NOVEMBER/DECEMBER 2014

NOVEMBER/DECEMBER 2014

Texas turkey operation added to supply manure

November/December 2014 Volume 12 • No. 6

Published by:

Annex Publishing & Printing Inc.

P.O. Box 530 Simcoe, Ontario N3Y 4N5

Editor

Margaret Land • (519) 429-5190, (888) 599-2228, ext 269 mland@annexweb.com

Contributing Editors

Tony Kryzanowski, Diane Mettler, Dennis O’Brien, Ann Perry

Advertising Manager

Sharon Kauk • (519) 429-5189, (888) 599-2228, ext 242 skauk@annexweb.com

Account Coordinator

Mary Burnie • (519) 429-5175, (888) 599-2228, ext 234 mburnie@annexweb.com

Media Designer Emily Sun

VP Production/Group Publisher Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

email: subscribe@manuremanager.com

Printed in Canada

Circulation

email: subscribe@manuremanager.com

Tel: 866-790-6070 ext. 211

Fax: 877-624-1940

Mail: P.O. Box 530 Simcoe, ON N3Y 4N5

Subscription Rates

Canadian Subscriptions

$35.24 Cdn, one year (with GST $37.00, with HST/QST $39.82)

U.S. Subscriptions: $47.00 USD, one year

Occasionally, Manure Manager will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher's written permission. ©2014 Annex Publishing and Printing Inc.. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher's approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Website: www.manuremanager.com

By Margaret Land

Back in the spring, I had the honor and pleasure of being part of a panel discussion at the EPA AgStar’s annual meeting in San Diego, Calif. The topic?

The media’s role in promoting anaerobic digestion.

I’ll be honest – I don’t consider myself much of a public speaker. In fact, I believe I express myself much clearer in print than in person. But after the talk, a very nice gentleman approached me and praised my enthusiasm for the topic because, after all, it’s pretty hard to find people who are enthusiastic about manure.

He had a point. Most of my days are filled with negative stories about manure – several thousand gallons spilled here, thousands of dollars in fines there, a tipped tanker or spreader accident over there. So when I find information promoting the benefits of animal excrement, I tend to get excited. But this latest pro-manure story has left me with mixed views.

About a year ago, an elderly woman in the Hunan province of China was diagnosed with terminal lung cancer. But rather than waiting to die, she decided to do something about it. Why she decided to do this particular something, I’m really not sure, but eight months ago, she began preparing and ingesting her own treatment. Now she says she’s cancer free. And what is this miracle cure, you ask?

Why, manure infused water of course.

In a cringe-worthy article currently making the rounds of the Internet, it’s claimed this Chinese lady, plus 20 of her neighbors, is cooking up her own poop soup using air dried cow and goat manure that is then stir-fried and ground up. One spoonful is mixed in a cup of water and drank twice daily. And everyone is feeling as healthy as a horse.

But how can this be? Here in North America, where leafy greens have to be practically sterilized before they’re considered free of E. Coli, the idea of drinking manure water would send the local health department running to your door. But it seems there is some truth behind this stomach-churning Chinese fad.

According to a research scientist with the Cancer Prevention Institute of California, who is also a member of the Stanford Cancer Institute, the human body needs to be regularly exposed to nasty bacteria and microbes because they can help people fight off illness.

According to Dr. Christina Clarke, the immune system can be stimulated by inhalation of endotoxins, which become airborne when cow or dog manure dries. It’s believed exposure to these microbes might play a role in cancer and inflammatory diseases.

Back in 1996, an Italian researcher by the name of Giuseppe Mestrangelo discovered that dairy farmers are 35 percent less likely to develop cancer and 51 percent less likely to develop lung cancer to other farmers. Why? Cow manure, of course.

He also found that the longer a dairy farmer worked with cattle plus the more land and animals he or she had, the less risk they had of developing lung cancer.

While it’s an interesting idea, I’m not sure if I’m 100 percent convinced. But if there are any readers out there who would like to put this hypothesis to the test, feel free. I’m sure Dr. Clarke would be interested in the end results as well.

By Tony Kryzanowski

Maryland is getting serious about controlling the amount of poultry-derived nutrients seeping into Chesapeake Bay, and poultry producer Millennium Farms is developing a manure processing technology that, if economical, could make a significant dent in controlling this problem.

Jason Lambertson, owner of Millennium Farms and a longtime poultry producer in the state, has partnered with a group of local businessmen and technical experts in a company called Planet Found Energy Development to build a pilot plant at the Pocomoke City area farm that will use anaerobic digestion of poultry manure to produce biogas as a fuel to generate power. The system includes nutrient separation technology

to ensure that phosphorous is reduced from the byproduct stream before it has the opportunity to potentially seep into Chesapeake Bay if land applied.

Construction on the pilot project began in the spring. Completion and commissioning will likely occur in early 2015. Developers are hoping to construct the pilot plant as economically as possible with the State of Maryland contributing over $674,000 to use primarily to install and refine the nutrient recovery system. It will separate the nutrient streams from the processed manure. The funds were provided through the state’s revitalized Department of Agriculture Animal Waste Technology Fund.

Because of the impact that nutrients flowing into Chesapeake Bay are having on water quality, the state is discussing the possibility of limiting raw poultry manure application, which could limit producers to application on only 15 percent of available farmland. Should this limitation proceed, this would result in a massive shortfall of land available for poultry manure application compared to the size of the industry.

“It could get to the point where it

would affect the poultry industry trying to be viable here if the farmers did not utilize the manure,” says Lambertson. “It could really harm the industry and that’s what we don’t want to happen.”

That’s why so many, including government representatives at various levels, are watching to determine the viability of the manure treatment technology being investigated at Millennium Farms. This is also what motivated Lambertson and other local investors to partner with a group of scientists with knowledge about anaerobic digestion on the Planet Found Energy Development business to build a pilot version of a potential system.

The anaerobic digestion technology being installed at the poultry farm was adapted from technology that has been common in other parts of the world for decades. However, this will be the first poultry anaerobic digester installed in Maryland with added nutrient separation.

The system starts with the farmer dumping loads of raw poultry manure into the introduction tank where the manure is mixed with water. From there, the slurry is pumped into one of two anaerobic digestion tanks. They are large, 200 cubic meter

Don’t let manure handling agitate you. Save time and fuel with More Than Manure® (MTM®) Nutrient Manager. MTM can break through crusts and solids in pits and lagoons, and cuts down on foam when pumping into tanks, so manure is easier to handle with less agitation. Visit us at sfp.com to request a free MTM kit.

tanks in which the biogas produced from processing the poultry manure bubbles to the top before being captured and transported to an engine where it is burned as fuel to drive a generator on site. The processed material exits the tanks and flows through the nutrient recovery system where the undesirable nutrients can be stripped out and the remainder transported to a post treatment pit where it is dried. At this point, it is a usable mulch that can be spread on the fields without restriction or sold as organic fertilizer. There are two other tanks in the system. One is a buffer tank that allows system operators to better control the material being processed in the anaerobic digesters so that they work at optimum biogas production efficiency. The other is a clean water holding tank that helps to control the water flow through the closed loop system.

“We were bent on building the pilot, but with the help of the state, it is making it that much easier for us to obtain quantifiable results and show farmers that there are some open pathways to be able to generate renewable energy on

site for their benefit,” says Lambertson. Monitoring and research assistance is being provided by the United States Department of Agriculture and the University of Maryland.

Even if the land application restrictions don’t come about and the system demonstrates how farms can produce fertilizer and reduce energy costs, Lambertson says, “it could be a win-win for the farmer.”

Millennium Farms was chosen as the ideal site for a pilot plant because it is a modern computerized and automated facility in an area where the land has high levels of phosphorus and it is close to Chesapeake Bay. So it is in the backyard of where the technology is needed the most. The farm produces 160,000 pullets for Tyson Foods annually, which equates to over 12 million broilers from the parent flock. In total, there are eight barns that generate about 1500 tons of manure. The manure is a mixture of wood shavings used as bedding and animal droppings. Millennium Farms also grows corn, wheat and soybean on 2000 acres, and typically their poultry manure would be land ap-

Puck Custom Enterprises high performance nutrient handling solutions

• Vertically Agitate thick solids using the Boat’s powerful nozzle velocities

• Variety of Boat settings service 3 ft to 50 ft depths effectively

• Proven to clean up the toughest jobs and provide consistent nutrient samples throughout the pump-out

• Outflow nozzles easily uncouple and connect to high-pressure hose fittings for pump-out

• Highly Responsive Lightweight Design: Easy to Operate, Set-Up, Clean-Up & Transport

• Lowest Maintenance, Operational & Ownership Costs = Highest Return on Investment

• Decrease agitation costs by 70% on a large scale

• NEW! PCE Voyager Control w/ remote display

plied as an organic fertilizer and a means of disposing of it. As with other poultry farms in area, the issue is the amount of phosphorus in that raw manure and its impact on local waterways.

The Lambertson family has been producing chickens since the 1950s, but Jason built his current farm starting with four barns in 2000 and adding four barns in 2009. Although they have had adequate farmland in the past to dispose of their poultry manure, the state’s consideration of limiting field application is a concern.

Once operational, the anaerobic digestion system will produce about 520 daily kilowatts (kW) of power that will be wheeled through the local Choptank Electric Cooperative transmission system. The farm will be compensated and save money on its power costs through a net metering system. Lambertson says because the system is a pilot project, they have yet to determine if the system will be capable of providing all of the poultry farm’s power needs.

“We’ll definitely be able to make a good reduction on our energy bills on the farm,” says Lambertson. They will know

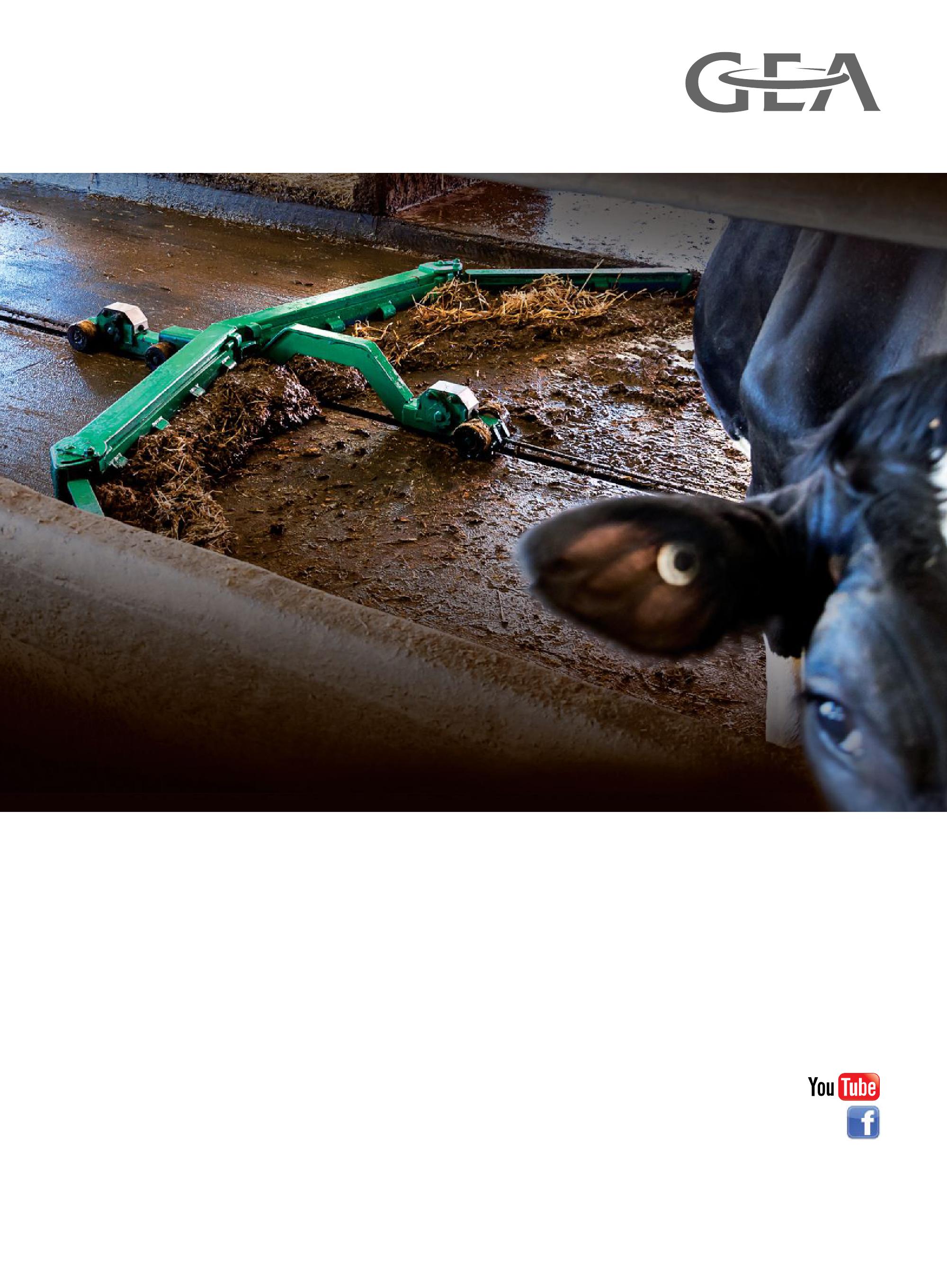

GEA Farm Technologies has always made its mark by developing efficient and long-lasting free stall manure cleaner systems. Whatever your barn condition is we have the solution to meet your highest expectations. 16°, Straight or V-Shape Scrapers. Adapted for rubber mats or concrete alleys. Pulled by galvanized or stainless steel cable, nylon rope, 1/2’’, 7/8’’ or pintle chains or hydraulically operated. It can be floor mounted, standard or deep groove guided or installed with an under floor channel. For alley lengths up to 2,585’ and between 73’’ and 204’’ wide... You have a farm. We have a solution.

A comprehensive line of products for free stall manure cleaning

GEA Farm Technologies Canada Inc.

Tel. 1.800.563.4685 / Fax. 1.819.477.0486 www.gea.com / www.geahoule.com

engineering for a

how much once the project is commissioned next year.

The byproduct that is discharged from the digestion tanks can be land applied, sold as fertilizer or potentially reused as bedding.

Heat generated by the anaerobic digestion system not needed to maintain the process could also be channeled to heat the poultry barns, thus creating the possibility of the farm saving a lot of money on propane heating costs. Additionally, some of the biogas could be used as heating fuel.

These are all the factors that are yet to be determined once the Millennium Farms system becomes operational.

If proven economical, Lambertson says that there are thousands of similar poultry farms in the state or Delvarva Peninsula where the system could be installed. The dream, once this technology is proven, is for Planet Found Energy Development to build and operate systems capable of producing significantly more power. They are working with the state to consider larger systems with a number of poultry producers supplying raw material

for one system. The goal is to develop a system where the farm owner will only need to replenish the system with raw poultry manure and remove the processed material to a storage area once a day.

There will be no water discharge from the system as it is described as a closed loop system where all the water used to create a raw material slurry at the front end of the digester is captured and recycled within the system, which in itself will control the amount of nutrient-rich water leaving the farm that could potentially seep into local watercourses.

As far as the nutrient separation technology, Lambertson says it can be adjusted according to the needs of a particular area. While the issue is controlling the phosphorus in Maryland, another area might have a problem with sulfur content. So the system is adjustable to local requirements.

They also want to build considerable flexibility into the system so that it will work using a variety of raw feedstock. For example, there are areas where there are no wood shavings mixed in with the manure, so it has to have the capability to be able to process, “a random mix of materials.”

It also has to have the capability of being customized in size to match the needs of individual farms, depending on how much manure the farm is generating.

The owners of Planet Found Energy Development expected extra costs to build what is essentially the prototype of their system at Millennium Farms, but Lambertson says they have already recognized many areas that can be changed in the future to streamline the system and reduce construction costs.

Should the byproduct prove useful as a reusable bedding material, this could be a substantial savings for Tyson Foods, which supplies the wood shavings bedding to its growers in that area.

The overall support being expressed for proving this technology has helped to maintain the momentum through the challenging construction phase of the pilot project.

“We have the Department of Environment, Agriculture and Energy all sitting there together, all agreeing how this could help, and it’s rare to have all three of them agreeing that something like this could help to solve some of our problems,” says Lambertson.

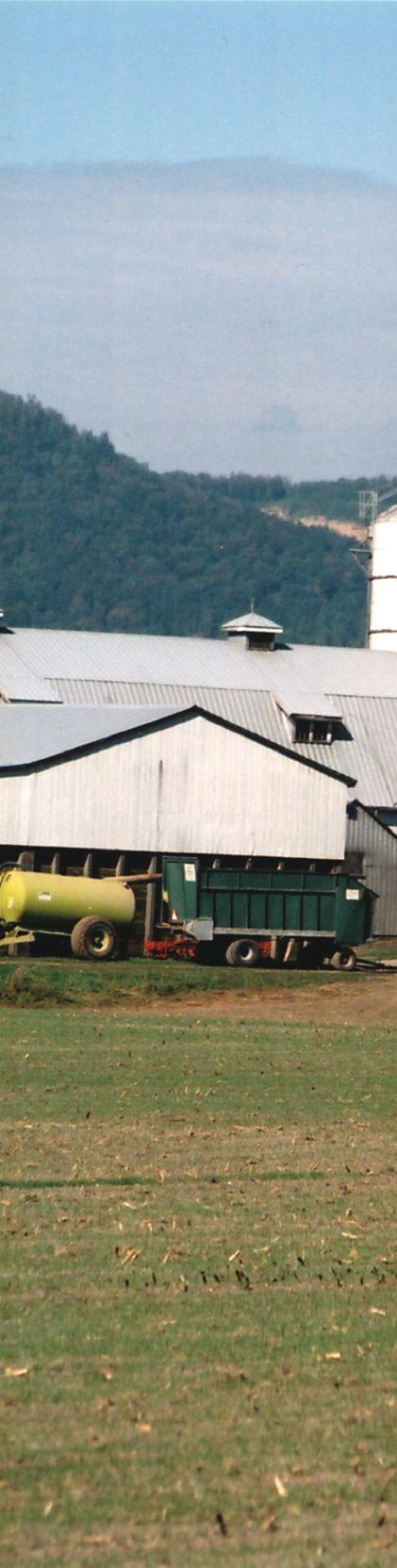

The Glaser family of Rogers, Texas, own 500 acres and lease another 250. On that land, which has been in the family for three generations, they run 200 cow/calf units. Contributed photo

By Diane Mettler

Bar G Ranch Poultry incorporated a turkey operation and significantly improved the cattle herd

Some farmers buy chicken litter for their fields to avoid using commercial fertilizers. The Glasers took it one step further. They added a large turkey operation –producing approximately 600,000 birds a year – to guarantee their supply.

The Glaser family, owners of Bar G Ranch Poultry in Rogers, Texas, owns 500 acres and leases another 250. On that land, which has been in the family for three generations, they run 200 cow/calf units. They also raise turkeys for Cargill Turkey Production, LLC, in four 450-foot by 50-foot turkey houses, with each house holding 30,000 birds.

The birds are raised from one day to six weeks, and are changed out five times year. When the birds come out, front end loaders come in and remove 250 to 300 tons of litter – one of the main reasons for the turkeys.

“We built the whole system to inte-

grate the turkey operation with the cattle operation,” says owner Darrell Glaser. “I saw right away that the litter was going to make the difference. That we could save a lot on fertilizer costs on our cattle operation, and improve our soil. It’s done so much for our organic matter and our water holding capacity of the soil. It’s turned our whole operation around.”

The transformation began 20 years ago in the mid 1990s. Darrell’s family farm wasn’t profitable and his mother Jeanette was faced with either selling or leasing the farm. Darrell, who was getting his master’s in nutrition, and his wife Shannon, who was completing her master’s degree in biochemistry, had to decide if they wanted to go back.

“Coincidentally, when I was completing my master’s degree, I took over a nutrition lab from a lady whose parents were contract-growing turkeys for Plantation Foods, and the whole idea started there,” says Darrell. “We had to figure out a way to make the family profitable. We started in research and ended up in production agriculture.”

Darrell and Sharon found a way to balance careers and farm life, and set out to turn the farm around. One of the first steps was adding turkeys to provide the much needed fertilizer.

“When I came back from college, we

had a farming ranch and we were running some row crop. We converted everything over to improve pasture with different coastal Bermuda grass, some Tifton 85 coastal. We also did some cross fencing for better rotational grazing, and then utilized the litter,” says Glaser, now 47.

Since then, the Glasers have doubled their stocking rate, all due to incorporating turkey litter, which in turn improved the soil condition, fertility and water holding capacity. They make it all happen with two full-time employees, as well as Glaser team, which includes Darrell and his four sons: Trenton, 18, Trevor and Troy, who are 13, and 11-year-old Travis.

When it comes time to spread, Darrell leans on a local farmer.

“He has a pretty good system,” explains Darrell. “He has three flat bottom floor trucks, and as soon as we bring the manure out of the houses, he loads it and takes it to the spots where it’s going to be put it on the farm ground.”

Luckily, the farm is located where spreading can take place year round, although it tends to take place most often in the spring and fall.

The litter that’s not spread on-farm is used by neighboring farmers. Nothing goes to waste – including the mortalities. Because the ranch is a brooder farm,

Börger AgrarTec offers a diverse line of agricultural liquid handling products including rotary lobe pumps, macerators, digester feed equipment and solid liquid separators. Börger specializes in custom-built solutions for farmers and biogas plants.

BIOSELECT RC

The Bioselect RC is fitted with a feed pump and a control unit for consistent solid liquid separation.

The Glaser family, who operate Bar G Ranch Poultry, guaranteed their annual supply of chicken litter by adding a large turkey operation – producing approximately 600,000 birds a year.

raising such young turkeys, they may lose 25 to 30 birds a day. The Glasers incinerate the mortalities and the ash is added to the litter that’s spread on the pasture.

“They’re very small, so you don’t really have a lot of mortality to deal with,” says Darrell. “That’s why the incineration works the best for us.”

The Glasers don’t have a lot of control over the turkey operations. It’s fairly standardized and most of the management decisions are made by Cargill. That works out, because the Glasers aren’t focusing on big margins with the turkeys. Instead, the focus is on the cows where they do have control and are trying innovative things.

“We run a purebred Beefmaster operation. And we use an embryo transfer program and work to establish cows that do better on grass and are more efficient converters of feed. So, we’re working on both sides of the system,” says Darrell. “What we’ve done in our cattle operation is we’ve tried to increase the quality of our cattle through better animals that use the grass better, which in turn allows us to market those for a premium also.”

Twenty years ago, when the Glasers set out to change things around, water quality management wasn’t yet an industry standard. But the ranch was proactive and has operated under a water quality management plan since the very first day birds were placed on the farm in 1994.

“We worked with the soil conservation service on managing our litter and following guidelines to try and make sure the soil was cared for and there was no over fertilizing,” says Darrell.

And the extra effort was worth it.

“We didn’t run into a lot of problems that a lot of places had where they had been raising birds for years prior and then they started testing their soils and found out they had a tremendous excess of phosphorus in the soil, then had to stop using their litter,” he says. “Because we started managing from the beginning, we’ve been able to continuously use our litter from the very start because we’ve kept a very close eye on the phosphorous

When the Glasers decided to increase their cattle, they built five new clay-bottom ponds, 6,000 yards each. The ponds provide a water source for the cattle, help handle drainage and run off and add value to the property because there is more water-holding capacity. The ponds also provide wildlife habitat and help prevent soil erosion.

levels in the soils. And we’ve managed our application rates to our yield goals, like how many cattle per acre or how much hay we wanted to produce. And we test every year to make sure that we’re not getting an imbalance of our nutrients.”

Management practices have worked well. To date, the farm has never had an excess nutrient buildup.

One of the other things the Glasers did when they decided to increase their cattle was to build five new clay-bottom ponds, 6,000 yards each, in addition to the five Darrell’s grandfather had originally dug. Again, they worked with soil conservation folks.

“They came out, looked at the property, surveyed and said here’s where you should put your ponds and that’s what we did,” says Darrell.

The ponds provide a water source for the cattle, help handle drainage and run off and add value to the property because there is more water-holding capacity. The ponds also provide wildlife habitat and help prevent soil erosion.

The work they’re doing has been getting recognition. This year, the farm was one of the recipients of the USPoultry’s 2014 Family Farm Environmental Excellence Award, where farms are judged on dry litter management, nutrient management planning, community involvement, wildlife enhancement techniques, innovative nutrient management techniques and participation in education or outreach programs.

Darrell believes education is the key to the future of family. That doesn’t mean doing anything more than just speaking to people and letting people know where their food comes from.

“We always talk about agriculture. Since we began our turkey operation we’ve raised almost 14 million turkeys. When someone asks that question and you say that, they’re very intrigued and want to know how in the world do you raise 14 million turkeys. Then I tell them the brands of product that you

The Glasers have integrated the turkey and cattle operations together to produce a least cost system. The turkeys benefit the cattle, in that they produce the litter, which saves the family a lot of money on commercial fertilizer.

would see that possibly would have come through our farm.

“In my opinion it’s absolutely critical to our industry that we be good stewards and also share the knowledge of what goes on in our farms in a factual manner because there’s so much out there that may not be true. They need to know that, for the most part, we take good care of the land because that’s where our livelihood comes from.”

The Glasers have lots of plans ahead –more ponds, better soil, improved cattle operation through breeding and efficiencies – and it still all hinges on the litter.

“The whole key is how we’ve integrated the turkey and cattle operations together to produce a least cost system. The turkeys benefit the cattle, in that they produce the litter, which saves us a lot of money on commercial fertilizer. Then the cattle benefit from the turkeys because the labor I use on the turkey farm also works on the cattle operation – maximizing my labor force. So it’s just a least cost system that just works really well.”

Darrell adds, “We’ve been able to do it for this number of years and are seeing continuing improvement. Some of the things we’ve put in place for years, we’re starting to see the plan come to fruition. After 20 years, we’re reaping the rewards.”

• Center agitation system evenly blends nutrients.

• Better utilization of “waste” translates into less purchased fertilizer.

• Designed and constructed using bolted glass-fused-to-steel panels for secure storage and high corrosion resistance.

• Above ground - minimizes the danger of run-off, leaching and ground water contamination.

• Environment-friendly odor control - releases odors above ground level into higher air currents.

345 Harvestore Drive Dakalb, IL 60115

Visit www.cstindustries.com to find your local dealer, or call 815-756-1551.

By Ann Perry

Manure disposal is a big concern for cattle feedlot operators,” says Agricultural Research Service agricultural engineer John Gilley. “Fortunately, producers can reduce their use of commercial fertilizer – and their production costs – by using manure to fertilize their fields.”

“Manure makes a great fertilizer because it has so many nutrients,” agrees ARS agricultural engineer Bryan Woodbury. “But more people are moving to rural areas and don’t like the odor, so we’re trying to find a way to help producers control odors more effectively.”

Wherever manure ends up, its decomposition releases volatile fatty acids, aromatics, sulfides, amides, and

Agricultural engineer Bryan Woodbury (front left) collects a soil sample to characterize soil conditions following the field application of beef manure while agricultural engineer John Gilley (front right) and biological sciences aides adjust small wind tunnel equipment to be used for air quality measurements.

alcohols that are responsible for the odors. There has been some research on reducing odors when manure is used for fertilizer, but much of the work has been focused on applications of swine manure and poultry litter, which can be very different than beef manure applications.

Another factor that affects beef manure odor emissions is diet. Some producers supplement livestock feed with wet distillers grains with solubles (WDGS), a coproduct of corn ethanol production. Adding WDGS to cattle feed can increase the dietary levels of phosphorus, nitrogen, and sulfur, which in turn can raise emissions of ammonia and other odor-causing compounds.

However, WDGS feed supplements are a cost-effective way for livestock producers to lower their expenses, so producers are interested in finding approaches to managing manure odors that do not limit their use. One alternative is identifying how different beef manure application methods affect the emission of odor-causing compounds.

Woodbury and Gilley decided to conduct a comprehensive study to identify compounds responsible for beef manure odor and to evaluate how diet, soil moisture, and application procedures affect odor emissions. Woodbury works in the ARS Nutrition and Environmental Management Research Unit in Clay

Center, Nebraska, while Gilley works in the ARS Agroecosystem Management Research Unit in Lincoln, Nebraska. ARS agricultural engineer Roger Eigenberg and microbiologist Daniel Miller also collaborated on the study, as did West Texas A&M University professor David Parker and University of Nebraska-Lincoln professor David Marx.

“Compounds that cause odor are really hard to identify, so we knew we had our work cut out for us,” Gilley says.

In their study, the team used manure collected from feedlot pens where cattle consumed diets containing 0, 10, or 30 percent WDGS. The scientists also evaluated two application methods – no-till surface manure application and disk tillage that incorporated manure into the soil –and collected air samples before and after water was added to the soil to assess the effect of moisture levels on emissions.

Beef cattle manure was applied at levels that provided 135 pounds of nitrogen per acre, which met the 1-year nitrogen requirement for corn. This meant that some plots received more manure than other plots, because varying levels of WDGS in the cattle feed resulted in different levels of nitrogen in the manure. This approach was selected so that study findings related to odor mitigation practices would have more real-world relevance for producers.

After collecting and analyzing the air samples, the researchers determined that two volatile fatty acids – isovaleric acid and butyric acid – and the aromatic compound 4-methylphenol were responsible for more than two-thirds of detectable beef manure odors. Most of these odors were released within 24 hours after manure was applied to the soil.

Incorporating the manure into the soil and irrigating afterwards reduced most of the odor compounds that were measured. But the manure needed to be incorporated almost immediately after it was applied to obtain the most effective odor mitigation.

The importance of tilling manure into soil was highlighted by emission measurements the researchers obtained for 4-methylphenol. The greatest emissions of this compound occurred from dry soils on no-till plots and were sometimes as much as 10 times more than similar emissions from tilled soils.

Biological sciences aide Charles Hinds

and microbiologist Daniel Miller apply beef cattle manure to experimental plots in studies to identify compounds responsible for manure odor.

The researchers also noted some significant differences between emissions produced by volatile fatty acids and aromatics and emissions produced by sulfide compounds. These differences were especially notable in soils amended with manure produced by cattle that consumed feed with 30 percent WDGS. This type of manure emitted two sulfide compounds (dimethyl disulfide and dimethyl trisulfide) at significantly higher levels than other manures in the study –sometimes as much as eight times more.

The researchers also saw something they didn’t expect to see: Overall emissions of the sulfide compounds increased when soil moisture levels increased, unlike the other odor compounds, where emissions decreased as soil moisture levels increased. They are currently conducting additional laboratory studies to determine why this occurred. “It was a big surprise to us,” Woodbury says.

“Our results basically confirm that producers who want to use beef manure

to improve soil quality can incorporate it into the soil to reduce odors and maintain nutrients,” Woodbury says. “Now we’re working on ways to manage manure in the feedlot that will improve its characteristics as a soil amendment.”

“Knowing the principal components that influence odors in feedlots – pen location, moisture, and temperature – will help us with these investigations,” Gilley adds.

This research, which was published in the Journal of Environmental Quality in 2013, was conducted as part of the GRACEnet (Greenhouse-Gas Reduction through Agricultural Carbon Enhancement Network) program. GRACEnet is an effort to coordinate research projects at multiple ARS locations and determine the effects of management practices on soil carbon sequestration, trace gas emissions, and environmental quality.

Ann Perry is a member of the Agricultural Research Service Information Staff.

Anaerobic digester byproduct wins award

Magic Dirt, an organic peat moss replacement and byproduct of DVO’s anaerobic digestion (AD) process, won the 2014 Bioproduct Innovation of the Year Award from the Bioproducts World Showcase and Conference.

Magic Dirt, introduced by Cenergy USA in 2014, is a certified organic Premium Potting Soil and sustainable alternative to peat moss. The production process of Magic Dirt helps reduce greenhouse gas emissions.

“The primary ingredient in Magic Dirt is the clean, fluffy, nutrient-rich fiber that remains after dairy and farm wastes have been heat-treated in an air-tight oxygen-free vessel for 20 days,” explained Ted Sniegocki, a partner with Cenergy USA. “The process is done exclusively in DVO’s patented Two-Stage Mixed Plug Flow anaerobic digester. The digester captures methane gas which is used to generate renewable energy, reduces greenhouse gas emissions, and makes the fiber used in Magic Dirt.”

“Magic Dirt is a groundbreaking product and certainly deserving of the Bioproduct Innovation Award,” added Steve Dvorak, owner and founder of DVO, Inc.

www.magic-dirt.com

Iowa’s EPC adopts federal

In a unanimous vote, Iowa’s Environmental Protection Commission recently adopted rules governing totally roofed confinement feeding operations.

The rules require these facilities to have a federal permit to discharge to waters of the U.S. Called a national pollutant discharge elimination system or NPDES permit, operations that need the permits

must meet federal design, construction and monitoring standards.

However, the NPDES permit allows discharges of effluent to a water of the U.S. under certain conditions such as heavy rainfall. Depending upon the location, an NPDES-permitted facility in Iowa would be allowed to discharge if more than 5.6 inches of rain fell within 24 hrs.

“Iowa has 167 open feedlots with NPDES permits,” said Bill Ehm, the state’s Department of Natural Resources (DNR) administrator for environmental services. “These unroofed or partially roofed facilities have historically had some runoff through the feedlot when it rains. I don’t expect many NPDES permits to be issued to confinements.

“Most confinements will not need the protection of an NPDES permit, because they are unlikely to discharge,” Ehm added. “Most manure releases we’ve had in Iowa have been caused by a one-time event -– like an accident or failure of a pipe -– problems that the producer can demonstrate have been fixed with permanent measures that eliminate the cause of the discharge.

“However, the owner of a confinement or open lot that is likely to discharge would be wise to apply for an NPDES permit and the protection it provides in severe weather conditions.”

Any NPSDES permit holders must continue to meet existing requirements of Iowa law for construction permits and siting, manure management plans and land application.

The Iowa Legislature directed the commission to adopt the federal rules. Adoption was also a condition of a work plan agreement signed between the DNR and the U.S. Environmental Protection Agency Sept.11, 2013.

More information is available at www.iowadnr.gov/afo/.

Vogelsang, a pump and grinder manufacturing company, recently announced the appointment of John Grucella to the position of product manager for maceration and grinding products. John will champion our constantly evolving line of grinding products.

“Vogelsang provides an exceptional opportunity to grow the XRipper and RotaCut business in North & South America,” said Grucella. “I look forward to working with our distribution network to increase the presence of our great grinding products in the municipal and industrial markets.”

Grucella comes to Vogelsang with more than 10 years of experience in the municipal water and wastewater business. Recently, he was a regional sales and product manager for grinding and screening technology at JWC Environmental. He also spent time on the distribution side of the business, representing a variety of grinding and process products for the Newman Regency Group of Dallas, Texas. He earned a mechanical engineering degree from Ohio University.

“John has an extensive background in all kinds of grinding and process technology,” said Russ Boring, president of Vogelsang. “His expertise will help us properly apply the products into new markets. We’re excited to have him join us.”

www.vogelsangusa.com

Ontarians invest over $1 million to turn poo into power

ZooShare recently announced it has raised more than $1 million for what is soon to be North America’s first zoobased biogas plant.

ZooShare bonds, which are being used to build the biogas plant, pay a

return of seven percent each year for seven years. The bonds have the added benefit of an environmental return: the facility will recycle animal manure from the Toronto Zoo and food waste from local grocery stores into renewable power, while cleaning the air and returning valuable nutrients to the soil (in the form of a high-quality fertilizer).

“We are so grateful for the 150 investors who helped us reach one million dollars,” said Daniel Bida, executive director, “We reached this goal in less than a year, which exceeded our expectations, proving the market demand for sustainable high-impact investments. Together, we can demonstrate the true value of organic waste.”

ZooShare Biogas Cooperative Inc. is building a 500-kilowatt biogas plant across from the Toronto Zoo. Scheduled to be operational by December 2015, the facility will produce renewable power for the Ontario grid, reduce greenhouse gas emissions by over 10,000 tonnes each year, and generate above average returns for local investors.

The US Poultry & Egg Association (US Poultry) recently released a second video in a series highlighting environmental stewardship on poultry and egg farms.

The video features one of US Poultry’s Family Farm Environmental Excellence Award winners Cooley Farms, of Roberta, Georgia.

Cooley Farms, owned and operated by Larry and Leighton Cooley, has more than 1,050 acres of land on which chickens and cattle are raised and hay is grown. The farm began operating in 1985 on 70 acres of land with two broiler houses.

Over the years, the farm operation grew and evolved, specifically in the area of chicken production. Today, Cooley Farms raises approximately 500,000 chickens per flock on behalf of Perdue Farms, which equates to three million chickens per year in their 18 poultry houses. Litter management is an important part of farm

management for the Cooleys.

The farm uses detailed record-keeping to implement precise nutrient management plans. The litter is applied to the land and hay fields at rates needed to maintain appropriate nutrient levels in the soil, and the remainder is sold to other farms.

“We are proud of our farm and strive to ensure we exercise the best environmental management practices possible, said Larry Cooley, Cooley Farms.

“US Poultry and our members recognise the importance of exemplary environmental stewardship. We are pleased to be able to provide a video series that highlights how our family farmers achieve this,” commented John Starkey, US Poultry president.

Cooley Farms is one of US Poultry’s past Family Farm Environmental Excellence Award winners, recognised for exemplary environmental stewardship by family farms engaged in poultry and egg production.

The video can be viewed on US Poultry’s YouTube Channel.

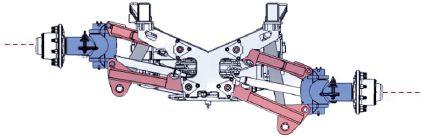

John Deere has made changes to its 5M-model lineup, including the addition of after-treatment systems to meet Final Tier 4 compliance, plus comfort, convenience, and performance features starting with model year 2015 tractors.

The changes impact the complete range of 5M Utility Tractors, ranging from 75- to 115-hp. The 3-cylinder 5075M model will have John Deere’s diesel oxidation catalyst (DOC) and diesel particulate filter (DPF) solution with no diesel exhaust fluid (DEF) required. The 5075M will also feature modern styling with chrome headlight bezels, a full range of isolated open operator stations and cabs, and new factory installed options such as front fenders and cab fender extensions, according to Brad Aldridge, product

marketing manager for 5M Tractors at John Deere.

“The no-hassle emissions regeneration system on the 5075M, combined with our durable 2.9 liter PowerTech engine, delivers simple ease of use and low cost of operation to customers,” Aldridge explains. “In addition, the new line of fully isolated platforms provides premium operator comfort, helping to maximize productivity and efficiency during long days in the field.”

The 4-cylinder 5Ms (5085M, 5100M, 5115M) will have a DOC/ SCR (selective catalytic reduction) solution using DEF to meet Final Tier 4 emissions standards. They also feature a compact cooling package and a new, low sloping hood that will improve in loader applications. Their 4.5-liter John Deere PowerTech engines are designed with an increased power bulge of up to four percent and a 30 percent torque rise for improved performance under load.

Servicing of the cooling system is easy with a slide-out condenser, sliding oil cooler, tiltable charge air cooler, and removable radiator screen. Optional LED worklights provide bright lighting for working late in the day or early in the morning.

These improvements are on top of the 16F/16R PowrReverser and 32F/16R PowrReverser transmissions, heavy-duty hitch capacity, and hydraulic capacity.

All 5M models can be matched with a variety of John Deere and Frontier implements.

www.JohnDeere.com/ag

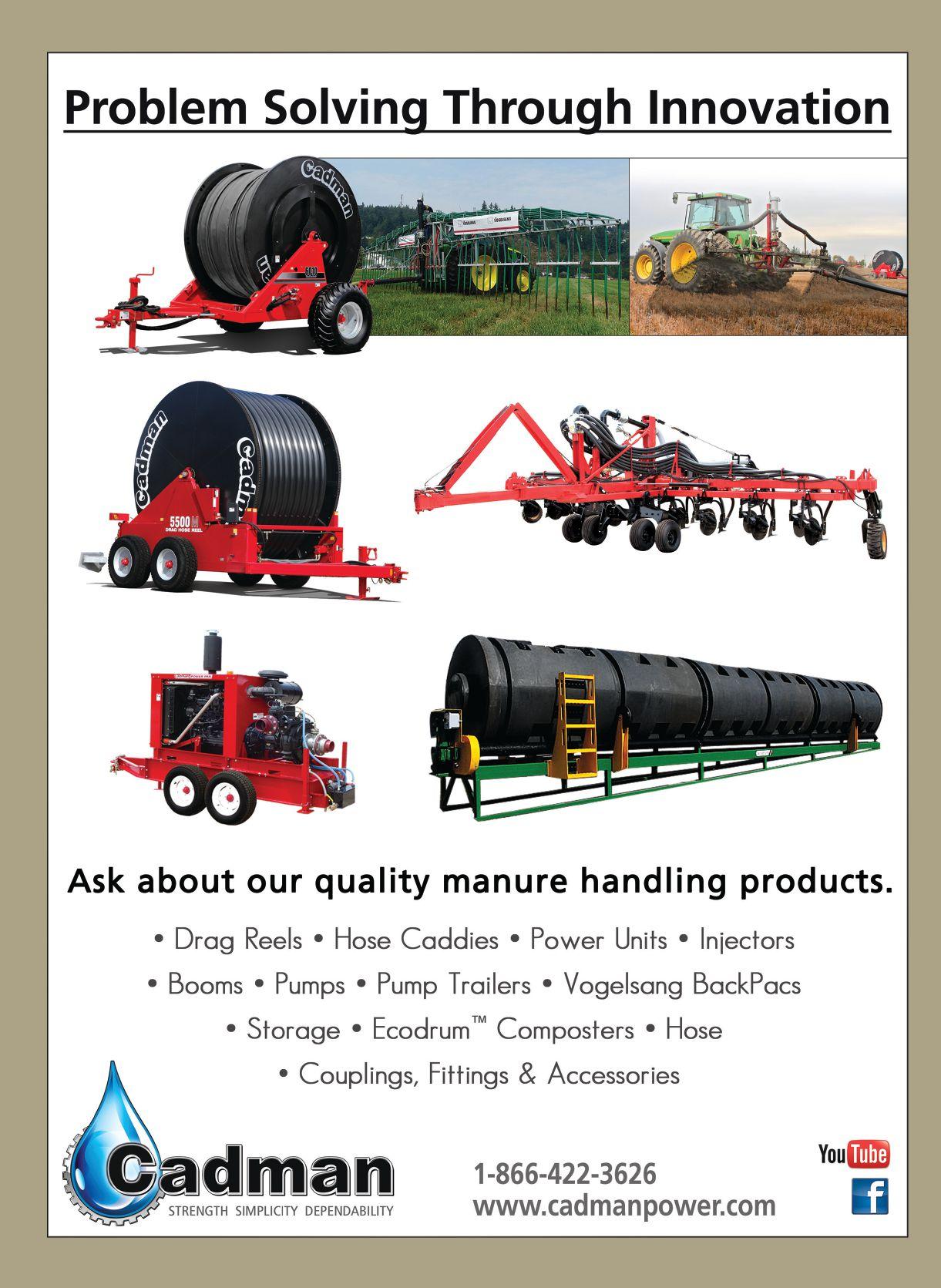

Cadman Power Equipment has utilized various Vogelsang technologies for a number of Cadman nutrient management products.

Earlier this spring, Cadman engineered a hydraulic manure injector featuring a Vogelsang ExaCut Distributor at its core.

“Every farmer has their own unique set of challenges,” said Craig Cadman, vice president of operations at Cadman Power Equipment. “We not only want to provide a solution, but we pride ourselves on coming up with a variety of quality solutions to effectively solve each of our customer’s own specific needs. Vogelsang products are a key component in some of our largescale nutrient handling equipment.”

Cadman Power Equipment now offers Vogelsang BackPacs as a part of their expanding nutrient handling suite. The BackPac umbilical system is an efficient way to spray manure, with maximum efficiency and minimal soil compression. Spreading can be done quickly and precisely using tanks or with a drag hose system.

“Using liquid manure instead of nitrogen and phosphorus-rich chemical fertilizer is the way of the future,” said Russ Boring, president of Vogelsang. “It’s best for crops and our watersheds. We’re excited to introduce our diverse line of agriculture products in North America.”

Cadman continues to introduce new products to the nutrient management market with the profitability of farmers in mind.

A joint collaboration between Chandler Equipment Company and SFP has led to the development of a spray unit mounted on Chandler spreaders allowing one-pass application of dry manures and More Than Manure (MTM) Nutrient Manager. The spray

assembly can either be factory installed or retrofitted to existing Chandler spreaders.

According to Michael Sosebee, national sales manager for Chandler Equipment Company, use of MTM on chicken litter previously required an additional pass to spray the product on applied litter 24 to 48 hours after application.

“No one wants to run their sprayers

that cost hundreds of thousands of dollars through applied chicken litter for obvious reasons,” Sosebee explains. “And farmers using chicken litter did not like making the separate application trip to apply MTM at a time when spray equipment is often tied up with other crop-related duties.”

The new spray kit, developed jointly by Chandler and SFP and offered on both pull-type and truck-mounted spreaders, avoids these obstacles and saves farmers the $7- to $10-per-acre application trip. In addition, farmers who purchase or retrofit their Chandler spreaders with the spray kit assembly are eligible for a $10-per-gallon credit on the purchase of More Than Manure – up to the actual invoice amount of the spray unit or a maximum of $8,000.

SFP regional manager Mark Fuchs, who covers the Mid-Atlantic region, notes that this new ability to apply MTM in conjunction with litter applications will be well received by no-till farmers because it will remove the need to incorporate the litter following application.

“This will be a big benefit for no-tillers who apply chicken litter – not only in the Southeast and Mid-Atlantic states, but throughout the U.S. where poultry production is well established,” Fuchs says.

The boom-less nozzles create a spray swath of 30 feet, which will cover the applied litter in the first pass. The spray kit also can be used to apply other crop-protection products that are labeled for tank mixes with MTM.

The spray kits for retrofitting and the spreaders with factory-installed spray nozzles are currently available nationwide through Chandler Equipment Companyauthorized dealers.

www.chandlerequipment.net

A & L CANADA LABORATORIES INC.

2136 Jetstream Rd.

London, ON N5V 3P5

Tel: 519-457-2575 Fax: 519-457-2664 www.alcanada.com

A & L CANADA LABORATORIES INC.

2136 Jetstream Rd.

London, ON N5V 3P5 Canada

Tel: 519-457-2575 Fax: 519-457-2664 www.alcanada.com

A & L GREAT LAKES LABORATORIES

3505 Conestoga Dr.

Fort Wayne, IN 46808 USA

Tel: 260-483-4759 Fax: 260-483-5274

e-mail: lab@algreatlakes.com www.algreatlakes.com

ABSOLUTE RESULTS

PO Box 6

Poole, ON N0K 1S0 Canada

Tel: 519-595-4117

Toll-Free: 1-855-595-4117

e-mail: tldiemand@cyg.net www.penergetic.ca

ACCENT MANUFACTURING, INC.

602-30731 Simpson Rd.

Abbotsford, BC V2T 6Y7 Canada

Toll-Free: 1-877-855-4890 Fax: 604-850-7909 www.accentmanufacturing.com

AERWAY/SAF-HOLLAND CANADA

LIMITED

P.O. Box 339

Norwich, ON N0J 1P0 Canada

Tel: 519-863-3414 Fax: 519-863-2398

Toll-Free: 1-800-457-8310

e-mail: aerway@aerway.com www.aerway.com

AG LEADER TECHNOLOGY

2202 South Riverside Dr. Ames, IA 50010 USA

Tel: 515-232-5363 Fax: 515-232-5363

e-mail: info@agleader.com www.agleader.com

AGCO CORPORATION

4205 River Green Parkway

Duluth, GA 30096 USA

Tel: 770-813-9200 Fax: 770-813-6038

Toll-Free: 1-877-525-4384

e-mail: AGCOanswers@AGCOcorp.com www.agcocorp.com

AGPROFESSIONALS, LLC

3050 67th Ave.

Greeley, CO 80634 USA

Tel: 970-535-9318 Fax: 970-535-9854

e-mail: tharen@agpros.com www.agpros.com

AGRIBRINK

RR 1, 8152 Con 16

Moorefield, ON N0G 2K0 Canada

Tel: 519-840-0919

e-mail: sales@agribrink.com www.agribrink.com

AGRIMENT SERVICES INC.

PO Box 1096

Beulaville, NC 28518 USA

Tel: 252-568-2648 Fax: 252-568-2750

Toll-Free: 1-800-641-6981

e-mail: agrimentservices@yahoo.com www.agrimentservices.com

AGSOURCE LABORATORIES

106 N. Cecil St. Bonduel, WI 54107 USA

Tel: 715-758-2178 Fax: 715-758-2620 www.agsource.com

AIM ENVIRONMENTAL GROUP

400 Jones Rd. Stoney Creek, ON L8E 5P4 Canada Tel: 905-560-0090 Fax: 905-560-0099

e-mail: info@aimgroup.ca www.aimgroup.ca

ALLIANCE TIRE AMERICAS, INC.

201 Edgewater Dr., Suite 285 Wakefield, MA 01880 USA

Toll-Free: 1-877-978-4737

Fax: 888-371-6195

e-mail: atamarketing@atgtire.com www.atgtire.com

ANAERGIA INC.

4210 South Service Rd. Burlington, ON L7L 4X5 Canada

Tel: 905-766-3333

e-mail: info@anaergia.com www.anaergia.com

AQUA INNOVATIONS LLC

655 Third St., Suite 100 Beloit, WI 53511 USA

Tel: 262-736-4211 Fax: 262-736-4214

e-mail: info@aquainnovationsllc.com www.aquainnovationsllc.com

ART’S WAY MANUFACTURING CO., INC.

PO Box 288 Armstrong, IA 50514 USA

Tel: 712-864-3131 Fax: 712-864-3312

e-mail: sales@artsway-mfg.com www.artsway-mfg.com

ATD WASTE SYSTEMS INC.

3099 West 24th Ave. Vancouver, BC V6L 1R7 Canada

Tel: 604-736-4474 Fax: 604-736-4493

e-mail: 1cleanfarm@hogmanure.com www.hogmanure.com

AUTOMATED WASTE SYSTEMS LLC

3115 - 320th St.

Hull, IA 51239 USA

Tel: 712-439-2081 Fax: 712-439-2078

Toll-Free: 1-866-918-2081 www.automatedwastesystems.com

BAG MAN

PO Box 162, 634 County Rd. T

Hammond, WI 54015 USA

Toll-Free: 1-800-796-5333

Fax: 715-796-5655

e-mail: info@afsbagman.com www.afsbagman.com

BALLAGH LIQUID TECHNOLOGIES INC.

121 North St. W. RR 2 Wingham, ON N0G 2W0 Canada

Tel: 519-357-4600 Fax: 519-357-4630

Toll-Free: 1-877-312-4600

e-mail: info@bliquidtech.com www.bliquidtech.com

BALZER, INC.

County Rd. 27E, Box 458 Mountain Lake, MN 56159 USA

Tel: 507-427-3133 Fax: 507-427-2364

Toll-Free: 1-800-795-8551 www.balzerinc.com

BAMBAUER EQUIPMENT LLC

19151 Kettlersville Rd. New Knoxville, OH 45871 USA

Tel: 419-753-2275 Fax: 419-753-3116

e-mail: info@bambauerequipment.com www.bambauerequipment.com

BAUER ENERGY DESIGN INC.

130 Louisa St. Baden, ON N3A 2T8 Canada

Tel: 519-634-9974 Fax: 519-634-9906 www.bauerenergydesign.com

BAUER NORTH AMERICA

107 Eastwood Rd. Michigan City, IN 46360 USA

Tel: 219-879-4986 Fax: 219-879-5160

Toll-Free: 1-800-922-8375

e-mail: r.hultgren@bauer-at.com www.bauer-at.com

BAZOOKA FARMSTAR

800 E. 7th St., PO Box 869 Washington, IA 52353 USA

Tel: 319-653-5080 Fax: 319-653-5806

Toll-Free: 1-800-775-7448

e-mail: spittman@bazookafarmstar.com www.bazookafarmstar.com

BBI SPREADERS

PO Box 630, 470 S. Wayside St. Cornelia, GA 30531 USA

Tel: 706-778-2767 Fax: 706-778-2787

Toll-Free: 1-800-282-3570 www.bbispreaders.com

BIOFERM ENERGY SYSTEMS

617 N Segoe Rd, PO Box 5408 Madison, WI 53705 USA

Tel: 608-467-5523 Fax: 608-233-7085

e-mail: info@biofermenergy.com www.biofermenergy.com

BIOLOGICAL SOLUTIONS INC.

PO Box 9617

Helena Lewis Clark, MT 59604 USA

Tel: 406-458-3855 Fax: 406-458-3906

BIOROTER.COM

1555 Hwy. 210 E., Box 575

St. Adolphe, MB R5A 1A2 Canada

Tel: 204-883-2378 Fax: 204-883-2869

Toll-Free: 1-866-943-0739

e-mail: dean@triplegreenenergy.com www.triplegreenenergy.com

Main Products/Services: The BioRoter is an in-vessel composter. Every unit is custom built to suit the individual’s needs. In-vessel composting is a very economical solution to manure management. BioRoters produce quality compost.

BOERGER, LLC

2860 Water Tower Place

Chanhassen, MN 55317 USA

Tel: 612-435-7300 Fax: 612-435-7301

e-mail: america@boerger.com www.boerger.com

BRAD PENN LUBRICANTS

77 N. Kendall Ave.

Bradford, PA 16701 USA

Tel: 814-368-1200 Fax: 814-368-1335

e-mail: rbyron@amref.com www.bradpennsgeo.com

BRENTWOOD POLYMER COATINGS INC.

324 Saunders Road, Unit 8 Barrie, ON L4N 9Y2 Canada

Tel: 705-792-0500 Fax: 877-411-6866

Toll-Free: 1-855-792-0500

e-mail: info@brentwoodcoatings.com www.brentwoodcoatings.com

BRITESPAN BUILDING SYSTEMS INC.

37651 Amberley Rd.

Lucknow, ON N0G 2H0 Canada

Toll-Free: 1-800-407-5846

Fax: 519-528-2890

e-mail: info@britespanbuildings.com www.britespanbuildings.com

BRODIE AG & INDUSTRIAL INC.

4490 Trussler Rd.

Ayr, ON N0B 1E0 Canada

Tel: 519-632-1190 Fax: 519-632-1189

e-mail: albrodie@megawire.ca www.brodieagandindustrial.ca

BTL SALES INC.

3451 SW Empire Dr. Prineville, OR 97754 USA

Tel: 541-447-0712 Fax: 541-447-0759

Toll-Free: 1-800-280-0712 (US only) e-mail: info@btlliners.com www.btlliners.com

BUHLER INDUSTRIES INC.

1201 Regent Ave. W. Winnipeg, MB R3C 3B2 Canada

Tel: 204-661-8711 Fax: 204-654-2503

e-mail: info@buhler.com www.buhlerindustries.com

C & E TANKS AND SILOS, LLC

PO Box 406

Menomonie, WI 54751 USA

Tel: 715-235-9647 Fax: 715-235-9433 www.cetanksandsilos.com

CADMAN POWER EQUIPMENT LTD.

Box 100

Courtland, ON N0J 1E0 Canada

Tel: 519-688-2222 Fax: 519-688-2100

Toll-Free: 1-866-422-3626

e-mail: inquiries@cadmanpower.com www.cadmanpower.com

CADY INC.

383 Illinois Hwy. 92

Tampico, IL 61283 USA

Tel: 815-438-5678 Fax: 815-438-5681

Toll-Free: 1-877-999-CADY

e-mail: cady@cadyinc.com www.cadyinc.com

CANADA’S OUTDOOR FARM SHOW

160 Research Lane, Unit 101 Guelph, ON N1G 5B2 Canada

Tel: 519-822-2890 Fax: 519-829-1777

Toll-Free: 1-800-563-5441

e-mail: info@outdoorfarmshow.com www.outdoorfarmshow.com

CH-FOUR BIOGAS INC

1390 Prince of Wales Dr., Suite 102 Ottawa, ON K2C 3N6 Canada

Tel: 613-224-8308 Fax: 613-224-1642

Toll-Free: 1-866-730-6500

e-mail: info@chfour.ca www.chfourbiogas.com

CHORE-TIME PO Box 2000

Milford, IN 46542-2000 USA

Tel: 574-658-4101 Fax: 574-658-3471

e-mail: choretime@choretime.com www.choretime.com

CLAAS OF AMERICA INC.

8401 South 132nd St. Omaha, NE 68138 USA

Tel: 402-861-1000 Fax: 402-861-1003 www.claasofamerica.com

CLEARSPAN FABRIC STRUCTURES

1395 John Fitch Blvd.

South Windsor, CT 06074 USA

Tel: 866-643-1010 Fax: 860-760-0210

e-mail: trussinquiry@clearspan.com www.ClearSpan.com/ADMM

CONESTOGA-ROVERS & ASSOCIATES

651 Colby Dr. Waterloo, ON N2V 1C2 Canada

Tel: 519-884-0510 Fax: 519-725-5256 www.CRAworld.com

CONNECT EQUIPMENT CORP.

P.O. Box 71

Mildmay, ON N0G 2J0 Canada

Tel: 519-508-7010 Fax: 519-637-5502

e-mail: sales@connectequipment.com www.connectequipment.com

COOKS COUNTRYSIDE TRUCKING, LLC

S7701A Denzer Rd. North Freedom, WI 53951 USA

Tel: 608-544-5445 Fax: 608-544-9955

Toll-Free: 1-877-261-0619

e-mail: cookscstllc@aol.com www.cookscountrysidetrucking.com

CORNELL PUMP COMPANY

16261 S.E. 130th Ave. Clackamas, OR 97015-8948 USA

Tel: 503-653-0330 Fax: 503-653-0338

e-mail: bjansen@cornellpump.com www.cornellpump.com

CROP QUEST INC.

PO Box 357, 74 Sylvia St. Mitchell, ON N0K 1N0 Canada

Tel: 519-348-1121 Fax: 519-348-0030

Toll-Free: 1-866-630-2767

e-mail: cropquest@quadro.net www.cropquest.ca

DARITECH, INC.

8540 Benson Rd. Lynden, WA 98264 USA

Tel: 360-354-6900 Fax: 360-354-7522

Toll-Free: 1-800-701-3632

e-mail: info@daritech.com www.daritech.com

DE BIE MANUFACTURING LTD.

720 Goshen Rd. Tillsonburg, ON N4G 4G7 Canada Tel: 519-842-6218

e-mail: info@debie.ca www.debie.ca

DEGELMAN INDUSTRIES

272 Industrial Dr. Regina, SK S4P 3B1 Canada Tel: 306-543-4447 Fax: 306-543-2140 Toll-Free: 1-800-667-3545

e-mail: info@degelman.com www.degelman.com

DFK EQUIPMENT SALES INC.

PO Box 938, 475 James St. S St. Marys, ON N4X 1B6 Canada Tel: 519-349-2080 Fax: 1-800-752-0934

Toll-Free: 1-800-881-3794

e-mail: sales@dfkequipment.com www.dfkequipment.ca

DIGI-STAR LLC

W5527 Hwy. 106

Fort Atkinson, WI 53538 USA

Tel: 920-568-6231 Fax: 920-568-9721

e-mail: sales@digi-star.com www.digi-star.com

DODA USA INC.

255 16th St. South St. James, MN 56081 USA

Tel: 507-375-5577

e-mail: admin@dodausa.com www.dodausa.com

DOW AGROSCIENCES LLC

9330 Zionsville Rd.

Indianapolis, IN 46268 USA

Tel: 317-337-3000 Fax: 317-337-6081 www.dowagro.com

DSM NUTRITIONAL PRODUCTS

45 Waterview Blvd.

Parsippany, NJ 07054-1298 USA

Tel: 973-257-8396 Fax: 973-257-8653 www.dsm.com

DUTCH BUNNING DISTRIBUTION LTD.

500 Portico Dr., PO Box 568

Pilot Butte, SK S0G 3Z0 Canada

Tel: 306-781-4820 Fax: 306-781-6038

Toll-Free: 1-800-663-8824

e-mail: sales@dutchbunning.com www.dutchbunning.com

DVO, INC.

PO Box 69

Chilton, WI 53014 USA

Tel: 920-849-9797 Fax: 920-849-9160

e-mail: info@dvoinc.net www.dvoinc.net

ELMIRA MACHINE INDUSTRIES/RIV QUALITY BRASS VALVES

20 Martin Lane

Elmira, ON N3B 2A1 Canada

Tel: 519-669-1541 Fax: 519-669-8331

Toll-Free: 1-800-801-6663

e-mail: info@elmiramachine.com www.elmiramachine.com

ENVIRONETICS INC.

1201 Commerce St. Lockport, IL 60441 USA

Tel: 815-838-8331 Fax: 815-838-8336

e-mail: info@environeticsinc.com www.environeticsinc.com

EUROVIX USA, INC.

PO Box 1808

Portage, MI 49081 USA

Tel: 269-329-1198

e-mail: pbperks@cs.com www.eurovix.us or www.eurovix.it

FAN SEPARATOR

107 Eastwood Rd.

Michigan City, IN 46360 USA

Tel: 219-871-1580 Fax: 219-879-5160

Toll-Free: 1-800-451-8001

e-mail: r.hultgren@bauer-at.com www.fan-separator.com

FARM CREDIT CANADA

100 - 120 Research Lane

Guelph, ON N1G 0B5 Canada

Fax: 519-826-2066

Toll-Free: 1-800-387-3232 www.fcc-fac.ca

FARM-FLEET INC.

23703 Wellburn Rd., RR 3

St. Marys, ON N4X 1C6 Canada

Tel: 519-461-1499 Fax: 519-461-1599 www.farmfleet.com

FARMER BOY AG INC.

50 West Stoever Ave.

Myerstown, PA 17067 USA

Tel: 717-866-7565 Fax: 717-866-6233

Toll-Free: 1-800-845-3374

www.FarmerBoyAG.com

FARMTEK

1440 Field of Dreams Way

Dyersville, IA 52040 USA

Tel: 860-289-7261 Fax: 860-289-4711

Toll-Free: 1-800-327-6835

e-mail: sales@farmtek.com www.farmtek.com

FEECO INTERNATIONAL, INC.

3913 Algoma Rd.

Green Bay, WI 54311 USA

Tel: 920-468-1000 Fax: 920-469-5110

Toll-Free: 1-800-373-9347

e-mail: sales@feeco.com www.feeco.com

FENDT TRACTORS

4205 River Green Parkway Duluth, GA 30096 USA

Tel: 770-813-9200 Fax: 770-813-6038

Toll-Free: 1-877-525-4384

e-mail: AGCOanswers@AGCOcorp.com www.fendtfielddays.com

FIRESTONE SPECIALTY PRODUCTS

250 W. 96th St. Indianapolis, IN 46260 USA

Tel: 317-575-7000 Fax: 317-575-7002

Toll-Free: 1-800-428-4442

e-mail: info@firestonesp.com www.firestonesp.com

FLOTECH PUMP

D1, 3911 Brandon St. SE Calgary, AB T2G 4A7 Canada

Tel: 403-236-2886 Fax: 403-225-8446

Toll-Free: 1-866-248-2886

e-mail: sales@flotechpump.com www.flotechpump.com

FTI FLOW TECHNOLOGY, INC.

8930 S. Beck Ave., Ste. 107 Tempe, AZ 85284 USA

Toll-Free: 1-800-528-4225 www.ftimeters.com

GEA FARM TECHNOLOGIES CANADA

INC., DIVISION GEA HOULE

4591 boul. St-Joseph Drummondville, QC J2B 6W3 Canada

Tel: 819-477-7444 Fax: 819-477-5565

Toll-Free: 1-800-563-4685

e-mail: geahoule@gea.com www.gea-farmtechnologies.com/houle/en

GEOMEMBRANE TECHNOLOGIES INC. (GTI)

370 Wilsey Rd. Fredericton, NB E3B 6E9 Canada

Tel: 506-452-7304

e-mail: covers@gticovers.com www.gticovers.com

GLOBAL REPAIR

33 Bellefair Ave.

Toronto, ON M4L 3T7 Canada

Tel: 416-686-3690 Fax: 416-686-1744

Toll-Free: 1-866-271-0719

e-mail: sales@globalrepair.ca www.globalrepair.ca

GORMAN-RUPP COMPANY

305 Bowman St. Mansfield, OH 44903-1600 USA Tel: 419-755-1011 Fax: 419-755-1251 www.GRpumps.com

GORMAN-RUPP OF CANADA LTD.

70 Burwell Rd. St. Thomas, ON N5P 3R7 Canada Tel: 519-631-2870 Fax: 519-631-4624

e-mail: grcanada@grcanada.com www.GRCanada.com

GREEN EARTH NATURALLY/EARTHCLEANZ

2314 Ridgefield St. NE Roanoke, VA 24012 USA

Tel: 540-362-5636 Fax: 540-362-9447

e-mail: info@greenearthnaturally.com www.greenearthnaturally.com

GROWING THE MARGINS CONFERENCE & EXHIBITION

c/o 1 Concord Gate, Suite 109, Box 26 Toronto, ON M3C 3N6 Canada

Tel: 416-426-7029 Fax: 416-426-7280

e-mail: info@gtmconference.ca www.gtmconference.ca

GSE ENVIRONMENTAL 19103 Gundle Rd. Houston, TX 77073 USA Tel: 281-443-8564 Fax: 281-230-6739 Toll-Free: 800-435-2008 e-mail: marketing@gseworld.com www.gseworld.com

H & S MANUFACTURING CO., INC. 2608 S. Hume Ave., PO Box 768 Marshfield, WI 54449 USA

Tel: 715-387-3414 Fax: 715-384-5463 www.hsmfgco.com

HAGEDORN

3098 Bruce Rd. 3 S., PO Box 129 Paisley, ON N0G 2N0 Canada Tel: 519-353-5642 Fax: 519-353-5871

Toll-Free: 1-800-707-7271

e-mail: info@hydra-spread.com www.hydra-spread.com

HANSEN MANUFACTURING Box 393

Agassiz, BC V0M 1A0 Canada

Tel: 604-316-3664 Fax: 604-858-9128

e-mail: glenhansen@live.ca

HAPCO

390 Portage Blvd. Kent, OH 44240 USA

Tel: 330-678-9353 Fax: 330-677-8282

e-mail: sales@hapco.com www.hapcoinc.com

HARCO AG EQUIPMENT

5808 Hwy. 9, RR 4

Harriston, ON N0G 1Z0 Canada

Tel: 519-338-2923 Fax: 519-338-2756

e-mail: harquip@wightman.ca

HAWKEYE STEEL PRODUCTS INC.

609 Main St.

Houghton, IA 52631 USA

Tel: 319-469-4141 Fax: 319-469-4402

Toll-Free: 1-800-553-1791

e-mail: sales@hawkeyesteel.com www.spantechbuildings.com

HCC, INC.

1501 First Ave.

Mendota, IL 61342-0952 USA

Tel: 815-539-9371 Fax: 815-539-3135

e-mail: info@hccincorporated.com www.hccincorporated.com

HCL MACHINE WORKS

15142 Merrill Ave.

Dos Palos, CA 93620 USA

Tel: 209-392-6103 Fax: 209-392-3000

e-mail: sales@hclmachineworks.com www.hclmachineworks.com

HORIZON LIVESTOCK & POULTRY SUPPLY LTD.

329 Bronstone Dr. Niverville, MB R0A 1E0 Canada

Tel: 204-388-9333 Fax: 204-388-5227

Toll-Free: 1-877-388-3887

e-mail: info@horizonhasit.ca www.horizonhasit.ca

HUSKY FARM EQUIPMENT LTD.

7440 Wellington Rd. 17 Alma, ON N0B 1A0 Canada

Tel: 519-826-5329 Fax: 519-846-9378

Toll-Free: 1-800-349-1122

e-mail: husky@huskyfarm.ca www.huskyfarm.ca

HUSSEY & COMPANY

11 Plaza Dr. Clear Lake, IA 50428 USA

Tel: 641-357-7000 Fax: 641-357-7008

Toll-Free: 1-800-944-1830

e-mail: josh@husseyco.com www.husseyco.com

HYDRO ENGINEERING

301 Industrial Blvd.

Norwood Young America, MN 55397 USA

Tel: 952-467-3100 Fax: 952-467-4000

Toll-Free: 1-800-833-5812

e-mail: sales@hydro-eng.com www.hydro-eng.com

IMPERIAL INDUSTRIES INC.

PO Box 1685

Wausau, WI 54402 USA

Tel: 715-359-0200 Fax: 715-355-5349

Toll-Free: 1-800-558-2945

e-mail: toma@imperialind.com www.imperialind.com

INDUSTRIAL & ENVIRONMENTAL

CONCEPTS, INC.

6009 Chapel Dr. Minneapolis, MN 55439 USA

Tel: 952-829-0731 Fax: 952-829-9770

Toll-Free: 1-888-829-0731

e-mail: anderson@ieccovers.com www.ieccovers.com

JAMESWAY FARM EQUIPMENT

12 Route 249

St-Francois-Xavier-de-Brompton, QC J0B 2V0 Canada

Tel: 819-845-7824 Fax: 819-845-5758

e-mail: marketing@valmetal.com www.jameswayfarmeq.com

JAYNE PRODUCTS/JENFITCH, LLC

17904 S. Star of India Lane Carson, CA 90746 USA

Tel: 310-715-3070 Fax: 310-327-4906

Toll-Free: 1-866-754-8062

e-mail: info@struviteremoval.com www.struvite.info

JBS LTD. (J. BOND & SONS LTD.)

Unit 103 - 31413 Gill Ave.

Mission, BC V4S OA1 Canada

Tel: 604-826-5391 Fax: 604-826-5392

Toll-Free: 1-855-826-5391 www.jbscanada.ca

JENI MOBILE WASH LTD.

Box 100

Fergus, ON N1M 2W7 Canada

Tel: 519-843-2672 Fax: 519-787-7608

Toll-Free: 1-800-361-3637

JIM HODEL INC.

2278 CR 1350 N. Roanoke, IL 61561 USA

Tel: 309-923-7106 Fax: 309-923-7655

Toll-Free: 1-800-562-8565

e-mail: jim@jimhodelinc.com www.jimhodelinc.com

JONES MANUFACTURING CO. 1486 12th Rd., PO Box 38 Beemer, NE 68716-0038 USA

Tel: 402-528-3861 Fax: 402-528-3239 www.mightygiant.com

JONKMAN EQUIPMENT LTD.

28355 Fraser Hwy. Abbotsford, BC V4X 1K9 Canada Tel: 604-857-2000 Fax: 604-857-2001 e-mail: info@jonkmanequipment.com

KARCHER PROFESSIONAL WASH SYSTEMS, DIV. OF CONNECT EQUIPMENT CORP.

2193 Line 29, RR 2 Tavistock, ON N0B 2R0 Canada

Tel: 519-655-2253 Fax: 519-655-3017 www.karcherpro.ca

KEY DOLLAR COMPANY

PO Box 49

Milton-Freewater, OR 97862 USA

Tel: 541-938-6336 Fax: 541-938-6282

Toll-Free: 1-800-241-2427

e-mail: key_dollar@hotmail.com www.keydollar.com

KIFCO IRRIGATION

700 S. Schrader Ave. Havana, IL 62644 USA

Tel: 309-543-4425 Fax: 309-543-4945

Toll-Free: 1-800-452-7017

e-mail: sales@kifco.com www.kifco.com

KLINE IRRIGATION NORTH AMERICA

4270 Hollywood Rd. St. Joseph, MI 49085 USA

Tel: 269-429-3000 Fax: 269-429-3700

Toll-Free: 1-866-665-5463

e-mail: info@k-linena.com www.k-linena.com

KOOLMEES EQUIPMENT INC.

285687 Airport Rd., RR 1 Norwich, ON N0J 1P0 Canada

Tel: 519-468-3356

e-mail: info@koolmees.ca www.koolmees.ca

KOOLMEES MARINE INDUSTRIAL SALES, SERVICE (IRRIGATION) Middletown Line 712651

Otterville, ON N0J 1R0 Canada Tel: 519-879-6878 Fax: 519-879-6319

e-mail: springfordenterprises@execulink.com

KUHN NORTH AMERICA INC. PO Box 167 Brodhead, WI 53520 USA Tel: 608-897-2131 Fax: 608-897-2561 www.KuhnNorthAmerica.com

KUNAFIN - THE INSECTARY PO Box 190 Eagle Pass, TX 78877 USA Tel: 830-757-1181 Fax: 830-757-1468

Toll-Free: 1-800-832-1113

e-mail: office@kunafin.com www.kunafin.com

KYTE CENTRIFUGE LLC

10 E Owl Creek Lane Fairview, NC 18730 USA

Tel: 832-368-2667 Fax: 407-369-4674 www.kytecentrifuge.com/manure

LAGOON PUMPING AND DREDGING INC. 4015 South 9th St. Columbus, NE 68601-6227 USA Tel: 402-563-3464 Fax: 402-564-1696

LAYFIELD GROUP OF COMPANIES 11120 Silversmith Place Richmond, BC V7A 5E4 Canada

Tel: 604-275-5588 Fax: 604-275-5589

Toll-Free: 1-800-558-8275

e-mail: corporate@layfieldgroup.com www.layfieldenvironmental.com

LEADING EDGE EQUIPMENT LIMITED

404878 Beaconsfield Road

Burgessville, ON N0J 1C0 Canada

Tel: 519-424-9112 Fax: 519-424-2667

e-mail: wayne@leadingedgeequipment.ca

LEON’S MANUFACTURING COMPANY INC.

135 York Rd. E.

Yorkton, SK S3N 3Z4 Canada

Tel: 306-786-2600 Fax: 306-782-1884

Toll-Free: 1-800-667-1581

e-mail: mkt@leonsmfg.com www.leonsmfg.com

LITCHFIELD ANALYTICAL SERVICES

535 Marshall St., PO Box 457

Litchfield, MI 49252 USA

Tel: 517-542-2915 Fax: 517-542-2014

e-mail: litchlab@qcnet.net www.litchlab.com

LIVESTOCK WATER RECYCLING, INC.

3637 - 44th Ave. SE

Calgary, AB T2B 3R5 Canada

Tel: 403-203-4972

Toll-Free: 1-855-597-4972

e-mail: marketing@livestockwaterrecycling. com www.livestockwaterrecycling.com

LOEWEN WELDING LTD.

33655 Harris Rd., PO Box 66

Matsqui, BC V4X 3R2 Canada

Tel: 604-826-7844 Fax: 604-826-6051

e-mail: rick@loewenwelding.com www.loewenwelding.com

LSC PRE-CAST SYSTEMS LTD.

8285A Lickman Rd.

Chilliwack, BC V2R 3Z9 Canada

Tel: 604-792-4244 Fax: 604-792-4241

Toll-Free: 1-888-796-2323

e-mail: lsc@lscprecast.com www.lscprecast.com

MANURE SYSTEMS INC.

3046 McMillan Rd.

Abbotsford, BC V2S 6A8 Canada

Tel: 604-226-6075

Toll-Free: 1-800-799-3740

e-mail: info@manuresystemsinc.com www.manuresystemsinc.com

MCLANAHAN CORPORATION

200 Wall St. Hollidaysburg, PA 16648 USA

Tel: 814-695-9807 Fax: 814-695-6684

e-mail: agdivision@mclanahan.com www.mclanahan.com

METAL 360

Box 59, RR 1 Ste. Anne, MB R5H 1R1 Canada

Tel: 204-355-7634

e-mail: info@metal360.ca www.metal360.ca

MEYER MANUFACTURING CORPORATION

574 W. Center Ave., PO Box 405 Dorchester, WI 54425 USA

Tel: 715-654-5132 Fax: 715-654-5513

Toll-Free: 1-800-325-9103

e-mail: sales@meyermfg.com www.meyermfg.com

MIDWEST BIO-SYSTEMS

28933 - 35E St. Tampico, IL 61283 USA

Tel: 815-438-7200 Fax: 815-438-7028

Toll-Free: 1-800-689-0714

e-mail: info@midwestbiosystems.com www.midwestbiosystems.com

MIGHTY GROW ORGANICS

870 Edward Loper Rd. Fruitdale, AL 36539 USA

Tel: 251-827-6668 Fax: 1-888-565-7378

e-mail: anne@mightygrow.com www.mightygrow.com

MILLER ENGINEERS AND SCIENTISTS

5308 S. 12th St.

Sheboygan, WI 53081 USA

Tel: 920-458-6164 Fax: 920-458-0369

Toll-Free: 1-800-969-7013

e-mail: sthiel@startwithmiller.com startwithmiller.com

MMI INTERNATIONAL

Box 544

Brush, CO 80723 USA

Tel: 970-842-5161 Fax: 970-842-3111

Toll-Free: 1-800-523-2614

e-mail: info@mixerfeeders.com www.mixerfeeders.com

MOBY DICK WHEEL WASHING

20 Highview Rd. Downington, PA 19335 USA

Tel: 610-613-2939 Fax: 610-458-9151

e-mail: ralodi@us.mobydick.com www.mobydick.com

MOHRLANG FABRICATION

18990 CR 29 Brush, CO 80723 USA

Tel: 970-542-0640

e-mail: bmohrlang@spreaderz.com www.spreaderz.com

NEBRASKA HARVESTORE SYSTEMS

3201 S. 13th St. Norfolk, NE 68701 USA

Tel: 402-371-0144 Fax: 402-371-6031

Toll-Free: 1-800-777-0501

e-mail: sales@nebraskaharvestore.com www.nebraskaharvestore.com

NEW LEADER/HIGHWAY EQUIPMENT CO. 1330 76th Ave. SW Cedar Rapids, IA 52404 USA

Tel: 319-363-8281

e-mail: info@highwayequipment.com www.highwayequipment.com

NOLT SERVICES LLC

728 Rettew Mill Rd. Lititz, PA 17543 USA Tel: 717-738-1066

e-mail: janolt@windstream.net

NUHN INDUSTRIES LTD.

PO Box 160, 4816 Line 34 Sebringville, ON N0K 1X0 Canada Tel: 519-393-6284 Fax: 519-393-5104

Toll-Free: 1-877-837-7323

e-mail: nuhnind@nuhn.ca www.nuhn.ca

OHIO DEPARTMENT OF AGRICULTURE

8995 East Main St. Reynoldsburg, OH 43068-3399 USA

Tel: 614-728-6201 Fax: 614-728-6310 www.agri.ohio.gov

ONTARIO SOIL & CROP IMPROVEMENT ASSOCIATION

1 Stone Rd. W. Guelph, ON N1G 4Y2 Canada

Tel: 519-826-4214 Fax: 519-826-4224 www.ontariosoilcrop.org

PACIFIC DAIRY CENTRE LTD.

34282 Manufacturers Way

Abbotsford, BC V2S 7M1 Canada

Tel: 604-852-9020 Fax: 604-852-5091

e-mail: office@pacificdairy.net www.pacificdairycentre.com

PARMA COMPANY

PO Box 190, 101Main St.

Parma, ID 83660 USA

Tel: 208-722-5116 Fax: 208-722-6012 www.parmacompany.com

PATZ CORPORATION

PO Box 7

Pound, WI 54161-0007 USA

Tel: 920-897-2251 Fax: 920-897-2142

Toll-Free: 1-800-236-7280

e-mail: info@patzcorp.com www.patzcorp.com

PENERGETIC CANADA

329 - 5525 West Blvd. Vancouver, BC V6M 3W6 Canada

Tel: 604-736-0907 Fax: 604-736-0901

Toll-Free: 1-888-737-0907

e-mail: info@penergetic.ca www.penergetic.ca

PICHON S.A.

BP 21, Z.I. de Lavallot Guipavas, F-29490 France

Tel: +33 298 34 41 00

Fax: +33 298 34 41 20

e-mail: jp@pichonindustries.com www.pichonindustries.com

PIK RITE INC.

60 Pik Rite Lane

Lewisburg, PA 17837 USA

Tel: 570-523-8174 Fax: 570-523-8175

Toll-Free: 1-800-326-9763

e-mail: sales@pikrite.com www.pikrite.com

PIPPING CONCRETE INC.

N5888 Center Rd. Brandon, WI 53919 USA

Tel: 920-872-2520 Fax: 920-346-2520

Toll-Free: 1-877-948-9661

e-mail: pippingconcrete@hotmail.com www.pippingconcrete.com

PREMIER EQUIPMENT LTD.

122 Church St. W. Elmira, ON N3R 2X6 Canada

Tel: 519-669-5453 Fax: 519-669-3403

Toll-Free: 1-800-265-6188

e-mail: elmira@premierequipment.ca www.premierequipment.ca

PRESS TECHNOLOGY & MFG., INC. 1401 Fotler St. Springfield, OH 45504 USA

Tel: 937-327-0755 Fax: 937-327-0756

e-mail: dberner@presstechnology.com www.presstechnology.com

PRICE BROS. EQUIPMENT CO. 619 S. Washington

Wichita, KS 67211 USA

Tel: 877-957-9577 Fax: 316-265-1062

e-mail: tprice@pricebroseq.com www.pricebroseq.com

PRO-ACT BIOTECH

PO Box 345

Warren, RI 02885 USA

Toll-Free: 1-800-772-3775

Fax: 401-633-6270 www.proactbiotech.com

PROFITPRO, LLC

408 1st Ave. S.

Albert Lea, MN 56007 USA

Tel: 507-373-2550 Fax: 507-373-2520

Toll-Free: 1-888-875-2425 www.profitproag.com

PUCK CUSTOM ENTERPRISES, INC.

1130 - 100th St.

Manning, IA 51455 USA

Tel: 712-653-3045 Fax: 712-653-3099

e-mail: jpuck@puckenterprises.com www.puckenterprises.com

QUANTUM BIOTEK

1394 Milton Ave.

Mississauga, ON L5G 3C6 Canada

Tel: 647-490-0095 Fax: 1-888-390-2655

Toll-Free: 1-800-263-0048

e-mail: garry@omnienviro.ca www.waterforfarming.com

RCM DIGESTERS INC.

PO Box 4716

Berkeley, CA 94704 USA

Tel: 510-834-4568 Fax: 510-834-4529

e-mail: contact@rcmdigesters.com

REDHAND LTD.

PO Box 989

Boissevain, MB R0K 1E0 Canada

Tel: 204-534-7382

REDWOOD METAL WORKS

36419 US Hwy. 71, PO Box 88

Redwood Falls, MN 56283 USA

Tel: 507-644-2893 Fax: 507-644-7000

Toll-Free: 1-888-644-2893 www.redwoodmetalworks.com

REINKE MANUFACTURING COMPANY

INC.

5325 Reinke Rd.

Deshler, NE 68340 USA

Tel: 402-365-7251 Fax: 402-365-4370

Toll-Free: 1-866-365-7381 www.reinke.com

REMOTE LOAD, INC.

2428 Hwy. 3

Dumont, IA 50625 USA

Tel: 641-425-6998

e-mail: kurtwolf@remote-load.com www.remote-load.com

ROACH & ASSOCIATES, LLC

856 North Main St.

Seymour, WI 54165 USA

Tel: 920-833-6340 Fax: 920-833-9851

e-mail: john@jmroach.com www.jmroach.com

ROTARY COMPOSTERS

503 School Rd. Denver, PA 17517 USA

Tel: 717-397-7237 Rotarycomposters.com

SENNINGER IRRIGATION

16220 East Hwy. 50

Clermont, FL 34711 USA

Tel: 407-877-5655 Fax: 407-905-8249

e-mail: info@senninger.com www.senninger.com

SFP - SPECIALTY FERTILIZER PRODUCTS

11550 Ash, Suite 220 Leawood, KS 66211 USA

Tel: 913-956-7500 Fax: 913-956-7506

Toll-Free: 1-888-446-GROW

e-mail: mberry@sfp.com www.sfp.com

SIDUMP’R

53577 Hwy. 20, PO Box 520 Plainview, NE 68769 USA

Tel: 402-582-4830 Fax: 402-582-4810

Toll-Free: 1-888-743-8677

e-mail: sales@sidumpr.com www.sidumpr.com

SOUCY INTERNATIONAL

5450 Saint-Roch St. Drummondville, QC J2B 6W3 Canada

Tel: 819-474-6666 Fax: 819-477-9423 www.soucyinternational.com

SPANJER MACHINES

50 - 715 Doon Village Rd. Kitchener, ON N2P 2A2 Canada

Tel: 519-897-1891

SPRUCEDALE AGROMART LTD.

Box 68

Hanover, ON N4N 3C3 Canada

Tel: 519-364-4070 Fax: 519-364-7716

Toll-Free: 1-888-289-2440

e-mail: hanover@sprucedale.com www.sprucedale.com

SRS CRISAFULLI INC.

1610 Crisafulli Dr. Glendive, MT 59330-1051 USA

Toll-Free: 1-800-442-7867 Fax: 406-365-8088

e-mail: srsc@crisafulli.com www.crisafullipumps.com

STEWART’S EQUIPMENT

9410 Wellington Rd. 124, PO Box 10 Erin, ON N0B 1T0 Canada

Tel: 519-833-9616 Fax: 519-833-2253 www.stewartsequip.com

STRATFORD AGRI ANALYSIS 1131 Erie St.

Stratford, ON NSA 6W1 Canada

Tel: 519-273-4411 Fax: 519-273-4411

Toll-Free: 1-800-323-9089

e-mail: info@stratfordagri.ca www.stratfordagri.ca

SUMA AMERICA, INC.

855 N. Wood Dale Rd., Suite A Wood Dale, IL 60191 USA

Tel: 847-427-7880 Fax: 630-354-6840

e-mail: gene@gosuma.com www.gosuma.com

SUMMIT LIVESTOCK FACILITIES

3823 W 1800 S Remington, IN 47977 USA

Toll-Free: 1-800-213-0567

Fax: 219-261-3193

e-mail: info@summitlivestock.com www.summitlivestock.com

SUNOVA WORX INC.

196679 19th Line, RR 1 Lakeside, ON N0M 2G0 Canada

Tel: 519-349-2770 Fax: 519-349-2310

Toll-Free: 855-386-(WORX) 9679

e-mail: info@sunovaworx.com www.sunovaworx.com

T-L IRRIGATION COMPANY

151 East Hwy. 6 & AB Road Hastings, NE 68902-1047 USA

Tel: 402-462-4128 Fax: 402-462-4617

Toll-Free: 1-800-330-4264

e-mail: sales@tirr.com www.tlirr.com

TASCH’S CUSTOM LLC

N9900 St. Paul Rd. Malone, WI 53049 USA

Tel: 920-375-0900

e-mail: chad@taschscustomllc.com www.taschscustomllc.com

TEAMCO 2, Rue Du Parc Warwick, QC J0A 1M0 Canada

Tel: 819-358-6808 Fax: 819-358-6806

e-mail: info@teamco.ca www.teamco.ca

TERRATEC ENVIRONMENTAL/AMERICAN WATER

200 Eastport Blvd. Hamilton, ON L8H 7S4 Canada

Tel: 905-878-2800 Fax: 905-878-4180

THE EXPERT COMPANY

PO Box 6

Clintonville, WI 54929 USA

Tel: 605-337-3737 Fax: 605-337-3400

e-mail: sarc@midstatesd.net www.expertcompany.us

THERMOENERGY CORPORATION

10 New Bond St. Worcester, MA 01606 USA

Tel: 508-854-1628 Fax: 508-854-1753 www.thermoenergy.com

THOMPSON PUMP

4620 City Center Dr. Port Orange, FL 32129 USA

Tel: 386-767-7310 Fax: 386-761-0362

Toll-Free: 1-800-767-7310