose. If not, an accidental movement of any control lever will cause the machine or an attachment to move, and will cause serious injury or death.

When the safety lock lever is at straight position, the safety locking system is UNLOCKED. Make sure to rotate safety lock lever down to correctly

See Chapter 3.17. “SAFETY LOCKING DEVICE".

2.2. CAUTION DURING OPERATING

2.2.1. BEFORE STARTING THE ENGINE

2.2.1.1. MAKE SURE THE WORK SITE IS SECURE

Check site conditions before starting the work. Examine the geological stratum and soil of the working site, and then decide the optimum working method.

Always work on a level site as possible. In case of working on-road, use a lead man or set up a barricade to make vehicular and pedestrian traffic secure (Use hand signals as told in Chapter 9.1. “Hand Signals").

Know where water pipes, gas pipes or high-voltage cables are buried, contact related company to spot their location.

When working in water or crossing a stream, check the condition of bed, depth and speed of the current in advance. If the upper rollers submerge in water, do not work.

For more information about permissible depth of water refer to "Chapter 4 13. Cautions During Operation".

2.2.1.2. CHECKS ON AND AROUND THE MACHINE

Be sure the machine is properly lubricated. Verify that fuel, lubricating oil, coolant and hydraulic oil reservoirs are filled to the proper levels according to the manufacturer’s instructions.

Walk around machine to check all safety related items, including guards or plates, and inspect if any maintenance is required. Visuallyinspect the machine for evidence of physical damage, such as cracking, bending, or deformation of plates or welds.

Loose or missing hardware, bolts, or nuts, should be properly tightened or replaced. Check for leaks of fluid. Hydraulic system leaks must be corrected before the machine is operated. Inspect all hydraulic hoses, especially those that flex in service, and replace if necessary. Secure all caps and filler plugs for all systems.

2.2.1.3. PREVENT FIRE

Flammable materials such as wood, twigs, dried leaves or paper near the engine may cause fire. Remove them.

Check for fuel, lubricant and hydraulic oil leakage. If leakage is present repair the defective parts before using.

Checking points Refer to 4.1. Inspections before starting the engine.

Know how to use the fire extinguisher and where it is kept.

2.2.1.4. VENTILATE INDOORS

Engine exhaust gases are extremely dangerous. If you start the engine, use solvents or perform welding indoors, ensure there is adequate ventilation indoors.

2.2.1.5. KEEP MIRRORS AND WINDOWS CLEAN

Clean the windows and lights. Adjust the rear view mirrors to obtain optimal visibility when sitting in the operator’s seat. Clean the mirrors and windows, replace any broken glass. Make sure the necessary headlights or working lights are installed in accordance with working conditions and are working properly.

Clean mud or grease from your shoes and walkways before you get on or operate the machine. Be sure the foot pedals are clean and dryto eliminate the risk of your shoes slipping off the pedals.

2.2.1.6. CHECK AROUND THE OPERATOR’S SEAT

Never put parts or tools around the operator’s seat. They may interfere with the safety-locking lever or switch and cause an accident. Use the machine’s tool box to store them.

Mud, oil or snow on the floor, levers, handrails or step, can cause you to slip or fall. Wipe them clean. The excavator cab is designed for only one person. Do not allow anyone other than the operator to get inside the cabin or on the machine. Check if the seat belt and fittings are damaged or worn excessively.

Safety belt Refer to "Chapter 3.46. SEAT BELT".

2.2.1.7. SIGNAL BEFORE STARTING THE ENGINE

Make sure no one is near the machine before you get on.

Never start the engine when a warning tag is hung on any control device. (Example:' Do not start' or 'Under maintenance')

Before starting the engine, give an alarm by sounding the horn.

Start the engine and operate the machine only when sitting in the operator's seat correctly and make sure the safety belt is attached.

2.2.1.8. CHECK TIRES

Recommended air pressure must be maintained in every tire

Daily checks assure that inflation is correct. If your periodic check discloses a tire that is continuously losing air, a leak is indicated and must be repaired. During your pressure checks, also inspect for:

Objects wedged between duals or embedded in tires.

Mismatched duals. Diameters should be equal as well as amount of thread wear.

Missing valve caps and wheel lugs.

Cuts, tears, and breaks that may need repair.

Abnormal or uneven wear.

Damaged or poor fitting rim or rim flanges.

Projecting body hardware, loose fender bolts, spring clips- anything that could contact a tire

WARNING

Do not burn or weld on wheels or rims.

Check Tire Pressure

Check pressure of tires before starting operation with the machine A certain air pressure rise during operation is normal and should not be reduced. Overloads or over speeds may produce increased tire pressure due to heat. Reduce your load or decrease speed or stop the machine until the tires cool down

2.2.2. AFTER STARTING THE ENGINE

2.2.2.1. PRECAUTIONS IMMEDIATELY AFTER STARTING ENGINE

Check all gauges and indicators for proper readings.

Check for any alarm message indications on instrument panel, if there is such a message, do not operate the machine.

Be sure the area is safe for operation.

Listen for unusual noises, sounds and vibrations.

Test the engine speed control switch.

Operate each control to check their functioning and to get the feel of the machine.

2.2.2.2. BE ALERT WHILE OPERATING

Do not read

Do not drink

Do not eat

Do not operate the machine when you are under the adverse influence of alcohol, drugs, or medication.

Do pay attention to your work. If you must turn your attention elsewhere, stop the machine.

You must not allow fatigue or intensive work requirements to negatively influence your concentration and your good judgment. Better safe than sorry!

2.2.2.3. DIRECTION OF MACHINE BEFORE TRAVELLING

Know for sure the direction of lower chassis before operating the traveling lever.

2.2.2.4. MAKE SURE NO ONE IS NEAR THE MACHINE BEFORE SWINGING OR REVERSING

Use a lead man in dangerous or poor visibility conditions.

Make sure no one exists within the swing radius zone or operating route.

Before moving, give an alarm by horn or signal and make sure that no one stays around the machine within the danger zone.

There are blind-angle portions at the rear of the machine. Pay attention to the area when swinging. Ensure the route is clear before reversing.

2.2.2.5. PRECAUTIONS DURING TRAVELLING

If traveling retract the attachment as shown in-the following figure, and raise it 40 ~ 50 cm off the ground.

When it is unavoidable to operate the attachment during traveling, do not operate the lever abruptly. When traveling on uneven road, keep the speed low. When turning, do not operate abruptly. Travel slowly when turning.

When driving over obstacles or on an inclined surface, operate the machine so as not to lean on one side more than 10 degrees.

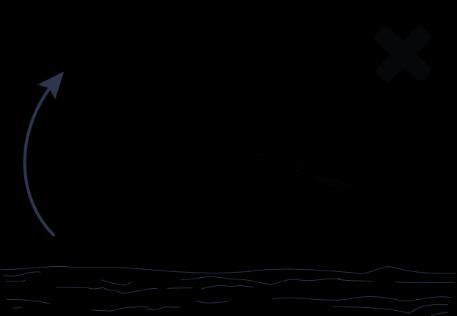

2.2.2.6. TRAVELLING ON A SLOPE

Pay attention not to roll over or slip while traveling on a slope.

If traveling on a slope, raise the bucket 20 ~ 30cm from the ground. In case of an emergency, immediately lower it onto the ground to stop. Never turn or traverse on a slope. If necessary, first come down to level ground, and make detour, then climb to your designated area.

Traveling on a slope Refer to 4 14. Cautions when traveling on a slope.

If traveling on a slope keep the machine longitudinal axis in line with the slope, and lower the traveling speed.

2.2.2.7. NEVER PERFORM DANGEROUS WORKS

Stop the machine far from the edges of a digging area.

Do not dig or undercut the ground supporting underneath the machine. The ground can collapse causing the machine to fall and/or to be buried. If necessary, prop up sufficiently so that the ground will not collapse.

Do not undercut overhead ground because the overhang could collapse onto the machine.

2.2.2.8. KNOW THE WORKING RANGE OF THE MACHINE

Be sure the attachment or load will not be obstructed during lifting or swinging. When lifting a load, do not lift, swing or stop unnecessarily fast.

Be sure the area is clear of the people before swinging or moving in any direction. Never swing or position attachment or load over people or vehicle cabs. Never allow personnel to walk or work under any part of the machine or load while the machine is operating.

2.2.2.9. NEVER APPROACH A HIGH VOLTAGE WIRE

You may receive an electric shock if the machine is too close to a high voltage wire. A narrow proximity even though without a physical contact will cause electrocution from the power line! Observe the following to prevent accidents: Maintain the recommended distance from the power lines. Use a lead man.

If the attachment contacts a live wire, stay in the cab, and if the machine is operational, try to break away the circuit by moving the attachment away from the high voltage wire.

If working near a high voltage wire, do not allow people to approach the machine. Contact the electric company before you start to work near overhead power lines. Secure the following distance between the machine and the wire for safety.

2.2.2.10. OVERHEAD OBSTRUCTIONS

Take special care when operating in places with limited height such as tunnels, underground bridges or power lines.

2.2.2.11. POOR LIGHTING CONDITIONS

When working in poorly illuminated conditions, use headlights.

In buildings, tunnels, etc., switch the lights on. Do not operate the machine when visibility is poor such as a heavy fog, snow or rain.

2.2.2.12. SNOW REMOVAL

An icy road is very slippery, so do not make sharp turns or brake suddenly. Particularly, when traveling on inclined surfaces, travel at low speed.

Take special care during snow removal work because the road condition can’t be seen.

2.2.2.13. UNSTABLE GROUND

When operating in dangerous places, take action to ensure safety before proceeding with the work. Danger of falling rocks or landslides are particularly high at the edges of steeps or pits.

When operating in areas with a risk of falling rocks, ensure the falling object protection structure (FOPS) is fitted.

2.2.2.14. WORKING ON A SLOPE

When swinging or operating the attachment on a slope, the machine may get unbalanced and roll over. Pay special attention.

It is very dangerous to swing downhill with a loaded bucket. Never operate in this manner.

If it is necessary to work on slopes, grade a level ground under the machine and then continue to work.

DO NOT SWING!

2.2.2.15. PARKING

Park the machine on level ground. If it is unavoidable to park on a slope, put a wooden block under each tire and lower the attachment to the ground.

If parking on a road is needed, arrange flags, barricade, lights or other warning markers without obstructing the traffic.

If you have to leave the machine, lower the attachment to ground, lock the safety-locking device, stop the engine, take the starter key and lock the door.

Do not leave the machine where there is a risk of falling objects, landslide or ground collapsing.

2.2.2.16. USE OUTRIGGERS FOR OPTIMUM STABILITY

If outriggers are available on your machine, use them for optimum stability. If it is necessary support with uniform pad.