5

British-built DAFs for Britain’s last wheelbarrow manufacturer

12

For the Lottery win and a Maserati MC20

18

DAF celebrates 30 years at the top of the British truck market

26

Dugdale Nutrition runs a varied own-account fleet to move its animal feeds

Exeter operator Geach Haulage chooses a new DAF XB

40

XF105 restored to become the world’s smartest shunter

4

Greetings from Matt the Publisher

46

And learn about over-the-air updates

47

John Jackson, Motus DAF, Hull

48

Avoid coupling accidents this Autumn

49

And win a DAF model truck

EDITORIAL

Publisher: Matthew Eisenegger

Managing Editor: Richard Simpson

Designer: Harold Francis Callahan

Editorial Address: Commercial Vehicle Media & Publishing Ltd, 4th Floor 19 Capesthorne Drive, Eaves Green, Chorley, Lancashire. PR7 3QQ Telephone: 01257 231521

Email: matthew@cvdriver.com

ADVERTISING

Advertising Sales: David Johns Telephone: 01388 517906 Mobile: 07590 547343 Email: sales@cvdriver.com

DESIGN

Art Editor: Harold Francis Callahan Telephone: 01257 231521 Email: design@cvdriver.com

CONTRIBUTORS

Mark Ballantyne

John Challen

Ronnie Hitchens

Karl Hopkinson

Mike Torpey

Pip Dunn

PUBLISHER

Commercial Vehicle Media & Publishing Ltd, 4th Floor, 19 Capesthorne Drive, Eaves Green, Chorley, Lancashire. PR7 3QQ Telephone: 01257 231521

NOTE

The publisher makes every effort to ensure the magazine’s contents are correct. All material published in DAF Driver magazine is copyright and unauthorised reproduction is forbidden. The Editors and Publisher of this magazine give no warranties, guarantees or assurances and make no representations regarding any goods or services advertised in this edition.

DAF Driver magazine is published under a licence from Commercial Vehicle Media & Publishing Ltd. All rights in the licensed material belong to Matthew Eisenegger or Commercial Vehicle Media and Publishing Ltd and may not be reproduced whether in whole or in part, without their prior written consent. DAF Driver magazine is a registered trademark.

If you are not going to keep this magazine for future reference please pass it on or recycle it.

“We’ve got the full low-down on the limited-edition trucks produced by DAF to mark its 30 continuous years as the leader of the UK’s truck market. The trucks are bang on trend as each one has more Union Flags than a Reform Party Conference incorporated into its livery and trim, they are just rather more nuanced and subtle!”

Publisher - Matthew Eisenegger

What does a wheelbarrow have in common with a Maserati MC20?

Well, you’ll find both within the covers of this issue of DAF Driver Magazine!

If you can’t quite afford the Maserati and would rather spend your money on something almost as exclusive but rather more useful, we’ve got the full low-down on the limited-edition trucks produced by DAF to mark its 30 continuous years as the leader of the UK’s truck market. The trucks are bang on trend as each one has more Union Flags than a Reform Party Conference incorporated into its livery and trim, they are just rather more nuanced and subtle!

It’s always interesting to play ‘spot the shunter’ when you visit a haulage yard.

There in a corner will be a grimy and unloved remnant of the company’s past. But you could be forgiven for mistaking the yard shunter at VLT Logistics for the prized mount of an owner-driver: this XF105 has been restored to a standard that would put many front-line trucks to shame and now wins prizes at truck shows when it’s not moving trailers around the yard. You can read the story behind this amazing rebirth on page 40.

We’ve also got news of DAF success in specialist fleets, plus valuable insights into what actually happens when your DAF truck receives an ‘overthe-air’ update.

You’ve also got the opportunity to win a model DAF truck in our latest easy-to-enter competition, and some seasonal advice on trailers from Simpson the industry sage.

Enjoy the magazine!

Matt

One of the UK’s most recognisable names in wheelbarrow manufacturing, The Walsall Wheelbarrow Company, chalks up another milestone in its long-running relationship with DAF Trucks after the delivery of two new XB 12-tonners supplied through trusted partner Greenhous DAF.

Wheelbarrows and trucks. Not too much to connect them, but for the aforementioned companies, a common denominator exists through their respective Builtin-Britain DNA. For the DAF brand, its manufacturing home resides in Lancashire at Leyland Trucks, while Walsall Wheelbarrow traces its roots back over three decades in the West Midlands. And for the best part of those three decades, it has been DAF providing Walsall Wheelbarrow’s delivery promises for its customers around the UK.

With the arrival of two New Generation DAF XB 190 12-tonners, that relationship has taken its next confident step – further cementing a partnership between operator, manufacturer, and dealer that has stood the test of time.

“We’re wheelbarrow specialists, not transport experts,” says Walsall Wheelbarrow’s Sales Director, Simon Thacker.

“When we started the business 30 years ago, there were just four of us –me, my brother, mum and dad – and when it came to moving product, we needed help. We looked at a number of truck manufacturers back then – Volvo, MAN, Renault – but DAF were the only ones willing to sit down and work with us. They didn’t just sell us a truck, they helped us procure the whole vehicle from the ground up. That level of engagement has never changed.”

That initial act of support led to a working relationship that has endured for nearly the entire life of the business. In fact, Simon reckons they’ve been with DAF for over 27 years

of their 30 in operation, with all seven trucks in the fleet today supplied by local dealer in Willenhall, Greenhous DAF, which also provides aftersales support. “Greenhous has been fantastic,” admits Simon. “They know our operation inside-out, and they’re always willing to go the extra mile, quite literally, to keep us rolling.”

Going down a storm Walsall Wheelbarrow’s seven-strong fleet now includes four 12-tonners and three 7.5-tonners, with the latter scheduled for replacement with more DAF XB 12-tonners in due course. That shift to a uniform 12-tonne fleet hasn’t come by accident. “It’s two-fold:” explains Transport Manager, Shawn Jowsey; “payload and driver retention. With more drivers coming in at Class 2, it makes sense to step up the spec. We carry a high-volume, low-weight

product, but the 12-tonners give us flexibility and future-proof the operation. Plus,” he says, “the drivers love them.”

Comfort, visibility and safety all rate high on the driver wish list and, Shawn reports, the new XBs deliver in all departments. The latest DAF cab designs have gone down a storm with his team, especially in terms of driving ergonomics, dash layout and safety features.

“There’s proper air-suspension, which makes loading and unloading safer and easier,” he explains. “The turning circle is really tight, which is important for our kind of work, getting into builders’ merchants, awkward store yards and high street locations. And with the full camera and sensor setup, they’re as safe as they are manoeuvrable.”

Even the little things, such as the PowerLine automatic transmission with its ‘urge to move’ feature, make a big difference for urban operations. “The drivers really appreciate the automatics,” Simon adds. “I used to be oldschool, preferred manuals, but now even I can see the benefits.”

Built for the business

If you think a truckload of wheelbarrows might not be particularly demanding for a vehicle, think again. Each delivery from Walsall Wheelbarrow is carefully configured, with up to 130 fully assembled units loaded by hand

Hand-loaded; up to 130 fully assembled wheelbarrows go out on every delivery

and secured using bespoke internal netting systems; another area where Greenhous DAF helped tailor the trucks for purpose.

“The new trucks were built to our exact spec,” Simon explains. “From chassis to body, we handed Greenhous a list and they took care of the rest. The body was key — it’s not your average curtainsider job. We needed fixed sides, full-length nets, and a loading height that would work for the team. Greenhous made it happen.”

Maintenance is covered too, with all vehicles supplied on full DAF MultiSupport Repair & Maintenance contracts. Vehicles are serviced overnight to minimise downtime, and it’s not unusual for vehicles to be dropped off in the evening and ready to roll again by 4am the next day. “That’s what we need,” Shawn stresses.

“There’s no slack in our schedule. If a truck’s off the road, we’re in trouble, especially with certain customers where missing a delivery slot can mean a £500 fine!”

That reliability has paid dividends. The fleet boasts a 100% MoT pass rate over the last five years and enjoys a solid ‘green’ OCRS rating. And with every truck running full telematics, the business keeps a close eye on operational performance across the board.

Keeping it British

There’s another layer to Walsall Wheelbarrow’s loyalty to DAF; it’s not just about uptime and utilisation. Provenance is very important to the company.

“British-built trucks delivering Britishmade products. That really matters to

us,” Simon says. “Our wheelbarrows are 100% made in our factory here in the West Midlands. Every wheel, tray and frame. We’re the only UK manufacturer left, and one of only two in Europe. We even keep our suppliers as local as possible to keep our carbon footprint down. When you look at DAF building its trucks in Leyland, it’s a perfect match.”

Sustainability isn’t just a buzzword, either. The company takes a practical, bottom-up approach. The majority of materials are UK-sourced, and the firm is actively looking at reducing emissions across the board. “Transport plays a huge part in our footprint,” says Simon. “Having modern, efficient trucks like the XB, backed by a UK-based service team, makes a real difference.”

The company itself is steeped in manufacturing heritage. Simon’s grandfather was the inventor of

the steel wheelbarrow, and Walsall Wheelbarrow now supplies everyone from independent builders’ merchants to national DIY chains. As Simon puts it, “Wheelbarrows are what we do — and we do them properly.”

‘Vertically integrated delivery model’

Part of what sets Walsall Wheelbarrow apart is its vertically integrated delivery model. Unlike many manufacturers who rely on third-party logistics, all product is delivered by the company’s own fleet, with drivers employed in-house. This, says Simon, provides complete control over delivery standards, customer interaction, and brand presentation.

“In a way, our trucks are mobile showrooms,” he says. “Customers notice when a vehicle turns up smart, clean, well-driven and on time, especially when there’s a big Union Jack on the side! It reflects who we are.”

It also means the company can respond rapidly to demand spikes and seasonal surges, with the XB’s uptime credentials proving a particular asset.

The Greenhous effect

Much of the operation’s ongoing success, Simon insists, is down to the Greenhous DAF team in Willenhall. “They’ve supported us every step of the way,” he says. “They know what we need, they understand our business, and they make it happen

without fuss. Whether it’s a spec change, a service call, or getting a part sorted fast, they’re always there.”

That kind of continuity is rare, and Shawn doesn’t take it for granted. “In 27 years, we’ve never had a serious issue,” he says. “If there’s a niggle, it’s sorted. The aftersales team at Greenhous just get on with it, and that gives us peace of mind. The same peace of mind we strive to offer our own customers.”

With a full fleet transition to 12-tonners on the horizon, a growing emphasis on sustainability, and strong demand from retail and merchant customers, Walsall Wheelbarrow shows no signs of slowing down. And if there’s one thing Simon Thacker has learned, it’s that the right partnerships make all the difference.

“You can’t do everything yourself,” he says. “We’re experts in wheelbarrows, and DAF are experts in building trucks. Greenhous are experts in support. Together, it works.”

Founded in the early 1990s, Walsall Wheelbarrow is the UK’s leading manufacturer of wheelbarrows, operating from a state-of-the-art facility in the West Midlands. The company produces a comprehensive range of traditional, galvanised, builder-grade and heavy-duty wheelbarrows – all made inhouse, from raw steel to finished product. The firm delivers nationwide with its own fleet of DAF vehicles, providing full endto-end control over service and delivery. Simon Thacker told us that, back in the day, there were four wheelbarrow producers in the UK. In 2025, only The Walsall Wheelbarrow Company survives.

It’s ‘only’ a V6, but developes 630bhp

Interiror evokes that of a racing car

Patience they say, is a virtue. And for fans of iconic Italian brand Maserati the wait for a new pure red-blooded supercar was a very long one. But the arrival of the MC20 marked the start of a new era for the brand with the trident badge, heralded as the ‘First of its Kind’ and built at the historic Modena plant in Italy.

Few people ever get the opportunity to drive a car that looks every penny of its £227,930 base price, let alone one with such volcanic performance. We’re talking seismic acceleration of 0-62 in 2.9 seconds, 0-124 in 8.8 seconds and a potential top speed of 202mph achieved courtesy of a twin-turbo V6 Nettuno engine developing 630bhp.

And if the use of a V6 in a car of this provenance raises an eyebrow or two well this is a patented, 100 per cent Maserati unit with combustion

technology evolved from the prechamber designs used in Formula 1 powertrains. For the technically-minded this sees the spark plug housed in a perforated chamber within the main combustion chamber, which fills with a standard fuel/air mixture prior to ignition. On ignition, jets of burning gas are ejected through the perforations into the main combustion chamber, which contains a leaner than standard fuel/air mixture. With the main ‘burn’ then being simultaneously initiated at multiple points across the combustion chamber, engine ‘knock’ is eliminated, emissions reduced, and power boosted.

This may be a car built to blast round the racetrack but Maserati has completed a phenomenal job in making it into a genuine everyday supercar, one you could drive on suburban roads at 30mph in perfect comfort and safety all day long.

“The steering wheel was developed and designed with input from Maserati Test Driver Andrea Bertolini, a former World Champion in the MC12”

Even on rough roads the MC20 moves with elegance and grace, sparing you the judder if skirting a pothole and remaining well-mannered throughout.

Weighing in at less than 1,500kg and courtesy of that whopping output the Maserati boasts a best-in-class powerto-weight ratio: the entire structure is built in carbon fibre and composites which enable otherwise impossible shapes – like the butterfly doors.

When you put your foot down the car delivers in spades: it’s a real thriller but without any dramas and performs with precision, balance and absolute stability.

There are five driving modes accessed via a selector, which is the most distinctive feature of the cabin and designed to resemble a luxury watch, each identified by its own colour - so WET mode is green, GT blue, SPORT red, CORSA yellow and ESC OFF is orange.

You can just put the car in GT and leave it to its own devices, which are incredible anyway, or flick through SPORT and CORSA to bring more sporty traction-control, exhaust, suspension, and gearbox settings into play for a truly exhilarating experience.

Inside, the entire focus is on the driver, so shapes are simple, with very few sharp corners, black materials and dark upholstery to prevent reflections in the

windscreen, while everything is laid out like the cockpit of a racing car.

It’s all pretty minimalist too, the central tunnel made from carbon fibre and only carrying the switches that are absolutely necessary, while the steering wheel was developed and designed with input from Maserati Test Driver Andrea Bertolini, a former World Champion in the MC12.

A thick steering wheel, available in Alcantara, helps maximise the car’s sporty feel and only houses essential buttons and switches – like the Start and Launch Control buttons.

While there’s a wealth of design, technology and racetrack experience in the MC20 there’s still the scope to considerably ramp up the price tab with extra-cost options.

For instance our model featured personalisation totalling £63,290 including bright yellow Giallo Genio

paint at £9,650, blue brake calipers costing £1,100, 20-inch birdcage gloss black diamond alloys (also £1,100) and black leather seats at £3,000.

But really ramping up the tab was an exterior carbon pack of dark exhaust tips, front splitter and rear diffuser plus door and wing sills in carbon fibre and a fibreglass bonnet together costing a princely £36,240.

Price: £227,930

Mechanical: 630bhp, 3,000cc

twin-turbo V6 petrol engine driving rear wheels via eight-speed auto transmission

Max speed: 202mph

0-62mph: 2.9 seconds

Combined mpg: 24.6

Insurance group: 50

CO2 emissions: 261g/km

Warranty: 4yrs/50,000 miles

In 1995, Blur and Oasis were locked in their notorious Battle of Britpop, making headlines and polarising opinion. While the nation agonised over whether ‘Country House’ or ‘Roll With It’ would claim the number one spot, another scrap was playing out away from the music scene.

Only 30 UK30 XG+ models are being offered – one for each year of DAF leadership

At the same time, DAF Trucks went straight in at number one in the UK truck market and, unlike the aforementioned and shortlived indie-pop rivalry, DAF’s charttopping success wasn’t temporary. It was the beginning of a 30-year run at the top of the hit parade, and a record that still stands today. DAF never appeared on Top of the Pops, but for truck operators, the brand was, and remains, a smash hit.

And so, after 30-years, at the RTX show earlier this year, DAF marked the occasion with something suitably exceptional; the Special Edition UK30 XG+. A truck not just built, but crafted

to celebrate this unprecedented milestone. Only 30 are being offered – one for each year at the top – and each can be ordered in a choice of four tractor unit configurations; the FTS 6x2 with twin-wheeled tag-axle, the FTG 6x2 twin-steer pusher, the FTN 6x2 rear-steer or the FT 4x2.

Phil Moon, DAF Trucks Marketing Manager in the UK, said at the time, “We’re excited to be presenting this beautiful truck at such a significant moment in the history of DAF Trucks in the UK. The UK30 Special Edition unit represents the pinnacle of the New Generation DAF range, with an exclusive touch which will have

huge appeal for the discerning truck operator. We’ve maintained market leadership for 30 years, representing an astonishing achievement for any vehicle manufacturer, and it brings us great pride in being able to mark the occasion with this ultra-special truck.”

United under the flag

Inside, the XG+ the Union Flag adds to the ambiance, without ever tipping into flag-waving. The upper bunk carries a bold patriotic graphic, while the driver and co-driver can relax into bespoke Xtra leather air seats with a business-class airline feel, complete with Union Flag embossed headrests. Outside, the same national pride is

carried through in subtle design cues, as a nod to DAF customers right across the UK.

“Even the paint-job tells a story,” said Ed Miles, DAF Product Marketing Manager, and a man who played a key role in spec’ing the truck for the UK. “We went with a metallic tone close to British racing green. In anniversary terms, green also marks 30 years, and it’s a colour that has real heritage. We’ve built-in little touches across the UK30 spec to make each one truly unique.

Selling fast

Even before its first public appearance, the Special Edition had already

generated a buzz. Several orders were confirmed ahead of RTX, and the remaining slots are now being snapped up. Deliveries begin later this year.

“It’s not only a collector’s piece, though that’s definitely important,” Miles said, “it’s a working truck that can be spec’d to the customers’ requirements. And we don’t want them all to be identical,” said Miles, “Each will have its own personality in terms of configuration, but they’ll share a visual harmony that ties them together.”

The UK30 Special Edition isn’t just about the here and now. It’s also a reminder of how far DAF has come.

At the end of 1994, DAF held a 19.1% share of the UK market above 6-tonne GVW, just behind Iveco Ford. A year later, it had overtaken its rival, starting a winning streak that remains unbroken.

Three decades on, DAF’s grip on the top spot remains firm, and what once may have looked like a passing phase is now a story of sustained dominance. If the Britpop battle was a whirlwind moment in British culture, DAF Trucks in the UK has been about consistency, reliability and staying power. Britpop faded. DAF endured. Thirty years later, its position at the top is not just intact, it’s as commanding as ever, with no sign of slowing.

While the UK30 Special Edition was designed in the Netherlands, all 30 will be built in the UK at Leyland Trucks. Furthermore, its distinct styling owes much to a Brit abroad. Stuart Purdy, Lead Designer at DAF Trucks in Eindhoven, has spent 17 years shaping the look and feel of the company’s vehicles. Born and raised in Norfolk, Purdy has given the UK30 XG+ a distinctly British identity. DAF Driver spoke to him for the designer’s-eye view.

Purdy grew up not far from Lotus in Hethel, and the iconic sports car maker made a strong impression. Combined with an early fascination for both art and physics, he was drawn to the creative and technical balance of automotive design. That path took him to a placement in the Netherlands in 1991, where he discovered a different design culture, and where he also met the woman who would later become his wife. After graduating in the UK, he returned to the Netherlands to begin his career in a design consultancy, working on trains, buses, trams and leisure vehicles before eventually joining DAF in 2008.

Since then, Purdy has helped shape programmes from the CF Euro 6 and CF Construction to multiple LF enhancements, aerodynamic developments and, most significantly, the New Generation DAF cab interior layout. His remit requires handling the complexity of the many different interior configurations, such as day and sleeper cabs. The role demands compromise; harmonising design ambition with production realities such as ergonomics, cost, safety and operator needs.

“From the beginning, we didn’t want the UK30 to feel like a production truck dressed up with a few bells and whistles,” said Purdy, “The aim was a coherent package where colour, detailing and interior all worked together. When you step into the cab or

see it in profile, everything should tell the same story, not look like a list of aftermarket options.”

That insistence on integrity shaped every stage of the project. For Purdy, styling is not about adding garnish, it’s about creating an experience where details reinforce each other and together deliver something cohesive.

“That woven flag under the bunk sums up the approach,” he continues. “A printed panel would have been faster and cheaper, but it wouldn’t have the same impact. Working with the supplier made it tactile, durable and a detail that rewards you every day.”

When DAF’s UK marketing team proposed the anniversary model, Purdy’s background and experience made him a natural choice to lead. Although the concept originated with DAF’s Design Director, Bart van Lotringen, it was Purdy who developed it into a considered execution. While the Union flag would serve as the unifying theme, he wanted it deployed with discretion.

Nine flags appear across the truck, inside and out, but always integrated with care. Each flag is muted to harmonise with the colour palette rather than dominate it. The deep metallic green – close to British Racing Green – offers an immediate link to UK motoring heritage, balancing tradition with contemporary styling. “The flag was central,” says Purdy, “but we wanted to avoid the obvious bright red, white and blue. Instead, we integrated it where people would discover it over time, on the seats, under the bunk, in the graphics. The muted palette keeps it smart and cohesive rather than shouting at you.”

Some of the most distinctive touches lie in how ideas were executed. Under the upper bunk, Purdy rejected the idea of a printed panel and instead worked with a supplier to weave the Union flag directly into fabric, ensuring a richer sensory effect. On the headrests, he commissioned a bespoke embossing tool for the Union Flag; an unusual investment for such a limited run but one that delivers a finish of genuine quality.

Attention to detail also extended to consistency. Purdy collaborated closely with DAF UK Product Marketing Manager, Ed Miles, to ensure design flourishes worked alongside practical requirements. Colour-coded exterior elements, unique customernumbered badging and bespoke interior trim tied the package together, adding cohesion across cab variants while leaving room for customer choice.

Exclusivity was a guiding principle from the outset. Limiting output to 30 units marked the anniversary in a tangible way while creating a rarity that justified the bespoke detailing. That scarcity also amplified desirability. Orders arrived even before the RTX Show launch, both from loyal DAF operators and from customers who would not normally consider the brand.

“Offering only 30 was deliberate,” explains Purdy. “Marking 30 years at number one should feel like a rare opportunity, not something anyone could order next month. That exclusivity justified the extra work, and the early demand showed it was the right approach.”

For Purdy, the UK30 Special Edition represents more than a commemorative project. It was an opportunity to draw on his full range of skills, from creative design vision to technical negotiation with suppliers. The finished truck blends heritage cues with modern precision, distinctive enough to stand apart yet practical for everyday work. To Purdy, that balance between tradition and innovation is what makes the UK30 Special Edition, in every sense of the word, special.

Dugdale Nutrition runs a varied own-account fleet to move its animal feeds to customers across the north of England, and have just put two very interesting DAFs on the road

When you run a fleet of lorries to support your business, they need to be specc’ed the exact way you want them, to maximise their performance within the company as a whole. Worrying about resale value and whether they are the right spec for the second user should be very low down on your list of priorities when ordering vehicles.

Dugdale Nutrition, based in Clitheroe, Lancashire, does that. It has a very mixed fleet, both in marques and specifications. It produces animal feed and delivers its produce all over the north of England, and up into Scotland and down into the midlands, and no one spec suits its needs.

It needs a lot of rigids as access to many farms can be very restrictive. But it also has bulk orders and long distance runs where an artic can be preferable. It is also celebrating its 175th

anniversary in business this year and while the trucks are there to do a job, and fundamentally to support the business, Transport Manager Dan Brown certainly makes sure they are not basic, no frills and cheapest kit. The lorries are all immaculately turned out and looked after, and the drivers take pride in the vehicles. And accordingly, the trucks are all well specc’ed and each driver really feels part of the team as a result.

The latest truck to go on the road is a DAF XF480 FAW rigid with a curtainsider body. The FAW designation tells you it’s a rigid, eight-wheeler with double-drive axles but the tridem setup, which is a factory built option from DAF. You can also order a DAF tridem FAQ model with a single drive axle.

For Dugdale, double-drive is important due to the terrain the trucks regularly cover, but the tridem set up also really improves the turning circle and makes

access so much easier on the most restricted of farms. In fact, tridems can often get into places where a 6x4 would struggle, and so it allows more payload to be carried which means it can do more drops and so becomes increasingly more efficient.

Dugdale has mostly bulk blower bodies with several compartments for the different drops or different types of animal feed. But the new truck is a curtainsider as the company also sells bagged animal feed, and this still heads to many locations with restrictive access.

To celebrate the milestone anniversary of this family owned firm, the new FAW has bespoke curtains designed by Hannah Dugdale, the company’s Marketing Director and sixth generation of the Dugdale family.

The fleet is mostly DAF and Scania, with some Renaults, recent additions to the line-up due to their availability

and price. A couple of Volvos also grace the fleet, but the new FAW is just the latest acquisition which Brown says, “has massively increased the presence of DAF in the fleet.”

The truck has the MX-13 engine rated at 483hp and has a high roof sleeper. Access to various loading sites, including the company’s own Clitheroe base, means Dugdale has to be careful on overall height – its previous XF, with the previous generation cab – could be a Space Cab but not a Super Space Cab while the Renault Range Cs have flat roof sleepers because both cabs would be too high in their tallest forms.

“The Driver, Chris Pope, does occasionally overnight in the new truck. He’s been with us for six years,” says Brown. The company also operates seven days-a-week, 363 days-a-year. In fact, the day we arrive, a Sunday morning, we see at least two trucks heading out for deliveries.

It’s fairly understandable, livestock eats 365 days-a-year, so farms function 365 days-a-year, they need support from their animal feed suppliers to match.

Brown prefers bigger engines and –where possible – bigger cabs. The XD, even with a high roof sleeper, might have seemed a better bet but that only comes with the MX-11 engine, so only goes up to 449hp. Interestingly, the older XF tridem bulk blower is a rare 430hp model for that same reason – the ability to have the bigger 12.9-litre engine.

“We chose the FAW tridem for better weight distribution and to avoid being overloaded on any axle. We also have a 6x2 bag wagon, but we get nearly five tonnes more payload on this compared with that; and accessibility to farms is better.” When you look at it like that, the tridem is a no brainer.

“We found we were running a mishmash of six-wheel kit and ended up with

two lorries neither of which we really want,” says Brown, “but that was before I joined. This FAW was the solution to get the exact wagon we wanted and needed.”

The FAW, which is the first tridem bag wagon in the fleet, operates with a Palfinger vehicle-mounted forklift truck and can carry an impressive 17-tonne payload. 12.5-tonne was the best you could get on a 6x2 – the Palfinger alone added 1.5-tonne to the unladen weight, but was a necessary piece of kit as most of the delivery points don’t have forklift trucks, and handballing pallets of 25kg heavy bags of animal feed would test the limit of any driver these days.

The truck has an axle weight monitoring system to ensure it doesn’t leave the yard overloaded… or indeed with spare capacity which could have been used. The bagged animal feed can come in pallets of small bags or in tote bags. The small bags are 25kg each and there are 40 on a pallet, so 1 to 1.5-tonne per pallet; the truck can take 17 pallets and there can be as many as 17 drops in a day. In fact the Palfinger only makes that kind of schedule possible – handballing 680 bags at 25kg would add considerable time to anyone’s day!

“Some of the smaller farms prefer bags as they don’t have the hoppers that can store the feed in bulk that is delivered

by the blower trucks, it’s all down to the preference of the customer what orders we get,” says Brown.

There is also a multitude of different animal feed types and some of the product lines really can only come in bagged form due to their short blending runs.

Different farms obviously need different feed types but there are also seasonal quirks – for example the company is very busy in the lambing season and farmers understandably want more sheep feed. “It’s all-handson-deck for those 6-8 weeks from mid-March to the end of April,” says Brown.

So having said there were two interesting DAFs added to the fleet, you may be wondering what the other one is alongside the FAW? Eagle-eyed readers may have spotted it in the fleet round-up but it’s an XF530 FT 4x2 tractor unit with the high roof sleeper option. It’s coupled to a five-compartment, twoaxle rear-steer Muldoon trailer. And here, I have to come clean and admit, I learned something when Brown tells me it’s plated to run at 38 tonnes, I thought he’d got it wrong, and he meant 35 tonnes. But no, it can legally run at 38 tonnes. And when I got home, I checked and double-checked and then just reminded myself every day is a school day, as they say. Perhaps you can teach old hacks new tricks, or should that be new trucks?

It’s an interesting truck, and despite being an artic, it can still get into most places you can get into with an 8x4 rigid and so useful it’s proving, that Dugdale’s are looking to add more of this type to the fleet in the future.

The XF530 FT, like the XF480 FAW, has the cornerview camera to supplement its conventional mirrors.

Most of the trucks are shared between two drivers on a four-on, four-off, shift pattern; 22 of the drivers work that way, so there will be at least eleven trucks out at any one time even on a Saturday and Sunday.

The DAF FAW is just used on day work, on a Monday to Friday basis and will, typically, do Harrogate and East Yorkshire on the Monday, into Cumbria on the Tuesday, West Cumbria on the Wednesday and Derbyshire, Shropshire and North Wales on the Thursday and then spend Friday doing local deliveries. It’s parked up over the weekend. “It could also go into Scotland – around Dumfries and Ayrshire for example, but it’s all dependent on product and orders.”

It tends to work days only however, with the odd night out, but it typically needs to return to base to reload anyway. Before the DAF, the driver had a Volvo FM for five years with a standard flat roof sleeper, so he’s gained a lot more room with the XF high roof cab.

“We opted for the 480 over the 430 engine because there are lots of hills where we operate,” says Brown.

And that is a good point. Dugdale’s trucks don’t spend too much time bombing up and down motorways. Instead they have to deal with a lot of single carriageway roads over hills and down dales with lots of bends, junctions and stop-start driving involved. The truck’s fuel consumption

of 9.5 to 10 mpg, therefore, is very commendable and very similar to the Volvo it replaced... with an extra five tonnes being carted around as well. And that is the figure after only five weeks, it is likely to improve as the truck loosens up a little bit.

The XF was sourced through Lancashire DAF at Preston with a three-year R&M package as well. DAF Service Dealer Lynch Truck Services at Altham does the servicing: “it does that work overnight which is very helpful for us,” says Brown, “and it’s only 15 minutes away – we have to go a lot further for the Scania and Renault maintenance. Both Lancashire DAF and Lynch have been excellent for us, and it’s a big reason why we have increased the number of DAFs in the fleet”.

Another bonus with this DAF was the quick delivery. “This was very quick, it was just a six-week lead time for the chassis then it went straight to the bodybuilder, and it had a slot, so

it was just three months from the order to it being on the road in early February. It was a similar price to the Renaults, but I fancied a DAF plus the cab offered the driver much more living space with the high roof sleeper. The driver was also very keen to have it and I was keen to try an FAW New Generation DAF as well.”

The truck is fitted with two corner cameras on the rear of the body and a camera inside the body, and has lights mounted in the footsteps so drivers have better visibility on night deliveries. Interestingly, despite a desire for modern technology to improve the driver’s vision, while the FAW has the excellent cornerview camera on the front it was still specified with conventional mirrors but. “Normal mirrors are my choice,” says Brown, “We’re not ready to go digital just yet with the type of work we do!”

The design was done to make the gap between the body and cab as narrow

as possible, and there is very little overhang. “It all came together very quickly, and I am very happy with it,” says Brown. “We listened to the driver a lot, after all he’s the man who has to drive it. We want all our drivers to be happy with the lorries they have.”

In fact, so happy with it, Dan is looking to have a FAW bulk blower priced up for a forthcoming order. The better payload of tridems for a marginal increase in the purchase price means Dugdale’s could actually look to reduce its fleet by a truck or two.

“We’ll most likely keep it for five years or 600,000km, but that is all dependent on the truck. We’ll keep it longer if needs must,” adds Brown. Indeed the FM it replaced was then kept to help through the winter period. “We did try and sell it, but there was no real interest, and then we decided to keep it through spring. We haven’t tried especially hard to sell it!”

Foster Commercials put the body on the FAW, while the curtains were from

Andrew Mitchell & Co of Wigan. Cab wrap was applied by Smaldon signs and vehicle graphics and the electricals were undertaken by Browns Auto Electrical in Preston. “We like to use local companies wherever possible.

“The driver had a lot of input into the specification as well. We had to measure to check the wheelbase would be spot on and the overhang would be legal.”

The fleet is now 28 trucks. Ten are DAFs, the XF480 FAW, the (old) XF430 FAW, two XF480 FTRs, two XF530s FTPs, three XF530s FTRs and one XF530 FT. They are joined by the three Renault Range C tridems, all 440 models. Three Volvos are also retained, one FM420 tridem (with the new cab) one V4 FM380 6x2 and a V4 FM420 6x2 that this DAF replaced. There are also 12 Scanias – one 460R Super tridem, one 420G Super tridem, two G410 tridems, and one elderly old cab P410 tridem. There is also a P410 8x4 with twin-

steer front axles and a 6x2 G360. Three 460R tag-axle tractors, and two R450 tractors.

All the Dugdale fleet have private plates, usually ending in DUG. The FAW has the plate BA65 DUG – so it sort of looks like BAGS Dug! It has some extra murals over and beyond the normal Dugdale livery, not to mention those special curtains, additional light bars – which aren’t just for show, they come in very useful for night time farm deliveries, makes it really stand out.

A special anniversary truck, likely to be a Renault C520 4x2 tractor coupled to a new Muldoon two-axle rear-steer bulk blowing trailer should also be going on the road later this year and that too will have some special artwork.

The Dugdale fleet is there to support the company’s animal feed production, but they are certainly not dull and boring. And most are rather quite innovative to boot...

Based in Clitheroe in Lancashire, Dugdale Nutrition is a family owned firm that has been serving farms in the north of England for 175 years now. It also has another site at Speke in Liverpool which was bought in 2017 and is also used to manufacture and distribute animal feed. It was bought to expand the business and has three trucks based there..

The Clitheroe site is immaculate and impressive. It also owns Home and Dry and RBC Agri, both of which cater for different types of animal feed and grass seeds.

The animal feed is distributed to farms and customers across the north of England and beyond.

The company does also cover the whole of the UK with the Home and Dry product, from Cornwall to Scotland and while most drivers are on day work, a few do tramp.

Like many before him, Lewis Geach spent his formative years in and around HGVs, yards and truck drivers. Again, in a familiar story, this seed was sowed because of his dad’s business (Geach Plant – a totally separate entity to his own). What followed was a career spent in and around tippers and trailers – firstly doing all the hard work and driving for other people, before taking the plunge to go it alone.

“I learnt the trade on machines and with diggers from a young age – and then got involved in trucks properly when I was still at school,” explains Geach. “A friend of mine used to drive a truck and I would often go out with him during school holidays. When I finished school, I became his right-hand man because unfortunately – for him – he suffered a bad injury, which meant he could drive, but not do a lot else. So I had to strap

In a short space of time, one Exeter-based operator has embraced the tipping life, helped in particular by one specific truck manufacturer.

Words:

John Challen Photographs: Karl Hopkinson

Reproduced courtesy of Commercial Motor

machines onto his low-loader and do all the other jobs because he had broken ribs, which put him out of action.”

Geach spent about 10 weeks working the low loader and then branched out – heading off into the coach world for a while and ended up working between that and a plant-hire company. When he got his licence, he chose the plant-

hire business and also got his first taste of tipper driving. But working for other people wasn’t always all it was cracked up to be, the final straw being a job at a quarry that wasn’t really making him or his employer any money.

Together with his wife, he decided in 2018 that he might just be able to go it alone – and make a success of

his own tipper business. Since then, Geach Haulage – and then the Geach Aggregates spin-off – has gone from strength to strength. It’s been quite the start in the transport business, but a story that shows Geach is willing to turn his hand to anything in the hope that it will all come up trumps. “We’ve had a good go at different things, but I think you have to,” he says, philosophically.

Going Dutch Geach has experience of different commercial vehicle brands: he has driven six and eight-wheel Renault and Scania trucks in the past, for example. But his heart has always been with DAF. It’s a relationship that continues today with the company’s latest recruit, an XB.

Kicking off the love-in with the Dutch brand, Geach’s original tipper was a CF eight wheeler with an aluminium body to maximise payload.

“We ran that one for six months, but the work was hard on the truck – partly because half of the journey was offroad,” says Geach. “We adapted it and changed the body because we ended up doing muckaway and more site work. I bought a steel body from an older truck and put that on. We then started a job for a Costa and a McDonald’s franchise and also ended up helping another haulier out. They said we could put four more trucks on the job if we could find them. So, I hired in four vehicles, spent a month on the job and soon worked out that

for the amount I’d spent in truck hire costs, I could’ve bought another truck outright. So, soon after that, we invested in another eight-wheeler in February 2020.”

Such was Geach’s keenness to get that truck – another CF, this time a 63-plate with a sleeper cab – up and running, he told the seller it needed to be on the road by March. And then Covid hit. The truck was parked up, the driver put on furlough and Geach spent a bit of time giving his original truck some TLC. However, before long he was back up and running – and finding new opportunities.

“One of the tipper firms in the area called me and told me that they weren’t taking drivers off furlough, but they were staggering their drivers and slowly picking work up – so I stepped in,” he explains.

“I had one month with only one truck on the road but, in that month, we decided to buy something a bit different,” he reveals.

Unwanted space in front in came an exTravis Perkins 12-tonne LF that offered the company another string to its bow.

“The problem with a tipper is, especially an eight-wheeler, it does what it does – and that’s it,” he reasons. “You’re literally a tipper firm that can move 20 tonnes of stone or muck and if that’s not what people want, you’re no good to them.”

The LF was another example of Geach’s ‘can do’ attitude and willingness to think outside-the-box and adapt to circumstances.

“We bought it in May 2020 and ran it as a flatbed with a crane and then at the end of the year, we cut it down, shortened the wheelbase and converted it into a tipper,” he recalls. “We got another contract with a builder’s merchant, so we bought another 18-tonne rear-mount LF. That went on the road in September 2020 so, aside from everything else with Covid, it was a bit of a mad year for us, really!”

While Geach is a fan of eight-wheelers and 18-tonne trucks, he also sees the value – and versatility – in the smaller ones. “It had a brick-grab and a hitch fitted so it could tow trailers and had a carrying capacity of up to nine tonnes,” he explains. “We did a lot of hot tubs down to Cornwall at that time.”

Such was the popularity with the converted LF, the Geach fleet expanded again soon afterwards as a sister truck six months newer arrived, going straight into work at the builders’ merchant.

“It got to the point where I was going there more and more and losing my own customers, because I was trying to keep the big client happy,” he says. “So that 12-tonner arrived and then we were contacted by a local sawmill. Long story short, we ended up buying another LF 18-tonner with a fairly big crane on it to fulfil their requirements. We’ve actually only recently replaced that truck – with another DAF, naturally.”

Like with the main truck supplier, Geach remains fairly loyal to the tipper and

crane suppliers on the fleet, with Hiab used predominantly for the cranes. “We’ve got three Hiabs, including the new one and I think we’ll stick with them in the future,” he says. Bodywise, there’s a mix of Abba and PPG/ Weightlifter because they were the two who could give Geach exactly the spec he was looking for.

Continuous expansion

Geach Haulage is currently running six trucks – all of which come from DAF. There are two eight-wheelers, one sixwheeler, an 18-tonner, a 12-tonner and the newly acquired XB. However, at the time of writing, he is in the process of signing the paperwork for another DAF 18-tonner that will go into another builder’s merchants taking the fleet up to seven vehicles.

As time has gone on – and the business has boomed – the quality of truck has gone up at Geach Haulage and the age has gone down. The first brand-new vehicle he bought was the 72-plate CF eight-wheeler. “It’s a hell of a thing,” says Geach. “It was a big, big decision

“GEACH’SORIGINAL TIPPERWASACF EIGHT-WHEELERWITH ANALUMINIUMBODY TOMAXIMISEPAYLOAD”

for us at the time [to buy brand new] because it was a lot of money – and we did wonder whether it was going to pay for itself. But it certainly is now, thankfully.”

Not only is it performing well, it has retained its fresh appearance, some 18 months on. “It still looks brand new and the driver looks after it – as he has done from day one. He works it hard, but when he gets in it’s shoes off, slippers on and he makes it like his home.”

Geach says he tries hard to keep one driver to one truck “because I always work on the theory that they feel like it’s their truck, so they will look after it”, he reasons. “Our drivers always keep the fleet looking presentable, which is pleasing.”

“When we bought the first new CF eight-wheeler, it was around the time the XG was coming out, so I asked the salesman if a CF equivalent was on its way. I was reassured that there wasn’t and that nothing was in the pipeline for the next 18 months. So I signed the paperwork – and within six months, DAF brought out the XD!” recalls Geach. “So we’ve actually ended up with the last CF eight-wheeler with a construction chassis. When it came to the XB, I was prepared and I knew more about the truck than the salesman did. I told him we wanted a 16-tonner because we needed to carry

more weight than the one that we’ve got. Our 12-tonner has only got a single extension crane, but we needed something with a bigger crane because we were doing a lot of hot tub moves at the time. So, we waited for the model to come out – everything was designed on LF chassis and then as soon as it was available, we switched it all over. I wasn’t going to get stung twice! I don’t regret buying the CF – it’s been a brilliant truck – but part of me thinks if we’d waited another six months, would we have got an XD? Probably.”

New kids on the block

For Geach’s XB, it was a case of ticking every box – as he did with the first brand new truck. It arrived in October last year and has been performing well, even though all the modern technology takes a bit of getting used to for this old-school trucker, when he gets behind the wheel.

“I got the eight-speed auto box in it, which was something out of my comfort zone,” he admits. “I’m from the era of a 16-speed manual being the way forward, but times have moved on and automatics seem the way forward. And, to be fair, the gearbox is really good. In fact, I don’t think I’ll go back to a manual.”

Coupled with the 290 engine, the digital dash and the XB cab, it has impressed Geach – “for a little lorry!”.

“It works on the haulage side but does a fair bit of aggregates work, he explains. “It could be doing dumpy bags in the morning, a loose load after that, or the other day it was lifting a load of steel into a building. Those are the type of jobs I wanted to be able to do.”

There is no doubting Geach’s allegiance to DAF, but there has been a different

Eight-wheeler is Geach’s first new truck

marque around the place recently, in the form of an MAN.

“My nephew is doing his apprenticeship at MAN Trucks and he mentioned that MAN Exeter had a TGX demonstrator in, so I saw it as free motoring for a week,” he admits. “Actually, we had it for a week and then I found enough work for it for another week, so when I dropped it back I asked if I could keep hold of it and they said yes. It was a TGX 440 eight-wheeler with mirror cameras, which I’m still getting my head around. They’re good for for visibility outside of the cab, because you haven’t got a great big mirror hanging in the way, but the cameras take getting used to and if you do break it and you’re out on the road, you’re essentially immobilised.”

It wasn’t the first time Geach has gone down the big truck route, having previously spent time with a DAF XG.

“Just before Christmas, we had one in on demo and hired in a trailer for a month,” he reveals. “I thought that we needed something else because we only had tippers. It worked, because we promoted the fact we had it and it worked to a point, but it was hard going.”

With Geach, an artic certainly seems to be the itch that needs to be scratched – not least because having one on the fleet really helped increase brand awareness. “Even though our trucks are bright yellow and have got lights everywhere, to some people, you haven’t made it until you’ve got an artic on your fleet,” he says. “When we had that truck, the amount of people who commented on it was unbelievable. I honestly don’t know if we’ll add one to the fleet next – the past few years have been a rollercoaster, so anything is possible.”

Lewis Geach owes much of his life in haulage to his dad, Dave who – along with Lewis’ uncle – has run Geach Plant since 1974. “Dad has been – and still is – a big part of the business and is always keen to get involved,” says Geach. “Recently there was meant to be three months of driving work during the week and the weekend and he was up for getting behind the wheel of one of the trucks to help us out, but it didn’t happen in the end. It’s still great to know that he is still keen, after all these years.”

Dave isn’t the only member of the family involved, though – “My other half is the transport manager and accountant and my sister-in law works in the office. Also, my brother’s got his licence so, even though he’s a builder by trade, I can always talk him into doing a weekend here and there if I need to,” he says.

VLT Logistics is based in Yeadon near Leeds Bradford Airport, boasting over three decades in haulage. The firm has built its reputation on a foundation of new, high-spec vehicles, primarily DAFs, but with top-tier Scanias and Volvos integrated for operational diversity. The current DAF line-up features six CFs, four XG tractors, and an XG+ tractor all powered by top-rated engines and furnished with premium specifications. The company always acquires new equipment, a decision that not only ensures reliability and efficiency, but also signals a commendable commitment to quality.

VLT’s operation extends beyond simple freight movements. The company focuses on warehousing, cross-channel logistics, customs management, and specialised transport services for both domestic and pan-European customers. A modern, secure facility at the core of its network ticks all the boxes for efficiency, safety and customer assurance.

When passion, dedication and workmanship come together, extraordinary things can happen, even in the most utilitarian of settings. Martin Dove’s DAF XF105.460 is a case point; a now-classic truck that went from everyday workhorse to truck show head-turner, and eventually getting the nod in DAF Trucks’ popular online picture competition.

One of Martin’s pictures was selected as ‘Truck of the Month’ for the DAF Trucks UK Facebook page, and then voted best of 2024.

The recognition is both a feather in the cap for Martin and a marketing win for VLT Logistics (aka Vernon Land Transport) the operator of the truck since it first hit the road in 2013. It is a powerful testament to what is possible when a passionate driver takes true pride in their machine.

Martin Dove’s connection with lorries runs deep. For him, like many, truck driving isn’t just a job, but an integral part of a professional heritage. “My dad was a truck driver, so I used to ride in the cab with him during school

holidays,” Martin recalls, “It all began in earnest with a stint as a driver’s mate at White & Co Removals, giving me a valuable European perspective on routes through Spain, Portugal and Germany. Those early days spent on continental hauls fuelled my curiosity and it certainly deepened my interest of lorries.”

From subsequent jobs on furniture deliveries for Marks & Spencer to operational roles in commercial vehicle hire, he steadily built his reputation. Eventually, a speculative message to Andy Land, boss at VLT (a friend of Martin’s already worked there) opened the door to his current post; proof once again that in road transport, initiative and character can matter as much as mileage logged.

The XF106: from neglect to rebirth

Every truck tells a story, but few have been as dramatically transformed as Martin’s ’13-plate DAF XF105.460. Originally employed on general haulage day work, the vehicle’s future became uncertain during the pandemic. Idle and languishing in VLT’s West Yorkshire yard, ‘F7 VLT’ became somewhat neglected. Martin, then working around the depot, spotted the truck and seized the opportunity to make use of it for shunting, hoping to glean some hands-on familiarity before obtaining his C+E license.

Yet, what began as routine yard duties soon shifted into a labour of love. Martin recalls the moment the restoration took on a life of its own.

“I just started cleaning it up,” he said, “the next thing I knew, I’d rebuilt half the truck. I was just tinkering around with it, but it became infectious and, while not an all-out obsession, it started occupying a lot of time and it turned into a full-on restoration.

Step-by-step, Martin took the battered old truck and infused it with individuality. Salvaged bull bars and spotlights were repurposed, and additions such as a visor-bar, air-horns, Eurobars, and roof markers brought distinction. For our photo-shoot he even hand-coloured the tyres – a toilsome detail he laughingly vows never to repeat! Most notably, the

cab interior stands apart from the rest of the VLT fleet, decked out with custom red upholstery.

The winner in red

The exceptional standard of workmanship did not go unnoticed. Photos of the XF105 – snapped in the yard and at local truck shows –caught the eye of competition judges at DAF Trucks, propelling Martin and his passion project into the national spotlight. For a vehicle used predominantly in the yard nowadays, and with over 676,000 km on the clock, such acclaim is well-deserved.

Although the XF105 is no longer on official work duties, its legacy within VLT is secure. These days, the

truck is employed occasionally on local deliveries, shunting duties and select show appearances, proving that headturning appeal and practical utility are not mutually exclusive. The only aspect Martin hasn’t yet returned to showroom quality is the steering wheel, a detail that you’ll notice, despite his best efforts, remains stubbornly untouched. “I keep asking Andy [Land] for a new one, but he keeps saying no,” Martin jokes.

Nonetheless, Andy Land is well pleased with Martin’s efforts. “Martin started looking after the truck off his own back and has done a fantastic job,” he says, “it looks great. I’m very grateful that he takes such pride in the fleet and the company.”

More than just a job

Unlike many high-profile restorations, Martin’s project was executed without backing, brand sponsorships or a large support team. Instead, it became a labour of love, undertaken in his own time and motivated chiefly by pride in the machine and its appearance. The project makes a statement about

professional identity, dedication and the small but crucial details that define job satisfaction in the haulage trade. This element of pride is not uncommon in the industry, but Martin’s approach raises the bar. His XF105 has become something of a symbol of quality at VLT, and an object lesson in the impact of treating trucks as more than mere assets. “It’s not just about hitting delivery deadlines,” Martin adds, “It’s about loving what you drive, looking after it and taking pride in your work.”

shows: recognition and rivalry

The truck show circuit is both a showcase and a battlefield, where attention to detail is scrutinised and reputations are won or lost. Over the years, Martin’s XF105 has garnered admiration at numerous local events, although it has yet to make an appearance in 2025. Plans are, however, in place for its imminent return to competition, where its distinctive presence is sure to attract attention, especially given its role as a ‘shunter’.

When asked if another restoration is on the horizon, Martin hesitates, candidly

acknowledging the time and effort involved in bringing this particular truck back to life. “This one took me five years, so I’m not rushing into it. Still, if another truck comes up and it’s got potential, you never know.”

Winning the DAF Trucks’ picture competition has brought Martin’s work to a wider audience, inspiring admiration among fellow professionals and enhancing VLT’s brand profile. For Martin, however, the accolade is not just about him. “It’s great for me personally, but it’s also good for the company. People are talking about it. They’ve seen the photos and it just shows what’s possible when you really get into something.”

Whether shunting pallets in a yard or taking centre stage at a local show, Martin Dove’s DAF XF105 stands as proof that the tradition of the driver-restorer, the team-player and the perfectionist, is alive and well. In an industry defined by schedules, compliance and deadlines, it’s these moments of personal dedication and workmanship that create truly enduring stories.

Truck restoration isn’t only a labour of love, it can also be a serious money pit. However, the return on investment can make it worthwhile. Take Martin Dove’s XF105; it stood out not just for its appearance but also its ability to work. In today’s classic truck scene, quality rebuilds are increasingly translating into prestige and strong resale value.

A thorough restoration that boosts reliability while staying true to the original design can dramatically increase desirability. Collectors, operators and specialist buyers are the key audience, and trucks that look authentic and perform well are fetching top prices. Authenticity is crucial. Retaining original specs, using OEM parts, and having a documented build history inspire buyer confidence. Provenance counts, especially for rare or historically significant models like the F7 VLT, now scarce on the open market. When historical accuracy meets craftsmanship, value often appreciates sharply.

Show recognition also adds value. Awards lend credibility to both the truck and restorer, acting as potent marketing tools in a competitive trade, serving as brand ambassadors.

A full rebuild typically involves everything from engine and drivetrain overhauls to chassis strengthening and cab refurbishment. Done right, a restored truck can rival or exceed modern counterparts in reliability and longevity, offering many years of dependable service. For fleets and small businesses, restoring a trusted workhorse can be more economical than buying new.

Restoration also supports sustainability. Unlike the high environmental impact of buying new, restoring trucks is far more resource-efficient. The heritage vehicle sector is gaining recognition for its low-carbon footprint, with emissions far below those of new production.

Still, the outcome depends heavily on execution. Poor workmanship or excessive modernisation can undermine both appeal and long-term value. Even top restorations require ongoing preventive maintenance, essential to protecting both investment and reliability over time.

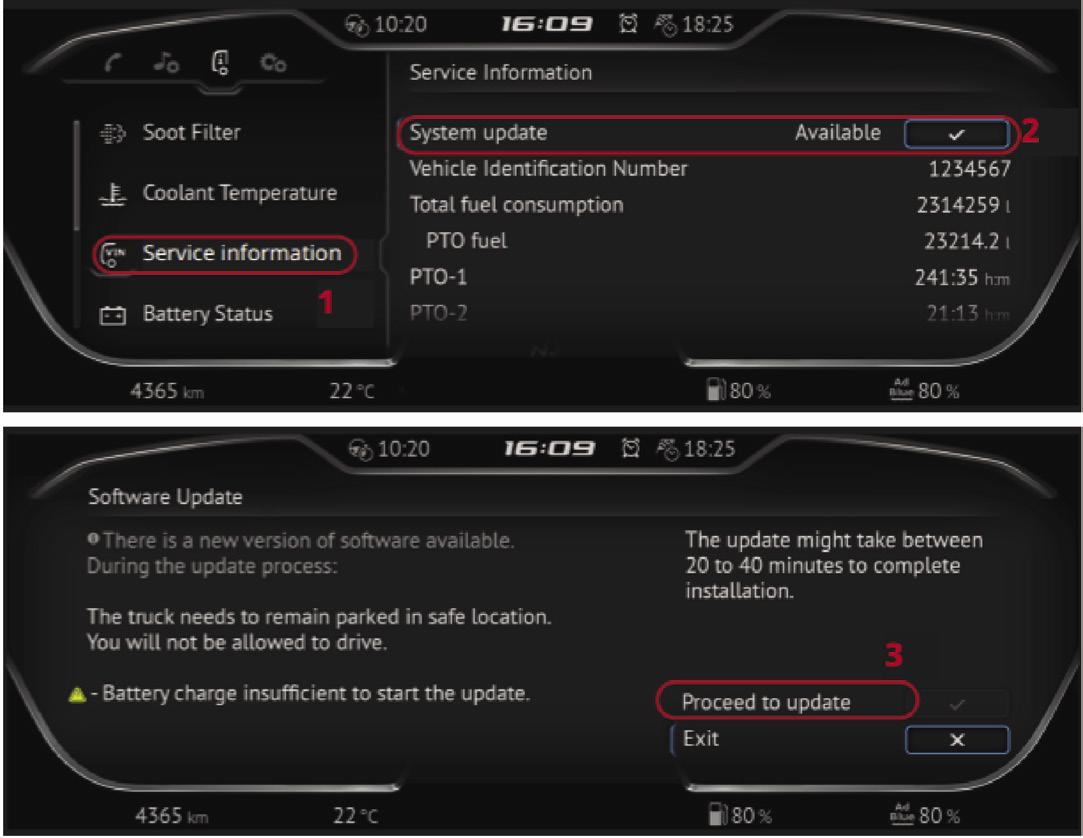

Mandy Wannerton is the DAF Press & Demonstration Driver

Keeping the ever-increasing number of electronic systems on our trucks up to date is more critical than ever before. Fortunately, DAF is now introducing Over-the-Air (OTA) software updates for some of the vehicle systems to help keep your vehicle running smoothly and efficiently. If you drive one of the latest DAF models, here’s what you need to know about this exciting new development and how it will impact your driving experience.

What Are Over-the-Air Updates?

OTA updates are exactly what they sound like—software upgrades delivered wirelessly directly to your truck. Instead of having to visit a dealership for manual software updates, you’ll now receive important improvements, bug fixes, and new features automatically. This means your truck’s systems stay current with the latest advancements without any hassle or downtime.

Why OTA Updates Matter to You

Modern trucks rely heavily on sophisticated electronics and software to optimise performance, safety, and fuel efficiency. By receiving OTA updates, your DAF truck can benefit from:

• Enhanced Performance: Software tweaks can improve engine management and transmission control, helping your truck run smoother and more efficiently.

• Improved Safety: Updates can include enhancements to driver assistance systems, helping keep you and other road users safer.

• Convenience: No need to schedule service appointments solely for software updates—everything happens wirelessly and often automatically.

• Reduced Downtime: Faster updates mean less time spent off the road and more time earning.

When an OTA update is ready for your truck, you’ll see a pop-up notification on your digital display. This alert lets you know that a new system update is available and ready to be installed. It’s important to pay attention to these notifications to keep your truck’s software current.

Before starting the update, there are a few key steps to ensure a smooth installation:

1. Check Battery Level: Make sure your truck’s battery is sufficiently charged to avoid interruptions during the update process.

2. Apply the Park Brake: Safety first— engage the parking brake before proceeding.

3. Switch Off the Engine: The engine should be off, but the ignition switched

on. Do not start the engine during the update.

Once you accept the update notification, the process is simple:

1. Navigate to the Standstill menu on your digital display using the steering wheel switches.

2. Scroll down to ‘Service Information’ and select the system update option if an update is available.

3. Follow the on-screen instructions, select ‘Proceed,’ and then choose ‘Install System Update.’

4. Wait patiently while the system downloads and installs the update. This may take several minutes.

It is crucial not to switch off the ignition or start the engine during the update. Interrupting the process could cause software corruption or other issues. Monitor the progress bar on your display and allow the update to complete and confirm with ‘System updated’..

If you have any questions or encounter difficulties during the OTA update process, your local DAF Dealer is ready to assist. Don’t hesitate to reach out for support to ensure your truck stays in top condition.

DAF now has Dealer Driver Trainers based across the country to help hand over new and used vehicles and we thought it would be good to get to know some of them a little bit better! In this edition we talk to John Jackson the DAF Dealer Driver Trainer at Motus DAF in Hull.

John and his wife Katie have a daughter together called Lotti who is four years old. John also has a son who is 20 now, and is serving in the REME. John spends most of his free time with Lotti and Katie, enjoying days out and visiting family. John also enjoys home improvements and loves reading; there is nothing better than sitting in a nice pub with a good book!

Q: When did you first join Motus DAF and what was your first job there?

A: I started working for Motus in January 2020 and my first role was as a driver.

Q: What did you want to be when you were at school?

A: At school I wanted to join the Army and ended up serving eight years in the Royal Artillery as an air defence specialist. After that I drove for a local bus company before joining Motus.

Q: When did you take your HGV licence?

A: I took my HGV license in 2020.

Q: What do enjoy most about your role?

A: No two days are the same and I really like the variety. One day I can be driving a car transporter to Scotland, the next I can be training a driver on his or her new vehicle.

Q: Do you have a top tip for a driver getting his or her new DAF?

A: My top tip is to take up the offer of

driver training. These latest vehicles have lots of new features and options that really improve the driving experience. Whether it’s your first truck or you’ve been driving for years, there is always something new to discover.

Q: What car do you currently drive and if money was no object what would you have?

A: I have a Volvo XC40 and if money was no object I’d have a chauffeur driven limo.

Q: What other responsibilities do you have within your role at Motus DAF?

A: On a day-to-day basis I take care of vehicle movements between bodybuilders, as well as preparing vehicles for final delivery, which takes up most of my time.

Q: If you weren’t doing this, what would your ideal job be?

A: I’m not sure what my ideal job would be - maybe this one with more money!

By Richard Simpson, industry pundit

It’s Autumn, which for the British transport industry means a time of peak demand for transport services, as first warehouses, then stores, and then finally the public themselves, all get stuffed for Christmas.

This increased demand brings with it more pressure on time, and danger for drivers. Darker mornings and evenings, slippery yard surfaces and catwalks and, quite possibly, the introduction of unfamiliar hired-in vehicles and trailers all pose challenges which are multiplied by tight schedules.

Trailer coupling/dropping incidents seem to peak at this time of year. There are obvious risks from dropped trailers rolling away or improperly-coupled trailers detaching themselves. These risks are multiplied by occasional interventions from warehouse staff or other drivers, who helpfully ask: “Are you going to move that f*cking thing before Christmas?”

One driver I know makes a point of restarting the entire trailer coupling and checking process every time he is interrupted. Eventually his impatient ‘helper’ takes the hint!

There are two parts of the process that are more important than ever. One is correct coupling of the ISO7688EBS control line, and the other is the parking brake ‘tug test’.

For a number of reasons, the ISO control line is sometimes either ignored or not connected correctly. This is a concern because it controls the trailer’s roll-sensing, loadsensing, and ABS functions.

Some drivers apparently believe that running with it disconnected will enable them to corner faster(!) so deliberately leave it misconnected, while others, working perhaps in poor light, will accidentally connect the trailer end of the line to its parking place on the tractor.

Others just find the plug is too damaged to connect, and press on regardless.

This is a mistake, as besides controlling the braking and stability systems, the line also determines that the trailer runs at the correct ride height. Some fleets which have investigated ‘unexplainable’ bridge-bashing incidents have found they occurred because the line was not connected properly. Any driver or operator caught in such an incident will know that a summons from the Traffic Commissioner and licence suspensions inevitably follow, and this happens after any court case.

The next important item is the ‘tug test’: pulling forward against the trailer brake. Traditionally, the prime purpose of this was to test the integrity of the coupling. But an increasing number of trailers, particularly those that are hired in or are drawn by third-party hauliers on behalf of large retailers, no longer undergo brake testing as part of their periodic maintenance inspections (PMIs).

Instead, they rely on something called electronic brake performance monitoring. This monitors the in-use performance of the trailer’s brakes electronically, and reports it in real time to the operator. Trailers fitted with electronic brake performance

monitoring systems (EBPMS) are exempt from roller brake testing at PMI, and this includes the workshop testing the effectiveness of the trailer’s parking brake.

Sadly, EBPMS as it stands is a very crude measure of total braking performance: it says nothing about how each wheel brake performs, and because it only works dynamically it does not assess the efficiency of the parking brake at all.

This puts more onus on the driver than ever to not only carry out the ‘tug test’ each time a trailer is picked up, but to also record the result, and to take action if there are doubts about its effectiveness.

The driver would also be very wise to examine the performance of the trailer brakes too, so far as is possible. A quick walk around after parking might show that while two wheels on one side of the truck are warm, the other is stone cold…because that brake isn’t working.

It’s a common misapprehension that as far as the driver and operator are concerned, the condition of a thirdparty or rental trailer is not their responsibility. This isn’t the case in reality, as far as DVSA, the courts, and the Traffic Commissioner are concerned, they are ‘users’ of the trailer and the offences they will be charged with, if the trailer is defective, are under Construction and Use regulations.

So, no matter what the time pressures, check and check again. You don’t want to end up being stuffed by the system in the Christmas rush, let alone crushed by a runaway trailer.

The prize in this edition is a DAF XG+ 4x2 tractor and tri-axle trailer miniature in 1:50 scale, for one lucky winner.

Simply spot and mark the four differences on the images above. Once completed, either cut out or photocopy and post to DAF Driver magazine, 4th Floor, 19 Capesthorne Drive, Eaves Green, Chorley, Lancashire, PR7 3QQ

The quality of a truck depends on the quality of the organisation behind it, which is why the DAF dealer network offers a unique advantage with the best geographical coverage of the UK, the most heavy truck experience and the longest opening hours of any truck franchise.

Area Dealer name Postcode Telephone

ABERDEEN Norscot Truck & Van Ltd ★▲ EV AB23 8JZ 01224 824444

ASHFORD Channel Commercials PLC ★▲ EV TN23 1EH 01233 629272

AVONMOUTH MOTUS Commercials ▲◆ EV BS11 0YL 01173 042800

CARDIFF Watts Truck & Van Cardiff ★ EV CF11 8AT 02920 308595 CARLISLE MOTUS Commercials ★ EV CA3 0HD 01228 539394

CROYDON HTC Croydon ★ CR0 4TD 0208 683 6200 DERBY MOTUS Commercials ▲ EV DE22 4NB 01332 824371 EDINBURGH Lothian DAF ★▲ EV EH20 9QH 0131 440 4100 GLASGOW MOTUS Commercials EV G51 4TH 0141 425 1530

GRAYS Harris DAF ★▲◆

RM20 4AU 01708 864426 GUILDFORD HTC Guildford EV GU1 1RR 01483 594900

MOTUS Commercials ★▲ EV B63 2RL 01384 424500 HEATHROW HTC Heathrow ▲ EV SL3 0ED 01753 681818

HUDDERSFIELD MOTUS Commercials ▲ HD2 1UR 01484 300500

HULL MOTUS Commercials ▲ EV HU9 5PJ 01482 795111

IPSWICH Chassis-Cab Ltd ★ EV IP6 0RL 01473 833003

LEEDS Ford & Slater DAF ▲◆ EV LS28 6SD 01132 571701 LEICESTER Ford & Slater DAF ★ EV LE3 2JG 01162 632900 LIVERPOOL North West Trucks ▲ EV L36 6AJ 0151

BT36 4PT 02890 342001

Lancashire DAF ★▲ EV PR5 8BW 01772 338111 READING HTC Reading ★ EV RG7 4AG 01189 300900 SHEFFIELD Ford & Slater DAF ▲ EV S13 9NR 0114 293 9200 SHREWSBURY Greenhous DAF ▲

WV13 3SF 01902 305090

5YT

MOTUS Commercials ▲ EV S71 3HS 01226 731870 BASINGSTOKE Adams Morey Ltd RG24 8FB 01256 811414 BATHGATE Lothian DAF EV EH48 2EY 01506 813 743 BEDFORD Brian Currie (Milton Keynes) Ltd MK41 9TG 01234 211241 BELLSHILL

Commercials B33 0SL 0121 784 4023

BIRTLEY Ford & Slater DAF DH3 2SP 0191 406 8888

BLACKWELL H W Martin (Plant) Ltd DE55 5JY 01773 813313

BOURNEMOUTH Adams Morey Ltd ★ BH8 0BL 01202 524422

BRIDGWATER Adams Morey Ltd TA6 5LB 01278 550 970

BURTON ON TRENT MOTUS Commercials ◗ DE13 7AB 01283 248899

BURY ST EDMUNDS Chassis-Cab Ltd EV IP32 6NL 01284 768570

CAMBORNE Adams Morey ◗ TR14 0PY 01209 721989

CAMBRIDGE Chassis-Cab Ltd ▲ PE28 9QR 0333 323 4040

CANTERBURY Channel Commercials PLC CT3 3DW 01304 841111

CARNFORTH Lakeland Trucks Ltd LA5 9DW 01524 734544

CASTLEFORD Pelican DAF ▲◆ WF10 5UB 01924 227722

CHESTERFIELD Ford & Slater DAF ▲ S40 2RG 01246 234213

CONWY Parrys Commercials Ltd LL28 5RA 01492 580303

CORBY Ford & Slater DAF ▲ NN17 4BA 01536 207980

COVENTRY Ford & Slater DAF ▲ CV3 4FL 02476 302856

CRAWLEY GB DAF Gatwick RH10 9NS 01293 537520

CRICK GB DAF DIRFT NN6 7BZ 01788 711699

CUMBERNAULD MOTUS Commercials ★ G67 3EH 0123 672 7771

DAVENTRY Brian Currie (Milton Keynes) Ltd ◗ NN11 8RF 01327 871770

DEESIDE MOTUS Commercials CH5 2QJ 01244 520853

DONCASTER MOTUS Commercials ▲ DN6 7BA 01302 727040

DONCASTER Fishlake Commercials Ltd ▲◆ DN8 4JD 01405 740086

DUMFRIES MOTUS Commercials DG2 0JE 01387 720820

DUNDEE Norscot Truck & Van Ltd ▲ DD2 4UH 01382 611166

DUNS J E Douglas and Sons ▲ TD11 3HS 01361 883411

DUNSTABLE HTC Dunstable LU5 4TP 01582 505464

EASTBOURNE Brewers DAF BN23 6PW 01323 745700

ELGIN Sheriffmill Motor Co Ltd IV30 6UH 01343 547121

FROME MOTUS Commercials ▲ BA11 2FD 01373 468520

GARVAGH TBF Thompson BT51 5JZ 02829 558353

HTC Greenford UB6 0FD 0208 9615863 GRIMSBY MOTUS Commercials

The extensive DAF national network delivers the best Back-Up in the business. Our flexible range of MultiSupport servicing,

Celebrate with us by joining our DAF 30 Market Leaders Promotions throughout 2025, with opportunities to claim rewards and win prizes through our quarterly promotions!

Using the best parts for your DAF Trucks just became even more rewarding!

Approved members have access to an online portal to track and claim rewards through our quarterly promotions in 2025!

Apply to join online by scanning the QR code to visit daf30marketleaders.co.uk entering your name and business details, and selecting your local DAF dealer.

2.4

DAF PSQL 2.4 SAE 10W-30 is a premium performance heavy-duty engine oil designed to meet and exceed industry and engine manufacturers performance standards in on and o -highway diesel applications.

7 PERFORMANCE INDICATORS

• Cam Wear

• Soot Handling

• Bore Polishing/Piston Cleanliness

• Liner-Ring-Bearing Wear

• Soot Induced Wear

• Bio Fuel Handling

• Oxidation Stability

• Increased fuel consumption may be experienced

• AdBlue usage may increase

• Higher operating/service costs may apply

• A lower service interval on the DPF is possible due to impacted calibration

• Higher risk of vehicle breakdowns

If an accident occurs on the road, resulting in a damaged electronic

THE BENEFITS OF THE DAF EMERGENCY MIRRORS

+ TIME AND COST-SAVING

+ EASY TO INSTALL

+ HOMOLOGATED BY DAF

+ SPECIALLY DEVELOPED FOR THE NEW GENERATION DAF TRUCK

Our accessories, your New Generation DAF