Only so many hours

Why some operators feel overworked, over-stressed and under-prepared. | 8

Cleaning up paradise

Could manure satisfy Hawai’i’s energy goals? | 14

Challenge accepted Manure meets potato farming. | 18

September/October 2024

Only so many hours

Why some operators feel overworked, over-stressed and under-prepared. | 8

Cleaning up paradise

Could manure satisfy Hawai’i’s energy goals? | 14

Challenge accepted Manure meets potato farming. | 18

September/October 2024

• Python, Hybrid II, & Rotary units have pivoting design built in for forward weight & contour following.

• No need for a 2nd bolt on pivoting bar & all that associated weight out the back.

• DSI’s signature injector

• 3 year warranty on all units

• Best Warranty

• Best actual coverage/injection of wide gallonage ranges

• Best options for various requirements

• 840 lb. coulter down pressure spring assembly

• 4 Sweep options for lower rates to 20,000+ GPA

• 4 Tube options, including plug-free wing drop

• Liquid stays where you inject it, properly placed for full utilization by crop

• Patented conical blade creates a wider furrow for higher GPA than conventional rotary injection

• Patented cupped covering blades aggressively move soil to cover excess liquid

• Heavy down pressure on covering blades

• Combination of rotary injector & disc incorporator

• 24” – 30” spacing

your dealer

• 30° left & right pivot angle to accomodate contours & end row turning on dragline

• Same time-proven Series 70 reliability

• Special design for tank or dragline toolbars

• Non-grease bearings in all hubs for maintenance free operation

• All units adaptable to any toolbar

• Swivel coulters reduce side loads

• 18” – 30” spacing

• 18” spacing and 2 Clozr blades result in higher GPA

• Patented conical blade creates a wider furrow for higher GPA

2024 Vol.22, Issue 5

Safety in the sun

Our annual safety issue discusses how to keep yourself safe in the warmest of conditions, with additional highlights from Expo Safety School.

8 14 18

Survey says

A sneak peek at the results from our 2024 Training, Talent and Operations survey, with commentary. BY

BREE RODY

A unique solution

Resarchers in Hawai’i think manure could be crucial for its netzero energy goals, but the setting poses challenges.

BY JACK KAZMIERSKI

Pass the potatoes Atlantic Canadian farmers were encouraged to farm with manure this summer. How did it affect their yields?

BY JIM TIMLICK

The results are in!

Late this past spring, we put out a survey to readers of Manure Manager to understand how manure businesses are faring these days. What sort of challenges are being presented by the economy, the environment, etc.? And how do those challenges relate to how those in the manure business attract, retain and train their employees?

The in-depth results are on Page 8, and even more in an upcoming eBook release, but I wanted to share some insight into the timing of the release of these results.

You’ll recall that SeptemberOctober is our annual safety issue. This is now my fourth safety issue since joining Manure Manager, and it’s always striking to me how there always seems to be a new angle through which to discuss safety. As time goes on, we’re understanding that safety covers a wide breadth of concepts. There’s the technical concepts – like how to formulate an action plan and ensure safe practices when entering a confined space, or the types of checklists one should follow before hauling manure in a commercial vehicle.

– or maybe seems less worthwhile – to address the smaller challenges, which is ironic because so many applicators appear to be facing these challenges. For example, only 12.5 percent of our respondents say they are “definitely” understaffed, but roughly two-thirds say that they do struggle at times with staffing and must make it work. Similarly, under 17 percent of respondents say their operators widely lack technical know-how, but 52 percent say that “some” operators lack knowledge, with others helping out.

Respondents also say operators are tired, stressed and overworked, that jobs are not completed in a timely manner, that operators don’t always use equipment to its fullest potential and that jobs are turned down. Business owners know that safety is a concern; it’s also one of the most desirable areas for re-training. One of our panelists pointed out that interest in safety courses seems to increase when a manure accident occurs.

What does this mean? Well, there’s probably more opportunity than crisis at play here. The desire, the teamwork, the passion and plenty of the knowledge is there.

Nevertheless, the fact remains that

“Turning down jobs can be positive, focusing on quality.”

But then there’s the more nuanced, ever-evolving matters – like how exhaustion can affect one’s ability to safely do their job, or the effects of mental strain. On Page 26, James Careless also looks into how heat stress can affect operators.

Our survey results offer a few insights into the small challenges that can bog down a business – or a whole industry. When there’s a massive, significant problem, it’s easy to make a sweeping or drastic change. It’s tougher

there are only so many hours in a day, and businesses have to make the most of the time and the manpower they have. As one of our panelists pointed out, turning down jobs can be a positive thing – because focusing on quality over quantity not only means your customers can continue to expect the best, but also means that your operators are more likely to do their job safely and with the supports they need. Keep prioritizing quality –it goes hand-in-hand with safety. •

The PSS8 is an innovative solution for large-scale dairy and biogas production.

Key Features:

• Ecological Efficiency

• High Capacity

• Lower energy consumption and operational costs

• Durability, long service life with easy maintenance

• Robust Design: Heavy-duty auger with sturdy bearing head

• Powerful Operation: 30 kW electric motor, compatible with 400V/50Hz supply

• The PSS8 enhances productivity while minimizing environmental impact

Canada is making changes to its Temporary Foreign Worker (TFW) program intended to reduce the number of migrant workers hired for low-wage jobs.

However, farms are less likely to experience a major impact to their workforce, as primary agriculture has been listed among the official exceptions.

The changes, which will be implemented by Sept. 26, state that the government will now refuse to process Labour Market

Impact Assessments in the low-wage stream, applicable in census metropolitan areas with an unemployment rate of six percent or higher. And, employers will be allowed to hire no more than 10 percent of their total workforce through the TFW Program. However, exceptions will be granted for jobs in food security sectors, which includes primary agriculture as well as food processing and fish processing. The maximum duration of employment for workers hired through the

BY

low-wage stream will now be reduced to one year, from two years.

The release stated, “Employers in Canada have a responsibility to invest in the full range of workers available in this country, such as young people, newcomers, and persons with disabilities, who are too often an untapped economic resource in Canada. They must also invest in retraining or upskilling to ensure that those they currently employ can adapt to the economy of the future.”

This past August, Manitoba’s minister of environment and climate change Tracy Schmidt announced the province’s firstever formal nutrient reduction targets.

The targets fall under the province’s Water Protection Act, which aims to establish a

21,020

Number of U.S. farm injuries in 2021-2022 that required time away from work. (1)

10

Parts per million (PPM) at which hydrogen sulfide can no longer be detected by smell.

benchmark to guide and assess progress in reducing nutrient levels in water bodies such as Lake Winnipeg. The regulations include specific nutrient concentration targets for sections of Lake Winnipeg, as well as loading targets for tributaries that feed into

the lake. Targets for Lake Winnipeg’s north and south basins and the narrows of Lake Winnipeg are 0.05 milligrams of phosphorus per litre and 0.75 milligrams of nitrogen per litre. Loading targets vary for different rivers and tributaries.

Schmidt said in

a statement that the establishment of these targets “will help Manitoba’s collective water quality efforts by guiding future nutrient reduction activities and best management practices, identifying priorities and helping track progress and outcomes over time.”

56%

Deaths in the agriculture, forestry, fishing and hunting industries that occurred to workers 55 years or older. (1)

50

PPM at which hydrogen sulfide can alter breathing.

1-15%

Concentration (by volume of air) at which methane is flammable or explosive.

500-700

PPM at which hydrogen sulfide can cause collapse within five minutes.

With a partnership that began in 2019, Farm Credit Canada (FCC) has renewed its financial commitment to Olds College to support their continued focus on advancing ag technology and applied research through the Olds College Smart Farm. The AgExpert Data Lab, established with FCC’s initial support, has become a cornerstone of this advancement, serving as a collaborative workspace for students, instructors, industry partners, and the Smart Farm Integration Team.

“FCC’s continued support has been instrumental in our development,” said Ben Cecil, president of Olds College, in a statement. “The advancements we’ve made in the AgExpert Data Lab over

the past five years have enabled us to analyze and demonstrate cutting-edge technology and practices. This renewal will allow us to further enhance our capabilities and provide even greater opportunities for entrepreneurs, companies, producers, and our students.”

Mohamad Yaghi, FCC’s VP, Innovation Hub and AgExpert, expressed enthusiasm about the ongoing partnership. “The AgExpert Data Lab has played a crucial role in teaching the next generation of farmers how to collect, manage, and utilize farm data effectively. With this renewed commitment, we aim to expand our efforts and ensure that Canadian agriculture remains at the forefront of global innovation and success and ensure that producers are renumerated for what they produce and preserve.”

With this renewed financial commitment, FCC and Olds College are poised to further their contributions to the agriculture and food industry.

The Michigan Alliance for Animal Agriculture (M-AAA) will invest $2.5 million across 23 new research and outreach projects led by Michigan State University and MSU Extension. The funding is available through the 23024 Michigan Department of Agriculture and Rural Development budget.

The funding was dedicated to addressing the short- and long-term challenges of the animal ag industries, including infectious diseases, improving animal welfare and bolstering environmental sustainability. Specific topics covered by the investments include improving dairy cattle fertility and other issues.

The M-AAA was established 10 years ago as the result of a partnership between Michigan’s agricultural and rural development department, MSU and a number of state animal ag organizations.

What we’ve gleaned from our 2024 Training, Talent and Operations survey.

BY BREE RODY

In late spring of 2024, Manure Manager launched a survey to gain insights into the current challenges of the manure application industry, especially as it relates to staffing, training, talent and operations.

Although manure hauling, handling and application remains a niche industry, it is still a growing industry in more ways than one. There are new entrants to the market, and plenty of passionate applicators are also looking to improve their practices and increase their knowledge. Outside factors such as policy changes, increased environmental awareness and high-profile manure accidents can also prompt businesses to decide it’s time to re-invest in training. But it’s not always simple to train. There are only so many hours in a day.

Over the course of the summer, 74 people participated in this short online survey, sponsored by Valmetal. The survey was promoted through Manure Manager’s print and digital editorial products, website advertising, social media and at the registration tent of the North American Manure Expo. Various associates of Manure Manager and the Expo also promoted their

survey to their academia and extension networks. Following the close of the survey on Aug. 31, the results were looked over by Manure Manager editor Bree Rody and a panel of three extension professionals in nutrient management, and two Ohio-based, professional manure applicators.

This is a preview of the results, with additional commentary from our panelists. Full results are available online at manuremanager.com.

Of the survey’s 74 respondents, nearly 78 percent identify as business owners, and most self-identify as having multiple roles – such as applicators and administrators.

Just shy of 37 percent were from the Midwest, representing the largest geographic group. This was followed by the Northeast U.S. (19.18 percent), Eastern Canada (13.7 percent) and Western Canada (12.33 percent). Nearly 60 percent of respondents have been in the business for 25 years or more, although the second-largest group of respondents

Licenses for commercial vehicles, like the one pictured above, are a key asset for new hires in the manure hauling business.

(15.07 percent) were relatively new to the market, at zero to five years in business.

Kevin Erb, conservation professional training program director at the University of Wisconsin Extension, appeared as one of the five. He says this matches the 2023 data from the Professional Nutrient Applicators Association of Wisconsin (PNAAW)’s data, which shows that new entrants to the applicator business market are outpacing exits from the market. The main exception in recent years was 2020, when Erb acknowledged that some businesses pivoted away from manure application and into adjacent industries due to the COVID-induced economic slowdown.

The results indicate that most manure application businesses run lean – one to three employees is all it takes to run a successful business. Just shy of 44 percent of respondents report having one to three employees, which was more than any other group. The next most popular choice was 10 or more employees, at roughly one quarter of respondents.

Panelist Mary Keena, livestock

environmental management specialist with North Dakota State University, says that in her state, a “big” business would be considered “maybe nine people,” but most of the business owners she knows do it all – hauling, applying, admin work and more. A few additional seasonal employs is more than typical in North Dakota.

Minnesota’s Melissa Wilson says in her experience, “Bigger operations are usually associated with the 10,000[-head] cattle operations,” while smaller manure operations usually work with smaller farms.

“Do you want to train someone who’s only with you for six weeks?”

While there is somewhat of a correlation between the age of a business and the size of a business – more established business are more likely to have four or more employees, and the numbers tick up with age – lean operations are consistent across the board,

whether a company is brand-new or longestablished.

Megan Dresbach, VP at W.D. Farms, and her father Eric, president of W.D. Farms, were also on the panel. As a family business, the Dresbachs represent one of the most typical models of business.

“Guys just starting out, you’re not going to have the capital, you’re going to have the equipment or the customer base to hire full-time,” says Megan. “[Many] start manure hauling on the side for something else you’ve got. After a few years, you’ll start to get established, you’ll have the longevity, and you can start to offer employee benefits.”

Indeed, attracting and retaining employees often comes down to competitive pay – respondents by far considered this the biggest appeal of the business – as well as work-life balance.

Much of the survey focused on businesses’ abilities to train and re-train employees, the biggest priorities for training, and the biggest roadblocks to adequate training.

Most new hires for manure applications have two things in common: first, they’re

far more likely to come into the business thanks to a pre-existing relationship (friends or family) or a referral than a job ad; secondly, they’re likely to come with general ag experience or a little bit of manure experience, but not with through, manure-specific experience.

Megan Dresbach added that it gets complicated when the job is not only very specific and niche, but it’s also often done by young workers who are not in it for the long haul. “In our operation, we’ve got a lot of young guys, and it seems we hire

them, we train them, they’re here for a few years, and then they find a better job.” There are no hard feelings, she says, but a strenuous, weather-dependent job can leave some yearning for the nine-to-five.

Keena adds that some owners have to be realistic about training. “Do you want to train someone who’s only with you for six weeks?” she asks.

The outlook for returning and senior employees is a little different than that for newbies. Most respondents report that re-training, continuing education and

certification, although not mandatory, is encouraged, and most businesses offer to support those endeavors on company money and time – or, at the very least, company money.

But most say lack of time is the biggest thing that keeps them from engaging in as much re-training and continuing education for operators as they’d like. As such, even though owners find courses, workshops and field days from extension and manufacturers alike to be beneficial, the knowledge-sharing from senior operators plays a crucial role in filling those gaps when there isn’t enough time for formal re-training. More than 85 percent of respondents say their primary method of training is through job shadowing with senior operators.

Most respondents say they either sometimes or definitely feel understaffed, and well over half say they experience either some or significant knowledge gaps.

Erb says the desire for more knowledge tends to come from longer-term employees and owners, in his experience, and sometimes the desire to skill up isn’t always there from less experienced operators who aren’t personally invested in manure.

“What I tend to see is that it’s the business owners or maybe those with long-term experience asking those questions, but the driver whose only been on the job two or three years really doesn’t care about soil health or compaction.”

The last segment of the survey focused on succession planning – how many applicators and business owners have a plan for their businesses – and themselves – once it’s come time to hang up their boots?

While more than a third of respondents say they do have a formal plan in place and all is going according to plan, the remaining two thirds aren’t so confident.

For example, 38.36 percent say they have some ideas of where they would like the business to go in the future, but they do not have a formal plan in place. Additionally, 13.37 percent say they do have a plan, but things are diverging from that plan and they have to adjust their expectations. Just shy of 11 percent say they do not have a plan.

Retirement is also a concern. A total of 41.1 percent of respondents say they may have to retire later than they planned. Even among businesses under five years

old, 36.36 percent already believe they may have to retire later than anticipated.

Of all respondents, 42.47 percent say one of their children or younger relatives is their first choice to take over the business. An additional 10.96 percent say one of their younger staffers (nonrelatives) would likely take over, and 9.59 percent plan to sell their business. However, 32.88 percent say that while they’d like someone to take over the business, they lack a solid plan.

For the Dresbachs, Eric says at 64, he has begun broaching the topic. “David and Megan already have a big chunk of the rein, but it isn’t official yet.” Megan began taking responsibility for the trucking side of the business in her late teens, and it became official in her twenties.

“We’re fortunate to have a parent who says ‘One day I’m going to die, and I want this business to survive, you guys are interested, so I’m going to let you do these things,” says Megan.

There are far more results online! Scan the QR code for our digital edition covering the full survey results including results of understaffing, demographic breakdowns and more! •

Kevin Erb

Conservation professional training program director, University of Wisconsin Extension

Melissa Wilson Associate professor and extension specialist, University of Minnesota

Mary Keena Livestock environmental management specialist, North Dakota State University

Eric Dresbach President, W.D. Farms Inc.

Megan Dresbach Vice-president, W.D. Farms Inc

Biogas is big business, and a growing number of farmers have come to realize that they can pocket a healthy profit by feeding their manure into digesters that transform this valuable commodity into fuel.

The profits can be significant. “If we accept all the costs of building a digester, and we accept all the costs of the gas upgrading system, then the farmer’s profit is basically cost free,” says Jeff Bowman, director of business development at Amp Americas, a green energy supplier based in Chicago. “Working with an anerobic digester partner can provide an additional one to two percent to the dairy’s overall revenue, free of capital investment. This kind of revenue can go directly to their bottom line.”

To tap into this lucrative industry, farmers

need to make sure that they can supply the kind of raw materials that are best for biogas production. “Most digester companies, and most gas upgrading facilities like ours, would prefer to have thick manure,” Bowman says. “It limits the size of the digester, and by default, limits cost. It also allows for better mixing, and it allows for better contact between the microbes and the volatile solids.”

In short, thicker manure is better, and Bowman uses California as an example of where that can be a challenge. “They have a lot of covered lagoon digesters that are taking two percent solids, and they have difficulties in mixing, and difficulties in settling. So, when you’re talking diluted manure, you’re talking massive water volumes. [By comparison,] thick manure can use a smaller digester; we can get better mixing and agitation, and we can get better gas per pound of volatile solids when the manure comes to us in a thick enough state.”

FLUSH SYSTEMS ARE A CHALLENGE

In parts of the country where water supply is a concern, Bowman explains flush systems can be a challenge. “When you need 2.5-million gallons of water a day to move the manure, then you have to consider that there are more effective ways to move the manure and keep it thick, especially since most farms of scale are adopting digester technology,” he says.

When it comes to digesters, the bottom line is that thick manure is king. Some farms with a flush manure system have tried to thicken their manure, but according to Ryan Winebrenner, business development director at Valmetal, that is not the simplest way.

“If you take flush manure and then just thicken it, you lose a lot of the volatile solids because the fine particles and dissolved solids are pumped out to the lagoons,” Winebrenner says. “They don’t go to gas production.”

Valmetal sells both flush and alley scraper

systems, and Winebrenner says that farmers used to shy away from alley scrapers in the past, simply because the older systems required a lot of maintenance and were difficult to keep clean. Valmetal’s newest alley scraper systems, however, eliminate all those headaches.

One of Valmetal’s innovative designs is the Nova-Cable high-performance cable scraper system, which can operate up to eight blades, even in heavy sand conditions. “It’s ideal for farms with between 1,000 and 10,000 cows that need a heavy-duty system that can even handle one-thousand-foot and more barn lengths,” Winebrenner says.

The Nova-Cable system is ultra-low maintenance, he adds, alluding to the added workload to clean and maintain alley scrapers – something that has often deterred farmers against investing in these units. “It’s unique in that the whole drum moves within the unit to keep the cable centered so that the cable doesn’t have to go back and forth,” says Winebrenner. “This keeps it very clean, resulting in a lower-maintenance system.”

Prior to this innovative design, alley scraper systems typically employed timing chains, sprockets and guide screws that were down

low in the manure and sand. “This would just tear them apart, and you weren’t able to keep these parts greased enough,” Winebrenner says. “So, we eliminated most mechanical parts and moved the rest up off the ground.”

With the new designs, all the mechanical parts are now three feet off the ground and encapsulated in grease. “When you look at the unit after it’s been running a year,” says Winebrenner, “you don’t see manure on the shaft. So just by getting everything off the ground and out of the manure, we were able to reduce the amount of wear and tear, and the need for extensive maintenance.”

Valmetal’s engineers also redesigned the location of the chains on the Nova-Cable alley scrapers, moving the chains up and out of the manure. “Now the chains run in a nice oil bath and never sees manure,” Winebrenner says.

The company has also engineered low-maintenance and low-horsepower piston pumps that feed digesters, operating between five and 10 horsepower to save both time and money. “It’s the perfect tool to feed the digester,” says Winebrenner, “because digesters love consistency. They want to be fed at the same speed, all day long, and our pis-

ton pumps are designed to do just that.

“Since we keep the manure thick, we don’t have to move large amounts of it,” Winebrenner says. “On the other hand, when you flush, you’re moving thousands of gallons of water to scrape a few hundred or a few thousand gallons of manure. With our alley scraper systems and piston pumps, we’re moving less gallons of manure, using less horsepower, and we can feed the digesters consistently with very little wear and maintenance needed.”

These new-and-improved systems didn’t come about by accident, Winebrenner explains. “We have worked hard to address the issues that farmers brought to our attention,” he says. “We now have new systems that are built for the industrial farm, and able to allow farmers to keep the manure thick, feed it into a digester, and enjoy all the benefits.”

For more information, visit valmetal.com.

Brought to you by

Manure could help Hawai’i toward its net-zero energy goals

BY JACK KAZMIERSKI

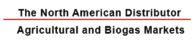

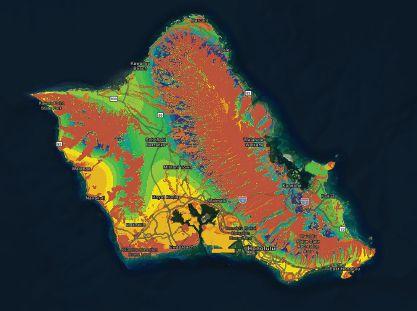

The University of Hawai’i at Mãnoa College of Tropical Agricultural and Human Resources (CTAHR) is launching research to help them asses how bioenergy generated from organic waste, including manure, could help Hawai’i reach their renewable energy goals, including “net-zero energy” by 2045.

The university has received a $150,000 grant from Sun Grant Western Region for this research, which will be headed by Professors Samir Khanal and Tomoaki Miura, along with Dr. Surendra KC, a research scholar with the same university.

“Hawai’i is in a unique situation,” says Khanal. “We are an island, we’re isolated from the mainland, we are tropical, and we have a unique energy situation.”

Khanal says that Hawai’i is doing everything possible to produce clean energy from a variety of renewable resources, including biomass. But before the island state can start erecting biogas plants

ABOVE

that will turn biomass into fuel, they first need to determine where to build these plants so that the raw materials, including manure, are in abundant supply nearby.

Khanal says that the National Renewable Energy Laboratory Biofuels Atlas, which identifies areas with an ample supply of feedstocks, does not have specific data for Hawai‘i.

That’s why the team at CTAHR has set out to provide this critical mapping information, which will combine geographical information system (GIS)-based modelling with bioconversion data. “The decentralized nature of bioresources across the Hawaiian islands has made it necessary for us to develop a comprehensive bioenergy feedstock map,” says Khanal.

Currently, this project is focusing on four of the main islands that make up this island state: O’ahu, Maui, Kaua’i, and the Island of Hawai’i. “These are the major islands where we have a lot of people and

The team at CTAHR has set out to provide this critical mapping information, which will combine geographical information system (GIS)-based modelling with bioconversion data.

more resources,” says Khanal. “The other islands are smaller, but we certainly could expand our research to include them as well.”

At present, the team is looking at the type of bioresources available on each of the four islands. “This includes animal manure and other types of waste that can be used to produce renewable energy, especially biogas,” says Khanal.

“Currently, we are just mapping resources,” says KC. “We want to identify what kind of biomass is available and how much biogas we can produce. We want to pinpoint where a biogas plant should be located, and how large it should be.”

“This helps us achieve environmental and energy sustainability at the same time.”

The entire project is still in its infancy. The research team received funding in April of this year, and started work in May. “There are no findings to report yet,” says Khanal. “We’re going to the different islands and doing a survey. We have extension agents who will be helping us to find the places where we have bioresources, including manure. We will be collecting samples, analyzing the potential for biogas based on the carbon content, or organic content, of the biomass.”

According to KC, the livestock industry in Hawai’i is rather small, when compared with mainland U.S. Most of the livestock, especially dairy and beef cattle, are pastureraised, which makes it difficult to collect their manure for biogas production. Pig and poultry manure is in short supply as well.

“The American Biogas Council estimates that we produce between 50,000 to 60,000 tons of manure per year,” he says, “but they left out poultry manure. Other sources estimate that we produce around 20,000 tons of poultry manure per year.” In comparison, the U.S. Department of Agriculture estimates that the United States produces as much as 1.4 billion tons of manure a year.

KC says that manure management is not a big issue in Hawai’i, “But our island

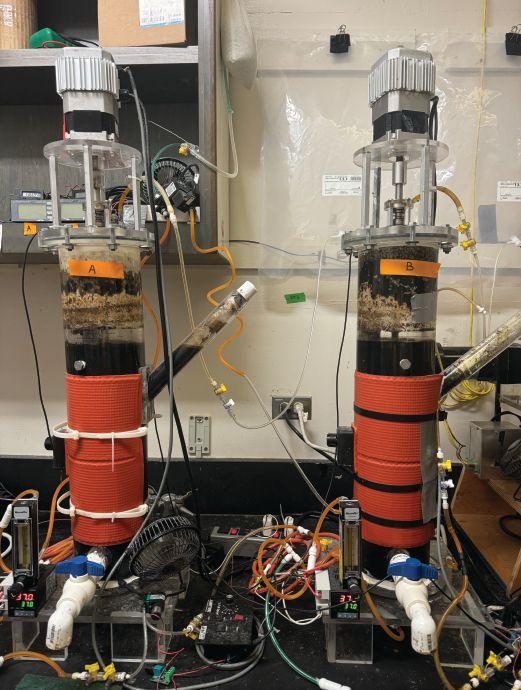

The university routinely conducts biomethane and biohydrogen potential tests of different substrates.

has a very limited land area, and contamination of water bodies is a big issue.”

This is why biogas plants have the potential to make a difference. “They will recapture the waste material and treat it by anaerobic digestion, producing energy and managing waste at the same time,” says Khanal. “So this essentially helps us achieve both environmental sustainability and energy sustainability, at the same time.”

Once built, these biogas plants will turn a range of organic waste products into fuel. In addition to manure, they will likely include a truly tropical mix of ingredients. “We’re going to use a range of agricultural waste residue,” says KC, “Including papaya waste, pineapple waste, coffee waste, and any organic waste coming from the cities.”

The fact that Hawai’i has a big tourism industry seems to be playing into the formula. “We have a lot of tourists, so we produce a lot of food waste, and that food waste has a very high carbon [content],” says Khanal. “Manure is a good nitrogen source, so it’s a good combination, which will give us a much better yield of biogas.”

According to Khanal, mixing food waste with manure to optimize biogas yield is a formula that can benefit communities in other parts of the world as well, not just Hawai’i. “Many

studies show that when you combine two or thee different types of substrate together, the system works much better, because it balances out all the nutrients, and the conditions we require for microbial conversion,” he says.

In addition, the resulting compost has a higher nutrient value, which in turn improves plant growth. “[This mixture] will also dilute toxic compounds you have in the substrate, which results in a better end product for agricultural applications,” says Khanal.

Finally, KC explains, mixing manure with other organic waste benefits the digester itself. “When we have a monosubstrate, like pig manure, it is high in nitrogen. So, if you want to operate a digester with pig manure, you’re going to have an ammonia toxicity issue,” he says. “The same will happen with poultry manure. But when we mix different substrates, things balance out.”

Attitudes towards digesters, and large “bioresource” projects in general, can vary. While some communities embrace them, others tend to fight them. Khanal says that residents of Hawai’i take the environment seriously, which is why the location of any biogas facilities is sure to undergo scrutiny.

“We have very strict rules, in terms of construction,” he says. “We have to meet all the requirements in terms of water quality, air quality and many other things. At the same time, we are very environmentally conscious, we’re focusing on waste management, and not discarding any waste into the system. So people see that what we’re doing is something positive. We’re managing the waste on the island, while also producing renewable energy for our use.”

Once the research is completed, and the various levels of government approve the project, KC believes that Hawai’i will likely have to build biogas facilities on all of its islands. “We can’t carry waste from one island to another,” he says. “The only question is where each plant should be, and how many each island should have.”

Placing biogas plants as close as possible to locations where both manure and organic waste is plentiful, is only part of the bigger picture. According to professor Tomoaki Miura, other key factors must also be considered.

“We’re looking at geography, as well as

economics,” he says. “We are considering locations where it would be best from an economic perspective, and that can be quite challenging.”

Miura admits that his research team doesn’t have the expertise in economics that would allow them to make all the decisions on their own, which is why these scientists are working hand-in-hand with economists.

Economists, on the other hand, aren’t mapping experts. “It’s new to them to incorporate GIS into an economic analysis,

GEA

That’s what needs to be hitched to your tractor.

which can be a challenge,” says Miura.

As ambitious as this project may be, the question now is how quickly the data that’s collected by the research team at CTAHR will be translated into building plans, and how quickly Hawai’i will see one or more biogas plants in use on one or more of their islands.

“So from what I understand, this has been a hot topic for the last 10 years,” says Miura. “This is just the starting point of our collaboration, and we’ll have to see how far we can get with this project.” •

• Reinforced pump head

• Gate valves all around

• Twin short agitation nozzle with position indicator

• Stainless steel nozzle ball joint

• Thicker sprocket and motor mount

• Inline cooling pump (no more belt)

• New oil cooling reservoir bolted on the housing

• Remote control

• Can reach up to 4’ in pit depth difference

• PTO stays connected on the trailer

• Transport mode locking mechanism on trailer

BY JIM TIMLICK

A contest designed to encourage producers on Prince Edward Island to reduce the amount of nitrogen-based fertilizer they use proved so successful in 2023 organizers decided to stage the event again this year.

The AAFC Plowdown Challenge is the brainchild of Agriculture and Agri-Food Canada (AAFC) science coordinator Scott Anderson and AAFC technician Roger Henry. The colleagues have long lamented the fact that while research has shown the value of proper nutrient and fertilizer management, uptake in the agricultural community has been slow.

It was during one such discussion that the idea for the Plowdown Challenge was born. The concept was simple: plant a crop of potatoes on a field at AAFC’s Harrington Research Farm, located about 10 kilometres north of Charlottetown. The twist was that no nitrogen-based fertilizer was used. Farmer and other members of the public were then asked to submit their guess on what the marketable yield would be after harvesting and grading.

ABOVE

“We were just trying to think outside the box and come up with a real visual demonstration that was different from most of the things we had done here in the area in the past,” says Anderson. “It wasn’t meant to be a science project. We just wanted to show people in general, including the farm community, that if you properly manage your soil and your previous crops you can grow subsequent crops with reduced fertilizer.”

“We wanted to show people that the soil does contribute to the crop,” adds Henry. “It’s not just fertilizer that grows the crop. In my opinion, people often underestimate the value of the soil component to the fertility of the crop.”

As part of last year’s contest, a field of red clover was plowed into the soil and a cover crop was planted soon after. The cover crop grew to about 18 inches before dying out due to frost. The potatoes were planted last spring, relying on only the nutrients in the soil provided by the red clover and held over winter by the cover crop.

The actual potato yield after harvesting

Scott Anderson, Paul Smallman, Carolyn Smallman and Roger Henry. Paul had the winning guess in the Plowdown Challenge.

the field was 169 hundredweight per acre. By comparison, a typical potato crop produced on the island without irrigation using fertilizer will yield about 300 hundredweight per acre. The winning contest entry of 177 hundredweight was submitted by Paul Smallman, a cattle farmer based in western P.E.I.

Anderson and Henry say they were pleased with the level of interest in last year’s inaugural contest. About 75 people submitted a guess, thanks in part to the fact the contest was heavily promoted by local media and on social media platforms like X (formerly Twitter).

“The general public was quite, quite interested in it. We had comments from people all over the place saying they thought it was fantastic and good job,” says Anderson. “The amount of interaction with producers was less but it gave us an opportunity to have the fertilizer discussion with the producer and from that point of view it was a success.”

Due to the positive response to last year’s contest, Anderson and Henry decided to launch a 2.0 version of the contest for 2024. Anderson says the duo wanted

to “outdo ourselves a little bit” this time around so they tweaked the contest a bit.

First, they set a deadline of June 1 for entries to provide all entrants with a more equal chance of correctly guessing this year’s yield. More importantly, they decided to spread manure prior to planting the potatoes..

Henry says the decision to add manure into the mix was made because an increasing number of farmers in P.E.I. have begun using manure again to boost the yield of their crops, but many aren’t cutting back on the amount of fertilizer they use in those fields.

“It doesn’t make any sense because manure has nutrients in it and you should be reducing your fertilizer if you’re using manure,” he explains.

Because manure was applied this year, the decision was made to plow the field in late November of last year and not plant a cover crop. The manure was applied to the field in May and the seedling potatoes were planted a few days later. It was applied using a conventional applicator and a set of cultivators was used later the same day to work it into the soil to trap nitrogen and better hold it in place.

Henry says the decision to apply manure in the spring was a conscious one.

“I don’t promote spreading manure in the fall. Why are you going to spread all that manure and have the rain go on it and it’s going to leach down and you are going to lose a significant amount of the nutrients,” he says.

“You get a bigger bang for your buck (spreading it in the spring). The problem with the spring is farmers are so busy. They’re getting their seed ready, they’re preparing the land, they’re planting and they only got about a month’s window to do all that work.”

One alternative for farmers who are too busy to apply manure in the spring, Henry says, is to spread manure on a growing cover crop during mid to late summer. Applying it to a cover crop later in the growing season allows the nutrients from the manure to be drawn into the ground via the cover crop. Henry cautions farmers to avoid applying manure to a cover crop just before it is destroyed because it needs time to “really grab hold of those nutrients.”

OCT 22, 2024

12:00PM ET

The Influential Women in Canadian Agriculture program honours women who have created lasting impacts on Canadian agriculture. Since 2020, the program has recognized 33 women who have positively contributed to the industry, whether actively farming, providing agronomy or animal health services, completing research, leading marketing or sales teams, and more.

The program receives dozens of incredible nominations every year, highlighting just how many influential women are working within Canada’s agriculture industry.

Join us in our annual virtual summit on October 22 at 12 p.m. ET. Featuring our hand-selected group of honourees and other prominent ag trailblazers, this free event will provide a platform for the exchange of knowledge and ideas as our guests share their thoughts through interactive sessions.

The North American Manure Expo hits New York State for the first time

BY Bree Rody

BELOW

The day one BBQ and trade show were among the many opportunities to network at the Expo.

For the first time, the North American Manure Expo came to New York State.

Held July 17 and 18 in Auburn, NY, the 2024 North American Manure Expo was a major hit. More than 1,000 attendees flocked to the event to witness equipment demonstrations and chat with dealers, meet fellow manure professionals and enthusiasts, gain continuing education credits and more.

The Manure Expo continues to offer a sharp contrast to more “general ag” farm shows due to its highly specialized nature. Kevin Erb, conservation training program director with the University of Wisconsin Extension and president of the Expo board of directors, explains how the niche focus on manure allows for a more interactive, showcasefocused experience.

“[With] manure equipment, it’s kind of hard to see more than one piece in action,” says Erb. “You’re going from one farm to another if you want to see what someone else has. The benefit here is that you can come and see three, four, five different agitators in action, see several different manure injectors or solid spreaders, compare that spreading pattern and say, ‘This is going to work best for the kind of manure I have and the type of management that I have on my farm.’”

NEW YORK, NEW ATTITUDE

With a new location comes a series of new opportunities for the Expo board.

Kirsten Workman, senior extension associate,

Cornell PRO-DAIRY and the 2024 Expo co-chair, says the team looked at it as a good opportunity to help educate the broader public about what the agriculture industry is doing to innovate its practices.

“The New York dairy industry is really excited about sustainability and being responsible stewards of their nutrients,” she says. “[Hosting the Expo] came as a request from dairy producers. They really like to highlight the innovation and the work that farmers do. They were really excited to show off what we do, but also to bring resources to show our farmers all the different kinds of technologies and research and professional nutrient management.”

She adds that the show attracted a lot of media attention, which was very positive for not only the Expo but also the New York dairy industry. “It’s given us a good platform to talk about the kind of work we do with our farmers on manure application, nutrient management and environmental stewardship.”

The Expo’s host farm was Patterson Farms, a seventh-generation dairy farm, with 1,800 milking cows.

Reilley Patterson, daughter of owners

and hosts John and Julie Patterson, served as something of the “first daughter” of the Expo. With the first day of the Expo landing on Patterson’s 18th birthday, she donned a celebratory tiara and happily led Expo-goers on a tour of her own family farm, which was so popular that an extra impromptu tour was added. In fact, all the off-site tours – one focusing on water quality, one on manure energy and one on soil health systems – were sold out prior to the start of the show.

Patterson was delighted for the chance to show attendees – some of whom came from as far as Texas – what her family business is all about.

“Our four pillars are safety, animal care, integrity and environment,” explained Patterson. “We want to make sure our employees are taken care of, and our animals are taken care of. We also want to ensure we’re taking care of our environment, and we have people to help hold us accountable to that.”

She adds, “We always want to look out to the future – we’re not doing anything out of selfishness. We want whatever we’re doing to be the best possible thing for our farm, for the people, for the cows.”

The 2024 Expo also marked a continuation of a number of new features introduced at the 2023 show. This included the interactive safety school (see Page 26), the evening barbecue and social, showcasing separators and incorporating drag line and injection manure application into the demonstrations. It also marked the return of the spill response demonstration, hosted by Erb, which took a year off in 2023.

Workman says overall, the Expo brought out the best in the local agricultural community, especially as it comes to collaboration. “To see farmers and manure applicators – other people might think they’re in competition with each other – really work together to put on an event… We’ve seen that even with our vendors, different companies working together to put on a demonstration. That sense of collaboration has been really great. We’ve been trying for a while to bring our custom manure applicators together, and this event was really a way to kick that off.”

The 2025 Manure Expo will be held in Wauseon, OH, July 30-31.

20 X 6” Hose Capacity. Lead & trailed units can be operated in unison or independently. TPH

• Available in 30’ and 40’

• Full galvanized frame

• WER Distributer

• Rear hitch (max towing 5000 lbs)

• Available in 30’/40’/60’

• Full galvanized frame

• WER Distributer

• C/W ball blow-out

• Rear hitch (max towing 5000 lbs)

Use as a stand alone unit, or as an addition to a developing drag line system. (3 models available).

The telescopic hyd width adjustment provides a large surface radius when moving hose.

Improve productivity by reducing blockages in the drag line system and reduce pump repairs.

The high grade chopping system, and auto-reverse function, ensure an obstruction free distribution.

Maximize Efficiency with better spread. Heavy duty construction & galvanized frame.

For the second year in a row, the North American Manure Expo offered an interactive safety school for attendees to keep up-to-date with their knowledge of manure and farm safety.

This year, the educational content of the safety school was expanded to cover the many different facets of manure safety, since there are different types of manure accidents and risks. The segments included road and vehicle safety, pump and dragline safety and confined space safety, along with the rapid release demonstration, better known as the hose break.

It’s important to cover many different aspects of safety, says local committee chair Jason Oliver, because the demands of the agriculture profession are so diverse and varied, presenting many different opportunities for risk.

“The goal is to really encourage them [workers] to pause and think about safety, and be equipped with the information to proceed with their profession in a safe manner,” says Oliver. “We want them to come home at the end of the day.”

Professionals both from the agricultural industry and from other specialties came in. For example, the road safety segment

Safety training included information on PPE, harnesses and retrieval systems.

included instruction from both the agricultural industry and from New York State Troopers David Nelson and Chris Lana. Nelson and Lana demonstrated a mock-up truck inspection, showcasing everything from tire safety to how to ensure one’s horns are working correctly.

The National Education Center for Agricultural Safety also brought in its confined space manure pit simulator. The session on gas and confined space safety was led by former fire chief turned professional fire trainer Tom Basher.

“It’s unfortunate, but a lot of people have to work near confined spaces,” says Basher. Not seeing or smelling anything bad doesn’t mean there is no danger present, warns Basher. “One or two breaths of hydrogen sulfide, you’re done… You’ve got to monitor the air, you’ve got to ventilate, you’ve got to have some sort of retrieval system, some sort of harness. Because, God forbid you go down, if we have to go down and get you, it puts someone else at risk.”

Basher and his team demonstrated how to create different retrieval systems and anchor bolts out of harnesses and ropes which can assist in hauling individuals, even unconscious ones, from hazardous areas.

Basher says the best first step one can do is to be aware and truly check for and catalogue risks. “Do a risk assessment,” he urges. “See what your hazards truly are. Once you realize what they truly are, ask yourself, ‘Can I mitigate that risk?’”

Harnesses, retrieval systems and air monitoring equipment are all a must, says Basher, who adds that they need to be high-quality and tested to ensure continued efficacy.

The hose break demonstration, first introduced in 2023 to demonstrate the power of a high-pressure hose when the pressure is released suddenly, made a return to the field.

Once again filling the hose with air, the crew initially shot to get the hose as close to 100 lbs/square inch (PSI) as possible, which was the level of pressure achieved in Wisconsin. Unfortunately, at around 60 PSI, the team begin to experience issues and were unable to get the hose to a higher level of pressure. The team made the

executive decision to pull the pin shortly thereafter, before the PSI crept under 50. The result? Even with just over half the pressure of last year’s break, the hose caused some undeniable damage.

The ultimate aim of the demonstration was to help attendees understand why it is important to keep a safe distance from a manure hose – especially because of how quickly things can go wrong. One new element added this year was an adult-sized dummy who was straddling the hose prior to its release.

The dummy, playfully nicknamed “Glen” by Expo board members (after Ohio State University professor and 2025 Expo chair Glen Arnold), served as proof that despite a lower maximum PSI this year, a burst hose can inflict serious damage on a human body. After only a few seconds, “Glen” was flung from the hose and wound up losing a limb amidst the carnage.

Editor’s note: The real Glen was fine.

“It hopefully scared the tar out of a lot of people,” says Joe Hesse, sales representative with Puck Enterprises, which served as one of the sponsoring suppliers of the event and the safety school in general. “Air safety is a huge concern and can be a very serious situation if not handled right.”

Hose breaks when the hose is filled with manure, or when it is being cleaned out with water, can also cause significant damage to people and/or equipment. A hose being cleaned out is just as dangerous as a hose filled with manure.

Safety school will return for Manure Expo 2025. •

Henry holds a sample of freshly dug potatoes from the Plowdown Challenge field.

For this year’s contest, composted dairy manure was used. The pen-packed mixture was a blend of straw, animal urine and feces.

“It’s a good mix,” says Henry. “You have the nutrients in the manure and urine and you have the carbon from the straw and the combination rots really nicely. Earthworms love it.”

Interest in using manure has been growing among potato producers in P.E.I. over the past several years. It’s no wonder. Henry says depending on the type of manure added, yields can be anywhere from 25 to 75 hundredweight per acre more when manure is applied. Typically, that increase presents itself in the form of larger tubers.

Not only can adding manure increase yields and overall soil health, but it can also boost the water holding capacity of the soil in a dry year.

“In a dry year, you can get a really big boost from manure,” Henry adds.

There is a catch, though.

The amount of manure available to farmers in P.E.I. has declined significantly over the past 20 years. The main reason is Mad Cow disease (BSE) decimated the Maritime cattle industry in the early 2000s. Many farmers got out of the beef business and never returned. A Statistics Canada reported recorded just 7,100 beef cattle on the island on Jan. 1 of this year compared to a peak of 16,000 animals in 2007.

“That’s big time true,” Henry says of the current scarcity of manure supply.

“There are a few potato producers on P.E.I. who are putting cattle back on their farms because they missed the manure that much. But there’s not near enough [manure available]. P.E.I. grows

somewhere around 80,000 to 85,000 acres of potatoes annually and you would need probably triple the livestock we have right now [to produce enough manure].”

The renewed interest in manure among potato producers on P.E.I. may be part of the reason why interest in this year’s Plowdown Challenge has also grown. Anderson and Henry had received so many entries by the June 1 deadline they still hadn’t tallied them by mid-month. It also helped that they had the entire winter to promote the contest at trade shows and other events producers

were at, unlike last year when they only began soliciting entries in May.

“I’d meet with eight or 10 farmers at an event this winter and say, ‘Do you want to put in a guess?’ They all said yeah, yeah, yeah,” Henry says, laughing.

Still, even the best ideas have a limited lifespan, and Anderson suggests this might be last call for the Plowdown Challenge.

“Personally, I think this will be it after this year. We don’t want to promote something too long. Maybe we’ll do something a little bit more wild and crazy next year.” •

Applying

manure safely in extreme heat conditions.

BY JAMES CARELESS

The summer of 2024 has passed after logging some extremely hot days. Thanks to a changing climate with an apparent tendency toward more extreme heat events, the summer of 2025 could match 2024’s extreme heat records, and possibly beat them.

Working in extreme heat can be dangerous for anyone working outdoors, but it comes with an extra risk for manure applicators. Here’s what the dangers are, and how to beat them.

The aroma that goes along with manure application is more than just a nuisance; it’s a potentially deadly odoriferous danger. One of the reasons is hydrogen sulfide along with other gases that can displace breathable oxygen. Hydrogen sulfide gas is emitted by decomposing manure. It is released whenever solid or liquid manure is agitated or moved, and is toxic to breathe.

“Hydrogen sulfide is produced by the action of certain bacteria, and obviously, as temperatures increase, bacterial action really speeds up,” says John Shutske, professor and agricultural safety and health specialist at University of Wisconsin-Madison. “Think of leaving a sandwich or other food product on the counter or picnic table in 85-degree weather versus 45-degree: Which will lead to faster bacterial spoilage? The same is true with respect to bacterial action in stored manure: As temperatures increase, some of the hydrogen sulfide and other gases produced by bacterial action escape to the ambient air. And when you begin to pump, agitate, and stir it up, it’s just like shaking a can of soda – the gases within are rapidly released. The effect is often magnified if the stored manure is crusted, because even more gas can be trapped in the liquid slurry to be released suddenly.”

liquid manure, rising up into your breathing area. If you breathe it in, you’ll suffer anything from a headache to unconsciousness and even death, depending on the concentration of hydrogen sulfide in the air around you.”

Donning a typical “air purifying” respirator won’t protect you from hydrogen sulfide or manure gases. However, a gas detection monitor can warn you of its presence.

“The monitors I recommend in the U.S., usually will have an audible alarm that will go off at the permissible exposure limit (PEL) of 10 parts per million (ppm),” says Shutske. “Ten ppm is high considering that the maximum short term exposure limit is only five ppm, and working for a full day at levels over one ppm is considered to be a threat to human health. Exposure at levels as low as two ppm will lead to headaches, nausea and significant respiratory problems with people who have asthma. Levels of 100 ppm or higher are considered immediately dangerous to life and health. Hydrogen sulfide is tricky because at those higher levels, the gas deadens your sense of smell, which means people who die often are no longer smelling the gas. At higher levels, a person no longer able to smell the noxious rotten egg odor might take a couple breaths that will result in rapid unconsciousness and death.”

Walter Grose is president of Husky Farm Equipment in Alma, Ontario and also serves as a safety advocate, including as secretary with the Wellington County Farm and Home Safety Association. In addition to being toxic, “hydrogen sulfide usually stays close to the ground because it’s heavier than air,” says Grose. “However, when you’re pumping out liquid manure and hauling it on the field, you’re doing a lot of mixing and stirring. This causes some of the hydrogen sulfide to escape as you apply the

Beyond the dangers of hydrogen sulfide, manure applicators face the same health-related risks as anyone working outdoors in extreme hot conditions. “The heat produced by your body while working plus high outdoor temperatures makes it more likely for your body to overheat,” says Dr. Laurel Harduar Morano, associate professor at Michigan State University. “In addition to the weather, other factors that may increase the body’s likelihood of overheating include the amount of clothing a person is wearing, such as the personal protective equipment (PPE) used to keep a person safe; the workload, such as pushing a heavy wheelbarrow; prior heat-related illness, sun burns, certain medications, obesity and chronic conditions such as cardiovascular disease or diabetes, make it harder for the body to maintain the correct temperature.”

There are many medical conditions that are caused by overheating, the most dangerous of which is heat stroke. “If symptoms of heat stroke occur in someone such as confusion,

slurred speech, fainting, nausea/vomiting, rapid pulse, seizures, hot dry skin or heavy sweating, call 911 immediately, then move the person to a cool place and help lower their temperature with a cool wet cloth and/or cool bath,” says Morano. “Remove any extra clothes such as shoes, socks, or PPE and do not leave the person alone. Ice, cold towels, or fans can be used to cool the individual by being placed on the person’s head, neck, face, armpits, and groin area. Individuals can also wash their head and neck with cool water.”

Other illnesses to watch out for:

• Heat exhaustion symptoms include fatigue, irritability, thirst, dizziness, lightheadedness or heavy sweating. It can be treated the same way as heat stroke.

• Heat rash presents as clusters of red bumps on the skin, usually on the neck, upper chest and skin folds. It is treated by keeping the affected area dry – don’t apply ointments or creams.

• Heat cramps are muscle spasms or pain usually taking place in the patient’s legs, arms, or the trunk. Treat heat cramps by having them drink water – eight ounces every two minutes – and eating a snack.

• Heat syncope symptoms are fainting or

dizziness. Treat by having the affected person sit or lie down. Have them slowly drink fluids.

• Rhabdomyolysis, often called rhabdo, is a medical condition associated with heat stress and prolonged physical exertion. Rhabdo causes the rapid breakdown, rupture, and death of muscle. When muscle tissue dies, electrolytes and large proteins are released into the bloodstream. This can cause irregular heart rhythms, seizures, and damage to the kidneys. “Anyone can get rhabdo, even people in great shape,” says Morano. “Dehydration doesn’t cause it but does make it worse. To treat rhabdo, stop activity, drink liquids such as water, and seek immediate medical care – ask to be checked for rhabdo.”

Heat stress can also cause many issues that impact the safety and well-being of individuals. With heat and fatigue can come distraction – forgetting to take key safety precautions and doing important steps “out of order” such as not turning off equipment before unhooking a piece of equipment or hose connection, or chocking the wheels of a tractor parked next to a lagoon.

There are many preventive measures that manure applicators can take to protect themselves during extreme heat. Avoiding heat is “not always practical,” sayd Shutske, “and thankfully in most cases, ‘application’ will be done in a vehicle or tractor with a cab and AC. Cabs with AC will increase comfort and reduce dust exposure leading to less fatigue.”

Even in ideal locations – at the edge or corner of a lagoon, with a good breeze blowing manure away, “Having a monitor with the pumping crew is important. In situations where you are pumping from a corner or side of a storage structure and the wind is blowing right toward the pump out staff, either consider moving the equipment if possible or waiting for a change in wind direction.”

Meanwhile, drink plenty of fluids; take frequent breaks in the shade and, if possible, reschedule high-energy tasks for earlier or later in the day, says Morano. As temperature and humidity rise, so should the number of breaks. One last tip: “Use the buddy system,” says Morano. “Often it is a coworker who first notices signs of heat stress in another worker.” •

Case IH has launched a number of new farmercentric solutions, most of which were debuted at this year’s Farm Progress Show.

Farm Progress Show launches include, but are not limited to:

The new FieldOps mobile and web application allows farmers to connect, view and manage their operations while expanded API integrations allow farmers to connect with third-party providers and manage mixed fleets. Additionally, the new Connectivity Included offering eliminates subscriptions on new qualifying equipment while precision technology packages simplify the technology purchase experience.

Model Year 2025 Puma series tractors, for 185 to 260 models, have been purposefully upgraded to provide flexibility to manage row crop and livestock tasks on diversified farms. Life-simplifying features, that include builtin, subscription-free tech, a new powershift transmission option, a factory-fit quick hitch, and a quiet cab, give the new Puma greater connectivity, power and comfort.

The Patriot 50 series sprayer and Trident 5550 combination applicator from Case IH offer more efficiency and accuracy with advanced technology to keep operators connected, informed and in control. For Model Year 2025, the Patriot 50 series sprayer and the Trident 5550 combination applicator include a new all-aluminum boom with factory-installed Boom Recirculation, increasing efficiency and chemical use.

For Model Year 2025, the Trident 5550 combination applicator also includes a new Dry Hi-Flow option, boosting productivity with higher product output and increased hydraulic flow

Vogelsang has recently launched the EP series, a line of positive displacement pumps designed specifically around the typical requirements of industrial pumping applications.

The EP series handles extreme conditions and constant high pressures. A heavy-duty gearbox allows for a uniform pressure output of up to 260 psi (18 bar). The pumps of the EP series consist of a one-piece housing that can reliably pump abrasive, chemically aggressive and explosive flow media at temperatures of up to 392° F (200° C). Helical gears in the gearbox ensure smooth performance and reduce noise emissions. Pulsation-free conveying reduces wear on the adjacent pipeline while providing a low-shear pumping action.

Vogelsang has additionally equipped its EP series with an AirGap for high operational reliability. The AirGap atmospherically separates the gearbox and pump chamber, ensuring that in the event of a leak, the liquid will drain off to the outside rather than leaking into the gearbox. The AirGap also protects the gearbox when pumping high-temperature media.

Vogelsang has worked with well-known manufacturers to develop two new kinds of sealing systems that allow EP series pumps to be used in demanding environments. The new seals increase the reliability of the pumping process and help to ensure maximum uptime.

Additionally, the manufacturer has officially launched its Split Separator in the U.S. The separator was showcased at the recent North American Manure Expo through Skinner Ag, a partner of Vogelsang.

The XSplit is a separator solution that transforms manure into material for bedding, boosting overall efficiency by separating liquids from solids using a screw press separator approach. The XSplit incorporates a high-quality elastomer sealing disc at the end of the pressing area to achieve a dry matter content of up to 40 percent. Another key innovation is the positioning of the gear reducer behind the solid matter outlet, thereby eliminating the need for an additional shaft seal. This design ensures liquid manure may never come into contact with the motor, gear reduction, seals or bearings.

Various sieve variants are also available to suit different media and consistencies, guaranteeing reliable separation results.

Firestone Ag has introduced the new Bridgestone tractor tires to the U.S. and Canadian markets, currently available as of Sept. 1.

The lineup consists of three tire models, all of which feature the brand’s triple-defense rubber compound, which is engineered to resist wear, protect against stubble and enhance durability. The design maximizes traction and minimizes soil disturbance and energy loss caused by tire slip, helping farmers reduce fuel costs. The models are:

• The VX-Tractor tire, available in 28” to 34” front sizes and 38” to 42” rears. It is engineered for operations that require frequent roading.

• The VT-Tractor tire, available in 30” to 34” front and 38” to 42” rear sizes. A high-horsepower tire, the VT is designed to help farmers optimize yield while protecting their soil by reducing compaction.

• The VX-R Tractor tire is a ride tread pattern available in 24” front and 30” and 34” rear sizes. The tire is designed for tractors of 135 horsepower or less.

CHRYSEID MODDERMAN | University of Minnesota Extension

Carol Bishop Hipps spoke of fall as “…the mellow, messy, leaf-kicking, perfect pause between the opposing miseries of summer and winter.” Personally, I think she should have added “manure-slinging” to her list of fall descriptors. Here are some reminders on best practices to make accurate applications and avoid nutrient loss.

• Sample your manure and get it tested. Manure is a variable product so knowing the actual nutrients (not “book values”) in the manure is important for accurate application.

• Soil sample. While we’re on the subject of nutrient analysis sampling, you will also need to have a recent analysis of your soil. The soil test tells you what nutrients are needed, while the manure test tells you how much of the nutrients you have. Both are an essential piece of the accurate application puzzle.

• Nitrogen calculations can be tricky. Did you know that not all of the total nitrogen in manure is plant-available in the first year? Manure provides two forms of nitrogen: the inorganic N (immediately plant-available), and the organic N (not immediately plant-available). The organic fraction will need some time to break down (called mineralization) to become usable by the plant.

need. When applying at a N-based rate, most manure supplies too much P for the plant to use, causing it to build up in the soil over time. Instead, if your soil test shows high P levels already, consider applying at a P-based rate. That means looking at how much P your plants will need, and applying at a rate that provides that amount of P.

• Wait for cool (<50oF) soils to apply manure. When applying manure in the fall, you’ve got a long wait until spring for a crop to use those valuable nutrients; and you want those nutrients to stay put in the soil and wait patiently. Nitrogen, unfortunately, has a knack for escaping into the environment, and nitrate is the most mobile form of nitrogen. Manure doesn’t contain significant amounts of nitrate, but the ammonium in manure (the plantavailable form) can convert to nitrate through a process called nitrification.

When calculating a nitrogen-based application rate, use the total nitrogen multiplied by the availability factor. You can find the availability factor at your local extension manure webpage.

• Don’t forget to credit all nitrogen sources. Was last year’s crop a legume? Was manure applied last year? Does your irrigation water contain nitrogen? Will you use a commercial starter fertilizer that contains N at planting? If you answered “yes” to any of those, you need to subtract that N in your rate calculations for this year.

• Avoid phosphorus buildup in your soils. Excess phosphorus in soil can lead to runoff and phosphorus pollution. To avoid P buildup, don’t blindly apply based on how much nitrogen you

Nitrate is easily lost through leaching and denitrification (lost as a gas), so we would like to keep manure nitrogen in the ammonium form, and not let it convert to nitrate. As long as the manure is incorporated into the soil, most of the ammonium will stay where you put it. How do we avoid this dreaded nitrification process? Apply to cool soils. Nitrification happens rapidly at high temperatures, but slows with cooler temps. Therefore, we recommend waiting until soils are 50oF or cooler to apply manure. Note that nitrification is not halted at cool temperatures, just slowed. Even around freezing, the process continues very slowly.

• Don’t apply when runoff is likely. Do not apply manure right before a big rainstorm or onto frozen or snowcovered soil. Check the forecast and keep an eye on your soil saturation.

• Incorporate manure into the soil. When there is not a crop to take up nitrogen, incorporating manure into the soil immediately after application is important for avoiding nitrogen loss to the atmosphere as a gas through a process called volatilization. If manure is left on the surface, nearly all of the immediately-plantavailable nitrogen (ammonium) will be lost, though organic N will remain. •

A brighter road ahead requires a change agent.

In this case, it’s cows.

Dairy farmers put up with a lot of cow… well, let’s just say “waste.” But there’s no reason for all that waste to go to waste, especially when you can turn it into sustainable fuel instead. Clean Energy is North America’s leading provider of renewable natural gas (RNG) for transportation. We’re actively developing production facilities at dairies nationwide which will drastically reduce greenhouse gas emissions while also generating an additional revenue stream for farmers. Now that’s real change.