SEPTEMBER/OCTOBER 2010

SEPTEMBER/OCTOBER 2010

Balancing production and conservation

September/October 2010

Volume 8 • No. 5

Published by:

Annex Publishing & Printing Inc. P.O. Box 530 Simcoe, Ontario N3Y 4N5

Editor

Margaret Land • (519) 429-5190, (888) 599-2228, ext 269 mland@annexweb.com

Contributing Editors

Tony Kryzanowski, James Careless, Alan Hahn

Advertising Manager

Sharon Kauk • (519) 429-5189, (888) 599-2228, ext 242 skauk@annexweb.com

Sales Assistant Mary Burnie • 519-429-5175 (888) 599-2228 ext. 234 mburnie@annexweb.com

Production Manager

Angela Simon

VP Production/Group Publisher Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: mweiler@annexweb.com

Printed in Canada

Circulation

e-mail: mweiler@annexweb.com

Tel: 866-790-6070 ext. 211

Fax: 877-624-1940

Mail: P.O. Box 530 Simcoe, ON N3Y 4N5

Subscription Rates

Canadian Subscriptions

$35.24 Cdn, one year (with GST $37.00, with HST/QST $39.82)

U.S. Subscriptions:

$47.00 USD, one year

Occasionally, Manure Manager will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher's written permission. ©2010 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher's approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Website: www.manuremanager.com

By Margaret Land

Western Ohio has a problem.

Grand Lake St. Marys, Ohio’s largest inland lake, is dying. Choked with blue-green algae and the toxins it produces, the 12,700-acre manmade lake has become so enriched with phosphates and nitrates, the Ohio Environmental Protection Agency (OEPA) is recommending people have “no contact with the water, do not allow pets to contact the water and do not take boats onto the water.” Eating any fish caught from the lake is also a no-no.

In order to save the lake, which was originally constructed in the mid-1800s to store water for the Miami-Erie Canal, and is a source of drinking water for the city of Celina, the OEPA joined forces with Ohio’s Department of Health, Department of Natural Resources and Department of Agriculture. The group released an action plan aimed at improving water quality at Grand Lake St. Marys on July 30, 2010.

Under the plan, entitled, “Promote manure hauling practice improvements,” the group suggests that an effective way of reducing nutrients delivered to the lake is to reduce the amount of manure land applied in the watershed. Currently, the USDA’s Natural Resources Conservation Service (NRCS)’s Environmental Quality Incentive Program (EQIP) is helping livestock producers transport manure outside of the watershed. But the program has experienced problems when farmers have attempted to ship manure into Indiana.

“Therefore, the state, through [the Ohio Department of Natural Resources], will request that USDA-NRCS establish greater flexibility under EQIP cost share to allow transportation of manure outside of the watershed, including to Indiana,” the report states.

This has raised the hackles of Ohio’s Indiana neighbors.

“We don’t need Ohio’s environmental problems,” states the headline of an editorial from the Aug. 31 issue of The Star Press, a newspaper based in Muncie, Ind.

“It’s unacceptable to shift an environmental catastrophe from one state to another in some kind of perverse shell game,” the editorial concludes. “Ohio needs to solve its own problem and not export it to us.”

It’s a sentiment shared by other Hoosiers.

“We have deep concerns,” Barbara Cox of Indiana CAFO Watch told the Fort Wayne, Ind., Journal Gazette. “If Ohio has a problem, the solution is not bringing it (manure) into Indiana watersheds.”

According to another report in The Star Press, there’s not a lot the Indiana Department of Environmental Management (IDEM) can do about the issue.

“IDEM has no authority to dictate where the (Ohio) manure can go,” IDEM spokesperson Barry Sneed is quoted as stating. “If the manure goes to an Indiana CFO/ CAFO, the receiving farm would still have to follow the manure management guidelines in their permit. If the manure goes to a farm that is not a CFO/CAFO, IDEM has no authority to govern it unless it is a threat to human health and the environment.”

What seems to be forgotten in this cross-state kerfuffle is that manure is not the only source contributing to the issues in Grand Lake St. Marys. Home septic systems, residential lawn fertilizer and commercial fertilizer applications to field crops also play a role in the lake’s diminishing health. But manure is always the bad guy, always the hot button topic.

I wonder what Indiana would be saying if Ohio had a surplus of lawn fertilizer to send their way.

By James Careless

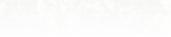

Compost pack system helps Ontario dairy reduce costs, boost production

Joan and Doug Cranston own Cranston Farms, a combined dairy and sweet corn operation in Ancaster, Ont. Until recently, they kept their 40 to 45 dairy cattle in a traditional tie stall barn, a management approach that left the cows little room to move around. The barn’s solid concrete floor was hard on the cows’ hocks as well, resulting in physical injuries. Meanwhile, the manure had to be regularly cleaned out and hauled away to a solid manure storage facility.

The Cranstons were aware of the trend in dairy farming to either go bigger, or go out of business. Since they are committed farmers, they decided to expand their operation. “At the same time, we wanted to do something different that would reduce costs, cut labour and make our cows more comfortable and healthier,” says Doug. “So my son James

and I spent three years looking into the options, and eventually decided on a compost pack barn.”

A compost pack barn mixes manure with sawdust, plywood/drywall shavings, or some other low-cost filler material to create a deep, thick and soft bedding for cattle. By mixing the manure and filler together, the farmer is able to dispose of the waste through the composting process right inside the barn. The high temperatures combined with regular aeration, bedding addition and mixing result in a low-odor fermenting base that ultimately can be removed and sold or used as fertilizer.

“Rather than having to clean out the stalls, we use a tractor with a chisel plough to add and then turn over the bedding once or twice a day, when the cows are being milked,” says Doug. “All of this is housed in an open concept barn – with natural light coming in through its skin, thus reducing electricity costs – rather than one divided by stalls. The cows are free to move around, congregate and generally enjoy a better, less stressed life. So they’re happy, which makes a difference when it comes to milk production and overall health.”

A few times each year, the compost pack is cleared out, specifically when its depth reaches around four feet – the height of the barn’s outside walls. Submitted photos

The compost pack system

The compost pack system – also known as a bedded pack system – starts with the filler material. The goal is to use something that is both low-cost and biodegradable. In the case of Cranston Farms, the filler is drywall crumbles and sawdust shavings, the remains of paper stripped from recycled drywall boards and the sandings from plywood manufacturing, all of which can be obtained at a rock-bottom price.

The initial one- to one-and-a-halffoot bed of filler is contained within a large concrete platform with four-foot outside walls. There are no concrete walls on the inside of the pack. Rollover gates on the scrape alley side of the pack allow for unobstructed airflow. The walls are vital, because the compost pack will eventually grow this tall before being removed. Some openings are left in the walls to allow the cows easy access to watering and feeding areas. The goal is to allow mobility, while also discouraging the cows from moving too fast, lest they injure themselves.

Unlike traditional barns, compost pack barns are designed to allow airflow through easy opening walls and high,

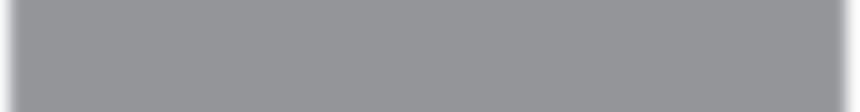

Trimble’s EZ-Guide 250 and EZ-Guide 500 lightbars can now provide record-keeping, tracking and feature mapping of your liquid and dry manure applications. Combine this new technology with Trimble’s proven guidance capability in order to more easily fulfill EPA and DNR manure handling record-keeping requirements. Increase efficiency by using colorful on-screen maps to eliminate gaps or overlaps, and avoid restricted application zones or tile lines. To find a Trimble dealer, visit www.trimble.com/agriculture or call 800-865-7438.

When the Cranston family near Ancaster, Ont., decided to expand their dairy operation, they studied the options and eventually decided on a compost pack barn.

well-ventilated ceilings. After all, the composting process creates a lot of waste gas that needs to be vented.

It doesn’t take long for the cows to deposit manure on the bedding. When they are out of the space for milking, the waste is turned under using the chisel plough. “We try to work it to a depth of 16 to 20 inches deep, adding extra drywall shavings on top to provide a drier surface,” Doug says. “The goal is to create a deep, soft bed that is dry for the cows to lay on, while the composting occurs beneath them. If the bedding gets moist, it’s time to add more filler on top.”

Aeration is the key to this process. It encourages the necessary bacterial action to break down the manure; vents the waste moisture and gas out of the bedding, and helps ensure that the topcoat remains dry – or, as Doug calls it, “crisp.”

“When the compost pack is right, it looks like dry sandy grit,” he says. “It’s not dusty and it is not damp. It is also very low odor, because this process removes about 90 percent of the smell.”

The Cranston herd lives in a “cold barn,” meaning the building is not heated during the winter months, when temperatures can go well below zero.

In a traditional barn, the cattle have to put up with the cold. In contrast,

The Cranston family have experienced great success with their compost pack barn, including winning a 2009 regional Premier’s Award for Agri-Food Innovation Excellence.

the 140 to 150°F fermentation process happening beneath their hooves provides some relief from the cold. In fact, it is common for the cows to dig down a bit in the bedding during the winter so that they can get warm from the compost below.

Studies have shown that cows are social animals who have a strong biological need to lie down at least 12 hours a day, and who have a preference for soft bedding. The open concept compost pack barn caters to all of these natural tendencies. It allows the cows to group together in social groups, lets them stay off their feet and keeps them comfortable.

Add the fact that the compost pack

method actually reduces harmful bacteria when compared to traditional methods – because the manure is removed from contact with the cows on a regular basis, plus they have enough room to lie where manure is not directly present – and this is clearly a healthy option for cattle. Strawberry foot rot has virtually been eliminated from the Cranston herd because of the dryness of the bedding and the composting nature of the pack kills the bacteria.

According to a research study from the University of Minnesota, reported at www.extension.org, the health benefits of compost pack bedding are staggering. “Statistical analysis of historical DHIA [Dairy Herd Improvement Association]

data indicated that 89 percent of the dairies had a significant increase in 305 mature-equivalent milk production when moving their cows from the previous housing system to the compost barn,” states the study, authored by Marcia Endres and Kevin A. Janni. “We found that 67 percent of the dairies had a reduction in mastitis infection rates.”

“We are seeing cows that are healthier, are not suffering the kind of physical hock injuries we used to see, and who can provide more lactation cycles during their lifetime,” says Doug. “We are also seeing better milk production and better attitude when it comes to handling them.”

At the same time, the compost pack system requires far less effort to maintain, compared to “mucking out the stalls.” It is also more pleasant work to do, especially because it can be done using a tractor and chisel plough. The pack itself only has to be cleared out when its depth reaches four feet, which is only a few times a year at most. When it is cleared out, the waste is usable fertilizer that is commercially valuable and environmentally safe.

“We sell some of it to local vegetable farmers, and the rest we put on our own fields,” he says. “There is no waste; we are taking manure and recycled drywall and shavings and creating a new product that is natural and in demand.”

The compost pack barn approach is working well for the Cranstons. It has reduced the cost of caring for their cattle, while improving the quality of that care. Meanwhile, milk production has gone up while health problems have declined – and the cows themselves appear to be happier.

Are there any downsides? “Not really,” Doug replies. “You do have to have filler on hand, and be prepared to add it more often during wet weather. You also have to stay on top of aeration for the composting to work properly. This is not something that you can take your hands off; you have to stay on top of it.”

The irony of the compost pack system, as far as he is concerned, is its resemblance to the process of milk production. “With compost bedding and cows, the method is the same: You have to feed the gut,” he explains. “In the compost system, this means adding more manure, filler and oxygen so that the fermentation process keeps going; just like keeping cows fed so that their bodies produce milk.”

Since shifting to the compost pack system, the Cranston family is seeing cows that are healthier and providing more milk, with fewer physical hock injuries than experienced on the farm in the past.

Atri-state team of researchers and university specialists will soon engage in a three-year study looking at gases emitted from mono-slope beef barns, and how building management impacts the emissions.

The team is composed of researchers from the United States Department of Agriculture’s Meat Animal Research Center (US MARC) in Clay Center, Neb., agricultural engineering specialists from South Dakota State University (SDSU) in Brookings, S.D., and extension program specialists from Iowa State University (ISU) in Ames, Iowa.

One purpose of the study is to gather baseline data for the levels of gas emissions from mono-slope beef barns for housing beef. The study will involve a total of four mono-slope beef barns in South Dakota and Iowa.

“Currently, beef producers report estimated air emissions from their concentrated animal feeding operation

(CAFO) based on data from open beef feedlots in the summer. These values may be too high for mono-slope beef barns. Data from this study will be useful in providing more accurate values for air emissions,” said Mindy Spiehs, animal scientist with US MARC.

The study will also evaluate two different manure-handling systems to determine which system emits lower levels of gases in the air. One barn system contains a manure pack that remains in the barn until the cattle are removed. The other barn system involves the weekly removal and storage of manure from around the bedded pack until it can be field applied.

“The study will provide information about which system is better for reducing gas emissions,” remarks Dick Nicolai, SDSU Agricultural engineer specialist and principal investigator for the study.

“A third, but important goal is to help beef producers learn how they can reduce the emissions from their mono-slope beef

barns,” said Beth Doran, ISU Extension beef program specialist.

“Producers are trying different things to increase animal comfort, some of which may impact air quality,” added Kris Kohl, ISU Extension agricultural engineer program specialist. The study will monitor the effects of season, diets and water consumption.

Funding for the research comes from a grant sponsored by USDA’s National Institute of Food and Agriculture (NIFA) and is one of 11 projects across the United States that addresses air quality issues. The projects will provide research-based information to develop effective mitigation strategies and best management practices to enhance air quality.

Inquiries about the tri-state air quality project may be directed to: Dick Nicolai, 605-688-5664, Dick. Nicolai@sdstate.edu

Mindy Spiehs, 402-762-4271, Mindy. Spiehs@ars.usda.gov

Beth Doran, 712-737-4230, doranb@ iastate.edu

By Tony Kryzanowski

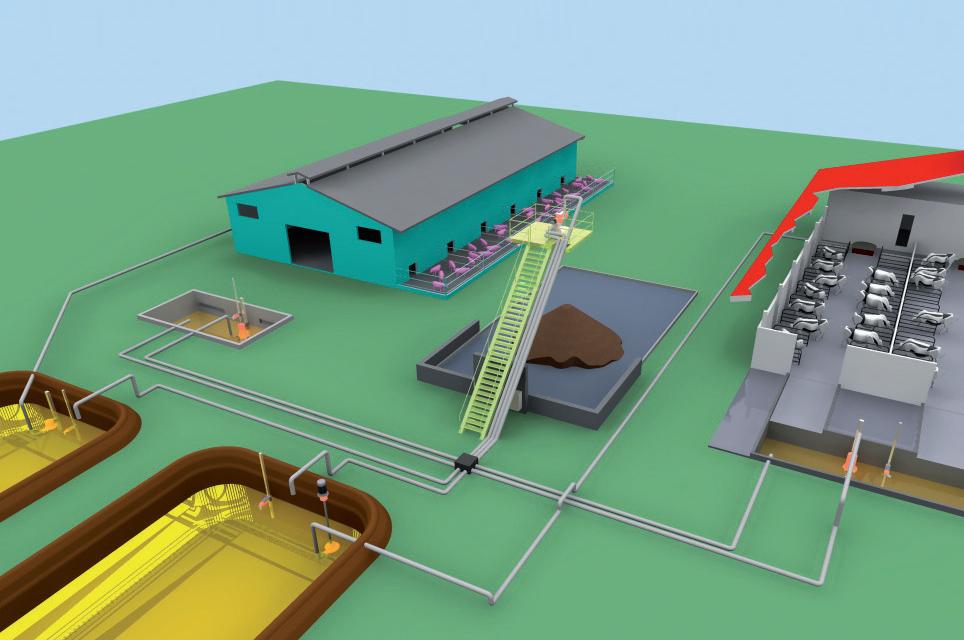

FPPC offers outreach on nutrient management and value-adding

Farms of all sizes now have more options to dispose of their manure and profit from its nutrient and energy value, thanks to the research work and demonstrations conducted over the past eight years by Farm Pilot Project Coordination Inc. (FPPC). They can also count on FPPC to weed out the technology contenders from the pretenders.

The sub-title on the FPPC name is “Technologies for Nutrient Management,” with funding for approved pilot projects coming from the federal government and overseen by the Natural Resource Conservation Service, a division of the United States Department of Agriculture (USDA).

“We’re an organization that is focused on doing research, but doing research on the farm,” says FPPC general manager Bob Monley. “Our laboratory is literally the farm, and we do projects that are farm-scale or full-scale so that we can get the learning curve in front of us.”

The FPPC has conducted around 45 projects throughout the United States and Hawaii since 2002. About 85 percent of the technologies they have tested produce the expected outcomes in terms of nutrient management from a technical point of view.

“We have our share of snake oil salesmen who want to offer a solution based on no data and based on enthusiasm only,” says Monley. “So we have a fine line to walk and we listen very attentively in seeking to get the data and the facts, as well as to vet and test the technology, not only in a realistic way, but to make sure it is credible information and not just self-serving for any of the vendors.”

The challenge is also to determine if the technology is economically viable.

FPPC can cite some commercial successes. One involves a client that is successfully manufacturing and marketing

Bio-char from poultry litter helps the environment through carbon sequestration, and can be returned to the soil as an important carbon source.

organic fertilizer from poultry litter to about 500 outlets. He is now working with FPPC to investigate the composting of poultry mortalities. Another is a dairy farm in Wisconsin that uses a combustion process to consume dried dairy solids to produce steam and power for the grid. He is able to compete with the cost of power being generated from traditional methods, and given his success, he is currently expanding his manure-based power generation operations.

“A lot of our farmers have been conditioned, or have been told that they have to take this waste and almost give it away,” says Monley. “That’s a problem we are trying to correct by transforming the waste to something value-added that the market will reward.”

FPPC’s specific mandate is to oversee the implementation and administration of pilot projects aimed at demonstrating economically viable innovation treatment technology systems that reduce the nutrient content of the waste stream from animal feeding operations (AFOs) by 75 percent or greater. However, since its formation in 2002, FPPC has discovered that the problem of nutrient management is much more multi-faceted than initially thought. For example, it is possible to consider energy production while using technology to capture nutrients from the waste stream. Removing solids from

the waste stream can result in a clean water resource. In removing solids for nutrient management, not only is the odor significantly reduced, but if an anaerobic digester is used to generate methane, farmers are eligible for a financial incentive to help the environment when that greenhouse gas is consumed. Thermo-chemical technology can also be applied to convert manure solids to a biochar that can be used as a carbon source and returned to the soil. It is a form of carbon sequestration, which is another positive for the environment.

“It’s a pretty exciting time now to see this waste go from what had traditionally been thought of as something to be minimized to now being understood as a resource stream with multiple benefits,” says Monley. “There is a growing awareness of the resources that we have available to us and what we can do to make the best use of them.”

The FPPC believes that conversion of manure into a variety of value-added products is the wave of the future and is a renewable resource – as long as Americans maintain their traditional diet of milk, meat and eggs.

“On a daily basis, milk, meat and eggs generate a waste stream from animal agriculture called manure. We are blessed that manure is a resource that has multi-dimensions to it,” says Monley.

added products. It has also aided in connecting farmers with legitimate service and equipment providers.

“I think with this resurgence in renewable energy, people have begun to realize that the manure waste stream coming from animal agriculture is loaded with water, nutrients and energy,” says Monley. “So naturally, I think there has been resurgence on what to do with this waste stream and what we can do to take advantage of it.”

Initially, a lot of FPPC’s focus was to educate and work with farmers about the best options for complying with their nutrient management planning.

“(The) jargon was something new to the farmer; not necessarily new in concept but in administration. Nutrient management plans were a basis for determining how much manure … their cropland could accept and what was

reasonable to apply, based on the uptake of the crops,” says Monley.

Growing environment consciousness, regulatory pressures and a greater interest in pursuing a toolbox of innovative technology have allowed FPPC to expand its farm services. The organization has become a focal point and a clearinghouse for technology concerned with treatment and conversion of manure into value-

FPPC has also undertaken demonstration projects related to action that owners of small farms can take to improve their nutrient management practices. It could be something as simple as investing a little more labor into composting manure instead of landspreading untreated waste, or learning how to prevent nutrients from endangering a nearby stream. FPPC can provide farmers with information on how to get started and manage manure in this fashion.

Monley acknowledges that some of the FPPC’s best efforts have been in research related to wet waste management from the hog and dairy industries, primarily concerning solids separation rather than research related to drier waste produced by cattle feedlots and the poultry industry.

“But we recognize that all of those, properly dried, can be used for energy production,” says Monley.

No longer an oxymoron moron o an oxy

A c cleleanener, b t etter sm l elliling g fa farm m is n no l longnger e a m myth – i it’s s a reaallity

That ’ s becaus e Pre sident nt of f Bauer r Ennergy y De sign, Inc.c., Walter r Bauer, with degree s from m

Univer sit y of f Guelph and Wilfrid d L aurier r Univer sit y, , has s de signed a proprietar y proce s s that t channgge s the e molecular ar strtructure e of f your well l water into a new w water with h highly y beneficial al and d te stable e proper tie s

This s dramatically y improved d water –– which h satisfied d users have e coined d “Bauer Wa W ter” ” ––uses a clinnical procees s to remove a and prevent t bioofilm bui u ldup This s ultimately changnges the e

While the need for continued research and demonstration of technology through pilot projects is obvious (given the public’s appetite for better nutrient management and value-adding), the economic downturn is a potential problem for future FPPC funding.

microflora in n an animal’s digestive system Manure e wil i l no lononger break down into the traditional metethane e and d hydrogen sulphide compounds No o bad d compounds; no bad d smells

Odor reduction, is just one of the many benefits of Bauer Water

“We do expect that it is going to be a lot tougher to get support for anything that requires funding,” says Monley. “That’s just the reality of trying to live within our means … but most people realize that because of the scarcity of energy worldwide, and because the cost of energy is likely to go up, all of the alternatives are going to become more attractive and competitive with traditional fossil fuels.”

“TThe Pototent t smel e l of f ou our manure ha has s signifiificacantly decreasased ed since e inststalllling g Walalter’s design gn B Baueuer r Watater has s defiefininitetely ly take k n the e ed edge off t the smeelll!”

Kei e th h Wideemaman, , Eaarly y Risse Je Jersesey Faarms m , El Elmi m ra, O Ontatarriio

Contact Walter directly for more info about the patented Bauer Water system

Bauer Energy Design Inc

1.519 634 9974 or acron@rogers.com www bauerenergydesign com

®

While not necessarily a household name in many farming communities, FPPC is definitely interested in raising its profile and sharing its knowledge and list of contacts with the farming community. It recently hosted regional technology summits in the Chesapeake Bay area and Des Moines, Iowa, and just hosted its annual Technology Summit in Saint Petersburg, Fla. Information about presentations made at the summits is available at www.fppcinc.org.

The new Anaerobic Digester Research and Education Center (ADREC) facility on the Michigan State University (MSU) campus will advance the science and technology of anaerobic digestion (AD) through cutting-edge research, and will play a key role in expanding Michigan’s bio-economy.

“Anaerobic digestion has proven to be a feasible technology to convert waste to resource while minimizing negative impact on the environment,” said Ajit Srivastava, chairperson of the Department of Biosystems and Agricultural Engineering. “However, due to the high cost, it can only be afforded by large dairy operations. Therefore, the goal of the ADREC is to develop off-the-shelf anaerobic digestion technology so it becomes cost effective for small to medium-size farms (200 to 499 milking cows). Since there are more than 2,200 dairy farms in Michigan that fall in this range, the potential of AD technology in converting animal manure to energy, all-the-while reducing green house gas emissions, is huge.”

Even more, the facility brings MSU’s research resources together under one roof.

“This facility actually brought together resources that we had spread across four different laboratories on campus,” said Dana Kirk, who will manage the facility. “By building this facility, we’re able to bring those researchers, the graduate students,

MSU researcher Steven Safferman with an anaerobic digester of the sort his team hopes to mate with power generators to produce power from animal waste. Photo by G.L. Kohuth

the undergraduates and the faculty and staff together under one roof where we can share instrumentation and work back and forth and share resources.”

Anaerobic digesters take waste from livestock and store it in a tank that is deprived of oxygen. This allows the waste

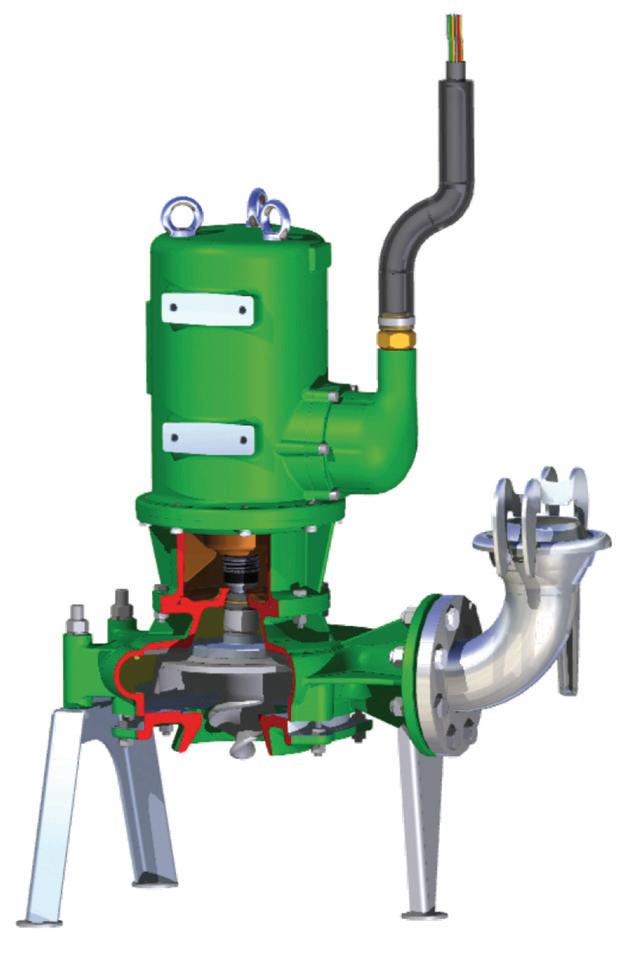

Pumps, Mixer and Separators specifically designed and manufactured for the manure management.

email: info@cri-man.com www.cri-man.com 2010 WORLD DAIRY EXPO IN MADISON

come and visit us at the Exhibition Hall, lot N° 6302, 6303 LOOKING FOR

CRI-MAN s.r.l.

materials to decompose quickly, and produces methane that can be used as biogas. Biogas is composed primarily of methane, a greenhouse gas 21 times more potent than carbon dioxide. Emitted from digesters, biogas is collected and used to produce electricity, heat or vehicle fuel.

Construction on the ADREC was started in September 2009 and was completed this spring. The building is a 6,000-square-foot facility. Laboratories, conference rooms and offices for researchers comprise 3,000 feet of the building. The other half of the city is comprised of a high bay for pilot-scale research projects.

“Several anaerobic reactors, ranging in size from two liters to 200 liters, are housed in the high bay section of the facility,”

Kirk said. The high bay portion of the facility also features a temperature-controlled room, which is vital to work with anaerobic digestion.

“We think MSU can play a very critical role in this industry as it evolves in this country because of the research we have both in the faculty, staff and now in the laboratory facilities,” said Steven Safferman, associate professor of biosystems and agricultural engineering.

It’s not just a hunch that Safferman’s playing either.

Recently the United States Environmental Protection Agency (EPA) and the United States Department of Agriculture (USDA) announced a new interagency agreement promoting renewable energy generation and slashing greenhouse gas emissions from livestock operations.

The agreement expands the work of the AgStar program, a joint EPA-USDA effort that helps livestock producers reduce methane emissions from their operations. The collaboration provides $3.9 million over the next five years, expands technical assistance efforts, improves technical standards and guidance and expands

outreach to livestock producers to assist with pre-feasibility studies.

The EPA estimates that there are currently 150 on-farm manure digesters now operating at livestock facilities across the country. In addition, the EPA estimates there are about 8,000 farms across the country that could be good candidates for capturing and using biogas.

If all 8,000 farms implemented biogas systems, methane emissions would be reduced by more than 34 million metric tons of carbon dioxide equivalent a year – roughly equal to the annual emissions from 6.5 million passenger vehicles. In addition, these projects could generate more than 1,500 megawatts of renewable energy.

“The methane gas can be used for any of our conventional energy sources,” Kirk said. “It can be used to directly replace natural gas – if we scrub out the impurities – it actually can be inserted in the pipeline and burned at your house. Typically and historically, methane gas has been converted into electricity by using it as the fuel source for a turbine or an internal combustion engine.”

The ADREC will work with the MSU Dairy Teaching and Research facility to collect manure from the barns and turn it into biogas. Additionally, Kirk said, the facility will collect other forms of waste to turn into gas. Researchers will experiment with food scraps from the Brody cafeteria, but they’re also testing different materials for numerous commercial clients.

The working model at MSU is serving as a model for the rest of the industry, Kirk said. The ADREC has been contracted by several private organizations to perform independent testing on different materials and will serve as a working classroom for MSU students.

“Instead of waste being an environmental burden to the environment, it now becomes an asset and a very much needed commodity,” said Safferman.

Penn State University played host to the 2010 Manure Expo, themed Balancing Production and Conservation.

By Margaret Land

More than 1200 livestock producers, custom applicators, manure management specialists and equipment dealers braved the heat of a mid-July day in Pennsylvania to take part in the 2010 Manure Expo.

The lush green hills of the state provided a stunning backdrop for about 58 equipment dealers, manufacturers and service providers who exhibited their products and services during the one-day event, hosted by Penn State University at the Russell E. Larson Agricultural Research Center, the home of the university’s Ag Progress Days. Twenty-two educational sessions were held over the course of the day, including calibrating manure spreaders, mortality composting, managing odor when applying manure, handling field storage of manure, making biochar, minimizing flies, and investigating anaerobic digesters, just to name a few.

Attendees also had a chance to view the latest in manure application equipment with demonstrations of solid manure spreaders, including the USDA Agricultural Research Service’s Poultry Litter Subsurfer during the morning, and

The lush green hills of Pennsylvania provided a stunning backdrop for 58 equipment dealers, manufacturers and service providers who exhibited their products and services during the oneday event.

liquid manure applicators and injectors during the afternoon.

Penn State University safety specialists also presented a demonstration highlighting the importance of ventilating manure storages to reduce risks utilizing a new mobile Ag Safety and Health Program

More than 1,200 people braved the heat to take part in the 2010 Manure Expo.

trailer developed for the purpose. The assembled crowd had an opportunity to view what can happen if someone enters a confined manure storage without adequately ventilating the area, and how long it can take to clear dangerous gases before it is safe to enter. The presenters also showed the appropriate safety equipment a person should be wearing and carrying before they enter the storage.

To conclude the educational day, Robb Meinen, senior extension associate with the Department of Dairy and Animal Science at Penn State and the chair of the 2010 Manure Expo, showed attendees first-hand how to properly manage an emergency manure spill response. Mimicking what could happen if a main manure hose breaks, Meinen utilized liquid manure sprayed from a nearby liquid tanker to show the sheeting behavior exhibited by the rushing manure, and demonstrated how to quickly dig earthen dams to move the manure to one spot. Using a tractor equipped with a front-end loader, a small hole was dug, allowing the manure to pool. A vacuum truck was backed into the field and quickly mopped up the mess.

Officials with the event were pleased with the turnout and considered the expo a success.

Next year’s event, entitled the North American Manure Expo, will be held July 20, 2011, in Norfolk, Neb., at the Northeast Community College Ag Complex, with the help of the University of Nebraska – Lincoln Extension. Visit www.manureexpo.org for regular updates.

Penn State University safety specialists present a demonstration highlighting the importance of ventilating manure storages to reduce risks utilizing a new mobile Ag Safety and Health Program trailer developed for the purpose.

Officials with Jamesway Farm Equipment find their own shade while awaiting their opportunity to demonstrate the Ultra-Trac liquid manure applicator.

PLEASE CHECK ONE:

Owner/Partner/Farmer

Manager/Foreman

Government Official & Regulations

Consultant

Equipment & Machinery Manufacturer

Distributor & Dealer

Education & Extension

Laboratory/Analysis

Other (please specify)

Cheque - Payable to Annex Publishing & Printing Inc.

Mail: Manure Manager Magazine

c/o Annex Publishing & Printing Inc. P.O. Box 530, 105 Donly Dr. S. Simcoe, Ontario N3Y 4N5

e-mail: mweiler@annexweb.com www.manuremanager.com

By Margaret Land

Manure applicator technology needs more refinement before variable rate (VR) fertilizer application techniques can be adapted to manure application, according to a recent Canadian study.

The three-year project – conducted by Agra-Gold Consulting and Farmer’s Edge Precision Consulting, both of Manitoba – did show that VR fertilizer rates could be adapted to manure applications but “overall … did not achieve its fullest potential,” reported Scott Dick, project leader.

The $54,750 study – funded by the Manitoba Rural Adaptation Council (MRAC), the Manitoba Pork Council and producer participants – involved 13 producers, each of who provided about 150 acres of land, a sampling base that represented a cross-section of Manitoba cropping conditions. Manure was applied using the drag hose application method. Tractor operators varied application rates according to GPS field maps indicating differing nutrient requirements in different parts of the fields. The three different rate zones were determined using satellite imagery. The zones were then individually soil tested to record the variability across zones and to determine the optimal nutrient application rate.

A total of 4632 acres was zoned and mapped for VR application with 3466 acres receiving the VR applied manure.

“Although we received generally positive feedback from producers on the methodology and agronomic benefits of the management style, producers had difficulty in justifying the cost of this increased management,” said Dick.

According to a survey presented to the participating producers, it was estimated the cost of applying manure during the study using VR techniques was about $8 per acre.

Even so, Dick says adapting VR techniques to manure application appears to have good potential but still requires refinement in the technology on the applicator.

“The technology used by commercial drag-line applicators today cannot efficiently and practically carry out this type of application,” he reported. “(The

equipment) just couldn’t accurately and efficiently vary application rates to match specific nutrient needs.”

Equipment operators could only adjust application rates by speeding up or slowing down the tractor speed. “On a half-mile run,” he said, “that could mean between one and three speed adjustments – not a major problem – but enough to affect accuracy.”

Another limitation was a lack of “on-the-go” nutrient sensing to determine soil nutrient levels. Instead, planners had to rely on past soil analyses to determine application rates.

“The only way to accurately measure nutrient levels was to send a sample to the lab after application,” Dick stated.

Finally, unlike commercial fertilizer applications where nitrogen and phosphorus can be applied independently to correct soil deficiencies, the nitrogen and phosphorus mix in manure is fixed. Operators can’t adjust individual N and P application rates as they go.

“(By) varying the rate based on nitrogen requirements … we unnaturally induced more phosphorous variability into the field,” the report stated.

“Though increases in technology and management can help to overcome these hindrances, it is our opinion that variable rate manure applications are not commercially feasible today.”

The study does outline ways producers can use precision farming techniques to increase yields and reduce environmental risks. The researchers, which also included Cliff Loewen and Wade Barnes, suggested producers apply a base rate of manure using conventional techniques then follow up with a variable rate application of commercial starter fertilizer at seeding time.

“This would allow the agronomist time to receive the manure analysis back from the lab and give a more accurate as-applied application report before the commercial fertilizer prescription map is developed,” the report stated.

A complete report of the project –Applying Manure to Defined Management Zones Using Precision Farming Techniques – is available at the Manitoba Livestock Manure Management Initiative’s website – www.manure.mb.ca – filed under Completed Projects.

Returning nutrients and organic matter to Texas Panhandle soils is the focus of a new federal grant awarded to the Texas Cattle Feeders Association (TCFA) and the Texas AgriLife Extension Service, according to project leaders.

Ben Weinheimer, TCFA vice president, said the three-year grant will help protect water quality in Panhandle streams and lakes. The project is designed to inform manure and compost contractors, machinery operators and certified crop advisors of best management practices for land application of feed yard manure and compost, Weinheimer said.

The project is funded through a Clean Water Act nonpoint source grant from the Texas State Soil and Water Conservation Board and the United States Environmental Protection Agency.

“This is a great opportunity for TCFA and our members to work with manure and compost haulers and landowners, who are an important part of the cattle feeding industry and help to ensure the beneficial use of manure on the land,” he said.

Weinheimer and his project coleader, Dr. Brent Auvermann, AgriLife Extension agricultural engineer, will develop a training curriculum in English and Spanish, establish demonstration sites and host seminars and field days to help machinery operators.

The curriculum will teach them how to calibrate spreader equipment so manure and compost are applied to cropland, according to recommended rates based on crop requirements and water-quality protection, Auvermann said.

“In the Panhandle, we work our soils pretty hard to achieve the levels of crop production that we’re able to maintain year to year,” he said. “If it’s done right, manure application is a tremendous way to boost soil health and productivity, including holding onto that precious rainfall.”

Weinheimer said he and Brady Miller, TCFA regulatory manager, have spent a great deal of time and effort during the past decade monitoring the nitrogen and phosphorus levels in cropland owned and controlled by the association’s member feed yards.

“Through our Environmental Services

A new federally funded project involving the Texas Cattle Feeders Association (TCFA) and the Texas AgriLife Extension Service informs manure and compost contractors, machinery operators and certified crop advisors of best management practices for land application of feed yard manure and compost. Photo by Margaret Land

Program, we have established a strong database of information on soils and manure, and assisted our members with managing nutrient applications,” Miller said. “It’s much easier to explain the importance of good environmental management practices when you have data and science in your hands.”

To document the importance of good land-application practices, Weinheimer and Auvermann have enlisted the help of an environmental soil scientist, Dr. Paul DeLaune, assistant professor with Texas AgriLife Research in Vernon.

“Dr. DeLaune brings a deep, research-based knowledge of soil fertility and soil chemistry to the project,” Auvermann said. “He has been working with nutrient management plans, phosphorus loading and water quality for over a decade.”

An international phosphorus workgroup has identified the lack of edge of field water quality monitoring data as the single largest scientific and management gap for addressing phosphorus loss, as well as pollutants from land use, said DeLaune.

“Due to the lack of data, many best management practices are not well

quantified as to their impact on water quality,” he said. “This project will allow us to address these regional and national issues.”

Building on more than 10 years of collaborative environmental work on cattle feed yards, Weinheimer and Auvermann decided to focus the project’s monitoring activities in the Sweetwater Creek watershed in the eastern Panhandle, which was listed as “impaired.”

Auvermann said while the major monitoring efforts will take place in and around Wheeler County, the training programs will be delivered in all of the major cattle-feeding regions of the Panhandle and South Plains.

“We’re focusing our data collection in Sweetwater Creek, but the lessons we learn about land-application practices ought to apply just about anywhere in this part of Texas,” he said. “Given our climate and our declining aquifer, we’ve got to protect as many of our surface-water resources as we can.”

“We’re challenged with reducing bacteria to acceptable levels in over 270 creeks and rivers across this state. Fortunately, not many of these impaired water bodies are here in the Panhandle,” said Aubrey Russell, Texas State Soil and Water Conservation Board member, who represents 49 soil and water conservation districts across 51 counties in the Panhandle.

“By partnering with the Texas Cattle Feeders Association on this project, we believe we can protect the quality of our local water resources while providing needed educational programs to benefit all landowners who utilize feed yard manure and compost to fertilize their crops and pastures,” Russell said.

Weinheimer said cattle feeders have intently focused on environmental management at the feed yard level for many years, and this project is the next logical step in TCFA’s environmental management efforts.

“Our soils need what manure and compost have to offer,” he said. “We believe it’s the right time to focus on the important role that land-application contractors and landowners serve in the cattle-feeding industry.”

Redhand Ltd. says that despite its 64-foot width, the company's custom manure applicator operates smoothly on cropland and corners with no issues. Submitted photos.

By Tony Kryzanowski

Manitoba custom manure applicator strives for efficiency by developing a wider, tow-behind manure injector

With the hog industry struggling financially, custom manure applicator

Redhand Ltd. knew it needed to find ways to operate more efficiently to manage its own rising costs. So the Manitoba-based company designed a new, tow-behind, 64-foot wide manure injection toolbar that is robust and nearly twice as wide as other injection toolbars in their fleet.

“Our costs go up every year, but we couldn’t raise our rates because of trouble in the hog industry,” says company coowner, Scott Rose. “We were running 33-foot injector toolbars before and we just couldn’t get a boom arm long enough without having major structural problems like stress breaks and stress cracks. We just kept beefing up that swing arm, and that made it heavier, which made it more prone to breaking.”

Rose says for the new, wider applicator to be effective, the boom

needed to be able to handle the stress of a 64-foot implement. Last spring, Redhand Ltd. injected 40 million gallons of manure with it, and the boom worked beyond their expectations. The applicator moved smoothly as it was towed across cropland and worked equally well with either hog or dairy manure.

“It just makes us that much more efficient to be able to run one machine at 64 feet versus two at 33 feet,” he says. “We didn’t think we could get more efficient two years ago, and now we have dropped a tractor, which is huge.”

By designing a wider, tow-behind toolbar, the company has been able to reduce the size of its equipment fleet, its fuel consumption when applying manure, and the number of its employees. At present, the company has nine employees.

“With other swing-mounted booms on applicators, they are typically mounted on the front of the machine and then pivot on top of that machine out to half the distance of the machine in either direction,” says Rose. “The one we built is tow-behind. So, we can basically build any width now because of our boom design. We were a little bit concerned about what would happen when we did a really hard turn (such as the hose tangling up at the far end of the toolbar) but we didn’t have any issues.” He adds the major difference between this manure applicator and other conventional injection systems

is that because it is a tow-behind boom, it is supported by wheels, whereas a freeswinging boom would be mounted at the front of an applicator.

The Redhand applicator has three Bambauer manifolds, and each manifold has 13 ports and 39 hoses leading to splitters, resulting in 78 drops leading to the Gentil injection system. Rose says the injection system looks almost like a golf green aerator. A series of knives, each about eight inches long, fracture and make holes in the soil where the manure is applied. Each knife is four inches apart, and the manure is injected approximately four inches into the ground, depending on soil conditions.

A second motivation behind designing this new applicator was to reduce crop stripping, a condition where some areas receive more nutrients than others, which becomes evident from crop growth patterns. This was occurring with some Redhand Ltd. customers, particularly in cases of low gallon applications of about 3,000 gallons per acre and where the liquid manure was of heavier consistency. The company has achieved row spacing of only about six inches with the design of its applicator, which it believes will significantly reduce problems with crop stripping.

Redhand Ltd. is owned by Scott Rose and Trevor Cowieson, with foreman and partner Paul Bell a key member of the team and a major contributor

The tow-behind feature of Redhand Ltd.’s custom manure applicator is what gives the tool its durability.

to the toolbar design. Rose, Cowieson and Bell are joint venture partners in another company located in Boissevain, Man., called Triangle Welding Ltd., which actually fabricates the complete applicator. Rose and Cowieson farm southwest of Brandon and operate the custom manure application business as a sideline.

Rose says he and Cowieson were part owners in a hog barn and given the expense of managing the manure in that operation, they decided it was something they wanted to consider doing themselves. They purchased the equipment owned by one of the companies servicing their hog barn eight years ago, starting out with tankers and eventually evolving exclusively into a draghose system about four years ago to address soil compaction issues being experienced by some of their customers. They also discovered that other draghose operators were able to work in wetter ground conditions, so the transition was made.

They are pumping and applying about 150 million gallons of liquid manure per year, almost exclusively for the hog industry. The majority of their business is conducted in spring and fall, with some custom application on pastures in summer, in an area largely within southern Manitoba.

Because their tow-behind applicator has proven itself in a commercial setting, Triangle Welding has started fabricating a second machine for Redhand through a relationship it has developed with

equipment fabricator Degelman Industries, based in Regina, Sask.

Rose says Degelman Industries was another key player in the design of the applicator. They modified the frame on a land roller implement to Redhand’s specifications, which was incorporated into the applicator’s overall design.

“One of the unique features of the Degelman machine is that it folds back and trails behind you and keeps everything in exactly the same position as it is in working field position,” says Rose. “It’s not a fold up machine.” The applicator is just over 13 feet wide for road transport and follows in the tracks of the tractor when turning, which enhances its maneuverability.

“We tow the applicator down the road at 24 miles per hour, no problem,” Rose adds.

In addition to the new, custom-built toolbar, their fleet consists of Ford New Holland tractors purchased from Mazer Implements in Brandon. Up until now, they’ve been operating three four-wheeldrive tractors in the 375-horsepower range to pull their 33-foot manure injection toolbars.

“That’s one of the efficiencies we tried to build into the design of our new toolbar,” says Rose. With the design of their new 64 foot tool bar, they now only need two 375-horsepower four-wheeldrive tractors, complemented by six front-wheel assist tractors for various operations such as manure pit agitation, equipment towing and hose management. Complementing their draghose

system are 52-foot Houle pit agitators and pumps, booster pumps and three miles of eight-inch hose for direct delivery of the manure to a pump in the field, which is connected to the manure applicator hitched to the tractor. The hose from the in-field pump to the applicator reduces from eight inches to six inches to increase the flow rate. Rose says they are able to pump at a rate of about 2,200 gallons per minute, even with three eight-inch and three six-inch lengths of draghose from the field pump to the manure applicator. The objective, he says, is to achieve as much flow rate as possible, as the speed of the tractor and the application rate is determined by the flow rate. An eightinch Krohne flow meter is located on the implement boom with controls in the tractor cab. Field tractors are equipped with GPS and auto-steer.

Rose says in addition to using the wider applicator themselves, they plan to fabricate the unit through Triangle Welding and market the product to other custom manure applicators in conjunction with Degelman Industries. He says making the transition to this custom injection unit would be relatively simple for custom applicators already equipped with eight-inch hoses. Application is at a slower speed, as the wider the injector, the slower the speed to apply the required gallons per acre. Although the application speed is slower, more volume is applied per pass and with a wider implement working at a slower pace, there is also less stress on equipment and operators.

In the article “Pig Pavement” in the May/June 2010 issue of Manure Manager, we quote Innoventor’s Rick Lux as saying “We liked the technology, and licensed it,” when referring to a process developed at the University of Illinois to turn hog manure into biooil. To clarify, that license was granted to Innoventor by a third party (WWBE) under an agreement that was terminated in February 2010. Innoventor’s paving trials with Pace Construction in April 2010 were conducted using its own bio-oil conversion process.

The Western United Dairymen (WUD) was recently awarded a grant to support development of a water balance approach for seepage measurements from liquid dairy manure storage ponds.

The $111,692 grant is a Conservation Innovation Grant (CIG) awarded by the United States Department of Agriculture (USDA).

“This project will demonstrate technology anticipated to help dairy producers find a more economical method to determine if lagoon ponds are leaking,” explained Paul Martin, WUD’s director of environmental services.

While the project has the goal of assisting California’s Central Valley dairies that are dealing with issues of ground water nitrate levels, it’s hoped dairies in other regions will also find the technology useful.

WUD is partnering on the project with UC Davis, Dairy CARES and Luhdorff and Scalmanini, Consulting Engineers. The Natural Resources Conservation Service (NRCS) grant provides half of the funding necessary. The balance of the funding will come through partner in-kind services, and a cash match of $80,000 will be provided from industry sources through the Dairy CARES coalition.

The project involves demonstration projects at five dairies. Following the demonstration and data collection phase, the partners will produce a technical field manual to facilitate widespread technology transfer.

BKN biostrom AG has signed an agreement with EnviTec Biogas AG for project management, development and longterm maintenance of biogas facilities within their joint venture company, ETBKN Holding GmbH & Co. KG.

In the coming years, both parties aim to conduct biogas projects with a volume of at least 15 megawatts through the joint venture company. EnviTec Biogas AG will hold the majority stake.

Financial terms were not disclosed.

A new University of California publication, entitled California Dairies: Protecting Water Quality, outlines key management

practices that protect surface and ground water quality.

The guide is aimed at lending institutions, consulting engineers and crop management companies that work with dairy producers, as well as regulatory bodies like county environmental health departments and regional water quality control boards.

Because each dairy is different, the guide describes a variety of management measures and summarizes four critical components that must be in place to protect water quality.

The 16-page guide was produced with funding from the California Department of Food and Agriculture’s “Buy California” Initiative, the United States Department of Agriculture, the USEPA Clean Water Act, and UC Sustainable Agriculture Research and Education Program (SAREP).

Free copies of the guide, ANR Publication 21630, are available through Tiva Lasiter at tlasiter@ucdavis.edu, or phone 530-752-0190.

The United States Department of Agriculture (USDA)’s Natural Resources Conservation Service (NRCS) Farm Bill conservation programs will invest approximately $11.8 million in 2010 into contracts with California dairy and other livestock farmers to implement conservation practices that will help them comply with regulations, manage and use the manure from their animals to fertilize their crops and improve water quality.

The $11.8 million is made available through the Environmental Quality Incentives Program (EQIP), the Agricultural Water Enhancement Program (AWEP) and the Cooperative Conservation Partnership Initiative (CCPI). EQIP contracts are made directly with agricultural producers, while AWEP and CCPI rely on industry and conservation groups to play a coordinating role to accomplish water quality and other conservation goals.

NRCS has focused effort to work with dairy operators for the past five years as the industry works on improving nutrient efficiency and complying with increasingly strict regulations.

“The dairy industry has been very responsive in working with us to develop and implement plans that take advantage of natural fertilizer occurring in livestock manure, and developing structures and management techniques to keep it away from water sources,” said Ed Burton, state conservationist for the NRCS California office.

In the past five years, NRCS has targeted roughly $47 million towards addressing the issue. Typically, producers put up half the cost of conservation projects, meaning the total NRCS industry investment approaches $100 million.

NRCS is working closely with Western United Dairymen, the University of California Cooperative Extension Service and others to bring information, training and financial assistance to dairy operators.

➤ Manure Pits,Channels & Covers

➤ Suspended Slabs - up to 40’ clearspan

➤ Hog & Cattle Slats - up to 25’ clearspan

➤ Weeping Walls - manure separation

➤ Milking Parlors

➤ Strainer Boxes

➤ Commodity Storage

➤ Bridges

➤ Bunker Silos (8 types)

➤ Syloguard Concrete repair

➤ Retaining Walls

➤ L & T Walls up to 16’ high

• Built to engineers’ specifications

• All sections are high strength, pre-stressed,reinforcedconcrete for longer life

• Quick & easy to build

• Air-tight seals and protectant using Syloguard products

Bauer Group has pumped up the power of its submersible pumps with the new Magnum CSP series.

The new Magnum CSP lineup includes 5.4-, 7.4-, and 10-horsepower models that can discharge 480 gallons per minute (gpm) up to 60 feet away — 30 percent farther than previous models. Service life and cutting power have also been extended with the addition of chrome steel blades and other parts that can be adjusted and replaced. Even the wear plate in the pump volute can be switched out.

The pump is driven by a three-phase submersible motor with an efficiency Class 1 rating of 88.3 percent. The class H insulation, temperature control, and special leakage sensor in the motor means the CSP can be used without restrictions in biogas plants.

The pumps can be used with Bauer separating systems, such as the Bedding Recovery Unit (BRU) and the new compact separators. They are ideally suited for re-pumping, mixing, rinsing pipes, or for filling slurry tankers. www.bauer-at.com

Premier Power, LLC of Alden, Iowa, has designed a new, mobile power take-off (PTO) power source for farm operations needing the flexibility of an efficient PTO power source in multiple locations.

“The Bull” features a compact, fourwheel, trailer-mounted power unit with a Tier III engine engineered to operate PTO-powered equipment at a lower engine revolutions per minute (RPM), providing tractor-free PTO power at significantly lower fuel costs. The unit can easily be pulled behind a pickup or SUV, eliminating the need to operate equipment with tractors, which are more difficult to move quickly between one location and another. “The Bull also offers better mobility and reduced wear on more expensive tractors.

“The Bull is ideal for powering equipment like manure pumps, generators and grain vacs, where you may need to operate them for hours at a time,” said Justin Jordahl, president of Premier Power. “In our testing, we’ve found that it can save up to three gallons of fuel per hour compared to a tractor. Running The Bull would save you a substantial amount of money in fuel costs alone.”

The Bull is available in two different models: the P150, which features dual output PTO (540 or 1000 RPM), two hydraulic quick coupler remotes and a 195 gallon tank, and the PX150, which also includes a Cat I and Cat II adjustable three point hitch, hydraulic leveling outriggers for stability in uneven terrain, a tool storage compartment and a 175-gallon tank.

www.pullthebull.com

Backhus has developed a new way to make additional profit out of manure – compost. Farmers no longer need to spend their precious working hours on a tractor, mixing and aerating compost piles, while burning up fuel and contemplating machine costs. And there is no need to spend money creating concrete bays, huge concreted compost pads, or buying expensive attachments for the tractor. The answer is the Backhus 16.30. Specially designed to meet the demands of farms, the compost turner is reliable, easy to handle and maintain, and provides a tremendous throughput with low fuel consumption. Its unique design allows operators to treat enormous amounts of material on a minimal footprint. The Backhus 16.30 also allows operators an opportunity to start a professional compost business with a minimum investment of time and money. Since uploading and unloading on a car trailer takes just a few moments, transporting the machine from site-to-site with a pickup truck is easy, allowing opportunities for operators to work as contractors for other farms or municipalities. www.backhus.us

American Refining Group (ARG) Inc. of Bradford, Pa., recently announced the edition of Biogas Engine Oils to its line of Brad Penn® Lubricants.

Brad Penn Biogas Engine Oils are stationary gas engine oils designed for use in applications where fuel gas is generated from anaerobic digestion of manure, compost and/or landfill residue.

Brad Penn Biogas Engine Oil SAE 40 is a high ash content (1.82 percent), high TBN (15) oil designed for use in stationary gas engines where influent biogas contains high levels of contaminants and corrosive materials, such as hydrogen sulfide, organic halides, and other harmful agents.

Brad Penn Medium Ash Biogas Engine Oil SAE 40 provides a midrange

TBN (8.9), medium ash content (0.99 percent) product for use in stationary gas engines where the influent biogas contains moderate levels of contaminants and corrosive agents or in applications where engine design and operation does not permit the use of high ash content.

“Essentially, an engine oil was needed with specific chemistry characteristics – like reserve alkalinity –to neutralize the acid produced and to protect engines from damage,” said Ken Tyger, a technical services representative with ARG. “Our involvement materialized out of necessity when we became aware of the growing populace of farmers incorporating anaerobic digestion technology without detailed background and explanation on the actual corrosive

nature and volatility of the digester gas.” Additionally, little guidance was provided on the selection of an appropriate engine oil lubricant.

“Farmers utilizing methane powered engines were essentially left to rely on word of mouth when selecting engine oil.”

ARG believes that supplying biogas engine oil also means providing service and expertise to the customer to ensure the product performs the way it should.

“Biogas engine oil is not a product that a manufacturer/distributor can simply supply to the end user/customer and walk away,” said Tyger.

Brad Penn Biogas Engine Oils are available in bulk, tote and 55 gallon drum containers. www.amref.com

Supporting the renewal of the agricultural sector and pp g g enabling co-operatives to better seize market opportunities Thhe e Ca Canadian a A Agric i ul u tuura

lo l an g guaarantee p program that t gi

farmers

easiier

access s to c creeddit. Farmmers, , incclu l di d ng b begegin i ning g f farme m rss, can us u e th these looanns s to estaabl b ish, h i impro r ve, and d develoop p faarms. A Agricul u turaal co co-oopeerativees s may also access loans to process, distribute, or market the products of farming

CALA features:

Up to $500,000 in loans for land and buildings

Up to $350,000 for all other loan Upto$350,000forallotherloanpurpospurposes es

Eligible applicants include:

Established farmers

Beginning/start-up farmers (i.e. less than 6 years of farming)

Farmers taking over the family farm Agricultural co-operatives with a majority (50% + 1) farmer membership

For more information: Contact your financial institution Call 1- 888 -346 -2511

Visit www.agr.gc.ca/cala

GHD Inc. and G3 Power Systems believe they have developed an anaerobic digester system and renewable power generation combination that is both economically attractive and permissible for use in California.

The two companies have teamed up to provide digester-powered fuel cells. According to the companies, the new technology will allow California dairy producers to meet existing and future regulatory requirements while turning their waste into additional revenue.

Digesters have been gaining in popularity across the United States in direct response to tightening regulatory requirements and restrictions for on-farm waste. However, in California, emissions from electrical production itself (typically combustion products from biogas gensets) have been a barrier to digester expansion.

GHD and G3 Power Systems believe the rapid commercial development of fuel cell technologies will change everything, as fuel cells are classified an “ultralow emission” system, meaning their emissions are so low, they are permitted to operate in downtown Los Angeles.

“Our proprietary process does not burn the biogas like some other processes,” explained Ray Brewer of G3 Power Systems. “Instead, it is converted through an electrolytic process into clean electrical power.”

The companies are offering third party financing and ownership for farmers unable to finance the project on their own. Farmers also have the option of owning their entire project, none of it, or a percentage. www.ghdinc.net www.g3powersystems.com

Building on the foundation of the 8R series tractors introduced in 2009, John Deere has developed and integrated the “smart-tractor” concept into its latest rowcrop tractors in the 235- to 360-engine horsepower range for 2011.

The new 8R/8RT series tractors

feature six models with wheels and three models with tracks, each offering 10 to 15 engine horsepower increases over the 2010 models. The tractors come with JDLink™ Ultimate Service and Service ADVISOR™ Remote, complimentary for one year, which allows the tractor to send location, operation and performance data via the web and cell phone.

The new 8R series also offer the new ActiveCommand Steering™ (ACS) option, which utilizes breakthroughs in steering technology to deliver the ultimate in comfort and control, especially at transport speeds.

In the cab, a new GreenStar™ 3 CommandCenter display can be loaded with AutoTrac and Swath Control Pro applications to eliminate the need for additional displays, reducing cab clutter. The optional touchscreen version integrates video for better visibility of implements.

All 8R and 8RT models are powered by new PowerTech™ PSX 9.0-liter engines that meet new Interim Tier 4 emissions regulations. These in-line, dual turbo-charged, six-cylinder engines utilize exhaust gas recirculation (EGR) technology and an exhaust filter that automatically cleans itself during normal machine operation – without the need for diesel exhaust fluid. All engines feature full-authority electronic controls, high-pressure fuel systems and air-toair after-cooling systems for hassle-free performance.

The 8R and 8RT series tractors will be available at local John Deere dealers in January 2011. www.JohnDeere.com

Global Greening Products, in conjunction with Honu Environmental, has introduced a line of manure decomposers that eliminate odors and turn manure to fertilizer within 48 hours, or into good water within 24 hours.

Now farmers can make their own fertilizer – either liquid or powder.

Using friendly microorganisms, the machines work like human stomachs – organic material goes in and the liquid and/or solids are processed and eliminated.

The machines are available in a variety of processing sizes, use minimal electricity, and have no escaping odors or gasses while processing.

Effective use of the decomposers will eliminate odors and ground water problems, while reducing pests, vermin and the potential of cross contamination. www.global-greening.com

Big Dutchman has introduced its new gasification system that transforms biomass from poultry manure into energy.

According to the company, the benefit of the Big Dutchman innovation is all the important components for fertilization (except for nitrogen) are preserved in the residual ash, resulting in a dual use independently of wind and sunshine.

Within the Big Dutchman system, the manure is dried, pressed into pellets and conveyed to a gasifier where it is converted into gas by means of a thermochemical conversion. The only byproduct that remains is ash, which can be used as a fertilizer. The energy produced is processed in the combined heat and power plant (CHP) to generate electricity and heat.

In addition to chicken manure, other byproducts such as digestate from biogas plants or sugar cane can also be used for the same purpose.

The amount of energy produced in a 150-kilowatt (kW) gasifier can supply thermal energy for 25 households for more than one year (maximum 10 kW heat output) and provide 200 households with electricity for a year (at an annual average use of 0.75 kW per household). www.bigdutchman.com

Imperial Systems Inc.’s heavyduty pneumatic slide gates deliver a positive shut-off to service machinery or to divert air. They operate using a compressed air cylinder, and help to reduce the risk of injury. Imperial Systems Inc.’s heavyduty slide gates are constructed from heavy-duty gauge steel. The slide gates are constructed for tough applications where material is a concern, and are available in a range of sizes, from four to 24 inches. www.isystemsweb.com

Supplier of engineered and innovated patented solid/liquid separation equipment.

• Complete system solutions

America – Europe – Asia

Contact in USA: m.stewart@few-separator.com Tel.: +1 (604) 932 7931

Germany: FEW Separator GmbH, Runtestr. 42

D-59457 Werl, Germany, Tel.: +49 - 2922 870 22-0 info@few-separator.com · www.few-separator.com www.food-energy-water.com

The new Bobcat S630 radial lift path skid-steer loader is designed and built to offer performance, efficiency and operator comfort.

Powered by a Kubota 55.4-kilowatt V3307-DI-TE3 Stage IIIA diesel engine, the S630 is the latest in the new generation loader range from Bobcat.

With an operating weight of 3,496 kilograms, a rated operating capacity of 989 kilograms and a tipping load of 1,978 kilograms, the S630 complements the recently launched S650 vertical lift path loader. The standard hydraulic flow on the S630 has been increased by more than 30 percent to 87.1 liters/minute, providing better attachment performance. The high flow version of this loader, the S630H, offers a hydraulic flow of 115.5 liters/minute.

Improved operator comfort is a key feature of the S630. The most prominent aspect is the forward-positioned cab, the largest on the market, which has been built in accordance with the idea that the more comfortable an operator is, the more productive he/she will be. The main features of the cab are as follows:

• Forward position offers 30 percent increase in all-round visibility for the operator

• Forward visibility further enhanced by 40% larger door

• Visibility through top, side and rear windows enhanced

• Adjustment in seat and suspension to suit individual preference

• Performance of heating and air conditioning system increased by 35 percent

• Optional selectable joystick controls

• Optional cab pressurization.

The cab pressurization is based on a new one-piece seal that goes all the way round the door, minimizing the dirt and dust that might enter the cab. The pressurized cab also reduces the heating/cooling load on the system.

The cab area has been increased by 10 percent over previous models, resulting in more space all round the operator. The threshold of the cab door has been lowered and the size of the cab door has been increased, making it easier for operators to enter and exit the cab.

The standard maximum travel speed of the S630 is 11.4 kilometers per hour, but this can be increased to 18.8km/h using an optional two-speed system. Traction has been increased by 15 to 20 percent to provide greater pushing and digging power. A larger fuel tank allows for longer work intervals between refueling.

Attachments approved for use on the S630 have a post for the removable hose guide that keeps the hose secure, clean and protected when the attachment is not in use. The hydraulic quick couplers are mounted directly to the front plate of the lift arm. A guard bar extends out in front of the coupler for added protection.

Other design features include the extra-strength 120 HSOC drive chains and the oversized axles and tubes. www.bobcat.com

Bobcat Company recently introduced the largest compact track loader the company has ever manufactured — the T870 — along with what will be the largest skid loader in its lineup, the S850.

The machines provide operators with more powerful hydraulics, increased fuel capacity, higher lift capacities and reach, increased pushing power and higher horsepower than any of Bobcat’s current loader models. In addition, the loaders will enable the operator to accomplish more work through performance and durability enhancements that provide more power and keep the loader working longer, while increasing operator comfort with a new cab forward design with improved visibility and a more spacious and comfortable cab. Job-enhancing features were also added to the optional Deluxe Instrumentation Panel featured in these machines.

The 10,008-pound S850 has a rated operating capacity (ROC) of 3,875 pounds — 17 percent more than the current largest skid loader, the S330. The 12,678-pound T870 has a ROC of 3,325 pounds, or 7 percent more than the current largest compact track loader, the T320. In addition, the loaders are the highest lifting loaders in the industry with 144-inches lift height. The highest lift height will be appreciated by those who load over tandem axle trucks with side boards added, hay wagons, and mortar mixers, as well as those stacking brick, blocks or other palletized material.

The S850 and T870 have the same increased hydraulic performance as the other M-Series loader models, enabling them to efficiently accomplish more work. The hydraulic systems on M-Series loaders have been engineered for higher standard flow and pressure that give attachments more power to work more quickly.

The standard auxiliary hydraulic flow on the S850 is 23 gallons per minute at 3,500 pounds per square inch and an optional high flow feature reaches 37 gallons per minute for maximum attachment performance. On the T870, the standard auxiliary hydraulic flow is 23.8 gallons per minute, with an optional high flow of 37.4 gallons per minute.

New job-enhancing features were added to the optional Deluxe Instrumentation Panel. Available only on M-Series machines, the panel intelligently monitors key loader functions, and the keyless start helps prevent theft. The new five-inch, full-color LCD screen offers better readability and interaction. Easy-to-read virtual sweep gauges allow the operator to quickly read and understand the machine’s performance.

The loaders are designed to work long hours on demanding

jobsites, and operators want to spend minimal time on routine maintenance to start the workday earlier. Simple checks and superior design make it easier to perform maintenance correctly at the proper intervals.

The hydraulic quick couplers are mounted directly to the front plate of the lift arm to provide a solid mounting, and quick coupler hoses completely run through the loader arms for better protection. A guard bar extends in front of the coupler for added security.