3 minute read

C -EVERY250 HOURS OF SERVICE

from Gehl CT6-18 Low Profile CT6-18 Turbo Telescopic Handler Operator's Manual 913223 - PDF DOWNLOAD

Perform the operations described previously as well as the following operations:

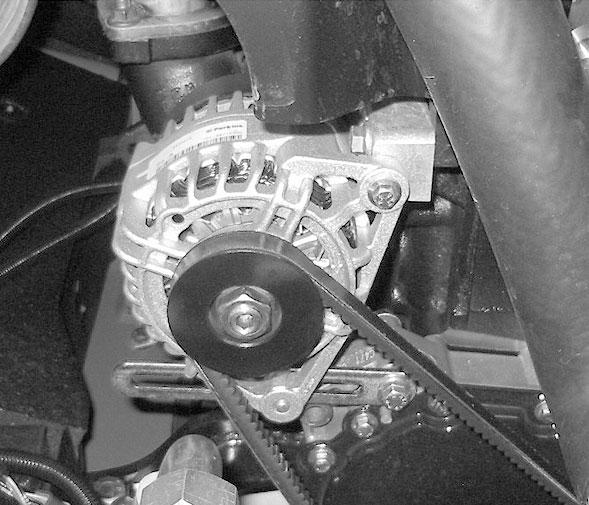

C1 -FANBELT TENSION CHECK - ADJUST

-Open the engine cover.

-Unscrew the fastening screws (1) (fig. C1/1).

-Remove the protective guard (2) (fig. C1/1).

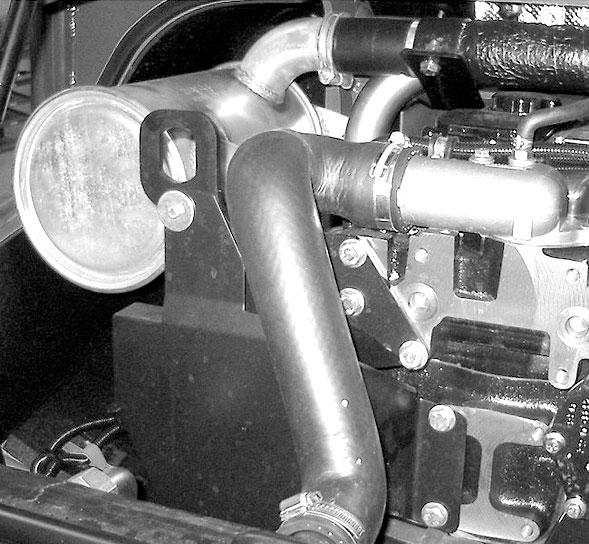

C2 -COMPRESSOR BELTS TENSION CHECK - ADJUST

-Open the engine cover.

-Unscrew the fastening screws (1) (fig. C2/1).

-Remove the protective guard (2) (fig. C2/1).

-Check the belt for signs of wear and cracks, and change if necessary (see chapter: 6 - MAINTENANCE: FILTER CARTRIDGES AND BELTS).

-Check the belt tension between the crankshaft pulley and the alternator pulley.

-Under a normal pressure exerted with the thumb 10 lbf. (45N), the tension should be approximately 3/8” (10 mm).

-Adjustment if necessary: a.Loosen screws (3) (fig. C1/2) by two to three turns. b.Pivot the alternator assembly to obtain the belt tension required. c.Retighten screws (3) (fig. C1/2) to a torque of 16 ft.-lbs. (22 Nm).

-Replace the protective guard (2) (fig. C1/1).

-Check the belts for signs of wear and cracks and change if necessary (see chapter: 3 - MAINTENANCE: FILTERS CARTRIDGES AND BELTS).

FAN TO COMPRESSOR BELT

-Check the belt tension between the fan pulley and the compressor pulley.

-Under normal pressure exerted with the thumb of 10 lbf. (45N), the movement should be approximately 3/8” (10 mm).

-Adjustment if necessary: a.Loosen screws (3) (fig. C2/2) two to three turns. b.Pivot the compressor assembly to obtain the belt tension required. c.Retighten screws (3) (fig. C2/2).

COMPRESSOR TO ALTERNATOR BELT

-Check the belt tension between the compressor pulley and of the alternator pulley.

-Under normal pressure exerted with the thumb of 10 lbf. (45N), the movement should be approximately 3/8” (10 mm).

-Adjustment if necessary: a.Loosen screws (4) (fig. C2/2) two to three turns. b.Pivot the alternator assembly to obtain the belt tension required. c.Retighten screws (4) (fig. C2/2).

-Replace the protective guard 2 (fig. C2/1).

NOTE: If the compressor belt is changed, check the tension again after 20 hours of operation.

NOTE: If the alternator belt is changed, check the tension again after 20 hours of operation.

C3 -TRANSFER BOX OILLEVEL CHECK

Park the telescopic handler on level ground with the engine stopped.

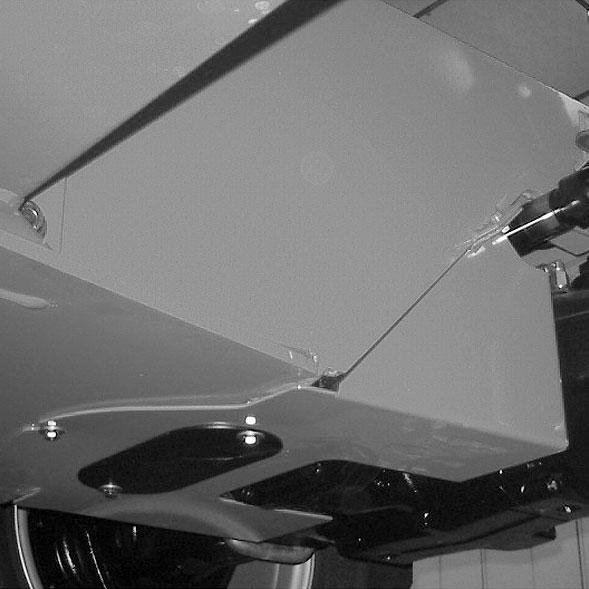

-Remove access panel (1) (fig. C3/1).

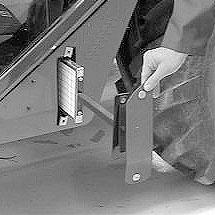

-Remove the cover plate (1) (fig. C4/2).

-Unscrew nuts (2) (fig. C4/3).

-Adjust the cable by loosening nuts (2) (fig. C4/3), until a clearance of 1/16” (1.5 mm) between cams (3) (fig. C4/3) and stops (4) (fig. C4/3) is obtained.

-Remove level plug (1) (fig. C3/2). The oil should be flush with the edge of the filler port.

Warning

The adjustment of the stops performed by the manufacturer must not be modified under any circumstances.

-If necessary, add oil (see chapter: 6 - MAINTENANCE: D11 - TRANSFER BOX OIL) by the same filler port.

-Replace and tighten the level plug (1) (fig. C3/2) 25 to 36 ft.-lb. (34 to 49 Nm) tightening torque.

C4 -PARKING BRAKE CHECK - ADJUST

Park the telescopic handler on a slope of less than 15% with the rated load in the transport position.

-Check the tightening adjustment by applying the parking brake in position A(fig. C4/1).

-The adjustment is correct if the telescopic handler is held stationary on a slope.

-Adjust if necessary.

Adjustmentof The Parking Brake Cable On The Frontaxle

-Press and release the brake pedal, then release the parking brake, by putting it in position B (fig. C4/1).

Adjustmentof The Parking Brake

-Leave the parking brake in position B (fig. C4/1).

-Progressively tighten the end piece of the lever (5) (fig. C3/1) and recheck braking.

-Repeat the operation until the correct braking adjustment is obtained.

C5 -CAB VENTILATION FILTER CHANGE

-Remove access cover (1) (fig. C5).

-Slide out cab ventilation filter (2) (fig. C5) and replace with new filter (see chapter: 6 - MAINTENANCE: FILTER CARTRIDGES AND BELTS).

-Re-install the filter and access cover.

C6 -FRONT AND REAR AXLE DIFFERENTIALOILLEVEL CHECK

Park the telescopic handler on level ground with the engine stopped.

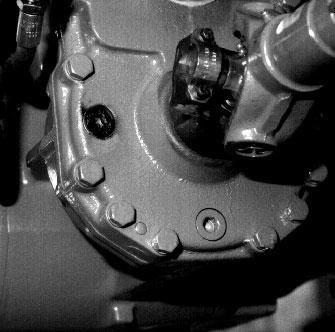

-Remove level plug (1) (fig. C6). The oil should be flush with the edge of the hole.

-If necessary, add oil (see chapter: 6 - MAINTENANCE: LUBRICANTS AND FUEL) at the filler port (2) (fig. C6).

-Replace and tighten the level plug (1) (fig. C6) [tightening torque: 25 to 36 lbs.-ft. (34 to 49 Nm)].

C7 -FRONT AND REAR AXLE PLANETARIES OILLEVEL CHECK

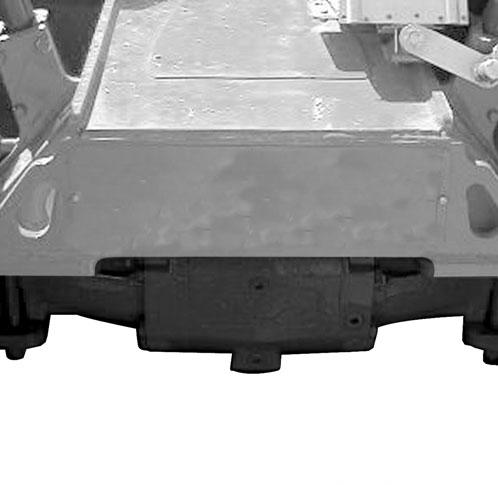

Park the telescopic handler on level ground with the engine stopped.

-Check the level on both front axle planetaries.

-Place level plug (1) (fig. C7) in the horizontal position.

-Remove the level plug; the oil should be flush with the edge of the hole.

-If necessary, add oil (see chapter: 6 - MAINTENANCE: LUBRICANTS AND FUEL) through the same hole.

-Replace and tighten the level plug (1) (fig. C7) [tightening torque: 25 to 36 lbs.-ft. (34 to 49 Nm)].

-Repeat this operation for both differentials.