Impact

September

impact of nutrition by Megan Ross, Monogastric Nutrition Associate at New Life

a Division of Parrish & Heimbecker,

Validation of new LED light bulb

FROM THE EDITOR

BY KRISTY NUDDS

Culling Controversy

The avian influenza (AI) outbreak in the United States was the worst animal health disaster in the country’s history. An unprecedented number of birds — more than 48 million — succumbed to the virus or were destroyed, forcing the United States Department of Agriculture to take a hard look at it’s policies on containment, destruction and disposal of AI positive flocks.

There’s no question that the sheer magnitude of the outbreak quickly stripped the USDA and its Animal Plant Health Inspection Service (APHIS) of available resources. With poultry farms that average in the hundreds of thousands and millions of birds, the USDA and industry were completely overwhelmed and the virus spread out of control.

That’s why APHIS has made some significant revisions to its Highly Pathogenic Avian Influeneza (HPAI) preparation plan so that the U.S., should it face HPAI again this fall or early next year, hopefully won’t suffer the losses it did this past spring and summer.

But the plan isn’t without controversy. The most significant change announced by APHIS is a new 24-hour “stamping out” policy, meaning that if a flock tests positive for HPAI, it is to be destroyed within 24 hours of the positive test. With flock sizes in the millions at one facility, typical methods of depopulation previously approved for use in the U.S. — foaming and CO2 gassing — aren’t always possible and in many cases, cannot complete the task in the 24-hour timeline. Consequently, APHIS has proposed a new option of “ventilation shutdown” for cases where other options are not feasible. The barn is essentially shut down and the birds are left to die from suffocation and heat.

When the announcement was made in mid-September criticism of the decision was swift. I’ll admit I am one of these critics; it’s definitely not an appealing option and seems inherently cruel.

However, given the magnitude of the 2015 outbreak I can understand the logic behind the APHIS decision even if I don’t agree with the method. A couple of weeks after the announcement was made, the 5th International Symposium on Animal Mortality Management was held in Lancaster, Pa. where depopulation and disposal was of course the focus. Invited speaker Mark Van Oort, complex manager for Center Fresh Egg Farm in Iowa really drove home the immense challenge faced by the industry in the face of HPAI. His company had to depopulate over 7 million laying hens and pullets at six facility locations. The amount of foam or gas required was not available and the labour requirement forced the company to bring in 200 people from other States, and it still could only manage to cull a little more than 250,000 birds per day.

When it takes three weeks for culling and disposal, it’s no surprise Van Oort feels that ventilation shutdown “might be the only way to control the virus.” Granted, his company is large, but on average, it took four to five days to euthanize birds on affected farms (see page 28), which is too long and allows the virus to continue thriving.

Van Oort feels the U.S. industry “needs euthanasia options that are large scale.” Indeed they do, but is ventilation shutdown the right way to do this? n

NOVEMBER 2015 Vol. 102, No.9

Editor

Kristy Nudds – knudds@annexweb.com 519-428-3471 ext 266

Digital Editor – AgAnnex Lianne Appleby – lappleby@annexweb.com 226-971-2133

Sales

Catherine Connolly – cconnolly@annexweb.com 888-599-2228 ext 231 Cell: 289-921-6520

Account Coordinator

Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Media Designer

Brooke Shaw

Group Publisher

Diane Kleer – dkleer@annexweb.com

Director of Soul/COO

Sue Fredericks

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT., P.O. BOX 530, SIMCOE, ON N3Y 4N5.

email: subscribe@canadianpoultrymag.com.

Printed in Canada ISSN 1703-2911

Circulation

email: subscribe@canadianpoultrymag.com

Tel: 866-790-6070 ext 201 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $30.00 per year (with GST $31.50, with HST/QST $33.90)

GST – #867172652RT0001

USA – 1 Year $ 66.00 USD

Foreign – $75.00 per year

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2015 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Great productssell.

Got Lubing? Contact your local Lubing Distributor for more detailed information about our innovative products or vist our website at www.lubingusa.com.

Scan code to see What’s New at Lubing.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

J. Dean Williamson Ltd.

London, Ontario

Tel: (519) 657.5231

Fax: (519) 657.4092

With more than 60 years of experience developing innovative products for poultry producers worldwide, Lubing has established a reputation of leadership by introducing new, cutting-edge technologies to the poultry industry.

Our innovative products are produced with the most modern manufacturing capabilities giving our customers a profitable advantage in productivity.

Curve Conveyors

Handle up to 60° angles

Belt Conveyors

Lengths up to 2,000 ft.

Transfer Tables

Rugged Construction - Built to last

Dirty Egg Returns

Superior design - Reliable performance

Nipple Drinking

Ideal water flow from pullets to layers

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

APHIS Releases HPAI Prep Plan WHAT’S HATCHING HATCHING

The U.S. Department of Agriculture’s Animal and Plant Health Inspection Service (APHIS) issued a report in late September on planning and preparations for highly pathogenic avian influenza (HPAI) in advance of a potential recurrence of the disease when birds begin to migrate south.

The HPAI outbreak in 2015 was the worst animal disease in U.S. history. It affected more than 48.8 million birds and 21 States before the final detection on June 17. The incredible scope of the outbreak presented many challenges to Federal, state and industry resources and clearly identified areas where greater coordination, preparation and communication were needed. APHIS and its partners have used the time since the last

positive detection to plan for the return of the disease, using a hypothetical worst case scenario in an effort to prepare.

APHIS’ planning activities incorporated its experience from this year’s response effort, its epidemiologic studies, and extensive feedback and input gathered from State partners, industry, academia and other stakeholders. The Fall 2015 HPAI Influenza Preparedness and Response Plan captures the results of this planning effort, organizing information on preparatory activities, policy decisions and updated strategy documents into four key areas:

• preventing or reducing future outbreaks;

• enhancing preparedness;

• improving and streamlining response capabilities; and,

• preparing for the potential use of AI vaccines. The report includes an

updated biosecurity selfassessment for the poultry industry, streamlined and updated procedures for providing indemnity and other payments, a draft vaccine use strategy and many other items of interest to the Agency’s stakeholders.

Key in the plan is APHIS and industry have agreed that depopulation within 24 hours of an HPAI diagnosis is optimal to reduce the risk of disease spread. Standard methods (foaming, CO2) are preferred, as APHIS feel they are the most humane and effective methods to depopulate large poultry flocks. However, APHIS has made the controversial decision to employ ventilation shutdown as a depopulation method if standard methods cannot achieve the 24-hour goal.

The APHIS National Incident Commander will approve its use on a case-by-case basis.

For more, visit: https:// www.aphis.usda.gov

Aviagen Hosts Young Farmers

CANADA

Three young Canadian farmers were recently welcomed by Aviagen to its global headquarters in Huntsville, Ala. Ranging in ages from 19 to 25, the young farmers were selected by the Canadian Broiler Hatching Egg Producers Association(CBHEPA) to participate in its Young Farmer program.

This year’s participants in the Young Farmer program included Paul James Groen of Freelton, Ontario; Rachel Jayne Malda of Barrhead, Alberta, and Mark Henricus Van Dieten of Bayfield, Ontario. Aviagen Canada’s Technical Manager Mark Belanger hosted the tours and meetings.

During their week-long

visit, they explored critical topics with Aviagen experts, including biosecurity for disease prevention and food safety, production planning, shipping and export processes, Ross® brand broiler/breeder traits and development, and

Milestone for Aviagen

GLOBAL

Aviagen celebrated 30 years of its local operating base in Latin America. The company’s operating base in Latin America began in September 1985, when Agroceres, a Brazilian company, and Ross® Breeders, a Scottish company, signed

a joint venture and began distributing Ross parent stock products. During this period of 30 years, Aviagen supplied grandparent and parent stock for the Brazilian market and parent stock for Paraguay, Uruguay, and Bolivia. Other countries in Latin America continued to be supplied with grandparent and parent

Vaccine Research

ALBERTA

VaxAlta Inc. is collaborating with the Faculty of Science at the University of Alberta to advance early stage livestock vaccines research.

Jason Ding, Acting CFO of VaxAlta Inc., a leading vaccine research and development company based in Edmonton said in a release that the investment will result in important research related

sustainability and animal welfare. They also toured several Aviagen facilities.

When they return home, Groen, Malda and Van Dieten will be provide a report to the CBHEPA relaying their experiences.

COMING EVENTS

NOVEMBER

November 18, 2015

Canadian Poultry Sustainability Symposium, Best Western Plus Lamplighter Inn and Conference Centre, London, Ont. For more information, visit: www. cpsustainability.com

November 19, 2015

Poultry Innovations Conference, Best Western Plus Lamplighter Inn and Conference Centre, London, Ont. For more information, visit: www. poultryindustrycouncil.ca

JANUARY

2016

January 26-28, 2016

International Production and Processing Expo (IPPE), World Congress Center, Atlanta, Ga. For more information, visit: www.ippexpo.com

January 28-30, 2016

stock from the Aviagen operations in the United States and United Kingdom.

In 2007 Aviagen acquired the rest of Agroceres poultry business, creating Aviagen do Brazil. In 2010, the company extended its territory throughout the region and created Aviagen Latin America.

Pacific Agriculture Show, Tradex Exhibition Centre (Abbotsford Airport), Abbotsford, B.C. For more information, visit: www. agricultureshow.net

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to:

to the development of critical, safe and effective livestock vaccines and that the vaccines will lead to safer foods and will support food producers as they continue to move away from the use of antibiotics on farms.

Canadian Poultry, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5; email knudds@annexweb.com; or fax 519-429-3094. Please write ‘Event Submission’ in the subject line.

From left: Mark Henricus Van Dieten, Paul James Groen, Mark Belanger, Rachel Jayne Malda

Flash 3300 Inlet

The Flash 3300 Inlet from Double L is ideal for situations where houses are wider, obstacles are in the airway, and there is no air through the nests. The Flash 3300 directs air perfectly over the cages so the cold air is never directed onto the birds.

The Flash 3300 insulated inlet has independent directional louver blades that allow for airflow to be steered in different directions. These louvers can be adjusted any time you like. The position of the louvers has a big impact on the capacity of the air inlet. The Flash 3300 insulated inlets are not only great for

BroMaxx® Crates Station

BroMaxx Crates Station

Easy supply and discharge of crates

Jansen Poultry Equipment has received a patent certificate for its innovative BroMaxx Crates Station. The station enables fast, labour efficient and animal-friendly harvesting of broilers. The system is placed behind the BroMaxx broiler colony system and enables convenient supply of empty crates and discharge of full crates. The BroMaxx broiler colony system is designed to produce a

extreme cold weather but for extreme hot weather as well.

Existing customers say the way the air enters the house, mixes, and then exits gives more control over the quality of the air in the house, which in turn helps achieve production results. They have also noted savings in energy usage.

For more information, contact Jeanne Zittergruen, info@doublel.com

Heat Recovery Ventilator

Lead Le Roy Concept has developed a heat recovery ventilator (HRV) that can be adapted to all kinds of livestock buildings. The Lead’Air HRV works by extracting the stale, humid air with an exhaust fan and blows it out through a heat exchanger core. A second fan draws fresh outside air through the opposite direction in the core so it is preheated before entering the building. The result is an improved climate within the building and reduced energy costs. The HRV can be integrated with existing ventilation controls or regulated with the optional RDC2 controller that has additional features unique for the operation of the exchanger.

www.jpe.org

maximum number of quality broilers that are free from excessive use of medication and have excellent meat quality. By harvesting the animals with utmost care the meat quality stays in perfect condition. Broilers stay free from bruises and broken wings and legs.

For more information, speak to your local Jansen dealer or visit: www.bromaxx. com

The poultry version, the Lead’Air 2800 model, comes equipped with a dust filter to help reduce cleaning time between batches by preventing dust contamination in the core. The optional automatic operation also has a cleaning cycle to remove dust from the filter according to a programmable schedule throughout the batch.

For more information contact Equipements Modernes in Quebec 800667-2781 or County Line Equipment in Ontario 800463-7622.

Production Egg Size The impact of nutrition

By Megan Ross, Monogastric Nutrition Associate at New Life Mills, a Division of Parrish & Heimbecker, Limited

Maintaining egg size in the large category is important to both egg producers and nutritionists, as this is the best way to maximize profitability over the life of a layer flock. Canadian egg farmers are paid for their eggs based on the size of egg they produce. The egg sizes are categorized as: pee-wee (less than 42 grams), small (42 to 48 grams), medium (49 to 55 grams), large (56 to 63 grams), extra-large (64 to 69 grams), and jumbo (more than 69 grams).

EGG SIZE AND NUTRITION

PROFITABILITY

Because the price paid for large and extralarge eggs is higher than the other categories, an egg producer’s best strategy to maximize profitability is to reach large egg size quickly and then stay in that category. While there are many factors known to affect egg size, nutrition can play a significant role in controlling egg size, both in the pullet and layer barn. Because nutritionists understand the need for large eggs, they pay close attention to the nutrients that have major impacts on egg size to ensure they are adequate to support the production of large eggs.

Nutritionist Megan Ross says paying close attention to the nutrients that have major impacts on egg size ensures they are adequate to support the production of large eggs

PULLET NUTRITION AND MANAGEMENT

A good pullet is the base for a good layer. Consequently, nutritionists focus on creating feeds that support the development of a good pullet. The nutrition and management provided during the pullet phases have long-lasting effects on egg size, and subsequent profitability, in the layer barn. The key to pullet nutrition is to ensure the nutrients being provided are supplied in adequate amounts to support the pullet’s ability to reach target body weights. This is important because pullets that are on or slightly above the target weights will be the best producing birds as there is a proven relationship between the body weight of the pullet at sexual maturity and egg size. The focus for pullet nutrition during the first fourteen weeks is on body frame development. Nutritionists focus on providing adequate levels of protein, fat, and calcium in order to support the development of the skeletal system, while still allowing for muscle growth and maintenance. By fourteen weeks of age, approximately 90 per cent of the body frame size is developed and at this point, the size of the pullet is essentially fixed. Beyond fourteen weeks of age, the nutritional focus of the pullet is turned towards supporting sexual maturity and preparing for the start of lay by providing calcium to build up calcium reserves for egg laying. During this

time, nutritionists are making sure the feed is providing adequate protein and fat levels to support the rapid growth of the reproductive system, but also ensuring the fat levels are not so high that the pullet becomes obese. Managing the feed to ensure the pullets are receiving adequate protein levels to create a solid frame, as well as supporting their nutritional needs throughout the development of their reproductive system, is the key focus for pullet nutrition.

FEED INTAKE OF THE LAYING HEN

Increased feed intake in the layer barn will typically encourage egg size, while decreased feed intake will lead to a smaller egg size as body reserves will be used as an energy source instead of contributing to egg formation. Monitoring feed intake is necessary to understand how much energy and protein the hens are consuming, as this impacts nutrition and management decisions.

PROTEIN AND AMINO ACID INTAKE

Protein and amino acids are the major nutrients that influence egg size and subsequent profitability. Approximately 50 per cent

of the dry matter of an egg is protein and each egg is created with the same amino acid composition, which highlights the importance of supplying amino acids to the laying hen for protein synthesis. When it comes to protein and amino acids, nutritionists are focused on providing balanced amino acids to the hens to make sure they have the amino acids they need to lay an egg every day. A diet that is unbalanced in terms of amino acids will cause a reduction in egg size or stop egg production because a hen is simply not able to produce an unbalanced egg. Protein intake is also very important because it is directly related to egg size. Egg size can be encouraged by increasing the protein level in the feed and can be manipulated by decreasing the protein level in the feed. Overfeeding protein will result in the egg size increasing too quickly and will increase feed costs, while potentially decreasing egg numbers. On the other hand, underfeeding protein will result in a drop in production. Nutritionists ensure a range of diets are available for the producers to feed to their hens during the lay cycle, with the understanding that changing the protein level of the diet is the best way to either encourage or control the egg size of the hens. It is important that producers understand the impact of dietary protein and amino acid levels

Egg size is a very important factor to consider and track in a layer flock because of the large impact is has on the producer’s profitability. It can be manipulated through many different factors, including pullet nutrition and management, as well as feed, protein, and fat intake in the layer barn.

MULTIFAN FIBREGLASS CONE FANS

• Maximum air performance

• High efficiency, high durability

• Optimal aerodynamic air intake

• Low noise level

• Easy to maintain, install and clean for optimal hygiene

• Lifetime bearings

Production

RECOV-AIRE HEAT EXCHANGERS

• Recovers wasted heat from exhaust and transfers to incoming air

• Reduces humidity and improves air quality for improved livestock performance

• Large tube type heat exchange core vs plate type stays cleaner longer and is, fully accessible for easy cleaning

• Many installations in poultry, swine and commercial applications have proven these models are cost efficient and effective

• Recovers in excess of 50% of wasted exhaust heat

• New split core for ease of cleaning

V-FLO FAN

• Optimal air distribution in the poultry house with the purpose to create an ideal climate

• Create an active microclimate at animal level

• Control humidity level

• Constant low airspeed at animal level

• Reduction in energy costs through vertical airflow with a special aerodynamic shaped conical outlet

SELECT DOSER AND SELECT DOSER

• Select Doser dispenses products accurately into low and high pressure watering systems through it’s tubing via compression and peristalic action.

• Aggressive products and powders never pass through the pumps mechanism that can cause premature wear and maintenance.

• New improved Model 640 is now simple to use with one tube size

• New Select Doser Max can now operate in high pressure and volumes

• Exacon’s brand name since 1987

• Available in sizes 12” to 60”

• White or Black polyethylene flush mount housings

• Designed to meet the rigorous demands of farm/agricultural ventilation

• Energy efficient Multifan, MFlex or North American motors

• Fiberglass housings available in 50” and 60” diameter

• The well known and proven Genius control line is now available as a Touchscreen interface

• Navigates like an I-Pad by simply touching, swiping or dragging on a 7” or 10” touch screen

• Available with up to 8 variable stages and between 15 to 30 on/off relays

• A slave is available to expand to 50 on/off relays

• Many options including light control, bird scales, perch scales and bin scales

• Built-in wifi allows easy access to the internet for managing, viewing and recording history on FarmQuest website

on egg size so they are able to choose the correct protein levels for their birds to achieve maximum profitability throughout the lay cycle. The easiest way to ensure the correct protein level is being provided to the hens is to weigh your eggs once per week from the same place at the same time. For example, weigh six flats of eggs twenty minutes into egg packing every Wednesday. This will allow you to compare your egg weight at a given age to the breed targets and ensure you are managing egg size to maximize profits in your operation.

FAT AND LINOLEIC ACID INTAKE

Egg size is dictated by the size of the yolk and is greatly influence by the body weight of the hen. The yolk is primarily made up of fat, which is why fat intake is very important for laying hens. Linoleic acid is also of particular importance because it is required in order for the developing yolk to take up increased fat levels. Nutritionists pay close attention to the fat and linoleic acid being provided to the hen during production and make sure that these levels are adequate to support the production of a large egg and maximize profits for the producer.

CONCLUSIONS

Egg size is a very important factor to consider and track in a layer flock because of the large impact is has on the producer’s profitability. It can be manipulated through many different factors, including pullet nutrition and management, as well as feed, protein, and fat intake in the layer barn. It is important to understand that while it is possible to manipulate egg size to a certain extent, the genetic potential of the bird will dictate how far egg size can be pushed. Nutritionists, working closely with the producer, must have a good understanding of how nutrition and management impact egg size and manipulate it to their advantage to control the egg size when it is too light or too heavy. This working relationship will help an egg producer maximize their profitability and achieve the optimum number of large eggs. n

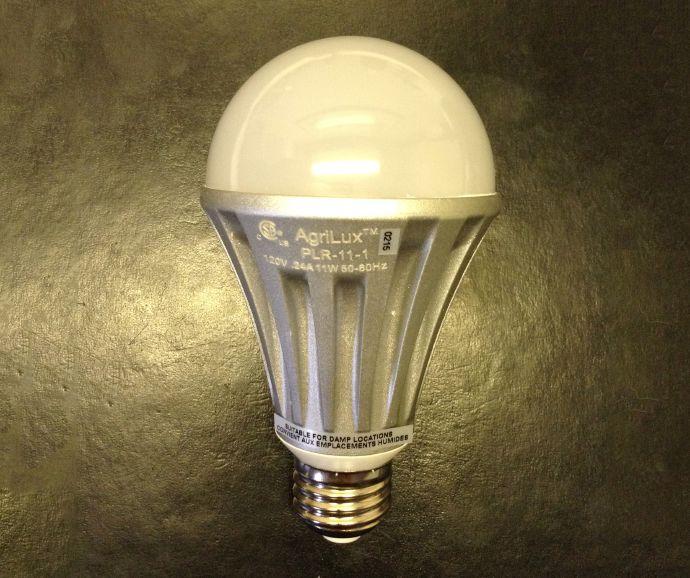

Research Validation of new LED light bulb

AgriLux has been specifically designed for the egg-laying industry

BY NERINE T. JOSEPH PH.D., LIVESTOCK RESEARCH INNOVATION CORPORATION ON BEHALF OF THE POULTRY INDUSTRY

COUNCIL

The current phasing out of incandescent light sources has created an urgent need for more energy efficient lighting systems in the poultry industry. To date, a lighting system designed specifically for egg producers has been lacking, but Dr. Gregoy Bedecarrats has developed a special LED light bulb to address this need

In an interview, Dr. Bedecarrats, a Poultry Physiologist from the University of Guelph, described the theoretical design criteria for an LED light bulb to be used specifically by the egg-laying industry.

“Firstly, in birds, light is perceived through retinal and extra-retinal (hypothalamic, pineal) photoreceptors capable of converting light into neuroendocrine signals. Secondly, direct photo-stimulation of the hypothalamus results in activation of the reproductive axis,” he explained. “And finally, our research shows that light from the red spectrum is critical to stimulate the reproductive axis and maintain high levels of egg production in hens, and this effect is mediated by hypothalamic photoreceptors.”

In partnership with Thies Electrical Distribution Inc., Dr. Bedecarrats has designed a new LED light bulb that delivers 60 per cent red spectral light.

The research approach undertaken to validate the new LED light bulb included

DESIGN THAT WORKS

U of G’s Dr. Bedecarrats has validated his lightbulb design that provides 60 per cent red spectral light for layers

testing its efficiency (electric consumption) and efficacy (on production parameters) with comparable light sources at the University of Guelph’s Arkell Research Station prior to testing in a large scale commercial barn in Ontario.

“Use of this 60 per cent red spectral output LED light bulb is capable of increasing egg production by three per cent, decreasing feed consumption by three to four per cent, and reducing electricity consumption by 80 per cent and 20 per cent respectively when compared to incandescent and compact fluorescent bulbs,” said Dr. Bedecarrats in describing the overall

findings of the validation studies of this new LED light bulb. “These results show that this light bulb can increase productivity and significantly reduce energy costs in a commercial setting. Thus, it represents a perfect option for barn retrofit or new barns in the egg-laying industry”.

This research was funded by the Poultry Industry Council, the Ontario Ministry of Agriculture, Food and Rural Affairs, Dykstra’s Poultry Farm, Thies Electrical Distribution Co., and the Canadian Poultry Research Council: Agriculture and Agri-Food Canada (Poultry Cluster 2). n

TIME IS MONEY.

Get faster development of immunity against coccidiosis with Coccivac-B52*

With spray application at one day of age and appropriate management, Coccivac®-B52 provides earlier immunity development against coccidiosis. This early protection helps enable your broilers to reach their full genetic potential, providing you with superior flock performance.

FASTER PROTECTION.

SUPERIOR PERFORMANCE.*

Industry

Put to the Test

Avian Influenza remains a clear and present threat that knows no geographic boundaries

BY EGG FARMERS OF CANADA

The spring and summer of 2015 have been challenging for the American egg industry. After losing more than 35 million laying hens to Avian Influenza, producers were put to the test in containing and mitigating the situation. Thankfully, American farmers are repopulating their barns and getting back in the game. Their unfortunate situation has certainly made us wonder if such a crisis could occur in Canada.

While it certainly could, the difference between our industry’s structure and that of the U.S. makes it less likely. In the U.S. they have a little over 200 egg farms concentrated in certain regions to feed more than 300 million people, we have over 1,000 egg farms across Canada to feed 35 million people. Obviously the number and scale of operations is also different between the two countries. The average flock size in Canada is 20,000 whereas in the U.S. the average is more than 1 million birds. This concentrated production, and the higher volume of vehicles, equipment and people in those areas, increases the potential for negative consequences due to Avian Influenza.

What allows our relatively small family farms to operate and thrive is supply management. By making it possible for smaller farms to stay in business generation after generation, we maintain ample farms in every province and in the Northwest Territories. That means all Canadians have access to local eggs, and it also means both farmers and consumers have price stability. This stability allow farmers to reinvest in

Although AI is a threat to Canada as well, our relatively small farm size in comparison to the U.S. will likely work in our favour

national animal welfare and food safety programs and industrial R&D.

That’s not to say we’re in any way impervious to Avian Influenza. In Canada, a large outbreak occurred in 2004 in B.C., and there were subsequent cases in 2008, 2009 and 2010. We also had cases last year in B.C. and earlier this year in Ontario. Canada has world class standards for onfarm food safety and biosecurity. Because of this, the Canadian Food Inspection Agency, working with industry and stakeholders at the national and provincial levels, was able to contain and eradicate each outbreak. U.S. biosecurity standards are very similar to Canada. However, the sheer size of U.S. operations make them more vulnerable to breaches due to the higher number of inputs and outputs at each farm.

In the wake of this crisis and with the fall migratory season looming large, Egg Farmers of Canada has invested $500,000 in research being led by the U.S.’s Egg Industry Center. This work will provide practical solutions for producers and ensure a safe and secure way forward for the North American industries.

So, while it is impossible to speculate about the future impacts, and while Avian Influenza remains a clear and present threat that knows no geographic boundaries, surely this is an illustration where our relatively modest size and scale of operations can be seen to be a strong plus on the side of sheet of things that work in our favour. And alongside that, would be a host of other factors—from price stability to continuous reinvestment to smaller scope and scale—that help us manage the risk. n

A big Deal? You Bet it is.

When is 3.0 a big deal? How about when it adds real money to your bottom line. Today’s Ross 308 has an annual feed conversion improvement rate of 3.0 points per year thanks to our technological advancements, including lifetime FCR over the last decade. The results are impressive: continuously improved feed efficiency for healthy birds and healthy profits for you.

On a million birds a week with today’s feed prices, that’s over $1.8 million per year. Yeah, that’s a big deal. Go with the Ross 308 — the FCR Leader!

www.aviagen.com

Research Beak Trimming

Proper trimming techniques minimize welfare impact, study shows

BY NERINE T. JOSEPH PH.D., LIVESTOCK RESEARCH INNOVATION CORPORATION ON BEHALF OF

THE POULTRY INDUSTRY COUNCIL

Research from the University of Saskatchewan shows that the impact of beak trimming poultry at a young age, if done properly, is minor. This is compared to the greater impact on flock welfare of not trimming.

Researchers globally have studied the impact of beak trimming and beak trimming methods, as this practice has been criticized for its impact on bird welfare.

“Research in our lab and labs of others have found that when beak treatment is performed appropriately, with proper techniques and at young ages, the negative impact of the treatment itself is relatively minor in comparison to the larger animal welfare concern of feather pecking and cannibalism,” writes Dr. Karen SchweanLardner in a report about the project.

In terms of beak treatment she explains that infrared beak treatment (IRBT) birds are less impacted from a welfare perspective than birds treated with hot blade trimming. She adds that there is some suggestion that using IRBT does not seem to affect all strains of birds in the same way, particularly white versus brown feathered strains

A research team led by SchweanLardner and Dr. Henry Classen has recently completed a three year project which addresses questions regarding the need to adjust IRBT settings for specific bird breeds.

INFRARED BEAK TREATMENT

Infrared beak treatment is a more welfare-friendly method but its effects are different depending on the strain of bird

The team worked with two white and two brown feathered commercial strains of laying hens. Their work looked specifically at beak morphology differences between the strains, and aimed to determine the impact of variation in IRBT settings on beak characteristics, healing and re-growth, production and welfare.

“It is imperative to establish guidelines for infrared treatment use that result in the benefits producers expect, while maintaining the welfare qualities of this procedure.”

In their report, Classen and SchweanLardner describe the main findings of the research team:

“IRBT settings should be adjusted for specific conditions, including strain, but it also suggests that some variation in treatment settings does not have important

welfare or production effects.”

They went onto explain: “The effects of IRBT are short-lived and minor, and likely a reaction to the treatment and beak sloughing. The nature of beak sloughing due to treatment was quite different and the effect was strain specific. However, despite these differences, growth and production later in life were unaffected.”

“This research will hopefully produce consensus on the value of the technique, and will also refine the technique to permit ever increasing success in beak growth in an animal welfare appropriate way.”

This research was funded by the Poultry Industry Council. The research team would like to thank Clark’s Hy-line Inc., Brandon Man. for allowing them to work in their facility. n

Review

Keel Bone Damage in Layers

A review of what is not known

BY PETER HUNTON

Iwas attracted to a review article on this topic in the September 2015 issue of the World’s Poultry Science Journal (HarlanderMatauschek et al, vol.71, pp 461472). It is the outcome of an International Keel Bone Workshop held in Switzerland in 2014. For local interest, I also reviewed the paper of Petrik et al in Poultry Science, vol.94, pp579-585.

Unusually for a review paper, this one is primarily targeted at what is not known, and mainly consists of 9 recommendations for further study.

Most scientists in the field, and also experienced managers of layers, intuitively know that the keels of laying hens are susceptible to damage during the laying cycle. This was first brought to light several years ago when scientists in England examined carcases of spent hens following slaughter, and found a high incidence of keel damage and breakage. The degree to which this causes pain or distress during the life of the birds is not known.

In live birds, damage to the keel can only be determined by palpation, and there is no recognized standard method, or protocol for evaluating or reporting the results. There is also the distinction between actual fracture of the keel, and various levels of distortion or deformity. Fractures usually result in a callus around the fracture site that can be detected on handling the bird. So the first recommendation in the review paper is to develop a uniform method of evaluating keel bone damage so that future results will be comparable. Petrik et al studied

WHAT WE KNOW

only keel fractures.

Despite what we know about keel bone damage, much more research is needed before industry would be able to take firm action to deal with this problem

The second recommendation was to investigate the kind of event or bird activity that results in keel damage. In non-cage systems, collisions with other birds and with furniture and equipment are thought to be some of the factors. However, even in conventional cages, keel damage occurs, but the reasons are not known.

Another unknown is whether initial deviation or distortion of the keel, from whatever cause, may result in keel fracture.

Do birds reared in different environ-

ments have different potential for keel bone damage in adult life? This is yet another unanswered question. Growing birds in an environment where wing flapping is encouraged is thought to improve locomotor skills and thus may avoid some of the (also largely unknown) challenges that result in keel damage.

In non-cage laying systems, individual birds as well as groups may display escape reactions to events that result in panic or fright. This can result in keel bone damage. These events may result from management activities and are thus susceptible to variation and potential

improvement, but they must first be identified and studied.

As with any, even imprecisely measured, characteristic, there is always the question of a genetic influence. Interestingly, these 21st century scientists managed to find a study reported in 1955 showing that the tendency to develop keel deformity could be altered by genetic selection. Whether the methods used in this selection experiment would be relevant to contemporary keel damage observations would need to be confirmed.

If genetics is involved, can nutrition also play a part in affecting keel bone damage? The answer to this question is, of course, related to how nutrition influences bone development and maintenance. And this in turn may be related to the interactions involved in egg shell deposition and bone integrity. The likelihood of direct involvement of calcium

balance as it affects shell deposition and keel bone integrity is probably low. This is because the calcium flow from bones to the egg shell gland is from the long bones and not the keel.

There are large differences in keel fracture incidence between housing systems and even within similar systems. Perches, although considered desirable from a welfare standpoint, seem to result in elevated keel damage and fracture. But different materials used for perches result in widely variable keel damage. Round metal perches seem to be inferior to other designs. Petrik et al’s work in Ontario compared keel fractures in conventional cages with single tiered floor housing and found almost double the incidence in the floor systems.

The final recommendation from the Harlander-Matauschek paper in to investigate and quantify keel bone damage

and production losses. A new report (as yet unpublished) shows that birds with keel fractures laid eggs with reduced shell breaking strength. This would represent a serious challenge if confirmed. The fact that most of the keel fractures appear to occur during the period of peak egg production would suggest that the nutrient status of the affected birds is inadequate to support both maximum egg production and bone maintenance. The inadequacy must be minimal though, since many flocks continue to lay at or near peak level for many months and if keel damage is compromising productivity, its effect must be very small.

In reading this research, one can sense the authors’ frustration at the lack of clear information. Obviously, much more research is needed before industry would be able to take firm action to deal with this problem. n

Industry Taking a Lead with Sustainability

How the Egg Farmers of Alberta is tackling sustainability, including a peek into PEEP

BY TREENA HEIN

Egg Farmers of Alberta (EFA) has always considered itself a pioneer, and right now, it is proving that as one of Canada’s poultry industry boards leading the way with sustainability.

“Farmers, EFA board members, the staff, we all believe in sustainability,” says Jenna Griffin, EFA industry development officer. “We all believe in improvements with our environmental impact, but we also understand that there are always trade-offs and interconnections. Every board policy decision, every onfarm decision, they all need to be socially responsible, environmentally sound and economically viable. It’s about finding the sweet spot.”

In February of 2014, EFA launched the Canadian egg industry’s first environmental initiative. The Producer Environmental Egg Program (PEEP) uses the Environmental Farm Plan as a starting point. This voluntary program helps producers identify the impacts of their operations on the environment and also leads them towards an increased use of industry best practices.

The PEEP assessment consists of ten questions (see sidebar for more) on key impact areas such as energy use, water consumption and manure management. EFA field staff work with egg farmers to complete the assessment, which typically takes about half an hour to complete.

HAVING A CONVERSATION

In late August, EFA hosted an “Environmental Stewardship Workshop,” which brought together members of the province’s entire egg supply chain, from farmers and graders to retailers and restaurants

Recommendations for improvement are given by EFA, based on the gaps discovered and opportunities identified. Griffin says every producer in the province participated last year, over 160 in all. “We’ve done over 130 follow-up re-assessments this year, and there has been widespread improvement in scores,” she notes. “The average score in 2014 was 60, which is a pass, and now it’s 68. We set a goal of having at least ten producers below 60 have a score above that this year and we’ve more than achieved that. It is an annual re-assessment so the hope is that there is improvement every year on each farm.”

At the same time there is hope that each farmer makes changes each year to reduce his or her farm’s environmental impact, Griffin says EFA recognizes that cost and other factors come into play. “Again, it’s about the sweet spot,” she explains. “Energy-saving practices are a large part of PEEP, and there are some low-hanging fruit for many producers –changes that they can easily make – but we also recognize the fact that it’s not always wise for a farmer to upgrade an old facility that’s going to be replaced in the near future.”

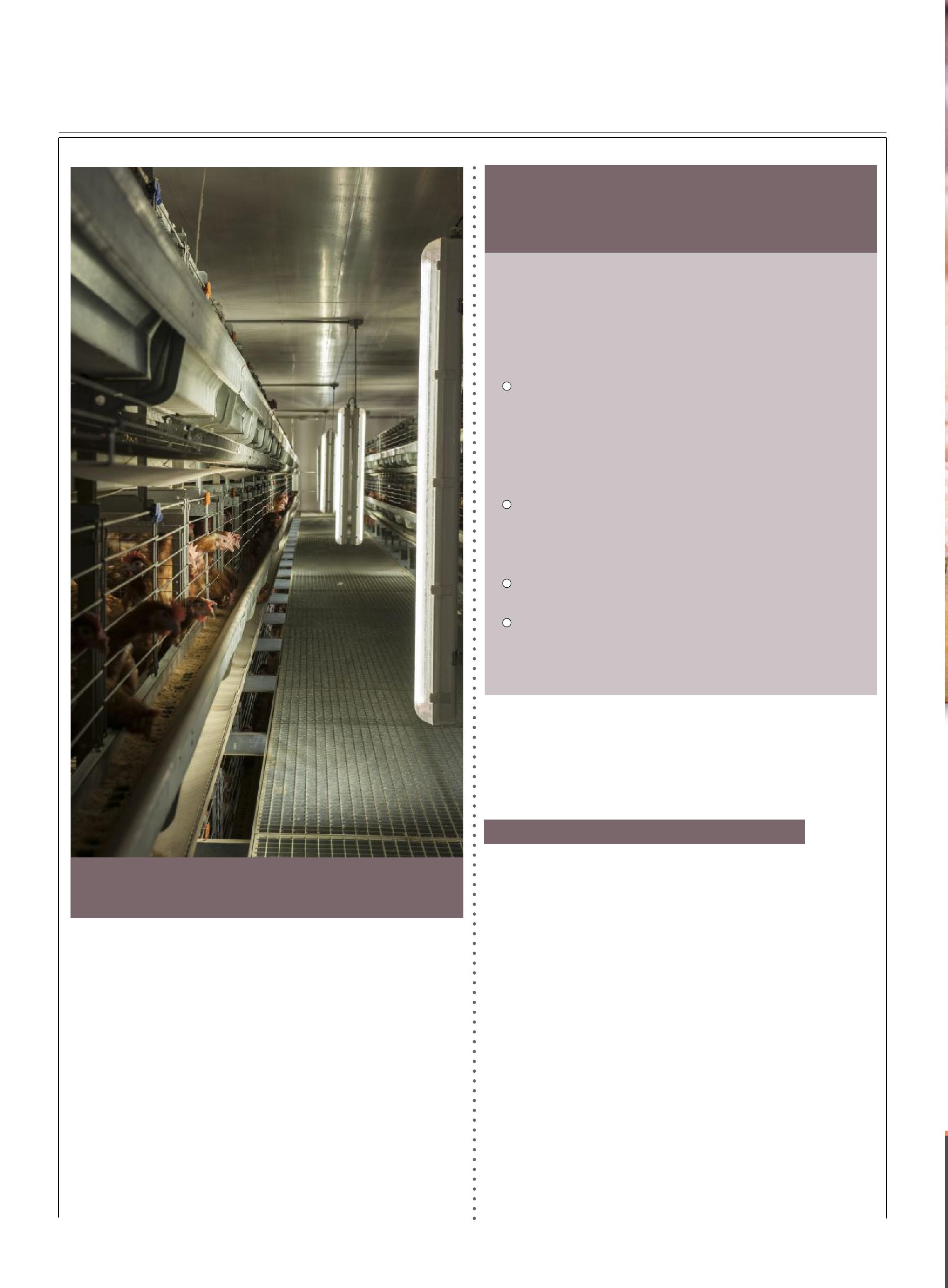

Griffin notes that 11 of the follow-up farms switched to LED lights. This means

“We

Joel Dykstra – FCC Customer

Industry

Example question from EFA’s PEEP questionnaire

Aperfect

score for the entire assessment would be 100, with 60 presently considered “a pass.”

Element 1 – Water Consumption - Knowledge of water use and water conservation.

(Please Circle)

A nipple-style watering device is used to reduce water spillage. If a high-pressure system is used, there are catch cups for the excess water. Water pressure meets the guidelines set out by the drinking system manufacturer and adjustments are made in line with flock needs. (10 points)

A nipple-style watering device is used to reduce water spillage BUT a high-pressure system is used and there are no catch cups OR water pressure is not appropriate for the system and birds. (7 points)

A non nipple-style watering device is used but there is a system in place to help mitigate water spillage. (5 points) A non nipple-style watering device is used, and there is no system in place to help mitigate water spillage. (0 points)

taking a look at this, but we also realize that layer manure management is integrated on some farms with manure from other livestock,” Griffin explains, “so these things can affect scores on management and storage.”

INVOLVING ALL STAKEHOLDERS

Installation of LED lighting is one of example of how producers can reduce their environmental impact

these producers are using less electricity from the grid, which is a benefit to everyone and the environment, and also saving money in the long term. “We estimate that lighting changes on these farms totals about 41 300 kg of carbon dioxide emissions reduction,” Griffin says. Based on the U.S. Environmental Protection Agency’s ‘TRACI’ methodology, 1 KWh = 1.02 kg, so this equates to a savings of 40,490 KWh.

Two of the ten PEEP assessment questions relate to manure management. Griffin says several farms missed out on full scores because while the producers are composting, they are not using the best practices that are involved in more tightlycontrolled manure management. The PEEP manual includes an education program about how to get there – how to better manage compost moisture content, when to test, when to turn – but there could be constraints as well. “We know farmers are

In late August, EFA hosted an ‘Environmental Stewardship Workshop,’ which brought together members of the province’s entire egg supply chain, from farmers and graders to retailers and restaurants. Personnel from various private companies, government agencies and non-governmental organizations also attended. An update on PEEP was presented, as well as EFA’s inaugural ‘Sustainability Report.’

“The workshop was a result of sustainability strategy planning,” says Griffin. “It’s another step towards more accountability and integration. It was our first effort at formal stakeholder engagement, and we wanted to start with the environment as we’ve just launched PEEP, but we also wanted to hear from, and be more connected to, the whole egg value chain.” She says the workshop has served as part of developing a platform for communication within and outside the industry, an opportunity to provide details and to tell stories around the numbers. “It’s not just about whether the average industry score was 60 or 68 with PEEP for example, but rather how has it impacted individual farm operations,” she says, noting that although the

PROVIDE QUALITY SPACE TO MAXIMIZE LAYER PERFORMANCE

A highly productive cage-free flock is no accident. It’s the result of a properly designed rearing system, trained management, and a healthy environment.

Our systems provide your flock with the ideal environment to grow as a pullet, and thrive as a layer.

From rearing to layer, our cage-free solutions will maximize your layer production and improve hen welfare while reducing your management time.

Let one of our cage-free specialists help you to be successful!

Bill Snow // Big Dutchman Cage-Free Specialist 574-265-3241 // bsnow@bigdutchmanusa.com

Industry

focus was on environmental stewardship, there was a great deal of important discussion among all the participants about the trade-offs between environmental stewardship, animal welfare, food safety, economics and more.

“On the second day, we heard from many attendees that these discussions matter,” says Griffin. “Strategies around sustainability must focus on more than the environment, since it’s all integrated. The fact there is a lot of diversity out there in terms of every farmer being in a different position with incorporating sustainability was also reinforced. It’s the same with every step of the value chain – every level is focussed on different audiences, which can be both a barrier and an opportunity.” She adds, “It was really positive that there was a strong willingness to share the story of sustainability together, even if there are some processors, retailers or food service chains that are in competition, since they all want to highlight sustainability. We know we all win if consumers feel comfortable purchasing our products.”

A workshop report has been produced and distributed to all stakeholders. In terms of next steps, Griffin says a strategy for the whole industry must be developed. “Several paths forward were given, and there are relationships that will become

stronger,” she notes. “Scientists, for example, want be more engaged with on a technical level with what’s happening with sustainability at various points in the value chain. For our own part, EFA also needs to come up with a stronger stakeholder engagement strategy. The awareness of what we do and how we do it needs to be better, and it’s a lesson for associations across the country.”

Susan Schafers, Chair of the EFA Board of Directors, is very pleased with how the workshop went. “We’re taking a step out and getting input from people outside the direct on-farm end of the industry and that’s important,” she says. “It’s going to take some time to tie it all together, and we want people who have an interest in this to continue to come forward. We are confident that will happen.”

FOR MORE

Canadian Poultry magazine will host its second Canadian Poultry Sustainability Symposium on Nov. 18, 2015 in London, Ont. Register here: http://www.agannex.com/canadian-poultry-sustainability/

Disease

Surviving a Tsunami

What happened during the AI outbreak of 2015

BY KAREN DALLIMORE

The Avian Influenza (AI) outbreak may be taking a break, but is it over?

Not as far as Dr.Helen Wojcinski is concerned. As the Manager of Science and Sustainability at Hybrid Turkeys, Wojcinski is still on guard. “Is this the new normal?” she asked delegates at a Poultry Industry Council Health Day in Stratford, Ont. “It better not be.”

Starting at what she called ‘Ground Zero’ in the US Midwest in February 2015, 223 separate AI outbreaks of were documented in 15 states within six months. “When a tornado strikes you can see the path,” said Wojcinski, “but this time it was a tsunami.”

Why did this Avian Influenza outbreak get out of control? The industry was prepared for a tornado, but not such mass destruction over such a huge area. The US has an excellent surveillance program in place under the National Poultry Improvement Program, opting to test all commercial chicken and turkey flocks for AI prior to slaughter. Biosecurity programs are in place on farms as part of company and/or state association plans to minimize and control disease, including the use of tabletop simulation exercises to assist with preparedness for HPAI. However these plans were based on infection due to a single point source - not on multiple introductions of the HPAI virus in multiple states over such a short period of time.

Initial cases in Minnesota, Missouri and Arkansas were easily contained through industry and government efforts but, as the number of cases rapidly increased throughout the Midwest,

OUT OF CONTROL

Dr. Helen Wojinski said the U.S. poultry industry was prepared for a tornado, but got hit with tsunami

resources to depopulate and contain the infection were quickly exhausted. At the beginning of the outbreak, the time from a presumed positive diagnosis of HPAI to flock depopulation averaged between five and ten days. As the outbreak progressed and expanded to include large million bird layer complexes, this time increased to as long

as 22 days as resources became overwhelmed.

Dead bird disposal also posed an issue. Flocks depopulated using foam presented composting challenges due to the huge volumes of water that were necessary. Wet weather prevented burial while large volume incinerators had operational issues.

Every delay in depopulation is disastrous, said Wojcinski. Every farm needs an individual depopulation and disposal plan designed specifically for the type of birds and facilities. The goal should be to have no more than 24 hours between presumed positive tests and depopulation. The longer infected flocks remain in the field, the more viruses are shed and the greater the challenge to other poultry within the area. Who will perform the depopulation? What are the options for timely and biosecure bird disposal?

This HPAI virus primarily impacted turkeys and layers, with 80 per cent of the affected birds being greater than 12 weeks of age. From the time of exposure to the onset of disease was seven to eleven days; with airborne transmission that time was reduced to between three and eight days.

Determining whether flocks were infected based on field observation alone was often ineffective. Once clinical signs

were noted – depressed activity, decreased consumption of feed and water, and neurological signs such as tremors - the birds started to die quickly, in many cases experiencing 95 per cent mortality within three days. Wojcinski noted that a drop in egg production in breeders was not a sign of the disease.

The one important question that remains unanswered is how do these viruses spread? Low pathogenic AI is fairly mild with low mortality, but high pathogenic AI is more severe: once mortality has started the flock will be dead in five days.

Surveillance will generally find the low pathogenic strains that can then be managed so they don’t circulate to susceptible flocks, but this virus got ‘fast-tracked’, said Wojcinski, possibly smoldering as a low pathogenic strain in wild waterfowl, tracking in to the Missouri River area in over one million ducks and geese that

migrate through that area. “They’re flying fecal factories,” Wojcinski called the wild birds. “They don’t even need water. They bedded down on corn fields.”

That’s just one possible piece of the infection puzzle though. Turkeys in six states were affected, with incidents in two different counties within two days. Was there one source for the virus or were there simultaneous changes in the virus? We don’t know.

What we do know is that virus can ride on dust, litter, feather and crop debris as aerosol spread. Wojcinski described ‘plume modeling’, where weather data was analyzed for five to seven days before the outbreak to predict how the virus would spread at certain wind speeds. The results showed that infection was four times more likely if you were in the plume. Air samples from six layer barns and their surrounding area turned up positive results or suspect samples within

70 to 150 metres of the barns, even as far as one kilometer away.

The results of the APHIS epidemiological analysis of the outbreaks in layer operations based on producer surveys showed the chance of infection was greater within a 10-kilometre zone of an infected barn, where there was a connectedness of shared people, vehicles or production equipment, renderers coming on farm, or visits by service personnel. People remain the number one vector of transmission. Having corn in nearby fields that attract wild waterfowl also increased the risk; 35 per cent of infected barns had issues with wild birds. Decreasing the risk were factors such as a greater distance away from roads and processing facilities, increased biosecurity, and not sharing equipment.

Disease

Biosecurity needs to be site specific with adequate training and resources provided. When it comes to the actual facilities, plan construction in advance for biosecurity, protecting breeding stock from commercial facilities. “In the past we considered the whole farm as the biosecurity unit of concern,” said Wojcinski. “This HPAI virus has illustrated that our thinking and biosecurity measures must now focus on protecting each barn within that farm unit.”

Vaccination has been shown to work under specific conditions, but it has to be part of a strict biosecurity initiative. “You can’t just vaccinate your way out of this,” said Wojcinski, An effective vaccine will decrease viral shedding and replication, which will in turn reduce the possibility of viral mutation. It is important to note however

that no vaccine is 100 per cent effective and infected flocks will still be depopulated.

The primary issue surrounding vaccination is the trade barriers that it imposes - vaccinating can be interpreted as an admission that the virus is endemic. Many key trading partners will ban all poultry products if HPAI vaccine is used anywhere within that country. Dr. John Clifford with USDA has clearly stated that although an effective killed vaccine has recently been developed and will be stockpiled, use of that vaccine will only be permitted under extreme circumstances.

As the industry braces for the potential of another HPAI tsunami, Wojcinski reminds producers that prevention is our number one tool followed by early detection and timely depopulation. n

SYMpOSIUM – 9:30 am to 4:30 pm

SpeakerS:

Nathan pelletier, Global ecologic

Nathan has been working with the Egg Farmers of Canada on life-cycle analysis of egg farming and will talk about measuring environmental impacts and what it means for sustainability

Jenna Griffin, Industry Development Officer at egg Farmers of alberta

Jenna will provide an update on the EFA’s Producer

Environmental Egg Program and how egg farmers in the province of Alberta are tackling sustainability

robin Horel, president & CeO of Canadian poultry & egg processors Council (CpepC)

What does sustainability mean to processors and what is expected of producers?

Cher Mereweather, M.SC., pMp, executive Director, provision Coalition

How the Provision Coalition is helping food and beverage associations with responsible sourcing and streamlining auditing processors for both farmers and food manufacturers

Join our Interactive round Table discussion

Where do we go from here?

poultry Industry Council and Canadian poultry’s aWarDS BaNQUeT

5:00 - 6:00 pm – Social Hour 6:00 pm – Banquet

key Note Speaker – Craig klemmer, FCC Sr agricultural economist

Craig Klemmer is a Senior Agricultural Economist at FCC with experience in agricultural markets and risk. He specializes in monitoring and analyzing the macroeconomic environment, modelling industry health and providing industry risk analysis. In addition to his speaking engagements on agriculture and economics, Craig is a regular contributor to the FCC Ag Economist blog.

presentation

• Poultry Industry Council’s Poultry Worker of the Year

• Canadian Poultry’s Sustainability Award

Research

Wild Birds as Sentinels

The Canadian Wildlife Health Cooperative (CWHC), continues to investigate the role of wild birds in the spread of the AI virus

BY KAREN DALLIMORE

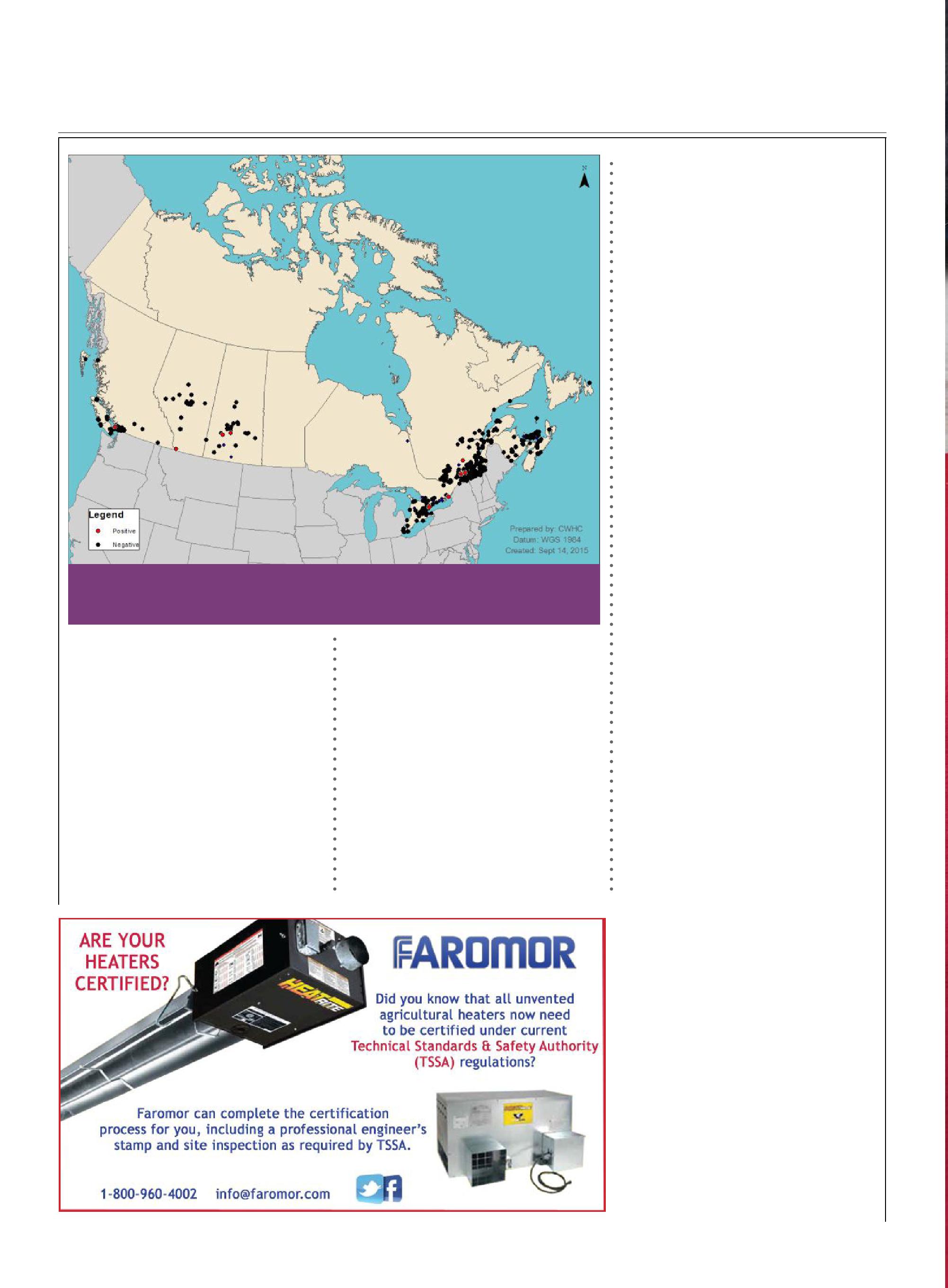

The 2015 Avian Influenza outbreak was the largest animal health event in U.S. history, affecting 48 million commercial birds at 223 farms in 15 states over six months. North of the border the outbreak affected 245,600 birds across Canada, at 11 farms in BC, three in Ontario.

But it was minus forty degrees when the AI virus first appeared in poultry flocks in the Midwest U.S. How did the wild birds interact with the poultry in that extreme cold? Are the wild birds really to blame?

While the experts still shake their heads about the reasons why the outbreak got out of control or even got started, Jane Parmley, Epidemiologist with the Canadian Wildlife Health Cooperative (CWHC), continues to investigate the role of wild birds in the spread of the Avian Influenza (AI) virus.

Parmley has been part of Canada’s Inter-Agency Wild Bird Influenza Survey coordinated by the CWHC since 2005. From 2005 through 2014, over 50,000 wild birds have been tested for the AI virus in Canada. The first screening determines if the birds carry AI of any type. Positive birds are then further tested for H5 or H7 specifically; further positive tests then lead to investigation of the origin and pathogenicity of the AI virus.

SCREENING FOR AI

Canada’s Inter-Agency Wild Bird Influenza Survey has been testing wild birds for the AI virus since 2005

Does the detection of low pathogenic AI in wild birds indicate a risk to domestic poultry? “We tend to blame wild birds when we don’t have an easy explanation,” Parmley told delegates at a Poultry Industry Council Health Day in Stratford, Ont., but would early detection of the AI virus in wild birds could provide a sentinel

to poultry producers?

It’s a global story: the high pathogenic H5N8 strain was originally identified in South Korea in 2014, showing similarities to a virus detected in 2014 in China, eventually reaching birds in Russia, North America, Europe and Japan. There were three HPAI virus strains seen in North

A lot of what we’ve achieved in the past 100 years wouldn’t have happened without you. That’s why your success is important to us and why we will never stop providing the best advice and support to maximize product performance. For working with us and driving us forward, thank you.

America in 2014/15: H5N8 Eurasian lineage, H5N1 and H5N2. It is believed that the North American viruses came across the Pacific because of their closer similarity to the Asian strain than the European strain, and the timing of arrival made more sense, said Parmley. So far the virus is not considered zoonotic, but that could shift quickly.

Wild birds that are considered as natural reservoirs of low pathogenicity strains include waterfowl (ducks, geese and swans), and shorebirds (such as waders and

Research

gulls). There are four flyways across North America – the Pacific, Central, Mississippi and Atlantic – connecting wintering and breeding grounds in every part of the continent, from Alaska and Greenland through to Mexico and the Caribbean.

Over 75 per cent of Canadian wild bird species spend at least half of the year outside of Canada; representatives of all of these species are in all the flyways. Because the greatest number and variety of viruses have been seen in waterfowl and shorebirds and their large population,

these birds have been the focus of live bird surveillance; most of the live birds sampled have been ducks.

On average, 16 per cent of live birds and one per cent of dead birds have so far tested positive for the low pathogenic North American viruses during the survey period. So far in 2015, 1134 live birds have been tested across Canada, with 93 positive for AI and three for H7 viruses that are not HPAI. In Ontario alone, 624 live birds have yielded 86 positives with no H5 or H7 so far. Also in 2015, 1576 dead birds have been tested across Canada, with 16 positive, four H5 and one H7 (not HPAI); in Ontario alone 266 have been tested with two positive and no H5 or H7. The updated results are available on the CWHC website at http://www.cwhc-rcsf.ca/data_products_aiv.php

But Parmley says that the surveillance effort has varied over the past ten years for several reasons. Survey objectives have changed and available resources have changed; sample sizes are low compared to real populations, and samples are taken haphazardly across the country, often piggybacking on bird banding procedures that may not necessarily be anywhere near poultry farms. We also need to be careful when extrapolating past results over a wide geographic region to the viruses of today.

Moving forward there are still many questions. Will virus based warnings even work? Can wild birds be sentinels? Ultimately we’re trying to develop an early warning system to predict risk and see how the virus is evolving, said Parmley, something she called “incredibly hard to do.” To better protect poultry farms, Parmley says this effort will take more resources –people, time and money.

When is the best time of year to test? How early do we disseminate findings to react in a timely manner? Does wild bird monitoring detect the risk sooner than monitoring the poultry population itself? Can we verify the signals and the risk associated with those signals to avoid an unnecessary response? Is there adequate infrastructure and political will to design

Continued on page 40

2015 Canadian Wild Bird Sampling Locations.

Photo courtesy of the Canadian Wildlife Health Cooperative

Industry Fresh from the cage-free barn

McDonald’s in Canada and the U.S. sets a bold ten-year timeline to go completely free-run

BY TREENA HEIN

In September 2014, A&W announced itself as the first national fast food restaurant in North America to serve eggs from hens fed a vegetarian diet. A month later, the chain became the first in North America to serve chicken raised without the use of antibiotics. In March 2015, McDonald’s also announced that it would switch to chickens raised without most antibiotics, and in April, raised pay for workers at company-owned stores, which represent about 10 per cent of its American locations.

As of early September, McDonalds in Canada and the U.S. followed up these statements with another one – this time the surprising sourcing commitment to transition to 100 per cent cage-free eggs (known as free-run in Canada) over the next 10 years.

McDonald’s Canada says it will begin this transition immediately by sourcing five per cent free-run eggs now. And to ensure a sustainable supply of free-run eggs, McDonald’s Canada stated in its press release that it “will work with industry stakeholders to identify the best path forward.” There are more than 1400 McDonald’s outlets in Canada with more than 85,000 employees from coast to coast.

For over ten years, McDonald’s has been pressured by the Humane Society of the United States to make this move.

McDonald’s has made the decision to source eggs only from free-run systems (shown here) within ten years TRANSITION TO FREE-RUN

Other companies such as Subway and Starbucks had already committed to switching to free-run eggs, but neither has presented a timeline. We asked McDonald’s Canada why it has decided to go free-run, instead of sourcing eggs from enriched cage systems for example. Was it pressure from animal rights groups, an attempt to match what competitors are doing or to boost slumping sales?

Media spokesperson Adam Grachnik says “I can tell you that at McDonald’s Canada, we are always listening to

our guests and our announcement on September 9th was about updating Canadian consumers about the progress we are making on a topic many of our guests have told us matters to them. This move is another step in our continuing journey to evolve our entire food experience to meet our guests’ changing expectations.” Grachnik adds “We know our guests care that the food they eat is made with responsibly-sourced, high-quality ingredients which is why we are making the move towards sourcing only 100 per cent

Photo courtesy of Burnbrae Farms

Industry

Canadian cage-free eggs for our Canadian restaurants. McDonald’s has been actively engaged in this topic since 2003 when we were the first food service company to adopt a standard for hen housing systems, which provided more space per bird than the official industry standard.”

HOUSING RESEARCH

McDonald’s is part of a group called the Coalition for a Sustainable Egg Supply (CSES) (http://www2.sustainableeggcoalition.org/research). This spring, the group released results from a three-year study showing that free-run systems have some disadvantages relating to both consumers and birds, and that they do not provide the highest sustainability scores, so we asked why McDonald’s went this way instead of with enriched cage systems, for example. Grachnik says the CSES research was done to better understand the impact of various hen housing systems on animal health and welfare, the environment, worker health, food safety and food affordability. “The goal of the research was not to identify a best hen housing system, but to instead help us better understand the benefits and potential drawbacks of a variety of hen housing systems. As we make this transition, we’ll use these insights to help identify opportunities and direct our focus on ways to improve cage-free hen housing systems.”

It seems that Egg Farmers of Canada (EFC, also a CSES member) is being consulted by McDonald’s now, but it’s unclear if the association was consulted before McDonald’s made their free-run announcement in early September. The association directed us to a statement on its website which says: “EFC, on behalf of Canada’s more than 1,000 farms, welcomes and accepts [McDonald’s] request for stakeholder and expert advice as they work through the

Industry

important operational and financial details of converting their supply chain.” When asked for its take on why McDonald’s Canada went with free-run, whether other big chains in Canada will follow suit, the ten-year timeline feasibility and the challenges for farmers to switch to free-run, EFC again directed us to its website statement. “As further evidenced by the recent study by the CSES, each major production system—conventional, enriched, free run, free range, and aviary—has tradeoffs across a wide variety of factors (e.g. costs, welfare, energy, human health, environment). Thus, we respect McDonald’s decision to leverage the research and transition over time and with the assistance of the North American industry.”

SUPPLY IN CANADA

Burnbrae Farms is the sole supplier of eggs for McDonald’s Canada. We spoke to President Margaret Hudson about whether her company was consulted before McDonald’s made their free-run announcement, and answer was yes. Hudson says Burnbrae was definitely part of the process and that the timeline is one Burnbrae felt it could achieve. Burnbrae has been producing free-run eggs for almost 20 years, and production has grown to being currently just under 10 per cent.

We asked whether Burnbrae is aiming for a certain amount of free-run production each year over the next ten years, and Hudson says “It will evolve as it makes sense, with our farms and contract farms. With such a long lead time, equipment needs to be replaced and it will be replaced with enough freerun equipment to meet McDonald’s needs. With that long of a timeline, I don’t see an issue.”

Will Burnbrae need to assist their contract farmers to deal with conversion costs? Hudson believes most farmers will be able to manage on their own. “We have a whole team of people whose job it is to interface with our farmer partners, and that will be a part of this,” she explains. “It’s an ongoing conversation. It’s a little more capital [for free-run] but not insurmountable. We are there if we are needed, but we don’t see that [our financial help] will be required.” Hudson notes that Burnbrae has farmed eggs for 70 years and served McDonald’s for over 30 years. “We’re excited about this process and working with them,” she says. “If this what they want for their customers, we are happy to move forward with them.”

SOUTH OF THE BORDER

In the U.S., McDonald’s already buys about 13 million cagefree eggs a year, but this represents only less than 1 per cent of the 2 billion eggs it purchases annually. That total is expected to rise as McDonald’s USA will begin offering some breakfast menu items all day starting in early October.

United Egg Producers (UEP, a cooperative representing about 95 per cent of all U.S. egg farmers) states that only about 6 per cent of the layers in that country are presently in cage-free facilities. UEP was not consulted before McDonald’s

made this announcement. We asked President and CEO Chad Gregory how American McDonald’s restaurants will be able to access enough free-run eggs even in 10 years (because the U.S. lags behind on the adoption of enriched systems, let alone free-run) and he says he believes ten years is ample time for suppliers to convert.

“UEP supports consumer choice, and we respect the decision made by McDonald’s,” Gregory says in a general media statement. Further in the statement, he adds “Over the years, many evaluations of hen housing systems have been conducted, including…CSES, that compared three different hen housing environments. Both UEP and McDonald’s are members of CSES, and through this process, as well as through the ongoing counsel of UEP’s Scientific Advisory Committee, our members have gathered information about developments in hen housing and appropriate care for hens.”

It may be that all fast food chains in Canada and the U.S. – as well as other restaurants and food service outlets – will eventually all demand only free-run eggs. The days of buying eggs from hens housed in battery cages, whether those eggs are at the drive-thru or from your favourite grocery store, could be numbered. n

CLEAN • CLEAN • CLEAN

SURFACE & AIRBORNE PATHOGENS

Research

Continued from page 34

and implement a sustainable system?

While wild birds are acknowledged as a reservoir for the AI virus, the relationship between hosts and virus remains diverse and complex. We need to further consider the epidemiological, climatological and agricultural differences across such a vast area, from the Arctic to the Caribbean, as well as at the interface between wild and farmed birds. So far we suspect that the virus can move through migratory birds, but it can also move through trade in poultry and poultry products as well as other human activities.

Nationally, for 2015/16, the goal of testing 1500 dead wild birds has already been exceeded. In Ontario the plan is to test 1500 live wild birds. One live trap site has been set within the control zone of the central Ontario AI outbreak in the spring of 2015.

Despite the challenges, so far Parmley reports a greatly improved understanding of the ecology and epidemiology of AI. We now have a better understanding of the role of waterfowl as a source and vector, the activity of the virus itself within the host, and a better grasp of how the virus is shed.

Beyond 2015, Parmley suggests a thorough process review to identify gaps, identify locations and populations that may be more vulnerable to infection, to help target both resources and surveillance. A national strategy would clarify roles, responsibilities and performance expectations.

“The virus keeps changing and so we need to keep learning,” said Parmley. The question that remains from the 2014/15 outbreaks in North America is how the virus got into poultry? “We can’t look at wild birds and domestic poultry separately – it is the points and places where these populations intersect where we need to focus our attention if we hope to prevent and prepare for the next outbreak.” n

PERSPECTIVES

BY BRUCE MUIRHEAD

An Inspired Canadian System

Food security and sovereignty are increasingly in the news these days. The former means that a country has reliable access to sufficient calories to feed its population, while food sovereignty suggests that the community has control over the way food is produced, traded and consumed. Why should we, in Canada, be concerned over either concept given that we have seemingly endless land on which to grow and raise food, a relatively low population per square kilometer, and highly developed supply chains that can speed it from farm to fork in a matter of days?

Well, we should care—a lot. These days, food seems to be regularly in the news and not always in a good way, from Alberta droughts to accounts of the toll that the sharp decline in global dairy prices exacts on producers in countries that mistakenly saw continually increasing exports as the surest way to financial security.

Canadian producers also understand that our supply managed production is under attack in various international negotiations, from the CETA with the EU to the TPP that is being negotiated with eleven other countries in the Pacific region. In both negotiations, competitors hope to set Canada’s food production agenda in their own interests. This would compromise our made-in-Canada system, and our food sovereignty.

The

issue

consumers, producers and processors, which levels that playing field. Egg and dairy farmers in countries like Australia and the UK, and poultry producers in the United States, face very uncertain times as they attempt to strike appropriate deals with megasupermarkets and processors.

I would suggest we don’t want these imported ways of doing business that severely disadvantage farmers and don’t benefit consumers, any more than we want chicken, eggs, milk or turkey from foreign places to crowd out our Canadian product on our grocery store shelves.

The demise of the Canadian Wheat Board (CWB) suggests what might happen should supply management disappear. The former CWB is now owned by a Saudi Arabian investment fund and an American agri-food company, and wheat farmers are certainly not ahead of the game. Most producers, if media accounts are correct, pine for the good old days of the single desk marketer. Farmers in that new world have had to become marketers, transporters, selling agents and whole host of other occupations. And the “little guy” is in serious jeopardy.

Supply management is a good system that works with farmers to allow them to make a living wage, while providing an excellent product at a competitive price for consumers.

of asymmetric