2010 BUYERS GUIDE Manure Manager

4TH ANNUAL GROWING THE MARGINS CONFERENCE AND EXHIBITION

3292 Victoria St., Oakville, ON L6L 5R3

Tel: 1-905-465-3147

e-mail: john.mcmullen@teksavvy.com

John McMullen

ACCENT MANUFACTURING INC.

602-30731 Simpson Road, Abbotsford, BC V2T 6Y7

Tel: 604-850-7799 Fax: 604-850-7909

Toll Free: 1-877-855-4890

e-mail: info@accentmanufacturing.com website: www.accentmanufacturing.com

Darryl Loewen

ACM - TEXAS, LLC

PO Box 270941, Fort Collins, CO 80527

Tel: 970-203-0005 Fax: 970-203-1090

website: www.neutracite.com

Bob McCreeless

ADVANCED AERATION, INC.

102 Midway Industrial Park, Angleton, TX 77515

Tel: 281-595-3456 Fax: 281-595-3458

e-mail: thickey@advancedaeration.com

Thomas Hickey

ADVANCED AGRI-DIRECT IN.

Box 298, Thorsby, AB T0C 2P0

Tel: 780-789-3100 Fax: 780-789-2447

Sean Heldt

AEROMIX

7135 Madison Ave West, Minneapolis, MN 55427

Tel: 763-746-8400 Fax: 763-746-8408

Toll Free: 1-800-879-3677

e-mail: aeromix@aeromix.com website: www.aeromix.com

AERWAY/SAF-HOLLAND

Box 339, Norwich, ON NOJ 1P0

Tel: 519-863-3414 Fax: 519-863-2398

Toll Free: 1-800-457-8310

e-mail: aerway@aerway.com website: www.aerway.com

Matt Mayer

AGCO

435 Lester Point, Waconia, MN 55387

Tel: 1-612-804-3230 Fax:1-952-442-8669

e-mail: arnie.sinclair@agcocorp.com www.agchem.com

Arnie Sinclair

AGPRO®, INC.

859 Airport Rd., Paris, TX 75462

Tel: 903-785-5531 Fax: 903-784-7895

Toll Free: 1-800-527-1030

e-mail: info@agprousa.com website: www.agprousa.com

Lynne Bertelson

AGPROFESSIONALS, LLC

4350 State Highway 66, Longmont, CO 80504

Tel: 970-535-9318 Fax: 970-535-9854

e-mail: tharen@agpros.com website: www.agpros.com

Thomas Haren

AGRI DAIRY MART

2926 Parsons Road, Edmonton, AB T6N 1A4

Tel: 780-462-5082 Fax: 780-461-0654

Frank Vanden Brink

AGRI DRAIN CORPORATION

1462 340th St., Adair, IA 50002

Tel: 641-742-5211 Fax: 641-742-5222

Toll Free: 1-800-232-4742

e-mail: info@agridrain.com website: www.agridrain.com

Stacy Richter

AGRI-WASTE TECHNOLOGY INC.

5400 Etta Burke Ct., Raleigh, NC 27606

Tel: 919-859-0669 Fax: 919-233-1970

e-mail: mmottern@agriwaste.com

website: www.agriwaste.com

Melissa Mottern

AGTECH PRODUCTS

W 227, N 752, Waukesha, WI 53186

Tel: 262-521-1717 Fax: 262-521-2442

Toll Free: 1-800-999-3899

e-mail: info@agtechproducts.com website: www.agtechproducts.com

Maryanne Bellot

ALBERS MANURE HANDLING SYSTEMS INC.

14470 S. Euclid Ave., Chino, CA 91710

Tel: 909-597-5537 Fax: 909-393-8784

Toll Free: 1-800-872-5441

e-mail: sales@albersdairyequipment.com website: www.albersdairyequipment.com

Teo Albers Sr.

ALLIANCE TIRE USA

4 - 2nd Ave., Ste. 106, Denville, NJ 07834

Toll Free: 1-877-978-4737

Fax: 973-664-9105

e-mail: mshah@alliancetireusa.com website: www.alliancetireusa.com

Manjri ShahEmanuele Cicero, President

ANGUS FIRE USA

141 Junny Rd., Angier, NC 27501

Tel: 919-539-6151 Fax: 800-334-3156 website: www.angusfire.com

ARMORED TEXTILES, INC.

9 Vose Farm Road, Peterborough, NH 03458

Tel: 603-924-2122 Fax: 603-924-2322

e-mail: mdonovan@armtexinc.com

Mark Donovan

ASSINIBOINE COMMUNITY COLLEGE

1430 Victoria Ave. East, Brandon, MB R7A 7E4

Tel: 204-573-3593 Fax: 204-725-8740

Toll Free: 1-800-862-6307

e-mail: nowosad@assiniboine.net

Trent Nowosad

ATD WASTE SYSTEMS INC.

3095 West 24th Ave. Vancouver, BC V6L 1R7

Tel: 604 736-4474 Fax: 604-736-4493

e-mail: 1cleanfarm@hogmanure.com

website: www.hogmanure.com

ADT Waste Systems Inc.

BALLAGH LIQUID TECHNOLOGIES INC.

121 North St. West, Wingham, ON NOG 2W0 Tel: 519-357-4600 Fax: 519-357-4630

Toll Free: 1-877-312-4600

e-mail: info@bliquidtech.ca website: www.bliquidtech.com

Byron Ballagh

BALZER, INC.

Co. Rd. 27E, Mountain Lake, MN 56159

Toll Free: 1-800-795-8551

Fax: 507-427-2364

e-mail: balzer@iowatelecom.net website: www.balzerinc.com

Jason Liechty

BAMBAUER EQUIPMENT LLC.

19151 Kettlersville Rd., New Knoxville, OH 45871 Tel: 1-419-753-2275 Fax: 419-753-3116

e-mail: bambauerequipment@nktelco.net

Doug Bambauer

BAUER NORTH AMERICA/FAN SEPARATOR

107 Eastwood Road, Michigan City, IN 46360

Tel: 1-800-922-8375

e-mail: rhultgren@bauer-at.com website: www.bauer-at.com OR www.fan-separator.de

Rob Hultgren

BAZOOKA FARMSTAR INC.

PO Box 869, Washington, IA 52353

Tel: 319-653-5080 Fax: 319-653-5806

Toll Free: 1-800-775-7448

e-mail: salesbfinc@iowatelecom.net

Steve Pittman

Bazooka Farmstar manufactures manure injection equipment, hose reels, power units and accessories needed to apply from 2500 to 30000 gallons per acre. Trained and knowledgeable dealers are located in Canada and the USA. Call or e-mail for more information.

BAZOOKA FARMSTAR, INC.

800 E. 7th Street PO Box 869, Washington, IA 52353

Tel: 319-653-5080 Fax: 319-653-5806

Toll Free: 800-775-7448

e-mail: salesbfinc@iowatelecom.net

Steve Pittman

B IG ASS FANS

2425 Merchant St., Lexington, KY 40511

Tel: -877-244-3267 Fax: 859-233-0139 website: www.bigassfans.com

BIG TIMBER SALES

400-16th St., Corning, IA 50841

Tel: 641-322-4358 Fax: 641-322-5411

Toll Free: 1-712-621-6515

e-mail: bigtimb@frontiernet.net

Gerry Walker

BIOTHANE CORPORATION

2500 Broadway, Camden, NJ 08104

Tel: 856-541-3500 Fax: 856-541-3366

e-mail: sales@biothane.com website: www.biothane.com

Ryan Johnston

BOERGER, LLC

Minneapolis, MN 55413

Tel: 612-331-8765 Fax: 612-331-8769

Toll Free: 1-877-726-3743

e-mail: bwe@boerger-pumps.com website: www.boerger-pumps.com

Bernhard Wessendorf

BRANSON’S (TBHS)

Box 328, Strathclair, MB R0J 2C0

Tel: 204-365-2213 Fax: 204-365-2201

Ian Branson

BRAUN ELECTRIC INC.

209 North Fourth Ave., St. Nazianz, WI 54232

Tel: 920-773-2143 Fax: 920-773-2724

Toll Free: 1-800-876-2234

e-mail: rbraun@braunelectricinc.com website: www.braunelectricinc.com

Alecia Braun

BROWN BEAR CORPORATION

PO Box 29, Corning, IA 50841

Tel: 641-322-4220 Fax: 641-322-3527

e-mail: sales@brownbearcorp.com website: www.brownbearcorp.com

David Gebhardt, Phil Brown

CADMAN POWER EQUIPMENT

38 Main St., Courtland, ON NOJ 1E0

Tel: 519-688-2222 Fax: 519-688-2100

Toll Free: 1-866-4CADMAN

e-mail: tim@cadmanpower.com

website: www.cadmanpower.com

Wayne Cadman

CADY INC.

383 Illinois Highway 92, Tampico, IL 61283

Tel: 815-438-5678 Fax: 815-438-5681

Toll Free: 1-877-999-CADY

e-mail: cady@cadyinc.com website: www.cadyinc.com

Randy Cady

Cady Inc. specializes in above ground positive containment Slurrystore Systems, Nutristore Liquid Fertilizer Storage, Houle Manure Handling Equipment, Flygt Submersible Manure Pumps, along with Parkson Sand Separator Systems.

CANAMER SERVICES INC.

S. 2964 Indian Creek Rd., Fountain City, WI 54629

Tel: 608-687-9800 Fax: 608-687-9901

e-mail: bob@canamerservices.com website: www.canamerservices.com

Robert Dotterwick

CAWI CANADA LTD.

Site 12, RR 6, Box 49, Calgary, AB T2M 4L5

Tel: 403-569-9481 Fax: 403-569-8490

e-mail: cawi@telus.net

Kase van Ittersum

CH-FOUR BIOGAS INC.

1390 Prince of Wales Drive, Suite 107, Ottawa, ON K2C 3N6

Tel: 613-224-1594 Fax: 613-224-1642

www.chfour.ca

Benjamin Strehler

CLAAS OF AMERICA INC.

8401 South 132nd St., Omaha, NE 68138

Tel: 402-861-1000 Fax: 402-861-1003

e-mail: inquiry@claas.com

website: www.claasofamerica.com

TC Truesdell

CLI

1062 Singing Hills Rd., Parker, CO 80138

Toll Free: 1-800-524-8672

Fax: 303-951-1971

e-mail: rvigil@coloradolining.com website: www.coloradolining.com

John Heap

CORNELL PUMP COMPANY

16261 SE 130th Ave, Clackamas, OR 97015

Tel: 503-653-0330 Fax: 503-653-0338

e-mail: bjansen@cornellpump.com website: www.cornellpump.com

Mr. Bob Jansen, Lloyd Spanke

Cornell Pump Company now offers over 25 models of waste-handling pump models with unique and innovative design features for low head transfer to high pressure application in the field.

COUNTRY MANUFACTURING, INC.

PO Box 104, Fredricktown, OH 43019

Tel: 740-694-9926 Fax: 740-694-5088

e-mail: info@countrymanufacturing.com

Dave Goossens

D & H FIELD SERVICES, INC.

15433 Cardinal Rd., Osakis, MN 56360

Tel: 320-352-6746 Fax: 320-352-7838

e-mail: dhfieldservices@hotmail.com

Darrin Herickhoff

DARITECH, INC.

8540 Benson Road, Lynden, WA 98264

Tel: 360-354-6900 Fax: 360-354-7522

Toll Free: 1-800-701-3632

e-mail: lauren@daritech.com

Lauren Christensen

de BIE MANUFACTURING

RR #2, Tillsonburg, ON N4G 4G7

Tel: 519-842-6216 Fax: 519-688-3072

e-mail: debiemfg@execulink.com

Stephan de Bie

DFK EQUIPMENT SALES, INC.

PO Box 938, 475 James St S., St. Marys, ON N4X 1B6

Fax: 800-752-0934

Toll Free: 1-800-881-3794

e-mail: sales@dfkequipment.com website: www.dfkequipment.com

DGH ENGINEERING LTD.

12 Aviation Blvd., St. Andrews, MB R1A 3N5

Tel: 204-334-8846 Fax: 204-334-6965

Toll Free: 1-877-334-8846

e-mail: dgh@dghengineering.com website: www.dghengineering.com

Irene Kutzak

DM MACHINERY INC.

1875 St.-Edouard Rd., Saint-Simon, QC J0H 1Y0

Tel: 450-798-2922 Fax: 450-798-2914

Toll Free: 1-888-798-2922

e-mail: info@dmmachinery.ca website: www.dmmachinery.com

Marcel Depeault

DODA U.S.A. INC.

255 16th St. S., P.O. Box 316, St. James, MN 56081

Tel: 507-375-5577 Fax: 507-375-5578

e-mail: dodausa@embarqmail.com website: www.DODA.com

Rich Miller; Marissa Hazzard, Media Buyer (484) 553-3873

DON THEMM ENTERPRISES, INC.

P.O. Box 146, Almont, MI 48003-0146

Tel: 810-798-8311 Fax: 810-798-8311

Toll Free: 1-800-808-4366

e-mail: donaldthemm@gmail.com

Don Themm

DOUBLE T EQUIPMENT LTD.

# 2 East Lake Way S.E., Airdrie, AB T4A 2J3

Tel: 403-948-5618 Fax: 403-948-4780

e-mail: solutions@double-t.com

Ron Blanchette

DRAEGER SAFETY INC.

101 Technology Drive, Pittsburgh, PA 15275

Tel: 412-788-5671 Fax: 412-787-2207

Toll Free: 1-800-615-5503

e-mail: prodinfo@draeger.com website: www.draeger.com

Shelli Cosmides

DSI, INC.

250 CR 1425 E., Goodfield, IL 61742

Tel: 309-965-5110 Fax: 309-965-2532

e-mail: bill@dsiag.com website: www.dsiag.com

Bill Dietrich

DSM NUTRITIONAL PRODUCTS

45 Waterview Boulevard, Parsippany, NJ 07054-1298

Tel: 973-257-8396 Fax: 973-257-8653

e-mail: robert.stock@dsm.com website: www.unlimitednutrition.na.dsm.com

Dr. Robert Stock, Dawn Bracy

DUSKE DRYING SYSTEMS

6901 Industrial Loop, Greendale, WI 53129

Tel: 414-529-0240 Fax: 414-520-0362

e-mail: ty.hogue@duskeengineering.com website: www.duskeengineering.com

Michael Uzelac

ENCON TECHNOLOGIES INC.

12 Aviation Blvd., St. Andrews, MB R1A 3N5

Tel: 204-338-2514 Fax: 204-334-6965

Toll Free: 1-866-345-2148

e-mail: info@enconcovers.com website: www.enconcovers.com

Dennis Antony

ENVIRONETICS INC.

1201 Commerce St., Lockport, IL 60441

Tel: 815-838-8331 Fax: 815-838-8336

e-mail: info@environeticsinc.com website: www.environetics.com

Steven Winters, V.P. Operations.

ENVIRONMENTAL POWER CORP.

One Cate Street, 4th Floor, Portsmouth, NH 03801

Tel: 603-431-1780 Fax: 603-431-2650

e-mail: info@environmentalpower.com website: www.environmentalpower.com

Diane Marcinonis

EVONIK DEGUSSA CORPORATION

1701 Barrett Lakes Blvd, Suite 340, Kennesaw, GA 30144

Tel: 678-797-4311 Fax: 678-797-4313

Toll Free: 1-770-778-4524

e-mail: kerri.mcguiness@evonik.com

Kerri McGinness

FARM TEK

1440 Field of Dreams Way, Dyersville, IA 52040

Tel: 860-289-7261 Fax: 860-289-4711

Toll Free: 1-800-327-6835

e-mail: sales@farmtek.com website: www.farmtek.com

FARMER AUTOMATIC

5571 South State Road 25, Rochester, IN 46975

Tel: 574-857-3116 Fax: 574-857-2112

e-mail: dleavell@farmerautomatic.com

David Leavell

FAROEX LTD.

Box 1950, Gimli, MB R0C 1B0

Tel: 204-642-6400 Fax: 204-642-6420

Jason Comeau

FIELD SILO & EQUIPMENT

1310 Business Hwy 18 & 151 East, Mt. Horeb, WI 53572

Tel: 608-437-5561 Fax: 608-437-4868

Brian Peterson

FIRESTONE

SPECIALTY PRODUCTS

250 W. 96th St., Indianapolis, IN 46260

Tel: 317-575-7000 Fax: 317-575-7002

Toll Free: 1-800-428-4442

e-mail: info@firestonesp.com website: www.firestonesp.com

Whether you’re working on waste management or water supply initiatives, Firestone Specialty Products offer the geomembrane products and expertise to ensure the success of even the most demanding projects.

FISHER PUMPS

2024 E. 8th St., Greeley, CO 80631

Tel: 970-353-6962 Fax: 970-353-0839

e-mail: rich@fisherpumps.com website: www.fisherpumps.com

Rich Helzer

FLAME ENGINEERING INC.

Box 577, LaCrosse, KS 67548

Fax: 785-222-3619

Toll Free: 1-800-255-2469

e-mail: mel@flameengineering.com

Mel Limone

FLO TECH PUMP

D1, 3911 Brandon St. SE, Calgary, AB T2G 4A7

Tel: 403-236-2886 Fax: 403-225-8446

Toll Free: 1-866-248-2886

e-mail: rdarker@flotechpump.com website: www.flotechpump.com

Don Darker

GEA HOULE INC.

4591 Boul. St-Joseph, Drummondville, QC J2A 0C6

Tel: 819-477-7444 Fax: 819-477-5565

e-mail: jhoule@jhoule.com website: www.jhoule.com

GEHL COMPANY

143 Water St., West Bend, WI 53095

Tel: 262-334-9461 Fax: 262-334-6689

e-mail: lheidecker@gehl.com website: www.gehl.com

Lori Heidecker

GES CORP

26000 Richmond Rd., Cleveland, OH 44146

Toll Free: 1-800-234-9686

e-mail: paf1222@bellsouth.net

GHD, INC.

PO Box 69, Chilton, WI 53014

Tel: 920-849-9797 Fax: 920-849-9160

e-mail: corporate@ghdinc.net website: www.ghdinc.net

Stephen Dvorak

GLOBAL REPAIR

33 Bellefair Ave., Toronto, ON M4L 3T7

Tel: 416-686-3690 Fax: 416-686-1744

Toll Free: 1-866-271-0719

e-mail: sales@globalrepair.ca website: www.globalrepair.ca

GLOBAL RESOURCE RECOVERY ORGANIZATION

1707 21st St., Eldora, IA 50627

Tel: 641-939-7476 Fax: 641-939-7539

Toll Free: 1-800-800-1812

e-mail: usm@adiis.net website: www.grootempest.com

Loran R. Balvanz

GOLLMER & HUMMEL

Gasslesweg 34, Straubenhardt D75334

Tel: 011-49-0-7082-9434-0

Fax: 011-49-0-7082-9434-99

e-mail: info@gollmer-hummel.de

Mathias Renke

GOLLMER & HUMMEL

North American Representative: R.G. Gibson & Associates Inc., Brownsville, TX 78520

Tel: 956-546-2920 Fax: 956-546-2920

e-mail: rgibson@aghoseman.com

GORDON & ASSOCIATES INC.

6975 N., 550 West, P.O. Box 25, Bentonville, IN 47322

Toll Free: 1-800-659-7645

Fax: 765-478-9073

e-mail: pgordon@gordonaggroup.com website: www.gordangroup.com

GORMAN-RUPP COMPANY

600 S. Airport Rd., Mansfield, OH 44903

Tel: 419-755-1011 Fax: 419-755-1251

e-mail: grsales@gormanrupp.com website: www.GRpumps.com

Laurie Leedy

GSE LINING TECHNOLOGY INC.

19103 Gundle Road, Houston, TX 77073

Tel: 281-443-8564 Fax: 281-230-6739

e-mail: marketing@gseworld.com

Jackie Nguyen

GUARDIAN CHEMICAL SPECIALTIES CORP.

PO Box 1743, York, PA 17405

Tel: 717-848-2540 Fax: 717-848-2570

Toll Free: 1-800-297-8266

Bruce Ketrick

GUILD ASSOCIATES, INC.

5750 Shier-Rings Rd., Dublin, OH 43016

Tel: 908-752-6420 Fax: 908-798-1972

e-mail: info@moleculargate.com website: www.moleculargate.com

Mike Mitariten

HAPCO

390 Portage Blvd., Kent, OH 44240

Tel: 330-678-9353 Fax: 330-677-8282

e-mail: sales@hapco.com website: www.hapcoinc.com

Authorized BAK & Demtech Heat Welding tool dealer, equipment is designed for welding GEO Liner materials for pits and ponds, Authourized Honda Power Equipment Dealer, Pumps, Generators and Replacement Engines.

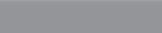

HCL MACHINE WORKS

15142 Merrill Ave., Dos Palos, CA 93620

Tel: 209-392-6103 Fax: 209-392-3000

e-mail: hcl@dospalos.org website: www.hclmachineworks.com

Casey Campbell

HELFTER FEEDS, INC.

135 N Railroad St., Osco, IL 61274-0266

Fax: 309-522-5021

Toll Free: 1-866-435-3837

e-mail: carrie@a-b-c-plus.com

HERSHEY EQUIPMENT CO., INC.

255 Plane Tree Drive, Lancaster, PA 17603

Tel: 717-393-5807 Fax: 717-291-1534

Toll Free: 1-800-432-0988

website: www.hequip.com

Wayne Hershey

HIGHWAY EQUIPMENT COMPANY

1330 76th Ave. SW, Cedar Rapids, IA 52404-7052

Tel: 319-363-8281 Fax: 319-632-3081

e-mail: info@highwayequipment.com website: www.new-leader.com

HODEL, JIM INC.

2278 CR 1350 N., Roanoke, IL 61561

Toll Free: 1-800-562-8565

Fax: 309-923-7655

website: www.jimhodelinc.com

Jim Hodel

HOLLAND EQUIPMENT LIMITED

20 Phoebe Street, Norwich, ON N0J 1P0

Tel: 519-863-3414 Fax: 519-863-2398

Toll Free: 1-800-457-8310

e-mail: matt.mayer@aerway.com website: www.aerway.com

Matt Mayer

HUSKY FARM EQUIPMENT LTD.

7440 Wellington Road 17, Alma, ON N0B 1A0

Tel: 519-846-5329 Fax: 519-846-9378

Toll Free: 1-800-349-1122

e-mail: walter@huskyfarm.ca website: www.huskyfarm.ca

Walter Grose

Husky has been manufacturing a full line of Liquid Manure Equipment for 50 years. 42 sizes of pumps up to 12” discharge, 12,000 GPM. 52 sizes of spreaders to 7400 Gallon. Injectors, Dragline Equipment, and Barn Cleaner Replacement Chain.

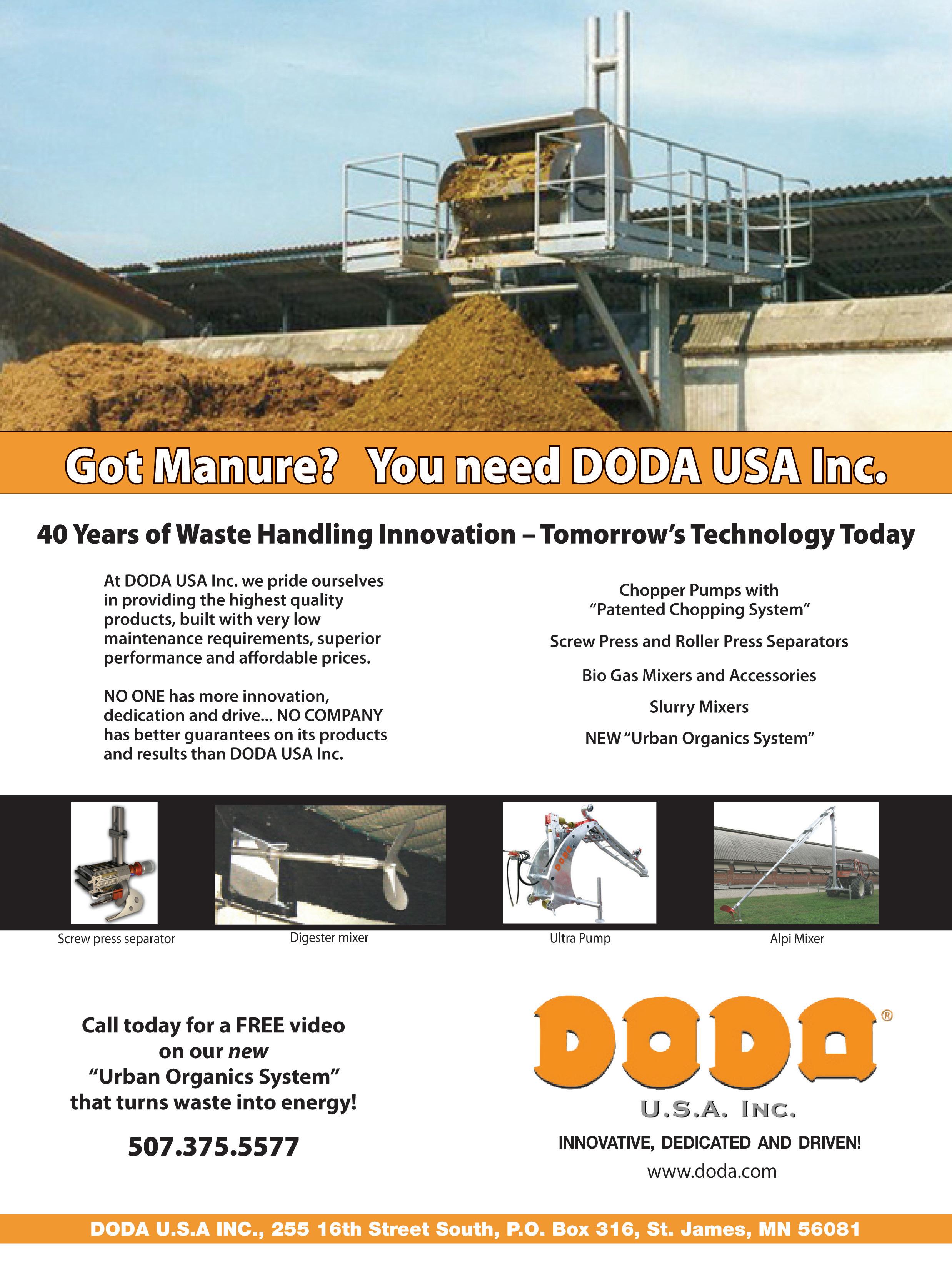

HYDRO ENGINEERING INC.

PO Box 300, Norwood, Young America, MN 55368

Tel: 952-467-3100 Fax: 952-467-4000

Toll Free: 1-800-833-5812

e-mail: sales@hydro-eng.com website: www.hydro-eng.com

Tom Huffman, John Hochstein

Manufacturer of the most advanced Draghose Manure Injection and Pumping Equipment with pumping units 1200 GPM to 1500 GPM. Hose reels handling 1 to 1.5 miles of hose. Injectors 16’ to 46’ Pull Type.

HYDROCAL INC.

22732 Granite Way, Laguna Hills, CA 92653

Tel: 949-455-0765 Fax: 949-455-0764

e-mail: info@hydrocal.com website: www.hydrocal.com

Olle Breen

IMPERIAL INDUSTRIES INC.

PO Box 1685, Wausau, Marathon, WI 54402

Tel: 715-359-0200 Fax: 715-355-5349

Toll Free: 1-800-558-2945

e-mail: toma@imperialind.com website: www.imperialind.com

INDUSTRIAL & ENVIRONMENTAL CONCEPTS, INC.

6009 Chapel Dr., Minneapolis, MN 55439

Tel: 952-829-0731 Fax: 952-829-9770

Toll Free: 1-888-829-0731

e-mail: mmorgan@ieccovers.com website: www.ieccovers.com

Mike Morgan, William D. Morgan

IOWA PORK CONGRESS

1636 N.W. 114th St., Clive, IA 50325-0009

Tel: 515-225-7675 Fax: 515-225-0563

Toll Free: 1-800-372-7675

e-mail: dfricke@iowapork.org

Doug Fricke

ITT WATER AND WASTEWATER

35 Nutmeg Drive, Trumbull, CT 06611-0943

Tel: 203-380-4700 Fax: 203-380-4705

Tobias Hahn

J & D MANUFACTURING

6200 Highway 12, Eau Claire, WI 54701

Tel: 715-834-1439 Fax: 888-972-4454

Toll Free: 800-998-2398

e-mail: jend@jdmfg.com www.jdmfg.com

Jennifer Dunbeck

JAMESWAY FARM EQUIPMENT

12 Route 249, St-Francois-Xavier-de-Brompton, QC J0B 2V0

Tel: 1-819-845-7824 Fax: 1-819-845-5153

e-mail: ralphf@jameswayfarmeq.com www.jameswayfarmeq.com

Ralph Fanning

JAY-LOR FABRICATING INC.

RR # 2, Orton, ON L0N 1N0 Tel: 519-787-9353 Fax: 519-787-7053

e-mail: sales@jaylor.com

Ron Descotes

JBS LTD. (J. Bond & Sons Ltd.)

5416-275th St., Langley, BC V4W 3X7

Tel: 604-862-5391 Fax: 604-856-1619

e-mail: jbond80@telus.net website: www.jbscanada.ca

Justin Bond

KETCHUM MANUFACTURING INC.

1245 California Ave., Brockville, ON K6V 7N5

Tel: 613-342-8455 Fax: 613-342-7550

e-mail: ketchum@sympatico.ca

Dr. Tom Clapp

KEY DOLLAR COMPANY, LLC

PO Box 49, Milton-Freewater, OR 97862

Tel: 541-938-6336 Fax: 541-938-6282

Toll Free: 800-241-2427 www.keydollar.com

Henry Svehaug

KOOLMEES MARINE INDUSTRIAL SALES, SERVICE

Middletown Line 712651, Otterville, ON N0J 1R0

Tel: 519-879-6878 Fax: 519-879-6319

e-mail: pdeboer@sympatico.ca

Abraham Koolmees

KORRAL KOOL

3355 North Reseda #1, Mesa, AZ 85215

Tel: 480-807-0290 Fax: 480-807-0248

Michael Klaseen

KROHNE INC.

7 Dearborn Rd., Peabody, MA 01960

Tel: 978-535-6060 Fax: 978-535-1720

Toll Free: 1-800-356-9464

e-mail: jewell@krohne.com website: www.krohne.com/northamerica

Sandy Olley

KUNAFIN

PO Box 190, Quemado, TX 78877-0190

Tel: 210-824-0500 Fax: 830-757-1468

Toll Free: 1-800-832-1113

e-mail: office@kunafin.com website: www.kunafin.com

KYTE CENTRIFUGE

100 Cyprus Drive, North Augusta, SC 29841

Tel: 803-279-4888 Fax: 803-279-4411

e-mail: kyte.ken@juno.com website: www.kcentrifuge.com

Ken Kyte

LAKESIDE SYSTEMS, INC.

2400 Plymouth St., New Holstein, WI 53061

Tel: 920-898-5702 Fax: 920-898-5705

Toll Free: 1-800-589-8429

e-mail: tinahonigschmidt@lakesidesystems.com website: www.lakesidesystems.com

Tina Honigschmidt

LAYFIELD GEOSYNTHETICS & INDUSTRIAL FABRICS LTD.

20 Staffern Drive, Vaughn, ON L4K 2Z7

Tel: 905-761-9123 Fax: 905-761-0035

Toll Free1-888-436-4273

e-mail: toronto@layfieldgroup.com www.layfieldgroup.com

LEON’S MFG. COMPANY INC.

PO Box 5002, Yorkton, SK S3N 3Z4

Tel: 306-786-2600 Fax: 306-782-1884

Toll Free: 1-800-667-1581

e-mail: mkt@leonsmfg.com website: www.leonsmfg.com

Ron Lummerding

LO-DELL AGRI SERVICES LTD.

34950 Saintsbury Line, RR #1, Lucan, ON N0M 2J0

Tel: 519-227-0489

e-mail: lo-dell@quadro.net

LOEWEN WELDING LTD.

33655 Harris Road, PO BOX 66, Matsqui, BC V4X 3R2

Tel: 604-826-7844 Fax: 604-826-6051

Wayne Raiche

LSC PRE-CAST SYSTEMS (Canada) Ltd.

5949 Chadsey Rd., Chilliwack, BC V2R 4P2

Toll Free: 1-888-796-2323

Fax: 604-823-4249

e-mail: lsc@lscprecast.com website: www.lscprecast.com

Brian Janssens

LYNDEN BRIM TRACTOR

350 South Duffner Dr., Lynden, WA 98264

Toll Free: 1-800-530-2746

Fax: 360-354-3438

MANURE MANAGER

PO Box 530, 105 Donly Dr. S Simcoe, ON N3Y 4N5

Tel: 519-429-5189 Ext 242

Fax: 519-429-3094

Toll Free: 1-888-599-2228 ext. 242 e-mail: skauk@annexweb.com website: www.manuremanager.com

Sharon Kauk

Manure Manager is published exclusively for the Manure Handling Industry across North America. Our editorial content focuses on leading edge equipment, technology and people in the industry.

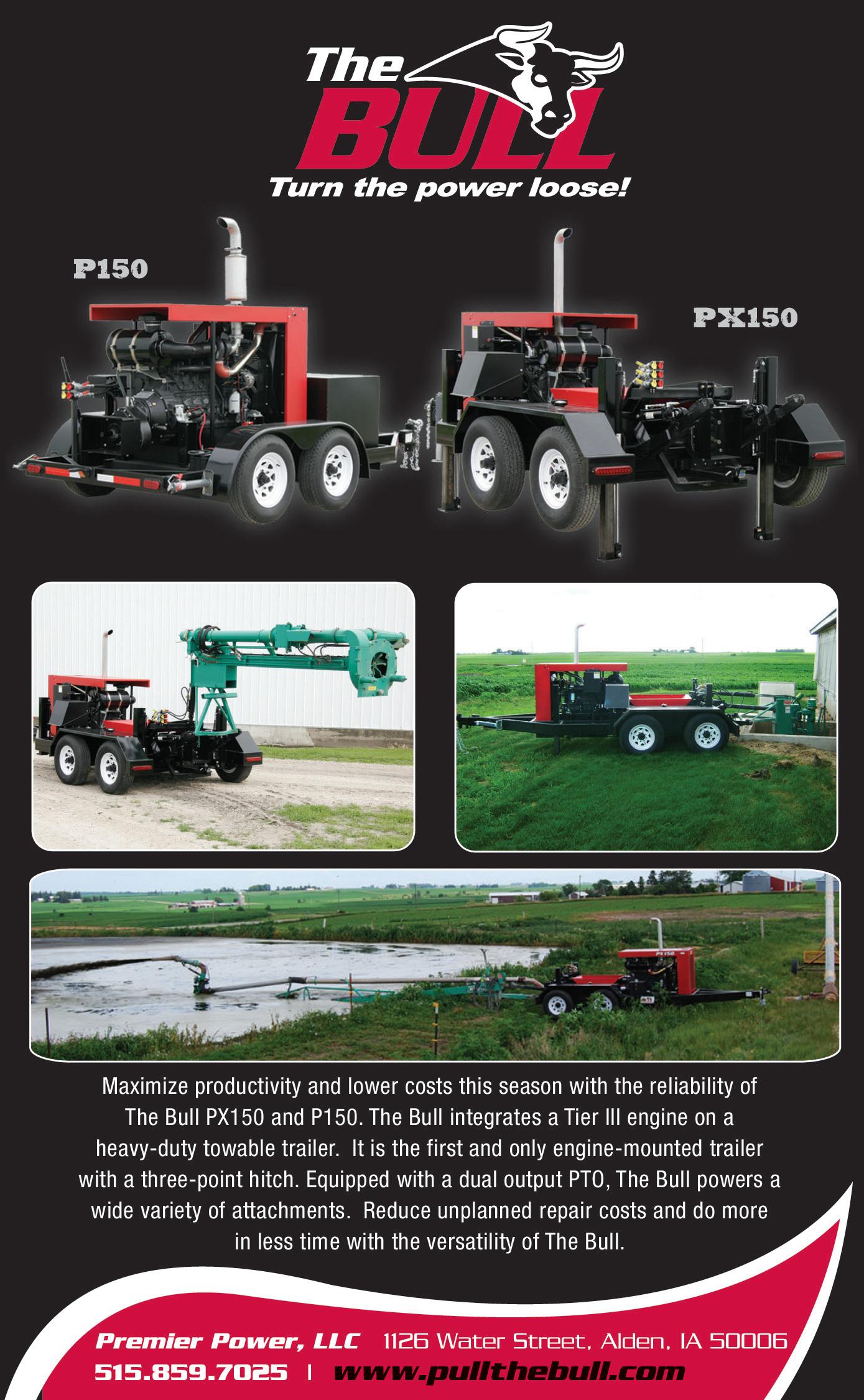

McLANAHAN CORPORATION

200 Wall Street, Hollidaysburg, PA 16648

Tel: 814-695-9807 Fax: 814-695-6684

e-mail: agdivision@mclanahan.com website: www.mclanahan.com

Renee Schrift

MEYER MANUFACTURING CORP.

574 W. Center Ave., Dorchester, WI 54425

Tel: 715-654-5132 Fax: 715-654-5513

Toll Free: 1-800-325-9103

e-mail: sales@meyermfg.com website: www.meyermfg.com

Larry Meyer

MICHELIN NORTH AMERICA

Box 19001, Greenville, SC 29602

Tel: 864-458-5963 Fax: 864-458-4150

Toll Free: 1-888-552-1213

michael.burroughes@michelin.com www.michelinag.com

Michael Burroughes, 864-458-4845

MIDWEST BIO-SYSTEMS

28933 35E St., Tampico, IL 61283

Tel: 815-438-7200 Fax: 815-438-7028

Toll Free: 1-800-689-0714

e-mail: mbs@midwestbiosystems.com website: www.midwestbiosystems.com

Kelly Setchell, Grey Williams

MMI INTERNATIONAL

Box 544, Brush, CO 80723

Tel: 970-842-5161 Fax: 970-842-3111

Toll Free: 1-800-523-2614

e-mail: info@mixerfeeders.com website: www.mixerfeeders.com

Randy Moore

MOBY DICK WHEEL WASHING SYSTEMS

20 Highview Road, Downingtown, PA 19335

Tel: 610-613-2939 Fax: 610-458-9151

Toll Free: 1-866-858-3353

e-mail: ralodi@comcast.net

Bob Lodi

MPC CONTAINMENT INTERNATIONAL

4834 S. Oakley St., Chicago, IL 60609

Toll Free: 1-800-621-0146 Fax: 773-650-6028

e-mail: mpcliners@aol.com

Ray Bertolozzi

N3 CONSULTING

5685 Bench Lane, Everson, WA 98247

Tel: 360-815-4851

e-mail: dhaggithn3@vericon.com

David Haggith

NEBRASKA HARVESTORE SYSTEMS

3201 S. 13th St., Norfolk, NE 68701

Tel: 402-371-0144 Fax: 402-371-6031

Toll Free: 1-800-777-0501

e-mail: sales@nebraskaharvestore.com website: www.nebraskaharvestore.com

Jim Mertz

NTH, INC

5 Berger Avenue, Barron, WI 54812

Tel: 715-537-9207 Fax: 715-537-3861

Toll Free: 1-800-236-1532

e-mail: nth@chibardun.net www.nthusa.com

Bryce Nesseth

NUHN INDUSTIRES LTD.

PO Box 160, Sebringville, ON N0K 1X0

Tel: 519-393-6284 Fax: 519-393-5104

e-mail: nuhnind@nuhn.ca website: www.nuhn.ca

Dennis Nuhn

OCTAFORM SYSTEMS INC.

520-885 Dunsmuir St., Vancouver, BC V6C 1N5

Tel: 604-408-0558 Fax: 604-408-0595

Toll Free: 1-888 -786-6282

James Johnson

ONTARIO SOIL & CROP IMPROVEMENT ASSOCIATION

1 Stone Road West, Guelph, ON N1G 4Y2

Tel: 519-826-4214 Fax: 519-826-4224 website: www.ontariosoilcrop.org

Andrew Graham

PAPILLON AG PRODUCTS

PO Box 203, Innerkip, ON NOJ 1M0

Tel: 519-469-3022 Fax: 519-469-3301

e-mail: currah@execulink.com

Jeffery Currah

PARK LAKE WELDING & MFG. LTD.

PO Box 962, Coalhurst, AB T0L 0V0

Tel: 403-381-4706 Fax: 403-381-3788

e-mail: henrietta@parklakewelding.com

John Van Schothorst, Henrietta Ziengs

PARKSON CORPORATION

2727 NW 62nd St., Fort Lauderdale, FL 33309-8399

Tel: 847-974-6610 Fax: 954-974-6182

website: www.parkson.com

PARMA COMPANY

101 Main Street PO Box 190, Parma, ID 83660

Tel: 208-722-5116 Fax: 208-722-6012

e-mail: parmacom@parmacompany.com website: www.parmacompany.com

Roger Blaylock

PATZ CORPORATION

PO Box 7, Pound, WI 54161-0007

Tel: 920-897-2251 Fax: 920-897-2142

e-mail: info@patzcorp.com website: www.patzcorp.com

Barb Sailer

PBS ANIMAL HEALTH

2780 Richville Dr., SE, Massillon, OH 44646

Tel: 800-321 0235 Fax: 330-830-2762

e-mail: info@pbsanimalhealth.com website: www.pbsanimalhealth.com

Robert K. Matthews

PEQUEA MACHINE, INC.

200 Jalyn Dr., New Holland, PA 17557

Tel: 717-354-4343

website: www.pequea.com

Abe Skibo

PHASON ELECTRONIC CONTROL SYSTEMS

2 Terracon Place, Winnipeg, MB R2J 4G7

Tel: 204-233-1400 Fax: 204-233-3252

e-mail: sales@phason.ca website: www.phason.ca

PIONEER PUMP, INC.

310 S. Sequoia Pkwy., Canby, OR 97013

Tel: 503-266-4115 Fax: 503-266-4116

e-mail: sales@pioneerpump.com website: www.pioneerpump.com

Bill Barrett

PRAIRIE PRIDE ENTERPRISES

12 Rothwell Rd., Winnipeg, MB R3P 2H7 Tel: 204-488-6077 Fax: 204-488-2376

Steve Bonner

PRO-ACT BIOTECH

PO Box 345, Warren, RI 02885

Toll Free: 1-800-772-3775

Fax: 401-633-6270

e-mail: ChristaG@proactbiotech.com website: www.ProActBiotech.com

Bill Campion

PUCK CUSTOM ENTERPRISES, INC.

1130 - 100th St., Manning, IA 51455

Tel: 712-653-3045 Fax: 712-653-3099

e-mail: info@puckenterprises.com website: www.puckenterprises.com

Ben Puck

PURATONE CORPORATION CANADA

Box 460, Niverville, MB R0A 1E0

Tel: 204-388-4741 Fax: 204-388-6745

Cheryl Wiebe

REDFERN FARM SERVICES LTD.

Box 660, Hamiota, MB R0M 0T0 Tel: 204-764-2259 Fax: 204-764-2046

Randy Tully

REEF INDUSTRIES INC.

9209 Almeda Genoa, Houston, TX 77075

Tel: 713-507-4251 Fax: 713-507-4295

Toll Free: 1-800-231-6074

e-mail: ri@reefindustries.com website: www.reefindustries.com

Gina Quevedo

REMOTE LOAD, INC.

421 2nd St. NE, Hampton, IA 50441

Tel: 641-430-3989

e-mail: jayme@remote-load.com

website: www.remote-load.com

Kurt Wolf, Jayme Murray

ROCK RIVER LAB

710 Commerce Dr. P.O. Box 169, Watertown, WI 53094-0169

Tel: 920-261-0446 Fax: 920-261-1365

e-mail: twilah_kulow@rockriverlab.com website: www.rockriverlab.com

ROTO-MIX LLC

2205 E. Wyatt Earp, Dodge City, KS 67801 Tel: 620-225-1142 Fax: 620-225-6370

e-mail: gsmith@rotomix.com website: www.rotomix.com

Allin Butcher

Roto-Mix LLC manufactures Roto-Spread waste handling equipment ranging from 362 to 532 cu. ft. trailers and 532 to 802 cu. ft. truck units. A line of Industrial Series Compost Mixers for the compost industry features the Staggered Rotor in sizes from 16 to 34 cu. yds. in both truck and stationary.

SAMSON ENGINEERING, INC.

162 - 10th St., Brandon, MB R7A 4E6 Tel: 204-727-0747 Fax: 204-725-9870

Phil Dorn

SASKATCHEWAN AGRICULTURE

3085 Albert St., Room 202, Regina, SK S4S 0B1 Tel: 306-787-5465 Fax: 306-787-1315

e-mail: andy.jansen@gov.sk.ca

Andy Jansen

SHAC ENVIRONMENTAL PRODUCTS

PO BOX 73, Medicine Hat, AB T1A 7E5

Tel: 403-528-4446 Fax: 403-529-9334

Toll free: 888-533-4446

e-mail: office@shac.ca www.shac.ca

Allan Dyck

SILO’S R US INC.

RR #1, Moundville, MO 64771

Tel: 417-944-2991 Fax: 417-944-9909

e-mail: dprincesilos@wildblue.net

Dale Prince

SIOUX AUTOMATION CENTER INC.

877 1st Ave. N.W., Sioux Center, IA 51250 Tel: 712-722-1488 Fax: 712-722-1487

Toll Free: 1-866-722-1488

e-mail: sales@siouxautomation.com website: www.siouxautomation.com

SLURRYSTORE - ENGINEERED STORAGE PRODUCTS CO.

345 Harvestore Dr., De Kalb, IL 601159607

Tel: 815-756-1551 Fax: 815-756-1659

SPARTAN CHEMICAL

1110 Spartan Dr., Maumee, OH 43537

Tel: 419-531-5551 Fax: 419-724-7500

SPERLING INDUSTRIES LTD.

51 Station St., Sperling, MB R0G 2M0

Toll Free: 1-877-626-3401

Fax: 204-626-3252

e-mail: sperling@sperlingind.com website: www.sperlingind.com

Bruce McCulloch

SRS CRISAFULLI INC.

1610 Crisafulli Dr., Glendive, MT 59330-1051

Tel: 406-365-3393 Fax: 406-365-8088

Toll Free: 1-800-442-7867

srsc@crisafulli.com website: www.crisafullipumps.com

STREAMSIDE SYSTEMS

7440 Twp. Rd. 95, Findlay, OH 45840

Tel: 419-423-1290

e-mail: eatucker@streamsidesystems.com website: www.streamsidesystems.com

Emily Tucker

SUNRISE CUSTOM MANURE INC.

72759 Blackbush Line, Zurich, ON N0M 2T0

Tel: 519 236-7468 Fax: 519-236-7602

e-mail: sunriseinc@hay.net website: www.sunrisemanure.com

SUSTAINABLE DEVELOPMENT

TECHNOLOGY CANADA

45 O’Connor St., Suite 1850, Ottawa, ON K1P 1A4

Tel: 613-234-6313 Fax: 613-234-0303

e-mail: info@sdtc.ca website: www.sdtc.ca

T-L IRRIGATION COMPANY

Box 1047, Hastings, NE 68901

Tel: 402-462-4128 Fax: 402-462-4617

Toll Free: 1-800-330-4264

e-mail: sales@tlirr.com website: www.tlirr.com

TEN CATE GEOTUBE

3680 Mount Olive Rd., Commerce, GA 30529

Tel: 706-693-1897 Fax: 706-693-1896

Toll Free: 1-888-795-0808

e-mail: v.ginter@tencate.com website: www.geotube.com

Tom Stephens

TRIPLE/S DYNAMICS

PO BOX 151027, Dallas, TX 75315

Tel: 800-527-2116 Fax: 214-828-8688

e-mail: sales@sssdynamics.com website: www.sssdynamics.com

Nathan Schmidt

UNITED LIVESTOCK SYSTEMS

Box 390, Bowden, AB T0M 0K0

Tel: 403-224-3454 Fax: 403-224-3388

Toll Free: 1-403-352-9118

e-mail: daryl@ulsindustries.com website: www.livestocksystems.com

Daryl Heit

UNIVERSITY OF WISCONSON

2611 East 29th St., Marshfield, WI 54449

Tel: 715-387-2523 Fax: 715-387-1723

VANDEN BUSSCHE IRRIGATION

2515 Pinegrove Rd., Delhi, ON N4B 2X1

Tel: 519-582-2380 Fax: 519-582-1514

Toll Free: 1-800-387-7246

e-mail: info@vandenbussche.com website: www.vandenbussche.com

Scott Smith

VAUGHAN COMPANY INC.

364 Monte-Elma Rd., Montesano, WA 98563

Tel: 360-249-4042 Fax: 360-249-6155

Toll Free: 1-888-249-CHOP

e-mail: info@chopperpumps.com website: www.chopperpumps.com

Josh Niels

VEENHUIS MACHINES B.V.

PO Box 35, Raalte, NL

e-mail: info@veenhuis.com website: www.veenhuis.com

Walter Veenhuis

VERSA CORPORATION

P.O. Box 747, Astoria, OR 97103

Tel: 503-325-6232 Fax: 503-325-0397

e-mail: nickw@versacorporation.com

Nic White

VINCENT CORP.

2810 E. 5th Ave., Tampa, FL 33605

Tel: 813-248-2650 Fax: 813-247-7557

e-mail: bob@vincentcorp.com website: www.vincentcorp.com

Screw Press Design and Manufacturer

Since 1931

WALCO INTERNATIONAL

7 Village Cr, Ste. 200, Westlake, TX 76262

Tel: 817-859-3017 Fax: 817-859-3017

e-mail: baileyj@walcointl.com website: www.walcointl.com

Josh Bailey, Director of Marketing

WARD LABORATORIES INC.

4007 Cherry Ave., Kearney, NE 68848-0788

Tel: 308-234-2418 Fax: 308-234-1940

WATER AGRICULTURAL LAB

2101 Calhoun Road, Highway 81, Owensboro, KY 42301

Tel: 270-685-4039 Fax: 270-685-3989 website: www.watersag.com

WELLMAN SERVICE

7347 Boyd Rd., Pavilion, NY 14525 Tel: 585-584-8502 Fax: 585-584-8503

Lenny Wellman

WESSUC INC.

973 Albertson Rd. S., Jerseyville, ON LOR 1R0

Tel: 519-752-0837 Fax: 519-752-0840

Toll Free: 1-866-4-WESSUC

e-mail: info@wessuc.com website: www.wessuc.com

WEST POINT DESIGN INC. / SPREAD ALL

P.O. Box 255, West Point, NE 68788

Tel: 402-372-2408 Fax: 402-372-2440

WEST TECHNOLOGY SYSTEMS, INC.

30152 Esperanza, Rancho Santa Margarita, CA 92688

Tel: 949-742-7010 Fax: 949-742-7015

e-mail: djohnson@westtechnosystems.com website: www.westtechnosystems.com

WESTERN TANK & LINING LTD.

12180 Vickers Way, Richmond, BC V6V 1H9

Tel: 604-241-9487 Fax: 604-241-9485

Toll Free: 1-800-551-4355

e-mail: info@wtl.ca website: www.wtl.ca

Mr. Bob Naylor

WESTERN UNITED RESOURCE DEVELOPMENT, INC

1315 K St., Modesto, CA 95354

Tel: 209-527-6453 Fax: 209-527-0630

WHITE MOUNTAIN CHAIN INC.

PO Box 869, Bonners Ferry, ID 83805

Tel: 1-800-439-9073 Fax: 877-492-8289

Toll Free: 877- 492- 8299

e-mail: wmchain@netscape.net

Ed Leach

WILDFIRE GROUP

170 Murray Park Road, Unit 2, Winnipeg, MB R3J 3X5

Tel: 204-889-3473 Fax: 204-897-3473

Toll Free: 1-800-426-5207

e-mail: wildfire@tycoint.com

www.wildfire-equipment.com

Manfred Kihn

WOODALL FARMS

4175 Anderson Store Rd., Lewisburg, KY 42256

Tel: 270-755-4141 Fax: 270-755-4624

Jimmy Woodall

WORLD WIDE BIO ENERGY, LLC

3518 West 73rd Terrace, Prairie Village, KS 66208

Tel: 913-362-6131 Fax: 321-256-2948

Toll Free: 1-913-226-4466

e-mail: gary@wwbioenergy.biz

Gary Showalter

YUNKER PLASTICS, INC.

251 O’Conner Dr., Elkhorn, WI 53121

Tel: 262-743-1234 Fax: 262-743-1233

Toll Free: 1-800-236-3328

e-mail: mark@yunkerplastics.com website: www.yunkerplastics.com

Mark Yunker

ZOSKE’S SALES & SERVICE

19308 Hwy. S-27, Alden, IA 50006

Tel: 515-855-4101 Fax: 641-855-4190

e-mail: mzoske@iowatelecom.net website: www.zoskes.com

Mick Zoske

AGITATION EQUIPMENT

AGPRO®, INC.

BALLAGH LIQUID

TECHNOLOGIES INC.

BALZER, INC.

BAMBAUER EQUIPMENT LLC.

BAUER NORTH AMERICA/ FAN SEPARATOR

BAZOOKA FARMSTAR, INC.

BOERGER, LLC

BRAUN ELECTRIC INC.

CADMAN POWER EQUIPMENT

CADY INC.

DM MACHINERY INC.

DODA U.S.A. INC.

DON THEMM ENTERPRISES, INC.

SLURRYSTORE - ENGINEERED

STORAGE PRODUCTS CO.

ENVIRONMENTAL POWER CORP.

HERSHEY EQUIPMENT CO., INC.

HODEL, JIM INC.

HUSKY FARM EQUIPMENT LTD.

ITT WATER AND WASTEWATER

GEA HOULE INC.

LAKESIDE SYSTEMS, INC.

LOEWEN WELDING LTD.

NEBRASKA HARVESTORE SYSTEMS

PARMA COMPANY

PATZ CORPORATION

REMOTE LOAD, INC.

SILO’S R US INC.

SIOUX AUTOMATION

CENTER INC.

SRS CRISAFULLI INC.

SUNRISE CUSTOM MANURE INC.

UNITED LIVESTOCK SYSTEMS

VANDEN BUSSCHE IRRIGATION

VAUGHAN COMPANY INC.

VEENHUIS MACHINES B.V.

WELLMAN SERVICE

WEST TECHNOLOGY SYSTEMS, INC.

WOODALL FARMS

ZOSKE’S SALES & SERVICE

BARN CONSTRUCTION

AGPRO®, INC.

AGPROFESSIONALS, LLC

DON THEMM ENTERPRISES, INC.

FARMER AUTOMATIC

LAKESIDE SYSTEMS, INC.

OCTAFORM SYSTEMS INC.

WOODALL FARMS

CLEANING AND SANITIZING EQUIPMENT

ACM - TEXAS, LLC

AGPRO®, INC.

BALLAGH LIQUID TECHNOLOGIES INC.

DFK EQUIPMENT SALES, INC.

SPARTAN CHEMICAL

WOODALL FARMS

COMMERCIAL MANURE APPLICATORS

AERWAY/SAF-HOLLAND

BAUER NORTH AMERICA/ FAN SEPARATOR

BRAUN ELECTRIC INC.

CADMAN POWER EQUIPMENT

CLAAS OF AMERICA INC.

HYDRO ENGINEERING INC.

JBS LTD. (J. BOND & SONS LTD.)

LEON’S MFG. COMPANY INC.

LYNDEN BRIM TRACTOR

MICHELIN NORTH AMERICA

MMI INTERNATIONAL

NEBRASKA HARVESTORE SYSTEMS

NUHN INDUSTIRES LTD.

PUCK CUSTOM ENTERPRISES, INC.

REMOTE LOAD, INC.

SUNRISE CUSTOM MANURE INC.

VANDEN BUSSCHE IRRIGATION

VEENHUIS MACHINES B.V.

WELLMAN SERVICE

WESSUC INC.

WOODALL FARMS

ZOSKE’S SALES & SERVICE

COMPOSTING

BALLAGH LIQUID

TECHNOLOGIES INC.

BAUER NORTH AMERICA/ FAN SEPARATOR

BROWN BEAR CORPORATION

DODA U.S.A. INC.

DON THEMM ENTERPRISES, INC.

DOUBLE T EQUIPMENT LTD.

FARMER AUTOMATIC

FARM TEK

GLOBAL REPAIR

HCL MACHINE WORKS

GEA HOULE INC.

JBS LTD. (J. BOND & SONS LTD.)

LAKESIDE SYSTEMS, INC.

LOEWEN WELDING LTD.

LSC PRE-CAST SYSTEMS (CANADA) LTD

MIDWEST BIO-SYSTEMS

MMI INTERNATIONAL

PARMA COMPANY

PATZ CORPORATION

ROTO-MIX LLC

CONSTRUCTION

CONTRACTORS

AGPRO®, INC.

BRAUN ELECTRIC INC.

FARMER AUTOMATIC

LAKESIDE SYSTEMS, INC.

LSC PRE-CAST SYSTEMS (CANADA) LTD

NEBRASKA HARVESTORE SYSTEMS

SILO’S R US INC.

CONTROL SYSTEMS

AGPRO®, INC.

BALLAGH LIQUID

TECHNOLOGIES INC.

BALZER, INC.

BIG ASS FANS

BRAUN ELECTRIC INC.

CADMAN POWER EQUIPMENT

KORRAL KOOL

LAKESIDE SYSTEMS, INC.

PHASON ELECTRONIC

CONTROL SYSTEMS

SILO’S R US INC.

WOODALL FARMS

DESIGN/ENGINEERING

CONSULTANTS

ATD WASTE SYSTEMS INC.

AGPRO®, INC.

AGPROFESSIONALS, LLC

AGRI -WASTE TECHNOLOGY INC.

ALBERS MANURE HANDLING SYSTEMS INC.

BRAUN ELECTRIC INC.

CADMAN POWER EQUIPMENT

DGH ENGINEERING LTD.

DON THEMM ENTERPRISES, INC.

FARMER AUTOMATIC FARM TEK

GHD, INC.

LAKESIDE SYSTEMS, INC.

LSC PRE-CAST SYSTEMS (CANADA) LTD

MCLANAHAN CORPORATION

PRO-ACT BIOTECH

SAMSON ENGINEERING, INC.

SPERLING INDUSTRIES LTD.

WOODALL FARMS

DIGESTERS

AGPRO®, INC.

AGPROFESSIONALS, LLC

BALLAGH LIQUID

TECHNOLOGIES INC.

BAUER NORTH AMERICA/ FAN SEPARATOR

BIOTHANE CORPORATION

BOERGER, LLC

CADY INC.

DODA U.S.A. INC.

DON THEMM ENTERPRISES, INC.

SLURRYSTORE - ENGINEERED

STORAGE PRODUCTS CO.

ENVIRONMENTAL POWER CORP.

FIRESTONE SPECIALTY PRODUCTS

GHD, INC.

ITT WATER AND WASTEWATER

LAKESIDE SYSTEMS, INC.

NEBRASKA HARVESTORE SYSTEMS

PRO-ACT BIOTECH

PURATONE CORPORATION CANADA

SHAC ENVIRONMENTAL PRODUCTS

SILO’S R US INC.

UNITED LIVESTOCK SYSTEMS

VANDEN BUSSCHE IRRIGATION

VAUGHAN COMPANY INC.

WOODALL FARMS

DRAINAGE MANAGEMENT

SYSTEMS

AGPROFESSIONALS, LLC

AGRI DRAIN CORPORATION

DUSKE DRYING SYSTEMS

SAMSON ENGINEERING, INC.

SILO’S R US INC.

WOODALL FARMS

HAPCO

DRYING SYSTEMS

FARMER AUTOMATIC

GLOBAL RESOURCE RECOVERY ORGANIZATION

PARKSON CORPORATION

SILO’S R US INC.

DUMP BOXES

BALLAGH LIQUID TECHNOLOGIES INC.

CLAAS OF AMERICA INC.

LYNDEN BRIM TRACTOR

SILO’S R US INC.

WEST POINT DESIGN INC. / SPREAD ALL WOODALL FARMS

EDUCATION

ASSINIBOINE COMMUNITY COLLEGE

FARMER AUTOMATIC GLOBAL REPAIR

ONTARIO SOIL & CROP

IMPROVEMENT ASSOCIATION

UNIVERSITY OF WISCONSON

ENVIRONMENTAL CREDITS

ASSINIBOINE COMMUNITY COLLEGE

FARMER AUTOMATIC GLOBAL REPAIR

ONTARIO SOIL & CROP IMPROVEMENT ASSOCIATION

UNIVERSITY OF WISCONSON

FEED ADDITIVES

DSM NUTRITIONAL PRODUCTS

HELFTER FEEDS, INC.

PAPILLON AG PRODUCTS

SHAC ENVIRONMENTAL PRODUCTS

GAS PURIFICATION SYSTEMS

GUILD ASSOCIATES, INC.

WOODALL FARMS

GOVERNMENT REGULATIONS

AGPROFESSIONALS, LLC

AGRI -WASTE TECHNOLOGY INC.

SASKATCHEWAN AGRICULTURE

WOODALL FARMS

HOSE REELS & CADDIES

BALLAGH LIQUID TECHNOLOGIES INC.

BALZER, INC.

BAMBAUER EQUIPMENT LLC.

BAZOOKA FARMSTAR INC.

CADMAN POWER EQUIPMENT

DODA U.S.A. INC.

FARM TEK

HODEL, JIM INC.

HUSKY FARM EQUIPMENT LTD.

HYDRO ENGINEERING INC.

JBS LTD. (J. BOND & SONS LTD.)

KOOLMEES MARINE INDUSTRIAL SALES, SERVICE

LAKESIDE SYSTEMS, INC.

PUCK CUSTOM ENTERPRISES, INC.

VANDEN BUSSCHE IRRIGATION

VEENHUIS MACHINES B.V.

WILDFIRE GROUP

WOODALL FARMS

HOSES

ANGUS FIRE USA

ARMORED TEXTILES, INC.

BALZER, INC.

BAMBAUER EQUIPMENT LLC.

CADMAN POWER EQUIPMENT

DODA U.S.A. INC.

FARM TEK

GOLLMER & HUMMEL

HODEL, JIM INC.

HUSKY FARM EQUIPMENT LTD.

HYDRO ENGINEERING INC.

KOOLMEES MARINE INDUSTRIAL SALES, SERVICE

LAKESIDE SYSTEMS, INC.

PUCK CUSTOM ENTERPRISES, INC.

SRS CRISAFULLI INC.

VANDEN BUSSCHE IRRIGATION

WILDFIRE GROUP

WOODALL FARMS

BAZOOKA FARMSTAR, INC.

ZOSKE’S SALES & SERVICE

INJECTION EQUIPMENT

BALLAGH LIQUID TECHNOLOGIES INC.

BALZER, INC.

BAMBAUER EQUIPMENT LLC.

BOERGER, LLC

CADMAN POWER EQUIPMENT

CADY INC.

CLAAS OF AMERICA INC.

DM MACHINERY INC.

DODA U.S.A. INC.

DSI, INC.

HAPCO

HODEL, JIM INC.

HUSKY FARM EQUIPMENT LTD.

HYDRO ENGINEERING INC.

IMPERIAL INDUSTRIES INC.

GEA HOULE INC.

KOOLMEES MARINE INDUSTRIAL SALES, SERVICE

LAKESIDE SYSTEMS, INC.

NUHN INDUSTIRES LTD.

PUCK CUSTOM ENTERPRISES, INC.

SIOUX AUTOMATION CENTER INC.

UNITED LIVESTOCK SYSTEMS

VANDEN BUSSCHE IRRIGATION

VEENHUIS MACHINES B.V.

WELLMAN SERVICE

WOODALL FARMS

BAZOOKA FARMSTAR, INC.

ZOSKE’S SALES & SERVICE

LAGOON COVERS

AGPROFESSIONALS, LLC

CANAMER SERVICES INC.

CLI

ENCON TECHNOLOGIES INC.

ENVIRONETICS INC.

FARM TEK

FIRESTONE SPECIALTY PRODUCTS

GSE LINING TECHNOLOGY INC.

HAPCO

INDUSTRIAL & ENVIRONMENTAL

CONCEPTS, INC.

LAKESIDE SYSTEMS, INC.

LAYFIELD GEOSYNTHETICS & INDUSTRIAL FABRICS LTD.

MPC CONTAINMENT

INTERNATIONAL

PRO-ACT BIOTECH

WOODALL FARMS

YUNKER PLASTICS, INC.

LAGOON LINERS

AGPROFESSIONALS, LLC

AGRI DRAIN CORPORATION

CANAMER SERVICES INC.

CLI

ENCON TECHNOLOGIES INC.

FARM TEK

FIRESTONE SPECIALTY PRODUCTS

GSE LINING TECHNOLOGY INC.

INDUSTRIAL & ENVIRONMENTAL CONCEPTS, INC.

LAYFIELD GEOSYNTHETICS & INDUSTRIAL FABRICS LTD.

LSC PRE-CAST SYSTEMS (CANADA) LTD

MPC CONTAINMENT

INTERNATIONAL

REEF INDUSTRIES INC.

SAMSON ENGINEERING, INC.

WOODALL FARMS

YUNKER PLASTICS, INC.

LIQUID MANURE TANKERS

ALLIANCE TIRE USA

BALLAGH LIQUID

TECHNOLOGIES INC.

BALZER, INC.

BAMBAUER EQUIPMENT LLC.

BAUER NORTH AMERICA/ FAN SEPARATOR

BRAUN ELECTRIC INC.

CADY INC.

CLAAS OF AMERICA INC.

DM MACHINERY INC.

HODEL, JIM INC.

HUSKY FARM EQUIPMENT LTD.

IMPERIAL INDUSTRIES INC.

GEA HOULE INC.

LAKESIDE SYSTEMS, INC.

LOEWEN WELDING LTD.

MICHELIN NORTH AMERICA

NEBRASKA HARVESTORE SYSTEMS

NUHN INDUSTIRES LTD.

OCTAFORM SYSTEMS INC.

REMOTE LOAD, INC.

SIOUX AUTOMATION CENTER INC.

UNITED LIVESTOCK SYSTEMS

VEENHUIS MACHINES B.V.

WELLMAN SERVICE

WOODALL FARMS

ZOSKE’S SALES & SERVICE

LOADERS & ACCESSORIES

ALLIANCE TIRE USA

GEHL COMPANY

LAKESIDE SYSTEMS, INC.

LYNDEN BRIM TRACTOR

MICHELIN NORTH AMERICA

WELLMAN SERVICE

WEST POINT DESIGN INC./ SPREAD ALL

WOODALL FARMS

MANAGEMENT CONSULTANTS

AGPROFESSIONALS, LLC

AGRI -WASTE TECHNOLOGY INC.

KUNAFIN

MIDWEST BIO-SYSTEMS

ROCK RIVER LAB

WESSUC INC.

WOODALL FARMS

MANURE ADDITIVES

ACM - TEXAS, LLC

AGTECH PRODUCTS

BALLAGH LIQUID

TECHNOLOGIES INC.

DON THEMM ENTERPRISES, INC.

GES CORP.

GLOBAL REPAIR

MIDWEST BIO-SYSTEMS

PAPILLON AG PRODUCTS

PRO-ACT BIOTECH

SPARTAN CHEMICAL

WOODALL FARMS

MANURE CONVEYOR SYSTEMS

AGPRO®, INC.

BALLAGH LIQUID TECHNOLOGIES INC.

CADY INC.

DON THEMM ENTERPRISES, INC.

FARMER AUTOMATIC

GEA HOULE INC.

JAMESWAY FARM EQUIPMENT

MCLANAHAN CORPORATION

PARKSON CORPORATION

PATZ CORPORATION

SILO’S R US INC.

UNITED LIVESTOCK SYSTEMS

WOODALL FARMS

MEASUREMENT SYSTEMS

AGPROFESSIONALS, LLC

FARMER AUTOMATIC

KROHNE INC.

PHASON ELECTRONIC CONTROL SYSTEMS

WOODALL FARMS

METHANE COLLECTION

DODA U.S.A. INC.

DON THEMM ENTERPRISES, INC.

FIRESTONE SPECIALTY PRODUCTS

GHD, INC.

LAKESIDE SYSTEMS, INC.

LAYFIELD GEOSYNTHETICS & INDUSTRIAL FABRICS LTD.

PRO-ACT BIOTECH

SILO’S R US INC.

UNITED LIVESTOCK SYSTEMS

WOODALL FARMS

MUNICIPAL WASTE MANAGEMENT

AGRI -WASTE TECHNOLOGY INC.

BAZOOKA FARMSTAR, INC.

BRAUN ELECTRIC INC.

BROWN BEAR CORPORATION

CADY INC.

DODA U.S.A. INC.

GORDON & ASSOCIATES INC.

HYDRO ENGINEERING INC.

GEA HOULE INC.

LSC PRE-CAST SYSTEMS (CANADA) LTD

MICHELIN NORTH AMERICA

ROTO-MIX LLC

SHAC ENVIRONMENTAL PRODUCTS

SPARTAN CHEMICAL

SRS CRISAFULLI INC.

TEN CATE GEOTUBE

NUTRIENT MANAGEMENT

AERWAY/SAF-HOLLAND

AGPROFESSIONALS, LLC

AGRI DRAIN CORPORATION

AGRI -WASTE TECHNOLOGY INC.

BRAUN ELECTRIC INC.

CADMAN POWER EQUIPMENT

DGH ENGINEERING LTD.

DM MACHINERY INC.

SLURRYSTORE - ENGINEERED

STORAGE PRODUCTS CO.

FARM TEK

GLOBAL REPAIR

GORDON & ASSOCIATES INC.

GEA HOULE INC.

LAKESIDE SYSTEMS, INC.

MIDWEST BIO-SYSTEMS

PARKSON CORPORATION

PRO-ACT BIOTECH

ROTO-MIX LLC

SILO’S R US INC.

SPARTAN CHEMICAL

TEN CATE GEOTUBE

UNIVERSITY OF WISCONSON

WARD LABORATORIES INC.

WESSUC INC.

WOODALL FARMS

BAZOOKA FARMSTAR, INC.

NUTRIENT TESTING

AGPROFESSIONALS, LLC

BIOTHANE CORPORATION

GORDON & ASSOCIATES INC.

MIDWEST BIO-SYSTEMS

ROCK RIVER LAB

UNIVERSITY OF WISCONSON

WARD LABORATORIES INC.

WATER AGRICULTURAL LAB

WOODALL FARMS

BAZOOKA FARMSTAR, INC.

POLYMERS

BRAUN ELECTRIC INC.

WOODALL FARMS

HAPCO

PORTABLE/TEMPORARY MANURE STORAGE

BAMBAUER EQUIPMENT LLC.

BOERGER, LLC

CADMAN POWER EQUIPMENT

FARM TEK

HODEL, JIM INC.

HUSKY FARM EQUIPMENT LTD.

LSC PRE-CAST SYSTEMS (CANADA) LTD

WOODALL FARMS

ZOSKE’S SALES & SERVICE

PUMPS

AGPRO®, INC.

ALBERS MANURE HANDLING SYSTEMS INC.

BALLAGH LIQUID TECHNOLOGIES INC.

BALZER, INC.

BAMBAUER EQUIPMENT LLC.

BAUER NORTH AMERICA/ FAN SEPARATOR

BAZOOKA FARMSTAR, INC.

CADMAN POWER EQUIPMENT

CADY INC.

CORNELL PUMP COMPANY

DM MACHINERY INC.

DODA U.S.A. INC.

DON THEMM ENTERPRISES, INC.

FISHER PUMPS

FLO TECH PUMP

GORMAN-RUPP COMPANY

HAPCO

HODEL, JIM INC.

HUSKY FARM EQUIPMENT LTD.

HYDRO ENGINEERING INC.

IMPERIAL INDUSTRIES INC.

ITT WATER AND WASTEWATER

GEA HOULE INC.

JBS LTD. (J. BOND & SONS LTD.)

KOOLMEES MARINE INDUSTRIAL SALES, SERVICE

LAKESIDE SYSTEMS, INC.

MCLANAHAN CORPORATION

NEBRASKA HARVESTORE SYSTEMS

NUHN INDUSTIRES LTD.

PARMA COMPANY

PATZ CORPORATION

PIONEER PUMP, INC.

PRO-ACT BIOTECH

PUCK CUSTOM ENTERPRISES, INC.

REMOTE LOAD, INC.

SILO’S R US INC.

SIOUX AUTOMATION CENTER INC.

SRS CRISAFULLI INC.

UNITED LIVESTOCK SYSTEMS

VANDEN BUSSCHE IRRIGATION

VAUGHAN COMPANY INC.

WELLMAN SERVICE

WILDFIRE GROUP

WOODALL FARMS

ZOSKE’S SALES & SERVICE

RESEARCHERS

ATD WASTE SYSTEMS INC.

DGH ENGINEERING LTD.

UNIVERSITY OF WISCONSON

SAFETY EQUIPMENT

AGRI DRAIN CORPORATION

DRAEGER SAFETY INC.

SEPARATORS

ACCENT MANUFACTURING INC.

AGPRO®, INC.

ALBERS MANURE HANDLING

SYSTEMS INC.

BALLAGH LIQUID TECHNOLOGIES INC.

BAMBAUER EQUIPMENT LLC.

BAUER NORTH AMERICA/ FAN SEPARATOR

BRAUN ELECTRIC INC.

CADY INC.

CAWI CANADA LTD.

DODA U.S.A. INC.

DON THEMM ENTERPRISES, INC.

FARMER AUTOMATIC

HYDRO ENGINEERING INC.

HYDROCAL INC.

GEA HOULE INC.

LAKESIDE SYSTEMS, INC.

LSC PRE-CAST SYSTEMS (CANADA) LTD

MCLANAHAN CORPORATION

NEBRASKA HARVESTORE SYSTEMS

PARKSON CORPORATION

PRO-ACT BIOTECH

SILO’S R US INC.

STREAMSIDE SYSTEMS

TRIPLE/S DYNAMICS

UNITED LIVESTOCK SYSTEMS

VINCENT CORP.

WELLMAN SERVICE

WOODALL FARMS

SPREADERS

ALLIANCE TIRE USA

BALLAGH LIQUID TECHNOLOGIES INC.

BALZER, INC.

BAMBAUER EQUIPMENT LLC.

BRAUN ELECTRIC INC.

CADY INC.

CLAAS OF AMERICA INC.

DFK EQUIPMENT SALES, INC.

DM MACHINERY INC.

GLOBAL REPAIR

HIGHWAY EQUIPMENT COMPANY

HODEL, JIM INC.

HUSKY FARM EQUIPMENT LTD.

IMPERIAL INDUSTRIES INC.

GEA HOULE INC.

JBS LTD. (J. BOND & SONS LTD.)

KOOLMEES MARINE INDUSTRIAL SALES, SERVICE

LEON’S MFG. COMPANY INC.

LOEWEN WELDING LTD.

LYNDEN BRIM TRACTOR

MEYER MANUFACTURING CORP.

MICHELIN NORTH AMERICA

MMI INTERNATIONAL

NEBRASKA HARVESTORE SYSTEMS

NUHN INDUSTIRES LTD.

PARMA COMPANY

PEQUEA MACHINE, INC.

ROTO-MIX LLC

SILO’S R US INC.

SIOUX AUTOMATION CENTER INC.

WEST POINT DESIGN INC./ SPREAD ALL

WOODALL FARMS

ZOSKE’S SALES & SERVICE

STORAGE LAGOONS

AGPROFESSIONALS, LLC

BRAUN ELECTRIC INC.

CANAMER SERVICES INC.

FIRESTONE SPECIALTY PRODUCTS

HAPCO

LAYFIELD GEOSYNTHETICS & INDUSTRIAL FABRICS LTD.

LSC PRE-CAST SYSTEMS (CANADA) LTD

MPC CONTAINMENT

INTERNATIONAL

PRO-ACT BIOTECH

SAMSON ENGINEERING, INC.

WEST TECHNOLOGY SYSTEMS, INC.

WOODALL FARMS

YUNKER PLASTICS, INC.

TANK SYSTEMS

BALLAGH LIQUID

TECHNOLOGIES INC.

BALZER, INC.

BAMBAUER EQUIPMENT LLC.

BOERGER, LLC

CADY INC.

CANAMER SERVICES INC.

CLAAS OF AMERICA INC.

SLURRYSTORE - ENGINEERED

STORAGE PRODUCTS CO.

ENVIRONETICS INC.

IMPERIAL INDUSTRIES INC.

JAMESWAY FARM EQUIPMENT

LAKESIDE SYSTEMS, INC.

LSC PRE-CAST SYSTEMS (CANADA) LTD

NEBRASKA HARVESTORE SYSTEMS

OCTAFORM SYSTEMS INC.

PRO-ACT BIOTECH

SILO’S R US INC.

UNITED LIVESTOCK SYSTEMS

WELLMAN SERVICE

WOODALL FARMS

ZOSKE’S SALES & SERVICE

TRAILERS

ALLIANCE TIRE USA

BALLAGH LIQUID TECHNOLOGIES INC.

CADMAN POWER EQUIPMENT

CLAAS OF AMERICA INC.

DFK EQUIPMENT SALES, INC.

HODEL, JIM INC.

HUSKY FARM EQUIPMENT LTD.

KOOLMEES MARINE INDUSTRIAL SALES, SERVICE

NUHN INDUSTIRES LTD.

PARMA COMPANY

PEQUEA MACHINE, INC.

PUCK CUSTOM ENTERPRISES, INC.

VEENHUIS MACHINES B.V.

WOODALL FARMS

BAZOOKA FARMSTAR, INC.

ZOSKE’S SALES & SERVICE

WASTE WATER TREATMENT

ATD WASTE SYSTEMS INC.

ADVANCED AERATION, INC.

AEROMIX

AGPROFESSIONALS, LLC

AGRI -WASTE TECHNOLOGY INC.

BALLAGH LIQUID TECHNOLOGIES INC.

CADY INC.

CANAMER SERVICES INC. DODA

U.S.A. INC.

SLURRYSTORE - ENGINEERED STORAGE PRODUCTS CO.

ENVIRONETICS INC.

FIRESTONE SPECIALTY PRODUCTS

GHD, INC.

HYDROCAL INC.

ITT WATER AND WASTEWATER LAKESIDE SYSTEMS, INC.

LSC PRE-CAST SYSTEMS (CANADA) LTD

PRO-ACT BIOTECH

SAMSON ENGINEERING, INC.

SHAC ENVIRONMENTAL PRODUCTS

SPARTAN CHEMICAL

TEN CATE GEOTUBE

UNITED LIVESTOCK SYSTEMS

WOODALL FARMS