4 minute read

D -HYDRAULIC ATTACHMENT AND MANUALLOCKING DEVICE

from Gehl CT6-18 Low Profile CT6-18 Turbo Telescopic Handler Operator's Manual 913223 - PDF DOWNLOAD

CT6-18

INSTALLING AN ATTACHMENT

-Ensure that the attachment is in a position for locking it to the carriage. If it is not correctly oriented, take the necessary precautions to safely position it.

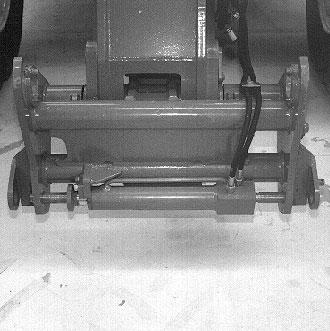

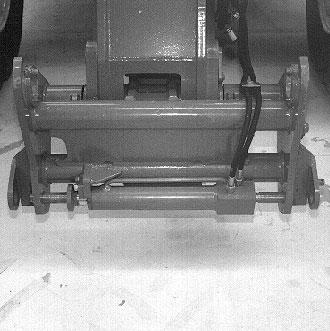

-Check that the locking pin and the clip are in position in the bracket (fig. A).

-Stop the engine.

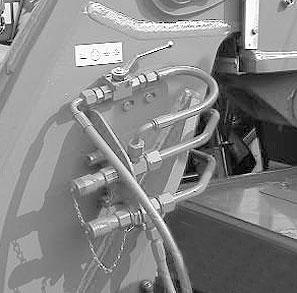

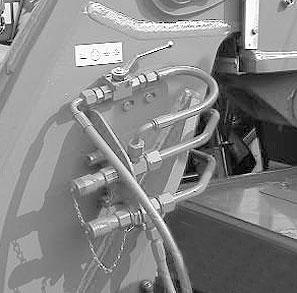

-Relieve the pressure from the attachment hydraulic circuit by operating the hydraulic control lever (1)(fig. E) several times.

-Connect the quick-connectors as needed for the attachment’s hydraulic movements.

IMPORTANT: Make sure that the quick-connectors are clean, and protect the connections that are not used with the caps provided.

MANUALRELEASING AND DISCONNECTING THE ATTACHMENT

-Proceed in the reverse order of paragraph MANUALLOCKING AND CONNECTING THE ATTACHMENT. Be sure to reinstall the locking pin and the clip in the bracket (fig. A).

REMOVING AN ATTACHMENT

-Proceed in the reverse order of paragraph INSTALLING AN ATTACHMENT. Be sure to place the attachment flat on the ground and in a closed position.

-Park the telescopic handler with the boom lowered in front of and in line with the attachment. Tilt the carriage forwards (fig. B).

-Bring the carriage under the mounting tube of the attachment, slightly lift the boom, and tilt the carriage rearward to position the attachment (fig. C).

E -HYDRAULIC ATTACHMENT AND HYDRAULIC LOCKING DEVICE

CT6-18 Turbo

INSTALLING AN ATTACHMENT

-Ensure that the attachment is in a position for locking it to the carriage. If it is not correctly oriented, take the necessary precautions to safely position it.

-Check that the pins (1) on the locking cylinder are retracted (fig. A).

-Park the telescopic handler with the boom lowered in front of and in line with the attachment. Tilt the carriage forward (fig. B).

-Lift the attachment off the ground to ease locking. MANUALLOCKING AND CONNECTING THE ATTACHMENT

-Remove the locking pin and the clip from the bracket (fig. A) and lock on the attachment (fig. D). Do not forget to replace the clip.

-Bring the carriage under the locking tube of the attachment, slightly lift the boom, and tilt the carriage rearward to position the attachment (fig. C).

-Lift the attachment off the ground to ease locking. HYDRAULIC LOCKING AND CONNECTING THE ATTACHMENT

-Place the selector valve in position A(fig. D), with the hydraulic circuit for the attachment locked open.

-Press button (1) (fig. E) on the hydraulic control valve joystick to lock the attachment on the carriage.

-Stop the engine, but keep the ignition “on.”

-Relieve the pressure from the attachment hydraulic circuit by pressing buttons (1) and (2) (fig. E) on the hydraulic control valve joystick four or more times.

HYDRAULIC RELEASING AND DISCONNECTING THE ATTACHMENT

-Close the attachment.

-Place the selector valve in position A(fig. D), with the hydraulic circuit for the attachment locked “open.”

-Press button (2) (fig. E) of the hydraulic control valve joystick down to release the attachment.

-Stop the engine, but keep the ignition “on.”

-Relieve the pressure from the attachment hydraulic circuit by pressing buttons (1) and (2) (fig. E) on the hydraulic control valve joystick up and down four or more times.

-Disconnect the quick-connectors of the attachment.

IMPORTANT: Make sure that the quick-connectors are clean, and protect the connections that are not used with the caps provided.

REMOVING AN ATTACHMENT

-Proceed in the reverse order of paragraph INSTALLING AN ATTACHMENT.

-Be sure to place the attachment flat on the ground and in its closed position.

F -HYDRAULIC ATTACHMENT AND HYDRAULIC LOCKING DEVICE

CT6-18 Option

INSTALLING AN ATTACHMENT

-Connect the quick-connectors as needed for the attachment’s hydraulic movements.

IMPORTANT: Make sure that the quick-connectors are clean, and protect the connections that are not used with the caps provided.

-Close the selector valve in position B (fig. D), with the hydraulic circuit for the attachment locking “closed.”

Warning

Always close the valve to position B (fig. D) after locking on the attachment, to avoid accidental unlocking, and to use the attachment safely.

-Ensure that the attachment is in a position for locking it to the carriage. If it is not correctly oriented, take the necessary precautions to safely position it.

-Check that the pins (1) on the locking cylinder are retracted (fig. A).

-Park the telescopic handler with the boom lowered in front of and in line with the attachment. Tilt the carriage forward (fig. B).

-Bring the carriage under the mounting tube of the attachment, slightly lift the boom, and tilt the carriage rearward to position the attachment (fig. C).

-Lift the attachment off the ground to ease locking. HYDRAULIC LOCKING AND CONNECTING THE ATTACHMENT

-Place the selector valve in position A(fig. D), with the hydraulic circuit for the attachment locked open.

-Move the hydraulic control valve lever (1) (fig. E) forward to lock the attachment on the carriage.

HYDRAULIC RELEASING AND DISCONNECTING THE ATTACHMENT

-Close the attachment.

-Place the selector valve in position A(fig. D), with the hydraulic circuit for the attachment locked “open.”

-Move the hydraulic control valve lever (1) (fig. E) rearward to release the attachment.

-Stop the engine.

-Relieve the pressure from the attachment hydraulic circuit by operating the hydraulic control valve lever (1) (fig.E) four or more times.

-Disconnect the quick-connectors of the attachment.

IMPORTANT: Make sure that the quick-connectors are clean, and protect the connections that are not used with the caps provided.

REMOVING AN ATTACHMENT

-Proceed in the reverse order of paragraph INSTALLING AN ATTACHMENT.

-Be sure to place the attachment flat on the ground and in its closed position.

-Stop the engine.

-Relieve the pressure from the attachment hydraulic circuit by operating the hydraulic control valve lever (1) (fig.E) four or more times.

-Connect the quick-connectors as needed for the attachment’s hydraulic movements.

IMPORTANT: Make sure that the quick-connectors are clean, and protect the connections that are not used with the caps provided.

-Close the selector valve in position B (fig. D), with the hydraulic circuit for the attachment locked “closed.”

Warning

Always close the valve to position B (fig. D) after locking on the attachment, to avoid accidental unlocking, and to use the attachment safely.