The news that Europe’s truck makers, in the form of industry body ACEA, have got around the table with the European Council to discuss reforming deadlines for the phase-out of fossil-fuelled trucks is good news for us all, even though the UK is obviously no longer under the direct control of the EC.

On the face of it, the manufacturers have performed miracles in getting a range of usable zero-emissions heavy-duty vehicles to market, while continuing with parallel development of the next (and final, at least as far as Europe and the UK are concerned) generation of diesel engines.

As far as both Europe and the UK are concerned, the real inertia in the zeroemissions heavy-duty market lies not with the vehicles, but with the operators and the infrastructure.

The latter is still only progressing in baby steps here in the UK. There are still not nearly enough truck-compatible charging stations at the strategic locations that would make longhaul electric road freight transport viable. We can only look with incredulity at the amount of public money poured into the black hole that is HS2, and wonder how much further down the road to net-zero freight just a fraction of that would have got us had it been invested in heavy-duty EV infrastructure instead.

But that cash is gone, and in the current financial climate there is little hope of the transport sector seeing anything like that kind of Government investment in the future. Heavy-duty long-haul infrastructure will come, but it will be funded largely by private investment, and in the early stages is most likely to be provided by early adopters of electric trucks opening their charging facilities to each other. Alongside this are the bus depots which are being electrified at some speed, and offer mutually beneficial business opportunities for bus and freight operators, being already capable of handling the requirements of large vehicles and under-used during the working day.

All of this points to a lightest-first model for electrifying road freight.

We’ve said it before, and we’ll say it again. Urban trucks in the 7.5 – 18-tonne segment are the most affordable to electrify and bring the most benefits in terms of air quality to the most people. They also fit easily into bus depots.

Hopefully, the UK Government will follow the lead of the European Council, and review the schedules and targets for zero-emissions trucks. British targets should be reset to place the emphasis on the lighter end of the twoaxle market.

Established European manufacturers are not going to be delighted if the emphasis moves from trucks of over 12 tonnes to those of 7.5 – 18 tonnes, but as the UK no longer has an indigenous truck manufacturer that need not concern us too much. Ultimately, two or three electric lightweights can be put on the road for the price of one electric heavyweight, which represents an overall gain for the environment.

In any case, the normalisation of electric power at the light end of the market will eventually drive an easier transition at the heavy end. Operators will have the chance to build up confidence in the technology, and some degree of certainty in residual values can be reached.

Lighter trucks are traditionally the entry point for many new drivers, too. Raising the next generation of truckers (and technicians) with electrons, rather than diesel, in their veins is a great way of progressively de-carbonising the sector.

But with the European manufacturers now heavily-invested at the heavy end of the battery truck market, who is going to lobby for such a change?

Over to you, Logistics UK and RHA! Matthew Eisenegger, Publisher

INFORMATION

EDITORIAL

Publisher: Matthew Eisenegger

Managing Editor: Richard Simpson

Designer: Harold Francis Callahan

Editorial Address: Commercial Vehicle

Media & Publishing Ltd, 4th Floor 19 Capesthorne Drive, Eaves Green, Chorley, Lancashire. PR7 3QQ

Telephone: 01257 231521

Email: matthew@cvdriver.com

ADVERTISING

Advertising Sales: David Johns

Telephone: 01388 517906

Mobile: 07590 547343

Email: sales@cvdriver.com

DESIGN

Art Editor: Harold Francis Callahan

Telephone: 01257 231521

Email: design@cvdriver.com

CONTRIBUTORS

Steve Banner

Dr Lee Jurby

Grahame Neagus

PUBLISHED BY

Commercial Vehicle Media & Publishing Ltd, 4th Floor, 19 Capesthorne Drive, Eaves Green, Chorley, Lancashire. PR7 3QQ

Telephone: 01257 231521

NOTE

The publisher makes every effort to ensure the magazine’s contents are correct. All material published in Destination Net Zero magazine is copyright and unauthorised reproduction is forbidden. The Editors and Publisher of this magazine give no warranties, guarantees or assurances and make no representations regarding any goods or services advertised in this edition.

Destination Net Zero magazine is published under a licence from Commercial Vehicle Media & Publishing Ltd. All rights in the licensed material belong to Matthew Eisenegger or Commercial Vehicle Media and Publishing Ltd and may not be reproduced whether in whole or in part, without their prior written consent.

5,

Destination Net Zero Magazine is a registered trademark. © 2025

If

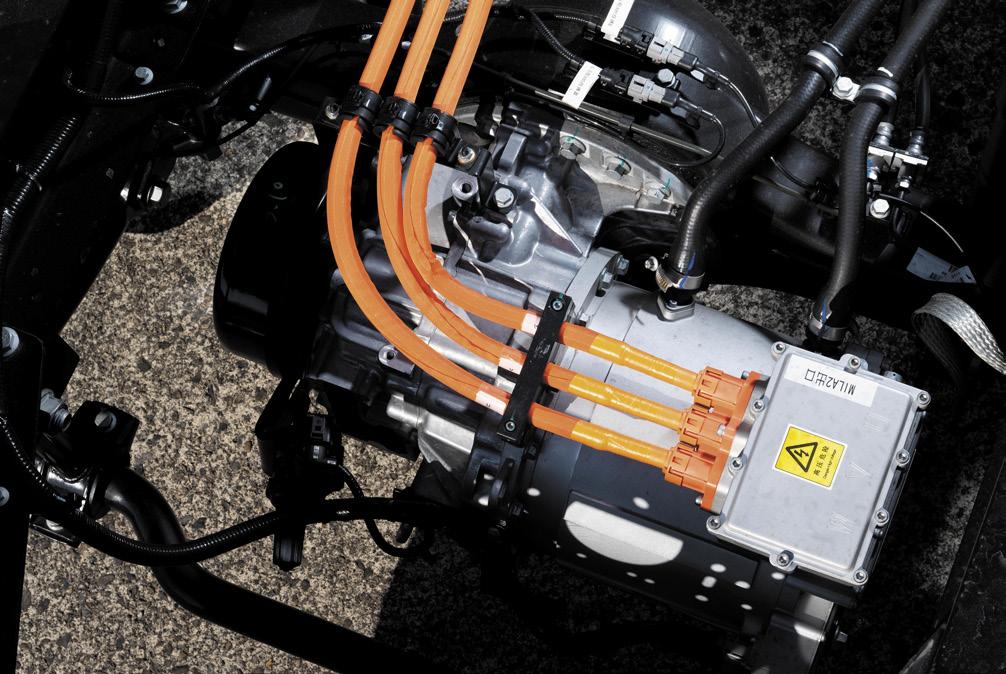

Using the traction battery from an electric tractor-unit to power a fridge trailer is possible using Carrier Transicold’s new eCool-Drive. The system transforms the battery’s DC power into AC to enable seamless and emissions-free temperature-controlled transportation.

European vehicle manufacturers’ association ACEA has warned the European Commission that more work is needed on infrastructure if electric trucks and buses are to take a greater share of the market, citing slow progress in improving grid capacity and installing megawatt chargers in addition to the need for greater incentives to encourage operator investment in vehicles.

ACEA said that a promise to revise CO2 targets in 2027 was too late.

“The vehicles are ready, but the enabling conditions are not,” warned Traton CEO Christian Levin. He added that he looked forward to swiftly working with the European Commissioners on “urgent, tailored measures” to address the situation.

Daimler Trucks CEO Karin Rådström reported: “We’re all-in on zero-emission transport, but we need real action on infrastructure and cost parity. Today, Europe has just 1,200 public truck charging stations. We need at least 35,000 charging points and 2,000 H2 refuelling stations by 2030. That’s 500 new charging points every month. And switching to zero emission has to make sense for our customers - they keep our society running by delivering goods and people.”

Renault Trucks has published an open-source map showing the location of public charging hubs for electric trucks in Europe. This is convenient tool giving a clear up-to-date overview of the current and planned state of the network. It provides proof that low carbon transportation is not just a promise, it is a reality: the charging infrastructure already available along the main highways means that electric trucks can now operate efficiently over long distances.

“A high-performance, dense and easily accessible public charging network is a prerequisite for a successful energy transition for freight transport,” the manufacturer said.

Charging facilities already in place or under development along the main European transport corridors allow transport operators to plan smooth electric truck journeys even over long distances.

Renault Trucks’ open-source map is regularly updated. It lists nearly 500 existing or soon-to-be-operational public charging hubs for trucks in Europe. Visit https://www.renault-trucks.com/en/trucks-charging-stations

Jean-Michel Vadecard, product girector, truck trailer international, Carrier Transicold, said: “At Carrier Transicold, our top priority is enabling a seamless transition to electric transport for our customers. “Through close collaboration with leading manufacturers of commercial heavy-duty vehicles, we ensure our solution fits easily into today’s electric fleets. We remain committed to offering reliable, flexible and safe technology that supports cleaner transport and helps reduce the industry’s carbon footprint.”

The 20kW eCool-Drive module is compatible with Carrier Transicold’s range of Vector units and all semi-trailers that support electrification. Its flexible integration capabilities offer fleet managers significant freedom to configure and optimise their vehicle fleets according to operational needs. eCool-Drive electrifies existing diesel refrigeration units, enabling fleets to upgrade to electric operation.

Compliant with R10 (electromagnetic compatibility) and R100 (highvoltage safety) standards, eCool-Drive features galvanic insulation to enhance system safety, efficiency and reliability.

“It’s one of the best things we’ve ever done.”

“The installation of Truckfile into our workshop and fleet has been a real breath of fresh air and is helping the whole operation to run much more smoothly.”

Chris Thompson, General Manager at James Shaw & Son

Compliance.

Done digitally.

Driver Check, Fleet & Workshop Management www.truckfile.co.uk

Renault Trucks has launched Zeroing In: a new video series designed to cut through the noise surrounding electromobility and help transport operators navigate the road to decarbonisation with confidence.

Streamed across Renault Trucks UK’s social channels, Zeroing In puts the brand’s inhouse electromobility experts front and centre, offering practical insights and clear guidance for fleet decision-makers grappling with the shift to electric transport. As a long-standing pioneer in electromobility: with its first series-production electric truck launched in 2020; Renault Trucks brings realworld experience and proven success to the conversation. That expertise now takes the spotlight in a dedicated digital hub featuring expert videos, whitepapers, and tailored resources, as well as exclusive updates for operators looking to join a growing community on the road to zero emissions.

The first three episodes will be released over the next few weeks, each exploring a key theme in the electric transition from decoding EV terminology to tackling infrastructure, energy management, and daily operations.

Hosted by Roger Clarke, Head of Electromobility and Customer Advanced Solutions at Renault Trucks, the series promises to make complex topics simple. Designed for busy professionals, every instalment delivers concise, high-impact content, supported by both long-form and short-form formats for maximum reach and engagement.

“We know the transition to electric can feel daunting,” said Alex Williams, Head of Brand and Communications, Renault Trucks UK & Ireland. “Through Zeroing In, we’re sharing our expertise

in clear, practical ways — answering the most pressing questions and giving operators the clarity they need to act with confidence.”

More than just an awareness campaign, Zeroing In aims to inspire action, challenge perceptions, and cement Renault Trucks’ role as a trusted leader in sustainable transport.

The series opens with a thoughtprovoking question from Clarke: “If electric is the future, how do we get there?” setting the tone for a programme designed to inform, engage, and empower.

The first episode of Zeroing In is now available on Renault Trucks UK’s social media channels and via the dedicated Zeroing In online hub.

Tesco supermarket has added 42 new natural-gas powered Iveco S-Way 4x2 trucks to its fleet in Livingston, Scotland. Transporting food and other goods to Tesco locations across Scotland, these trucks are each expected to cover 200,000km per year, meaning a potential annual saving of up to 6,473 tonnes of CO2 across the fleet.

Powered by the new xCursor13 CNG engine, the new S-Way produces a class-leading 500hp, making it the most powerful monofuel natural-gas truck on the market. In addition to exemplary performance, the S-Way can yield up to 95% CO2 saving versus an equivalent diesel truck when running on bio-CNG. Mirrorcams also greatly reduce drag in comparison to a standard mirror, a technology that further improves vehicle efficiency and boosts driver visibility.

In addition to the rapidly growing CNG refuelling network in the UK, Tesco has worked with CNG Fuels to create a refuelling station adjacent to its Regional Distribution Centre for added flexibility. Drivers can refuel these trucks with ease, in a way comparable to conventional diesel trucks, ensuring they quickly return to service while benefiting from the sustainability of CNG.

Retailer Co-op Group has replaced 30 diesel tractor units with new Scania P340 4x2 tractors powered by CNG. Besides running over 2300 of its own food stores, Co-op is also a wholesale provider to about 6000 additional outlets. Operating from depots in Avonmouth, Lea Green, and Newhouse, the 30 gas-burning Scanias will reduce CO2 emissions by an estimated total of 1800 tonnes a year. They use Scania’s OC09 fivecylinder gas engine which produces up to 1600 Nm of torque driving through Scania’s G25 gearbox.

Aberdeen-based Keenan Recycling has expanded its fleet with 10 new Iveco Eurocargo CNG trucks, reinforcing its commitment to sustainable food waste collections. The trucks burn bio-methane produced from Keenan’s collected food waste, reducing CO2 emissions by up to 95 per cent compared to diesel. The 220 hp trucks’ range is extended by adding three additional 140-litre gas tanks to the standard six 115-litre tanks, and the Macpac 110 bodies fitted carry 11 cu m/eight tonnes of waste, loading via a side-lift capable of handling 1280-litre bins.

Are you aiming for a smaller CO2 footprint, high performance and a long operating range? Then look no further... The Volvo FH Aero gas-powered is a long-haul truck shaped for aerodynamic efficiency. Running on bio-LNG and HVO, it reduces your CO2 footprint and let’s you cover long distances with high payloadscarbon neutral when calculated from tank to wheel. Your efficiency. Extended.

Contact your local Volvo Trucks dealer or visit volvotrucks.co.uk

German automotive giant Bosch is using a hydrogen truck powered by its own fuel-cell technology at its Nuremberg plant.

The Iveco S-Way 6x2 tractor is equipped with a Bosch FCPM fuel-cell power module and has a range of up to 800 km. It is operated by freight-forwarder Schäflein which rents the vehicle from Hylane, a specialist in emissionsfree trucks. The truck, which primarily transports products from the plant’s own manufacturing operations, is expected to cover 12,000 km per year.

With the Iveco FCPM truck, Bosch has put its own fuel-cell system into operation in Europe for the first time: it previously provided the equipment to the failed Nikola venture in the USA. The truck’s five hydrogen tanks hold up to 70 kilograms at a pressure of 700 bar. Its fuel-cell system delivers a total output of over 200 kilowatts. Its e-axle is powered by the fuel-cell system, while two battery packs installed centrally in the truck serve as energy storage. The truck has a system output of 400 kilowatts and a gross weight rating of up to 44 tonnes. In addition to its robustness and long range – which, unlike battery-electric vehicles, is not affected by ambient temperature – the truck offers refuelling times similar to those of a diesel truck.

Daimler Truck has completed a year of customer trials for its Mercedes-Benz GenH2 truck in Germany. Five prototypes were deployed with partners including Air Products, Amazon, Holcim, INEOS Inovyn, and Wiedmann & Winz. The tests evaluated reliability and efficiency under real operating conditions, covering more than 225,000 km.

The Mercedes-Benz GenH2 Truck prototypes demonstrated consistent fuel cell performance using technology developed by cellcentric: a joint venture between Daimler Truck and Volvo Group. Hydrogen consumption averaged between 5.6 kg/100 km and 8 kg/100 km, with gross weights from 16 to 34 tonnes.

Customers reported ranges exceeding 1,000 km and refuelling times of 10 to 15 minutes. Drivers reported smooth handling, strong power delivery, and low cabin noise. The GenH2 Truck features a 300-kW fuel cell system with a 70-kWh battery to support peak power demand.

High hydrogen and insurance costs continue to make achieving a positive total cost of ownership (TCO) difficult. Daimler Truck plans to begin a second trial phase in late 2025 with additional customers and expects to launch small-series production of 100 fuel cell trucks by the end of 2026. However, the slow pace of refuelling infrastructure development may postpone large-scale hydrogen truck operations until the early 2030s.

Chemical company TALKE USA is adding two converted hydrogen-powered Class-8 Freightliner Cascadia heavy tractor units to its drayage fleet. The trucks will be retrofitted by Symbio North America utilizing the group’s proprietary fuel cell system and hydrogen-electric powertrain design to meet the performance and safety demands of chemical logistics.

This collaboration marks a significant step in TALKE USA’s efforts to decarbonize chemical logistics while maintaining the highest standards of safety and reliability. The new hydrogen-powered trucks are engineered for the rigorous requirements of tanker work, supporting environmental goals and operational excellence.

The new trucks will be tailored for TALKE’s tanker drayage operations, supporting short-haul movements while reducing emissions. This initiative is part of TALKE’s broader ESG program, Crafting Responsible Logistics, which focuses on climatefriendly solutions that meet today’s operational needs while preparing for tomorrow’s challenges.

The units are expected to be fully operational in 2026, furthering the move towards TALKE’s targets for carbon reduction, while maintaining reliability and service standards.

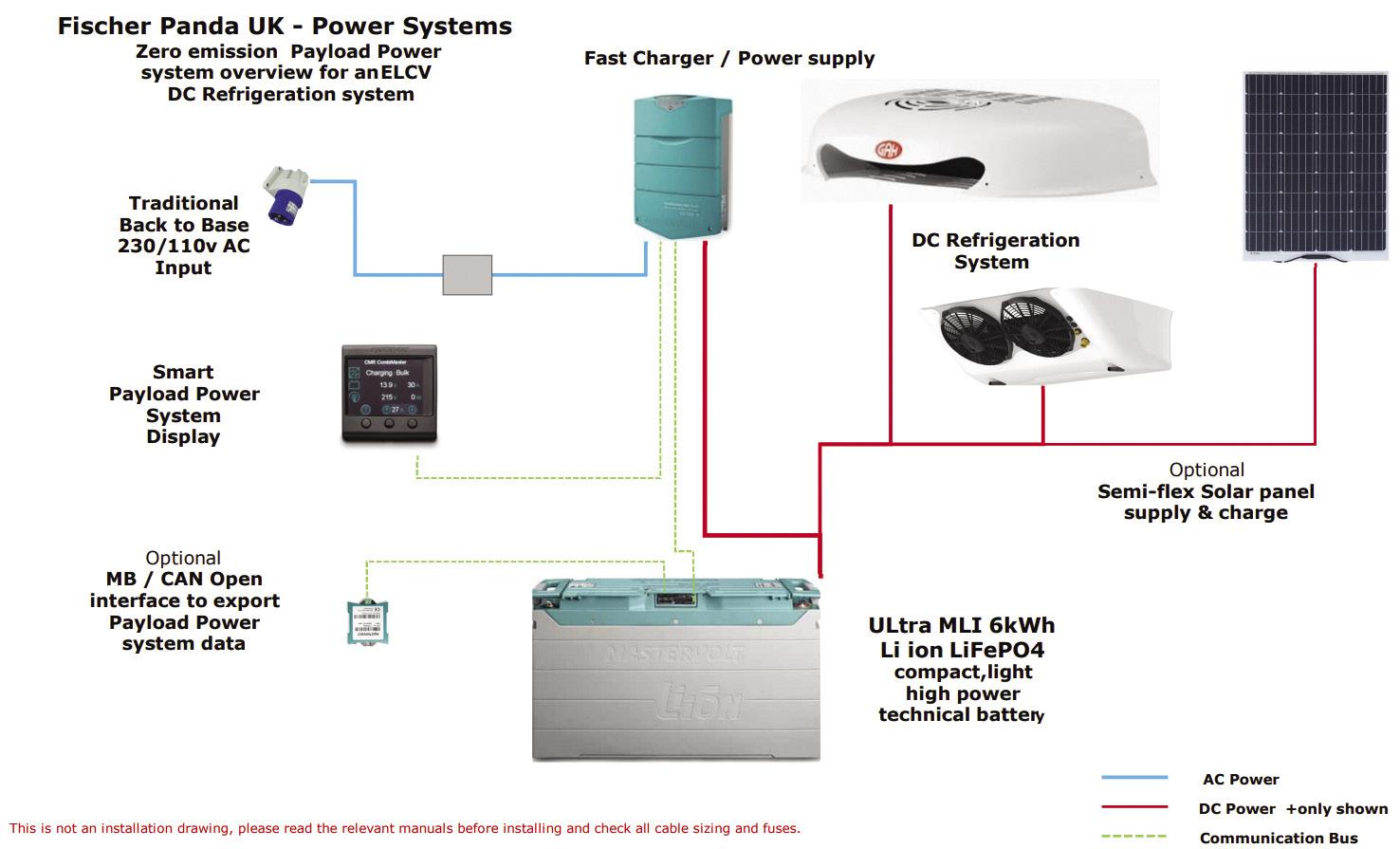

Cold chain logistics, particularly pharmaceutical transport, is one of the most demanding areas of modern transport. Companies across the UK are collaborating to find optimised solutions to power zero-emissions energyintensive refrigeration systems without compromising payload, range, or reliability.

In the UK, road transport emissions account for approximately 30% of total greenhouse gas emissions, with road vehicles responsible for about 89% of domestic transport emissions. To address this, the UK has committed to phasing out the sale of new petrol and diesel vans by 2035, with zero-emission commercial vehicle sales expected to surge as fleets prepare for the transition.

However, moving to electric vehicles poses a significant challenge: energyintensive refrigeration systems can drain onboard power quickly, leading to range anxiety and reliability concerns. For pharmaceutical transport, the stakes are even higher. Medicines, vaccines, and biologics must be kept within tightly controlled temperature bands – often +2°C to +8°C for chilled and -20°C for frozen products – with continuous monitoring to ensure patient safety and regulatory compliance. Any deviation risks costly spoilage, reputational damage, and

even public health. In this context, a reliable, efficient onboard power system is not just an operational need but a critical safeguard.

Refrigerated transport operators face mounting pressure to reduce emissions while maintaining strict standards for temperature-sensitive goods. Operators need solutions that guarantee reliable, consistent cooling performance while completing routes without compromising vehicle range.

A pioneering collaboration

Fischer Panda UK | Power Solutions addressed this challenge in a pioneering project with Mertrux, a UK MercedesBenz commercial vehicle dealer.

Working in partnership with GAH, DBS Ltd, GRP-Group, and Pace Technology, the team delivered a fully integrated, zero-emission refrigeration solution based on the 4.2-tonne Mercedes-Benz eSprinter. At the heart of the solution

is a compact Mastervolt MLI lithium battery paired with a Chargemaster, delivering long-duration, independent cooling while maintaining the vehicle’s OEM range. Complementing this, a high-performance refrigeration system from Mertrux ensures reliable and consistent temperature control for sensitive pharmaceutical cargo. A slimline solar array extends runtime sustainably and reduces reliance on external charging, while an integrated monitoring system provides realtime data on temperature, battery performance, and energy consumption, giving operators full oversight and confidence on every route.

“Any deviation risks costly spoilage, reputational damage, and even public health.”

Mertrux highlighted the success of the collaboration: “The battery powers both fridges and runs directly from the vehicle’s electrical system. Thanks to Fischer Panda UK’s hands-on support, we delivered a reliable result.”

The first vehicle of this model was commissioned in March 2025 and displayed at this year’s Commercial Vehicle Show. Around the same time, Fischer Panda UK was recognised with the ‘Innovation in Vehicle

Fischer Panda UK Ltd offers full-system design capability, servicing and aftercare as a leading distributor of diesel generators, air-conditioning systems, hybrid electric solutions and integrated mobile power solutions for a variety of commercial and specialist application vehicles. Renowned worldwide as innovative, reliable and extremely quiet, the extensive Fischer Panda range of compact diesel generators includes its next generation highly efficient and powerful variable

speed iSeries-Generators. Other world-class products from Fischer Panda UK | Power Solutions include the sustainable power solutions from Clayton Power and EFOY. The company is working as the sole UK automotive distributor for Mastervolt and a wide range of refrigeration and air conditioning solutions as the UK exclusive distributor for Autoclima and Eberspächer Breezonic. Fischer Panda UK | Power Solutions was among the first companies to achieve ISO

Enhancement’ award at the 2025 Motor Trader Commercial Industry Awards, reflecting the company’s ongoing commitment to advancing onboard technology across the commercial vehicle sector.

This case study demonstrates how the right onboard power solutions can make sustainable, compliant, and high-performance cold chain transport a reality for the pharmaceutical sector. By integrating advanced low-emission power solutions tailored to the specific demands of refrigerated fleets, it is possible to balance sustainability goals with dependable real-world performance. These innovations reflect a wider shift across the cold chain sector: one that prioritises emissions reduction without compromising reliability, safety, or customer confidence. It is this blend of sustainability, resilience, and technical excellence that will define the next chapter of cold chain logistics in the UK.

For more information or to discuss your own tailored mobile power solution visit: www.fischerpanda.co.uk.

UKAS 9000:2015 accreditation and operates from a purpose built 9,000 sq. ft facility in Verwood, Dorset. Active in the military and automotive sectors, the company works with UK MOD and other military units around the world providing solutions for specialist vehicle and landbased applications. Two-thirds of Formula 1 mobile truck units install Fischer Panda generators, as do the BBC, Sky and many other mobile broadcasting vehicles.

Waste management, demolition and recycling specialist, Collard Group, has cited ContiLifeCycle’s sustainable retread tyres as the reason for a 50 percent overall reduction in blowouts across its fleet within the last two years.

Collard Group operates from nine recycling facilities across Hampshire, Surrey, Berkshire and Oxfordshire.

Lee Troddyn, transport manager at Collard Group, said: “In under two years, I can wholeheartedly say that our retread tyres have led to a 50 percent reduction in blowouts across our entire fleet. Statistics like this are impossible to ignore. On top of that, it’s reassuring to know that while the tyres are delivering outstanding quality and performance, they’re also a more sustainable choice – helping us reduce our environmental impact without compromise.”

One specific product that has consistently proven its value for Collard Group is the BIG D – a retread tyre produced under the Bandvulc brand, which is a key element of the ContiLifeCycle premium hot retreading service. As well as offering ‘like new’ quality, retread tyres major on sustainability by conserving significant natural resources, using less energy and producing fewer greenhouse gas emissions compared to new tyres, while reducing landfill waste by giving worn casings a second life.

Faster charging speeds are essential for the wider adoption of electric vans, says the Association of Fleet Professionals (AFP). Most models are rated around 50-125kWh, meaning that even the best will take around 40 minutes to charge from 10-80% in ideal circumstances, and are usually slower.

Paul Hollick, chair at the AFP, said: “When it comes to tackling the reasons behind slow fleet adoption of electric vans, prominence has been given to issues of range and payload but there has been limited discussion of charging speeds.

“In fact, as discussed at a recent meeting of members who operate very large fleets, charging-speeds tend to be a bigger real-world frustration. Having a driver sitting around for an hour while their van charges is expensive.

“If vans were capable of faster charging then, to a significant extent, other issues affecting them tend to become more manageable. For example, the negative impact of higher payloads on range becomes less important if you can recharge to 80% every 125 miles in 15 minutes.

“Our members would be willing to pay more for faster charging capacity. Over a typical six-year fleet lifecycle, the additional cost of a rapid-charging van would be more than outweighed by increasing availability.”

Prometeon Tyre Group UK & Ireland has been named ‘Tyre Manufacturer of the Year’ by the National Tyre Distributors Association.

The award – widely regarded as the most prestigious accolade in the UK tyre industry – recognises Prometeon’s exceptional progress, innovation, and commitment to sustainability since entering the UK market in 2018.

Judges commended tyre manufacturer Prometeon’s focus on innovation, product reliability, and sustainability, underpinned by strong customer relationships and a high-performance culture. The company’s UKbased SuperTruck network, launched in 2023, has strengthened national coverage and support for fleets, while its Pro Retread lifecycle solution helps operators reduce environmental impact and total cost of ownership.

In addition to its win, Prometeon was also shortlisted for the Environmental & Sustainable Solution of the Year Award – recognition of its strong progress on sustainability. The company has achieved a 35.8% reduction in greenhouse gas emissions since 2016, a 98% waste recovery rate, and a clear path to net-zero by 2040, all validated by a Low Risk ESG rating from Morningstar Sustainalytics.

Continental has launched the VanContact A/S Eco van tyre. As the first all-season tyre with the highest rating in all categories of the EU label including rolling resistance, it is claimed to set new standards in performance in the van segment, and can offer EV operators excellent grip in all conditions without compromising range.

Nicolas Jackisch, Continental’s product manager Van Tyres, EMEA, said: “Thanks to its optimised rolling resistance, the VanContact A/S Eco contributes to reduced energy consumption and lower CO2 emissions, while maintaining high standards in safety and comfort.”

The VanContact A/S Eco meets the highest EU labelling standards (A/A/A): rolling resistance has been reduced by 21 percent, noise and vibration have been reduced by more than one decibel compared to its predecessor and the VanContact A/S Eco offers significantly improved grip in aquaplaning conditions by increasing resistance to tyre float by ten percent.

It has been developed to be suitable for ICE and BEV drivelines. The tyre is marked with the EV Checkmark symbol on the sidewall, indicating its suitability for electric vehicles.

Class-leading range of up to 180 miles, the Yutong TE7 7.5t electric truck is the perfect vehicle to begin electrifying your fleet

Following good growth over the last few years, 2025 has seen the HGV and LGV market continue to normalise, with slightly fewer registrations of new vehicles and tractor units in the UK so far this year. Despite the slow down, many of these require funding and at Close Brothers Asset Finance, we have been doing just this for customers looking to buy new or upgrade existing fleets.

Year LGVs Registered % Change YoY

2023 352,000 +20.5%

2024 363,000 +3.3%

2025 127,875 (Jan–May) —

*Source: Gov.UK

Year LGVs Registered % Change YoY

2023 352,000 +20.5%

2024 363,000 +3.3%

2025 127,875 (Jan–May) —

*Source: SMMT John Fawcett

John Fawcett, CEO of Close Brothers Asset Finance’s Transport division explained: “There are various products that come under the broad umbrella of asset finance with one of the key ones being refinancing or capital release; it’s a proven way to make your assets work for you and release cash back into the business.

“It’s pretty straightforward and works by the finance company purchasing the asset and financing it back to you, with repayments calculated in line with the income the asset is expected to generate; at the end of the refinance term, you own the asset.”

John added: “It’s important to understand that at Close Brothers Asset Finance we ensure each deal is bespoke to a customer’s needs; by offering a personal face-to-face or virtual service, we look outside the box to provide the solution needed.

“Each product is tailored to a customer’s individual needs - it’s not one size fits all. Our evolution is about ensuring we’re flexible to customers’ changing needs, offering agreements that fit their cash flow requirements at a given point in time, rather than merely providing a standard vanilla offering.”

• Hire Purchase is a product where the borrower agrees to pay for an asset in instalments over an agreed period, during which they are responsible for the maintenance and repair of the asset. When the agreement ends, the borrower has the option of purchasing the asset outright

• Sale and HP Back is a form of refinance where the lender purchases an asset and finances it back to the borrower. Repayments are calculated in line with the income stream that will be generated by the asset, and at the end of the refinance term, the borrower owns the asset

• Finance Lease lets the borrower use equipment without having to buy it outright. Rent is paid to the lender for its full use, and the rental period is flexible and can be tailored, depending on requirements. During the rental period, the borrower pays the full cost of the asset, including interest

• Operating Lease is a type of asset finance where the borrower rents the asset for a short period. At the end of the lease term, the borrower can choose to either return the asset or continue leasing it

Grahame Neagus, Head of LCV, Renault

In the last issue I wrote about the growth in zero-emission commercial vehicle uptake in Norway and other parts of Europe compared with the UK, and the kinds of incentives we need to drive a genuinely zero-emission future here.

Yet across both the LCV and HGV sectors, from a vehicle manufacturer’s perspective, the industry remains under intense pressure. The legislative framework is tightening, forcing manufacturers across Europe to juggle compliance, innovation and cost in ways that test even the most resilient organisations.

Perhaps what is most frustrating is that as an industry our message still isn’t resonating with customers. Despite products becoming ever more technically capable, indeed, closer than ever to matching what traditional diesel engines deliver, operator confidence often lags behind the technology itself.

Part of the problem may be perception. The commercial vehicle industry is sometimes its own worst enemy when it comes to communicating what electric vehicles can

do, rather than what they can’t. There’s also an element of unfamiliarity. Even though the language of the electric car is becoming mainstream, the terminology of the battery-electric van or truck still feels new to many. Faced with uncertainty, some operators default to the old adage: “better the devil you know.”

A few years ago, one operator told me he wouldn’t consider an electric commercial vehicle until it could “do exactly what my diesel can.” What he meant was twofold: he wanted equivalent performance, and he wanted the technology to reach a point of maturity where progress became incremental, predictable and stable. It’s an understandable view. After all, the diesel powertrain has offered that kind of dependability for decades. A 13-litre, 480-500hp diesel engine remains a

familiar workhorse in articulated transport. Operators like that constancy – and so do residual values.

The good news is that within the 3,500–4,000kg LCV sector, I believe we’re now approaching that same level of technical maturity. The latest generation of 85–90kWh batteries can deliver real world ranges in excess of 280 miles, and can recharge in around 40 minutes. That makes them genuinely usable for most day-to-day logistics operations.

Design innovation has played its part too. Battery packs for panel vans are manufactured to be long and wide, but low in height to sit low and flat beneath the floor, avoiding intrusion into load space while ensuring enough ground clearance over sleeping policemen or

“The latest generation of 85–90kWh batteries can deliver real world ranges in excess of 280 miles”

rough ground and maintaining a low centre of gravity, important for handling and safety. But physical limits are being reached. Most OEMs have already maximised the available space under a 3.5-tonne van, so unless there’s a stepchange in battery chemistry, we won’t see 150kWh packs squeezed into the same footprint any time soon.

The question then becomes: do operators really need that? For many fleets, the answer is no. Most 3.5-tonne vans in national or public-sector fleets cover 50 to 150 miles per day on a return-to-base model. For these users, a 250-mile range offers more than enough flexibility, while still ensuring a viable second-life market when the vehicle is four or five years old.

And it’s not just light commercials. In the rigid truck world, particularly at 16 and 18-tonne GVW, we’re witnessing similar technological maturity. Research suggests that 70 - 80% of typical operations undertaken by an 18-tonne 4x2 rigid could transition to batteryelectric power today without operational compromise. Vehicles like the Renault Trucks E-Tech D are already proving their worth, day in and day out, across UK cities, cutting emissions while maintaining productivity.

So, what is the way forward? In my view, 2025 marks a watershed moment: the electric, zero-emission 3.5-tonne LCV is now demonstrably more financially attractive than its diesel equivalent. Taking into account purchase price, infrastructure, in-life maintenance, energy costs and residual value,

• Grahame Neagus

typical operators can expect savings of more than £4,500 over five years and 100,000km of use.

In other words, the technical and fiscal barriers have largely fallen away. What remains is the human one: changing longheld habits, challenging old assumptions and inspiring confidence that switching to electric makes commercial sense as well as being better for the planet and people. That’s where the real work begins. For vehicle manufacturers, it’s now about educationhelping operators understand that today’s BEV commercial vehicle is no longer a compromise, but a credible, capable, and cost-effective choice. Technology has done its job: the next step is winning hearts and minds.

excels in “youth wisdom” when it comes to compliance, safety and sustainability

Established in 2024, HILT Material Supplies Ltd has rapidly positioned itself as a trusted partner in the construction industry by ensuring that safety and sustainability are at the heart of its day-to-day operations.

The Essex-based distributor has proudly achieved Mission Zero, whilst adding a WRRR Gold accreditation (equivalent to FORS Gold), and a Sustainability 2 accreditation (aligned to the UN Sustainable Development Goals), taking them to the very highest level of accreditation within the Mission Zero scheme.

Michaela Dunn at HILT said, “Mission Zero isn’t just a certificate on the wall, it’s a clear statement to our customers, suppliers and team, that safety and sustainability are part of our DNA.”

As the UK’s fastest-growing fleet accreditation scheme, Mission Zero has been designed to support all vehicle types providing customers with a realistic framework to ensure they achieve and maintain a legally compliant, safe, and sustainable transport operation.

Michaela added “Mission Zero provided us with a clear, straightforward framework that truly supported our compliance journey. The guidance and assistance were impeccable, ensuring we never felt alone.”

Although Mission Zero counts some of the UK’s largest fleets amongst its ranks, it was also designed to enable new or smaller fleet operators demonstrate the same high commitment and standard. With audits starting at only £380, no subscription fees for operators with 10 vehicles or less and over 70 free resources (policies, procedures, training etc), it has never been more affordable or easier for operators to achieve a recognised UK accreditation standard. Mission Zero is also the leading alternative to FORS Bronze, Silver and Gold.

Paul Grafton, Head of Compliance at Mission Zero said “We are incredibly proud to have HILT Material Supplies Ltd as part of the Mission Zero family, which is a remarkable achievement for such a young business. Their accreditation demonstrates that Mission Zero is more than just an audit, it’s a partnership that helps ambitious businesses thrive whilst raising standards across the industry.”

Michaela concluded “The framework is simple, the online portal makes compliance easier, and the Mission Zero team are always there to guide us. That support has given us the confidence to grow quickly while still doing things the right way. This achievement reflects our dedication to professionalism, environmental efficiency, and being an integral part of our customers’ success.”

As the UK’s fastest-growing fleet accreditation scheme, Mission Zero has been designed to support all vehicle types providing customers with a realistic framework to ensure they achieve and maintain a legally compliant, safe, and sustainable transport operation.

Mission Zero is the only alternative accreditation scheme officially accredited as equivalent to FORS Bronze, Silver, and Gold accepted by TfL, HS2, National Highways, and others

pted by the Traffic Commissioners of Great Britain, on Zero’s full legal compliance audit protects your ator licence and business.

As the only scheme aligned to the United Nations Sustainable Development Goals, it provides the most realistic framework to achieving a long-term sustainable transport operation

With free registration, no subscription fees for fleets under 10 vehicles, and access to over 70 free resources, it couldn’t be more affordable or simpler!

introduced its first fully-electric distribution truck in 2018, it became a pioneer in sustainable transport. Fast-forward to today, and the Dutch manufacturer has taken another bold step forward. The New Generation DAF XD Electric and XF Electric don’t just follow the electric trend — they set a new benchmark for what modern zeroemission logistics can achieve.

Built on DAF’s award-winning XD and XF diesel platforms, the electric versions have the same focus on quality, efficiency, and safety, with an extra dose of futuristic technology under the cab. From supermarket supply chains to waste collection and regional haulage, these trucks are purpose-built to handle demanding commercial tasks — quietly and cleanly.

“A drive that’s not just powerful, but incredibly smooth and refined”

Visually, the Electric models remain true to their diesel siblings but add subtle touches like blue detailing on the grille and headlights. Inside, drivers will find a familiar yet advanced cockpit, with a digital instrument cluster that displays real-time energy consumption, charging data, and range. Even the integrated navigation can point you to the nearest available charging stations: a thoughtful addition for life on the road.

Quiet strength

The heart of the new generation lies in the PACCAR EX-D1 and PACCAR EX-D2 electric drive-units. Compact, efficient, and remarkably powerful, these permanent magnet motors deliver between 170 kW (230 hp) and 350 kW (480 hp).

The EX-D1 is optimized for lighter duties (GVWs up to 29 tonnes), while the EX-D2

takes on the heavyweights — with torque figures up to 2,400 Nm and GCWs reaching 50 tonnes. Clever engineering ensures seamless power delivery: at lighter loads, only one motor engages for maximum efficiency, while both come alive when climbing hills, accelerating, or braking regeneratively.

The result? A drive that’s not just powerful, but incredibly smooth and refined.

Range meets Reality

DAF’s modular battery system allows from two to five lithium-iron phosphate (LFP) packs, ranging from 210 kWh to 525 kWh to be

fitted. These batteries are cobalt- and nickelfree, ultra-durable, and thermally stable — with an eight-year warranty for peace of mind.

Depending on configuration, the trucks can deliver over 500 km of zero-emission range per charge. With smart route planning and intermediate charging, operators can realistically achieve up to 1,000 km of daily electric operation.

LFP chemistry also allows 100% charging cycles without degrading lifespan, while DAF’s smart energy management system ensures every watt is used efficiently.

“Standard DC fast charging up to 325 kW means a three-pack setup can recharge from 0–80% in under 45 minutes”

Standard DC fast charging up to 325 kW means a three-pack setup can recharge from 0–80% in under 45 minutes. Even the largest five-pack configuration tops up in about two hours. For added versatility, an optional 22 kW AC onboard charger provides slower, overnight charging when fast DC options aren’t available.

Aerodynamics play a crucial role in range optimization. The tapered cab design, rounded corners, seamless panels, and mirror-replacing digital cameras

all contribute to exceptional energy efficiency. Side skirts, deflectors, and an aerodynamic underbody further reduce drag: proving that form and function can coexist beautifully.

DAF’s reputation for driver-centric design continues here. The cabs: accessible via two steps on the XD and three on the XF; are spacious, quiet, and ergonomically laid out. Adjustable seats and steering wheel, 220-cm-long beds, and crisp digital displays should make long shifts a pleasure.

One standout feature is one-pedal driving, where the accelerator doubles as a regenerative brake on release. Drivers can choose three levels of braking force (33%, 66%, or 100%), making energy recovery as intuitive as it is efficient.

Safety remains a top priority, with the DAF Digital Vision System, Corner View, and City Side Assist providing unmatched visibility and awareness — especially in busy urban environments.

DAF’s modular battery placement allows for incredible body-builder flexibility. Whether it’s a refrigerated box, mounted crane, or sideloader waste system, the chassis layout can be customized to suit. Optional e-PTO systems (25 kW and 90 kW) can power auxiliary equipment, while DAF’s pre-fitted Bolt & Play package simplifies installation for specialist applications.

Available as 4x2 tractors and rigids, as well as 6x2 configurations, the XD and XF Electric are

ready to serve in multiple roles, with even more variants expected in 2026.

As Bart Bosmans, DAF’s board member for marketing and sales, puts it: “These trucks were designed with electrification in mind from day one. They’re the perfect combination of driveline and vehicle concept, supported by a full ecosystem of services — from driver training and charging solutions to connected fleet management.”

The New Generation DAF XD and XF Electric are not just electric versions of existing trucks — they represent a complete rethinking of what a heavy-duty EV should be. With industry-leading range, fast charging, superior comfort, and practical modularity, DAF’s latest offerings prove that sustainability and performance can indeed share the same road.

“One standout feature is one-pedal driving, where the accelerator doubles as a regenerative brake on release”

Can fuel cells off zero-emissions haulage without the payload penalty of large batteries. Japanese automotive giant Toyota is finding out.

Words: Steve Banner

While the range between recharges offered by battery-electric trucks is increasing, many operators remain sceptical about their viability on long-distance intercity runs.

Battery-electrics may be perfectly capable if all they are transporting are parcels or hanging garments, but what if they are asked to haul heavy cargo such as bricks or glass? Surely the weight of their battery packs will eat into their maximum permitted payload despite the gross weight concessions that are allowed, making their use uneconomic?

Charging times are another concern. Admittedly they are getting shorter, but they are unlikely to get as short as the time it takes to fill a truck’s fuel tank with diesel.

Toyota reckons the answer to both of these concerns is the hydrogen fuel cell. It has put four trucks using the technology into service to help distribute parts to dealers across Europe from its sprawling warehouse complex at Diest in Belgium.

They are not encumbered by tonnes of batteries, and the time taken to replenish their hydrogen tanks fully is measured in minutes. The only emission they produce is water.

Running at 40 tonnes, and tipping the scales at 11 tonnes, the 4x2 tractor units used are based on 3.8m-wheelbase day-cab DAF CFs. They have been converted to hydrogen power by Netherlands-based VDL Groep, which has involved equipping them with Toyota’s own fuel cell modules.

•

The Japanese automotive giant has been building fuel-cell cars for the past decade and its Burnaston, Derbyshire operation has been instrumental in developing a prototype fuel cell Hilux pick-up. Toyota fuel cell modules are being supplied to other manufacturers.

Range between refuelling stops achieved by the converted CFs is over 400km says Toyota, with the trucks regularly operating at maximum gross weight.

Each truck has a tower of hydrogen tanks stacked behind the cab at a pressure of 350 bar. They can hold 39kg of hydrogen.

A 360kW/480hp electric motor has been fitted and the package includes a 210kWh battery. It can be employed as a get-you-back-to-base option should hydrogen be unavailable, with a range of 100km.

Since May the trucks have covered approximately 80,000 kilometres on four routes across three countries linking Diest with Amsterdam and Rotterdam in the Netherlands, Lille in France and Cologne in Germany.

Drawing hydrogen from eight refuelling stations, they have consumed around 7kg per 100km apiece, saving over 80,000kg of CO2 when compared with a diesel truck on the same work says Toyota.

A half-hour trip along the roads around Diest showed that the trucks are remarkably quiet compared with a diesel, with zero vibration. Drivers should remember that all the torque delivered by the electric motor is available the instant they pull aware from rest however, and observe appropriate caution.

Each truck is operated by a different third-party haulage contractor on Toyota’s behalf. Vos Transport Group, CEVA Logistics, Groupe CAT and Yusen Logistics have all come to the party.

Why has Toyota committed itself to what must be an expensive project? It forms part of the brand’s plan to achieve carbon neutrality across Europe by 2040. cont.

“The next steps will be to extend the range of the fuel cell trucks with 700bar tanks, boost power and efficiency”

“These trucks are the future of our logistics,” states Toyota Motor Europe (TME) executive vice president, Shinichi Yasui. “Our common enemy is CO2, and we need to reduce it as soon as possible.”

Another route to environmental virtue could be to convert existing truck engines to run on hydrogen as a combustion fuel.

It would be a less-complicated option than installing fuel cells agrees Toyota senior research and development manager, Charles Ollivier. “However fuel cells are more efficient,” he observes.

He goes on to point out that burning hydrogen generates some NOx which has to be dealt with using an emission control system, so it is not completely emission-free.

The next steps will be to extend the range of the fuel cell trucks with 700-bar tanks, boost power and efficiency by installing Toyota’s third-generation fuel cell module, and cut refuelling times even further.

Other planned future developments include the arrival of a fuel-cell system that is packaged so it can be fitted to sleeper-cab tractor units, and deploying car transporters with fuel-cell technology.

At present, fuel-cell trucks are produced in small numbers in Europe, which means they are even pricier than already-painfullyexpensive electric models.

The lack of a truly-comprehensive refuelling infrastructure makes their operation over long-distance routes all around Europe a

challenge. Furthermore, the hydrogen has to be green hydrogen and priced competitively.

Toyota believes that the Chinese are showing the way. Their country now boasts five major hydrogen hubs supporting 400 refuelling stations, with 4,000 fuel cell trucks in operation.

In China hydrogen costs a modest 5 euros a kilo compared with from 9.9 to 18 euros a kilo along the European routes Toyota’s trucks are using.

That low-cost Chinese hydrogen is classed as grey hydrogen, however. Grey hydrogen is made through a process known as SMR – Steam Methane Reforming – which can pump out up to 12 tonnes of CO2 for every tonne of hydrogen produced, somewhat defeating the object of the exercise.

Toyota always aims to use green hydrogen instead. There are reasons for optimism.

Hydrogen should become more widely available across the European Union in the coming years says Toyota as a consequence of AFIR, the Alternative Fuel Infrastructure Regulation. It requires the installation of hydrogen refuelling stations for cars and trucks in all major urban areas, and every 200km along key intercity routes, from 2030 onwards.

On this side of the Channel green hydrogen specialist Lhyfe has announced plans to establish a plant in Wallsend, Tyne & Wear, which should be capable of making up to 8.0 tonnes of green hydrogen a day. A number of green hydrogen production projects are under way in mainland Europe.

Says Thiebault Paquet, TME vice-president and head of its fuel cell business: “Europe is showing long-term confidence in hydrogen, and so are we. We will continue to develop fuel cell passenger cars and other lightduty vehicles while we have broadened our focus towards heavy-duty transport to support the expansion of a viable hydrogen infrastructure.”

“Their country now boasts five major hydrogen hubs supporting 400 refuelling stations, with 4,000 fuel cell trucks in operation”

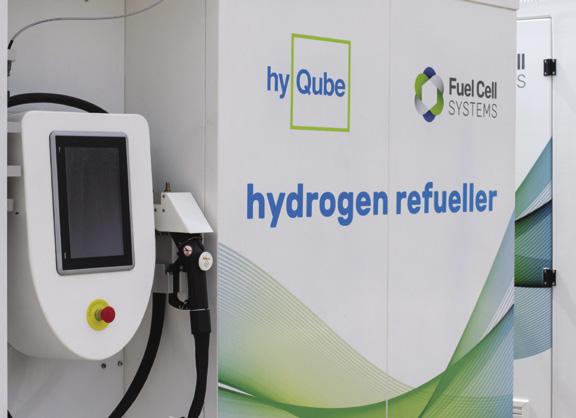

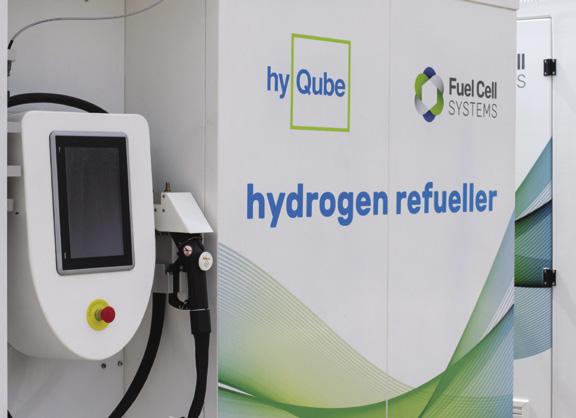

Dr Lee Jurby CEO at Fuel Cell Systems explains how hydrogen presents a chance to build indigenous manufacturing and production capabilities in net zero transport that could create domestic value and export opportunities.

The UK has the potential to play a leading role in the global shift toward hydrogen as a fuel source. Through the creation of fuel cells, electrolysers, hydrogen freight and refuelling infrastructure, the UK can abate many heavy-emitting, high-utilisation transportation sectors and grow its domestic industries to export scale.

Yet to do this requires effort and investment – time and money, spent strategically. It also requires a focus on a long-term mission over short-term gains. If the history of other clean technologies is anything to go by, we could be left behind. However, there is no reason for dismay: hydrogen refuelling is an opportunity for British leadership.

Learning from the past

The UK is breaking records in registrations of electric vehicles, evidence of the building momentum in the transition to electrified cars and vans. Yet, at the same time, due to a complex combination of factors, we have not established ourselves as one of the main manufacturing hubs for EVs, their components, or charging infrastructure. China dominates, while the US and European nations follow. For the

UK, although overseas manufacturing can mean lower-cost vehicles and infrastructure, it ultimately leads to gaps in our domestic capabilities. These undermine our broader manufacturing potential, and are likely to cost us money and jobs over the longer term.

For example, the UK has a ‘gigafactory gap’ when it comes to the manufacture of EV batteries, with only one plant producing roughly 2GWh per year: the Chinese-owned AESC factory in Sunderland. The lack of domestic battery capacity forces UK companies to purchase imported batteries, with money flowing abroad rather than to British businesses.

“The UK also has the opportunity to control and grow large portions of the hydrogen refuelling and transportation value chains”

What goes for EVs and their batteries also goes for solar panels, wind turbines and other components in the cleantech ecosystem. We must learn from these lessons, supporting and encouraging domestic production throughout the hydrogen fuel and refuelling supply chains.

Compared to other energy sources, hydrogen is in the early stages. Globally, hydrogen refuelling manufacturing is in the formative stages. There are proven technologies –including the range of different stationary and mobile solutions we create at Fuel Cell Systems – and many companies are hurrying to scale them. But because this is an earlystage market, there are not yet any dominant international refuelling manufacturers. The early mover advantage is therefore open to those organisations ready to take it, and we have every reason to want that to be a UK company.

The UK also has the opportunity to control and grow large portions of the hydrogen refuelling and transportation value chains, from design and engineering, through to manufacturing, service, support, and fuel production. There are many players in the UK hydrogen sector, all capable of ultimately supporting a domestic industry and pushing it toward export scale. What’s more, there’s the opportunity to support the uptake of hydrogen powered large vehicles, like long-distance coaches and heavy goods vehicles, and ensure that there are off-take agreements in place for fuel producers.

A model of this full value chain is the development of the UK’s first hydrogen freight corridor, for which Fuel Cell Systems is providing the refuelling stations. The project will place three stations at strategic locations along the M4 to maximise availability for fleets and utilisation of the assets. The UK Government is funding the project through the Department for Transport’s (DfT) Zero Emission HGV and Infrastructure Demonstrator (ZEHID) programme, with most of the support going to British companies.

The case for building UK domestic capacity for refuelling infrastructure alongside other parts of the hydrogen supply chain is economic: it creates jobs and value that flow back to the UK economy. There are also clear operational benefits from prioritising British companies and supporting British industry. British companies have immediate service proximity benefits compared to international ones. Commercial hydrogen refuelling stations, for example, will refuel substantial numbers of vehicles per day. Freight corridor infrastructure must run 24/7, too. When a problem occurs, support services will be needed immediately to keep trucks on the road. Localised service and support from UK-based companies can respond to technical issues much faster than those based overseas.

The UK is in the early stages of developing its hydrogen infrastructure. And as such, it faces an infrastructure gap when compared to continental Europe, with around six refuelling stations in operation while there are already around 100 in mainland Europe. The right support is needed to encourage UK hydrogen fuel and refuelling to grow.

The Hydrogen Energy Association (HEA), in tandem with the Road Haulage Association

(RHA) and the Construction Plant-hire Association (CPA), have called for specific measures. These include a roadmap for hydrogen fuel and refuelling infrastructure to give investors confidence, and setting demand-side targets to stimulate supply chains and secure supply. On top of this, they are calling for 12-13 new strategically placed refuelling stations along freight corridors, alongside support for back-tobase refuelling hubs.

These would clearly provide a valuable boost to UK infrastructure, but some level of ringfencing must accompany whatever financial support is provided. A portion of the money made available should be committed to UK companies to encourage longer-term domestic capacity.

We’ve seen what happens when strategic cleantech industries develop without being prioritised domestically: dependency on overseas suppliers, lost manufacturing capabilities, and economic value flowing abroad. But that doesn’t need to be the case for hydrogen refuelling. The early-stage nature of the global market means first-mover advantages remain available if we act decisively now, and we have model blueprints for how the government can provide focused support.

With coordinated government support, strategic ringfencing of funding and commitment to the full value chain, Britain can lead the hydrogen economy. But there are no second chances; onshoring production 15 to 20 years from now will be much more costly and disruptive than supporting domestic manufacturing today. www.fuelcellsystems.co.uk

“British companies have immediate service proximity benefits compared to international ones”

has launched the eDELIVER 75 fully-electric 7.5-tonne truck for the UK’s light-tomedium-duty transport sector. Designed for regional, urban, and last-mile operations, the new model is said to combine high performance, advanced safety technology, and comprehensive aftersales support: positioning it as a strong contender in the zero-emission logistics market.

The eDELIVER 75 represents a major milestone in MAXUS’s mission to accelerate the shift toward sustainable commercial transport. Backed by Harris Group, the new vehicle brings together cutting-edge engineering. A 120kWh lithium-iron phosphate (LFP) battery, offers a WLTP Combined range of 155 miles and supports 120kW DC fast charging. The system enables a 20–80% recharge in just 30 minutes, minimising downtime and maximising fleet productivity.

Inside, drivers benefit from a modern, well-equipped cab featuring cruise control, a heated multi-function steering wheel, keyless start, and Vehicle-to-Load (V2L) functionality. The 12.3-inch infotainment system integrates Apple CarPlay, Android Auto, DAB radio, and a 360-degree camera system, ensuring comfort, convenience, and safety on every journey.

cont.

With a payload capacity of up to 4,590kg and two wheelbase options, the eDELIVER 75 combines versatility with capability, making it suitable for a wide range of applications — from regional distribution to urban logistics.

“a WLTP Combined range of 155 miles and supports 120kW DC fast charging”

Fully GSR II (General Safety Regulation) compliant, the eDELIVER 75 sets a new standard in vehicle safety. A comprehensive Advanced Driver Assistance System (ADAS) package is included as standard, incorporating:

• Lane Departure Warning & Lane Keeping Assist

• Front Collision Warning & Automatic Emergency Braking

• Blind Spot Information & Moving Off Information Systems

• Driver Fatigue Monitoring

• Alcohol Interface Preparation

• Traffic Sign Recognition with speed limit detection

Dual airbags and an integrated 360° camera system with reversing sensors further enhance driver confidence and situational awareness.

“The specification and technology are built around real operational needs,” said Ross Davies, MAXUS UK Sales Director. “We’ve created an agile, versatile and safe electric truck that can handle everything from mid- to final-mile delivery, while offering an optimised chassis ready for specialist bodybuilder integrations.”

Acknowledging that charging remains a key obstacle in EV adoption, MAXUS UK is taking a vendor-neutral approach to depot charging support — a strategy that mirrors its successful electric van rollout.

“We’re neutral to charging hardware and software providers,” explained Davies. “Most of our customers already use AC depot charging, ideal for vehicles that return overnight. For fleets requiring faster turnarounds, we can facilitate partnerships with DC charging providers to keep operations running smoothly.”

A structured product rollout will see customer previews and pricing announcements followed by demonstration vehicles in December. Customer deliveries will follow MAXUS’s established 20-week order timeline, with a planned pipeline of stock vehicles for rapid deployment through its UK-wide dealer network.

“The launch of the eDELIVER 75 marks a defining moment — not just for MAXUS, but for the future of zero-emission logistics in the UK,” said Brian Patterson, Managing Director of Harris Group. “With class-leading range, fast-charging capability and outstanding payload, this truck redefines expectations in its class. We’re offering a technologically advanced, cost-effective solution backed by trusted aftersales support. MAXUS isn’t just joining the electric truck market — we’re taking the lead.”

With its blend of power, payload, range, and safety, the eDELIVER 75 establishes a new benchmark for electric 7.5-tonners. Supported by a robust national dealer network and proven aftersales infrastructure, MAXUS aims to make the transition to zero-emission trucking both practical and profitable for UK fleet operators.

The MAXUS eDELIVER 75 goes on sale this autumn — marking the next step in the brand’s mission to drive the UK’s commercial transport sector toward a cleaner, electrified future.

“For fleets requiring faster turnarounds, we can facilitate partnerships with DC charging providers”

innovator Voltempo has officially begun series production of its advanced HyperCharger megawatt charging system (MCS) — a breakthrough designed specifically for electric heavy goods vehicles (HGVs). The milestone marks a major leap forward in the UK’s transition to zeroemission road freight.

The new production line was inaugurated on 23 September at Tyseley Energy Park (TEP) in Birmingham, where Voltempo has rapidly expanded over the past 20 months from a team of just three to more than 50 employees. The event was formally opened by Sir Vince Cable, Chair of the eFREIGHT 2030 consortium, who hailed the launch as “a major step forward for the UK’s transition to zero-emission road freight.”

“a major step forward for the UK’s transition to zero-emission road freight.”

Powering the UK’s Zero-Emission Freight Future

Voltempo leads the eFREIGHT 2030 consortium, part of the UK government’s £200 million Zero Emission HGV and Infrastructure Demonstrator (ZEHID) programme, delivered in partnership with Innovate UK. As the consortium’s charging infrastructure provider, Voltempo’s HyperCharger is central to enabling large-scale electrification of freight transport.

Under the eFREIGHT 2030 project, seven fleets and two charging hubs are deploying Voltempo’s megawatt-capable systems, each with at least six charging bays and 1,000kW capacity. A further two fleets are installing Voltempo’s lower-powered units. The first operational site is already live, with the full network — the UK’s largest of its kind — set to be completed by Q2 2026.

Each HyperCharger is designed to evolve with the market, allowing on-site upgrades to support next-generation MCS-equipped trucks capable of charging at 700kW and beyond.

Built for Trucks, from the Ground Up Unlike retrofitted car chargers, the HyperCharger has been engineered specifically for HGVs. Its striking “halo” design lifts and supports the heavy charging cables, protecting them from wear and improving safety and usability in busy logistics yards.

The LED halo interface makes operation simple — no screens, cards or apps are required — while OCPP 2.0 compliance ensures compatibility with all plugand-charge-enabled vehicles. Designed

for durability and minimal maintenance, the system aims to maximise uptime and operational efficiency.

Scalable, Smart and Sustainable

Delivering over 1 megawatt of dynamically distributed power across up to six vehicles simultaneously, the HyperCharger is built for scale. It also incorporates energy-efficient technology, including low-power LEDs and reduced standby consumption, helping fleet operators cut both costs and carbon.

“Starting series production of the HyperCharger is a defining moment — not just

for Voltempo, but for the UK’s journey towards zero-emission freight,” said Michael Boxwell, CEO of Voltempo. “We’ve designed this technology from the ground up to meet the real-world needs of logistics operators, while creating green jobs and driving innovation right here in Birmingham.”

British Innovation at Work

The opening event drew praise from industry leaders and partners.

Sir Vince Cable commended Voltempo’s progress, saying: “The HyperCharger is central to the success of the eFREIGHT 2030

programme and demonstrates how British innovation can create skilled jobs, attract investment, and build the infrastructure we need to compete in the global clean transport economy.”

David Horsfall, Director of Property and Sustainability at Tyseley Energy Park, added: “Voltempo’s rapid growth and pioneering technology embody what TEP stands for — a national hub for clean energy and low-carbon transport innovation.”

Neale Ryan, Head of Land and Maritime Transport at Innovate UK, highlighted

the broader impact: “Designed and manufactured in Great Britain, the HyperCharger showcases UK innovation in zero-emission freight. This programme will provide vital insights into the future of road transport and accelerate progress towards net zero.”

With series production now underway, Voltempo’s HyperCharger is set to become a cornerstone of the UK’s emerging electric freight infrastructure — proving that British engineering and innovation are powering the move to a cleaner, more sustainable transport future.

“Designed and manufactured in Great Britain, the HyperCharger showcases UK innovation in zero-emission freight.”

DAF’s commitment is to help you make your business even more sustainable. Tailor-made solutions guarantee seamless operations, optimal return on investment and peace of mind. Together, we analyse your day-to-day activities. Providing insights on electric vehicles, charging solutions, connected and uptime services. We advise with route planning, charging strategy and offer driver training. DAF – powering your success on the road to sustainable transport. WWW.DAF.CO.UK/DAF-ELECTRIC

Driving zero emissions