Professional PASTA

Focus on pasta production in China

Nutritional value and heat damage of gluten-free pasta

Nutritional value and heat damage of gluten-free pasta

Editor in Chief

Claudio Vercellone

Scientific Coordinator

Mia Marchini

PhD in Food Science Scientific and technical committee

Luigi Pelliccia Head of Federalimentare market and research department

Roberto Ranieri Food industry innovation and technology

Roberto Tuberosa

Agricultural Genetics

Editing Lorenzo Bellei Mussini ufficiostampa@avenue-media.eu

Advertising Paola Zerbini pizeta@avenue-media.eu

Edition, management, editorial, advertising and administration

Avenue media Srl Viale Antonio Aldini, 222/4 40136 Bologna (Italy) avenuemedia@avenue-media.eu www.avenuemedia.eu

Subscriptions office dir@avenue-media.eu

Subscription

Ue countries € 45.00

Outside Ue € 60.00

Back issues (if available): € 15.00 each plus postage

MIG - Moderna Industrie Grafiche Srl

Via dei Fornaciai, 4 - Bologna (Italy)

Registration

N. 7875 of 9/9/2008 Court of Bologna

All coprights belong to Avenue media Srl May not be used without permission Responsibility of the advertisements belongs to the firms

Personal data processing in accordance with Regulation (EU) 2016/679.

Privacy Policy is available on Avenue media website www.avenuemedia.eu on “Privacy Policy - Publishing” page: www.avenuemedia.eu/en/privacy-policy-specialist-publishing/

PASTA PRODUCTION

While most of the grain compartment has recorded decreases, in the marketing year 2023/24 durum wheat prices have continued to be affected by strong volatility.

In summer 2023 a severe lack of soil moisture caused Canadian harvest to drop by 30% to its second lowest level after 2021/22. Production problems were recorded in other important areas as well: in the US insufficient rainfall caused output to shrink by 7.8%; in Mexico smaller areas led to a 10% harvest contraction.

On the demand side, North Africa

was hit by drought for the second year in a row, causing a further drop in production; while in the EU, smaller areas and stagnating yields led to a crop reduction of 6.3%. But in the EU issues were not limited to harvest quantity: ill-timed precipitations led to a severe quality deterioration, especially regarding test weight. The impact was so significant that several grain exchanges in Italy had to open a new sub-category of durum wheat in order to allow the commercialization of the crop.

At a global level, production in 2023/24 fell by 9.3% according to

IGC data, marking the fifth consecutive marketing year of deficit and leaving ending stocks at a historical low.

The lack of product availability in consuming countries led to soaring imports requirements, especially in the EU where the scarce quality of the harvest posed serious problems for pasta production. The higher demand could hardly be met by the traditional origins given the sharp drop in North America’s production. This factor ignited a price rally which caused high quality durum quotations to rise by 21% between June and August on the Bologna exchange, +31% for Saskatchewan durum delivered to elevators.

After a summer of bullish volatility, an unexpected factor emerged: Turkish production exceeded all expectations, reaching the unprecedented value of 4.3 Mio t. The record production allowed the country to become a net exporter for the first time, providing, together with Russia, an abundant and

unforeseen inflow of durum in Europe and North Africa. This has put a downward pressure on prices both in Europe and in North America, as the presence of Turkish and Russian durum eased demand on other origins and filled the needs of European mills.

Right now, all eyes are on the prospects for the next marketing year. In the Mediterranean area, planting season has concluded recently. In the EU, preliminary forecasts show declining areas, as the complications of the previous harvests might have induced farmers to divert their efforts to crops with a smaller degree of uncertainty. Furthermore, the new CAP (Common Agricultural Policy) takes away some of the previous incentives for durum wheat cultivation in Italy, which is responsible for around 50% of EU’s total production. In addition, heavy rains in France and high temperatures and lack of precipitations in Southern Italy have delayed sowings. These two factors make it hard to forecast

an abundant output for next marketing year, but weather in the coming months will be a decisive factor.

North Africa is still affected by lack of rain, albeit as of the beginning of 2024 appeared to be less problematic than last year. In Turkey, the good margins gained in the current marketing year seem to have pushed farmers to expand areas up to 10%, which in presence of average yields would maintain production at high levels.

As for North America, the first official estimates see a rebound in Canadian yields which would lead a 34% increase in output, while exports are expected to grow by +36%. Nonetheless, Canada will not start sowing until spring, therefore the current estimate could be revised depending on price movements, which could encourage a further area expansion, and weather during the summer months, which will have a decisive impact on yields.

The evolution of North America’s plantings and yields in the Mediterranean area will have to be closely monitored as they will be decisive to assess the equilibrium between supply and demand, and therefore the future of durum prices. As stocks are currently very limited, the market remains highly exposed to volatility. If the current expectations were to be confirmed, in the next marketing year durum wheat could see its first global production surplus after several years: this would allow for some stock accumulation, making the market less susceptible to exogenous and endogenous shocks. Nonetheless, given the current scarcity of product availability, more than one year will be needed to bring stocks back to an average level.

Carlotta De Pasquale

On an ordinary day in Hertsmere Industrial Park, the Dell’Ugo pasta factory hums with the activity of 180 staff members, producing a staggering 500 million stuffed pasta parcels annually. Recently, the factory was graced by the visit of celebrity TV chef Gregg Wallace, known for his inquisitive nature and love for food. The occasion was the filming of his acclaimed documentary series, a deep dive into the production processes of popular products. Wallace’s exploration of the factory was far from a cursory tour. He delved into the operations, tracing the journey of one of Dell’Ugo’s best-sellers, the crab and crayfish ravioli, from the intake of frozen crayfish tails to the final packaging process. The special ravioli, filled with crayfish and crab sourced from Cromer, Norfolk, is a testament to the factory’s use of local ingredients.

This factory is the first newly built one in Podravka’s food segment in the last 17 years. The construction and installation of new machinery took a year, and thanks to state-of-the-art equipment, the technological process of pasta production has been modernised and further improved, the company said in a statement on Friday. The factory was ceremoniously launched by the Prime Minister of the Republic of Croatia, Andrej Plenković, and the CEO of Podravka, Martina Dalić, in the presence of high officials, employees, company management, and business partners. In the new Pasta Factory, built on more than 4,800 square meters, industrial pasta will be produced for the manufacturing of Podravka soups, as well as twisted and short pasta under the Zlato polje brand. With this investment, Podravka enhances its pasta production capacity, laying the foundation for further sales growth in the soup category and the development of new pasta-related products.

Nearly a year after London learned it would be home to an Italian pasta manufacturer’s first North American plant, the provincial government has announced funding for its construction. Premier Doug Ford said the provincial government will be giving Andriani Ltd. $1.5 million toward its $33.6 million new facility in London’s Innovation Park at Bradley Avenue and Veterans Memorial Parkway. “Your $33 million investment is a huge vote of confidence in London, in our province, in the agri-food sector, and most importantly the people here in London,” said Ford. He added that the new 61,225 square-foot, state-of-the-art facility will spur growth throughout the province’s agri-food supply chains and help further establish London as a hub for food production, technology, and innovation. Andriani’s new gluten-allergen and GMO-free pasta plant will employee 42 people to start and will procure raw materials from Southwestern Ontario for its products. London was announced as the site for the company’s first North American facility last February.

The Minister of Agriculture of the Republic of Kazakhstan, Aidarbek Saparov, engages in a meeting with Federico Vecchioni, General Director of Bonifiche Ferraresi, a leading Italian agricultural holding, to discuss plans for exploring processing and pasta production, Ministry of Agriculture of Kazakhstan reported. This meeting resulted in the signing of a memorandum of cooperation between the Agrofirma TNK group of companies and BF International Best Fields Best Food Limited, a subsidiary of Bonifiche Ferraresi. The collaboration aims to foster mutual growth and development, with a focus on technology exchange, seeds, and employee training in the initial stages. Subsequently, both companies plan to explore processing and pasta production.

Heinz and Paramount have joined forces to create a brand-new pasta sauce inspired by the iconic Paramount Pictures film “The Godfather”. The limited-edition Heinz & The Godfather Pasta Sauce features the ingredients detailed in the film by Peter Clemenza as he teaches Michael Corleone how to cook the perfect pasta sauce. However, unlike revenge, this pasta sauce is a dish best served hot. In this exciting new partnership, Heinz and Paramount have joined forces to create a brand-new pasta sauce inspired by the iconic film. But how did Heinz do it? Well, you take some good sun-ripened tomatoes - grown by the Heinz tomato masters in Italy, of course. They’re the best. Then, put them in a pot with a little bit of olive oil and garlic, shove in some meatballs, some sausage. Add salt and pepper to taste.

Prince George’s favourite food is an Italian staple loved by the masses - and its even sparked a sweet Royal Family hobby with Kate and Charlotte. Celebrity chef Aldo Zilli revealed that the young prince is quite fond of the Mediterranean classic, spaghetti carbonara. The Italian born chef, 68, from Surrey, is an ambassador for the youth homeless charity Centrepoint, where he has had a few run-ins with Prince William, 41, who is patron of the organisation. Speaking to Femail, Aldo told how his chats with the Duke of Cambridge over the years allowed him to learn more about the three young royals - Princess Charlotte, 8, Prince Louis, 5, and 10-year-old Prince George. Aldo said William talked animatedly about his children, and at one point revealed Prince George’s favourite meal.

Aldi has recalled a pasta bake over the presence of an undeclared allergen, making it a potential health risk. The supermarket giant was obliged to pull its Meat Feast Pasta Bake from shelves after the packaging failed to mention it contains mustard. In a customer notice, the Food Standards Agency (FSA) declared that mustard could potentially present issues to allergic persons. The FSA said: “Aldi is recalling the above product from customers and has contacted the relevant allergy support organisations, who will tell their members about the recall.The company has also issued a point-of-sale notice to its customers. These notices explain to customers how the product is being recalled and tell them what to do if they have bought the product.” Aldi also issued a statement about the recall on its website, stating: “Anyone who bought this product should return it to their store for a full refund.”

Panzani diversified its activities. In addition to dry pasta, sauces and couscous, the French ETI announced on February 7 its launch on the fresh pasta department starting in March. Gnocchi, stuffed pasta, or simple tagliatelle will appear on the French shelves. Although he does not yet communicate the names of his partners, the boss of the company Albert Mathieu says he has agreed with two Italian manufacturers to manufacture new products. “This is an ambitious project in a complicated context for major brands, compared to private label (MDD) brands that are progressing,” acknowledges Albert Mathieu, CEO of Panzani.

“Seminary of the History of Science” University of Bari

Lecturer in Anthropology of Food Department of Agricultural and Food Sciences, University of Bologna

In Europe, we are all quite familiar with the history of dried pasta. Its invention is usually attributed to the Arabs, though its origins could be more specifically located in Persia. Then, via Sicily, it reached the Italian peninsula during the Middle Ages. However, this is just one part of the story. According to a longstanding myth (which was based on a misinterpretation of Marco Polo’s account), pasta was invented in China. This is not true. Actually, Chinese pasta has an equally fascinating – but independenttradition. Pasta, known as “mian” in Mandarin, has a rich heritage in China dating back over two millennia. It is believed that its origins trace back to the Han Dynasty (206-220 CE), where noodles made from wheat flour began to play a key role on the

According to a long-standing myth pasta was invented in this country

table. Initially, noodles were reserved for the elite due to the scarcity of wheat, but they gradually gained popularity across all social classes. The Silk Road played a major role in the spread of pasta-making techniques over Central and Eastern Asia, facilitating cultural exchange and culinary innovation. Regional variations emerged over the course of time. For instance, Zhajiangmian is a Beijing dish featuring ground pork and onion cooked in a savoury brown sauce made with soy, and served with cucumber. Or Dan dan noodles of Sichuan, one of the most famous street foods in the province, made with pork and peanut flakes, and topped with spicy sauce. During the Tang Dynasty (618-907 CE), the art of noodle-making flourished,

with skilled chefs perfecting techniques like hand-pulling and knife-cutting. Noodles thus became synonymous with prosperity and longevity, symbolizing good fortune in Chinese culture, often served during festive occasions and celebrations.

In contemporary China, the pasta industry has undergone a remarkable transformation, reflecting the country’s rapid economic development and changing dietary habits. With a population exceeding 1.4 billion and a growing middle class, the demand for pasta products has surged, driving innovation and

expansion within the industry. Revenue in the pasta market amounts to US $28.88 billion in 2024, and the market is expected to grow annually by 7.78%. This is quite interesting since, in global comparison, most revenue is generated in China. China, alongside other countries of the Asia-Pacific region, holds the biggest market share in the industry (38.16% in 2020). In the last years, the biggest importers of Chinese

Pasta is knowned as “mian” in Mandarin

pasta have included Japan, followed by Germany, France, and the United Kingdom.

Large-scale manufacturers utilize advanced technology and automated production lines to meet the soaring demand for pasta,

ranging from traditional noodles to modern pasta shapes like penne and fusilli. What is more, China’s diverse culinary landscape has spurred the development of specialized pasta products tailored to regional tastes, such as handpulled noodles in the north and rice noodles in the south. The pasta industry has also embraced globalization, with international brands entering the Chinese market and influencing consumer preferences. Health-conscious consumers have also fueled demand for healthier alternatives, leading to the production of whole wheat and vegetable-based pastas. Ecommerce platforms have further revolutionized the pasta market, providing consumers with convenient access to a wide range of products and facilitating directto-consumer sales for smaller producers.

Pasta consumption in China has been steadily increasing over the past few decades, driven by urbanization, rising disposable

Lamian noodles

Lamian noodles

incomes, and changing dietary habits influenced by globalization.

After 2020, Chongqing emerged as the larger pasta and noodles

Recently demand for pasta products in China has surged

market in the country, followed by Shanghai and Beijing.

Hypermarkets and supermarkets are the leading distribution channels in the Chinese pasta sector. They account for a value share of more than 60% of all the distribution channels, followed by convenience stores, E-retailers, and food & drink specialists.

Traditional Chinese noodles remain popular. The World Instant Noodle Association has estimated that the Chinese population consume an

average of thirty-six packets of instant noodles per-capita every year. About 50 billion servings of noodles are consumed every year

in the country. However, in recent years, there has been a growing appetite for Western-style pasta dishes among consumers, particularly in urban areas.

It is estimated that the per-capita pasta consumption is ca. 1.5 to 2 kilograms every year (for reference, in Italy it is about 23 kilograms). However, this number is influenced by various factors, including age, regional preferences, socio-economic status, and cultural influences.

For instance, pasta is mostly consumed by people aged between 25 and 45 years old, while it is not popular among over 55year-old consumers.

Coastal regions and major metropolitan areas tend to have higher pasta consumption rates compared to rural areas. According to other estimations, the average volume per person in the pasta market is expected to amount to almost 5 kilograms in 2024 (source: www.statista.com). The leading companies by values after 2020 include Tingyi Holding Corp., UniPresident Enterprises Corp., and Zhejiang Baixing Food Co., among others. Companies offer lower-carb variants and products with added

health benefits such as fiber, protein, omega-3 fatty acids, gluten-free pasta, and more.

Shapes, colours, and types of pasta

Several types pasta are consumed daily in China. For instance, lamian, or hand-pulled noodles, are a staple particularly in the northern regions. Made from wheat flour dough, lamian are hand-stretched and pulled to achieve their characteristic long, chewy strands. These noodles are often served in hearty broths or stir-fried with meat, vegeables, and sauces. Min tiao refers to a broad category of Chinese noodles, encompassing various shapes and sizes, including flat, round, and thin noodles. They can

Western pasta has been also incorporated into fusion recipes blending

be made from what or rice flour and are used in a wide range of dishes. Western-style pasta made from durum wheat semolina, including penne, spaghetti, fusilli, and farfalle, are relatively popular in urban areas and especially among younger generations. They are used in recipes inspired by Italian cuisine, but also in creations that incorporate Chinese flavours. Wonton

wrappers are thin sheets of dough made from what flour and water, commonly used to make filled dumplings. The top categories in the Chinese pasta sector include ambient pasta, chilled pasta, and dried pasta. Dried and instant noodles represent the leading category, while the chilled pasta category is forecast to register the fastest value growth in the next years.

Pasta or rice? Pasta with rice!

Pasta made with rice, known as rice noodles or “mi fen” holds a cherished place in the country’s culinary repertoire. Rice noodles are a staple food in many regions, particularly in southern China, where rice cultivation is prevalent.

These delicate, translucent noodles are made from rice, flour and water, resulting in a soft and slightly chewy texture that pairs well with a variety of flavours and ingredients. Rice noodles are consumed in a multitude of dishes.

One of the most iconic ones is “guilin mi fen” from Guilin, a city in the Guangxi Zhuang Autonomous Region.

The dish features thin rice noodles served in a fragrant broth made from pork bones, dried shrimp, and spices, topped with sliced pork, pickled bamboo shoots,

peanuts, and fresh herbs.

In Yunnan province, Guo Qiao Mi Xian (“crossing-the-bridge noodles”) is a famous rice noodle dish that originated from the city of Kunming. Legend has it that a devoted wife would cross a bridge every day to deliver hot soup and fresh ingredients to her husband studying on a remote island. The dish consists of a bowl of piping hot chicken or pork broth served with separate plates of thinly sliced meats, vegetables, and rice noodles. Rice noodles are also used in stir-fries, salads, and soups. They

provide a gluten-free alternative to wheat-based noodles. With the rise of health-conscious eating habits, rice noodles have gained popularity for their light and nutritious qualities.

In recent years, the consumption of Western-style pasta in China has significantly increased. The influence of globalization has been playing a major role in this process, alongside the exposure to Western culture through media, travel, and international culinary trends. Italian cuisine, in particular, has gained widespread popularity in China: Spaghetti Bolognese (or al ragù), carbonara, and pesto pasta are among the most commonly enjoyed Italian pasta dishes in the country. However, Western pasta has been also incorporated into fusion recipes blending Italian and Chinese flavours, such as spaghetti with garlic and soy sauce, or pasta dishes featuring traditional Chinese ingredients like black bean sauce, Sichuan peppercorns, or spicy chili oil.

Andrea Maraschi

Engineering and Agro-Food Processing, Rome

Rice (Oryza sativa L.), along with wheat and corn, is a staple food worldwide. As a matter of fact, it contains carbohydrates (75-80%), proteins (7-8%), lipids (3%) and is also rich in fibre, minerals and vitamins, especially when consumed as a wholegrain. In recent years, the demand for gluten-free food products has grown significantly due to the increase in diagnosed or self-reported gluten intolerances and consumer preferences for more digestible foods. Rice pasta is one of the most popular glutenfree food due to its pleasant taste, high digestibility and hypoallergenic properties. The production of gluten-free rice pasta requires the use of other cereals, pseudo-cereals or legumes, additives or specific technological processes which can improve its organoleptic and sensory properties. Among the elements that influence the technological and nutritional properties of rice

the most, we find the ratio of amylose and amylopectin, the two polysaccharides that constitute starch. In particular, a high amylose content has been observed to be associated with a better texture and cooking quality of rice pasta as well as a reduction in the glycaemic index compared to pasta made from low-amylose content varieties. Therefore, high-amylose rice varieties seem to be more suitable for pasta production.

Among the technological processes applied to brown rice, the hydrothermal treatment, also known as parboiling, is able to improve nutritional properties, due to the migration of vitamins and minerals towards the interior of

the grain, thus limiting their loss during cooking. This process leads to an increase in the level of resistant starch, that gives considerable benefits to human ‘colon’ health, as part of the soluble fibre. Moreover, parboiling can modify the physicochemical properties of starch, by reorganising amylose and amylopectin, in particular by making it harder, and inducing the synthesis of lipid-amylose complexes and aggregation of soluble proteins. Such modifications have been shown to have positive effects on the sensory quality of rice pasta, in terms of decreased stickiness and increased firmness. Despite the higher nutritional value, brown rice and its processed products are consumed less than white rice and

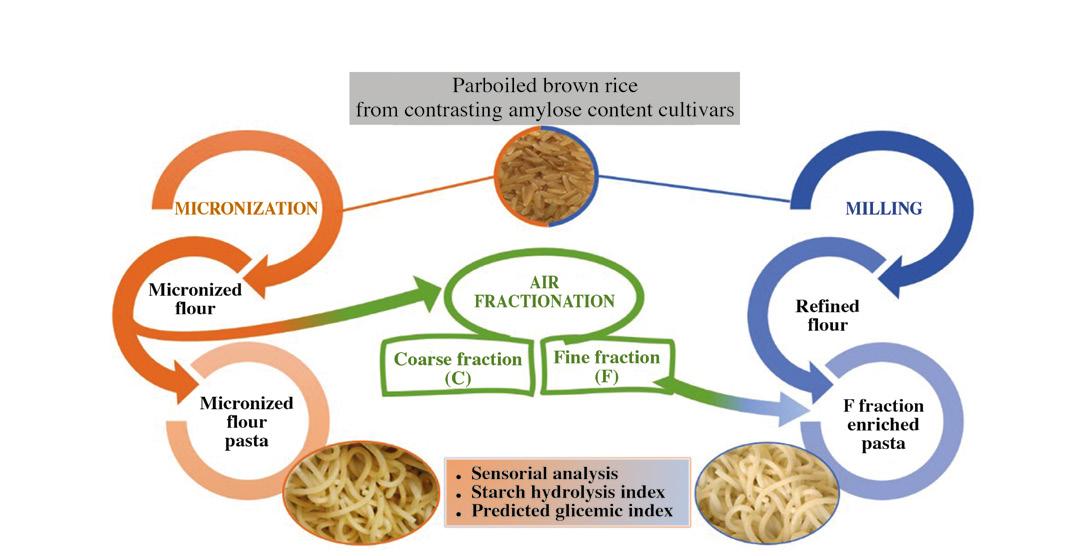

its processed products. In fact, the presence of the bran layers results not only in poor palatability, but also makes it difficult to process flour and dough with repercussions on the technological quality of the same. Innovative milling techniques such as micronization and physical technologies, such as air classification of flours (turbo separation), address most of the technological and sensory issues of the wholemeal products. In particular, micronization makes it possible to obtain wholegrain flour whose very fine particle size improves its quality characteristics in technological and sensory terms. By means of air classification, on the other hand, exploiting the different particle size and density, it is possible to obtain fractions rich in bioactive and healthy compounds, such as antioxidants and dietary fibre, to be used to enrich refined flours. These technologies, based exclusively on physical methods, have been used at the Research Centre for Engineering and Agro-Food Processing in (CREA-IT) Rome to produce rice pasta, without adding any other ingredients, from two japonica rice cultivars with

contrasting amylose content, Gladio (high) e Ronaldo (mediumlow) (Figure 1). This study made it possible to investigate the effects of amylose content and technological process on the nutritional properties of raw materials and pasta, on which cooking quality and starch hydrolysis index were also evaluated.

Micronization produces wholemeal flour with a very fine particle size

Pasta production process

Brown rice kernels of Gladio and Ronaldo cultivars were subjected to parboiling process, which involved conditioning in water for 4 hours, until a moisture content of 15-16% was reached and then they were steam cooked at 120 ± 1 °C, 2.1 bar for 10 minutes. The steamed kernels were dried at 30 °C for 48 hours until 11% moisture was reached. A part of the parboiled whole grain

was ground by LABORMILL 4RB (BONA, Monza, Italy) milling plant to obtain refined flour, while the residual part was micronized using the KMX-500 device (Separ Microsystem, Brescia, Italy) at a frequency of 170 Hz to obtain wholemeal flours. Micronized wholemeal flours were fractioned by an air classificator (Separ Microsystem, Brescia, Italia) which made it possible to obtain two fractions, a coarse (C) and a fine one (F). Two pasta formulations were produced for each cultivar: (i) 100% micronized wholemeal flour; (ii) 85% refined flour + 15% F fraction. Pasta was produced using an experimental press (NAMAD, Rome, Italy) with a capacity of up to 20 kg/h, equipped with a teflon-coated extruder comprising 164 holes, diameter 1.80 mm, for the production of spaghetti under the following conditions: 15 minutes of kneading in a vacuum chamber (1 bar) at a temperature of 50 °C and extrusion screw speed 42 rpm. Pasta was then dried horizontally in an experimental dryer (AFREM, Lyon, France) for 18 hours, applying a low temperature drying cycle (T max=58 °C) and a progressive reduction of moisture content from 85% to 70%

throughout the whole drying process. The final moisture content of dried spaghetti was 12.5%. The diagram of the applied processes is shown in Figure 2

The effect of processes on the nutritional characteristics of raw materials and flours In both cultivars, brown rice, parboiled rice, micronized wholemeal flour, and the C fraction showed no significant differences in total starch content, which averaged about 80%, while the F fraction of both cultivars showed lower total starch values (about 70%). This could be explained by the fractionation mechanism operated by the turboseparator, which led to a different distribution of starch and fibre among fractions of different sizes. In particular, larger or heavier fractions (C fraction) showed a higher starch content and a lower fibre content, and in contrast, the smaller and lighter fractions (F fraction) showed a higher fibre content and a lower starch content. Further analysis of the turboseparated fractions showed that the F fraction was richer in proteins, bioactive

compounds and antioxidants, and therefore it has been selected to improve the nutritional potential of rice pasta, which was obtained using the traditional durum wheat pasta-making process. In particular, the enrichment of refined rice flour with 15% of the F fraction was considered a good compromise to improve nutritional aspects without neglecting the palatability of the final product.

Two pasta formulations were produced for each rice cultivar, Gladio and Ronaldo: one from 100% micronized wholemeal flour and the other from refined rice flour enriched with 15% F fine fraction (Figure 2). Unlike rice pasta on the market, these two pasta formulations are obtained by “nonconventional” technological processes and by enrichment in fibre and antioxidants with fractions of

flour selected from the milling of the rice itself. The analysis of amylose and resistant starch content showed no differences between the two pasta formulations within the same cultivar, although both pasta samples of the Gladio cultivar (high amylose) showed definitely higher amylose and resistant starch values than those obtained from the Ronaldo cultivar (medium-low amylose), confirming the positive correlation between amylose and resistant starch content. The protein content also did not differ significantly between the two pasta formulations, although Gladio pasta, made from refined rice flour enriched with the F fraction, showed 1 percentage point less than pasta from micronized flour (7.7 vs 8.9%). However, it is interesting to note that the addition of 15% of the F fraction, the richest in protein (9.8% in Gladio and 8.9% in Ronaldo), led to an increase in the protein content of refined rice flour and pasta derived from it. In contrast, the two types of pasta showed differences in fibre content; in particular, the pasta obtained from micronized flour had a higher fibre content than those enriched

with the F fraction. In fact, although the F fraction was the richest in fibre among the flours obtained (about 12% in Gladio and 8% in Ronaldo), the 15% enrichment did not achieve the fibre content present in the micronized flours of Gladio (6.2%) and Ronaldo (5.2%). However, it should be noted that the fibre content of pasta enriched with the F fraction was as high as 4.5%, a value that could be defined as a “source of fibre”.

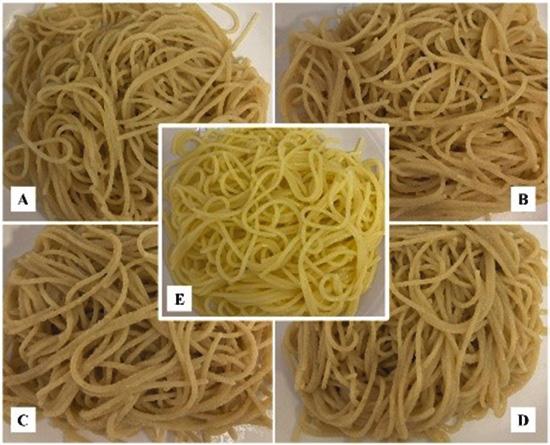

The antioxidant activity measured on the two types of pasta showed no differences, indicating that enrichment with 15% of F fraction enabled refined flour to reach antioxidant capacity values comparable to those of micronized wholemeal flour. Pasta was also assessed for ash content, which, in all four pasta samples, fell within the Italian legal limit for whole durum wheat pasta (1.8%). Moreover, all the rice spaghetti produced in the present study showed yellow indices (b*) between 23 and 26 considered good for semolina pasta; this result is probably due to the Maillard reaction occurred as a result of parboiling. Also, this thermal treatment, along with the presence of bran layers, increased brown and red index values in the two rice pasta formulations compared to those found in durum wheat pasta. However, both types of pasta showed a similar colour to durum wheat pasta, a characteristic that is

The glycemic index is lower than for semolina pasta

highly appreciated by regular pasta consumers (Figure 3).

In addition, the cooking quality of pasta was compared with that of semolina pasta. The optimal cooking time, evaluated as the time required for the spaghetti core to disappear, was significantly higher in semolina pasta (10’30’’) than in

rice pasta (8’50’’ in micronized wholemeal flour pasta and 8’15’’ in pasta enriched with F fraction). The shorter cooking times in rice pasta are due to the absence of gluten and the presence of fibre that can absorb water faster than gluten proteins. Moreover, in both varieties, the amount of water absorbed during cooking by pasta made from micronized wholemeal flour was approximately half that absorbed by pasta made from refined flour enriched with F fraction. This behaviour is due to the higher presence of starch, which is able to retain more water than fibre does. Furthermore, both types of rice pasta, due to the lack of gluten, showed a greater loss of organic substance during cooking than semolina pasta; this loss was particularly evident in pasta derived from Ronaldo cultivar. The sensory analysis of pasta was based on three parameters related to the technological quality of spaghetti, such as stickiness, firmness and bulkiness; each parameter was given a score ranging from 1 to 100 (Figure 4). Pasta produced with the

Cooked rice pasta: 85% refined flour + 15% F fraction of Gladio (A) and Ronaldo (B); 100% micronized wholemeal flour of Gladio (C) and Ronaldo (D); durum semolina pasta (E)

following parboiling, results in a lower glycemic index. In fact, the parboiling process, by inducing the crystallisation of amylose, limits the accessibility of starch by hydrolytic enzymes, thus lowering the glycemic index.

Gladio variety obtained better scores for all three parameters, highlighting the importance of the variety choice to obtain pasta with suitable characteristics that are appreciated by consumers. In fact, the higher amount of amylose and resistant starch in the Gladio variety proved to be responsible for the sensorial parameters, influencing the firmness of pasta. Furthermore, pasta obtained from the enrichment with the F fraction scored better in terms of stickiness and bulkiness

than pasta obtained from micronized wholemeal flour. The predicted glycaemic index, i.e. obtained from the starch hydrolysis values, was also determined on cooked pastas (Table 1). All rice pastas showed lower hydrolysis indices and, consequently, lower glycemic indices than semolina pasta. Furthermore, Gladio pasta showed a lower glycemic index than Ronaldo pasta, indicating that a high amylose content, reflected in a higher proportion of resistant starch

The results of this study highlighted the importance of the amylose content in the grain for the production of rice pasta, not only for the repercussions on the technological and sensorial quality of the pasta, but also on the nutritional quality, as amylose is related with resistant starch and glycemic index. Besides the characteristics of the raw materials, the technological processes applied also played a role on the technological and sensorial characteristics of pasta. In particular, parboiling led to an increase in the proportion of resistant starch and the enrichment with the F fraction, obtained by turboseparation, resulted in a rice pasta with superior sensorial characteristics compared to pasta obtained from micronized wholemeal flour and with comparable nutritional properties.

Laura Gazza et al.Within the same column, values with different letters indicate significant differences determined using Duncan’s test (p < 0.05)

1 Full Professor, Department Agricultural, Environmental and Food Sciences, University of Molise

2 Assistant Professor, Department Agricultural, Environmental and Food Sciences, University of Molise

3 Full Professor, Department of Science and Technology for Sustainable Development and One Health, Università Campus Bio-Medico di Roma

The consumption of glutenfree products has become popular due to the increasing number of patients diagnosed with coeliac disease and the introduction of gluten-free diets unrelated to disease. The production of glutenfree foods (pasta, bread, biscuits, etc.) with high sensory quality and nutritional characteristics requires a careful selection of gluten-free raw materials, and/or the use of appropriate technologies to realize products that are as close as possible to those obtained with conventional raw materials (Marconi and Messia, 2012). Pasta is an important and popular product, also in a gluten-free diet, due to its long shelf-life and ease of use. Good quality pasta is characterised by an adequate cooking performance that depends on raw materials, in particular on the quantity and quality of the proteins that generate a gluten network capable of containing the starch release (Cubadda et al. , 2007). In the case of gluten-free pasta, the industry uses several ingredients

(corn flour/starch, rice, tapioca, pseudocereals and legumes) to develop a pseudo-gluten network and may add emulsifiers, hydrocolloids or apply unconventional pasta-making processes (Marti and Pagani, 2013). Excellent sensory, nutritional and cooking attributes are important factors in order to avoid excluding people with coeliac disease and gluten intolerance from a nutritional and psychological point of view.

Different types of flours (legumes, corn, rice), starches and pseudocereals can be included in gluten-free pasta making.

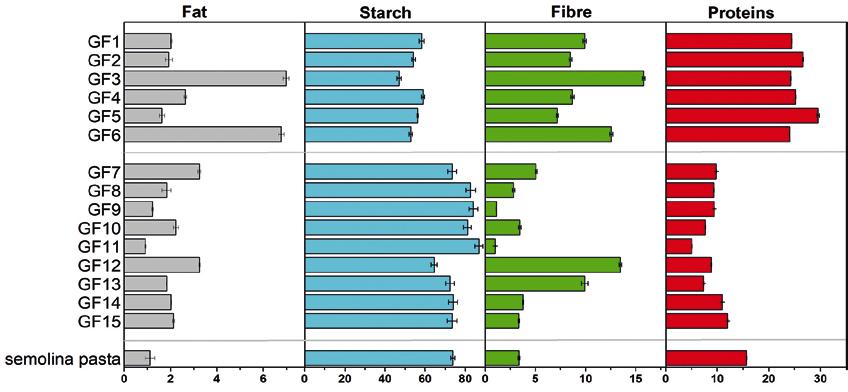

By reading the labels of commercial gluten-free pasta samples considered in this study

( Table 1 ), 40% were made exclusively of legume flours (peas, red lentils, lentils, chickpeas), only two samples were made with 100% corn or 100% buckwheat flours, while the others contained a mixture of cereals (corn, rice, and teff), pseudocereals (amaranth, buckwheat, and quinoa) and legume flours. Only one of the tested samples claimed the presence of emulsifiers (mono- and diglycerides of fatty acids) in the ingredients list on the label.

Mixtures of different ingredients result in a major difference in the chemical composition of glutenfree pasta, which can, therefore,

Gluten-free pasta - 100% legume flour

GF1

GF2

GF3

GF4

GF5

GF6

GF7

GF8

GF9

GF10

GF11

GF12

GF13

GF14

GF15

100% Green pea flour

100% Red lentil flour

100% Chickpea flour

100% Green pea flour

100% Lentil flour

100% Green pea flour

Gluten-free pasta Cereal, pseudocereal and legume flours (100% or mixed)

100% Buckwheat flour

75% Corn flour, 10% Rice flour 10% Buckwheat flour, 5% Quinoa flour

75% Rice flour, 25% Quinoa flour

36% Brown rice flour, 32.5% Yellow corn flour, 20% White corn flour, 8% Rice flour, 3% Potato starch, Emulsifiers (mono and diglycerides of fatty acids)

100% Corn flour

Corn flour, Rice flour, 10% Amaranth flour, 5% Teff flour, 5% Quinoa flour)

Corn flour, Rice flour, 8% Bamboo fibre

Corn flour, 30% Pea flour, Rice flour

Corn flour, 30% Red lentil flour, Rice flour

have extremely different nutritional values compared to conventional pasta made of durum wheat semolina only.

The use of legume or pseudocereal flour (quinoa, buckwheat, amaranth) as a basic ingredient results in pasta with a higher fibre and protein content (Figure 1). The fibre content can also be increased by using ingredients such as amaranth, quinoa and teff, usually as whole grain flours, or by adding bamboo fibre. Some of the pastas tested (Figure 1) had a fibre content which, according to Regulation (EC) No 1924/2006, meet the requirements for the ‘high fibre’ nutrition claim on the label.

Carbohydrates are the main component in most types of pasta, from semolina to special pasta, and therefore their analysis is interesting from a nutritional point of view. The starch in the tested gluten-free pasta had an average content of about 68g/100g dry matter (min 47% - max 87%). While gluten proteins play a key role in the properties of conventional semolina pasta, starch takes on a structuring role - thanks to the fact that its macromolecules tend to re-associate and interact after gelatinisationand becomes a crucial component in giving gluten-free pasta a semolinalike texture. As to sugar, sucrose was found in the highest concentrations (average value = 1738 mg/100g),

but relevant amounts of reducing sugars were also found, such as galactose (average value = 142 mg/100g), glucose (average value = 184 mg/100g) and fructose (average value = 145 mg/100g), which, although representing only a small part of the carbohydrates, are nevertheless relevant as they may be directly involved in the Maillard reaction. Maltose (average value 103 mg/100 g), and maltulose (average value 23 mg/100 g), which can be formed by isomerisation of maltose during heat treatment, were also found in all samples. The protein content in commercial samples ranged from 5.06 to 29.53% dry matter with an average concentration of 15.6% (Figure 1).

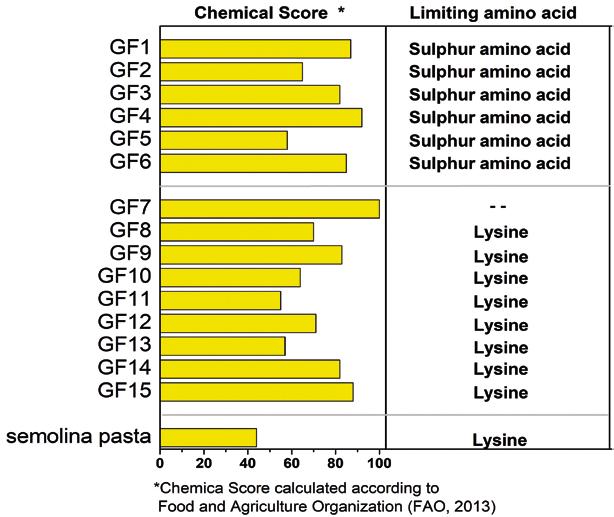

The high variability in protein content as well as in other components is related to the type of ingredients used in the formulation. The biological value of proteins is closely related to their composition in essential amino acids whose quality-quantity profile can be influenced by the raw materials used in formulations. For instance, legume proteins are characterised

by a low content of sulphurcontaining amino acids, whereas cereal proteins are low in lysine. The Chemical Score (CS) is the parameter used to describe the protein quality in terms of their potential ability to provide the appropriate amount of essential amino acids. Proteins with a CI close to or equal to 100 are considered to be better from a nutritional perspective, and therefore able to properly meet human needs. Pasta whose formulation includes legume flour (peas or chickpeas) or 100% buckwheat flour (GF7) achieves higher CS values (Figure 2), significantly higher than that of conventional durum wheat semolina pasta, thus proving a better nutritional quality of the

proteins in the ingredients used for pasta making.

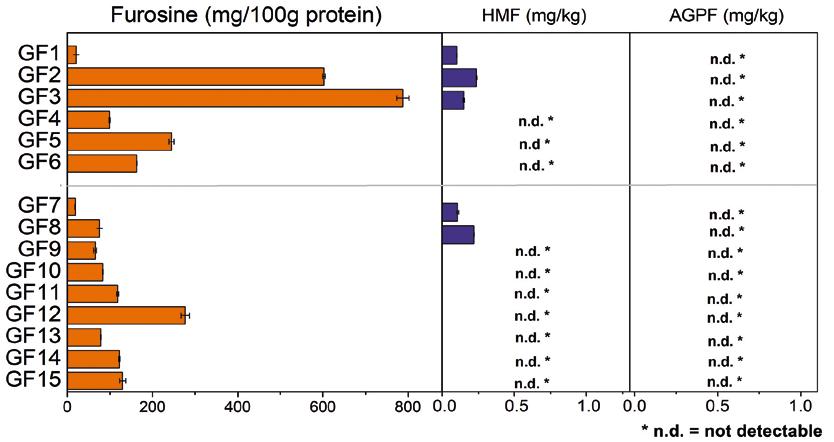

Drying is a fundamental step in the production of (conventional and gluten free) pasta, designed to allow the product to reach a moisture content of less than 12.5% as required by Italian Presidential Decree No. 187 of 09/02/2001. This type of process extends the shelf life of pasta by reducing water activity and inactivating enzymes. The heat applied can cause “heat damage” generally associated with the Maillard reaction, also known as non-enzymatic browning. The course of the Maillard reaction depends on the initial composition of the food matrix, the extent of heat treatment applied, water activity, pH and moisture, and for gluten-free pasta, the use of different technologies should also be considered. As a matter of fact, compared to traditional pasta production, the process can be modified according to the different raw materials used in order to help the creation of a suitable structure for a good product after cooking. The Maillard reaction occurs when the reducing sugars and amino groups of free amino acids and

proteins interact. Among all amino acids, Lysine is the most susceptible to the reaction, and when interacting with sugars it is irreversibly blocked in the Amadori compound. The Amadori compound can be indirectly evaluated through the formation of the ε-N-2furoylmethyl-L-lysine (furosine), an unnatural amino acid formed with the acid hydrolysis of the Amadori compound. Together with furosine, other indicators of the Maillard reaction should also be considered, such as hydroxymethylfurfural (HMF) and glucosyl isomaltol (AGPF) which are formed in the second step of the reaction, after the decomposition of the Amadori compound.

The furosine value of semolina pasta has been demonstrated to be influenced by drying cycles (Cuomo et al., 2023). Furosine levels can vary from 45 to 200 mg/100 g protein for pasta made with a combination of low temperature and long time, to values from 400 to 600 mg/100 g protein and more for combinations of high temperature and short time. Generally, short pasta made from 100% semolina is characterized by lower furosine values (< 200 mg/100 g protein) compared to long pasta due to the different effects of drying cycles applied on the different shapes (Giannetti et al., 2014). The furosine average value in the hydrolysate of the tested pasta was about 192 mg/100 g protein, with a range varying between 18.9 and 787.6 mg/100g protein, proving the wide variability in both drying conditions and raw

materials as well as the presence of free proteins/amino acids and reducing sugars in such molar rations that they favour the triggering of the Maillard reaction and lead to the formation of the Amadori compound. The analysis of furosine values showed that gluten-free pasta, even when produced using the same type of raw material, can show different levels of thermal damage, reaching furosine values even higher than those found in 100%

semolina pasta (Figure 3). However, there was no evidence of the Maillard reaction progressing in the advanced phase in any of the samples tested; this was confirmed by the values of HMF and AGPF markers that were present in negligible or undetectable amounts in the analytical method used.

Evaluating the quality of glutenfree foods is essential to ensure

that people with coeliac disease can fully meet their needs and to assess the possible changes that products may undergo during production processes. The combination of different, properly selected raw materials helps formulate gluten-free pasta with high biological value proteins (see Cheminal Score). The amino acids and reducing sugars in the flours used for the production of commercial gluten-free pasta are present in such molar ratios that they favour the triggering of the Maillard reaction. The level of furosine, used as marker of the heat treatment intensity, can reach high values (which are also higher than those in pasta made from 100% semolina), whereas the advanced phase markers of the Maillard reaction (hydroxymethylfurfural and glucosyl isomaltol) were present in negligible or undetectable amounts.

Maria Cristina Messia, Francesca Cuomo, Emanuele Marconi

For further information: Messia, M.C., Cuomo, F., Quiquero, M., Verardo, V., Marconi, E. (2023), Assessment of Nutritional Value and Maillard Reaction in Different Gluten-Free Pasta, "Foods" 12(6),1221.

• Cubadda R.E., Carcea M., Marconi E., Trivisonno M.C. (2007), Influence of gluten proteins and drying temperature on the cooking quality of durum wheat pasta, “Cereal Chem.” 84(1), pp. 48-55.

• Cuomo, F., Quiquero, M., Trivisonno, M.C., Angelicola, M., Messia, M.C., Marconi, E. 2023, Mitigation of Maillard reaction in spaghetti by optimization of the drying conditions, “LWT”, 184, art. no. 114990.

• FAO/WHO. 2013, Dietary protein quality evaluation in human nutrition, “FAO Food Nutrition Paper” 92, pp. 1-66.

• Giannetti, V.; Boccacci Mariani, M.; Mannino, P.; Testani, E. (2014), Furosine and

flavour compounds in durum wheat pasta produced under different manufacturing conditions: Multivariate chemometric characterization, “LWT - Food Science and Technology”, 56, pp. 15-20.

• Marti A., Pagani M.A. (2013), What can play the role of gluten in gluten free pasta?, “Trends Food Sci Technol.” 31(1), pp. 63-71.

• Marconi E., Messia M.C. (2012), Pasta made from non traditional raw materials: technological and nutritional aspects, in Durum wheat chemistry and technology, (Eds), AACC St Paul, MN (USA).

• European Regulation (EC) No. 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutrition and health claims made on foods.

With more than 170 project references and offering pasta production technologies with high efficiency in line with the needs of production facilities, Italian AXOR provides flexible solutions to maximize the production efficiency of its business partners. With its production lines for different pasta cuts, turnkey projects and engineering solutions, AXOR analyses the needs of producers and offers the most efficient plan for them.

Pasta production facilities can produce pasta with different shapes and ingredients based on different types of raw materials. At this point, analysing the needs

plays a critical role in the complete planning of production lines and processes. In its R&D center, AXOR is able to perform quality control tests for the specific needs of pasta producers and thus offer the most efficient plan for producers.

Thanks to the consultancy offered by AXOR for project designs, pasta producers can minimize cost and time losses in their investments and achieve successful results in their projects. AXOR enables pasta producers to use their capital in the most efficient way by providing a project plan that provides cost advantage and efficiency to optimize the processes in existing or to be established factories.

AXOR offers full line services in line with the needs of pasta producers with its specialized engineering. Offering flexible engineering solutions for all processes from automation to process control in pasta production facilities, AXOR can make the production processes of enterprises efficient.

AXOR serves as a solution partner in the turnkey projects of pasta producers. Providing services from the construction of production facilities to the preparation of automation systems with more than 170 project references worldwide, tailor-made solutions which provided by AXOR, prevent problems and time losses that pasta producers may encounter in producers’ new investments.

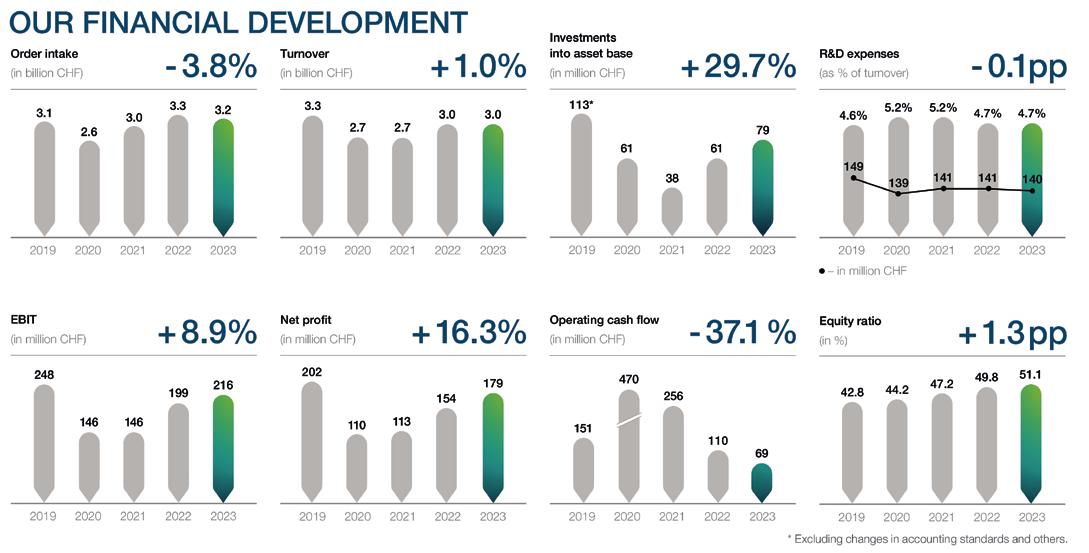

At Group level and in Swiss Francs, Bühler performed well with a slightly increased turnover of CHF 3.0 billion (+1.0%). Order intake was CHF 3.2 billion (-3.8%) and the order book remained high at CHF 2.0 billion. EBIT rose by 8.9% to CHF 216 million with a corresponding EBIT margin of 7.2% (prior year: 6.7%). Net profit increased by 16.3% to CHF 179 million (prior year: CHF 154 million), corresponding with a margin of 5.9% (prior year: 5.2%). The impact of foreign exchange rates was significant. In local currencies, orders improved by 2% to CHF 3.3 billion, turnover by 7% to CHF 3.2 billion, and EBIT by

17% to CHF 233 million. In 2023, Bühler continued to strengthen its financial position, increasing the equity ratio to 51.1% (prior year: 49.8%).

Advanced Materials experienced another strong year

In 2023, the Advanced Materials business continued its success. Whereas turnover grew strongly by 15.9% to CHF 778 million, order intake fell by 11.2% to CHF 774 million, indicating that business volumes were normalizing. In local currencies, turnover increased by 22.9%, while order intake reduced by 5.3%. With these results, the Advanced Materials business confirmed that it is in an upswing

mode after a particularly strong order intake in 2022, driven by transformation in its industries. This enabled it to reach a record high turnover in 2023. The Die Casting business area experienced significant growth reflecting the burgeoning demand for structural components for car bodies, including battery cases for electric vehicles, as well as for advanced megacasting solutions such as the new Carat 840 and 920 series. The Leybold Optics business area gained significantly from glass coaters for architectural applications and for car glass, from capacitors for e-mobility, grid applications, and the ongoing strong market trends in photonics and semiconductors.

Grains & Food performance driven by food security

In a challenging business environment, Grains & Food performed solidly. Turnover fell by 3.1% to CHF 2,204 million, while order intake was down 0.7% to CHF 2,357 million. In local currencies, turnover increased by 2.2% and order intake grew by 4.8%. The global demand to improve food security was a key driver for the Milling Solutions and Grain Quality & Supply business areas. While the challenging economic situation in China worked as a damper in most areas, especially in the Value Nutrition business, Grain Quality & Supply secured several larger orders for ship unloaders as a result of governmental efforts to improve food security. Milling Solutions, the largest business area of Bühler, benefited from a global catch-up demand for large milling

projects for grain processing, including numerous greenfield installations. Projects were awarded to Bühler from all over the world - United States, Saudi Arabia, Venezuela, Europe, Africa, and Southeast Asia, among others. Turnover growth was remarkable in the Chocolate & Coffee business area, and the Consumer Foods business area continued to recover both in volumes and profitability.

Services have become even more important for customers

Services continued to be a key strategic pillar in 2023, as they are the fastest lever to improve the productivity and consequently also the sustainability of Bühler customers’ operations, by minimizing energy, waste, and water. Bühler’s Customer Service business grew by 1.2% amounting to CHF 966 million, representing a 32% share of Group turnover.

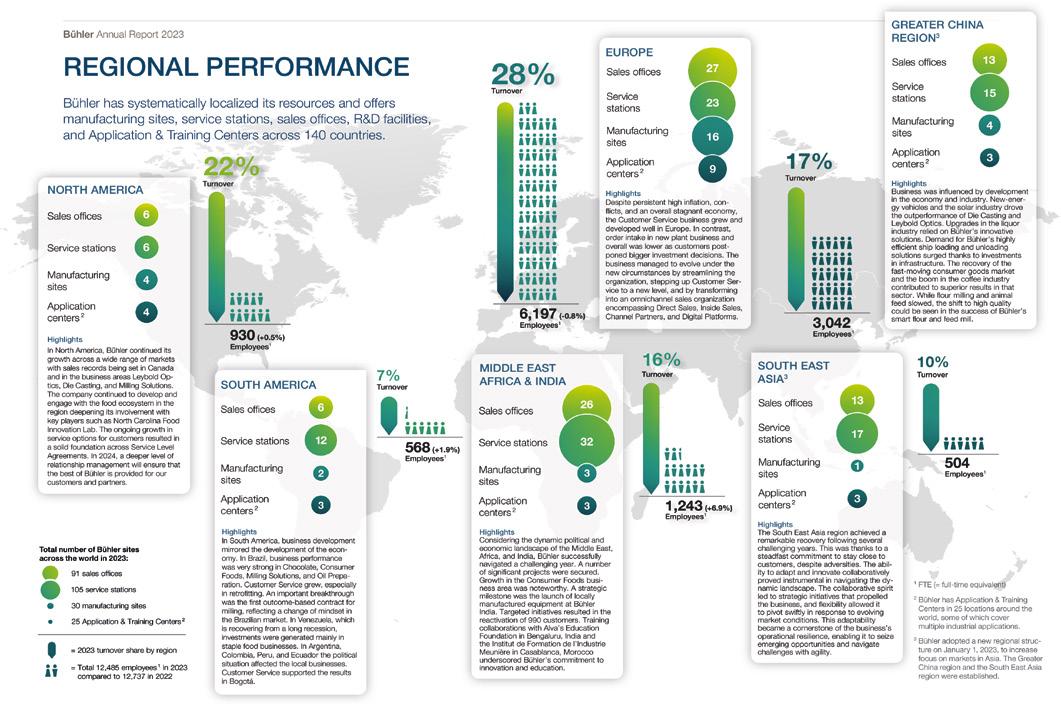

Balanced global business footprint

While the economic environment differed strongly across key markets, Bühler’s balanced geographical footprint allowed the company to benefit from market expansions and thus offset

lower business volumes in other markets. The most notable developments were strong turnover growth in the Americas and significantly lower turnover volumes in China. Overall, Bühler’s regional share of turnover was as follows: Americas 29%, Europe 28%, Asia 27%, Middle East Africa & India 16%.

In 2023, expenses for R&D remained at a high level at CHF 140 million (4.7% of turnover) and around 50 new customer

solutions were launched. “We see profitable growth as a prerequisite for creating positive impact for a better world. This conviction guides our investments in the future development of our company, into innovative products and services, as well as in the development, education, and training of people,” says Stefan Scheiber. In 2023, Bühler focused on the further implementation of its sustainability strategy. The highest impact Bühler can thereby create is with its customer solutions (Scope 3). In this respect, Bühler has committed to having solutions ready to multiply by 2025 that reduce energy, waste, and water by 50% in the value chains of customers. For its own operations (Scopes 1 and 2), it has developed a pathway to achieve a 60% reduction of greenhouse gas emissions by 2030. By the end of 2023, Bühler achieved a reduction of nearly 20% compared to the 2019 baseline.

In 2023, Bühler continued to focus on training and education

of both customers and employees. Customers not only benefited from training at different specialist schools on all continents, but also from the broad offering of courses in the 25 Application & Training Centers around the world. With the opening of new locations in Brazil and Switzerland in 2023, Bühler added further to its capability to support its customers along complete value chains, from recipe development to final product development, and industrial scaling. For its nearly 12,500 employees, Bühler built on its programs for development and lifelong learning. These enable its people to adapt and develop the skills needed to keep pace with a quickly changing and increasingly challenging work environment. Part of the concept is the Bühler Energy Center in Uzwil, Switzerland, which was opened in June. It contains three pillars: Health & Lifestyle, focusing on health management; Lifelong Learning, focusing on vocational and adult learning; and Prototyping & Production, focusing on new manufacturing technologies. In 2023, Bühler trained 544 apprentices globally, 293 of whom in Switzerland.

The economic climate in 2024 is still likely to be characterized by continued volatility. Nevertheless, Bühler is well positioned to navigate through dynamic times and to benefit from new opportunities that arise. A carryover of CHF 2.0 billion orders serves as a stable starting position for the business in 2024. Bühler remains committed to its strategic goal of profitable growth, its sustainability targets, and supporting the further development of its customers and employees.

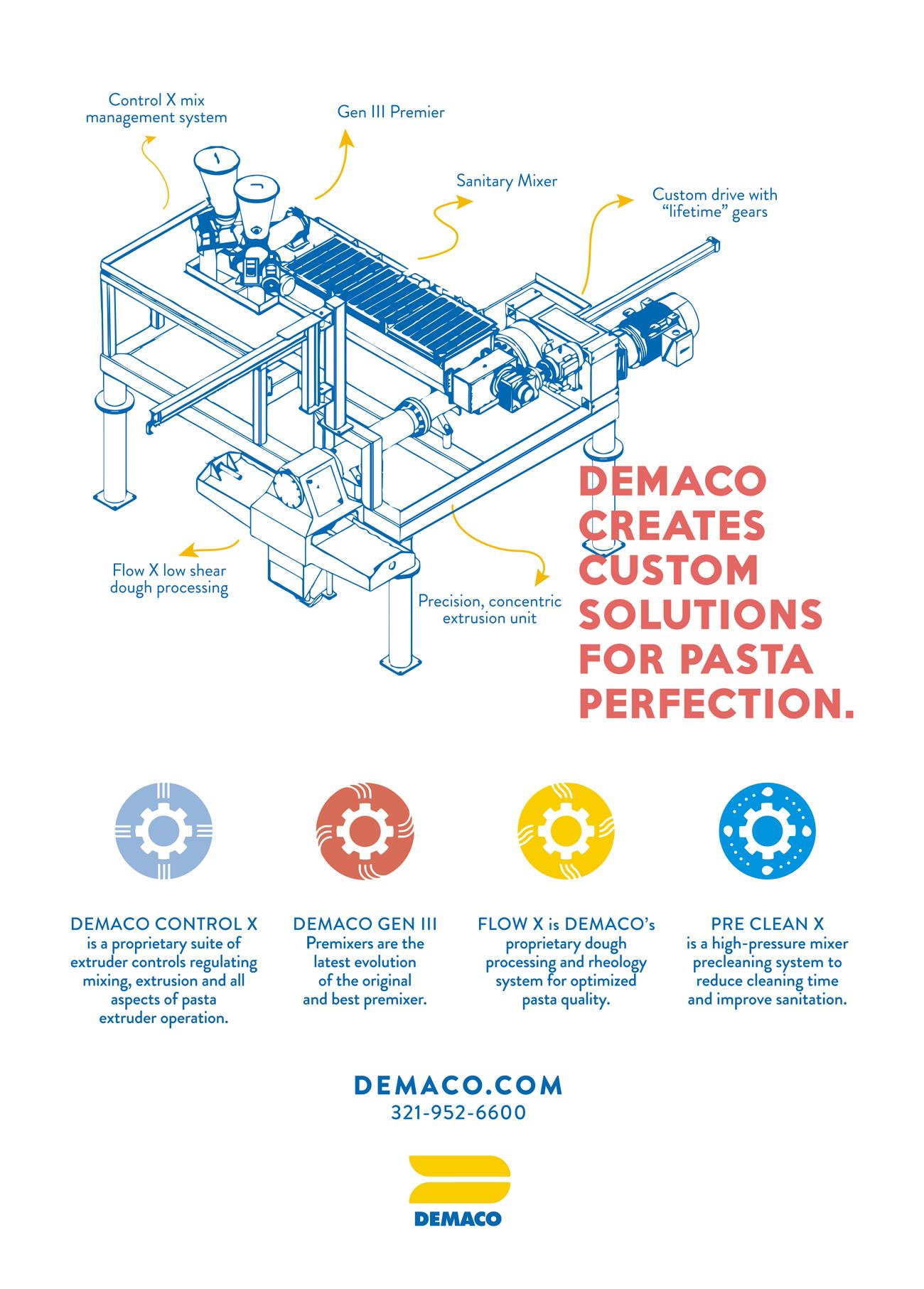

Manufacturing macaroni as golden as the California sun, the Costa Macaroni Manufacturing Company began as the handmade pasta selection in the Costa family’s Italian store.1 2 Hailing from Corleone, Sicily,3 Mariano Costa and his family opened their storefront in the Eastside Italian enclave of Los Angeles, where their advertising tagline was “The House of Quality”.4 5 As the Italian American Museum of Los Angeles states, “Los Angeles’s Italian enclaves, like other Little Italies, functioned as extensions of the mother country and eased the immigrant’s transition to the new land.”6 The family officially trademarked their brand in 1923

due to their pasta’s popularity among local restaurateurs.7 Joseph L. DeFrancisci from DEMACO, who was the general manager for Costa 2000-2001, said Charlie Campo, the plant manager of Costa for many years, focused on quality manufacturing, which built a loyal following. The company grew steadily offering a wider range of products and expanding into additional food service markets, such as hotels, schools, colleges and the military. As Stephen Zoccoli (a fourth-generation member of the Costa family)

recalls, the company weathered the Great Depression in the United States as pasta was a “popular and inexpensive food item.”8 The popular brand still exists today, manufactured by Pasta Montana in Great Falls.

Rosemary DeFrancisci National Pasta Association History Committee / DEMACO

1. Pasta Montana website, “Costa Pasta,” Pasta Montana, n.d., https://pastamontana.com/brands/costapasta#: ~:text=Today%2C%20Pasta%20Montan

a%20continues%20in,exceptional%20high% 20protein%20durum%20wheat.

2. “Costa Macaroni Co. Give Good Bargains”, Lincoln Heights Bulletin-News, Los Angeles, California, volume XVI, number 14 (August 8, 1935), page 1.

3. Pasta Montana website, “Costa Pasta.”

4. Photo Record, n.d., 555-531-17, Italian American Museum of Los Angeles, Los Angeles, California.

https://iamla.pastperfectonline.com/photo/785 3B453-497A-4848-92B9-086323383001.

5. Costa advertisement, Lincoln Height Bulletin, Los Angeles, California, volume VII, number 44 (March 18, 1927), page 1.

6. Italian American Museum of Los Angeles (IAMLA), “History,” IAMLA, n.d., https://www.iamla.org/history/.

7. Pasta Montana website, “Costa Pasta.”

8. Stephen P. Zoccoli, Email Interview with the author, February 23, 2024.