DELIVERING DISTRICT ENERGY

BOND Building is a premier full-service construction management and general contracting company delivering innovative solutions and collaborative client partnerships.

As a key area of expertise, we are focused on INTEGRATING DISTRICT ENERGY SYSTEMS into existing facilities, new construction and comprehensive preconstruction and pre-planning.

BOND Building ensures successful outcomes that are safe, reliable, and cost effective.

BOND Building has been working in the power & energy industry for many decades.

Navigating today’s complex energy landscape takes expert leadership, investment in fast-developing technology and focused engagement.

Our mission is to help our clients navigate through this complex environment and find solutions that achieve their energy and power goals now, and well into the future. BOND Building understands that power & energy is the lifeblood that enlivens campuses, hospitals, communities, and urban districts.

MEET

Tim is responsible for leading BOND Building’s District Energy market sector, with a focus on developing new strategies and integrated solutions that exceed client expectations. A licensed professional engineer, Tim has over 30 years’ experience in the evolving power & energy industry, specializing in campus district heating, cooling and micro-grids. He has also provided engineering and consulting services to the District Energy industry. Prior to that, Tim worked at Cornell University for over 22 years exclusively focused on their district energy systems. ,

SYSTEM EXPERTS THAT DELIVER WORLD-CLASS DISTRICT ENERGY PROJECTS

OUR DISTRICT ENERGY TEAM

PEER, P.E. Vice President

PEER, P.E. Vice President

JOHN TURNER

Project Executive

TIM

JOHN TURNER

Project Executive

TIM

SENIOR LEADERSHIP

JESSE CONKLIN

Project Executive

Project Executive

STEVE LIECHTI

BOND Building’s MARKETS

DISTRICT ENERGY

HEALTHCARE & LIFE SCIENCES

EDUCATION

Massachusetts | Rhode Island | Connecticut

OUR DISTRICT ENERGY SERVICES

Program Management

Feasibility Assessments

Design-Build

Condition Assessments

Technology Selection & Procurement

Budgeting & Scheduling

Laser Scanning & 3D Model Creation

OUR PARTNER ASSOCIATIONS

| Mid-Atlantic

DISTRICT ENERGY AT A GLANCE

BOND Building has been working in the power & energy industry for many decades. However, energy generation, delivery and resources are continually undergoing transformation. Resiliency and sustainability are becoming key factors that must be addressed as the landscape continues to evolve. As this market develops and our clients’ requirements change, we continue to position ourselves to meet the expanding needs of our clients. With Tim Peer spearheading the District Energy focus, we will provide various enhanced integrated solutions to assist clients through the entire life cycle of each project.

THE FUTURE OF DISTRICT ENERGY & POWER GENERATION

Navigating today’s complex energy landscape takes expert leadership, investment in fast-developing technology and focused engagement. BOND Building understands that power & energy is the lifeblood that enlivens campuses, hospitals, communities and urban districts. It’s also an ever-changing landscape, with a variety of fuel types and renewable energy sources. Our mission is to help our clients navigate through this complex environment and find solutions that achieve their energy and power goals now and well into the future.

DISTRICT ENERGY SOLUTIONS

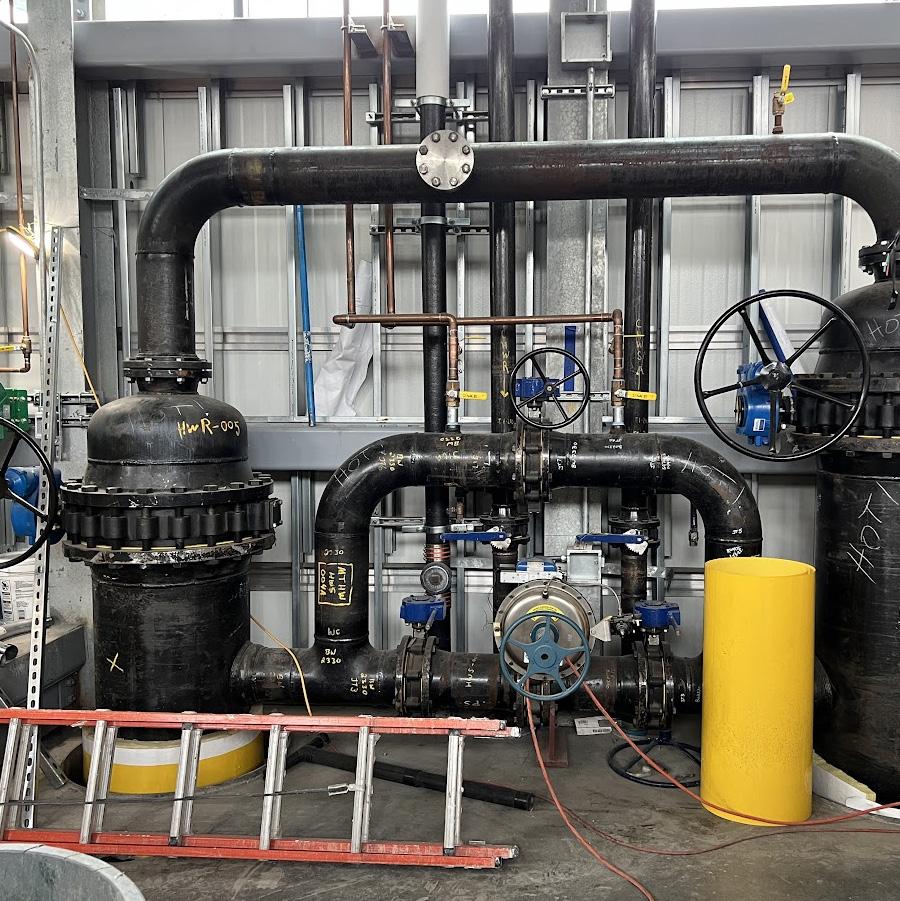

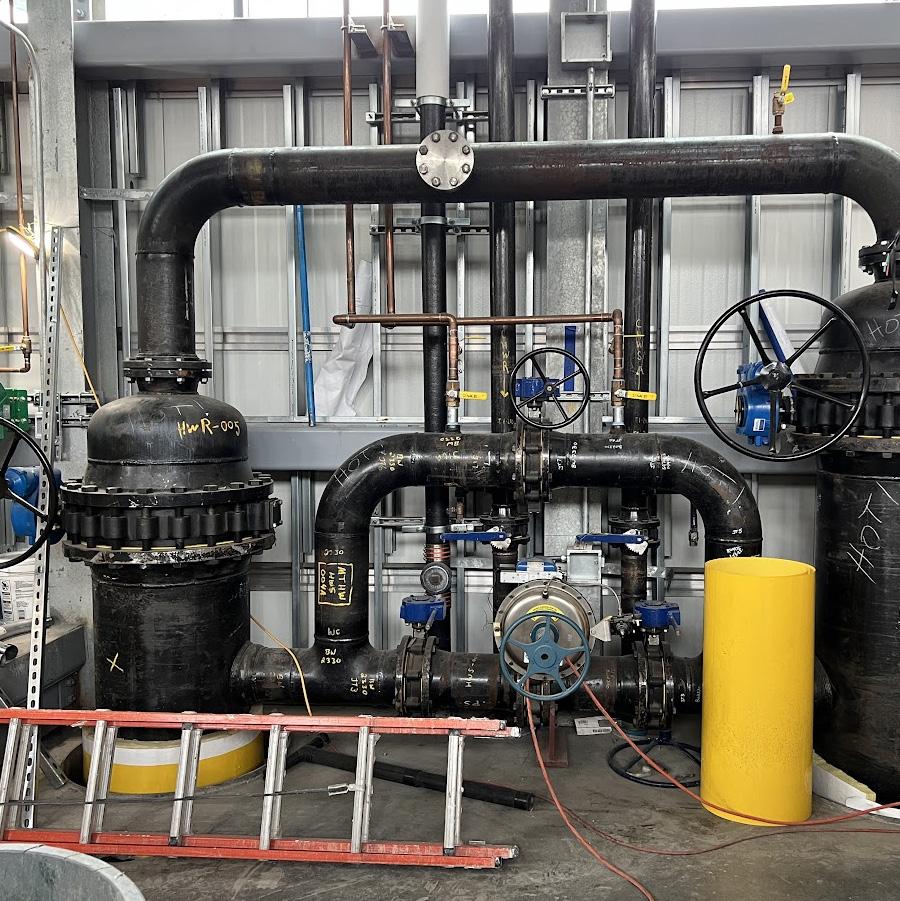

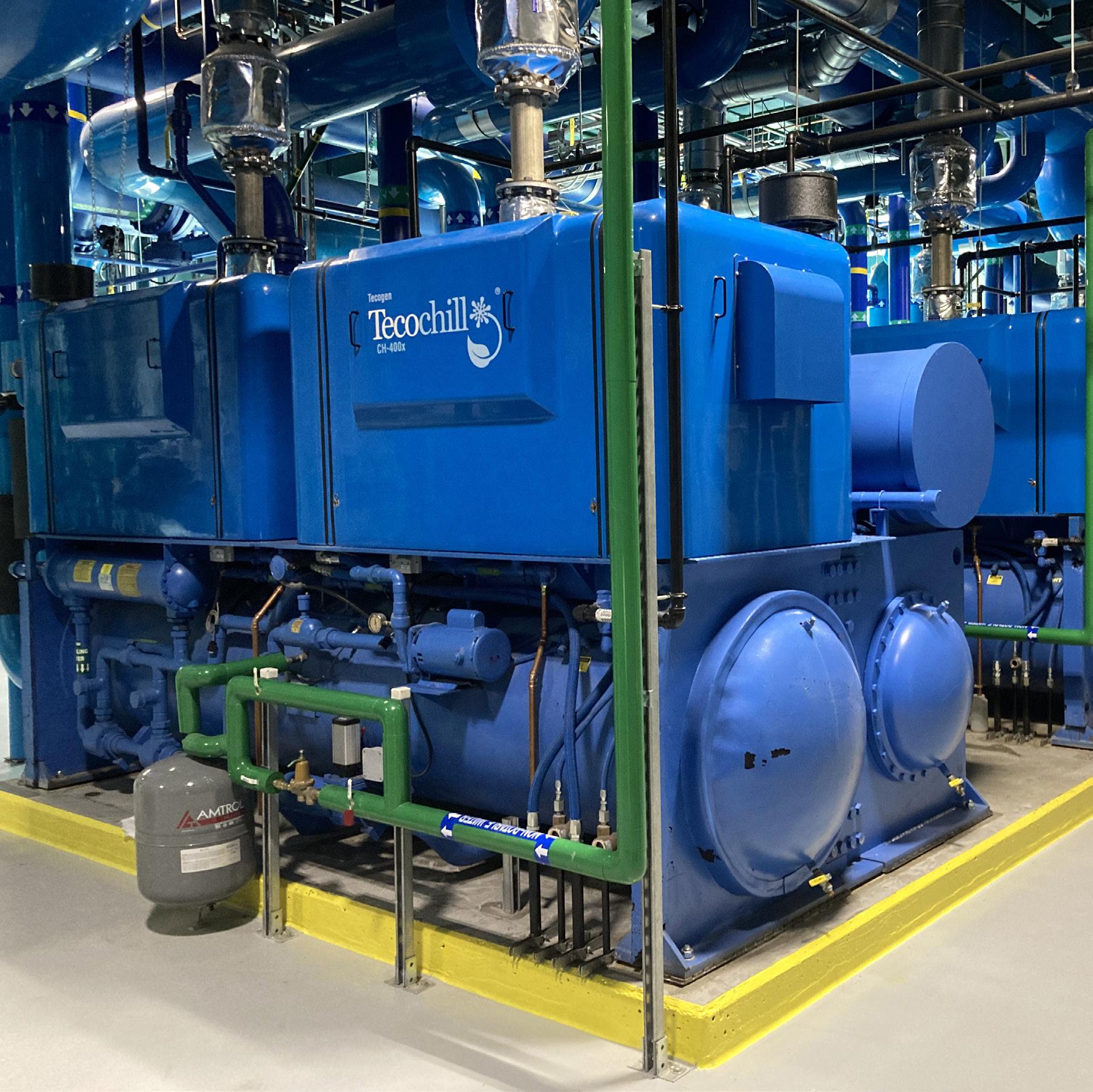

BOND Building’s construction of district heating and cooling systems improves energy efficiency, reliability and maximizes cost efficiency for our clients. District energy systems produce steam, hot water, chilled water and/or electricity at a central plant and then distributes them underground to individual buildings within a specific district. These systems provide cost-effective, reliable energy to the districts or campuses they serve.

DISTRICT ENERGY SPECIALIZATION

Design-Build

Geothermal Systems

Campus Thermal Distribution systems

Steam to Hot Water Conversions

Combined Heat & Power Systems

Central Plant Chiller & Boiler Renewal and Upgrades

New Ground Up Central Plants

Power Distribution, Substations & Upgrades

DISTRICT ENERGY SERVICES DESIGN-BUILD

BOND Building’s experienced professionals provide Design-Build (DB) delivery for steam, chilled water and combined heat & power projects. District energy and central plant related projects are not simple construction undertakings. They require a specialized team to ensure a seamless transition within the operating facility. Our team knows how to manage critical components which allows our customers to stay focused on their core business needs.

The BOND Building team will design, build and commission any central plant project including chillers, boilers, CHP (combustion turbine, steam turbine, or reciprocating engine) while the customer stays focused on their job. Our team understands the complexity of these projects. We have in-depth knowledge of the operations, engineering and design.

designbuild case studies

CENTRIO ENERGY

Syracuse University Modernization Project

$72 MILLION 2027

contract value

est. completion

ENGINEER

cha consulting

DESIGN-BUILD

bond builidng’s services

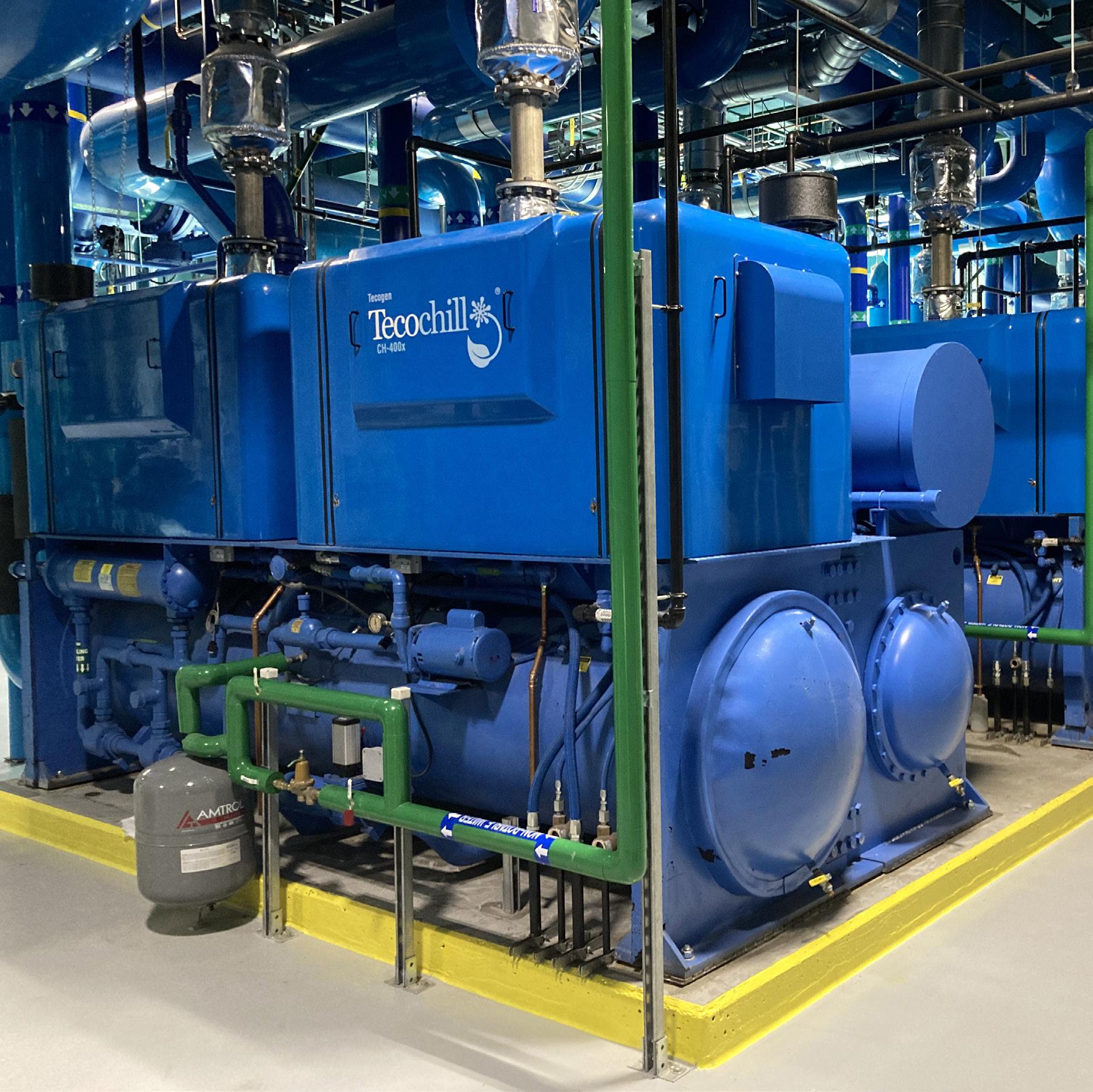

The Project consists of integrating new assets with the existing buildings, systems, and utilities that reside within the battery limit of SU/CenTrio’s central utilities facility to produce electricity, steam, and chilled water for Syracuse University. Electricity will be produced by an 8 MW combustion turbine (CT) with a heat recovery steam generator (HRSG). Steam upgrades include 2 x 75 KPPH packaged watertube boilers and ancillaries. Chilled water will be produced by five (5) new 2,500-ton electrical centrifugal chillers. Included are additional site and plant upgrades including system-wide controls & automation system and a new 15MVA utility service entrance.

SWARTHMORE

COLLEGE Campus Resiliency

$9 MILLION

contract value

year completed

ENGINEER

cha consulting

DESIGN-BUILD

bond’s building services

BOND Building, in collaboration with CHA, successfully executed a fast-tracked progressive design-build project aimed at enhancing the electrical infrastructure of Swarthmore College. The project involved the installation of modular stand-by generators with a combined capacity of 5MW, a new campus MV Switchgear, and automation for islanding capability to improve the college’s electrical resiliency and meet its growing energy demands. The team conducted the work in two phases, managing the engineering design, site preparation, equipment installation, start-up, commissioning, and staff training. Additionally, BOND Building/CHA provided air permitting and facilitated the utility electrical interconnection to ensure the seamless integration of the new infrastructure with the college’s electrical grid.

2023

LAHEY HOSPITAL & MEDICAL CENTER

Combined Heat & Power Facility

year completed

ENGINEER

aecom

MILLION

contract value

DESIGN-BUILD

bond’s building services

Under a design-build arrangement, BOND Building constructed this 3MW facility powered by a Caterpillar G260-12 3MW engine. The generator is fueled by natural gas from the local distribution utility and housed in the new 4,800 SF addition. The system generates both steam and hot water in the energy recovery systems. To increase the resiliency of the system, BOND Building also installed a new custom main NSTAR switchgear station. This allows the facility to respond to loss of power and switch from redundant grid feeds to self contained island mode. An intensive logistics plan was developed to minimize disruption to an operational health facility with 4,000 visits a day.

$12

2014

new central plants case studies

COMMONWEALTH

FUSION SYSTEMS

SPARC Tokamak Demonstration Facility

contract value

Our Client

est. completed

ENGINEER hdr, cfs CM AT RISK bond building’s services

Founded in 2018 with a mission to commercialize fusion energy in a timeframe to combat climate change. CFS is transitioning from start-up to operating company with over 200 emmployees.

The Mission

Collaborating with MIT’s Plasma Science and Fusion Center to build SPARC, the world’s first net energy fusion device

Mission validation accomplisehd mid-2025

SPARC is an important step to accelerate the development of commercial fusion energy

$225

2026

MILLION

UNIVERSITY OF CONNECTICUT

Supplemental Utility Plant (SUP)

$52 MILLION 2022

contract value

year completed

ARCHITECT

richard turlington & associates

CM AT RISK bond building’s services

This project is located at the western edge of the university’s proposed new Science quad. The first phase for the SUP will increase the university’s current capacities chilled water, steam and on-site electrical generation in order to meet both near-term and long-term needs. The new plant will be integrated into the university’s current infrastructure distribution and controls network in order to provide both redundancy and flexibility in meeting campus loads. The SUP has been designed to reflect and accommodate the growing utility demands of the campus. The current approach is for a phased project that is timed with campus energy needs. Phase 2 will be 16MW of CHP.

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

Central Utility Plant Upgrade

$160 MILLION 2021

contract value

year completed

ENGINEER

vanderweil engineers

CM AT RISK bond building’s services

BOND Building delivered this significant project which includes 42MW of CHP that is based on two Solar Titan 250 combustion turbines with Hamon Deltak Heat Recovery Steam Generators (HRSG). Included in this project is a 90,000-gallon basement/below-grade fuel storage capacity, new high-pressure gas service, gas compressors, and a 2MW diesel generator. The plant has a black start and campus islanding capability. The entire system is designed and constructed for resiliency and severe weather events.

HARVARD UNIVERSITY

Allston District Energy Facility & Energy Distribution Systems

contract value year completed

ENGINEER

rmf engineering (cep)

CM AT RISK

bond building’s services

BOND Building implemented a District Energy Facility (DEF) with distribution systems in support of Harvard University’s expansion of campus energy systems in Allston, MA. The 60,000 SF facility includes hot water boilers and Combined Heat and Power (CHP) to supply the Low Temperature Hot Water (LTHW) distribution system. Chilled Water (CW) is supplied by high efficiency electric centrifugal chillers and includes stratified thermal storage. The scope of work included the LTHW, CW, and 13.8 kV electrical distribution systems for the campus. The entire system is designed and constructed for resiliency and severe weather events.

$165 MILLION 2020

HARVARD FACULTY OF ARTS & SCIENCES

Central Northwest Laboratories Central Energy Plant

contract value

$29 million (cep)

year completed

ENGINEER

rmf engineering (cep)

CM AT RISK bond’s building services

BOND Building provided preconstruction and construction management for a new 500,000 SF science building which included dry, wet, teaching and physics laboratories; seminar rooms; collections facilities and a Central Energy Plant (CEP). Prior to the start of building construction, an extensive enabling phase with underground utilities was completed. BOND Building oversaw a cost-saving and innovative “up-down” construction methodology to accelerate the schedule by mining four below-grade stories in conjunction with the construction of four above-grade stories. Located on a tight urban site adjacent to a residence hall required extensive vibration monitoring, careful coordination of utility cut-overs and a detailed plan to dispose of contaminated soils.

$224

2008

MILLION

central plant renewal & upgrades case studies

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

Medium Temperature Hot Water Expansion

year completed $32 MILLION 2023

contract value

ENGINEER vanderweil engineers

CM AT RISK bond building’s services

BOND Building provided construction management at risk services for the penthouse addition on the existing Central Utility Plant Chiller Plan Building. The Central Utility Plant Chiller building converts steam to medium-temperature hot water with a total capacity of 320 MMBTU/HR. The project initially provides medium-temperature hot water instead of steam to Building 44 and Building 46 sites and will eventually provide medium-temperature hot water for the entire campus in lieu of steam. The addition includes a provision made for future heat exchangers and pumps when an additional load is added.

UNIVERSITY OF CONNECTICUT

Central Utility Plant (CUP) Boilers

$37 MILLION

contract value

to be completed 2023

ENGINEER

bvh integrated services

CM AT RISK bond building’s services

BOND Building was retained by the University of Connecticut (UCONN) to perform major upgrades to its Central Utility Plant. Phase 1 will be to Prepurchase the major equipment. Phase 2 will be to upgrade the campus utility tunnel and demolish three field-erected boilers in the CUP. Phase 3 includes the installation of two 100 KKP package boilers in the Central Utility Plant and a third 100 kpph boiler & ancillaries at the Supplemental Utility Plant. The total project is phased over a 4-year period.

Replacement

$15 MILLION

contract value

2023

to be completed

ENGINEER rmf CM AT RISK bond building’s services

BOND Building is currently providing construction to Yale under a Master Project Services Agreement (MPSA). This approach helps Yale to estimate, schedule, and execute various central plant, MEP/HVAC and utility projects as they are identified, developed, then funded. Individual projects are executed under these services based on the best model suited for each project including construction management, self-performing, and design build.

YALE UNIVERSITY CPP Cooling Tower

UNIVERSITY OF CONNECTICUT

Central Utility Plant (CUP) Chillers

contract value $14 MILLION

year completed

ENGINEER

bvh integrated services

CM AT RISK bond building’s services

BOND Building was retained by the University of Connecticut (UCONN) to replace two of the four gas fired chillers, heat exchangers and pumps, as well as the cooling towers within the Central Utility Plant (CUP). Associated equipment piping was also modified and replaced. Changes were made to the chilled water pumping, piping and controls between the CUP chiller plant and the Cogen chiller plant. Temporary chillers and pumps were necessary for a portion of the project duration to minimize impact to the campus.

2020

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

Central Utility Plant Expansion / Boiler and Deaerator Upgrade

MILLION

contract value

year completed

ENGINEER

rmf engineering

da upgrade

power engineers

boiler

CM AT RISK

bond building’s services

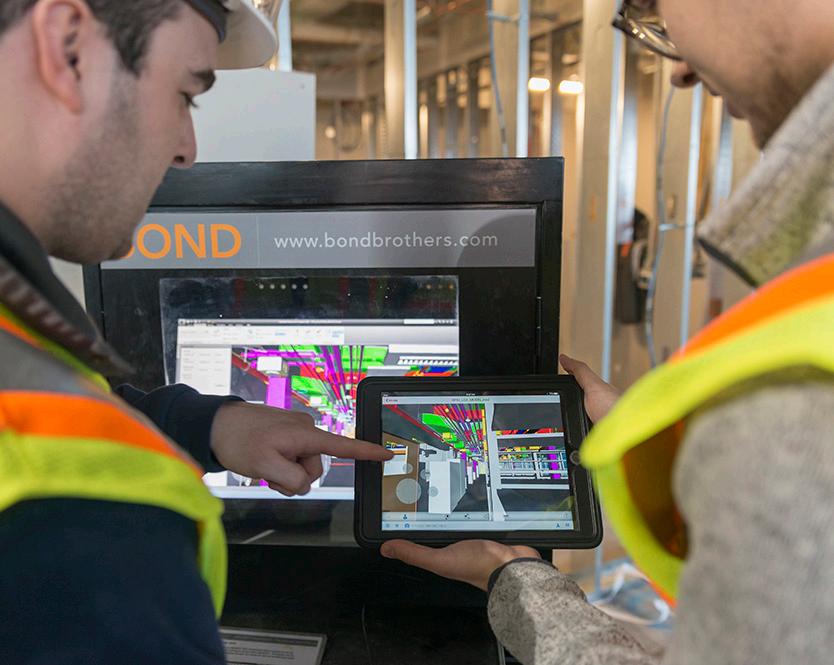

This project included the installation of a new 100,000 pound per hour boiler, new deaerator as well as a 5,000 sf addition to house the new equipment. Located within a tight urban site abutting the existing CUP, nearby railroad and parking lot slated for future construction, the new building required creative planning and coordination. To address this, BOND Building developed a pre-task analysis and coordination plan which was documented in the team’s tablet-based BIM 360 software.

Through close collaboration with MIT, BOND Building delivered a logistics plan that facilitated the safe delivery of the equipment without incident.

$13

2012

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

Chiller Plant Expansion, Chiller # 9 & #10

$30 MILLION

contract value

year completed

ENGINEER

vanderweil engineers

CM AT RISK

bond building’s services

BOND Building constructed a new 60,000 sf addition housing two new 2,500 ton electric chillers, two cooling towers, an elevated common 200,000 gallon condenser water sump and electrical switchgear room. The new steel frame addition spans an active railroad requiring significant advanced planning and intensive mitigation and safety strategy. The installation of equipment while maintaining an uninterrupted supply proved to be a challenge but was worked through successfully. Building Information Modeling (BIM) was utilized to plan for building construction over the active rail line as well as the installation of equipment into the structure.

2012

geothermal & campus utilities case studies

SMITH COLLEGE

Geothermal Energy Project

ENGINEER

salas o’brien

year completed $160 MILLION 2028

contract value

CM AT RISK

bond building’s services

BOND Building is currently delivering the Smith College campus-wide steam to Low-Temperature Hot Water (LTHW) with ground source heat pumps. In order to reduce the overall carbon emissions produced by the College, the systems used for heating and cooling are planned to be electrified. In lieu of steam for heating (and absorption-cooling), the campus will transition to a decentralized, low-temperature-hot-water (LTHW) system. LTHW will be distributed to the campus buildings at a temperature of 130°F. (3 campus facilities are being converted through a multiphase project delivery model.

UNIVERSITY OF MASSACHUSETTS AMHERST

Central Campus Core Utilities, Landscaping and Accessibility

contract value year completed $29 MILLION 2020

ENGINEER hoyle, tanner & associates

CM AT RISK bond building’s services

The University of Massachusetts Building Authority (UMBA) engaged BOND Building for preconstruction and construction management services for a comprehensive upgrade in the heart of the campus from the new Worcester Commons to the renovated Student Union. The project included waterproofing underground levels of the Campus Center Garage, area utility improvements, new hardscape, and landscape construction, the re-establishment of Ellis Way as a main pedestrian corridor, and bringing most pathways into Americans with Disabilities Act (ADA) compliance.

BRANDEIS UNIVERSITY

Skyline Residence Hall Geothermal

year completed

ENGINEER aecom

$32.7 MILLION 2018

contract value

CM AT RISK bond building’s services

Brandeis University engaged BOND Building to provide preconstruction and construction management services for its new 50,000 SF, 160-bed residence hall. The new building features the following: a new common space for students with large kitchen, study spaces, four lounges, a kitchen, and a courtyard. The project followed LEED Gold standards and is the campus’ greenest and most sustainable building. Solar panels on the roof partially power the Residence Hall to help with peak campus demand management. Geothermal wells provide all heating, cooling, and domestic hot water, eliminating the need for fossil fuels.

UNIVERSITY OF MASSACHUSETTS BOSTON

Central Utility Plant Upgrade / Campus-Wide Utility Corridor

$224 MILLION 2019

contract value year completed

ENGINEER

bvh integrated services

CM AT RISK bond building’s services

BOND Building upgraded the Central Utility Plant (CUP) and replaced the utility distribution systems for the entire campus. The CUP upgrade included state-of-the-art controls. The energy distribution systems are being upgraded in quality and size to deliver the energy demands of existing and future planned buildings. Systems include: hot water, chilled water, domestic water, sanitary sewer, fire protection, fiber optic network wiring and electrical services. Selective upgrades to gas, sanitary and storm drainage are also included. The construction program necessitates extensive planning and coordination with campus operations.

REALITY CAPTURE | VIRTUAL DESIGN & CONSTRUCTION | MEP SERVICES

INTEGRATED SERVICES START WITH THE END IN MIND.

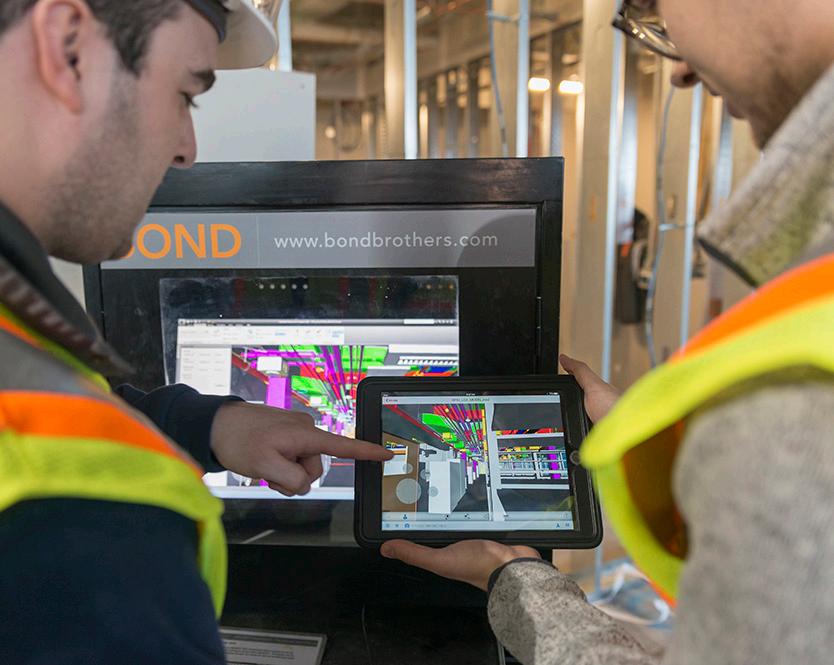

BOND Building’s Integrated Services model is a collaborative approach that combines the latest technology innovations with the brightest teams to manage a project’s entire life cycle.

Develop Logistics Plans Supported by Model Renderings, 4D Timeline Simulations and Critical Pick Rigging Animations

Conduct Constructability Peer Reviews

Provide Laser Scanning Services that Create Accurate As-Built Models of Existing Conditions

Evaluate Installation Accuracy with use of Hololens Augmented Reality, BIM Box and BIM 360 Field

Resolve Spatial Conflicts and Constructability Issues

Provide Solution-Based Clash Detection

Manage “Supplemental” Revit Model to Enhance the Detail of the Coordination

Long Lead Equipment Validation

Touch QA/QC Technology for Real-Time Analytics and Metrics (Accessed in the Field on iPads)

Deliver Long-Term Operations & Maintenance (O&M) Ready Facilities

TRUST

BOND Building uses Lean construction strategies on all projects as a means to minimize costs and maximize value. This process challenges each project stakeholder to develop, and apply, better ways to manage the construction process.

LEAN APPROACH ELIMINATE

WASTE. ADD VALUE.

TRUST

EXPER IENCE

BOND Building considers protecting every person within or near the construction site its foremost priority. No priority overrules safety at any time. We integrate safety into our construction planning and activities. This is represented by OUR 2022-2023 EMR RATING OF .79

SAFETY FORWARD BEST PRACTICES.

EXPER IENCE

CAPABILITIES/ SERVICES

BOND Building is not just a construction management company. Our District Energy team offers professionals who have integrated the core strengths of the firm’s construction management philosophy into years of experience building, commissioning, operating and maintaining utility (district energy) systems. With extensive college, university and healthcare experience, we understand the complexities and nuances of constructing and operating these types of facilities in those environments. At BOND Building, we put that experience to work for our clients!

BOND BUILDING’S KEYS TO SUCCESS

Incorporate operations and maintainability into design reviews

Integrate specific commissioning requirements in the design

Customize schedules that incorporate tasks that are unique to energy systems

Budget to include trades, vendors and specialty contractors required to construct, pre-test and commission utility grade mechanical, electrical and controls systems

Collaborate with the critical constituencies such as the interconnecting utility, permitting and approval agencies and fuel suppliers

Create logistics plans that incorporate the challenges of working in operating, mission-critical facilities

Work with the plant operations and maintenance staff to incorporate their institutional knowledge and expertise

Understand and analyze future expansion needs in the initial equipment sizing and subsequent design reviews

Outline the project turnover requirements early in a manner that supports, and seamlessly integrates, into the long-term needs of the client

Support the project after turnover to the owner with ongoing operator training and support

BOND-BUILDING.COM Tim Peer, P.E. Vice President, District Energy 617.394.6287 office | 607.592.2198 cell | tpeer@bond-building.com

PEER, P.E. Vice President

PEER, P.E. Vice President

JOHN TURNER

Project Executive

TIM

JOHN TURNER

Project Executive

TIM