November /december 2012

November /december 2012

south CArolinA

Poultry fArm

GAsifyinG litter

Poultry litter a ‘gas’

South Carolina poultry litter gasification project an important steppingstone

Technology and turkeys

Bullard Farms incorporates turkeys and a lot of technology to produce quality birds, compost and fertilizer 18 In the News

Cover: Poultry litter is augered into M.Marsh Farms’ BGP gasifier at a rate of 200 pounds per hour. Submitted photo

November/december 2012

Volume 10 • No. 6

Published by:

Annex Publishing & Printing Inc. P.O. Box 530 Simcoe, Ontario N3Y 4N5

editor

Margaret Land • (519) 429-5190, (888) 599-2228, ext 269 mland@annexweb.com

contributing editors

Tony Kryzanowski, Diane Mettler, Natalie Rector

Advertising manager

Sharon Kauk • (519) 429-5189, (888) 599-2228, ext 242 skauk@annexweb.com

Sales Assistant

Mary Burnie • (519) 429-5175, (888) 599-2228, ext 234 mburnie@annexweb.com

media designer Gerry Wiebe

vP Production/Group Publisher Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: subscribe@manuremanager.com

Printed in Canada

circulation

e-mail: subscribe@manuremanager.com

Tel: 866-790-6070 ext. 211

Fax: 877-624-1940

Mail: P.O. Box 530 Simcoe, ON N3Y 4N5

Subscription rates canadian Subscriptions

$35.24 Cdn, one year (with GST $37.00, with HST/QST $39.82)

U.S. Subscriptions: $47.00 USD, one year

Occasionally, Manure Manager will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher's written permission. ©2012 Annex Publishing & Printing Inc.. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher's approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Website: www.manuremanager.com

IBy Margaret Land

n early October, testimony finally began in a lawsuit that pitted the Waterkeeper Alliance of New York City against Hudson Farm, a small poultry operation in Maryland, and Perdue, the poultry integrator the farm produced for.

I first started writing about this fiasco back in late 2009. At that time, the Wall Street Journal featured an article on what I described as the poultry poop police, a group of “volunteers” who fly over the Delmarva looking for piles of chicken manure, photograph them, and then sample the surrounding streams and ditches looking for elevated bacterial levels. I expressed alarm at this, likening it to a person being presumed guilty until proven innocent.

A few months later, I wrote of how the poultry poop police plot was thickening. At that time, the Assateague Coastkeeper and the Waterkeeper Alliance had just filed notice to sue Hudson Farm and Perdue, citing violations of the Clean Water Act.

Then the Maryland Department of the Environment (MDE) became involved and inspected the Berlin-area poultry and beef operation. Inspectors discovered the pile wasn’t poultry litter but Class A biosolids from a local municipality. Alan and Kristin Hudson were ordered to move the biosolids away from a nearby drainage ditch and repair the area where the pile had originally been situated. They were also issued a $4,000 administrative penalty for improper storage of sludge, a fine they later had removed under appeal.

According to the MDE, “while sampling results showed elevated bacterial levels at the Hudson Farm, levels in the area immediately adjacent and downstream of the sludge were not as high as levels further downstream. The source of the bacteria was not conclusively identified.”

This didn’t stop the Waterkeeper Alliance from continuing on with its ridiculous lawsuit, claiming instead that poultry litter is contaminating water through exhaust fan dust and bacteria tracked out of the barns on boots. To add insult to injury, the group is having its legal representation provided free of charge by the taxpayer-funded University of Maryland’s Environmental Law Clinic – a situation described by Maryland’s governor Martin O’Malley as an “injustice.”

Meanwhile, the Hudson family has been relying on donations and money raised through the Save Farm Families organization to help pay its legal bills, which are estimated at more than $300,000.

Testimony for the lawsuit wrapped up in mid-October and final arguments are scheduled for the end of November.

There is some hope justice will prevail for the Hudson family. In pretrial court documentation, Senior United States District Judge William M. Nickerson stated: “there are elements of this litigation that the Court finds disturbing … it seems clear that the original Plaintiffs in this action were looking for an opportunity to bring a citizen suit under the CWA against some chicken production operation under contract with a major poultry integrator.”

He added that once a farm was found, they acted like they had found their “bad apple.

“(The) Plaintiffs’ case has now gone from a large pile of uncovered chicken manure to small amounts of airborne litter from the exhaust fans, trace amounts brought out on shoes and tires, and a dustpan of litter left on the heavy use pads.”

It would appear Judge Nickerson isn’t having the wool pulled over his eyes, adding that the court can award attorney fees to the “prevailing defendant.”

A decision in the case is anticipated before Christmas. Hopefully it will result in a happy gift for the Hudsons, who have suffered enough.

By Tony Kryzanowski

Carolina poultry litter gasification project an important steppingstone

Like clockwork, South Carolina farmer Marc Marsh watched a manure broker cart away and market the poultry litter gleaned from cleaning out his 12 barns after his pullets matured or egg layers reached the end of their productive lives. While it didn’t cost him a dime to dispose of the litter, he didn’t make any money on the transaction either.

He got to thinking that maybe there was some way that the farm could benefit from the litter, and that led him down the road to poultry litter gasification to produce the fuel to generate power.

With financial support from the United States government’s Farm Pilot

Project Coordination (FPPC) program and mentoring from FPPC engineer Preston Burnette, the nearly $1 million poultry litter gasification demonstration project –intended to generate 20 to 30 kilowatts of power – is essentially in place.

While the project has proven that gasification of poultry litter to produce fuel to generate power is technically possible, Marsh sees greater potential in his farm operation to use the system to convert the poultry litter into a product called biochar that he can use in his turf business. Biochar contains many of the same beneficial chemicals as commercial fertilizer except for the nitrogen, but conversely, contains more carbon.

Marsh and his wife, Melanie, own M. Marsh Farms near Cheraw, S.C., about 70 miles southeast of Charlotte. It is a combination high-security, poultry breeding operation and turf business.

The eggs produced on the farm are used by other poultry farmers to raise their egg-laying flocks and the high-quality turf grass grown on the 185-acre farm is used on golf courses, sports fields, lawns and commercial applications.

In 1990, Marsh graduated with a bachelor’s degree in poultry science from North Carolina State University, which led to a job with Tyson Foods. In 2001, the couple purchased its own farm.

The poultry operation generates more than 1,200 tons of litter annually, consisting of a combination of kiln-dried wood fiber bedding and scratching material mixed with chicken droppings. That bedding material is commonly used in South Carolina’s poultry industry because it doesn’t contain fungus, spores and moulds that could harm the flock. The farm houses about 100,000 chickens at a time, consisting of 50,000 laying hens

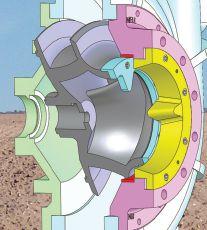

The BGP gasifier is assembled at M. Marsh Farms. The goal is to consistently produce 20 to 30 kilowatts of power from the fuel produced from gasifying poultry litter.

Now, more than ever, pork producers recognize the impact their operations can have on the world around them. Proactive eco-management with MicroSource S can help reduce environmental burdens. By feeding MicroSource S, producers benefit from:

• Reduction in noxious manure gases, like ammonia and VFAs, for less odor – resulting in better community relationships

• Increased nitrogen retention in manure - resulting in improved N:P Ratio

• Lower manure viscosity - resulting in less power required for pump outs and the ability to pump out more manure

• Decreased stickiness of manure resulting in reduced labor requirements due to easier/less cleaning MicroSource S contains selected microbes that digest the solids in hog manure. It begins to work even before the manure hits the floor and continues to act on manure during handling and storage. Fed throughout the pig’s lifecycle, MicroSource S can help you better balance the challenges of efficient pork production with environmental stewardship.

To learn more, contact your feed supplier, go to www.unlimitednutrition-na.dsm.com, or call 1 800 526 0189.

and 50,000 pullets that are grown to become egg layers. It takes the pullets up to 21 weeks to reach maturity. It takes up to 45 weeks for the egg layers to complete their productive cycle. In the past, a contractor and farm employees would take between six and eight weeks to remove the poultry litter using a Bobcat and then sterilize the barns for the next batch of chickens at the end of each cycle. Prior to installation of the gasifier, a litter broker typically sold the poultry litter to other farms for use in corn and soybean crops as organic fertilizer.

Now, with the farm’s poultry litter gasifier in place, the barn cleaning is handled internally, the manure is stored securely on site, and conveyed, as needed, to the gasifier as fuel.

Burnette designed the overall M. Marsh Farms gasification system, finding off-the-shelf components to fit each step of the design specification.

“The problem with using poultry litter as a fuel has not been the energy content

but how to actually gasify it and convert it into energy,” says Burnette. “A lot of people have tried in the past 20 to 30 years and really haven’t gotten anywhere because of material handling problems.”

He says that poultry litter isn’t a consistent product; it can be sticky and has moisture problems.

“Everything that coal is, poultry litter is not,” he says.

Proper material handling of the litter from moving it from the barns to the storage sheds to feeding it into the gasifier was evaluated extensively as part of this demonstration project to find an effective solution.

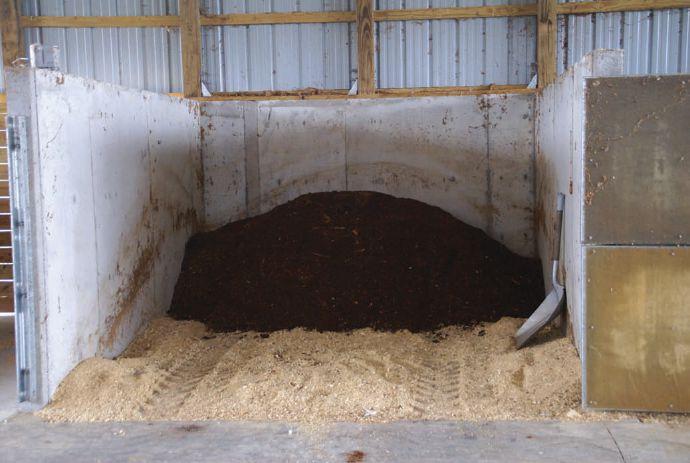

With installation of the gasification system, M. Marsh Farms has purchased equipment to handle the barn cleaning in house. The poultry litter is now stored in two sheds with financial support from the United States Department of Agriculture’s EQIP program, consisting of about 10,000 square feet of storage. Farm employees fill a hopper located in the manure shed

twice a day and it augers the manure into the gasifier at the prescribed rate of 200 pounds per hour.

The gasification process is a two-stage process called the Brookes Gasification Process (BGP) provided by a Canadian company called BGP Inc. Propane is used to heat the primary and secondary chambers initially to reach their operating temperatures. The heat cooks the poultry litter that enters the primary chamber, which creates off-gases. Some of these off-gases are used to substitute for the propane, at which point it can be turned off. A chimney draft propels the remainder of the off-gases to a secondary chamber where it ignites in a controlled, high heat environment. The heat from that ignition passes around a Cain heat exchanger to heat water to about 220 F. A pump circulates the heated water from the heat exchanger through an ElectraTherm-brand Organic Rankin Cycle, where it boils a refrigerant that drives a turbine to create power.

Impeller

Agitating tough pits takes less time and less fuel so you can start hauling

Turbine revolutionizes manure pump performance. Incredible intake suction pulls solids into the cutter knives, reducing the toughest crust to nothing in just seconds. The turbine combines high-volume mixing of a propeller agitator with the power and reach of a lagoon pump, the resulting hybrid design radically outperforms both.

The ash byproduct created by poultry litter gasification is of a much smaller volume than the raw material and is a good

“You can sustain gasification of poultry litter theoretically all year long,” says Burnette. However, because the M. Marsh Farms installation is a demonstration project, it has run continuously for just three to four days at a time. Burnette says that this gasification technology applied to poultry litter is at its very early stages.

He adds the M. Marsh Farms project fulfils FPPC’s mandate, which is to demonstrate technology that finds alternative uses for nutrients, in this case, an alternative to spreading poultry litter on soil. Gasification produces energy and an ash byproduct, which has much less volume and weight, can be used as a soil amendment and is easier to store.

“We’re still not sure if these systems will work out economically,” says Burnette. The system components themselves are a bit expensive because so few are commercially available.

“Is this type of technology viable?” Burnette asks. “Yes. We know that we can generate electricity from poultry litter. This project in South Carolina served as a steppingstone and learning curve for us.”

One lesson learned is that farmers need to be able to use the equipment to generate more than electricity to achieve a return on investment. Because of the unique nature of this farm as a breeding operation, the energy is only used to produce electricity but poultry litter gasification demonstrates that it can also potentially generate heat for commercial poultry operations. This concept is being studied extensively by FPPC in other projects in the Chesapeake Bay Watershed States.

Marsh says installation of the gasifier provides the farm with a number of benefits. It allows them to dispose of the litter on the farm, eliminates the biosecurity risk of the manure broker coming to the farm, and will also produce a new revenue stream, “which at the end of the day is our main goal.” In addition to sale of power, the process produces ash, which is sold as a soil amendment.

On-farm disposal helps the overall operation because they can now store and dispose of the manure when it is generated, which was a problem dealing with brokers because the manure sometimes became available when it was not optimal timing to land apply the product.

“There is not always a dependable

Once heated up with propane, the BGP gasifier is self-sustaining, with some off-gases produced by poultry litter gasification used to fuel the system.

market at a dependable price,” says Marsh. “We wanted to try to increase the value of the return of the product back to the farm.”

It took seven years for the poultry manure gasification concept to evolve from idea to reality. Marsh began talking about it in 2005 as he was working on his animal waste management plan. He says Burnette has been on the farm nearly every day of the week helping to inch the project forward. Other organizations such as the State of South Carolina, the federal Agriculture Department, and the Chesterfield Soil and Water Conservation District have also recognized the potential for poultry litter gasification and have provided financial support for the project. The Marshes have invested about 20 percent of the cost of the project themselves.

When Marsh and Burnette teamed up, Burnette was in the process of investigating the potential of a BGP brand gasifier in farm applications at North Carolina State University. The timing for launching the demonstration project was also good because the South Carolina’s Department of Agriculture had issued a request for grant proposals for alternative energy from biomass, which yielded a $200,000 grant.

So far, the project has produced power for sale to the local Lynches River Power cooperative intermittently and Marsh says he has yet to receive any large checks from the coop because of the small amount of power that the system has been able to generate consistently so far. However, he says that he has absolutely no regrets about becoming involved in the project, keeping in mind that it is a demonstration project aimed at investigating the technology, evaluating its potential, and discovering where there needs to be improvements. Burnette says that he is confident with potentially upgrading the capacity of the gasifier and a bit of tweaking, that the M. Marsh Farms poultry litter gasification system will be able to produce between 20 and 30 kilowatts of power consistently.

As a result of this project and the lessons learned, and with encouragement from FPPC, the State of South Carolina has submitted a proposal to develop a model to help guide the design performance characteristics of these gasification systems.

By Diane Mettler

Bullard Farms incorporates turkeys and a lot of technology to produce quality birds, compost and fertilizer

In 2006, the Bullard family was growing crops and raising hogs and decided to expand their operation by raising turkeys. In less than a year, they were raising 64,000 turkeys and this year they won the North Carolina Poultry Federation Grower Environmental Excellence Award.

The Bullards are not strangers to farming. Collins is a fifth-generation farmer who runs the Bullard farm with his parents and wife, Alison. With the addition of turkeys, they also have three houses for the operation’s 3,000 hogs and farm 1,500 acres, where they grow corn, wheat, beans, watermelons, and this year, a new crop – sorghum.

When the Bullards decided to add turkeys to their portfolio, the idea became a reality in an incredibly short amount of time.

They approached Prestage Farms about raising birds for them and discussions began immediately.

“Prestage put together numbers and we looked at sites – trying to figure out where exactly we wanted to put things.

Over about a six-month period we were up and running,” says Collins.

Getting up and running required the construction of eight, tunnel ventilated barns to house the turkeys from four to 20 weeks of age and around 42 pounds. Each barn is 50 feet wide by 500 feet long, or 25,000 square feet, and holds around 8,000 turkeys.

The barns are state of the art, says Collins.

TOP: The Bullard family of North Carolina raises 64,000 turkeys and recently won the 2012 North Carolina Poultry Federation Grower Environmental Excellence Award. INSET: The Bullard family operates eight, tunnel-ventilated barns to house the turkeys from four to 20 weeks of age. Each barn is 50 feet wide by 500 feet long, or 25,000 square feet, and holds around 8,000 turkeys. Submitted photos

TOP: The Bullard farm has two sheds –one 50 feet by 100 feet and the other 50 feet by 200 feet, with a total of 14,000 square feet to keep the litter covered and off the ground.

MIDDLE: The Bullards use a forced-air compost system to handle mortalities. Under a covered structure, any turkey mortalities are layered between organic matter, such as shavings and roadside grass clippings. The rows are kept at a specific moisture level and a temperature between 150 to 160 F for 30 to 45 days.

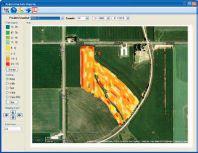

BOTTOM: The Bullard family uses litter testing combined with grid soil sampling to closely monitor the amount of nutrients being applied to the operation’s 1,500 acres.

Submitted photos

“They provide superior environmental control for optimum bird comfort, with a cooling system in each house.”

The houses have a central computer system, which allows not only viewing of all eight houses, but also monitoring via a laptop. And an extensive alarm system will alert Collins if there is a failure in the feed, water, ventilation or other system.

“We were the first tunnel farm for Prestage, and one of the first tunnel farms in this area,” says Collins. “At the time, Prestage didn’t know exactly how these things were going to work and neither did I. So, there were some growing pains in the beginning. But we worked through things.”

Part of the learning process involved the computer system and learning what it could do and how to set it up to do what Prestage and the Bullards wanted – for example, adjust to temperatures that can vary substantially from day to day.

“Today, we still have to put in the programs, and the program depends on the size of the bird,” says Collins. “Everything is on a memory card. You insert that into the computer and the computer will automatically update everything.

Computers also play a part in litter handling. The Bullards raise about three flocks a year. To handle the majority of the litter, Collins uses a caking machine, moving the litter from near the feed and water lines, where the bulk of the waste accumulates.

Introducing EnergyJet, Pre-Mixing System

EnergyJet provides a thoroughly conditioned liquid feed to the digester that is homogeneous and free of damaging solid objects.

Mix cosubstrates such as corn silage, grass silage or most any plant silage with liquid manure to create a slurry prepared for maximum gas output.

“When it’s time to remove it, the litter is a little on the damp side and that’s when our sheds come into play,” says Collins.

The farm has two sheds – one 50 feet by 100 feet and the other 50 feet by 200 feet, with a total of 14,000 square feet to keep the litter covered and off the ground.

“We’ll go in weekly and turn it and by turning it we’re drying it out, also breaking it up, making it easier to spread.”

The litter can be stored in the sheds for as long as necessary, until it’s time to apply. This year, the Bullards will pull about 2,880 tons, which will be either immediately applied or stored.

Before any application though, Collins performs grid soil sampling.

“It gives us a better idea of what nutrients need to go where and to land-apply the litter based on of those soil samples. The litter has a real high phosphorus content and it works well with a wheat and corn and beans rotation.”

If spreading requires going off the turkey farm, the Bullards contract haul it with litter trucks.

“If not, we have a BBI 20-ton spreader that we can load that is used on the tractor,” says Collins.

The farm has also incorporated GPS with its grid soil sampling to help them stay right on target and avoid over applying.

“And all the tractors have auto-steer on them,” adds Collins. “Because of that, it’s essential that the material is broken up so it spreads evenly.”

The hogs’ manure management system is completely different. The hog houses have a slatted floor and the waste is collected in a pit below. The waste is gravity fed to a lagoon where the water is recycled to wash out the house, and it is also pumped onto the hay fields when needed.

It’s all automated, says Collins.

“The tanks pump two or three times a day and constantly wash out the underside of the house. In the lagoon, we have markers that give us our low point, high point, and acceptable water.”

As with the turkeys, the Bullards take samples of the lagoon waste as well as soil samples and apply the manure based on the results. With the pigs, however, the waste is liquid and much easier to handle than the dry turkey litter.

One of the things that sets the Bullard farm apart, and helped them achieve the 2012 environmental award, is its forcedair compost system, which was installed in 2010 by Advanced Composting. The system not only is an environmentally friendly way to handle mortalities (versus burying or burning) but also provides an end product.

Under a covered structure, any turkey mortalities are layered between organic matter, such as shavings and roadside grass clippings. The rows are kept at a specific moisture level and a temperature between 150 to 160 F for 30 to 45 days.

During that time, air is pumped in, rotating from bin to bin, and monitored via a computer.

“We also wet it and recycle the juices that come off of the animals as they break down, and we introduce some enzymes to that material, which helps with the breakdown process,” says Collins.

By the end of the 45 days, the bird carcasses are completely broken down,

except for the harder bones, which are ground down.

“The finished product comes out a real even fertilizer; about a 15/15/15,” says Collins. “It’s also really a dry product, easy to spread, and easy to manage.”

One of the reasons for the composting facility is that the Bullards could see there would soon be regulations coming from the U.S. Environmental Protection Agency and the state on dead stock disposal. It made good business sense to be proactive.

“We felt it was a good time figure out what we were going to do.”

The benefits of this system turned out to be many. The finished product is comparable to commercially available fertilizer. It acts as predator control and helps keep coyotes, dogs and buzzards away from the turkey houses. The high temperatures also help reduce pests, such as mice and flies.

The Bullards continue to buy some commercial fertilizers, such as liquid nitrogen for corn, but their overall purchase of commercial fertilizers has gone down significantly.

“I don’t think we’ll ever replace fertilizer completely, just because the litter doesn’t have a uniform nutrient content. For example, if we pull a load out from under the feed line, it has … more nutrient value than what’s in the center of the house where there are more shavings,” says Collins. “That’s why we mix it a lot and why we use the grid soil sampling. It’s a good way of keeping up with how much you’re putting out there from year to year and if you need to back off of a certain area for some time.”

The composting and litter storage facility both keep odors down, but it can’t be completely eliminated, especially during application.

“We try to be courteous neighbors,” says Collins. “When we are landapplying, we work it into the ground with a disc right behind the litter spreader.

It’s obvious that the Bullard farm embraces technology. Some other farmers shy away from it, but Collins welcomes it. Technology is one of the reasons the farm has been able to grow. Collins’ great-great-grandfather started with about 40 acres; today the farm is at 1,500 acres and requires only Collins, his dad and two employees to manage everything.

“If we didn’t have any problems, two people could manage this farm,” he says.

“I like the technology. I think if you don’t try to keep up with technology, you’re going to get left behind. The technology is there; you might as well use it because everything is heading in that direction. We want to stay in this business and, in order to do so, we have to be productive. I think technology helps the productivity of this farm.”

Collins is a next-generation farmer and

the awards he is receiving are the proof. Not only has he received the North Carolina Poultry Federation Grower Environmental Excellence Award but he has also won the Young Farmer of the Year from the Cumberland County Board of Commissioners, Outstanding Young Farmer from the County Farm Bureau. Another environmental award is pending.

What Collins is most proud of is the farm’s consistency.

“We continue to produce a quality bird for Prestage Farm.”

A new manure management and air quality education website has been launched by University of Minnesota Extension.

The new website provides educational materials, and current research from the university in the area of manure management and air quality in livestock production.

Major categories in the new website are manure management, feedlot and manure storage, air quality, milk house wastewater, manure pathogens, manure treatment, and manure application.

The website will also provide an events calendar with local and regional manure management educational opportunities.

The website can be accessed at www1.extension.umn.edu/agriculture/ manure-management-and-air-quality/.

The Maryland Department of Agriculture (MDA) recently released its Final Notice to Adopt the state’s revised nutrient management regulations.

The regulations took effect Oct. 15, 2012, and are designed to achieve consistency in the way all sources of nutrients are managed and help Maryland meet nitrogen and phosphorus reduction goals spelled out in its Watershed Implementation Plan (WIP) to protect and restore the Chesapeake Bay.

The final regulations include one technical, non-substantive change in the provision that refers to nutrient application setbacks and the department’s consideration of new practices developed by the USDA’s National Resources Conservation Service and the University of Maryland. MDA revised the provision to add “and other land grant universities.”

A copy of the final regulations is available on MDA’s website.

A Frequently Asked Questions document is available online.

The Nutrient Management Advisory

Committee has been working on the revised regulations for nearly two years. The new rules were originally introduced October 2011; however, due to overwhelming feedback, Governor Martin O’Malley asked that the proposed regulations be placed on hold to provide an additional opportunity for stakeholders to further discuss the proposal as well as hear input from his BayStat Scientific Panel. The regulations were revised and published in the Maryland Register on June 29, 2012. The MDA then held a series of four public meetings across the state in July to provide information to farmers, environmental interests, local governments and other stakeholders on the proposed changes to Maryland’s Nutrient Management Regulations and offer an opportunity for public comment.

Amy Shober and Jennifer Volk have joined the University of Delaware College of Agriculture and Natural Resources and Cooperative Extension to work on nutrient management issues such as nutrient runoff and water quality issues that impact the Delaware inland bays and the Chesapeake Bay.

Amy Shober came on board Sept. 1 as Extension specialist and assistant professor for nutrient management and environmental quality. Her expertise is in nutrient management and soil fertility.

Shober comes to UD after having served as an associate professor in the soil and water science department at the University of Florida. She earned both a bachelor of science degree in environmental science and a bachelor of arts in chemistry from Virginia Polytechnic Institute and State University. Shober received her master’s degree in soil science from Pennsylvania State University and her doctorate in plant and soil science from the University of Delaware.

Jennifer Volk joined UD this summer as an Extension specialist in environmental quality and management.

Prior to coming to UD, Volk worked as an environmental scientist with the Delaware Department of Natural Resources and Environmental Control’s Watershed Assessment Section. She has assisted in the development of total maximum daily loads (TMDL) for nitrogen and phosphorus, and has worked with stakeholder groups to identify strategies to reduce non-point source pollution. Volk led efforts to develop and implement a watershed implementation plan in Delaware’s portion of the Chesapeake Bay watershed. She received both her bachelor’s degree in chemistry and her master’s degree in marine studies from the University of Delaware.

While Shober’s office is in Townsend Hall in Newark, and Volk works primarily from the Kent County Extension Office in Dover, they both actively travel the state.

There’s a lot of nutrients to apply onto fields in Wisconsin as fall crops are harvested. Until Mother Nature touches Wisconsin with winter conditions, there will be lots of work activity around manure storage and handling facilities.

A new fact sheet – entitled Nonenclosed Manure Storage Safety Tips – is now available at http://fyi.uwex.edu/ agsafety/files/2012/09/Non-enclosedmanure-storage-safety-tips-wi-9.4.12.pdf.

Farmers are encouraged to take time to discuss these safety tips with their families and/or employees. If farmers hire custom nutrient applicators, they should use this information as a means to discuss safety requirements with the business owners and employees.

There’s lots of work to get done before the snowflakes fall and that means long workdays ahead. In recent years, there have been a number of crashes on public roads involving manure application equipment. Slow down and take breaks. Fatigue can greatly influence safety.

Whether you’re at the farm site, in the field or on the road, work safely.

American Refining Group recently announced that Brad Penn Medium Ash Biogas Engine Oil has been reformulated with a new additive package tailored for engines running on different types of fuel gases, such as biogas and landfill gas. According to the company, the additive package is more efficient in sour gas (high sulfur) conditions where acid and base controls (alkalinity) are limiting factors. The new formulation provides a base number of 10.0 with sulfated ash of 0.99 per cent. The reformulated engine oil recently completed an extensive field trial at an anaerobic digestion facility located on a New York state dairy farm. www.amref.com

The Energy Series of three- and fourwheel AC electric 1.5 to 3.0 ton forklifts from Stärke Material Handling Group are being marketed as delivering material handling solutions.

Stärke Energy electric forklifts provide a quiet, environmentally friendly, no-emission option to reduce carbon footprints and keep workers safe from potentially harmful fumes and noise pollution. The Energy Series is available in a choice of traditional cushion tires for durability in indoor/warehouse operations, or resilient/pneumatic tires for a smooth ride on rough indoor or outdoor terrain.

SME AC controller functions include:

• Anti-roll back with adjustable

ramp stop time

• Regenerative braking

• Acceleration/deceleration

• Management of static return to function

• Overheating protection for inverters and motors

• Full short circuit/open circuit protection

All Stärke Energy Series Models are equipped with domestic-sized battery compartments and a wide-view mast and are backed by a two-year/4,000-hour warranty.

www.starkecanada.com

www.starkeusa.com

Christophe Malvezin, agricultural counselor, and Catherine Rogy, deputy agricultural counselor, from the Embassy of France in Washington, D.C., recently visited Enginuity Energy LLC to learn about the Ecoremedy gasification technology that can convert agricultural waste – specifically poultry manure –into energy.

France is a leading poultry-producing country in the European Union, and a recent report by the French Agricultural Ministry outlined a number of key imperatives for the poultry industry and poultry farmers with a focus on economies of scale, renewable energy and improved efficient technology.

“When a country has a large poultry industry, there is a challenge with handling the vast amounts of manure which is generated from these operations,” stated David Heck, VP of operations and global business development for Enginuity Energy. “Increasingly stringent governmental regulations are imposed to protect land and waterways. What makes us excited about our technology is we take what seems to be a ‘negative’ situation and turn it into a ‘double positive’ renewable energy and nutrient-rich ash to be used as a substitute for chemical fertilizers.”

“We were pleasantly surprised by

the beneficial impacts of the Ecoremedy technology,” says Malvezin. “We were unaware that this technology exists today and with France’s initiatives to create additional biogas from agricultural waste, the technology seems to be a good fit with France’s agricultural and energy strategy.”

www.enginuityenergy.com

Robin Starkenburg recently joined Digi-Star LLC in the newly developed marketing manager’s role. She will manage Digi-Star’s marketing and communications programs, supporting the continued growth in company sales.

“Robin’s experience and dedication to excellence in agriculture make her a natural fit,” said Ken Klubertanz, DigiStar’s director of sales and marketing. “She will be the driving force in DigiStar’s brand awareness in all marketing segments.”

Starkenburg’s career developed and grew from an early age on a dairy farm in Washington State to a degree in ag communications from Washington State University. She continued to hone her communications skills with roles in farm broadcasting and dairy genetics marketing. She also brings international experience to Digi-Star with positions at ABS Global and Holstein International.

Residing in Deforest, WI, Robin and her family are actively involved in their local 4H and FFA programs showing sheep, beef cattle, market hogs and poultry.

Digi-Star manufactures electronic weighing systems, providing measuring solutions to optimize agricultural performance. This is done through precision load cells, sensors, indicators and feed management software programs.

With anaerobic digestion becoming increasingly popular, ensuring that

ThermoEnergy’s Thermo ARP™ high-efficiency ammonia recovery system is an unbeatable option for operators of anaerobic digesters who want to both comply with nitrogen regulations and recover ammonia as a valuable product. Thermo ARP recycles the ammonia in digester wastewater into ammonium sulfate or ammonium nitrate for the production of valuable fertilizers and industrial products. Thermo ARP is energy efficient, extremely robust, and compact – suitable for even rugged field conditions. We Turn Anaerobic Digester Wastewater Streams into Revenue Streams

For more information email info@thermoenergy.com or visit our website at www.thermoenergy.com .

biogas systems perform to maximum capacity is a crucial consideration.

To meet this need, Omex Environmental has introduced the new Biogas Plus range of micronutrient supplements to ensure that anaerobic plants are supplied with all the necessary trace elements needed for successful bacterial growth and function.

It is rare for anaerobic digester systems to have the complete range of nutritional elements present for optimal

bacterial growth. Shortages of specific micronutrients, which are critical components of enzyme systems in the bacteria, often occur. This can mean that the digester plant does not run at full efficiency with a consequential loss of performance and output.

The Biogas Plus range of trace element additives (TEA) from Omex provide customized solutions to meet the individual micronutrient needs of specific anaerobic systems and operational requirements.

Before prescribing the appropriate TEA dosage, Omex will assess a plant’s needs by laboratory analysis of influent and effluent flows. It will then produce a tailor-made TEA solution in a form that is fully bioavailable in anaerobic conditions.

Biogas Plus is the latest in a range of safe-to-use bioavailable micronutrient supplements available from Omex, created to help farmers get more from their investment in anaerobic digesters.

www.omex.co.uk

Juniper Systems recently announced its partnership with Pennsylvania-based SDG Systems to market the Mesa Rugged Notepad with Android (AOSP) 2.3 operating system, a handheld computer known as the Rampage 6 and distributed exclusively through SDG Systems.

Availability of the Rampage 6 is scheduled for the fall of 2012.

The Android (AOSP) 2.3 operating system on the Rampage 6 offers advantages for data collection, including multitasking, a modern user interface, rich programming environment, multiplatform development, abundant application data storage, open source flexibility and the opportunity for a custom Android interface developed by SDG Systems. Additionally, its optional kiosk mode allows only certain applications to be accessible by the user, successfully creating a single-purpose device without distractions.

The Rampage 6 features a large 5.7-inch viewing display, IP67 ingress protection rating for water and dust, integrated two-to-five-meter GPS receiver, optional integration of a 1D/2D barcode scanner, and optional Class I, Division 2 certification for use in hazardous locations.

www.sdgsystems.com

ADVANCED BIOLOGICALS

314 N 7th St.

Clear Lake, IA 50428 USA

Tel: 641-357-0706

e-mail: josh@advancedbiologicalsllc.com www.advancedbiologicalsllc.com

AERATION INDUSTRIES INTL.

4100 Peavey Rd.

Chaska, MN 55318 USA

Fax: 952-448-7293

Toll-Free: 1-800-328-8287

AERWAY/SAF-HOLLAND EQUIPMENT LTD.

20 Phebe St.

Norwich, ON N0J 1P0

Tel: 1-800-457-8310 Fax: 519-863-2398 www.aerway.com

AFRASIA CANADA

10 Wilkinson Rd., Unit 9 Brampton, ON L6T 5B1

Tel: 905-840-7833 Fax: 905-840-7337

e-mail: info@afrasia.ca www.afrasia.ca

AGCO AG CHEM EQUIPMENT

128 Ray Ave. Jackson, MN 56143 USA

Tel: 507-250-2271 Fax: 507-847-4981 www.terragator.agcocorp.com

AGPRO, INC.

859 Airport Rd. Paris, TX 75462 USA

Tel: 903-785-5531

Toll-Free: 1-800-527-1030

e-mail: Info@agproUSA.com www.agproUSA.com

AGPROFESSIONALS, LLC

4350 State Hwy. 66 Longmont, CO 80504 USA

Tel: 970-535-9318 Fax: 970-535-9854

e-mail: tharen@agpros.com www.agpros.com

AGRIMENT SERVICES INC.

PO Box 1096

Beulaville, NC 28518 USA

Tel: 252-568-2648 Fax: 252-568-2750

e-mail: agrimentservices@yahoo.com www.agrimentservices.com

AGSOURCE LABORATORIES

106 N. Cecil St.

Bonduel, WI 54107 USA

Tel: 715-758-2178 Fax: 715-758-2620

e-mail: bonduel@agsource.com www.agsource.com

ALLIANCE TIRE AMERICAS

201 Edgewater Dr., Suite 285 Wakefield, MA 01880 USA

Tel: 877-978-4737 Fax: 888-371-6195 www.atgtire.com

ATD WASTE SYSTEMS INC.

3099 West 24th Ave. Vancouver, BC V6L 1R7

Tel: 604-736-4474 Fax: 604-736-4493

e-mail: 1cleanfarm@hogmanure.com www.hogmanure.com

AUTOMATED WASTE SYSTEMS LLC

3115 - 320th St.

Hull, IA 51239 USA

Tel: 712-439-2081 Fax: 712-439-2078

Toll-Free: 1-866-918-2081

www.automatedwastesystems.com

AVATAR

1981 N. Broadway Walnut Creek, CA 94596 USA

Tel: 925-274-7600 Fax: 925-210-9070

BAG MAN

PO Box 162, 634 County Rd. T Hammond, WI 54015 USA

Tel: 1-800-796-5333 Fax: 715-796-5655

e-mail: info@afsbagman.com www.afsbagman.com

BALZER, INC.

County Rd. 27E, Box 458 Mountain Lake, MN 56159 USA

Tel: 507-427-3133 Fax: 507-427-2364

Toll-Free: 1-800-795-8551 www.balzerinc.com

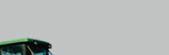

BAMBAUER EQUIPMENT LLC

19151 Kettlersville Rd.

New Knoxville, OH 45871 USA

Tel: 419-753-2275 Fax: 419-753-3116

e-mail: bambauerequipment@nktelco.net

BAUER NORTH AMERICA/FAN SEPARATOR

107 Eastwood Rd.

Michigan City, IN 46360-8943 USA

Tel: 1-800-922-8375 Fax: 219-879-5194 www.bauer-at.com

BAZOOKA FARMSTAR, INC.

800 E. 7th St., PO Box 869 Washington, IA 52353 USA

Tel: 319-653-5080 Fax: 319-653-5806

Toll-Free: 1-800-775-7448

e-mail: salesbfinc@iowatelecom.net www.bazookafarmstar.com

BBI SPREADERS

PO Box 630, 470 S. Wayside St. Cornelia, GA 30531 USA

Tel: 706-778-2767 Fax: 706-778-2787

Toll-Free: 1-800-282-3570 www.bbispreaders.com

BEM INDUSTRIES INC. DBA MOHRLANG FABRICATION

18990 CR 29 Brush, CO 80723 USA

Tel: 970-542-0640

e-mail: bmohrlang@spreaderz.com www.spreaderz.com

BIOFERM ENERGY SYSTEMS 617 N Segoe Rd, PO Box 5408 Madison, WI 53705 USA

Tel: 608-467-5523 Fax: 608-233-7085

e-mail: info@biofermenergy.com www.biofermenergy.com/us

BOERGER, LLC

2860 Water Tower Place Chanhassen, MN 55317 USA

Tel: 612-435-7300 Fax: 612-435-7301

e-mail: america@boerger.com www.boerger.com

BRAUN ELECTRIC INC.

209 North Fourth Ave.

St. Nazianz, WI 54232 USA

Tel: 920-773-2143 Fax: 920-773-2724

Toll-Free: 1-800-876-2234 www.braunelectricinc.com

BRITESPAN BUILDING SYSTEMS INC.

37651 Amberley Rd. Lucknow, ON N0G 2H0 Fax: 519-528-2890

Toll-Free: 1-800-407-5846

e-mail: info@britespanbuildings.com www.britespanbuildings.com

BRODIE AG & INDUSTRIAL INC.

4490 Trussler Rd.

Ayr, ON N0B 1E0

Tel: 519-632-1190 Fax: 519-632-1189

e-mail: albrodie@megawire.ca www.brodieagandindustrial.ca

BUFFALO TURBINE

180 Zoar Valley Rd.

Springville, NY 14141 USA

Tel: 716-592-2700 Fax: 716-592-2460

e-mail: info@buffaloturbine.com www.buffaloturbine.com

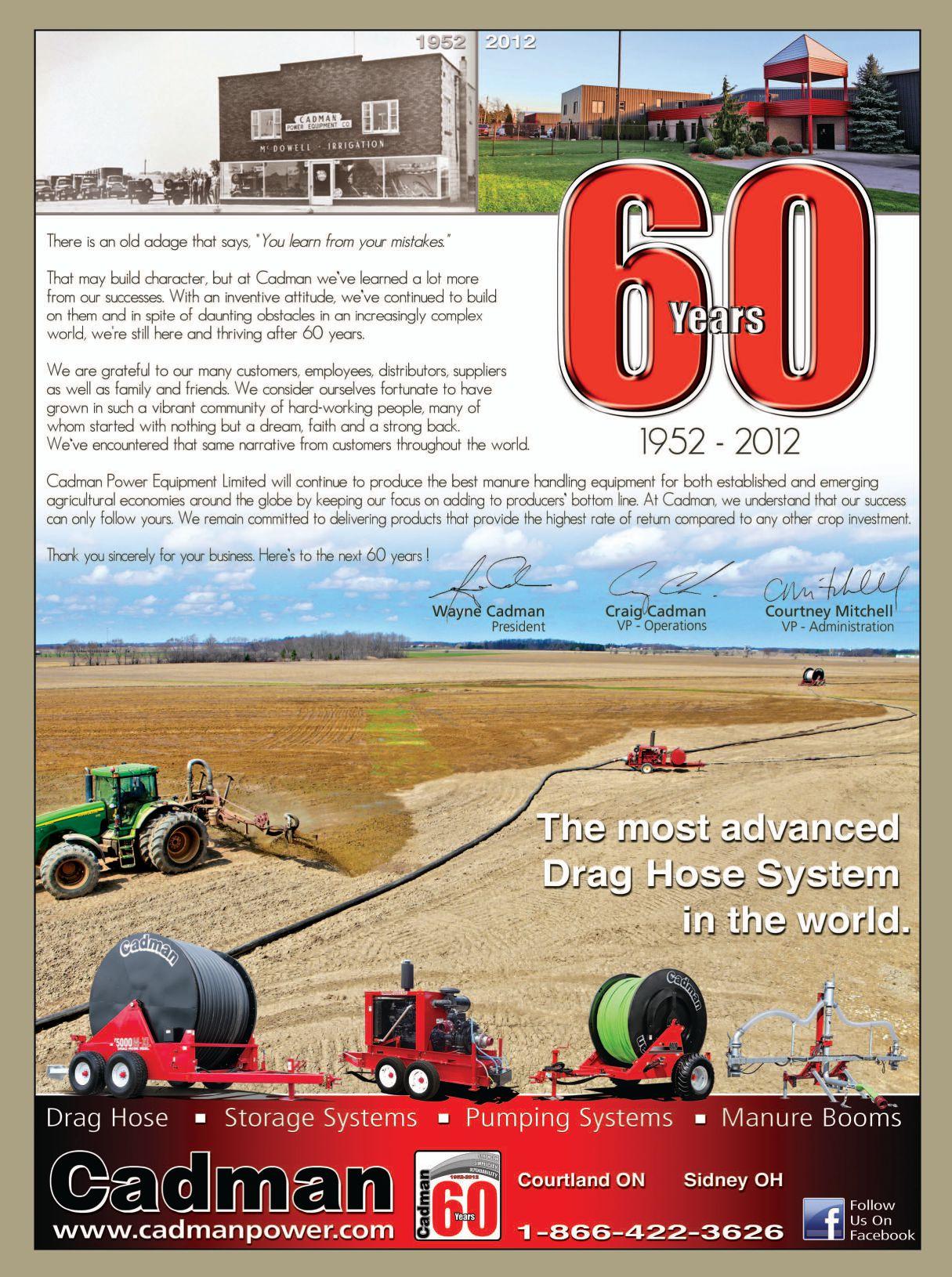

CADMAN POWER EQUIPMENT LTD.

38 Main St., PO Box 100 Courtland, ON NOJ 1E0

Tel: 519-688-2222 Fax: 519-688-2100

Toll-Free: 1-866-4CADMAN www.cadmanpower.com

CADY INC.

383 Illinois Hwy. 92

Tampico, IL 61283 USA

Tel: 815-438-5678 Fax: 815-438-5681

Toll-Free: 1-877-999-CADY

e-mail: cady@cadyinc.com www.cadyinc.com

Cady Inc. specializes in Above Ground Positive Containment Slurrystore® Systems, Nutristore® Liquid Fertilizer Storage, GEA Houle Manure Handling Equipment, Flygt Submersible Manure Pumps, along with GEA Houle Manure Separator Systems.

CANADA'S OUTDOOR FARM SHOW

160 Research Lane, Unit 101 Guelph, ON N1G 5B2

Tel: 519-822-2890 Fax: 519-829-1777

Toll-Free: 1-800-563-5441

e-mail: info@outdoorfarmshow.com www.outdoorfarmshow.com

CANADIAN INTERNATIONAL FARM SHOW

TORONTO

c/o PO Box 565, 48 Broad St. Saint John, NB E2L 3Z8

Tel: 506-658-0018 Fax: 506-658-0750

Toll-Free: 1-888-454-7469

e-mail: info@mpltd.ca www.masterpromotions.ca

CARLISLE TIRE

645 McMurray Rd.

Waterloo, ON N2V 2B7

Tel: 519-885-0630 Fax: 519-885-0781

CAWI CANADA LTD.

Site 12, RR 6, Box 49 Calgary, AB T2M 4L5

Tel: 403-569-9481 Fax: 403-569-8490

e-mail: cawi@telus.net

CHORE-TIME EGG PRODUCTION SYSTEMS

PO Box 2000

Milford, IN 46542-2000 USA

Tel: 574-658-4101 Fax: 574-658-3220

e-mail: egg@choretime.com www.choretimeegg.com

CLAAS OF AMERICA INC.

8401 South 132nd St. Omaha, NE 68138 USA

Tel: 402-861-1000 Fax: 402-861-1003 www.claasofamerica.com

CORNELL PUMP COMPANY

16261 S.E. 130th Ave.

Clackamas, OR 97015-8948 USA

Tel: 503-653-0330 Fax: 503-653-0338

e-mail: bjansen@cornellpump.com www.cornellpump.com

Cornell builds high quality, efficient, heavy-duty centrifugal pumps for the toughest applications. Solids handling pumps with up to 87% hydraulic efficiency and pressures over 200 PSI.

CRI-MAN

Via Costituzione, 50/F 42015 Correggio, (RE) Italy

Tel: +39 0522 732204 Fax: +39 0522 746363 www.cri-man.com

DARITECH, INC.

8540 Benson Rd. Lynden, WA 98264 USA

Tel: 360-354-6900 Fax: 360-354-7522

Toll-Free: 1-800-701-3632

e-mail: info@daritech.com www.daritech.com

DEGELMAN INDUSTRIES

272 Industrial Dr. Regina, SK S4P 3B1

Tel: 306-543-4447 Fax: 306-545-6221

Toll-Free: 1-800-667-3545

e-mail: sales@degelman.com www.degelman.com

DIGI-STAR LLC

W5527 Hwy. 106

Fort Atkinson, WI 53538 USA

Tel: 920-568-6255 Fax: 920-568-9721

Toll-Free: 1-800-225-7695

e-mail: sam.vorpahl@digi-star.com www.digi-star.com

DM MACHINERY INC.

1875 St-Edouard Rd.

Saint-Simon, QC J0H 1Y0

Tel: 450-798-2922 Fax: 450-798-2914

Toll-Free: 1-888-798-2922

e-mail: info@dmmachinery.ca www.dmmachinery.ca

DODA U.S.A. INC.

255 16th St. S. St. James, MN 56081 USA

Tel: 507-375-5577 Fax: 507-375-5578

e-mail: admin@dodausa.com www.DODA.com

DOW AGROSCIENCES LLC

9330 Zionsville Rd. Indianapolis, IN 46268 USA Tel: 317-337-3000 Fax: 317-337-6081 www.dowagro.com

DRAEGER

101 Technology Dr. Pittsburgh, PA 15275 USA

Tel: 412-788-5671 Fax: 412-787-2207

Toll-Free: 1-800-615-5503

e-mail: prodinfo@draeger.com www.draeger.com

DSM NUTRITIONAL PRODUCTS

45 Waterview Blvd. Parsippany, NJ 07054-1298 USA Tel: 973-257-8396 Fax: 973-257-8653

DURATECH INDUSTRIES INTERNATIONAL, INC.

PO Box 1940 Jamestown, ND 58401 USA

Tel: 701-252-4601 Fax: 701-252-0502 www.haybuster.com

DUSKE DRYING SYSTEMS

6901 Industrial Loop Greendale, WI 53129 USA

Tel: 414-529-0240 Fax: 414-520-0362 e-mail: info@uzelacind.com www.duskeengineering.com

DUTCH INDUSTRIES

300 Portico Dr., PO Box 568 Pilot Butte, SK S0G 3Z0 Tel: 306-781-4820 Toll-Free: 1-800-663-8824 www.dutchopeners.com

DVO, INC.

PO Box 69

Chilton, WI 53014 USA

Tel: 920-849-9797 Fax: 920-849-9160

e-mail: info@dvoinc.net www.dvoinc.net

EC APPLICATIONS (BIOGAS COVERS)

650 N Batavia St. Orange, CA 92868 USA

Tel: 714-921-9848 Fax: 866-475-1225 www.BioGasCovers.com

ELMIRA MACHINE INDUSTRIES/RIV

QUALITY BRASS VALVES

20 Martins Lane

Elmira, ON N3B 2A1

Tel: 519-669-1541 Fax: 519-669-8331

Toll-Free: 1-800-801-6663

e-mail: info@elmiramachine.com www.elmiramachine.com

ENVIRONETICS INC.

1201 Commerce St.

Lockport, IL 60441 USA

Tel: 815-838-8331 Fax: 815-838-8336 www.environeticsinc.com

ENVIRONMENTAL FABRICS, INC.

85 Pascon Ct.

Gaston, SC 29170 USA

Tel: 803-551-5700 Fax: 803-551-5701

Toll-Free: 1-800-910-5280

e-mail: info@environmentalfabrics.com www.environmentalfabrics.com

EUROVIX USA, INC.

PO Box 1808

Portage, MI 49081 USA

Tel: 269-329-1198 Fax: 269-329-1198

e-mail: pbperks@cs.com www.eurovix.us

EXPERT COMPANY

PO Box 6

Clintonville, WI 54929 USA

Tel: 605-337-3737 Fax: 605-337-3400

e-mail: sarc@midstatesd.net www.expertcompany.us

FAN SEPARATOR (USA), INC.

107 Eastwood Rd.

Michigan City, IN 46360 USA

Tel: 219-871-1580 Fax: 219-879-5160

Toll-Free: 1-800-451-8001

e-mail: fanusa@fan-separator.com www.fan-separator.com

FARM CREDIT CANADA

100 - 120 Research Lane

Guelph, ON N1G 0B5

Fax: 519-826-2066

Toll-Free: 1-800-387-3232

e-mail: richard.gruener@fcc-fac.ca

FARM TEK

1440 Field of Dreams Way

Dyersville, IA 52040 USA

Tel: 860-289-7261 Fax: 860-289-4711

Toll-Free: 1-800-327-6835

e-mail: sales@farmtek.com www.farmtek.com

FARMER BOY AG INC.

50 West Stoever Ave.

Myerstown, PA 17067 USA

Tel: 717-866-7565 Fax: 717-866-6233

Toll-Free: 1-800-845-3374

e-mail: LindsayB@FarmerBoyAg.com www.FarmerBoyAG.com

FAROEX LTD.

Box 1950

Gimli, MB R0C 1B0

Tel: 204-642-6400 Fax: 204-642-6420

Toll-Free: 1-888-547-3353

FEECO INTERNATIONAL, INC.

3913 Algoma Rd.

Green Bay, WI 54311 USA

Tel: 920-468-1000 Fax: 920-469-5110

Toll-Free: 1-800-373-9347

e-mail: sales@feeco.com FEECO.com

FEW SEPARATOR GMBH

Runtestrasse 42

D-59457 Werl 59494 Germany

Tel: +49 2922 87022-0 Fax: +49 2922 87022-20 www.few-separator.com

FIRESTONE SPECIALTY PRODUCTS

250 W. 96th St. Indianapolis, IN 46260 USA

Tel: 317-575-7000 Fax: 317-575-7002

Toll-Free: 1-800-428-4442

e-mail: info@firestonesp.com www.firestonesp.com

FRONTLINK INC.

1492 Windham Rd. 12

Simcoe, ON N3Y 4K3

Tel: 519-428-9812 Fax: 519-428-2640

Toll-Free: 1-877-553-2524

e-mail: sales@frontlinkinc.com www.frontlinkinc.com

GEA FARM TECHNOLOGIES CANADA

INC., DIVISION GEA HOULE

4591 boul. St-Joseph Drummondville, QC J2B 6W3 Fax: 819-477-5565

Toll-Free: 1-800-563-4685 www.gea-farmtechnologies.com/houle/en

GEMACO SALES LTD.

669 Derwent Way

Annacis Island, Delta, BC V3M 5P7

Tel: 604-540-7574 Fax: 604-540-7594

Toll-Free: 1-800-663-7574

e-mail: info@gemacosales.com www.gemacosales.com

GLOBAL REPAIR

33 Bellefair Ave.

Toronto, ON M4L 3T7

Tel: 416-686-3690 Fax: 416-686-1744

Toll-Free: 1-866-271-0719

e-mail: sales@globalrepair.ca www.globalrepair.ca

GLOBAL RESOURCE RECOVERY ORGANIZATION

1707 21st St. Eldora, IA 50627 USA

Tel: 641-939-7476 Fax: 641-939-7539

Toll-Free: 1-800-800-1812

e-mail: usm@heartofiowa.net www.grrotempest.com

GORDON & ASSOCIATES INC.

6975 N., 550 West, PO Box 25 Bentonville, IN 47322 USA

Tel: 1-800-659-7645 Fax: 765-478-9073

e-mail: pgordon@gordonaggroup.com www.gordonaggroup.com

GORMAN-RUPP OF CANADA LTD.

70 Burwell Rd. St. Thomas, ON N5P 3R7

Tel: 519-631-2870 Fax: 519-631-4624

e-mail: grcanada@grcanada.com www.GRCanada.com

GREEN EARTH NATURALLY/ EARTHCLEANZ

2314 Ridgefield St. NE Roanoke, VA 24012 USA

Tel: 540-362-5636 Fax: 540-362-9447

e-mail: info@greenearthnaturally.com www.greenearthnaturally.com

GREENFIELD SPREADING & SALES INC.

PO Box 634, 2300 Hwy. 18 E. Algona, IA 50511 USA

Tel: 515-320-3528

e-mail: qns@netamumail.com www.greenfieldspreading.com

GREENLITE LIGHTING CORPORATION 115 Brunswick Montreal, QC H9R 5N2 Tel: 514-695-9090 ext 111 Fax: 877-695-9093

Toll-Free: 1-877-255-0004 ext 111

e-mail: serge@greenlite.ca www.greenlite.ca

H & S MANUFACTURING CO., INC.

2608 S. Hume Ave., PO Box 768 Marshfield, WI 54449 USA

Tel: 715-387-3414 Fax: 715-384-5463 www.hsmfgco.com

HANSEN MANUFACTURING

Box 393

Agassiz, BC V0M 1A0

Tel: 604-316-3664 Fax: 604-858-9128

e-mail: glenhansen@live.ca

HARCO AG EQUIPMENT

5808 Hwy. 9, RR 4

Harriston, ON N0G 1Z0

Tel: 519-338-2923 Fax: 519-338-2756

e-mail: harquip@wightman.ca

HAWKEYE STEEL PRODUCTS INC.

609 Main St.

Houghton, IA 52631 USA

Tel: 319-469-4141 Fax: 319-469-4402

Toll-Free: 1-800-553-1791 www.spantechbuildings.com

HCC, INC.

1501 First Ave.

Mendota, IL 61342-0952 USA

Tel: 815-539-9371 Fax: 815-539-3135 www.hccincorporated.com

HCL MACHINE WORKS

15142 Merrill Ave.

Dos Palos, CA 93620 USA

Tel: 209-392-6103 Fax: 209-392-3000 www.hclmachineworks.com

HELLMANN NORTH AMERICA

11 - 1311 Springbank Ave.

London, ON N6K 1Z9

Tel: 519-453-3913 Fax: 519-453-3996

e-mail: hellmannpoultry@bellnet.ca www.hellmannpoultry.com

HODEL, JIM INC.

2278 CR 1350 N.

Roanoke, IL 61561 USA

Tel: 309-923-7106 Fax: 309-923-7655

Toll-Free: 1-800-562-8565

e-mail: jim@jimhodelinc.com www.jimhodelinc.com

HUSKY FARM EQUIPMENT LTD.

7440 Wellington Rd. 17 Alma, ON N0B 1A0

Tel: 519-826-5329 Fax: 519-846-9378

Toll-Free: 1-800-349-1122

e-mail: husky@huskyfarm.ca www.huskyfarm.ca

HYDRO ENGINEERING

115 East Main St.

Norwood Young America, MN 55397 USA

Tel: 1-800-833-5812 Fax: 952-467-4000

e-mail: sales@hydro-eng.com www.hydro-eng.com

INDUSTRIAL & ENVIRONMENTAL CONCEPTS, INC.

6009 Chapel Dr. Minneapolis, MN 55439 USA

Tel: 952-829-0731 Fax: 952-829-9770

Toll-Free: 1-888-829-0731 www.ieccovers.com

INFINEUM

1900 E. Linden Ave. Linden, NJ 07036 USA

Tel: 908-474-2841 Fax: 908-474-2829

e-mail: megan.roesch@infineum.com www.infineum.com

IOWA SELECT FARMS

811 South Oak St., PO Box 400 Iowa Falls, IA 50126 USA

Tel: 641-648-4479 Fax: 641-648-4251 www.iowaselect.com

J & D MANUFACTURING

6200 Hwy. 12

Eau Claire, WI 54701 USA

Tel: 715-834-1439 Fax: 715-834-3812

Toll-Free: 1-800-998-2398

e-mail: jdmfg@jdmfg.com www.jdmfg.com

J.G. VANOOSTRUM FARM EQUIPMENT LTD.

1790 Hwy 358

Port Williams, NS B0P 1T0

Tel: 902-582-3311 Fax: 902-582-7621

Toll-Free: 1-888-582-3311

e-mail: sales@vanoostrums.com www.vanoostrums.com

JAMESWAY FARM EQUIPMENT

12 Route 249

St-Francois-Xavier-de-Brompton, QC J0B 2V0

Tel: 819-845-7824 Fax: 819-845-5758 www.jameswayfarmeq.com

KELLER, INC.

PO Box 620 Kaukauna, WI 54130-0620 USA

Tel: 920-766-5795 Fax: 920-766-5004

e-mail: lstellmacher@kellerbuilds.com www.kellerbuilds.om

KEY DOLLAR COMPANY, LLC

PO Box 49

Milton-Freewater, OR 97862 USA

Tel: 541-938-6336 Fax: 541-938-6282

KIFCO IRRIGATION

700 S. Schrader Ave. Havana, IL 62644 USA

Tel: 309-543-4425 Fax: 309-543-4945

Toll-Free: 1-800-452-7017

e-mail: sales@kifco.com www.kifco.com

KLINE IRRIGATION NORTH AMERICA

4270 Hollywood Rd.

St. Joseph, MI 49085 USA

Tel: 269-429-3000 Fax: 269-429-3700

Toll-Free: 1-866-665-5463

e-mail: info@k-linena.com www.k-linena.com

KOOLMEES MARINE INDUSTRIAL SALES, SERVICE (IRRIGATION)

Middletown Line 712651 Otterville, ON N0J 1R0 Tel: 519-879-6878 Fax: 519-879-6319 e-mail: springfordenterprises@execulink.com

KUHN NORTH AMERICA INC. PO Box 167 Brodhead, WI 53520 USA

Tel: 608-897-2131 Fax: 608-897-2561 www.KuhnNorthAmerica.com

KUNAFIN

PO Box 190 Quemado, TX 78877-0190 USA

Tel: 1-800-832-1113 Fax: 830-757-1468 www.kunafin.com

KYTE CENTRIFUGE LLC 10 E Owl Creek Lane Fairview, NC 18730 USA Tel: 832-368-2667 Fax: 407-369-4674 www.kytecentrifuge.com/manure

LAGOON PUMPING AND DREDGING INC. 4015 South 9th St. Columbus, NE 68601-6227 USA Tel: 402-563-3464 Fax: 402-564-1696

LAKELAND EQUIPMENT

Country Road 5 Hall, NY 14463 USA

Tel: 585-526-6325 Fax: 585-526-6073 www.lakelandequipment.com

LAKEPOINTE ENVIRONMENTAL GROUP INC.

5001 SW Orchid Bay Dr. Palm City, FL 34990 USA

Tel: 772-287-7698 Fax: 877-530-1806

Toll-Free: 1-866-429-6466 e-mail: js@lakepointegroup.com www.lakepointegroup.com

LAYFIELD GROUP OF COMPANIES 11120 Silversmith Place Richmond, BC V7A 5E4

Tel: 604-275-5588 Fax: 604-275-5589

Toll-Free: 1-800-558-8275

e-mail: corporate@layfieldgroup.com www.layfieldgroup.com

LES EQUIPEMENTS HARDY, INC.

100 Rue Saint Arthur Notre Dame de Portneuf, QC G0A 2Z0 Tel: 418-365-7551 Fax: 418-365-7954

IMPERIAL INDUSTRIES INC.

PO Box 1685

Wausau, Marathon Co., WI 54402 USA

Tel: 715-359-0200 Fax: 715-355-5349

Toll-Free: 1-800-558-2945

e-mail: toma@imperialind.com www.imperialind.com

Toll-Free: 1-800-241-2427

e-mail: key_dollar@hotmail.com www.keydollar.com

Toll-Free: 1-877-994-2739

LINDSAY CORPORATION 2222 North 111th St. Omaha, NE 68164 USA

Tel: 402-829-6800

Toll-Free: 1-866-404-5049 www.lindsay.com

LITCHFIELD ANALYTICAL SERVICES

535 Marshall St., PO Box 457

Litchfield, MI 49252 USA

Tel: 517-542-2915 Fax: 517-542-2014

e-mail: litchlab@qcnet.net www.litchlab.com

LIVESTOCK WATER RECYCLING, INC.

3637 - 44th Avenue SE Calgary, AB T2B 3R5

Tel: 403-203-4972

Toll-Free: 1-855-597-4972

e-mail: marketing@livestockwaterrecycling.com www.livestockwaterrecycling.com

LSC PRE-CAST SYSTEMS LTD.

8285A Lickman Rd.

Chilliwack, BC V2R 3Z9

Tel: 604-792-4244 Fax: 604-792-4241

Toll-Free: 1-888-796-2323

e-mail: lsc@lscprecast.com www.lscprecast.com

MANURE MANAGER

PO Box 530, 105 Donly Dr. S. Simcoe, ON N3Y 4N5

Tel: 519-429-3966 Fax: 519-429-3094

Toll-Free: 1-888-599-2228 ext. 242

e-mail: skauk@annexweb.com www.manuremanager.com

MANURE SYSTEMS INC.

3046 McMillan Rd.

Abbotsford, BC V2S 6A8

Tel: 604-226-6075

Toll-Free: 1-800-799-3740

e-mail: info@manuresystemsinc.com www.manuresystemsinc.com

MCLANAHAN CORPORATION

200 Wall St. Hollidaysburg, PA 16648 USA

Tel: 814-695-9807 Fax: 814-695-6684 www.mclanahan.com

MELROSE CHEMICALS LTD

2323-46th Ave.

Lachine, QC H8T 3C9

Tel: 514-631-2998 Fax: 514-631-2997

Toll-Free: 1-800-663-2997

e-mail: info@melrosechem.com www.melrosechem.com

MEYER MANUFACTURING CORPORATION

574 W. Center Ave., PO Box 405 Dorchester, WI 54425 USA

Tel: 715-654-5132 Fax: 715-654-5513

Toll-Free: 1-800-325-9103

e-mail: sales@meyermfg.com www.meyermfg.com

MIDWEST BIO-SYSTEMS

28933 - 35E St.

Tampico, IL 61283 USA

Tel: 815-438-7200 Fax: 815-438-7028

Toll-Free: 1-800-689-0714

e-mail: mbs@midwestbiosystems.com www.midwestbiosystems.com

MIGHTY GROW ORGANICS

870 Edward Loper Rd. Fruitdale, AL 36539 USA

Tel: 251-827-6668

e-mail: anne@mightygrow.net www.mightygrow.com

MMI INTERNATIONAL

Box 544

Brush, CO 80723 USA

Tel: 970-842-5161 Fax: 970-842-3111

Toll-Free: 1-800-523-2614

e-mail: info@mixerfeeders.com www.mixerfeeders.com

MT-ENERGIE CANADA INC.

480 University Ave., Suite 1500 Toronto, ON M5G 1V2

Tel: 416-598-7105

www.mt-energie.com/ca

NEBRASKA HARVESTORE SYSTEMS

3201 S. 13th St. Norfolk, NE 68701 USA

Tel: 402-371-0144 Fax: 402-371-6031

Toll-Free: 1-800-777-0501

e-mail: sales@nebraskaharvestore.com www.nebraskaharvestore.com

NEW-WAY PUMP & SLURRY

6003 54 Ave.

Taber, AB T1G 1X4

Tel: 403-223-3591 Fax: 403-223-2839

Toll-Free: 1-800-561-4608 www.newwayairr.com

NORTH CAROLINA PORK COUNCIL, INC.

2300 Rexwoods Dr., Suite 340

Raleigh, NC 27607 USA

Tel: 919-781-0361 Fax: 919-510-8546 www.ncpork.org

NORTHERN BIOGAS LLC

PO Box 643

Fond du Lac, WI 5496-0643 USA

Tel: 920-848-3216 Fax: 866-301-3075

e-mail: info@northernbiogas.com www.northernbiogas.com

NOVA ANALYTICAL SYSTEMS INC.

1925 Pine Ave.

Niagara Falls, NY 14301 USA

Toll-Free: 1-800-295-3771 www.nova-gas.com

OCTAFORM SYSTEMS INC.

520 - 885 Dunsmuir St.

Vancouver, BC V6C 1N5

Tel: 604-408-0558 Fax: 604-408-0595

Toll-Free: 1-888-786-6282

e-mail: info@octaform.com www.octaform.com

ONTARIO SOIL & CROP IMPROVEMENT ASSOCIATION

1 Stone Rd. W. Guelph, ON N1G 4Y2

Tel: 519-826-4214 Fax: 519-826-4224 www.ontariosoilcrop.org

PARMA COMPANY

PO Box 190, 101 Main St. Parma, ID 83660 USA

Tel: 208-722-5116 Fax: 208-722-6012 www.parmacompany.com

PATZ CORPORATION

PO Box 7 Pound, WI 54161-0007 USA

Tel: 920-897-2251 Fax: 920-897-2142

Toll-Free: 1-800-236-7280

e-mail: info@patzcorp.com www.patzcorp.com

Established in 1948, Patz is a designer, manufacturer and worldwide marketer of material handling equipment. Products include pumps, agitators, alley & shuttle box scrapers, gutter/stable cleaners, conveyors, and compost mixers.

PENERGETIC CANADA

329 - 5525 West Blvd. Vancouver, BC V6M 3W6

Tel: 604-736-0907 Fax: 604-736-0901

Toll-Free: 1-888-737-0907

e-mail: info@penergetic.ca www.penergetic.ca

PHASON ELECTRONIC CONTROL SYSTEMS

2 Terracon Place

Winnipeg, MB R2J 4G7

Tel: 204-233-1400 Fax: 204-233-3252 www.phason.ca

PICHON S.A.

BP 21, Z.I. de Lavallot

Guipavas F-29490 France

Tel: 819-998-5563 Fax: +33 298 34 41 20 e-mail: gd@pichonindustries.com www.pichonindustries.com

PIK RITE INC.

60 Pik Rite Lane

Lewisburg, PA 17837 USA

Tel: 570-523-8174 Fax: 570-523-8175

Toll-Free: 1-800-326-9763

e-mail: sales@pikrite.com www.pikrite.com

NUHN INDUSTRIES LTD.

PO Box 160, 4816 Line 34

Sebringville, ON N0K 1X0

Tel: 519-393-6284 Fax: 519-393-5104

Toll-Free: 1-877-837-7323

e-mail: nuhnind@nuhn.ca www.nuhn.ca

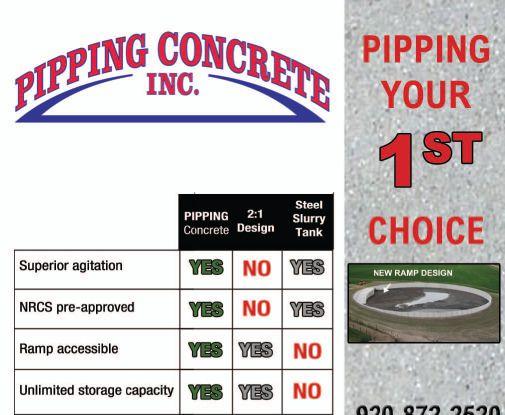

PIPPING CONCRETE INC.

N5888 Center Rd.

Brandon, WI 53919 USA

Tel: 920-872-2520 Fax: 920-346-2520

Toll-Free: 1-877-948-9661

e-mail: info@pippingconcrete.com www.pippingconcrete.com

PRO-ACT BIOTECH

PO Box 345

Warren, RI 02885 USA

Tel: 1-800-772-3775 Fax: 401-633-6270 www.proactbiotech.com

PROFITPRO, LLC

408 1st Ave. S.

Albert Lea, MN 56007 USA

Tel: 507-373-2550 Fax: 507-373-2520

Toll-Free: 1-888-875-2425

www.profitproag.com

PUCK CUSTOM ENTERPRISES, INC.

1130 - 100th St.

Manning, IA 51455 USA

Tel: 712-653-3045 Fax: 712-653-3099

e-mail: info@puckenterprises.com www.puckenterprises.com

RCM DIGESTERS INC.

PO Box 4716

Berkeley, CA 94704 USA

Tel: 510-834-4568 Fax: 510-834-4529

e-mail: contact@rcmdigesters.com

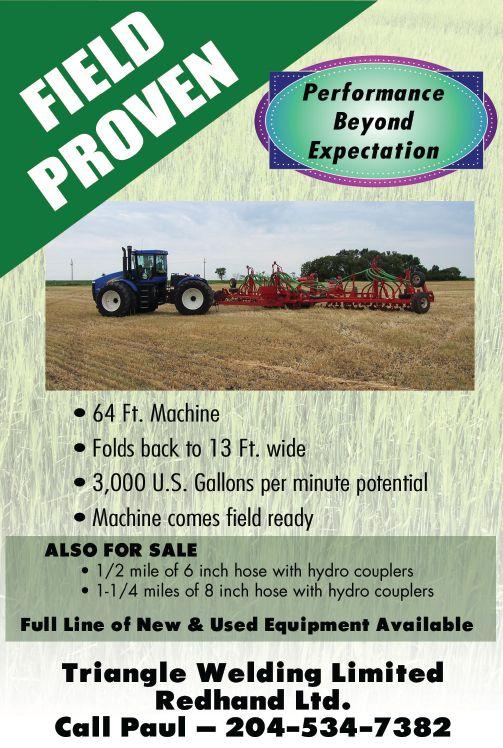

REDHAND LTD.

PO Box 989

Boissevain, MB R0K 1E0

Tel: 204-534-7382

REEF INDUSTRIES, INC.

9209 Almeda Genoa

Houston, TX 77075 USA

Tel: 713-507-4251 Fax: 713-507-4295

Toll-Free: 1-800-231-6074

e-mail: ri@reefindustries.com www.reefindustries.com

REINKE MANUFACTURING COMPANY

INC.

5325 Reinke Rd. Deshler, NE 68340 USA

Tel: 402-365-7251 Fax: 402-365-4370

Toll-Free: 1-866-365-7381 www.reinke.com

REMOTE LOAD, INC.

2428 Hwy. 3 Dumont, IA 50625 USA

Tel: 641-425-6998 www.remote-load.com

SENNINGER IRRIGATION

16220 East Hwy. 50

Clermont, FL 34711 USA

Tel: 407-877-5655 Fax: 407-905-8249

e-mail: info@senninger.com www.senninger.com

SFP - SPECIALTY FERTILIZER PRODUCTS

11550 Ash, Suite 220

Leawood, KS 66211 USA

Tel: 913-956-7500 Fax: 913-956-7506

Toll-Free: 1-888-446-GROW

e-mail: macklin@sfp.com www.sfp.com

SIDUMP'R

53577 Hwy. 20, PO Box 520 Plainview, NE 68769 USA

Tel: 402-582-4830 Fax: 402-582-4810

Toll-Free: 1-888-743-8677

e-mail: sales@sidumpr.com www.sidumpr.com

SILO'S R US INC.

RR #1

Moundville, MO 64771 USA

Tel: 417-944-2991 Fax: 417-944-9909

SIOUX AUTOMATION CENTER, INC.

877 1st Ave. N.W.

Sioux Center, IA 51250 USA

Tel: 712-722-1488 Fax: 712-722-1487

Toll-Free: 1-866-722-1488

e-mail: sales@siouxautomation.com www.siouxautomation.com

SUMA AMERICA, INC.

321 N. Clark St. Ste. 1425 Chicago, IL 60654 USA

Tel: 312-377-6125 Fax: 312-644-0738 www.gosuma.com

SUN-NORTH SYSTEMS LTD.

92 Railway St., PO Box 668

Seaforth, ON N0K 1W0

Tel: 519-527-2470 Fax: 519-527-2560

Toll-Free: 1-800-774-9319

e-mail: cvanneste@sunnorth.com www.sunnorth.com

SUNOVA WORX INC.

196679 19th Line, RR 1 Lakeside, ON N0M 2G0

Tel: 519-349-2770 Fax: 519-349-2310

e-mail: info@sunovaworx.com www.sunovaworx.com

T-L IRRIGATION COMPANY

151 East Hwy. 6 & AB Road Hastings, NE 68902-1047 USA

Tel: 402-462-4128 Fax: 402-462-4617

Toll-Free: 1-800-330-4264

e-mail: sales@tirr.com www.tlirr.com

TECHNICAL PUBLICATION ASSOCIATES, INC.

PO Box 5333

Morton, IL 61550 USA

Tel: 309-263-8792

e-mail: tpainc@mtco.com www.tpainc.ws

THERMOENERGY CORPORATION

10 New Bond St. Worcester, MA 01606 USA

Tel: 508-854-1628 Fax: 508-854-1753 www.thermoenergy.com

THOMPSON PUMP

4620 City Center Dr. Port Orange, FL 32129 USA

Tel: 386-767-7310 Fax: 386-761-0362

Toll-Free: 1-800-767-7310 www.thompsonpump.com

TRIMBLE AGRICULTURE

935 Stewart Dr. Sunnyvale, CA 94085 USA

Tel: 408-481-8000

Toll-Free: 1-800-TRIMBLE (874 6253) www.trimble.com/agriculture/livestock.aspx

TRINITY TRAILER MFG., INC.

8200 Eisenmann Rd. Boise, ID 83201 USA

Tel: 208-336-3666 Fax: 208-336-3741

Toll-Free: 1-800-235-6577 www.trinitytrailer.com

U.S. POULTRY & EGG ASSOCIATION

1530 Cooledge Rd. Tucker, GA 30084-7303 USA

Tel: 770-493-9401 Fax: 770-493-9257 www.poultryegg.org

U.S. SCREEN

462 County Rd. 40 Sullivan, OH 44880 USA

Tel: 419-736-2400 Fax: 877-329-5614

e-mail: info@us-screen.com www.us-screen.com

UNIVERSITY OF WISCONSIN

2611 East 29th St. Marshfield, WI 54449 USA

Tel: 715-387-2523 Fax: 715-387-1723

UNIVERSITY OF WISCONSIN CUSTOM MANURE TEAM

c/o UW-Extension, 1150 S. Bellvue St. Green Bay, WI 54302 USA

Tel: 920-391-4652 Fax: 920-391-4617

e-mail: kevin.erb@uwex.edu

UNVERFERTH MFG. CO., INC.

PO Box 357

Kalida, OH 45853 USA

Tel: 419-532-3121 Fax: 419-532-2468

Toll-Free: 1-800-322-6301

e-mail: info@unverferth.com www.unverferth.com

UTS RESIDUAL PROCESSING LLC

109 S. Main St., Suite C, PO Box 237 Eaton Rapids, MI 48827 USA

Tel: 517-663-0663 Fax: 517-663-0979

e-mail: info@uts-residuals.com www.uts-residuals.com

V & C CONSTRUCTION CO., INC.

397 Henpeck Rd. Walnut, IL 61376 USA

Tel: 815-379-2148 Fax: 815-379-9049

e-mail: vandc@thewisp.net www.vandcconstruction.com

VANDEN BUSSCHE IRRIGATION & EQUIPMENT LTD.

2515 Pinegrove Rd. Delhi, ON N4B 2X1

Tel: 519-582-2380 Fax: 519-582-1514

Toll-Free: 1-800-387-7246

e-mail: info@vandenbussche.com www.vandenbussche.com

VAUGHAN COMPANY INC.

364 Monte-Elma Rd. Montesano, WA 98563 USA

Tel: 360-249-4042 Fax: 360-249-6155

Toll-Free: 1-888-249-CHOP

e-mail: info@chopperpumps.com www.chopperpumps.com

VEENHUIS MACHINES B.V. PO Box 35 NL-8100AA Raalte Belgium

Tel: +31 572 35 21 45 Fax: +31 572 35 83 84

e-mail: info@veenhuis.com www.veenhuis.com

VENTRAC BY VENTURE PRODUCTS INC.

328 East Water St., PO Box 148 Orrville, OH 44667 USA

Tel: 330-683-0075 Fax: 330-683-0000

Toll-Free: 1-866-836-8722

e-mail: info@ventrac.com www.ventrac.com

VINCENT CORP.

2810 E. 5th Ave.

Tampa, FL 33605 USA

Tel: 813-248-2650 Fax: 813-247-7557

e-mail: pat@vincentcorp.com www.vincentcorp.com

VOGELSANG

7966 State Route 44, PO Box 751

Ravenna, OH 44266 USA

Tel: 330-296-3820 Fax: 330-296-4113

Toll-Free: 1-800-984-9400

e-mail: sales@vogelsangusa.com www.vogelsangusa.com

VTI LLC

2709 Airport Rd. Washington, IA 52353 USA

Tel: 319-653-8950

e-mail: vti.llc22@yaoo.com www.vtillc.com

WALLENSTEIN VACUUM PUMPS

20 Martins Lane

Elmira, ON N3B 2A1

Tel: 519-669-1541 Fax: 519-669-8331

Toll-Free: 1-800-801-6663 www.wallypumps.com

WAM USA INC.

1300 Triad Blvd.

Ft Worth, TX 76131 USA

Tel: 817-232-2678 Fax: 817-232-2676

e-mail: texas@waminc.com www.waminc.com

WARD LABORATORIES INC.

4007 Cherry Ave. Kearney, NE 68848-0788 USA

Tel: 308-234-2418 Fax: 308-234-1940

Toll-Free: 1-800-887-7645 www.wardlab.com

WARNER PLASTICS AND LINERS, INC.

7370 NW 6th Dr. Ankeny, IA 50023 USA

Tel: 515-289-2404 Fax: 515-289-1632

Toll-Free: 1-888-945-9701

e-mail: luke@warnerplastics.com www.warnerplastics.com

WATER AGRICULTURAL LAB

2101 Calhoun Road, Hwy 81

Owensboro, KY 42301 USA

Tel: 270-685-4039 Fax: 270-685-3989

e-mail: Kginfo@watersag.com www.watersag.com

WE COVER STRUCTURES

22694 Victoria Rd.

Thamesville, ON N0P 2K0

Tel: 1-877-849-9049 Fax: 877-577-7263

e-mail: sales@wecover.net www.wecover.net

WELLMAN SERVICE, LLC

7347 Boyd Rd. Pavilion, NY 14525 USA

Tel: 585-584-8502 Fax: 585-584-8503

WESSUC INC.

1693 Colborne St. E. Brantford, ON N3T 5L4

Tel: 1-866-4-WESSUC Fax: 519-752-0840

e-mail: info@wessuc.com www.wessuc.com

WEST POINT IMPLEMENT AND DESIGN

PO Box 255

West Point, NE 68788 USA

Tel: 402-372-2408 Fax: 402-372-2440

e-mail: jean@westpointimp.com www.westpointimp.com

WHEAT-BELT INDUSTRIES

262055 Balzac Blvd.

Balzac, AB T4B 2T3

Tel: 403-291-1489 Fax: 403-291-1490

Toll-Free: 1-800-644-6050 www.wheat-belt.com

WORLD DAIRY EXPO

3310 Latham Dr. Madison, WI 53713 USA

Tel: 608-224-6455 Fax: 608-224-0300 www.worlddairyexpo.com

WW WILLIAMS, INC.

1176 Industrial Parkway North Brunswick, OH 44212 USA

Tel: 330-558-8545 Fax: 330-273-8110

Toll-Free: 1-800-338-1989

e-mail: hdrake@wwwilliams.com www.wwwilliams.com

YUNKER PLASTICS, INC.

251 O'Connor Dr. Elkhorn, WI 53121 USA

Tel: 262-743-1234 Fax: 262-743-1233

Toll-Free: 1-800-236-3328 www.yunkerplastics.com

Feed Additives

DSM Nutritional Products

Penergetic Canada

ProfitPro, LLC

World Dairy Expo

Manure Additives

Advanced Biologicals

Agriment Services Inc.

Dow AgroSciences LLC

DSM Nutritional Products

Eurovix USA, Inc.

Farmer Boy Ag Inc.

Global Repair

Green Earth Naturally/EarthCleanz

Lakepointe Environmental Group Inc.

Midwest Bio-Systems

Penergetic Canada

Pro-Act Biotech

ProfitPro, LLC

SFP - Specialty Fertilizer Products

VTI LLC

World Dairy Expo

AGITATION EQUIPMENT

Agpro, Inc.

Balzer, Inc.

Bambauer Equipment LLC

Bauer North America/Fan Separator

Bazooka Farmstar, Inc.

Braun Electric Inc.

Cadman Power Equipment Ltd.

Cady Inc.

Daritech, Inc.

DM Machinery Inc.

DODA U.S.A. Inc.

Expert Company

Fan Separator (USA), Inc.

FEW Separator GmbH

Hodel, Jim Inc.

Husky Farm Equipment Ltd.

Jamesway Farm Equipment

Kifco Irrigation

Manure Systems Inc.

Nebraska Harvestore Systems

New-Way Pump & Slurry

Parma Company

Patz Corporation

Pichon S.A.

Reef Industries, Inc.

Remote Load, Inc.

Silo's R Us Inc.

Sioux Automation Center, Inc.

Suma America, Inc.

Vanden Bussche Irrigation & Equipment Ltd.

Vaughan Company Inc.

Veenhuis Machines B.V.

Wellman Service, LLC

Wessuc Inc.

World Dairy Expo

ANAEROBIC DIGESTERS

Avatar

DVO, Inc.

Environmental Fabrics, Inc.

Livestock Water Recycling, Inc.

Manure Systems Inc.

Northern Biogas LLC

Vanden Bussche Irrigation & Equipment Ltd.

Vaughan Company Inc.

Vogelsang

WW Williams, Inc.

U.S. Poultry & Egg Association

World Dairy Expo

BUILDING/BARN CONSTRUCTION

Agpro, Inc.

Agprofessionals, LLC

Britespan Building Systems Inc.

Daritech, Inc.

Expert Company

Farmer Boy Ag Inc.

Faroex Ltd.

Hawkeye Steel Products Inc.

J & D Manufacturing

Keller, Inc.

Octaform Systems Inc.

Sun-North Systems Ltd.

V & C Construction Co., Inc.

We Cover Structures

World Dairy Expo

CLEANING & SANITIZING EQUIPMENT

Buffalo Turbine

Elmira Machine Industries/

RIV Quality Brass Valves

Melrose Chemicals Ltd

New-Way Pump & Slurry

Ventrac by Venture Products Inc.

World Dairy Expo

COMMERCIAL MANURE APPLICATION

AGCO Ag Chem Equipment

Agriment Services Inc.

Bauer North America/Fan Separator

Bazooka Farmstar, Inc.

Braun Electric Inc.

Cadman Power Equipment Ltd.

CLAAS of America Inc.

Degelman Industries

Elmira Machine Industries/RIV Quality

Brass Valves

GEA Farm Technologies Canada Inc.,

Division GEA Houle

Greenfield Spreading & Sales Inc.

Hansen Manufacturing

Harco Ag Equipment

Hydro Engineering

Key Dollar Company, LLC

MMI International

Nebraska Harvestore Systems

Nuhn Industries Ltd.

Pichon S.A.

Puck Custom Enterprises, Inc.

Redhand Ltd.

Remote Load, Inc.

Trimble Agriculture

University of Wisconsin

Custom Manure Team

Vanden Bussche Irrigation

& Equipment Ltd.

Veenhuis Machines B.V.

VTI LLC

Wellman Service, LLC

Wessuc Inc.

World Dairy Expo

Bauer North America/Fan Separator

Brodie Ag & Industrial Inc.

Buffalo Turbine

Daritech, Inc.

DODA U.S.A. Inc.

Eurovix USA, Inc.

Expert Company

Fan Separator (USA), Inc.

Farm Tek

Gemaco Sales Ltd.

Global Repair

Green Earth Naturally/EarthCleanz

Hawkeye Steel Products Inc.

HCL Machine Works

LSC Pre-Cast Systems Ltd.

Manure Systems Inc.

Midwest Bio-Systems

Mighty Grow Organics

MMI International

Parma Company

Patz Corporation

Penergetic Canada

ProfitPro, LLC

Trimble Agriculture

World Dairy Expo

Iowa Select Farms

Design Consultants

Farm Tek

Manure Systems Inc.

Northern Biogas LLC

Management Consultants

Agprofessionals, LLC

Agriment Services Inc.

Expert Company

Iowa Select Farms

Kunafin

Midwest Bio-Systems

ProfitPro, LLC

VTI LLC

Wessuc Inc.

World Dairy Expo

Engineering Consultants

Agprofessionals, LLC

Agriment Services Inc.

Braun Electric Inc.

Cadman Power Equipment Ltd.

Degelman Industries

DVO, Inc.

EC Applications (BioGasCovers)

Expert Company

Farm Tek

Kifco Irrigation

LSC Pre-Cast Systems Ltd.

McLanahan Corporation

Pro-Act Biotech

CONTROL

AGCO Ag Chem Equipment

Agpro, Inc.

Balzer, Inc.

Bazooka Farmstar, Inc.

Braun Electric Inc.

Buffalo Turbine

Cadman Power Equipment Ltd.

CAWI Canada Ltd.

Farmer Boy Ag Inc.

Greenlite Lighting Corporation

J & D Manufacturing

Phason Electronic Control Systems

Silo's R Us Inc.

Sunova Worx Inc.

World Dairy Expo

DRAINAGE MANAGEMENT SYSTEMS

Agprofessionals, LLC

Silo's R Us Inc.

World Dairy Expo