TOP 10 UNDER 40

Celebrating the next generation

Meet 10 rising stars who are setting the standard for the next generation of leadership.

10 Working together

The Aggregate Producers Association of Canada (APAC) hosted representatives from one side of the countr y to the other in Mississauga, Ontario for the fifth APAC Forum.

12 At last

We take a closer look at the 2.5-kilometre-long Gordie Howe International Bridge, which is now expected to open in early 2026.

16 Partnerships matter

Selecting the right rental partner keeps your construction project safe, efficient and on track

26 Sneak peek

With CONEXPO-CON/AGG 2026 only a few months away, here is a glimpse of what you can see at next year’s Las Vegas show.

In good hands

This year's Top 10 Under 40 list represents the diversity of the industry and country

This edition is our annual celebration of those 40 years and under who are making a real difference in the industry.

It’s not easy narrowing down our submissions to just 10 names, but this year was more difficult than most. However, the 10 names we eventually landed on represent not just the wide swath of Canada’s aggregate and road building industries, but also the country.

We have representation from north Vancouver and Brandon, Manitoba.

From Quebec, we have those living in Candiac and Montreal.

From Ontario, we have people who call Concord, Ottawa and St. Catherine’s home. In the Maritimes, we have someone from Miramachi.

And the north is on the list with someone from Whitehorse.

As well, their roles in the industry are equally as diverse. The list includes those working in quarries, asphalt plants, logistics, human resources and equipment manufacturing.

I always find it rewarding to speak with those with those from across the country and the industry.

The conversations are insightful and entertaining, and I come away with a much better understanding of this industry and our nation.

One insight that came up again and again was how some in our top 10 never envisioned a career in this industry. Instead, they had attended school or trained for another career but through a variety of circumstances, found themselves here and quickly realized it was a great fit.

Marino Di Bendetto at Amrize Builidng Materials had worked in the airline industry before joining Amrize.

David Hunter wanted to be a profes -

sional golfer.

Adam Mahany was studying computer engineering when he first began as a flagger on a road crew.

Jason Mountney had planned on a career in mechanical engineering.

However, each found their way into the industry and, once here, thrived.

Another insight that came up in my conversations was what the future looks like and, in particular, how to attract more young people into this industy.

I wish I could report that these conversations resulted in us solving the problem, but, sadly, we did not.

There was a general agreement that the industry should place a greater focus on reaching out to high school students so they can see the opportunities that exist.

A few years ago, a friend's daughter was set on becoming a physician and she had the grades for it. But in her last year of high school, she took an electrician course and fell in love with it. Her career plans immediately changed.

So, perhaps providing teenagers with more hands-on exposure to aggregates and road building sectors can help. How to do that, I'm not quite sure.

I do know this is a problem that requires a solution as the demand for aggregate will continue to grow over the coming decades.

Final Thought

This edition of Rock To Road marks the last edition that associate editor Macenzie Rebelo is involved in.

Macenzie has received a well-deserved promotion and is taking over as editor of Crane and Hoist Magazine.

Stay tuned for our January/February edition in 2026 where will introduce our new associate editor.

MIKE lacey

RocktoRoad

NEW IntelliPac ™ Moisture System

Astec paves the way for sustainable, innovative asphalt plants. The new IntelliPac Moisture System is a revolutionary solution that integrates seamlessly with Astec control systems. This provides unparalleled, real-time visibility into virgin aggregate moisture content. IntelliPac empowers operators to optimize mix design, minimize energy consumption, and reduce environmental impact. With Astec, you get superior asphalt production – better for the environment, better for your business.

BUILT TO CONNECT

industry news

Mike McSweeney retires

The executive director of the Ontario Stone, Sand and Gravel Association (OSSGA) has retired.

Mike McSweeney’s final day was Nov. 14, 2025.

“Mike has made an indelible impact on OSSGA by strengthening the industry's standing with government and developing a strategy that will protect and guide our industry for years to come,” said OSSGA chair John MacKay. “Beyond Mike's professional achievements for OSSGA, he has been a friend, mentor and a source of wisdom to me personally. It has been a privilege to work alongside Mike, and I'm grateful for the time and lessons he has shared.”

McSweeney joined OSSGA two years ago. Prior to that, he served for a year as

Assinck hosts open house

the CEO of the Ontario Road Builders Association and 12 years as president and CEO of the Cement Association of Canada.

“It has been an honour to work with OSSGA's dedicated board of directors and talented team over the past two years,” McSweeney says. “Together, we have advanced a successful strategy that highlights the essential role stone, sand and gravel play in Ontario's construction supply chain, while rebranding and refocusing our efforts at Queen’s Park and with municipalities. With strong leadership, new team members and a clear path forward, I am confident OSSGA is well-positioned to continue this important work.”

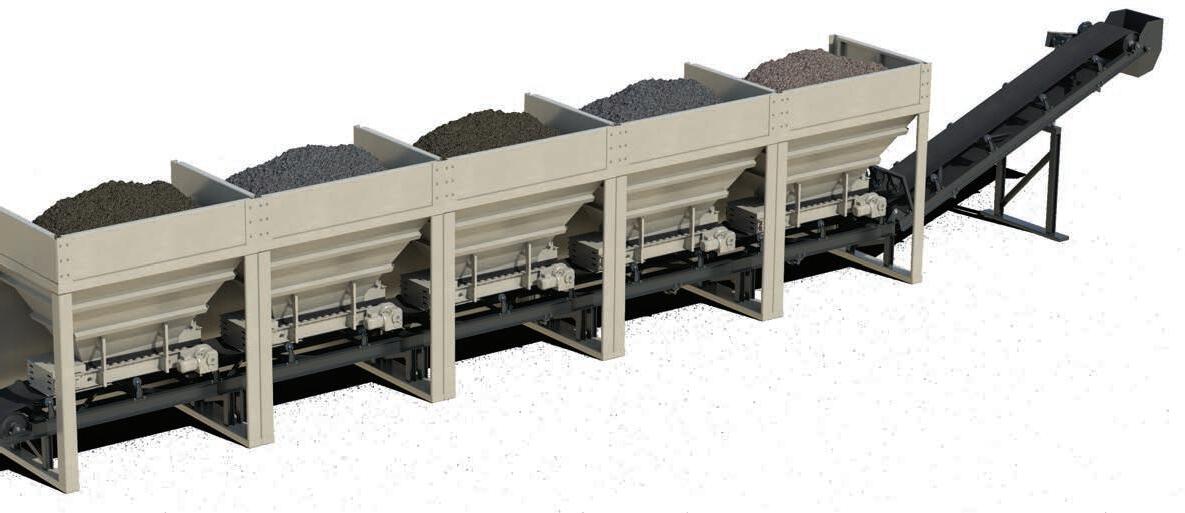

Assinck hosted its inaugural Assinck and Partners Industry Open House on Oct. 30 at its facility in Scarborough, Ontario. The event brought together colleagues, customers and suppliers from across the aggregate and material handling sector. The event included plant tours, live equipment demonstrations and a technical Lunch & Learn session.

Assinck offered a look at its manufacturing facility, and its approach to conveyor and material-handling solutions, along with the conveying parts and components used to support reliability and operational continuity in the field. Industry partners also contributed throughout the day, bringing forward the systems, components and expertise that support operations across the material-handling landscape. Those in attendance included:

• Brunone Innovation: Belt-handling and conveyor alignment systems that support safe, consistent bulk material transport.

• VDG ( Van der Graaf): Enclosed drum motor drive systems designed for low-maintenance, heavy-duty conveyor performance.

• Polydeck: Modular screen media systems that help improve uptime and throughput in aggregate screening applications.

• Dodge Industrial: Mounted bearings and power transmission solutions for continuousrun conveyor environments.

• Weir Minerals: Processing and wear-resistant solutions used across mining and quarry applications.

• RTI Equipment Solutions Inc: Equipment supply, rental options and field support services.

• Chambers & Cooke Limited and Sovereign Fusion Inc.: Industrial parts supply, fabrication and on-site service capabilities.

Assinck plans to continue hosting this open house format every six months, with the next event planned for spring of 2026.

Great Lakes limestone trade down in October

The Lake Carriers Association announced shipments of limestone on the Great Lakes totaled 3.2 million tons in October, a decrease of 3.8 percent compared to 2024. Limestone cargos were also below the month’s five-year average by 10.7 percent.

In October, shipments from Canadian quarries increased 6.8 per cent to 626,805 tons while loadings in U.S. quarries totaled 2.6 million tons, a 6.1 per cent reduction.

In September, shipments from Canadian quarries totaled 663,144 tons, a decrease of 2.3 per cent. Loadings from U.S. quarries decreased 13.5 per cent from last year to 2.7 million tons. Year-to-date, the limestone trade stands at 22.8 million tons, a decrease of 5.6 per cent compared to a year ago. Loadings from Michigan and Ohio quarries decreased 4.5 per cent from last year to 18.6 million tons, while shipments from Ontario quarries total 4.2 million tons, a decrease of 10 per cent.

Komatsu opening new full-service parts distribution centre in Edmonton

Komatsu is doubling the size of its parts distribution footprint and transform its Edmonton, Alberta, parts depot into a fullservice distribution center.

Komatsu states this expansion marks a significant step in the company’s ongoing effort to enhance service levels, reduce lead times and better support dealers and customers across Canada.

The new facility, spanning approximately 135,000 square feet, will double the capacity of Komatsu’s existing warehouse. This upgrade enables Komatsu to store and distribute fastmoving parts directly from Edmonton, significantly improving delivery times, including 24-hour delivery capabilities to its dealers in western Canada.

The expanded Edmonton facility will transition from a regional depot to a fully integrated parts distribution hub and serve as a cornerstone of Komatsu’s North American logistics network and streamlining supply routes from Komatsu’s global manufacturing hubs in Japan and Indonesia.

Key features of the new operation include:

• Expanded capacity for faster-moving and strategic inventory

• Advanced system integration with Komatsu’s global planning and warehouse management system (WMS) platforms

• Improved warehouse efficiency through updated layouts, automation and new equipment

• Enhanced workforce capacity, with plans to add additional staff and technological support

CSA Group releases Canada’s new highway bridge design code

CSA Group has released the first bridge design code in Canada to provide engineers with guidance on designing for future risks of climate change. CSA S6:25, Canadian Highway Bridge Design Code, is the 13th edition of the Code, and the first edition to use predictive modelling to account for future climate change risks, according to CSA. It establishes consistent national direction to help ensure bridges across Canada are safer and more reliable now and into the future.

Canada is warming at two to three times the global average, putting vital infrastructure like bridges at greater risk, states CSA. For decades, bridge designs were based on historic climate data, much of it from the 1960s, under the assumption that conditions would remain stable. With more than 50,000 publicly owned bridges in Canada, engineers must plan for future realities such as higher temperatures, stronger windstorms, sea level rise and higher river flows.

“Bridges are long-term investments in our communities and our economy,” said Dwayne Torrey, director of construction and infrastructure standards at CSA Group. “This new code gives engineers the tools they need to design infrastructure that anticipates evolving environmental impacts. By building climate-ready bridges today, we can help keep people safe, goods moving, and communities connected for decades to come.”

Highlights of CSA S6:25 include:

• Climate-resilient design guidance: A national standard that helps engineers adapt bridge designs to a changing climate.

• Use of predictive climate modelling: Tools to plan proactively for risks such as flooding, ice buildup, and stronger storms.

• Focus on long-term performance: Design approaches intended to extend bridge lifespans, reduce repair costs, and minimize disruptions.

Learn more at www.csagroup.org

Rock to Road magazine is circulated free of charge to qualified individuals holding management and supervisory positions with companies engaged in the aggregate, roadbuilding, ready-mix concrete and asphalt production industry in Canada.

The Publisher reserves the right to determine qualification.

Association News Working together

Supporting a stronger, unified, national industry through the Aggregate Producers Association of Canada

Earlier this fall, representatives from one side of the country to the other gathered in Mississauga, Ontario for its fifth APAC Forum.

The Aggregate Producers Association of Canada (APAC) is a not-for-profit organization aimed to connect aggregate producers across the country to support a stronger, unified, national industry that is safe, sustainable and growing, through networking, advocacy and the sharing of best practices. APAC formed in 2019 with only three provinces (Alberta, British Columbia and Ontario) but has since grown to include representatives from all provinces in the country. With one to two representatives from each province, virtual meetings are held three times a year with in-person meetings scheduled every one or two years. APAC’s last forum was held in B.C. in 2023.

The forum included five areas of exchange between provinces including:

1. A description of each respective provincial association;

2. An outline of aggregates production in 2025 and beyond;

3. Ongoing initiatives and priorities;

4. Current industry challenges;

5. Expectations of APAC moving forward.

Five provinces were present for the forum, including Alberta, British Columbia, Nova Scotia, Ontario and Quebec, also representing the five largest producing provinces of the country (or roughly 90 per cent of the national production.) To help complete the national picture, input was also provided ahead of time from each Manitoba, New Brunswick and Newfoundland & Labrador who were unable to attend due to conflicting schedules.

Dedicated aggregate industry associations exist in only three of the provinces (Alberta, B.C. and Ontario) while aggregate related topics are mostly addressed through committees that were formed within the roadbuilding and/or heavy construction associations in the other provinces.

Canada produces more than 400 million tonnes of aggregates per year with one of the highest annual consumption rates in the world at approximately 10 tonnes per capita. Sand and gravel are still the leading aggregate produced over crushed stone sources with Mother Nature limiting options to sand and gravel due to geology in the Prairies. Recycled aggregates are difficult to estimate and are mostly only prominent in large urban centers. At roughly 5 per cent of the

total aggregates, this number is low in comparison to other parts of the world. From a national perspective, Canada is forecasting a decline of 5 per cent overall in 2025 across the country (a reduction of roughly 25 million tonnes.) This is driven predominantly by two of the largest producing provinces (Ontario and B.C.) who are forecasting lower volumes versus 2024, significantly outweighing the double-digit growth currently seen in maritime provinces Nova Scotia and New Brunswick. Initial forecasts for 2026 were not too optimistic with another slight decline anticipated in Canada. However, this was before the recent federal infrastructure bill announcement which aims to fasttrack projects of national interest. Of note as well has been the growing interest from major aggregate producers in coastal quarries in both the east and west of Canada for shipment of aggregates by barge or vessel to American coastal markets such as California and Florida, where aggregates are already scarce. It is estimated that aggregate exports to the U.S. can grow up to 50 per cent over the next decade. Aggregate shipments to the U.S. are currently exempt from tariffs.

When discussing individual provincial initiatives, the Alberta Sand & Gravel Association (ASGA) continues to promote its truck registry program which remains a priority in the province and has recently formed its own trucking committee. Although activity has dropped in the province over the last decade, the total number of trucks registered grew by more than 25 per cent versus 2023, the revenue generated through the truck registry was the highest in 2024 since the program was introduced.

The British Columbia Stone, Sand & Gravel Association (BCSSGA) has been working on an outreach program to grow its membership and increase engagement with its members which now includes more than 300 members and more than 80 per cent of the province’s production. Established in 1988, the BCSSGA has essentially doubled its membership over the last five years through its outreach efforts.

In the Maritimes, the Nova Scotia Roadbuilders Association (NSRBA) partnered with the Mining Association of Nova Scotia (MANS) in conducting a public opinion survey which revealed that 67 per cent of Nova Scotians believe that mining and quarrying is important to the provincial economy and that 72 per cent agree that it also plays an important role in

economic development in rural areas. The survey results indicate that substantially more people support quarry operations in the province than those who oppose them.

The Ontario Stone, Sand & Gravel Association (OSSGA) has recently relocated and are now sharing their office with the Ontario Roadbuilders Association (ORBA) in Mississauga. The two provincial associations are collaborating more and combining efforts in lobbying days and conferences to support and strengthen government relations.

In Quebec, the ACRTCQ (Association des constructeurs de routes et grand travaux du Québec) has perhaps the largest provincial profile within the country, as it represents the interests of more than 2,000 members of the roadwork sector and producers of aggregates, asphalt and concrete. The ACRTCQ brings aggregate producers together through an internal group called the RPPG (Regroupement professionel des producteurs de granulats – Quebec Aggregate Producers Group) which includes more than 65 member companies and 75 per cent of the province’s production. Discussions focus on technical aspects of aggregates as well as contractual, environmental, regulatory and land use issues.

In discussing ongoing industry challenges from one province to another, one theme was consistently repeated around the difficulties in accessing mineral resources. An identical survey to the one conducted in 2022 revealed that the major issue for aggregate producers today has shifted strongly to access to resources and environmental compliance. Terms and conditions appear to be more complex, dramatically increasing permitting costs and raising uncertainty around adding or extending current activities. Provinces discovered that issues were incredibly similar across the country and were learning different methods or approaches at tackling common challenges.

The forum also included a discussion with the Ontario Roadbuilders Association (ORBA) and a presentation from the National Stone, Sand & Gravel Association (NSSGA) to raise awareness on ongoing initiatives and trends of the aggregates industry in the United States.

As the meeting ended, there was an overwhelming positive response from each of the

participants on the value creation in APAC.

“We learned so much from what the other provinces are doing that have been successful,” said Sharon Armstrong, OSSGA Vice-President of Industry & Stakeholder Relations.

“There’s so much overlap on topics and so much to gain from these exchanges,” added Derek Holmes, BCSSGA Executive Director. “The next meeting will definitely need to be longer.”

“I came to this meeting knowing it would be a valuable exchange, but it has greatly

exceeded my expectations,” concluded Rob Fragoso, ASGA Executive Director.

There is no set date or location for the next APAC forum, but it is anticipated in early 2027 and intended to be held in conjunction with an annual provincial association event or conference. It will be a topic for discussion at the next APAC virtual meeting which is scheduled before the end of the year.

A LONG WAY TOGETHER

wherever you are, bkt is with you

No matter how complex your tasks, BKT offers an extensive range of tires designed for every use in the industrial sector from warehouse and port to excavation operations. Strong, safe, reliable, and resistant to cuts, tears and punctures - these tires stand out for durability, superior performance, and comfort, even under extreme conditions.

BKT: always by your side, in any operation.

Joe Dias

Eastern Zone Manager

Directeur Régional, Est du Canada

BKT Tires (Canada) Inc.

Cell: 514-792-9220

Web: www.bkt-tires.com

Brent Morrey is president and co-founder of the Aggregate Producers Association of Canada.

AT LAST

2.5-kilometre-long Gordie Howe International Bridge is expected to open in early 2026

BY GRANT CAMERON

> For more than seven years now, a small army of construction workers and heavy equipment operators has been working on the landmark Gordie Howe International Bridge, a 2.5-kilometre-long, cable-stayed span that will link Highway 401 in Windsor with Interstate 75 in Detroit.

The impressive and long-awaited, multi-billion-dollar structure crosses 600 metres of the Detroit River. Work associated with the project has included building new ports of entry (POE) on both the Canadian and U.S. sides of the waterway along with a new interchange, road and pedestrian bridges, and other related works along a

three-kilometre stretch of the I-75.

The project has provided a muchneeded jobs boost to the area. All in, the project has directly employed more than 3,900 workers, with more than 46 per cent being from the region.

Anticipated opening date of the bridge has been set for 2026. But it has been a long time coming. In fact, the only constant of the project has been the delays and escalating price tag.

The project was announced in 2012 and construction started in October 2018. It has experienced at least two major delays. The first was a 10-month hold-up

caused by the COVID-19 pandemic. That pushed back the planned bridge opening from the end of 2024 to fall 2025.

The Windsor-Detroit Bridge Authority (WDBA), the Crown corporation overseeing the project, recently announced that, although the project is progressing well toward construction completion this year, the opening will now be delayed until 2026 so testing can be done on the bridge’s fire suppression system as well as technology that will be used to analyze traffic connectivity.

“As is standard practice on large complex projects, we are currently focused on

The Gordie Howe International Bridge spans 600 metres of the Detroit River. PHOTO: Windsor-Detroit Bridge Authority

commissioning and testing to ensure we identify as many potential issues as possible for us to resolve before the opening of the bridge,” said Heather Grondin, chief relations officer for the WDBA.

All border agencies and operating teams are also being given more time to “achieve operational readiness,” she said.

COST HAS BALLOONED

The cost of the project has ballooned by $700 million. Disruptions due to COVID led to negotiations with the private-sector partner on the project, Bridging North America (BNA). Initial cost of the span and associated work was $5.7 billion but after the pandemic the figure was hiked to $6.4 billion.

Video from a recent flyover of the site showed crews still working at the site. The bridge deck is connected and paved, and installation and stressing of the stay cables is complete. Crews have been working on the final steps to prepare the bridge, including application of stay cable protective finishings, installation of electrical and drainage systems, barriers, fire suppression system, signage and lighting, and completion of a multi-use path on the structure for walking or cycling.

Deconstruction of the bridge tower cranes has been completed. The cranes were 822 feet tall and took more than a month to dismantle.

At the Canadian POE, crews have been working on the interior of buildings and structures. Border agencies have started equipment fit-up, testing and commissioning. Work is wrapping up on 24 primary inspection lanes at the Canadian POE and on 16 toll booths. The Canadian side is 130 acres, with 133,881 square feet of building space.

Meanwhile, at the U.S. POE, crews are finishing work on 36 inspection lanes and an eight-foot-tall security wall along the southern border. A non-climbable, precast concrete barrier wall that faces West Jefferson Avenue between Green and Campbell streets has also been completed. The barrier wall features an aesthetic treatment that pays tribute to historic Fort Wayne. The U.S. site is 167 acres, with 326,335 square feet of building space.

Landscaping, paving and fence installation is also underway at POE sites on both sides of the river.

Along a stretch of I-75 in Michigan, four road bridges have been constructedat Springwell, Green, Livernois and Clark streets - and are open to traffic. Construction of pedestrian bridges continues at Solvey, Waterman, Beard, Junction and Lansing streets.

Four interchange ramps connecting I-75 to the U.S. POE have been paved with signage installations underway. Roads have been widened at key intersections to allow transport trucks to make full uninterrupted turns.

THE BRIDGE

The bridge was built to handle anticipated growth in cross-border trade and traffic between Windsor and Detroit and provide an alternative to the Ambassador Bridge, with better highway-to-highway connectivity.

Before building up the bridge, construction crews had to build down. Six shafts had to be drilled into the bedrock to a depth of 118 feet, for each tower pylon or leg, the equivalent of a 10-storey building. Each shaft was filled with 69,000 gallons of concrete.

Lead the Market with ME Elecmetal

Born in Mining. Built for Aggregate.

At ME Elecmetal, we don’t just supply wear parts — we engineer performance. With the same grit that built our mining legacy, we now lead the aggregate market in speed, quality, and custom solutions that help distributors outperform OEMs.

Optimization Without the OEM Hassle - Our data-driven tools and expertise make it easier to fine tune performance and improve wear life — without the long lead times or locked-in specs.

Total Product Development Partner - We don’t stop at crushing. We innovate in: apron feeder flights, safety tooling, rubber wear components, reverse- and custom-engineered solutions, and more.

About 5,250 feet of post tensioning cables were also required to connect the footings from end-to-end. The tower legs stand 722 feet tall, rivaling the height of the GM Renaissance Center, the tallest building in Detroit.

A total of 201,500 wick drains were installed at the Canadian and U.S. POEs to create a solid base for the facilities and bridge towers.

The bridge itself is made up of three parts - an approach bridge on each side of the Detroit River and the main span. The crossing will be among the top five longest bridges in North America.

The main span will have six lanes. The cables or stays run directly from the towers to support the deck. The cables end up transferring the load of the deck to the foundations below. There are no piers in the water.

The deck of the bridge is about 150 feet above the river, and the top of the bridge is about 722 feet above the water line. Width of the bridge is about 123 feet. The multi-use path on the bridge will have a surface that is skid resistant and retroreflective.

The bridge tower shape will reflect the curvature of a hockey stick in a slap shot. Colour of the span will range from white to dark grey. LED lighting will illuminate the structure.

OPENING SOON

A specific date for the bridge opening had not been announced as of press time, but it is expected to take place early in 2026 after final testing and commissioning have been completed.

The lights on the bridge were tested for the first time in September, when about 5,000 LED, individually programmable lights were illuminated.

Equipment at toll lanes at the POEs, including payment systems and overhead signage, have been tested to make sure they can be read at all hours and in various conditions.

With the bridge nearing completion,

the project team and City of Windsor recently opened a multi-use path that connects Malden Park to the structure. The path extends roughly half a mile from an existing trail at Ojibway Parkway. The path will link up with broader regional trails.

David Henderson, CEO of private-sector partner BNA which built the bridge, said everyone involved in the project is proud of the path which was funded through the project’s Community Benefits Plan.

“This new trailhead provides improved access to the park’s trail system, and the connection to the rest of the city as well as to the Gordie Howe International Bridge.”

Construction of the Gordie Howe International Bridge began in 2018 and has employed 3,900 workers. PHOTO: Windsor-Detroit Bridge Authority

Along with construction of the bridge, other work included building new ports of entry (POE) on both the Canadian and U.S. sides of the waterway. PHOTO: Windsor-Detroit Bridge Authority

The right rental partner will keep your construction project safe, efficient and on track PARTNERSHIPS MATTER

BY SHAYNE JENNINGS, COOPER EQUIPMENT RENTALS

> Your crew is halfway through grading a section of road when the machine suddenly breaks down.

There’s no backup on-site and the rental company says a replacement won’t arrive for at least three days. Meanwhile, your team is stuck and labour costs keep rising.

On another section of the road, excavation begins – only to strike a utility line that wasn’t properly marked during the pre-construction survey. Then a trench dug for a new stormwater drainage pipe collapses, narrowly missing a worker and burying several tools.

Setbacks like these aren’t rare in road construction. Project delays, safety hazards and unexpected costs are constant risks. Success in this high-stakes environment takes more than hard work. It requires smart planning, the right equipment and dependable partners from day one.

Long before the first layer of asphalt is laid, critical prep work sets the tone for the entire project. Site clearing, grading, trench safety, utility management and compaction – every phase demands precision. Building the road is the finish line. Managing everything before it is the race. The difference between just getting by and finishing strong often comes down to who’s in your corner and the right rental equipment provider gives you the confidence to keep your project moving, both safely and efficiently.

PLAN EARLY AND AVOID DELAYS

Your workers face a lot of daily hurdles: harsh weather, tight margins, strict safety regulations and inevitable delays. Your rental equipment shouldn’t add to that list. In road construction, better planning means

Whether you’re dealing with an accidental release of pollutants or a threat to freshwater sources due to flooding, your rental provider should have the capacity to act quickly with the right pumping tools and recommendations.

finding partners who understand your work and keep you on schedule (and on budget) – even when things go sideways.

Engaging a rental provider early gives you access to the right equipment, exactly when you need it. While reliable machines are essential, the level of service and support you receive can be just as crucial. Specialized equipment like customized trench safety systems, heaters, or pump and power solutions require thoughtful planning and jobsite assessments.

Take trench safety, for example. You’ll need to work with your rental provider to engage this crew first. They should handle the specifications for trench equipment, provide engineering solutions and offer upfront, transparent pricing. Most importantly, they’ll

help design a custom system that keeps your crew safe and your site compliant.

If your project involves working near water mains or environmentally sensitive areas, a specialized pump and power team can manage water removal safely and ensure you’re using properly sized pumps and generators – critical for avoiding power failures, environmental risks and costly delays.

Identifying these needs upfront provides a clear roadmap. And when it comes to larger projects, early planning becomes even more important as some equipment (like heaters) can be limited in the fall and early winter. If you’re waiting until November to secure rentals for winter roadwork, you may be out of luck.

PHOTO: Cooper Equipment Rentals

PRIORITIZE SAFETY FROM THE GROUND UP

When we overlook safety on the road, the consequences can be severe. The headlines tell the story: a worker killed when a supervisor fails to provide proper trench safety equipment. Another suffers serious injuries when trapped between heavy machinery. A fall from height changes someone's life forever. Across the country, similar roadwork accidents unfold far too often.

Whether you're building highways, working in trenches, or navigating around utilities and power lines, there’s no room for error. Safety must be built into every phase of your project.

That’s why your rental partner matters. They should bring a safety-first mindset to help you navigate and maintain a safe project from day one. Look for a provider with high safety standards within their own team. Up-to-date, well-maintained gear, smart fleet management tools, and a team trained to understand safety regulations, assess risks and recommend solutions is a must.

Remember, even the best equipment can’t make up for lack of training. Make sure to properly train every operator so they understand manufacturer guidelines

and follow regulatory requirements. Safety isn’t a box to check – it’s the foundation of every successful jobsite.

MORE INFORMATION, LESS RISK

Technology also plays a huge role in jobsite safety and efficiency. Visibility into equipment usage may help you spot a problem before it becomes a hazard and, when timelines are tight, those insights are invaluable. When machines are connected with telematics, teams can make faster, more informed decisions that keep crews moving and schedules on track. Telematics also gives you visibility into machine use, so you know when equipment needs service, when it’s idle and when it’s overworked. The result? A right-sized fleet, fewer unnecessary rentals, and less wear and tear.

Your rental partner can help cut through the noise and focus on the data that matters most to your job. For example, if you're pouring concrete during colder months, temperature monitoring tools can track temperature, strength and humidity in real-time. This helps you avoid delays that can lead to costly rework in materials, labour and time.

Choosing the right tech starts with understanding your goals. Before diving

into the data, work with your rental provider to define your priorities. Want to reduce downtime? Look for advanced usage tracking. Concerned about theft or lost equipment on site? GPS tracking is your answer. Need to streamline billing or reduce paperwork? Telematics can help automate documentation and reporting. Identify the goals, collect the data and turn those insights into actionable results.

SUCCESSFUL ROADWORK STARTS WITH THE RIGHT PARTNER

In road construction, the work begins before the first crew hits the site. Every choice you make impacts efficiency, safety and overall project success. So, know your jobsite, anticipate challenges and align with partners who bring the right tools, specialized equipment and expertise to match. From trench safety and power solutions to telematics and real-time data, the equipment you choose can shape the outcome of the entire project.

An equipment provider may rent you machines, but a true partner delivers 24/7 support, safety-first solutions and the technology to help you make better decisions at every stage.

CRUSHING SCREENING

TOP OF THE CLASS

These 10 rising stars are setting the standard for the next generation of leadership

BY MIKE LACEY AND MACENZIE REBELO

MELANIE CHOOK

Human Resources Advisor, CRH Canada

Concord, Ontario

When Melanie Chook joined CRH Canada, she quickly learned how diverse the aggregate industry truly is.

It’s not just blasting and hauling rock.

“There's so much more,” says the 35-yearold, adding she was particularly surprised by how people focused the industry is. “You don't realize it's very people focused until you get in it, especially right now there's a huge generational gap with a lot of people leaving and going into retirement. So, we're having to make changes to support people coming in and trying to attract new people.”

That can be difficult, she explains, because the younger generation has certain expectations around work-life balance that are difficult to provide in this industry.

However, once hired, she said retention is rarely an issue as there are many career options available in the industry.

“You can develop into any role, as long as you have that knowledge, put the time in and show interest,” she says. “You're not stuck in one position for the rest of your life. There's a lot of growth in the aggregates industry.”

A colleague in the HR field once gave her advice that has not only stuck with her but also proven important when working with those in the industry.

Listen.

“They’re so focused on the outcome of getting the work done. They're not used to HR coming and talking to them, listening and really hearing them out. It's built a lot of credibility in my career where I am right now. People trust me more because they know they can pick up the phone, talk through an issue, get some insight, and hear my perspective on the best approach.”

As for those entering the industry, she advises them to learn the roles of those around them.

“You’re never going to know everything,” she says. “But asking questions and learning builds credibility. It helps you make better decisions when you understand what's going on around you and it builds trust with your colleagues,” she says.

MATTHEW DICKIE

Applications Specialist and Training Manager, Softree Technical Systems

North Vancouver, BC

Matthew Dickie thought all he needed to do was find the right solution to the problem.

He didn’t realize how wrong that was until he received some lasting advice from mentor Jeremy Araki.

“He just said, ‘OK, if you can't communicate what you're doing, there's no value in the fact that you know how to do this stuff. At all,’” recalls the 36-year-old. “Finding the best solution to the problem has really no value if you can't communicate it and actually get the people that are going to implement things or approve things on board with it.”

That advice still guides him in his current role with Softree Technical Systems. He joined the company in 2019 after a stint as a forestry engineer in British Columbia, followed by working in the mining sector where he was involved in planning and designing access infrastructure.

At Softree, he is involved in product development and was instrumental in co-developing Path Explorer AI, a patent-pending tool for generative road design.

This is a particular highlight of his career and something he is quite proud of.

“But a lot of a lot of credit gets to go to the broader team that put it together. They are some brilliant developers,” he says.

He is also responsible for leading training sessions and webinars. In 2022, he spearheaded a four-part webinar series focused on reducing the environmental footprint of road design.

He advises those entering the industry to find a role they enjoy and lean into it.

“Being able to find something that you like or focus on the parts of something that you like really does make it a lot easier to grow,” he says. “If you like what you're doing, people are going to want to work with you more, they’re going to feel a lot more comfortable sharing projects with you and giving you something to run with if they [know] you think that this stuff is important and you're going to do a good job. Use these opportunities to learn and find better solutions.”

MARINO DI BENEDETTO Rail Modal Manager, Amrize Building Materials Montreal, Que.

Marino Di Benedetto, Rail Modal Manager, Amrize Building Materials, did not follow a conventional path into the industry.

“My background is actually in aviation -- 14 years working for an airline,” he says.

When air travel came to a halt in 2020 due to the COVID-19 pandemic, he suddenly found himself grounded and unsure of what came next. Ten months later, he applied for – and landed – a position with Amrize, then known as Lafarge Canada, in Montreal.

Transitioning from aviation to building materials meant learning an entirely new language of supply chain dynamics, inventory management, and transportation logistics. Fortunately, many of those skills were transferable.

“I was initially drawn to the opportunity to work on tangible, real-life projects,” says Di Benedetto. “In this industry, you get to see things come to life – whether it’s someone’s home, a commercial building, or major infrastructure.”

While he stepped into the role of rail modal manager in October of this year, Di Benedetto previously served as customer service and logistics supervisor for Amrize’s cement division. In that position, he oversaw the completion of on-road cement orders and delivery services, managing the logistics and transportation of up to

2.5 million metric tons of cement annually across eastern Canada. He recalls 2022 as a turning point. At a time when the industry as a whole was navigating the aftermath of COVID, marked by supply chain disruptions and high demand for cement, it paved the way for a story of resilience and clarity.

“There were tight schedules, a lot of moving parts, things got very complicated,” he recalls, but notes he weathered the storm. “It was that moment that I knew I wanted to build a career at Amrize. The work is hands-on, impactful and there's a lot of pride in knowing we’re helping build the communities around us.”

His advice for someone entering the industry? Don’t be afraid to ask questions.

Focus on what you can control, and don’t waste energy on what you can’t, he advises newcomers to the field.

“Stay calm under pressure and focus on finding solutions with the experience and tools at hand.”

Throughout his career, Di Benedetto has proven that success doesn’t always follow a straight path, but with passion, adaptability and purpose, it can take you exactly where you’re meant to be.

BUILD YOUR AMBITION WITH US

At Amrize, we’re proud to celebrate the talent and dedication of our industry-leading team—trusted experts empowering the growth of our future cities and communities.

Congratulations to Marino Di Benedetto on being selected for this year’s Rock to Road Top 10 under 40.

Your leadership is shaping a world where better building means better living for all.

To learn more about Amrize, visit amrize.com

COREY HOGAN

Production Manager, Superior Industries Inc.

Miramichi, New Brunswick

Eight years ago, the stars aligned for 33-year-old Corey Hogan when he was switching careers, and Superior Industries was hiring in his hometown. For several years, Hogan was a travelling industrial mechanic in the mines of remote Western Canada.

“I was basically born with a wrench in my hand,” says Hogan, who grew up loving anything mechanical. Around 2017, he decided it was time to find a job close to home and settle down. Within the first couple of weeks as an assembler, Hogan fell in love with the work.

“I really love the industry, but even more so the company. What they stand for, their work culture and how they treat us employees.”

In his role, Hogan realized just how much the country depends on manufacturing equipment. He adds, “You have the ability to make sure that a small family business receives that new conveyor to make sure they're happy. I take pride in that.”

People and community are incredibly important to Hogan, especially now in his current role as production manager. Throughout his career with Superior, he has seen how great leadership impacts the work culture.

“From an early stage, I took a very big interest in positive leadership,” remarks Hogan. “And creating an environment for people so they enjoy coming to work.”

SIGN UP TODAY

Rock To Road is more than a magazine. It is your comprehensive source for ongoing industry expertise tailored for the Canadian aggregate and roadbuilding sectors.

Sign up for our newsletter and each week you will have practical information directly affecting your daily operations delivered to your inbox. Our weekly newsletter includes:

During the pandemic, Hogan’s optimism rubbed off on his colleagues despite the uncertainty the industry faced. According to his colleague Corey Poppe, marketing manager at Superior, Hogan quadrupled the size of his team while keeping quality and safety high amidst a product surge.

It was a challenge for Hogan to become the leader he felt his team required to be successful – as he knew how much a leader, good or bad, impacts the workplace.

“Managing people requires a lot of personal growth,” says Hogan. “I want to be the best leader I can be.”

His biggest piece of advice to someone entering the industry is to have an open mind.

“Don’t think you have all of the answers,” he says. “There are so many people in this community with legacy knowledge that you can learn and grow from.”

• In-depth coverage on vital topics affecting the industry.

• Practical, real-world case stories on quarry and highway construction operations.

Essential updates on new products and equipment.

• Helpful maintenance tips and other items of interest to aggregate producers and roadbuilding contractors.

DAVID HUNTER Operations Manager, Arro Crushing Ltd. Milverton, Ontario

David Hunter of Dunoon, Scotland, left school to pursue his dream of becoming a professional golfer. But like with many dreams, his came with a caveat – money, and Hunter had to find a way to fund his expensive pursuit.

“My dad said I had two options: I could either get a job or join the military,” says Hunter. I was a bit too young for that, so I got a job in civil construction.”

Now at 39, Hunter has been working in the industry for over two decades. At first, he struggled with the physical demands of the job as “civil construction is difficult, you’re outside in the elements,” explains Hunter. But after getting married, he recognized a real opportunity to provide his family with financial security.

“Construction hasn't been easy for me. I started as a labourer at 15, and worked hard to get to where I am today,” he says. “In my years in the industry, I have learnt a vast amount of things from laying pipe, grades, layout, operating equipment and supervisory skills.”

In 2021, Hunter and his family immigrated to Canada in the dead of winter to further his career as a site supervisor before being promoted to a project manager for a contracting company.

‘It was a bit daunting,” says Hunter. But, he soon found himself enjoying the work as the landscape was vastly different from Scotland.

In January of this year, Hunter started his role as operations manager with Arro Crushing, where he has developed a sense of community among his coworkers. As a family man, Hunter deeply values his relationships with his colleagues and strives to be the best team lead he can be. According to Jared Kuepfer, CEO and founder of Arro Crushing, Hunter has been a key figure in safety culture. He prioritizes ensuring that every worker makes it home to their family safely each day. Hunter explains that his favourite part of the job is the people — they’re what make work enjoyable.

“Training and educating your team, and getting a job done right, is very rewarding,” he says.

His biggest piece of advice to anyone entering the industry is to always have a positive attitude.

“Have respect for your fellow workers and have grace, you will do very well in this industry.”

ADAM MAHANEY

Western Asphalt Products, general manager Brandon, Manitoba Adam Mahaney’s first job in the industry was as a college summer student working as a flagger on a road crew near his Marathon, Ontario home.

At the time he was studying computer engineering, as well as home and building automation at Fleming College. That first summer job as a flagger on a Cold In Place Recycling crew led to regular work each summer until graduation.

After graduation, he looked for jobs in the field he studied for but realized he enjoyed working on a road crew. Plus, there wasn’t much difference in the pay.

“I told my supervisor to give me a bit of a raise and I never looked back.”

That’s when he realized it was more than a summer job and he could make a career out of it.

He continued to take on different roles over the years, including foreman, supervisor and eventually general manager.

“I really worked my way up the ladder over the years.”

By the age of 26, he was superintendent of a Cold In Place Recycling crew for Seeley and Arnill Construction in Ontario.

In 2012, he signed on to help start Western Asphalt Products.

“The plan was to build two emulsion terminals in Western Canda -- one in Brandon Manitoba and one somewhere in the Edmonton area in Alberta,” explains friend and Western Asphalt Products president Dean Arnill. “We had no idea how to make, test or produce asphalt emulsions. We learned everything from the ground up including building two asphalt emulsion terminals within two years back-to-back.”

Working out of an old NAPA Auto Parts building, the two men were busy.

“Over the course of the winter of 2012, we basically built an emulsion terminal and we were in operation, I believe, in July of 2012,” Mahaney recalls.

Once the Brandon terminal was operational, Mahaney was left to run it on his own. At the time, there was just Mahaney and one other employee. Today, they have about 15 people working at the terminal.

He loves the variety his job provides.

“I could go from sitting on my desk to out at a gravel pit or a quarry managing operations there, possibly running some of the equipment to help out. Or, I am at a job site dealing with customers, maybe just doing site visits or maybe there is a complication or an issue that I'm going there to try and solve. I could be working with the laboratory, developing new products, trying to bring something to market. I really do quite a variety of everything.”

JASON MOUNTNEY

General Manager, Tomlinson Infrastructure Ottawa, Ontario

The biggest challenge facing the industry is replacing an aging workforce, explains Jason Mountney.

That’s why the 36-year-old believes it’s important for him to help young people realize there are many career paths in this field.

“It’s not just digging holes,” he jokes. “We're working with stateof-the-art technologies, state-of-the-art equipment. We’re working on some of the biggest projects in the province.

“I think there's a lot of people out there that don't consider construction that would be excellent in construction.”

He should know. This was not his initial career path. While he worked in construction during high school, in college he studied mechanical engineering. However, upon graduation, he couldn’t find work in that field.

“Tomlinson happened to have a construction project very close to where I was living at the time. I handed in a resume to a foreman in the field and started that way,” he recalls.

He knew on his first day this was the company, and industry, for him.

“I really didn't know what I was getting into because I had done much smaller scale construction, but, working on a crew, part of a team, the problem solving, I was hooked on day one.”

It’s that day-to-day problem solving that he enjoys most about his role.

“Working on a large team, there's a million touch points every day with dealing with people, problems, projects. It's that challenge of problem solving and keeping the pace going.”

He began as a flagger and labourer, but over his 17 years with

Tomlinson has served in a variety of roles including a grade man on a road crew, a field engineer, project co-ordinator, project manager and construction manager. Today, he is general manager overseeing construction operations for Kingston and portions of Ottawa.

That hands-on experience at every level has helped shape him into a well-rounded leader.

He is a three-time winner of Tomlinson’s Innovation Award and has consistently delivered improvements that enhance safety, efficiency and sustainability.

“His leadership in these areas has had a lasting impact on Tomlinson’s operations and serves as an example across the broader construction sector,” states his nominator, Megan Tomlinson.

He has also served on the Kingston Construction Association Board for the past three years and actively participates in other industry groups.

He regularly volunteers for both internal and external charitable initiatives, including events supporting BGC South East and other local organizations.

For those entering the industry, he advises they take that first step.

“Get in the industry, get in a role. It might not be the role you want to do or where you want to be, but there is such a clear path once you're in to advance,” he says.

CONGRATULATIONS ADAM MAHANEY

RYLEY O'CONNOR

Quarry and Land Treatment Facility Manager, Castle Rock

Enterprise

Whitehorse, Yukon

Ryley O'Connor of Whitehorse, Yukon, got his start in the construction industry at only 14, working for Castle Rock Enterprise (CRE) during summer breaks. O'Connor’s grandfather, Rick Bonnycastle and father, Ron Bonnycastle, founded Castle Rock in 1995.

“Construction has always been a big part of our family,” says O'Connor. “My dad inspired me to pursue this path. I grew up watching the work ethic, pride, and dedication it takes to build something lasting, and I knew early on that I wanted to be part of it.”

After graduating high school in 2011, O'Connor immediately got to work, managing the gravel quarry and operating CRE’s Whitehorse asphalt plant.

“The role gave me a lot of hands-on experience in production, maintenance, quality control and leading a crew,” he says. “And my dad has taught me 99 per cent of what I know.”

In this role, O’Connor was responsible for pit design, planning, development and running equipment. Three years later, O’Connor attended Lethbridge Polytechnic to pursue a diploma in civil engineering technology.

Now at 32, O'Connor is the CRE quarry and land treatment facility manager.

“Over the years, I've had the opportunity to help train and mentor new employees,” says O’Connor. “Sharing what I've learned along the way and watching them grow into confident and capable operators is what I take pride in.”

O’Connor finds his role to be invaluable, especially because he sees firsthand how infrastructure growth positively impacts his local community. Because CRE is based in Whitehorse, O’Connor has encountered both labour and environmental challenges, as everything has to be planned for the short construction season.

“There is pretty much no room for error,” says O’Connor. “You quickly learn the importance of creative problem solving, adaptability and strong teamwork to keep things moving.”

Besides the people, O’Connor’s favourite part about the industry is how dynamic it is.

“No two days are the same,” he says.

According to Christine Burns, HSE manager at CRE, O’Connor leads with precision and a clear emphasis on quality and community impact.

“The more you learn about the bigger picture, the more valuable you become to your team,” says O’Connor. “The best lessons always come from being in the field and asking questions.”

RYAN PINTAR

Senior Director of Customer Service and Transportation, Major Wire

Candiac, Quebec

Within the four years 39-yearold Ryan Pintar has been at Major Wire, he has made a big impact on both customers and colleagues.

Pintar’s role as senior director of customer service and transportation involves day-today interaction with customers to improve their experiences with the company, in addition to collaborating with every department at Major Wire.

Pintar got involved in the industry unexpectedly when he reached out to an old colleague, Ian Edwards, who is the vice president of global sales at Major Wire, to be a reference for his CV.

“Next thing I knew, I was here working at Major Wire as director of customer service,” says Pintar.

Coming into his new role, Pintar didn’t realize how challenging and complex the aggregate industry was.

“When you look at it from the surface level, you’d think we're just screening rocks,” says Pintar. “That’s what I thought it was.”

It took Pintar by surprise how much there was to know, and he admits ‘the learning curve was steep.”

He spent his time working closely with customers to better understand their needs and remarks that it is essential to his role to learn something new every day.

His hard work paid off—just one year after being hired, Pintar was promoted to Director of Customer Service and Transportation. He credits his success to a passion for problem-solving, explaining that customer service is his bread and butter.

“I know people always say they’re detail-oriented, but I actually am,” he says. “Daily, I am talking with customers to find a solution to their problem. I need to know the details to figure out the missing link. Every day, it is something new, which I genuinely love.”

Pintar rebuilt Major’s transportation department, which enhanced logistics and the delivery performance. According to his coworker, Arianne Bourke-Meagher, marketing manager at Major Wire, his work led to significant improvements in process efficiency and customer satisfaction.

His biggest piece of advice for anyone entering the industry is not to underestimate how technical and advanced it truly is. “Aggregates are complicated; it’s a lot more than making big rocks into small rocks.”

MARIO TANAZIO

Engineering Design and Diagnostics Technologist, Haver & Boecker Niagara St. Catherine's, Ontario

Born and raised in Brazil, 30-year-old Mario Tanazio grew up as a self-described “mechanical engineer enthusiast.” His uncle, Milton, also a mechanical engineer, was a major inspiration and motivated Tanazio to pursue his passion as a career.

Tanazio took his advice and accomplished his master's degree in mechanical engineering and design at the Universidade Estadual de Campinas. In 2019, he had an opportunity to participate in an internship with Haver & Boecker Latinoamericana in Monte Mor, Brazil.

“I fell in love with the product development,” says Tanazio. “Because the job is so fast-paced, you are always learning. That really pushed me.”

In 2023, Tanazio was offered a job at Haver & Boecker Niagara as a mechanical engineer, design and diagnostics technologist. Tak-

ing the plunge, Tanazio moved to St. Catherine's, Ont., and started working full-time at the Niagara plant.

“I truly felt I had found my place during my first few months at Haver & Boecker,” he says. “Bringing new solutions to our products and improving our quality, this is what I like most about my role. It is an environment that fosters innovation and adopts new technologies; it is inspiring to be here.”

Dieter Takev, vice president of engineering and technology at W.S. Tyler Canada, explains that Tanazio’s initiative and curiosity are what keep the Haver & Boecker Niagara team efficient and inventive.

A project Tanazio is most proud of is the major retrofitting initiative at Haver & Boecker Niagara for one of the world's largest openpit iron ore mines, explains Tanazio, who led the entire corrective process—from root cause analysis to redesign and material selection.

“It was a high-stakes project, and being at the forefront of solving it through technical leadership, collaboration, and persistence made it truly rewarding.”

Today, his uncle Milton remains a trusted mentor, offering Tanazio invaluable guidance and unforgettable advice.

“Even in the most demanding situations, take your time before making a decision.”

This simple yet powerful statement is something Tanazio would share with anybody entering the industry.

For Your Aggregate and Road Building Business

•

• Webinars, podcasts and video

• Tradeshow marketing content

• Automated content marketing supported by first-party data ....and so much more!

SNEAK PEEK EVENT SHOWCASE

We pull the curtain back to offer a glimpse at what you will find at CONEXPO-CON/ AGG 2026

> As 2025 ends, all eyes are now turning to 2026 and what is on the calendar that year.

Topping the list of events taking place is CONEXPO-CON/AGG 2026, North America’s largest event of the construction industry. It hits Las Vegas March 3 to 7.

Every three years, CONEXPO-CON/ AGG brings together the construction industry and serves as the launchpad for the latest equipment and technology. The 2026 event will also feature 190 education sessions covering the wide swath of the construction industry.

New to this year’s show is the Ground Breakers Stage. This stage will feature the industry’s top innovators and visionaries showcasing autonomous technology, sustainable solutions and workforce innovations.

While the complete list of speakers will be announced closer to the show, it has already been announced that Jahmy Hindman, senior vice president & chief technology officer with John Deere, is one of the featured keynote speakers for the stage.

Hindman will be joined by John Deere colleagues Maryanne Graves, manager, product management, as well as Jonny Spendlove, manager, precision construction, on the Ground Breakers Stage on Tuesday, March 3 at 11 a.m., spotlighting the innovation and technological advances propelling the construction industry forward.

Another keynote speaker is Amazon Web Services (AWS) director of AWS IoT services Dave Kranzler.

Kranzler will take the Ground Breakers Stage on Thursday, March 5 at 10 a.m., spotlighting how advances in AI, automation and connected technologies are reshaping

the construction industry, reducing costs and creating safer, more sustainable jobsites.

ON DISPLAY

With more than 2,000 exhibitors spread out over 2.9 million square feet of space, there is plenty of new equipment on display. Below is just a small slice of what is available to see.

HAVER & BOECKER NIAGARA

Booth: C32616 in Central Hall

Haver & Boecker Niagara will highlight Pulse Condition Monitoring (CM) system and other state-of-the-art mineral processing solutions at this year’s show. Pulse CM is designed to monitor the health of

vibrating screens using modern algorithms and artificial intelligence. It provides accurate measurements and forecasts complemented by information that is easy to understand. Pulse CM is a wireless diagnostics tool that helps mineral processing operations be proactive, rather than reactive, when it comes to maintenance efforts. This leads to increased efficiency, decreased downtime and improved reliability.

ASTEC’S VARI-FREQUENCY TECHNOLOGY

Booth: C30236 in Central Hall

Astec Industries will be showcasing its groundbreaking Vari-Frequency technology at ConExpo/ConAgg 2026. The technology has been implemented on its 6203 LP Horizontal Screen, a next-generation solution

CONEXPO-CON/AGG 2026 takes place in March in Las Vegas, Nevada. Photo: CONEXPO-CON/AGG

built to boost screening performance.

Astec states the new design minimizes blinding and maximizes uptime, giving producers a smarter, more reliable way to keep processing material.

Installed on the bottom deck of a horizontal screen, the patented Vari-Frequency deck significantly increases throughput and efficiency while minimizing plugging and blinding. The live portion of the deck’s flexible surface is supported by a system of tensioned cables that create rapid, localized g-force spikes across the screen, stimulating the screen media and material to maintain throughput.

Built for standard side-tensioned screen cloth and requiring no external power source, the Vari-Frequency technology provides an adaptable, energy-independent solution that integrates into existing systems.

The company plans to incorporate Vari-Frequency technology into additional screen models across its product portfolio. Attendees of ConExpo/ConAgg 2026 will have the opportunity to preview the eightfoot model, the next piece of equipment in the technology rollout.

VOLVO CONSTRUCTION EQUIPMENT

Booth: F24029 in the Festival Grounds

Volvo Construction Equipment is ready to help quarry, aggregate and mining professionals at this year’s show.

The company’s booth will have feature equipment and technology for industries like commercial and residential construction, utilities, quarry/aggregates and mining.

Amidst Volvo’s biggest-ever launch period, CONEXPO 2026 will be the first opportunity for most people to see several of the next generation models in one place. About 20 machines will be in the booth, including models from the new articulated dump truck, excavator and wheel loader series — some of which are launching at

the show.

Updated rigid haul trucks, soil and asphalt compactors and electric machines will also be on display. This includes larger electric machines well suited to quarry applications, such as the midsize L120 Electric wheel loader and 23-ton EC230 Electric excavator.

Demonstrations of new and updated productivity-boosting technologies like Connected Load Out and Load Assist will connect the dots between equipment and outcomes.

It wouldn’t be a Volvo CONEXPO experience without an operating pit, where visitors can test-drive diesel and electric excavators.

At educational sessions in the West Hall, Volvo experts will speak about two key services that improve uptime and profit margins:

• Buy the Use, Not the Iron: Equipment as a Service: Wednesday, March 4, at 1 p.m.

• The Value of Proactive Telematics Monitoring: Thursday, March 5, at 10:45 a.m.

CEDARAPIDS CRH5064 PORTABLE

HSI IMPACTOR PLANT

Booth: SV2357 in Silver Lot

Cedarapids states its CRH5064 Portable HSI Impactor Plant is engineered for unmatched productivity and durability, positioning it as the ultimate solution for demanding, large portable crushing operations. At its core is the TI5064 horizontal shaft impact crusher, which Cedarapids states is a powerhouse designed to deliver exceptional throughput and reliability even in the toughest primary crushing jobs.

The 400 hp (300 kW) crusher motor provides superior crushing. The TI5064 impact crusher features a massive rotor with quick-change impact bars, supported by a high-strength, high-inertia four-bar rotor assembly. Material input is managed by the 60-inch by 20-inch VGF6020 vibrating grizzly feeder. The removable AR400 feed

hopper module provides a 19 yd³ (14.5 m³) capacity, featuring an offset taper that reduces bridging in slabby materials. Optional components, such as a grizzly reject conveyor or a self-cleaning magnet, can be added to enhance efficiency.

MAGNA MT130J JAW CRUSHER

Booth: SV2357 in Silver Lot

Terex is showcasing its MAGNA MT130J mobile jaw crusher at this year’s show. The machine was developed for large-scale quarry and mining operations. It can operate as a standalone primary crusher or integrated into a mobile or static crushing and screening plant.

The plant can move easily between locations as it can be split down and reassembled without the need for heavy crane assistance on site.

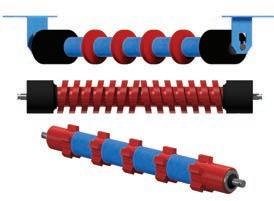

LUFF INDUSTRIES URETHANE RETURN ROLLERS

Booth: C30104 in Central Hall

Luff Industries has introduced a variety of urethane products to its product lines, including several return roller options. At the 2026 event, the Urethane Return Rollers will be on display. Luff Industries states the rollers offer efficient cleaning and beltfriendly designs that outlast and outperform rubber return rollers up to five times. Clean Weave spiral design cleans the bottom side of the conveyor belt through an augering action. The roll discs are always contacting the belt in a new area increasing the cleaning action. The Urethane Beater Return Roller effectively cleans the belt and is engineered to be safe for cleated belts.

The R2, high performing and very compact track mobile impact crusher, has been designed to complete Keestrack’s product range of impactors. The R2 is easy to operate within city centres where high flexibility and mobility are essential. In a lot of European cities there is a need for pure electric plug-in construction equipment. With the ZERO-drive, a full electric plug-in drive version, without any combustion engine onboard, Keestrack provides the ideal solution. The new impactor has a capacity up to 150 t/h.

The crusher design features are like the bigger R3 impactor. The hopper (4 yard³) with integrated vibrating feeder (10-feet 10-inches by x 2-feet 8-inches) and prescreen (4-feet 1-inch by 2-feet 8-inches) also has a asymmetric design to feed the material easy into the inlet (2-feet 10-inches by 2-feet 4-inches) which is equipped with a replaceable entry beam.

The newly designed rotor, with a width of 2-feet 9-inches and a diameter of three feet, is made of Hardox steel. The rotor has the same design concept as the bigger R3, R5 and R6, designed to minimize wear. Rotor speed can be adjusted by a hydrostatic drive to finetune the desired grain size. The impact aprons can be serviced from the top which facilitates service maintenance.

The R2 impactor is fully equipped in closed circuit with a 3-foot 11-inch by 10foot single deck after screen, magnet separator and windsifter. It has a total weight under 30sT and a transport length of 42feet 10-inches. The return conveyor of the closed circuit can also swivel outside to be used as a stockpile conveyor for oversize.

The diesel/hydraulic R2 version is driven by the new DEUTZTCD 5.2 L4 engine, which is very efficient, powerful and clean. It applies to all EU Stage V and US EPA Tier 4 and is able to run on ecological biodiesel. The R2 is also available in ZERO drive version, which is full electric plug-in and has no combustion engine.

SUPERIOR INDUSTRIES

Booth: SV2374 in Silver Lot

Superior Industries is returning to CONEXPO-CON/AGG with its largest outdoor footprint yet.

The company will showcase new equipment, system-wide solutions, and hands-on experiences from its booth, where more than 60 Superior team members will welcome visitors from across the industry. Here are some of the new Superior products making their debut in Las Vegas:

Independence High Frequency Screen Plant

Built to make spec from challenging feed, this new plant pairs a multi-slope six by 20 two-deck design with a vibrating feed box that spreads material evenly for stronger stratification and maximum open area utilization. Outboard motors simplify inspection and maintenance, VFD control allows individual tuning for each deck, and a fully-enclosed body reduces dust. An automated clean out cycle helps move sticky material, resulting in up to 20 per cent more capacity in the same footprint.

Next-Generation Cemco Vertical Shaft Impactor

Merging the strengths of the legacy Cemco platform with features from Superior’s Valor VSI, Superior states its redesigned crusher delivers optimized rock on rock performance. New rotor and chamber geometry boosts efficiency, and a rotating anvil ring extends component life. The platform maintains parts commonality across models and offers multiple chamber and rotor options. A C1920 with a v-twin drive will be displayed in the booth.

600 HP Crushing Performance on a P500 Frame

A factory-approved power upgrade now rates the P500 Patriot Cone for 600 horsepower, giving portable operators more output without oversize permits or heavy haul requirements. The show unit will be

mounted on a rear feed, rear discharge portable chassis equipped with hydraulic leveling legs and a large observation platform.

Self-Contained Portable Radial Stacker

Superior says its redesigned self-contained stacker delivers dependable performance at a competitive price point. Updates to the truss depth, power supply and load zone hopper improve efficiency while the onboard engine powers up to 500 TPH. A steeper angle creates larger stockpiles in less space. Visitors will see a 36" by 80' model with hydraulic controls for the hopper wings, undercarriage and folding head section.

Conveyor Transfer Zone

Skirting Solutions

Superior is introducing an updated set of skirting solutions designed for cleaner, tighter control across load and transfer zones. Newly designed Adjustable Skirtboards arrive in preassembled sections with trim to fit mounting legs to match individual conveyor designs.

MAJOR WIRE INDUSTRIES

Booth: C32269 in Central Hall

Major Wire Industries states its FLEX-MAT tensioned screens maximize production and efficiency with every stroke. The screens feature high-frequency vibration technology that accelerates material stratification and separation. Engineered for performance in both dry and wet applications, these screens increase throughput, reduce blinding and pegging, and deliver longer wear life. Major Wire Industries is also showcasing its FLEX-MAT modular panels, which the company states bring the same high-frequency benefits of FLEX-MAT to modular setups. Designed for snap-in installation, they offer open area and faster material separation. With reduced maintenance and extended wear life, Major Wire Industries states these panels are perfect for maximizing uptime and productivity in high-impact screening environments.

> JAN. 14-15, 2026

Alberta Sand and Gravel Association Convention Edmonton, Alberta www.asga.ab.ca/convention#learn

> JAN. 19-22, 2026

World of Concrete Las Vegas, Nevada www.worldofconcrete.com/en/home.html

> FEB. 2-4, 2026

Ontario Road Builders’ Association Convention Toronto orba.org/events

> FEB. 11-12, 2026

Canadian Concrete Expo Mississauga, Ont. www.canadianconcreteexpo.com

> FEB. 17-19, 2026

Ontario Stone, Sand and Gravel Association Toronto, ON www.ossga.com/events/event/ossga_ conference/

> MARCH 3-7, 2026

CONEXPO-CON/AGG

Las Vegas, Nevada www.conexpoconagg.com

> MARCH 26-27, 2026

Atlantic Heavy Equipment Show Moncton, New Brunswick www.ahes.ca

> APRIL 23-24, 2026

National Heavy Equipment Show Mississauga, Ont. www.nhes.ca

> JUNE 3-4, 2026

British Columbia Stone, Sand and Gravel Association Conference and Trade Show Vancouver, BC gravelbc.ca/events/

one more load Unearthing potential

Investing early in resource evaluation pays dividends

I recently worked on a project that highlights a common issue in the aggregate industry: the risks of not fully understanding the extent and quality of a resource.

Unfortunately, the lack of comprehensive, propertywide evaluations and complete delineation of deposits is far more common in the aggregate sector than it should be.

Our team was asked to complete an aggregate resource assessment on a long-standing pit that plays a critical role in sustaining a company’s downstream businesses. Without reliable aggregate feed, their road construction, ready-mix and asphalt operations would potentially face severe challenges from raw material shortages or would incur unexpected costs of sourcing aggregate elsewhere to satisfy their near-term needs. Fortunately, the company realized the potential threat of not having a clear picture of the deposit’s quantity and quality, and requested a more comprehensive evaluation to assist in decision making to develop a plan moving forward.

Like many aggregate pits, it began operations almost two decades ago as a small open cut with no supporting drilling data. Mining followed a typical “strip, excavate, crush, screen” approach, “chasing” the material as the pit expanded. As demand grew, the disturbed area spread rapidly. Ten years into operations, the company drilled a handful of exploratory holes. This initial limited program, based largely on visual logging with little analytical confirmation, provided only an incomplete short-term perspective. No comprehensive, property-wide exploratory program was ever completed.

In one instance, a portion of the site had trees removed and overburden was stripped ahead of an already active pit face in anticipation of excavating additional pit run; however, this was completed without drilling or analytical data to confirm the quality of the resource in advance of the additional stripping in this area. The aggregate unfortunately and unexpectedly diminished immediately behind the active operating pit face. That area that ended up yielding unsuitable aggregate and still required reclamation to then be undertaken, at a cost.

Regulatory approvals were amended several times at this operation due to a lack of full knowledge of the

potential mining limits. Regulators imposed amendment requests also came about after discovering the company had marginally exceeded the initially approved boundaries while the company was “following” the deposit. Such breaches can potentially trigger regulatory action, fines, reputational damage, or even an order to cease operations. Amending approvals is becoming considerably more time consuming and expensive, often requiring years of studies, hearings, and negotiations with the added burden of lost credibility. In this case, regulators imposed additional reclamation requirements before allowing any further pit expansion (required partial reclamation before continuing).