BY MATT JONES

Construction is underway for a new 240metre bridge over the Petitcodiac River between Moncton and Riverview in New Brunswick. As part of that construction, commuters passing over the existing Gunningsville Bridge have become accustomed to seeing a large mobile crane towering over the site in recent months. The work

on the bridge has been divided into a number of contracts, as companies with varied specialties have taken over different aspects of the job. The major crane operations have been under the purview of Canam-Bridges, which is tasked with erecting the structure and the bearings on the bridge.

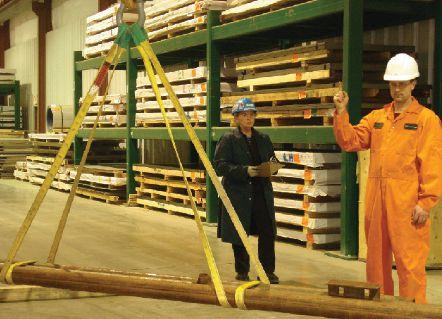

Judy Mellott-Green committed to improving standards for overhead crane industry

BY ANDREW SNOOK

here are few people with more years dedicated to standards in Canada’s overhead crane industry than Judy Mellott-Green. The president and CEO of the All Canadian Training Institute (ACTi) has been active in the industry for nearly three decades, and is just as passionate as ever about promoting safety and improving standards across Canada.

Working on police escort phase-outs, permitting automation and harmonization

BY ANDREW SNOOK

The Specialized Carriers & Rigging Association (SC&RA) have been busy on this side of the Canada-U.S. border, working with the Ministry of Transportation of Ontario (MTO) on the current phase-out of Ontario Provincial Police (OPP) escorts in the province for superload permit moves.

The phase-out began on July 1, 2018 with a contingency period offered, in which the OPP could fill in until there were an adequate number of newly certified escorts made available through the Certified Superload Escort Program. Effective January 1, 2019 the OPP will stop providing paid duty escorts to assist in the movement of Oversize/Overweight (OS/OW) Superloads.

Steven Todd, vice-president of transportation with the SC&RA, says the program is the first of its kind in North America that will fully phase out police escorts.

“This is very unique new program and new policy,” he says. “It gave our industry an opportunity for the first time to give serious deliberation of replacing all police escorts as we know it.”

Beloeil, Quebec 2005 Boul. De L’Industrie St Mathieu 450-467-2642 ebeauvais@fdrapeau.com Maugerville, New Brunswick 1617 Route 105 506-357-0211 boydequipment@mail.com

Editor – Andrew Snook asnook@annexbusinessmedia.com • Tel: 289-221-8946

Account Manager – Amanda McCracken amccracken@annexbusinessmedia.com • Tel: +1-226-931-5095

Art Director – Svetlana Avrutin

Regular Contributors

Saul Chernos, Nelson Dewey, Matt Jones, Carroll McCormick

Group Publisher – Scott Jamieson • sjamieson@annexbusinessmeda.com

President & CEO – Mike Fredericks

Circulation Manager – Barbara Adelt

badelt@annexbusinessmedia.com

Subscriptions – Bona Lao • blao@annexbusinessmedia.com

Tel: 416-442-5600 • 1-800-668-2374 (CDN) , ext. 3552 Fax: 416-510-6875 or 416-442-2191 www.craneandhoistcanada.com

Annex Privacy Officer – Privacy@annexbusinessmedia.com Tel: 800-668-2374

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher. A subscription to Crane & Hoist Canada (six issues) is $37 + Tax per year in Canada. For subscriptions in the USA the price is $37 USD. Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875.

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT. 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1 ISSN 1923-788X

Next Advertising Deadline: January 25, 2019

Don’t miss the opportunity to be part of this exciting new industry publication. For more information, or to reserve space in the next issue, call Amanda McCracken at our Advertising Department Tel: +1-226-931-5095 • amccracken@annexbusinessmedia.com

Next Editorial Deadline: January 25, 2019 For writers’ guidelines and submission requirements get in touch with the editor, Andrew Snook, at 289-221-8946 Email: asnook@ annexbusinessmedia.com

rom British Columbia and The Yukon to St. John’s, Newfoundland, Crane & Hoist Canada is searching Canada’s crane industry for the best and brightest young workers in the industry.

FThis program will recognize 10 outstanding individuals from across Canada who had made significant contributions to the industry before their 40th birthdays. This can include anyone who was under the age of 40 as of December 31, 2018. Nominees can come from anyone who is involved in Canada’s crane industry, including business owners and management within all aspects of the industry, crane operators, technicians, trainers, industry association employees and researchers.

WHAT ARE THE QUALIFICATIONS TO NOMINATE AN INDIVIDUAL, YOU ASK?

Here are the guidelines to the Top 10 Under 40 contest:

• Nominees must be younger than 40 before Dec. 2018.

• Nominees must either be working in Canada or of Canadian nationality.

• Nominations are due by September 1, 2019.

MUST THE NOMINEE BE CANADIAN?

No. The nominee can be of any nationality, but must be employed in Canada. We also encourage the nominations of Canadians working outside of the country.

WHO CAN NOMINATE SOMEONE?

Nominators can include advisors, supervisors, coworkers, or colleagues familiar with the nominee’s work and character.

Have photos of unique cranes and hoists?

Email a photo and brief description to editor Andrew Snook at asnook@annexbusinessmedia.com.

WHAT TYPE OF INFORMATION SHOULD BE INCLUDED ABOUT THE NOMINEE?

Potential information to submit about the nominee can include (but is not exclusive to): Projects or initiatives the individual is or has been involved in; results from past projects; day-to-day job responsibilities; workplace initiatives outside of regular job duties; and community involvement.

IS A SECONDARY REFERENCE FOR THE NOMINEE REQUIRED?

No. However, the nomination form includes fields for a secondary reference, which is suggested to include. All nominees that are selected for Crane & Hoist Canada’s Top 10 Under 40 program will receive a framed certificate recognizing their achievement, and will be featured in the November/December 2019 issue of the publication. Who knows, one lucky individual might even end up gracing the front page!

HAVE MORE QUESTIONS?

For more information on the Top 10 Under 40 program, or how to nominate an individual, contact editor Andrew Snook at asnook@annexbusinessmedia.com, or call 289.221.8946.

Good luck to all the nominees. We look forward to featuring the industry’s best and brightest in 2019!

This antique Grove RT is still getting the job done for JJ Curran Crane Company. It was originially purchased in 1962 by John “JJ” Curran when he started his crane company in Detroit, Mich. JJ Curran Crane Company uses the crane for a variety of tasks that require a compact crane, such as lifting inside of steel mills, refineries and cement plants, and working outside, transporting boats or handling materials on the job site. Curran estimates the crane has completed some 300 jobs in the last seven years alone.

Image and text courtesy of Manitowoc.

BY MATT JONES

On the morning of October 24, a mobile crane was involved in a collision with a tree branch in Surrey, B.C., which tore the tree in half. The incident took place on 128th Street, and resulted in a road closure for several hours, minor injuries to a passerby and damage to the crane cab.

The 200-ton Liebherr hydraulic mobile crane, owned by Mega Cranes Ltd., was passing through a construction zone when traffic cones directed it in the area normally used as a bike lane. Part of the boom winch appeared to have caught on an overhanging tree. Part of the tree struck a woman who was walking by at the time, who was taken to the hospital with minor injuries.

“The way that the road is, the truck wouldn’t normally have connected with the tree, but with the construction in the area, they had cones averting traffic over to the one lane where the bike lane is,” says Surrey RCMP media relations officer Elenore Sturko. “That contributed to the truck moving over to accommodate for the construction and the tree was overhanging on the roadway.”

CSturko says that the construction crew hadn’t anticipated how larger vehicles could connect with the overhanging tree when laying out the traffic cones; however, no charges are being pursued against either the driver or the construction company. Mega Cranes Ltd., however, feel that the city is liable as the permit-issuer and are pursuing a claim against the municipality.

“It was a lane closure and a permit was issued by the City of Surrey to close the lane, and on the lane we were required to go on there was a low hanging tree,” says Mega Cranes Ltd. vicepresident Kelly Petersen. “Not only did it injure a person, but it

damaged our equipment, so we believe that the city is responsible for it. It’s their jurisdiction to make sure the streets and roadways are free for navigation and this was not provided.”

Peterson says damages to the cab have been estimated to exceed $10,000. As of press time, they had not yet heard back from the city regarding their claim. In the meantime, Petersen says the company has ensured that the incident was reviewed in their monthly safety meeting, so that employees are aware of what happened and will take extra diligence when traversing through a construction zone, even when being directed by traffic cones.

BY SAUL CHERNOS

Aanada’s largest trade event for the heavy equipment industry is making its return to Mississauga’s International Centre on March 28 and 29, 2019. As part of its 22nd year, the event is planning a variety of special pavilions and activities for all corners of the industry.

Every two years, industry leaders head to this event for big sales, networking, and a glimpse at what’s on the horizon for i.e. the various sectors of the construction industry, such as road building, snow removal, snow and ice removal, crushing and screening aggregates, and beyond.

With enticing features including a strong educational program, recruiting efforts and a focus on safety products, the show offers an unmatched chance to get on top of current industry trends and prepare for the big projects of tomorrow. Some of the 2019 highlights will include:

Rental Pavilion

Housed in Hall 1, the Rental Pavilion will showcase the latest equipment, tools and products for sale or rent to the tens of thousands of contractors and professionals who attend the show. It offers exhibitors a unique opportunity to influence the rental frequency and volume of both large and small contractors.

Since its first edition in 1997, well over 100,000 visitors have walked the floors at the National Heavy Equipment Show. The majority of attendees are comprised of professionals from contracting, equipment rental, and government sectors – meaning thousands of serious buyers on the show floor. With over 13,000 visitors in both 2017 and 2015, next year’s event is expected to draw larger crowds than ever, including key decision makers and purchasers.

If you’ve ever been involved with the National Heavy Equipment Show, you know that booth space fills up fast. The show is a sell-out year after year - so if you’re interested in exhibiting at the largest heavy equipment event in Canada, it’s a good idea to get space booked early. Contact Mark Cusack (mcusack@mpltd.ca) or Mike Neeb (mneeb@ mpltd.ca) and visit NHES.ca for complete exhibit package and pricing.

Show details

Thursday, March 28, 2019 • 9 a.m. to 5 p.m. Friday, March 29, 2019 • 9 a.m. to 5 p.m.

International Centre, 6900 Airport Roadm Mississauga, Ont. L4V 1E8 www.NHES.ca

Submitted

21-day strike that saw crane operators and other heavy machine operators set up picket lines at construction sites across much of Nova Scotia in late October ended on Nov. 14, and both sides are heading for binding conciliation. Members of the International Union of Operating Engineers Local 721 walked off the job after a year of negotiations with the Nova Scotia Construction Labour Relations Association, which represents the unionized industrial commercial institutional construction sector.

“Our contract expired the end of April,” Local 721 president and business manager Joey MacLellan said, describing pay equity with other unionized construction workers as the key demand.

MacLellan expressed frustration with the process. Revisions in the 1980s to the Nova Scotia Trade Union Act limits strikes by any one local to 21 days unless three of the province’s 13 construction trades locals happen to be in a legal strike position at the same time. In this case, however, all but two locals have already reached agreements, leaving Local 721 and an elevator constructors’ local without full striking rights. MacLellan said he believes the provision legitimately responded to a series of back-to-back strikes that significantly disrupted construction activity in Nova Scotia. “This was put in place in order to try to correct that and get things back under control,” he said.

While the provision forced striking members back to work, it put into play binding conciliation where each side appoints a representative, with a third member either mutually agreed to or appointed by the provincial labour ministry to act as chair. The panel can ultimately impose a settlement, though these must be consistent with settlements achieved by the other locals. The measure indeed tempered job action. Local 721 hadn’t gone on strike since 1989 except for a weekend-long picket three years ago that started late one Friday night and was resolved by Sunday. Now, though, MacLellan said some adjustment is needed towards the unions because the 13 locals each have individual needs and priorities and there’s little chance any three of them will have simultaneous contract issues.

This time, for instance, Local 721 members are seeking wage parity but are generally satisfied with union hall hiring, dispatch rules and other “language” issues, whereas for other locals it might be the polar opposite.

“Getting them all to agree or be in a position together and be willing to stay together can be very difficult,” MacLellan said, adding that labour relations needs to weigh employers and workers equally. “You have to keep it in perfect balance in order for things to work. The scales were once tilted way too far towards the unions, so they corrected it, but then it continued and it’s now tilted way too far to the management side.”

NSCLRA president Robert Shepherd said its wage proposal “is consistent with the majority of the other trade unions that we already have signed new collective agreements with.”

Shepherd said the 21-day strike rule provides stability for the construction industry.

With the 21-day strike period now concluded, operators and other local members are back on the job and the panel selection process is underway. During the strike, Local 721 members picketed various job sites, including Queen’s Marque on the waterfront and the Curve/YMCA, both mixed-use developments. “Most of the work that pertains to our trade is in the Halifax area so it’s concentrated there,” MacLellan said.

Northern Pulp in Pictou and other sites across Nova Scotia were also affected, except for Cape Breton, where Local 721 members signed an earlier, separate collective agreement.

LRT 1090-2.1: 47 m / 154 ft full power boom

LRT 1100-2.1: 50 m / 164 ft pinned boom

Safe & Strong High lifting capacities with a maximum of safety due to VarioBase®

Globally uniform load charts conform to ANSI, EN and further standards

Safe access points and flat deck

Comfortable Simple and easy to operate

Operator friendly extra wide and tiltable crane cabin

Sales and service directly from the manufacturer

Liebherr-Canada Ltd. 1015 Sutton Drive

Burlington, Ontario L7L 5Z8

Phone: +1 905 319 9222

E-mail: info.lca@liebherr.com www.facebook.com/LiebherrConstruction www.liebherr.ca

continued from cover

Todd said a similar program was run in Pennsylvania but it was on a much smaller scale, replacing a small number of police-required escorts.

“This is certainly the first time any government we worked with went the whole nine yards,” he said.

The SC&RA had its concerns about the new escort program at first; but after having the opportunity to deliberate with the MTO on how the program was being implemented, the association was far more comfortable.

“We went from a fairly high level of concern, to a fairly high level of endorsement,” Todd says. “Reason being that we were satisfied with the training program the MTO is requiring.”

Although the SC&RA is extremely satisfied with how the program is moving forward, it does have one remaining concern: the ability to request police escorts in extraordinary circumstances.

“We’re 99 per cent very satisfied,” Todd says. “In an extraordinary circumstance, in the interest of safety, I believe they would allow that. General motorists tend to respect red and blue flashing lights more than they do yellow.”

There are currently 116 SC&RA member companies across the country. Of those, about 40 of them are based in Ontario. Todd says this represents anywhere from 5,000 to 10,000 people across the country. The SC&RA is fully endorsing the new program and believes it will generate cost savings for its members operating in Canada.

“Not just in terms of what we would normally be charged by OPP versus private,” Todd says. “The real cost savings we’ll see is once this program gets stocked with enough fully trained pilots… we’ll be able to schedule and make these moves in a much more cost-effective manner.”

A shortage of trained escorts is currently the program’s biggest hurdle. To date, there have only been a handful of companies through the program and there are currently not

enough escorts to meet demand in 2019. That said, business is expected to continue as usual.

“One way or another, we as an industry will correct that imbalance; if there is one,” Todd says. “We certainly won’t stand for not moving our loads.”

For questions or interest in the Certified Superload Escort Program, contact the Business Innovation Team at BIT@ontario.ca.

One of the SC&RA members’ biggest issues in Canada right now is related to a lack of automation within the permitting processes in Ontario for some Oversized/Overweight (OS/OW) permits and routine loads. Automation of certain OS/OW permitting processes has already been implemented in more than 30 U.S. States and interest in the process is continuing to grow south of the border. Automated permitting allows for an application to be received, analyzed, and if approved, issued instantaneously without human contact 24 hours a day, seven days a week.

Todd says that there is a consensus among the participating U.S. States that safety and efficiencies have improved thanks to the automation processes. These benefits, as described by both government officials and industry leaders, include:

• The average permit turnaround time (PTA) decreased from several days and hours to just minutes for most routine and some OS/OW permits;

• Nearly all U.S. States that have implemented automated systems report a moderate increase in total permits applications and issuance;

• Increased automated permit volume has proportionally increased revenues;

• Accuracy of permits has dramatically improved;

• A higher percentage of carriers have ordered, obtained,

and travelled on State-issued permits following implementation of automated permit systems;

• Roadway safety for all motorists has improved;

• The infrastructure integrity, including the maintaining of bridges and overhead structures, has improved;

• As a result of moving to automated permitting, U.S. States are able to achieve staff efficiencies and reduce costs. Fewer people are required or less time is needed to review and process OS/OW permits, freeing up employees to handle customer service inquiries; and

• U.S. States have more flexibility with internal headcount issues.

Todd stresses that safety is improved as a result of automated permitting systems, and that the speed at which the permits are being processed reduces the temptation for operators to run without one.

“While we prefer to think everyone in the industry did things legally and in the right way, some carriers and crane companies will run without a permit,” he says, adding that this is often due to delays caused by the manual issuing of permits sometimes taking days or weeks. “Because time is money, it stands to reason that the longer it takes government to issue a permit, the greater the temptation by the carrier and their customer to run without a permit... carriers are far less likely to move without a permit if they know they’ll get their answer moments after they submit.”

The increased speed at which an OS/OW permit can be processed through automation is especially important for smaller operators and owners, that often only have time to order permits in the evenings, nights and weekends after their travels.

Todd calls the automation process a win-win-win scenario for all parties involved, including governments, industry and taxpayers. The SC&RA are stressing to the provincial gov-

BY SAUL CHERNOS

Like many megaprojects, construction of the Muskrat Falls Generation Facility on the Lower Churchill River in Labrador has faced its share of challenges.

When shovels hit the ground in 2013, completion was anticipated by 2017 at a cost of roughly $7.4 billion. The proponent, Nalcor Energy, now projects work to continue into 2019 with the price tag revised to $12.7 billion. A concrete formwork collapse and crane tip-over have also occurred, and concerns have been raised about flooding and methyl-mercury pollution in waterways. In September, Premier Dwight Ball ordered a public inquiry, calling Muskrat Falls “the greatest fiscal mistake in Newfoundland and Labrador’s history.”

While the various challenges get sorted out, construction continues apace, and a series of customdesigned electrically operated lifting platforms are helping workers reach the enormous exterior of the dam’s 47-metre-tall powerhouse, considered to be the literal heart of the project.

The Hydro Mobile F300 platforms are supplied by Hydro Mobile and Special Projects Group, two divisions of Montreal-based AGF Access Group.

Canmec-CRT, a joint-venture between the Canmec Group and CRT Construction that was created to oversee construction of some of the dam’s major components, purchased a dozen of the platforms in 2014 to provide closeup access to sections of the concrete spillway structures. The contractor has now moved these platforms to the powerhouse gates and brought in nine additional ones.

Essentially, the platforms replace conventional scaffolding as well as the need to use cranes to get workers and materials where they need to go. The key,

“More and more nowadays you’ll see work platforms which have the ability to move up or down, to transport material and allow workers to access the facade.”

says Alex Di Domenico, AGF’s vice-president of major projects, is that the platforms each have two independent bridges that can move up and down, much like twin elevators.

“More and more nowadays you’ll see work platforms which have the ability to move up or down, to transport material and allow workers to access the facade,” Di Domenico says.

Di Domenico says the company has supplied platforms for a wide variety of construction jobs, from

the Champlain Bridge in Montréal to the World Trade Center reconstruction in New York City following 9/11.

The technology is based on a drive system that can be either gas or electrically powered. In this case, electricity is supplied by generators.

The platforms, designed for projects generally exceeding 100 feet in height, essentially consist of bridgelike sections bolted together. The two independent sections can travel up or down on a single mast at speeds of up to 38 feet a minute. Combined, they can support up to 12,000 lb.

The mast itself can consist of either a gear rack system or a ratchet-and-rung-type system. For ratchet-and-rung, imagine climbing a ladder one foot and one hand at a time. “It’s kind of a similar technology,” Di Domenico says. “We’re using lifting hooks that climb the mast tower. In the case of Muskrat Falls we used a mast tower consisting of a rack-and-pinion drive system with electrical motors driving the entire platform up and down.”

Di Domenico says the platforms feature customdesigned fixed and mobile extensions and bridges. Semiautomatic greasing systems ensure the gear rack mounted on the tower remains lubricated, oil heaters enable work to continue during moderate wintertime weather, and safe zone detection systems enhance safe access and work in areas that are particularly confined.

“In the past, general and specialty contractors used standard scaffolding for dam construction,” Di Domenico says. “Depending on the environment and application, scaffolding can be a very inefficient option because it’s time consuming to erect and dismantle and needs to be built up in phases following each construction step.”

The up-and-down movement of the platforms simplifies the overall operation and increases efficiency, while their modular design enables them to be easily moved to different parts of the project — as when the dozen units were relocated from the spillway to the powerhouse — or even reassembled for other projects elsewhere.

“The mast tower consists of five-foot section pieces that are bolted together and can be erected in 20-foot segments,” Di Domenico says. “Once the base core unit is in place we can erect the work platform mast tower by its own system without relying on an independent mobile device.”

While scaffolding could be used at a site like Muskrat Falls, Di Domenico says choosing between the different options comes down to cost efficiency and site requirements. “Each job site would be analyzed to determine which access solution is best suited,” he adds.

Louis-Phillipe Robillard, marketing manager with AGF, said the company signed a non-disclosure agreement that doesn’t allow it to disclose contractual details. But, depending on their configuration, standard platforms without customization can range between $20,000 and $150,000. Further customization is on a case-by-case basis.

“Service, installation and training are a big part of such projects,” Robillard said. “We have different types of units — we even have one you can carry on the back of a pickup truck. That, for sure, is a very more affordable unit. But a project of this scale is using the cream of the crop.”

The powerhouse is the last major component required for creating the final Muskrat Falls reservoir. Some of the project’s biggest cranes, including two 340-tonne overhead machines capable of making a tandem lift of 650 tonnes, have also seen duty at the powerhouse.

Once in operation, the 824-megawatt facility is expected to become the second largest hydro plant in Atlantic Canada.

BY MATT JONES

ANova Scotia First Nation band and a metal fabrication company have collaborated on a new crane service; which has already begun performing lifts in the area. Mi’kmaq Crane Services Inc. is the result of collaboration between the Eskasoni First Nation Corporate division and East Coast Metal Fabrication (ECMF). Steve Parsons, general manager for Eskasoni Corporate, says one of their mandates is to identify employable opportunities for band members.

“Three and a half years ago, we sent six guys from Eskasoni to do the formal training for cranes,” Parsons says. “Since then, we’ve had four of the individuals working for other companies and our thought was that if we could find a partner, that we would certainly look at creating a joint venture whereby we would not only be able to provide an opportunity for band members to work in that sector, but also to create a revenue stream.”

Eskasoni Corporate had an existing relationship with ECMF – several band members had trained with the company in metal fabrication and two were still working there. A formal partnership soon followed, with the First Nations community owning 51 per cent of the business.

“It brings a lot of benefits to us in so many ways, since we’re dealing with steel and steel erection on a day-to-day basis,” says Sam Hines, safety coordinator and administrative assistant for ECMF. “We do a lot of subcontracting of cranes. We don’t mind subcontracting the work, but to be able to do it ourselves with our own employees and our own cranes is quite a benefit to us.”

Parsons says the company aims to be versatile, and able to supply any need for cranes in the industry. The company has 110-ton cranes and a couple of boom trucks, and has already utilized them on a variety of projects. The company helped Marine Atlantic replace the bumpers on their wharves in North Sydney and erected the steel for an ice rink at the Membertou First Nation in Sydney, N.S. They have also performed work for Nova Scotia Power and the Donkin Mine.

“So we have some major corporate entities as customers,” Parsons says. “But we’re also prepared to serve anybody that requires a boom truck. We’re open for business and giving quotes every day for services. We’re picking away at it in the local area, and I think we’ll be successful moving forward.”

As they continue to operate, Mi’kmaq Crane Services are learning what balances they need to strike for maximum effectiveness. Crane work by its nature is not cheap; however a young company also needs to be competitively priced. And working around the scheduling demands of your customers can be challenging.

“Some companies that we deal with require crane turnaround in 24 or 48 hours, so we need to be able to meet the demands and supply the capacity for each and all jobs,” Parsons says. “Sometimes you need to provide it today. Service is key and our mandate is to provide good quality service at a reasonable price.”

This is Eskasoni Corporate’s second attempt at launching a crane company. In 2014, Memski Projects (a collaboration between the Eskasoni and Membertou bands) signed an agreement with Scotia Crane Rentals to form a new crane service. However, Scotia Crane Rentals went out of business in 2016. With Mi’kmaq Crane Services already moving forward with some significant clients, however, Parsons is hopeful for their future.

“We are a new company but we’ve got experienced operators on our cranes and our general manager is well-rounded with over 30 years of experience in the crane industry,” he says. “All we want is a fighting chance to quote jobs. And given the opportunity to quote the jobs, we feel that we can be very competitive in nature of pricing and provide above and beyond expectation when it comes to delivery of service.”

Crawler crane market growing at 7% CAGR to reach US$3 billion by

According to a new research report by Global Market Insights, the crawler crane market to is expected to exceed US$3 billion by 2024.

The shipments are expected to grow at a CAGR of over four per cent. Increasing utilization of crawler cranes in the energy sector is anticipated to drive the crawler crane market growth. Several manufacturers have developed energy sectorspecific machines that will experience a high demand. For instance, Manitowoc has launched a wind power crane, Grove GTK1100, used for wind turbine operations such as erection and construction. Additionally, the crawler crane market is witnessing growth opportunities due to the increasing infrastructure projects across the globe. Companies profiled in this report are based on business overview, financial data, product landscape, strategic outlook and SWOT analysis. They include The Liebherr Group; Escorts Limited; Konecranes; Terex Corporation; Link-Belt Cranes; Palfinger AG; Sany Group; Komatsu America Corp.; Jekko s.r.l.; Kobelco Construction Machinery USA, Inc.; and Effer S.p.A.

Economic growth across the globe, especially in China, India, and Southeast Asian markets, has led to increased infrastructure demand. Growing building and construction spending due to a rise in per-capita disposable income, along with enhanced infrastructure in Asia Pacific and Latin America, will drive the crawler crane market. Growth in Latin America will be led by an increase in infrastructure spending, mainly transportation and energy, closely followed by spending on non-residential structures. The key areas of construction growth in emerging economies are social, transport, energy, defense infrastructure, and government accommodation.

High maintenance costs and initial investments are the major factors hindering the crawler crane market development. The high cost is discouraging several business manufacturers and OEMs from deploying high-end machines. Companies consider that investments for automated equipment must meet the global quality and manufacturing standards. In addition, the cranes are available on lease from the manufacturers at a lower price than the newer machines. Instead of procuring new equipment, some customers commonly prefer renting equipment, which is anticipated to hamper the market.

The construction application segment in China dominated the industry with a market share of around 40 per cent in 2017. Construction applications offer a huge impetus for growth in the market. The global construction spending registered US$7.2 trillion in 2013 and is anticipated to reach US$15.9 trillion by 2024. Increasing construction spending is a major factor escalating the crawler crane market growth. Rising government focus toward infrastructure development projects along with the consumer preference for luxurious and aesthetic constructions fuels the market demand. Growing necessity for houses and high investment requirements, such as smart city projects and high construction spending, in economically stable countries are expected to contribute to the industry demand.

The crawler crane market is witnessing demand for low-level access units, niche machines, and customized choices. Growing installation and maintenance activities for the upgrade of fire stations, street lights, glasswork, and other associated infrastructure coupled with increasing organization of several events such as concerts, corporate events, and festivals, are driving the need for these machines across several regions.

The Asia Pacific crawler crane market is witnessing a high adoption in the construction and mining sectors and expected to grow at a CAGR of over five per cent from 2018 to 2024. Global companies are expanding their business operations in the region by collaborating with local manufacturers. For instance, in December 2016 Jekko s.r.l. collaborated with Lee Hyun Soo and Dennis Shin for establishing a new subsidiary, Jekko Korea in Seoul. Countries including India, China, and Japan are adopting advanced automated technologies in industrial sectors for enhancing their business operations. The escalating infrastructure development projects in countries, including India, will favour the crawler crane market growth. To browse the report, visit: www.gminsights.com/industry-analysis/crawler-crane-market.

Submitted by Global Market Insights.

continued from cover

Judy still participates as a technical committee member on the CSA B167 Overhead Crane Standard and has participated on all revisions of this standard. She has participated in committees with the CSA for many years and looks back on her years working with CSA committees with great fondness.

“It’s been a very good working relationship,” Judy says during a meeting at ACTi’s head office in Edmonton, Alta.

That feeling is obviously mutual, as the CSA presented Judy with the CSA 2016 Award of Merit in recognition of her exemplary goal-oriented leadership.

In addition to her work on the CSA B167

Crane Standard, Judy is the CSA’s recognized liaison to the American Society of Mechanical Engineers’ ASME B30 Standards – the first Canadian to have ever been recognized as the CSA liaison on the ASME B30 Standards Committee. This work is vital to Canada’s overhead crane industry, as the ASME B 30 Overhead Cranes standards are recognized and utilized by all applicable industries across Canada. There is good reason Judy was selected for such an important role.

Judy got her start in the industry in 1989 working hand-in-hand with her husband Bill Green at All Crane Parts & Service, an overhead crane inspection and maintenance company in Edmonton. Bill had the industry experience and he encouraged her to get involved, and Judy learned quickly, and recognized a need for improved safety regulations within the industry in Alberta.

“The existing occupational health and safety regulations for overhead cranes contained limited content, and were in need of revision,” she says.

From there, Judy began her work finding ways to improve safety regulations for crane operators in Alberta. She met with Alberta Workplace Health & Safety (AWHS) director Ray Cislo to discuss updating these sections of the code. Cislo said they could set up a meeting to discuss the need for changes and Judy would need to bring industry to the table, to discuss revision of existing safety codes to current CSA B167 standards. Judy gathered more than 15 of the largest companies in Alberta; resulting in forming an industry occupational health and safety working committee. The Safety Code for Overhead Cranes was successfully revised and published. Since that time, Judy has been responsible for forming three AWHS industry revision committees – she was the chairperson for two of them – and that work has resulted in two “Industry Best Practices Bulletins” being published by AWHS, including two subsequent revisions. These practices still stand as the current industry minimum requirements in Alberta.

It wasn’t long before she became a CSA committee member on the B167 Overhead Crane Standard, participating on three revision committees to the current CSA B167-16. Since CSA references the ASME B30 standards, there was an important need for CSA to have representation on the ASME B 30.2 Overhead Cranes standards, as they are utilized by Canadian industries across Canada. This was proposed to David Shanahan, director for CSA B167 and Michael Merker, executive director for ASME B30 standards and was approved. Judy is the first Canadian to be approved and recognized as CSA Liaison on the ASME B30 Standards. The purpose of this alliance is to ensure the ASME B30 Standards are also recognized and utilized in all applicable industries across Canada.

In addition to her work with the CSA and ASME over the years, Judy still actively works with AWHS, assisting in revising the codes and regulations related to overhead cranes.

Judy was also a task force member for the National Commission for Certification of Crane Operators’ (NCCCO) certification program for overhead crane operators. Her work on this task force resulted in the NCCCO changing the certification exam requirement to be applicable to all overhead lifting equipment five tons and over.

And when she’s not busy helping organizations improve standards, she is an active writer for various international industry magazines (Crane & Hoist Canada included, starting with our March/April 2019 issue).

To say she has kept her plate full over the years would be a severe understatement. This is especially true since she has performed all of this volunteer work while running the All Canadian Training Institute for the past 25 years, which provides industry with safety training for overhead crane operators and supervisors. This training provides operators and supervisors across Canada and the U.S. with all the necessary tools to ensure the safety training they provide to their employees is current and compliant with all applicable CSA and ASME standards.

Without question, Judy Mellott-Green’s commitment to improving safety standards within the overhead crane industry has made a significant impact in the improvement of standards not only in Alberta, but the rest of Canada as well. To any other individual that is equally passionate about advancing standards within the industry, Judy offers this advice:

“All types of powered lift equipment from a pallet jack, forklift, to a mobile crane, etc. has the potential to result in an injury accident or fatality, if improperly operated,” she says. “Please ensure all lifting equipment is inspected and maintained in accordance to applicable CSA-B167 and ASME B30 standards, prior to operating. Ensure all equipment operators are properly trained on the equipment, as well as rigging hardware, inspections, load calculations and applications. It is ACTi’s objective to ensure every worker is safe at the end of shift.”

For more information about the All Canadian Training Institute Inc., visit www.actisafety.ca.

In preparation for the 21st anniversary celebrations, the Crane Rental Association of Canada (CRAC) is accepting applications for its annual Safety Awards. The criteria and application form can be found on the CRAC website. The Safety Awards are open to member crane rental companies and companies receiving the awards will be listed on the CRAC website and covered in partner publications.

Renewal time!

‘Tis the season to renew your CRAC membership or join if you are not already a member. Here are some of the other advantages of becoming a member of CRAC:

• All members receive a copy of the CRAC Electronic Member Directory;

• Each member has an equal vote regardless of size;

• Non-union and union member companies are welcome;

• Members receive an annual Membership Certificate;

• Members have the opportunity to participate in various committees;

• Attending the CRAC Conference is a benefit of membership – exclusive to member companies and their employees can attend the conference;

• Members receive the latest information from manufacturers, suppliers of equipment and services;

• Our annual Safety Awards, which were launched at the 2017 AGM with the first edition taking place in 2018;

• Longevity Awards will be presented at the 2019 AGM;

• The Boom Dolly Research Committee, which involves 27 companies dedicated to managing the transportation risks and working to improve weight restrictions in every Canadian province; and

• Members have opportunities to become directors and take on leadership roles in the association.

Take advantage of the Early Bird Discount and sign-up for the Crane Rental Association of Canada’s 2019 Annual Conference taking place at the Delta Hotels Prince Edward in Charlottetown, P.E.I.

Three days of business and social events for all members and spouses of the association.

The theme for the 2019 conference is “Navigating the changes!” and will feature speakers addressing topics of wide interest including the growing millennial workforce, the legalization of marijuana, and Indigenous rights and partnerships.

Spouses will be invited to attend some of these sessions as well as participate in the spousal program.

For membership information or to register for the conference, please visit www.crac-aclg.ca or email claire@crac-aclg.ca.

Wishing everyone a Happy New Year and great success in 2019!

BY ANDREW SNOOK

Mini-cranes are used in a variety of applications across Canada from glass installations to construction in areas requiring lifting equipment with smaller footprints, and plant and mill maintenance. Depending on where you are in Canada, the application for these unique machines can differ significantly.

In the larger urban areas with very active condominium and commercial markets, like Toronto, Montreal and Vancouver, glazing and steel work are significant contributors to the increasing demand for mini-cranes, and they’re looking for serious reach.

“We’re definitely seeing a move towards the larger mini crane versions,” says Jimmy Latta, sales representative for Up & Down Lifting Solutions based in Ayr, Ont., which has cranes all over Canada but does a lot of work servicing the Greater Toronto Area. “We have mini-cranes with up to 90 feet of boom in them. Previously it was single-floor, second-floor jobs, but now we’re seeing a lot more jobs requiring 80 or 90 feet of boom. It’s mainly a change in terms of reach than capacity.”

Although extended reach is the biggest driver for the increased demand for larger mini-cranes, the weight of glass installations has also played a factor. The glass is getting larger and larger, making it increasingly difficult for companies to do it manually anymore.

“The glass is really taking a change in terms of much larger installations,” Latta says. “It’s not uncommon for glazers to install 500-lb. to 1,000-lb. pieces of glass. They used to use five or six guys [to install the glass], now they’re bringing in mini-cranes.”

The constant demand for more sophisticated building designs with tighter building envelopes and more modern architecture has been a big driver for the mini-crane market.

“It’s always been a popular tool for window and curtain wall installations,” says Tony Inman, president for Maeda USA. “The architects and designers keep designing with more glass and heavier glass.”

Inman says he has also seen an increased demand for minicranes for applications like steel erection and steel installation.

“Especially when it comes to building expansions, or working on a building that already exists, on a roof, or new construction,” he says, adding that it can be more efficient to use a mini-crane for some of these applications where a tower crane cannot reach, or to prevent unnecessarily tying up a tower crane on a jobsite.

In Western Canada, Leavitt Cranes has also experienced an uptick in interest in mini-cranes. The B.C.-based company has locations in the Vancouver and Calgary areas, as well as branches in Seattle and Mount Vernon, Wash. They are the Jekko importer for Canada and a distributor for SpyderCrane in Washington and Oregon. They have a total of 32 mini-cranes in their fleet between rental and new equipment inventory, and they’re being used for more than glass and steel applications.

“We’ve been in the mini-crane business since 2014 and I think it’s picking up momentum,” says Erick Zampini, general manager for Leavitt Cranes. “We’re starting to see the concrete guys utilize these machines [usually for stripping or placing concrete forms], as well as cruise ships… definitely the main two would be glazers and the concrete companies.”

Latta says bringing in larger capacity mini-cranes has expanded the number of applications where various types of contractors can use them.

“It’s staying fairly busy,” he says. “I think you’re seeing a lot wider a variety of customers using them… before it was some steel and glazing companies, now were doing some installations in shopping malls for Christmas trees, sign companies, it’s definitely growing for sure.”

On some jobsites, zero emissions lifting systems are required. Jerry Clermont of Clermont Crane and Rigging Service Ltd. in Westbank, B.C. has DC battery-powered mini-cranes with 110-volt charging systems for these applications, and has rented his electric mini-cranes out for a variety of work with BC Hydro, small gas plants in Alberta, arenas

in Calgary and Edmonton, and work on the MICA Dam, a large hydroelectric dam on the Columbia River located approximately 135 kilometres north of Revelstoke, B.C.

“DC battery powered with 110-volt charging systems makes for more friendly power systems,” Clermont says. “There’s always 110-volt around, it’s a safe power.”

With a lot of the mini-crane rental opportunities in his region being for maintenance work in sawmills, pulp mills and the odd plywood plant, there isn’t a great deal of demand for electric-powered units. That said, Clermont sees a lot opportunity for battery-powered mini-cranes in the future for heavier manufacturing and big indoor applications.

“I like the zero-emission conversion on the small cranes, it’s just an absolute natural, I think that works,” he says.

Up & Down Lifting Solutions has also seen an uptick in battery-powered units.

“We’re definitely bringing in more battery-powered units than we have in the past,” Latta says. “Fully battery powered units or dual units, a lot of these units are working indoors in malls. Obviously, the battery-powered ones have zero emissions and they’re quiet… all of our large units we bring in now are diesel and battery powered units.”

For any large maintenance type of application – such as maintenance for steel and lumber mills or gas plant turnarounds – mini-crane demand will become more prominent as the years progress, Zampini says.

“I think at the end of the day, the true benefit of these units is their compactness and versatility, and it’s just about the product getting to the masses,” Zampini says. “It does save cost in applications… it’s about understanding what those applications are, and making sense of those costs.”

Inman expects the market to continue to grow for unconventional lifting applications, particularly in construction and plant maintenance in Eastern Canada.

“It’s all kind of trades that use them in construction,” he says. “It’s primarily oriented to inside buildings and confined areas.”

“We’re seeing a wider variety of customer base from glazers to steel erectors, to sign installers to landscapers – people are seeing them out there and trying them out,” Latta adds. “It might not be an everyday use for these companies but a lot of the times it’s an out-of-thebox solution to assist with their jobs.”

BY MATT JONES

Since 1967, drivers on Winnipeg’s Portage Avenue have been accustomed to the sight of a Lockheed T-33 Silver Star jet, which was erected as a monument in Woodhaven Park. Over 50 years of exposure to the elements has taken its toll, however, and the plane was recently crane-lifted off its pedestal for repairs, restoration and refurbishment. The jet is now back in position sporting a shiny new red paint job reminiscent of the Red Knight military pilot group who flew from 1958 to 1969.

“This particular T-33AN Silver Star Mk. 3 entered service with the RCAF (Royal Canadian Air Force) in 1955, the first part of its service life in RCAF Stations Gimli and McDonald as a trainer, and later serving in Ontario and Nova Scotia,” says Jason Bell, parks capital projects manager for the City of Winnipeg Public Works department. “It was declared surplus in 1967 and as part of the Canadian Centennial, it was presented to the City of St. James [a district of Winnipeg] to commemorate the long connection between the RCAF, the aviation industry and the City of St. James.”

Western Industrial Services was awarded the contract for removing the jet and replacing it after refurbishment. Subcontractor Prairie Iron Erectors hired Calado Crane, who utilized a 90-ton hydraulic Link-Belt mobile crane to lift the approximately 7,000-lb. aircraft from the pedestal and covered it with tarped scaffolding in a fenced area of Woodhaven Park in September.

“That crane provided the reach and weight that we could lift it up without any issues,” says Calado Crane dispatcher Chris Downey. “Everything went pretty smoothly. They got it strapped up and off the pedestal very easily.”

Over the next couple of months, paint and corrosion were removed from the aircraft’s aluminum skin with a soda blasting process, the skin and steel mounting arms were repaired and the plane was re-painted and re-decaled to Red Knight specifications. The concrete pedestal and mounting plates were also repaired and repainted. As of press time, Calado Crane was scheduled to replace the crane on the pedestal in early December.

The total cost of all work associated with the project is estimated at $170,000, which is being funded by the City of Winnipeg Capital and Land Dedication Reserve funds, a private donation of paint, and a significant contribution from the Slaughter family –Brigadier-General Bill Slaughter flew 26 solo aerobatic performances as a Red Knight in 1963 and 1964. In spring of 2019, a public event will be held to officially unveil the restored jet.

BY CHRIS MACHUT

Crane safety is an outlier, in comparison to the safeguards other industries possess and promote. That these features are the result of the pushand-pull between consumers and corporations, that resistance by executives is a thing of the past, that most companies would not think to manufacture —and we would not think it acceptable to buy — a car without seatbelts, or a house without smoke detectors, or a baby carriage without brakes is proof of the heightened demand for safety. And yet, the features we take for granted in one realm, such as rear-view cameras, are less common in the more dangerous world of construction.

I mention these cameras because insurers value them, drivers enjoy them, and critics praise them. The irony is that similar technology is available for crane operators, but it elicits silence or silent protests from the insurance industry. Put another way, the safety features that insurers insist on — that they reward automobile companies for adopting and car owners for activating — do not extend to an environment in which visibility is already hard to see, while what workers can see may look safe when it is in fact more treacherous than they can discern.

“Let us strive to elevate safety, so it can be the priority it should be; the priority it must be. Let us go forward with clarity of vision and a clear conscience.”

These risks are more than an issue of physical safety, despite the loss of the construction industry’s most versatile and valuable workers; whose loss is most visible by the injuries they bear or the headstones that bear their names; whose lives are a testament to what should have been done — to what could have been avoided — if crane operators had the means to see what the naked eye cannot see alone.

The risks are economic, too, because knowledge of a danger is often proof of liability. Translation: If a construction company knows a worksite is most likely dangerous — that the danger is more probable than simply possible — a jury will have no sympathy for that company, should a lawsuit and trial ensue.

The moral fault does not, however, belong to the company in question. That statement is a matter of opinion — that is my opinion — because insurers should reward companies for equipping construction cranes with cameras. Unless, of course, insurers want to pay multimillion-dollar settlements and verdicts on behalf of the clients they represent.

As these verdicts increase, and they will increase, the construction industry will have three choices: install crane cameras right now, so workers can be safe and projects can continue apace; do not install crane cameras, and hope — no, gamble — that nothing will go wrong; or demand that insurers absorb the cost for the purchase and installation of crane cameras, since they will recoup any upfront expenses with fewer payouts and more profits.

Remember, too, that failure to act can bankrupt even the biggest crane companies. It threatens to disrupt, and not for the better, the construction industry as a whole. It threatens to disrupt construction throughout the Canada and the U.S., acting as a tax businesses cannot honour and a price real estate developers cannot afford to pay, because a torrent of litigation is too much for any one company to weather or all companies to withstand.

If insurers do not appreciate this threat, crane companies must nonetheless mitigate this risk. They must agitate for the change they want — and the reimbursements they deserve to receive — by refusing to allow the insurance industry to perpetuate the status quo. They must be free to choose the right course — the only course — by giving insurers no course but one: the industry-wide adoption of crane cameras.

If insurers leave it to lawyers to decide their fate, they will regret not only their decision but their punishment, too. They will regret having to issue cheques — with many commas and zeros — for what they should have foreseen; for what they can already see for themselves, that crane cameras save lives and save everyone money.

Now is the time for crane companies and operators to make the case for enhanced visual technology — to enhance safety at a construction site and to make it a sight to behold.

We have it in our power to do that, and more.

Let us strive to elevate safety, so it can be the priority it should be; the priority it must be.

Let us go forward with clarity of vision and a clear conscience.

Christopher Machut is the founder and chief technology officer for Netarus, LLC, a Norfolk, Va.-based company. Netarus manufactures and sells industrial-grade video monitoring solutions, which improve employee productivity and workplace safety in the construction, industrial, marine and transportation industries.

Working with Austrian rope manufacturer, Teufelberger, Liebherr has developed a new type of high-tensile fibre rope for hoisting applications which will increase the lifting capacity.

During the development project, more than 100 different fibre rope prototypes, measuring around 70,000 metres in length, were developed. These underwent extensive testing on test benches specially developed for the project and in field tests conducted in five different countries. These tests provided confirmation that the fibre rope not only weighs around onefifth of a conventional steel rope, but also lasts four times as long and is significantly easier to handle. Operational safety is also guaranteed – the different wear states are clearly identifiable.

First of all, there were various tests in classic rope bending machines. Furthermore, a crane rope test bench with a hoisting height of 42 metres was constructed. This enabled ropes with a thickness of up to 31 millimetres to be tested with a test load of up to 45 tonnes on a rope drum with multiple rope turns. The tests for the 20 millimetre ropes have already been concluded.

Liebherr also built a climate chamber for this project; in which the rope was subjected to a wide range of weather conditions. The chamber generated temperatures of up to 80 degrees and as low as minus five degrees. It also added sand or dust to the air to simulate site conditions in the desert. The next moment it generated monsoon-type rain.

High-tensile fibre ropes in various diameters have been undergoing field tests on 11 tower cranes in Germany, Austria, France, Belgium and Switzerland since 2016. The benefits of the significantly lighter rope are particularly noticeable during the assembly and dismantling of the crane – fibre ropes can often be fitted on the crane by hand and without any auxiliary reeving winches. Re-reeving the hook block is also quicker and easier. The cleanliness and lack of maintenance required during operation received special praise as the rope does not require lubrication due to its plastic fibres.

The high-tensile fibre rope is extremely wear-resistant and can withstand a high number of bending cycles. It has fourfold the service life of a steel rope. This longer service life can reduce the number of rope changes.

The crane operator can easily and safely identify when the rope requires changing. Liebherr has used a redundancy strategy in this case to enable the end of a rope’s service life to be identified reliably in all rope constellations and applications. The end of the rope’s service life is primarily identified optically by the jacket on the rope undergoing defined wear shown by the colour which clearly indicates when the rope must be changed. Furthermore, the fibre rope can withstand multiple notches without suffering immediate damage. The winding pattern of the new fibre rope is similar to that of a steel rope. If the lower layers have less tension than the upper ones, however, the new fibre rope is more tolerant. In the event of notching, it will free itself unlike steel ropes which generally become enmeshed.

To achieve the controlled wear of the fibre rope, Liebherr selected the time-tested Lebus winding system from the very outset of the development. A clean winding pattern on the cable drum minimizes wear and thus extends service life.

At bauma in April 2019 in Munich, Germany, a new tower crane series will be launched featuring the fibre rope. www.liebherr.com

Manitowoc Cranes’ smartphone app that helps customers to diagnose technical issues on their cranes has been updated. The free app enables users to understand the numeric diagnostic codes that are generated by their on-board control systems.

In addition to diagnostic codes for Grove and Manitowoc branded cranes that run on Manitowoc’s Crane Control System (CCS) and GMK cranes with ECOS1 and ECOS2 systems, the app now provides diagnostic codes for National Crane models NBT30H-2, NBT50, NBT55, NTC55 and NBT60 and for select Grove and National Crane Rated Capacity Limiter Systems.

The latest version of the smartphone app is available now for free in both the App Store (Apple) and Google Play (Android) by searching for “Manitowoc Diagnostic Code App.” www.manitowoccranes.com

TerraPro Inc., Canada’s second largest remote access matting company, has officially opened its doors to the Ontario market with the creation of TerraPro East Inc. Through TerraPro East Inc., the company now offers access matting sales, rentals, and logistics to energy and utility companies within Ontario. They have also finalized an agreement with the International Union of Operating Engineers, Local 793.

“We’re excited to be Ontario’s newest matting provider and see great opportunity to increase our involvement in energy infrastructure projects Canada-wide,” says TerraPro’s Co-CEO and chief financial officer Jeff Schellenberg. “This expansion aligns with our corporate vision and is significant to our company growth strategy.”

TerraPro Inc. has provided terrain protection and environmental remediation solutions to oil extraction, pipeline, and electrical transmission companies in Western Canada since 2006. The company is known for its customer service and its dedication to safety, excellence and accountability.

“Working with the International Union of Operating Engineers, we feel confident in our ability to build a team out here that’s able to deliver the high-quality services that our customers have become accustomed to in other areas of the country,” says Colin Schmidt, Co-CEO of TerraPro.

The company has already established three initial Ontario yard locations in Mount Albert, Sudbury, and Wallaceburg and is planning to open a fourth in Morrisburg in 2019. TerraPro East Inc. will hire local talent and maintain an inventory of access mats and equipment in Ontario. Source: TerraPro Inc. www.TerraProInc.com

Link-Belt is bringing a new 100RT (90-mt) rough terrain crane to the market with the longest full-power boom available. Other notable features for the 100RT include Link-Belt’s latest operator cab design, Pulse 2.0 operating system with remote software updates via Wi-Fi, V-Calc asymmetrical outrigger options, a new simple-toassemble fly, latest Cummins technology with a Stage V engine, and Link-Belt’s Vision package. Following rigorous on-site and field testing, shipments of the new 100-ton (90mt) 100RT rough terrain crane are scheduled to begin first quarter 2019.

The 100RT delivers outstanding reach with a five-section 12.3 m to 47.2 m full-power formed boom, built to LinkBelt’s specific boom profile and tolerances at their Lexington, Ky. campus. An available two-piece (10.7 m to 17.7 m) onboard offsettable fly provides greater flexibility and range, and manually offsets at 2, 15, 30 and 45 degrees. A 4.9 m lattice insert extension provides a maximum tip height of 72.2 m.

The 100RT will be the first Link-Belt rough terrain crane to utilize the new fly erection technology from Link-Belt’s latest telescopic truck and telescopic crawler cranes. A fly assist cylinder makes erecting and stowing the fly a oneperson operation and minimizes work at height. Boom head speed screws and numbered spring loaded latches provide intuitive assembly. Given the natural elevation of a rough terrain crane boom, Link-Belt has simplified fly assembly with new ground level carrier controls. One control raises and lowers boom angle from 0 to -3 degrees, and another control is used for the fly assist cylinder.

The 100RT’s six-speed transmission is powered by a Cummins Stage V QSB 6.7L 232 hp (173 kW) diesel engine which is dual compliant for both Tier IV and Stage V standards. Four 29.5x25 tires mounted on axles affixed to the carrier via greaseless 4-link suspension, eliminate 10 previ-

ous grease points. Centralized electrical locations, remote mounted filters, and easy-access fluid checks make routine service a breeze.

A 24-volt electrical system makes running diagnostics quicker and easier. The wiring is a Controller Area Network (CAN bus) system. The 24-volt system yields the ability to multiplex with modules placed near dedicated functions like outrigger beams and winches. In total, there are five modules

located throughout the machine that allow crane functions to continue working in instances where other modules are being diagnosed or serviced.

Six points of access to the carrier deck are maintained with new ergonomic ladders, and regardless of slew angle, the operator has easy egress to the flat deck from the cab. The 100RT exterior features all new durable “tough skin” paint, along with a new slip-resistant paint on the carrier deck to provide better footing for access and egress.

Link-Belt’s V-CALC (Variable Confined Area Lifting Capacities) system features 12 different outrigger configurations with real time 360-degree charts. V-CALC has proven itself in general construction and infrastructure applications on the 75RT. Outrigger beams (either fully retracted, intermediate or fully extended) are setup in pairs from side-to-side or front-to-rear. Once outriggers are set, the user-friendly Pulse 2.0 system indicates the crane’s available capacity. The system then previews the operator’s real time capacities given the crane’s current configuration at the next five radiuses for a set boom angle.

Upon selection, Link-Belt Pulse 2.0 provides a live view of the working area with colour-coded quadrants. If the chart exceeds capacity at a given slew angle, swing arrest will initiate five degrees prior – allowing the crane to come to a smooth stop.

High strength steel used in the upper frame accommodates a new winch design with ultra-wide drums for increased line pull at higher working layers. Maximum winch line pull of 23,632 lb. (105.1 kN) provides a wider range of applications and contractor needs. Hydraulic outboard routings and wiring harness improvements offer form-fitted design, providing greater serviceability over the life of the crane. Three slabs of removable upper counterweight totalling 28,800 lb. (13.2-mt) is standard equipment. www.linkbelt.com

Deep tread with sturdy lugs

Longer tire life

High crack resistance

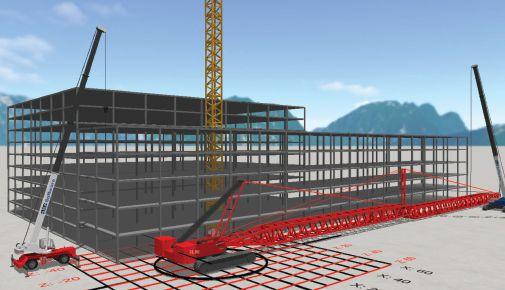

A1A Software LLC continues to improve the interface and features of 3D Lift Plan, making it easier for customers to use the crane lift planning program as a sales tool, for bid proposals, crane selection and setup, lift planning, and documentation.

“We have utilized WebGL technologies to enable the display of 3D content in Chrome, Firefox, and Microsoft Edge web browsers to improve the interface for customers no matter their preferred browser,” said Tawnia Weiss, president of A1A Software. “This flexibility is important because 3D Lift Plan is a cloud-based program, eliminating the need to download and update software to individual computers.”

When using one of these browsers, users simply select the WebGL version.

New features expand the options for users as they plan which type of crane pads or mats are best for the ground conditions. Ground bearing calculations can now be made for steel mats with an option for layering steel mats over timber for better distribution of outrigger loads. This is in addition to the previous ability to select wood mats or DICA’s SafetyTech or FiberMax engineered outrigger pads or crane pads. Likewise, printouts of the crane mats in a lift plan now display corresponding images of steel mats instead of wood when steel mats are selected as part of the plan.

Other improvements provide users greater control of planning for unique lifting scenarios. Examples include the flexibility to:

• Override the boom angle when using a load chart with fixed boom angles;

• Establish one crane in setup mode while simultaneously putting other cranes in normal operation mode for the creation of erection and dismantling plans; and

• Knife-jack a lattice boom with luffer to verify procedures for lowering long lattice/luffer combos into stowed position. Finally, a new rigging configuration has been added to the standard options in the Advanced Rigging Design portion of the program. The new configuration features two spreader bars and four roll-blocks. When this configuration is selected, 3D Lift Plan will calculate the sling angles and tension.

“Our programmers are continuously working to improve the features of 3D Lift Plan based on the feedback we receive from customers,” Weiss said.

3DLiftPlan.com • iCraneTrax.com

Unirope is one of only a few companies in Canada that can make terminations for high-performance crane ropes, which meet the very stringent EN-13411 standard.

This standard demands that the termination be able to withstand 75,000 cycles between 15 and 30 per cent of the wire rope’s minimum breaking strength while maintaining a minimum remaining strength of 90 per cent. www.unirope.com

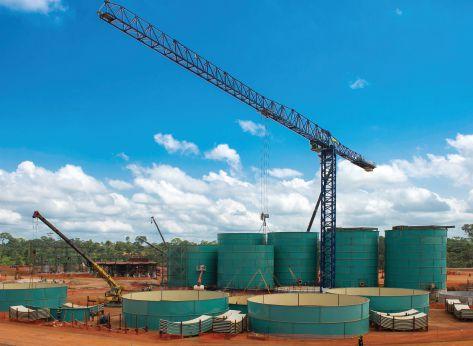

Comansa has increased the maximum load capacities for these large flat-top tower cranes by up to 50 tonnes (110,230 lb.), among other improvements. The design of new solutions for the 21LC1050 flat-top tower crane allowed Comansa’s research and development team to apply some of these developments to two of the manufacturer’s most successful cranes. Thus, models 21LC660 and 21LC750, mainly designed for large industrial projects, energy, mining and PPVC construction, have improved their performance significantly.

The versions of 24, 36 and 48 tonnes of both models have increased their maximum load capacity to 25, 37.5 and 50 tonnes. This improvement is achieved thanks to the use of a compacted wire rope, of smaller diameter, and an optimized design of the now lighter trolley-hook set. Such change does not only increase the maximum load capacity of the crane, but also improves the loads in all radius, including the jib-end load.

During the design of the 21LC1050, space restrictions at construction sites that exist in some countries due to regulation were taken into account. That is why a highly modular counterjib was created for such model, which allows up to six different configurations according to the jib length. The advantages of this new counterjib and its good reception in the market encouraged Comansa to apply this design to cranes 21LC660 and 21LC750, which will improve the counterjib radius of both models when they are erected with reduced jib-lengths. Thus, when the 21LC750 crane is erected with a 50-metre jib, the counterjib radius is 25 metres instead of 31 metres, of the previous design.

As a novelty in terms of jib length, Comansa now offers an optional 90-metre radius for special applications. This option is available for the 21LC660 and 21LC750 models, as well as for the 21LC1050 crane.

Models 21LC660 and 21LC750 (except the 20t version of 21LC660) now feature a new optional hoist mechanism (132 kW/177 hp), which allows speeds of up to 300 metres per minute.

When specifying a hoist for use in industrial applications that demand beamtraversing motion, attention should also be paid to the trolley on to which the hoist hooks.

According to JD Neuhaus (JDN), trolley factors such as carrying capacity, ease of installation, explosion protection and ability to negotiate curves, must all be considered if the application is to be optimized.

Comansa also added the Effi-Plus system to the optional 110 kW hoist mechanisms (148 hp), available for all versions of such models. This system, which was already implemented in the other motors of both models, increases the hoist speed by almost 15 per cent with light loads. These two mechanisms greatly improve the productivity of the crane, especially when working at large heights. Both motors can have wire rope capacity of 720 or 1,570 metres, which allows these cranes to work with heights under hook of up to 785 metres.

To simplify and unify the range of tower sections, the 21LC750 now has the D36B as standard section. This mast is the same as that of the 21LC1050 Flat-Top and the LCL700 luffing-jib crane, and is fully compatible with the D36 mast section, with was the standard for the 21LC750 and will now be discontinued.

The newly updated 21LC660 and 21LC750 cranes are now available worldwide and are shipped with the XL-size CUBE cab as standard. Thanks to its fully glazed front part and its spacious design, this new cab represents an important improvement in the productivity and comfort of the crane operator.

www.comansa.com

Three versions are available to facilitate the lateral motion of suspended loads: manual trolleys (LN) for pushing or pulling by hand; reel chain trolleys (LH) for moving by unwinding the reel chain; and motorized trolleys (LM) powered by an air motor. While the standard industrial series stops at a single 20-tonne trolley, higher capacities can be achieved with the benefit of eight-wheel and even 16-wheel systems. Additionally, custom designs or utilization of the monorail series offer traversable load placement for the entire JDN catalogue of capacities up to 100 metric tonnes. Importantly, for suitability in hazardous areas, all JDN trolleys offer explosion protection to Ex II 2 GD IIA T4/ II 3 GD IIB T4 classifications. Higher classifications are available upon request. For instance, with even further increased spark protection for explosion group IIC, the trolleys incorporate running wheels and travel gearing manufactured in bronze for an impressive EX II 2 GD IIC T4 rating.

Careful design and development by JDN’s expert team has led to a host of industry-leading standard features, whereby the company’s trolleys have become synonymous with ease of installation and a robust structure that requires little maintenance. Anti-climb and anti-drop devices are also included as standard. JDN trolleys are designed to

tackle all sorts of unique applications, which can include curved beams. JDN specialists are on hand to give advice on any project where curved beams are involved.

For those seeking an even higher specification, options for JDN trolleys include a rack and pinion drive for safe load handling on offshore platforms and seafaring vessels, a spark-resistant package and offshore paint to suit rigorous operating environments. Energy can be fed by various systems, including energy chain, C-shaped rail, square rail or spiral hose, to best suit application requirements. Of course, some applications have restricted headroom, which is why JDN also offers a specialpurpose series of low-headroom trolleys, meaning tight load placements can still traverse economically utilizing JDN’s special low-headroom design. The standard range offers carrying capacities from 0.5 to 6.3 tonne, with higher capacities available for custom-built projects. This alongside other JDN traversing solutions creates a multitude of trolley capabilities.

Also able to negotiate overhead rail curvature, JDN’s low-headroom trolleys feature extended tie bars for bulky or elongated loads. The same options and energy feeding systems available for JDN’s standard trolley range, can also be offered to users of low-headroom versions, with the addition of hose trolley energy feeding to the list of choices. All hoists and trolleys can be remotely controlled by the recently introduced JDN radio control systems, offering ease of use and convenience. The remote controls are an effective alternative to where long control hoses are required and for use in hard-to-reach areas, providing simultaneous control of multiple hoists and trolleys. Comprising a transmitter and receiver, the JDN-RC (Remote Control) is available for both new and retrofit applications. www.jdngroup.com

BY HOWARD ELMER

Trucks, currently, have never been more important to a manufacturer’s bottom line. Not only because they are selling in ever increasing numbers but because there just doesn’t appear to be a price ceiling. Customers keep loading up new pickups with luxuries that only a few years ago were found only in sedans. It’s this hunger for constantly increasing content that pushes prices up as these upmarket extras quickly add up; and of course this is where builders earn the most money.

Ford knows this full well. They currently offer nine distinct trim packages and an extensive list of options. So, each year in this pickup war Chevrolet responds to Ford’s increasing number of trim levels with their own increase in luxury, accessories, special editions and personalization. This is the current state of the heated pickup market and it shows no sign of cooling down.