MARCH/APRIL 2015

MARCH/APRIL 2015

DAIRY BIOGAS HELPS UTILITY MEET GOAL

March/April 2015

Volume 13 • No. 2

Published by:

Annex Publishing & Printing Inc.

P.O. Box 530 Simcoe, Ontario N3Y 4N5

Editor

Margaret Land • (519) 429-5190, (888) 599-2228, ext 269 mland@annexweb.com

Contributing Editors

Matt Dickinson, Tony Kryzanowski, Diane Mettler, Douglas Renk, David Schmidt, Steven Sell, Jason Vance

Advertising Manager

Sharon Kauk • (519) 429-5189, (888) 599-2228, ext 242 skauk@annexweb.com

Account Coordinator

Mary Burnie • (519) 429-5175, (888) 599-2228, ext 234 mburnie@annexweb.com

Media Designer Emily Sun

VP Production/Group Publisher Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: subscribe@manuremanager.com

Printed in Canada

Circulation

e-mail: subscribe@manuremanager.com

Tel: 866-790-6070 ext. 211

Fax: 877-624-1940

Mail: P.O. Box 530 Simcoe, ON N3Y 4N5

Subscription Rates

Canadian Subscriptions

$35.24 Cdn, one year (with GST $37.00, with HST/QST $39.82)

U.S. Subscriptions: $47.00 USD, one year

Occasionally, Manure Manager will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher's written permission. ©2015 Annex Publishing and Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher's approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Website: www.manuremanager.com

By Margaret Land

Keeping abreast of the latest legal happenings involving manure application and nutrient management in the U.S. is enough to give a person a migraine.

In late December 2014, the Wisconsin Supreme Court released a decision that had many livestock farmers scrambling to review insurance policies. The court reversed a past decision in a case involving a dairy producer and an insurance company. In the court’s decision, manure that contaminates a well is a pollutant and not covered under a farm’s general liability insurance policy.

With this ”precedent setting” ruling, many livestock operations in Wisconsin who relied on a standard liability policy were suddenly left without coverage for claims involving well contamination from manure. And law firms across the state were quickly contacting their agricultural clients, urging them to review their insurance policies.

“It is critical that you evaluate how your policy defines a ‘pollutant,’ how policy exclusions would apply to your operation, and whether you have additional coverage (such as specialized pollution coverage) that may be able to provide insurance coverage for damage caused by manure,” stated law firm Michael Best & Friedrich in an alert to clients.

A few weeks later, the U.S. District Court for the Eastern District of Washington ruled that manure from a Yakima Valley dairy should be treated as a solid waste under the Resource Conservation and Recovery Act. It was the first time the act had ever been applied to land applied manure.

According to Christopher Bryant, a lawyer with Bergeson & Campbell, P.C., a Washington, DC, law firm, the court found that manure can be considered a solid waste under the RCRA if it is applied to the land without regard for the nutritional needs of the crop or stored in such a way that results in release of the manure to the environment.

“The case could have major implications for concentrated animal feeding operations as it would subject certain manure applications to regulation as solid waste,” Bryant stated in an opinion piece on the ruling. “Given the resounding implications of this decision, it is almost a certainty that industry groups will appeal the decision and seek to have it reviewed by the U.S. Court of Appeals for the 9th Circuit. If the Appeals Court upholds the ruling, it could force CAFO operators that do not have Clean Water Act permits to seek such permits or to ensure that their surface impoundments meet RCRA regulations.”

On top of this, state and local legislators in Iowa, Ohio, and Wisconsin are grappling to pass bills that would see a tightening of manure application laws while, in some cases, cutting budgets to programs that help farmers and the environment. While the iron fist brandishes its legislative stick, the carrot is being removed.

Farming has never been a career choice for those slow to adapt. But it would seem these recent legal decisions mean operators might have to add paralegal and state lobbyist to their already crammed skill sets.

NOTE: The January/February 2015 issue of Manure Manager featured a stunning photo supplied by Prestige Air Photo in the Western Feedlots feature on pages 6 to 10. I’d like to thank them for allowing us to use the image.

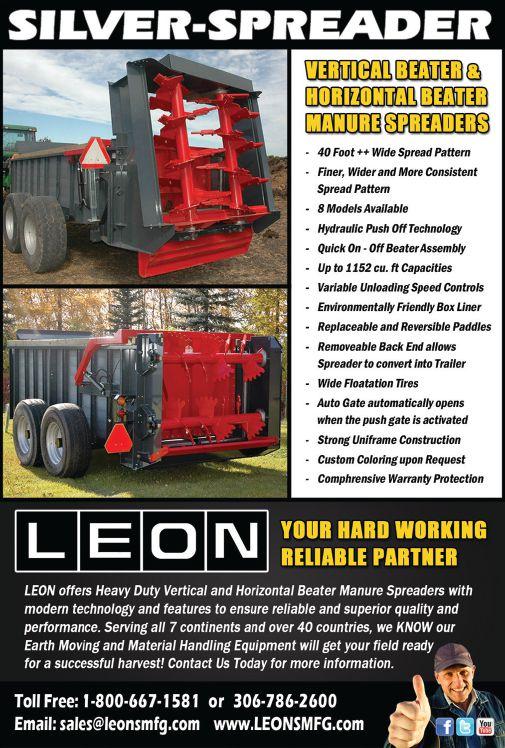

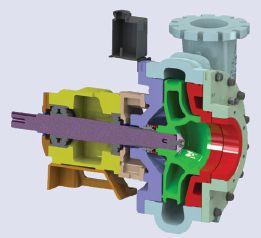

The PUMPELLER® Hybrid Turbine revolutionizes manure pump performance. Incredible intake suction pulls solids into the cutter knives, reducing the toughest crust to nothing in just seconds. The turbine combines the high-volume mixing of a propeller agitator with the power and reach of a lagoon pump, the resulting hybrid design radically outperforms both.

for professional

Jamesway’s new MAXX-TRAC tankers deliver maximum performance.

By Tony Kryzanowski

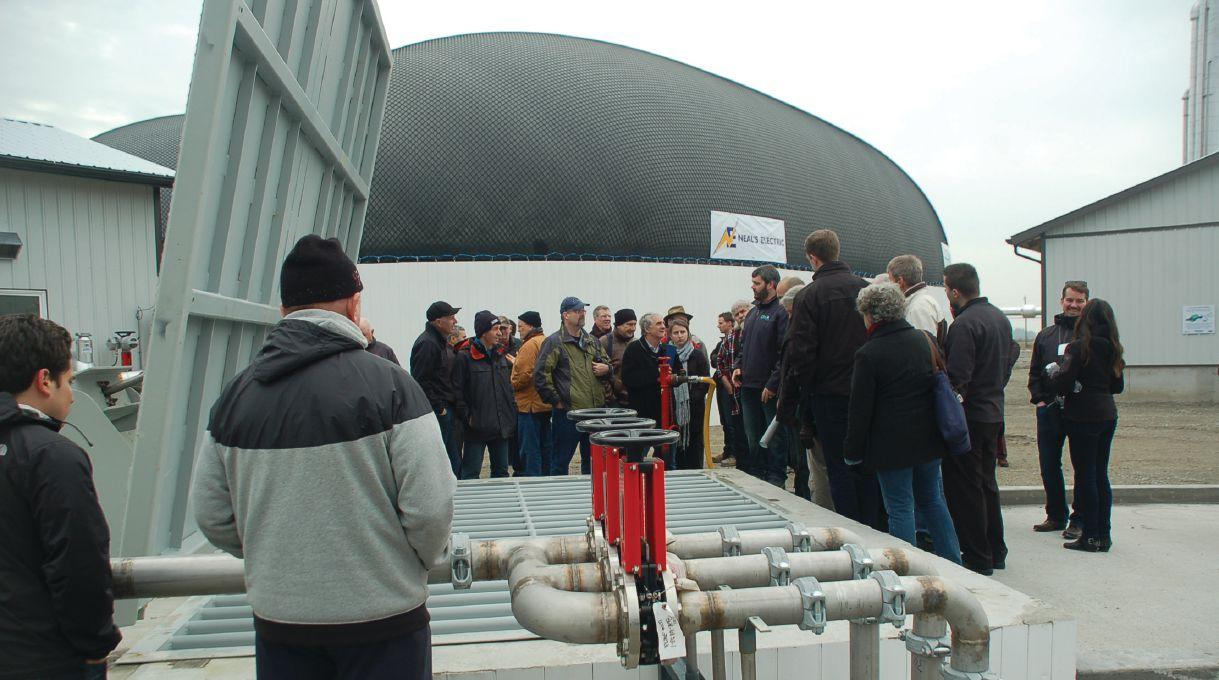

Biogas-generated power from four Michigan dairies chosen to help utility meet green energy goal

Four Michigan dairies have been chosen to supply renewable power to Consumers Energy, using biogas fuel harvested from anaerobic digestion of their manure. While three of the farms already have digesters installed, one is spending more than $8 million to install a new manure processing, biogas production and renewable power facility.

Michigan passed a law in 2008 requiring Consumers Energy, Michigan’s largest, privately owned power utility, to generate 10 percent of its power from

renewable sources by the end of this year. To meet that goal, it launched it Experimental Advanced Renewables Program (EARP) in 2010, with the goal of purchasing renewable energy from a variety of sources.

Anaerobic digestion is a biological process where raw manure is fed into large concrete tanks and mixed with water in an oxygen-free environment. The manure is mixed for a specified number of days at a set temperature, allowing bacteria to break down the raw material, producing methane gas that rises in the tank, which is then harvested and burned as fuel in an engine that drives a power turbine.

Beaver Creek Farms, located new Coopersville, Mich., has chosen Sustainable Partners LLC (Spart) to build an anaerobic digester and biogas power system at its over 3,000 head dairy. The installation will produce 1.4 megawatts (MWs) of power.

“We have been interested in a

digester for a long time,” says Bill Henke, Beaver Creek Farms owner. “It just finally made sense when Consumers opened up the EARP with a reasonable price for purchasing power.”

The dairy generates about 100,000 gallons of manure per day.

Michigan has about 2,650 dairies.

Greg Northrup, Spart’s co-owner, says that, “every one of the 100 largest dairies in Michigan could be producing power.” However, the challenge to this point seems to have been the rate that power utilities have been willing to pay for the generation of that power.

In addition to dairy manure, which Northrup says will supply the digester on the Beaver Creek Farms location with, “a constant supply of feedstock which allows the plant to produce energy 24/7, 365 days a year,” the digester will also process fats, oils and greases from restaurant grease traps.

“Biogas projects also generate valuable renewable energy credits and carbon

credits which can be used by third parties to achieve regulatory compliance,” says Northrup.

Henke says the anaerobic digester on Beaver Creek Farms will generate extra cash and help with manure management.

“We reduce our volume of manure since some of it is consumed in the digester,” he says, “and there are other things like the potential use of the solid output of the digester to bed cows and just the general reduction in the hassles of manure management.”

Other benefits to sending the manure to the digester are that the farm retains the nutrients for land application, “but loses the odor,” Henke says.

He and Spart plan to partner in a new company that will own and operate the biogas and power production facility and intend to break ground on the Beaver Creek Farms digester in June. They plan to apply for a $500,000 grant available for these types of projects through the United States Department of Agriculture. Participants in EARP have two years from

their notice to construct their system and begin generating electricity to achieve their Commercial Operation Date (COD). Once that is reached, they can begin to make money from the power they generate. Of the 1.4 MWs produced at Beaver Creek, 400 kWs will be used by the dairy and to operate the digester system, while 1 MW will be sold to Consumers Energy.

“The addition of anaerobic digestion brings more diversity to our existing renewable energy supply from wind, solar, biomass and hydroelectric dams,” says Timothy Sparks, Consumers Energy’s vice-president of energy supply operations.

Brian Wheeler, Consumers Energy spokesman, says what EARP offers the four selected dairies is greater certainty of income by locking in the price they will receive over the life of each power purchase agreement (PPA), adding that the company decided to engage with the agriculture industry because it is the second largest industry in Michigan with plenty of opportunity for biogas production build

out. A total 2.6 MWs will be purchased from the dairy farms under Consumers Energy’s EARP. The power generated is estimated to be enough to supply 2,800 homes.

Besides Beaver Creek Farms, the other three dairies chosen to participate in EARP were Brook View Dairy in Freeport, Green Meadow Farms Inc. in Elsie, and Scenic View Dairy in Fenneville. Some already have experience selling power generated by their anaerobic digesters to the power company.

Consumers Energy offered program participants two rate options when applying for the program. The first is what the company calls a ‘levelized’ rate that will pay $86 per MW/hour for the full 20-year term of the PPA it has with the dairies. The second option is a rate payment schedule that will allow participants to specify the term of their PPA to be between 10 and 20 years. Three of the dairies opted for a 20-year PPA, and one a 10 year PPA.

Consumers Energy officials say the company developed its EARP in consul-

tation with Michigan State University and the agriculture community. The university helped with the dairy selection process and it provided resources to help project developers perform an initial screening of potential projects to determine if further investigation was warranted. This was accomplished with the use of two evaluation tools. One was the Michigan Waste Biomass Inventory, which helped developers locate potential feedstocks for their proposed digesters, and the second was the Anaerobic Digestion Development Iterative Tool (ADDIT), which assisted in the screening of different digester parameters.

The Green Meadow Farms dairy in Elsie is one of the largest dairy farms in Michigan. It’s owned by Velmar and Margaret Green, and their children: son, Craig, and his wife, Darcy, and daughter. Margie. They manage 9,500 head of cattle and farm 6,500 acres, and have a close relationship with Michigan State University. Their dairy is home to the university’s Training Center for Dairy Professionals.

“Before, we were selling electricity to Consumers Energy off of the board price,” says Darcy Green. “This new program sets the price at a higher, more stable level.”

The dairy has developed a complex system for treating manure that starts with using six MacLanahan sand-manure separators to separate the sand bedding from the raw manure collected from barns on two farms. After separation, the manure is either land injected or treated with ferric chloride and a polymer. The ferric chloride neutralizes the manure’s pH and the polymer binds the nutrients

together. A belt filter press separates the solids from the liquids from this mixture, resulting in two products – clear water that is recycled to flush parlor floors and to separate sand from the manure, and a fibre cake that is land applied as a fertilizer or composted by a third party company called Morgan Composting.

The dairy added a methane digester in 2006 through a project with Michigan State University’s Department of BioSystems & Agricultural Engineering. It was part of a study investigating how to create methane at a dairy that uses sand bedding. All the raw manure previously destined for the treatment plant is now processed through the anaerobic digester before it is sent to the treatment plant. According to the dairy, this reduces the amount of ferric chloride added to the solid by-product.

The Green Meadow Farms anaerobic digester consists of three tanks, each capable of holding 900,000 gallons of manure. The biogas produced by the digester is burned in a Caterpillar V16 engine that powers a generator capable of producing 800 kW per hour.

Scenic View Dairy and Brook View Dairy are sister dairies run by various members of the Geerlings family. Both are located about an hour from Grand Rapids, Mich.

Scenic View Dairy milks about 1,900 cows with an additional 1,500 dry cows and heifers. Its $3.2 million anaerobic digester consists of a three-tank system, which began producing power in 2006. The dairy generates about 28 million gallons of manure per year.

Brook View Dairy milks 2,200 cows,

with an additional 1,000 dry cows and heifers. Its anaerobic digester was installed in 2008, consisting of three digester tanks, each with a holding capacity of 930,000 gallons. The dairy generates about 24 million gallons of manure per year.

In addition to dairy and heifer manure, the digesters also process syrup stillage, waste produce, fats, oils and greases. The biogas generated by the digester at Brook View is burned in two Caterpillar G3516 co-generation engines, each capable of generating 800 kWs per hour.

The spent digestate from the tanks is processed through FAN separators, creating a liquid and a solid stream. The nutrient-rich liquids are land applied as fertilizer and the pathogen-free solid stream is used for animal beddings both on and off the dairy site.

Andy Austin, anaerobic digester manager for both dairies, says they were already marketing their power under contract to Consumers Energy at about the same rate as is being offered under EARP. What participation in EARP provides them is a guaranteed market for their power for the next 20 years. Having that market was a concern as their PPA with Consumers Energy was expiring at the end of this year.

Both the Scenic View and Brook View dairies also sell carbon offsets generated from diverting their farm manure through the digestion process and creating biogas to generate renewable power rather than simply land applying it. This has created another income stream for the dairies, which has helped to offset the cost of the digester installations.

Put nutrients where they belong with a combination GEA Slope Screen and AGM Decanter system. Together, the system effectively dewaters manure. Screened solids can be dried and used for bedding. Solids produced by the decanter are nutrient-rich and can be used for compost or spread on fields. Recovered liquid can be stored in a lagoon or applied directly to the fields. And since phosphorus levels in the liquid are lower, it can often be sprayed at a higher rate per acre.

The process starts with a Slope Screen that removes large material from the manure. After this, the remaining liquid-solid mixture runs through a high speed AGM Decanter that automatically adjusts to different flow rates and solid levels. With almost all the solids removed, the remaining liquid is much cleaner.

Efficient and cost-effective, the equipment can be used with or without an anaerobic digester.

Learn how GEA can help you improve and add value to your manure management program. Call 800-563-4685 or email geahoule@gea.com.

Toll-Free: 800-563-4685 www.gea.com

By Tony Kryzanowski

It’s been in the works for about a decade, but North American and international patents have been issued to Himark BioGas International for its unique technology, noted for its ability to use high solids feedstock like open-pen feedlot manure to produce biogas through anaerobic digestion.

Developed initially through the Alberta Research Council, it was refined and commercialized by Himark through further research at a working feedlot, biogas and ethanol production facility near Vegreville, Alberta. It later was marketed and demonstrated successful on a much larger commercial scale at a feedlot, biogas, and ethanol facility in Kansas.

Patents have been issued for Himark’s High Solids Infeed System (HiSIS) for handling and processing mixed waste and its Clean Slate anaerobic tank grit removal system.

“It’s part of our strategy to protect the core intellectual property that makes our system work better than anybody else’s,” says Trevor Nickel, Himark general manager. “We’ve been very careful to try to broadly protect our patents as much as possible.”

He adds that obtaining these patents is a major achievement for Himark because of the protection it affords the company and because it can now be more open with its technology, especially in important markets like the United States.

“The United States is big market place, 10 times the size of Canada,” says Nickel. “So, just on the numbers alone, we couldn’t ignore the U.S. As it has turned out, we have had very good success marketing our technology into the United States. There is a high demand for it, and there are a number of programs that have made anaerobic digestion uptake faster and easier in the States.”

They are currently building three projects in the half to one megawatt, biogas-fueled, electricity production scale for NEO Energy in Massachusetts and Rhode Island. In this case, they are using food waste and agricultural by-products as the raw material, converting it to biogas and organic fertilizer byproducts.

Nickel says Himark can now more

openly show potential clients “how our system ticks,” with less concern about revealing too much. It will allow potential clients to independently assess the engineering of the system, which will give them the confidence that the system works as advertised.

Having this ability should result in greater market penetration of the technology and greater uptake of licensing. It will also help clients arrange for financing. Now, clients can approach financial institutions stating their intention to purchase the rights for this patented technology, which gives financial institutions more confidence in what they are being asked to finance.

Nickel says that Himark has a number of projects on the front burner related to applying its technology with cattle feedlot manure being the main feedstock.

“We’re definitely the world leader in dealing with open-pen feedlot manure,” he says. What the company has noticed is not so much interest from feedlot owners themselves because of financial constraints. Where Himark is attracting considerable interest is from renewable energy investors that see the opportunity of using open-pen manure as a large source of the raw material needed to produce biogas for renewable energy production.

When Himark first started refining the technology about 10 years ago, they discovered many biogas production challenges and in some cases, anaerobic digester failures, when solid feedstock material, such as material from open-pen feedlots was being fed into digester tanks. They noticed that many of the prevailing technologies resulted in considerable solid build up in the tanks over time. Given that several of Himark’s company directors also operate a feedlot, they recognized a potential business opportunity if they could develop a system that focused specifically on addressing the issue of solids management before the raw material enters the tank as well as continuous removal of solid build up within the tank.

Removal of solid and indigestible material such as sand, rocks, plastic and metal prior to it entering the digester using the HiSIS system is important for two reasons. First, the materials can interfere with mechanical, chemical and biological processes in the anaerobic digester. Second, solids can build up in the anaerobic digestion tanks.

In addition to the HiSIS deterrent system on the front end, Himark’s Clean Slate technology takes the matter of handling solids a step further. It removes

Manure from open-pen feedlots can contain anything from rocks, to cement, to sand and plastic. Himark Biogas has earned patents for two of its technologies to manage these undigestibles before they enter anaerobic digestion tanks and before they begin to accumulate within the tanks. Contributed photo

indigestible solids and inorganic foreign objects settled on the tank floor during the production of methane-rich biogas. What Clean Slate provides is continuous production from using open-pen feedlot manure without the expensive and inconvenient need to shut down the anaerobic digestion tanks and clean them out.

Nickel says this dual ability of the Himark system is really what makes the company’s technology unique in the world and why the company put such a priority on obtaining patent protection for its system. He adds that not only is there an opportunity among open-pen feedlot operators for the use of this technology, but also in municipal waste systems where there is a lot of solid material in the raw waste stream.

Patents for the HiSIS and Clean Slate systems also permit the company to more aggressively promote its hybrid anaerobic digester approach, which delivers the best of both a wet and dry anaerobic digester

system. Wet systems produce biogas using feedstock with high liquid content, but they have historically had difficulty dealing with feedstock with high solids content. A dry system produces biogas from drier feedstock, but those systems tend to have an overall lower biogas yield than a wet digester. Himark’s hybrid approach proposes to deliver high-energy yield comparable to a wet digester system but with the ability to process drier feedstock through its now patented material management systems.

“Small footprint, high throughput, high output, and low water use – all of those things are possible in a Himark hybrid digester,” says Nickel.

In addition to the United States, Himark has identified several high priority markets for its technology. They look for growing economies where there are poorly developed waste management systems.

• Center agitation system evenly blends nutrients.

• Better utilization of “waste” translates into less purchased fertilizer.

• Designed and constructed using bolted glass-fused-to-steel panels for secure storage and high corrosion resistance.

• Above ground - minimizes the danger of run-off, leaching and ground water contamination.

• Environment-friendly odor control - releases odors above ground level into higher air currents.

Visit www.cstindustries.com to find your local dealer, or call 815-756-1551.

There’s been a lot of talk about food and farming lately – online, in the media and at the dinner table.

That’s a really good thing. It means people are concerned about their health and wellbeing, and that they’re in a position to make positive choices about what they eat. It also spells opportunity for Canada’s agriculture industry. What we do has never been so important to so many people here at home and around the world.

Unfortunately, too many of these conversations are generating false perceptions about what we produce and how we produce it. That’s often because for all the people talking about food, too few are actually part of the agriculture industry. And if we’re not telling our story, someone else will. The good news is, it’s not too late – and we’ve got lots of positive news to share.

Canadian agriculture is remarkably diverse and dynamic. Yet for all the change

the industry has seen over the years, one important constant remains: the family farm. In fact, 98 per cent of Canadian farms are family farms. That’s a key part of the conversation, because from the ground up, what we eat every day is produced by people who want the same things all families want: safe, nutritious food. Those same values also extend to how our food is produced. Canadian farms produce more than ever in ways that are more sustainable than ever. What a great legacy for future generations!

You’re

an important part of the conversation. So speak up – tell the real story.

Canadian agriculture has a lot going for it, and sharing the facts is a great way to join the conversation. Our resource section is filled with timely, interesting content – including dozens of easy-to-share fact photos. And each one tells an important story. Here are just a few:

Canada’s opportunity: world food demand is set to grow 60% by 2050

Source: CropLife

Canada

The world is growing, and everyone deserves to have access to safe, high quality food. It’s a huge responsibility and an incredible opportunity for Canadian agriculture. Canadian farmers are responding by producing more food than ever, all while using fewer resources. That’s good news here at home and around the world.

56,000

Thanks to Canada’s ag and food industry, more than 2.2 million Canadians are bringing home the bacon (pardon the pun) every day. That’s like the entire population of Vancouver. The impact on Canada’s economy, and on our communities and families, is truly remarkable.

Never has Canadian agriculture offered more – and more diverse – career options than right now. There are opportunities in research, manufacturing, financial services, marketing and trade, education and training, and more. And all of these positions need to be filled by talented, energetic people. Visit the website and consider what the facts mean to you. Then join the conversation! AgMoreThanEver.ca

Joining the ag and food conversation isn’t always easy. What you say is important. So is how you say it. If you’re feeling a little unsure about what to do next, you’re definitely not alone. Fortunately, we’ve got practical expert advice to help you become an effective agvocate.

Our online webinar series brings recognized experts in communication, social media and media relations right to your screen. Topics include:

• The art and science of the ag and food conversation

• Social media 101 for agvocates

• Getting in on the tough conversations

• Working with the media as an agvocate

Visit AgMoreThanEver.ca and click on Ag Conversations.

Looking to channel your passion for ag? Adding your name to our agvocate list is a great way to get started. You’ll join a community of like-minded people and receive an email from us every month, with agvocate tips to help you speak up for the industry.

Visit AgMoreThanEver.ca/agvocates to join.

“ The natural environment is critical to farmers – we depend on soil and water for the production of food. But we also live on our farms, so it’s essential that we act as responsible stewards.”

- Doug Chorney, Manitoba

“ We take pride in knowing we would feel safe consuming any of the crops we sell. If we would not use it ourselves it does not go to market.”

- Katelyn Duncan, Saskatchewan

“ The welfare of my animals is one of my highest priorities. If I don’t give my cows a high quality of life they won’t grow up to be great cows.”

- Andrew Campbell, Ontario

Safe food; animal welfare; sustainability; people care deeply about these things when they make food choices. And all of us in the agriculture industry care deeply about them too. But sometimes the general public doesn’t see it that way. Why? Because, for the most part, we’re not telling them our story and, too often, someone outside the industry is.

The journey from farm to table is a conversation we need to make sure we’re a part of. So let’s talk about it, together.

Visit AgMoreThanEver.ca to discover how you can help improve and create realistic perceptions of Canadian ag.

By Diane Mettler

Cornerstone Renewables, a group of primarily dairies with anaerobic digesters, teams together to have a bigger presence in Ontario

For farmers trying to procure offfarm feedstock, it can be a time consuming process. Also, once the feedstock has been procured, its availability and pricing can turn out to be unstable. What’s a farmer to do? Enter, Cornerstone Renewables, a group of Ontario digester operators (primarily farmers), acting as one voice to secure volume and pricing.

idea

Travis Woolings, general manager of Cornerstone Renewables, describes the group and its formation. “These are farms that generally have built digesters within the last five to 10 years. They didn’t want to be competing against each other

anymore, and felt one voice would give them a lot more stability in pricing. They felt it would offer a much better solution to the producers of the waste. When the opportunity came up for me to work with them and that sort of sped things up.”

Travis previously worked with other waste companies developing compost markets, ag based solutions and other projects involving waste. That business development knowledge, as well as knowledge of the industry, is part of what Travis brought to Cornerstone. When the operators discussed the idea with him he says: “I laid awake for a couple nights thinking this is an amazing idea.”

The idea was simple. Cornerstone would provide a solution for waste producers in the province – diverting their organics away from landfills. The farms would get a stable feedstock for their digester; they could create methane gas, which they would use to generate electricity to be fed back into the grid. Lastly, the digestate from digesters is a rich in nutrients and could be applied to their crops, improving soil and saving on commercial fertilizers.

“It was a quadruple win,” says Travis.

When the 10 operators decided to move forward, they hired an outside consultant to help put together their thoughts and ideas. The consultant helped structure the company and its goals.

“On a structural side, the company has ten board members, and one additional member in the University of Guelph,” explains Travis. “It’s run, however, through an executive committee as well, where we have four executive members – a chair, a treasurer, and then two other individuals that have their own roll within the executive committee. The executive and I talk and meet regularly to discuss results, goals, and the happenings within the industry and then we meet as an entire group every quarter. It’s a very well thought out structure. And everyone has skin in the game, which makes a big difference.”

Of the 11 Cornerstone sites, nine are on-farm anaerobic digesters, ranging from 250 to 800 kW. And two are what Travis call merchant sites –commercial sites that can process up to 70,000 tons per year each. These sites also have certificates of approval allowing them to take

more diverse feedstocks.

Geographically, they lie as far west as Windsor and as far east as Belleville. The remainder is located around the Kitchener/Cambridge/Waterloo area.

Another unique aspect of Cornerstone’s future has to do with one of its members – the University of Guelph Ridgetown Campus anaerobic digester.

The university site is quite small, and is more of a research facility, which provides added benefits to Cornerstone. Travis says it’s a mutually beneficial. The university gets a steady supply of feedstock and Cornerstone can market the university’s involvement.

The company celebrated its one-year anniversary on January 1, 2015. In that year, Cornerstone has experienced amazing results.

The group, as a whole, has the capacity to process approximately 220,000 annually. When Cornerstone launched, the members were processing less than 50 percent of their capacity. “Now as a group, we’re at around 75 percent. We’ve

grown tremendously and we did that without cannibalizing volumes away from out other sites.”

He adds it’s not all about volume though.

“We can be at 75 percent of our volume, but we could be 90 percent of our electricity. There’s a difference. So you can have low volumes, but high-energy feedstock. So from a production standpoint, we’re a good 75 percent average, and that’s probably a little conservative.”

The increase in volume is credited to the group’s ability to manage the incoming feedstock better between group members. But also the growth is due to that “single voice.”

“As a small farm, when you approach a large company and say, ‘I’d like your grocery store waste’, you’re looked at differently than when you approach them as a group called Cornerstone that has 11 locations across the province, servicing multiple stores. It’s a different pitch and you’re seen in a different light,” says Travis.

One of the largest challenges facing Cornerstone is the lack of knowledge in the marketplace and the need to educate

CORNERSTONE MEMBERS

The Ontario Cornerstone Renewables members include:

• Ben Gardiner Farms Kirkton, Ont.

• Woolwich Bio-En Elmira, Ont.

• Koskamp Family Farms Stratford, Ont.

• Birch Lawn Farms Atwood, Ont.

• Seacliff Energy Ltd. Leamington, Ont.

• Athlone Farms Tavistock, Ont.

• Marl Creek Elmira, Ont.

• Greenholm Power Ltd Embro, Ont.

• Clovermead Farms Ltd. Alma, Ont.

• Ridgeline Farms Stirling, Ont.

• University of Guelph Ridgetown Campus Anaerobic Digester Ridgetown, Ont.

Under current Ontario regulations, a farm can receive up to 10,000 tons per year of off farm waste according to Travis Woolings, general manager of Cornerstone Renewables. But some of the newer systems are able to take in up to 50 percent off farm waste. Contributed photo

the right people. And Travis has put 150,000 km on his truck this year going door to door, helping companies understand.

“For example, large companies don’t understand that if your waste is clean – there’s no packaging in it – we’ve got nine different sites that can handle that product for them. If you have dirty packaged waste, we have two other sites that can handle that.”

Also changing people’s behavior is difficult. It’s one thing to convince an upper manager or CEO that Cornerstone is a good, greener solution, but creating a new system where people change their habits and separate their waste, is more difficult, says Travis.

The logistics of getting the right waste to the right digester, and with the least amount of travel, can also become challenging.

A large part of the organic waste in Ontario comes from its urban centers, not ideally located next to a farm.

“We work with all kinds of different waste haulers and trucking companies,” says Travis. “But we also work with the waste producers to help them find solutions. We pride ourselves in being very hands on and flexible that way.”

In one instance, a Cornerstone member was able to suggest brining the waste in tote bins versus using large bulk loads in dump trailers or walk-in floor trailers or roll off bins. The unique solution not only allowed the company to find a greener solution for their waste but saved them considerable money as well.

“Because our operators are so hands on, they’re the ones that have been able to instigate these unique changes,” says Travis with pride.

Another challenge looming ahead is a good one – how to grow the company.

“I probably have no less than 10 sites in Ontario and more that would like to be a part of Cornerstone, and I’ve got some very strong interest in Eastern Canada as well,” says Travis.

To date, Cornerstone hasn’t brought any new members on board. The current members are a close group and they’re not only picky about who joins, but want to ensure certain goals are met before they go forward.

“Our sites are just basically, great big, enormous mechanical stomachs and we want to make sure those stomachs are full before you bring more on,” says Travis. “We definitely would like to add mores sites in Ontario and we’re considering outside the province too. We’re also looking into some unique niche markets that center around anaerobic digestion and gas. This year will be an interesting year. I believe we will be part of some very good change and innovation.”

In the meantime, the company is taking it slow. There are lots of farms that would be a good fit and ideas worth expanding on, but the group is exercising patience.

“You have to be controlled and calculated in your growth,” says Travis. “It’s the smart thing to do.”

And there are other elements to consider too, like changing regulations in the industry. For example, farm digesters are currently regulated under the nutrient management act, and are managed through their respective farm plans.

“Under the current set of regulations, a farm can receive, generally speaking, up to 10,000 tons per year of off farm waste,” explains Travis. “The new regulations have been changed and allow some of the newer systems to be able to take in up to 50 percent of off farm waste. So that’s a big game changer.”

Travis says he can’t speak for the group, but this incredible first year has filled him with pride and optimistically looking ahead.

“I’m extremely happy with the positive market presence that we have earned. We have gone from a group of individuals to a respected and go-to type of entity where many people are coming to us asking us for help, knowledge and advice. We’re quite happy with that.

“Personally, I feel very fortunate to be a part of this because I think it’s extremely innovative I look forward to making a lot more positive change within the industry. It’s a win-win for everybody. My children will benefit from the things that we’re doing. We’re creating a better environment and we’re creating a very sustainable solution for our clients.”

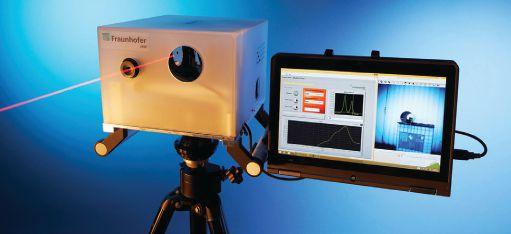

Researchers have developed a demonstrator that, without making contact, detects biogas or natural gas escaping from leaks through the use of a laser. Contributed photo

Servicing biogas plants is challenging. Methane leaks are particularly problematic – from a security, a technical, an economic as well as an environmentally friendly perspective. Researchers are working on a technique that helps to better detect leaks. In this process, a laser discovers the leaks from several meters away.

The requirements for the operation and maintenance of gas plants are high. Leakage is particularly problematic. Even small leaks from the joints of the gas lines or fermenters can have consequences. Escaping methane can result in fires, economic damage and a worsening of the carbon footprint of the gene-rated electricity.

In a project funded by the German Federal Ministry of Food and Agriculture (BMEL), researchers and a measuring equipment manufacturer are now addressing this issue. After 18 months, the experts have developed a demonstrator that, without making contact, detects biogas or natural gas escaping from leaks through the use of a laser.

The technology developed at the Fraunhofer Institute for Physical Measurement Techniques IPM in Freiburg, Germany, is based on optical emission and backscattering spectroscopy. In the process, the light of a strong laser beam detects escaping methane. Simultaneously, the gas irradiates part of the light back. The scientists analyze this proportion and determine the gas concentration from the absorption spectrum of the escaping substance. Since the gas spectrum is very precise, only methane is very selectively measured, and not any other gases. The technology is located in a box-shaped demonstrator. It stands on a three-legged tripod and is directed at the part of the equipment that is to be inspected. The optical portion of the measurement system comprises the laser, detector, camera and range finder. A connected tablet PC collects the data and evaluates it. The screen displays the graphically edited information concerning the escaping methane and the exact position of the leak. Measurements from up to 15 meters of distance are possible.

Dr. Johannes Herbst, measurement technology expert at the Fraunhofer IPM, expects the technology to be ready for the market in the next three to five years.

“In the future, the measurement team will be able to easily check the entire system from the ground. It used to be necessary to climb ladders and identify the leaks on the spot,“ said Herbst.

NT 460 with AutoLog ™ • Record keeping made simple • GPS and weight combine to verify manure applications

By Matt Dickinson

Anyone who works in B.C.’s poultry industry is aware that a creative, cost-effective disposal solution is required for the excess volumes of used poultry bedding accumulating from the more than 100 million chickens and turkeys produced annually.

Finding a way of turning this abundance of bedding into a valuable resource is even harder. But that was the goal of the BC Agriculture Research and Development Corporation (ARDCorp), BC Sustainable Poultry Farming Group (SPFG), Ritchie-Smith Feeds and Diacarbon Energy, who optimistically embarked on a trial to turn this material back into fodder.

Used poultry bedding has been used for centuries as a soil fertilizer. But only so much of the bedding can be used on the

land before the nutrients start leaching into the environment, becoming a risk rather than an asset. Transporting the bedding to other geographical locations is often uneconomical, so the bedding remains close to source. For the Lower Mainland, which raises close to 90 percent of B.C.’s poultry, the current nutrient surplus is a concern. The poultry sector’s quest for a viable alternative to the land application of bedding was the reason for this recent feed study.

In other parts of the world, some success has been achieved with turning used broiler bedding into biochar and adding it to broiler feed, thereby improving the broiler’s feed conversion and increasing final weight. Fueled by the success of others, ARDCorp, the SPFG and the Ministry of Agriculture hoped that through conducting their own experiment, they could create demand for roughly ten per cent of the used broiler bedding in the Lower Mainland; and, at the same time,

improve production.

Biochar is made by burning biomass material at extreme heats of more than 500 C in an oxygen-free environment. This process – called pyrolysis (thermochemical decomposition) – is a very effective disinfection technique, ensuring that the biochar is free of any possible pathogens. Once the biochar is made, this highly porous charcoal-like substance can be added to livestock feed to improve absorption of nutrients and aid in digestion.

For this study, used broiler bedding was taken from a commercial broiler barn in the Fraser Valley and dried before being delivered to Diacarbon’s pyrolysis unit in Agassiz, B.C. Once processed, the resulting biochar was transported to Ritchie-Smith Feeds in Abbotsford, B.C., where it was incorporated into commercial starter, grower and finisher broiler feed. The feed was delivered to S.J. Ritchie Research Farms Ltd in Abbotsford for a floor pen study.

Biochar is made by burning biomass material at extreme heats of more than 500 C in an oxygen-free environment. This process – called pyrolysis – is a very effective disinfection technique, ensuring that the biochar is free of any possible pathogens. Contributed photo

The study involved 288 broiler chicks arbitrarily placed into twenty-four specially constructed pens. The chicks in each pen were given feed supplemented with biochar or feed without biochar for 35 days. The broilers were weighed individually once weekly and the weights recorded. All feed was also weighed weekly and any feed remaining in the feeders was weighed back and replaced.

Unfortunately, the hoped-for outcomes of the study did not come to pass. The broilers did not show any perceptible improvements in feed conversion or increases in final weight.

The biochar feed study might have ruled out one opportunity, but it has opened doors for others. The main objective, after all, is to find sustainable ways of managing used broiler bedding. And if supplementing broiler feed with broiler bedding biochar did not work as expected, then the question should be: where can the industry look next?

Allen James, chair of ARDCorp, and a member of the SPFG hopes researchers can find a positive way to convert the poultry bedding into energy.

“As long as there’s an excess of bedding, we’ll be looking for a solution.” He is hopeful we will find a local solution to our local situation.

Other applications of biochar have proved successful, but perhaps not economically feasible for the Lower Mainland. Biochar has been used as a soil conditioner to improve water retention and nutrient density to aid in the growth of plants and increase yield. Biochar is also considered a superior growing medium in hydroponics, which is a rapidly growing technology. All of these areas could be expanded upon, creating financial opportunities for the poultry industry.

“Many studies have been done in the States,” explains James, “but none of them relate to B.C. and our particular situation. We’ll keep pressing on as long as the industry has this situation to deal with.”

For B.C., a new study is planned for this year to convert poultry litter into heat and electricity. This project could potentially have positive impacts on both the environment and animal waste management, and be one solution to how trash can be turned into treasure. The public will have to wait for the results to come in, and look forward to future projects, which will help to answer the burning question.

Matt Dickinson, MEM, is the renewable agri-energy program manager with the B.C. Agricultural Research and Development Corporation.

For more on Applications, visit www.manuremanager.com

By David Schmidt

From a cow comfort and cow health perspective, nothing beats sand for bedding. From a management perspective, however, sand has many significant challenges.

First, it is more expensive than sawdust, straw or composted manure. Second, it has no nutrient value so spreading it on the land is not an option. Besides, it is hard on manure spreading equipment and, later, harvesting equipment.

Many farmers use long settling channels to separate the sand from the manure. Not only does that require lots of land near the barn, but it is also difficult to reclaim the sand.

In recent years, several systems have been developed to separate sand from manure. Most use a lot of water and are therefore best suited to flush barns. So what can farmers with non-flush barns who still want to use sand do?

When Nelson Dinn, farm manager of the University of British Columbia Dairy Education and Research Centre in Agassiz, B.C., went looking for a sand separation system, he decided on the Daritech Sand Cannon manure separator system.

When Nelson Dinn, farm manager of the University of British Columbia Dairy Education and Research Centre in Agassiz, B.C., looked for a sand separation system to handle the slurry from the 400 animals on the farm, he had four requirements:

• it needed to minimize use of fresh water

• it needed to have a small footprint

• it had to be cost-effective

• it had to have no negative impact on cow health

After looking at systems across North America, he found the answer just across the border in Lynden, Wash: a Daritech Sand Cannon manure separator system.

The system is very water-efficient, primarily using the liquid from the slurry to operate, says Dinn, the only water added to the system is that used to wash the parlor.

“We want to store nutrients, not water,” he says, noting the only time they added extra water was one day when a fierce

wind “dried out the manure too much.”

The key to the system is a poly holding tank with three exit lines, two along the side at differing heights and one at the bottom. The liquid from the solids-liquid separator and the sand cannon are pumped into the tank, then removed through the exit lines after being given time to settle. The cleanest and clearest liquid accesses the highest exit line and is sent to an exterior holding tank. The liquid at the bottom, which contains any residue the separator has failed to remove, is re-circulated through the system. The liquid from the middle of the tank, which is free of residues but still dirty, is used to operate the sand cannon.

“The computer-controlled system only puts through as much new liquid slurry as is taken out of the holding tank,” Dinn explains.

To keep a solids-liquid separation system operating, the fiber screens in the separator need to be cleaned regularly. While most systems use water to do that, the Daritech system uses water

once every six cleanings. The other five cleanings are done with bursts of air.

Except for the external fluid holding tank, the entire system is housed in a structure smaller than an average silage bunker. That includes the sand cannon, the holding tank, the solids-liquid separator, holding areas for the sand and solid manure, the computer control system and a small settling channel to remove the fine sand.

“The sand cannon works best with coarser sand so we still use a settling channel to remove the fine sand. Because most of the sand has already been removed we only need a tiny settling channel,” Dinn says, adding the amount of fine sand in the system is steadily being reduced over time.

“After just three months of use, we are getting almost 80 percent sand recovery and I expect that to be over 90 percent in the next few months,” he states.

There are several cost benefits to the system. Removing all the sand before the solids are applied on the fields is “easier on farm equipment,” reducing maintenance and replacement costs. But the biggest benefit is the cost savings resulting from not having to bring in a lot of fresh sand.

“A 1,000-cow dairy in New York using the system has been able to reduce their annual sand requirements to just two truckloads,” Dinn notes.

He believes those savings gives the system a payback of “less than eight years.”

Dinn says reusing the sand has not had any negative impacts on cow health at UBC nor at any of the other sites he visited. He notes one of the Michigan farms he visited while checking out the system was recently included in Hoard’s Dairyman’s list of dairy farms with the lowest somatic cell count in the United States.

Although the technological complexity might put off some farmers, Dinn notes the system is run off a single, simple PLC (programmable logic control) panel. The PLC panel can be accessed remotely, meaning support staff can “tweak” it without a site visit.

Although not a factor in Dinn’s decision to go with the Daritech sand cannon separation system, there is an added benefit.

A few years ago, UBC scientists developed a nutrient recovery system to

remove phosphorus (struvite) from liquid manure. They recently built a pilot plant at Agassiz and say the liquid produced by the system is ideally suited for the recovery system.

“The clearer the liquid, the better it flows through our recovery system, explains UBC Department of Civil Engineering associate professor Jim Atwater, who is coordinating the struvite recovery project.

Farmers are anxiously awaiting results of that project as many fields in B.C.’s Fraser Valley are showing high

levels of phosphorous. Some areas in Europe already place a limit on manure applications based on their phosphorus content and the same could happen here in future.

As a next step, Atwater says the liquid output from his system, now minus its phosphorus, could feed an anaerobic digester.

“Separated liquid manure run through a struvite recovery system generates the best input for an AD and might even eliminate the need to add outside feedstuffs,” he says.

By Douglas Renk

Gas production and energy potential typically dominate the spotlight in the anaerobic digestion (AD) technology world, while benefits of residues and nutrient management from AD are overshadowed. However, utilizing AD residues and considering the value of properly managing nutrients, such as phosphorus, may makeor-break projects considered uneconomical based on energy production value alone.

Nutrient management benefits from digestion should be considered to help keep residuals on the positive side of the balance sheet. For example, agricultural waste management is typically not considered a profit center. Monetizing the benefits in terms of removal and cleanup cost or value as fertilizer is vital, but can be challenging. A full spectrum of valuable nutrients and minerals can be captured from AD residues, such as phosphorus (P).

Phosphorus is an essential element for all cellular growth and demand for it is growing in the U.S.; only 28 years of phosphate deposits remain in the U.S. assuming a two percent market growth, unless more recovery is developed. Still, until scarcity and increased production costs drive phosphorus prices higher,

incentives such as cost savings and reduced hauling are sought for implementing phosphorus recovery.

When compared to the aerobic organic treatment processes, anaerobic digestion retains nutrients throughout the process, transforming complex, organically bound phosphorus into a more biologically- available form.

The management of phosphorus levels post-digestion can save farmers time and cut hauling costs. Phosphorus levels in manure limit the allowable amount that can be applied in a season, and many soils are already at their maximum phosphorus levels. Manure may be applied to help meet the nitrogen needs of a crop growing in soils with concentrations up to 50 mg/kg of P; however, the P applied is not to exceed the amount taken up by the crops over a rotation cycle. If a field’s P levels exceed 100 mg/kg, then no P additions in manure or fertilizer are permitted. Nutrient planners encourage phosphorus removal from digestate slurries in these areas in efforts to allow more nitrogen requirements to be met by digestate, rather than supplementing nitrogen from other sources.

Controlled application is the key factor in proper nutrient management. Solid nutrient capture is valuable in reducing hauling costs, according to Sara Walling, section chief with Wisconsin DATCP Nutrient Management and Water Quality. For example, if

Fluidized bed crystallization-struvite

Dissolved Air Flotation/decanter

Phase separation/clarifier

Mechanical separation/centrifuge

Membrane separation

Polymer/belt press/dryer

Biological uptake-managed wetland or aquatic growth

a farmer pays a contractor one to two cents per gallon to haul and spread manure, the material could be separated into two streams where more concentrated material can be taken to further fields, while the lower concentration can be applied by drag-hose nearer the farm.

Although phosphorus and other nutrients are valuable to farmers, excess nutrients carried in wastewater pose a serious threat to waterways. Decades of management practice and regulatory efforts have been established to combat the growth of oxygen-depleting algae as a result of phosphorus runoff. Unfortunately, both prevention and recovery of nutrients from waterways is difficult and expensive. When watershed protection is mandated by regulatory compliance, nutrient recovery technology is deployed for concern of fines or operational shutdown. For example, phosphorus cleanup from a body of water can cost from $5/pound to $100/pound; the present nutrient market value is about $0.53/pound for phosphorus pentoxide (P2O5). It

is important to note that reduction of nutrients in discharge is not a linear function. The cost of reducing the first 90 percent of phosphorus in a waste stream may cost $5/pound, however, it may cost $50/pound to reach 90 to 99 percent reduction.

One method of meeting nutrient reduction requirements is through Nutrient Credit Trading (NCT) or Water Quality Trading, which focus greatly on phosphorus. NCT’s are earned by capture of nutrients from non- point sources by virtue of base conservation activities, such as strip farming, no-till farming, and contour farming. Capture techniques such as these can be as effective in nutrient planning as recovery of P from AD liquid and manures. With proper documentation, phosphorus removed from AD effluent can qualify for NCTs.

Some nutrient recovery techniques manipulate pH and require the addition of minerals to optimize recovery from the solution. Phosphorus recovery is aided by anaerobic digestion as the process converts and homogenizes inputs into more available form.

The management of organic material through anaerobic digestion has many offerings outside the gas and energy production. There are a multitude of uses for residues from anaerobic digestion: animal bedding, compost, fertilizer, fiber, and biochar to name a few; this material recovery component distinguishes renewable biogas from solar, wind and hydro energy. High product standards for residuals management enhance overall digester value and benefit sustainable agriculture by replacing depleted resources.

Douglas Renk is a biological commissioning engineer with BIOFerm Energy Systems

By David Schmidt

British Columbia dairy operation installs anaerobic digester, believing one day a cow’s manure could be worth as much as its milk

Can you change manure from a cost to manage to a prime revenue generator on the farm?

Jerry Keulen of Seabreeze Farms in Delta, B.C., not only believes you can but believes a day may come when a cow’s manure could be worth as much as its milk. That’s why Seabreeze has become the first commercial B.C. dairy farm to install an anaerobic digester.

After seeing digester’s on several European dairy farms, Keulen was convinced anaerobic digestion could address several issues for his farm:

• the additional income from

green waste tipping fees and from the gas being produced would help support the three families (Keulen and his two sons) who rely on the farm for their livelihood,

• it would process the manure so liquid could be reused to flush the barns and fiber reused as bedding for his 250-cow milking herd, thereby also reducing the amount of waste which needed to be spread on his 80-acre farm,

• it would reduce odors emanating from the farm, an important consideration for farmers in the urban shadow, and

• it could remove nutrients from the manure, thereby reducing the risk of nutrient overloading on the fields.

Seabreeze started pumping biomethane into the Fortis BC gas pipeline at the beginning of February but this was no overnight project. Planning began almost five years earlier and included a long, often “frustrating” process of obtaining approvals from government and the Agricultural Land Commission. Unique to B.C., the ALC’s mandate is to maintain

land for agriculture (the Agriculture Land Reserve). As part of that mandate, it must approve any non-farm uses of land within the ALR and power generation is considered a non-farm use. The ALC also requires that at least 50 percent of the inputs come from the farm itself (this requirement also applies to on-farm processing, packaging and marketing).

Keulen got off easy. George Dick of Dicklands Farm in Chilliwack, B.C., started down the same road about the same time and has yet to put a shovel in the ground.

The process starts with obtaining a power purchase agreement from Fortis BC for gas production and/or BC Hydro for electricity production, then getting it approved by the BC Utilities Commission.

Once BCUC has approved the agreement, the project goes to the ALC and local council. That requires support from the B.C. Ministries of Agriculture, Environment and Forests, Lands & Natural Resource Operations. Dick notes it took him over a month just to complete the nutrient management plan (NMP) the BCMA required. The ALC then hired an independent consultant to review the NMP before even considering his project.

Dick says all parties need a “firm grip on reality” to make AD’s happen.

nitrogen and 30 percent of the potassium in the original mix.

“We all have to have an ideological shift. All stakeholders need to recognize the value of recovered organic nutrients.”

The Seabreeze system will use 12,500 m3/year of its own dairy manure and about 12,000 m3/year of organic waste from Metro Vancouver’s zero waste initiative and produce enough biomethane for about 1,000 homes.

Solid green waste is mixed with water, then mixed with liquid green waste and dairy slurry and fed into the digester. It spends about 25 days in the digester producing a biogas of about 60 percent methane and 40 percent carbon dioxide. The gas is compressed and fed through a closed-loop water scrubber, which removes the carbon dioxide, harmlessly sending it into the atmosphere.

“We recover 98 percent of the methane,” says Ricardo Hamdan of Greenlane Biogas.

The gas only reduces the original volume by about 20 percent, so there is still a lot of “digestate” to deal with.

That goes to the second part of the operation – a Trident Nutrient Recovery System.

“No AD project is economic without a nutrient recovery system,” says Michael Hellenkamp, business development manager of PlanET Biogas Solutions in Ontario.

Eric Powell of Regenis in Washington agrees, noting the off-farm inputs mean the farm ends up with more nutrients than it started with. Unless something is done about the excess nutrients, an digester actually increases the risk of nutrient overloading in the fields.

Developed in Abbotsford, BC, by Manure Systems Inc. using made-inNorth America technology, the Trident system uses a multi-step process to extract the fiber and a concentrated “cake” of nutrients from the digestate. The fiber is dewatered to 35 percent moisture content so it can re-used as bedding for the cows.

The digestate is passed through a diffused air filtration system that uses polymers to capture the nutrients. This then goes through a press which creates a cake, now about one-fifth the original volume, which contains about 85 percent of the phosphate, 50 percent of the

Initially, the Keulens intend to use the cake to fertilize the field although the eventual aim is to pelletize it for sale off-farm.

After the fiber and the nutrient cake are removed, what is left is a virtually nutrient-free liquid with just 1.5 percent solids, which can be reused as flush water or as irrigation in the fields.

B.C. Environmental Farm Plan advisor Dave Melnychuk believes the there will be many more anaerobic digesters dotting the BC dairy landscape in future.

“I see a great future for anaerobic digestion,” he says. “Nutrient recovery technology offers great potential for the dairy industry.”

BMO senior agriculture manager Steve Saccomano says some projects are showing returns of 10 to 15 percent. As a result, banks are prepared to finance projects “which improve a farm’s efficiency and reduce its environmental impact.” To be considered, projects must be based on proven science, have a sound business plan with contingencies, a long-term supply contract with tipping fees for off-farm inputs and long-term purchase contracts.

By Steven Sell

An Internet search for manure-related spills can lead to an exhausting list of news articles and images of damage.

In Wisconsin alone, the volume of reported manure spilled during 2013 was the most since pre-2007, indicating the problem is not on a downward trend. With each and every manure spill comes increased scrutiny by the public on manure management – this perception also affects the anaerobic digestion (AD) industry in both positive and negative ways. As the number of manure spills on both large farms and those without digesters increases, so does favorability of the AD industry.

The AD industry is an established solution for nutrient management that also provides energy production in ways that are much less detrimental than conventional energy production. Positive mentality towards AD on farms is mainly due to the added manure storage onsite that comes with an installation, as well as the control over manure volume and flow. Anaerobic digestion systems help solve manure treatment issues by removing some of the biological oxygen demand of the waste stream which is the main contributor of downstream eutrophication. Because of this, it is plausible to say a spill of digester treated effluent would be less harmful to the environment than raw manure. The fertilizer value is not lost through the digestion process and effluent is still suitable for land application. In addition, anaerobic digestion systems produce biogas as a useful energy source that can be combusted to create electricity or heat.

However, because farms with AD are more closely monitored, a spill occurrence results in highly touted, bad press that

significantly impacts the public’s perception. Photos and images can provide lasting impact on brands or digester types that leave readers or viewers with the thought that AD causes more environmental damage than assistance. This article aims to provide a better understanding of the levels of prevention, detection, and control that are in place for manure handling on farms and AD facilities.

Determining the cause of previous manure spills or leaks is the first level of understanding. Evaluation of spills in Iowa by the Iowa Environmental Council and Iowa Farm Bureau found most spills occur during transportation of manure and are caused by human error or equipment failure. The development of manure spills is affected by numerous factors, including, but not limited to: snow fall, cold temperatures, storage volume, farm size, and conveyance method. Wisconsin’s 2013-2014 winter was filled with especially harsh temperatures and snowfall, putting more strain on piping and liquid storage.

The first level of protection against manure spills is prevention. Manure spills are preventable with proper design, operation, and upkeep. However, as a factor of safety, multiple levels of protection should be used. Prevention can be as simple as minimizing water use and addition to manure supply; this will decrease total volume of manure as well as the likelihood of the manure to flow. Treatment of runoff or wash water in a separate

area will help minimize the volume of high-strength wastewater. In addition to volume reduction, farm managers should strive for minimal transportation from production to enduse. Doing so limits the duration inside piping and vehicles and will decrease the potential impact area. Regardless of manure transport type, manure must be stored in some manner. Storage units should be professionally designed and evaluated on a regular basis for performance. When it comes to anaerobic digestion, manure is most often stored in constructed tanks.

Properly constructed tanks should be visually inspected on a regular basis to ensure structural integrity. Commonly, tank levels will vary as manure is treated during an anaerobic digestion process. Using level sensors with redundancy or backup will help keep readings accurate in the event of a unit failure. Today’s technology allows operators to receive immediate updates on AD process output and function. Plant errors and warnings can be connected to phone dial-outs or on site-displays to notify changes in process performance. These readings can provide the following key information:

• High-level readings – may indicate pumping or addition to the tank is occurring too rapidly and the outlet to the tank is blocked or malfunctioning. Control logic should be set in place to shutdown feeding to the tank if this occurs. Some examples of sensors that work well for

high level readings are float sensors or capacitance probes set at the correct height.

• Low-level readings – may indicate pumping or removal of material from the tank is occurring too rapidly and the inflow is not working properly. It could also indicate a leak in the tank at some location. Some examples of sensors that work well for low-level readings are float sensors or capacitance probes set at the correct height.

• Continuous level transmitters – this type of measurement displays height or change in height of the storage vessel. Radar, sonar, pressure, or capacitance sensors may be used to obtain liquid height within the tank. Monitoring the level change over time will show how rapid the level is increasing or decreasing and could help pinpoint the type of error.

Liquid manure is often conveyed via pumps, drag hose, or piping. Since this step involves transport of manure underground or in exposed conditions – and sometimes long distances – the risk of leakage remains high. Simple flow and pressure sensors can be installed on suction and discharge sides of pumps to detect piping and pump performance; this helps indicate pipe blockages or leaks as a leak on the discharge side can be detected by a zero gauge pressure or a lack of flow in a down stream flow meter. Control logic can be setup to immediately shutdown this type of situation, preventing large spill volumes.

Proper control and operation of manure handling systems is the first line of defense against large manure spills. Operators should be equipped with safety plans and emergency procedures. However, with today’s advancements in facility controls and software, operators can be notified of plant errors by dial-out and can control the plant remotely via phone or Internet connection. This is a unique feature with the potential to decrease leak time through proper and immediate response to isolate areas.

Unfortunately, no matter how efficient plant operations may be, structural failure is always a possibility. For this reason, each state will inspect and require a containment zone. This level of inspection will typically be handled by the natural resources permitting agency and will require all storage structures to

be properly lined to prevent groundwater leakage, be surrounded by a secondary containment structure that can hold all the liquid within the vessel in the event of a rupture, and provide a safe spillway to reroute excess contaminated water away from environmental habitat. Manure storage tanks or anaerobic digestion reactors can be equipped with overflow piping to convey spills to properly sized and constructed storage ponds. Overflows can be equipped with simple flow sensors to provide operators alerts that an extraordi-

nary event has occurred.

There are numerous manure spill response plans established by each state’s Natural Resources Department, a list of guidelines from the United States Geological Survey - Natural Resources Conservation Services (USGS NRCS), and other organizations to help keep these organized. However, the best response plan starts with manure spill prevention.

Steven Sell is a biologist and application engineer with BIOFerm Energy Systems

Sustainable energy production entered a new era in California recently as a consortium of American companies joined together with state energy officials to launch the Calgren Ethanol Biodigester, which utilizes waste from dairy farms to power the production of tens of millions of gallons of ethanol, all consumed in the Central Valley.

The two-stage mixed plug flow digester was designed by DVO, Inc. of Wisconsin and constructed by Regenis, an anaerobic digester builder based in the western U.S. It is the first California digester to use agricultural waste to create renewable natural gas to power another renewable energy facility, creating a step forward in a virtuous, zero waste lifecycle.

The process begins with local dairy, Four J Farms, sending its cow waste to the Calgren digester, which captures methane and burns it as clean biogas. While Calgren will be utilizing the renewable gas to power its facility, the digester will also greatly reduce bacteria and pathogens so dairy farmers can reuse the liquids safely on their crops, saving millions of gallons of water and protecting watersheds.

Digesters have other advantages as well, including reducing air and odor emissions, both important issues in California’s Central Valley. According to the American Biogas Council, replacing just 10 percent of California’s natural gas supply with renewable gas would reduce greenhouse gas emissions by tens of millions of metric tons per year, while cutting wildfire, air pollution and landfilling – issues raised by the California Energy Commission (CEC) when they invested $4.6 million in the project.

“The San Joaquin Valley is challenged with some of country’s worst air pollution,” said Janea A. Scott, commissioner at the CEC. “The Pixley Biogas anaerobic digester is the first anaerobic digester on a California farm permitted to use all feed stocks, including municipal green waste and food processing waste. This type of innovative technology helps California meet its clean air, petroleum reduction, and climate goals.”

Lyle Schlyer, president of Calgren Renewable Fuels, echoed her thoughts.

“I am proud of the contribution that Calgren can make to this incredibly green, low-carbon intensity project,” he said. “Digesters are often talked about, but actually building one and getting it into operation doesn’t happen all that often. This is a marriage of industrial and dairy interests.”

Currently, California is forced to import more than 90 percent of its natural gas, costing the state thousands of jobs and billions of dollars. In fact, California constructed nearly half of all the new natural gas-fired power plants built in the U.S. in 2013. Renewable natural gas could significantly change that equation by utilizing organic waste to power farms, factories and communities.

In January, the CEC issued rules that could send the number of digester projects around the state skyrocketing, a subject touched on by Bryan VanLoo, vice president of Regenis.

“Our mission is to reimagine reusable resources,” he said. “In the case of California, that potential is almost limitless. Utilizing digesters would not only create hundreds of new construction and operation jobs in rural communities like Tulare County, but there is enough organic

waste to power two to three million homes or to generate 2.5 billion gallons of clean, ultra-low carbon transportation fuels.”

The digester launch coincided with the opening of the World Ag Expo just up the road from the Calgren facility, as a way to share the technology with those who need to dispose of farm or food waste, and who could generate additional revenue while helping the state to reach its environmental goals.

“The launch of the Pixley anaerobic digester is a great opportunity for the community to learn about the possibilities of anaerobic digestion,” said Steve Dvorak, owner and president of DVO. “DVO digesters are a unique, efficient and high-performance waste management solution for agribusinesses and municipalities. We’re proud to have partnered with Regenis and Calgren on this exciting installation.”

The Pixley digester was also heralded at the event for being the first system in California to be 100 percent American made and constructed.

“Benjamin Franklin, America’s greatest inventor, reminded us ‘waste not, want not.’ Agribusinesses, food processors and municipalities are realizing that Franklin’s words ring as true today as they did over 200 years ago. We’re proud to be a part of that American legacy,” VanLoo said.

Livestock Water Recycling, Inc. president Ross Thurston was in Toronto recently to accept the 2015 Small Business Achievement Award for Innovation of the Year at the second annual Small Business Achievement Awards.

“Our business is our passion,” said Thurston. “We are proudly shaping the future of livestock manure management and to be recognized for that achievement is a great honor.

“We work with some of the most forward thinking and progressive livestock industry leaders who are changing the way an entire industry manages manure. We are proud to offer them a solution that not only improves their overall operation, but that significantly impacts their environmental footprint.”

LWR will receive a personalized, one-on-one mentorship session with Bryan Pearson, president and CEO of LoyaltyOne, a profile in Canadian Business magazine, and 10,000 AIR MILES reward miles.

Paulo Flores, a nutrient management specialist at the NDSU Carrington Research Extension Center, has developed an Excel spreadsheet (NDSU Manure Application Calculator for Corn) that allows farmers to compare the nutrient value, on a cash basis, of solid beef feedlot manure as a source of nitrogen (N) and phosphorus (P) to commercial fertilizers for corn production in North Dakota.

Calculations are based on the assumption that the cost per unit of nutrients

for manure and commercial fertilizers are the same, and they vary according to the price of different fertilizer sources that producers can choose from in the spreadsheet.

Information regarding field (area, soil nutrient content), crop (yield potential, nutrient recommendations), commercial fertilizers (price, nutrient content, application cost and rate), manure (nutrient content, availability factors, additional nutrient value, application cost and rate) and interactions amongst some of those variables are taken into consideration in the calculations.