NOVEMBER/DECEMBER 2010

NOVEMBER/DECEMBER 2010

Specially rigged trucks help applicator

Volume 8 • No. 6

Published by:

Annex Publishing & Printing Inc. P.O. Box 530 Simcoe, Ontario N3Y 4N5

Editor

Margaret Land • (519) 429-5190, (888) 599-2228, ext 269 mland@annexweb.com

Contributing Editors

Don Comis, Tony Kryzanowski, Steve Werblow

Advertising Manager

Sharon Kauk • (519) 429-5189, (888) 599-2228, ext 242 skauk@annexweb.com

Sales Assistant

Mary Burnie • (519) 429-5175, (888) 599-2228, ext 234 mburnie@annexweb.com

Production Artist Krista Misener

VP Production/Group Publisher Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: mweiler@annexweb.com

Printed in Canada

Circulation

e-mail: mweiler@annexweb.com

Tel: 866-790-6070 ext. 211

Fax: 877-624-1940

Mail: P.O. Box 530 Simcoe, ON N3Y 4N5

Subscription Rates

Canadian Subscriptions

$35.24 Cdn, one year (with GST $37.00, with HST/QST $39.82)

U.S. Subscriptions:

$47.00 USD, one year

Occasionally, Manure Manager will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher's written permission. ©2010 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher's approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Website: www.manuremanager.com

By Margaret Land

Ishould have been a lawyer.

Growing up, my mother encouraged me to follow a career in the law, perhaps sparked by my great ability to enrage my father during family “discussions.” What can I say; I loved to argue just as much as he did.

I shied away from the bar, uncomfortable with the prospect of having to defend someone who I knew was guilty or, horror of horrors, failing someone I believed to be innocent. It takes a person with a deep love of the black and white (and green) aspects of the law to be a lawyer. I’ve always been too wrapped up in shades of grey.

Lately, I’ve been reconsidering my lost law opportunity, particularly in light of a presentation made by Marvin Childers, president and chief lobbyist of the Poultry Federation, which represents the poultry industries of Arkansas, Missouri and Oklahoma. Childers provided an update of the Oklahoma poultry litter lawsuit during the 2010 National Poultry and Animal Waste Management Symposium, held in late October in Greensboro, N.C.

The lawsuit, filed in June 2005, was launched by then Oklahoma Attorney General Drew Edmondson and involved 11 named defendants from eight different poultry integrator companies. The attorney general was seeking $800 million in natural resource damages and $1.5 billion in remediation requests, claiming land applied poultry litter was polluting the Illinois River Watershed.

“[We] were certain that, prior to me being here today, we would have a ruling from the district judge,” Childers explained. “And I could really talk about what the state of Oklahoma was doing in respect to their appeal. Unfortunately, we’re not there yet.”

As of the date of the composing of this editorial (Nov. 15, 2010), there is still no decision on the almost six-year-old lawsuit and, according to recent articles out of Tulsa, there may never be one. Following the recent U.S. elections, Oklahoma has a new Attorney General elect, Scott Pruitt, who has already announced that once he takes office, he plans to review whether the state will continue with the lawsuit. Oklahoma Governor elect Mary Fallin has stated that she also will be reviewing the litigation.

Despite the uncertain future of the lawsuit, Childers had words of caution for poultry industries in other states.

“I would say you can expect trial lawyers looking for state business,” he said. “Once they were employed by the Oklahoma Attorney General, they marketed that litigation –or, as they call it, their business model – to many state’s attorney generals.

“I believe that’s what other states have to look forward to. They’ve already spent this money now in Arkansas and Oklahoma. They’re going to have the base of their research.”

Childers added that “those carpet-bagging trial lawyers from South Carolina,” famous for orchestrating the class action lawsuit against the tobacco companies, have already spent more than $30 million in costs and experts.

And you can expect that if they can’t earn that money back in Oklahoma, they’ll be searching for another state to pay back their investment.

Hang on to your wallets. When prompted by an audience member to divulge how much poultry companies have spent defending against the lawsuit, Childers said, “I can’t comment on that. I mean it’s quite a bit more than that (the $30 million spent by the plaintiff).”

Now, more than ever, pork producers recognize the impact their operations can have on the world around them.

Proactive eco-management with MicroSource S can help reduce environmental burdens. The result:

• Reduction in noxious manure gases, like ammonia and VFAs, for less odor

• Increased nitrogen retention in manure for an improved N:P ratio

• Lower manure viscosity so less power is required for pump outs

• Decreased stickiness of manure for easier/less cleaning.

MicroSource S contains selected microbes that digest the solids in hog manure. It begins to work even before the manure hits the floor and continues to act on manure during handling and storage. MicroSource S can help you balance today’s environmental challenges with efficient pork production.

To learn more, contact your feed supplier or go to www.unlimitednutrition-na.dsm.com.

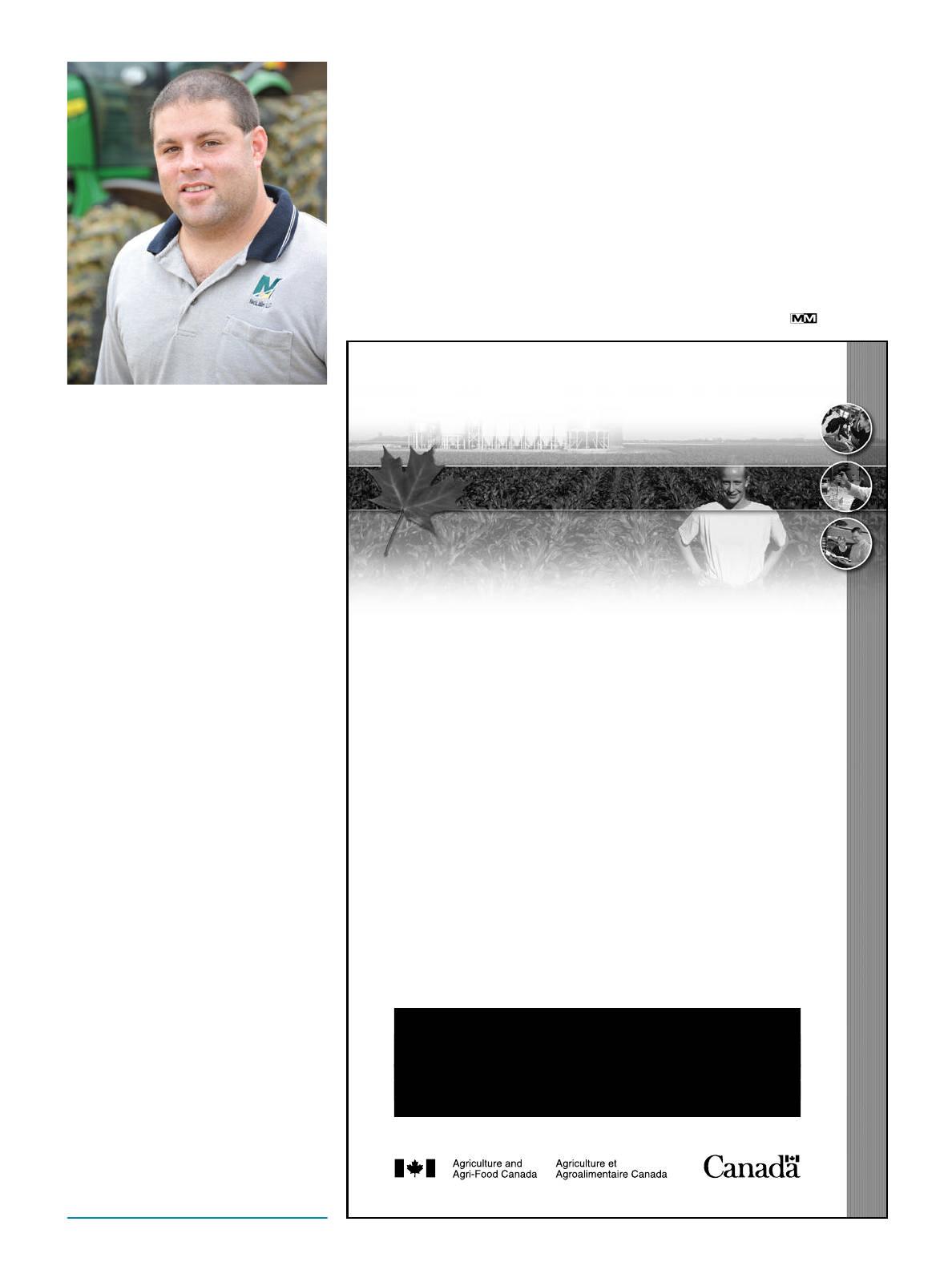

Phillip McLain has been working to stay on top of advances in high-speed radial flotation tire technology. “If we can get more speed in the future, that’s my ticket to expansion,” he says. “I can haul more gallons, and I can knock those tractors out of the way.”

Photo by Steve Werblow

By Steve Werblow

Specially rigged trucks keep this North Carolina applicator at the head of the pack

Phillip McLain is a man on the move.

When he’s not dispatching his five full-time drivers on manure hauls around Statesville, N.C., he’s checking in on his family’s 5,000-acre farm or its oilseed crushing mill, or exploring the latest farm software technology to integrate into his precision agriculture consulting business. Crackling with entrepreneurial energy, it’s no surprise that McLain has zeroed in on making his manure hauling equipment as

fast and efficient as possible.

McLain has converted six Mack trucks to high-efficiency manure hauling rigs that provide him and his team of drivers with versatility, speed and economy.

McLain buys used over-the-road haulers and replaces the duals on their rear axles with 700/40-22.5 flotation tires. He makes sure they’re outfitted with 40,000-pound rear ends for stability, and geared at 4.10:1 or 4.17:1 ratios for reliable pulling power. He keeps standard 22.5-inch truck tires on the front axles to aid in steering and resist the push from the heavy, 8,000-gallon Diller Equipment tanks his team is pulling.

Perry Reid, McLain’s top driver, says the tractor-trailer setup is more stable on the road than trying to haul a tank with a farm tractor.

“A tank behind a farm tractor will push the tractor,” Reid notes. “On a farm tractor, the weight’s on the drawbar. On

one of these, the weight’s right over the drive axle, right on top of the wheels.”

One of the immediate appeals of McLain’s system is cost – he figures he can put a rig on the road for about one-third the cost of a new tractor.

McLain points out that the efficiency of his system goes well beyond cost efficiency.

“Efficiency means lots of things,” he says. “It means cost. It means speed. It means agility in the field. On the road, we’re going 20 to 30 miles per hour loaded, and empty, we’re probably going 10 miles per hour faster than that. At that speed, I can do three loads with a truck versus one load with a tractor.”

Part of the edge comes from equipment, but logistics plays a key role, too. “Our technique and logistics are two things that we have pioneered

over the years to protect our customers’ fields and our reputation,” McLain says. “We combine those two things with our equipment setup, and it’s been the hallmark of our success.”

The result is that McLain can be extremely cost-effective on the typical three-to-five-mile haul, and can outcompete other applicators on hauls as far as 10 miles from the lagoon. His team can also run on steep or wet ground that can keep most tractors stuck in the turnrow.

“We can do things on these tires that you couldn’t do on a regular truck, and when you’ve got wet grass, we can go where nothing else can go,” says Reid. He says one customer marveled at Reid’s ability to spread manure with his truck on a hillside that no tractor had been able to conquer.

Phillip McLain keeps standard 22.5-inch truck tires on the front axles to aid in steering and resist the push from the heavy, 8,000-gallon Diller Equipment tanks his team is pulling.

McLain uses Alliance flotation tires on his drive axles, a brand he first encountered on his tanks. Comparing them to other flotation tires, he quickly realized that not all flotation tires are created equal –where the other tires wore bald in a single season, McLain had plenty of tread left on the Alliance tires after two years and 20 million gallons per rig.

The deep tractor lugs on his 331 drive tires provide excellent traction and side-hill stability without excessive soil compaction, he says, while the blockier 390 tread pattern on his tanks – sized at a beefy 710/50R 30.5 to spread the tanks’ heavy load over a very wide footprint – is geared toward protecting grass and other crops.

Like any tool, tires require attention

and care. Maintaining the appropriate air pressure for load and speed is vital for safety and performance, McLain notes. So is constant attention to his tires, a job he and his drivers share with Clark Tire of Hickory, N.C.

“We’re checking them every day, and we have a professional checking them every week,” he says. “We also get great service, which is huge for us. The way we run, we’ve got to have someone out here when we need him.”

Reid adds that tread design and rubber compound also reduce road noise – no small benefit when it comes to staying friendly with the neighbors. In fact, when he first drove a rig outfitted with the

When Phillip McLain is not dispatching his five full-time drivers on manure hauls around Statesville, N.C., he’s checking in on his family’s 5,000-acre farm or its oilseed crushing mill, or exploring the latest farm software technology to integrate into his precision agriculture consulting business.

331s, he stopped and got out to see if something was wrong because the truck was running so quietly.

“I live right in the middle of three dairies we haul from, and I would listen to those old tires at night,” Reid says. “I could see why neighbors might not like us. Now it’s a lot quieter. That’s important, especially when we’re running at night.”

McLain and his crew have built a reputation for looking out for neighbors and customers. In 2009, when relentless heavy rains kept even his trucks out of local fields, many ponds were close to overflowing, and there was no break in sight. Reid and fellow driver Greg Johnson rigged up a 40-gpm pump at the outlet of one of their tanks, ran it to a 1/5inch pipe, and created a mobile big gun system. From the road, they could shoot clear over power lines to surface-apply manure and start draining the lagoons.

“We had to get it done,” recalls Reid. “And we saved our dairies from a lot of trouble with the EPA.”

Helping customers comply with state and federal regulatory agencies is another part of McLain’s service.

“We do a lot of record-keeping for our customers,” McLain says. “We keep manure records in Excel so we know how many gallons of manure we have in any part of a field, and we monitor changes in N, P and K in the samples we take.”

He uses FarmWorks software to view

field maps, and coordinates with a local crop consultant who uses SST to direct variable rate applications by identifying areas that need spot-spray applications. “We’re doing innovative things that the Department of Water Quality really likes,” he says.

McLain has been working to stay on top of advances in high-speed radial flotation tire technology.

“If we can get more speed in the future, that’s my ticket to expansion,” he says. “I can haul more gallons, and I can

knock those tractors out of the way.”

He also sees great potential for his business to spread to other areas, either directly under his management or in some sort of franchise-like arrangement with other innovative custom applicators. McLain says he can envision an arrangement in which he trains teams of applicators to bring his business model home to their markets.

Of course, lesson one would be outfitting trucks the McLain way. “We can do things on these tires that you couldn’t do on a regular truck,” he says. “We can embrace new challenges.”

Are you interested in helping to develop Canada’s newest and brightest graduates for a career in the agriculture industry? The Career Focus Program provides employers with up to $20,000 in matching funds to create internship opportunities for recent graduates from agriculturerelated programs.

For employers, the program offers an economical way to attract new talent and helps provide new graduates with a valuable first job that will help pave the way to a career in the ever-changing agriculture and agri-food industry.

Eligible employers:

• Must offer projects that will give graduates meaningful agriculture career-related work experiences in Canada and skills acquisition through mentoring and coaching.

• Could include organizations such as farm businesses, industry, not-for-profit organizations, provincial and municipal governments, associations, boards, councils, colleges and universities.

Eligible interns:

• Must be a Canadian citizen or landed immigrant

• Must be 30 years old or younger

• Must have graduated from a university, college, CEGEP or provincial institution within the last three years, specializing in biology, agriculture, veterinary sciences or applied technology.

Deadline for the first round of 2011-12 applications is December 31st, 2010.

To find out more about the Career Focus Program and to obtain a project proposal form:

Visit: www.agr.gc.ca/careerfocus Call: 1-866-452-5558 E-mail: careerfocus@agr.gc.ca

NS019_AC: 4.625" X 7.5"

IMPORTANT: A proof must be faxed to Compass Communications for approval before

By Tony Kryzanowski

Poultry litter pyrolysis manages manure and delivers value-added byproducts

Because the United States is the world’s largest producer and exporter of poultry meat and second largest egg producer, there can be little doubt that managing poultry litter is no yolk.

However, Virginia Polytechnic and State University is working with a company called BioEnergy Planet Inc. to commercialize a pyrolysis litter disposal method. The disposal method not only has the potential to give poultry and egg producers a way to safely dispose of millions of tons of poultry litter produced annually, but the process produces two value-added commercial products – bio-oil and biochar. The bio-oil can be used as fuel to heat farm operations or reprocessed into polymeric material such as substitutes for petroleum-based plastics. The biochar works well as a soil fertilizer because of its high carbon, potassium, phosphorus and calcium content.

BioEnergy Planet Inc. chief executive officer Luda Kopeikina says the company was looking for a business opportunity that would convert a feedstock like poultry litter, into useful products.

After investigating various technologies, they settled on pyrolysis, and recognized the potential of the Virginia Tech system because not only did it dispose of the poultry litter, it also generated products that could be sold in commodity markets.

“Pyrolysis reactors can be small and the nature of the industry is such that those farms are usually small and independently owned,” says Kopeikina. “So to make it economical and for it to make business sense, we needed to have scaleable processing capacity that could potentially be moved.”

The company’s intention is to negotiate litter supply agreements under strict quality control parameters with poultry farms and operate the pyrolysis

units themselves, marketing the bio-oil and biochar byproducts. Kopeikina says that no further refining of the bio-oil is required. It is useable in the state it is produced, except for the addition of a stabilizer like methanol. It can also be mixed with traditional, petroleum-based oil.

In terms of the equipment itself, BioEnergy Planet will conduct further engineering on the pyrolysis technology essentially to build more robust units based on the prototype developed by the university. The units will be built to scale according to the needs of farmers within a defined radius and located in a centralized location to keep transportation costs reasonable.

While the company’s focus is currently on poultry litter, BioEnergy Planet is working on further research with Virginia Tech as to the potential of using this pyrolysis technology to dispose of other types of manure. Poultry litter lends itself more to pyrolysis than other types of manure because it has between 30 and 35 percent moisture content versus 70 percent in other types of manure. So current research is focused on how to manage the moisture content with other types of manure as part of this pyrolysis process, and then possibly offering it in other agriculture sectors.

Virginia Tech research scientist Dr. Foster Agblevor was already actively engaged in developing pyrolysis technology related to producing biooil from hardwood residues when he was approached by a group of poultry producers from Virginia’s Shenandoah Valley to see if his method was viable for disposal of poultry litter. Various types of biomass, including wood fibre, are

Once Virginia Tech announced that it had developed transportable technology to convert poultry litter to bio-oil and biochar, its phone started ringing off the hook from all over the world. Contributed photo

commonly used as litter ingredients in the poultry and egg industry. The poultry producers were looking for an alternative method for litter disposal to land spreading. Because of the volume being produced, the cost of transporting it further and further away for land spreading was becoming quite costly. The area produces about 453,000 tons of poultry litter per year.

Dr. Agblevor indicated to the farmers that he was interested in pursuing a more permanent solution to their problem.

“When I analyzed the poultry litter and saw the composition, it just struck me that with a little tweak, we should be able to do the same thing as we were doing with the wood residues,” says Dr. Agblevor.

Test results couldn’t have been better as researchers discovered that the higher protein content in the poultry litter actually resulted in higher energy bio-oil.

A lab-scale pyrolysis unit was constructed for use at the university and a larger, transportable unit was constructed and operated on a farm managed by Oren and Cheryl Heatwhole, in Dayton, Va., with financial support provided by the Farm Pilot Project Coordination organization.

Oren Heatwhole has been producing poultry since 1986, and is currently raising about 38,000 broilers annually for Tyson Foods.

“The litter could not be spread on area fields because the phosphorus content in

the soil was already high,” says Heatwhole. “The reason for the pyrolysis was to take the liability and turn it into an asset.”

The poultry litter tested from the Heatwhole farm as well as litter supplied by surrounding farms produced a viscous brown bio-crude with a pH of about 6 when pyrolyzed at between 450 and 550 C.

“The poultry litter biocrude oils have much higher calorific value than the corresponding hardwood biocrude oil, but have relatively high nitrogen content compared to hardwood biocrude oils,” says a report published in the academic journal, Waste Management, and co-authored by Dr. Agblevor. “The higher calorific value of the poultry litter biocrude oils appear to correlate directly with the protein content of the raw litter.”

Dr. Agblevor says that the pyrolysis concept developed at the university has been proven in other test laboratories, and once the university announced the breakthrough, they began receiving phone calls from around the world, asking the university to build pyrolysis units for them.

That’s when the university invited companies to submit proposals to commercialize the technology, which led to a partnership with BioEnergy Planet. They will refine the technology and build

commercial units to meet the demand. The university is licensing its technology to them. Heatwhole is highly supportive of what the university has been able to accomplish for poultry producers.

“Once everything is running and going as planned, it’s basically a homerun because everything you make from the litter, you make into a value-added product,” he says. “Also, we no longer have a litter disposal problem and there are basically zero emissions.”

While there were no design changes to the pyrolysis unit to adapt to the poultry litter, the material itself is quite difficult to handle because of its moisture content and odor. To deal with the odor issue, Dr. Agblevor says they invented a product called Amosoak, which absorbs the ammonia in the poultry litter and alleviates the odor problem. It also makes the litter easier to feed into the pyrolysis unit. The Amosoak is typically applied on the farm in the litter house prior to delivery to the pyrolysis site.

In future, Dr. Agblevor says consistency of litter supply in terms of the type, quality and quantity of the litter material, and how often the litter is removed, will be critical to the performance of the pyrolysis process. It will be

purchased based on its energy content.

Although it may appear that the Shenandoah Valley producers are dealing with a high quantity of poultry litter, Dr. Agblevor says a smaller transportable pyrolysis unit will likely serve their purposes. However, much larger units would be the choice for poultry and egg producers on the Maryland eastern shore, where those producers have to dispose of over one million tons per year.

Heatwhole says that as a condition to his participation in the project, he will take ownership of the test pyrolysis unit. However, he hopes that over the medium term, a larger, commercial unit will be installed in the area that would be capable of disposing of between 10 and 20 tons of litter per day, which would accommodate the needs of about 30 area poultry operations.

BioEnergy Planet’s initial commercial foray will likely be in Virginia. Then they intend to expand to other areas of high poultry production in the United States.

At present, Kopeikina’s focus is not so much serving the market, but arranging the financing and attracting passionate investors to help develop the business. The company also has a number of grant applications pending.

By Margaret Land

Dairy farm to use psychrophilic SBR digester to achieve optimum biogas yield

Adairy operation in Oregon is hoping low is the way to go as it adds a psychrophilic sequential batch reactor (SBR) anaerobic digester to its manure management regime.

The technology, which is being provided by Bio-Terre Systems Inc. of Quebec, Canada, will utilize mixed flush and scrape manure from the 1,200-head dairy operation to feed two glass-lined steel tanks in sequential batches.

Psychrophilic anaerobic digestion relies on bacteria that work at temperatures between 5 and 28 C, with the optimum range being 20 to 25 C.

“These bacteria are known to be very robust,” explained Elise Villeneuve, an engineer with Bio-Terre Systems, as she presented a case study describing the project during the 2nd Annual Canadian Farm and Food Biogas Conference held

in early 2010. “There are more families of bacteria present at work.”

Even with the large number of bacterial families, psychrophilic bacteria can take a longer time to degrade the material. In light of this, Bio-Terre went with a sequential batch approach using the two tanks.

“There is a cycle that is very short; in this case it’s a seven-day cycle,” said Villeneuve. “The first 3.5 days, one of the reactors is being fed the material and then is being put to rest. We don’t mix at all. We wait for the settling that occurs. By doing this, we’re able to retain those solids that are not yet treated. We keep them in the bottom (of the digester tanks) and then we let go what has been treated.

“We do that on purpose; we really want that sediment to build up.”

By doing this, Bio-Terre is able to artificially create a long retention time for the solids plus decrease the ratio of food to biomass so there is more biomass working at degrading. Through this method, they are able to get the maximum potential of biogas without creating a longer hydraulic retention time.

“For this project, we’re talking about an equivalent of 22 days’ hydraulic retention time,” said Villeneuve.

With the sequence batching and the sedimentation phase, biogas production

A dairy operation in Oregon is hoping low is the way to go as it adds a psychrophilic sequential batch reactor (SBR) anaerobic digester to its manure management regime. Contributed photo

in the Bio-Terre system occurs in curves, she said, adding that by having the two tanks in sequence, production becomes equal. Yet it can still vary.

“The biogas storage with our technology is important,” said Villeneuve. “The last thing these guys want is to flare.”

While most of the sediment in the bottom of the tanks does degrade over time, management of the tanks must be performed periodically, she said.

“We don’t mix for the process but we do have a system installed to put everything back in suspension just to make sure that over time it doesn’t build up.”

The Oregon system also includes a decant tank and a solids management area with a sloping screen and screw press.

“The decant tank was a little bit of a debate,” said Villeneuve. “We were not sure whether we should install one or not. It ended up being a yes, mainly because we wanted to ease the solid management for the bedding operation.

“We didn’t want to force the operation of that to be on the same timing

of the effluent from the digester.”

While the system will be based at the Oregon dairy, it is owned and operated by Revolution Energy Solutions LLC (RES), a project developer for renewable energy projects, which has a long-term host site agreement with the dairy operator. RES, which focuses its renewable energy projects on concentrated animal feeding operations (CAFOs), currently has site control agreements with 100 other farms.

“They pay for everything,” said Villenueve. “The farmer doesn’t have to pay one cent.”

She added that the first criteria for the company is not to change the farmer’s life. “They want to enhance the manure management system but not to change it.”

As such, they look for technology that can easily fit into the farmer’s current manure management system, can be standardized, can be controlled remotely, and can be quickly constructed.

“These guys are looking at deploying 100 sites in the next six or seven years so they need to construct fast with the minimum vendors possible,” said Villeneuve.

RES hopes to produce about 150 kilowatt- hours of electricity from the Oregon project.

“There’s no feed-in tariff and it’s not on net metering,” said Villeneuve. “(The company) is just simply selling at a not very high price – around seven cents – back to the grid 100 percent of the electricity produced.”

She added that the company also hopes to recoup costs and generate revenue through state and federal tax credits on approved capital costs for the project, by trading Renewable Energy

With the sequence batching and the sedimentation phase, biogas production in the Bio-Terre system occurs in curves. By having the two tanks in sequence, production becomes equal. Contributed photo

Certificates (REC) on the market, by selling greenhouse gas (GHG) credits, and by making solid fertilizer an important part of their model.

Cows may be getting a bum rap over their greenhouse gas emissions — or not.

Mathematical equations used in predicting cows’ methane emissions are inaccurate and

need improvement to help dairy farmers mitigate greenhouse gas releases, says a new study by a research team that includes scientists from the University of Guelph, the University of Manitoba and Wageningen University & Research Centre in the Netherlands.

The study appears in the November issue of the journal Global Change Biology.

Livestock accounts for about 18 percent of all greenhouse gas emissions, according to the United Nations Food and Agriculture Organization. Methane (CH4) is the most important greenhouse gas produced on dairy farms and is 25 times more potent than carbon dioxide, another important gas implicated in global warming.

These researchers used data from studies in Canada, the Netherlands and the United Kingdom to assess how well widely used equations predicted methane production. They found that nine equations used in whole-farm greenhouse gas models over- or underestimate cows’ methane emissions.

“We over- or under-predict CH4 emissions as a result of these equations,” said Dr. James France with the University of Guelph’s Department of Animal and Poultry Science. “Agriculture needs more accurate estimates based on better science.”

Jennifer Ellis, a Guelph PhD student and lead author of the new paper, notes there’s “a lot of concern right now about the impact of farming and human life in general on the environment. The prediction accuracy of these equations is small, and the equations are not suitable to quantify methane production of cows.”

Whole-farm models used to estimate the effect of on-farm management changes – such as manure and crop management, breeding, and basic nutrition – don’t account for effects of dietary changes, she said.

For example, the equation currently used by the Intergovernmental Panel on Climate Change fails to distinguish between the effects of simply feeding cows more and the effects of feeding them higher-fat diets, said Ellis, who has begun a post-doc at Wageningen University. “A higher feed intake will increase methane production. A rise in dietary fat content will decrease methane production.”

AgriLab Technologies completes new installation

AgriLab Technologies, LLP has completed installation of its second project in North America.

The newest installation is on a dairy heifer calf raising facility near Albany, N.Y. The facility maintains 2,000 head when full. The farm’s new composting and heat recovery system will help to eliminate the operation’s dependence on propane, while reducing diesel, electric and grid-based energy dependence.

AgriLab Technologies has demonstrated that the farm can capture in excess of 1,000 BTUs of energy from each ton of composting feedstock, per hour. The installation will process approximately 500 tons of material weekly, generating an average of 190,000 BTUs per hour or 4,560,000 BTUs daily. Systems are designed to scale needs.

The heat will be used to meet the facility’s 11,000-gallonper-day hot water needs and heat buildings on the complex. Finished, stabilized compost material will be used as livestock

bedding and ultimately field applied, reducing the farm’s dependence on chemical-based fertilizer derived from fossil fuels. This will help the farm improve soil health while protecting water resources and the environment.

Systems are powered by low energy, in-line electric fans on timers to create negative aeration through compost feed stock. Standard zone valves facilitate water circulation needs.

This technology is applicable to any farm or facility managing and composting organic waste feed stock, such as a livestock operation looking to maximize the benefits of waste diversion through aerobic composting.

www.agrilab.ca

Mountains of manure from cows and chickens are helping to heat houses and cook dinner.

Canada’s first biogas upgrading system is now up and running at an Abbotsford farm about 80 miles southeast

of Vancouver, B.C. Catalyst Power is aggregating the dairy, poultry and vegetable waste from several local farms and converting it into pipeline-quality natural gas that is injected directly into the local utility grid, helping to provide energy to more than 900,000 customers across the province.

The system is using a waterscrubbing process from Flotech Inc, a New Zealand-based company, to upgrade the methane to natural gas quality. The water scrubber installed at the B.C. farm has the capacity to process 460 standard cubic feet per minute – the

equivalent of about 1.5 megawatts of electricity or enough to heat about 1,000 homes. The system has the lowest energy consumption per unit feed of any biogas or landfill upgrading system operating in the U.S. and Canada, according to Sean Mezei, president of Flotech North America. It also boasts a 98 percent yield of methane from raw biogas and delivers a methane purity level of 97 percent.

With the first of the natural gas now flowing into the grid, Catalyst Power has its sights set on building a number of similar systems at farms across Canada. Flotech is also actively involved in a

number of larger projects in the U.S. that are expected to come online early next year.

Farm Power breaks ground on second dairy digester

Farm Power, a Washington renewable energy company, broke ground on its second anaerobic manure digester in late June.

The new digester project will serve the energy needs of local homes and businesses through Puget Sound Energy (PSE)’s Green Power program.

The dairy digester, based in Lynden, Wash., is expected to go online before the end of the year, and will produce up to 750 kilowatts of energy – enough electricity to meet the needs of 500 homes.

Skagit County residents and brothers Kevin and Daryl Maas founded Farm Power in 2007 to address concerns about the health of the environment and the future of the traditional family farm. Farm Power works with local dairy farmers to build regional digesters that serve multiple farms. Anaerobic dairy digesters transform cow manure and other agricultural waste into clean, renewable energy by converting waste into methanerich biogas needed to fuel an electric generator.

Currently, Farm Power has one digester in operation, located near Mount Vernon, Wash., which processes manure from neighboring dairy farms in Skagit County to produce up to 750 kilowatts of energy. All of the digester’s energy output is used by PSE’s Green Power.

EnviTec Biogas AG has won the first contracts for the construction of biogas plants in France.

The company has teamed up with agricultural firm Le Crom to build a biogas plant rated for an electrical output of 500 kilowatts in the locality of Rohan in Brittany.

EnviTec Biogas AG has also won contracts for the construction of biogas plants from three other French customers. In Ribeauville, the company will build a 1.2-megawatt biogas plant for Agrivalor Energie. In Etreville, a biogas plant with an electrical output of 1 megawatt is scheduled to go into service before the end of2010. A 1.7 megawatt plant will be erected in the southeast of France, in the community of Romans-sur-Isere. The plant is expected to produce enough heat to supply the community’s industrial area.

New Holland’s new HydraBox™ hydraulicpush box spreaders are built for simplicity, easy maintenance, and fast, productive performance.

Unlike traditional chain floor spreaders, HydraBox hydraulic-push spreaders feature a staggered, twin cylinder pushing system with vertical beaters instead of the traditional horizontal beaters. There are fewer moving parts and no apron chains, which may stretch and wear over time. The staggered cylinders provide a shorter tongue length for better maneuverability in tight barnyards, feedlot pens, and end-of-row turns. Each of the twin push cylinders is individually serviceable, and much less costly to replace than the stacked and welded cylinders with ported rods used on many other spreaders.

The patent-pending reverse top segment vertical beater ensures fast, smooth, uniform unloading of material with complete cleanout. The heavy-duty flighted beaters provide many years of service even when spreading sand- laden manures, occasional stones and frozen manure slabs, and can be removed and installed easily for stockpiling.

The box frame features solid virginpoly floors and sides for strength while reducing friction, so loads move more easily, especially in freezing conditions, to avoid material buildup inside the spreader. The tongue is designed to pull directly from the axle, not the box, for greater strength when hauling heavy loads.

New Holland’s two HydraBox models meet the requirements of a variety of dairy, beef, poultry and mushroom operations. The 425V spreader model features a 425 heaped bushel capacity for medium-sized producers. The lower

side height of this model is ideal for side loading with a skid steer or small wheel loader. The larger 550V HydraBox spreader model boasts an impressive 550 heaped bushel capacity for larger operations where telehandlers and large wheel loaders are utilized for cleanout. www.newholland.com

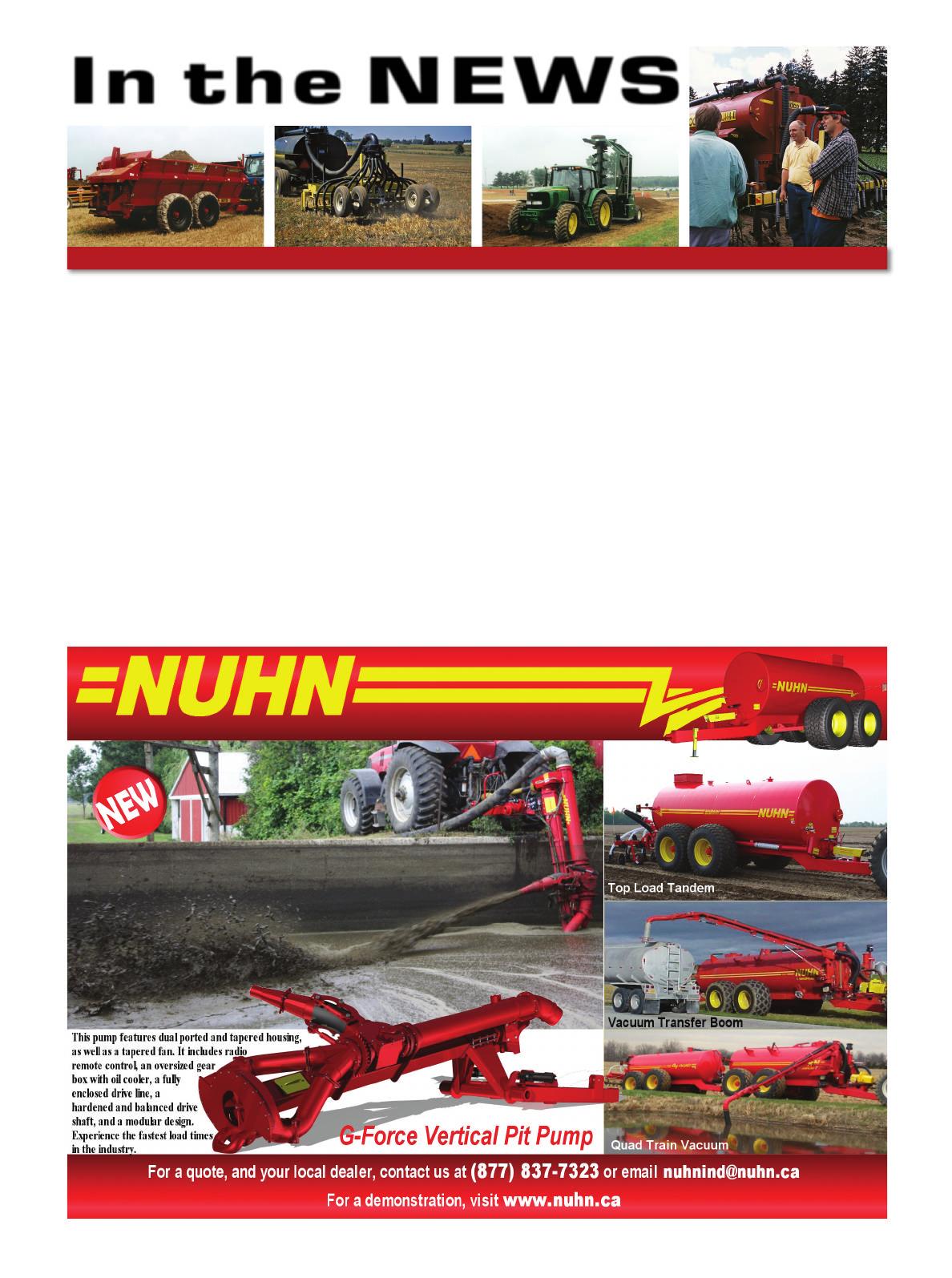

The new Nuhn Vertical Pit Pump features a dual ported and tapered housing patented by Nuhn. The liquid is able to leave the pump housing via two opposite outlets. The Nuhn pump has a tapered fan, much like a boat impeller, that lifts the liquid while rotating in the housing. This design allows the Nuhn pump to produce 6,000 (US) gallons per minute at 1,000 r.p.m. with little input horsepower. Most eight-inch pumps on the market are in the 3,000 to 4,000 (US) gallons per minute range. Nuhn accomplishes these volumes at 640 r.p.m.

Other standard features of the Nuhn Vertical Pit Pump include a radio control, oversized gearbox with oil cooler; a fully enclosed drive line; a hardened and balanced drive shaft, and modular design. www.nuhn.ca

Gehl Company is turning heads with brand-new additions to their product lines: Gehl compact articulated loader models 140, 340 and 540.

The three different sized loaders are designed to fit both the budget and the application at hand. Gehl articulated loaders feature tipping loads ranging from 1,900 to over 5,100 pounds (when not articulated) and rated operating capacities from 950 to more than 2,550 pounds. These machines can run virtually

all universal-type attachments, putting tools customers already own to good use. Compact sizing – from as narrow as 41 inches on the model 140 – allows for easy access to extremely tight spaces. Articulated steering allows for turns up to 45 degrees, which further enables these compact loaders to navigate confined spaces while minimizing damage to sensitive surfaces and reducing tire wear.

Gehl articulated loaders come equipped with Yanmar diesel engines, which feature Interim Tier IV-certified emission technology with excellent performance in all applications. Horsepower ranges from 23-horsepower on the model 140, to 47-horsepower on the model 540.

Gehl articulated loaders are designed to go almost anywhere and do almost anything. A heavy-duty oscillating joint offers 45-degree turning angles to the left and right, and 10 degrees of oscillation in both directions, for optimal traction and maneuverability. The bucket and tires follow a constant turn radius, so the rear tires of the loader follow the path of the front tires. Narrow machine widths allow access to tight, confined spaces that most skid-steer loaders with comparable operating capacities cannot access.

Hydraulic performance and timesaving features on the Gehl articulated loaders give customers hydraulic power and precision. Two easily accessible auxiliary hydraulic lines with flat-face couplers power a variety of tools and make attachment changes easy. Lift arm and bucket float features allow for “floating” of the lift arm and bucket for light scraping and rearward leveling actions.

The uniquely designed lift arm on the Gehl articulated loader is designed to achieve maximum strength, excellent visibility and fast cycle times. The paralleltype linkage on the models 140 and 340, and “Z” bar-type linkage on the model 540, provide excellent bucket breakout forces. The unique linkage design allows for mechanical self-leveling action in both the up and down directions, excellent bucket dump angles at the mid- and top-ranges of the lift path, as well as outstanding forward reach.

A complete cab enclosure option is available on the models 340 and 540, providing comfort and safety for daylong operations. A 360-degree visibility is achieved by positioning the operator above the load for safe operation and excellent view of the attachment. A multifunction joystick controls the lift arm, bucket, float, travel direction, differential lock and auxiliary hydraulic functions. An inching pedal allows operators to vary ground speed while maintaining a fixed engine speed, to optimally run attachments while enabling precise machine speed control. www.gehl.com

JCB and Volvo Construction Equipment have entered into a framework agreement under which they will co-operate on the engineering and manufacturing of skid steer loader and compact tracked loader products for distribution under their respective brands and through their respective global dealer networks.

It is envisaged that the first mono boom Volvo branded machines will be in production at JCB’s Savannah, Ga. facility by the end of 2010. Volvo Construction Equipment will then transition skid steer loader models over time from its Pederneiras facility in Brazil.

“This agreement will allow us to combine forces in this key product area enabling both brands to compete more effectively,” said John Patterson, deputy chairman of JCB.

“Volvo customers will benefit from a wider range of models that maintain the high level of product safety and functionality that they expect,” said Olof Persson, Volvo Construction Equipment president. www.jcb.com www.volvo.com/ constructionequipment

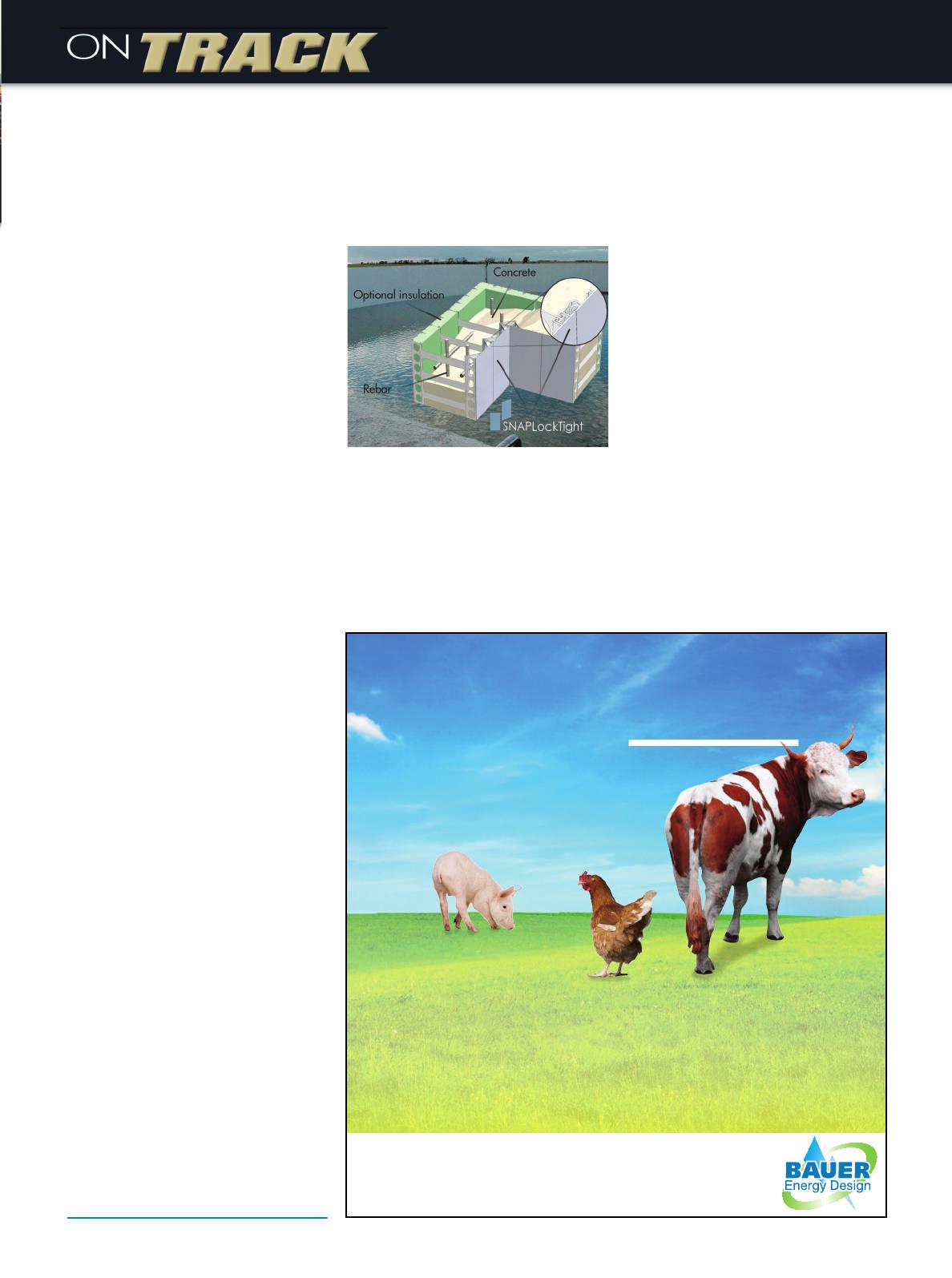

Octaform Systems Inc. recently announced the launch of a new wall panel for use with its stay-in-place PVC Finished Forming System.

The product, called SNAPLockTight, allows users to construct corrosion resistant concrete tanks without the need for caulking, linings or epoxy coatings.

SNAPLockTight extends Octaform’s

tank construction capabilities into the growing biomass to energy production market. Specific applications for the technology will include anaerobic digester tanks, open-air algae ponds and substrate storage.

Dave Richardson, president of Octaform Systems, says the development of SNAPLockTight was a natural product extension for the company.

“We pride ourselves on our one step, one system philosophy,” he said. “Our products are designed to integrate a number of the processes involved in concrete tank construction.

SNAPLockTight enhances our Finished Forming System by combining the steps of concrete forming and watertight protective finishing into one system.”

The Octaform Finished Forming System can also incorporate insulation between the finished wall panels and the concrete. This is particularly useful in anaerobic digester tank construction, where insulation is typically wrapped externally around the tank.

“The highly corrosive environments experienced in biomass storage tanks and gas capture zones in fermentation tanks result in significant ongoing repair and maintenance costs for facility owners,” said Richardson. “Due to the durable nature of SNAPLockTight’s rigid PVC construction, we’ve eliminated the ongoing relining or coating maintenance that’s required in steel, fiberglass or bare concrete tanks.”

These maintenance costs can reach into the hundreds of thousands of dollars depending on the size of the compromised tank(s). www.octaform.com

No longer an oxymoron

A cleaner, better smelling farm is no longer a myth – it’s a reality.

That ’ s becaus e Pre sident of Bauer Energy De sign, Inc., Walter Bauer, with degree s from Univer sit y of Guelph and Wilfrid L aurier

Univer sit y, has de signed a proprietar y proce s s that change s the molecular structure of your well water into a new water with highly beneficial and te stable proper tie s This dramatically improved water – which satisfied users have coined “Bauer Water” –uses a clinical proces s to remove and prevent biofilm buildup This ultimately changes the

microflora in an animal’s digestive system Manure will no longer break down into the traditional methane and hydrogen sulphide compounds No bad compounds; no bad smells

“The Potent smell of our manure has significantly decreased since installing Walter’s design Bauer Water has definitely taken the edge off the smell!” Keith Wideman, Early Rise Jersey Farms, Elmira, Ontario

Bauer Energy Design Inc. 1.519 634.9974 or acron@rogers.com • www.bauerenergydesign com

By Don Comis

It isn’t even fully patented yet, but the Poultry Litter Subsurfer prototype invented by Agricultural Research Service soil scientist Dan Pote is on order by a research coalition across five Chesapeake Bay states: Delaware, Maryland, Virginia, Pennsylvania, and New York.

The coalition, led by ARS’s Peter Kleinman and counterparts at Pennsylvania State University at University Park and Virginia Polytechnic Institute and State University at Blacksburg, recently received a $786,000 Chesapeake Stewardship Fund grant to test four prototypes of Pote’s Subsurfer in applying poultry litter and composted cattle manure to no-till fields and pastures across the Chesapeake Bay Watershed.

Pote is at the ARS Dale Bumpers Small Farms Research Center in Booneville, Ark.

ARS is applying for U.S. and international patents on the equipment. One company has applied for a license to commercialize it.

The Subsurfer can carry up to five tons of litter for application below the surface of pastures without damaging the grass, much as a no-till planter places seeds. It can also apply poultry litter below no-till fields before planting.

In prior tests on Arkansas pastures, Pote found that subsurface application of litter lowers nutrient runoff and ammonia emissions at least 90 percent, while increasing forage yields. Kleinman and colleagues at the University of MarylandEastern Shore tested several versions of ARS subsurface litter applicators on no-till fields and pastures in Maryland and Pennsylvania, documenting lower phosphorus runoff and ammonia loss and greater corn yields. Jack Meisinger, soil scientist at the ARS Henry A. Wallace Beltsville Agricultural Research Center in Beltsville, Md., also reports lower

An ARS soil scientist observes as an ARS technician operates their invention, the Poultry Litter Subsurfer — the first commercially viable machine for applying dry poultry litter below ground. Photo courtesy of USDA-ARS

ammonia losses from corn plots.

In 2009, Pote demonstrated the Subsurfer at a Soil Conservation District/ USDA Natural Resources Conservation Service meeting in southern Maryland as well as at the 31st Southern Agricultural Systems Conference on Virginia’s Eastern Shore.

In spring 2010, Pote teamed up with Karamat Sistani of the ARS Animal Waste Management Research Unit in Bowling Green, Ky., to test the Subsurfer on a farmer’s corn field near Owensboro, Ky. “This is the largest scale test we’ve done on corn fields,” Pote says. “We are comparing the Subsurfer to the traditional method of surface-broadcast application under field-scale conditions.”

As a collaborative project, Pote led development of the Subsurfer for pastures and no-till fields, while ARS agricultural engineer Tom Way’s team at the ARS National Soil Dynamics Laboratory in Auburn, Ala., focused on developing a different prototype with adjustable row spacing for litter application in row-crop systems and pastures.

The two machines have such

different delivery systems that Pote and Way sought different patents. Pote’s Subsurfer uses a unique auger system that crushes litter and distributes it to soil trenches, allowing precise control, including very low rates not previously feasible. His tractor-drawn Subsurfer simultaneously opens eight trenches (two inches wide and three inches deep), each one foot apart.

Throughout the southeastern and Middle Atlantic states, poultry production is the primary source of income for many small family farms. Poultry litter is an excellent source of crop nutrients, but the common practice of spreading it on the soil surface promotes odor emissions, exacerbates nutrient runoff to nearby waterways — most notably the Chesapeake Bay – and allows ammonia nitrogen to evaporate. By minimizing nutrient losses, farmers can improve air and water quality and increase crop productivity.

Don Comis is a member of the Agricultural Research Service’s Information Staff.

ADVANCED AGRI-DIRECT INC.

Box 298, Thorsby, AB T0C 2P0

Tel: 780-789-3100 Fax: 780-789-2447

AERATION INDUSTRIES INTL., INC.

4100 Peavey Rd., Chaska, MN 55318 USA

Tel: 952-448-6789 Fax: 952-448-7293

Toll Free: 1-800-328-8287

AERWAY by SAF-HOLLAND

P.O. Box 212 Custer, WA 98240 USA

Tel: 604-574-7491 Fax: 604-574-0244

Toll Free: 1-800-457-8310

e-mail: ken.tanner@aerway.com

AERWAY/SAF-HOLLAND EQUIPMENT LTD.

20 Phoebe St. Norwich, ON N0J 1P0

Tel: 519-863-3414 Fax: 519-863-2398

Toll Free: 1-800-457-8310

e-mail: matt.mayer@aerway.com www.aerway.com

AGPRO®, INC.

859 Airport Rd. Paris, TX 75462 USA

Tel: 903-785-5531 Fax: 903-784-7895

Toll Free: 1-800-527-1030

e-mail: info@agprousa.com www.agprousa.com

AGPROFESSIONALS, LLC

4350 State Hwy. 66, Longmont, CO 80504 USA

Tel: 970-535-9318 Fax: 970-535-9854

e-mail: tharen@agpros.com www.agpros.com

AGRI DRAIN CORPORATION

1462 340th St., Adair, IA 50002 USA

Tel: 641-742-5211 Fax: 641-742-5222

Toll Free: 1-800-232-4742

e-mail: info@agridrain.com www.agridrain.com

AGRICULTURAL ENGINEERING ASSOCIATES, INC.

1000 Promontory Dr., Uniontown, KS 66779 USA

Tel: 620-756-1000 Fax: 620-756-4600

Toll Free: 1-800-499-5893

e-mail: webmaster@agengineering.com www.agengineering.com

Main Products/Services: Four decades of experience with leading edge facility troubleshooting, design and permitting. All types of waste management systems for dairy, beef, swine and poultry. Nutrient management, nutrient partitioning and renewable energy.

AGSOURCE LABORATORIES

106 N. Cecil St. Bonduel, WI 54107 USA

Tel: 715-758-2178 Fax: 715-758-2620 www.agsource.com

ALLIANCE TIRE USA

4 - 2nd Ave., Ste. 106, Denville, NJ 07834 USA

Fax: 973-664-9105

Toll Free: 1-877-978-4737 www.alliancetireusa.com

AMERICAN HEARTLAND INSURANCE AGENCY INC.

2118 23rd Street, Columbus, NE 68601 USA

Tel: 402-563-3441 Fax: 402-563-4114

Toll Free: 1-800-524-3498

e-mail: dan@ahia.com www.ahia.com

ART’S WAY MANUFACTURING CO., INC.

PO Box 288, Armstrong, IA 50514 USA

Tel: 712-864-3131 Fax: 712-864-3312

e-mail: kevinz@artsway-mfg.com www.artsway-mfg.com

AVATAR

1981 N. Broadway, Suite 430

Walnut Creek, CA 94596 USA

Tel: 925-274-7600 Fax: 925-210-9070

Toll Free: 1-877-AVATAR-0

e-mail: lisa.arrow@verizon.net www.avatarenergy.com

BALLAGH LIQUID TECHNOLOGIES INC.

121 North St. W., Wingham, ON NOG 2W0 Tel: 519-357-4600 Fax: 519-357-4630

Toll Free: 1-877-312-4600

e-mail: info@bliquidtech.ca www.bliquidtech.com

BAMBAUER EQUIPMENT LLC

19151 Kettlersville Rd.

New Knoxville, OH 45871 USA

Tel: 419-753-2275 Fax: 419-753-3116

e-mail: bambauerequipment@nktelco.net

Main Products/Services: We handle a complete line of liquid manure handling equipment. Large stock on mainline and drag hoses!

BAUER ENERGY DESIGN INC.

139 Louisa St. Baden, ON N3A 2T8

Tel: 519-634-9974 Fax: 519-634-9906

e-mail: wbauer@bauerenergydesign.com www.bauerenergydesign.com

BAUER NORTH AMERICA/FAN SEPARATOR

107 Eastwood Rd.

Michigan City, IN 46360-8943 USA

Fax: 219-879-5194

Toll Free: 1-800-922-8375 www.bauer-at.com OR www.fan-separator.de

BAZOOKA FARMSTAR, INC.

800 E. 7th Street PO Box 869 Washington, IA 52353 USA

Tel: 319-653-5080 Fax: 319-653-5806

Toll Free: 1-800-775-7448

e-mail: salesbfinc@iowatelecom.net www.bazookafarmstar.com

Main Products/Services: Bazooka Farmstar manufactures manure injection equipment, hose reels, power units and accessories needed to apply from 2,500 to 25,000 gallons per acre. Distributors of couplers, Cornell pumps, drag and feeder hose. Trained and knowledgeable dealers are located in Canada and the USA. Call or e-mail for more information.

BIO TECH NUTRIENTS

818 W Brooks Ave. North Las Vegas, NV 89030 USA Tel: 702-315-5121 Fax: 702-315-5161

e-mail: sales@biotechnutrients.com

BOERGER, LLC

740 NE Harding St., Minneapolis, MN 55413 USA Tel: 612-435-7300 Fax: 612-435-7300 Toll Free: 1-877-726-3743

e-mail: info@boerger.com www.boerger.com

BOLDT FABRICATION AND DESIGN INC.

4412 West 3rd Ave. Amarillo, TX 79106 USA Tel: 806-683-2297 Fax: 806-364-0119 www.boldt-fab.com

BROCK EQUIPMENT COMPANY

Box 100, Bailey, NC 27807 USA

Tel: 252-235-4111 Fax: 252-235-4112

Toll Free: 1-800-849-7569

e-mail: lee@brockequipment.com

www.brockequipment.com

Main Products/Services: Brock Equipment Co., representing the finest in manure handling equipment, Cadman, GEA Houle, HydroEngineering, Aerway, Nuhn, Kuhn Knight and Eco-Drum. Custom made fittings and hoses. We Fed Ex daily.

BROWN BEAR CORPORATION

PO Box 29, 2248 Ave. of Industry Corning, IA 50841 USA

Tel: 641-322-4220 Fax: 641-322-3527

e-mail: sales@brownbearcorp.com www.brownbearcorp.com

38 Main St. Courtland, ON NOJ 1E0

Tel: 519-688-2222 Fax: 519-688-2100 Toll Free: 1-866-4CADMAN www.cadmanpower.com

PO Box 2000, Milford, IN 46542-2000 USA

Tel: 574-658-4101 Fax: 574-658-3220

e-mail: egg@choretime.com www.choretimeegg.com

Main Products/Services: Chore-Time Egg Production Systems, a division of CTB, Inc., designs, manufactures and sells egg production systems including an innovative manure dryer which creates marketable manure in a matter of days.

CLAAS OF AMERICA INC.

8401 S. 132nd St., Omaha, NE 68145-0031 USA

Tel: 402-861-1000 Fax: 402-861-1003 www.claasofamerica.com

16261 SE 130th Ave.

Clackamas, OR 97015-8948 USA

Tel: 503-653-0330 Fax: 503-653-0338

e-mail: bjansen@cornellpump.com www.cornellpump.com

Main Products/Services: Cornell Pump Company now offers over 60 models of wastehandling pumps with unique and innovative design features for low head transfer to high pressure application in the field.

COUNTRY MANUFACTURING, INC.

PO Box 104

Fredricktown, OH 43019 USA

Tel: 740-694-9926 Fax: 740-694-5088

e-mail: info@countrymanufacturing.com

DAIRYMASTER USA INC.

2120 Tuley Rd.

Indian Springs, OH 45015-1333 USA

Tel: 513-942-0868 Fax: 513-942-2934

Toll Free:1-877-340-MILK

e-mail: usa@dairymaster.com www.dairymaster.com

DARITECH, INC.

8540 Benson Rd.

Lynden, WA 98264 USA

Tel: 360-354-6900 Fax: 360-354-7522

Toll Free: 1-800-701-3632

e-mail: advertising@daritech.com www.daritech.com

DEGELMAN INDUSTRIES

272 Industrial Dr.

Regina, SK S4P 3B1

Tel: 306-543-4447 Fax: 306-545-6221

Toll Free: 1-800-667-3545

e-mail: sales@degelman.com www.degelman.com

DFK EQUIPMENT SALES, INC.

PO Box 938, 475 James St S. St. Marys, ON N4X 1B6

Toll Free: 1-800-881-3794

Fax: 800-752-0934

e-mail: sales@dfkequipment.com www.dfkequipment.com

DM MACHINERY INC.

1875 St - Edouard Rd.

Saint - Simon, QC J0H 1Y0

Tel: 450-798-2922 Fax: 450-798-2914

Toll Free: 1-888-798-2922

e-mail: info@dmmachinery.ca www.dmmachinery.com

DODA U.S.A. INC.

255 16th St. S., P.O. Box 316 St. James, MN 56081 USA

Tel: 507-375-5577 Fax: 507-375-5578

e-mail: dodausa@embarqmail.com www.DODA.com

DRAEGER

101 Technology Dr., Pittsburgh, PA 15275 USA

Tel: 412-788-5671 Fax: 412-787-2207

Toll Free: 1-800-615-5503

e-mail: prodinfo@draeger.com website: www.draeger.com

DSM NUTRITIONAL PRODUCTS

45 Waterview Blvd.

Parsippany, NJ 07054-1298 USA

Tel: 973-257-8396 Fax: 973-257-8653

e-mail: robert.stock@dsm.com www.unlimitednutrition.na.dsm.com

ENVIRONETICS INC.

1201 Commerce St. Lockport, IL 60441 USA

Tel: 815-838-8331 Fax: 815-838-8336

e-mail: info@environeticsinc.com www.environetics.com

EVEREST FINANCIAL NETWORK LLC

5668 Red Fern Court, Suite 300 Littleton, CO 80125 USA

Tel: 303-948-9999 Fax: 303-948-2242

e-mail: leeburnett@e-f-n.com www.e-f-n.com

EXPERT COMPANY

PO Box 6

Clintonville, WI 54929 USA

Tel: 605-337-3737 Fax: 605-337-3400

e-mail: sarc@midstatesd.net www.expertcompany.us

F & M TRAILERS INC.

10321 N. Troyer Rd. Box 243 Laketon, IN 46943 USA

Tel: 260-982-4384

Toll Free: 1-888-982-4384

FARM CREDIT CANADA

100 - 120 Research Lane

Guelph, ON N1G 0B5

Tel: 519-826-2007 Fax: 519-826-2066

e-mail: richard.gruener@fcc-fac.ca www.fcc-fac.ca

FAROEX LTD.

Box 1950

Gimli, MB R0C 1B0 Tel: 204-642-6400 Fax: 204-642-6420

FEW SEPARATOR GmbH

Runtestrasse 42

D-59457 Werl, Germany

Tel: +49 2922 87022-0 or 604-932-7931

Fax: +49 2922 87022-20

e-mail: m.stewart@few-separator.com or info@ few-separator.com www.few-separator.com

FIRESTONE SPECIALTY PRODUCTS

250 W. 96th St. Indianapolis, IN 46260 USA

Tel: 317-575-7000 Fax: 317-575-7002

Toll Free: 1-800-428-4442

e-mail: info@firestonesp.com www.firestonesp.com

FIRST AMERICAN SCIENTIFIC CORP.

201 - 30758 South Fraser Way Abbotsford, BC V2T 6L4

Tel: 604-850-8959 Fax: 604-850-8904

e-mail: help@fasc.net www.fasc.net

FIRST AMERICAN SCIENTIFIC CORP.

PO Box 10004, Portland, OR 97296 USA

Toll Free: 1-877-644-6699

Fax: 503-644-9820

e-mail: info@pacwestglobal.net www.pacwestglobal.net

FISHER PUMPS

2024 E. 8th St., Greeley, CO 80631 USA

Tel: 970-353-6962 Fax: 970-353-0839 www.fisherpumps.com

GEA HOULE INC.

4591 Boul. St-Joseph Drummondville, QC J2A 0C6

Tel: 819-477-7444 Fax: 819-477-5565 www.gea-farmtechnologies.com

GHD, INC.

PO Box 69, Chilton, WI 53014 USA

Tel: 920-849-9797 Fax: 920-849-9160

e-mail: corporate@ghdinc.net www.ghdinc.net

GLOBAL REPAIR

33 Bellefair Ave., Toronto, ON M4L 3T7 Tel: 416-686-3690 Fax: 416-686-1744

Toll Free: 1-866-271-0719

e-mail: sales@globalrepair.ca www.globalrepair.ca

GORMAN-RUPP PUMPS

600 S. Airport Rd., Mansfield, OH 44903 USA

Tel: 419-755-1011 Fax: 419-755-1251

e-mail: grsales@gormanrupp.com

www.GRpumps.com

Main Products/Services: Gorman-Rupp manufactures high performance, high quality pumps and pumping systems for lasting service in the construction, municipal, water, wastewater, sewage, industrial, petroleum, fire, agricultural and OEM markets.

HANSEN MANUFACTURING

Box 393, Agassiz, BC VOM 1A0 Tel: 604-316-3664 Fax: 604-858-9128

390 Portage Blvd. Kent, OH 44240 USA Tel: 330-678-9353 Fax: 330-677-8282

e-mail: sales@hapco.com www.hapcoinc.com

Main Products/Services: Authorized BAK & Demtech Heat Welding tool dealer, equipment is designed for welding GEO Liner materials for pits and ponds, Authorized Honda Power Equipment Dealer, Pumps, Generators and Replacement Engines.

HARCO AG EQUIPMENT

5808 Hwy. 9, RR 4 Harriston, ON N0G 1Z0

Tel: 519-338-2923 Fax: 519-338-2756

e-mail: harquip@wightman.ca

HCC, INC.

1501 First Ave. Mendota, IL 61342-0952 USA Tel: 815-539-9371 Fax: 815-539-3135 e-mail: info@hccincorporated.com www.hccincorporated.com

HCL MACHINE WORKS

15142 Merrill Ave. Dos Palos, CA 93620 USA Tel: 209-392-6103 Fax: 209-392-3000 e-mail: casey@unwiredbb.com www.hclmachineworks.com

HELLMANN NORTH AMERICA

11 - 1311 Springbank Ave. London, ON N6K 1Z9 Tel: 519-453-3913 Fax: 519-453-3996 e-mail: hellmannpoultry@bellnet.ca www.hellmannpoultry.com

equipment is reconditioned. Check our website for details.

HUSKY FARM EQUIPMENT LTD.

7440 Wellington Rd. 17, Alma, ON N0B 1A0

Tel: 519-846-5329 Fax: 519-846-9378

Toll Free: 1-800-349-1122

e-mail: walter@huskyfarm.ca www.huskyfarm.ca

Husky has been manufacturing a full line of Liquid Manure Equipment for 50 years. 42 sizes of pumps up to 12” discharge, 12,000 GPM. 52 sizes of spreaders to 740 Gallon. Injectors, Dragline Equipment, and barn Cleaner Replacement Chain.

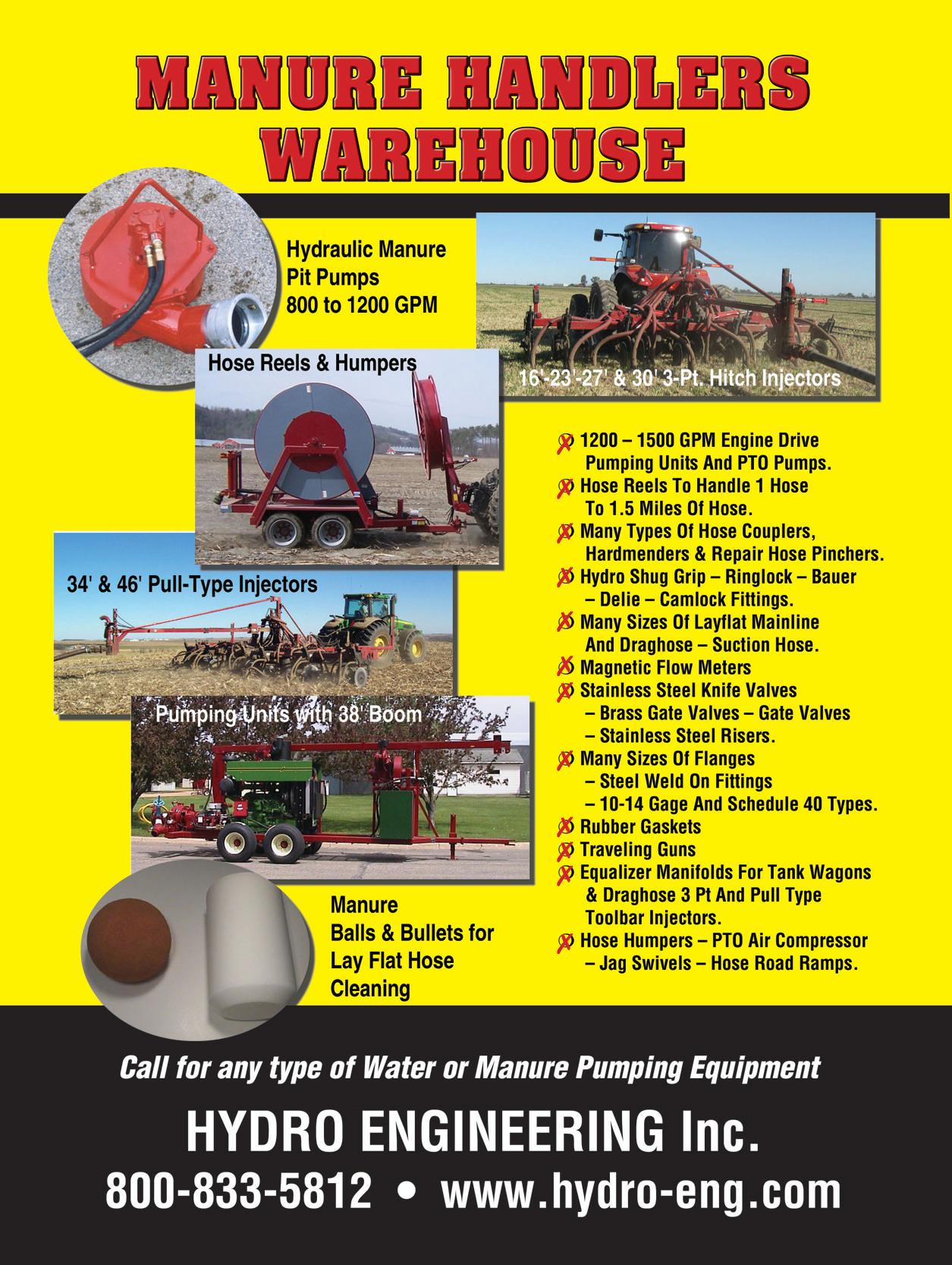

HYDRO ENGINEERING INC.

PO Box 300

Norwood, Young America, MN 55368 USA Tel: 952-467-3100 Fax: 952-467-4000

Toll Free: 1-800-833-5812

e-mail: sales@hydro-eng.com www.hydro-eng.com

Main Products/Services: Manufacturer of the Most advanced Draghose Manure Injection and Pumping Equipment with pumping units 1200 GPM to 1500 GPM. Hose reels handling 1 to 1.5 miles of hose. Injectors 16’ to 46’ Pull Type.

IMPERIAL INDUSTRIES INC.

PO Box 1685, Wausau, WI 54402 USA

Tel: 715-359-0200 Fax: 715-355-5349

Toll Free: 1-800-558-2945

e-mail: toma@imperialind.com www.imperialind.com

INDUSTRIAL & ENVIRONMENTAL CONCEPTS, INC.

6009 Chapel Dr., Minneapolis, MN 55439 USA

Tel: 952-829-0731 Fax: 952-829-9770

Toll Free: 1-888-829-0731

HODEL, JIM INC.

2278 CR 1350 N., Roanoke, IL 61561 USA

Tel: 309-923-7106 Fax: 309-923-7655

Toll Free: 1-800-562-8565 www.jimhodelinc.com

Main Products/Services: In business for over 50 years, we have the equipment and expertise to help you manage your nutrients. Used

e-mail: mmorgan@ieccovers.com www.ieccovers.com

Main Products/Services: Industrial & Environmental Concepts, (IEC) is widely recognized as the leader in the design, manufacturing and installation of both industrial /agricultural cover and liner systems for ponds, tanks and lagoons.

INNOVATIVE PROBIOTICS

4151 N. Mulberry Dr., #275

Kansas City, MO 64116 USA

Tel: 816-231-5580

Toll Free: 1-800-950-1953

e-mail: gholt@occutec.com www.innovativeprobiotics.com

Main Products/Services: We offer products and service solutions for odor and/or nutrient management in agricultural, industrial and livestock operations. Our offerings reduce the costs and eliminate headaches associated with wastewater and large-scale composting operations.

J & D MANUFACTURING

6200 Highway 12

Eau Claire, WI 54701 USA

Tel: 715-834-1439 Fax: 715-834-3812

Toll Free: 1-800-998-2398

e-mail: jdmfg@jdmfg.com www.jdmfg.com

JAMESWAY FARM EQUIPMENT

12 Route 249

St-Francois-Xavier-de-Brompton, QC J0B 2V0

Tel: 819-845-7824 Fax: 819-845-5758 www.jameswayfarmeq.com

JBS LTD. (J. Bond & Sons Ltd.)

7116 Beatty Dr., Unit D Mission, BC V2V 6B4

Tel: 604-826-5391 Fax: 604-826-5392

e-mail: sales@jbscanada.ca www.jbscanada.ca

KELLN CONSULTING LTD.

PO Box 94

Lumsden, SK S0G 3C0

Tel: 306-731-2224 Fax: 306-731-2774

Toll Free: 1-888-731-8882

KETCHUM MANUFACTURING INC.

1245 California Ave.

Brockville, ON K6V 7N5

Tel: 613-342-8455 Fax: 613-342-7550

e-mail: ketchum@sympatico.ca

KIFCO IRRIGATION

700 S. Schrader Ave.

Havana, IL 62644 USA

Tel: 309-543-4425 Fax: 309-543-4945

Toll Free: 1-800-452-7017

e-mail: sales@kifco.com www.kifco.com

KOOLMEES MARINE INDUSTRIAL SALES, SERVICE

Middletown Line 712651

Otterville, ON N0J 1R0

Tel: 519-879-6878 Fax: 519-879-6319

KYTE CENTRIFUGE SALES & CONSULTING

100 Cypress Dr.

North Augusta, SC 29841 USA

Tel: 803-279-4888 Fax: 803-279-4411

e-mail: kyte.ken@juno.com www.kcentrifuge.com

LAKEPOINTE ENVIRONMENTAL GROUP INC.

5001 SW Orchid Bay Dr. Palm City, FL 34990 USA

Tel: 772-287-7698

Toll Free: 1-866 4 BYOGON (429-6466) www.lakepointegroup.com

LAYFIELD GEOSYNTHETICS & INDUSTRIAL FABRICS LTD.

11603 - 180th St. Edmonton, AB T5S 2H6

Tel: 780-453-6731 Fax: 780-455-5218

Toll Free: 1-800-840-2884

e-mail: amills@layfieldgroup.com

LEON’S MFG. COMPANY INC.

PO Box 5002

Yorkton, SK S3N 3Z4

Tel: 306-786-2600 Fax: 306-782-1884

Toll Free: 1-800-667-1581

e-mail: mkt@leonsmfg.com www.leonsmfg.com

LITCHFIELD ANALYTICAL SERVICES

535 Marshall Street, P.O. Box 457 Litchfield, MI 49252 USA

Tel: 517-542-2915 Fax: 517-542-2014

e-mail: litchlab@gcnet.net www.litchlab.com

LOBEPRO ROTARY PUMPS

2610 Sidney Lanier Dr. Brunswick, GA 31525 USA

Tel: 912-466-0304 Fax: 912-466-0086

Toll Free: 1-888-997-PUMP www.lobepro.com

LOEWEN WELDING LTD.

33655 Harris Rd., PO Box 66 Matsqui, BC V4X 3R2

Tel: 604-826-7844 Fax: 604-826-6051

LSC PRE-CAST SYSTEMS (Canada) Ltd.

5949 Chadsey Rd. Chilliwack, BC V2R 4P2

Toll Free: 1-888-796-2323

Fax: 604-823-4249

e-mail: lsc@lscprecast.com www.lscprecast.com

MANURE EXPO

c/o Ted Bay, Grant Co. UW Extension, 916 E. Elm St. Lancaster, WI 53813 USA

Tel: 608-723-2125 www.manureexpo.com

MANURE MANAGER MAGAZINE

PO Box 530, 105 Donly Dr. S. Simcoe, ON N3Y 4N5

Tel: 519-429-5188 Fax: 888-404-1129

Toll Free: 1-888-599-2228 ext. 242

e-mail: skauk@annexweb.com

www.manuremanager.com

Main Products/Services: Publication exclusively for the Manure Handling Industry across North America. Our editorial content focuses on leading edge equipment, technology and people in the industry.

MANURE SYSTEMS INC.

3046 McMillan Rd. Abbotsford, BC V2S 6A8 Tel: 604-226-6075

e-mail: info@manuresystemsinc.com www.manuresystemsinc.com

McLANAHAN CORPORATION

200 Wall St. Hollidaysburg, PA 16648 USA

Tel: 814-695-9807 Fax: 814-695-6684

e-mail: hderensis@mclanahan.com www.mclanahan.com

METAL PLESSIS

1683 Sucreries Blvd. Plessville, QC G6L 1W4 Tel: 819-362-2221 Fax: 819-362-6974

MEYER MANUFACTURING CORP.

574 W. Center Ave. Dorchester, WI 54425 USA Tel: 715-654-5132 Fax: 715-654-5513

Toll Free: 1-800-325-9103

e-mail: sales@meyermfg.com www.meyermfg.com

MICHELIN NORTH AMERICA

Box 19001 Greenville, SC 29602 USA Tel: 864-458-5963 Fax: 864-458-4150

Toll Free: 1-888-552-1213 michael.burroughes@michelin.com www.michelinag.com

MIDWEST BIO-SYSTEMS

28933 - 35E St.

Tampico, IL 61283 USA

Tel: 815-438-7200 Fax: 815-438-7028

Toll Free: 1-800-689-0714

e-mail: mbs@midwestbiosystems.com www.midwestbiosystems.com

MIDWEST LABORATORIES, INC.

13611 B St.

Omaha, NE 68144 USA

Tel: 402-334-7770 Fax: 402-334-9121

e-mail: rferris@midwestlabs.com www.midwestlabs.com

MORBARK INC.

8507 S. Winn Rd.

Winn, MI 48896 USA

Tel: 989-866-2381 Fax: 989-866-2280

e-mail: dan.brandon@morbark.com

NEBRASKA HARVESTORE SYSTEMS

3201 S. 13th St.

Norfolk, NE 68701 USA

Tel: 402-371-0144 Fax: 402-371-6031

Toll Free: 1-800-777-0501

e-mail: sales@nebraskaharvestore.com www.nebraskaharvestore.com

NEW LEADER

1330 76th Ave. SW

Cedar Rapids, IA 52404 USA

Tel: 319-363-8281 Fax: 319-286-3850

e-mail: information@highwayequipment.com www.highwayequipment.com

NORTHEAST AGRI SYSTEMS INC.

Flyway Business Park Lititz, PA 17543-9293 USA

Tel: 717 569-2702 Fax: 717-569-9748

Toll Free: 1-800 673-2580

NTH USA

5 Berger Ave., Barron, WI 54812 USA

Tel: 715-537-9207 Fax: 715-537-3861

Toll Free: 1-800-236-1570

e-mail: nth@chibardun.net www.nthusa.com

NUHN INDUSTIRES LTD.

PO Box 160, Sebringville, ON N0K 1X0

Tel: 519-393-6284 Fax: 519-393-5104

e-mail: nuhnind@nuhn.ca www.nuhn.ca

OCTAFORM SYSTEMS INC.

520 - 885 Dunsmuir St. Vancouver, BC V6C 1N5

Tel: 604-408-0558 Fax: 604-408-0595

Toll Free: 1-888 -786-6282

OHIO DEPARTMENT OF AGRICULTURE

8995 East Main St.

Reynoldsburg, OH 43068 USA

Tel: 614-387-0469

PACIFIC DAIRY CENTRE LTD.

34282 Manufacturers Way

Abbotsford, BC V2S 7M1

Tel: 604-852-9020 Fax: 604-852-5091

PARMA COMPANY

101 Main Str., PO Box 190

Parma, ID 83660 USA

Tel: 208-722-5116 Fax: 208-722-6012

e-mail: parmacom@parmacompany.com www.parmacompany.com

PATZ CORPORATION

PO Box 7, Pound, WI 54161-0007 USA

Tel: 920-897-2251 Fax: 920-897-2142

e-mail: info@patzcorp.com

www.patzcorp.com

Main Products/Services: Designer, Manufacturer and Worldwide Marketer of Material Handling Equipment for the Agricultural, Industrial and Commercial Markets.

PENNER FARM SERVICES

Box 90

Blumenort, MB R0A 0C0

Tel: 204-326-3781 Fax: 204-326-1411

Toll Free: 1-800-461-9333

www.pennerfarmservice.com

PHASON ELECTRONIC CONTROL SYSTEMS

2 Terracon Place

Winnipeg, MB R2J 4G7

Tel: 204-233-1400 Fax: 204-233-3252

e-mail: sales@phason.ca www.phason.ca

PREMIER POWER

1126 Water St., P.O. Box 406

Alden, AL 50006 USA

Tel: 515-859-3204 Fax: 515-859-3312

PRO-ACT BIOTECH

PO Box 345, Warren, RI 02885 USA

Toll Free: 1-800-772-3775

Fax: 401-633-6270

e-mail: ChristaG@proactbiotech.com www.ProActBiotech.com

PROFESSIONAL NUTRIENT APPLICATORS ASSOCIATION OF WISCONSIN (PNAAW)

c/o Kris Robaidek, N3077 Cty Rd. F Pulaski, WI 54162 USA

Tel: 715-758-8505 www.wimanuremgt.org

PUCK CUSTOM ENTERPRISES, INC.

1130 - 100th St., Manning, IA 51455 USA

Tel: 712-653-3045 Fax: 712-653-3099

e-mail: info@puckenterprises.com www.puckenterprises.com

RAVEN INDUSTRIES, INC.

205 E 6th St., Sioux Falls, SD 57104 USA

Tel: 605-336-2750 Fax: 605-331-0426

e-mail: raveninfo@ravenind.com www.ravenind.com

RCM DIGESTERS INC.

PO Box 4716, Berkeley, CA 94704 USA Tel: 510-834-4568 Fax: 510-834-4529

e-mail: contact@rcmdigesters.com

REDHAND LTD.

PO Box 179, Souris, MB R0K 2C0 Tel: 204-483-0008 OR 204-724-0287 OR 204-534-7382

e-mail: sbkt@mts.net

REINKE MANUFACTURING COMPANY, INC.

5325 Reinke Rd., Deshler, NE 68340 USA Tel: 402-365-7251 Fax: 402-365-4370

Toll Free: 1-866-365-7381

e-mail: timgoldhammer@reinke.com www.reinke.com

ROTO-MIX LLC

2205 E. Wyatt Earp Blvd. Dodge City, KS 67801 USA Tel: 620-225-1142 Fax: 620-225-6370

e-mail: gsmith@rotomix.com www.rotomix.com

SALFORD FARM MACHINERY

364018 McBeth Rd., Salford, ON N0J 1W0 Tel: 519-485-1293 519-532-0037 Fax: 519-485-1311

e-mail: phil@salfordmachine.com

SAN JOAQUIN VALLEY DAIRY EQUIPMENT, INC.

830 Commercial Ave., Tulare, CA 93274 USA Tel: 559-688-2888 Fax: 559-688-5977

SENNINGER IRRIGATION

16220 East Hwy. 50, Clermont, FL 34711 USA

Tel: 407-877-5655 Fax: 407-905-8249

e-mail: info@senninger.com www.senninger.com

SERVI TECH LABORATORY

1602 Park West Dr. Hastings, NE 68901-0169 USA

Tel: 402-463-3522 Fax: 402-463-8132

e-mail: hansb@servitechlabs.com www.servitechlabs.com

SHAC ENVIRONMENTAL PRODUCTS

35, 2269 - 2 Ave., Medicine Hat, AB T1B 0K3

Tel: 403-528-4446 Fax: 403-529-9334

Toll Free: 1-888-533-4446

e-mail: office@shac.ca www.shac.ca

SILO J-M LAMBERT INC.

4250 Vachon, Drummondville, QC J2B 6V4

Tel: 819-474-6989 Fax: 819-474-8620

e-mail: info@silojmlambert.com www.silojmlambert.com

SIONIX CORPORATION

2801 Ocean Park Blvd., Suite 339 Santa Monica, CA 90405 USA

Tel: 847-235-4566 www.sionix.com

SIOUX AUTOMATION CENTER INC.

877 1st Ave. NW, Sioux Center, IA 51250 USA

Tel: 712-722-1488 Fax: 712-722-1487

Toll Free: 1-866-722-1488 www.siouxautomation.com

SPARTAN CHEMICAL COMPANY, INC.

1110 Spartan Dr., Maumee, OH 43537-0110 USA

Tel: 419-531-5551 Fax: 419-536-8423

Toll Free: 1-800-537-8990

e-mail: customerservice@spartanchemical.com

SPRUCEDALE AGROMART LTD.

Box 68, Hanover, ON N4N 3C3

Tel: 519-364-4070 Fax: 519-364-7716

e-mail: hanover@sprucedale.com www.sprucedale.com

SRS CRISAFULLI INC.

1610 Crisafulli Dr., Glendive, MT 59330-1051 USA

Tel: 406-365-3393 Fax: 406-365-8088

Toll Free: 1-800-442-7867

e-mail: srsc@crisafulli.com www.crisafullipumps.com

Main Products/Services: SRS Crisafulli manufactures dredges and pumps for handling sludges, residuals, biosolids, slurries, sediment, fly ash, slimes, tailings, irrigation, stormwater runoff, tailwater reuse and flood control.

TIRY ENGINEERING

PO Box 44, Chippewa Falls, WI 54729 USA

Tel: 715-723-6777 Fax: 715-723-6842

Toll Free: 1-866-944-6777

e-mail: contact@tiryengineering.com www.TiryEngineering.com

TURN AND SCREEN.COM INC.

1818 Martin Luther King Jr. Blvd., Ste. 330 Chapel Hill, NC 27514 USA

Tel: 919-240-5077 Fax: 919-967-2252 www.turnandscreen.com

U.S. POULTRY & EGG ASSOCIATION

1530 Cooledge Rd., Tucker GA 30084-7303 USA

Tel: 770-493-9401 Fax: 770-493-9257

e-mail: tscott@poultryegg.org

UNIVERSITY OF WISCONSIN

2611 East 29th St., Marshfield, WI 54449 USA

Tel: 715-387-2523 Fax: 715-387-1723

UNIVERSITY OF WISCONSIN CUSTOM MANURE TEAM

c/o Kevin Erb, UW-Extension, 1150 S. Bellevue St. Green Bay, WI 54302 USA

Tel: 920-301-4652 Fax: 920-391-4617

e-mail: kevin.erb@uwex.edu

UNVERFERTH MFG. CO., INC.

PO Box 357, Kalida, OH 45853 USA

Tel: 419-532-3121 Fax: 419-532-2468

Toll Free: 1-800-322-6301

e-mail: info@unverferth.com www.unverferth.com

VANDEN BUSSCHE IRRIGATION

2515 Pinegrove Rd., Delhi, ON N4B 2X1

Tel: 519-582-2380 Fax: 519-582-1514

Toll Free: 1-800-387-7246

e-mail: info@vandenbussche.com www.vandenbussche.com

VAUGHAN COMPANY INC.

364 Monte-Elma Rd., Montesano, WA 98563 USA

Tel: 360-249-4042 Fax: 360-249-6155

Toll Free: 1-888-249-CHOP (2467) USA only e-mail: info@chopperpumps.com www.chopperpumps.com

VENTRAC BY VENTURE PRODUCTS INC.

328 East Water St., PO Box 148 Orrville, OH 44667 USA

Tel: 330-683-0075 Fax: 330-683-0000

Toll Free: 1-866-836-8722

e-mail: info@ventrac.com www.ventrac.com

VINCENT CORPORATION

2810 East 5th Ave., Tampa, FL 33605 USA

Tel: 813-248-2650 Fax: 813-247-7557 www.vincentcorp.com

WABASH INDUSTRIAL SERVICES

675 East 250 South, Wabash, IN 46992 USA

Tel: 260-563-5767 Fax: 260-563-5762

e-mail: wabashindustrial@yahoo.com

WALCO INTERNATIONAL

7 Village Cr, Ste. 200 Westlake, TX 76262 USA

Tel: 817-859-3000

Toll Free: 1-877-289-9252 www.walcointl.com

WALLENSTEIN VACUUM PUMPS

20 Martin Lane, Elimira, ON N3B 2A1

Tel: 519-669-1541 Fax: 519-996-8331

Toll Free: 1-800-801-6663

e-mail: info@elmiramachine.com www.wallypumps.com

WARNER PLASTICS AND LINERS, INC.

7370 NW 6th Dr. Ankeny, IA 50023 USA

Tel: 515-289-2404 Fax: 515-289-1632

Toll Free: 1-88-945-9701

e-mail: luke@warnerplastics.com www.warnerplastics.com

WATER AGRICULTURAL LAB

2101 Calhoun Rd., Hwy. 81 Owensboro, KY 42301USA

Tel: 270-685-4039 Fax: 270-685-3989 www.watersag.com

WELLMAN SERVICE, LLC

7347 Boyd Rd., Pavilion, NY 14525 USA

Tel: 585-584-8502 Fax: 585-584-8503

WEST POINT DESIGN INC. / SPREAD ALL P.O. Box 255, West Point NE 68788 USA Tel: 402-372-2408 Fax: 402-372-2440

WESTERN UNITED RESOURCE DEVELOPMENT, INC.

1315 K St., Modesto, CA 95354 USA

Tel: 209-527-6453 Fax: 209-527-0630

WHEAT-BELT INDUSTRIES

262055 Range Rd. 10, Balzac, AB T0M 0E0 Tel: 403-291-1489 Fax: 403-291-1490

Toll Free: 1-800-644-6050 www.wheat-belt.com

WHEATLAND COUNTY

Hwy. 1, RR 1, Strathmore, AB T1P 1J6 Tel: 403 934-3321 Fax: 403-934-4889

YETTER MANUFACTURING CO.

Box 358, Colchester, IL 62326 USA Tel: 309-776-4111 Fax: 309-776-3222

Toll Free: 1-800-447-5777

YUNKER PLASTICS, INC.

251 O'Connor Dr., Elkhorn, WI 53121 USA

Tel: 262-743-1234 Fax: 262-743-1233

Toll Free: 1-800-236-3328

e-mail: mark@yunkerplastics.com www.yunkerplastics.com

AGITATION EQUIPMENT

ADVANCED AGRI-DIRECT

AGPRO®

BALLAGH LIQUID TECHNOLOGIES

BAMBAUER EQUIPMENT

BAUER NORTH AMERICA/FAN SEPARATOR

BAZOOKA FARMSTAR

BROCK EQUIPMENT

CADMAN POWER EQUIPMENT

DARITECH

DM MACHINERY

DODA U.S.A.

EXPERT COMPANY

FIRST AMERICAN SCIENTIFIC

GEA HOULE

HODEL, JIM INC.

HUSKY FARM EQUIPMENT

KELLN CONSULTING

KIFCO IRRIGATION

LOEWEN WELDING