The impacts of tariff-induced cost uncertainty are being felt in the construction market, but the results of our readership polling, part of the Top Contractors report that starts on page 29 of this edition of On-Site, illustrate both the resilience and optimism that will carry Canada’s construction sector forward through 2025.

Admittedly, there are pockets where construction activity is struggling, but some segments are booming. The infrastructure sector, for example, continues to run hot as governments appear to be firmly in favour of supporting the publicly funded projects that will support our nation’s internal and external trading needs and population growth. As such, contractors are expecting to be busy over the next 12 months.

That’s good news, but it puts a spotlight on some of the other challenges that our industry continues to grapple with, namely labour and productivity.

With the residential sector expected to push into growth mode over the next year or two, and a wave of retirements hitting the industry as we speak, finding new workers is an issue that is growing. And while apprenticeship registrations are on the rise, and the number of females working in the sector is growing, there is still a need to attract more people to the sector.

www.on-sitemag.com

READER SERVICE

Print and digital subscription inquiries or changes, please contact Angelita Potal

Email: apotal@annexbusinessmedia.com

Tel: (416) 510-5113

Fax: (416) 510-6875

Mail: 111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1

PUBLISHER | Peter Leonard (416) 510-6847 pleonard@on-sitemag.com

EDITOR | Adam Freill (416) 996-2391 afreill@on-sitemag.com

MEDIA DESIGNER | Lisa Zambri lzambri@annexbusinessmedia.com

ASSOCIATE PUBLISHER | David Skene (416) 510-6884 dskene@on-sitemag.com

ACCOUNT COORDINATOR | Kim Rossiter (416) 510-6794 krossiter@on-sitemag.com

AUDIENCE DEVELOPMENT MANAGER | Urszula Grzyb (416) 510-5180 ugrzyb@annexbusinessmedia.com

CEO | Scott Jamieson sjamieson@annexbusinessmedia.com

Established in 1957, On-Site is published by Annex Business Media 111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1 Publications Mail Agreement No. 40065710

ISSN: 1910-118X (Print) ISSN 2371-8544 (Online)

Get the latest construction news!

Follow us on @OnSiteMag

We recently hosted WorkForce ’25, an event featuring panel discussions and business sessions outlining the challenge of attracting and retaining workers while illustrating some of the tactics that leading companies in the industry are doing to keep their workforce excited, engaged and growing. Catch a summary of the event on page 24, and session videos on our YouTube channel.

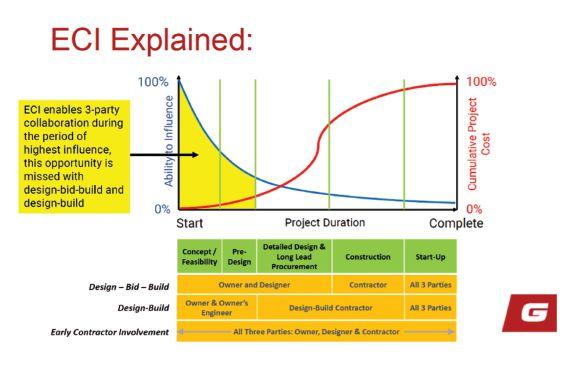

On the productivity front, David Bowcott’s discussion about the value of not rushing through the early planning stages of a project (page 52) as well as Jacob Stoller’s notes about data collection on page 50 are great reads. Much like measuring twice before cutting once, a little time spent on the front end can reduce headaches on the back end.

Until next time, stay safe and do good work.

Adam Freill / Editor afreill@annexbusinessmedia.com

SUBSCRIPTION RATES Canada $50.49 CAD per year, United States $115.26 CAD per year, Other foreign $139.23 CAD, Single Copy Canada $13.50 CAD. On-Site is published 5 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues. Occasionally, On-Site will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Business Media Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

Content copyright ©2025 by Annex Business Media may not be reprinted without permission.

On-Site receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. On-Site, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

DISCLAIMER This publication is for informational purposes only The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals.

MEMBER OF

Aecon Kiewit Nuclear Partners, a general partnership between Aecon and Kiewit Nuclear Canada, has been awarded an alliance construction contract by Ontario Power Generation (OPG) for the execution phase on the Darlington New Nuclear Project (DNNP) in Clarington, Ont., that will see the delivery of North America’s first grid-scale Small Modular Reactor (SMR).

Expected to be completed and in commercial operation in 2030, the project is being delivered under an Integrated Project Delivery (IPD) model. During the execution phase, Aecon Kiewit Nuclear Partners will work collaboratively with partners OPG, GE Vernova Hitachi Nuclear Energy and AtkinsRéalis. The scope of work during this phase includes project management, construction planning and execution.

“OPG’s Darlington New Nuclear Project is a trailblazing undertaking, leading the way in delivering the next generation

of nuclear plants across North America and internationally,” said Jean-Louis Servranckx, president and chief executive officer at Aecon Group Inc. “Aecon is proud to bring its diverse nuclear expertise and multidisciplinary capabilities to play a prominent role in safely executing this exciting project to meet the energy demands of future generations in Ontario.”

“Backed by over five decades of nuclear experience and the collective capacity of our project team, we are well positioned to successfully execute the next phase of this clean energy project with a steadfast commitment to safety, quality, schedule and cost performance,” added Aaron Johnson, senior vice-president for nuclear at Aecon Group. “Aecon continues to pursue strategic growth across a full spectrum of nuclear opportunities spanning large-scale new builds, SMRs, and life extension programs in existing and target priority markets.”

The Vancouver Fraser Port Authority has announced its plan to issue a request for qualifications this July for a construction partner to deliver the landmass and wharf component of the Roberts Bank Terminal 2 Project, marking a significant step towards delivering the project.

The port authority says the new marine container terminal at the Port of Vancouver will be a transformational, nation building project that will support Canada’s economic security and trade resilience, enabling the trade of more than $100 billion in goods annually once fully operational.

More than 18,000 jobs will be created during construction and, once operational, the facility is expected to generate more than 17,000 long-term jobs, adding more than $3 billion in GDP annually.

Based on ongoing discussions with industry, the port authority will pursue a progressive design-build procurement model,

The approval of this project is the first of four SMRs that are to be built at the Darlington site. Once complete, this SMR will be the first of its kind in the G7, producing enough electricity to power the equivalent of 300,000 homes.

The BWRX-300 is a small-scale nuclear reactor that uses commercially available uranium to generate power. Once complete, the four reactors will produce 1,200 megawatts (MW) of electricity, helping to bridge a power gap that could emerge in the early 2030s in the absence of net-new baseload power sources added to the grid.

The first SMR will cost $6.1 billion, in addition to costs for systems and services common to all four SMRs valued at $1.6 billion. Costs are expected to decline with each subsequent unit as efficiencies are gained, similar to the Darlington Refurbishment Project.

which it says will allow for greater flexibility in the design process, strengthen collaboration, and enhance cost and schedule certainty.

The contract will include the delivery of a marine terminal landmass, wharf structure and berth pocket, widened causeway, expanded tug basin, and environmental mitigation and offsetting projects. Construction mobilization and early works are expected to occur in 2027, with major land reclamation works expected to begin in 2028. Terminal operations are set to begin in the mid-2030s.

In April, he Ontario government marked the start of construction of the new CHEO Integrated Treatment Centre with a groundbreaking at the Ottawa site. The fully accessible and state-of-the-art children’s treatment centre will provide integrated and coordinated care under one roof to better serve children and youth living with complex medical, developmental and behavioural needs, connecting them to the care they need, closer to home, says the Ministry of Children, Community and Social Services.

Construction technology firm Procore has announced significant investments in its Building Information Modeling (BIM) capabilities. The company has acquired Novorender and FlyPaper, a pair of companies who have notable 3D modeling tools.

Procore says the additions will empower owners and contractors worldwide to unlock BIM, streamline coordination and connect critical BIM data seamlessly across the Procore platform.

“Today’s groundbreaking is another step in our commitment to protecting Ontario’s provincial health care by improving services for children and youth with developmental needs,” said the department’s minister, Michael Parsa. “We are deeply grateful for the work of CHEO, the CHEO Foundation’s Board of Directors and all the community advocates, organizations and local MPPs who have helped make this new facility a reality.”

The new CHEO Integrated Treatment Centre will consolidate services and programs across eight locations under one roof. Once completed, the state-of-the-art centre will serve approximately 13,700 children and youth with special needs, along with their families, in eastern Ontario. The centre will be connected to Ottawa’s CHEO hospital, allowing for more convenient and connected care for children and their families.

EllisDon Infrastructure OCH Inc. is building the 200,000 square foot centre, which

“We’re excited to combine the power of Novorender and FlyPaper’s best-in-class BIM solutions into the Procore platform. BIM is an accelerant in the future of datadriven construction, and these additions will supercharge Procore’s existing BIM capabilities,” said Steve Davis, president, Product and Technology at Procore.

Novorender is noted to be one of the world’s fastest 3D model viewers, while FlyPaper Technologies is the maker of the Navisworks plugin Sherlock.

The Manitoba government’s prompt payment regulation, which aims to facilitate the timely flow of construction payments, came into force in April.

“Construction projects are complex and involve many parties, including owners, contractors, sub-contractors, engineers, labourers and material suppliers, and often conflicts between these parties can result in withholding funds,” said Public Service Delivery Minister Mintu Sandhu. “These regulations make sure the local contractor at the end of the chain is protected, as they are often the one who are affected by delayed payments.”

The regulation addresses concerns raised by the construction industry about delayed payments causing problems through project payment chains, noted the minister, adding that the legislation will help the industry avoid the disruptive effect of non-payments as it strives to manage projects in a timely manner.

The Nuclear Waste Management Organization (NWMO) recently named the five companies selected to work with the organization to design and plan Canada’s deep geological repository for used nuclear fuel in northwestern Ontario. Working on the project will be WSP Canada Inc., Peter Kiewit Sons ULC (Kiewit), Hatch Ltd., Thyssen Mining Construction of Canada Ltd. and Kinectrics Inc.

Last November, the NWMO chose Wabigoon Lake Ojibway Nation and the Township of Ignace to move forward in the process as host communities for Canada’s deep geological repository for used nuclear fuel.

While Canada’s used nuclear fuel is safely managed in interim storage at reactor and laboratory sites, NWMO explained that this approach is not appropriate over the long term, so the aim will be to build a deep geological repository that uses a series of engineered and natural barriers

The inaugural Alberta Equipment Expo made a powerful debut, drawing 6,760 industry professionals to the city’s Expo Centre for a dynamic two-day event in late April. Showcasing the latest in heavy equipment and innovation, the event brought together key players from across Western Canada’s construction, forestry, aggregate and transportation sectors.

“We had an outstanding turnout in Edmonton for the first edition of this event,” said national show manager Mark Cusack. “It’s clear the heavy equipment industry has strong momentum, and this show highlighted just how large the sector is growing across Western Canada.”

The show, which was held by Master Promotions, featured almost 180 booths featuring products and services from leading OEM exhibitors, top truck body and equipment manufacturers, and equipment dealers.

The show is set to return from April 22 to 23 in 2027.

that work together to contain and isolate used nuclear fuel between 650 and 800 metres underground.

The five companies selected will work on facility infrastructure design and engineering, mine design, mine construction planning, nuclear management advising, and nuclear systems and facilities design.

NWMO says construction will only begin once the deep geological repository has successfully completed the federal government’s multi-year regulatory process and an Indigenous-led regulatory assessment and approval process, which will be

NWMO Vice-President and Chief Engineer Chris Boyle addresses vendors at the NWMO Discovery and Demonstration Centre.

developed and implemented by Wabigoon Lake Ojibway Nation.

The NWMO is using an Integrated Project Delivery model to design and build the repository. The companies and the NWMO will work as one team, co-located to move the project forward.

“We look forward to the opportunity to work with our project partners to deliver this invaluable project, an important step forward for Canada’s current and future nuclear energy production,” stated Marie-Claude Dumas, president of WSP in Canada.

“We are excited to bring our expertise to this project’s collaborative model, which will benefit Canada and local communities for generations to come,” added Patrick Lamarre, president of Kiewit Canada Group.

A selection of data reflecting trends in the Canadian construction industry

Despite a small slip in March, year-over-year investment in building construction was up more than five per cent, reports Statistics Canada. Declines in the residential sector were somewhat offset by gains in the non-residential sector, putting overall investment in building construction 0.9 per cent in the red for the month, but still solidly 5.4 per cent ahead of March 2024. Overall, the month came in at $22.2 billion, off $192.2 million from February. The residential sector fell 1.8 per cent to $15.3 billion, while the non-residential sector rose 1.3 per cent, coming in at $6.8 billion. Y

The decrease in residential building construction was driven by the multi-unit segment, which dipped 3.8 per cent. That was tempered by single-family home investment, which rose by a half per cent. Multi-unit investment dropped $313.9 million from February to land at $8 billion in March.

Investment in non-residential construction marked its the eighth consecutive monthly increase, with March growth spread across the three subsectors. Institutional investment grew 2.4 per cent to $2 billion, commercial rose one per cent to $3.3 billion, and industrial nudged up by 0.3 per cent, to post in at $1.5 billion.

The total value of building permits issued in Canada decreased by $549.4 million in March, falling 4.1 per cent to $12.9 billion, reports Statistics Canada. The decrease was led by the non-residential sector whose $716.3 million drop was tempered by a $166.9 million gain in the residential sector. Non-residential building permits posted a 14.5 per cent decline from February, landing at $4.2 billion. Commercial construction intentions drove the fall, dropping $474.1 million, or 19 per cent, to $2 billion. The institutional component was not far behind, falling 14.4 per cent to $1.4 billion, $238.5 million behind the February values. The industrial component managed to stay almost flat, dipping just a half per cent, or $3.7 million, to come in at $783 million, but that segment has been on a downward trend since October of 2024. The residential picture was a bit better across Canada, with a two per cent rise in intentions bringing the March figure to $8.7 billion. A $322.5 million gain in the multi-family component brought that segment to $5.9 billion. That was partially offset by a decline in the single-family component, which fell $155.6 million to $2.8 billion.

Canada’s construction sector dropped slightly in April, shedding 1,800 jobs, perhaps reflecting the national employment picture, which was little changed for the month as well, reports Statistics Canada in its most recent Labour Force Survey. Across all sectors, there were 7,400 more people working in Canada in April, although the employment rate slid by a tenth of a per cent to 60.8 per cent and the unemployment rate rose by 0.2 percentage points, to 6.9 per cent. On a seasonally adjusted basis, Canada’s construction sector employed 1,640,600 workers in April, down 0.1 per cent from March, but up 1.6 per cent from April of 2024.

Total Employment in Canada

20,969,300 Unemployment Rate

6.9% Construction Employment

1,640,600

Amidst a backdrop of change, CCA members met in historic Quebec City to navigate challenges and opportunities.

Positioned right between the swearing in of a new prime minister and a pending election call that would see Mark Carney be affirmed as prime minister, as well as a constantly shifting list of tariffs in a trade war with the United States, this year’s Canadian Construction Association (CCA) conference took on a political flavour, while also serving up slices of Canadiana, recognizing key contributors to the industry, and providing insights into some of the challenges facing the sector.

“Donald Trump will dominate the electoral conversation, because how could it be otherwise?” predicted (with accuracy) journalist Chantal Hebert during her keynote address to kick off the event at the Chateau Frontenac in Quebec City.

Perhaps showing an uncanny ability to predict future election outcomes, Hebert spoke about the trend towards minority governments in Canada, which she said has been our norm since 2000.

“There are some advantages to minority governments, in the sense that the government has to be more open to the opposition parties,” she explained, adding that there are significant downfalls as well. “One of those is a minority government is even less into long-term thinking than a majority government.”

Beyond election discussions, tariffs were a driving topic of many conversations during the conference, including during the CEO power lunch, where CCA president Rod Gilbert spoke with Zey Emir, president of Revay, and Patrick Lamarre, president of Kiewit Canada Group, about how tariffs are challenging the industry. Lamarre noted that corporate planning could face revisions as quickly as the next press release from the White House, which was not helping projects.

“It forces us to reevaluate risk, reevaluate opportunities, and also forces us to really look deep down in our contracts,” he explained.

“We’re at economic war. There’s no doubt about that,” stated Paul Smetanin, president of the Canadian Centre for Economic Analysis in his presentation, a dive into the need for long-range planning in Canada’s residential and infrastructure sectors.

“Infrastructure is not viewed for what the proper role of infrastructure in socioeconomics actually means: increasing the productivity of current and future generations,” he explained, pointing at the need for increased investment. “Infrastructure is not sexy … but it’s the very environment and surface that we play on.”

After a heavy day of facing the challenges of an industry, the CCA lightened things up with an evening of ice carving, music and dancing with the famous Painchaud family.

Also bringing up the energy of the event was the annual Innovator’s Pitch CONtact Mentorship breakfast, which kicked off Day 2. Featuring an assortment of products and innovations that have been developing within the CCA’s mentorship program, this year’s selection of presentations did not disappoint, from wall and ceiling panels made from seaweed to the winning product, R-Blocks made from recycled plastics.

Winning CEO Davin MacIntosh outlined the suitability of the blocks for construction applications. “Most of our work to date has focused on our ability to recycle large volumes of low value plastic, and the CCA mentorship helped us to test assumptions and develop more use cases for R-Blocks,” he explained.

With an eye to the needs of the industry, panel discussions dove into such topics as workforce and labour policies, artificial intelligence, and sustainability.

The final conference day opened with a celebration of the industry’s best and brightest at the CCA National Awards breakfast. This year’s list of winners included Geza Banfai, PCL Construction, the Construction Association of Nova Scotia, the Calgary Construction Association, Westcor Construction Ltd., Groupe AGF, Enviro-Ex Contracting and Anthony DeVito, who was awarded the 2024 Young Leader Award.

The awards presentations were followed by a pre-election discussion about the changing political landscape in Canada, tariff discussions over lunch, and a fireside chat discussing the achievements of women in Canada’s construction sector, before wrapping up with an impressive masquerade gala.

is on the rise.

BY NATE HENDLEY

Compact loaders, mini excavators and other small but mighty construction machines are becoming increasingly popular, due to several perceived advantages.

“A lot of new equipment owners are coming to the market and are choosing compact over heavy equipment because it’s at a relatively competitive price point. They’re highly versatile machines, so they can tackle a lot of different jobs and applications,” says Julie Portillo, prod-

uct marketing manager for construction products at Bobcat. “You’ll see a lot of cab advancements, like heated air suspension seats, torsion suspension, touch screens, and a lot quieter cab experience too. These types of features are all becoming more important because many of the equipment owners are also operators.”

Smaller machines are also getting more advanced, tech-wise.

“In compact equipment, 2D grade controls fit the need today, whether it’s for

an excavator or a compact track loader with a box blade or grader,” states Jonathan Gardner, product manager for construction equipment at Kubota.

“With excavators, Dig Assist and those types of guidance controls are starting to show up in compact,” echoes Darren Ashton, product manager for compact, sales region North America, Volvo Construction Equipment.

“Telematics fleet management systems are migrating their way from

ACROSS THE BOBCAT LOADER LINEUP, YOU’LL FIND MORE MODELS WITH TWO-SPEED TRAVEL AND INDUSTRY-LEADING SPEEDS THAT DOMINATE THEIR SIZE CLASS. RAISE THE BAR WITH FAST CYCLE TIMES. BOBCAT LOADERS HELP YOU ACCOMPLISH MORE, WHEREVER THE JOB TAKES YOU.

heavy construction equipment to compact machines,” adds Jake Sherman, dozer and compact track loader product manager at Develon. “Many OEMS are offering telematics for compact equipment, some as a standard machine feature.”

Electrification continues to be an ongoing trend, and a field where compact and mini equipment has an edge. Pint-sized machines have lower power requirements than larger models and take smaller batteries, which can be recharged relatively quickly using standard electrical outlets.

“During the last five years, manufacturers have introduced a variety of electric-powered mini excavators, compact track loaders and compact wheel loaders,” notes Sherman. “They’re certainly an attractive option for contractors performing inside work like demolition.”

“We’ve starting to see the rise of the electric, smaller machines,” agrees Ashton. “Some of the bigger stuff is moving a little slower down the electrical path than compact is.”

With this in mind, here’s a look at what’s new and/or noteworthy in compact equipment:

The Cat 903 compact wheel loader, introduced in 2024, sports a Tier 4 Final 48 hp (36 kW) Cat C1.7 litre engine and diminutive design.

“The added horsepower results in improved performance when grading or pushing, along with improved multi-function capabilities,” explains Brock Bahr, product application specialist at Caterpillar.

The 903 is 185 inches (4,693 mm) long, including bucket, and has an operating weight of 9,200 pounds (4,173 kg) making it “the perfect machine for transporting from jobsite to jobsite, whatever the task,” says Bahr.

The loader also boasts a rear hood for quick access to the engine compartment, and a choice between standard (121 inch/3,086 mm) and high-lift (127 inch/3,227 mm) configurations. Bucket capacity ranges from 0.8 to 1.3 cubic yards (0.6 to 1 cubic metre). The user-friendly design also features a comfortable oper-

Purchasing your first piece of equipment is a big investment when you run your own small business and Jason Rottier was intent on getting it right.

“It was a giant, and I mean giant, step for a small company less than three years old,” explains the owner of Rottier Excavating in Wallaceburg, Ontario. “I looked at used and new machines, I looked at horsepower, hydraulic output, high flow capability, user comfort, I looked at ever ything.”

Jason’s exhaustive research led him to purchase the Kubota SLV65-2 compact track loader in early 2022 but with his company rapidly expanding, he found himself back at his local Kubota dealer less than two years later to buy the new SVL75-3.

MORE COMFORT

“When you have big boots, you need a big area and there’s a lot of leg room in the SVL75-3,” says Rottier, who measures in at over six feet tall. The Air Ride seat is nice.

I have lower-back issues, and I can sit in that thing for 10 hours a day.”

“THE SVL75-3 IS A SWISS ARMY KNIFE FOR MY BUSINESS.”

ator seat with new adjustment controls, coloured yellow “to make them easier to find,” says Bahr.

“All Cat compact wheel loaders from the 903 up to the 920 come equipped with Cat Product Link. Product link allows for machine monitoring and gives information such as location, hours, fuel usage, productivity, idle time and diagnostic codes,” he adds, referring Caterpillar’s telematics solution.

MORE PRODUCTIVITY

“The pushing power of the SVL75-3 is great - it’s like a small dozer. I use it for everything – landscaping, bushremoval, loading dump trucks, cutting wood, and I’m not easy on things. If it lasts for what I do, then it’s a solid piece of equipment.”

MORE ATTACHMENTS

Thanks to its compatibility with all types of attachments, Rottier says his new machine has opened the door to additional opportunities.

“The SVL75-3 is a Swiss Army Knife for my business I have a grapple bucket. I do a lot of brushing and moving material. I have a trencher for putting in hydro, gas and waterline trenching. I have a Kubota land plane. Forks, buckets, an HLA SnowBlade, you name it!”

MORE EASE OF MAINTENANCE

“It’s nice when you can get your arms in and see the hydraulics and not have to dismantle ever ything and take all the panels off,” explains Rottier. “With the SVL75-3, you open the door and flip the hatch up and the whole thing’s open.”

Kubota released three new small-sized construction machines earlier this year: its U17-5 and KX040-5 compact excavators and the SVL97-3 compact track loader.

The zero-tail swing U17-5 compact excavator is 11 feet, 7.7 inches (3,550 mm) long, seven feet 9.3 inches (2,370 mm) tall and weighs 3,902 pounds (1,770 kg). Expandable tracks extend the track frame width to 51 inches for added stability and maneuverability, while LED boom lights boost nighttime visibility.

The KX040-5 offers five customizable, preset attachment oil flows, a larger cab with increased foot space, reduced engine noise and enhanced hydraulics. If the control levers of the machine are in neutral for more than four seconds an Auto Idle function automatically decreases engine RPM. A rearview camera is optional, as is a Kubota hydraulic six-in-one angle blade.

Weighing in at 11,929 pounds (5,411 kg), the SVL97-3 model is equipped with a seven-inch digital colour LCD touchscreen panel, an integrated Bluetooth radio, two speeds – a 5.5 mph (8.9 km/h) low gear and an 8.4 mph (13.5 km/h) high gear – and new LED work lights. When going into a material pile or turning, the company’s Auto Shift function will take the machine from high to low gear. It also has Auto Idle and a heated air-ride seat.

Also available is KubotaNOW, the company’s telematics solution that allows operators to “geofence your equipment, receive maintenance reminders, and know where your equipment is at all times,” states Gardner.

Develon introduced the DTL35 compact track loader, the company’s first machine of this kind, last year. Fitted with a 115.3 hp Develon D34 engine for high torque and power, the DLT35 is available with a standard auxiliary hydraulic flow of 22.2 gpm (84 L/min) and an optional high-flow system of 39.9 gpm (151.2 L/min). Two-speed travel varies between 6.1 mph (9.8 km/h) and 9.2 mph (14.8 km/h).

The compact track loader weighs 12,785 pounds (5,799 kg), with a dump height and dump reach of 96.7 inches (2,457 mm) and 46.3 inches (1,175 mm) respectively. Designed to offer enhanced traction and jobsite maneuverability, the DLT35 is 165.7 inches (4,210 mm) long, with its bucket on the ground.

An optional around-view monitor (AVW) camera system offers enhanced visibility, a feature that’s “particularly useful when the machine is working in a tight area or near other equipment. Ultrasonic sensors alert the operator to nearby objects when the machine is backing up, for enhanced safety,” says Sherman.

Also new in 2024 were the DX35Z-7, DX42-7, and DX62R-7 mini-excavators.

As “part of the popular three to four metric ton size class, [the DX35Z-7 and DX42-7] are used largely on commercial and residential construction sites,” suggests Andy Jeong, mini excavator product manager at the company. He says that applications

might include digging footings or foundations for smaller commercial structures, grading and leveling, lifting and moving pipes, and creating utility trenches.

The reduced tail-swing DX62R-7 is intended for larger projects involving demolition, site preparation, and debris removal, he adds. Like all Develon mini-excavators, it has a standard enclosed cab with heat and A/C. Develon mini-excavators and the DLT35 also come standard with My Develon telematics fleet management software, which offers location tracking and geofencing for theft prevention. Owners can use the system to remotely monitor machine data via a smartphone app.

Develon plans to launch a new mini wheel excavator in the near future, as well as

a second compact track loader that “will be smaller than the DLT35,” says Sherman.

Volvo introduced two new compact excavators to North America last year, the EC37 and ECR40, and updated its L30 and L35 compact wheel loaders. The EC37, which weighs 8,344 pounds (3,785 kg) and the ECR40, which weighs 8,785 pounds (3,985 kg) both sport a 24.8 hp Stage V, Tier 4 engine. In addition to being more fuel efficient than previous models, these machines have bigger, quieter cabs.

They share another unique feature as well: “When you’re specifically looking at the 37 and the 40, we elongated the undercarriage,” says Ashton. “That extra length on the ground has made [these machines] quite stable.”

The updated L30 and L35 compact wheel loaders, meanwhile, now have more ergonomic, multi-functional joysticks, bigger displays and standard, reversible cooling fans for dusty work conditions.

“We added the seven-inch display that you’re seeing in most of our compacts with the jog wheel,” states Ashton, of the L30 and L35. “We’ve improved the sensors, we’ve reduced [the exhaust stack], so visibility is better, not only out of the front because the dashboard is noticeably smaller but also out of the backend, where you don’t have an exhaust stack getting in the way anymore.”

INTRODUCING THE TB395W WHEELED EXCAVATOR — YOUR NEW GO-ANYWHERE, DO-ANYTHING FAVORITE FOR TACKLING YOUR TOUGHEST TASKS. HARNESSING 114 HP, THIS ALL-STEEL WORKHORSE OFFERS THE RAW TAKEUCHI POWER YOU LOVE WITH PRECISION PILOT CONTROLS THAT KEEP YOU CALLING THE SHOTS. AVAILABLE WITH TWO-WHEEL STEERING OR FOUR-WHEEL CRAB STEERING THAT MAKES TERRAIN AN AFTERTHOUGHT. ON-ROAD PERFORMANCE AND AN 18-MPH TOP SPEED SAVES TIME AND TRANSPORT COSTS MOVING FROM SITE TO SITE. AND WITH A HEAVY-DUTY, TWO-PIECE SWING BOOM AT YOUR COMMAND, YOU’LL REACH ALL YOU NEED, BOTH NEAR AND FAR. IN THE TB395W, NOTHING WILL STAND IN YOUR WAY.

THE MARK OF TOUGHNESS

» DIG INTO THE DETAILS AT TAKEUCHI-US.COM/TB395W

The new sensors monitor cooling and engine performance.

Volvo also introduced a straight boom option for the 1.8-ton EC18 battery-electric compact excavator earlier this year with a longer reach than a conventional two-piece boom. The straight boom has a 13-foot (3,960 mm) working height with bucket and can be fitted with attachments weighing as much as 450 pounds (204 kg).

Compact electric excavators are very well-suited for indoor demolition work, due to the machine’s lack of emissions and noise and small-size, notes the manufacturer.

This April, Bobcat introduced what it calls its “most powerful mini track loader.”

Called the MT120, this mini loader boasts a 1.2-litre, non-diesel particulate filter (DPF) engine, weighs 3,720 pounds (1,687 kg), has a rated operating capacity of 1,200 pounds (544 kg), and ground pressure (rubber) of 4.26 pounds per square inch (psi). It’s narrow 36-inch width enables

it to “fit through a standard doorway … for indoor demolition,” says Portillo.

The company says the MT120 also has more comfort features than Bobcat’s previous MT100 mini track loader, including “a 4.3-inch colour display, and password protected keyless start,” continues Portillo.

Mini-track loaders are “really popular,

versatile machines, so you’ll see them within a lot of different [construction] applications. They can run a lot of different attachments because they have a little bit of hydraulic power behind them,” she adds.

“In construction, you’ll see them used for anything from trenching, to digging and moving materials, demolition … you can

also see them for site preparation … They’re just really good machines for fitting in smaller, tighter spaces.”

In terms of technology, the MT120 minitrack loader “features some smooth, responsive and precise pilot drive controls that will really improve the operator experience and make it easier to operate and reduce operator fatigue,” says Portillo.

Case’s new 421G compact wheel loader “fits the sweet spot for both muscle and versatility,” states product manager Neil Detra.

Weighing 19,775 pounds (8,970 kg), with a lifting capacity of 15,806 pounds (7,170 kg), the 421G is larger than most compact loaders but nimbler than a full-size model. As such, the 421G is well-suited for a wide range of applications, particularly with its standard 416 JRB-style coupler, says Detra.

An impressive 146.2-inch (3,714 mm) hinge pin height also means “operators can reach greater heights and dump materials

into taller trucks, bins or hoppers,” he adds. Case also launched a low-noise, emissions-free CL36EV electric compact wheel loader this year. The CL36EV is 211.4 inches (5,369 mm) in length without bucket, 65 inches (1,650 mm) wide, 96.6 inches (2,453 mm) tall, and weighs 8,803 pounds (4,042 kg), Powered by a 23-kWh battery, Detra says it is a good choice for worksites where noise might be an issue, and for indoor construction applications, adding that it “performs like a similar-sized diesel loader” and can be charged “at any J1772 Level 2 automotive charging station.”

A skid steer coupler that’s compatible with grapplers, forks, and other attachments, adds versatility to the model. The CL36EV also has a hinge-pin height of 121.6 inches (3,088 mm), making it ideal for loading applications.

Case compact track and wheel loaders come standard with SiteWatch telematics to track performance, location and operational data.

Nate Hendley is a freelance writer and author and is a regular contributor to On-Site Magazine.

25_003459_On_Site_Magazine_JUN_CN Mod: April 1, 2025 12:34 PM Print: 04/24/25 page 1 v2.5

BY SARA VINCENT

Safety must be the top priority for workers and supervisors who use Mobile Elevating Work Platforms (MEWPs). These versatile machines, which enable efficient completion of tasks at height, require strict adherence to safety protocols and operational best practices. Based on industry standards and guidance from JLG’s safety and product reliability department, this comprehensive guide outlines key safety considerations that all MEWP operators and supervisors should understand and implement.

One of the most critical aspects of MEWP safety is ensuring that the equipment undergoes regular inspection. Industry standards require that an annual machine inspection be performed no later than 13 months from the date of the prior annual inspection. These inspections must be conducted by qualified personnel who possess the exper-

tise to inspect the specific make and model of MEWP.

Before operating any MEWP, the operator should verify that all components included in frequent inspections have been examined, that manufacturer-specified items for annual inspection have been checked, that the MEWP is properly registered with its manufacturer, and that all open safety bulletins have been addressed. Also imperative is ensuring that any identified malfunctions or problems have been corrected.

Since MEWPs are frequently required to operate in challenging weather conditions and varying climates, understanding and adhering to temperature limitations is crucial for maintaining both equipment performance and workplace safety.

MEWPs are typically designed to operate within specific temperature ranges, generally between 0°F (-20°C) and 104°F (40°C).

When operating in extreme conditions, there may be some additional safety measures.

For example, use cold-weather packages for temperatures below 0°F (-20°C), and never operate equipment below -40°F (-40°C). And when working in low temperatures, ensure that appropriate engine and hydraulic oils are being used, based on the ambient temperatures.

In hot weather, request hydraulic oil cooler packages when working above 100°F (38°C) and avoid operation in temps exceeding 120°F (49°C). Also monitor hydraulic oil temperatures in high ambient temperatures, and during extended operation.

As the critical point of contact between the MEWP and the ground, proper tire and rim maintenance is fundamental to both machine stability and safe operation, particularly when working at height. The condition and maintenance of tires significantly

impact both performance and stability.

Daily tire inspections should be part of pre-operation checks. Verify proper tire pressures, and monitor foam-filled tires for damage, cuts or tears. Report tires showing signs of significant wear or damage and ensure that any replacement tires match original specifications for size, ply rating and load capacity. When replacing pneumatic tires with foam-filled options, use manufacturer-approved tire fill materials.

Proper positioning and shutdown procedures at the end of operations or during work breaks are essential steps in preventing accidents and protecting both equipment and personnel from potential hazards.

When parking MEWPs, operators should select a well-protected area, fully retract and lower the boom over the rear axle, shut down all controls systematically, engage all emergency stops, position the platform/ground select switches to “off,” and protect the control panels from environmental exposure. If space constraints require parking with an elevated boom, ensure it remains retracted.

Proper preparation and securing for transport between job sites is as critical as operational safety. When preparing MEWPs for transport, it’s important to know the tie-down procedures and lifting requirements.

For tie-down, position the unit in its stowed configuration, then engage the turntable locks (when equipped), secure the machine at its designated tie-down points using adequately rated tie-down equipment, and remove all loose items before transport.

When lifting a MEWP, attach lifting devices only to designated lifting points and ensure the lifting equipment is properly rated for the machine’s weight. Maintain level positioning during lifting operations.

Given that MEWPs are specifically designed to elevate workers above ground level, implementing proper fall protection systems is one of the most crucial aspects of ensuring operator safety and regulatory compliance. Fall protection requirements vary by MEWP type and configuration.

All personnel must wear fall protection

devices, at all times, when using boom lifts. Use full-body harnesses with appropriate lanyards, and attach only to manufacturer-approved anchorage points, with only one person per anchorage point.

For scissor and vertical mast lifts, fall protection may not always be required by standards, but is recommended.

Certain specialized applications require additional precautions and specific procedures to ensure worker safety and equipment integrity. When working from barges, for example, ensure the barge size exceeds MEWP footprint and that the barge surface can support the machine weight. You will also want to maintain current inspection status and verify that operator training is complete and current.

Be sure to follow all applicable safety procedures, including wearing appropriate personal flotation devices when over water. Limit list and trim to a maximum of one degree and secure the MEWP appropriately to the barge. Also disable the machine’s drive functions, except during the process of loading and unload.

One of the most critical moments in elevated work occurs when operators need to transition between the MEWP platform and an adjacent structure, requiring precise positioning and careful attention to fall protection protocols.

When transferring from a MEWP platform to an adjacent structure, follow all applicable regulations and safety procedures. Position the platform within one foot of the secure structure and implement 100 per cent tie-off using two lanyards. Ensure that you maintain platform attachment until securely attached to the structure.

While MEWPs are designed to operate on firm, level surfaces, job site conditions often present challenging terrain that requires careful consideration and proper use of cribbing techniques to establish a stable working platform.

When operating on uneven surfaces, use only manufacturer-approved cribbing methods and follow manufacturer specifications for maximum heights. Verify ground conditions can support maximum loads, avoid slopes exceeding five degrees, and only crib two wheels on the same side or end.

Use appropriate materials and construction methods, implement drive and steer lockout procedures, and maintain proper wheel positioning on cribbing.

Integrating safety practices into daily work routines is essential for preventing accidents and ensuring compliance with industry regulations. In general, operators and supervisors should complete all required training before operating any MEWP and ensure that daily inspections are performed before each shift.

Document all inspections, maintenance and operator training, understand and adhere to the specific limitations of each MEWP model, and stay current with safety bulletins and manufacturer updates. Above all else, prioritizing worker protection over production demands.

Sara Vincent is the director of marketing at JLG, a designer, manufacturer and marketer of access equipment, including aerial work platforms and telehandlers.

Progressive companies are taking steps to attract and retain good

It is no secret that the construction sector is experiencing a labour crunch, and it is one that’s projected to get more and more difficult to navigate as the current Canadian workforce gets closer to retirement. To help navigate the labour challenge, and to share some of the things top Canadian companies are doing to attract and retain their workers, On-Site Magazine, Electrical Business Magazine and HPAC Magazine teamed up to present WorkForce ’25 this past May.

The event, sponsored by GCPay, a cloud-based construction software developer whose platform helps construction companies manage pay applications, lien waivers, electronic payments, and other accounting needs, brought together speakers and panellists to share insights and experiences with the aim of exploring real strategies for attracting, developing and retaining the skilled workforce companies need, and will continue to need for the foreseeable future.

Even with more workers in the construction sector, population increases are driving up the unemployment rate, explained keynote speaker Bill Ferreira, executive director of BuildForce Canada. With the construction sector expected to grow over the next several years, he acknowledged a need to add more workers to the sector but illustrated that the real the labour challenge for the industry will be keeping pace with retirements.

“We’re going to need to find an additional 111,000 individuals to join the construction workforce over the next 10 years,” he stated. “When we take

BY ON-SITE STAFF

into account the 268,000 individuals that we anticipate will retire over that period, the industry will need to hire an additional 380,000 people.”

While the industry is likely to find 272,000 new entrants in that timeframe, he said the gap of 180,000 workers will have to be recruited, including from outside the country.

On the positive side, apprenticeship numbers are up. “This is one of the success stories that we’ve seen in the last little while,” he said. “In 2023, which is the latest data that we’ve been able to track, new registrations were just under 72,000 and women now represent just slightly over eight per cent of the overall registrations into the industry, which is good news.”

And those numbers will likely be needed, despite the uncertainty of the impact associated with the current tariff war, as both residential and non-residential sectors are forecast to rise over the coming decade, as are other industries that will also be competing for attention from the younger workers who are currently in elementary and high school.

“This is not a time to ease up,” advised Ferreira. “The industry is going to have to remain quite active, promoting careers in construction.”

With the challenge laid bare, the day’s sessions dove into the topic of marketing these careers to a new generation of worker.

“We know, courtesy of Bill’s opening presentation, that the construction workforce is in need of employees going forward,” stated Doug Picklyk, editor of HPAC. “Skilled trade workers are definitely in demand, and the challenge is in attracting a new generation.”

Panel members Jim Berry of PCL construction, Anna Lary from of the ConnectHER Hub at BCIT, and Lea Valcourt from Support Ontario Youth dove in, providing advice that can help contractors make the construction space more inviting for potential new workers.

“Young people think differently access media, and access information in a very different way that those of us of a slightly older generation do. And we have to adjust,” stated Lary. “When I launched the ConnectHER Hub, I had a panel of tradeswomen influencers. They showcased the work that they do in a very authentic way, showing their daily lives, and the young people really connect with that.”

“You have kids that are coming out of high school that that went through their entire high school career using technology. This is where their media platforms lie. They’re going to be on Instagram, they’re going to be on TikTok. They’re going to be probably not so much on Facebook anymore,” added Valcourt, who suggested that organizations seeking to employ youth create an Instagram account to reach them on their level. Especially since videos can help navigate some of the negative stereotypes often associated with construction.

“One of the things we like to work with is as a shadow program, bringing people in to come walk with a journeyman and see how they control things, how they use the tools, and how they mitigate hazards,” explained Berry.

His company was one of a dozen general contractors who recently formed the Canadian Construction Safety Council, which is committed to fostering consistent safety performance and reducing critical injuries within the construction industry by championing proactive safety measures.

Finding workers is one thing; keeping them presents a whole other challenge, but one that leading companies in the industry are tackling head-on, as evidenced by the panellists in the second business session of the day: a look at retaining workers through training, growth and purpose.

Panellists Ravi Tangri of Simul Corp.,

Jay Mallan of JJM Mechanical Group, Alicia Maxim-Welsh of Graham, and Sarah Harkness of EllisDon explained that a paycheque isn’t enough to keep workers around.

Skilled employees want more than just a job: they want stable and inspiring management, opportunities for advancement, and purpose in their careers, and if your company doesn’t provide that, they’ll find an employer who does, they advised.

“In the wake of the COVID-19 pandemic, we saw a lot of people reprioritizing and looking for a greater level of flexibility and work life balance,” explained Harkness. “It isn’t just about a salary anymore. People are looking for more.”

“People want to have opportunity to grow; to have opportunity to develop,” added Tangri, who explained that he uses the term “life-work balance,” since he feels life should come before work. “I’ve seen so many cases where people will turn down more money … there’s a different trade off here, and there’s a different value that people are looking at.”

Maxim-Welsh explained that a large part of the retention puzzle is personal development, and growing people as they fill and advance their roles.

“We’ve launched two key programs that are really making an impact,” she said. “The first is our graduate program, which is a really in-depth, two-year journey designed to help new grads explore their career path at Graham … second, we support them with formal learning mentorship.”

Those efforts are having solid impact, with her company reporting an 85 per cent retention rate in participants.

And retention efforts are not just for large companies with hundreds or thousands of workers. Mallan has grown his company

through doing the little things that matter, like listening, and ensuring that they have training opportunities, as well as a chance to have fun with their co-workers.

“We don’t want to throw people in the deep end; we want them to feel supported throughout the year,” he explained.

A great workplace culture is important and, as Tangri said in his session, wages are only one aspect of the big picture, so the final session of the day provided insights into one of the tools a company can use to show the flexibility that new workers often desire from their employer — their benefits plans.

Pascale Mapleston, founder and CEO of The Benefit Code, spoke about the need to evolve so that companies are providing what today’s workers view as relevant to them.

“Benefits aren’t just perks,” she stated, explaining that they are tools to compete for new workers, and to retain good people.

“To retain talent, especially women, we need to offer practical, personalized benefits,” she explained. “There’s a massive untapped potential here, but if we want more women on the jobsite, we have to meet them where they are. That means benefits like paid parental leave, childcare support, flexible schedules and, let’s be blunt, safe and clean washrooms also help a lot.”

These steps need not be difficult, nor more expensive to implement, she said.

“Very progressive companies are really amping up their on-site offerings in terms of health,” she said. “Solving skilled labour shortages means changing how we take care of people; it’s time to build a stronger benefits foundation.”

Great onboarding isn’t about paperwork – it’s about people.

BY SUZANNE MCKAY

Picture this: it’s your first day at your new job. You show up, and your manager’s waiting for you and greets you with a warm welcome. They walk you around the jobsite and introduce you as the newest member of the crew. Everyone stops what they’re doing, shakes your hand and asks a little about you. You’re given a blue safety vest and a mentor to shadow.

It’s a far cry from the alternative where you show up and have no idea where to go. The door to the trailer’s locked. The site is in disarray and people are too busy to greet you, let alone point you in the direction of your manager. Eventually, you get placed in front of a computer, for two days of watching outdated training videos and filling out compliance forms.

Which job would you stay at?

feedback, both with their coworkers and their leader. When onboarding new employees, a foundation of trust and a solid bond with their new team is critical. It’s their first real exposure to your values in action.

Simple gestures like introducing new hires to the team or preparing their workspace ahead of time go a long way.

New hires must quickly learn new safety practices and hone their skills to match their new environment. People learn through a combination of education (like training videos), exposure (job shadowing) and experience (doing it themselves). If your training process is more than a few years old, it’s worth taking a fresh look at it. Does it reflect your current practices and technology? Is it too boring to keep their active attention? Remember: any training you provide to new workers is quickly forgotten unless they can actively practice it.

Onboarding is about so much more than filling out paperwork, checklists of tasks, and “learning the ropes.” It’s about clarity, communication, consistency and, most importantly, culture. Creating an experience that leaves new employees feeling connected, motivated and ready to thrive will last much longer than any training video.

Building the right company culture isn’t easy. It takes effort, intention and consistency. People should feel and see your culture in action. The values you post on your website or lunchroom wall mean nothing if you don’t practice what you preach.

Start by creating a safe environment where employees feel comfortable voicing concerns, asking questions and sharing

The talent pool is limited. We’re all competing to attract skilled workers and retain them long-term. The latest generation of workers isn’t afraid to leave a steady job in search of a better work environment.

The “perfect” candidate on paper may have all the right experience, but without the right mindset and culture fit, they simply won’t stay long enough to help the team. Now, more than ever, we must think outside the box when it comes to hiring strategies. While technical skills are important, many of them can also be taught.

Consider revising your recruitment strategy to attract a broader talent pool by valuing adaptability and development potential over specific skills.

One way to tackle this challenge is through mentorship programs. It’s a great way to support new workers while keeping them engaged and accountable. Our trainees go through a six-month mentorship program with an experienced teammate. For safety, we have our mentees wear blue vests so others can easily identify them in the yard and help them stay safe.

Embedding a mentorship culture right from the start sets the tone. It also provides more experienced employees the opportunity to share knowledge and skills, which can be both satisfying and strengthen their own skills.

Onboarding is a process that doesn’t end after the first day, or the first week. Fostering the development of engaged, motivated, safe and productive new hires who want to stay long-term? That’s just good business.

Suzanne McKay is the senior human resources business partner at Cooper Equipment Rentals.

THE TOP 40 Page 33

SURVIVING AND THRIVING Page 34

TOP 5 UNDER 50 Page 40

LISTINGS Page 44

Top contractors face unique challenges and complex risk that requires diverse expertise. At American Global, we operate as a single, unified team—across all departments and regions—to ensure every client has access to the best resources for their business. So, while the world may seem divided, our commitment remains rmly intact: to serve our clients’ best interests, regardless of where they reside. One team. One focus. One goal. Expect more from your broker.

• Local Presence (Ontario, Alberta & Quebec) with Global Knowledge

• Cross Border Broker for Seamless Service & Advisory

• Construction Industry Experts and Technical Specialists on Staff

•

• True Collaboration That Drives Real Innovation

www.americanglobal.ca

Building a stronger Canada through partnership.

American Global Canada is extremely honoured to be this year’s sponsor of On-Site Magazine’s Top Contractors issue, and to stand alongside the industry leaders that are shaping Canada’s future.

While Canada may face challenges with respect to our economy and our place in the world, one lesson learned from the recent election is that there is a desire for meaningful change and action, and an emerging consensus to remove the barriers to growth, innovation and investment that are needed to ensure our prosperity into the future.

Despite economic headwinds and shifting global dynamics, Canada’s construction industry remains a force of resilience and ingenuity. According to BuildForce Canada, non-residential construction investment is forecast to grow 2.5 per cent annually through 2028, supported by public infrastructure, energy projects and housing-enabling developments. Contractors continue to innovate, investing in people and technology while managing workforce shortages, supply chain challenges and geopolitical uncertainty. One thing we do know for certain is of the need for us all to continue collaborating as an industry, regardless of geography, to continue the progress we’ve made.

At American Global Canada, we’re proud to see that strength in action. Major projects, like the Contrecoeur Terminal Expansion at the Port of Montreal, are transforming Canada’s trade capacity and economic resilience. Whether it’s ports, transit, housing or energy, our nation’s contractors are leading the way in building a better tomorrow.

American Global’s role is to support all those who build — not simply with programs and policies but through partnership. As one of North America’s largest privately held brokerages with a sole focus on construction, we support contractors throughout the entire scope of their projects and across every milestone of their business. We are here, not only to protect clients against the risks and exposures specific to the construction industry, but to help navigate risk, unlock opportunity and make confident, data-driven decisions. Our proprietary project model and advisory platform, C-RISQ, helps provide clarity when it matters most, and our team is your trusted advisor.

While market conditions may shift, our commitment does not. No matter how uncertain the economy, or how divided the world may seem, we believe in the collective power of collaboration. At American Global Canada, we’re proud to work side by side with contractors, carriers and clients to drive progress and prosperity, together.

To all those recognized in this year’s Top 40 Contractors list: Congratulations! Your leadership continues to shape the future of this country, and we’re honoured to build it with you.

Sincerely,

Kent Peters President, American Global Canada

Health care is the heartbeat of community. From new hospital design build projects, to retrofits within operational facilities, to specialized clinics and mental health spaces, PCL is Canada’s Top Contractor and proud to lead the way in advanced health care construction across the country.

Coming off a period of high inflation, followed by a half-year of tariff uncertainty, it will surprise few that 2024 and 2025 are presenting a mix of financial results and expectations amongst Canada’s leading construction firms. While not all companies experienced revenue growth last year, many did –some even hitting historic highs.

Among those who saw their revenues retreat, major projects either wrapping up or getting closer to completion were often cited as reasons.

Overall, On-Site’s survey of readers suggests that Canada’s construction sector continued to climb in 2024. Looking at the Top 10 from our list of the 40 largest companies, by revenue, their cumulative reporting was almost a billion dollars higher than in 2023. That’s very good news.

While 2025 forecasting has a significant number of companies tempering their expectations, results in next year’s list may be tied to which segment, or segments, a company serves. Publicly funded projects appear to be showing stability and growth, and the term cautious optimism is percolating within the sector.

Once again, the team at On-Site would like to thank all of the companies that took the time to participate in our annual survey. Your valuable contributions make this research possible and allow us to share trends and insights with our industry.

1 2 3 4 5

BY ADAM FREILL

With PCL leading this year’s Top 40 Contractors list with a robust $11.3 billion in 2024 revenues, a rise of $1.3 billion, one could assume that Canada’s construction sector is riding a nice wave of growth, but the full picture is quite a bit more complicated than simply pointing an arrow. While some companies saw some significant growth, others experienced a decline in their annual revenue totals.

Based on some of the responses to On-Site Magazine’s annual survey of readers, as well as conversations with several of the industry’s leading companies, the segment, or segments, one plays in is a major factor in reported revenues this year, as is the stage of progress of some major projects. Looking ahead, 2025 expectations are somewhat muted as companies navigate an unusual mix of high need but low demand for new housing in the residential sector, and economic challenges that are impacting both lending rates and project cost certainty, which is putting privately funded projects at risk of pause or cancellation. Publicly funded projects are providing some significant opportunities, however, as are certain pockets of the private sector.

“There’s no question that economic pressures are creating some headwinds. Project delays and cancellations are happening, especially in the private sector, where financing is tighter and clients are more cost-sensitive,” says Omar Rawji, CEO of Prism Construction. “That said, the types of work we specialize in — design-build, commercial and industrial projects, and tenant improvements — are still moving. We’re seeing steady demand in light industrial builds, retrofit projects, and upgrades for existing tenants who are staying put and investing in more efficient or reconfigured spaces rather than relocating.”

Despite facing some economic uncertainty, the fast adoption of new technologies, and an ongoing labour shortage, “cautiously optimistic” remains a common assessment of prospects for the coming 12 months.

Perhaps the most heavily used term of 2025 has been tariffs, but despite the instability, the actual impact of cross-border tariffs on Canada’s construction industry has not been as severe as may have been feared, with contractors using a mix of strategies to mitigate the impact on projects that are moving forward, including some learned navigating price escalations during the pandemic.

“Overall, volatile trade policies have had a dampening effect on the sentiment in the industry and elevated the risk profile of most projects,” says Thomas Strong, senior vice-president of Construction Technology & Innovation at NFP. “For in-flight projects, many general contractors are conducting a detailed review of material origin so that they can get out in front of any issues that they might have. General contractors are expediting the supply of material to the job site where possible, or working to prequalify new alternative suppliers, to minimize disruption and budget impact.”

“When the risk of tariffs first appeared a few months ago, there was a real concern as to the supply chain and cost impact to projects. Since that time, and [looking at] some analysis on the potential tariff impacts,

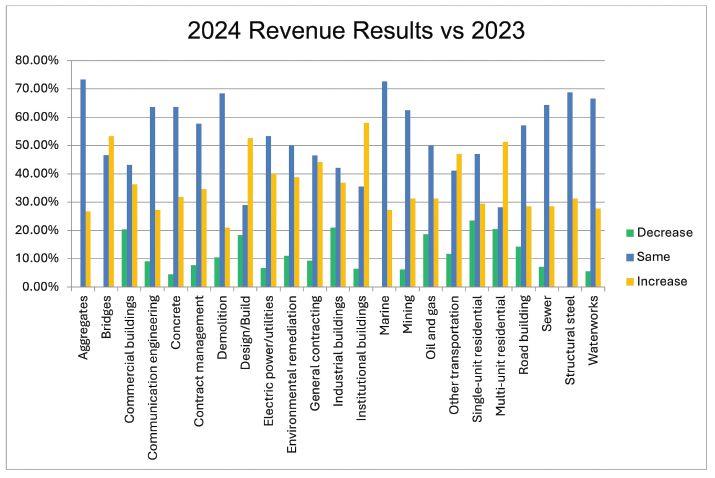

Although individual corporate performance varies, the survey figures reported for 2024 show no category where the decreases were greater than the increases, indicating that the industry was either holding steady or growing in all surveyed categories last year.

there are solutions that can minimize the impacts, and in some cases create opportunities for the Canadian market,” says Mike Wieninger, COO of Canadian Operations at PCL Construction. “This doesn’t mean there won’t be supply chain and cost impacts, but the impact doesn’t appear to be significant from a cost perspective.”

“Some contractors are now entertaining calls from international suppliers they would’ve never considered,” adds Kent Peters, president of American Global Canada. “One key shift we’ve seen since the pandemic is how inflation risk is being passed upstream. Suppliers, subs, and GCs are building that into contracts, often pushing more of the risk onto the owner.”

Industry associations are also working to help contractors navigate the cost uncertainty that tariffs may present.

“ORBA has been working closely with the Ministry of Transportation to develop contract language and procurement guidance that allows for tariff-related relief,” reports Steven Crombie, senior director of public affairs at the Ontario Road Builders’ Association. “These efforts are helping to stabilize projects and give contractors more confidence in their bids.”

As projects continue to roll forward, so too does the challenge of finding and retaining new workers for the industry. The pressure of replacing an aging workforce that is losing numbers to retirement is real, and will only grow as segments like housing find their feet, which may see the industry looking to government for support.

“According to industry data, around 40 per cent of the construction workforce is over 45 years old, and a significant portion is nearing retirement age. We are seeing those retirements happen, particularly among skilled trades,” states Wieninger. “Construction capacity will be a real issue if there is growth in both private and public development. Governments and industry leaders need to address this issue and promote and attract talent to the construction workforce to meet the expected demands in the coming years.”

“The labour shortage is very real. The projected retirements are happening, and we are seeing them,” says Rawji. “Retention, in our experience, is just as much about culture and purpose as it is about pay. Workers want to feel valued, safe, respected, and part of something bigger.”

One way the industry is looking to do more with the labour pool that it does have is by embracing of technology. According to this year’s Top Contractors readership survey, the use of Artificial Intelligence (AI) is on the rise in Canada’s construction sector.

“With the global talent shortage impacting all organizations and roles remaining vacant, economists are suggesting that the shortage needs to be addressed through productivity enhancements,” says Wieninger. His company, and many others, are looking at ways to harness AI to reduce the time needed for daily tasks.

“While the adoption of AI in construction is still in its early stages compared to other sectors, its impact is steadily growing,” explains Brandon Milner, chief information officer and senior vice-president at EllisDon. “From optimizing project schedules and enhancing safety through predictive analytics, to streamlining

workflows and enabling real-time decision making, AI is becoming a game-changer.”

“Common use cases targeting general contractors include contract review, quantity takeoff and even earned value reports from reality capture products,” says Strong. “AI, so far, is not replacing knowledge workers, but rather it is improving their productivity as they adapt these products to gather, enhance and enrich information for decision-making.”

“While a lot of the current conversation about AI is high-level or theoretical, we’re starting to see real, tangible applications in construction,” agrees Rawji. “At Prism Construction, we’re not interested in hype for hype’s sake. We are using AI and machine learning tools in estimating, project scheduling, predicting maintenance needs, and many administrative functions. Tools such as generative design and predictive modeling are also starting to make a difference.”

“AI’s real impact today is personal. It’s less about big, complicated systems and more about helping people work smarter every day, whether it’s summarizing notes, generating reports, or brainstorming ideas. That kind of practical, daily integration is what’s pushing the industry forward,” says American Global’s Chris Greene.

Milner adds that AI is not a passing trend. “The construction world is moving toward data-driven decision-making, and AI provides the tools to stay competitive and improve efficiency,” he explains. “Those who embrace AI now will position themselves as leaders in an increasingly digital industry, while those who delay risk falling behind.”

With new technology helping the workers that are in the industry, an expectation of some relief on the financial front, and a new federal government that proclaimed “Build, baby, build” on election night, the industry is navigating a mix of expectations this year but appears to be staying positive in its general outlook.

“With the new federal government’s prioritization of construction and trade diversification, we remain cautiously optimistic that Canada’s construction industry will see greater support and partnership from the federal government, which will help us overcome the challenges our industry is presently facing,” states Rodrigue Gilbert, president of the Canadian Construction Association.

“Industry sentiment across Canada’s construction sector is cautiously optimistic,” confirms Greene. “While challenges like tariffs and labour shortages persist, factors such as declining interest rates, stabilizing material costs, and robust government infrastructure investments are fostering confidence.”

“Contractors in the civil sector are pragmatic,” adds Crombie, saying that companies in his organization are “cautious about project risk and cost volatility, but generally

We don’t just build projects, we create futures.

At EllisDon, people are the foundation of everything. From our teams in the field to the communities and partners we work alongside, great relationships are what drive us forward. Driven by our values, we create opportunities to grow, and build a future full of possibility.

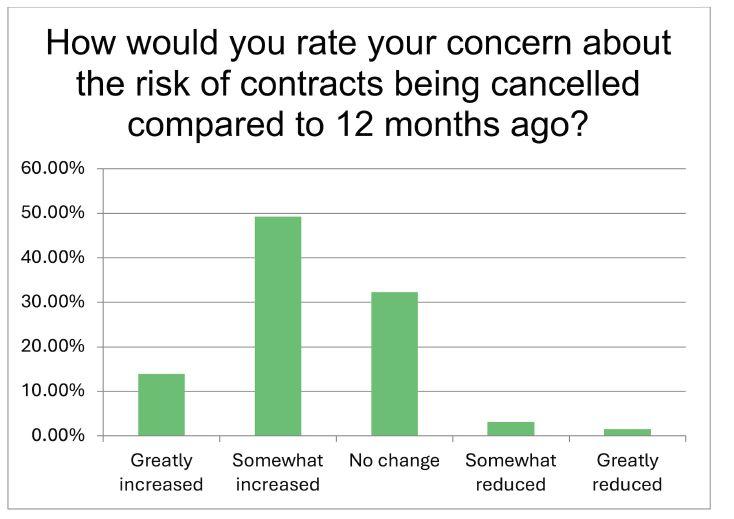

Uncertainty in the economy is making it more difficult for some projects to proceed, with some significant privately funded projects already being put on pause. This has contractors concerned about the potential of contract cancellations.

confident that work will remain steady. There’s optimism tied to continued public investment, but also a recognition that smarter procurement and contract risk-sharing will be key to maintaining momentum.”

“Overall, there is a healthy amount of construction in the market today and it appears the industry has the capacity to execute the work,” says Wieninger. “The private sector is in a current lull and will at some point increase the amount of development. The public sector continues to be strong and will likely grow if the federal government holds true to infrastructure development to increase Canada’s trade diversification and economic growth.”

This leads Rawji to say the industry is, “Realistic,” when asked to sum up the mood of the sector. “We understand there’s economic uncertainty, but it’s times like these where good builders shine.”

From morning to night, EBC proudly builds alongside you in a responsible, equitable and sustainable way since 1968.

The future is bright for EBC

Our employees are ready to take on upcoming challenges motivated by deep values, unparalleled expertise and an ambition to shine throughout Canada.

BY TREENA HEIN

There are hundreds of excellent smaller construction firms in Canada. From coast to coast, these outstanding teams are taking on impressive projects and truly leading the industry in various ways – but only a few are chosen each year as the “Top 5 in Canadian Construction Under 50 Employees.”

Among our 2025 winners, Fillmore Construction of Edmonton tops the list, and not for the first time. Fillmore debuted as in top spot in 2023 and achieved the same honour in 2024 as well. During that span, its revenues have climbed from an impressive $170 million to almost $190 million as it has taken on many innovative projects.

A recent one that stands out is Ever Square in Edmonton, a 5.79-acre development that features a cast-in-place concrete six-storey commercial-professional building. Fillmore Construction president Chris Fillmore describes it as a case study in his firm’s operational approach: listen first, provide detailed and effective feedback, and work with the client to provide an amazing product.

The project presented many challenges, including pricing volatility and a hydrocarbon-soaked brownfield site, but over the span of 12 months of collaborative design assistance, creative problem solving and open-book budgeting with trade partners, Fillmore says his team carved $6 million out of the initial estimate, without any significant alteration to the building’s performance or aesthetics.

Fillmore Construction’s Ever Square project in Edmonton includes a sixstorey office building, a Krispy Kreme Doughnuts (inset), a lube service station, and retail shops. In addition to finding itself at the top of the Top 5 Under 50 Employees list, Fillmore is also on On-Site’s Top 40 Contractors listings this year.

In relation to the project, Sam Narayan, president of Ever Real Estate Developments, praises Fillmore for its detail-driven, collaborative approach in completing this building.

“They involved our team in key decisions, solved problems before we saw them, and delivered exactly what we envisioned,” he says. “With Fillmore, collaboration is at the forefront of what they do. It’s part of

every schedule, every drawing, every discussion and touchpoint.”

The Fillmore team is very proud that Narayan has already awarded them with his follow-up projects as well, Ever @ Mattson and Ever @ Baseline.

Michael DoBush, senior vice-president at Giusti North Construction, which completed nearly all of the structural concrete on the

FILLMORE CONSTRUCTION MANAGEMENT INC

Headquarters: Edmonton, Alta. | 2023 Revenue: $190,000,000 | www.fillmoreconstruction.com

M BUILDS

Headquarters: Thunder Bay, Ont. | 2023 Revenue: $148,000,000 | www.mbuilds.ca

JR CERTUS CONSTRUCTION CO. LTD.

Headquarters: Vaughan, Ont. | 2023 Revenue: $112,400,000 | www.jrcertus.com

CLOBRACON CONSTRUCTION INC.

Headquarters: Saint-Laurent, Que. | 2023 Revenue: $106,000,000 | www.clobracon.com

MATRA CONSTRUCTION INC.

Headquarters: Burnaby, B.C. | 2023 Revenue: $50,000,000 | www.matra.ca

development, has similar comments.

“Working with Fillmore isn’t just about getting the job done, it’s about building something great together,” he says. “They treat us like true partners, involving our team early, listening to our insights and making decisions that benefit the whole project. It’s that level of collaboration that makes us value every opportunity to work with them.”

This, however, is likely the last time you’ll see Fillmore in this particular Top Contractors list, as the company will surpass the 50-employee threshold this year. On that note, the company’s vice-president of major projects, Brian Drew, says, “We’ve been very methodical about our growth. We’ve added people where we saw persistent bottlenecks, not where we saw short-term upside. The litmus test is simple: if a hire doesn’t enhance client experience, we don’t make it.”

At the same time, Fillmore’s core values will never change.

“You don’t lose your small-company DNA just by adding more key people into the fold,” says Drew. “What you can lose is focus. So, we are doubling down on what has already made us successful: transparency, early engagement and looking after the people who look after us, clients and trades alike.”

Using the unique capabilities and passions of its leadership team and dedicated personnel: that’s what enables Clobracon Construc-

tion in Saint-Laurent, Que., to complete larger commercial, multi-residential and industrial projects than one would expect from a smaller firm.