SEPTEMBER/OCTOBER 2011

Wisconsin hopes for cleaner lakes with Cow Power investments

Dane County, Wis., hopes for cleaner lakes with Cow Power investments.

Compost offers sustainable solution

Si-Ellen Farms spends a decade creating an ideal manure management system for its 10,000 animals.

September/October 2011

Volume 9 • No. 5

Published by:

Annex Publishing & Printing Inc.

P.O. Box 530 Simcoe, Ontario N3Y 4N5

Editor

Margaret Land • (519) 429-5190, (888) 599-2228, ext 269 mland@annexweb.com

Contributing Editors

Robert Burns, Don Comis, Tony Kryzanowski, Diane Mettler

Advertising Manager

Sharon Kauk • (519) 429-5189, (888) 599-2228, ext 242 skauk@annexweb.com

Sales Assistant

Mary Burnie • (519) 429-5175, (888) 599-2228, ext 234 mburnie@annexweb.com

Production Artist Kate Patchell

VP Production/Group Publisher Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: kthomson@annexweb.com

Printed in Canada

Circulation

e-mail: kthomson@annexweb.com

Tel: 866-790-6070 ext. 211

Fax: 877-624-1940

Mail: P.O. Box 530

Simcoe, ON N3Y 4N5

Subscription Rates

Canadian Subscriptions

$35.24 Cdn, one year (with GST $37.00, with HST/QST $39.82)

U.S. Subscriptions: $47.00 USD, one year

Occasionally, Manure Manager will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher's written permission. ©2011 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher's approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Website: www.manuremanager.com

By Todd Janzen

I recently came upon this article written by Todd Janzen, “a Kansas farm boy” who is now a practicing attorney with Plews, Shadley, Racher & Braun in Indianapolis, Ind. He does such a great job explaining the issue and its importance to farmers, I thought I’d use it for a Guest Editorial for Manure Manager. If you want to read more by Todd, visit his blog at www.janzenlaw.blogspot.com. – Margaret Land.

Afew years ago i wrote an article about whether a livestock farmer would be insured under his (or her) general liability policy if he were faced with a lawsuit alleging injury or damage caused by “manure.” the potential problem for the farmer is that his insurance policy likely contains a “pollution exclusion” that attempts to exclude claims involving “pollutants” that would otherwise be covered. in my prior article, titled Is Manure a Pollutant?, i explained how this issue might arise:

a typical [commercial general liability] policy contains an exclusion for claims “arising out of the actual, alleged or threatened discharge, seepage, migration, dispersal, release or escape of ‘pollutants.’”

Pollutant is typically defined as “any solid, liquid, gaseous or thermal irritant or contaminant, including smoke, vapor, soot, fumes, acids, alkalis, chemicals and waste. Waste includes materials to be recycled, reconditioned, or reclaimed.” manure is generally not a specifically listed pollutant. Whether it falls within or outside of a pollution exclusion is a legal matter for a court to determine. i concluded back then, based upon a long line of cases holding that industrial, commercial and household wastes were not “pollutants” under common pollution exclusions, that indiana’s appellate courts would likely conclude that “manure” was not a “pollutant.” although there was no case in point, the arkansas Supreme Court had determined that human septic waste was not included in the definition of “pollutants” in minerva enterprises, inc. v. Bituminous Coal Corp., 851 S.W.2d 403 (ark. 1993).

in minerva, a tenant sued his mobile home park owner after returning to his home to find that a defective septic system had caused an overflow of sewage into his home. the park owner’s insurance carrier refused to provide defense and indemnity because of a pollution exclusion. the arkansas Supreme Court disagreed, finding the pollution exclusion to be ambiguous. the court held that the pollution exclusion was intended to exclude industrial wastes, not household wastes. moreover, “the pollution exclusion was never intended to cover those who are not active polluters but had merely caused isolated damage by something that could otherwise be classified as a ‘contaminant’ or ‘waste.’”

the minerva court declined to apply the pollution exclusion to septic waste. recently, the delaware Superior Court was asked to decide whether “manure” was excluded from coverage under a number of different insurance policies’ pollution exclusions. in tyson foods v. allstate insurance Company, tyson foods was faced with complaints that its poultry manure handling practices caused property damage to the illinois river Watershed and bodily injury to certain individuals living nearby. tyson foods’ insurers denied coverage for these claims, citing the “pollution exclusions” in various policies. on aug. 31, 2011, the delaware Superior Court disagreed. applying arkansas law, it held that, based upon minerva and cases that followed, the pollution exclusions were ambiguous and therefore did not obviously exclude the alleged damage caused by tyson foods’ poultry waste applications. the court ordered the insurers to provide a legal defense to tyson foods against the allegations of property damage and bodily injury. this is a significant victory for tyson foods as its insurers will now be required to provide it with a legal defense against the allegations. this case should be a lesson to livestock farmers to check their insurance policies for pollution exclusions that an insurer might assert to exclude coverage for manure-related incidents. the case also teaches that a policyholder may challenge an insurer’s denial of coverage and ask a court to resolve the dispute.

The AgriInvest program helps you manage small income declines on your farm. Each year, you can make a deposit into an AgriInvest account, and receive a matching contribution from federal, provincial and territorial governments. You can then withdraw the funds when you need them the most.

To participate in AgriInvest for 2010 you must:

• submit your 2010 AgriInvest form;

• open an AgriInvest account at a participating financial institution of your choice (if you haven’t already); and

• make your deposit to your AgriInvest account at your financial institution by the deadline shown on your AgriInvest Deposit Notice.

Application deadline for 2010 is September 30, 2011.

Please note: If you miss the deadline, you can still submit the form until December 31, 2011. However, the amount used to calculate your maximum deposit will be reduced by 5% for each month (or each part of the month) past the due date of your application.

For more information, call 1-866-367-8506 or visit www.agr.gc.ca/agriinvest.

Le Programme Agri-investissement vous aide à gérer la légère baisse de revenu de votre exploitation agricole. Chaque année, vous pouvez déposer un montant dans votre compte Agri-investissement et ainsi recevoir une contribution de contrepartie des gouvernements fédéral, provinciaux et territoriaux. De cette façon, vous pouvez retirer les fonds lorsque vous en avez le plus besoin.

Afin de participer au Programme Agri-investissement 2010, vous devez :

• soumettre votre formulaire Agri-investissement 2010;

• ouvrir un compte Agri-investissement dans l’institution financière participante de votre choix (si vous en n'avez pas déjà un);

• faire un dépôten respectant la date d’échéance indiquée sur votre avis de dépôt Agri-investissement.

La date limite de présentation des demandes de 2010 est le 30 septembre 2011.

Remarque : Si vous dépassez la date limite, vous avez quand même jusqu’au 31 décembre 2011pour soumettre le formulaire. Cependant,pour chaque mois (ou chaque partie du mois) de retard à soumettre votre demande,le montant utilisé pour calculer votre dépôt maximal sera réduit de 5 %.

Pour obtenir de plus amples renseignements, composez le 1-866-367-8506 ou visitezle www.agr.gc.ca/agriinvestissement.

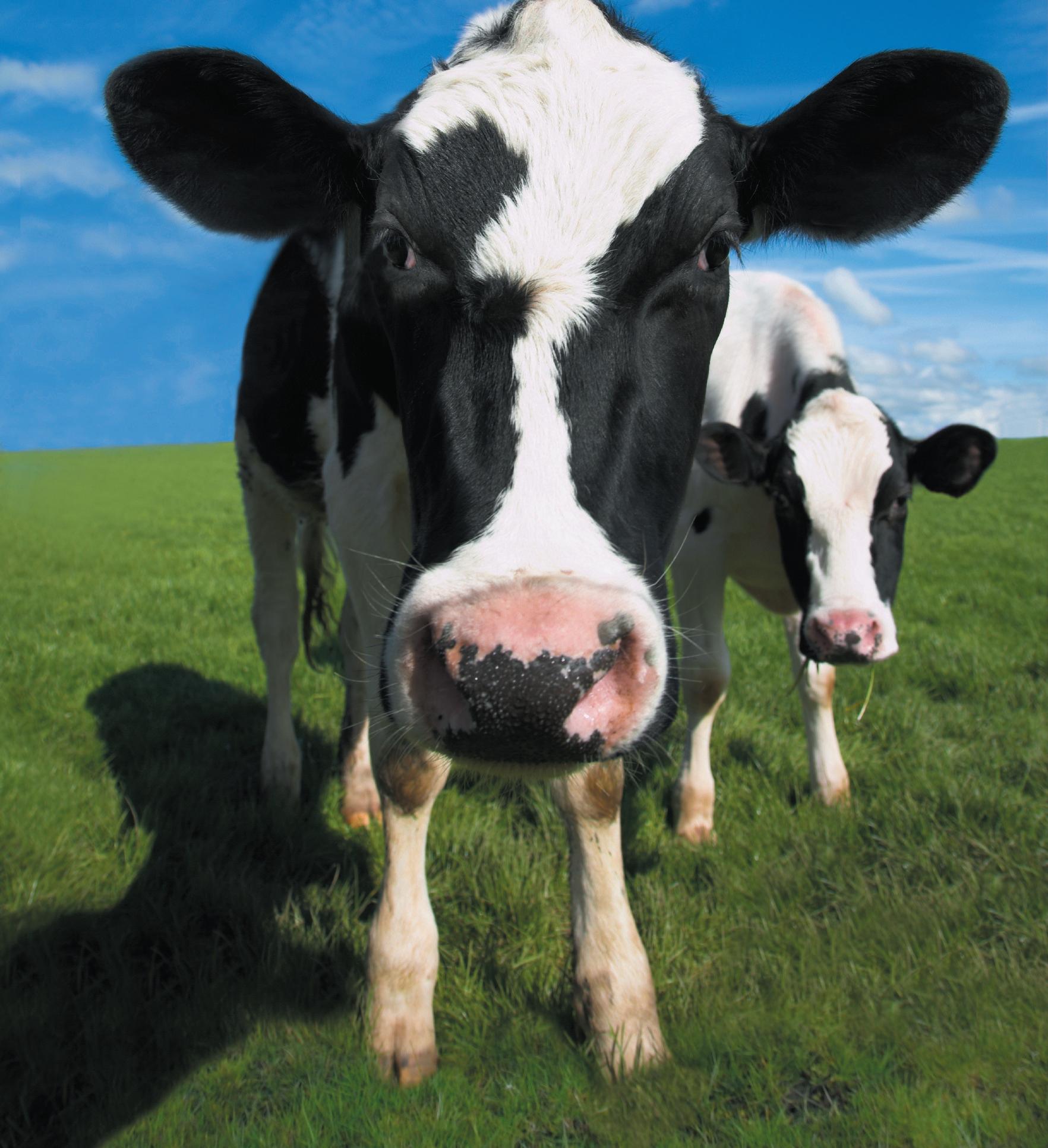

By Tony Kryzanowski

It only takes one look at the foam cheese heads among fans at a green Bay Packers game to realize how proud Wisconsin is of its dairy industry. now, it can take pride in something else – how it is trying to responsibly manage the waste generated by that industry.

Power production has just started at d ane County’s new “Cow Power” facility, where three million gallons of liquid manure from three dairies is gathered in one location and processed through an anaerobic digester operated by Clear h orizons llC. the biogas captured by the anaerobic digestion process is burned as fuel to generate power. the power generated from this facility will produce about $2 million worth per year of electricity and enough power for 2,500 homes.

this is the second facility built and operated by Clear horizons in the

state, but the first that combines liquid manure from three dairies. in addition to treating the liquid manure from three dairies, the $12 million facility also uses cutting-edge phosphorus removal technology. it removes 60 to 70 percent of the phosphorus in the nutrient-rich liquid stream coming from the digester, which is piped back to the dairies for their use in irrigating cropland. this was a major driver behind the construction of the facility, as a number of Wisconsin residents were concerned with how runoff from raw manure applied on cropland was influencing the health of local lakes and rivers – particularly the Yahara Chain of lakes that includes the lake mendota watershed. Phosphorus in the manure is believed to be the leading cause of algae and weed growth in dane County’s lakes.

the State of Wisconsin made a $3.3 million contribution to the installation of the Centrisys centrifuge separation technology that removes phosphorus from the liquid stream. the same amount has been approved for a second Cow Power facility planned for Springfield township, with construction expected to start in spring, 2012.

“the Centrisys system has

operated very well,” says Clear horizons representative leo maney. “it is one of the things we are most pleased with at the dane County digester. their equipment has operated the best, and they have been very supportive of us. this is one of their first ventures into the manure waste energy market.”

he adds that at this point, the facility is meeting and exceeding the amount of phosphorus removed as required by Wisconsin’s department of natural resources. the contribution from the state also was a major contributor to the economic viability of the project.

“ o ur Cow Power project is a victory for family dairy farms and our lakes,” says dairy farmer Chuck r ipp, one of the three farmers that have signed up to supply the d ane County digester.

“a griculture can help to keep our lakes blue while creating green energy that will help sustain d ane County’s important economy.” i n addition to improving the quality of local streams

Power produced from biogas captured from these three Dane County, Wis., digesters will produce $2.2 million worth of power per year.

Submitted photo

and lakes and creating valuable byproducts, the air also smells a lot fresher around the three dairy farms participating in this project.

the second Cow Power facility in Springfield township near middleton that will involve the gathering of liquid manure from four dairy farms and processing through an anaerobic digester is awaiting final approval from dane County. Clear horizons will also construct and operate that facility.

to put the importance and influence of the dairy industry in dane County into perspective, county executive Kathleen falk says it’s a $700-million-per-year industry that employs about 4,000 people. While dairy is big business in dane County, she estimates that the 400 dairies in the county that are milking about 50,000 cows are also generating about two billion pounds of manure per year.

the county invited companies to offer a solution to solve its issue with nutrient runoff into area lakes and streams, and local company Clear horizons came out the winner. the company had several advantages going into the competition. it offered a total solution of both building and operating the facility. all the dairy farms had to do was manage and collect their liquid

manure streams in tanks located on their farms to the company’s standards, and Clear horizons took care of the rest, including the construction of pipelines from the on-farm collection tanks to the centralized anaerobic digester. the liquid manure is stored in a holding tank at the digester location prior to processing. the participating dairy farms can also truck more solid manure to the facility where it is ground and agitated into the Clear horizons holding tank. the company also had an edge in the competition because it already had the experience of building and operating an anaerobic digester and biogas power plant at Wisconsin’s Crave Brothers dairy.

maney says that having the opportunity to build and operate the dane County facility was tremendously beneficial for the company. it gave them the experience of not only designing, building and operating a powergeneration facility from a single dairy, but now gathering manure from a number of dairies at an anaerobic digester and biogas power plant in a central location. the dane County digester is also about one-third larger than the Crave Brothers dairy digester, and consists of three digestion tanks. in addition to size, another major difference between

the dane County and Crave Brothers installations is where the equipment came from. Because europe is more advanced in its development of power generation from biogas, a lot of the technology used at Crave Brothers came from germany, which presented its own challenges from a language and time zone perspective. Clear horizons made a conscious effort to “buy american” for the dane County facility, which not only supported the local economy but also made the facility easier to install and service.

the challenge for Clear horizons as it relates to using the biogas to generate and market the power is on the operational end, as it has considerable technical experience and resources to design and build these facilities. operating them is a relatively new venture, and maney explains just how challenging a task it can be. in the case of working with a number of dairy farms that provide liquid manure to a central location, firstly they must all be within reasonable proximity to a centralized anaerobic digester for the project to make sense. then there are the agreements that must be put in place for a project to proceed. this includes long-term agreements with individual dairy farms to ensure a steady supply of raw material,

as well as with power purchasers such as alliant energy, which has agreed to purchase the power generated by the dane County Cow Power facility. failure to reach accord on any one of about 10 agreements required per facility will bring the project to a standstill. also, in the case of several dairies supplying one facility, the dairies have to be practically within view of the centralized digester for the piping of the liquid manure to the facility to make economic sense.

What has helped Clear horizons pursue business opportunities in the state is the objective Wisconsin has set for each conventional power provider to deliver a set percentage of its power from alternative energy. the challenge, says maney, is to have legislators treat power generation from biogas with the same attractive power rates that are offered to the solar and wind industries.

Clear horizons derives its income from a variety of byproducts generated by the anaerobic digestion process, which generates gas, liquid and solid byproducts. the gas is burned to generate power. the nutrient-rich liquid is piped back to the farms for use in crop irrigation. a portion of the solid byproduct, which is converted into compost is sold back to the dairy farmers as bedding. the remainder is sold to a fertilizer company.

the raw manure is agitated within the anaerobic digester tanks to encourage the biological anaerobic process that produces the biogas that rises to the top of each tank, where it is piped to the gas clean-up system and then burned in a ge Jenbacher power generator. the manure stays in the tank for 20 to 30 days and then is pumped from the tank into the Centrisys centrifuge separator where

Feeding cows natural plant extracts can reduce odors, feed costs

With citizens’ groups seeking government regulation of foul-smelling ammonia emissions from large dairy farms, scientists report that adding natural plant extracts to cow feed can reduce levels of the gas by one-third while reducing the need to fortify cow feed with expensive protein supplements.

they reported recently in d enver, Col., at the 242nd n ational m eeting and e xposition of the a merican Chemical Society ( a CS).

d r. J. m ark Powell described the results of three studies undertaken to determine how adding plant substances called tannins to cow feed affects the emission of ammonia from dairy barn floors and farm fields fertilized with mixtures of cow manure and urine.

“ for dairy farms, cow urine is the source of the ammonia emission problem,” said d r. Powell, who is with the u .S. d epartment of a griculture ( u S da ) a gricultural r esearch Service ( ar S). “ d airy cows excrete large amounts of urine, about 3.5 gallons daily for each cow. that’s almost 1,300 gallons per year. a nd there are about 10 million dairy cows in the u nited States alone. Cows usually are fed a high-protein diet, and they produce various nitrogen compounds when they digest protein. they release the excess nitrogen mainly in their urine, and enzymes convert it into ammonia.”

ammonia has an acrid, eye-tearing odor and has potential adverse health effects on both cows and humans. Citizens’ groups several months ago petitioned the u.S. environmental Protection agency (e Pa) to begin regulating ammonia under the Clean air act, intensifying the search for practical, inexpensive ways to reduce emissions of the noxious gas. Besides its pungent odor, ammonia adds to air pollution, forming particles that travel long distances and contribute to environmental issues such as smog, acid rain and nutrient pollution.

the liquids are separated from the solids and most of the phosphorus is removed from the liquid stream. the liquids are transported back to lagoons on the dairy farms where they are used for irrigation. the solids proceed into either a drying or composting operation.

maney says the anaerobic digestion mix includes the addition of various fats, oils and grease substrates, mostly from restaurants, to improve biogas production. this may in fact represent an additional future income stream for the company, as it can charge tipping fees to accept this material.

he concludes that the Clear horizons business model of building and operating anaerobic digesters and biogas power plants, which is rather unique within the biogas power generation sector of the alternative energy industry, is working well for the company and is profitable.

the ammonia problem originates with the nitrogenrich protein in cow feed. Cows’ digestive systems are inefficient, and barely one-third of the nitrogen in their feed ends up in milk. the rest exits in urine and feces. the nitrogen in urine is in the form of urea, and enzymes contained in cow manure on the barn floor quickly convert it into ammonia gas.

tannins apparently reduce urea production by allowing more protein to escape digestion in the stomach and enter the cow’s intestines, where it’s used to produce milk protein.

d r. Powell began investigating tannins in animal feed 20 years ago in West a frican communities where he lived and worked. tannin-rich shrubs were grown as windbreaks to reduce soil erosion and to feed livestock. tannins also are a key part of the diets of cattle, sheep and goats in tropical areas where vegetation tends to be naturally higher in the astringent plant chemicals. h owever, tannins have attracted relatively little attention elsewhere, d r. Powell said.

h e hopes the addition of tannins to animal feed will become much more widespread in light of the findings about their potential for curbing ammonia emissions. the tannin extracts used in the studies are already approved for animal feed and would cost only a few cents a day, he said. tannins are perhaps best known for their use in tanning leather, and the quebracho and chestnut trees are sources for both leather tanning and cattle feed. d r. Powell said that it may be possible to produce synthetic tannins at a lower cost.

next on dr. Powell’s agenda is research to determine whether tannins also can reduce emissions of methane gas from cattle production. about 25 percent of methane emissions in the united States are from enteric fermentation (mostly belches) of domestic cattle.

By Diane Mettler

Si-ellen farms spends a decade creating an ideal manure management system for its 10,000 animals

Si-ellen farms has been dealing with growing pains and manure management issues for more than 15 years. they feel only now do they have the ideal program in place.

in the mid-1990s, Si-ellen farms was several farms in Washington State. urban sprawl has caused owner and C eo mike roth to consider moving the operation. after much looking, they found a perfect location – Jerome, idaho. the land was back from the road and on a slope with southern exposure.

a new dairy was designed and built and the Washington dairies consolidated there.

“for the first time they were dealing with 2,000 milk cows,” says operations manager david mezes, who has been with Si-ellen farms for 23 years and oversaw the construction.

The first system

the original 2,000 cows was a big operation for the roth family at the time and they brought in an engineering firm from oregon to install a separator and flush system.

“We went to quite a bit of expense, but it only lasted two or three years,” says mezes. “it was too high maintenance, so we pulled it all out and went to triple slope screens and settling ponds – a more conventional separator system.”

Current system today, the farm houses 10,000 animals –6,500 milk cows and the rest heifers. and on 7,809 acres, they grow all the corn silage and about one-third of the alfalfa needed.

the flush system is fairly simple. Being on a southern slope, the manure flushes down to the open ditches that run along

The flush system at Si-Ellen Farms is fairly simple. Being on a southern slope, the manure flushes down to the open ditches that run along the back of the corrals and to pumping stations. Contributed photo

the back of the corrals and to pumping stations. using houle pumps, the slurry is pumped to a central pumping station.

“We use a lot of houle pumps,” says mezes. “We’re hard on pumps and they are easy to maintain. they’re made of steel that we can weld and they’re not highly expensive. We also use u.S. farms Systems — its the sister company. they have a very similar pump set up and it works quite good as well.”

from that central pumping station there are three slope screen separators built approximately 14 feet high. the solids pile under the screens and there is room for the farm’s volvo loaders to drive in and remove the piles without touching the screens.

the screens remove about 25 percent of the largest solids. the sand and very fine debris go through the screens and then on to a series of small settling ponds, which are 50 feet long, 20 feet wide and only eight inches deep.

“ every day we take a small tractor and scrape out the wet, small sludge and sand mixture from these little settling ponds. i t’s mixed with the straw

bedding from the calving operation, which is fairly clean. n either the manure from the separators nor the straw will compost on their own but, mixed together, they create a great composting ratio,” says m ezes.

the solids from the settling ponds and the slope screens along with the straw are trucked to a couple of 200foot by 200-foot concrete slabs, where they are mixed. they are mixed on slabs because of the high liquid content — up to 80 percent. Because of the amount of liquid, the slabs have a one percent grade back to a catch area.

the liquids that flow from the settling ponds move on to larger (40-feet-wide, three-feet-deep and 200-feet-long) ponds. “these ponds are cleaned in much the same fashion as the others, except we clean them twice a week” says mezes. “We have a specially modified bucket on the loader so we can drag that product out onto a concrete area for mixing.”

At the compost site once the straw and the manure are mixed for composting, the material is trucked

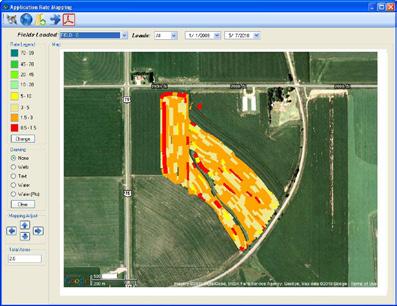

Trimble’s EZ-Guide 250 and EZ-Guide 500 lightbars can now provide record-keeping, tracking and feature mapping of your liquid and dry manure applications. Combine this new technology with Trimble’s proven guidance capability in order to more easily fulfill EPA and DNR manure handling record-keeping requirements. Increase efficiency by using colorful on-screen maps to eliminate gaps or overlaps, and avoid restricted application zones or tile lines. To find a Trimble dealer, visit www.trimble.com/agriculture or call 800-865-7438. Trimble

The screens remove about 25 percent of the largest solids. The sand and very fine debris go through the screens and then on to a series of small settling ponds. Contributed photo

approximately half a mile away, where it is placed in rows approximately eight feet wide and six feet tall.

“once it’s rowed, we use a 416 Wildcat with a large roller to turn it,” says mezes. “it has its own engine, but we pull it with a tractor. it’s fairly aggressive. it takes something like 250 horsepower to turn the rotor in this machine, which turns the rows inside out.”

in the winter, the rows aren’t turned but during the spring and summer, they’re turned once a week for four to six weeks. during that time, the rows lose about 60

The liquids are stored in large storage lagoons until the crops are in, then irrigated onto the fields through several miles of pipeline. Contributed photo

percent of the volume. When the rows are about three feet tall, two rows will be moved and combined into one.

“By moving them, we get the very bottom where it’s still wet,” explains mezes. “and after we’ve combined rows, we’ll turn it once again. then it’s trucked out for the neighbors to buy or we give it to our corn growers to grow corn for us.”

Making growers happy

While some may think putting all this work into composting and then giving it away doesn’t make good financial sense,

Once the manure mixture rowed, the operation uses a 416 Wildcat with a large roller to turn it. Contributed photo

Si-ellen sees real value.

“We need a certain amount of corn silage from our neighbors, because we don’t have enough land to do it all,” says m ezes. “We pay them for the corn, the compost is an extra benefit, so they don’t go and sell the corn to other dairies. Plus we have a lot of this compost – 100,000 tons a year. there is a need to use it up and our neighbors’ ground is very good because it’s not too far from the dairy.”

normally, Si-ellen will truck the compost within a 10-mile radius, but

it’s not uncommon to drive as far as 20 miles. and mezes says the compost is a good product to truck – versus something like liquid manure – because it’s dry and doesn’t smell. “the average person wouldn’t be able to tell it from dirt,” he says.

of course, some of the compost is used on their own fields. the compost supplies all the fertilizer needed for the alfalfa, but the corn requires some additional nitrogen.

“the fertilizer bill for a big farm can be in the hundreds of thousands, and our compost cuts down two-thirds of that cost,” says mezes. “it’s a substantial amount of money. But it probably works out fairly even because by the time you consider all the trucking involved and everything, it’s still not free.”

Si-ellen chose going the composting route after looking at other dairies and their success.

the operations manager’s education has come from a variety of courses, seminars and asking advice from other commercial composters.

“it’s also been a bit of trial and error over the years to get to the system we have now – understanding the carbon ratios and the timing and the weather.”

Si-ellen employs about 200 people, of which about a dozen work solely on composting “We run about six trucks, two loaders, a tractor, and composting machine that are directly related to composting and then we have more support people in semi trucks carrying the compost away to the fields.”

The leftover liquid

h andling the solids and creating the compost is only half the battle — there are still the liquids to deal with. they are stored in large storage lagoons until the crops are in. then the liquid is irrigated onto the fields through several miles of pipeline.

“We can’t put it on too thick, so we try to dilute it down to about 20 percent with the irrigation water,” says mezes. “then we spread it on our crops through the pivot system. We have elaborate systems with a complete manure line system underneath the freshwater system, so the manure water doesn’t actually ever get into the irrigation water. Zero contamination.” in short, they have dual irrigation systems covering more than 800 acres.

Then and now Si-ellen hasn’t changed in that it continues to grow. in addition to this

In

Once the straw and the manure are mixed for composting, the material is trucked approximately half a mile away, where it is placed in rows approximately eight feet wide and six feet tall. Contributed photo

dairy, Si-ellen has another dairy with approximately 3,000 cows and nearly as many heifers, about 10 miles away. “We do very much a similar process there,” says mezes. “So the total number of animals we’re dealing with is at least 20,000 head.”

Before composting, wet manure was a challenge and mezes says they didn’t have a sustainable long-term plan without spreading it on nearby fields. “Composting, and reducing the volume and moisture, has allowed us to do more economical trucking so it’s going the needed distance,” says mezes. “Plus it’s cleaner and smells better and there are very low bacteria and pathogens, in well-

made compost.”

the wastewater too had been a constant challenge, and because of an elaborate – and also expensive – system it’s clean enough to move without clogging up pipelines.

mezes is proud to say that the farm has finally developed a composting and water system on a big enough scale to handle its volume. “it’s no longer a constant headache. But it’s taken a long time to develop it.

“according to the banks, we are not the most profitable dairy. We put a lot of money back into the farm,” says mezes. “But when people come here they say, ‘What a clean, wonderful dairy!’”

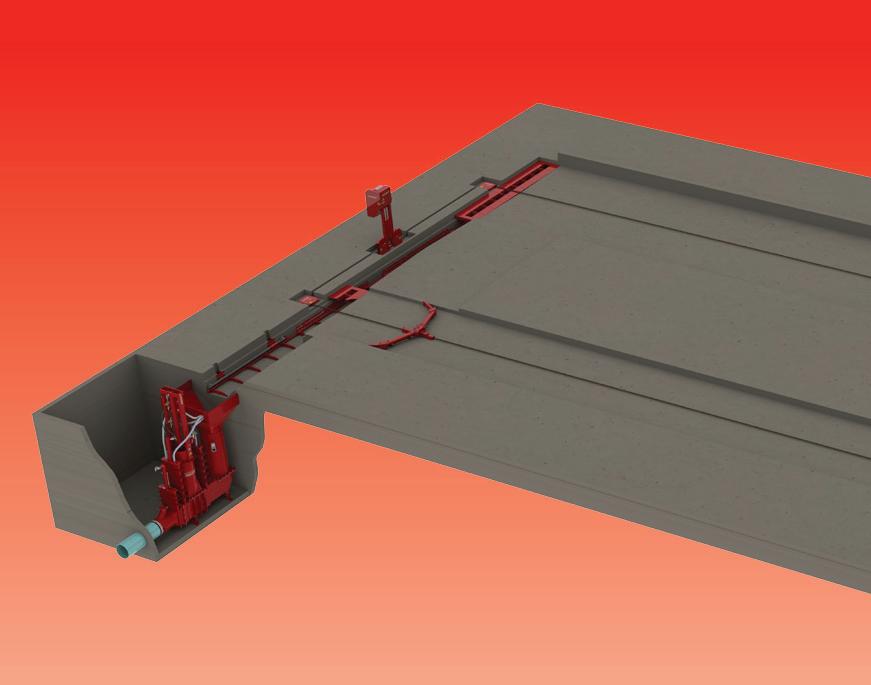

GUTTER-CAT

B-15/16 CROSS CLEANER

B-15/16 CHAIN SCRAPER

LIQUI-TRANS PISTON PUMP

FLUSH-FLUME SYSTEM SOLID-TRANS PISTON PUMP SEMI-TRANS PISTON PUMP

VERTICAL PUMPS

DURA-CHAIN SCRAPER

LIQUII-T PISTO OR

PROP AGITATOR MECHANICAL PISTON PUMP

JAMESWAY FARM EQUIPMENT, INC. FACTORY: St. Francois-Xavier (Quebec) USA WAREHOUSE: Tomah, WI PHONE: 819-845-7824

ULTRA-PUMP 3PH PUMPS & PROPS

PTO PUMPS ULTRA-PUMP TRAILER LAGOON

XD-SERIES CABLE SCRAPERS

The discovery that a bacterial species in the australian tammar wallaby gut is responsible for keeping the animal’s methane emissions relatively low suggests a potential new strategy may exist to try to reduce methane emissions from livestock, according to a new study.

globally, livestock are the largest source of methane from human-related activities, and the third-largest source of this greenhouse gas in the united States, according to the u.S. environmental Protection agency.

Wallabies and other marsupials –mammals such as the kangaroo that develop their offspring in a pouch – are dependent on microbes to support their digestive system, similar to livestock such as cows, sheep and goats, but tammar wallabies are known to release about 80 percent less methane gas per unit of digestible energy intake than do livestock animals.

Scientists have used dna sequence data to devise a way to isolate and grow

cultures of a dominant bacterial species from the tammar wallaby gut and test its characteristics. the analysis confirmed that this bacterium would contribute to a digestion process that produces low levels of methane. using this information, scientists hope to devise a way to augment the microbial mix in livestock animals’ digestive systems and therefore reduce their methane emissions.

an added bonus for the wallabies, the researchers say, is that the presence of this bacterium frees up more digestible energy for nutritional purposes in host animals. the energy the fermentation process uses to produce methane gas during digestion actually robs animals of some of the nutritional quality of their food.

“our long-term goals are really to improve nutrient retention by livestock, and reducing methane emissions is just one area where we seek to have a positive impact, both on animal productivity and the environment,” said mark morrison, senior author of the study and a professor

of animal sciences at ohio State university. morrison is also the science leader in metagenomics for CS iro (Commonwealth Scientific and industrial research organization) division of livestock industries based in Brisbane, australia. the study is in press in the journal Science.

marsupials are often considered similar to ruminants – a class of mammals that have multiple compartments, including one called a rumen, in their stomachs – because both groups have a digestive system that supports a “pre-digestion” of food by microbes, to process their plant-based diets. and this process, which includes a period of fermentation to break down the foods and release nutrients, causes the animals to discharge methane gas.

over time, however, researchers have noted that tammar wallabies, in particular, produce only about a fifth of the amount of methane produced by livestock ruminants as a result of differences in anatomy and microbial compositions in their guts.

early research in this area showed that methane emissions from tammar wallabies amount to one to two percent of their digestible energy intake, compared to methane emissions of roughly 10 percent of digestible energy intake in sheep. in addition, marsupial and ruminant gut anatomies differ, which influences how quickly food moves through the digestive system.

morrison and his colleagues at CS iro and the university of queensland have previously shown that marsupials have fewer methane-producing microbes in their guts than do ruminants, and that certain bacteria in marsupial guts might use up hydrogen and carbon dioxide that normally would be used by methaneproducing microbes to grow.

last year, morrison and colleagues reported that there were key bacterial and enzyme-based differences between the gut contents of tammar wallabies and other herbivores, including cows. the scientists are employing metagenomics, the application of dna sequencing of organisms and computational methods to study entire communities of microbes. from that complex microbial community of roughly 500 bacterial species in the tammar wallaby gut, the researchers determined that one of the dominant bacteria there belonged to the Succinivibrionaceae family. the researchers were able to isolate and grow this bacterium, called Wg-1, in culture to test and confirm its properties. it produces succinate as a main end product of fermentation – not one of the usual end products associated with higher methane production.

“there are also Succinivibrionaceae in the rumen; however, there has not been a lot of focus on those bacteria, especially from the context that they might contribute in any way to a reduction in methane production,” morrison said. “our findings with the tammar wallaby were a bit of a surprise, but we think they provide an important clue for how rumen fermentation might be directed away from methane formation.”

much more analysis will be needed, he noted. now that the researchers have isolated and grown Wg-1 in culture, they want to isolate bacteria in livestock digestive systems that are probable distant relatives to the wallaby bacteria. Better understanding of how these target bacteria behave should help researchers figure out how to increase their numbers and their contributions to livestock digestion, morrison said.

“We hope that in the next few years,

in addition to there being strategies that inhibit the abundance of methaneproducing microbes in livestock, we will have identified how to augment the growth of other bacteria so that feed digestion and fermentation remain optimal but also are accompanied by reduced methane emissions,” he said. this work is supported by CS iro’s office of the Chief executive (o C e) Science leader and transformational Biology Capability Platform grant programs, a CS iro o C e Postdoctoral fellowship and the u.S. department of energy Joint genome institute Community

Sequencing Program.

Co-authors of the study include Phillip Pope, Wendy Smith, Stuart denman and Chris mcSweeney of CS iro livestock industries; Susannah tringe, Kerrie Barry and Philip hugenholtz of the u.S. department of energy Joint genome institute; and alice mchardy of the max Planck institute for informatics and heinrich-heine university, düsseldorf. Pope is also affiliated with the norwegian university of life Sciences and hugenholtz is now the director of the australian Centre for ecogenomics, based at the university of queensland.

Global industry analysts inc. (gia) recently released a global report on the biogas plants market, forecasting that world biogas plants markets are expected to reach $8.98 billion by the year 2017.

Biogas is a clean gas obtained from biomass, a renewable energy resource derived from food processing wastes, sewage treatment sludge, as well as animal and human excreta. narrowing cost differential between fossil fuels-based electricity generation and biogas energy in recent years has further augmented interest in renewable resources. today, biogas competes on par with petroleumbased fuels in terms of performance, cost, and other additional benefits such as reduced greenhouse gas (ghg) emissions.

Biogas is primarily used as a fuel for cooking and lighting purposes in various countries, whereas a key motivating factor for development of liquid biofuels is to replace petroleum fuels. advances in biotechnology, molecular science and microbiology contributed to enhancements in biogas yields production, which led to the development of commercial biogas plants. Biogas plants can convert energy crops, organic industrial and municipal solid waste, and manure, into efficient fertilizer and reduce the odors associated with traditional manure management. in terms of both consumption and production of biogas, europe is ahead of the other nations mainly due to increased government regulation for environment friendly initiatives. although europe dominates biogas production, the trend is also catching up fast in countries like Japan, australia, new Zealand and the united States. the asia-Pacific biogas plants market is displaying strong appetite for growth, thanks to the continuous infrastructure development and business expansion in the region, especially in the emerging markets such as China and india. the recent worldwide economic recession has not had much impact on the global biogas plants market, as the prospects for such emerging renewable energy technology are stored for future. the growing clamor over cleaner and more environmentally friendly energy technologies is offering new market opportunities for alternative energy solutions such as biogas. however, the biogas plant market is resilient and not immune from the business cycle. recent turmoil in the global credit markets, and substantial reductions in asset

value across business enterprises and households, resulted in reduced energy requirements and difficulties in obtaining finance for biogas and other renewable energy projects. this, coupled with poorly performing foreign markets and high substrate prices that reached their peak in September 2008, scuttled all previously set targets. at the same time, the cost of natural gas delivered to electric power plants declined in 2009 to nearly half the 2008 level and that, coupled with significant expansions of pipeline capacity, had cast downward pressure on biogas prices. government stimulus packages proved to be the silver lining from the downturn in the global economy. various government policies, in terms of subsidies, incentives and investments by the biopower companies, shielded the biogas plants market from the devastating effect of the crisis.

as stated in the new market research report, europe and the u.S. account for a lion’s share of the global biogas plants market. the biogas plants market is primarily localized in europe, with germany accounting for a major share of the global production and consumption, while the united Kingdom, italy and Spain represent other significant regional markets. although the continued difficult economic scenario is a factor to consider, the industry trends bear out an optimistic assessment, as fundamental market drivers for renewable technologies continue to remain strong. innovations will continue in processes and feedstocks, while companies, government, and

academic institutions pour in funds and expertise to support research and development in the field of renewables.

Biogas has distinct advantages in comparison to other renewable energies, which provides a very strong reason to be sanguine about the future of the biogas sector. the increasing application of renewable fuels in the transport sector across the world also supports the growth of biogas industry. renewable fuels, such as biodiesel and bioethanol, demonstrate limitations in terms of reduction in greenhouse gases and resource efficiency. Biogas, prepared from byproducts of biodiesel and ethanol, and from the anaerobic digestion of energy crops and organic residues, holds an advantageous position in terms of resource efficiency and environmental perspective. Biogas can also be purified and subsequently upgraded in quality, as exhibited by natural gas for its injection into the natural gas grids.

the research report – titled Biogas Plants: a global Strategic Business report announced by global industry analysts, inc. – provides a review of market trends, issues, drivers, company profiles, mergers, acquisitions and other strategic industry activities. the single-segment report provides market estimates and projections for major geographic markets including the u.S., Japan, europe, China, india, and the rest of the world.

for more details about this market research report, visit http://www. strategyr.com/Biogas_Plants_market_ report.asp

Technician Todd Boman collects soil electrical conductivity readings as he drives through a vegetative treatment area. These values are used to generate maps illustrating nutrient distribution in the vegetative treatment area.

By Don Comis

The same precision farming techniques that work with crops can work with manure management on cattle feedlots. agricultural engineers roger eigenberg and Bryan Woodbury, and colleagues at the agricultural research Service environmental management research unit at the roman l hruska u.S. meat animal research Center in Clay Center, neb., map the distribution of manure on the surface of feedlots and the flow of liquid manure in rain runoff. this research could lead to both precision harvesting of manure and precision application of manure to crop fields, while controlling nutrient losses and gas emissions.

Agricultural engineers Roger Eigenberg (left) and Bryan Woodbury evaluate a soil electrical conductivity map of a vegetative treatment area.

the scientists map manure distribution by towing a g PS-equipped sensor on a trailer pulled by an all-terrain vehicle over feedlot pens and cropland at about six miles per hour. the sensor estimates the amount and quality of manure in various places on the feedlot surface by measuring the manure’s ability to conduct electricity.

manure contains about 5 to 10 percent salt by dry weight, which comes from salt supplements in cattle feed. Salt in solution is an excellent conductor of electricity; therefore, dissolved salt in manure and manure-amended soils increases their electrical conductivity.

eigenberg, Woodbury, and colleagues used a computer program called e Sa P –for electrical Conductivity Spatial analysis Program – to choose spots on the feedlots

and a nearby hayfield to sample soils, rather than sample randomly. the u.S. Salinity laboratory in r iverside, Calif., developed the program. eigenberg and colleagues used the program to associate high soil conductivity levels with manure solids and with the chloride in the salts found in manure.

in more recent work, Woodbury, eigenberg and colleagues found that they could also use the program to correlate high soil conductivity with nitrogen, phosphorus and the volatile fatty acids associated with manure odors.

in the earlier study, eigenberg and Woodbury compared two experimental beef cattle feedlot pens at Clay Center –each having a very different, but common, management style – and found the correlations worked well in estimating the quantity and quality of manure solids on the feedlot floor in both pens.

the soil conductivity and modeling techniques could be used to help feedlot operators recover valuable byproducts from the feedlot. for example, manure with higher nitrogen and phosphorus content could be harvested for use as fertilizer. this would have the added benefit of reducing nutrient losses, and it could identify areas prone to odors so they could be treated with improved drainage or, possibly, with antimicrobial compounds.

eigenberg and Woodbury also mapped a vegetative treatment area downslope of the Clay Center feedlot. r ain runoff from eight pens flows into a settling basin at the base of the feedlot. after the solids settle, the liquid manure flows through tubes onto a hayfield designed to capture and use manure nutrients.

the scientists could tell from the soil conductivity maps that the liquid manure was being unequally distributed. With this information, they made adjustments to the flow tubes, resulting in a more uniform distribution of the runoff and improved effectiveness of the treatment area.

“ the idea is to have more of the nitrogen and phosphorus fertilizing hay than being lost to the environment,” e igenberg says. “ this work will help improve techniques for handling manure on both feedlots and crop fields. m anure can be harvested for the greatest value possible, whether for energy or fertilizer, and used more efficiently, which should greatly reduce pollution and odors.”

Don Comis is with the Agricultural Research Service Information Staff.

By Tony Kryzanowski

Given its reputation as an environmental leader, one might expect that California would be among the first adopters of new custom manure application technologies. however, some areas are just learning about such techniques as manure injection overtakes flood irrigation on farmland.

Businesses like Perfection injection are pioneering manure injection in California’s Central valley. a couple of years ago, company owner, Bob Borba was the owner of a dairy struggling to make ends meet during the economic downturn. one of his

major expenses was hiring tanker trucks to surface apply his manure. he sat down to scope out the pros and cons of manure injection as an alternative and just couldn’t come up with a good reason dairies located in that area of northern California between fresno and Sacramento wouldn’t be interested in injection over surface applying their manure.

Why this type of manure application has not been widely practiced in the Central valley area becomes more of a mystery when one considers the intensity of agricultural production and variety of crops grown year-round in that highly fertile area. farmers will sometimes harvest as many as three crops in a single year, starting with a corn/oats forage mix

in winter from october to april, then a crop of corn that comes out in august or September, and sometimes adding a crop of sorghum as a third rotation.

“We’re very diverse out here, you know, dairy, trees, almonds, vines, everything that you can imagine except oranges,” says Borba. “in terms of our manure injection business, we’ve known that there are valuable goodies in what the cow excretes, and we have turned that into a heck of an opportunity and manure management solution.”

unlike states further north, the manure injection business is only down for a couple of months in winter when it is simply too wet. other than that, Perfection injection is open for business. among the

biggest challenges faced by the company is to overcome the ingrained practice of disposing of dairy manure through flood irrigation. however, with dairy expansions resulting in more highly concentrated manure in storage, as well as the high cost of commercial fertilizer, Borba feels it is only a matter of time before more dairymen realize the benefit of taking greater advantage of what they have in the organic fertilizer stream provided by their dairy cows.

“if you over apply on a third of your land parcels by flood irrigating and under apply on the remaining twothirds, and then have to go out and purchase commercial fertilizer, it makes no sense,” says Borba. “Why not apply it agronomically, save on the commercial fertilizer, and build up your organic matter?” he adds that by injecting the ammonia into the soil, he has been able to build up his organic matter from 1.6 percent to 2.2 percent per pound, meaning that the beneficial microbials are able to work a bit better.

injection also satisfies agencies such as the water quality and air quality boards because injection removes the potential danger of over applying by using surface flood irrigation, a process that increases

the potential for leaching. a properly injected field produces no odor.

Borba’s goal, now that he has made a significant investment in a fully equipped, hydro engineering manure injection setup, is to convince enough customers of the extra value provided by manure injection over tank spreading in this particular area and make it pay. last year, the company injected about 110 million gallons and this year it expects to do 150 million. Perfection injection works primarily for larger dairy customers, those with 200 acres or more of land surrounding their dairy operations.

Borba has first-hand experience of how much it costs to properly handle manure based on his own 1,200-head dairy farm, which is of about average size for that area of California. he conducted his own experiment of tank spreading his manure without it being worked into the soil and discovered that 70 percent of the ammonia was lost to the air after only a few days. it didn’t make sense to be paying $110 per load to have it tank spread a mile away from the dairy with that amount of potential fertilizer loss. there were also odor problems and dusty roads that resulted in a number of complaints from neighbors, not to

mention soil compaction in fields by the tanker trucks. nor was it a particularly accurate system for applying the manure where it was most needed. that prompted him to consider manure injection as an option on his own farm and as a custom manure application business for surrounding dairies.

“i was talking with a friend, alvin azevedo, who is also in the dairy business and well known for his proactive approach for managing manure. We started thinking that there has got to be a better way,” says Borba. “he showed me an advertisement with that drag hose and it was like ‘wow.’ it was just one of those ideas that we thought we had to push and i told him that if he wasn’t going to run with it, i would.” as it turned out, the opportunity dropped into Borba’s lap, and he’s now in his second year of business. he researched drag hose setups and manufacturers. it was an easy decision, he says, to go with hydro engineering, knowing that company owner tom hoffman invented the drag hose idea; with hoffman’s over 20 years of experience, Borba felt he couldn’t go wrong. What’s really helped him learn the ropes and establish good customer relations is mentoring from another custom

October 4-8, 2011

2011 World dairy expo, madison, Wisconsin, alliant energy Center. visit: www.world-dairy-expo.com

October 31-November 2, 2011

11th annual BioCycle Conference, madison, Wisconsin, madison marriott West visit: www.jgpress.com/conferences

January 18-19, 2012

minnesota Pork Congress, minneapolis Convention Center, minneapolis, minnesota. visit: www.mnpork.com

January 24-26, 2012

international Poultry expo, georgia World Congress Center, atlanta, georgia. visit: www.ipeweek12.org

January 25-26, 2012

2012 iowa Pork Congress, iowa events Center, des moines, iowa. visit: www.iowapork.org

February 14-16, 2012

2012 World ag expo, international agri-Center, tulare, California. visit: www.worldagexpo.com

February 15-18, 2012

national farm machinery Show, Kentucky exposition Center, louisville, Kentucky. visit: www.farmmachineryshow.org

February 22-24, 2012

Western united dairymen 2012 annual Convention, temecula, California. visit: www.westernuniteddairymen.com

March 13-15, 2012

2012 midwest Poultry federation Convention, Saint Paul riverCenter, Saint Paul, minnesota. visit: www.midwestpoultry.com

May 21-24, 2012

4th international animal By-Products Symposium, doubletree hotel, dearborn, michigan. visit: http://cwmi.css.cornell.edu/ symposium2012.pdf

August 22, 2012

2012 manure expo, Prairie du Sac, Wisconsin. visit: www.manureexpo.com

manure injection owner, John george, who owns Jag Pumps & application equipment in iowa, as well as from hoffman.

Borba’s equipment fleet includes a Peterbilt truck with a flatbed, equipped with a 65-foot boom to extract the manure from deep pit lagoons, as well as two John deere diesel engines. one powers the hydraulics and the other pumps the manure slurry through manure injection hoses to surrounding fields for injection. Perfect injection has over 1.5 miles of six-inch hose, which is connected to a booster pump. its purpose is to boost the flow rate once it drops below 1,500 gallons per minute to maintain consistent flow to the field. their optimum flow rate is between 1,400 and 1,700 gallons per minute. a five-and-ahalf inch hose extends from the booster pump to the injector bar connected to a tractor in the field, giving the company the

• Monitor application rates on-the-go by displaying tons/acre

• Combines GPS and weight verification of your manure applications

• Easily generate reports in PDF, Excel, SHP, KML, or BMP files

• Indicator displays actual tons/acre

• Document manure applications with scales on your spreader

• Comply with EPA and DNR CAFO regulations with application information

Perfection Injection in California’s Central Valley expects to inject about 150 million gallons this year, and give dairy farmers an alternative to flood irrigation.

capability to apply manure within a two-mile radius of the storage pit. to inject the manure eight inches into the soil, the company uses a 24-foot injector bar. two Case magnum tractors are used on site. a magnum 190 tractor, called the humper tractor, is used to move the drag hose around as needed, and a magnum 275, equipped with front and rear duals for better flotation and a creeper gear, injects the manure on the field. it is also outfitted with accompanying flow control equipment, and timble computer software in the cab for tracking location and application rates. the computer software automatically adjusts the application rate by adjusting the tractor speed, depending on where the tractor is located on the field. the creeper gear allows Perfection injection to travel at a slower speed if necessary, and provides it with the capability to apply anywhere from 10,000 to 30,000 gallons per acre with a 24-foot bar simply by adjusting their speed. as the manure is injected, the trench is sealed to minimize odor and loss of nutrients to the atmosphere.

“We also have an onboard nitrogen tester,” says Borba. “if the material is concentrated and the producer chooses to back off, we just speed up.” When combined with the g PS navigation technology located in the cab, he says Perfection injection is able to avoid over applying. once they begin applying, they prefer to run around the clock because once the storage pit agitation is in motion, it is important to keep it in motion to maintain slurry nutrient consistency. two houle 52-foot, agitation pumps are connected to Case 71 series tractors to agitate the pits. the application rate is carefully determined through discussions involving the producer, his crop consultant and Perfection injection, with one of the outcomes being the generation of g PS maps showing recommended application rates based on the tested nutrient content of the manure slurry.

if the company is required to cross a road with its drag hose, Perfection injection will pay to bore a hole under the road to accommodate the hose, and it will be there for the next service call. By taking this approach, transporting the manure slurry doesn’t damage roads in the vicinity of the dairy farm.

Borba says there are both agronomical and manure management benefits to opting for manure injection. firstly, he says farmers are going to achieve better nutrient uptake from their organic fertilizer than with surface flood irrigating. Secondly, manure injection also allows farmers to manage their storage capacity better because manure injection allows them to better balance their applications with the amount of manure slurry in storage.

“We have noticed that we are more accurate than tank application of the manure, we are cleaner and we are definitely n atural r esource Conservation Service compliant,” says Borba. “ every producer that we do work for praises the idea that we are quiet, we are not destroying dirt lanes, there is no soil compaction, and we are under the radar as far as exposure to neighbors.”

Canadian biogas company Carbon Control Systems has teamed with german technology provider agriKomp with the aim of becoming Canada’s first turnkey anaerobic digestion system provider.

Starting with a 135-kilowatt on-farm reference biogas plant in millbrook, ont., the joint venture now known as CCSagriKomp has made it their mandate to help kick-start anaerobic digestor technology in north america.

o ffering tours of the biogas plant to local farmers, CCS-agriKomp plans to not only showcase the g erman technology at the m illbrook build but to work toward innovative Canadian product as well.

on site, farmers are given a comprehensive overview of a complete biogas plant. most of the feedstock comes from the 100 cows on CCSagriKomp managing director Chris ferguson’s 150-acre farm, corn silages and grease from nearby restaurants. the end result is enough energy to dry grain in a 180-metric-ton batch dryer, power CCS-agriKomp’s 7,600-square-foot headquarters and provide electricity to more than 50 homes.

“i want to bring the awareness to local farmers that this model works here and around the world and definitely fits into the typical agricultural system that is here and the resources that are here,” says ferguson.

vancouver-based octaform Systems – a stay-in-place P vC concrete forming system used for the tanks – has allowed CCS-agriKomp to build better and faster, eliminating the need for secondary seals or treatments.

“We decided to go with octaform because we wanted to be hands on in building the tanks,” says ferguson. “the octaform panels don’t require special trades to assemble and that was a huge cost savings to us.” octaform not only provided an easy system for building the

tanks, but its airtight panels also protect the concrete from the highly corrosive anaerobic digestion environment.

With more than 400 biogas plants built in the last 11 years, agriKomp’s technology is a proven source of power in europe. down time is costly in the biogas game and agriKomp’s systems boast operational output rates of over 95 per cent.

www.ccs-agriKomp.ca

By Kris Kohl

the iowa State university (i S u) Beef Center is sponsoring a project to look at the costs associated with pumping the settled effluent from open feedlots. With this project, small sewage pumps are being installed to pump the runoff water to cornfields, where it will soak into the soil, preventing any runoff water from leaving the property. one of the sites is the armstrong research farm, in lewis, ia., which has a one-acre feedlot that could hold 200 head. Currently, it has a settling basin and small secondary treatment area.

the preliminary data looks very exciting. We have spent less than $3 per head to set up a 0.5-horsepower sewage pump to pump the settled effluent onto a cornfield, preventing the runoff water from flowing down a grass waterway and into a water of the state.

Since the start of the project on april 14, we have had 25 days of rain with 13 days of runoff. the cost of pumping an acre-inch of runoff is only 35 cents at the armstrong site. the total rainfall has been 11.51 inches; the electricity cost to pump the runoff has been just $1.70. normal rainfall in iowa is about 30 inches per year so we should triple the cost to just over $5. this is still less than three cents per head to prevent 90 percent of the runoff from leaving our property.

With any new project come some problems that must be overcome. the grass from the lawn mower has plugged

some of our distribution holes as has the rust from the “free” steel pipe we used from the iron pile. We have had good luck pumping from lots with at least 80 square feet per head while those with less than 40 square feet have produced thick slurry that has not pumped well.

the distribution holes are on 60-inch centers so there is one wet row next to dry rows, which has helped with the distribution and has prevented damage to corn. We started with half-inch holes that plugged easily and made scour holes in the soil. We increased to three-quarterinch holes that have increased the flow down the field to about 75 feet and are not scouring.

a field day was held this past summer at the armstrong research farm to show how we can use pumps to distribute our runoff water to better use manure nutrients and protect our streams.

Kris Kohl is an agricultural engineering specialist with Iowa State University (ISU) Extension.

Slave lake is one of three communities in northern alberta that will benefit from renewable energy projects supported by the Climate Change and emissions management (CC em C) Corporation.

Projects in high level and hairy hill, near vegreville, are also receiving funding. Combined, the three projects are estimated to reduce greenhouse gas emissions emissions by more than 2.3 megatonnes over 10 years, the equivalent of removing 46,000 cars from the road. for every dollar CC em C invests in these three projects, about another $7.50 is also invested.

growing Power hairy hill will be the world’s first large-scale carbon-neutral biofuel plant. the integrated biorefinery also includes other operations such as fertilizer manufacturing and biofuel feedstock production with systems

powered by waste.

the high north rtP Project in high level will be the world’s largest fast pyrolysis plant, converting wood waste from tolko’s sawmill at high level to pyrolysis oil, which generates power for a series of modified diesel engines. Waste heat will be recovered and used for drying lumber.

the Slave lake Pulp Bio-methanation Project will integrate an energy-efficient anaerobic digestion system into an existing effluent treatment system. the new system will treat effluent and produce biogas that will generate electricity and heat for use in the pulping process.

the CC em C is a not-for-profit organization whose mandate is to establish or participate in funding for initiatives that reduce greenhouse gas emissions and support adaptation. the CC em C invests in discovery, development, and operational deployment of clean technologies.

Livestock manure, ag byproducts to produce biogas

a team of researchers from the institute for animal Science and technology of the universitat Politècnica de valència (Spain) has developed a project that combines pig slurry and agricultural byproducts to optimize biogas production. thus, it manages to

add value to farms’ excess slurry and offers a sustainable use for some of the byproducts from the fruit and vegetable processing industry.

the project’s main researchers, maría Cambra-lópez, verónica moset and Pablo ferrer, are agronomists co-ordinated by Prof. antonio torres.

Pig farms generate large amounts of slurry, consisting mainly of animal excreta, cleaning water and feed residues, the management of which normally consists of storing it in pools and then using it as fertilizer in agricultural fields.

however, because of the manure’s properties, rich in nutrients – such as nitrogen and phosphorus – and organic matter, it can cause pollution to soil, water and atmosphere as a result of excessive accumulation of these nutrients in soil and water and the emissions of greenhouse gases and ammonia.

in areas such as the north of Castellón and inland valencia, where there is a high concentration of pig production, there is not enough agricultural land to absorb the large volume of slurry produced on local farms. the transport of this slurry to other areas involves extra costs – because of its high water content – that farmers are not willing to accept, says maría Cambra-lópez.

therefore, the Spanish researchers have studied the combined processing of pig slurry and agricultural byproducts to produce biogas, in order to provide a sustainable use for these products. this combination can avoid undesirable environmental side-effects and the project offers to turn pig slurry into a valuable product: energy.

Slurry on its own does not produce much energy, explains verónica moset, and therefore a biogas plant is not a profitable business for farmers. however, if farmers combine slurry with certain fruit and vegetables from the region that

are not good enough to sell, the methane level can be increased and produce biogas cost-effectively.

So far, researchers have tested in vitro the combination of pig slurry with peppers, tomatoes, peaches and kaki to study their potential to produce biogas and the optimal combination of both substrates. the engineers found that peppers increased methane production by 44 percent compared with slurryonly; tomatoes, by 41 percent; and peaches, by 28 percent. they did not observe any difference in methane production using kaki.

With this encouraging data, Pablo ferrer says they will carry out trials in large-scale digesters and simulate real biogas production processes using peppers, tomatoes and peaches. the researchers believe that in another year, they will be able to offer results and could transfer the technology to real-scale centralized biogas plants.

the researchers are also working closely with the Centre for animal research and technology of the valencian institute for agricultural research (ivia) to evaluate the effect of adding agricultural byproducts such as rapeseed oil, orange pulp or rice husk in pig feed, on methane emissions from manure, which could also increase biogas production.

unveils

massey ferguson® recently introduced the new massey ferguson 7600 Series high-h P row crop tractors to north american producers in search of a versatile, hardworking tractor that combines technology with exceptional

comfort features.

the new mid-frame row crop tractor is modeled after the popular massey ferguson 8600 Series and replaces the 6400 and 7400 Series. four completely new models ranging from 170 to 225 engine horsepower (140 to 180 Pto h P) give producers more choices in power, productivity and comfort from massey ferguson.

the 7600 Series boasts some innovative technology. the new series is powered by tier iv interim emissionscompliant ag C o P o W er™ diesel engines with e3™ selective catalytic reduction (SC r) clean-air technology for improved emissions, minimal maintenance and exceptional fuel consumption. ag C o’s new generation 2 e3 SC r system incorporates a catalytic converter and diesel oxidation catalyst

that work with the tractor’s engine to maximize efficiency and simplify maintenance. this approach provides a functional SC r system and offers owners best-in-class total fluid usage.

With a choice of dyna-6 (24-speed, partial-powershift) or dyna-vt™ (Cvt) transmissions, plus redesigned cabs that offer a wide-angle view and superior operator comforts, these machines are designed to make a long day of work more enjoyable. to make the most of the Cvt transmission, dynamic tractor management (dtm) provides greater communication between the engine and gearbox so that the engine speed can automatically adjust to the load for more consistent power to the ground and improved fuel efficiency.

SC r is regarded as a well-designed engineering answer to meet new exhaust

Innovative projects require innovative products, like Firestone Geomembranes. From anaerobic digesters, which convert animal waste into an alternative energy source, to constructed wetlands that provide environmentally sound water treatment – Firestone is proud to be a part of the solution. Our geomembrane products’ durability and elasticity even in exposed applications, combined with our expertise, help ensure the success of even the most demanding projects.

SUCCESSFUL APPLICATIONS INCLUDE:

• AGRICULTURAL PITS AND PONDS

• ANAEROBIC DIGESTER COVERS

• CONSTRUCTED WETLANDS

• IRRIGATION CANALS

• FLOATING COVERS

• STORMWATER MANAGEMENT

• WASTEWATER MANAGEMENT { Eco Friendly Solutions }

emission rules. unlike the alternatives, it does not require any additional valves, extra turbochargers, expanded cooling packages or extensive changes to existing engine designs. it also does not employ any complex internal engine components or external filter housings and is nearly maintenance free.

SC r technology allows these ag C o P o W er engines to run better, stay cooler and last longer. the 7600 Series comes with a 114-gallon-capacity diesel fuel and 11-gallon diesel exhaust fluid (def) tanks to allow for longer periods of work between refueling.

n ew for the 7600 Series is the inclusion of an o pti r ide™ Plus cab suspension system. this cab suspension system relays information through an electronic control unit to automatically adjust the cab suspension to control bounce, rolling and pitching for a comfortable ride in the field or down the road.

inside the redesigned cab, a right-hand control armrest, new multipad control and new multi-function joystick provide easy-to-reach, fingertip control and ergonomic design that are comfortable for the operator to use. a new datatronic CC d display offers greater performance and functionality and increased legibility so producers can accurately monitor and adjust tractor and implement settings.

www.masseyferguson.com

domor equipment recently unveiled its new generation skid-steer (SS) line of heavy-duty, road-grading attachments that mount on Bobcats, skid steers, newer tractors or even backhoes, and grade forward or backward, thanks to a patentpending four-blade design.

the new SS series features a lower-profile design and a new color, and offers greater operator visibility of

the material-mixing area. the grader’s new 0.5-inch thick steel corner bracing allows for removal of the cross supports opening up the entire flow-thru mixing area to the view of the operator, while still maintaining the four-inch tubular steel frame and 0.5-inch thick rolled side pans. the SS series equipment attaches directly to the front of a skid-steer, Bobcat or newer tractor using the universal mounting bracket, or it can be used on a backhoe with the optional backhoe bucket attachment, and on a mini-skid steer with a universal mini-hitch plate. the high-carbon steel cutting

edges can handle any surface from dirt to weeds to gravel and can be used for clearing brush and small trees. the SS series is available in five, six, seven or eight-foot widths, with two types of fixed blades, as well as hydraulic and manually adjustable blades.

“a ttachments for Bobcats are like apps for an iPhone – they add functionality that defines the machine,” says d o m or e quipment sales manager Brad a rnold. “ n o one else has an attachment that does what our SS series does.”

www.domorequipment.com

Are you interested in helping to develop Canada’s newest and brightest graduates for a career in the agriculture industry? The Career Focus Program provides employers with up to $20,000 in matching funds to create internship opportunities for recent graduates from agriculturerelated programs.

For employers, the program offers an economical way to attract new talent and helps provide new graduates with a valuable first job that will help pave the way to a career in the ever-changing agriculture and agri-food industry.

Eligible employers:w

• must offer projects that will give graduates meaningful agriculture career-related work experiences in Canada and skills acquisition through mentoring and coaching; and

• could include organizations such as farm businesses, industry, not-for-profit organizations, provincial and municipal governments, associations, boards, councils, colleges and universities.

Eligible interns:

• must be a Canadian citizen or landed immigrant;

• must be 30 years old or younger; and

• must have graduated from a university, college, CEGEP or provincial institution within the last three calendar years, specializing in biology, agriculture, veterinary sciences or applied technology.

Project proposals fowr 2012-13 will be acwcepted effective October 3, 2011 untwil December 30, 2011w. To help expedite the review process,w prospective employewrs are encouraged to submit their appwlication as early was possible.

To find out more abwout the Career Focwus Program and to obtain a prowject proposal form: w Visit: www.agr.gc.lca/careerfocus Call: 1-866-452-5558 l E-mail: careerfoculs@agr.gc.ca

Wastecorp Pumps, manufacturer of the mud Sucker® diaphragm pump, has a pump that simplifies the transfer of wastewater, dirty water, slurry and more. the mud Sucker’s products – the 2B-eC and 2B-m – are two-inch pumps equipped with a ball valve to crush solids and transfer up to 20 g Pm of tough slurry.

the mud Sucker 2B-eC is available with an electric, hydraulic or pneumatic drive system. the pump features a marine grade aluminum pump body with steel frame and can be mounted almost anywhere. the 2B-eC features a seveninch diaphragm with an exclusive contoured velocity channel to enhance the movement of liquid. the standard drive is a one h P, 1800 r P m, 3-phase-60 hz 110/220v motor. d C and single-phase motors are also available. a wheel kit and accessories are also available for the 2B-eC.

for engine driven pump needs, the mud Sucker 2B-m offers powerful performance, including a three h P honda® g X-100

engine. the 2B-m is available with a 1.5- or two-inch connection to meet specific industry needs.

mud Sucker diaphragm pumps are heavy-duty pumps designed for municipal and industrial applications. mud Sucker’s are available in more than 150 single or double diaphragm models with capacities ranging from 20 to 230 u S g P m www.wastecorp.com

hydroflo Pumps u Sa inc., a pump manufacturer, recently unveiled another domestic assembly facility in grand island, neb., plus its first international assembly facility in david, Panama. these plants will assemble and distribute hydroflo’s entire line of vertical and submersible turbines, including the company’s newest Zero lead Pump. the announcement marks the company’s sixth and seventh facilities.

headquartered in fairview, tenn., hydroflo operates additional assembly facilities in indiana, arkansas, texas, California, nebraska and Panama. www.hydroflopumps.com

Kyte Centrifuge supplies reconditioned or new centrifuges for manure dewatering and fine particle separation. Benefits include: uses no screens / filters, separates particles to less than 50 microns in size, and reduces phosphorus, nitrogen and potassium in wastewater.

By Robert Burns

Though it may not sound very glamorous, a new method of extracting ammonium from liquid animal manure could be exciting news for both confined animal operations and environmental groups, according to a texas agrilife extension Service engineer.

the method uses gas-permeable membrane technology that tests have shown could remove 50 percent of the dissolved ammonium in liquid manure in 20 days. the removed ammonium is “not scrubbed but captured,” said dr. Saqib mukhtar, agrilife extension engineer and interim associate department head of the texas a&m university department of biological and agricultural engineering.