3 minute read

CH APTER 14

SE T- UP & ASSEMBLY

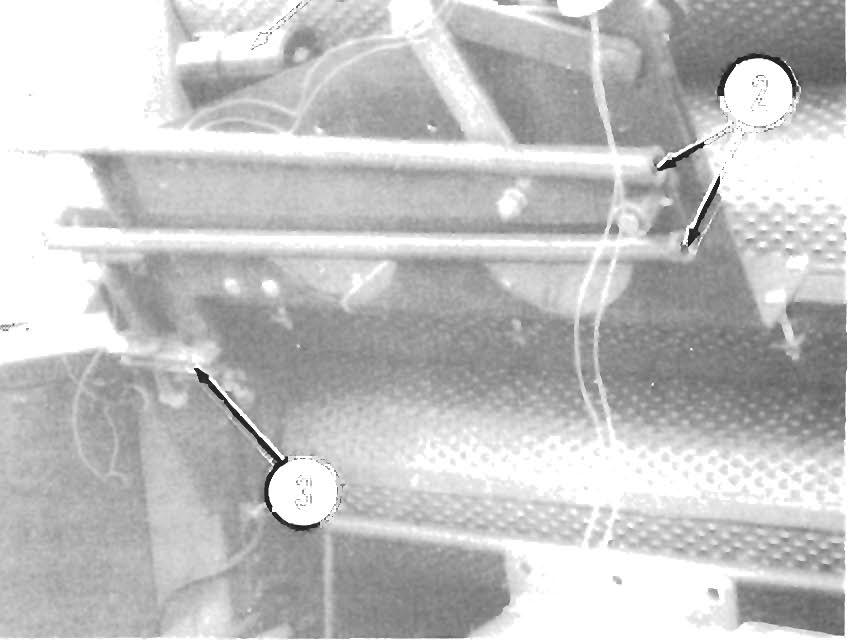

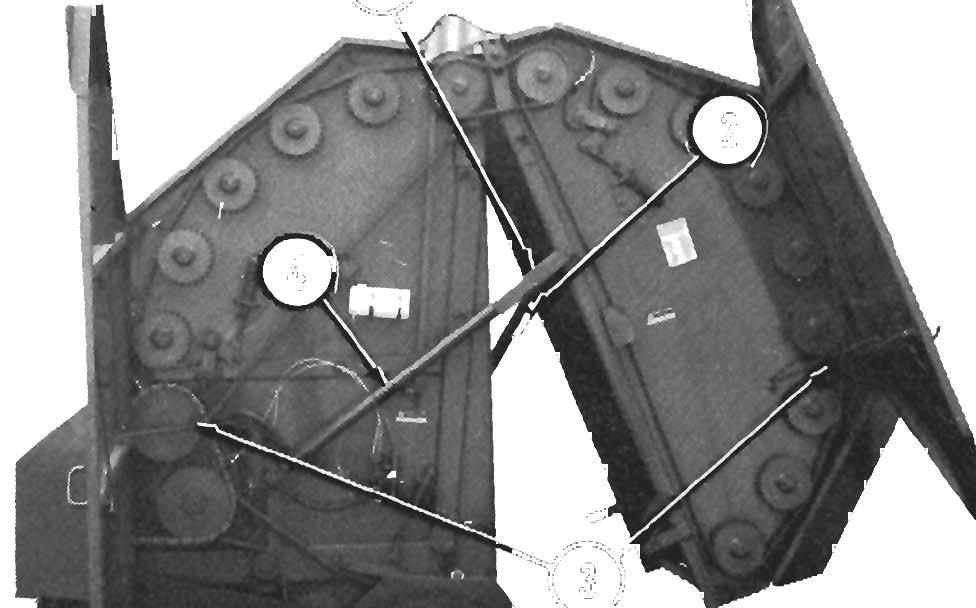

SHIPPING HARD WA RE (Figs. 14-1 & 14- 2)

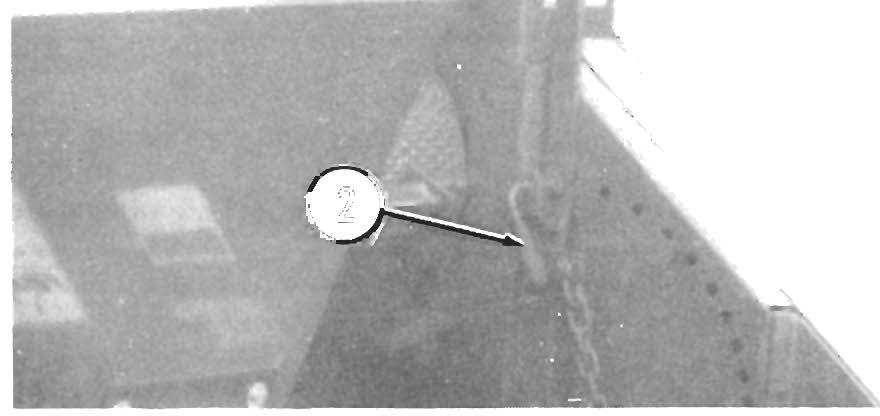

NOTE: The RB 171 0 Baler is shipped from the factory with the Rear Door bolted closed. BE SURE to remove the (2) Shipping Bolts (one on each side of the Baler, as shown), BEFORE attempting to open the Rear Door for the first time.

NOTE: Some units may also be shipped with a Door Lock Bracket arrangement on the Door Handles of the two Large Hinged Doors on the left side of the Baler. These brackets are used to keep the Doors closed during shipment and should also be removed and discarded.

WHEELS & TIRES

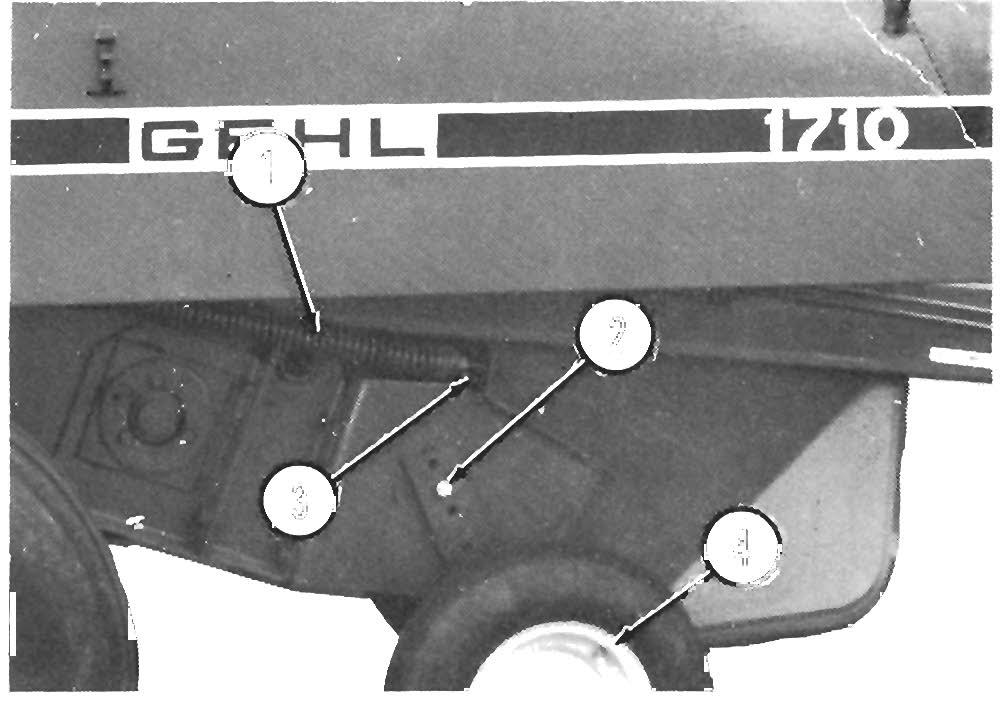

For transportation purposes, the RB 171 0 Baler may have been shipped from the factory without the Wheels and Tires mounted. If so, install the Wheels and Tires and tighten the Lug Nuts to 90 ft-Ib (124 Nm). Inflate the Tires to the pressure as listed in the Tire Pressures chart in the Service chapter.

Twine Tie System

Manual-Electric-controlled Tie System

Power Cable Routing

Make the Power Cable connection to the Plug on the Electric Actuator and route the tractor end connection along the Hydraulic Lines on the left side of the Drawbar, over the top of the Hitch Clevis and up toward the back end of the tractor. Install two (2) Nylon Tie Straps to secure the Power Cable to one of the Hydraulic Lines.

Tractor Control Box Installation

A Bracket is provided for attaching the Receptacle onto the tractor. The Bracket should be located on the rear of the tractor in a position which prevents the Cable from being caught by the PTO.

Appropriate hardware and mounting brackets are provided for attaching the Control Box to a non-supportive member (such as the cab or a fender) on the tractor. BE SURE to locate the Control Box within convenient reach. Make the Red (+) 12-volt and White (-) 12-volt tractor battery/ground connections for powering the Control Box.

Auto-Electric-controlled Tie System Control Box (Fig. 14-3)

1. If NOT already preassembled, install and secure (3) Magnets (067040) to the bottom of the Mounting Bracket (088345) using (6 each) #10-24 x 1/2 Round Head Machine Screws, Lock Washers and Nuts.

2. Secure the Control Box (088340) to the Mounting Bracket (088345) using the (2) M8-1.25 Nuts provided.

3. Set Control Box and Bracket Assembly aside.

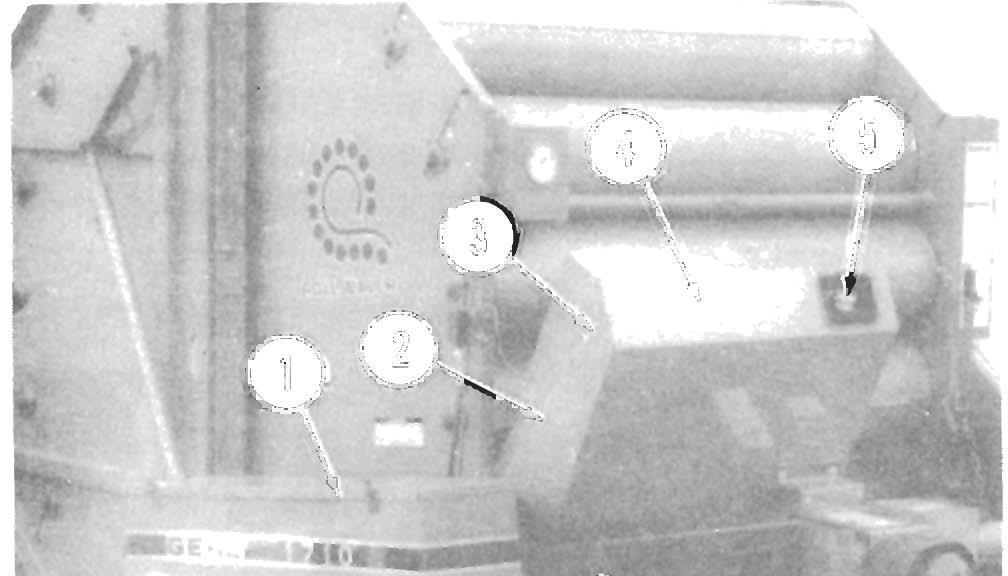

1 • Magnets (3)

2

• Mounting Bracket

3· #10·24 x 1/2 RHMS, L & N (1 each of 6)

4

• Control Box

5 • M8·1.25 N (2)

Fig. 14·3

Baler to Trac t or Wir ing Harn ess Routing & Conn ections (Fig. 14-4)

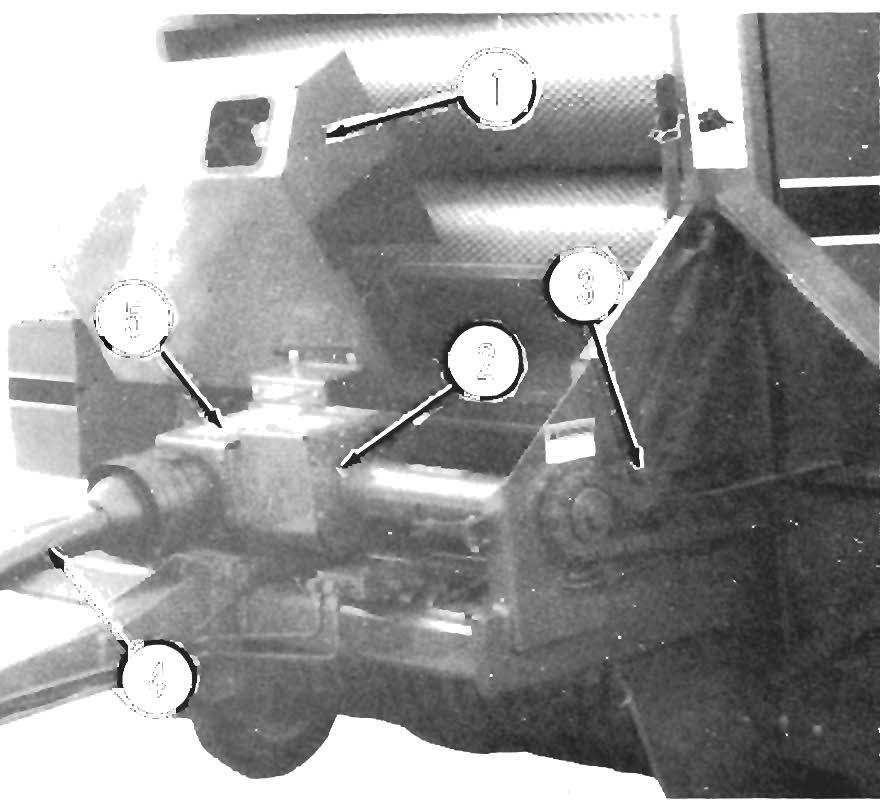

1. On the Baler end of Harness, connect the Harness Plug (Red and Yellow Wires) to the Plug from the Electric Actuator. Connect the Green Wire of the Harness to the Green Wire from the Delay Switch and anchor them to a hole in the Twine Mounting Plate with a #8-32 x 1/2 Round Head Machine Screw, Internal-Tooth Lock Washer and #8-32 Nut, making sure a good ground is made with the Plate

2. If Baler Harness is NOT al rea dy so equipped, cut the Ring Terminal Connec tor off the Brown Wire. Then, install the Spade Termi nal on the Harness Brown Wire. Then, connec t the Brown Wire of the Harness to the Brown Wire from the Delay Switch.

NOTE : The lengths of the Orange and Blue Wires are designed to match the requirements of several different models of Balers. Do NOT cutoff and attempt to splice together either wire. Form a loop with the excess Wire and anchor it around existing mounting brackets, when applicable.

3. Route the tractor end connection along the Hydraulic Lines on the left side of the Drawbar, over the top of the Hitch Clevis and up toward the back end of the tractor. Install two (2) Nylon Tie Straps to secure the Power Cable to one of the Hydraulic Lines.

Tractor Power Harness

NOTE: Some recent production tractors have "accessory power" terminals readily available in the cab or console to simplify electrically-powered accessory wiring.

Depending on the tractor provisions, properly and securely attach the RED Wire of the Power Harness (088341) to the positive (+) side of the tractor battery and the BLACK Wire to the battery's negative (-) side.

1 • Delay Switch Green (Ground) Wire· Connected to Com. Terminal & Anchored to Plate (along with Green Wire from Harness) with a #8·32 x 1/2 Round Head MachIne Screw, Internal Tooth Lock Washer & Nut Brown Wire· Connected to N.O. TermInal and to Brown WIre from Harness

2 • Actuator Power Plug

3

• Orange & Blue Wires Routed from Harness to Pressure Switch· Only Orange Wire Is Used, Blue Wire is Capped

4 • ElectrIc Actuator

5

• Orange WIre

6 • Pressure Switch