January/february

January/february

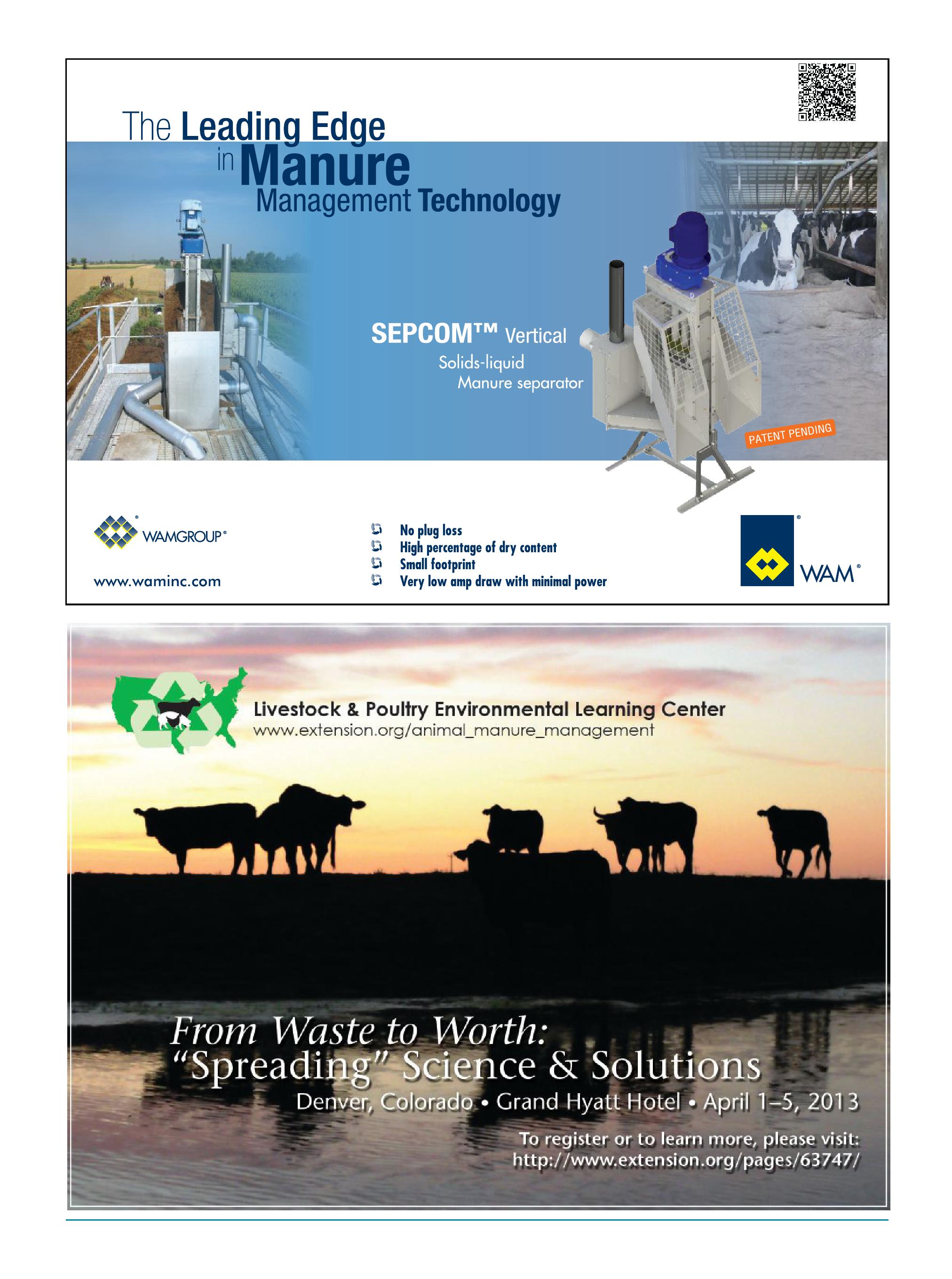

For over half a century, Doda has provided Organic Waste Solutions by manufacturing a broad variety of products for agricultural use with strict adherence to cost/benefit advantages.

FREE EXHIBIT HALL PASS (Value of $15.00)

• Valid for combined GRO/Biogas exhibit hall on Monday or Tuesday

• Does NOT include access to any speakers or meals

• Must register online via the website under “Exhibit Viewing Only ” and enter “MM04” to be eligible.

Ohio

Volume 11 • No. 1

Published by:

Annex Publishing & Printing Inc. P.O. Box 530 Simcoe, Ontario N3Y 4N5

editor

Margaret Land • (519) 429-5190, (888) 599-2228, ext 269 mland@annexweb.com

Contributing editors

Nigel Key, Tony Kryzanowski, Diane Mettler, Stacy Sneeringer

advertising Manager

Sharon Kauk • (519) 429-5189, (888) 599-2228, ext 242 skauk@annexweb.com

Sales assistant

Mary Burnie • (519) 429-5175, (888) 599-2228, ext 234 mburnie@annexweb.com

Media Designer Brooke Shaw

VP Production/Group Publisher Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: subscribe@manuremanager.com Printed in Canada

Circulation

e-mail: subscribe@manuremanager.com

Tel: 866-790-6070 ext. 211

Fax: 877-624-1940

Mail: P.O. Box 530 Simcoe, ON N3Y 4N5

Subscription rates

Canadian Subscriptions

$35.24 Cdn, one year (with GST $37.00, with HST/QST $39.82)

U.S. Subscriptions: $47.00 USD, one year

Occasionally, Manure Manager will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher's written permission. ©2013 Annex Publishing and Printing Inc.. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher's approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Website: www.manuremanager.com

ABy Margaret Land

lan and Kristin Hudson, fourth-generation poultry producers, received fantastic news this past December – a federal judge in Baltimore, Md., ruled against the Waterkeeper Alliance in a lawsuit that pitted the Berlin, Md., farmers against the New York-based environmental group.

What a relief for the young family.

The 50-page decision brings an end to the legal nightmare that has haunted the Hudson family since 2009, when a flyover of their farm led to the investigation of a pile of what was suspected to be poultry litter placed adjacent to a drainage ditch. The alleged litter actually turned out to be treated Class A bio-solids. Working in conjunction with the Maryland Department of Agriculture and the Maryland Department of the Environment, the Hudsons moved the pile, cleaned up the area and were cleared of any wrongdoing by the state agencies. But the Waterkeeper Alliance persisted in moving forward with a lawsuit against farm and poultry integrator Perdue Farms, alleging that dust from ventilation equipment and litter tracked out by boots and vehicle tires was polluting nearby waterways and, ultimately, the Chesapeake Bay.

Senior U.S. District Judge William M. Nickerson disagreed.

“The court has no disagreement with (the) plaintiff that the Chesapeake Bay is an important and vital resource, that it is seriously impaired, and that the runoff from factory farms, including poultry operations, may play a significant role in that impairment,” he stated in his decision. “Nor does the court disagree that citizen suits under the Clean Water Act can play a significant role in filling the void where state regulatory agencies are unable or unwilling to take appropriate legal action against offenders. When citizen groups take up that mantle, however, they must do so responsibly and effectively. The court finds that in this action, for whatever reason, Waterkeeper did not meet that obligation.”

Judge Nickerson’s decision was met with enthusiasm by the Save Family Farms organization, which has helped the Hudson family both financially and emotionally.

“Judge Nickerson’s ruling reinforced what the Maryland Department of the Environment concluded three years ago: That Alan and Kristin have not done anything wrong and are not guilty of violating the Clean Water Act,” said Lee Richardson, president of the Wicomico County Farm Bureau and a member of Save Family Farms. “The Hudsons were unjustly accused in a witch hunt by the Assateague Coastal Trust, the Waterkeeper Alliance and their agenda against modern agriculture.

“We are grateful that justice prevailed and common sense won the day. However, we remain concerned that other farmers will suffer the same fate as the Hudsons at the hands of bullies armed with millions of celebrity fueled dollars and an attitude of taking farmers down at all costs, with or without evidence.”

Save Family Farms is urging Judge Nickerson to award legal costs to the Hudsons and Perdue Farms and is asking the Assateague Coastal Trust, the Waterkeeper Alliance and the University of Maryland Environmental Law Clinic, which argued the Waterkeeper’s case, to issue a public apology to the Hudsons and the taxpayers of Maryland, “who unwillingly financed this wasteful lawsuit.”

While Alan and Kristin Hudson express relief at the end of the lawsuit and the uncertainty that has faced their family and farm, the Waterkeeper Alliance said it is considering appealing the case.

Hopefully, Waterkeeper and the UM Environmental Law Clinic drop this issue completely. Enough time and money has been wasted on an issue that was moot from the beginning. The Hudson family has suffered enough from the Waterkeeper’s ineptness. Leave them alone.

Nutrient water management is a critical part of your livestock operation. Only T-L irrigation systems use safe, reliable hydrostatic power that delivers smooth, even effluent distribution.

You too can experience improved crop production, low maintenance and years of dependability. Hydrostatic power is “Proven Technology – That Works” and is something you know and work with every day.

Let T-L Irrigation Co. and T-L dealers give you the lasting value you are looking for. Call your local T-L dealer or T-L Irrigation Co. at 1-800-330-4264 today. T-L irrigation systems are “Easier on You – For a Lifetime!”

Call your local T-L dealer or contact T-L Irrigation Co. at 1-800-330-4264.

For more information, contact T-L Irrigation at 1-800-330-4264 or email us at sales@tlirr.com

By Tony Kryzanowski

The Funk family farm in central Illinois was established in 1824, a mere 48 years after the signing of the American Declaration of Independence. The land continues in agricultural production today with a feedlot and cropping operation owned by the founder’s descendants and the farmland’s productive integrity is being maintained by a strong commitment to environmental stewardship.

For example, the 7,000 to 8,000 tons

of cattle manure generated by the farm’s feedlot is converted to compost and land applied to the farm’s 2,000 acres of corn and soybean crops and 300 acres of pasture. This practice, started about eight years ago, delivers both an environmental and a financial dividend by reducing the volume of manure when it is composted by about 50 percent and by providing an organic alternative to commercial fertilizer, which saves the farm about $40 to $50 net per acre.

While the cropland benefits from the composted cattle manure, it returns the favor by providing corn stalks and soybean stubble for cattle bedding, which becomes the manure that is converted into compost. The farm has about 10

acres set aside for its composting operation.

There are three creeks that run through the Funk Farms Trust property. The farm has been careful to establish fenced buffers around the creeks to minimize the impact that cattle constantly grazing adjacent to the creeks could have.

For its efforts, the farm was chosen as a finalist in the 2012 National Cattlemen’s Beef Association Environmental Stewardship Program. The farm has also had a major impact on the agriculture industry as a whole as this is where the first varieties of hybrid seed corn were developed.

The farm, which is a trust managed by a board of trustees consisting of four

Dan Koons, general manager at Funk Farms Trust, says composting cattle manure makes both financial and environmental sense for the farm. Contributed photo

members from various branches of the Funk family, was at a crossroads in 2010. Farm manager Dan Koons is responsible for the day-to-day management of the farm and he has held that position since 1970. Brian Bangert, crops manager, and Adam Green, cattle manager, are responsible for the day-to-day operations of the composting and manure management system. Koons says it came to a point where the feedlot had to expand or the farm had to get out of that business. The management board chose to expand and also to branch out into custom livestock feeding in addition to raising its own herd. What aided in their decision was an opportunity to custom feed Holstein cattle, which reduced the risk to the farm because they were

essentially being paid to raise cattle owned by someone else. Today their herd is about two-thirds custom-fed and onethird Funk farm cattle. Koons says that decision brought the herd back to about the size it was when it was established. The board’s decision to expand included a decision to upgrade the farm’s buildings and invest in a new barn with a monoslope roof designed by FBi Buildings. The barn was custom-designed for good airflow, better control of runoff and easy management of the bedding pack and manure in each of the six pens. In terms of manure management, the only significant difference with the new facility is that the manure is stored indoors rather than outdoors prior to regular removal. It does provide the farm with a covered,

short-term storage option in the event that weather makes it difficult to remove and apply the manure to cropland. The barn’s major benefit to the farm is that the airflow through the structure has created a healthier environment for the cattle, and Koons says that is having a positive impact on the conversion ratio. At full capacity, the barn can house about 900 head. Cattle graze on pasture grass in the summer and are housed and fed at the feedlot through the winter.

About once a week, the farm moves the cattle from each pen to a staging area outside the barn and uses a skid steer to scrape refuse from the apron around the feeding bunks as well as the manure from the pens into three manure bays, manufactured from large concrete blocks.

The bays measure 12 to 16 feet wide and span the entire length of the barn for a distance of about 75 feet. A bedding pack is maintained in each pen, and once each pen is cleaned, fresh bedding material is added as needed.

“On average, we can clean those aprons and pens three to four times before we have to empty the storage manure bays and haul that out to the compost site,” says Koons. “It’s a little more labor as compared to a slatted floor where you have deep pit confinement, but our initial cost was much less in this sort of system where you are using a bedding pack.”

The collection of the manure for composting and compost manufacture does not occur year round. During the

winter, the manure from the feedlot barn is place directly on the cropland. As the farm begins to prepare cropland for spring tillage, which typically occurs from March 1 to 15, it will start to accumulate the manure at its compost site. Compost manufacture occurs from the beginning of March to the end of September.

The manure is placed in windrows measuring approximately eight to 10 feet wide, and five to six feet high.

The decision to compost is part of the farm’s Concentrated Nutrient Management Plan for its feedlot that determines the amount of manure it can apply to the farmland. It didn’t require the purchase of a lot more equipment as they already had the skid steer and dry manure spreader.

“The only thing we needed in addition to that was the compost turner,” says Koons.

The farm purchased a compost turner manufactured by an Illinois-based company called Midwest Bio-Systems, which cost in the range of $35,000 to $40,000. Under normal conditions, it takes about 120 days to make compost from the manure.

The compost site is about a quarter mile from the barn, and Koons adds they had to be careful where they established the site because of concerns about runoff. It had to be a minimum of 200 feet from a stream, and the farm has established a grass buffer between the compost heap and the nearest watercourse.

In terms of the nutrients within the

compost, the Funk farm has its manure and compost laboratory tested at least once a year for its nutrient value.

“In this Concentrated Nutrient Management Plan, there are limits as to how much phosphorus, nitrogen and so forth you can apply per acre based on soil tests from our cropland,” says Koons. “It’s well monitored in terms of the quantity of compost that we can put on.”

On average, the farm applies between 10 to 15 tons of compost per acre and the only commercial fertilizer supplement the farm applies is nitrogen for its corn crop.

“One of the things that cattle and swine feeders haven’t done in the past is that we’ve thought that manure was a by-product and just hauled it to the closest field from the barn just to get rid of it,” says Koons. “In the last few years, with input costs rising so dramatically especially for corn, we’re now placing a really fair market value on that manure that we didn’t used to.”

Koons and staff start to spread the compost on its cropland just as soon as the crops are harvested, which is typically

around the middle of September, and will continue to apply it until the supply is exhausted, at which point they will switch to applying raw manure from the barn.

Koons says that composting is still not a particularly widespread practice among cattle feeders in that part of the United States, but interest and implementation is growing.

“I would guess that less than 10 percent are using the compost system but I think it is a concept worth pursuing for several reasons, one being the environmental concerns and the environmental rules and regulations we have to follow,” he says. “It’s probably going to be something that is going to be done a little more in future.”

Because of the number of creeks running through the Funk Family Trust property, minimizing runoff and maintaining good water quality in the midst of a large farm operation is both a concern and a challenge for the owners. Given their conscientious approach to minimizing their environmental impact, for example, having very wide setbacks from the creeks as compared to many other

TOP LEFT: Funk Farms Trust uses an aggressive grazing rotation system and grass buffers along creeks to minimize the impact its feedlot has on the environment. Contributed photo

BOTTOM LEFT: Funk Farms Trust composts its cattle manure from spring to fall, and applies it as organic fertilizer on its cropland until the supply is exhausted. Contributed photo

ABOVE: The Funk family applies the cow manure compost to the operation's 2,000 acres of corn and soybean crops.

farm operations, Koons says, they have seen a positive result.

“I can recall not only here in Illinois, but in Iowa, Minnesota, and other states, where you’d have a feedlot right on a creek and it would be just one big mud bath,” says Koons, “but it was a source of water. Environmental rules and regulations changed all that and I think we became more aware of the environment.”

He adds that he has definitely seen an improvement in the water quality in the creeks traversing through the farm over the years, and part of the reason is how they have modified their grazing operation, using an intensive management grazing approach where they rotate the cattle through grazing cells every three days.

“In one instance, we have cattle completely fenced out except for flash grazing for a day or two,” says Koons.

The farm has a long history of having an open-door policy and a strong willingness to share its ideas on farm management, as well as involvement in many boards and associations advocating for the industry.

Agitating tough pits takes less time and less fuel so you can start hauling sooner!

The PUMPELLER Hybrid Turbine revolutionizes manure pump performance. Incredible intake suction pulls solids into the cutter knives, reducing the toughest crust to nothing in just seconds. The turbine combines the highvolume mixing of a propeller agitator with the power and reach of a lagoon pump, the resulting hybrid design radically outperforms both.

By Diane Mettler

demonstrates creative solutions

The spring of 2010 is one the Ziegmann brothers, Bob and Kermit, will long remember. The snow had piled high in Wall Lake, Iowa, and in early March it began to melt. The ground was frozen, and with no place for the water to go, the snow melt ran downhill, quickly filling the manure containment area for Ziegmann’s 800-head open cattle lots. The containment area overflowed and the liquids made their way to a ditch, and then continued on to a nearby stream. The Ziegmanns were fined and that’s when things got really interesting.

Background

The containment issue didn’t happen overnight. Bob and his brother have been

farming for nearly 50 years. Each year their farm grows a little and at the same time regulations get a little stiffer. By 2010 their operation had grown to 1,800 acres (around 1,000 that they can spread on), two 2,500 wean to finish hog units and an 800-head feedlot.

As the farm grew, the Ziegmanns hired Tucker Consulting to prepare their manure management plan. Bob Ziegmann says Tucker Consulting takes soil samples, and ensures spreading is done in the right areas and in the correct amounts.

The manure management plan, however, wasn’t the problem. The Ziegmann brothers had a decade earlier built a containment area for the manure from the feedlots, which no longer met current regulations.

Looking for answer

Bob says he immediately started working with the state’s Department of Natural Resources (DNR) to find a solution that wouldn’t break the bank, but wasn’t finding an answer.

“I kept coming up with ideas, but they weren’t working,” says Bob. “They would tell me that my ideas would help, but wouldn’t

solve the problem.”

Things turned around when Bob was introduced to Shawn Shouse, an agriculture engineer with Iowa State University Extension. Shouse frequently works with smaller farms, designing systems that are both effective and economical.

“I and another engineer from Extension met with Bob at the site and spent an afternoon walking around, visiting with him about his objectives and what we thought we might be able to do,” says Shouse. “It took me a few weeks to draw up my suggestion. The hardest part sometimes is just the head scratching on the site trying to figure out how you make things fit with the lay of the land so that it doesn’t cost a fortune to build things.”

Shouse has designed a number of manure containment systems for Iowa farmers, particularly those in the western and southwestern parts of the state.

“The landscape tends to be relatively steep, and it’s a lot more difficult to control that water coming out of the pens on a steep hillside.”

Bob says that once Shouse came on board, pieces fell into place.

“Shawn worked closely with the DNR

ABOVE: Primary solids settling basin below the larger pens.

TOP RIGHT: Access ramp into secondary basin. Water is pumped to the field in the background.

MIDDLE RIGHT: Secondary basin holds dirty water to be pumped through blue flex hose to the field to the right.

BOTTOM RIGHT: An example of the concrete wall and earthen berm between the Ziegmann feedlot and the road.

and every step that we made then was OK’d with the DNR and I finally got a plan,” he says.

The overall plan was quite simple. Direct any runoff from the first containment center through an underground pipe along the road (and ditch) and down to a secondary containment system in a field on the other side of the building site. If a record rainfall should happen, any liquid that could potentially overflow from the second containment area would overflow into a 40-acre field.

“It’s similar to what a lot of the big permitted feed lots would do in concept,” says Shouse. “It’s the same kind of philosophy, but because Ziegmann are

not covered by the federal permit rules, we were able to do it with less expensive construction and materials. Because they’re smaller, they don’t have to store such a huge volume of water.”

Bob was able to get right to work with his contractor as soon as he had a plan. It took about five months to go from initial talks to completion.

Most of the work was done outside the two pens. “Nothing had to be done inside the large pen,” says Shouse. “Bob already had a solid settling basin outside the pen. He enlarged it though and put a different outlet to get the water into his underground pipes to keep water out of the road ditch. For the smaller pen, right next to

the road ditch, Bob built a concrete wall to hold that water in the pen until he could get it down into the pipeline.”

Bob also added cement to the first containment area.

“We put the cement right down the middle so that I could clean the solids out as soon as possible,” says Bob. “When we clean it out (spring and fall) we use a skid loader and put it in a slinger type spreader and spread it on the fields.”

He adds, “A 700-foot-long, 12-inch-wide pipe now runs along the south side of our site, down to the secondary containment center we built. We cemented about 20 feet of the total containment center where the water enters and the solids settle off first. That way, I can clean that about any time.”

Bob says he uses an electric sewage pump to pump the water off and dry it up.

“At this point though I don’t see that much solids get to the secondary holding site because I’m able to capture quite a bit at the first holding area.”

There is one area of potential concern, and that’s the underground pipe.

“Any time you use an underground pipe, you have the risk of things either freezing up in the winter, or plugging up with manure solids or grass or something that gets into the pipes,” says Shouse.

To help avoid potential clogs, simple steps were taken.

“Every 200 feet we put an access tube into the pipe,” explains Bob. “If I ever did plug it, I could water jet it and open it up. But the way I’m getting the solids out before I drain into the secondary, I don’t anticipate any clogs.”

Bob is also using crops to help handle the manure.

“Over the last few years, we’ve started to grow continuous corn in a lot of ground around the feedlots. Before we used to be a corn/bean rotation, so now I can handle a little bit more [manure].

“We are also putting in a cover crop of rye out on some of the ground, so we take a crop of rye off and then come back in and plant corn or beans. So it’s almost like double cropping and it lets us add a little more manure.”

Another benefit of capturing more of the manure is a lower fertilizer bill. The Ziegmanns still purchase some fertilizer (mostly nitrogen), but the quantity has definitely dropped.

More Than Manure® (MTM®) Nutrient Manager is the first and only manure manager proven to reduce nitrogen loss and phosphorus lock-up in manure. That means improved nutrient efficiency for your crops, and better results in the bin. When pre-treated in a pit or lagoon, MTM can also reduce solids and ammonia levels, which will make your pit or lagoon almost, well…pleasant. To get your free starter pack and to learn more, visit us at morethanmanure.com.

|

Tour participants take a closer look at how the concrete wall and earthen berm work at controlling feedlot runoff.

The new system has been running for a year now and is working exceptionally well — no liquids from the feedlots have reached the ditch or stream. It has been a dry year, and the system hasn’t been tested by heavy rains, but Bob is confident that his system is set to handle them when they come.

Shouse says a big part of the success of any system is its management, and Bob is doing a great job.

“A really good manager can make something work without spending a lot of money,” says Shouse. “The more you want it to operate itself without you having to pay attention to it, the more expensive it gets to try to build a system that can do that.”

Ziegmann’s innovative and economical system was showcased this past October at an Iowa State University Extension field day. Around 40 people showed up to take a look.

“The field day is part of a cooperative effort with ISU Extension and Outreach, the Iowa Department of Natural Resources, the Iowa Department of Agriculture and Land Stewardship, the Natural Resources Conservation Service of USDA, the Iowa Cattleman’s Association, and the Iowa State Dairy Association, and focuses on small, open beef and dairy feedlots,” says Shouse. “We’re looking at those smaller farms not required to have EPA discharge permits. We’re helping them to do a better job of protecting water quality, as many small feedlots are close to streams in Iowa. Ziegmann’s was an example of a small feeding operation that had some challenges and managed to make some really good improvements without spending an awful lot of money.”

Shouse adds, “There are a lot of these small feedlots out there and it’s easy for outsiders to say they should all have permits and do it the way the big ones do. From a water quality point of view, that would work quite well, but some of these big lots spend up to a quarter of a million dollars building those systems. These small and medium size feed lots are typically one-family operations, and it would be like asking you or I to spend a quarter of a million dollars. They just can’t afford to do the same things. So we have to get a little creative sometimes on how we protect water resources economically.”

By Tony Kryzanowski

Ohio custom applicator avoids cutting corners on service, equipment

Customers often ask custom manure applicator Eric Dresbach to point out where he has land applied the manure from their hog or dairy farms because when they inspect the job, they can’t smell it. He takes that as a compliment. It means that his philosophy of providing good training for staff and delivering quality service for more than 25 years is working. He believes that if applicators want to be treated like professionals, then they have to behave like professionals. He adds that the JCB tractors, Houle honey wagons

and Dietrich shanks, which he uses exclusively in his fleet to apply the manure exactly where it is needed to maximize nutrient value to crops, also deserve a lot of credit.

Dresbach owns W.D. Farms Inc, located in Circleville, Ohio, about 25 miles from Columbus. They custom apply between 30 and 40 million gallons of liquid manure annually, typically transporting the manure to fields five to eight miles from the manure source, and have worked in Ohio, Indiana and Michigan. Normal business radius is about 200 miles from home base. The company employs five to 10 people, depending on the time of year.

After finishing college in 1980 with a degree in agronomy from the Agricultural Technical Institute (ATI), a branch of Ohio

State University, Dresbach began farming in partnership with his dad and brother.

“The early ’80s was a tough time for a beginning farmer, so I started a grain and fertilizer trucking company called W.D. Farms in the fall of 1985,” he says. He bought out his partner in 1995 and at that time began focusing entirely on custom manure application.

“Our specialty is liquid manure,” says Dresbach. “It can be anything from up close ‘pump and dump’ with tractors and honey wagons to where we put it in a semi, run it up the road, transfer it to a honey wagon and then apply the product. We have become a very good traveling circus because of this practice.”

The majority of the company’s business is done with hog producers. He and his staff also provide their services

A typical setup at W.D. Farms Inc features a JCB 8250 tractor with a Houle 7300 honey wagon pulling a nine shank homemade chisel outfitted with Dietrich shanks.

to the dairy industry. They typically inject hog manure and broadcast dairy manure.

Dresbach prefers to describe his company as a custom provider of “organic nutrient recycling” rather than custom manure application because this description presents manure as having value as a natural fertilizer. But he also recognizes that it requires careful management.

“We always do what is right no matter what and always assume someone is watching.” That’s the first principle that the company has posted on its website, closely followed by, “we believe in good housekeeping at all times.”

Dresbach knows that his service isn’t the cheapest among custom manure applicators in his area, and that can be a tough position to take in a weak economy with the agriculture industry struggling. But he is more interested in building a clientele of repeat customers who understand the value in his service than in racing around a field doing a

mediocre job just to pad his bottom line.

“In the long run, we’re the cheaper option,” he says, “but in the short run, it’s more dollars today but you have someone who cares.” He agrees with local agriculture extension experts who say that the value of the manure depends on the quality of the application. When the manure is properly injected, the nitrogen is retained in the soil and neighbors are happy because there is minimal odor emanating from the field.

“I tell my employees that I don’t care if you are over the hill and behind the woods and you are faced with a situation where you could do it right or fast and easy,” says Dresbach. “You do what’s right.”

Dresbach is the president of the Midwest Professional Nutrient Applicators Association, representing manure haulers in Ohio and Indiana. He is also a past board member of the Great Lakes Bio-Solids Management Association (USEPA Region 5). He, his tractor operators, and two of his three teenage children who are actively engaged and interested in being part of the business, have taken training to receive their Ohio certified livestock manager licenses. The Ohio Department of Agriculture requires this license for anyone handling more than 4,500 dry tons per year or 25 million gallons of liquid manure. Dresbach’s daughter has also started college at ATI, working toward her degree in agriculture business.

W.D. Farms Inc. has a fleet consisting of three 7,000-gallon Houle honey wagons with Dietrich shanks for incorporation, pulled by 8310 and 8250 JCB Fastrac tractors. Each piece of the company’s fleet has been carefully selected for the value it brings to help W.D. Farms operate efficiently while performing quality service for customers.

“We’ve been very happy with our new 8310 JCB tractor because we get about 15 percent better fuel economy and 42 miles per hour road speed,” says Dresbach. “It’s not unusual for us to move 50 miles at a time, so the road speed is huge and the suspension improves the quality of life for the operators.”

The company has been using Houle honey wagons for about 16 years and staff appreciate the suspensionless steering system on the wagons. Dresbach describes it as a hydraulically captured loop system on the three-axle wagons, which allows it to roll over the terrain better, keeping the load more

level and thus avoiding a weight shift to a single axle. This reduces breakage and the likelihood of putting a 40,000-pound load on one axle.

“It also rides a lot smoother,” says Dresbach. “Combined with the suspension that is also on the tractor, when you come across a rise or a bump, it won’t even chatter. We don’t have drawbar wear and it’s an operator comfort issue.”

Also, Dresbach says, with the honey wagons’ front and rear axles that can turn when traveling down the road,

the wagons do practically no damage to roads compared to wagons on a fixed-axle system, which sometimes skid especially on turns. This also contributes to reduce wear and tear on their wagons. They’ve had two axle issues in 16 years with the Houle honey wagons.

The hydraulic braking system on the tractor is also tied to the braking system on the honey wagon, resulting in improved safety.

Behind the honey wagons, W.D. Farms pulls custom-built, nine shank incorporators with Dietrich manure

injection systems. The amount that the company is able to apply, given the length of their incorporation system has a definite impact on the bottom line, as they are paid by the number of gallons applied.

“Other tanker wagon companies are typically pulling only four or five shanks at 12 or 14 feet, but we are pulling nine shanks at 22.5 feet,” says Dresbach, which means that they can apply more manure in the same amount of time. The honey wagons are also equipped with a custom-built transfer system to pump the liquid manure from the semi-trailer trucks to the wagons.

Dresbach has high praise for the Dietrich shanks, which shatter and fluff the soil and allow the manure to be applied exactly where it is needed.

“We have very little manure showing on the surface,” says Dresbach. “It’s in the right place and undercover so that it doesn’t run off. That’s the only shank I will run.”

The company’s fleet also consists of a 9220 John Deere tractor and four semitrailer trucks with double conical tanks for long distance transport. Using this type of tank on each semi means it has a lower center of gravity, making transport

more stable and the solids flow out of the tank from a lower centralized point. Dresbach says it is easier to keep the tanks clean, especially when transporting material with high solids content.

They also have a VMI dredge to recover valuable solid nutrients from the bottom of lagoons. It is a valuable organic fertilizer because it can be up to five times richer in nutrients than standard hog manure. This piece of equipment is also helpful to remove settled sand in dairy lagoons, as more dairies move toward sand bedding for their animals.

Rounding out the fleet is a collection of Houle, Godwin and Cornell agitation and transfer pumps.

Dresbach says he has chosen to build his business around a tanker fleet because many of his customers, particularly dairy farmers, don’t own extra cropland next to their farms where the liquid manure could be land applied. That area of the United States in particular has attracted many dairy farmers from the Netherlands who are focused specifically on their dairy operations. Many have purchased 70 acres of land and have established a 2,000-cow dairy on that piece of land,

which means that they must negotiate with other landowners to land apply their manure. In this case, a drag hose system would only be part of the solution because liquid manure often needs to be transported several miles away for application, and the farms where it is applied tend to be a collection of several smaller parcels of land. In fact, that is a big part of Dresbach’s business – facilitating a dialogue between the hog or dairy farms and crop growers to arrange for custom application of the manure, which he says can be one of the most challenging parts of his job.

“You have to get all parties on board on timing, rates, and financial contributions from both sides to pay my bill,” says Dresbach.

Dresbach says that his hog producer clients tend to recycle their manure generally on their own cropland as organic fertilizer. Most are contract growers who have attached a hog operation to their corn crop business to add another income stream to their farm. When a situation arises where some of the manure can be transported short distances, W.D. Farms will partner with a colleague who operates a drag hose system.

PCE Agitation Boats mix with 3 downward, high pressure out ows, and are remotely controlled from shore. Easily access all areas of any size of lagoon. Call for details, and ask about PCE pumping systems to quickly take all this rich nutrient to the eld.

By Diane Mettler

Afew simple steps will avoid some frustration and increase efficiency

Drag hoses don’t come cheap. Depending on the system, hoses can represent a substantial capital investment. Getting a long life out of your drag hoses is good for the bottom line.

But healthy hoses aren’t just good for the pocketbook; they are good for the body and spirit as well. No farmer wants the extra aggravation in the field mending a damaged hose.

Here are just a few simple steps for keeping your drag hoses in good condition and performing properly.

before winding

Prior to storage, hoses needs to be

thoroughly cleaned.

Jim Hodel of Jim Hodel Inc. has worked with a lot of used equipment, and says one of the most important things a farmer can do to get the maximum life out of his hose is to clean it before storing it. “I advise him to run a Styrofoam pig through the hose before winding it up for storage,” says Hodel. “Wind it up clean.”

Take the time to wind up the hose on a cart when it’s not in use. When a hose is lying on the field is when it’s most susceptible to damage, including extreme temperatures, oils, solvents and rodents.

“We don’t recommend letting the hose lay on the ground for extended periods of time,” says Hodel. “Critters will gnaw into it and we’ve even seen hunters shoot holes through it.”

Hodel adds that another risk of leaving

your hoses out in the field is the risk of equipment being driven over them, and, although there are kits to mend drag hoses in the field, the life expectancy of the hose will definitely be shortened if it takes the beating of other machines.

Another reason for winding up and storing idle hoses on carts is to keep them out of the sun. In fact, storage in a barn is ideal.

While your hose is lying out in the field, the sun’s UV rays are working on every exposed square inch. Hodel says, “If the hose is wound up and stored, the sun can only reach the hose exposed at the top wheel.”

Jeremy Puck of Puck Enterprises, a company that not only sells equipment but also spreads over 200 million gallons

Prior to storage, hoses needs to be thoroughly cleaned. Applicators should consider running a Styrofoam pig through the hose before winding it up for storage. Contributed photo

ABOVE: Take the time to wind up the drag hose on a cart when it’s not in use. A hose is most susceptible to damage, including extreme temperatures, oils, solvents and rodents, when it is lying on the field. Contributed photo

RIGHT: As commercial fertilizer prices increase, it becomes more economical for the farmer to have manure pumped farther distances. This can be more of a challenge for the applicators but can be done in a safe manner with correct pump placement and by monitoring hose pressures.

of manure a years, says it’s all about maintenance.

“We take for granted that once you roll hose up onto the cart it’s going to come off exactly like you put it on,” says Puck. “Over the course of sitting all summer, there can be some deterioration of the hose that is exposed to sunlight. Also, the couplers can be pinched against other hoses on the reel. So, when you pull the hose off the wheel you could see some damage if you don’t take good care when rolling it up when you park it for the summer.”

Rate hoses before the season starts Puck recommends inspecting and rating your hoses before you begin each season.

“Our company lays out the hoses and then we rate them. We color-code them by spray painting toward the end of the hose. Green would be a hose that is good and yellow is used on a hose that has

some nicks and cuts – so we’d make sure not to use that hose near a ditch or water trough or anything like that. We use the color red if the hose has had a splice put in it – if it was compromised at one point in its life — maybe a blowout or a tear or snagged on something.”

These colors let Puck Enterprises identify the hoses as they are coming off the cart “We know immediately if it’s a safe place to lay a hose or if we should choose to put it somewhere else,” says Puck.

Follow the pressure guidelines

Take the time to ensure the pressure in the hoses is at or below its rated working pressure. “The hose should have more burst pressure than working pressure,” says Hodel. “Otherwise, you may get in trouble.”

OSHA also suggests changing pressure gradually to prevent excessive

surge pressures, as well as protecting hoses from severe end loads.

Ensure you’re getting maximum use of your pumps

Often an extra pump or a different pump placement can improve efficiency as well as add longevity to your hoses. At Puck Enterprises’ “pump school” applicators learn that there is a certain amount of math and physics that goes into spreading the load between hoses and maximizing flow.

“By teaching applicators how their pump can perform and what environment to run it in, we can usually increase their flow and they can get more work done in the same time just by putting their pump in the correct place.”

He adds, “If you have two miles of hose out, we always thought we should put the pump in the middle – one mile on each direction – but that’s not always true,

ABOVE: A hose isn’t much good if the pump is in poor working order. Pumps should receive a general inspection each season. It’s a good practice to remove the suction cover and check the wear ring and the impeller to make sure they are in good shape. If they show any damage or wear it’s a good time to replace them. Contributed photo

RIGHT: How long can a drag hose be expected to last? Depending on how it is cared for, applicators can expect to get five to seven years life from a drag hose. Contributed photo

depending on hose diameters and elevation and everything else. At the end of the day, getting as much done as we can is what we’re after because that’s how we get paid.”

Your hose isn’t much good if your pump is in poor working order. Puck recommends a general inspection each season. It’s a good practice to remove the suction cover and check the wear ring and the impeller to make sure they are in good shape. If they show any damage or wear it’s a good time to replace them.

“You can also inspect the mechanical seal on the back of the pump to make sure it’s in good condition and

not leaking or broken,” says Puck. “Also, change the oil and bearing case after every season. Pumps are pretty simple. “

Is distance of application changing?

As commercial fertilizer prices increase it becomes more economical for the farmer to have manure pumped farther distances. This can be more of a challenge for the applicators but can be done in a safe manner with correct pump placement and monitoring hose pressures.

“We’re pumping a little bit farther than we used to, and we are probably doing it safer than ever before because of pump placement. We’re putting more booster pumps in line to keep our overall line pressures lower,” says Puck.

How long can you expect your hoses to last? Well, that all depends on how you treat your hose, says Puck. “I would say five to seven years is probably an average life. But the first hose you buy never lasts as long as the last one you buy.” Puck says this from experience. “We don’t inflict the damage to the hose that we used to. We know what to look for, how it behaves and how to work with it.”

By following these simple steps you will not only be extending the life of your hose, but saving yourself time and money. And if you’re lucky, maybe you’ll get a boost in your efficiency as well.

Vogelsang has you covered with Dribble Bar Systems from 20’ to 118’ wide!

Optimum liquid manure coverage provides the right amount of nutrients to the soil for maximum crop yield. Vogelsang systems are precise and clean with minimal odor. Choose from seven unique and versatile series tailored to fit your space and application requirements.

According to a recent Wisconsin Bioenergy Initiative (WBI) study, Wisconsin could become a national leader in bioenergy production using waste from the state’s prosperous agriculture and food processing sectors.

In dairy cow manure alone, the report found 4.77 million dry tons available per year, which is the potential energy equivalent of replacing one large-scale coal plant.

The report was part of an effort coordinated by the Wisconsin Division of Energy Services with WBI and accounting firm Baker Tilly to assess the opportunity and effect of renewable energy production in Wisconsin. The report, titled Wisconsin Strategic Bioenergy Feedstock Assessment, can be downloaded at www. wbi.wisc.edu/policy-analysis/.

“Too often biomass assessments only provide a snapshot in time of feedstock quantity,” said Gary Radloff, WBI director of Midwest energy policy analysis and project lead. “To filter out barriers and better see what makes strategic sense for Wisconsin, the WBI looked at a combination of biomass quantity, quality, price factors and conversion technologies.”

The research identified high-density biomass sources that create opportunities for regional production. These clusters present an opportunity to produce energy from waste without disrupting other state industries.

The waste can be diverted from dairy farms, food processing facilities, landfills and municipal wastewater treatment plants into biogas.

Woody biomass from timber can be used for thermal energy. Corn stover can be used for advanced biofuels and other co-products. Additionally, smaller regional pockets exist for dedicated woody crops and perennial grasses.

According to the Wisconsin State Energy Office’s annual energy report,

the state spent $18.68 billion in 2009 importing energy to support growing energy demands.

The WBI report explores opportunities to keep that money in the state and grow the economy by converting homegrown Wisconsin feedstocks into usable energy. The assessment identifies specific opportunities and determines how they can work in concert with Wisconsin’s agriculture, paper and timber industries.

“With no fossil fuel resources in Wisconsin, it is imperative to evaluate the state’s bioenergy resources,” said Kevin Vesperman, division of energy services administrator in the Wisconsin Department of Administration. “In order to accomplish this, we engaged an inclusive stakeholder group at every stage of assessment development. These reports provide the essential information for moving plans forward whether you’re a food manufacturer, farmer or biomass developer.”

For more information, visit http:// www.energyindependence.wi.gov.

The board of directors of the American Biogas Council recently announced the election of four directors.

Joining the board for first terms are Juliette Bohn from Humboldt Waste Management Authority and Chris Voell from BioCNG, LLC. Nora Goldstein from BioCycle and Paul Greene from O’Brien & Gere are both rejoining the board for their third term.

Directors are elected by the 160 member organizations of the American Biogas Council (ABC), which include anaerobic digester developers and builders, engine and turbine manufacturers, farmers, wastewater utilities, landfill operators, engineering and law firms, financiers, non profits, universities and the entire biogas supply chain.

Bohn, Voell, Goldstein and Greene join directors Amy Kessler from Turning Earth, Ben Mathews from Caterpillar, Bernie Sheff from UTS Residual Processing, Christine McKiernan from BIOFerm Energy Systems, Kerry Kelly from Waste Management, Norma McDonald from Organic Waste Systems, Paul Relis from CR&R, Shane Chrapko from Himark bioGas and Wayne Davis from Harvest Power to round out the ABC Board.

Voell has more than 25 years of experience in the biogas industry from the Solid Waste Association of North America (SWANA) and from the US EPA’s Climate Change Division’s Landfill Methane Outreach Program and AgSTAR Program. He currently works for BioCNG, a subsidiary of Cornerstone Environmental Group, which sells fuelling systems for biogas as a vehicular fuel.

Bohn currently works for Humboldt Waste Management Authority (HWMA) in Humboldt County, California, where she is responsible for the development of a Regional Organic Waste Digester and the utilization of the landfill gas resource at the closed local landfill. She is active in the development of organic waste policies in California, which makes her an important contributor to the growth of the biogas industry and the work of the ABC’s legislative and regulatory affairs committee, of which she is an active member.

Goldstein is the editor of BioCycle, a magazine for advancing composting, organics recycling and renewable energy. She was one of the principal architects behind the formation of the ABC and has authored numerous articles on all facets of composting and organics recycling, and more recently anaerobic digestion. In her last term, Goldstein served as co-chair of the education and outreach committee and secretary of the council.

Greene is vice-president of O’Brien & Gere, has been a part of the anaerobic digestion industry for 20 years and leads his firm’s waste-to-energy practice. Like Goldstein, Greene was a principal architect behind the formation of the

ABC and has served as chair of the board since its formation in 2010.

As the ABC welcomes some new and familiar leaders, the council also extends a special thank you to the leadership of Melissa VanOrnum from DVO, Inc. (formerly GHD, Inc.) and Shonodeep Modak from GE Energy for their service on the ABC board since 2010. VanOrnum has served as ABC’s treasurer from the beginning and also as chair of the membership and fundraising committee and co-chair of the education and outreach committee. Modak served as co-chair of the legislative and regulatory affairs committee and played a central role in creating a strong policy-presence for the ABC from the very beginning.

Manure haulers and brokers and agricultural producers are reminded to exercise caution when managing animal waste to minimize health risks.

The U.S. Department of Agriculture Natural Resource Conservation Service has raised concerns that the use of gypsum for bedding may increase the production of hydrogen sulfide in manure storage facilities. Gypsum is a low-cost byproduct of drywall and contains sulfur. Producers are urged to use extra caution when managing manure storage facilities on operations where gypsum is used.

Hydrogen sulfide can cause discomfort, headaches, nausea and dizziness. At levels above 200 ppm, collapse, coma and death due to respiratory failure can occur within seconds after only a few inhalations. Those who manage animal waste should take the following precautions:

• Always have first-aid equipment nearby.

• Wear personal protective equipment, including air packs and face masks, a nylon line with snap buckles, a safety harness, floatation devices, safety signs and hazardous atmosphere testing kits or monitors.

• Do not enter a manure pit unless absolutely necessary and only then if the pit is first ventilated, air is supplied to a mask or a selfcontained breathing apparatus, a safety harness and attached rope is put on and there are two people standing by.

• To minimize hazards, agitation of manure is best done on windy days.

• Understand the symptoms and effects of gas poisoning.

• During agitation and pump out operations, ensure non-essential workers or bystanders are away from the manure storage facility.

In addition to the above tips, farmers should:

• Have an emergency action plan, including telephone numbers of local emergency personnel.

• Train all family members and employees in first aid, CPR techniques and safety procedures.

• For open storage facilities, put a

fence around them and post “Keep Out” signs that warn of the hazard.

• Give special instructions to children and those who cannot read on dealing with the dangers of manure storage facilities.

For more information about manure storage safety, visit www.nrcs.usda.gov, search manure management and click on the document titled, Manure & Nutrient Management. Scroll to the bottom of the page and click Safety and Health –Manure Storage Pits.

The Galaxy Muddy Buddy from the Alliance Tire Group introduces a superdeep-tread design to the Alliance lineup of skid steer tires.

The Muddy Buddy’s extra-deep tread, shallow lug angle and sharp shoulders provide better traction on slick or slushy surfaces, and offer more highdurability rubber for longer service life. The lugs’ sharp shoulder angle provides a superior grip on soft and uneven surfaces, adds Seth Walters, vicepresident of marketing and supply chain for Alliance in Wakefield, Mass.

“We engineered the Muddy Buddy specifically for long service and dependability in slick or muddy environments like dairy farms and other livestock operations,” Walters notes. “Whether it’s managing manure, mixing feed or handling bulk fertilizer, farmers’ skid steers have to be ready for whatever conditions Mother Nature sends their way.”

The Muddy Buddy is available in sizes 10-16.5 and 12-16.5.

www.atgtire.com

Jack Danner joins DigiStar LLC as its new sales manager.

In this role, Danner will be responsible for the growth and development of the North American market for the company.

“Jack’s outgoing nature and experience are ideal to guide Digi-Star’s account management team to new levels of success,” said Kevin Klubertanz, director of sales and marketing.

Danner has had leading roles in production and sales prior to joining Digi-Star. Most recently he was responsible for the sales management of

two implement dealers and a grain and feed mill.

“Digi-Star is poised for rapid growth that can only be achieved with strong leadership and determination,” said Klubertanz. “Jack has a proven track record that indicates a great fit for Digi-Star.”

Danner will be based out of the company’s Wisconsin office.

He has a bachelor of science in business and economics from the University of Wisconsin – Parkside and an MBA from the University of Wisconsin – LaCrosse.

Jamesway Farm Equipment’s Pumpeller hybrid manure pump was one of several manure application and handling technologies that earned 2013 AE50 Awards recently.

The Pumpeller turbine integrates a propeller mixer in the center of a volute pump. The resulting hybrid ingests and homogenizes even the most difficult manure solids while taking less time and fuel.

The turbine produces two outputs simultaneously: a high-pressure cannon discharge and a high-volume propeller wash. Manure is actively pushed into the impeller blades around the outer edge of the turbine by the outward flow from the propeller core, providing improved cannon and load out performance in thicker slurry.

The turbine housing features large openings in the back wall that permit the excess flow exiting the propeller core to travel straight through the housing. The combined discharges of the cannon and the propeller create a high suction at the turbine inlet that pulls solids toward the pump.

The Pumpeller homogenizes solids as they pass through the turbine instead of relying on the cannon jet pressure or an external propeller.

The AE50 Awards are presented annually by the American Society of

Agricultural and Biological Engineers in recognition of that year’s product innovations in the areas of agricultural, food and biological systems. www.jameswayfarmeq.com

Kelley Manufacturing recently won a 2013 AE50 Award for its KMC 6400 Litter Windrower.

The KMC 6400 litter windrower forms windrows for composting bedding material in poultry houses, inverts the windrows, and spreads the bedding material for the next flock. Operators realize greater than 30 percent reduction in work time.

The KMC 6400 is PTO powered to maximize horsepower transfer from the tractor. Blade angle and position are adjustable using hydraulic cylinders. Hydraulic rear gauge wheels adjust the blade height, preventing floor gouging and allowing an even spread of litter. A floating hitch link keeps the blade parallel to the floor. The dual overlapping auger system has a rotation direction that reduces the dust thrown toward the operator and discharges material into the windrow instead of pushing it forward.

A discharge grill and chopper blade system breaks up large clumps of litter, releasing trapped ammonia and homogenizing moisture for more uniform composting.

The AE50 Awards are presented annually by the American Society of Agricultural and Biological Engineers in recognition of that year’s product innovations in the areas of agricultural, food and biological systems. www.kelleymfg.com

Mitas recently introduced its premium product line sold in North America to accommodate demands from the farming community with locally made

products manufactured at its Iowan radial farm tire factory. All Mitas-made premium tires delivered to U.S. farmers will bear the Mitas brand name. These tires are based on Continental agricultural tires, which Mitas has made under license since 2004.

“Mitas is extending its dealer network, growing sales to original equipment manufacturers and improving Mitas’ premium warranty conditions,” said Neil Rayson, who is responsible for sales in North America. “The simplified brand offer will help farmers choose the right tire. Now, nine Mitasbranded lines are designated as premium because they offer improved benefits to the farmer.”

These include the Super Flexion Tire (SFT). Shipments of Mitas premium tires made in Charles City (IA) started in July, delivered to customers including John Deere and Case IH.

The Mitas premium product lines include AC85, AC70T, AC70G, AC70H, AC70N, AC90, AC65 and SFT. As production capacity at Mitas’ Charles City factory increases over the next two years, the share of premium tires manufactured in Iowa will increase.

Highway Products Inc. has introduced the Pickup Pack, a custom storage system for pick-up trucks that combines quick and easy access to stored content, lockup security, and maximum storage in pick-up beds.

The pack includes a gull wing saddle box, two lockable low side boxes, a flat or dome center hatch, a headache rack and a removable ladder rack. When closed, the hatch locks the tailgate, making the bed area secure and weather resistant.

An optional 2000-pound capacity roller coaster cargo tray is also available. It installs in the truck bed and slides cargo out of the truck bed fast and easy.

The marine grade aluminum unit is available to fit all truck brands, models and bed sizes, and comes with a lifetime warranty. It installs in minutes. www.800toolbox.com

Veris Technologies offers three different soil-sensing systems that can provide information on soil type, organic matter and pH levels individually or in any combination of the three.

Soil EC sensing involves using soil electrical conductivity, a measurement of how much current your soil conducts. It’s an effective way to map soil type and texture because smaller soil particles, such as clay, conduct more electrical current than larger silt and sand particles. Soil texture has a major impact on productivity, affecting water holding capacity, cationexchange-capacity (CEC), drainage, topsoil depth and nutrient use efficiency. Mobile nutrients, like nitrogen, are leached through light soil and lost through de-nitrification in heavy soils. Immobile nutrients, like P and K, will vary with reason, especially crop removal variances. Soil EC maps define the soil texture variability, so samples are in the right spot and the prescription can change where the soil does.

Soil OM sensing involves the measurement of the level of organic matter contained within soil. To vary inputs based on productive capacity, a precise map of organic matter is crucial. Soil OM is an indicator of past productivity, and a driver of current productivity. Because OM forms slowly over time, soils that are higher in OM possess the combination of soil texture, internal drainage, landscape position, and other factors that, over a long period of time, have consistently generated additional plant growth, resulting in higher soil OM. Increased soil OM level also leads to even higher productive capacity due to better water- and nutrient-holding ability, nitrogen mineralization and soil structure. On fields where organic matter is added through manure and other amendments, an OM map reveals where levels are low, and could benefit from additional OM.

Soil pH sensing involves the measurement of the levels of pH contained with soil. Soil pH is an important factor in crop production. Nutrient usage, crop growth and herbicide activity are all affected by the pH of the soil. Grid samples are simply not dense enough to do the job. Within 2.5-acre grids, there are a wide range of pH values, often ranging from soils that call for lime to soils that are extremely high in pH.

Growers, consultants and suppliers are using these technologies to devise management zones, set sampling locations, vary seed rates, irrigation and nematicides, variable rate population, nitrogen management, soil amendments, herbicides and cultivar selection. www.northernequipment.ca

Retrofittable on mechanical or electronic engines

Improve pump efficiency

Multiple inline engine control

Reliable with built in Safety features

(519) 349 2770

www.sunovaworx.com

info@sunovaworx.com

By Nigel Key and Stacy Sneeringer

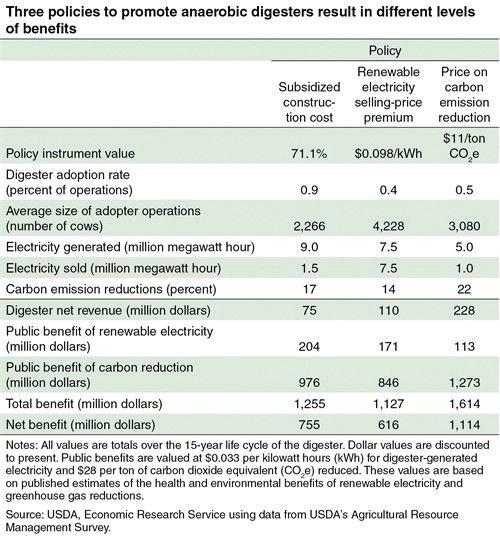

Anaerobic digesters capture methane from lagoon or pit manure storage facilities on farms and use it as fuel to generate electricity or heat. In addition to providing renewable sources of energy, digesters can reduce greenhouse gas (GHG) emissions. Methane is a potent greenhouse gas and burning it lessens its contribution to global warming. Rising fuel prices and the public’s desire for new sources of renewable energy and reduced carbon emissions have led to government policies that support the adoption of anaerobic digesters by livestock producers. A USDA Economic Research Service (ERS) study considers how the design of such policies would affect farmer adoption rates of digesters, farm incomes, and environmental benefits from use of the technology.

Policies currently in place in the U.S. that aim to make digesters more profitable for operators include:

• construction-cost subsidies (e.g., loan guarantees, accelerated depreciation, cost-share programs);

• renewable energy standards that raise the price of digester-generated renewable electricity; and

• carbon offset markets that pay farmers for their emissions reductions.

The ERS compared these three policy approaches in terms of their effect on operator net returns, digester adoption rates, electricity generation and sales, GHG emissions, and program costs. For each policy, researchers also estimated the net benefits to society from greater renewable energy production and lower GHG emissions plus the increase in producers’ profits from digester adoption, net of the policy costs.

Under a scenario with a hypothetical policy budget of $500 million over a 15-year period, the construction cost-share program (providing a 71 percent subsidy) was found to induce the largest number of operations to adopt a digester and stimulate the most renewable electricity generation. The carbon

pricing policy (paying $11 per ton of carbon dioxide equivalents) was the most effective mechanism for reducing GHG emissions from dairy manure management, and the renewable energy subsidy (resulting in a price premium of 9.8 cents per kilowatt hour of renewable electricity) encouraged the greatest amount of electricity sales.

For all three policy approaches considered, the public benefits from lower GHG emissions and higher renewable electricity production exceed the net

AD Findings Table

returns to farmers from selling electricity and carbon credits (the private benefits). In addition, for all three policies, the net benefits are positive – that is, the total private and public benefits outweigh the policy cost. While farmers might not necessarily find it profitable to adopt a digester without any government financial assistance, the study shows that public programs can stimulate digester adoption that results in substantial environmental benefits.

This finding is drawn from Carbon Emissions, Renewable Electricity and Profits: Comparing Alternative Policies to Promote Anaerobic Digesters on Dairies, by Nigel Key and Stacy Sneeringer, in Agricultural and Resource Economics Review, Vol. 41, No. 2, August 2012, pp. 139-157.

fendt.com/us

Even in the manure business, we’re not afraid to stand behind our tractor.

Hauling and spreading is tough on a tractor. That’s why we not only make our tractors as tough and capable as they come, but we also back them with a service program that is second to no one.

From the speed and safety of our Vario transmission and Reactive Steering System, to our Fendt Gold Star Customer Care program that gives you 3-years or 3,000 hours of comprehensive warranty with included routine maintenance, there is no better partner for your operation than Fendt.

In the hauling business, you need a tractor that’s capable and dependable.

That’s why the best run operations run Fendt.