MILESTONES MEMORIES &

1925 to 2025

1925 to 2025

By Alan Knights

This book is dedicated to Croda’s wonderful global family, past and present, who created this story.

By Steve Foots Chief Executive Officer, Croda International Plc

To be CEO of this great company of ours at any time in our history would be an honour - but I feel particularly proud and privileged to hold this position as we reach this important milestone: our centenary. A hundred years that has taken us from a tiny family firm to a multibillion pound global organisation. A company that my predecessors and our first managing director, A P Wood, could hardly have dreamt of.

This book looks at some of the other milestones along our journey. To many, it will be fascinating to look back to the days when we didn’t just manufacture speciality ingredients, but we were amongst the leading suppliers of industrial paints, adhesives and printing inks, or perhaps somewhat surprisingly, that we were once the UK’s second largest producer of honey, the UK’s largest private label soap producer, as well as a leading manufacturer of road tars and bitumens.

At times, the road was bumpy and undoubtedly, we sometimes strayed off-track - but it was those occasional detours that led us to where we are now. That taught us a valuable lesson. To keep our eyes on the road and focus on what we do best: naturally derived speciality ingredients. And that’s because sustainability is enshrined in our history, right back to those early pioneering days of refining woolgrease to make lanolin. Today, Croda is synonymous with growth, sustainability and innovation, which can be summarised by Our Purpose: Smart science to improve lives™.

It is that Smart science that led to the development of Polawax back in the 1940s, a particularly effective emulsifier for cosmetic creams and lotions. Smart science that, at the turn of this century, led to the development of Matrixyl - an age-defying, anti-wrinkle active ingredient used in numerous cosmetic products, which is today almost as well known by the consumer as the end products themselves.

Smart science that harnesses the opportunities that biotechnology can offer the Home Care sector, such as a new generation of probiotic cleaning ingredients, providing safe and sustainable solutions by letting nature do the work.

Smart science that led to the creation of our lipid-based delivery systems for the first Covid-19 vaccines – technology that has contributed to protecting billions of lives globally. And then, as an innovation partner to major crop science companies, applying our expertise in delivery systems and seed enhancement to meet the sustainability challenges created by climate change.

Sustainability is enshrined in our history. “ “

But science can only be as smart as the people behind it. That’s why, above everything else, Croda is a people company, and our continuing success is a tribute to the many loyal, creative and visionary people who have contributed to our story. So, along with the milestones, this book also looks back at some of the memories and recollections, gathered over many years, from friends and colleagues. Some, sadly, are no longer with us, but we will always remember them, along with all the others, too many to mention, who together have created Croda’s wonderful, talented and quite unique global family to whom this book is dedicated. Here’s to the next hundred years!

1925

Croda is founded at Rawcliffe Bridge in Yorkshire, by Mr Crowe and Mr Dawe (hence the derivation of the name), to make lanolin from woolgrease. Crowe’s nephew, A P (Philip) Wood, is appointed Manager.

In October, the first order – three barrels of lanolin – leaves the factory by horse and cart to Rawcliffe station.

1928

Eric Cannon joins the Board of Croda. The Board, which comprised Crowe and Wood, Crowe’s son, Louis (who lived abroad and played little part in the running of the company) and Eric Cannon, remained unchanged until 1946.

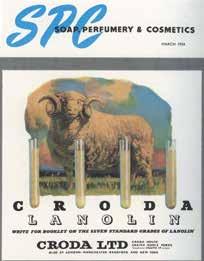

Lanolin is a soft, yellow paste that is actually a refined form of wool wax, more commonly known as woolgrease, one of the most ancient of substances used by mankind.

The Goole Times is the weekly local newspaper for the inland port and town of Goole in East Yorkshire, England, UK. On 26 April 1925, it carried a brief announcement that the disused waterworks in the nearby village of Rawcliffe Bridge had been acquired by a director of the Crowe Manufacturing Company, with the possibility of a new company being formed ‘for the manufacture of grease’.

That new company was called Croda. The name was derived from the meeting of a man with money, Mr Crowe, and a man with an idea, Mr Dawe.

George Crowe, who was born in 1870, was a successful ship owner whose family had been based in Greece since the 1840s. He was approached by Dawe about the possibilities of manufacturing lanolin in England, and had decided to back the idea.

Lanolin is a soft, yellow paste that is actually a refined form of wool wax, one of the most ancient of substances used by mankind. Due to the physical nature of the product, the raw wool wax is more commonly referred to as woolgrease, a product that is surprisingly complex and quite unlike any other fat or oil.

Woolgrease is a protective lipid (fat) that is secreted onto the surface of sheep’s wool to protect the animal from weather and seasonal climatic changes. When the fleece has been removed from the sheep by shearing, and before it can be processed into woollen textiles, this fatty coating must be removed by washing, a process that was generally undertaken at a woollen mill.

It is important to note that as the wool has already been removed from the sheep, there is no harm to the animal during the subsequent processing. The resulting greasy water is then treated by various processes to recover the woolgrease, a yellow-brown fatty material with a characteristic smell.

During the late 19th century, processes were developed on the continent, mainly in Germany and Belgium, to refine woolgrease into lanolin, improving the colour and odour. It was used in a variety of industrial applications, such as leather dressing, textile waterproofing and rope lubricants.

By some means, Dawe had acquired or developed such a technology, and the new company acquired the old waterworks at Rawcliffe Bridge as its manufacturing site for the new venture. However, Dawe’s concept never worked properly, and the Crowe and Dawe partnership that had provided the name, did not survive many months. Undaunted, George Crowe was determined to continue with the venture, and called upon his nephew, A P (Philip) Wood, hiring him as manager at a salary of £7.00 per week.

George

In the period after the First World War, when young Wood had left school, he had been engaged in a number of projects for his Uncle George, none of which had been successful. However, this new assignment fired both of their imaginations, and Wood duly set off from his home in Greece to Yorkshire to get to work, arriving on 14 April 1925. His diary entry for that day read ‘First day at Rawcliffe Bridge. Inspected works.’ He was then just 22 years old. The shell of the main building needed little structural alteration. There was a house on the site, formerly occupied by the waterworks manager, in which Wood took up residence. He employed a Belgian chemist, Felix Desmedt, to supervise the process, all of which was watched with great interest by the local villagers.

Not yet married, Wood led a fairly sheltered life focusing mainly on his work, initially supervising the plant construction, and then actually making the first batches of lanolin. His evenings were mainly spent creating direct mail circulars using a battered old typewriter. It was the beginning of a philosophy he maintained throughout his life on the paramount importance of sales and marketing. Indeed, much of Croda’s early success was built on the use of direct mail to generate leads, often recruiting friends and family to address envelopes to carefully selected contacts compiled from trade directories.

Despite the failings of Dawe’s process to make lanolin, Wood persevered. His persistence combined with optimism were necessary traits in the gloomy days of the late 1920s. Eventually, he managed to acquire a workable process and on 20 October 1925, the first order of three barrels of lanolin left the works by horse and cart bound for Rawcliffe station. The workforce consisted of three men running the plant; the chemist, Felix Desmedt; a bookkeeper; a typist; and Wood himself.

By July 1925, Wood had married and was joined by his wife at the small house at the works. In May 1926, their son was born there, christened Frederick Ambrose Stuart Wood – later to become Managing Director and then Chairman of a business that Wood senior could hardly have dreamt of.

Trading conditions became very difficult and the original capital was running away at an alarming rate. By early 1927, the strain was beginning to tell on Wood, and his doctor advised him to move away from the house at the works. He and his family moved to Doncaster where they found themselves next door to a couple of a similar age, a Mr and Mrs Cannon. The two couples got on well and later that year, Eric Cannon joined the company as Secretary. Wood, who was somewhat introverted, was complemented by the more outgoing Cannon, who joined the Croda Board in 1928.

By the end of the decade, the business was virtually insolvent, sustained only by personal guarantees to the bank from Crowe and Wood. It was timely, therefore, that in 1929, fortune smiled…

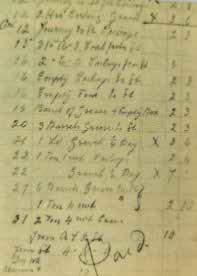

The cashbook used by Mr Stones, the haulier, showing delivery of raw materials, packages and building materials. Note the entry for 20 October: ‘3 Barrels Grease to St(ation)’. This was

In 1986, the Annual General Meeting was held at Cowick Hall, where a very special guest was Mr J Stones from the nearby village of Stillingfleet. It was his father who transported by horse and cart the very first three barrels of lanolin to be made at Rawcliffe Bridge in 1925 – Croda’s first year of operation.

In fact, as a centrepiece for the accompanying exhibition at the AGM, Mr Stones kindly arranged transport to Cowick Hall of the very same cart that was used back then. Today, the cart has a permanent resting place at Mr Stones’ farm. Mr Stones was a young lad at the time but he remembered A P Wood as a ‘big chap – we were always pleased to see him at the works as he could load two kegs at a time, so we could be on our way to the station much quicker!’

1930

Report from National Physical Laboratory shows that lanolin is an effective rust preventive, leading to the development of Croda Fluid to meet the NPL specification.

1931

Croda’s first profitable year.

1932

Edgar Lower, later to become Croda’s first Technical Director, joins the company as a 14-yearold to help out in the laboratory.

1933

Development of range of lanolin bases for use in cosmetic manufacture, including Cremba and Isocreme.

1935

Lanolin successfully split into lanolin fatty alcohols and fatty acids, resulting in the creation of Hartolan (‘the Heart of Lanolin’), a superior emulsifying agent for cosmetic creams and lotions.

1937

London office established.

1939

Outbreak of war leads to close collaboration with the Government to produce a variety of wartime speciality products.

As the 1920s drew to a close, the National Physical Laboratory published a report on the effectiveness of lanolin compared with existing types of rust preventives. This showed lanolin to be far more effective than the other products in use. With this authoritative backing, it was decided to proceed immediately with the manufacture of a rust preventive to the specification outlined by the National Physical Laboratory – and so, ‘Croda Fluid’ was born. The product recommended was a 30% solution of lanolin in white spirits. The method of manufacture was simple to say the least. The lanolin was melted in an empty 40 gallon steel drum standing on a few bricks over an open fire. When it was melted, the fire was put out and white spirits quickly poured in and mixed.

Working alongside government departments and leading engineers, what was initially a single grade was expanded to create a range of products for different engineering applications, including car plants and assemblers of consumer durables. These applications were soon to diversify further. With the darkening clouds of war, more and more manufacturers turned to armament production, where freedom from rust was essential. The early ‘30s saw a turning of the tide, and 1931 was a profitable year.

Although Eric Cannon had originally joined the company as Secretary, like A P Wood, he ‘wore a number of different hats’. When not out selling, his principal role, he worked in what was euphemistically called ‘the laboratory’, which was actually the kitchen of the house on the site in which Wood had lived.

Whilst working in the laboratory, Cannon was joined in 1932 by a 14-year-old local lad who had instructions to wash the pots and the floor, and make himself generally useful. This boy, Edgar Lower, displayed an almost fanatical determination to master every aspect of lanolin and associated products, eventually becoming a world authority on the subject. He joined the Croda Board in 1946 as Croda’s first Technical Director, retiring from that role in 1974. But that was a long way in the future from the mid 1930s, when he gradually took over the laboratory from Cannon and became Chief Chemist.

Much of Croda’s early product range was devised in this period by Edgar Lower. Because lanolin also possessed emollient or ‘skin softening’ properties, it was a natural choice, literally, for cosmetic preparations. Lower became increasingly interested in this field and began to develop a range of lanolin bases for cosmetic manufacture.

In 1934, Edgar Lower and Eric Cannon started experiments to chemically separate lanolin into its two major components: lanolin alcohols and lanolin fatty acids. This was already being done in Germany and it was known that the alcoholic fraction was a superior emulsifying agent for cosmetic creams and lotions. Despite the somewhat crude laboratory facilities and their own relative alcoholic fraction, which A P Wood named Hartolan (i.e. containing

the ‘Heart of Lanolin’). The subsequent development of a product that was soon to become known around the world showed an early sense of ingenuity and creativity – traits that were to characterise Croda’s future progress.

As an example of this, the plant needed to manufacture Hartolan in bulk was elaborate and expensive at a time when Croda had very little money. At the same time, A P Wood became aware that a large and prosperous Bradford wool mill, W & J Whitehead Ltd, was planning to enter the lanolin business. To counter this, Wood proposed to Whitehead’s that instead of making lanolin, and thereby creating unnecessary competition, they should manufacture this remarkable new product, Hartolan, which in turn, Croda would market. Perhaps surprisingly, Whitehead’s actually liked this idea, resulting in a fruitful and long-term partnership between the two companies. The whole episode was an example of Wood’s early preference to concentrate on sales and marketing. However, as Croda embarked on its quest to achieve the highest standards of quality and performance in an increasing regulatory world, the benefits of a strong manufacturing base and a skilled, dedicated workforce, would become increasingly apparent.

As the decade progressed, thanks to steady sales of lanolin and its new derivatives, Croda managed to increase profits slowly and stay afloat. There were frequent slack periods, however, when manufacturing had to be stopped and men had to be laid off, affecting morale. Diversification was tried. A new company called Charlotte Toilet Lanolin Company was formed to pack lanolin into small tubes and pots for the retail market. This was not successful, however, serving to hammer home the message that there was a world of difference between industrial selling and retail marketing. The moral of the story: the cobbler should stick to his last – stick to what you know and what you do best (advice that would prove to be almost prophetic at times during Croda’s centenary journey).

An indication of the austerity of the times is that it was common practice for the bosses to pass down their clothes to the workers. The workforce was not much bigger than a large family and indeed, there was a strong family ethos, exemplified by annual one-day trips to the seaside.

Eventually, however, the relentless quest for new markets began to bear fruit. The general economy started to improve and with it, Croda’s fortunes. By 1938, the number of men employed in the works had crept into double figures. Wages at that time were one shilling per hour. Eric Cannon was spending more and more time out selling, particularly in the south of England, so it was decided to set up a London office where he would be based.

Cannon also travelled regularly to Europe where Croda was starting to establish new and important markets. But then, just as fortunes had changed at the beginning of the decade, the dawn of a new one was to bring further massive change with the outbreak of war.

Edgar Lower’s focus shifted rapidly to studying Government specifications, selecting those products that Croda could supply. Fortunately, the existing plant, although quite basic, was ideally suited for blending operations, and the know-how Croda had quickly acquired whilst working closely with the Government’s own technical staff was to prove invaluable in shaping the next chapter of the Croda story.

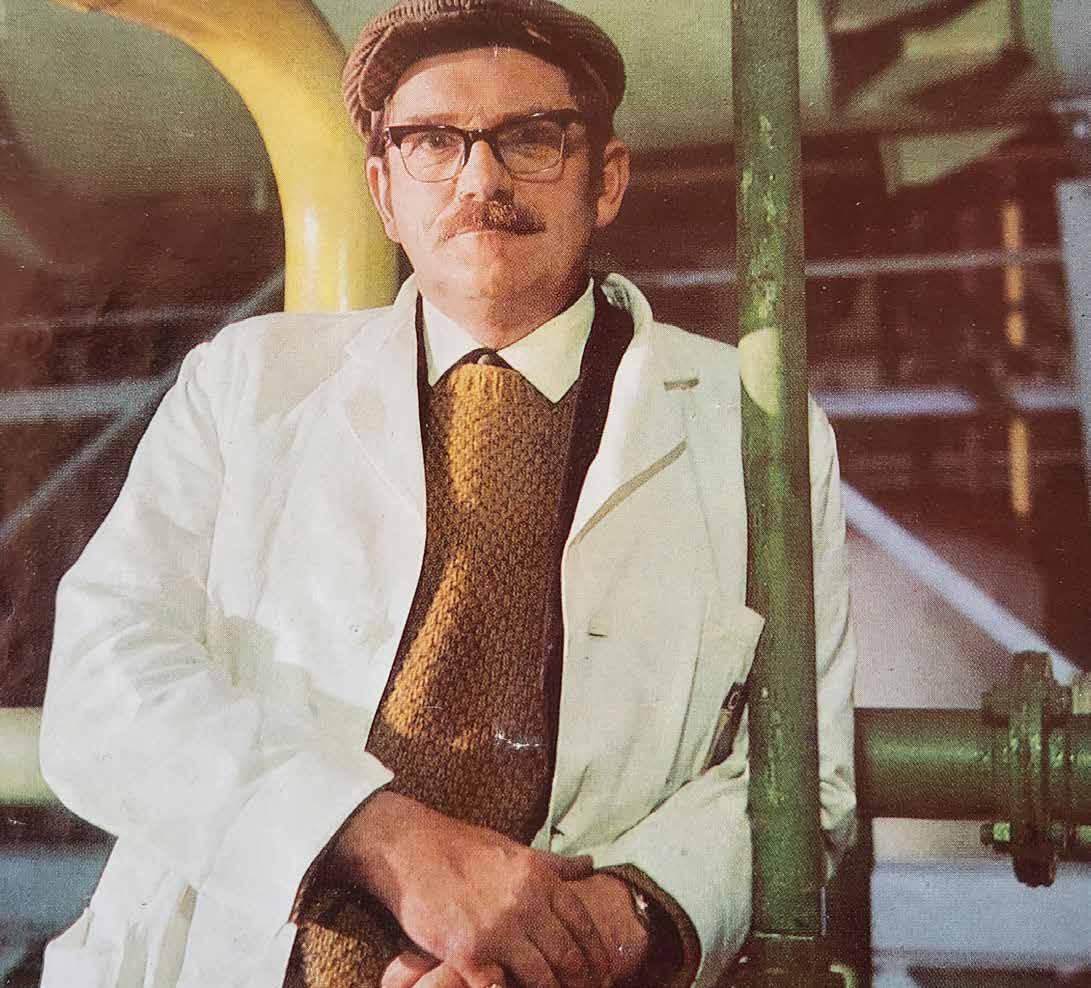

By Edgar Lower

My first day at Croda will never be forgotten – I was terrified! I was 14 and had left school during the Christmas holiday. My role in the organisation, between joining in 1932 through to 1936, was manifold.

I washed the office floor, opened all the mail with one of our typists (Miss Setterington) and, in my role as Assistant Chemist, made up samples and helped out in the works whenever and wherever I could.

Here my duties included firing up the boiler, cleaning the grease traps out, along with the dyke that ran through the site, helping with a little extemporary pipe fitting, stencilling barrels of lanolin and stamping the post. At that time, Mr Wood (senior) was very keen on sending out samples of ‘White Swan Lanolin’ with every circular letter, so apart from preparing hundreds of samples, I also helped to insert them in the envelopes and transport them to the post room in my special ‘carrier’… a waste paper basket. I seriously consider that sending out samples in this way helped to establish Croda Limited.

“

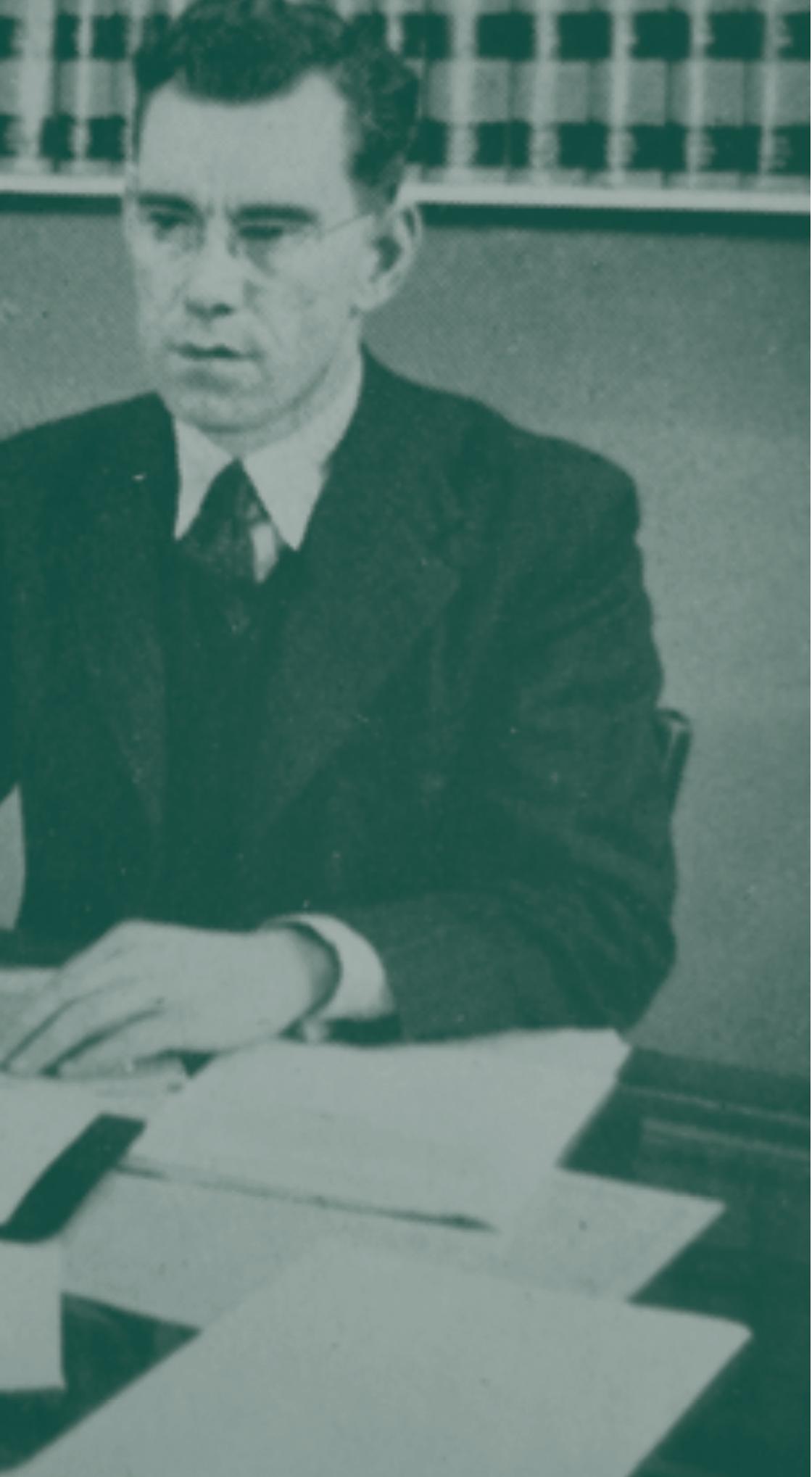

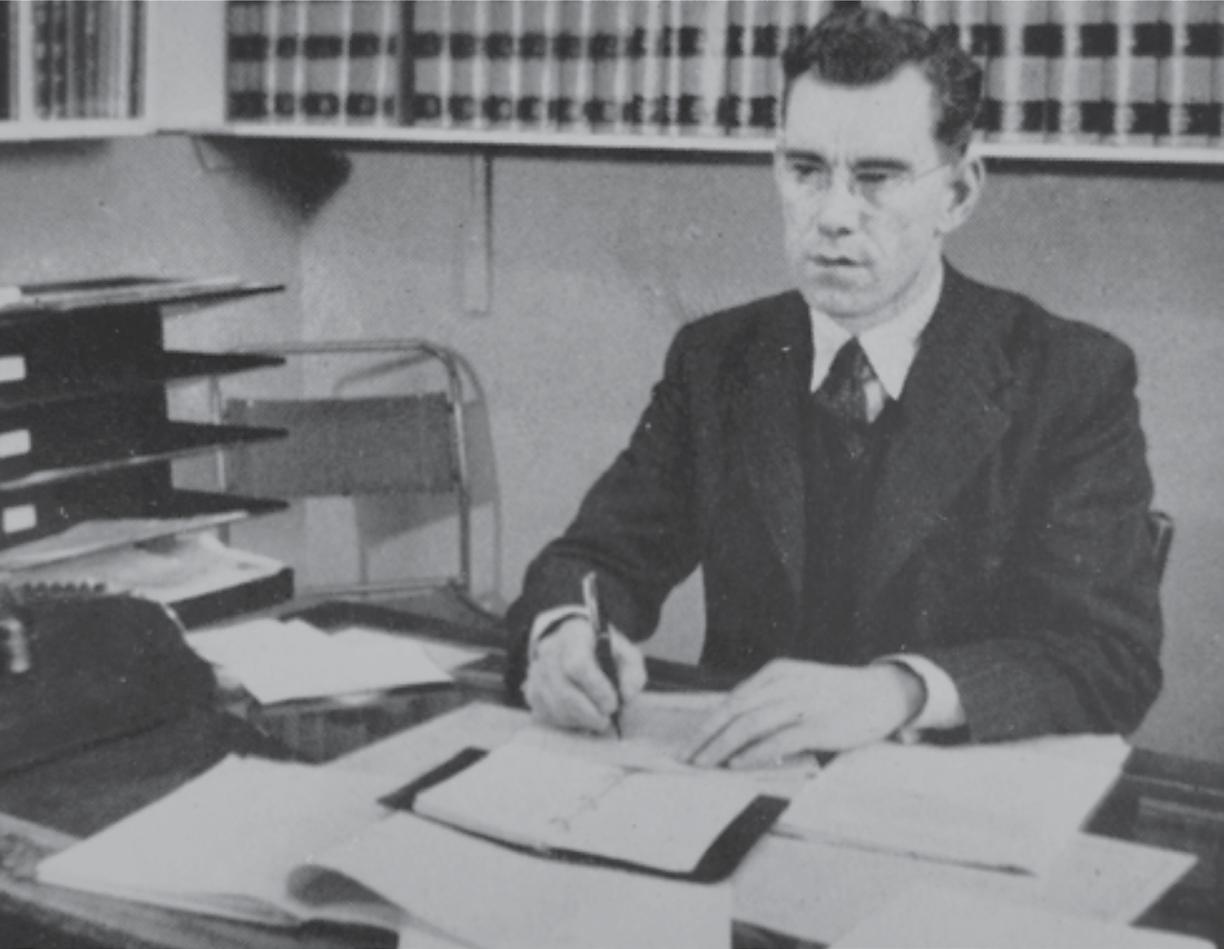

Edgar Lower joined the technical staff in 1932, rising to the position of Chief Chemist.

He was elected to the Board in 1946 as Croda’s first Technical Director.

1946

Edgar Lower becomes Croda’s first Technical Director.

New generation of lanolin derivatives and surface active agents developed, including Isocreme, Cremba and Polawax, which is still widely used today in cosmetic preparations.

Industrial and decorative paints developed to replace camouflage paints used during war.

Headquarters move to a former vicarage in Snaith, re-named Croda House.

1949

A P Wood dies at the early age of 46. George Crowe and the Board opt for committee style management, with Fred Wood appointed Sales Director at the age of 23.

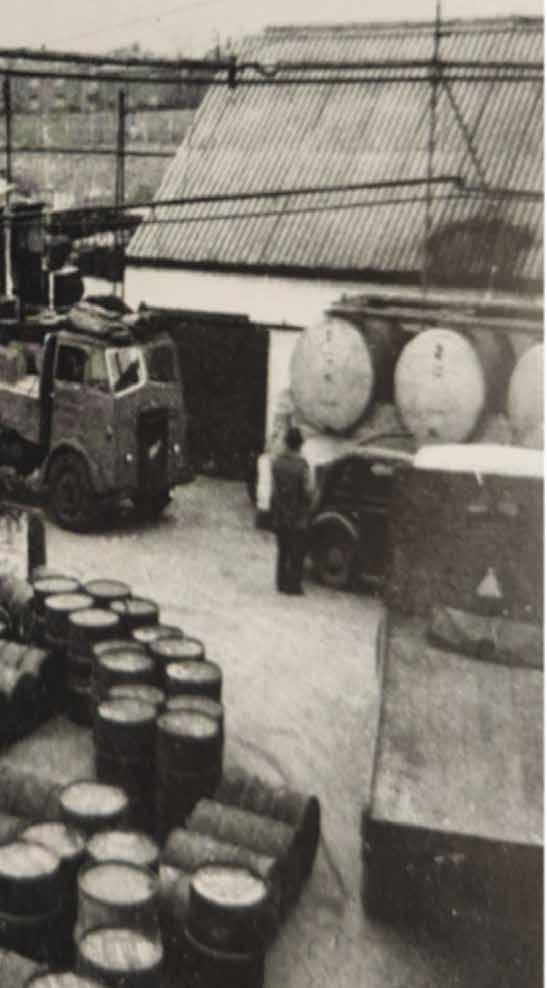

The factory worked day and night to meet Government demand for various wartime products

When the Second World War broke out, with the threat of wide-scale bombing, the Government decided to camouflage aerodromes, army camps, power stations and industrial premises.

As a result, one of Croda’s first contracts was to supply huge supplies of camouflage paint, requiring the installation of paint manufacturing equipment, which would in the future become a valuable asset in meeting post war shortages.

Edgar Lower made a study of the whole range of Government specifications to ascertain which products Croda could make.

The demand for Government specification rust preventives rose sharply with the armament drive, made for every theatre of operations, from the Arctic to the Burma jungle.

Vast quantities of dubbin protective (a waxy product to soften and waterproof leather) were required by all branches of the Armed Forces – more than three million tins were despatched to all parts of the world. Camouflage face creams were produced for commando operations. Over two million tins of foot soap left the Croda works, along with gun cleaning oil and soldering solutions, de-icing fluids for aircraft and barrage balloons, and anti-gas oil.

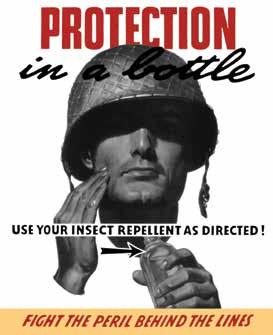

As the war moved towards the east, new foes were encountered – the insects and mites which initially took a huge toll on both men and materials. It quickly became clear that every soldier must be given some means of personal protection, which resulted in Croda handling another new product: insect repellent. Ever increasing quantities were required and by the end of the war, Croda had supplied the enormous total of over six million tins and bottles.

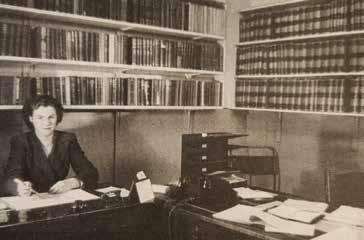

As time went on, almost all of the men at the site were called up for the Military and by the end of the war, much of the actual process and manual work, and all of the office work was carried out by women.

When the war finished and the men came home, Croda was a very different company to the one they had left six years earlier. The company had invested heavily in the new plant that was needed for the expanded product range, but profits had been capped by Excess Profits Tax Legislation, so whilst of a reasonable physical size, Croda was grossly under-capitalised. This did not bode well for the difficult years ahead as many of the newly developed wartime markets largely disappeared.

Nevertheless, for a time, all was well. Sales were booming to the extent that a new home was required for the sales office, which was no longer fit for purpose and still embedded in the middle of the Rawcliffe Bridge site. Without the funds to build a new office, the company looked around for an existing building. As it happened there was a large, old Georgian vicarage in the town of Snaith, where Wood was now living, some five miles from the Rawcliffe Bridge site. Negotiations with the church authorities took place and the vicarage was bought and transformed into what became the company headquarters from 1946 to 1955.

A new pilot plant and a paint research laboratory were opened, developing a full range of industrial and decorative finishes replacing crude camouflage paints, with a ready-made market for a public starved of consumer goods.

Following on from the research work carried out by Edgar Lower to develop new lanolin-based derivatives, such as Hartolan, Cremba and Isocreme, another post-war development was the introduction on a commercial scale of surface active agents, not just for cosmetic applications, but across industry generally, acting as emulsifiers, detergents, wetting agents and solubilisers. Innovative new surface active agents were sold under the names of Crill, Crillet and Cithrol, some of which were so effective they are still used in cosmetic preparations today. (There are several twists of fate in the Croda story. Crills and Crillets were the Croda counterparts of the industry leaders, Spans and Tweens – products that would in turn become part of Croda’s portfolio when Uniqema was acquired some 60 years later).

Despite this wealth of new products and what was initially a sort of commercial honeymoon, trading became increasingly difficult, and the late 1940s were mainly concerned with returning to peace time normality. The war had been beneficial in terms of business expansion but much of this was of a largely profitless nature. In fact, the last quarter of 1948 saw the company actually trading at a loss for the first time in over a decade.

The Board, which had remained unchanged since 1928, was now augmented by Norman Duckels, the pre-war Secretary, who on his return from war service, took over Production. His younger brother, Leslie, joined the company as Secretary. Edgar Lower was the Technical Director. The new Board was faced with a dilemma. Should they deliberately cut back Croda to something like its pre-war size or should they go forward, armed with their growing product portfolio? Leslie Duckels prepared a document: ‘The diagnosis and the remedy’, suggesting that they aim for a profit of £1,500 per month using Croda’s tried and tested traditional method of increasing sales.

The disappointing management accounts were the last ones A P Wood was to see. In March 1949, he made a hurried trip to New York to draw together the old pre-war lanolin business. On his return, he went into hospital for what should have been a straightforward operation, but sadly died of complications the following day at the early age of 46.

To Croda’s management, the loss of their leader seemed an overwhelming catastrophe. Wood hadn’t had time to delegate much of his work, and the crucial decision regarding whether to expand or contract in line with Leslie Duckels’ recommendations, had still to be taken. Things looked bleak as the first 25 years of Croda’s history drew to a close.

By Kurt Neulinger

Does anyone still recall the offices at the Old Vicarage – ‘Croda House’ - in Snaith back in 1948? ‘APW’ and his son, ‘FASW’ (Philip and Frederick Wood) presided in the Boardroom, which also served as their office, across the street from the church and cemetery – laughingly called the ‘retirement arrangement’. Norman and Leslie Duckels led the administrative functions, and lunched at a separate table in the downstairs canteen. Phil Thompson and Walter Shand (Purchasing) and later Eric Miller (Paints) and myself ate at a small table for four. The Export department, which I joined as a refugee from communism in Czechoslovakia, consisted of Miss Walters and George Rochester (Shipping). Edgar Lower at Rawcliffe Bridge was the pioneer of woolgrease and lanolin technology.

I will never forget the camaraderie and gracious welcome all of them extended to me and my wife, Bozena (Bobby) as we adjusted to our new life of freedom. Apologies to anyone whose name I omitted, but all these great people were the nucleus from which the current, magnificent, worldwide Croda company originated.

before transferring to the US where he became VP

1950

Croda celebrates its 25th anniversary. Fred Wood sets up sales office in New York.

1953

Fred Wood returns to the UK to become Managing Director. He is succeeded in the US by Mike Cannon, the son of Eric Cannon, A P Wood’s colleague of 25 years earlier.

Croda’s first major merger with C M Keyworth of Leek, a supplier of fatty acid esters to Croda.

1954

Founder and Chairman George Crowe dies and is succeeded as Chairman by his brother, Sir Edward Crowe, a former diplomat.

1955

Croda acquires the lease to Cowick Hall, a beautiful but neglected noble mansion which, after renovation, becomes the group headquarters.

Lanolin manufacturing operation established in Italy, Croda Italiana, headed by Harry Rosson from the UK.

1957

Croda Inc, USA purchases the lanolin business of Hummel Chemical Company, renaming it Hummel Lanolin Corporation. Production is transferred to a newly constructed plant at Newark, NJ.

1959

Sales operation, Croda GmbH, established in Germany, headed by Maurice Thwaite, a former sales representative in the Midlands.

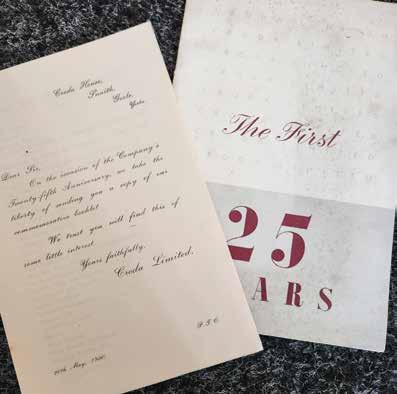

Brochure and covering letter to celebrate

As Croda entered the new era of the 1950s, the original team that had started the company twenty five years earlier had virtually gone. A P Wood had recently died and Dawe had left the scene many years earlier. George Crowe had left the running of the business for the first 25 years to his nephew, but he remained as Chairman. Now, aged 80 and in poor health, he found himself without a successor to A P Wood, so decided to try and draw the management team together. In the absence of an obvious leader, Crowe and the Board settled for committee management without designating a Chief Executive – a management structure that was to last for the next three years.

The new Board agreed that they must press ahead, even without the man whose name had been synonymous for many with the company itself. Recovery was slow, but by April 1950 it was sufficiently advanced for a celebration to be held in the Co-operative Ballroom in Doncaster, attended by some 125 employees out of a total workforce of 130. A brochure celebrating the first twenty-five years was produced concentrating wholly on growth. Croda was still small in size but it had survived the crisis and looked forward with optimism: optimism that turned out to be well founded.

The pattern of trading initially returned to the basic model focusing on lanolin and derivatives, mainly developing in two directions. The first was as a supplier of speciality raw materials for other manufacturers’ products, such as lanolin in cosmetics. However, this was soon to diversify, leading Croda to develop an evergrowing product portfolio for a wide range of markets. Cosmetic applications led to pharmaceutical and veterinary applications, and then into other areas such as household products.

The other principal stream was the manufacture of simple industrial products, often blends based on lanolin and other oleochemicals. This had already been done before the war with simple rust preventives, but in time these became more sophisticated, developing into industrial paints and lacquers, specialised lubricants and steel rolling oils, and a new generation of rust preventives. An interesting development in rust preventives was the introduction of plastic type anti-corrosives. There were two types of material, one a ‘hot dip’ product called Crocell, that left the metal part sealed with a tough, thermoplastic skin, which exuded a fine oil on the metal during storage. The other was a ‘cold type’ product marketed as Lowerite (named after Edgar Lower) which resulted in a much thinner skin. Both types could be easily removed by slitting open the skin, so the plastic film could be peeled off.

The driving force was the marketing system employed by Croda. Initially, under A P Wood, it had focused almost exclusively on direct mail, but increasingly it relied on market intelligence supplied by a team of ambitious local sales representatives, whose aim was to forge strong relationships with customers – a strategy that still applies today. Their role was to determine just what the customer needed and then the laboratory would try to come up with the right product. This emphasis on close customer relationships and problem solving often resulted in unique, tailor-made products, that not only satisfied the customer but made the business more secure. In effect, Croda had become a market-focused company - before anyone at the company really knew what that meant.

For its size, Croda had built a reasonably large sales force of high calibre, many of whom were young men who had returned from the war, keen to make headway in a post-conflict world. This resulted in a steady, but strong increase in sales, reflected in the fact that many of those representatives went on to take senior management positions within the company.

Overseas sales were beginning to expand, mainly via a welldeveloped and extensive network of agents and representatives in many countries. The directors were well aware of the potential of the North American market, where most of the world’s leading cosmetic manufacturers were based. In 1950, Croda made contact with an American wool magnate, Arthur O Wellman, who wanted to make lanolin in that country from his by-product, woolgrease. Wellman agreed to a joint venture on a novel basis. Croda would develop its activities in the US through the venture and, in return, Wellman would provide office space and salary for one man for one year. That man was Fred Wood, the son of A P Wood, who, at the age of just 23, had recently been appointed as Sales Director. The move to America with his wife and baby daughter seemed a good way for Wood to prove his worth.

The US venture was very much a marketing effort and by the end of 1951, a reasonable profit had been made. Fred Wood hired a secretary and then a salesman, who was destined to figure prominently in the history of Croda in America. His name was Kurt Neulinger, and he had joined Croda in the UK as a sales manager, but decided early in 1952 to try his hand in the US, later becoming VP and Director of Marketing for the US companies.

The sales office in New York initially offered the Croda range from UK supplies, but gradually developed a product range made in the US on a contract or toll basis. To say the existing US lanolin manufacturing companies were not too worried about Croda’s entry into the market was an understatement. Jack Butscher, who was to become VP of Croda Inc, was at the time working for Hummel Lanolin Corporation, a long established producer – who were eventually acquired by Croda. While attending a meeting of American lanolin producers in the early 1950s and enquiring why Croda was not represented, a senior executive of one of the companies present replied: “They only have a collection of tin huts that they call a plant, they’ve never made any lanolin, and they’re only nuisance value.”

However, ‘the nuisance’ was in fact doing very well and by 1953, four separate manufacturers were supplying Croda with its required products. The increasingly successful marketing effort was spearheaded by a prolific industrial direct mail campaign whilst forging close relationships with customers, in very much the same way as the parent company had done a quarter of a century earlier under A P Wood.

Buoyed by Fred Wood’s success in the US, by mid 1953 it was agreed that he would return to the UK to take over as Managing Director. In another of those twists of fate, he was succeeded in the US by Mike Cannon, who had been training in the UK for a number of years and was the son of Eric Cannon, Wood’s father’s partner of 25 years earlier. The successful US operation demonstrated a good example of two Croda characteristics: providing ingenious solutions to customers’ problems, and exploiting the marketing strength of the management.

Back in the UK, business had settled down on a rather dull plateau. Sales were split between those products made at the company’s only factory at Rawcliffe Bridge, and those made on its behalf by other manufacturers, including lanolin alcohols (Whiteheads), fatty acids (Universal Oil Company), castor oil (Premier Oils) and fatty esters made by C M Keyworth & Company of Leek in Staffordshire – the latter becoming an increasingly important supplier of products to Croda.

C M Keyworth was strong on technology but weak on marketing, so the two companies complemented each other. In 1953, the owner, Maurice Keyworth, decided to sell his company. Following a hurried Board meeting, Croda made a successful bid. Fred Wood noted that this first major merger illustrated the significant benefits that can arise from a combination of strategic mergers or acquisitions with organic growth.

Croda advertising in the mid 1950s

They only have a collection of tin huts that they call a plant. “ “

As mentioned in the narrative, from its earliest days, a highlight in the social calendar was the annual Croda trip. Mary Bruines, formerly of Cowick Hall (1950 to 1989), recalls: “No-one will forget those wonderful trips to Blackpool, Scarborough and London, with the men carrying crates of beer and bacon sandwiches on board our own private, early morning train.

A favourite of mine was the Festival of Britain outing to London’s South Bank on 26 May 1951. Note that the train left Goole station at six in the morning and didn’t arrive back in Goole until quarter to five the following morning, almost 24 hours later.”

John Chester (Croda Chemicals, 1956 to 1994) recalls another Croda trip to the Lake District, during which the company had organised a boat trip on Lake Windermere. “Most of us arrived at the jetty early and settled down to wait for the boat. It was a very hot day and Bert Taylor, the then Rawcliffe Bridge Works Manager, sat on a bollard, took off his flat cap and dropped it in between his feet whilst he mopped his brow.

“By this time, the jetty was becoming quite crowded as people were arriving to board their various boats. One of the lads from the works, walking past Bert, threw a few coppers in his hat for a joke. This started the ball rolling, and as other passengers walked past, many others similarly tossed coins into Bert’s hat. Bert, renowned for his dry sense of humour, kept a straight face and held his ground – or should I say his seat on the bollard. He was eventually coaxed off and boarded the boat, where he – and the rest of the Croda gang – collapsed into fits of laughter. When we had all recovered, we counted the money Bert had ‘collected’ and found it to be a not inconsiderable sum. The somewhat ill-gotten gains were spent on drinks aboard the boat and, thanks to the generosity of the Great British public, a very merry time was had by all!”

Croda House, the former vicarage in Snaith, had served the company well as its headquarters since 1946, but the steady growth of the business and the workforce brought with it accommodation problems. Fred Wood was on the lookout for something more suitable. The answer to his, and Croda’s requirements, was actually located a few miles away from Snaith, just off the main road to Goole, and also close to the company’s main factory at Rawcliffe Bridge: Cowick Hall, the former country seat of Viscount Downe. Once the home of aristocrats, tycoons and farmers, this still noblelooking building with its rich façade, one of the finest late 17th century houses in the land, was in a sorry state and the subject of a demolition order.

Though mainly interested in its potential as a new headquarters, Fred Wood admired the architectural distinction of the Hall and felt that it would make an appropriate visual statement of the Croda organisation. Accordingly, in 1955, a lease of the Hall was obtained from the then owners accompanied by a grant towards the external repairs by the Ministry of Works. The terms of the agreement gave the company the option to purchase within the ten-year period of the lease and, in 1963, that option was exercised. Croda bought the Hall and the surrounding 73 acres of land, giving a new extension of life to Cowick Hall, which has remained as the group’s headquarters ever since.

A further overseas base was established in 1955 when Croda started a lanolin manufacturing operation near Milan in Italy, in partnership with Marzotto, a large Italian textile company. Croda’s manager was a young Englishman, Harry Rosson, who, with his wife, Wilma, built up the business. As in the US, however, it was soon found to be better to go it alone, and production was moved to a new site outside the village of Mortara.

With lanolin sales increasing in the US, in 1957 Croda Inc purchased the lanolin business of Hummel Chemical Company, renaming it Hummel Lanolin Corporation, and transferring production to a newly constructed plant at Newark, NJ.

In 1959, Croda started a sales operation, Croda GmbH, in Germany near Düsseldorf. The venture was initially staffed by just one man, Maurice Thwaite, a former sales representative in the Midlands, who gradually built up a strong sales team. Back in the UK, Fred Wood, who by then was firmly at the helm, was able to push forward his ideas, including a sweeping reorganisation of the sales team, rapidly promoting some of the company’s younger men.

George Crowe had died in 1954 and was succeeded as Chairman by his brother, Sir Edward Crowe, a former diplomat. Following Sir Edward’s death in 1960, Fred Wood became Chairman as well as Managing Director. The cumulative effect of these changes on profits was almost immediate, heralding the dawn of a new decade.

By Sir Frederick Wood Former Chairman and CEO, Croda International

In October 1950, I found myself in New York with a briefcase, a small desk and a mandate to start up a Croda subsidiary in America – but no capital. Back home in England, Croda had survived a crisis and was a sturdy growing enterprise, so I felt justified in printing an introductory advertisement in a leading US technical journal which said: ‘Croda – the fastest growing name in fatty chemicals.’

This was, of course, whistling in the dark. It was the child sticking his chest out in the world of giants – but in fact the child grew faster during the ensuing 25 years than any of its competitors and thus justified that outrageous statement.

1960

Sir Edward Crowe dies. Fred Wood becomes Chairman as well as Managing Director.

1964

Croda becomes a public company. Croda Nippon formed in Japan as a joint venture with Sansho Oil & Fat Trading Co.

1965

Croda Inc purchases site at Mill Hall, PA, to expand manufacturing facilities in the US.

1967

Croda buys United Premier Oil Company, a long established company involved with oil seed crushing and refining.

1968

Croda buys British Glues & Chemicals, a major producer of gelatin and tallow, an important raw material for the manufacture of fatty acids.

Croda Canada formed in Toronto by John Brown, formerly of BGC.

Croda buys Bowmans Chemicals of Widnes, a manufacturer of food acids and specialised chemicals for metal finishing.

Croda buys three small companies in Australia to form Croda Federal Chemicals headed by George Hembrough, who previously ran Croda’s Leek factory.

Cowick Hall Aviation formed to transport executives throughout the UK and Europe.

In 1960, annual profits had leapt to £134,000 and in the next three years grew dramatically so that by June 1964, Croda could go public. The shares were duly offered for tender by L Messel & Co. Press comment was reasonably favourable, but not overenthusiastic, although one notable and influential exception was John Davies of the Observer, and before that the Financial Times. Over the years, he had developed strong views about the ingredients of a successful company, many of which he saw in Croda, in particular having the right sort of leader in Fred Wood. Although Fred Wood now had the means to buy companies, he decided to set up Croda in Japan as a joint venture with Sansho Oil Fat and Trading Company, a company specialising in lanolin derivatives and with whom Croda had a close relationship stretching back many years. This joint venture, Croda Nippon, unlike some before it, was to become very successful. Meanwhile, in North America, Croda Inc purchased a site at Mill Hall, PA, to expand manufacturing facilities in the US.

By 1966, Croda was establishing a strong reputation in the chemicals field. The company’s rating was good and the market view of the management was so favourable that a takeover or merger of significant size became a distinct possibility. A provisional list of possible targets was compiled, although many of the names seemed to be too large and well known to be persuaded to join Croda.

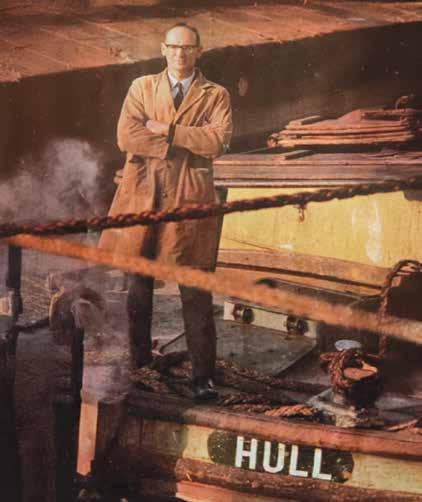

The first name on that list was Hull-based United Premier Oil & Cake Company (UPOC), whose main activity was crushing and refining oil seeds and nuts, such as castor, soya bean, groundnut and rapeseed. One of the companies in the group was Universal Oil Company, which manufactured fatty acids, vital building blocks of the oleochemicals industry and sold to a wide range of industries. After the acquisition of C M Keyworth in 1953, fatty acids became an important raw material for Croda as they were needed to manufacture fatty esters. A link up with Universal Oil Company seemed logical, but a tentative approach to the company was quickly rebuffed.

Instead, Croda began to look again at the whole UPOC group of companies and by the summer of 1967, was ready to make a bid, riding on the back of the fact that its reputation as a small but dynamic and growing company was high in Stock Exchange circles, whereas UPOC had just returned its lowest profit for some years. Despite the disparity in size, Fred Wood thought that a merger might be possible and an offer was duly made. Despite strong resistance from the UPOC Board, with further offers and rejections, a deal between the two companies was eventually sealed on 30 June 1967.

By Mary Bruines Croda International, 1950-1989

How often, when we meet ex-colleagues, after first asking if they are keeping well, the next question is usually ‘Do you remember when…?’ Well – I remember when:

I started at Croda House in Snaith in August 1950 at a salary of one pound ten shillings per week (£1.50). The first person I saw was Peggy Claxton at the complicated ‘plug-in’ switchboard that we all had to learn how to use. We had a hand-operated franking machine and every night a junior had to carry the mail bag to the Post Office.

Croda Way magazine started off as ‘Concorde’ and we all used to write articles. A group of us wrote one including bits about The Beatles and Cliff Richard. In 1956 we moved to Cowick Hall – files and furniture first, then personnel on the Croda bus, with typewriters on our knees.

Walt Bentley, the gardener/handyman (his wife, Mrs Bentley, ran the canteen) drove off from Cowick Hall with the bank bag on top of the van – panic stations… We went out with a search party and found it just outside the gates on a grass verge! And, of course, there was Walt’s dog, Sandy – a favourite at Cowick.

Croda trips – no-one will forget those wonderful trips to the seaside and sometimes London – and the Croda dances at the Baths Hall in Goole and Co-op Ballroom in Doncaster, when the Twist was in its heyday!

I lived at ‘The Lodge’ in the grounds of Cowick Hall – my little ‘Shangri-La’. So many happy, happy times and precious memories – nothing to replace them…

Further plans begin to gel

In the early days after the merger, Fred Wood visited the Universal fatty acids plant at Hull with Cecil Manson, a former UPOC Board member who had been appointed as a Managing Director at Croda. As they walked around the yard, they noticed a drum of tallow, a major raw material in the manufacture of fatty acids, marked ‘British Glues & Chemicals’, prompting a discussion of this company as a possible future acquisition.

British Glues & Chemicals (BGC) had in fact been on Croda’s radar for some time as a possible takeover target, mainly due to its position as one of the two major UK producers of gelatin. Gelatin was used extensively in photographic film, foods and pharmaceuticals - the type of product that fitted well with Croda’s fast growing portfolio. BGC was also strong in animal glues and synthetic adhesives, including the well-known ‘Croid’ brand for hobbyists.

Most important, however, there was also the production of some 18,000 tons of tallow – more than enough to hedge Universal’s needs for fatty acid production. With a dozen or so factories around the UK, and bone processing works in Austria and Holland, BGC was larger in assets, turnover and employees than Croda, even after the UPOC merger. However, the disparity in size held no fear for Croda. Whilst strong technically, BGC noticeably lacked flair and imagination – key Croda attributes.

In July 1968, an offer was made by Croda which was speedily rejected by the BGC Board. A series of increased offers were made, all of which were similarly rejected. The whole process became increasingly acrimonious, and was widely reported by the business press, who were themselves beginning to take sides. On 14 September 1968, an increased offer was finally accepted, ending a long and bitter ‘David and Goliath’ type confrontation in which, once again, Croda, cast firmly in the role of ‘David’, had prevailed.

When the battle was over, the respective Croda and BGC Board members sat down to share their views on the future. Despite the strenuous opposition to the Croda bids, there were no recriminations – indeed, as with the UPOC merger, many of the BGC personnel were keen to avail themselves of the opportunities that arose within the expanded Croda organisation. John Brown went on to establish a sales office in Canada. Another former employee, George Bates, went on to become Secretary at Croda, also joining the Main Board, along with several other senior BGC personnel.

A key commentator of the time, Mike Hyde, who was editor of the influential Chemical Age magazine, stated: “The ability of Croda I most admire is that of seeking out the hidden talent in acquired companies on which the future could be built.”

Press cuttings at the time of the Croda bid for BGC

By Jack Thewlis Croda Chemicals, 1964 to 1998

It was just as I’d seen it before: ‘The Croda’. That’s what people called it when I was a kid. The last time I saw this incongruous collection of industry, plonked in the middle of a sleepy little village, I was barely into my teens.

I had no idea what they did. What mysteries all of those tin sheds and hundreds of drums contained. And the chimney – the tallest thing for miles. And the black stuff, ash-like and crunchy under foot. It was everywhere – down the slope to the gates by the canal. And there were bikes. There were bike sheds everywhere. But what do they do here? “Paint,” said the old chap nearby. “They make paint.” So now I knew. Looking around at the drums and sheds and the name written large, I reckoned he was right. It was green paint, for sure.

So here I was again. It was 1964. I was 21, straight out of university and rarin’ to go. As I ventured down the slope, I was a little concerned about the effect that the black stuff might have on my shiny new ‘winkle-picker’ shoes and the bad impression it might create.

On arriving at the offices, I realised it didn’t matter. The trails of the black stuff went everywhere; from the bike sheds, into the offices and straight to the boss’s door. The boss, who was known as ‘ND’ (Norman Duckels), sat behind an enormous wooden desk. He looked the part. I was nervous, but confident. Having just graduated in chemistry, I thought I knew it all.

Following his welcome and a brief description about what went on at Rawcliffe Bridge, he threw me a few questions about fats and fatty acids. This is easy, I thought. Then, sitting forward in his chair, ND was clearly about to deliver the key question. It was make or break time. “What do you know about Molecular Distillation?” Whaaat… I screamed to myself. But I swallowed, looked him straight in the eye and replied, “Oh, a little.” “Good,” he said. “Can you start next week? You’ll be running a molecular still, it produces Stutz.” It turned out that Stutz was the code name for Super Hartolan. There were lots of names like that, names of American cars. The Big Boss (Fred Wood) loved American cars and drove one around the town. So that’s where I started learning about Super Hartolan. It eventually took me 34 years to ‘know it all’.

Before the dust had settled, Croda made a successful bid for another company on its list of possible targets: Bowmans Chemicals of Widnes, who manufactured important food acids such as lactic acid and malic acid, as well as speciality chemicals for metal finishing. By late 1968, Croda had not only acquired the mighty BGC, but also the not inconsiderable Bowmans Chemicals. Meanwhile, an important move was made overseas in Australia. Throughout the early 1960s, Croda had been considering the possibility of manufacturing lanolin there because of the large local production of woolgrease. Following a visit to Australia in early 1968 by fellow directors Don Jackson and George Hembrough, they managed to seal a deal to purchase Lanoline Products Limited, a small but successful manufacturer of high quality lanolin, along with two family run chemical businesses, E I Noble & Co Ltd and Federal Holdings Ltd. In just three short months, Croda had laid the foundations to becoming a significant player in the Australian chemical industry.

After the explosive growth during 1967 and 1968, it was time to concentrate on reorganising the management structure both at home and abroad in order to absorb the new businesses. All trading activities were split into five major divisions: Chemicals (the original activities at Rawcliffe Bridge and Leek, plus the Universal fatty acid plant at Hull); Food Products (the gelatin activities of BGC plus the acidulants that had been part of Bowmans Chemicals); Polymers (the former glue manufacturing plants of BGC and former Paints operation at Luton); Agricultural (the collection and processing of bones before they were turned into gelatin or glue); and finally, Premier (the edible oil activities of the former UPOC group).

In addition, there were one or two small operations that did not fit into any of the above divisions, a notable one being Standard Soap Co Ltd, formerly part of BGC. A bold decision was made to dispense with the company’s existing trade to focus entirely on private label operations, making soap and toiletry products such as the popular ‘Soap on a rope’ for some of the leading cosmetic houses. As a result, Standard Soap was to become one of the fastest growing operations in the Croda organisation.

The group now had quite a wide spread geographically, both in the UK and Europe, with its executives faced with an increasing amount of travel. Several of the team had service in the RAF or Fleet Air Arm during the war, so the company was ‘aviation minded’. It was no surprise, therefore, that Fred Wood decided to buy his own light aircraft in the early 1960s and learnt to fly. The idea of having a company aircraft and professional pilot became increasingly attractive and in 1968, Croda purchased a twin-engined Cessna 336, engaging the services of a recently retired RAF Squadron Leader, Bill (Captain) Olsen, as the company pilot. Cowick Hall Aviation, as it was called, was soon expanded to two planes and two pilots.

Whilst this breathing space with a period of consolidation had been much needed, after the heady and exciting days of the swinging sixties, Fred Wood and the Board were never going to rest on their laurels. Once again the time was ripe for further growth.

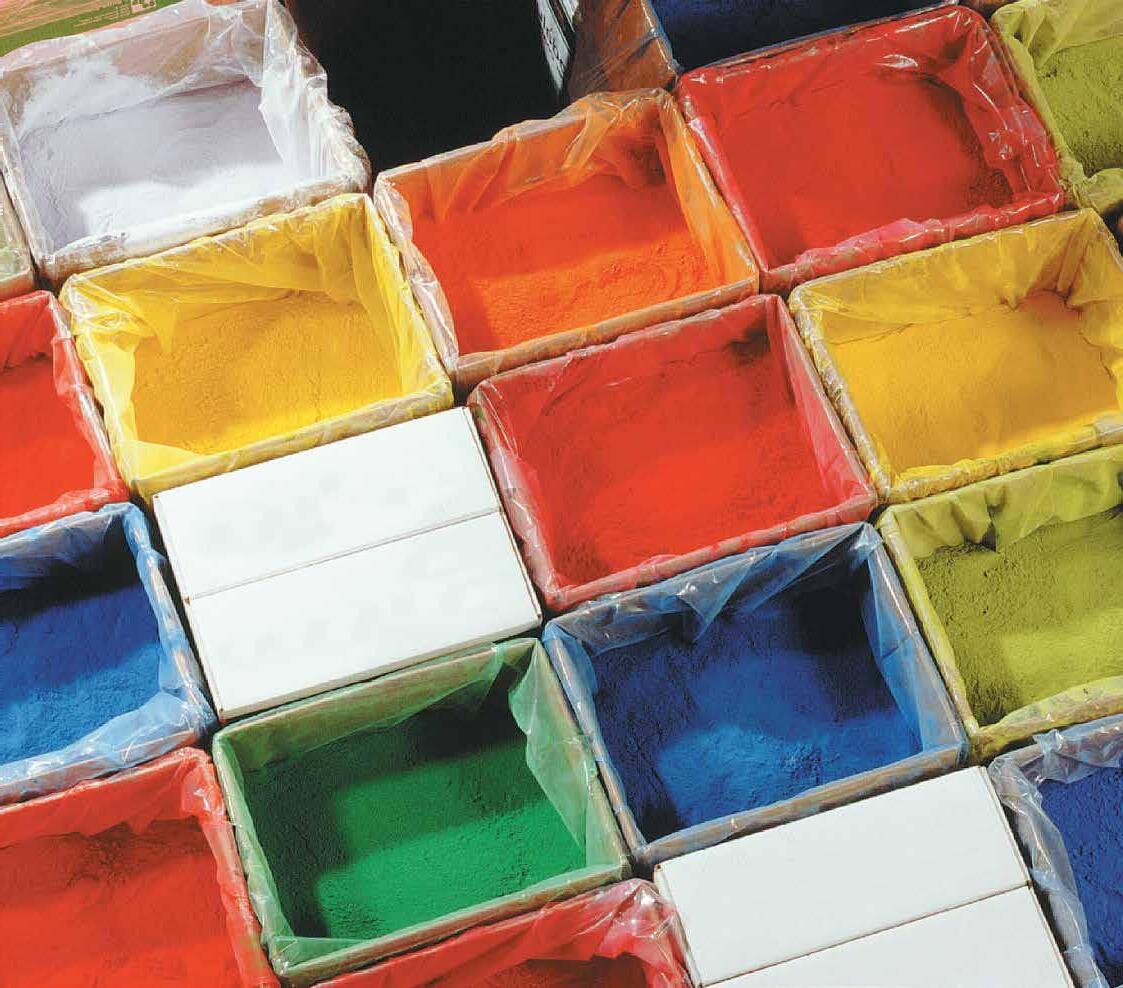

Any colour you like – as long as it’s black… and green, yellow, blue and red.

Within a short space of time, Croda had changed from being a relatively small to a medium sized company. In turn, it had to start thinking about itself in different terms and the ‘image’ it portrayed. Croda’s corporate identity had always been important. Even from the early days of A P Wood, much attention had been paid to items such as stationery and packaging, and this passion for good design was obviously a family trait, inherited by Fred Wood. Inevitably, with new companies joining the organisation, the overall image had become fragmented, so it was decided to create a definite and tightly controlled ‘house style’ that would be applied to every aspect of Croda’s image.

The company retained a Manchester-based design consultant, Norman Wilson, to oversee the project, creating a new identity that would reflect a dynamic, modern thinking and by now, much larger organisation. A design manual showing detailed guidelines was created and the company even set up its own in-house printing department at Cowick Hall to oversee the implementation of the new image, which has continued to evolve over the years under Croda’s design consultant, Anthony Dawson, who was Norman Wilson’s associate way back in the 1960s.

For several years in the 1980s, the corporate identity reflected the group’s organisation. Each of the four principal subsidiaries had its own corporate colour: Chemicals (green), World Traders (yellow), Organic Chemicals (blue) and Polymers (red). Each colour was applied to all aspects of their respective corporate identities – from stationery to signing, even extending it to sartorial applications, such as ties and headscarves, proudly worn at exhibitions and corporate functions. Visually, it was colourful and good fun, even invoking a sense of competition (the ‘Reds’ were particularly proud of their vibrant variant).

But it was far more than just visual. Each of the principal subsidiaries had its own central management. No longer just one company, Croda had evolved into four competing operations. The corporate identity had become diluted, but of far greater concern, Croda itself had become fragmented. The principal subsidiaries were soon dismantled and, with the formation of an Executive Committee, Croda once again became a single company with a unified purpose.

Croda launched its new branding as part of its centenary celebrations early in 2025. “ “

By Captain Bill Olsen, Company Pilot, Croda International 1968-78

During the ten years that I was associated with our aviation operation, we flew in fair weather and foul, much of it in and out of our Cowick Hall airfield. For several months of the year, return to Cowick Hall after a day’s work meant having to land in the dark on a nottoo-long, grass runway. At the larger airfields, this was no problem, with approach and runway edge lighting. However, the expense of full electric runway lighting for our small operation could not be justified, so we got round it using Croda’s well established approach to innovation and problem solving…

We bought a couple of dozen car front number plates and attached them to wooden stakes at prescribed distances along the edge of the runway. When the aircraft was at about half a mile or so on its landing approach, the aircraft landing lights would be switched on by Stuart Tasker and his trusty Cowick Hall site maintenance team… and, hey presto… the highly reflective runway lighting sprang into view.

During my time with the flight department, we travelled many thousands of miles during the five thousand or so flights, landing at over a hundred aerodromes and airstrips throughout Western Europe – and happily, we didn’t bruise any passengers along the way!

Croda buys L&H Holdings, which makes processed vegetable oils at Hull and Barking.

Croda buys A B Fleming, which makes printing inks, graphic supplies and synthetic resins, also giving it a foothold to form Croda South Africa.

Croda buys London Oil Medina, a leading distributor of edible oils for the food and bakery industries.

Whilst remaining as Chairman, Fred Wood hands over his Chief Executive responsibilities to Ernest Tyerman, formerly head of the Polymers division.

Formation of Croda France, Croda Brazil and Croda Japan.

Croda acquires Midland Yorkshire Holdings, which makes synthetic chemicals, road tars and bitumens.

Croda buys Kenneth Thelwall & Co of Doncaster, a long established manufacturer of blended oils and greases for the mining and automotive industries.

In Australia, Croda acquires the Lusteroid group of companies, which makes printing inks and paints.

Croda Japan develops Super Refining technology to create ‘Snow White Lanolin’. Croda celebrates its 50th anniversary.

1976

Croda launches Crotein Q, the first in a long line of market-changing protein derivatives for hair care.

Chairman Fred Wood receives knighthood. Croda buys Kimpton Brothers, traders in spices, waxes and gums, which also includes Manley Ratcliffe, the UK’s second largest honey producer.

Croda buys Thornley & Knight, which makes vehicle paints.

Joint venture formed in Mexico, Quimica Croda.

Croda expands printing ink operations in US with the purchase of Richardson Ink Co. of Chicago.

Croda buys J C Bottomley & Emerson, which makes dyestuffs and pigments.

Sir Frederick Wood once again takes over reins as Chairman and Chief Executive.

There

was a strong synergy between printing inks and Croda’s long established paints business.

“ “

The commercial doctrine of the day seemed to be the bigger and more diversified the company, the more resistant it would be to economic downturns, and therefore the greater its prospects of success. Indeed, this philosophy had served the company well in its transformation from a small, family run business to a multinational corporation, so by the second half of 1970, Croda was once again ready for further growth.

With the acquisition of United Premier in 1967, Croda had acquired a 48% interest in a group known as L&H Holdings, which made processed vegetable oils for use mainly in paints and inks. Croda purchased the remaining 52% and its two sites at Hull and Barking were integrated into the group to form the Processed Oils division.

In 1971, Croda made a further acquisition of A B Fleming (Holdings) Ltd, a loose collection of four fairly autonomous operations manufacturing printing inks, graphic supplies and synthetic resins. Whilst quite a departure from its other activities, the new companies had strong synergies with the adhesives already sold to the packaging industry and Croda’s thriving paints business.

Flemings also had a successful, well-established business in South Africa and this too fitted in well with Croda’s plans to expand in that country. This latest acquisition was a good example of the company’s acquisition and merger philosophy, combining areas of common ground whilst providing opportunities for expansion into the new fields that Croda was looking for.

The market was now so accustomed to Croda’s appetite for headline-making acquisitions that it was less aware of the number of organic growth and technological developments that were taking place. Food acidulant sales were expanding rapidly and a start was made on a new malic acid plant in Widnes. A new edible oil refinery was constructed at Barking to complement the existing Seatons plant in Hull.

1973 saw another flurry of purchases, including London Oil Medina, a leading distributor of edible oils for the bakery and food industries. Overseas, a printing ink factory was purchased in Holland followed by another in Milan, Italy. 1974 saw the formation of Croda France, headed by Dennis Crowley from Croda in the UK, and Croda Brazil, headed by John Hughes, formerly of Croda Canada.

Croda Japan was formed at Shiga, headed by Tony Chell, formerly one of Croda’s first management trainees. The company pioneered huge advances in refining technology with its unique Super Refining process, bringing new levels of product purity and quality, including the aptly named Snow White Lanolin. Fifty years on, the process is still one of Croda’s key global technologies in our pharmaceutical and Beauty businesses.

Whilst remaining as Chairman, Fred Wood handed over his Chief Executive responsibilities to Ernest Tyerman. Already well known to many Croda employees as head of the Polymers division, Ernest Tyerman was a classic example of progress from office boy to Chief Executive over a career that spanned 24 years.

By Noel (Nobby) Curley Formerly of Croda Chemicals

As one approaches the end of a working life, one remembers all the old friends who have gone before. Hubert (Young), Ted (Hughes), Bert (Taylor), John (Barnes), Frank (Banham) – and many more, too numerous to mention. Croda people. Croda has been my life. I have never regretted a moment of the time I have spent here, and never thought I would work anywhere else. Whilst at Croda, I’ve married, brought up children, who have brought up their own children. I still remember walking down the empty yard at Rawcliffe Bridge at four o’clock in the morning to collect my lorry to start the long day’s journey. The smell of the woolgrease ovens; the coal fired boiler with the boilerman feeding it by hand. I remember that first long distance journey – as a novice driver who had never travelled more than 50 miles from home. Two hundred and fifty miles to Port Talbot in South Wales, and no motorways. And then bumping into one of our own drivers, Eric Smith – boy, was it good to see a friendly face – who showed me around the giant steelworks there.

During those 18 years, those long days were to be my life, with fellow drivers Ken Maynard, Eric Smith, Jack Stones, Arthur Gelder, and later, Joe McGeever and John Lister. Every day holds a memory. In 1966, the day before England won the World Cup, I was on my way to Port Talbot again, with a batch of rolling oil, when at Monmouth the tanker caught fire. I had to leave it to be repaired and began ‘thumbing’ my way home. On the Saturday, the day of the final, the roads were deserted. When England scored that memorable, final goal, I was hitching a ride through Nottingham.

The annual pensioners’ dinner at Cowick Hall has always been a special time to meet old friends. I used to drive the bus and help with the bar. On one occasion, I was driving through Worcester, when one of the back wheels fell off the wagon. But Lady Luck smiled on me and I managed to hitch a ride home, just in time to get everyone on the bus in time for dinner. In time to share a memory or two with those friends and colleagues who dedicated large parts of their lives to building up this great company of ours.

I never thought I would work anywhere else. “ “

Away from the headlines of the City pages, various small and successful companies were absorbed into the group involved in a range of industries, from pet foods to dripping manufacturers, which, like an earlier foray into dried egg production, saw Croda entering new areas that were increasingly removed from its core businesses.

Meanwhile, in Australia, Croda’s operations were doubled overnight with the acquisition of the Lusteroid group of paint and printing ink companies. In 1975, the company took over Midland Yorkshire Holdings, which made synthetic chemicals, road tars and bitumens. It then expanded its metal treatment activities, buying the longestablished Doncaster-based company, Kenneth Thelwall & Co, which made blended oils and greases, mainly for the mining and automotive industries.

When Croda celebrated its 50th anniversary in 1975, it was a vastly different company from the one that celebrated its 25th anniversary in the Co-operative ballroom in Doncaster, and likewise, a far cry from the company that had gone public in 1964.

Profits had slowly but surely risen from zero to £230,000 in 1964 and, by 1974, in the order of £12 million. Some 6,600 staff manned 36 plants around the world compared with just 350 employees at four factories in 1964. Croda had not only grown faster than any other firm in the chemical sector worldwide over the previous 25 years, but was one of the fastest growing enterprises of any industry in the UK for the previous decade, thereby justifying the accolade that Fred Wood had awarded it some years earlier: ‘Croda – the fastest growing name.’

Investors and the financial press were impressed and Croda was ranked fourth in the 1975 Management Today British Business Growth League. However, 1975 profits went down for the first time in ten years, although this was not allowed to interrupt the company’s expansion programme and the takeovers continued –occasionally straying even further into unchartered waters for what was predominantly a speciality chemicals company. In 1977, Croda acquired Kimpton Brothers, which traded in spices, waxes and ethnic foods. Kimptons also included Manley Ratcliffe Ltd, which overnight made Croda the UK’s second largest retail supplier of honey, even embarking on a TV advertisement for its innovative ‘Honey in a tube,’ voiced by the well-known actor Richard Briers.

Returning to more familiar territory, this was followed by the acquisition of Thornley & Knight, which made specialised vehicle paints, and then in 1978, Croda expanded its printing ink operations with the acquisition of Chicago-based Richardson Inks. A year later it bought Brighouse-based J C Bottomley & Emerson, which made dyestuffs and pigments.

By the end of the decade, Croda had grown into a huge and diverse conglomerate. However, one former director had observed that Croda was beginning to find itself in businesses it did not truly understand. Whilst there was a ‘colourful’ synergy between say dyestuffs and its long established paint operations, and then the move into printing inks, conversely trading in spices and selling honey to the retail market was a vast departure from Croda’s usual sphere of activities – and expertise.

As seems to be a trait, the end of a decade often heralded a period of great change or transition for Croda, and this was to be no exception.

In 1979, Ernest Tyerman transferred to the role of Joint Deputy Chairman alongside Don Jackson, so Fred – by this time, Sir Frederick Wood (he was knighted in 1977) - once again took over the reins as Chairman and Chief Executive. But even with Sir Frederick back firmly at the helm, concerns about

Croda’s direction of travel were mounting, exacerbated by heavy increases in interest charges producing what were described as ‘unexciting results’ and little movement in share price. Croda – so often the predator, was about to become the prey…

There is a pleasing link with Croda’s former honey activities and the vital role bees have to play in their invaluable contribution to biodiversity at a number of Croda sites. One example is Sederma, where the team welcomed 40,000 bees along with their two hives to their new home on a lawn at the site, near a pond. Nine months later, the buzzy little bees produced their first honey harvest – an impressive 33kg! Similar activities have been established at other sites, including Rawcliffe Bridge, Croda Denmark and Croda Chocques.

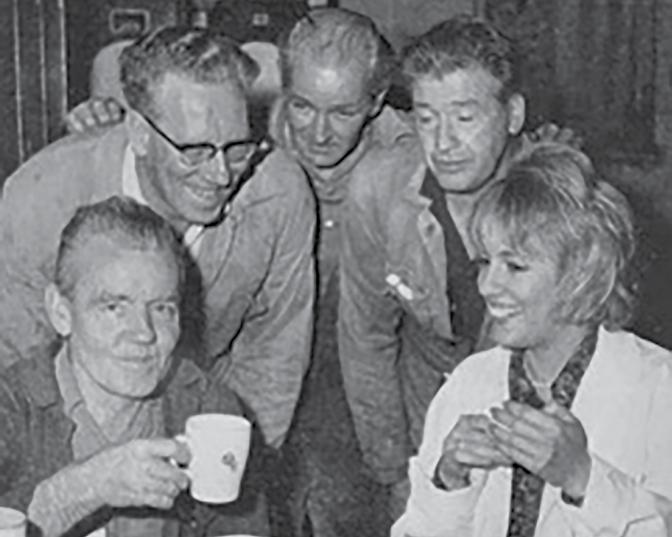

During the early 1970s, Croda Way, the company magazine, featured visits by well-known TV celebrities of the day to different Croda sites where they met and chatted with employees working in different departments, including the offices, labs and production.

These included Esther Rantzen (Croda Wigan), Barbara Windsor (Luton), Margaret Powell (Oldham) and Una Stubbs (Widnes) and many more. After her visit to Widnes, Una Stubbs told Croda Way: “The bit I enjoyed most was the spaghetti machine which extruded long gelatin noodles – if only they would let me and my two children loose on that machine we could have tremendous fun!

1980

Croda expands Colours division with acquisition of Colne Vale Dyestuffs & Chemicals, followed by Frado BV, a Dutch manufacturer of sulphanilic acid.

1981

Croda opens new factory in Campinas, Brazil.

Burmah Oil makes abortive bid for Croda.

1983

Croda sells its Synthetic Chemicals business to the Royal Dutch/Shell Group.

1984

Croda purchases R Castelein & Co, a Belgian manufacturer of adhesives and sealants.

1985

Sir Frederick Wood hands over executive responsibilities to Mike Cannon, President Croda Inc.

Croda becomes first company to develop a wheat-based protein ingredient.

Croda sells its UK printing inks business followed by its Premier Oils business.

Croda purchases Richards & Appleby, a branded private label and contract toiletries manufacturer, followed by Kolmar Cosmetics and the Dutch soap manufacturer, Hilko.

1986

New regional office opened in Singapore.

Sir Frederick Wood retires and becomes Honorary Life President.

1987

Mike Cannon appointed Chairman and Keith Hopkins appointed Group Chief Executive.

Acquisition of firefighting chemicals business of John Kerr & Co, followed by Uniser SA (France).

1988

Foundations laid for the redevelopment of Rawcliffe Bridge factory.

1989

Despite the harsh economic climate, with profits on what Chairman Sir Frederick Wood described as a plateau, diversification continued, and the flurry of takeover activity that characterised the previous decade continued into the early months of 1980. The new Colours division was expanded by the purchase of a Dutch business, Frado BV, followed by Colne Vale Dyestuffs, a small firm based in Huddersfield.

The September issue of Croda Way, the company magazine, carried the headline ‘Hard Times’, reflecting the reasons behind Croda’s disappointing drop in profits for the first six months of 1980, exacerbated by the worst economic recession for many years.

Sir Frederick Wood addressed the situation with a three point plan focusing on improved sales and margins, reduced borrowing and a radical programme of spending cuts and cost reduction. Alongside the drop in profits, the share price fell, making Croda an attractive takeover target.

True to form, just before Christmas 1981, Burmah Oil bought 14.9% of Croda’s shares in a £12 million ‘dawn raid’ on the Stock Exchange, as a prelude to a full bid which, as expected, was announced shortly afterwards. From the outset, Croda’s Board was determined to resist the offer, which it felt was against the interests of its employees and shareholders. In the ensuing battle, Croda’s unusual and spirited defence employed the old maxim ‘The best form of defence is attack’.

A comparison of the respective track records of the two companies highlighted the fact that Croda would not be short of ammunition, reinforced by almost unanimous support from the financial press. For several weeks, blow was matched by counter blow, but thanks to a combination of factors, primarily a detailed and optimistic report on Croda’s future prospects, the pendulum began to swing in Croda’s favour. Burmah finally gave up its bid in March 1982.

A key factor in Croda’s defence strategy was the continuing loyal support of its shareholders. Even before the Burmah bid, the company had decided to ‘open its doors’ via an innovative approach to its Annual General Meetings. Moving away from the traditional hotel venues, Croda decided to give shareholders and employees an insight into various aspects of the company ‘in action’ by holding the meetings at different Croda sites in large marquees, accompanied by exhibitions, factory and laboratory tours, along with Open Days for customers and suppliers, schoolchildren and members of the local community. Visitors had the opportunity to see products and processes at first hand, whilst engaging with employees actually working at their respective jobs, whether in the plant, laboratories or offices.

The first such event kicked off at Croda Polymers, Harefield, in 1981 when the company focused on paints and printing ink manufacture. Subsequent events moved to Newark (Croda Adhesives), Berinsfield near Oxford (Manley Ratcliffe: private label honey), Ashby-de-la-Zouch (Standard Soap: private label soaps and toiletries), Luton (gelatin) and Croda’s global headquarters at Cowick Hall, which included a visit to its first-ever factory at nearby Rawcliffe Bridge. At the Cowick Hall event in 1986, shareholders were given a copy of that day’s Financial Times in which Croda had taken out a full page advertisement describing how its products formed an important part of other people’s end products.

Reproduction of full page advert in the Financial Times on AGM day, 30 May 1986

The legacy and lessons learnt from the whole Burmah episode forced the company to re-think its strategy of growing primarily by acquisition and of being a diversified conglomerate. It had meted out a harsh, but by now, somewhat familiar lesson: stick to businesses that you understand. Croda undertook a review of its operations and, after two decades of acquisitions, began to divest the parts that did not form part of its core strategy – but at the same time, continuing to invest in companies that would contribute to its future. And that future would be focused on what it had always been best at: natural-based speciality chemicals. Going forward, Croda would focus on those end-markets that showed good growth, such as personal care and household products. High value products for niche markets were the aim.

Despite being ‘non-core businesses’, many of the companies acquired over the years had benefited from considerable investment, with some, such as Standard Soap and Manley Ratcliffe, occupying leading positions in the market, enhanced by their extensive private label activities.

The growth and vigour of retailing in the UK confirmed the view that consumer products could still be a profitable area of expansion so, whilst somewhat outside of the renewed focus on speciality chemicals, Croda proceeded with a number of strategic acquisitions, including several private label and contract soap manufacturers.

However, in other areas, difficult decisions had to be made. An early casualty was Croda Synthetic Chemicals, whose products were subject to the vagaries of demand for a small number of littleknown commodity chemicals. Another casualty was Croda Foundry Chemicals based in Halifax. In 1985, Croda sold its UK printing inks business to Fishburn Printing Ink. With the crushing and refining of edible oils from oilseeds increasingly conducted in large-scale modern plants in the US and continental Europe, the Premier Oils operation became barely profitable and was sold to the major US concern, Cargill, in late 1985.

Stick to businesses that you understand. “ “

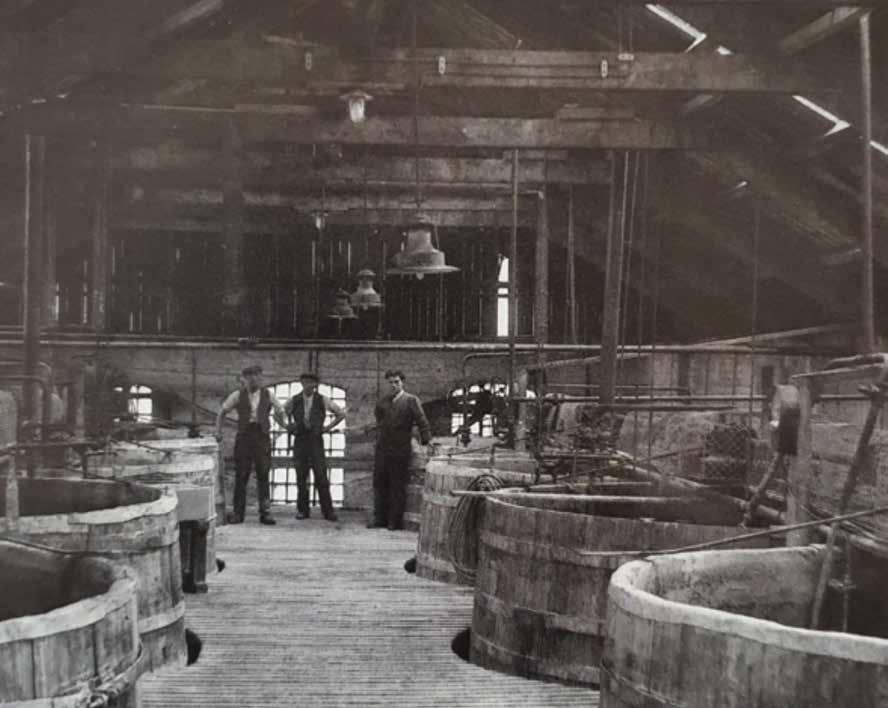

Bowmans Chemicals 1905

The original ‘Vat House’ pictured when Mr Bowman started his company in 1905. The photograph was kindly sent by Croda shareholder Mr J Calland, who recalled his time working at the Widnes factory: “When Mr Bowman died, we had a Managing Director called Mr Pert, who knew very little about the processes, but used to roam around and we called him ‘The Happy Wanderer’. If he spoke to me, I had to remove my cap, stand to attention and say ‘Sir’. He was a nice man and always left me with the same words: ‘Carry on working!’

Croda’s vegetable-based derivatives imparted the same beneficial characteristics as animal-derived products

Marketing insights, particularly from the US, indicated growing demand for the use of naturally derived products in cosmetics and toiletries, aligning with Croda’s sustainability credentials. For example, the discovery that adding a protein derived from silk to a hair conditioner made the hair ‘silky’ was significant – not just because the product performed well, but its origin enabled manufacturers to market their products as truly ‘natural’. In 1985, Croda became the first company to develop a wheat-based protein ingredient, imparting the same beneficial characteristics as animalderived products.