2 minute read

9.2. Transport position with ISOBUS Terminal

7 9.2 Transport position with ISOBUS Terminal

Danger!

When raising/lowering the rotors, make sure that nobody is in the pivoting area. There is a risk of injury. – Direct all persons out of the danger area. – Switch off the machine at once, if necessary. – If necessary, interrupt the control unit with the “STOP” key. Never work on the machine while the tractor's engine is running. – Switch off the engine. – Remove the ignition key.

Note!

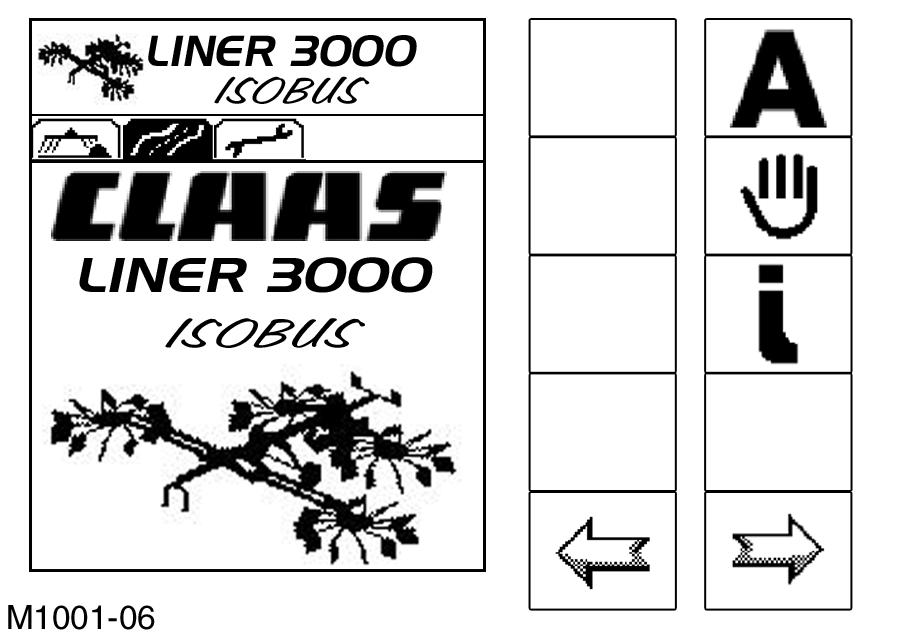

For further information see the operator's manual of the terminal being used, or Operation –CLAAS Communicator, page67. The symbols are explained in chapter 11 Operation – ISOBUS Terminal from page 75.

• Switch hydraulic system to pressure. • Turn the terminal on.

See the operator's manual of the terminal being used or Switching on/off the CLAAS Communicator, see page69. Press the “Soft Key”.

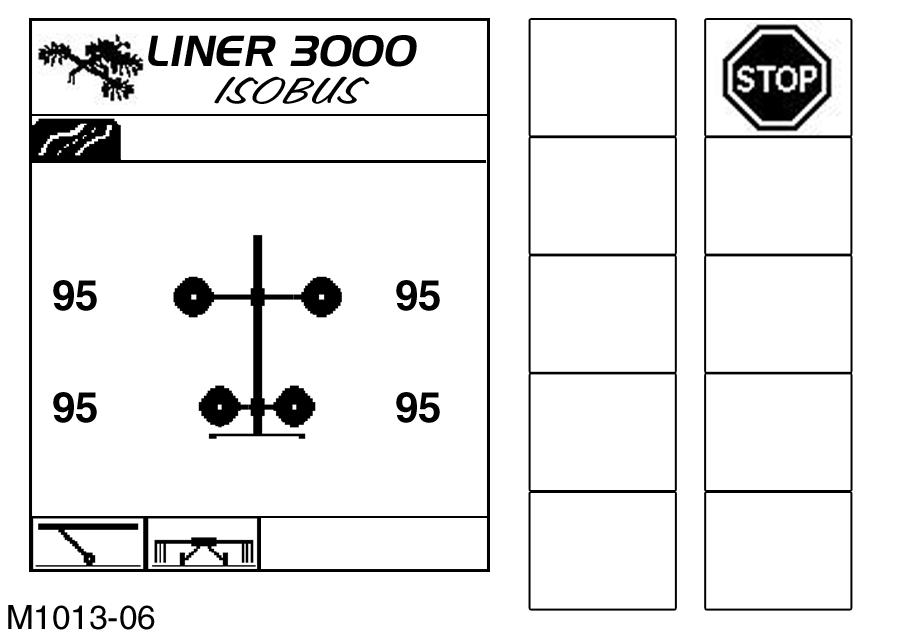

(Fig.7)

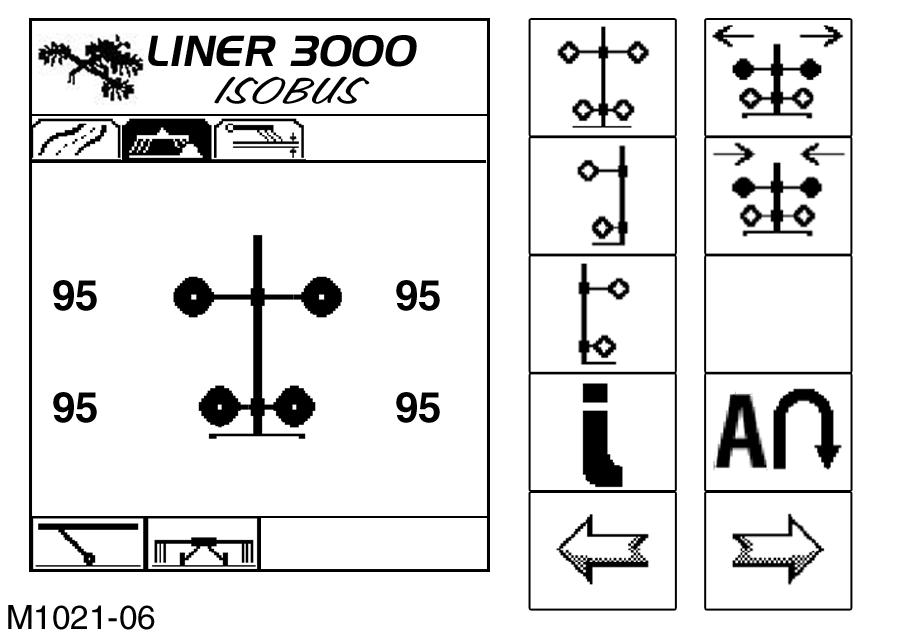

The tabs are changed with the following soft keys: “next” = next menu,

“back” = previous menu –see Soft Key icons, page77.

Note!

The “Road transport” menu can be opened from all menus shown in the tab.

8

71494

P

9

As an example, switching tabs with the “Working Position” screen (Fig.8) is described below: In the screen “Working Position” (Fig.8) press the “Soft Key”. – The submenu “Road transport” is opened –the

“Road transport” icon is shown inverted (Fig.10). (Fig.8)

• Switch off PTO shaft.

• If necessary secure the tractor with wheel chocks to prevent it from rolling. • Release parking brake on the tractor and on the swather. • Never actuate the foot brake and/or the parking brake while extending or retracting the running gear. (Fig.9)

Attention!

In transport position the PTO shaft must not be switched on, otherwise the PTO drive and the universal drive shafts may be damaged. – Switch off PTO shaft.

Attention!

Blocked wheels on the swather can lead to damage of the swather's running gear, because the running gear cannot be swivelled. – Release parking brake on the tractor and on the swather. – Do not operate foot brake.

10

11

12

Press the “Soft Key” (Fig.10).

– The machine is automatically set to transport position.

Note!

The automatic sequence can only be interrupted by means of the “STOP” key.

Note!

As soon as the axle has been swung into the transport position, the machine's hydraulic system must be depressurized (after about 10seconds). When the transport position has been reached, the control unit is automatically switched to “Stand-by” (Start menu) after about 2minutes.

– The display switches to the “automatically approach working position” screen (Fig.11).

After reaching the transport position: • Lower the three-point linkage –make sure there is sufficient ground clearance. • Depressurize the machine's hydraulic system. • Close the shut-off valvesfor the rear rotors –see Closing the shut-off valves for rear rotors (up to Serial No. 60501857), page40. (Fig.8,9,10,11,12)

For further procedures –see Before transport, page55.