Installation Requirements

Requirements Eaton AutoShift/UltraShift Gen 3 transmission systems installed at OEM facilities must meet the requirements and be approved using the Eaton Transmission Application Approval Form. Please contact Eaton Application Engineering or your OEM's Application department for the latest Application form. 1.

Cab Floor Access Plate - A cab floor access plate is necessary for access and removal of components from the transmission top. Plate size must be sufficient to allow removal of the transmission Controller or the Electric Shifter.

2.

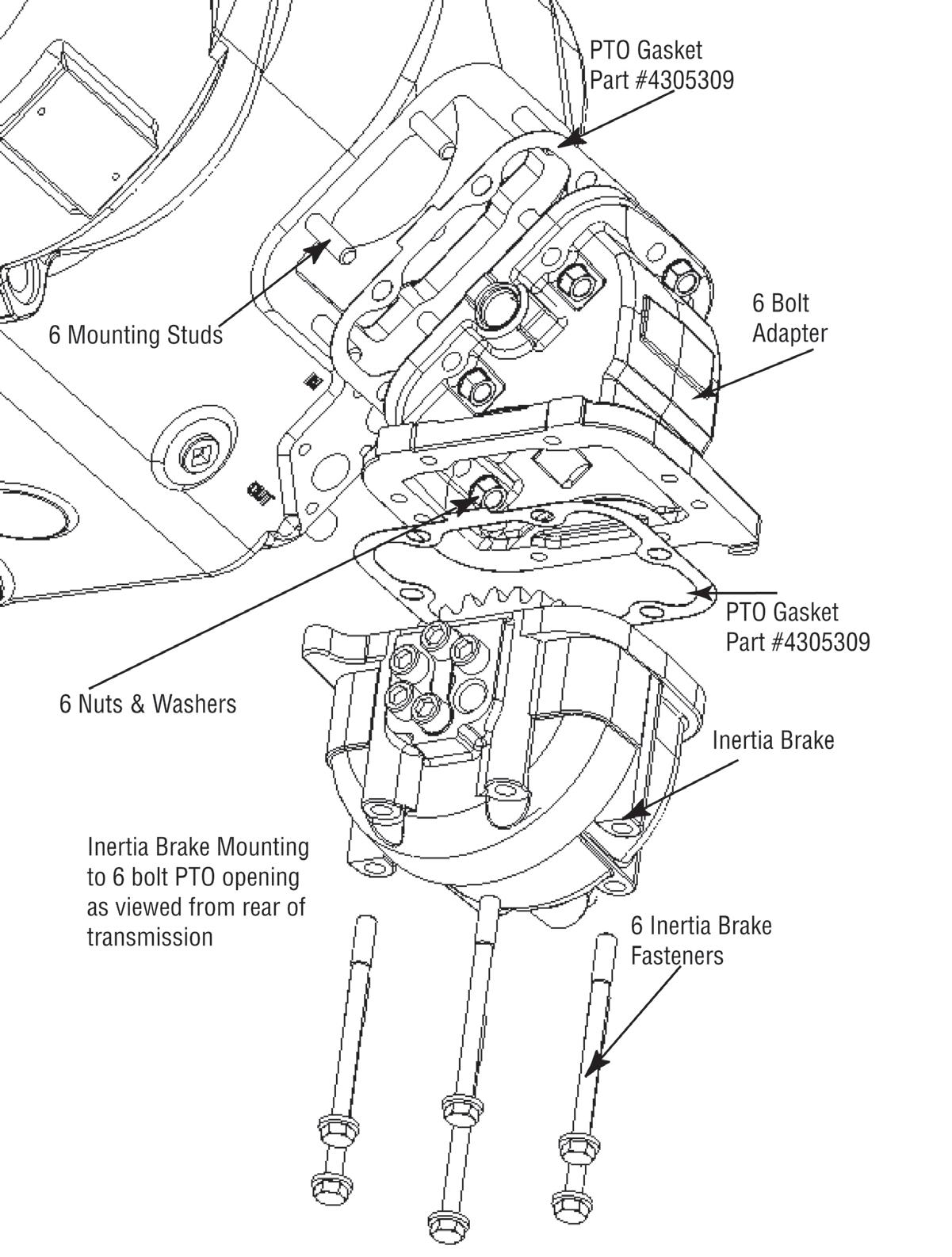

Clutch Requirements - Power assisted clutch release system is required for all rear engine coach applications. All Heavy Duty AutoShifts require adjustment free clutches. All UltraShift DM3 use the DM Clutch module. It is the OEM responsibility to ensure the engine is not allowed to idle between 625 and 825 rpm with HD UltraShift DM3 clutch modules. Base engine idle is recommended at 625 rpm and all methods (cruise/idle/PTO switch) used to raise the idle have a 200 rpm increment.

3.

Lubrication Requirements - Transmission Gear Box - Eaton® Roadranger® CD50 or equivalent E500 synthetic as specified in Eaton publication TCMT0021.WetClutch for UltraShift AW3 uses synthetic Dexron III, VI, or Allison TransSynd. Approved lubricants are specified in Eaton publication TCMT0021.[see page 16]

4.

Electrical Wiring Requirements - It is the OEM responsibility to provide power and ground to the Transmission Controller (TECU) from a reliable battery source from the battery which supplies the starter. The power (+) connection must include overload protection per Federal Motor Carrier Safety Regulations, Section 393.31.The TECU Main Power and Ground must be a direct connection from the battery posts to the TECU connector. At 120°C, these conductors must be able to carry 30 amps @ 9 volts with no more than 0.05 ohms per wire (0.1 ohms total) for a total voltage drop from the battery posts to the TECU connector not to exceed 3.0 volts. •

All wiring installation shall conform to Federal Motor Carrier Safety Administration Regulations Sections 393.27 Wiring specifications; 393.28 Wiring to be protected; 393.29 Grounds; 393.31 Overload protective devices; and 393.33 Wiring, installation.[see page 37]

•

The cable for the Deutsch connector shall be:

-

16 GXL max 18 TXL min for Communication and control wires 12 GXL for Power Supply wires 12 GXL or 14 SXL for V-Ignition wires

Note: These sizes are requirements for proper connector sealing and current carrying capacity.[see page 37]

2

•

When the Eaton Push Button Shift Control is used the CAN (Control Area Network communications link between the Shift Control and the Transmission Controller) must be a J-1939/15 twisted pair cable.[see page 49]

•

The J-1939 (the communications link between the Transmission ECU and the Engine Controller ECM) must follow SAE J-1939 specifications for either J-1939/11 or J-1939/15. [see page 61]

•

The diagnostic connector (6-pin required 9-pin recommended) must be easily accessible and mounted on the drivers side of the cab.[see page 60]

•

Splices are not allowed.[see page 37]

•

The Main Power 30 amp fuse connection for the Transmission ECU must be identified with a tag at the battery.[see page 56]

•

Battery Positive and Negative must be disconnected PRIOR to any type of welding on any Eaton Automated transmissionequipped vehicles.[see page 54]

•

Battery Negative must be disconnected PRIOR to removal or installation of ECU harness connectors.[see page 54]