BAKERY SCENE

Produce your entire line of buns and rolls with a single, versatile Vemag Dough Divider

n Gently handles dough

n Unmatched scaling accuracy

n Precisely scales a wide range of dough portions

n Produces a variety of crumb structures

n Handles absorption rates from 45% to 95%

n No divider oil needed

n Fast, easy changeovers

n Come run your product with us at the Reiser Customer Center.

Vemag 500 dough divider

WORKSHOP. The Farmer-Miller-Baker Summit was a hit.

8 Moncton bakery scene

We explore successful N.B. bakeries that run on innovative and varied business models

12 BAC Bulletin

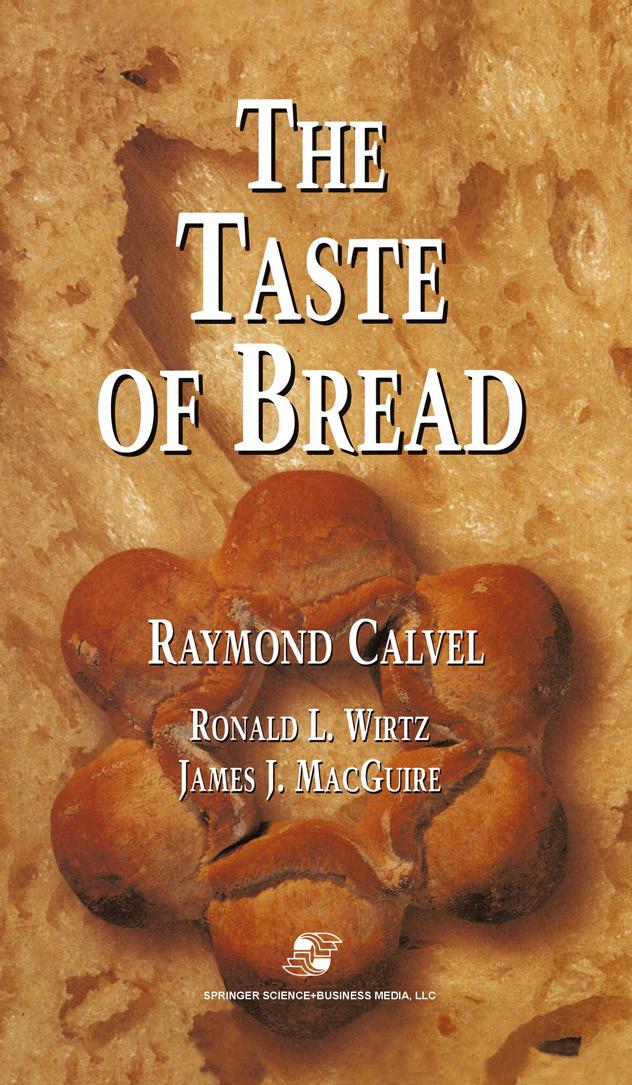

Get up to date with the activities of the Baking Association of Canada, learn about autolyse and the important contributions of celebrated baking professor Raymond Calvel

14 Bakery Showcase preview

Learn about exciting sessions and the Bakery Cup of Canada competition planned for Bakery Showcase next May

4 From the Editor Milling about in Moncton

22 Concepts for Success

ON THE COVER

We check in with successful bakeries with unique business models in the Moncton area, following the first Atlantic FarmerMiller-Baker Summit. See page 8.

16

DEPARTMENTS

From the Editor

Jake the Baker

16

Tackling key topics

Experts share tips on training, succession planning at the Baking Expo

Breaking into the luxury baked goods market means valuing your time

Selling luxury products is about recognizing the time it takes to ensure your artistic cakes, sculptures, and other products are memorable and worth the premium price. That was the message successful sugar artist Alene Paulk delivered at IBIE. Learn more at bakersjournal.com!

Seven easy ideas to increase bakery sales around New Year’s Eve

JOURNAL EXTRAS | BAC updates and webinars | Legislation affecting bakeries | Stories of independent bakeries | Showcase information | Irresistible recipes …plus the latest industry news and new products. bakersjournal.com www.bakersjournal.com

MONCTON

BY COLLEEN CROSS

LEARNING IN MONCTON

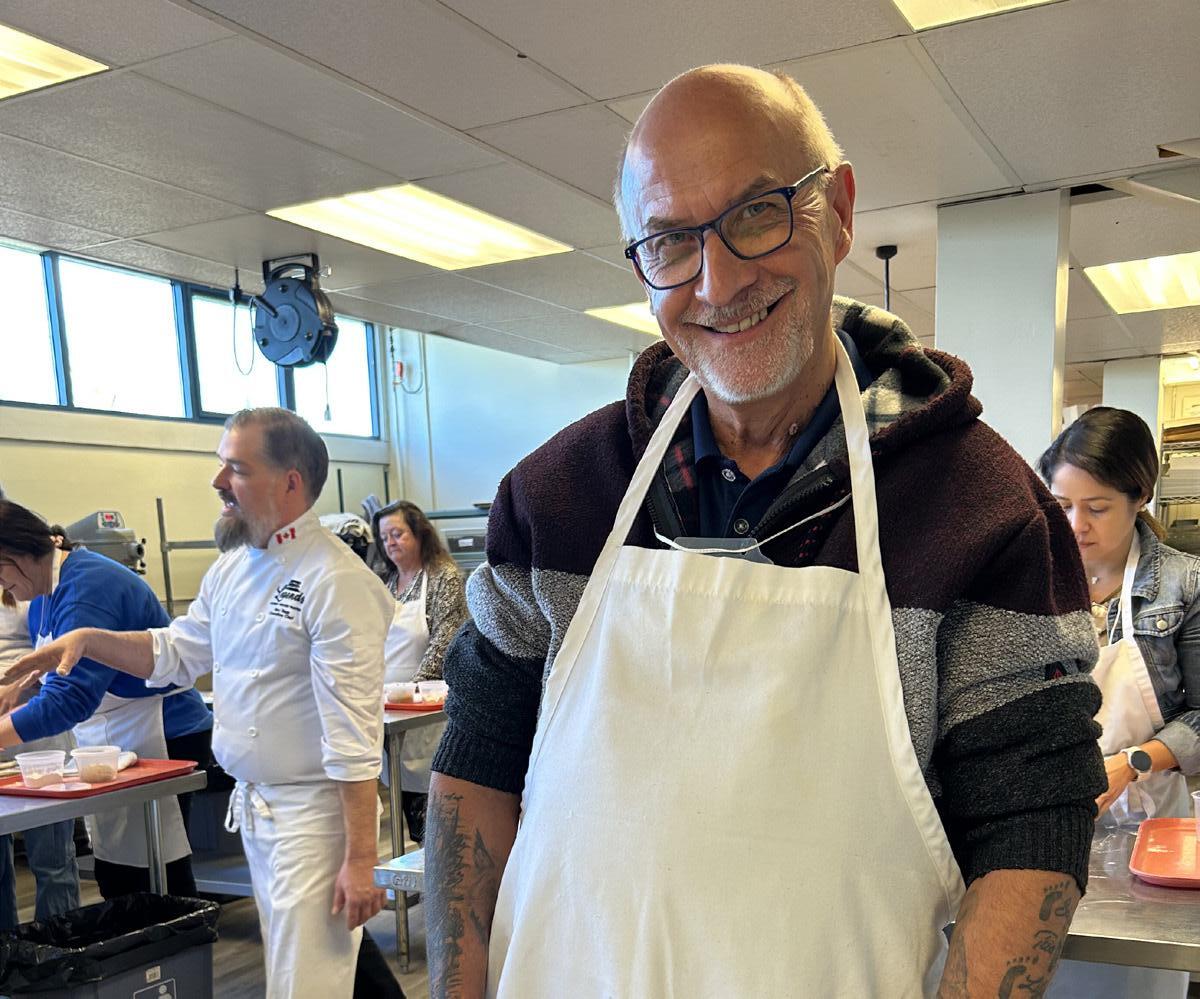

Artisan baking and knowledge transfer is alive and well in Atlantic Canada. In October the farming, milling and baking community gathered at New Brunswick Community College to learn, network and find inspiration.

The Baking Association of Canada presented the one-day Farmer-Miller-Baker Summit that connected bakers using freshly milled local flours, farmers milling or cleaning their grains, small-scale millers and bakers milling their own grains.

About 30 participants, including teams from Mrs. Dunster’s, Nick the Dutch Baker and Made With Love by Cinthia, attended three demonstrations highlighting the characteristics and benefits of sustainably sourced, freshly milled, local flours.

Award-winning chef Alex Haun, head chef at Legends Coliseum, focused on incorporating freshly milled flour into sourdough and guided participants through the process of shaping and braiding challah. Tony Holden, owner of Tony’s Bistro and Patisserie, Atelier Tony, Boulangerie Tony and Tony’s on Botsford, showed just how versatile brioche dough can be with sweet and savoury bakes. The BAC’s Martin Barnett, a longtime artisan baker, made no-knead-style purple wheat flour bread and led an interactive demonstration of how to mill, mix and bake bread using 50 per cent purple wheat respecting the grain’s special characteristics. Participants watched a small wooden mill in action and received a detailed formula and details about the flour from Midmore Farms in Alberta.

Owen Brinson, coordinating instructor of culinary programs in the School of Business, Hospitality and Tourism at NBCC, and Chef Alex Braun, chef instructor of the microcredentials program, spoke about the innovative, short, focused programs developed in partnership with local employers to help students 16 and up gain specific, in-demand skills employers need. Working in pairs, students learn about yeast doughs, cookies, pies, tarts, baking science, kitchen best practices and more. A course is planned for Saint John starting in January with 15 spots available.

Participants got hands-on at NBCC in Moncton during three demos that highlighted the unique characteristics and benefits of sustainably sourced, freshly milled flours.

Mike Raftus, director of sales, Canada, at Ardent Mills, presented the top five trends motivating consumer purchases based on the company’s Trend to Table report. Among many insights, Raftus shared that culturally inspired breads are becoming popular and people have the “Desire to Do Good” but don’t always know how to get there.

Jacqui Quigg of Food and Beverage Atlantic talked about programs and resources to assist bakeries such as masterclasses, digital marketing and monthly webinars. They are expanding their entrepreneur Retailer Pitch Assistance Program to Ontario in 2026.

Barnett moderated an intriguing panel talk on the benefits, challenges and opportunities of baking with sustainable, freshly milled flours. Holden, Oliver and Marc Hofer of Oliver’s German Bakery, Jean-Guy Poirier of Ferme Le Champdoré and Dean Cummings of Speerville Flour Mill shared their experiences and insights. Challenges expressed were the relatively short shelf life and lack of space to store flour. All agreed that continuously educating the customer on characteristics and benefits is key.

Participants agreed that connecting, staying in touch and supporting one another is important. More FMB events are planned for 2026, beginning with Okanagan College in Kelowna, B.C., on Feb. 23. Ardent Mills was Rising Sponsor, NBCC were gracious hosts and Sysco sponsored the delicious lunch prepared by NBCC staff and students. It was encouraging to see this meeting of the minds!

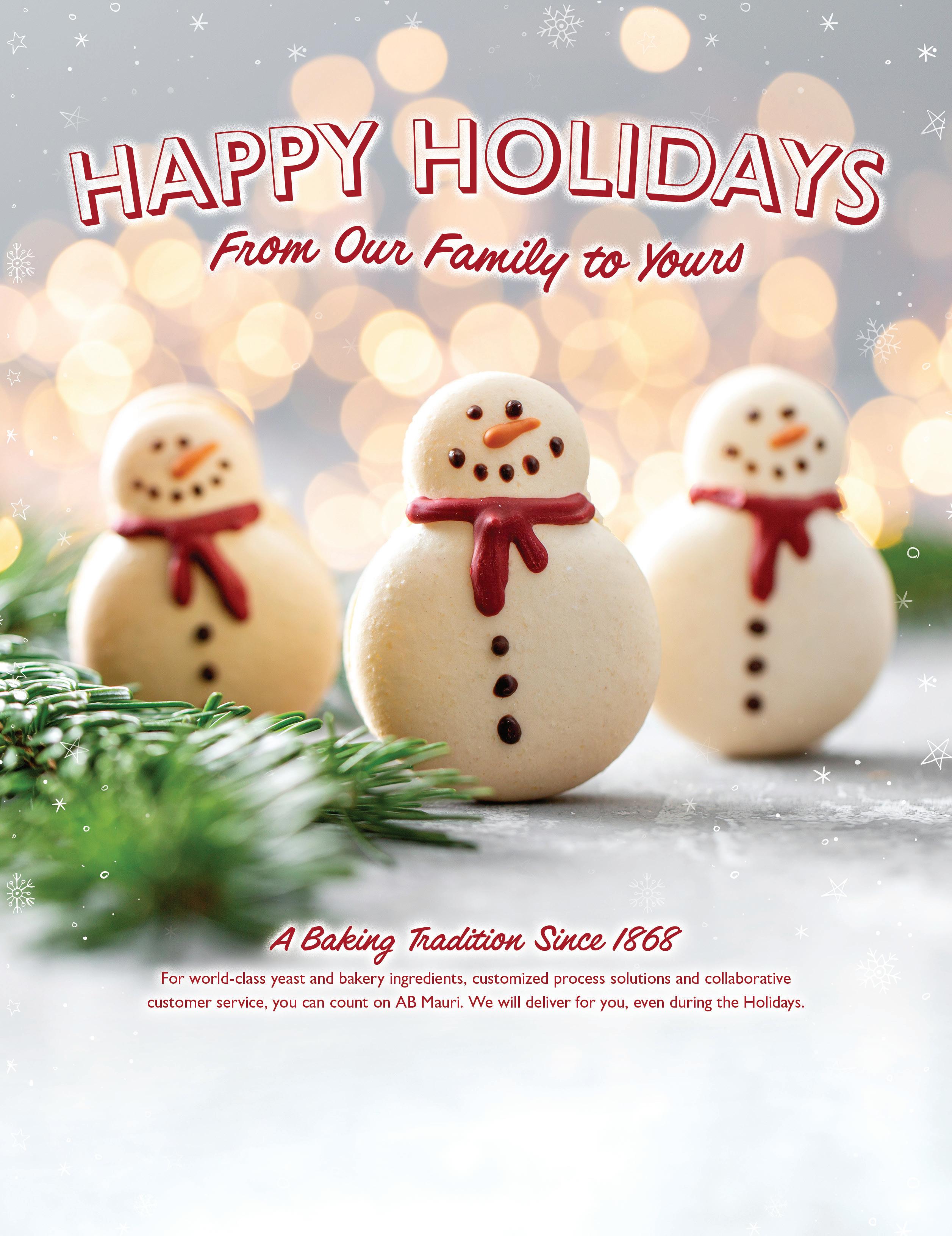

Best holiday wishes from all of us at Bakers Journal and we’ll see you in 2026! / BJ

DECEMBER 2025 | VOL. 84, NO. 6

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | Colleen Cross ccross@annexbusinessmedia.com 519-429-5227

TECHNICAL

EDITOR | Julie Istead, Puratos Canada jistead@puratos.com

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexbusinessmedia.com 705-826-2254

ACCOUNT COORDINATOR | Trish Ramsay tramsay@annexbusinessmedia.com 416-510-6760

MEDIA DESIGNER | Jaime Ratcliffe

GROUP PUBLISHER | Adam Szpakowski aszpakowski@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER | Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-510-5182

CEO | Scott Jamieson sjamieson@annexbusinessmedia.com

Mailing Address P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710.

ISSN 0005-4097

Published six times per year (Feb, Apr, June, Sept, Oct, Nov) by Annex Business Media.

Subscription Rates

— 1 Year $ 32.64

— 1 Year $74.97

- 1 Year $86.19 Single Copy Canada - $5.00

All prices in CAD funds.

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2025 Annex Business Media. All rights reserved. Printed in Canada.

Sunflower kernels are:

available raw or roasted

an excellent alternative to nuts

mild in flavour and add a pleasant crunch to food

a good source of fibre, Vitamin E, zinc and folate

ideal for a variety of foods including: bakery products, granola, snack bars, salad toppings and plant-based foods

¦ industry news ¦

briefly | Award-winning Toronto bakery marks 20th anniversary with new downtown location; Barry Callebaut opens third chocolate factory in Canada; Tariff remission relief extended for Canadian bakery imports: BAC | For more news in the baking world, check out our website: bakersjournal.com

George Brown hosts gingerbread house competition

George Brown Polytechnic Chef School showcased 33 talented and creative student bakers at its annual gingerbread house competition, held in the college’s Atrium on Nov. 18.

This year, students in the baking and pastry arts, culinary and hospitality programs were invited to create a gingerbread building inspired by a building in their favourite movie, book or TV series.

Quinn Hearndon earned top honours for Grand Budapest Hotel, which featured dual perspectives on the ornate fictional hotel represented in the movie of the same name. One side represents the hotel as it is in the movie and the flip side, displaying the plain gingerbread used in construction, is the hotel in the modern day when the story is being told.

Durrey Shehwar Niazi’s Victorian home inspired by Charles Dickens’ A Christmas Carol impressed judges with its extensive and elaborate piping and more than 100 separate pieces.

Holly Schlamb, Gusteau’s restaurant from the movie Ratatouille, inspired by Schlamb’s time spent staging in Lyon, France, and by respected chef Paul Bocuse.

Tahera Fatima Jahfri‘s tribute to the TV series Stranger Things, featuring the upside-down world with hands pulling at the roof, won the people’s choice award.

Sponsor Dawn Foods generously provided cash awards of $2,000 for first place, $1,000 for second place and $500 for third place. All four students received innovative baking books from Wiley.

Dawn has sponsored the competition for years. Ken Weir, director of marketing, Canada, said the company likes to support innovation and paid tribute to the “really outstanding work” of this year’s students. “At Dawn Foods Canada we’re thrilled to a supporter and sponsor of this event. We like to think that we were there at the start of the baking journey for a lot of the students.”

Prof. Sue Fleming, who organized the competition, thanked the students for their hard work and commitment to the baking industry. “You should all be extraordinarily proud of your work.”

Judges for the event were Dufflet Rosenberg, Dufflet Pastries; Joanna Yolles, pastry chef, instructor and judge on Wall of Bakers; and Colleen Cross, editor at Bakers Journal.

Canada on track to become number 1 exporter of highquality, highprotein wheat

Cereals Canada has released its annual New Wheat Crop Report to global and domestic customers of Canadian wheat. The report includes information on milling performance, flour/semolina quality, and end-product functionality for Canada’s 2025 wheat crop. “Canada is on track to be the third largest wheat exporter and number one exporter of high quality, high-protein wheat,” said Dean Dias, chief executive officer of Cereals Canada, in a news release. “In 2025-26, 27.4 million tonnes of wheat is expected to reach over eighty international markets, with the quality and protein content that customers expect.” Find the report at cerealscanada.ca.

ABA pledges to remove FD&C colours Tariff remission relief extended for Canadian bakery imports: BAC

In a landmark move toward cleanerlabel baking, the American Bakers Association has announced a twophase commitment to eliminate certified FD&C food dyes from baked goods. The first phase targets school nutrition programs, with ABA members pledging to remove all synthetic dyes from products served in K–12 schools by the 2026–27 academic year. Building on this momentum, the broader industry pledge aims to eliminate FD&C colours from all baked goods in the U.S. by the end of 2028. With more than 90 per cent of member companies already on board, this initiative aligns with evolving consumer expectations and recent FDA guidance, reinforcing the baking industry’s dedication to transparency, quality and community.

In November, the BAC released the following statement on ABA’s FD&C dye phase-out initiative:

The Baking Association of Canada applauds the American Bakers

Association’s commitment to eliminate certified FD&C food dyes from baked goods in schools by 2026 and nationwide by 2028. This proactive initiative reflects a growing industry-wide shift toward transparency, cleaner labels and consumer trust.

Canadian bakers have long prioritized quality, safety and community health. As our U.S. counterparts lead this transition, BAC encourages members to explore dye-free reformulations, collaborate with suppliers on natural alternatives, and communicate their efforts clearly to schools, families, and retail partners. Aligning with this movement not only supports public health – it reinforces our shared values of integrity, innovation and leadership in baking.

Together, we can ensure that the baked goods we offer – whether in lunchrooms or on store shelves – reflect the best of our craft and our conscience.

The Canadian government has extended tariff relief for Canadian bakeries that import essential ingredients, processing equipment, and packaging materials from the U.S. and China.

The Baking Association of Canada provided the following information as part of a longer update in its latest newsletter to members:

Effective Oct. 15, 2025, the Government of Canada has implemented the Order Amending the China Surtax Remission Order (2024) and the United States Surtax Remission Order (2025). Known together as Remission Order 2025 1, it provides extended tariff relief for Canadian bakeries that import essential ingredients, processing equipment, and packaging materials from the U.S. and China.

The amended orders appear in Part II of the Canada Gazette on Nov. 5, 2025.

The union is engaged in discussions with Wonderbrands to assist affected members to receive the support they need, including transition programs, retraining opportunities and support services.

MONCTON BAKERY SCENE

In October, when the Baking Association of Canada took us along to New Brunswick Community College in Moncton for the Farmer-Miller-Baker Summit, we hit the streets to visit some thriving bakeries. It turns out the region has many excellent bakeries, featuring artisan bread and pastry products in unique locations with unique business models.

TONY’S FAMILY OF BUSINESSES

Tony’s Bistro & Patisserie in Moncton under the careful guidance of owner and talented baker Tony Holden has grown steadily to a constellation of thriving businesses.

Before opening the Bistro in 2001, Holden’s long career included positions as pastry chef at Jasper Lodge, Keltic Lodge and Hotel Newfoundland. In 2020, he opened Boulangerie Tony and Atelier Tony, an adjacent bakery and café in Dieppe, N.B., and last spring a café called Tony’s on Botsford near the downtown.

Tony and his wife June look after the bakery, son Christopher oversees the dining room and handles PR, and son Jordan is a corporate chef focusing on the savoury side at Atelier Tony and Botsford. The business will be in good hands, says their father, if he ever decides to retire. Coming up on age 65, he has no immediate plans to leave.

Botsford anchors an apartment building that houses their landlord and architect on the floor above. “There is quite a bit of walk-in traffic there, it’s an appealing spot and a corner lot is good,” he says. “We were looking for another café because our bakery in Dieppe has the capacity to supply other cafés. My son, Jordan and his wife took on that project. He’ll be taking over.”

At the bakery, they are experimenting with sourdough: “We’re planning to turn each of our products into a sourdough product. Our baguettes already are made

using sourdough. We’re thinking about turning our croissant dough into a natural sourdough as well.”

Incorporating sourdough is relatively easy, he says, but croissants are tricky. “You have to get the proper formula that can transform your croissant recipe,” he explains. “Sourdough has more liquid. Adding a natural ferment, 100 grams of natural ferment to replace 10 grams of yeast. You have to subtract that liquid. People are asking for that too. With the levain in our starter, we put a bit of whole wheat and rye in there too. That’s the direction we’re going with all our breads, croissant dough, etc. We’re not going to rely on commercial yeast.”

They have about 80 employees in total, some of whom have been with them for a dozen years. New employees are trained by current staff. Expectations are

important. “We make sure employees know what we’re looking for,” he says. “Once they show us that they’ve got the recipe down, we give them freedom to do different projects.”

Although they have capacity to supply another café or two, they are not in a hurry to grow right now. “We’ve got great staff and we’re enjoying it. What we always work on in the background is getting the product better every time.”

COPAIN ARTISAN BREAD CO.

CoPain Artisan Bread Company anchors a very different type of business – a daycare centre. Originating as a service within that daycare and graduating from the local weekly markets, CoPain has come full circle with a newly built permanent location across Bonaccord Street a few blocks from Moncton’s downtown.

PHOTO:

Oliver’s German Bakery in Hillsborough, N.B., mills organic flour and produces healthy baked goods.

Owner Elki Imbeault owns several daycares in the area, general manager Nicole McLean told us about the bakery’s origin.

McLean used to work in the restaurant business, and when her family was young did some cooking and baking for Imbeault and the daycare.

When they crossed paths with Tanguy Jacobs, a baker from France, a small business took shape. Jacobs brought formulas for croissants and sourdough. He handled European-style breads; McLean handled the North Americanstyle breads.

“We started taking breads to the market,” she says. “That’s where our roots are, the customers are wonderful.”

By 2018 they had built a two-storey building across the street with much of the first floor and the entire second dedicated to the daycare (a separate business). In time, they expanded the bakery to encompass entire the first floor.

Today they have a well-equipped kitchen and store, including a large oven out back, another up front, a walk-in fridge and a walk-in fermentation room to proof the sourdough for 10-12 hours.

The interior of the bakery has a unique, open design with big windows visible to people on the street that is “100 per cent intentional.”

All sourdough, baguettes and rustic breads are baked in the deck oven that people can see from the street. “Sourdough makes up about 50 per cent of our bread business and the deck oven is going all day and night,” McLean adds.

Transparency is important to the team. “We want you to see what we’re doing,” she says. We tout that our bread has only four ingredients and real people behind it. We’re not a factory, we’re people.”

CoPain delivers to at least half a dozen businesses and market-style stores around the Moncton area and are hoping to get a few more locations in the next year or two. “We want to hit Saint John and maybe Nova Scotia. We have one truck –that’s limiting.”

They have about 32 full- and part-time staff. Much of the training is on-the-job. They have the recipes and printed guides and each section has its own plan. Experienced staff are always supervising, she says. “New employees start out watching and listening. In the second week they are doing, while supervised.

They do that for a couple of weeks, then move on to work independently.”

She enjoys managing. “I love, love, love what I do. I was originally a baker. I worked too hard and my body couldn’t handle the stress it was under. I transferred to management. I love to see CoPain grow and to have a hand in that growth.”

McLean reminisces: “Our first customers were those parents and their kids. We knew it was kind of a gamble: we had to be a destination. We’re downtown. We’re not on Main Street. Having that combination of the parents and the kids is great. They are very supportive of us.”

“We’re almost nine years in, and we’ve seen very good growth. With growth comes changes and challenges. We adjust, adjust, adjust. If at end of day we’ve made a consistent, good product, we are happy.”

OLIVER’S GERMAN BAKERY

Oliver’s German Bakery in Hillsborough, N.B., once home to a church congregation, now houses a flour mill, silo, bakery and local businesses renting space.

We met Oliver Hofer and son Marc Hofer at the Farmer-Miller-Baker Summit, and later spoke with Marc to learn more about the family’s bakery that uses organic ingredients. The family moved to Canada from Germany in 2003 and started a European bakery and café in Dieppe, N.B. They operated the bakery for more than a decade and did good business but decided to focus on wholesale baking.

They bought the more than 100-yearold historic former Hillsborough Baptist Church in 2015. “We had to renovate the whole thing,” Marc says.

The Hofers make breads, buns, bagels, baguettes, pita, pizza crusts, pretzels, stollen and other sweet items. They use their own traditional sourdough, brought all the way from Germany, in all bread products. They believe in creating healthy bread that also tastes great.

Oliver’s wife, Tatjana, focuses on preparation, cooking and delivery. Marc, a recent graduate in business, is learning the business full time and hands on. He bakes alongside sister Tanja, the head baker who does most of the baking. Younger brother Nick makes deliveries and handles many renovations. Oliver oversees and prepares ingredients and manages the two Cinelli ovens.

They added a large silo about three years ago that feeds the grain through the wall directly into the mill. The new setup is a big improvement as they used to use a bucket to fill totes and drag them into the mill room – which involved “two hours of pretty intense labour.”

Farmer Jean-Guy Poirier of La Ferme Champdoré in nearby Grande-Digue, supplies them with about 1,000-1,500 pounds of grain per week. They have a great relationship, Oliver says. “I have helped him harvest. You see the farming operation for yourself and you trust (the quality and process).”

Grains are milled the same or one day before use. Marc describes the milling process: “We turn the auger on and it pulls the grain into the mill. My dad fills a big container that holds about 50 gallons of flour. It takes about seven hours to mill 50 gallons and that will last you a week and a half. The mill makes fine flour and gives us the wheat flour and the bran so that we don’t lose the residue.”

What keeps things challenging is that every year’s harvest is different. “There was not much rain this year, which can change the grain itself and add a bit of thickness to it,” Marc says. To counteract this, they occasionally have to add a bit of organic commercial flour. Thus, you can get some inconsistencies. “Sometimes the bread rises more than other times,” Marc says. “Customers know it’s local grain and Oliver’s mills it every week: it doesn’t get much fresher than that.”

Like Tony’s and Co-Pain, the Hofers are big on supporting other local businesses. Oliver’s has become a community hub, renting out space to other businesses. They buy eggs and cheese from local farms. “We definitely see the value of keeping ingredients local and healthy even though it may cost more,” Marc says. They started a hobby farm with two rye fields, vegetables and cattle that helps supply the bakery. They sell their own beef. A local farmer harvests the rye and they collect the grain from him.”

The goal is to be the cornerstone of their community and to have some influence by making healthy food. “We think that should be more of a priority everywhere. We’d love to be strong example of that change.”

You can read more about Tony’s, CoPain and Oliver’s and see more photos online at bakersjournal.com. / BJ

Notes from the Executive Director

BOARD MEETINGS IN OTTAWA

We wrapped up several days of in-person board meetings in Ottawa Nov. 5-7. On Wednesday we had the privilege of meeting with government officials from Agriculture Canada and the Privy Council as well as the Canadian Dairy Commission. We had very informative conversations with all of them and touched on tariffs, interprovincial trade and butter supply for the baking and pastry sector. Our voice was made stronger as we had delegates from our newly formed Canadian Bakery Executive Council attend along with the board.

The next day we welcomed Karen Proud, president and chief adjudicator of the Office of the Grocery Code of Conduct, who walked us through the launching of this important initiative and answered many questions we had on the workings of this volunteer oversight of the Canadian grocery retail sector (please sign up to be registered for support at https:// canadacode.org). Meetings continued with a federal budget and temporary foreign worker update from Kristina Farrell, chief executive officer of Food and Beverage Canada, along with Jean-Emmanuel Poitras, director of policy and regulatory affairs. Our regular board meetings

followed with a board training session and reports from the executive director and director of food policy and sustainability. The reports included a BAC budget review and proposal based on the stable financial health of the association. Spending for 2026 will include enhancements in membership support and development, support of the Canadian team for the Coupe du Monde (World Baking Cup) as well as continuing with our regional education programs such as FarmerMiller-Baker Summit.

AUTOLYSE REVISITED

In the 1980s, Raymond Calvel, France’s most influential baking professor, published Le Goût du Pain ( The Taste of Bread ), a landmark defense of traditional breadmaking. Its success in Japan sparked interest in an English edition, and a chance meeting between translator Ron Wirtz and baker James MacGuire launched the project. Published quietly under the Aspen imprint, the book became a technical reference rather than a bestseller.

James MacGuire contacted us since we published technical comments in the September Bulletin about “autolyse” which referenced the book. I was

BAC goes to Ottawa Autolyse revisited: Letting the dough rest

honoured, delighted and humbled that he read the piece and wanted to engage. I have had the pleasure of corresponding with both James and Jeffrey Hammelman since then with long emails about not only the technical side of breadmaking but also shared histories of our lives in the industry. James was typically self-depreciating about the value of the book, and questions autolyse as well as the “improved mixing” methods Calvel promotes. However, I think the book is relevant, as a historical document and as an inspiration for bakers transitioning from commercial to artisan. If you can find a copy (I cherish mine) it is a must for any serious pain-ophile collectors.

Below is a summary of James MacGuire’s thoughts on Calvel and on the publication of the book’s translation.

RAYMOND CALVEL AND THE BIRTH OF AUTOLYSE (AS TOLD BY JAMES MACGUIRE)

Raymond Calvel, a revered figure in French baking, is best known for developing the autolyse method – a technique that revolutionized breadmaking by improving dough handling, flavour and structure. Though Calvel officially introduced autolyse in 1974, its roots trace back to a crisis in 1956, when a devastating frost wiped out France’s winter wheat crop. To compensate, high-gluten wheat from

Manitoba was imported, but it proved unsuitable for traditional French bread. Bakers proposed milling it into farine de gruau, a strong flour previously banned during wartime. Even then, the flour’s excessive strength hindered oven spring and ear formation. Calvel’s early solution was to pre-mix part of the flour with water and salt – excluding yeast – and let it rest overnight before completing the dough. The results exceeded expectations. Years later, while teaching at the French National Milling School, Calvel revisited this idea. Frustrated by the waste of inert dough used for shaping practice, he wondered if it could be repurposed. This sparked a series of tests with varying percentages of overnight autolyse, revealing consistent improvements: reduced mixing time, enhanced flavour, better loaf volume and more defined slashes.

Despite its benefits, Calvel worried bakers might resist the added step, especially when done 18 hours in advance. Over time, a more accessible version emerged – typically a 20-minute rest using flour not included in preferments, with no salt or yeast. While the term “autolyse” traditionally refers to enzymatic cell breakdown, Calvel’s usage was more practical than scientific. He wasn’t an academic but a passionate teacher who began his baking journey at 17 after a childhood of farm labour and self-driven learning.

ABOUT RAYMOND CALVEL

In 1936, Calvel joined the École Française de Meunerie, where he taught for 60 years. Though he never attended university, he studied alongside his students and credited his technical growth to mentors like Nuret and Ougrimoff. His first article came just two years into his teaching career, and his curiosity never waned.

Autolyse wasn’t entirely unprecedented. A. Boland described a similar process in 1855 involving intermittent mixing and resting. Calvel noted that early mechanical mixing mimicked this rhythm, long before high-speed mixing introduced oxidation risks. He also acknowledged that even short rests – five minutes or so – can benefit dough, regardless of salt or yeast presence. His openness to experimentation led to innovations like

autolysing brioche dough with eggs and sugar, which dramatically reduced mixing time.

Understanding autolyse’s mechanics remains elusive. Researcher Hubert Chiron suggests that short autolyses rely on capillary action, allowing water to penetrate flour agglomerates. Longer rests may activate proteolytic enzymes, especially in darker flours. Calvel, with his sensitive palate, cautioned against autolyses exceeding 20 hours due to potential acidification.

Ultimately, autolyse’s value lies in its results. In side-by-side comparisons, doughs with autolyse consistently outperform those without, requiring less mixing and yielding superior crumb colour and texture. Calvel humbly attributed his discovery to intuition, experimentation and luck. His legacy endures in every baker who pauses to let the dough rest.

The Taste of Bread appeared in French,

Japanese and Spanish but prospects of an English edition seemed bleak until I leaned on the wife of a childhood friend who worked for a publisher of technical books. There remained plenty of challenges. The photographs in the original edition were badly taken but depicted technically perfect loaves. Replacing them was dropped in my lap so we ended up with skillfully taken shots of my own far from perfect loaves. Calvel would do his writing longhand in tiny, perfect letters and could go for page after page with nothing crossed out. He insisted that the book was perfect and wanted no changes or additions. Our solution was that since the photographs had to be replaced anyway, addition material such as information on North American flours would appear in fine print as captions and in sidebars. In the end, it seems to me that Ron and I received $500 US and never heard from the publisher again. Reviews and other notice were minimal, and Calvel, who was never big on compliments, was unhappy with the photographs and many other aspects of our work. More than 20 years later, with all that has happened in French bread baking, the book is completely out of date. In an interesting twist of fate, the use of refrigerated doughs has allowed bakers to revisit the traditional baguette similar to those Calvel discovered when he arrived in Paris. France being France, the dreaded pain blanc baguette still exists, and some Parisian bakeries make both pain blanc and pain de tradition .

My wonderful friend Ronald Létourneau Wirtz, with his Québecois roots, was key to launching the translation project and its eventual success. His French was excellent and his day job at the AIB had given him knowledge of baking.

After this discussion, some readers might wonder if there could be something good about pain blanc. It’s an obligatory component of the Vietnamese banh mi sandwich. –James MacGuire

Martin Barnett, Executive Director Baking Association of Canada mbarnett@baking.ca

If you’re curious about what’s new in baking – products, trends, techniques, new talent, checking in with other bakeries – Showcase is for you! | BY

BAKERS JOURNAL STAFF

TORONTO BAKERY SHOWCASE PREVIEW

Bakery Showcase is set for May 3-4, 2026, at the Toronto Congress Centre.

If you’re looking to see what’s new in baking – products that might help your bakery work smarter, not harder; trends other bakers are talking about and what challenges and successes they are experiencing, Bakery Showcase is for you!

Here is a glimpse of the sessions planned for this annual industry event and hub of activity.

SUNDAY, MAY 3 – EDUCATIONAL SESSIONS AND DEMOS

Annual General Meeting and Meet-andGreet: Find out what the hardworking BAC has been doing on your behalf and meet board members over morning coffee and pastries.

Educational Panel: Update from BAC Food Policy and Sustainability Committee

The Baking Association of Canada’s Food Policy and Sustainability Committee will provide an information – packed update on their advocacy activities on behalf of the BAC members in the baking industry.

Educational Panel: Transitioning Your Bakery to an Employee, presented by FCC Food and Beverage

Texture Is the New Taste: Puratos Presents the Cake Texture Collection: The Cake Texture Collection is a curated showcase of cake textures from around the world designed to help baking professionals understand and appreciate the diversity of textures. Each one is evaluated through visual appearance, tactile feel, and mouthfeel, providing a comprehensive reference for how cakes look, feel, and taste. Puratos experts will be your guide as you experience, compare and learn about six different cake textures.

Ardent Mills Presents Cocoa Replace

MONDAY, MAY 4 – EDUCATIONAL SESSIONS AND DEMOS

Panel: Delectable Dessert Trends: Innovative

An exciting panel, “Delectable Dessert Trends” will see innovative chefs discuss their most successful desserts, what customers seek and current trends.

chefs share how they take their most successful desserts from conception to execution to plating presentation, what customers seek in a dessert and what trends they see taking off.

Panel: Farmer-Miller-Baker Summit in the City: Farmers, small-scale millers and artisan bakers share their experiences, learnings, priorities, challenges and rewards in working with freshly milled, locally sourced flours. Learn to elevate your bakery’s products with the nutrition, texture, and quality today’s customers crave. Discover the unique characteristics and benefits of sustainably sourced, freshly milled, local flours. Connect with fellow bakers on the grains-to-table journey, exchanging insights on farming practices, grain processing, artisanal baking and consumer engagement.

Educational Panel: Baking Trends Outlook: What consumer, ingredient and product trends are on the horizon and how will they impact your bakery?

Educational Talk: Steps Toward a Sustainable Bakery

Demonstration: No-Knead Style Purple Wheat Flour Bread: Martin Barnett, seasoned artisan baker of Seraphina’s Oven Professional Baking and Pastry Arts and the Baking Association of Canada, will take participants through a hands – on, interactive demonstration of how to mill, mix and bake bread using 50 per cent purple wheat respecting the grains special characteristics and the careful process. Taste the delicious, wholesome, tangy results as Martin pulls fresh loves from the oven!

Continued on page 20

Get the best out of the Holiday Baking Season

Make these Holidays extra special by adding naturally sun-dried and no sugar added California Raisins to all kinds of bakery applications. Don’t miss on the must-have ingredient that will add a naturally sweet touch to both traditional and unconventional formulations.

Because only California Raisins:

• Are the most consistent supplier in dried fruits

• Have unmatched quality and safety standards

• Are beloved by consumers for taste, nutrition, versatility and affordability

• Reduce added sugar because of their natural sweetness

• Reduce fat content due to their plump, soft “chew” that mimics fat’s richness

No matter how you look at it, it all adds up to California Raisins being a star ingredient for a perfect Holiday baking season.

Visit CaliforniaRaisins.ca/professionals for more information.

Filling Ingredients

• 1⅓ Cups California Raisins

• 1¼ Cups Dark Rum

• 2 Cups All Purpose Flour*

• 1 Teaspoon Baking Powder

• 1 Tablespoon + 1 teaspoon Cinnamon

• 1 Teaspoon Nutmeg

• 1 Teaspoon Ground Ginger

• ½ Teaspoon Ground Cloves

• 1 Teaspoon Kosher Salt

• ½ Cup Butter, softened

• 1 Cup Dark Brown Sugar

• Zest of 2 lemons

• Zest of 2 oranges

• 2 Teaspoons Vanilla Extract

• 3 Eggs, room temperature

• ¼ Cup Vegetable Oil

Topping Ingredients

• ⅓ Cup California Raisins

• ⅓ Cup Dark Rum

• ¾ Cup Powdered Sugar, sifted (¾ cup up to 2 cups) depending on desired consistency and sweetness)

• ¼ Cup + 2 TB Milk RUM RAISIN CAKE

Procedure

All ingredients need to be at room temperature beforeyou begin.

Put California Raisins and rum in a small saucepan. Heat uncovered on low until boiling, about 7-10 minutes. Turn off the heat after boil, set aside, and allow to come to room temperature.

Preheat oven to 350 degrees. Sift flour, baking powder, cinnamon, nutmeg, ginger, cloves, and salt in a bowl. Place butter and dark brown sugar, lemon zest, and orange zest in a kitchen aid bowl fitted with a paddle attachment. Whip on high speed for five minutes until light and fluffy. Add vanilla, then add eggs one at a time, scraping down the sides of the bowl with a rubber spatula after each addition. Mix on high for another three minutes. Add dry ingredients, in three portions. Scrape down the sides after each addition. Do not over mix! Mix just until combined.

Remove batter from the kitchen aid machine and fold in rum and California Raisins with a spatula. Grease or oil Bundt pan. Pour batter into the Bundt pan and smooth top with a spatula. Tap pan against the table to remove air bubbles and pockets. Bake 35-40 minutes or until a toothpick inserted in the center comes out clean. Cool in pan for 10 minutes on a wire rack. The cake can be served warm.

Ideally, invert cake onto a plate, wrap in plastic to mature flavors overnight, and then add the glaze.

Glaze:

Heat rum and raisins in the microwave for 30 seconds. Allow to cool to room temperature. Blend milk with California Raisins and rum mixture until smooth. Whisk together with sifted powdered sugar. Spoon or pipe onto Bundt cake.

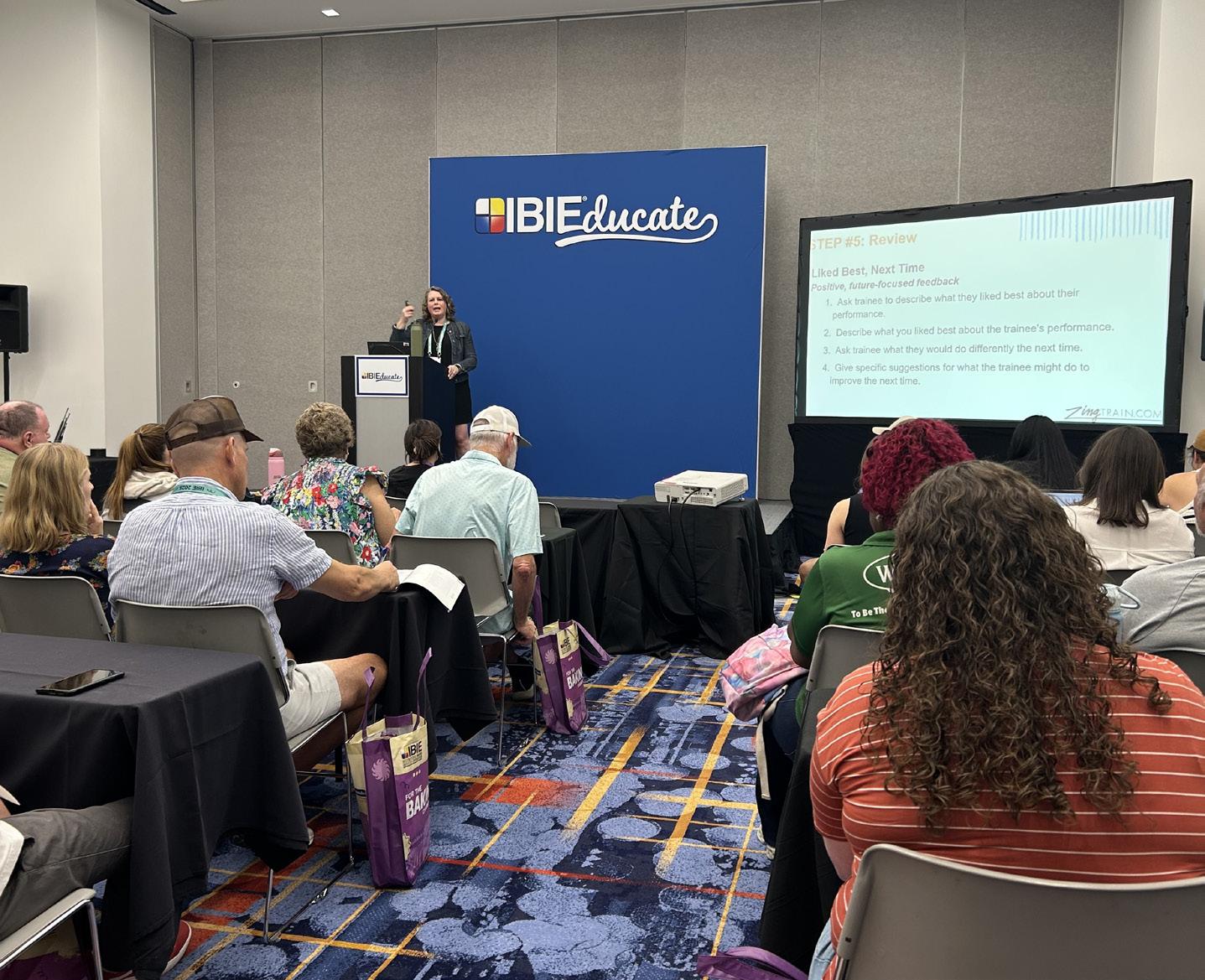

TACKLING KEY TOPICS

Two learning sessions we attended at September’s Baking Expo helped break down two processes all bakeries could use some guidance: training and succession planning.

TRAINING YOUR BAKERY STAFF TO SUCCEED

Elnian Gilbert, a trainer with Zingerman’s Delicatessen in Ann Arbor, Mich., loves to train and it showed in her stimulating session, “Five Steps to Effective On-Shift Training.” Gilbert started as a seasonal holiday employee at Zingerman’s Mail Order then became a trainer with the company’s ZingTrain program in 2007.

ZingTrain is built on a compact in which “the trainer agrees to document clear performance expectations, provide training resources, recognize performance and reward performance” and the trainee agrees to “take responsibility for the effectiveness of their training.”

Gilbert demonstrated her training skills by showing attendees how to identify four stages of learning: unconsciously incompetent, consciously incompetent, consciously competent and unconsciously competent.

The goal is to be unconsciously competent, a stage in which the employee has had so much practice with a skill that it has become second nature, they can perform it easily and they can even teach it to others. Think about taking a phone order or rolling a croissant. But, although an unconsciously competent person may be fastest and most efficient, there is a potential to develop bad habits, slip into complacency or fail to adopt and adapt new concepts. These labels encompass both trainees and trainers. For example, a consciously competent person may make the most effective

trainer.

It’s a deceptively simple framework that helps get to the heart of training issues. However, it takes some practice to get the hang of identifying these stages, as the audience showed by working through a pop quiz that asked them to link commonly seen behaviour to the different stages; for example, a new employee who asks a lot of questions on the first day might be labelled consciously incompetent: they

recognize they don’t know everything and need to learn and build their confidence.

The speaker, who has a business degree and customer-service experience, walked owners and managers through five steps of effective training: prepare, tell, show, do and review.

FIVE TAKEAWAYS

Here are takeaways from each of the five steps:

The Bakery Expo (IBIE) brought together the professional baking industry.from around the world.

Prepare: Have answers to the four training plan questions for a shift learning to answer the phone:

1. By the end of this two-hour training, trainee will be able to: answer the phone using the standard script, put a customer on hold and take a phone order.

2. Phone standard operating procedure, co-worker.

3. Observation and feedback for answering the phone and performance test / role play for hold and phone order.

4. Signed off on training plan and available to be scheduled for shifts covering the phone.

Tell: Explain to your trainee, why it’s important the task be done the way you’re teaching them to do it. Tell the trainee what to do if you get pulled away.

Show: Have the trainee walk you through the steps. Have them tell you each step and you do it. Lift your hands up if they get it wrong.

Do: Don’t walk away! You don’t want trainees to spend their time practising the wrong thing. Give them some space.

Review: Try the positive, future-focused

“Liked Best, Next Time” approach to feedback. Ask your trainee to describe what they liked best about their performance. Describe what you liked best about the trainee’s performance. Ask the trainee what they would do differently the next time. Finally, give specific suggestions for what the trainee might do to improve the next time.

Perhaps the most powerful and easily applicable tip Gilbert shared was to tweak your phrasing from the openended “Any questions?” to the more effective “What questions do you have?” This signals to trainees that questions are normal, expected and, in fact, an important way to absorb material. It also helps make your business a safe space in which to make mistakes, creates a positive atmosphere and gives gentle redirection when needed.

Gilbert applied this at the end of the session by asking not “Did you learn anything from this session?” but instead “What is one thing you’ll do differently the next time you are training someone on-shift?” They were eager to share their a-ha moments. These included the concept of demonstrating a task, such as rolling a croissant, at full speed before slowing down the steps to help staff master the process.

Our nation-wide network of financing experts is helping you transform the Canadian food and beverage value chain. If you process it, produce it, pack it or move it, we can help your food and beverage business start strong or take the next step.

Elnia Gilbert, a trainer with Zingerman’s Deli in Ann Arbor, shared practical tips for on-shift training.

TRANSITIONING YOUR BUSINESS TO FAMILY

Marc Anderson, president of Linda’s Bakery in Salem, Wis., shared his experiences and hard-won wisdom transitioning his successful bakery business in “Succession Planning Basics for Family Bakeries,” a well-attended talk at the Bakery Expo.

In 1980, Anderson became partners with sister Linda in her business, established in 1973. In 2008 Anderson and his wife Sue became sole owners and today have more than 70 full-time, part-time and seasonal employees and server some 1,000 customers on their busiest days. Most recipes have remained the same for more than 50 years, but they have added modern items like gourmet espresso coffee drinks.

In 2018 they started planning to exit the business, an ongoing process that was stressful at first but now enjoyable as it has allowed the couple some freedom while still being as involved in the bakery as much as they want to be.

Common pitfalls for owners include ignoring reality, waiting too long to act, lacking formal human resources processes and having an emotional attachment to the business.

When owners make that decision to start transitioning the business to family members, key decisions are how the business will be structured and who will lead it. It’s important to put people in roles that suit their skillsets, Anderson told the audience of baking professionals. “Equal is not always fair

and fair is not always equal,” he cautioned, explaining that not everyone is cut out to be a manager.

Timing is a big consideration, Anderson said. He suggested the ideal time to start planning for your transition falls somewhere between the owner being ready to retire and the successor having gained enough skills to take over operations: a sweet spot. In other words, if these two things overlap, this will give current owners time to teach and successors time to learn from them while current owners are still available for advice.

It’s important to have standard operating procedures for recipe consistency, efficiency and training materials written down and illustrated so that anyone can follow them.

And of course, getting legal and financial advice from experts you trust is crucial. That means working with trusted attorneys and accountants, preparing financial statements, establishing wills, trusts and buy/sell agreements, and buying appropriate insurance

STEPS TO GET STARTED

Getting started can be simple. Let your family members know what you’re thinking, ask for their input and discuss your long-term goals for the business. Anderson suggests starting with an emergency plan. This may include writing a buy/sell agreement funded with term life insurance, having an attorney create trust documents, adding future owners to bank accounts,

insurance policies and government documents, and having your passwords safe and accessible to those who need them.

Anderson recommended starting a management committee to oversee the transition and start making decisions – then give them real authority to make decisions. Prepare your business as if you are selling it, involve all your staff, let multiple people know all critical jobs and assign priority projects to the manager or managers.

Anderson had memorable advice for retiring owners. “Make yourself dispensable, start with small steps and it’s OK if your successors don’t do it like you would have.”

He recommended successors get formal and/or on-the-job training, be willing to start with small steps, be open to advice and find ways to add your own ideas to what’s tried and true.

Remember that succession is a process, not a one-time event, the speaker concluded. / BJ

Robert and Ernesta, founders of Casasanta.

The Artisan Village was a popular spot for learning, and bread and panettone competitions.

SHOWCASING TOP TALENT

Don’t miss the chance to see talented bread bakers and pastry chefs show off their excellent technique and teamwork as they vie to win the Bakery Cup of Canada. A Quebec edition of this competition tested the concept at Montreal Showcase in April 2025 and it was a huge success! This year’s national competition will celebrate baking excellence in baguettes, croissants, viennoiserie, specialty breads and artistic showpieces.

Six candidates, each with an assistant/ apprentice, will demonstrate their skills on a national – and potentially international

“The quality of Canadian bakery dramatically improved and is as good as any in the world,” he said. “Now is the time to showcase the great skills Canadian bakers have,” said Alan Dumonceaux, who will serve as president of the Bakery Cup jury. “We hope this competition might motivate other bakers watching to set themselves apart by competing. Competition is all about organization, timing and adaptability. If other bakers see someone under that pressure test, they might say, ‘I can use this challenge as a way to improve my own operation.’ ”

Candidates will compete in three

in their professional baking career. It will help them connect with fellow bakers.

Prizes will be awarded in the following categories and all competitors and their assistants will receive custom chef’s jackets and coverage in Bakers Journal.

Thank you to Lallemand, Platinum Sponsor; Les Moulins de Soulanges, Bronze Sponsor, and to Chicago Metallic, our Pan Sponsor, and Puratos, our Ingredient Sponsor.

Sponsors for Showcae include BakeMark, AB Mauri, Les Margarines Thibault, Puratos and FCC.

Our readers and attendees of Bakery

•

•

•

•

•

(DIVISION OF A & L FOOD DISTRIBUTORS INC.)

SUPPLIER OF FROZEN AND RAW INGREDIENTS FOR THE BAKING INDUSTRY

Tel: (416) 252-4660 Fax: (416) 252-9993 25 - 8 Connell Ct., Toronto, ON M8Z 1E8

• Whole Grain Flours, Hard & Soft Wheat, Rye, Soya, Sorghum, Teff, Quinoa, Malt

• Flax, Sunflower Seeds, Spelt, Kamut, Oats, Barley, Buckwheat, Corn, Chia

• Custom Milling, Blending and Packaging

• Over 2,000 Conventional & Organic Products

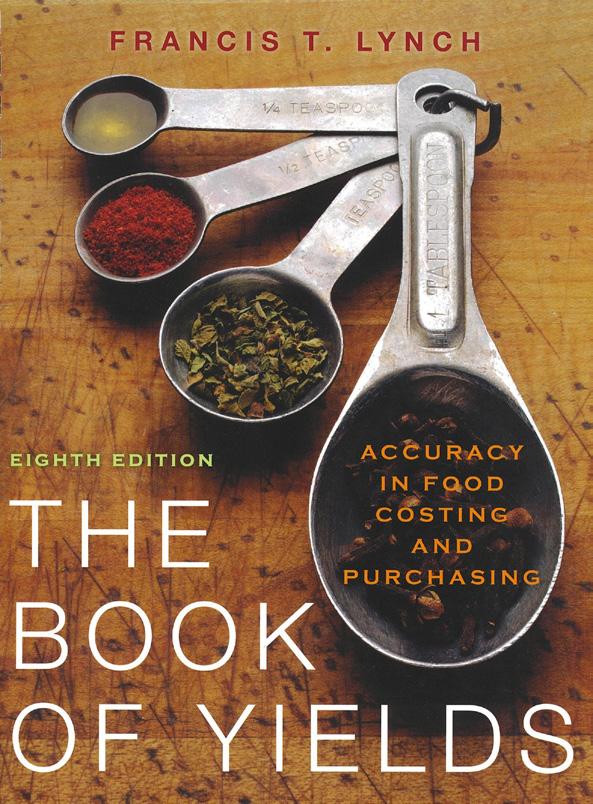

The only product with yield information for more than 1,000 raw food ingredients, The Book of Yields, Eighth Edition is the chef’s best resource for planning, costing, and preparing food more quickly and accurately. Now revised and updated in a new edition, this reference features expanded coverage while continuing the unmatched compilation of measurements, including weight-to-volume equivalents, trim yields, and cooking yields. With helpful worksheets; a clear organisation by food type; and a convenient, durable comb binding, The Book of Yields, Eighth Edition is a must-have culinary resource.

$55.95 | Item #0470197493

BY DIANE CHIASSON

SEVEN EASY IDEAS TO INCREASE BAKERY SALES AROUND NEW YEAR’S

This is the right time to focus on festive offerings, strategic online promotion and creating an inviting in-bakery experience.

New Year’s Eve is fast approaching, when your guests turn to your bakery for beautiful desserts for their parties, family gatherings and religious celebrations. It is the perfect time of year to boost your sales and increase your visibility.

1. CLEAN BEFORE UPDATING YOUR NEW YEAR’S DECORATIONS

Make sure your bakery sparkles before you begin updating your holiday decorations. Dust all your fixtures, clean the windows, and ensure your walls, ceilings and floors are spotless. Assign each staff member a specific section of the bakery to expedite the process.

2. RE-EVALUATE, ORGANIZE AND CREATE A FESTIVE ATMOSPHERE

Double-check your holiday decorations, assess what you have, and make sure everything is in perfect working condition and looks clean and fresh. Do they match your bakery’s brand identity?

Decorate your bakery with festive lights, window stickers, colourful decorations and music to entice passersby to enter. Make sure your bakery feels cosy and welcoming; your customers will appreciate a calm space for that much-needed break from the shopping rush.

Review last year’s inventory and make sure you have the necessary ingredients for your popular items.

Showcase your skills. The holidays are ideal for creating desserts that not only look good but also taste special. Nothing draws a crowd like special New Year’s items with festive decorations such as gold and silver edible glitters, sparkles, and ribbons.

3. DRESS UP LIGHTING FIXTURES

For New Year’s Eve, consider making a complete change to your lighting arrangements. To create an absolute festive mood, add a few brighter lights to make the entrance more inviting. By stringing mini lights throughout your bakery, you instantly add a festive touch.

4. PREPARE FOOD THAT SYMBOLIZES PROSPERITY, GOOD

FORTUNE

If you want to attract more customers, incorporate ingredients that symbolize prosperity, luck, happiness and good fortune in various cultures, such as pomegranates (Middle Eastern, Greek, Mediterranean cultures). and oranges, tangerines, and pomelos (China, Southeast Asia cultures). These citrus fruits resemble gold coins, attracting wealth and good fortune. Grapes (Spain, Latin American cultures). The tradition in these countries involves eating 12 grapes at the stroke of midnight on New Year’s Eve to ensure luck for the entire year.

5. ADD NEW YEAR’S SPECIAL ITEMS TO YOUR BAKERY MENU

The holidays are an ideal time to incorporate festive specials into your bakery menu, which can be a lucrative strategy for attracting customers and boosting sales. Add some drink specials in popular winter flavours, such as white chocolate peppermint mochas.

On New Year’s Eve, many people think of toasts, bubbly and all things celebratory. Elegant and delicious, champagne-flavoured macarons would be a sophisticated addition to your NYE menu. Create champagne bottle-shaped cookies with dusted gold and silver edible glitters.

Accommodate your customers by offering bite-sized desserts alongside large cakes that feed a crowd, and don’t forget to create a special children’s menu featuring holidaythemed items to attract families and children. It will not only delight young diners but also encourage families to choose your bakery for their holiday outings.

What about offering a New Year’s Day brunch special or a hangover brunch?

Create special takeout holiday packaging with festive branding. Include coupons for a future order to drive repeat business in the new year. Add small touches, such as offering free cookies with orders. You can also print or hand-write holiday greetings on boxes to show appreciation.

6. ADVERTISE NYE PARTY PLATTERS

A great way to attract these customers is by offering party platter options.

Focus on popular options, such as a classic cheese and charcuterie board featuring cheeses, cured meats, crackers, and fruits; a hot ham and cheese slider platter; or classic sausage rolls and cornbread. Advertise mini pastry platters featuring mini tarts, bite-sized eclairs, or an assortment of your best cookies, pastries, croissants, scones and muffins. You could offer a beautiful, tiered display of cupcakes and other sweet items.

7. LEVERAGE YOUR SOCIAL MEDIA WITH VISUAL STORYTELLING

Post high-quality photos and videos of your festive products on Instagram, Facebook and the increasingly popular TikTok. Use engaging content, such as behind-thescenes footage, to foster excitement and interact with your customers. Show cake-decorating workshops, how-to videos and customer spotlights. This will transform your bakery brand into a must-follow destination. / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping foodservice, hospitality and retail operators increase sales for over 35 years by providing innovative and revenue-increasing food service and retail merchandising programs, interior design, branding, menu engineering, marketing and promotional campaigns. Contact her at 416-926-1338, send her an email at chiasson@chiassonconsultlants.com, or visit www.chiassonconsultants.com

Taste Tomorrow is the world’s largest ecosystem for consumer understanding in the patisserie, bakery, and chocolate sectors. Developed by Puratos over a decade ago, this visionary consumer research initiative offers a dynamic global perspective on the food industry today and provides predictions for its trajectory tomorrow. Explore the latest trends, innovations and insights that will shape the future of food.

www.puratos.ca/en/consumer-insights/taste-tomorrow