BY JAY KOBLUN

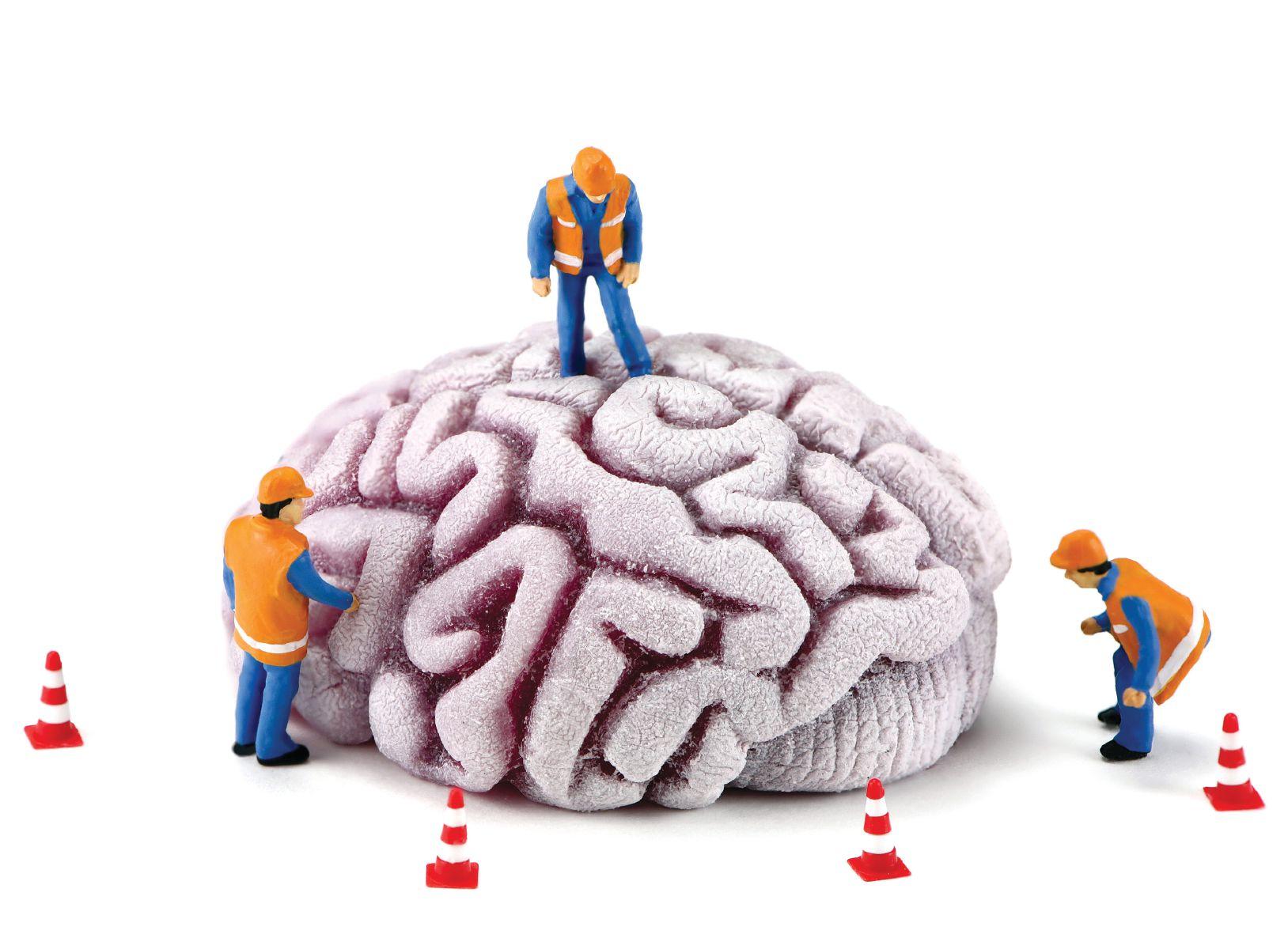

Caterpillar decided mental health and wellness in construction is not a topic that can be ignored any longer. Mental wellness is an often-overlooked, but critically important element of workplace safety. Workers who are struggling with depression and anxiety are more likely to be involved in incidents that harm themselves or others, especially around the holidays.

Caterpillar doctor John Pompe and Michelle Walker from Construction Alliance for Suicide Prevention discussed risk factors in the industry, warning signs that an employee may be struggling, and actions employers and managers can take to help in a mental health awareness webinar.

“In 2016 the CDC released a study that ranked suicide death by occupation, and construction ranked at the top of that list,” said Walker. “Construction is the industry with the highest level of suicide.” Walker grew up in a small oil town with a parent in the industry. She said she understands the innate stoic behaviour many individuals have towards mental health in the construction industry.

“I understand the culture of a construction worker; stoic, tough guy, get it done. It’s what draws some people to the industry and is a positive aspect of the industry,” she said. “But those same positive characteristics of being self-sufficient and handling everything on your own, and not asking for help can also create risk factors around mental health for not seeking treatment if it’s necessary.”

The moderator of Caterpillar’s event said the goal of the webinar was to talk about the complex aspects of safety that are less understood. The psychology behind it. How employers and managers can create a culture focused on safety and overall mental health with a focus on construction industry and trades.

continued on page 12

Publications Mail Agreement #PM40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

• Largest under 100 ton tele-boom crawler on the market.

Market leading up to 4° out-of-level capabilities with auto-switching load charts, and 90 ton capacity up to 2.5°

• Full power boom with ability to telescope 100% rated chart capacity

OptiWidth™ for asymmetrically positioned tracks and load charts increasing lifting capacity over 30% compared to symmetrical tracks in tight conditions

• Supported use of vibratory equipment for driving and extraction without the need for a separate power pack (depending on equipment)

Easy transport with improved optional carbody jack system. Over 50” jacking height and clearance for up to 10 ft wide trailers

Pick and carry the full load charts Tadano Hello-Net Telematics

High-power hydraulic track extension with track-width sensing – no pinning required

©

Premier John Horgan and Carole James, Minister of Finance, have released Stronger BC for Everyone: BC’s Economic Recovery Plan. The plan outlines the latest steps the Government of British Columbia is taking to help people, businesses and communities recover and come out of COVID-19 stronger and better prepared. B.C.’s total provincial response to the COVID-19 pandemic exceeds $8.25 billion.

British Columbia entered the pandemic as an economic leader in Canada, making it among the best-positioned provinces to support a strong recovery. Since moving forward with a safe restart plan in mid-May, B.C. has had stronger-than-expected consumer spending, housing activity and employment gains. As of August 2020, almost 250,000 jobs had been restored, equal to 62 per cent of the total jobs lost due to the pandemic.

The next steps in B.C.’s recovery plan will help build a stronger, more resilient economy for everyone.

Making health care better by hiring 7,000 new front-line health-care workers. This includes thousands of health-care aides to manage outbreaks in long-term care homes and 600 contact tracers to help stop further spread in the community. The plan will also increase support for mental health care in the workplace and introduce a new Hospital at Home initiative that will allow patients to receive medical services in their own home from a team of health professionals.

Creating jobs and opportunities by investing in targeted and short-term training in the skills people need to get work in high-demand fields, including for those who want to move into new, front-line health, child care and human-service positions. The plan will also expand Indigenous skills training and accelerate the creation of affordable child-care spaces so that more parents, particularly women, can get back to work. It includes investments of over $100 million to support tourism-related businesses and communities.

Helping businesses grow and rehire with a 15 per cent refundable tax credit based on eligible new payroll. It will also introduce a small- and medium-sized business recovery grant to support approximately 15,000 hard-hit businesses, while protecting as many as 200,000 jobs. Tourism operators will be eligible for a special top-up. The plan will also provide a temporary 100 per cent PST rebate on select machinery and equipment to make it easier for eligible businesses to make the kinds of investments that will allow them to grow and become more productive.

Supporting strong communities by investing over $400 million to revitalize community infrastructure and support local governments to provide the valuable services people depend on. This includes $100 million in infrastructure grants for shovel-ready projects that will create jobs right away. The plan also earmarks over $1 billion in provincial and federal investments to help keep people moving, whether by transit, TransLink or BC Ferries. An additional $540 million in combined federal/ provincial funding will help B.C. communities address other local challenges impacted by COVID-19.

The plan includes $1.5 billion in economic recovery spending measures that respond to immediate needs. This money was earmarked for recovery spending in the spring. It is in addition to $660 million in tax measures and more than $1.86 billion in federal and provincial restart funding for municipalities, transit and education. It also builds on B.C.’s record $22 billion investment in public infrastructure over the next three years. Those capital projects are estimated to create 100,000 direct and indirect jobs over the life of the projects.

Surrey, B.C. – Falcon Equipment announced that effective September 19, 2020 their Surrey service shop will be open for bookings on Saturdays. The Saturday shift will consist of a full team of four heavy-duty mechanics, an experienced customer service representative and a parts representative.

FALCON’S SERVICE HOURS ARE NOW:

Day Shift: Monday to Friday from 7:00 a.m. to 5:00 p.m.

Night Shift: Monday to Thursday from 3:30 p.m. to 2:00 a.m.

Saturday Shift: 7:00 a.m. to 4:00 p.m.

Service Truck Shift: Monday to Saturday throughout B.C.’s lower mainland

“Falcon is proud to launch a Saturday parts and service shift at our Surrey branch. By offering a full Saturday service shift, along with our regular Monday to Friday shift and our current night shift, we hope to reduce our customers downtime and better accommodate their busy schedules. We know it hurts to pull equipment off the road for repairs so we are looking to do whatever we can to keep our customer’s trucks earning money,” said Blair Norberg, vice president.

Falcon Equipment is looking forward to welcoming their customers in on Saturdays. For more information visit, www.falconequip.com.

Crane Industry Services (CIS) is offering custom virtual training courses in order to accommodate COVID-19 safety regulations. Converting OSHA and ANSI accredited courses from classroom instruction to a virtual environment ensures that training can continue. Virtual training courses include OSHA 10, Leading Safety Works, Site Safety for Construction Supervisors and Utility Supervisors, Use Load Charts Like A Pro, and Crane Site Safety.

“The impact of COVID-19 on training schedules throughout the heavy construction industry is unlike anything we have ever seen. Naturally, the demand for virtual training has skyrocketed. Offering virtual training classes allows us to do more for our customers,” said Ray Rice, business development manager for CIS.

Free 45-minute introductions to Crane Site Safety and Leading Safety Works are available for customers to explore whether these courses are a good fit for their training organization. For individuals exploring careers in construction, CIS offers a free Employability in Skilled Trades presentation. “In recognition of Careers in Construction Month in October, we encourage career and tech educators to share this information with students,” said Debbie Dickinson, CEO of CIS.

Konecranes and Cargotec’s board of directors signed a combination agreement and a merger plan to combine the two companies. The proposed combination will be implemented as a statutory absorption merger whereby Konecranes will be merged into Cargotec. Prior to or in connection with the completion of the merger, Cargotec will issue new shares without payment to the shareholders of Cargotec in proportion to their existing shareholding by issuing two new class A shares for each class A share and two new class B shares for each class B share, including new shares to be issued to Cargotec for its treasury shares.

\Upon completion, Konecranes’ shareholders will receive as merger consideration 0.3611 new class A shares and 2.0834 new class B shares in Cargotec for each share they hold in Konecranes on the record date. This implies that Konecranes shareholders would own approximately 50 per cent of the shares and votes of the future company, and Cargotec shareholders would own approximately 50 per cent of the shares and votes of the future company. In addition to the merger consideration shares, all the existing class A shares of Cargotec will be listed on Nasdaq Helsinki in connection with the merger.

LaPrairie Group of Companies, a Canadian-owned, full-service crane and transportation and logistics company acquired ENTREC Alberta and Capstan Hauling, both divisions of ENTREC Corporation.

Through the acquisitions, ENTREC and Capstan will become subsidiaries of the LaPrairie Group of Companies and be managed and operated as separate businesses.

“We look forward to the added value that these acquisitions will bring. Through the offering of jack and slide services, additional transport trucks and a modern fleet of platform heavy haul trailers, we will be in a position to offer a one stop solution to existing and new customers in these complimentary industries,” said Scott LaPrairie, president and CEO of LaPrairie Group of Companies. “These additions will allow us a total load haul and place of oversized Alberta-manufactured oil and gas plant modules, contributing significantly to the transport effectiveness in the oil and gas sectors in western Canada.”

As a part of the acquisitions, LaPrairie welcomes over 65 experienced driver operators and continuity by retaining the existing on-the-ground management team. Both companies will continue to operate as their own entities under the LaPrairie Group of Companies, with a shared focus on increasing their service footprint in Grande Prairie and Fort McMurray.

The Specialized Carriers & Rigging Association (SC&RA) is planning on holding live events in 2021. The events will follow CDC guidelines and local and state guidance including social distancing, mandatory masks, hand sanitizing stations, a no-handshake policy, and utilizing as many outdoor spaces as possible for activities.

“COVID-19 has created great challenges and unusual circumstances for all of us; 2020 is likely a year none of us will ever forget but one that delivered some valuable lessons,” the SC&RA stated. “Through direct experience and member feedback, we know with total certainty, no matter how hard we try, technology is no substitute for our live events. We are pleased to report that based on member input and board-direction, we are moving back to our live meetings for 2021.”

The association stated health and safety is a top priority and is now at the stage of establishing proper direction to begin to restore operations, knowing that recovery from 2020 will not be immediate or easy.

“If any single term can describe our position, it would be a balancing act,” stated the SC&RA. “In terms of restoring operations, one of the most difficult decisions we have been faced with is when to open our live meetings. While responsibly following COVID guidelines and putting the politics of the pandemic aside, based on national trends, direct member feedback and ongoing dialogue with our hotel partners and related service providers.”

The SC&RA we will be hosting its 2021 events as follows:

• January Board and Committee Meetings, Sun Valley, Idaho, January 6-9

• Specialized Transportation Symposium, Birmingham, Alabama, February 16-18

• Annual Conference, San Antonio, Texas, April 12-16

• Crane & Rigging Workshop, Chicago, Illinois, September 14-16

“After straight 10 years of healthy growth in our meetings and exhibits, we know live meeting attendance will not be its norm for 2021 but with consistent focus, your continuing support, and our ongoing commitment, we are confident our meetings business will be back to healthy levels by 2022. At the end of the day, it’s all about delivering solid value to our members,” stated the association.

No matter how challenging your needs, AIROMAX AM 27 is your best ally for mobile cranes in industrial applications. The tire is particularly suitable for road usage. Thanks to its All Steel casing and the special tread design, AIROMAX AM 27 provides extraordinary traction along with high load capacity.

AIROMAX AM 27 is BKT’s response to withstand the toughest conditions in the construction industry.

Mammoet won the safety award for its reverse signalling solution and also won an award for the design, build, and debut of its Trailer Power Assist (TPA), in the ‘Innovation: end user’ category.

Mammoet says while reverse alarms have long been a safety feature when trailer drivers are reversing, they can obstruct communication between the driver and their spotter when operating in a noisy environment. To overcome this challenge, Mammoet’s engineers designed an alarm shutoff button that allows the spotter to turn the reverse alarm off to enable a clearer communication channel with the driver, while simultaneously triggering two flashing orange LED lights on the back of the trailer to warn other operators working near the trailer.

The second ESTA award Mammoet won was for its TPA technology, which is an alternative to SPMTs and conventional prime movers. The TPA is based on the K25 trailer and consists of six axle lines, with the middle four driven by a 1,000-horsepower hydraulic Power Pack Unit, delivering 40-metric-tons of traction power. This pulling force removes the need for multi-truck configuration and therefore offers significantly increased maneuverability and safety.

By removing the requirement for multiple trucks to be used in the same operation, the TPA offers customers and their projects greatly improved sustainability. The combination of these capabilities and their benefits contributed to Mammoet receiving the ‘Innovation: end user’ award.

Palazzani introduced an app to help stay more connected with its customers. The app provides immediate and free information about Palazzani machines, from any device, on Android, iOS, and Windows platforms.

By scanning a QR code placed on new Palazzani Spider Lifts, end users open a page link which includes the manual, electricalhydraulic schemes and spare parts book of its machine, as well as a list of easyuse and recovery videos which guides to use and troubleshoot the Spider Lift very quickly and in total autonomy. Users can quickly call, open a chat in WhatsApp or WeChat, or write an email to Palazzani dealer’s after-sale staff or Palazzani after-sale staff.

AWinnipeg man who pleaded guilty to defrauding his former crane company out of more than $4.2 million was sentenced Sept. 22. Peter Ramdath received a six-and-a-half-year prison sentence in a Manitoba court. He has also been ordered to pay restitution of approximately $4.2 million. Ramdath, the former chief financial officer for the local company Litz Crane & Rigging, pleaded guilty to one count of fraud over $5,000 in January 2020.

2 - November 4, 2020

Ont.

BC Road Builders AGM & Winter Celebrations

3 - December 5, 2020

B.C.

Manitowoc is launching a new version of its 53 tonne National Crane NBT60L truck crane; the NBT60XL.

The NBT60XL is not merely a counterweight upgrade to the NBT60L. To achieve its capacity and reach, the crane can be fitted to several standard truck options expanding layout configuration options for customers. The NBT60XL features a hydraulically removable counterweight configurable from zero to 16,000 pounds, allowing it to take on heavier picks. When equipped with the National Truck Crane (NTC) package, the machine will feature additional jobsite setup flexibility with four outrigger positions, optional two-camera system for increased jobsite visibility, and a fully integrated wireless wind speed indicator.

“In order to get even more capacity and maintain overall agility, these ‘truck crane’-style counterweights offer many combinations allowing operators to take what is needed for the job and still meet any roading regulations,” said Bob Ritter, product manager of boom trucks at Manitowoc.

The NBT60XL comes standard with several operator-centric features, such as the deluxe tilting cab with heated seat and a Bluetooth/AM/FM radio and speakers. Additional state-of-theart features on the NBT60XL include electric over hydraulic controls with a function to adjust the speed, an easy-touse colour graphic display and real-time diagnostics for simplified troubleshooting without the need for a laptop.

Construction industry employers and workers must remain vigilant as cases of COVID-19 continue to rise. That was the takeaway from a webinar sponsored by the Residential Construction Council of Ontario (RESCON) and several industry partners.

“It is important for the construction industry to remain united, resist complacency and continue to follow best practices, regulations and public health guidelines as we battle the pandemic,” says Andrew Pariser, RESCON vice president, who emceed the webinar. “The industry did an incredible job mitigating the spread of COVID-19 on construction sites, but we need to be prepared for the second wave.

The virtual event, titled Protecting Your Workforce during the Second Wave: COVID in Construction, provided participants with information to keep worksites and offices safe and operating. Labour, Training and Skills Development Minister Monte McNaughton, and chief prevention officer Ron Kelusky spoke and there were panel discussions with industry leaders on best practices.

McNaughton thanked the industry for working together and developing protocols early in the pandemic, but he noted that the fight is not over and it’s important to communicate and share best practices.

“We have to remain vigilant and protect workers and the public as we face this second wave of the pandemic,” McNaughton said in his remarks. “We have to work together as we have to turn the tide.”

Kelusky said modelling shows the caseload is expected to increase, so the industry has to keep its guard up and workers must continue to maintain physical distancing and follow health and safety protocols. “Safety is our priority,” he said. “An ounce of prevention is worth a pound of cure.”

The event featured a panel on best practices with Gilliam Group president Craig Lesurf, Infrastructure Health and Safety Association president Enzo Garritano, and Tribute Communities senior manager of health and safety Ketan Patel. A second panel on what companies should do in the event of a confirmed case featured Maple Reindeers national health and safety manager Craig Sparks, Tridel health and safety manager Daniel dos Santos, and ConDrain Group health and safety manager Darrin Husack. Dan Fleming, manager GTA at NORCAT, moderated the second panel.

The panelists noted that:

• Resources related to COVID-19 best practices are available at ihsa.ca.

• Companies should continually update their risk assessment protocols.

• Everybody on a worksite must be educated about best practices to follow.

• Social distancing must be adhered to on worksites and staggered shifts are a good idea.

• Companies should continue to share best practices with one another.

• Stickers and posters on worksites are good reminders for workers.

• Communication is key on a worksite because safety is not proprietary.

• A group email is one way to keep workers informed of any changes on a site.

• Contractors should keep protocols and rules consistent across multiple sites.

• The industry must learn from the first wave and make the necessary adjustments.

• Having a plan in place makes it easier to respond to a confirmed case.

David Frame, director of government relations at the Ontario General Contractors Association, provided closing remarks at the webinar. He noted that health and safety is always a priority for the construction industry and contractors are committed to working with government to keep worksites safe.

Steven A. Todd will now serve as president of Pit Row Transportation Solutions and partner of Pit Row Legal Solutions

The Pit Row Group announced Steven A. Todd as president of Pit Row Transportation Solutions (PRTS) and Partner of Pit Row Legal Solutions (PRLS). Todd began his duties October 1.

Todd has more than 20 years of senior management experience, including serving as chief of permits for the Illinois Department of Transportation, and most recently as vice president of transportation for a global trade association, Specialized Carriers & Rigging Association (SC&RA).

“Steven is the right leader for PRTS,” said Mike Morgan, Pit Row Group chairman of the board. “Steven’s extensive background, and impeccable track record of impacting and advancing the interests of the specialized transportation industry, will serve us well as we introduce our two latest, state-of-the-art software solutions—permit manager and pilot car manager. Furthermore, his role as a partner in PRLS strengthens the deep, comprehensive expertise of our existing team as we continue to serve as industry leaders in the areas of Expert Witnessing, Training and Consultancy.”

At SC&RA, Todd co-authored two U.S. DOT Federal Highway Administration Best Practice Reports – Automated Permitting of Oversize/Overweight Vehicles and Law Enforcement and Pilot Escorts which also included a first of its kind National Training Curriculum. He served on both the U.S. Department of Transportation’s Emergency Route Working Group and the National Coalition on Truck Parking, The Transportation Research Board’s Size & Weight Committee as well as the American Association of Highway Transportation Officials (AASHTO) National Advisory Committee.

Todd, began his transportation career as a self-employed consultant in both the civil engineering and public transportation industry, specializing in funding and organizing municipal infrastructure and public transportation initiatives throughout Illinois. This led to a career with the Illinois Department of Transportation where he served in areas including oversize/overweight permits, fixed weigh stations, and public transportation earning a reputation amongst specialized carriers for achieving permit policy harmonized successes that carried over to other Midwestern states.

Manitex announced Joseph Doolan has been named senior vice president and CFO of the company, effective October 20, 2020. Doolan, a CPA, since 1986, comes to Manitex with approximately 25 years of experience in senior financial executive roles at public industrial and financial services companies, following nine years at KPMG in its financial services practice.

“Joe is an exceptional professional with the technical accounting experience and credentials, that will make him extremely valuable to the team,” said Steve Filipov, Manitex CEO. “In addition to the CPA and international accounting resources he brings, he has a proven track record as a leader in financial reporting, planning and analysis, both internally and externally, making a positive impact on balance sheet management and expense controls wherever he has been.”

Laura Yu, the company’s current CFO since October 2018, announced her resignation effective October 2, and has agreed to remain in a consulting role at Manitex to oversee the transition to Doolan.

“We are also grateful to Laura Yu for her commitment and outstanding work at Manitex and we wish her well in her future endeavours,” concluded Filipov.

BC Crane Safety reached a ground-breaking Mutual Recognition Agreement (MRA) with the European Crane Operator License Foundation (ECOL) recognizing that the certifications issued by the two organizations are equivalent and interchangeable. The agreement is based on a detailed comparison and alignment of standards governing the safe and effective operation of mobile cranes.

“What this means is that mobile crane operators who are certified by BC Crane Safety are now eligible to work in parts of the EU without undertaking additional training or testing,” says Fraser Cocks, executive director of BC Crane Safety. “It also means the same for EU operators who want to work here to help meet temporary surges in demand for operators to support major projects when we can’t find qualified operators in Canada.” ECOL currently licenses operators in the Netherlands and Belgium but is working toward the inclusion of all EU states.

“This is truly a landmark agreement which demonstrates our mutual commitment to the highest professional crane operator safety standards,” said Cocks. “Through our partnership we have made a world-class quality crane operator certification system and this work is only the beginning. We look forward to deepening our ties with ECOL while bringing the benefits of this MRA to the rest of Canada.”

The crane operator profession impacts a wide range of sectors – from utilities to resource development and major construction projects. Canadian companies with global interests will have the ability to employ their Canadian operators on overseas projects, while providing assurance that they meet the highest standards of professionalism in the world.

“Agreements like this will enhance crane operator training on a worldwide level,” says Ton Klijn, director of ESTA, the organization that established ECOL. “ECOL can improve both safety and employment flexibility, allowing good operators to work wherever they are needed – something that will be a significant plus, especially for the big international operating companies.”

The ECOL MRA is the first MRA that BC Crane Safety has agreed but the organization hopes to have further MRAs in place in the near future.

BC Crane Safety is the crane certification and licensing authority for BC and was established by WorkSafeBC in 2005 to design, administer and maintain the certification system for safe, professional crane operations as required by provincial law. BC Crane Safety provides leadership for health and safety development within the crane hoisting industry; serves as an advisory body on regulatory and safety matters; works closely with industry, labour and government to develop and implement new standards of assessment and certification; and provides leadership in the establishment, maintenance and support of industry-specific assessment tools (theory and practical) which result in a BC Crane Operator designation.

The ECOL is a non-profit organization, structured as a foundation under Dutch law and governed by a supervisory board with representatives from the crane users, crane manufacturers and crane operator labour unions. ECOL was created by ESTA – the European association of abnormal road transport and mobile cranes – which was founded in 1976. ESTA represents national trade associations whose members are mobile crane and access platform, rental and abnormal road transport companies. Today, ESTA has active members in 21 countries.

Company now has five RTG cranes working in yard

concrete structures. Their manufacturing plant spans over 150,000 sq. ft., is located in Alberta and they are involved in projects from Manitoba to Vancouver Island.

Eagle Builders acquired their first Shuttlelift gantry crane more than 10 years ago, back in 2007. Since then, Eagle Builders has substantially grown and so has their Shuttlelift rubber-tired gantry crane lineup. As one of western Canada’s largest precast concrete manufacturers, they now have five Shuttlelift cranes in their yard, which includes: two SB50s, two ISL70Bs, and one ISL50B. That’s a total lift capacity of 290 tons between all their Shuttlelift cranes.

Eagle Builders is a family-run Canadian based manufacturing and construction company specializing in the design, engineering, fabrication and building of precast

“Once digging into the designs of different gantries, the Eagle Builders team liked Shuttlelift’s torsion flex in the crane’s corners,” said Craig Haan, director at Eagle Builders, explaining why they have continued to trust Shuttlelift for their lifting needs.

“Our Shuttlelift cranes are easy to operate and have been reliable over the years. They are able to help us move and store product more efficiently in the yard. As our company expands our yard has had to expand with us.

Our Shuttlelift gantry cranes have helped us avoid process bottle necks from stripping to storage,” he continued.

Throughout their many years of owning and operating Shuttlelift gantry cranes, Eagle Builders has worked closely with Kendrick Equipment who is their local Shuttlelift dealer. Kendrick’s headquarters is located in British Columbia, in addition they offer local service in Alberta.

Looking forward

Eagle Builders is currently in construction of the largest precast concrete parkade in western Canada at the Vancouver International Airport Airport. They are producing NU girders for various highway projects, which are some of the largest precast concrete products in the country, exceeding 55-metres in length and weighing over 230,000 pounds.

BY JAY KOBLUN

What are we talking about when we say ‘mental health’? “When we say mental health, we are talking about common conditions and common experiences that can be really disruptive in our lives at home, at work, and in our communities,” said Pompe. “When we experience mental health conditions and major stressors in our lives it impacts our productivity and our attendance and quality of our work. Putting us at risk for accidents and injuries.

“So, it can be really disruptive. Good news is mental health conditions are really treatable and there is lots of help available—just most people don’t get the help that’s available to them,” he said.

Pompe said employers need to be invested in employee engagement, productivity, safety, creating the right kind of culture and just taking proper care of the people that help your businesses succeed.

Why get involved?

Walker said she chose to get involved in mental wellness after a risk management professional brought it to her attention. She learned of the stigma; heard stories of people who don’t ask for help due to fear of looking silly, burdensome, or weak at home or at work.

“Seeing it all get brushed under the rug took me back to high school. I lived in an oil town, in a macho, blue-collar environment and my dad’s best friend lost his life to suicide. I recall emotions and feelings around that when everyone knew how he had died but no one would talk about it or say it,” she said.

Learning years later that conversations around mental health are still the same, Walker was compelled to make talking about mental health in the workplace more prevalent in her career.

“Operating heavy equipment in risky locations and environments while under mental duress is putting the workforce and the public at risk. When we look at potential distractions going on in somebody’s life and combine that with mental health conditions, it’s going to reduce the capacity to focus and perform safely each day and, on each task,” walker explained. “Mental health is a continuum. When someone is experiencing mental illness or a personal situation; relationship issue, couples with children, death or loss in family, financial struggles—we look at all those things. That’s going to impact somebody’s ability to focus and concentrate and be attentive to the task at hand because their mind may be elsewhere.”

Warning signs for managers to look for Pompe said when telling managers what to look for, he separates warning signs into three different categories:

1. What is the employee saying?

2. What is the employee doing?

3. What you know is going on in their lives

What are they saying?

“Are they talking about suicide or being depressed or feeling anxious?” asked Pompe. “Losing interest in things they enjoy or saying they feel like a burden? Are they sending you signs with the words they are using that they are struggling?”

What are they doing?

“These are behavioural signs. Do we see increased absenteeism? Unexplained productivity or performance decline? Is the employee removing themselves socially where once they were more socially active? Do they eat alone now? This comes down to how we are seeing people change at work,” said Pompe.

What you know is going on in their lives

“Pay attention. Listen for stories of major stressors. Do you know an employee is going through a divorce or having a hard time with their child? Were they or their spouse recently laid off? Have they experienced a major loss or death in the family? Pay attention to what we know about the people around us. See this as good information to inform us as what may be going on with them in terms of mental health,” explained Pome.

Mental health during a pandemic

The global COVID-19 pandemic has no doubt caused some sort of stress in our lives.

“All of us have been experiencing more stress and disruption in our lives with the pandemic,” said Pompe. “Our comfort zones have been turned upside down. There is stress and anxiety out of concern for our own personal health and our communities. Whenever there is a major stressful event, like a natural disaster, mental health professionals see rates of mental illness go up. It’s a little bit too early on to know all of that data right now but we do anticipate seeing it rise.”

Pompe said early on in the pandemic he saw most people and companies rise to the occasion and meet the demands put in place by governments and businesses, but is concerned the longer it plays out.

“Everyone rose to the occasion to meet the new demands of staying home and other safety precautions, and used their own resources to cope early on. I get concerned as the event carries on that we will become burned out, tired, and our coping resources will start to be taxed,” he said. “The risk of mental health is greater the longer it plays out.”

Pompe said the message here is not to wait until you’re in the depths of depression or significant symptoms to act or reach out for help.

“Notice early on when you’re starting to struggle and use the tools and resources you have. Now is best time to think about stress management and how you cope with difficult times.

“Make sure you are engaging in behaviours that build resilience and help you manage stressors in your life.”

Myths of mental health conditions

Pompe said there are myths surrounding addressing mental health that keep workers from reaching out, but there are resources available and he encourages managers to be attentive and pay attention to their employees.

“I want people to know that treatments are readily available and that no one is alone and no one is a burden. There are people who can help and want to help and none of these myths are true,” said Pompe.

• Moral failure: It is a personal defeat and weakness to admit I need help.

• Rare: Only happens to others can’t happen to me.

• Mentally instability: People with mental health conditions are crazy and really sick.

• No one will understand me: No one will be able to help or understand what I’m going through.

• Burden: Nobody wants to deal with this. No one will want to take me on.

Resources: preventconstructionsuicide.com cat.com/safetyleadership

“When we say mental health, we are talking about common conditions and common experiences that can be really disruptive in our lives at home, at work, and in our communities.”

Rider Levett Bucknall Crane Index (RLB), a global real estate advisory firm, released its Q3 Crane Index. The index shows North America saw the first decline of construction cranes in years with Toronto as an exception. The city now represents a third of the index count.

Rider Levett Bucknall’s Crane Index for North America is published biannually. It tracks the number of operating tower cranes in 14 major cities across the U.S. and Canada. The Crane Index tracks the number of fixed cranes on construction sites and gives a simplified measure of the current state of the construction industry’s workload in each location.

Toronto

The Toronto crane count has increased marginally since the last survey. Residential projects continue to dominate the market. While COVID-19 does not seem to have affected the number of cranes in use, that could change next year, as high-rise residential sales have dropped 30 per cent in 2020. The work-from-home trend may also impact future commercial office tower construction.

Q3 Summary

This survey was the first decrease since the July 2017 edition of the RLB Crane Index, with the count dropping by 40 cranes. Of the 14 cities surveyed: four experienced an increase; four are holding steady; and five saw a significant decrease ranging from -27 per cent to -76 per cent. In an early response to the coronavirus, some cities imposed a pause on non-essential construction. While these bans have

As part of the Association of Equipment Manufacturers (AEM) steadfast commitment to building on the momentum of a sustainable future, AEM has announced the establishment of a Sustainability Council comprised of leaders from member companies.

The council will help advance member companies’ efforts in addressing issues of sustainability and to provide a framework for the adoption of best practices and innovation.

“Our members are committed to supporting a sustainable world by serving as a catalyst for conversation and innovation in the manufacturing industry,” said Curt Blades, senior vice president of Ag Services at AEM. “The Sustainability Council will work to spark ideas for establishing sustainability priorities for the equipment manufacturing industry and provide a framework that supports best practices for a more viable world.”

AEM is committed to supporting a sustainable world by serving as a catalyst for conversation and innovation in the equipment manufacturing industry, and has worked to address societal and safety issues on behalf of the industry. This includes:

Health and well-being of the industry: Leading the effort on equipment safety through our safety materials programs, enabling the development of worldwide standards on topics related to seat belts, Roll Over Protective Structures (ROPS), cab fil-

been lifted and projects have resumed, the pandemic induced recession is expected to have far-reaching effects.

The RLB said lenders are less likely to support large, new developments in sectors that have been significantly impacted, like sports and hospitality. The RLB says it is already seeing more competitive bidding for the fewer projects that are coming online. To view the whole report, visit rlb.com.

tration and many others. In fact, we have been a leader in promoting equipment safety since we were founded back in 1894.

Economic growth and security: The equipment manufacturing industry pays 35 percent above the national average for all manufacturing sector jobs. This demonstrates the commitment our industry has to ensuring employees are appropriately valued by receiving a fair and living wage.

Industry innovation and infrastructure: Equipment manufacturers are uniquely familiar with integrating innovative technologies into our operations and working to modernize our infrastructure, whether it includes using precision agriculture techniques to ensure an efficient harvest for farmers or deploying smart technology to ensure sustainably, efficient methods when building our nation’s roads, rails, highways, bridges, ports, and more.

Sustainablity priorities: AEM has identified seven of the UN’s 17 Sustainability Goals, to be priorities for the Association and its member companies. The Sustainable Development Goals are all interconnected and considered to be the blueprint to achieve a better future by addressing global challenges.

• 120 t (120 USt) capacity

• 11,3 m–60 m (37.2 ft–197 ft) seven-section MEGAFORMTM boom

• 10,5 m–17,6 m (34.5 ft–57.6 ft) manual or hydraulic bi-fold lattice swingaway extension with offsets up to 45°

• Max Tip Height with swingaway extensions 80.8 Meter 265’ Feet”

• Crane Control System (CCS)

• New wider full vision cab with 20° cab tilt

• MAXbase variable outrigger positioning system

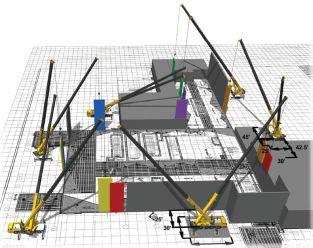

CM Labs stresses four pillars of thought that make up a good crew; effective communication, mutual understanding, critical thinking, and complimentary skills.

Drew Carruthers, director of product strategy at CM Labs, shared in a webinar this week how simulation can help a heavy lifting company have a safer and more effective crew.

“Crew training is learning to work with other people on your team. There’s a huge difference between group and solo work,” said Carruthers. “To me, crew means group and operator means solo. Crew is about being aware of others around you. Appreciating their trains of thought and many different perspectives.”

The webinar titled, “How to Use Simulation for Safe and Effective Crew Training” held virtually on Sept. 30, hit on how important it is for crews to work together on a jobsite and how training simulators can save money, cut down on training time, give operators an opportunity to take training more seriously, and ease stress on supervisors.

“Stress free—I wouldn’t say that exactly,” said Carruthers. “I like to see an operator actually sweat while they’re doing a scenario, that’s great and it means they’re engaged and present. I say it’s stress free for the instructor during some of these complex scenarios, not the operators.”

CM Labs is based in Montreal and has more than 1,000 simulation installations worldwide.

“We build simulation-based solutions to help clients design advanced equipment and prepare for skilled operations. CM Labs provides capabilities for training simulators, mission rehearsal, serious games, virtual prototyping, and testing,” said Carruthers. “With over 1,000 simulators in 30 countries using CM Labs’ simulation technology, our markets are global.”

There are several different types of training at CM Labs including crew training, signalperson training, and instructor operating training.

Crew training

Participants can expect; collaborative training between up to four operators in the same virtual environment; repetition of complex scenarios; learning from their mistakes risk-free; and reduce miscommunication and advance skills.

“Learning from mistakes unfortunately does not exist in the real world of training,” Carruthers said.

“It’s an open training environment and there are exercises for scenarios like tandem lifts for rough terrain cranes and crawler cranes, and exercises for excavators and dump trucks.”

environment.

One of the main points Carruthers hoped the roughly 40 webinar participants would take home is that crew training enables organizations to graduate operators that are better prepared for the real world.

Signalperson training

Signalpersons are a crane operator’s eyes and ears on the ground and have a major responsibility in guiding operations. A signalperson is required when the point of operation is not in full view of the operator, or the crane operator’s view is obstructed in the direction of where the equipment or load is travelling.

The Crane Rental Association of Canada welcomes the following new Members:

Allied Crane Ltd., Maple Ridge, BC

Hoods Crane Rental, Grovedale, AB

Marchant Crane Inc., Red Deer, AB

“A signalperson has a unique training solution designed to work with crane training packs. One trainee operates a crane while another works co-operatively within the virtual jobsite, providing signals and guiding the operation,” said Carruthers. “The training is an effectively platform for teaching; correct signaller positioning; effective crew co-ordination; and safe direction of lift operations.”

Instructor operating station

“An instructor is able to manage those in crew training with the Instructor Operation Station (IOS), which allows instructors to control and even participate in the training from their seat,” said Carruthers.

The station gives a 3D view of the virtual work site and allowed for more efficient, timely and stress-free communication with access to performance metrics in real-time with the student database.

• Effective communication: Facilitates good collaboration which improves quality and safety on the jobsite.

• Mutual understanding: Having the opportunity to “walk in the other person’s shoes” ensures that the entire crew understands the challenges each team member is facing. This enables collaboration and work site efficiencies.

• Critical thinking: Facing complex scenarios and environments challenges operators to develop good problem-solving skills.

• Complimentary skills: Diverse skill sets encourages team cohesion which can result in more productive work.

• Simulations have been shown to cut training costs per operator and that it lets operators learn more efficiently.

“We’ve had clients tell us that one hour on a simulator is equal to almost four hours on a real crane and can reduce training costs per operator by roughly $30,000,” said Carruthers. “We’ve reported increased trainee confidence when transitioning to real equipment, high classroom engagement rates, and increased productivity.”

KEYNOTE SPEAKER

Within 20 seconds, Spencer received 3rd and 4th degree burns to his entire body. He fought through the fire to escape to live. Spencer opens his heart and relives his story to share with the audience how every fearful and painful moment was to become a blessing. By using his expert story-telling and amazing sense of humor Spencer will ignite the audience to believing in the power of help.

CRAC Member Event: December 2nd at 10 am Mountain Time

Irving Equipment was challenged with removing a 60-foot-long, 58-ton rail bridge earlier this summer in New Brunswick. The site was restrictive, the accessway was narrow, and the likely option of using a crane would have required Irving Equipment to bring in too much fill. So, the company met the challenge with what it called a self-propelled cantilevered truss hoist.

“A crane pad would have required us to bring in so much fill, it would have basically filled in a beach on some neighbouring property and we did not want to do that,” said Ryan Long, director of business development at Irving Equipment, which is based in Saint John, N.B.

Julien Raby, engineering manager at Irving Equipment said they took some of their selfpropelled modular trailers (SPMT) and engineered them into a machine that could get the job done. A SPMT is a trailer with hydraulic suspension that is computer controlled

and modular where you can attach or combine them in any nature; side to side, end to end. SPMTs can be remotely paired so there is no physical connection between them.

“Once given the challenge of not using a crane, we sketched a concept out on paper of what we could use with the tools we already had in our toolbox,” said Raby. “We ended up with 12 lines of SPMT, two modular six lines connected.”

The team repurposed a 100-foot-long truss that Irving Equipment had from a previous project meant to lift modules, which isn’t what the truss was designed to do. The team had the machined analyzed and found it needed structural upgrades that they completed in the yard.

“We cantilevered the arm out close to 55 feet, which allowed us to pick up the 60foot bridge using air hoists,” said Raby. “We ended up with 264 thousand pounds of counterweight shifted at the back end of the trailer to lift the bridge. Essentially acting like a seesaw, same way a crane does.”

The re-engineered SPMT could fit through the narrow accessway easier than some other pieces of equipment may.

The site also had significant rock cut and a slope. Irving Equipment brought in Gulf Operators, a civil construction and excavation company, to complete all the pre-emptive work needed to gain access to the bridge through a farmer’s field. “There was significant rock cut and a 14 per cent grade descent,” said Long. “Gulf Operators prepared the sites for us to remove the bridge.”

Irving Equipment said its customer owned a series of decommissioned rail bridges that were a liability to them and wanted them removed because ATV operators and other people were using the old rail beds as a throughway and jumping cliff.

“The customer wanted that liability removed,” said Long. “There were five bridges total. We secured a fixed-price contract to remove all five.”

That’s when Long said the SPMT cantilevered beam came to light and that it would have a nice narrow footprint. The goal was to minimize any impact on the environment.

“From an environmental point of view, we wanted no debris in the water from a piece-bypiece dismantling of the bridge and certainly wanted no impact to the neighbouring beach. We had to take it away in one whole shot. There was almost no additional fill material used than what was required for the SPMT. And the bridge was removed in a single piece. We basically cut a few bolts with a torch and that was it. No excessive dust and debris, or pieces of rail ties left behind. It came out very clean,” said Long.

Another challenge facing the crew was the whole project was built around an estimated weight.

“Due to the age of the bridge, there were no drawings available. So, the weights we had been working off were done by a take-off estimate done by our engineering department. Throughout the project the team basically nailed it on their estimates,” said Long. “You can imagine if the team had been off by 10 or 20 per cent, we could hit the up button on the hoists and the thing wouldn’t budge. And that’s a potential risk.”

The actual bridge removal took two days to complete. The equipment was disassembled from the yard on Aug. 31 and brought to the site. The next morning the equipment was re-assembled and the bridge was removed that afternoon.

“We took out five bridges and the one we used this machine on was the fourth,” said Long. “It took from June through October to remove all five. We started to make plans for this particular bridge in early August. So, it was a really big effort with a dedicated team to develop and prove this concept so quickly. We relied on a couple of subcontractors to do some of our fabrication for us, sister companies of ours, and it was a very quick turnaround.”

“The project was a chance for us to think outside the box and use existing tools in a new way. At the end we were all really happy and satisfied that we managed to pull it off as a team. Safely.”

The four other bridges were able to be removed through typical crane operations. Raby said a project highlight for him was trying something new and seeing it completed successfully.

“It’s the classic story of being told your idea is odd and not going to work,” Raby said. “Then working through the numbers and sketches and showing that it would work. And proving in our yard that it would work before we moved forward, then executing the job and making it work. Also, having the freedom to test these new concepts is great.”

Long said he appreciated having a customer who was willing to try and entertain something different.

“The project was a chance for us to think outside the box and use existing tools in a new way. At the end we were all really happy and satisfied that we managed to pull it off as a team. Safely,” said Long. “It was all the things you would want. Before schedule. Under budget. And safe.”

The success of this project encourages the team at Irving Equipment to think of more creative ideas for future, similar projects.

“Using SPMTs in an unconventional way makes you think of how to look at other jobs differently and approach them from a different angle. Sometimes a crane isn’t always the tool for the job,” said Raby. “You can do other things that may end up being safer or more cost effective.”

The Palazzani RPG 2900 mini crane is the first model of the Palcrane range. It is able to operate both indoors and outdoors, on flat or uneven ground and on slopes or stairways.

“They [customers] were asking us for a versatile and high-performance product, equipped with specific attachments, therefore we decided to open a new Division of Products: Palcrane, the mini spider cranes that combine the characteristics of Pick & Carry with compact mini cranes,” said Paola Palazzani, Palazzani commercial director.

Through a refined hydraulic management, combined with a double standard motorization (Bi-energy version), diesel engine and electric motor (single-phase or three-phase according to the customer choice), the Palazzani RPG 2900 mini crane is able to operate both indoors and outdoors, on flat or uneven ground and on slopes or stairways.

Designed to be powerful (2.9 tons at 1.5 metres) and compact (730 millimetres wide), RPG 2900 passes through a normal access door and can operate on delicate floors even with reduced capacity.

For anyone who grew up in the ‘90s, Jurassic Park, was the movie, which created dinosaur madness across Canada. Look no further than Toronto’s new basketball team, which chose to be called the Raptors back in 1995. The movie spawned a franchise that is still going strong today, after two sequels, and a new Jurassic World franchise.

In the automotive world, dinosaur names are definitely not common. However, a few years ago, Ford decided to take its F-150 pick-up truck, turn it up to 150 per cent, and call it the Raptor. Since it debuted, it has not had a competitor in the ultimate performance pick-up truck space. Until now.

Anyone who has watched any of the Jurassic Park/World movies, knows that in the franchise there is only one dinosaur that is fiercer and mightier than the Raptor, and that is the T-Rex. Therefore, it is no surprise that FCA has decided to compete with the Ford Raptor, by naming its truck the Ram 1500 TRX, or as everyone will call it the T-ReX.

“The all-new 2021 Ram TRX sets the benchmark for extreme performance pickup trucks and solidifies Ram Truck’s position as the off-road truck leader,” said Mike Koval, Head of Ram Brand, FCA - North America. “Ram has a strong history of high-performance trucks and TRX adds to that while expanding the light-duty lineup with the segment’s best combination of performance, capability, luxury and technology.”

For starters, the TRX will be the latest member of FCA’s 700 horsepower club; joining the likes of the Dodge Charger and Challenger, and Jeep Grand Cherokee. In this application it will offer 702hp and 650 foot/pounds of torque from a 6.2 litre supercharged HEMI V-8 engine. Offering some mouth-watering numbers, it will go 0 to 60 mph (0-96 kph) in 4.5 seconds, 0 to 100 mph (0-161 kph) in 10.5 seconds, and the quarter mile in 12.9 seconds (at 174 km/h). Its top speed is 190 km/h. The engine is mated to an eight-speed automatic transmission, which has high torque capacity.

The powerful engine goes into a TRX that takes the standard Ram 1500 and stretches it, much like Bruce Banner turning into the Hulk. TRX is 203 millimetres wider, has a 152mm wider track, the front axle is 20mm farther forward, brakes are 381mm, ride height is 51mm higher (with ground clearance of 300mm, and water fording of 813mm), 18-inch wheels with 35” tires are exclusive. Being able to stop all the power and brawn is important, so Ram has put 15-inch (381mm) rotors all around on the TRX.

system (more on that later on). LED headlights and taillights are standard.

“Ram has a strong history of high-performance trucks and TRX adds to that while expanding the light-duty lineup with the segment’s best combination of performance, capability, luxury and technology.”

Ram decided that the front end on the standard Ram 1500 wasn’t big enough (it’s already one of, if not, the largest on the market), so it has larger and unique RAM badge, grille, skid plates, and steel bumpers. An aluminum hood has a hood scoop which allows for 50 per cent of air going into the engine, with the other 50 per cent going in through the grille, part of the dual-path air induction

The back of the truck now offers larger box outers (while still allowing for use of blind spot monitoring), a Rebel inspired RAM badge is located on the tailgate, a bed-mounted spare tire carrier is available, with the standard spare tire located under the bed, along with oversized tow hooks.

The interior of the truck is based on the Ram 1500 Limited, but with some changes. Front seats are new with more upper bolsters and TRX logos, while a new seat back system allows for items to be weaved in place. The steering wheel is an SRT flat-bottom design with aluminum paddle shifters, while a console mounted performance floor shifter is a departure for those familiar with RAM’s console turn shifter.

TRX has five dynamic drive modes (auto, sport, tow, snow, and custom) that control the four-wheel-drive system, throttle response, transmission, paddle shifters, suspension, and electric power steering. Also, three dynamic off-road modes (mud/sand, rock, and baja) can be chosen. Launch control button is standard.

The Uconnect system standard on the TRX is a 12” model, and can be paired to a Harmon Kardon audio system with 900-watts and 19 speakers. An available head-up display can show up to five items at one time (lane departure, lane keeping, adaptive cruise control, navigation, speed, gear and speed limit).

Moving on to the performance of the TRX, the massive horsepower and torque numbers are helped by use of a

dual-path air induction system. As mentioned earlier, air goes into the hood scoop and upper part of the grille, to a 29L air box that filters out the things you don’t want going into the engine (dirt, water, sand, and debris). The air box has a one-way drain to get rid of water, while two air filters provide 198.4 sq./in of surface area.

For those times when using the TRX to do performance runs, standard launch control manages tire slip, by way of wheel speed sensors stopping wheel hop at launch, and helping to get the most grip available. While in motion, sometimes the need to be airborne may arise in the TRX. Naturally, Ram added jump detection, which can detect when a vehicle is in the air and change engine speed and torque, gear, transfer case torque split, damping rates, and others to help protect the vehicle.

TRX has a new independent front suspension, and a fivelink coil system in the back that allows the Dana 60 rear axle to move up to 330mm. The rear springs are 600mm in length, and the Bilstein Black Hawk e2 shocks are 64mm. Ram also offers pages (visible in the instrument cluster) to help the driver keep tabs on what is happening in and out of the vehicle. Off-road pages show the driver: ride height, transfer case position, pitch and roll, and accessory gauges. While performance pages show timers, g-force, gauges, and engine performance.

Safety and technology wise the TRX has the driver covered. It offers a 360-degree camera view, which includes a forward-facing camera that is used for off-roading. An available digital rear-view mirror replaces the glass view

of 30.2 degrees, breakover angle of 21.9 degrees, and departure angle of 23.5 degrees.

TRX can go 161km/h while offroad, has an approach angle of 30.2 degrees, breakover angle of 21.9 degrees, and departure angle of 23.5 degrees. TRX has a towing capacity of 3,674kg, and a payload capacity of 594kg.

with a view from the rear camera. As with other versions of this style mirror, it can be revered to a regular rear-view mirror. A sampling of safety features includes standard backup camera, ESC, and six air bags; and available blindspot monitoring, adaptive cruise control, forward collision warning, and much more.

A little food for thought, according to FCA, the TRX can go 161km/h while off-road, has an approach angle

Now while not exactly a truck meant to tow or haul stuff in the bed, the TRX has a towing capacity of 3,674kg, and a payload capacity of 594kg. Therefore, for those time when not having fun off-road, the truck can take the boat to the cottage, or help a friend move their furniture.

FCA will start selling the TRX in a Launch Edition, of which 100 will be sold in Canada. It will feature a unique grey paint job, and offer a red and brushed-aluminum centre console badge.

“The Ram team is as excited about the all-new 2021 Ram 1500 TRX as our customers are,” said Mike Koval Jr., Head of Ram Brand, FCA - North America. “Many of those customers have been asking for something special, even above the TRX’s already-loaded features.”

The battle of the dinosaurs (pick-ups) now pits the TRX against the stalwart Raptor. With the latter having been on the market for a few years without much competition, it is now time for the Raptor to respond to the TRX’s challenge.

Mario Cywinski is the editor of Machinery and Equipment MRO magazine and Food and Beverage magazine, a member of the Automobile Journalists Association of Canada, and a judge for Canadian Truck King Challenge. He has more than 12 years of editorial experience; more than two years of maintenance, reliability, and operations experience; more than 16 years of automobile industry experience, as well as small business industry experience.

DICA announced a brand name change for its acquired Linton Rigging Gear line of products to “LiftGuard Magnetic Sling Protectors.” LiftGuard joined the DICA family of engineered products following the company’s acquisition of Linton Rigging Gear earlier this year.

LiftGuard Sling Protectors prevent damage to slings caused by contact with abrasive edges, corners, or protrusions from loads being lifted. They also keep the sling away from other significant contact points during lifting operations. Medium Duty, Heavy Duty, and Coil Edge protectors have magnets installed to make the placement of these edge protectors simple, safe, and efficient.

LiftGuard protectors weigh 1/7th the weight of steel. They are available with optional Velcro straps to ensure proper sling placement, allowing the protectors to stay attached to the slings when removing them from loads placed at higher elevations.

When using synthetic web slings, the capacity of Medium and Heavy Duty LiftGuard Edge Protectors is calculated at 12,500 psi/1” of sling width per protector. When using synthetic round slings, wire rope slings, or chain slings, LiftGuard product capacities are 12,500 psi of compressive strength per protector.

LiftGuard Magnetic Sling Protectors are available in Medium Duty and Heavy Duty models. Specialty Grooved units are designed for I-beams and Coil units are available for lifting steel coils.

Medium Duty Protectors are ideal for use with all synthetic web slings. They can be used with wire rope and chain slings when lighter loads or lower frequency use is planned.

Heavy Duty Protectors are specially designed for lifting heavy loads with wire rope and chain slings. The additional material thickness allows for better load distribution and long-term durability.

Grooved Protectors are available in both Medium and Heavy Duty models. These protectors allow for a secure connection to the flange of an “I-Beam” or the edge of a steel plate.

Coil Protectors are designed to fit securely within the centre bore and top radius of steel coil.

Maeda launched its new crawler crane, 8.1t model CC1908S-1. The CC1908S-1 is the largest mini crawler crane in the series, with a five-section main boom offering a 20.1 metre maximum tip height and a maximum radius of 19.2 metres.

Supplied with the optional 1.5 tonne fully hydraulic luffing jib—which provides a tip height of 26 metres—features include Stage V diesel power, a 3.5 tonne pick & carry capacity, a 360-degree camera system, optional blade, and full control radio remote system.

Sarens is using a 100-ton capacity Radiolink plus load cell from Straightpoint (Crosby|SP), to complete delivery of seven 85-tonne Christmas trees for a major oil and gas company. It also utilized Crosby|SP’s 1,000-metre range SW-HHP handheld reading device.

The trees (an assembly of valves, spools and fittings) are being stored in Nacala-Porto, a city on the northern coast of Mozambique, from where they will be sold on by an oilfield services company.

Sarens, a provider of crane rental services, heavy lifting and engineered transport, is responsible for offloading the trees from a vessel, transporting them to the site, and offloading them prior to temporary storage. Sarens, which boasts an extensive crane fleet in the region, selected a 250ton capacity Demag CC1100 crawler crane to complete lifting operations.

“Generally, my role includes preparing the daily lift plan, supervising each lifting operation, leading talks with the personnel involved in each operation, and sending weekly and monthly reports to the office,” said Julio Paco, lifting operations supervisor at Sarens.

He explained that the company’s scope of work also includes testing and inspection to ensure that the trees are working properly before they are moved onto a jobsite. The trees are identical and measure approx. 17.8 feet (5,438mm) by approx. 16.6 feet (5,068mm). For each, Paco and his team utilized various items of rigging gear including chains, slings and shackles, which were sourced from Sarens’ local stock, where products range from low capacity up to 250t items.

rosby|Straightpoint launched its Insight software that allows users to monitor up to 126 load cells from up to 700 metres away, before and during a lift. Using the multi-channel display and data logging mode, users can view and log load data from connected individual and multiple load cells, live on screen and directly into a .csv file for later analysis at speeds of up to 200Hz.

The visualization mode is designed for more complicated lifts and allows import of a photo of the lift in addition to drag and drop load cell displays by making the screen look like the lift. Proof load testing capability allows real-time graphing of load tests and auto-generates test certificates. Insight can be used to weigh and calculate the centre of gravity of large items and structures. Insight is used to scan for wireless load cells within a 700-metre area, which allows an entire site to be monitored, or a select number of load monitoring products on a planned critical lift. Users can select load cells within the system based on their serial numbers.

Insight utilizes Crosby|Straightpoint’s Proof Test plus software to record data gathered by a Radiolink plus load cell, load shackle or compression load cell, for example. It can create a pass or fail certificate that includes test data and graphs charting data from the load versus time throughout a test. Another Insight feature is a visual and audible alarm that indicates overload, underload, low battery and communications errors.

Mammoet launched the FOCUS30, a crane designed specifically to operate in areas with complex infrastructure and space limitations, such as petrochemical plants and inner cities. It delivers a high capacity crane that can be assembled within the smallest area possible, allowing more work to continue around it than would be the case for a crawler crane. It can be erected swiftly in 14 days to allow projects to start and finish sooner. Its boom system is assembled vertically in sections, allowing erection to take place from just a 30-metre by 40-metre footprint. This also contributes significantly to safety as it ensures no part of the crane overhangs buildings, plant or people during assembly and disassembly activities.

Mammoet says the crane’s compact footprint allows customers to complete more work alongside heavy lifting operations, while its low ground bearing pressure limits the impact on surrounding infrastructure and reduces the amount of civil work that is required for lifting to begin.

FEATURES:

• High lifting capacity – a 2,500 tonne class crane with a 30,000t/metre load moment

• Low ground bearing pressure – minimum of 6-tonne/m2

• Erection that does not overhang site infrastructure

• Small assembly area and footprint, allowing more work to continue around the crane

• Large and variable operational window, allowing more lifts to be made using the same crane

Jekko delivered its 2000th crane, exactly 20 years after its first mini crane prototype, to French dealer ATN Platforms. It has been 20 years since Jekko developed the first model of a mini crane in 2000.

From that moment on, the Italy-based company has been investing in new models and new lifting solutions, supported and rewarded by a growing interest coming from the market, gaining an important place among the most relevant mini crane producers worldwide.

The 2000th unit is the new SPX650 model, the latest machine launched last July during a live streaming presentation. This mini crane embodies cutting-edge technical solutions and innovations and has already drawn the attention of the experts, promising to become a flagship model of Jekko range. The 2000th crane was delivered to ATN Platforms, which recently took the place of Fassi France and is now a Jekko dealer in the French market. JDL exhibition was therefore the perfect setting for a symbolic delivery of the machine, sealing a new relationship which has already started in the best way possible.

“We are so glad of having reached this important milestone and delivering our 2000th crane to our French distributor ATN Platforms makes us very proud,” said Alberto Franceschini, Jekko export manager.

IS AG expanded its LP electric chain motor series for the entertainment industry with the addition of two new models, the LP1600 and LP2500. The latter takes the capacity range to 6,300kg. At the same time, the new GHF/GMF generation of manual and motorized trolleys is also being put to market.

The manual (GHF model) and motorized (GMF model) trolleys, meanwhile, are available in four sizes, and are adapted to the new LP motors. The push trolley with manual parking brake is available especially for the entertainment industry. Both the LP series electric chain motors and the GHF/GMF trolleys are Swiss made and offer the combination of functionality, reliability and durability. Compared to the previous models, the hoists are designed for up to four times and the trolleys up to two times the service life, guaranteed by an extended warranty of three years.

A second brake can be easily mounted on the existing shaft without the need for a housing extension. The hoists can be used as climbing or stationary motors and can easily be supplemented with incremental as well as absolute encoders for path measurement, load sensors, temperature or brake monitoring. The two motors can thus be configured in accordance with the application and country-specific requirements.

The LEGO Technic 42082 Rough Terrain Crane is the largest and tallest LEGO Technic crane to date, pre-August 2018. Activate the Power Functions and select upper or lower crane mode for complete control over an array of easytooperate, motorized functions. Lower the stabilizer legs, rotate the superstructure through 360 degrees, operate the lifting winch or send the extendable boom a metre into the air. Manual functions include 4-wheel steering, 4-wheel drive, detailed V8 engine with moving pistons and fan, and adjustable wing mirrors, plus a detailed operator’s cab with an opening door. The model also includes two opening compartments with tools, chains and a fire extinguisher, plus four outrigger landing plates and four LEGO Technic building sections that can be lifted and assembled.

Help young LEGO builders understand the basics of gears, force and movement with the LEGO Technic 42097 Compact Crawler Crane. This detailed, robust model comes with an array of realistic features and functions, including extendable outriggers that move both laterally and vertically, an extendable boom, a hoist with extensive cabling and safety lock, and a 180-degree-rotating superstructure. The crawler crane folds into a compact vehicle that travels on rugged crawler tracks and comes with a classic yellow and black colour scheme with authentic sticker detailing. Rebuild this 2-in-1 construction toy to create the LEGO Technic Compact Tower Crane.

A family building game where players try to build projects depicted on the building cards. Players lift building blocks of different shapes with a crane hook to form the correct structure within the time limit shown on each building card. Each correctly placed block scores a point and additional points are scored if player manages to build the structure correctly within the time limit. Once players begin to gain points, they also start to have duels against each other in building a structure, or they have to explain the building project to another player who builds it based on the explanation, or they must attach the hook to their head and build the structure that way.

Boom Truck Outrigger pads

Heavy Duty Blocking

Standard & Custom Sizes

Top capacities in all lifting classes

Long telescopic booms with variable working equipment

High mobility and short assembly times

Comprehensive comfort and safety features

Worldwide customer support by manufacturer

Liebherr-Canada Ltd.

1015 Sutton Drive

Burlington, Ontario L7L 5Z8

Phone: +1 905 319 9222

E-mail: info.lca@liebherr.com

www.facebook.com/LiebherrConstruction www.liebherr.ca