Models Available

A) SPL/65-2-22WLED 4914

B) SPL/65-3-22WLED 6794

C) SPL/65-2-28WLED 5567

D) SPL/65-3-28WLED 8151

Maintenance

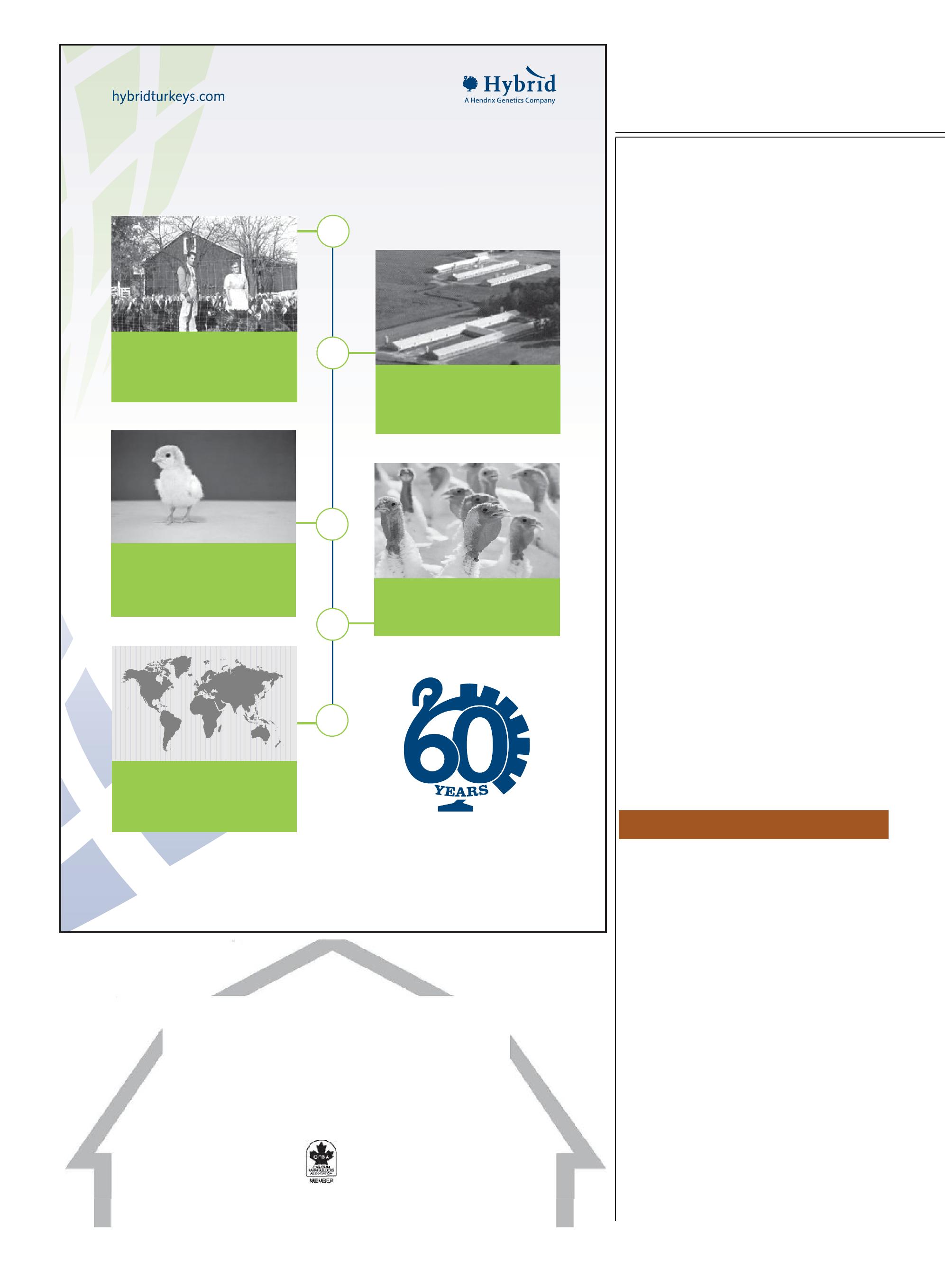

INDUSTRY: Hybrid Turkeys Celebrates 60 Years

An idea six decades ago becomes a major contributor to the poultry industry By

Karen Dallimore

POLICY: Farm Help Is Hard to Find Challenges in finding and retaining qualified workers

By David Manly

RESEARCH: More Than Connecting Dots

forum for research collaboration and co-operation By

Lianne Appleby

INDUSTRY: New PIC Executive Director Named Education and outreach to be a priority By

David Manly

BIOSECURITY: Speaking From Experience Things change when you’ve seen a crisis first-hand By

David Schmidt

BIOSECURITY: Ticket to Ride Can the hiring process prevent biosecurity breaches? By Treena Hein

INDUSTRY: The Future, One Class at a Time Fifty years for the Arbor Acres Production Management School By

Karen Dallimore

BY LIANNE APPLEBY

In 2003, I was looking forward to a visit from my Long Lost Uncle, who lives somewhere on the south part of New Zealand’s north island. I had only ever met him once, when I could barely form a sentence, so the whole thing was much anticipated.

It never happened though.

Not because there was an untimely crisis on his part, or because someone in my immediate family suddenly died or fell ill. It was because the chance of falling ill deterred him from visiting Canada. Yes, that’s right . . . he cancelled the trip because of the SARS outbreak in the Greater Toronto Area.

Sure, I’d heard the media talking about the rising number of cases and the inability to keep the virus contained, but it was still something that couldn’t affect me – until my uncle cancelled his trip. Surely, if someone was missing out on the chance to visit this great country (and me), they must be reasonably concerned about the health risk. My uncle is a smart man, so if he chose to abort his trip, what did that mean for my family – all of us apparently flirting with death an hour away from the epicentre?

You can form your own opinion of how the media covers certain stories, and whether the coverage is warranted or simply the result of a slow news day. Was SARS really as serious as all that? My uncle thought so.

What then when it comes to the current avian influenza outbreaks in China, or Arkansas? Are you following those stories closely? Have you stepped up your on-farm biosecurity in order to protect your birds and your livelihood? Or, like me in 2003, are you thinking that the H blank N blanks always happen somewhere else, so there is no need for alarm?

Farmers, it has to be said, are famous for the “it won’t happen here” attitude.

Someone high up in the federal government once dismissed bovine spongiform encephalopathy as something that “would never happen in Canada,” and we know how that one turned out. When avian influenza hit British Columbia in 2004, poultry producers in other provinces did pay attention, but how many actually changed their daily routines – honestly?

In late May of this year, it was reported that the H7N9 strain of avian influenza seems to develop resistance to Tamiflu, the main flu drug, and is already resistant to the only other classes of flu drugs – the adamantanes. We’re not just talking animal health with these viruses, we’re talking human health too – and that does catch the attention of the media.

Consider this: In the first quarter of 2013, the Greater Toronto Airports Authority saw 1,068,785 international passengers enplaned and deplaned. At the end of 2012, that total was 34,912,029. Those stats are for just one Canadian international airport.

I wonder how many applicable persons actually say “yes” when asked by Border Services if they’ve recently been to a farm or will go to one in Canada? I wonder how many people have said no, and then come to your barn’s open house or simply popped into the same coffee shop as you?

If you think about the human traffic that enters Canada from countries like China, which are experiencing outbreaks of poultry diseases, and those little white lies to the customs officer, the need for proper biosecurity protocols – and for firm compliance – is a no-brainer.

SEPTEMBER 2013 Vol. 100, No. 8

Editor Lianne Appleby – lappleby@annexweb.com 888-599-2228 ext. 266 226-970-1139

Associate Editor David Manly – dmanly@annexweb.com 888-599-2228 ext. 261

Publisher/Sales Manager Marilyn White – mwhite@annexweb.com 519-400-2424 888-599-2228 ext 237 • fax: 888-404-1129

Sales Assistant Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Media Designer Alison Keba

Group Publisher Diane Kleer – dkleer@annexweb.com

President Mike Fredericks – mfredericks@annexweb.com

Mailing Address P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

Return undeliverable Canadian addresses to Circulation dept., P.O. Box 530, Simcoe, ON N3Y 4N5. e-mail: subscribe@canadianpoultrymag.com.

Printed in Canada ISSN 1703-2911

Circulation e-mail: subscribe@canadianpoultrymag.com Tel: 866-790-6070 ext 201 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $30.00 per year (with GST $31.50, with HST/QST $33.90)

GST – #867172652RT0001

USA – 1 Year $ 66.00 USD Foreign – $75.00 per year

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2013 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

[ spek-tak-yuh-ler ] Of the nature of a spectacle; impressive or sensational.

Scan code for details

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Lubing’s all-new Opti GROW Nipple is designed to work in today’s challenging broiler environment. Because the nipple has been optimized for growth, you will be amazed by the first-week performance and explosive bird growth. OptiGROW offers:

Large body and pin

Acid resistant design

Easy triggering for day-old birds

Low mortality

Increased side-action flow

Larger flow range for jumbo birds

Increased weight gains

Improved feed conversions

To find out more about this specktacular new product, please contact your local Lubing Representative.

J. Dean Williamson Ltd.

London, Ontario

Tel: (519) 657.5231

Fax: (519) 657.4092

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

to the site can tour the barns and fields of each farm to get a close up view of what’s happening and learn more about where their food comes from.

TNew farms have been added to www. virtualfarmtours. com, providing a farm experience to customers.

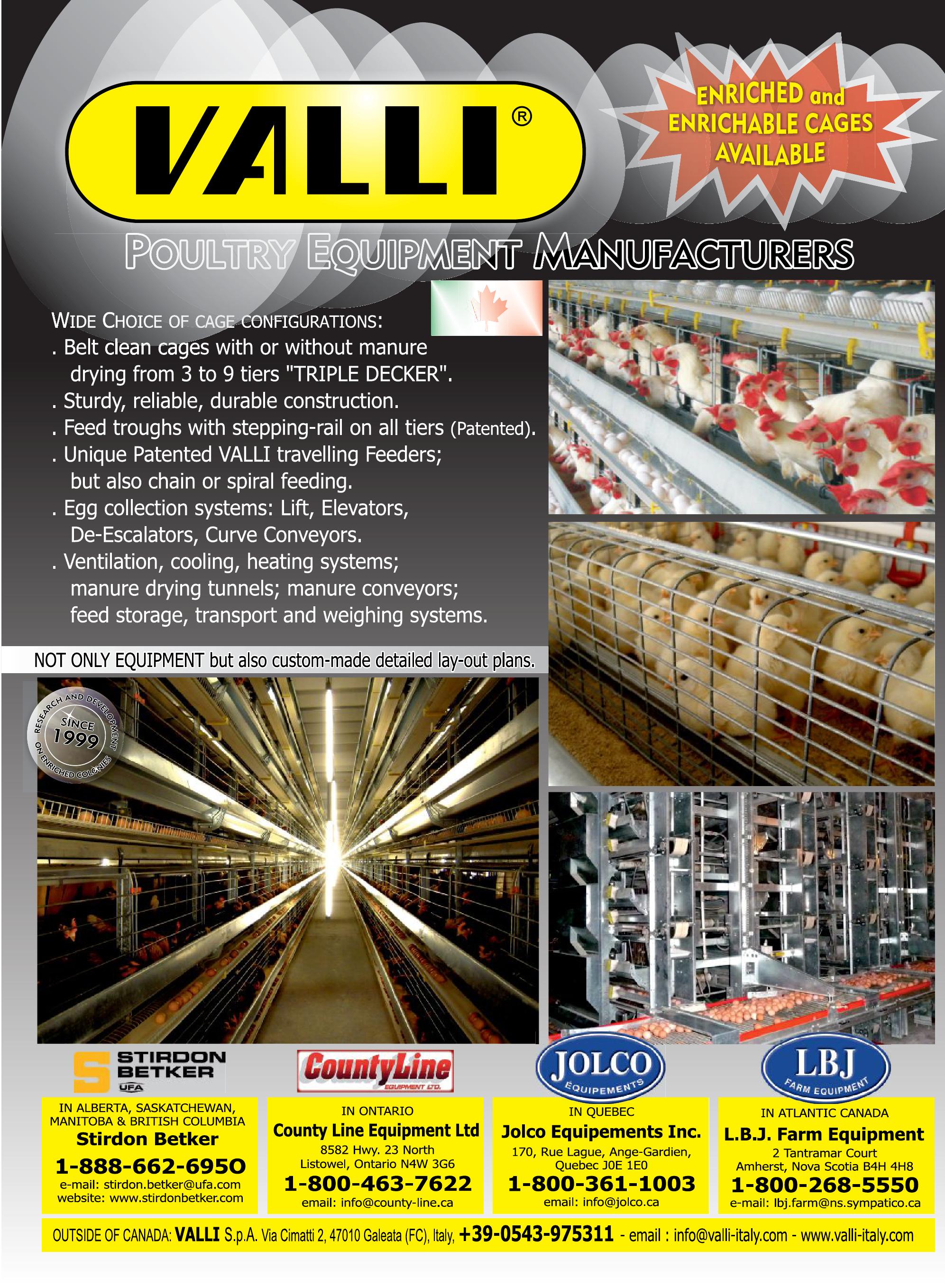

wo new egg farm tours have been added to the popular www.virtualfarmtours.ca website, bringing the total number of Canadian farms available for viewing to 25, including five different egg farm tours.

Filming of the two additional tours – an aviary egg farm and an enriched colony egg farm – was sponsored by Burnbrae Farms Ltd., which also funded costs associated with upgrading the entire virtual farm tour website to make it compatible for mobile tablets and smart phones.

The website, developed and managed by Farm & Food Care Ontario, is designed to offer a farm experience for people who might never otherwise have the chance to visit a real farm. Visitors

The new tours, available in both English and French, complement already-existing tours of conventional, freerun and free-range egg farms. Each focuses on topics that are key to egg farmers – caring for birds, housing options, what the birds eat and drink, reasons behind biosecurity programs, on-farm food safety initiatives and much more.

Video clips are an additional feature that helps introduce viewers to the farmers and capture many unique aspects of farm life.

Margaret Hudson, President of Burnbrae Farms says, “Consumers want to know where their eggs come from - they want to know that they’re safe and that the hens are being well cared for. We’re proud of how our hens are cared for, regardless of the

type of housing system they live in.”

Kelly Daynard, who is Communications Manager for Farm & Food Care Ontario, says that traffic to the site has increased every year since it was first launched in 2006. “We now have about 150,000 visitors annually,” she mentions. A packaged teacher’s guide and CD format of the tour is also available for educators to use in their classrooms.

Other tours on the site show beef and dairy cattle, sheep, deer, elk, pig, veal calves, goat farms, ratites, and chickens, with more planned in the future.

Farm & Food Care was launched in Januiary 2012 from the Ontario Farm Animal Council (OFDAC) and Agricultural Groups Concerned about Resources and the Environment (AGCare).

For more information, visit www.farmfoodcare.org.

on the much larger Canadian agri-food trade with the United States.

The George Morris Centre has released a new commentary, entitled “Canada’s Cross Border Agri-Food Trade: Lost in Translation”, which builds upon recent work with the Cross Border Institute of the University of Windsor on Canada-U.S. agri-food trade and its border crossings.

This commentary contrasts current Canadian public policy focus on major trade agreements and market access with the day-to-day operational challenges and continued border security and numerous agri-food regulatory demands

In 2011, the Poultry Industry Council, University of Guelph and Ontario Ministry of Agriculture, Food and Rural Affairs worked together to create a video entitled “Practical Biosecurity: From Farmers, For Farmers.”

The purpose of this 20-minute DVD was to raise awareness and educate farmers on biosecurity through practical examples and engaging messaging, while avoiding the inherent risks presented by having producers visit other farms.

Through multiple site visits and interviews with a number of farmers and industry

“The daily movements of agri-food products in both directions across numerous border crossings, primarily by truck, involves a much more complex, diverse cross border trade requiring continued investments by private and public sectors in management capacity, technology, infrastructure and constant regulatory reform” notes the author, Bob Seguin, Executive Director of the Centre.

The commentary referemces the ongoing efforts by both levels of national government and industry to undertake

experts, extra footage was collected that could not fit into the final video.

As a result, a series of 20 short clips were created to ensure this useful information was still communicated to the industry.

These videos are featured in the Poultry Industry Council’s “Biosecurity Video of the Month” series, and cover a variety of biosecurity topics ranging from flock monitoring to pest control, barn specific clothing, manure management, and beyond.

The Biosecurity Videos of the Month can be accessed from the Poultry Industry Council website (http:// www.poultryindustrycouncil. ca/2012/06/04/biosecurityvideo-of-the-month/), and are also sent out via a monthly email.

If interested in receiving the monthly alert, please

major regulatory initiatives –such as Beyond the Border and the Regulatory Cooperation Council – to assist in improving cross border flows across all sectors. The report concludes on the need to maintain momentum on these joint Canada-U.S. initiatives, build upon successful pilots and widen the application across all segments of the Canadian, and the US, agri-food sectors, while continuing to invest in management capacity, technology and needed infrastructure.

The George Morris Centre is a not-for-profit economic research institute that is focused exclusively on the agriculture and food industry. The report can be found at www.georgemorris.org.

SEPTEMBER

September 10-12, 2013

Canada’s Outdoor Farm Show, Canada’s Outdoor Park, Woodstock, Ont. For more information, visit: www.outdoorfarmshow.com

September 17-19, 2013 Poultry Welfare Auditor Course (PAACO) Quality Hotel & Suites, Woodstock, Ont.

For more information, visit: http://www.animalauditor. org/events/

September 17-21, 2013 2013 International Plowing Match and Rural Expo, NULANDIA Dairy Farm, Perth County, Ont. For more information, visit: http://www.ipm2013.org/ index.html

OCTOBER

email Laura Bowers, PIC’s Education Programs Manager at lbowers@poultryindustrycouncil.ca.

The full Practical Biosecurity: From Farmers, For Farmers video can also be viewed from the PIC website (http://www.poultryindustrycouncil.ca/education2/biosecurity/videos/).

In addition to the Biosecurity Video of the Month series, extra information collected through the Practical Biosecurity video project was also incorporated into five factsheets.

These cover the topics of access management, cleaning, disinfecting, flock health and pest control, and are available on PIC’s website (http:// www.poultryindustrycouncil. ca/2012/06/04/biosecurityfactsheets/) along with other biosecurity factsheets and resources.

October 1-3, 2013 XXXVIII Poultry Service Industry Workshop, The Banff Centre, Banff, Alta. For more information, visit: www.poultryworkshop. com/index.php

NOVEMBER

November 7-8, 2013 Poultry Innovation Conference, Best Western Lamplighter Inn, London, Ont. For more information visit: www.poultryindustrycouncil.ca/training-andevents/innovations-conference

November 20, 2013 Rendez-vous Avicole AQINAC 2013, Best Western Plus Hotel Universal (Drummondville), Que. For more information, visit: www.rv-aqinac.com

Anew report from the U.S. Centers for Disease Control says an investigation into a bout of foodborne illnesses in Alberta points to Salmonella-contaminated eggs from a lunch truck as the source of the outbreak.

The incident, in late 2010 and early 2011, resulted in 91 confirmed Salmonella enteritidis infections in Alberta,

most of which were in Calgary. The investigators do not list the name of the catering company that sold food through the truck, but they say it bought eggs from an illegal supplier.

The caterer was prosecuted for breaching Alberta public health legislation and the illegal egg supplier was eventually fined and jailed for 14 days.

Maple Leaf Foods has entered into definitive agreements to sell its commercial turkey farms to Ernald Enterprises Limited and its breeder farms and hatchery operation to Cuddy Farms Limited.

Maple Leaf’s turkey growing operations employ more than 100 employees in southern Ontario in a hatchery and six breeder farms that supply turkey eggs and poults to domestic and international markets. It also includes six commercial farms that supply market-ready live birds to Maple Leaf’s turkey processing

facility in Thamesford, Ont. The terms of the transaction include a long-term supply of live birds to Maple Leaf from Ernald Enterprises, as well as that the vast majority of employees will transition to Ernald Enterprises and Cuddy Farms once the transactions are completed.

“Divesting our turkey growing operations will allow us to focus on, and direct capital to, growth and innovation in our valued added turkey processing business,” says Michael H. McCain, President and CEO, Maple Leaf Foods.

JANUARY 2014

January 28-30, 2014

International Production and Processing Expo (IPPE) 2014, Georgia World Congress Center, Atlanta, Ga. For more information, visit: www.ippe14.org

MARCH 2014

March 19-20, 2014

Midwest Poultry Convention, Sain Paul RiverCentre, Saint Paul, Minn. For more information, visit: http://midwestpoultry.com/

APRIL 2014

April 9-10, 2014

London Poultry Show, Progress Building, Western Fair District, London, Ont. For more information, visit: www.westernfairdistrict. com

OCTOBER 2014

XXXIX Poultry Service Industry Workshop, The Banff Centre, Banff, Atla. For more information, visit: www.poultryworkshop. com/index.php

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5; e-mail lappleby@ annexweb.com; or fax 519429-3094. Please write ‘Event Submission’ in the subject line.

Research activities under the first Canadian Poultry Science Cluster officially ended March 31, 2013. Below is a quick overview of the scope of the Cluster project with highlights of its outcomes. For more details, search for “Cluster” on our website, www.cp-rc.ca, or please feel free to contact us directly.

The term “cluster” is used to describe an approach to science that encourages researchers to work together to reach common goals. Specifically, the Poultry Science Cluster was formed to address a number of research goals identified by the industry and the research within that spanned the “innovation continuum” from basic discovery to practical application. It encompassed 10 core activities involving 21 principal scientists at seven university and government research institutions across the country. This research contributed to training and professional development of over 40 students, postdoctoral fellows and visiting scientists. Technical information resulting from this research has been shared with the research community through peer-reviewed publications and scientific meetings, and practical information has been shared with industry stakeholders. A number of patent applications and invention disclosures are a direct result of activities within the Cluster.

Here are a few highlights of the results from this work:

• A new understanding of the biology of C. perfringens, a bacterium associated with necrotic enteritis (NE) in poultry. In order to cause NE, a C. perfringens, strain must have a specific genetic makeup that includes certain genes in its chromosomes and others found on plasmids that can be passed from one bacterium to another.

Strains of C. perfringens that have acquired the right set of genes have a competitive advantage

in the gut and, when conditions are right, are primed to cause disease.

• Progress towards an improved vaccine against Salmonella enteritidis, the design and delivery of which is hoped to simultaneously reduce colonization in the gut of laying hens and prevent spreading infection throughout a flock and potentially on to consumers.

• Demonstration that plant-based essential oils can be used to fight bacterial infections in poultry. Research has shown that encapsulated oils were able to protect birds from NE just as well as dietary antibiotics.

• A new understanding of how avian influenza (AI) virus adapts to and causes disease in modern poultry, including identification of a genetic determinant that “switches” AI virus from low to high pathogenicity.

• Demonstration that airborne transmission could play a role in the spread of AI infection, and that only a very small amount of virus is needed to transmit the disease by indirect contact.

• New information on the bird’s immune reaction to AI infection.

• A prototype virosome-based vaccine that elicits broad immune responses thought to be necessary for adequate protection from AI infection.

• Demonstration that specific compounds (adjuvants) can be combined with the virosome vaccine to further improve immune responses.

• Development of a vaccine vector system (based on a virulent fowl adenovirus) that can be engineered to carry genes coding for specific antigens, and

demonstration that it can be used elicit appropriate immune responses upon in ovo (in the egg) injection.

• Progress towards development of a turkey adenovirus-based vector system.

• Development of a DNA-based vaccine that, using a specific administration route, can protect poultry from a highly pathogenic AI virus.

• Demonstration that inclusion of a vitamin D precursor (HyD) in turkey diets, particularly early in life, has beneficial effects on meat yield and early immune function. The study suggests that industry-recommended HyD levels can be reduced by as much as 50 per cent after six weeks of age without loss of benefit, thereby reducing production costs.

• Confirmation that diets containing fibre supplements and/ or appetite suppressants may be a viable solution to prevent chronic hunger in feed-restricted broiler breeders.

• Demonstration that toe trimming represents a potential welfare improvement for female turkeys, but the practice may not be beneficial for males.

While the Cluster is officially complete, research projects related to many of its initiatives are ongoing and moving to “next steps.” We’ll keep you posted on future progress.

For more details on these or any other CPRC activities, please contact The Canadian Poultry Research Council, 350 Sparks Street, Suite 1007, Ottawa, Ont., K1R 7S8, phone: 613-566-5916, fax: 613241-5999, e-mail: info@cp-rc.ca, or visit us at www.cp-rc.ca.

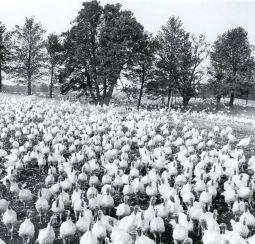

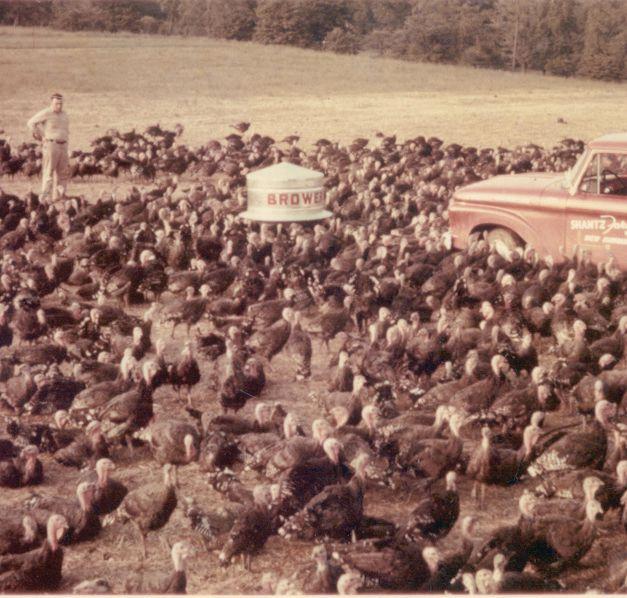

BY KAREN DALLIMORE

It was 1953, sixty years ago, when Earl Habel and Milo Shantz began raising turkeys in New Hamburg, Ont. That was when Queen Elizabeth II was crowned, Sir Edmund Hillary climbed Mount Everest, bread cost 16 cents a loaf and a gallon of milk was 94 cents.

By 1957 the farm had incorporated as Shantz Turkeys Ltd. In 1958, Earl Habel started his own growing business, leaving Milo, his brother Ross and their father, Irvine, running the family operation. In 1966, Ralston Purina purchased the turkey breeding, growing and processing enterprise that by then consisted of three companies: Three Star Farms, Shantz Processing and Shantz Hatchery.

Hybrid Turkeys was a name that emerged in 1970 when the Shantz brothers bought back the breeding and growing enterprises. Ralston Purina retained the processing part of that turkey business which had been trading as Checkerboard Farms.

Ross Shantz, now 74, recalls the early days of the business, before further processing was introduced.

“Hybrid Turkeys entered into primary breeding and commercial growing of broiler type turkeys, as it was known at that time, seeing a consumer need when a local processor saw a market for yearround production of a five- to ten-pound table-ready whole bird.”

They needed to build a new turkey, but the genetics they needed for a smaller

white bird with superior conformation that could be produced year-round were not available at that time.

Over the next 20 years, Hybrid Turkeys grew to be among the top three breeding companies in the world.

In 1981, Hybrid was sold to Euribrid, but the familiar Hybrid name continued. By the late 1980s Hybrid had become a major global player in turkey genetics with farms in Brazil and Hungary. Ross Shantz remained as president until 1986 and served on the board of directors until 1991.

Milo Shantz reached out beyond the turkey industry to actively promote the business community in St. Jacobs, Ont. He was recognized by Wilfrid Laurier University with an honorary doctorate of laws before he passed away in 2009.

In 2007 Hendrix Genetics acquired the animal breeding division of Euribrid, from Nutreco BV, including its related Animal Breeding Research Centre. Today the turkey breeding division is formally known as Hybrid Turkeys, A Hendrix Genetics Company. To most people though, it’s still just Hybrid Turkeys.

In an address to employees at a 60th anniversary celebration held in June 2013, Dave Libertini, managing director of Hybrid Turkeys, predicted that the company’s future will be similar to the past, and will involve following the same strategy of listening to its customers and the market.

“As a survivor and with 60 years of wisdom, we also intend to look for new ways to deliver what the market wants and we will also look to influence the turkey sector so that it can grow and we can all prosper. The turkey business needs leaders and we think we can offer leadership.”

Ross Shantz also believes the secret of the success of Hybrid Turkeys over the last 60 years was listening to consumer market trends, as well as the needs of the company’s direct customers. He gratefully acknowledges the dedicated employees and consulting people they had worked with over the years.

“It is very humbling to see how an idea 60 years ago has turned into a major contributor to the poultry industry in the 21st century,” says Shantz. “Thanks, Hendrix Genetics and Hybrid employees for keeping the dream alive.”

Universal applicator for use with different disinfectants

Efficient use of disinfectant – (min 75% less disinfectant than standard foot baths)

Ultimate solution for indoors & outdoors in all poultry farms, hatcheries and poultry processing premises

Non-splashing of disinfectant solution

Withstands heavy loads

www.atescoindustrialhygiene.com

BY DAVID MANLY

Farm Credit Canada recently noticed a large disparity among full-time agricultural wages across the last seven years, with the majority of wages shifting from less than $12 an hour to between $12 and $19.99 per hour – an average increase of 22 per cent. This is significantly higher than the 15 per cent wage increase across the entire economy, according to Statistics Canada.

“The industry has grown quite a bit, and that has generated a stronger demand for farm labour,” says J. P. (Jean Philippe) Gervais, the chief economist at FCC. “The limited supply of available and qualified workers has resulted in higher wages for employees in the farm sector.”

Higher wages show potential employees that a career is a viable option. However, cautions Gervais, higher wages translate to increased costs for producers and farm businesses.

“But, I would argue that in the long term,” he says, “that if you think of the industry and not your own business, it is actually a good thing that we offer higher wages. It is a sign that the industry is growing.”

In addition to higher wages, the agricultural sector also must deal with an increasingly aging population, urban expansion on farmland and immigration trends. As well, agriculture competes with the oil, gas and mining industries for both skilled and unskilled labour, which

further emphasizes the need to recruit outside the traditional pool of workers.

“We need to reflect positively upon the non-traditional pool of workers that would not necessarily consider working on a farm or in a food business,” says Gervais.

Despite the difficulties, Canadian farmers and agriculture workers still need to build the value of positions. Gervais says that this could help retain and convince other potential workers that your business is a good place to work.

“But we’re not there yet, as an indus-

try,” he adds. “Given the pressure we’re facing on wages and higher labour costs we’ve faced in the past, we’re going to have to move in that direction.”

To help, FCC is encouraging people to speak positively about the industry and the jobs that are available on www. agriculturemorethanever.ca. The website aims to help improve perceptions among the general public about the agriculture industry across Canada.

The reasoning is simple, says Gervais: “When our customers succeed, we succeed. It is as simple as that.”

BY LIANNE APPLEBY

The poultry industry could never be accused of resting on its laurels.

It seems that every day there are new initiatives being undertaken to ensure that poultry producers have access to information, technology and the people who can help their farms remain successful.

Now, you can add one more initiative to the growing list – the University of Guelph’s Poultry Health Research Network (PHRN). Guelph has had a longstanding commitment to animal health, but now, the PHRN aims to further tighten technology transfer and enhance poultry research by creating a network of experts, consisting of poultry researchers and poultry health specialists, who address problems ranging from very basic biological processes to environmental concerns and industry-relevant issues.

Dr. Shayan Sharif is leader of the PHRN, which was established in 2012.

“What we are basically trying to do is to create a network of people, poultry researchers, who can address any sort of problem from basic to a very applied type of research,” he says. “This network is part of an integrated plan within the university and is a priority for both the Ontario Veterinary College and the University of Guelph. We are attempting to solidify the interactions between researchers and departments.”

The network aims to provide a forum for collaboration and co-operation not

Dr. Shayan Sharif is leader of the new Poultry Health Research Network at the University of Guelph.

only among researchers within Guelph, but also between Guelph and other Canadian campuses. It will also, hopefully, reduce duplication where applicable.

While Sharif admits that there are other similar initiatives in Canada, and one in Georgia, he says that Guelph’s is unique because rather than focusing on production, as the name implies, this

one focuses on health. But the idea is that all will complement each other.

The roster for the network currently includes 36 names, each one, says Sharif, being a “poultry health researcher and specialist.” Most participants (who could be approached or volunteer to participate) are from Guelph, with department affiliations varying from pathobiology and animal

Meller offers the “Euro 2012” Enriched Group Housing System for Laying Hens

Integrated into each cage are perches, large nesting area, scratch area, LED lighting and manure drying capabilities.

The Euro 2012 System offers heavy duty manure drives, chain feeding systems, overhead or lift type egg collection and the “Egg-Ease” egg saver system.

“The Cage Specialists” RR#1 Jarvis, Ont. Canada N0A 1J0 For more information call Louis or Chris Bill

Phone (519) 587-2667 Fax (519) 587-2959 E-mail: meller@optionsdsl.ca Website: www.meller.ca

science to food science and mathematics –even engineering.

“Our team member from engineering is looking at the effect of poultry industries on the environment and human health. The computer science department is looking at modelling of poultry diseases, mathematically, but using computer software.”

The consumer studies and geography departments are also looking at the influence of poultry production on livelihoods of people, especially women in developing countries.

“In Africa, for example, women are the ones who look after raising chickens, while men look after raising cattle, and that actually has something to do with their social status,” says Sharif. “So, the researcher’s hypothesis is that by changing the way poultry is raised, you can

[increase] social status.”

Within the network there is also a lot of expertise in vaccine development and diagnostic testing. There are also two industry members, Tim Nelson (Livestock Research Innovation Corporation, LRIC) and Brue Roberts (Canadian Poultry Research Council, CPRC). Both organizations fully endorse the initiative, along with the Poultry Industry Council.

The ultimate goal of research programs within the PHRN is to increase poultry health in Canada by facilitation and provision of means for production of safe, healthy and ethically produced poultry and poultry products. A key component is that the network is trying to strengthen interaction with industry, and that is also a top priority for the initiative.

Sharif says another item that’s high the

to-do list is to create training programs that will help to qualify personnel for specific tasks. Ideally, he sees opportunities for both students and professionals so that they can become qualified via degree or non-degree programs. OVC has already taken steps toward reaching this goal by providing funding to hire a faculty member in avian diseases and health.

“We have managed to justify the hiring of a faculty person, even in this climate of economic downturn,” muses Sharif. “This person will be able to help with promotion, as well as officially being the avian disease specialist.”

Because the initiative is receiving some funding, the OVC will ensure that the network meets its objectives and remains accountable through a quarterly reporting system that goes directly to the Dean of the OVC, Dr. Elizabeth A. Stone. The network is set up similarly to a board. With Sharif as the leader and coordinator, meetings will be called on a fairly regular basis, given the research work and many hats worn by each of its members. Sharif hopes that they can physically get together at least every three to four months.

The network’s first official meet-andgreet, which took place on July 30, was informal, allowing the participants to become more familiar with one another and their respective research. Sharif says he’s also hoping to hold an industry day to showcase the network. This would be an opportunity for industry stakeholders to interact with members and learn more about what they do, and foster and strengthen interactions with industry.

There are no immediate plans to have the PHRN function as an incorporated organization with brick-and-mortar offices, but Sharif says that is a possibility for the future that obviously would require funding and much support from the industry level to ensure it is warranted.

The PHRN now has a website (www. uoguelph.ca/phrn), and a Twitter account will follow, which will highlight network information, news and events.

It is key not to confuse what the PHRN does with organizations like the Poultry Industry Council (PIC), CPRC or LRIC.

The PIC remains very involved in setting poultry research priorities and in developing and delivering programs that put the research results to work for industry more effectively and efficiently. Its board decides what it will and won’t fund.

CPRC’s mission, on the other hand, is to address national marketing boards and processor needs through the creation and implementation of programs for poultry research in Canada – which may also include societal concerns.

Says Tim Nelson, “LRIC’s mandate is to work on behalf of all livestock and poultry in Ontario to deliver a better return on investment for our research dollars. We also take on the administration of research for the various sectors, creating a simplified ‘one-window’ approach to research management from OMAF’s perspective and the research provider’s perspective (University of Guelph).”

Within the university, it also is important not to confuse the PHRN with the pre-existing Poultry Program Team (PPT).

The PPT combines the strengths and resources of Ontario’s poultry industry, the provincial government through OMAFRA and the university itself. Only five people, including Sharif, are a part of that team. The others are Gregoy Bedecarrats, Michele Guerin, Csaba Varga and Al Dam. Sharif says the PHRN is a bigger group who can collaborate and co-operate effectively and efficiently, and while the PPT has similar goals, it does have limited scope and mandate, given the narrower expertise.

“PPT will not necessarily phase out. At the time it was formed, it was an important initiative. The PHRN will envelope the PPT and I see it as a very well cemented nucleus to the larger group.”

Right now, Sharif says that as the coordinator, he is spearheading the PHRN, but that doesn’t mean that his research priorities are overshadowed.

“As a part of our vision, there is the provision for funds for an NSERC (National Sciences and Engineering Research Council) industrial chair in poultry health,” says Sharif. “And if that does

take place, then the incumbent would take over direction of the whole initiative. They would then have a lot of administrative responsibility and would likely be relieved of some other duties in order to focus more attention to the PHRN. We will likely talk to the four marketing boards about helping to fund this as well.”

Sharif says the PHRN also helps to fulfil the expectations of the new Animal Health Lab and Pathobiology building where his office is situated.

“We’re sitting in a 2 ½-year-old building that was built with $70-75 million of taxpayers’ money – money that came to the university based on the premise that we would be enhancing our diagnostic capacities and animal health research related capacities. I don’t think that there is another facility like this anywhere in North America. We have the critical mass. We have the momentum and the PHRN will help us to maintain that forward impetus.”

PHRN members have expertise in:

• diseases of poultry (diagnostics, mechanisms, prevention, treatment, modelling and epidemiology)

• poultry production, nutrition, welfare and economics

• public health and environmental impacts of poultry production

Current Members

• Dr. Agnes Agunos, Public Health Agency of Canada

• Dr. John Barta, Pathobiology

• Dr. Gregoy Bedecarrats, Animal and Poultry Science

• Dr. Andrew Bendall, Molecular and Cellular Biology

• Dr. Patrick Boerlin, Pathobiology

• Dr. Martina Brash, Pathobiology

• Dr. Hugh Cai, Animal Health Laboratory

• Dr. Sylvain Charlebois, Management and Economics

• Mr. Al Dam, Ontario Ministry of Agriculture and Food

• Dr. Rob Deardon, Mathematics and Statistics

• Dr. Joshua Gong, Agriculture and Agri-Food Canada

• Dr. Michele Guerin, Population Medicine

• Dr. Mansel Griffiths, Food Science

• Dr. Alice Hovorka, Geography

• Dr. Robert Jacobs, Pathobiology

• Dr. Gordon Kirby, Biomedical Science

• Dr. Steven Leeson, Animal and Poultry Science

• Dr. Emily Martin, Animal Health Laboratory

• Dr. Eva Nagy, Pathobiology

• Mr. Tim Nelson, Livestock Research Innovation Corporation

• Dr. Davor Ojkic, Animal Health Laboratory

• Dr. John Prescott, Pathobiology

• Mr. Keith Robbins, PIC Executive Director

• Dr. Bruce Roberts, Canadian Poultry Research Council

• Dr. Jan Sargeant, Centre for Public Health and Zoonoses

• Dr. Shayan Sharif, Pathobiology

• Dr. Durda Slavic, Animal Health Laboratory

• Dr. Dale Smith, Pathobiology

• Dr. Trevor Smith, Animal and Poultry Science

• Dr. Deborah Stacey, Computer Science

• Dr. James Squires, Animal and Poultry Science

• Dr. Patricia Turner, Pathobiology

• Dr. Bill Van Heyst, School of Engineering

• Dr. Csaba Varga, OMAFRA

• Dr. Qi Wang, Agriculture & AgriFood Canada

• Dr. Keith Warriner, Food Science

• Dr. Tina Widowski, Animal and Poultry Science

SPENT FOWL IMPORTS THREATEN YOUR FARM AND YOUR INDUSTRY

THEY TAKE AWAY YOUR PRODUCTION OPPORTUNITIES AND COST THE INDUSTRY MILLIONS OF DOLLARS!

Whereas chicken is subject to import controls, spent fowl isn’t. In 2012, Canada imported 106 million kilograms of spent fowl from the U.S.: that’s a displacement of over 10% of you and your fellow farmer’s production to the tune of $591 million dollars and 8,900 jobs.

THE THREAT OF SPENT FOWL IS GROWING!

Imports have increased more than 50% over the past three years. Based on first quarter statistics, Canada’s imports of spent fowl will reach 120 million kilograms in 2013; equivalent to 109% of all the spent fowl processed in the U.S.

CONSUMERS AREN’T GETTING THE CHICKEN THEY WANT!

There’s no consumer labeling requirement for the sale of spent fowl: though imported as such, it can be sold as fresh broiler chicken. This is misleading to consumers who expect to buy fresh, local, Canadian chicken from your farm: 74% of Canadians want spent fowl to be clearly labeled.

BY DAVID MANLY

With Tim Nelson, the former executive director of the Poultry Industry Council (PIC) of Canada having left to become the CEO of the newly formed Livestock Research Innovation Corporation, a suitable (and worthy) replacement needed to be found.

And according to Dr. Helen Anne Hudson, the PIC chair, the ideal candidate was Keith Robbins, a 19-year veteran and division manager of Ontario Pork. “After an extensive review of several highly qualified candidates,” says Hudson, “the PIC board determined that Keith’s abilities and expertise best suited our needs as we move forward.”

Starting Aug. 1, 2013, Robbins became the new executive director of the PIC and is already eagerly looking forward to the challenge of working in a new agriculture sector and creating worthwhile programs for poultry growers. But Robbins is aware that there will be a steep learning curve.

“[My] first few months will primarily be spent looking at the programs and assessing an inventory of skills and programs, as well as what types of opportunities and educational materials are available through PIC,” he says.

Through that, Robbins hopes to understand how growers produce, and the various production systems that

Keith Robbins, a 19-year veteran and division manager at Ontario Pork, is the new executive director of the Poultry Industry Council.

farmers have in place, as well as the programs used and how they can be delivered in the most cost-effective way.

From his experiences with Ontario Pork, Robbins wants to focus on learning about the business and production side of the PIC and the Canadian poultry industry, but also on education and outreach.

Therefore, during his first few months in his new position, Robbins hopes to introduce a client and customer satisfac-

tion survey in order to determine what the PIC should continue to do, and what it should cancel.

“It is important to understand from the stakeholders and membership – what products and services they are looking for from the PIC,” he adds.

The next step will be for the PIC executive to make a plan that will “identify the key foundation areas that the PIC has been involved in, such as education and extension, but also research and

research co-ordination.”

Following that, he hopes to expand the various opportunities of the PIC, including more collaborations on events with organizations and sponsors, co-moderating seminars and more. “The goal is to consistently deliver high-quality programs to both members and producers,” says Robbins.

At Ontario Pork, Robbins created print and video programs for educational use, in addition to others used within the agriculture and trade industries. Eventually, he rose to become the director of communications and consumer marketing, followed by the division manager for communications, consumer marketing, research and more.

Robbins sees that the PIC has a significant role to play in education and extension across Canada by helping to fund and promote various research and education programs that benefit its members, clients and the general public.

“But the only way to guarantee success is to meet with players across the industry and encourage them to work collaboratively,” he says. “There are lots of opportunities to work together, but they just need to be identified.”

The biggest hurdle that Robbins sees as the new executive director of the PIC will be maintaining a steady level of funding so that existing programs can continue and new ones can be introduced.

But according to Robbins, the most important part of the organization is to continue to serve the growers and industry partners in the best way possible through constant communication and feedback. “We need to assess the best ways and do that,” he adds.

“We need to stay relevant to the growers, and make sure that the programs being offered are what they need when they need it.”

Ray Nickel shares his thoughts on biosecurity, having experienced “trauma” firsthand

BY DAVID SCHMIDT

Unlike the rest of the country, where adoption of biosecurity protocols is voluntary, British Columbia’s poultry biosecurity program is mandatory for all commercial table egg, hatching egg, chicken and turkey producers in the province.

B.C.’s four poultry marketing boards and commissions used their regulatory authority to make the industry-developed biosecurity program mandatory, but received little negative reaction because producers were keenly aware of the economic and mental devastation caused by the avian influenza (AI) outbreak in the Fraser Valley in 2004. That outbreak shut down an entire industry and led to the depopulation of about 18 million birds.

“People don’t often do anything unless they’ve experienced trauma. We experienced trauma,” says B.C. Poultry Association president, Ray Nickel.

A chicken, turkey and egg producer with multiple farms, Nickel felt the trauma personally as his layer farm was one of the infected flocks. Although the farm was outside the five-kilometre zone established around the initial infected farm, “we were in line with the wind currents.”

At the time, it was believed the AI virus was too heavy to be airborne, but Nickel’s experience suggested that it could move with the wind. The 2004 situation was exacerbated by a complete lack of biosecurity protocols: few farms had gates,

ID

In B.C., each building that houses poultry has an identification number. PREMISES

workers wore no special clothing, there were no visitor logs, no protocols for service staff and few restrictions on human and vehicle movement among farms.

Although it took only “a few days” to depopulate the 60,000 birds in Nickel’s barn, it took two crews working full time a month to do the cleaning and disinfecting (C&D) the Canadian Food Inspection

Agency, required.

“The C&D for my barn alone cost about $180,000,” he says. “We could have done it cheaper but that would have taken much longer.”

Since the industry could not restart until all the infected barns had been cleaned and disinfected, “much longer” was not an option. To ensure the C&D

was done at full speed, industry picked up the C&D costs for the infected barns (including Nickel’s).

For Nickel, the C&D was complicated by the fact that his 1960s-era barn used a post-and-beam design with raised floors.

“We have changed the way we plan, build and retool our barns based on what happened in 2004,” he says, noting it took “less than a week” to hot wash his new 30,000-bird layer barn.

In what has become common practice in B.C., Nickel now uses a manure belt system with exterior manure storage in his layer barns (which makes cleaning easier) and cleans all his short-cycle barns, both broilers and turkeys, after every cycle.

One of the greatest benefits of B.C.’s mandatory biosecurity program is that it ensures that “everyone’s doing the same thing.” Important elements include managing access points (gates or other methods to limit site entry and anterooms at entries to bird holding areas), tracking (each building housing poultry has an identification number and each individual bird holding area within that barn has a subsidiary number) and surveillance (all farms except broilers are sampled regularly).

The IDs are linked to a database, which includes complete contact information for each premise and can be accessed by any of the marketing boards, the B.C. Ministry of Agriculture (BCMA) and/or the CFIA. The BCMA animal health centre in Abbotsford has also been upgraded since 2004 and is now one of only two laboratories in Canada accredited as a full-service (Level 3) veterinary diagnostic lab. If a disease is suspected, it can be typed very quickly so that officials quickly know what they’re dealing with.

On Nickel’s own farms, his biosecurity measures include wearing separate boots and coveralls or smocks in each barn and limiting staff travel between farms.

In addition to developing biosecurity protocols for their farms, producers developed protocols for the feed companies, equipment dealers, catching crews and other service sectors. Since

marketing boards have no enforcement authority over allied trades, it is up to producers to ensure the protocols are being followed. While initially reluctant, the allied trades have become much more compliant in recent years.

As an example, catching crews are much more vigilant because they “don’t

want to be affected,” Nickel says, noting several crews went out of business as a result of the 2004 outbreak.

To make the program work, producers have agreed to open disclosure within the industry. “If you don’t have that, you’re operating in darkness,” Nickel stresses, “you can’t have confidentiality

if you have a disease threat which could affect the entire industry.”

As well, an emergency protocol and an incident command structure have been developed, with three people, including both producers and marketing board staff, available round-the-clock.

Although it was formed as a response to the AI outbreak, the structure is being used to manage outbreaks of federally and provincially reportable diseases, in addition to even non-reportable diseases. Although group members may change, whoever is atop the command structure at the time of an outbreak takes control, regardless of where it occurs. If the lead is a chicken board staff member, he or she is in charge even if the outbreak occurred in turkeys or table eggs and affects only that sector.

As soon as an outbreak is identified, the entire industry is immediately notified not only of the disease but exactly where it is. Nickel recently had an infectious

laryngotracheitis (ILT) outbreak in one of his broiler flocks. Because his is a double barn with two floors in each barn and each floor has a separate ID number, he was able to specify exactly which of the four flocks was infected.

“Since the other three flocks tested negative, I was able to ship them as normal,” he notes.

The system has proved its efficacy several times since its inception. For example, when routine surveillance uncovered instances of low path AI on a local duck and goose farm, surrounding farms were immediately alerted and took heightened action to protect their farms. As a result, the industry carried on without little or no interruption.

When a case of low-path AI was detected at a turkey farm in 2009, almost no one outside the industry was even aware of it. All farms within the three-kilometre zone were immediately tested and the appropri-

ate permits obtained to ensure they could carry on business as usual.

However, unlike the 2004 outbreak, those farms had to absorb the cost of C&D themselves.

“Because we had a system in place, we didn’t have to shut down the entire industry. That took the pressure off to get those farms cleaned up as quickly as possible. Not having to do C&D in a panic also meant the farms could go about it in the most cost-effective way for them,” Nickel says.

Although the marketing boards are actively involved in the program, Nickel stresses producers must not rely on them to manage biosecurity.

“Producers and their associations need to take responsibility for what’s taking place on the ground.”

For more on poultry health, visit www.canadianpo p ultrym y agg.com. www.canadian ultr

“All areas of my production have improved since I started using drySTART®!”

Johnny Heemskerk of Heemskerk Farms Ltd. owns and operates a broiler chicken unit in Norwich Ontario, where he has been farming since 2001. Johnny averages 21,000 per crop and has 5.8 crops per year.

Johnny has been using drySTART® on the floors of his chicken barns since 2011. He was using straw and was finding that it would stick and cake to the floors. After watching the drySTART® information DVD, he decided to give drySTART® drying powder a try. Once he tried it, Johnny said, “The difference was like night and day, the manure did not stick to the floors, which greatly reduced clean-out times and the birds looked a lot healthier and cleaner.”

Johnny uses drySTART® on both concrete and plywood floors. He applies drySTART® followed by a layer of straw. Some things Johnny has to say about the benefits of using drySTART® are: “All areas of my production have improved since I started using drySTART®. My birds are a lot more even and I have less condemns, clean-out times are a fraction of what they used to be and my hydro bill is less because I do not have to use my fans as much to keep the barn dry.”

Johnny has found great success in using drySTART® and looks forward to continuing to see the benefits in his chicken barns.

BY TREENA HEIN

It sounds extreme, but it’s really true. The only thing that could stand between disease on your farm and an industry outbreak is one person. Only one visit to a poultry farm where biosecurity protocols aren’t followed to the letter can lead to industry reputation damage, economic hardship and worse.

Researchers have found that compliance with biosecurity protocols is not always complete, and the reasons for this span from lack of knowledge and comprehension about the how’s and why’s to personality traits and ineffective or absent education programs.

There may also be inadequate physical set-up in the barn that actually impedes producers and their employees from using protocols every time. This usually means a lack of room or space, proper signage, barriers and supplies.

These are the findings of Manon Racicot, Jean-Pierre Vaillancourt and their colleagues, who are leaders in the study of farm biosecurity protocol compliance in Canada.

Racicot is a veterinary epidemiologist working for the Office of Animal Biosecurity within the Canadian Food Inspection Agency, and Vaillancourt is a professor in the Faculty of Veterinary Medicine at the University of Montreal, and director of the university’s Epidemiology of Zoonoses and Public Health research group.

With their colleagues, they have published numerous research papers examining to what extent poultry producers in Quebec, their employees and farm visitors comply with biosecurity measures when entering and exiting poultry barns – and to put it bluntly, they’ve found that it can be very low.

The study used a combination of visible and hidden cameras, as well as audits.

six layer and one breeder farm.

The good news is that they have also unearthed the factors behind why compliance doesn’t occur, and what needs to be put in place for protocols to be carried out correctly each and every time. To do their research, they employed a combination of hidden cameras, visible cameras and frequent audits.

Their most recent studies have been on Quebec farms, covering 15 broiler,

Vaillancourt says he’s found biosecurity compliance to be a bit better on breeder farms than on broiler/layer farms.

“Biosecurity on layer farms is more likely to be better than on broiler farms, because layer farms have the chickens for a longer time and biosecurity is therefore more critical.”

He notes that while 23 farms might seem like a low number and thus not a representative sample, over 2,300 visits

Disinfectant

were measured, which in his mind is a significant sample size.

Vaillancourt says the results are definitely representative of what occurs

across Canada, and he has seen similar results in Ontario, North Carolina, France, Mexico, and other locations. He notes that “everywhere I have consulted, I observe the same problem [of low biosecurity compliance].”

In one recent study that involved industrial psychologist André Durivage, the researchers asked 114 workers and farm owners (involved in a total of 2379 filmed visits on 23 Quebec poultry farms), fill out a personality test.

“We found that three personality traits seem to be important in compliance: responsibility, complexity and action-oriented,” says Racicot.

Not surprisingly, people who scored high on “responsibility” followed biosecurity guidelines and those who scored low for this trait are more likely to defy

authority and ignore rules. The trait of “complexity” relates to approaching life with logic and rationality, and those who score high with this trait are more likely to use complex strategies to solve problems, which is needed to correctly apply biosecurity measures. “Action-oriented” folk tend to evaluate options before making risky decisions, react quickly to constraints in their environment, and act energetically when faced with tasks to accomplish and challenges to overcome.

In contrast, people who score low with action orientation tend to take unnecessary risks, which often leads to mistakes.

“This trait information can be used in hiring practices,” notes Racicot. “So, in selecting a poultry barn manager or worker to hire, you should try to determine whether or not the applicants display these traits by asking questions about their past demonstration, general tenden-

cies and attitudes and so on.”

Poor biosecurity compliance may also be related to unwillingness.

“Errors can be intentional or unintentional,” she says. “Intentional errors seem to be related to beliefs and attitudes, like when a visitor reports in the logbook that he put on coveralls, although he did not.”

Unintentional errors are related to lack of understanding – for example, donning coveralls in the contaminated area, and not applying the protocol properly. This might include dropping farm coveralls in the contaminated area but still putting them on for the barn visit, or not using footbaths properly. There may also be spatial challenges to compliance, she notes.

Racicot says the main non-compliance issue she and her colleagues have observed is a lack of respect of the con-

taminated and clean areas.

“Having sufficient space to change boots and clothing without cross-contamination is very important,” she explains.

All the farms that she and her colleagues visited had clearly marked hygiene barriers (defined demarcation zones for the changing of footwear, such as a bench) but ignoring these areas remained the most frequent error. How much these areas were ignored seems to depend on the type of demarcation, duration of the visit and of course, if someone is watching.

“Generally, when the visit was short (less than 17 minutes), errors were more frequent,” Racicot notes.

“Therefore, growers should be aware of people coming in for short visits (or looking for the farm managers) because they may be less likely to comply with things like signing the logbook and donning boots and coveralls.”

Not surprisingly, when there was a red line or footbath, ignoring of clean and contaminated areas was more frequent than if the demarcation were a bench or door.

The researchers also found that not changing boots was the second most frequent error, and Racicot says this is likely because individuals did not understand the potential of disease transmission by footwear.

The third most frequent error observed was related to hand washing.

Besides hands, clothing is also an important potential source of contamination that the researchers found is being neglected.

“Lots of microbes – Mycoplasma gallisepticum, iowae, and synoviae for example –can survive on cotton for two to six days,” Racicot explains.

“However, few farms that we studied required coveralls. And when they did, this measure was often neglected.”

Lastly, despite the fact that the logbook was clearly visible and accessible, almost 70 per cent of visits were not recorded.

“A logbook allows for a rapid and effective traceback of visitors in the case of an outbreak, and contributes to the control and eradication of diseases,” Racicot says. “Not having it filled in correctly is a serious biosecurity risk.”

Racicot and her colleagues have found that visible cameras don’t work to increase compliance; they only work on a shortterm basis.

“Where there was a camera visible in the barn entrance, it enhanced overall short term visit compliance and more specifically boot and area compliance, but that did not last,” she notes.

“Six months later, compliance significantly declined.” Audits, she adds, also have no impact on compliance, as everyone is careful to do things perfectly during an audit … and tend to go back to their old habits afterward.

In terms of what works to significantly boost biosecurity compliance, Racicot says the first thing to understand is that there must be several corrective actions taken.

1. Educate every employee and remind him or her often that biosecurity is important. Of particular importance is emphasizing that biosecurity measures must be applied with the same rigor, no matter the length of the visit or when it occurs. They should consider the area a potential biohazard zone at all times.

2. Demonstrate how to apply all protocols to make sure employees know how to do them correctly. Have them demonstrate regularly that they know how.

3. Identify highly compliant employees, recognize their excellence and have them train others.

4. Revisit biosecurity protocols several times throughout the year.

5. Change the barn entrance to help everyone follow protocols properly and replace the demarcation lines with a simple bench or wall and door. Please make sure there is enough space for at least two people to complete protocols in the change area, and that there is enough equipment (hand washing products, boots, coveralls, etc.) and position it within easy reach. If the entrance area is not large enough for this, and/or to frame a wall and put in a door, a renovation is required.

6. Post checklists on each door leaving the biosecurity area so that employees can check off their actions.

7. Visitors should be educated on the spot about protocols and supervised to make sure they are followed.

8. Keep all barn access doors locked at all times.

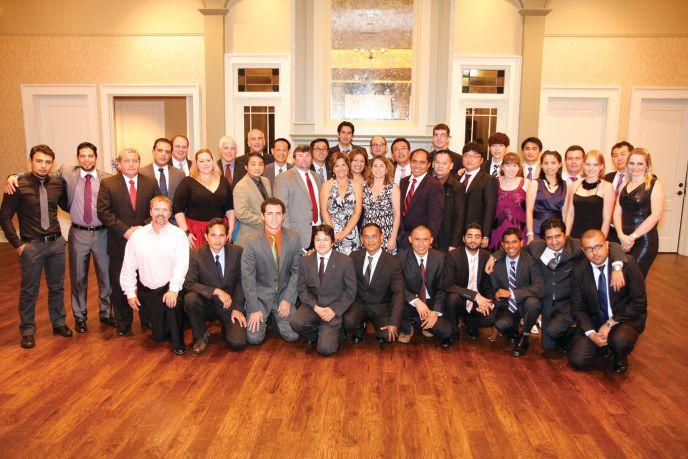

BY KAREN DALLIMORE

The Arbor Acres Production Management School opened its doors in 1967. Since then, more than 1,500 poultry professionals from 62 countries have graduated, and this year Aviagen is celebrating the graduation of its 50th class worldwide.

The school is just as relevant today as it was then, teaching the fundamentals of poultry husbandry and production to Aviagen employees and customers, and allowing them to immerse themselves in every facet of poultry production.

In the early days, students would live at the school for up to three months where they learned how their roles and companies fit into a larger global industry. And, perhaps most importantly, they took their newly acquired knowledge home with them to share with their colleagues.

“Much of the modern poultry industry came about because of their school,” says Neal Scanlon, who ran the school after it was relocated to Huntsville, Ala., following Arbor Acres’ merger with Aviagen.

“It really helped create generations of industry leaders. These were people who were expected to move up in their companies, and they’re hand picked to attend. And when they return home and share those best practices with others, it elevates their entire company, even the poultry industry in their entire region.”

The 2013 curriculum will feature

Fifty years in, the Arbor Acres Production Management School is still graduating bright young leaders.

19 field trips and workshops focusing on fertility, ventilation, gut health, feed formulation and more. “We get people right into the facilities so they understand how everything works,” says Scanlon.

“You can show your students what a good male looks like, or can have your best technical guy on one table doing a necropsy on a bird and another showing the proper way to vaccinate a bird. It’s complete immersion.”

And students learn from the best with 30 different instructors and experts sharing lessons that at times can be eye opening. “The way most people learn the industry is by picking up how things are done at your company, but those aren’t always the best or latest

approaches,” says Scanlon, who directed the school from 2004 to 2012.

The month-long course immerses students in lessons on poultry nutrition, veterinary science, hatchery operations, genetic selection, production and farm management best practices for managing successful breeder and broiler operations.

Insights from industry experts and faculty from local and international universities – both staples of the program since its inception – frequently prompt students to question long-held assumptions.

Most hands-on sessions and field trips take place at Aviagen production facilities, including the company’s Product Development Center (PDC) in

Albertville, Ala. Weekly written exams culminate in a formal graduation dinner and awards ceremony.

International demand has grown so much in the past decade that Aviagen has expanded the school to other regions: an annual, weeklong school launched in 2007 in China, a trilingual school for Latin America launched in 2011 and three weeklong annual schools have been serving students in Europe, the Middle East and Africa since last year.

Aviagen plans to continue innovating, says the current school director, Mark Wright. “We’ll also be expanding our regional schools, with more schools based on the modular, one-week format of the European school. This is all about helping to support future generations of poultry professionals.

“Over the years we have evolved the school agenda and design to encourage students to not only learn from the eminent lineup of presenters from academia and industry, but also from each other,” he adds. “This environment fosters business relationships and friendships that last throughout a career as well as a lifetime.”

The school offers a unique environment for networking as well.

“Students create bonds at the school that last their entire careers, and they make connections that help them not just

at their current company, but for years into the future,” comments Wright. “They learn from each other; they learn how people work in different parts of the world. They understand the entire industry so much better when they leave.”

Aviagen has also launched a secure online forum, which allows school participants and graduates to be part of a growing social community that further establishes bonds between students.

On June 27, the top performing students were recognized at a graduation dinner:

• Kirsty Jensen, Baiada Poultry, Australia and Mirko Botasso, Frigorifico De Aves Soychu S.A., Argentina –tied for the top honour

• Ronan Benigno Mamacus, Bounty Fresh Foods Inc., Philippines – Second highest honours

• Nick Daunt, Maple Lodge Farms, Canada – Third highest honours

As Wright says, “In every class since the beginning, you get to see the rising stars of the industry on their way up. Where else can you do that?”

Poultry Farm Manager for an integrated broiler operation in BC. Permanent, full time. Will be responsible for all aspects of farm management for the broiler operation. Good record keeping skills with attention to detail a necessity. Competitive salary package with benefits. Apply with references to hazel@farmcrestfoods.com.

BY ROY MAXWELL

Whenever you are on a long road trip, checking the rearview mirror or odometer to appreciate how far you have come can often provide a psychological lift. This is particularly true if you have kids in the back who repeatedly ask if you’re almost there. The answer is usually “not quite yet.” The road to biosecurity is similar. It’s a long haul and we have come a long way, but we aren’t quite there yet.

It is difficult to say when biosecurity began, because farmers have been practicing basic biosecurity for a long time. However, using a combination of science-based biosecurity practices is relatively new. For Ontario chicken farmers, it began in the late 1990s when two projects were happening simultaneously in the industry. One was the introduction of the On-Farm Food Safety Assurance Program (OFFSAP) and the other was the creation of Chicken Farmers of Ontario’s Emergency Management and Crisis Communications Plan. The two went hand in hand with respect to disease control, and, today, you can add traceability to the mix.

For Ian Richardson, it began in Ottawa at a meeting of the National Avian Biosecurity Advisory Council, following the avian influenza outbreak of 2004 in British Columbia. Richardson is president of e-Biz Professionals Inc. and recognizes that biosecurity has come a long way, but that it was not always a smooth road. With respect to compliance, Richardson talks about an adoption curve and describes pioneers in biosecurity and emergency preparedness as cheerleaders.

Ten years ago, few people would have predicted there would be a biosecurity initiative for agricultural fairs, but there is. Mark Beaven is the general manager of the Ontario Association of Agricultural Societies and he is in charge of providing biosecurity tips and guidelines to organizers and volunteers at more than 200 Ontario fairs. Beaven believes farmers are very aware of the relationship between livestock, poultry and people, but is not so sure they appreciate the importance of biosecurity at fairs.

Remember, there can be a lot of poultry at agricultural fairs, including birds that various commodity boards use to communicate with visitors about poultry and egg farming. Last year, a number of people became ill after attending fairs or swine shows in the United States. The swine virus was zoonotic, meaning it could jump to humans. Nobody wants that to happen to fair-goers in Canada.

The biosecurity tips and guidelines project for Ontario fairs, which began in January and finishes this fall, is designed to inform fair organizers, volunteers and visitors how to reduce the chances of getting sick, and explain the important role people play in preventing the potential transmission of animal and poultry viruses. Educational material will include fact sheets, signage, hand-washing stations and the like.

It’s a long haul and we have come a long way, but we aren’t quite there yet

“Cheerleaders don’t make things happen, but they raise consciousness and then the adopters pick it up,” he says. “Agriculture is impacted a lot by government programs, so the question is often asked: should these practices be voluntary or mandatory?”

Regardless of the answer, I believe biosecurity in the agrifood industry will be an easier sell in the future because the federal government and provincial governments, along with the Canadian agri-food industry, understand the importance of biosecurity from both an economic and a public health perspective.

To explain my optimism, let me refer to a 2013 biosecurity project in Ontario, funded by the Agricultural Adaptation Council which demonstrates how far biosecurity has come.

Beaven, who is also the executive director of the Canadian Animal Health Coalition, has spent more than 20 years in the poultry and livestock sectors. He says, “It is not just about people getting sick from animals; it’s also about animals getting sick from people and from other animals.”

Information about the tips and guidelines project for Ontario fairs has been made available to the public on several occasions, but Beaven doubts it gets much air time at local coffee shops. He encourages poultry and livestock farmers to contact their local agricultural society to provide welcomed input and suggestions.

So, yes, biosecurity is coming to a fair near you, which shows just how far the industry has come. But, like that kid in the back seat, I can’t resist asking if we are almost there. The answer is, “No, but we are headed in the right direction and making good time.

“We’ll be there soon.”

Small amounts of ß-mannans in soybean meal can waste valuable energy in swine and poultry.

By breaking down ß-mannans, Hemicell minimizes the FeedInduced Immune Response (FIIR) to spare more energy for performance.

“With over 31 days over 30 degrees Celsius in the summer of 2012, the ne Cool Cell as a ri al ie e of e ui ment for the Clar oultry o era on,

Installed before the summer commenced, the system delivered excellent results for the summer of

“We re orded the outside tem erature at 32 degrees, and inside the arn, the tem erature measured 2 degrees el ius, 1 from the ell at the front of the arn a dro of degrees

“With the system erforming this ell, Clar oultry as a le to ma imi e ird erforman e and rodu on in even the ho est eather of the summer

hile the summer of hasn t been as arm, the ool ell con nues to deliver exce onal outcomes

co uchan of uchrest arms stated, “ have seen the ene ts of the system this summer through im roved feed e ien y, and im roved eight gain he system is useful not only in e treme heat, ut also in moderate heat uchrest arms is able to set a tem erature for de rees and maintain it, rovidin ideal ro th condi ons for their oc lar ystems is a roud su lier of the I va ora ve oolin system, com lete ith the ired and roll seal, hich len thens the life of the ad by rotec n from harsh anadian inter eather If you are interested in increasin your summer erformance for , and maximi in your roduc on, call lar ystems today to discuss your retro t or arran e a tour

CLARK AG SYSTEMS is proud to be a supplier of the I line of e uipment

“You can’t manage what you can’t measure For the month of September, target your bird performance and recieve 10% off GSI Electronic bird scales.