Passion for Support

EDITORIAL

MATT NICHOLLS is editor of Helicopters

arlier this fall, I had the distinct pleasure of visiting with Helicopter Association of Canada (HAC) president and CEO Fred Jones at the association’s new home in the nation’s capital. Jones is one of the people I respect most in the Canadian aviation and aerospace industry, as few people are more connected, committed and passionate about the success of their respective area of expertise – and the industry they work so hard to protect.

Jones is also one of the most amicable and approachable industry leaders, and our annual conversation about the state of the industry is easily one of my most-anticipated conversations of the year. It’s always informative and insightful, and since we both love to talk – a lot – it usually extends much longer than the anticipated interview time frame we agreed upon. Case in point, our discussion in Ottawa – it went on and on, to a point where both of our significant others were sending “Where are you?” messages to our phones. (For more on our conversation see, “Accepting the Challenge,” pg. 14)

As any great leader comprehends, the success of an organization is predicated on the high capabilities of the team – a shared perspective from idea generation to workload execution. The HAC team certainly fits this premise. Each team player does an admirable job in providing leadership and commitment to its members and to important advocacy efforts as a whole. HAC is celebrating its 20th anniversary this year and in many ways, it is just getting started – rounding

A Collective Effort

Joining Forces in the Name of Safety

helping to create a safer, more controlled operating environment.

As Jones aptly points out, it has been a collective effort industry initiative to get it to this point. HAC has certainly done its part, but other associations such as the International Helicopter Safety Team (IHST), the hard work of individual operators to implement Safety Management Systems (SMS), and of course the efforts of the dedi cated volunteers that have worked hard to create the Best Practices in so many key sectors, have all contributed to an industry that is undergoing significant change for the better.

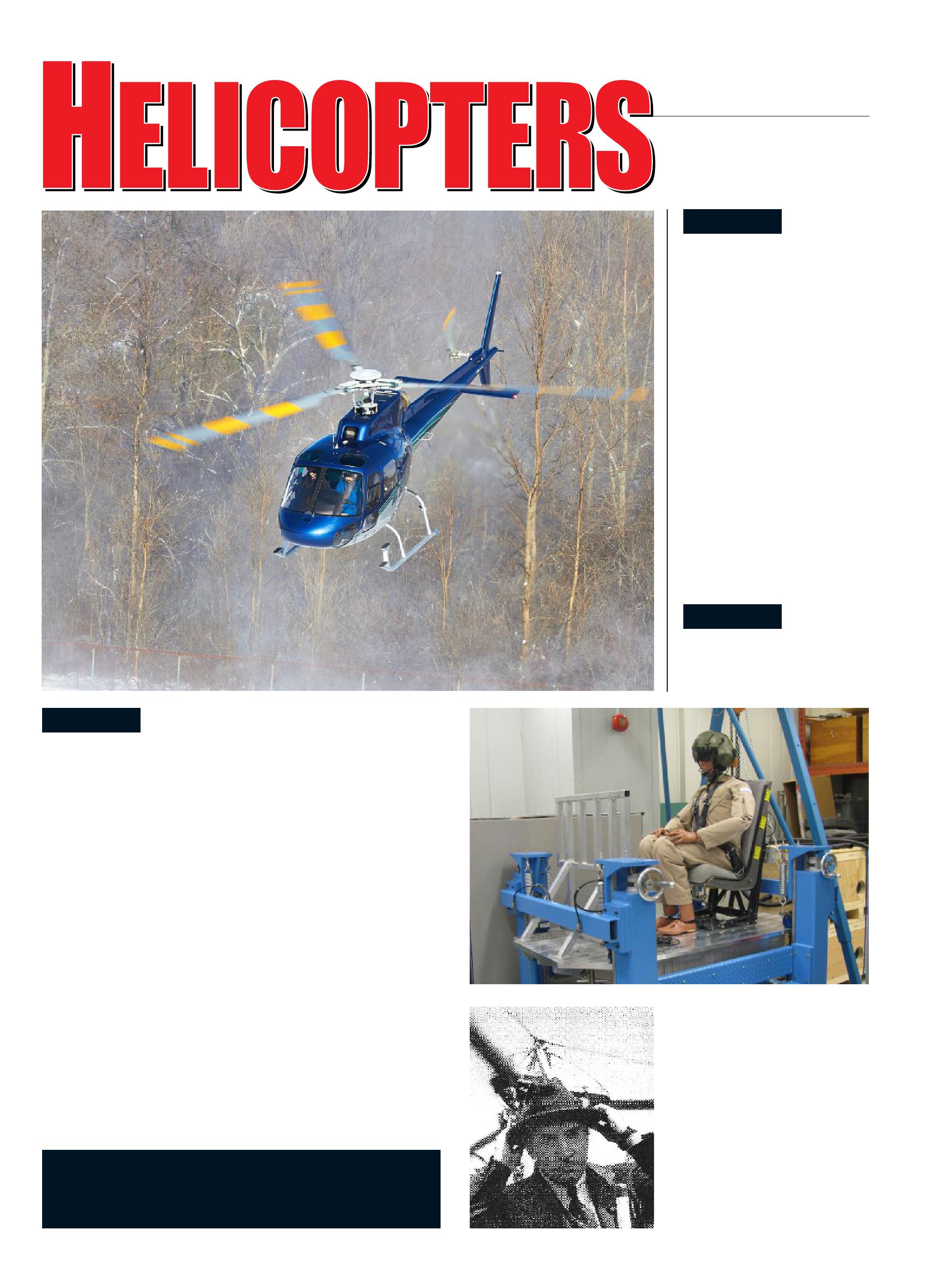

Also contributing to raise the bar are the various OEMs and sup pliers who are creating state-of-the-art products and services that help keep the blades turning from coast-to-coast. Technologically advanced aircraft such as this month’s cover model, Airbus Helicopters’ H130, which recently completed a nationwide tour, are just some of the highly capable products available.

Airbus’ Innovation in Safety Award – awarded annually at the conference to an individual or group of individuals who are working to raise the safety envelope – is another way OEMs are highlighting sound safety practices. I am delighted to take part in the process as one of the judges and it’s always impressive to see the level of commitment each nominee brings.

Another key safety initiative to be rolled out at this year’s show is the introduction of HAC’s new “Blue Skies” training certificate program. The designation will be handed out to operators and employees once they have completed an educational course based on a specific Best Practice. The program will commence with the utility Best Practice; it’s just another way operators and employees can raise their personal safety standards.

HAC is celebrating its 20th anniversary this year and in many ways it is just getting started.

into form with a strong advocacy push, an insightful and useful convention alternating in different parts of the nation, and a highly capable team of volunteers driving safety and education in several facets of the industry.

The 2015 operating season in Canada, though slow and challenging for operators and suppliers alike from a revenue-generating point of view, was also one of the safest on record. It follows up yet another safe operating year in 2014, and while there are no statistics to accurately measure the value of HAC’s safety push and Best Practices programs, it appears they are certainly contributing in

HAC’s Best Practices committees have been instrumental in the development of important educational programs for the past 20 years, and the benefits of their hard work cannot be accurately measured. As Jones aptly notes, “They really have done the heavy lifting,” and all who have taken part should be commended.

No, the 2015 operating season wasn’t the most lucrative one on record – but it definitely was a safe one. It is apparent that the collective efforts of operators, OEMs, suppliers, HAC, and other industry associations, are paying dividends in helping to create a safer working environment nationwide. Keep up the good work.

• 5 seats + baggage compartment

• Base price under $900,000 USD

• Available with optional autopilot

Greased Lightning: AW609 Sets Speed Record

If one thing’s for sure about the new commercial version of the AW609 TiltRotor helicopter, it’s certainly fast –very fast, indeed.

The AW609 set a new “point-to-point” record for a 1,000 kilometre journey in September, travelling some 1,161 km (627 nautical miles) from its Yeovil facility in southwest England to its Cascina Costa facility near Milan, Italy. The helicopter did the journey in a time of 2 hours, 18 minutes.

AgustaWestland officials maintain the AW609 TiltRotor has the capacity to revolutionize commercial air travel – just as the trip from Yeovil to Northern Italy illustrates. These “point to point” journeys are common in

The commercial version of AgustaWestland’s AW609 TiltRotor set a speed record for a 1,000 km “point-to-point” journey.

aviation, and this aircraft can offer a unique solution, according to the company.

The flight started with a vertical takeoff from Yeovil.

The aircraft climbed to its en route cruising altitude of 25,000 ft. (8,000 m). The

aircraft passed north of Southampton, just south of Paris, over the Alps and Piemonte in Italy, before descending and landing at Cascina Costa near Milan.

The aircraft is capable of transporting up to nine

VECTOR INKS DEAL WITH DND

Global MRO leader Vector Aerospace has signed a new deal with the Department of National Defense (DND) to perform all MRO services for its T-58 engines on Sea King helicopters.

Vector Aerospace has been a registered overhaul facility for CT-58 and T-58 engines since 1976. Between 1996 and 2003, the firm was instrumental in developing and implementing an upgrade program for 109 DND T-58 engine conversions from the -8F to -100 configurations. Vector also repairs the T700-T6A1 engines for the AgustaWestland CH-149 Cormorant (AW101) and is currently conducting Assemble Inspection and Test (AIT) for the

CT7-8A7 engines for the new Sikorsky CH-148 (H92) Cyclone helicopters in Canada.

passengers in its pressurized cabin and can be used for a variety of missions from corporate transport to SAR to medical transport. It is set to achieve a number of certifications in 2017 and start deliveries shortly thereafter.

“We are thrilled to have been re-selected by DND to be their sole T-58 engine MRO provider,” said Paul Cockell, president, Vector Aerospace Helicopter Services – North America. “We have been a proud supporter of DND for over 20 consecutive years, consistently providing top quality products on time and on budget.”

One BIG UAV!

Laflamme Aero in Saint Joseph-de-Coleraine, Que. wants to make a rather big splash in the UAV market.

The company has launched a $2.3 million project to develop and demonstrate a 300 kilogram unmanned helicopter known as the LX300. The aircraft would become the largest commercial UAV in the world. The two-and-a-halfyear project will culminate in demonstration flights by 2017. The project is funded in part by the Consortium for Aerospace Research and Innovation in Canada (CARIC).

HELICOPTERS MAGAZINE

P.O. Box 530

105 Donly Drive South Simcoe ON N3Y 4N5 Tel.: 519-428-3471 Fax: 519-429-3094

Toll Free: 1-888-599-2228

Website: www.helicoptersmagazine.com

EDITOR MATT NICHOLLS email: mnicholls@annexweb.com 416-725-5637

MEDIA DESIGNER GERRY WIEBE

CONTRIBUTING WRITERS

Laflamme Aero’s proposed UAV is set to weigh approximately 300 kilograms.

Other partners involved in this project are N.G.C. Aerospace, Roy Aeronef and Avionique Simulation, and Sinters America. They will respectively take care of the aircraft guidance, navigation and control system, of the highdefinition simulator, and of a specialized embarked computer. Two universities also support the consortium: Polytechnique Montréal and the école de technologie supérieure (ETS). Laflamme Aero will be the project leader, allowing the company to demonstrate its expertise and technologies, which mostly come from the LAF-01 helicopter project developed by Réjean Laflamme.

Among the applications for the unmanned helicopter will be agriculture, mining prospection, search and rescue (SAR) as well as naval applications.

Robotic Landing a Future Asset?

The research team at U.S.based Defense Advanced Research Projects Agency (DARPA) has come up with a unique solution to deal with uneven landings.

As the team from DARPA explains, helicopters are incredibly maneuverable in the air, but during landing and takeoff their traditional skidand wheel-based landing gear requires stable, flat surfaces –surfaces that are often unavailable in helicopter-needy environs such as forward operating areas, ships at sea and natural-disaster zones.

Having the ability to land on and take off from angled, irregular and moving surfaces would greatly expand the effectiveness of helicopters across many military and national security missions.

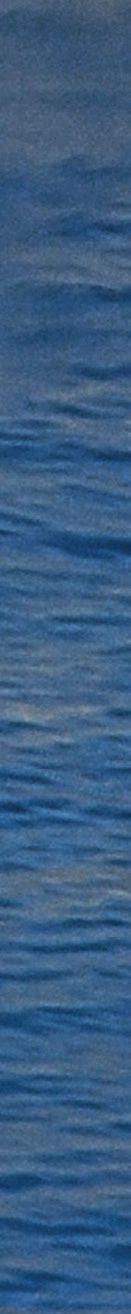

As part of its effort to provide such a breakthrough capability, DARPA has conducted an experimental demonstration of a novel robotic landing gear system. The adaptive system replaces standard landing gear with four articulated, jointed legs that are able to fold up next to

the helicopter’s fuselage while in flight and are equipped with force-sensitive contact sensors in their feet. During landing, each leg extends and uses its sensors to determine in real time the appropriate angle to assume to ensure that the helicopter stays level and minimize any risk of the rotor touching the landing area.

Along with comprehensive dynamic simulation and structural analyses, the demonstration flight –conducted near Atlanta –indicated possible benefits including:

• Reduced risk of damage during hard landings, by as much as a factor of five, compared to conventional

landing gear

• Stable landing and takeoff on sloping terrain of up to 20 degrees, more than twice current limits, and on craggy, boulder-strewn or otherwise irregular terrain

• Ship landings in violent sea states

• Significant increase in capabilities with only a modest increase in landing gear weight

The robotic landing gear system was developed with funding from DARPA’s Mission Adaptive Rotor (MAR) program, and is now undergoing continued development by the Georgia Institute of Technology.

RICK ADAMS, DAVID CARR, BRIAN DUNN, PAUL DIXON, WALTER HENEGHAN, FRED JONES, JAMES MARASA, CARROLL MCCORMICK, COREY TAYLOR, AMANDA WINTERS

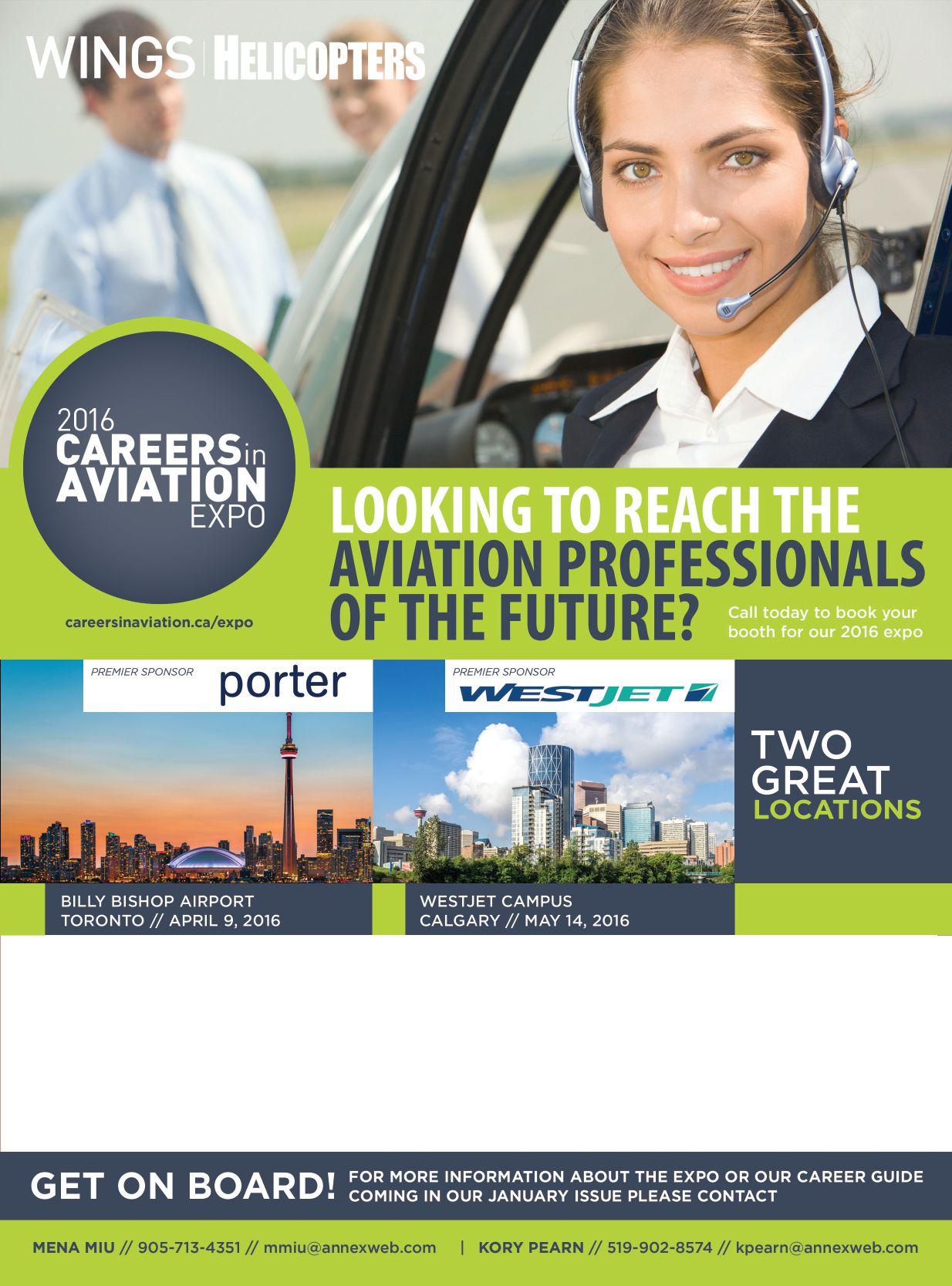

NATIONAL ADVERTISING MANAGER MENA MIU email: mmiu@annexweb.com 905-713-4351

ACCOUNT MANAGER KORY PEARN email: kpearn@annexweb.com 519-902-8574

ACCOUNT COORDINATOR

STEPHANIE DEFIELDS email: sdefields@annexweb.com 1-888-599-2228 ext. 257

GROUP PUBLISHER MARTIN MCANULTY email: mmcanulty@annexweb.com

DIRECTOR OF SOUL/COO SUE FREDERICKS

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO ANNEX PUBLISHING & PRINTING INC., P.O. BOX 530, SIMCOE, ON N3Y 4N5 CANADA. email: subscribe@helicoptersmagazine.com

Published five times a year by Annex Publishing & Printing Inc. Printed in Canada ISSN 0227-3161

CIRCULATION email: subscribe@helicoptersmagazine.com Tel: 1-450-458-0461 ext 208 Fax: 877-624-1940 Mail: P.O. Box 530 Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES Canada – 1 Year - $25.00 (all taxes included) USA – 1 Year $35.00 Foreign – 1 Year $45.00

Occasionally, Helicopters magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2015 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Helicopters Magazine is a corporate member of the

Helicopters Magazine is an associate member of the following Canadian aviation associations:

DARPA’s new robotic legs would make landing on uneven ground much more efficient. (Photo courtesy of DARPA)

NEW PRODUCTS

New aviation solutions

Talking out loud, new EASA certified products, and a fancy UAV.

Now You can be heard

AEM has come up with a new Loud Speaker System that has been installed and certified by AgustaWestland on the AW139 helicopter.

The latest requirement was for one system on a search and rescue (SAR) role helicopter for a customer in South Korea. The system includ ed the LSA800-001 Loud Speaker (LS) amplifier and a custom designed and manufactured 900W speaker to meet the mounting location requirements

of the AW139.

Bell expands its accessory base

Bell Helicopter, a Textron Inc. company, has announced its Aeronautical Accessories brand has received four new approvals from the European Aviation Safety Agency (EASA). The products can be applied to multiple Bell Helicopter models including the Bell 407, 212, 412 and 429. The products include:

• Bell 407, High Frequency HF) Antenna Kit

• Bell 212, 412, 412EP, Quick Mount Kit, Spectrolab Nightsun SX-16 Searchlight

• Bell 429, Tail Rotor Pedal Removal Kit and Bell 429 Retractable Hardpoint System/ Fast Rope Kit

• Bell 412EP, Left Hand Aft Equipment Shelf

AEM’s 700W system is also certified on the AW139 and has been delivered to numerous operators around the world. AEM Corp successfully completed DO-160G and DO-214 testing on its new line of LSA Series Amplifiers and LS Series Speakers. They are the only amplifiers and speakers in their market/class today with this level of qualification. The LS and LSA series components are used in various combinations to create the new 300W, 600W, 900W and 1200W external PA systems. Info: www.aem-corp.com

The HF Antenna Kit increases reception in remote areas and is designed to interface with many types of HF radios. The Towel Bar-style HF antenna runs the full length of the underside of the tailboom.

The Quick Mount Kits provide for installation of the Spectrolab, Inc. Nightsun SX-16 searchlight, and the kit includes a redundant auto-stow centering feature with panel mounted position indicators.

The Bell 429 Tail Rotor Pedal Removal Kit modifies the tail rotor pedals to allow for a quick disconnect from the flight control system. This kit allows operators to quickly remove pedals from the co-pilot area and prevent passenger interference with the flight controls. When flight operation is required from the co-pilot area, the pedals can be quickly and securely re-installed.

The 412EP L/H Aft Equipment Shelf mounts in the upper left avionics bay and provides added provisions for up to 130 pounds of additional avionics equipment. Info: www.aero-access.com

In the eye of an eagle

EagleEye Systems S.A., (EES) has pioneered the world’s first operating system for unmanned aerial vehicles (UAVs) – and now the Bergen County Office of Emergency Management (BCOEM) in New Jersey has selected this Next Gen technology.

The BCOEM is the lead agency for preparedness, response, recovery and mitigation across the county. Its role includes flood, hurricane and thunderstorm preparedness, traffic incident diversions, animal emergencies and damage assessment and recovery. It will limit use of the new UAVs specifically to emergency situations and search and rescue (SAR) operations.

Unlike traditional drones, which are operated remotely, UAVs powered by EagleEye’s operating system can function autonomously. This allows them to strictly enforce no-fly zones, conduct accurate area coverage searches and reduce the risk of human error.

A major factor in BCOEM’s selection of smart UAVs from EES was the company’s focus on security. Each EEV-powered UAV utilizes a NATO-standard secured link and a tamper-proof record of the machines’ position and what the cameras detected. This greatly reduces the risk of intrusion by hackers. Info: www.eagleeyesys.com

Photo courtesy of EagleEye Systems

PhotocourtesyofAEM

COLUMN

was thinking this past summer about the pain the industry has experienced as a result of the broad downturn in the economy. Across the board, from east to west, flying hours were reduced in mining and exploration, and in the oil patch, with the added pain of a reduction in “adhoc” work. If not for the dozens of large wildfires in Western Canada, the industry may well have experienced a major retrenchment, (something that in my opinion is long overdue).

In tough times, there are additional pressures on company finances. One need only look at the carnage in Alberta’s oil patch to see this. Massive lay-offs coupled with downward pressure on suppliers to “sharpen their pencils” places additional stresses on all aspects of the supply chain. This phenomenon is in full swing out west, and the helicopter industry has not been immune. There have been moves taken by some operators to limit per diems paid to pilots, reduce daily rates and salaries and modify schedules and touring rotations to save money. There may even be a movement to the “contractor” model whereby pilots and AMEs are hired short term, on contract, without benefits and with no job security. The question one must ask though is this: Is safety compromised in a down economy?

Let’s start with government. Cuts to safety programs appear to start at the top, with Global News having reported earlier this spring that federal government budgets for funding programs at Transport Canada (TC) have been reduced, from a drop of 32 per cent in the Dangerous

Staying in the Zone

Be Wary of Tough Economic Times – Safety May Suffer

helicopter industry, published accident rates for all aircraft in Canada, do offer some insight. Overall rates have decreased, year to year, every year from 2005 to 2014 (except for 2008), going from 6.7 accidents per 100,000 hours to 4.6 per 100,000 in 2014. Specifically for the helicopter industry, during the 2008/2009 recession, accident totals decreased from 42 to 29 in 2010. The TSB data therefore appears to indicate that a recession does not lead to increased numbers of accidents or significant shifts in the accident rate. This is good news.

Everybody involved in the helicopter industry has a tough task these days. There is significant pressure on costs, so operators are looking at every cost centre. I spoke with one owner over the summer who has shifted completely to contract employees, downsizing from more than 30 full time staff to four and now using term contract pilots and AMEs almost exclusively. In addition, he is still in a cockpit, running the company and doing business development!

I also have concerns about the “contractor” model, especially in a down economy. Will these companies hire the best talent available or the cheapest? Will modified crew rotations lead to more fatigue, more error and more accidents? Will contract employees feel equally empowered to “speak up” when they see sub-standard maintenance practice or when they are pressured to extend their tours, push the weather or push their aircraft? I don’t have data to support one perspective (full time employees) over the other (contractor model), as the dominant paradigm during the 2008 recession was still the full time employee model but it may be worth watching.

The question one must ask though is this: Is safety compromised in a down economy? ‘‘ ’’

Goods directorate to almost 10 per cent for Aviation Safety. Further cuts are programmed in the funding levels for safety programs across the board at TC through 2018. These cuts can’t be good for industry oversight.

What about the data? When I began writing this column, I was curious if the TSB data would reveal any trends. There are two possible trains of thought here. Would fewer flying hours lead to fewer accidents or would the downturn encourage corner-cutting behaviour, resulting in more carnage?

While the available data does not provide a rate specifically for the

But we can take measures. We can adopt the Tony Kern model of striving and acting as professional pilots and engineers to protect our customers and ourselves. We can continue to insist on being paid a fair wage for the skills we bring with us to the table. We can ground an aircraft that needs maintenance. Indeed, a common TC audit finding is that pilots verbally report unserviceability items to AMEs who then enter (or not) the item in the defect log.

Pilots: Write the defect in the journey log and the issue must be addressed. Period. Engineers: Change the part when it is out of tolerance. Owners: Never forget the golden rule: if you think safe and best practices are expensive, try having an accident.

Walter Heneghan is the vice-president for Health, Safety and Environmental Protection with the Summit Air Group of Companies, Ledcor Resources and Transportation, based in Edmonton and throughout Western Canada.

WALTER HENEGHAN

PAUL DIXON

We are on the way to winter now, but it was a long, hot summer out west, and it is looking more and more like this is the new normal – whatever “normal” is supposed to be. Looking at the planet as a whole, July 2015 was the warmest month since records were first kept back in the 1880s. The ideal for most is long, dry and hot summers following on the heels of milder winters with decreased precipitation – this is what we seem to want this new normal to be.

We’re long past the denial stage, of course, and there has been a definite change in the weather. And all indications are the things are going to get a whole lot worse before they get better. The question I have for those who make the big decisions on these matters and ultimately write the cheques is if they have any appreciation for what is happening today and what we are looking at in the very foreseeable future.

One thing you can count on for sure with any large-scale disaster, be it wildfire, flood, tornado, ice storm or whatever, is that such a catastrophe will draw politicians like ants heading to a picnic. I don’t mean the local mayors and councillors, because they are often working harder than anyone else. It’s the provincial and federal leaders with their handlers and the media circus that flop down in the middle of the action to make comforting noises to the public at large to demonstrate their level of concern.

Ever wonder how much of a disruption these visits are to the people who are in the middle of the action? There was a scene this summer in

Getting it Right

More Coordination Needed for Effective Resource Management

The theory of emergency management in this country starts with the individual. We are initially responsible for our own safety and wellbeing. When events happen that are beyond our control, we call for help and, in most communities, that takes the shape of our police, fire and ambulance agencies. When they find themselves unable to cope, they in turn will ask for assistance from surrounding jurisdictions. It’s the same model for civic works and engineering. Move up a level and the provincial government gets involved, either to take over direct management of the situation or to act as a source of resources. When a local government declares a state of emergency it makes provincial funding available for emergency supplies and resources. The role of the federal government in these situations is largely financial, ensuring the money is available to address the situation.

Of course, it all looks good on paper, but there comes a time when decisions have to be made and a lot of those decisions lead directly to the spending of money – tax money – and in some cases, it’s a lot of money. There is incredible pressure on front-line supervisors and managers to only make “good” decisions when it comes to spending money.

More than one helicopter operator has told me this year that there has been a significant decrease in the days they were put on standby for firefighting, because they’ve been told that if a helicopter is put on standby and then not used, someone is going to answer for that. Maybe that’s true and maybe it’s not, but after years of hearing politicians of all stripes talking about looking for “efficiencies” as a way of keeping costs down, I know which side I’m leaning towards.

Ever wonder how much of a disruption these visits are to the people who are in the middle of the action? ‘‘ ’’

B.C. that saw a group of wildland firefighters rounded up on their rest period to provide a suitable backdrop for the talking heads. The premier was talking about how we need a national firefighting strategy. Has anyone told her that we do have a national firefighting strategy?

That’s the disconnect. It’s not that we don’t have a national strategy, because we do. What we have is a political philosophy that demands that costs must be continually cut. Our national firefighting strategy follows the same model as our national emergency management strategy, with CIFFC at the top of the pyramid as the national coordinating agency.

At least one province failed to maintain its training program for community-based wildland firefighters, with the result that at the height of the fire season, they were critically short staffed and were desperately trying to set up training sessions, in some cases relying on people coming out of retirement to conduct the training. So, how much money was saved by not maintaining that level of training in the first place?

A little bit of critical thinking and not a whole lot of money can take what is basically a very sound system that works well at every level in this country, but we have to make that commitment and stick to it. You’ve heard it before and it really fits here – you can pay me now or you can pay me later . . . I don’t want to think about what the future costs will be if you aren’t going to do it now.

Paul Dixon is a freelance writer and photojournalist living in Vancouver.

OCOREY TAYLOR

ne of my favourite dictums can be summed up as, “wrenches turn nuts and hammers drive nails.” I use it a lot because I see many instances where people are in the wrong positions for their aptitude or are handed tasks they are ill prepared for and someone else should be doing.

This boils down to management’s failures to use the appropriate tool for the job. Not only do people in the wrong positions impact a company’s ability to deliver service to the client, the impact on said employee in terms of morale and job satisfaction (including their influence on their peers) is no small thing.

Expanding this concept to helicopters and the risks we, as operators, face, it is clear that some clients have failed to conduct a comparative risk assessment of their programs before issuing their various standards to be applied to helicopter operators. A quick review of basic risk assessment techniques shows this all too clearly. Although there are many methods and techniques most align with the basic five-step process:

• Hazard Identification – What are the dangers and pitfalls we face?

• Hazard Analysis – How likely is the hazard to affect us and how bad might it be?

• Control Development – What can we do to prevent or minimize the impact of a given hazard?

• Implementation of Controls – Execute the policy or equipment

Comparative Risk

How Clients Can Cause

Accidents

line crossings, long distances to medical care, rapidly changing weather, capricious mountain winds and a variety of external loads.

If we were to apply the hazard control measures that we know would give us the biggest bang for our buck, we would be talking about appropriate experience levels for the pilot, sufficient training, management of landing sites (requires client participation), load control, fuel husbandry, weather minima specific to the project locale and season and a host of other considerations.

While the above may be obvious to those in the Canadian helicopter industry, it doesn’t seem to have trickled down to the desks of the various aviation consultancy firms out there. When you have auditors that ask you what the company’s “Stabilized Approach” policy is, you’ll know you’re in for trouble. Most companies in Canada, have a graduated process where pilots get more responsibility and opportunity as they gain experience.

After so many hours (hours are only one metric) of flat land flying, we get a mountain course. After so many hours and loads on the belly, we get going with a long line. After so many hours and loads with a long line, we start building drills. And after so many hours of building diamond drills, we get to swing seismic drills in the mountains or build towers on a windy peak. There is no safer way to do things.

By failing to understand the risks of the program, the client’s attempts to reduce or eliminate risk actually increases it. ‘‘ ’’

changes necessary to control the risks we face to as low a level as possible.

• Closed Feedback Loop – Check to see how the controls are working and make changes as necessary.

If we were to analyze a typical (Day VFR) helicopter job in Canada, whether it is mineral exploration, fire fighting or seismic, we would find that most of the hazards are shared in all circumstances. These would be confined areas, off level landings, uncontrolled staging areas with large FOD potential, fuel management challenges, visibility issues, traffic congestion, power

Unfortunately, most clients have standards prepared by aviation consultancies or advisors that are predominantly based on an offshore background. The offshore standards with regard to aircraft and equipment are without argument the highest, because of the inability to land within a few minutes. The same cannot be said about the pilot requirements, however, as we see in so many of these standards documents. Oftentimes requiring IFR, unrestricted ATPH licenses, and many hours on type eliminate every qualified pilot in an operator’s stable.

By failing to understand the risks of the program, the client’s attempts to reduce or eliminate risk actually increases it. Since pilot decisions are still responsible for most accidents, we must do our best to choose the right ones, reducing this risk to an undetectable level.

Corey Taylor is vice-president of Global Business and Product Development for Great Slave Helicopters.

STAND HEAD

RICK ADAMS

Are drones the new green lasers?

In more than a dozen instances this year, aerial firefighting operations have been suspended because reckless operators of recreational drones were buzzing around wildfires, apparently seeking viral YouTube fame or hoping to cash in by selling dramatic footage to television producers.

In August, eight helicopters and six air tanker skimmers were grounded for five hours – 14 aircraft brought down by the presence of a toy drone – when they could have been fighting the Testalinda Creek fire which scorched more than 4,000 hectares in southern British Columbia near Oliver. Earlier in the summer, a drone forced a helicopter down at the Westside Road wildfire in West Kelowna, B.C. along Okanagan Lake.

In the U.S., the Forest Service said unmanned aircraft interfered with 13 wildfires thus far this year.

Northeast of Los Angeles, Calif., in July, five drones were reported in the airspace around a wildfire that jumped across the I-15 interstate highway and engulfed 30 vehicles. The San Bernardino Sheriff’s Department said one drone even trailed a spotter plane into the fire zone area. Firefighters turned on helicopter sirens, and three drones departed the scene, but two remained and the firefighting aircraft had to be grounded for 25 minutes while the fire raged.

California Department of Forestry and Fire Protection pilot Jason Thrasher, ferrying seven firefighters to a Nevada City blaze last year, had to take evasive action at 500 feet altitude when a four-rotor drone

The Fire Files Irresponsible Drone Operators Force Call For Tougher Restrictions

Thrill-seeking drone operators have introduced a dangerous new element into firefighting and other first responder emergency situations. They cost taxpayer money when legitimate aircraft are grounded (CAD $35,000 daily plus $13,000 per flying hour). And they endanger lives and property while illegally intruding into restricted airspace.

Sterling Cripps, president of Canadian Unmanned Inc. in Alberta, who has trained more than 800 unmanned air vehicle students, including 250 police and first responders, calls the hobbyist drone operators “shameless and selfish.” They have “a complete disregard for the safety of the public and those on the front line looking after containing fires.”

Wildfire areas are already flight-restricted zones, whether for drones or general aviation aircraft. In Canada, the radius is five nautical miles around the fire to an altitude of 915 metres above ground level. California has launched an education campaign, “If you fly, we can’t,” and B.C. officials plan something similar.

But legislators on both sides of the border are also advocating toughening penalties for drone operators who venture into restricted areas. The current maximum fine is $25,000 and up to 18 months in jail. Morris said he’d like to see even stiffer punishments.

In the States, Congressman Paul Cook, representing Apple Valley, Calif., introduced a law that would make it a federal offense to fly over a forest fire with a fine and prison term up to five years. State legislators in California also want to grant immunity to emergency responders who may “damage” drones during fire or rescue operations.

We have to determine how we’ll safely integrate these things into our existing tactical aircraft fire traffic area ‘‘ ’’

suddenly appeared 10 feet from his helicopter windscreen. “If that drone came through my windshield, I have no idea what could have happened,” Thrasher said. “If that drone hits my tail rotor, for sure it’s going to be catastrophic.”

Some experts predict 2015 will top 2006 as the worst fire year ever. The Canadian Interagency Forest Fire Centre reports that through August 6,669 fires burned nearly four million hectares, nearly twice as much land area as the 10-year average. B.C. and Alberta bear the brunt. In the U.S., nearly eight million acres have been destroyed, an area about the size of Massachusetts, in more than 43,000 fires.

There are, however, potential positive uses of unmanned aircraft for firefighters. The U.S. Department of the Interior recently tested a Boeing ScanEagle drone during a forest fire in Olympic National Park, using infrared video to guide water-dropping helicopters to high-priority target areas. Using heat signatures, drones might also be used for searchand-rescue missions, especially at night or in smoky conditions. “We have to determine how we’ll safely integrate these things into our existing tactical aircraft fire traffic area,” said Brad Koeckeritz, the Interior’s national unmanned aircraft specialist.

And establish just how to keep amateur droneheads out of professional airspace.

Rick Adams is chief perspectives officer of AeroPerspectives, an aviation communications consultancy based in the south of France, and is editor of ICAO Journal. He has been writing about technology and training for 30 years.

STAND HEAD

AMANDA WINTERS

The rise in popularity and use of unmanned aerial vehicles (UAVs) has attracted much attention recently. We have recently seen a major uptick in drone use by private companies. Drones have been regulated for some time through federal aviation regulations, but the accessibility of drone technology has led Transport Canada (TC) to consider revisiting the regulations to ensure they keep pace with current interest and use.

In many industries, both private actors and government bodies are using UAVs in new and innovative ways. Arising from this technological leap forward are a number of new legal issues, particularly in the area of privacy. A special consideration for companies employing or supplying drones for public or para-public use is the possibility of infringing on privacy rights protected by s. 8 of Canada’s Charter of Rights and Freedoms. Canadian citizens have a right to privacy, including rights that prevent the government from collecting information about them in certain circumstances. The use of drones to take photographs or video, or to collect other data, can be open to challenge.

For example, in the Supreme Court of Canada case of R. vs. Tessling, 2004 SCC 67, the RCMP used an airplane equipped with forward-looking infra-red (FLIR) cameras to obtain images of heat radiating from a building suspected of housing a marijuana grow-op. The FLIR images did not show the inside of the building. Using these images, the police obtained a search warrant to search the suspect’s

Eyes in the sky

Para-public UAVs and the Canadian Charter of Rights and Freedoms

Because police forces are clearly linked to the government, their use of UAVs is subject to the Charter. But what about private companies that provide services to public bodies? Is the Charter something they should consider when using UAVs? At the moment, Charter implications for using drone technology remains an open legal question. To date, there are no reported court decisions that consider the issue.

Some guidance may be taken from a line of cases where the courts consider whether a private citizen or entity is acting as an “agent” for law enforcement. In these cases, courts consider whether the private citizen or entity has been asked or directed to assist with a search. For example, in R. v. Wilkinson, 2001 BCCA 589, a landlord took it upon himself to investigate the residence of a tenant and, after finding a marijuana grow-op, advised the police. Because the landlord was not asked or told to investigate by police, the court allowed the evidence found during the search to be used against the accused. However, in R. v. Liang, Yeung, et al, 2007 YKTC 18, police asked a Yukon Electric employee to go onto the accused’s property in search of an electrical bypass. The employee discovered the bypass, and the police used that information to make an arrest. The court concluded that because the police had specifically directed the Yukon Electric employee, the employee was an “agent” of the police and his actions were subject to the Charter

Arising from this technological leap forward are a number of new legal issues, particularly in the area of privacy. ‘‘ ’’

property, finding the grow-op they suspected was there.

The suspect argued that the FLIR photographs breached his s. 8 right to privacy. The Supreme Court disagreed, noting that the images produced by the current FLIR technology were not truly invasive, because they did not allow the police to “see” inside the suspect’s home. The Court emphasized, however, that improvements in the technology may lead to a different result in future challenges. The principles in Tessling have been applied to other types of searches where authorities have used non-traditional surveillance techniques.

Based on these cases, private contractors hired for the specific purpose of conducting searches should be aware that the results of those searches may be subject to Charter scrutiny. Ultimately, the impact on the non-government actor may be minimal, as the remedy for a Charter breach is to expunge the evidence from the record. However, beyond the Charter issues, there are general privacy concerns that may expose a company to civil liability, or even criminal charges. Private contractors may wish to seek a lawyer’s opinion regarding the legal implications of their UAV activities.

Amanda Winters is an associate of the Aviation Practice Group at Alexander Holburn Beaudin + Lang LLP. The Aviation Practice Group handles legal matters of special concern to the aviation community across Canada and internationally. For more information, go to www. airlawblog.com.

Accepting the Challenge

HAC President/CEO Fred Jones Sets Sights on Safer 2016

BY MATT NICHOLS

He’s the biggest advocate for the helicopter industry in this country and when you have the opportunity to stop by and meet up with Fred Jones, the energetic president and CEO of the Helicopter Association of Canada (HAC), you certainly must capitalize on the chance – especially when you are in the Capital Region. Helicopters caught up with Jones in late August at the Helicopter Association of Canada’s brand new office in Ottawa to have an open discussion about several key issues: the upcoming HAC Western conference and trade show, the growing influences of UAVs, and more. As always, Jones was more than happy to share his point of view – and he couldn’t stop beaming about the new digs.

Helicopters: What was your take on the 2015 season and what have you heard from operators?

FJ: “2015 was a very slow one from a growth and revenue standpoint, a tough year for many operators and certainly the OEMs. Fortunately, the fire season was a robust one and it was a shot in the arm for the industry, which has come through some rough years recently. It was shaping up to be a bleak year with the price of oil down and the mining industry very slow. This was a real bonus for the industry as a whole.”

Helicopters: Let’s talk about key issues affecting the industry. What will be the most pressing concern – other than the taciturn economy

– affecting operators in the months and years ahead?

FJ: “It will certainly be the flight and duty time issue and it is difficult to say if it will be one year or five years before we get around to it again.

Transport Canada [TC] published in Gazette 1 a Notice of Intent [NOI] and it was intriguing to me why they would use the NOI construct. I can only remember maybe twice that TC has used in my 20 years in Ottawa. Usually they go to Gazette 1, get the comments back, take a certain amount of time to review them and disposition them, then they proceed to Gazette 2. But the reasons for the NOI I believe

Accepting

were many. First, a federal election this year was an issue; they were not going to publish anything at all, not even the most benign regulatory amendments. And flight and duty time is a complex issue under ordinary circumstances. TC reduced the scope of the regulation by 95 per cent between what it was they were proposing last September and what was in the NOI. And I think principally, it was going to be a very complicated drafting exercise.

What’s unclear to me is what will TC do post election. It’s uncertain how quickly a new minister will be prepared to move on these new regulations, particularly given their challenging nature in the run up to the NOI. And with the coalition of associations and the entire industry opposing it, calls to MPs and from MPs to the minister – there is a lot going on. It is also difficult to know whether this will be a priority for a new minister.

Potentially they could go forward with the NOI items – there is only a list of four or five in this NOI, all of which deal with CARS 705, airline operations. They may also roll others into this same Gazette 1 publication. So, they could take what they have in the NOI and add in other elements affecting other segments of the industry. I don’t think they would do it without consulting again in some form or another.

Helicopters: So, how do you think the issue will be rectified?

FJ: If the new minister comes in and says, Let’s do what is best from a safety perspective, I think TC staff are going to be hard pressed to articulate it. The TSB has virtually never identified a fatigue-related cause from the accidents that they have investigated. The pilots will give you anecdotes here and there, and the airline pilots will talk about working the backside of the clock, but the reality is, it is a hard safety case to make. There is very little empirical evidence.

TC crafted regulations that were fashioned after the growing consensus that existed between the airline pilots and their employers – and at the same time it ended up straying way off the anchor points in the scientific data which were supposed to be our guiding principle in the working group deliberations. This is unfortunate, because the consen-

LEFT: A stronger commitment to safety is paying dividends.

(All photos courtesy of Airbus Helicopters)

BELOW LEFT: IHST’s initiatives, HAC’s best practices, SMS – all have helped create a safe culture.

BELOW: Some 80% of companies flying in Canada are HAC members.

suses were built around airline principles and not necessarily for small seasonal float operators or helicopter operators.

Helicopters: Where is all of this going?

FJ: I think they are going to have to consult again, determine whether they are going to proceed with the NOI elements and then do a consultation to figure out how to proceed with the rest of the industry – and for CARS 705 because they have made it clear that they are not done with 705 yet. What it is in the NOI is just the beginning.

Helicopters: Let’s talk about safety. Are operators maximizing their own safety responsibilities, creating appropriate safety cultures at their operations? Is the industry on the right track?

FJ: I think part of it is defining industry best practices . . . and you will see that commitment from HAC at the convention in November. It’s a credit to our committees because they do the heavy lifting in this area. The next step for best practices is to educate operators and flight crews on the content of the best practices. What you are going to see at this year’s convention is we are rolling out a new concept. We are calling it a “Blue Sky Certificate,” which will be a certificate evidencing a course of education orienting operators – and their employees – to the context of our best practices. We are rolling it out with the utility flight operation best practice. At the end of the course, following an exam, participants will receive a certificate saying you have been oriented and educated on the content of the best practice.

Helicopters: How can you try to influence operators who are not members of HAC to elevate their safety commitment?

FJ: We conducted a survey showing our reach in Canada. It was determined that HAC members operate 80 per cent of the commercial helicopters turning the blades in Canada. This is better penetration than any other association, so I am quite pleased with this. However, I would say the difficulty is partly financial, partly that smaller operators do not have the time or spare capacity to look at issues that are three to five years out on their radar – flight and duty times, for example. But if we ignore this, we will be hit by it. However, if we can develop the best practices and this Blue Sky Certificate, then the customers will drive operators, whether they are members or not, to take the course. And my policy with the association is, what we do –we do for the whole industry. We do not limit access to our best practices; we do not limit access to our professional development courses, or our training courses. You have to

lead with value so that operators of all sizes can see what they are getting for their membership dollar.

Helicopters: Generally speaking, do you feel the industry as a whole is getting safer?

FJ: The statistics certainly reveal that it is. Last year was our first in several years where we had no fatal accidents. We have had one this year that I am aware of, but the numbers appear to be declining. I wouldn’t begin to attribute this to any particular cause or intervention – but it is clear there is something changing in the culture.

Helicopters: When you think about hours flown and the number of helicopters in the skies across the country at any one time, this is a great accomplishment.

FJ: IHST’s initiatives, HAC’s best practices, SMS – they are all driving this commitment to educating flight crews and companies about how to create a sound safety culture.

Helicopters: Let’s talk about UAVs. How is the UAV culture changing the landscape in Canada and how can operators react and capitalize on its growth?

FJ: It’s changing quite rapidly and it’s really amazing. When I started at the association almost seven years ago, I encouraged operators to embrace UAV technology. They are best positioned to promote it and sell what emerging technology to their customers. Now, they can offer a range of services and say, given the mission that you have described, it may be better done with a

UAV. If you want filming, if the operation is close in, not beyond the line of sight, or is at a particularly low level, perhaps you can do it cheaper, safer, and more efficiently using a UAV than a conventional helicopter. And then there are some new opportunities for pipeline, power line patrol, aerial survey work, or other areas that could be more hazardous to operate a helicopter. There are many opportunities here for helicopter operators.

Helicopters: What about safety and the growing UAV culture. How do we keep the skies safe?

FJ: The scariest part of UAVs for me is not so much commercial operators; it’s the recreational ones. And then there are the ones and the ones that just don’t understand the hazard a UAV can present on final approach of an aircraft at a major airport. That’s the crazy part – some people out there just don’t know.

The next scary chapter – and I don’t believe TC has it under control yet – are the recreational users. I am more comfortable with commercial operators, because they are just line of sight right now and are operating under a SFOC permit. The next frontier – and they have already been discussing the regulations for this segment – is beyond line of sight operations where you will have a point of view camera mounted on the UAV and the pilot could be sitting in his bedroom or basement somewhere flying this thing around looking at a computer screen and getting visual cues shot from the UAV. I think the UAV community, however, has taken a very responsible stance on this with

The ongoing flight and duty time issue will certainly affect Canadian operators. (Photo courtesy of Airbus Helicopters)

a requirement for sense-and-avoid technology and remote termination of the flight, qualifications for the pilot, this kind of thing.

Helicopters: Were there other issues of potential concern that have been solved heading into the New Year?

FJ: One of the big ones operators were in line to deal with was responsible aerodrome development. Helicopter operators were potentially heavily impacted by it. As it turns out, they have been exempted completely from the application of this regulation. I think this is mainly because helicopter operators haven’t caused a big problem – and regulators as a rule tend to respond to issues raised. This issue had its genesis in some of the high profile float operators that were generating noise around communities and the airports that sprung up out of nowhere in the oil patch in northern Alberta.

Ultimately, what the minister decided to do is to move forward with a regulation that recognizes that if you are operating a certified heliport, there already is an obligation to consult. These are the ones that provide scheduled service, they exist in a built up area or it is in the public interest, for example.

There also haven’t been a lot of high profile problems associated with operators establishing temporary helipads or bases for helicopter operators across Canada. It is a complicated issue because helicopters are so transient, they can set up a temporary helipad to transport school kids back and forth across a river during freeze up or break up in a remote community, or set up a helipad for firefighting operations. Helipads like this are here-today-gone-tomorrow operations – up for two weeks, four weeks and then they are gone again. You just don’t create a helipad in the same way you create a new airport.

In the end, TC just decided to exclude helicopter operators, helipads and heliports from the applicability of the new regulation, which we were pleased with. It had the potential to be a big problem, so we devoted a lot of time and effort to the issue.

Helicopters: What opportunities do you foresee for operators in 2016?

FJ: We are all hoping the oil and gas and resource sectors will open up a bit because it was booming for so long, but with the price of oil and the economy being down, it has affected our business is a big way. Fires are always a wild card and you never know who to believe from season to season, and as long as there have been helicopter operators, they have been speculating on what will happen. So, trying to predict it is really a mugs game.

Helicopters: It seems like more operators are looking to diversify in the U.S. and internationally.

FJ: There certainly are more doing this. I think the ones that are survivors in our industry are the ones that can mitigate the feast and famine cycle that occurs with fires. If that is the only tool in your arsenal and it rains all summer, you could be hurting.

The evolution for operators in our business has been to try to diversify – in Medevac work or aerial survey or specialized

photography, or moving your machines to the other side of the world during the winter here to try to offset a slow winter season in Canada.

It would really be nice to see the industry turn around and have a sustainable future. Our industry is closely connected to the economy.

I realize that, in the resource sector that it has been a challenge the past few years... but I am hoping things will turn around for a stronger tomorrow.

THE HELICOPTER PILOTS HANDBOOK

BY PHIL CROUCHER

One problem with helicoptering is that there are virtually no flying clubs, at least of the sort that exist for fixed wing, so pilots get very little chance to swap stories, unless they meet in a muddy field somewhere, waiting for their passengers. As a result, the same mistakes are being made and the same lessons learnt separately instead of being shared. Even when you do get into a school, there are still a couple of things they don’t teach you, namely that aviation runs on paperwork, and how to get a job, including interview techniques, etc. – flying the aircraft is actually less than a third of the job.

This book is an attempt to correct the above situations by gathering together as much information as possible for helicopter pilots, old and new, professional and otherwise, in an attempt to explain the why, so the how will become easier.

FEATURE

Thriving in Uncharted Waters

Calgary’s Eagle Copters has Brought Leasing Helicopters to a New Level

BY PAUL DIXON

Eagle Copter was born in Calgary some 40 years ago, but don’t let its journey into middle age fool you – the company shows little signs of slowing down.

Mel O’Reilly and three partners started the company with a single helicopter but today, Eagle serves a wide range of government and business customers in Canada and around the world. The company has developed a reputation for having the expertise and ingenuity to solve tough problems and create solutions that stump organizations many times its size. Along its development, O’Reilly bought out his original partners, and in 2003, his son, Mike, succeeded him as president and CEO.

The management team got that much stronger in August when Barry Kohler, former president of Bell Textron Canada and chair of the Aerospace Association of Canada (AIAC), joined the team, replacing O’Reilly as president and CEO. Shortly after Kohler came aboard, Helicopters had the opportunity to chat with both Mike O’Reilly and Kohler, to discuss how the company got to be where it is today and where it’s headed in the future.

THE SECRET RECIPE

O’Reilly attributes the company’s success in many ways to the concept that “you have to be lucky to be good and good to be lucky.” Seeing an opportunity at the right time is one thing, but it also takes foresight and more than a little bit of courage to head off into uncharted territory.

The business opportunity that Mel O’Reilly recognized and developed was leasing helicopters to other operators. Some four decades ago, leasing was an untested concept in the rotary world, though it was gaining momentum in fixed-wing aviation, especially the large commercial airlines. In the helicopter universe, however, leasing turned out to be a very attractive way for an operator to make money using the helicopter without taking on

the additional responsibilities that come with owning that aircraft. The timing was also right, as there was a distinct shortage of helicopters. Leasing also made helicopters available to operators that didn’t necessarily qualify for the financing required to make a purchase. And from the lessor’s perspective, helicopters became even more valuable, as they proved to appreciate in value over time, which enabled Eagle to grow its lease fleet at an accelerated rate.

O’Reilly said his father also introduced the concept of “power by the hour” – a strategy standard in the Canadian helicopter industry. The “power by the hour” concept – paying for the helicopter on an hourly basis based on job or operation – made life a lot simpler for operators, enabling them to concentrate on making money with their helicopters, while at the same time Eagle was developing its own in-house repair and overhaul capacity.

A STAR IS BORN

By 1985, Eagle’s basic business model was in place. Individual operators could attain a helicopter and lease it out, and get access to a 10,000 square foot repair and overhaul facility. From this point on, O’Reilly says, growth was steady. “It was a very linear growth model, no spikes at all, it just evolved,” he said. “Demand dictated it, and up until 2008, there was a really steady demand for our business.”

Today, Eagle Copter has some 65 helicopters operating under lease programs around the world, and has sold more than 100 helicopters to boot. Its repair and overhaul facility in Calgary now takes up 90,000 square feet, but as O’Reilly notes, it hasn’t all been roses over the past decade. “We didn’t (use to) experience the ups and downs like the OEMS, because there would be lot of fire activity that made up for the highs and lows in the oil and gas business,” O’Reilly said. “What changed in 2008 was the unbelievable oversupply situation we ended up with and I can’t explain that.

Eagle was already acting as the Canadian distributor for various parts and accessories as well as developing some STCs of its own. But the big step forward, O’Reilly notes, happened at a social gathering during a conversation with his insurance broker. “I knew they insured Dart Aerospace as well, so I asked him if he knew what their succession plan was and funny enough, he did,” O’Reilly said. “That enabled me to reach out to Jim Bradly at Dart and, while it took five years, that was the set up and we eventually bought Dart into the fold. It has not only expanded our ability to grow our business, but put a different spin on our repair and overhaul business and our ability to supply parts to the market place. It also provided capacity to the group for manufacturing and engineering services, which was not something we had in the repair and overhaul sector prior to that.”

Kohler has his own perspective of Eagle’s diversification and specifically, O’Reilly’s keen business acumen and foresight. “Mike is being really humble, but Mel had the original idea and grew the business incredibly well,” Kohler noted. “Then Mike came into the business with a fresh set of eyes and brought an entrepreneurial spirit to it from the perspective of diversifying the overall business portfolio. What Mike has been doing very successfully for more than a decade is figuring out how to grow adjacently in the marketplace, including CSFs in Chile and Australia as well as other partnerships in the global leasing business. What has been very encouraging from our perspective in this unpleasant economy is the diversity and capability of the company, which includes being fairly unique in being able to do engineering projects such as the Eagle Single and 407HP. I think Mike is underselling how well he has been able to look around the helicopter business and decide where we can have a significant impact.”

Those associated with the Canadian helicopter industry need to realize how important it is to read and adapt to market conditions, but it’s even more important to understand your own strengths and weaknesses, and capitalize on an opportunity when it presents itself. Kohler knows this all to well, which is why he joined the Eagle team when he did.

Global climate change has put us more in the same situation as the OEMs, and we have been experiencing these ups and downs in much the same way.”

While Eagle staked its claim by building the lease, sales and maintenance business, diversification into related and allied fields – which was well under way before the economy fell out – is allowing the company to navigate with a higher degree of assurance in a continuing climate of economic uncertainty.

When O’Reilly took over from his father as president in 2001,

“We are definitely experiencing a downturn in the industry right now and this requires a lot of decisions to be made,” O’Reilly said. “My forte is not necessarily operational and economic metrics, so I was looking for an individual who could help us in those areas. I wasn’t looking at Barry specifically, but we had known each other for a long time on a business level and a personal level. The timing was right for Barry and I was lucky to have him join us at a time when I need his expertise more than anything else.”

From Kohler’s perspective the offer made sense both on a professional and personal level. After serving as president of Bell Helicopters Canada for several years, he had taken a position at Bell’s head office in Texas. “My family had spent a lot of time in Canada and they were very comfortable here and wanted to remain (in Canada). Mike and I have always had a strong relationship.

ABOVE: Eagle Copter has some 65 helicopters operating under lease programs around the world. (Photo Courtesy of Eagle Copters)

RIGHT: New Eagle Copters president Barry Kohler. (Photo courtesy of Eagle Copters)

New Eagle president Barry Kohler has his eyes set on the Canadian Forces Griffon Limited Life Extension Program. (Photo by Paul Dixon)

This is something we have both talked about from time to time over the past couple of years and neither of us had killed the idea, so for me it was the perfect storm, if you will.

“I love the helicopter industry, my time with Bell was fantastic and they could not have been more graceful when I made my decision to come to Eagle. My time at Bell gave me insight into the operator community and there was always something in the back of my mind about working in this environment and facing these challenges –the ability to have a more entrepreneurial approach to what I do.”

Kohler describes his first few weeks on the job as “useful and entertaining” as there have been times where his business approach and the company’s have been a little different so to speak. “Melding the two (styles) going forward is going to benefit Eagle,” he said. “I bring a company skill set and Mike brings an entrepreneurial skill set and we want to apply these to a growing company. The benefit of bringing wildly differing viewpoints to situations, is very valuable in allowing us to hone in on an ultimate solution.”

A NEW PATH

The road ahead is far from easy for the new Eagle team. The economic climate is not going to improve overnight, but the diversity O’Reilly has worked to create is going to allow Eagle to ride the storm in relative comfort. “The OEMs aren’t having a lot of fun right now,” O’Reilly said, “and businesses that exist in just one or two markets are going through some degrees of pain that we are fortunately not experiencing. It’s no fun for anyone, but it’s more tolerable for us.”

Eagle’s international footprint – something that has grown steadily since it established a solid base is Canada – is now quite strong. The company has a foothold in Chile, which services the Latin American market, but also has an established clientele in Spain and Portugal. “There is still opportunity for growth down there,” O’Reilly said. “Looking at our basic portfolio, the markets are still growing and we look at them to backfill what we’ve been doing in Canada for the last 20 years.”

Eagle’s new base in Australia represents a window to markets in Southeast Asia –another region that offers growth potential. “It would be very difficult to tap into that market without a local presence and knowledge,” O’Reilly said.

Such a globalized perspective gives the Eagle team a sense of optimism over the next decade. The goal is to take the current product offerings and expand on them,

looking to the DART model for some perspective. While Eagle has been known in the industry as being Bell-centric from Day 1, DART has product offerings that are represented by all OEMs.

As Eagle matures and widens its standing in the marketplace, the increased level of capabilities and sophistication in engineering and design is one more example of a company that is ready, willing and able to do what few other companies could dream of. The Eagle Single program, for example, which was developed in-house, sees the Bell 212 converted from a twin-engine to a single-engine helicopter.

This ingenious approach has now been

environments.

Honeywell approached O’Reilly and Eagle after the U.S. government cancelled the Armed Reconnaissance Helicopter (ARH) program that Bell was developing. The commercial variant was to be known as the Bell 417, but when the government cancelled the military project Bell decided it was not financially feasible to develop the 417.

Honeywell then found itself with an engine, the HST900D-2, without a hull. Eagle had worked closely with Honeywell on the Super Eagle and this led the Honeywell business development people to approach O’Reilly. Subsequently, Eagle,

I ended up being very impressed with the engineering capabilities of the people here and the ability to do things without the vast intellectual horsepower of a huge OEM.

followed by the 407HP program, which transforms a good helicopter, the Bell 407, into a really good helicopter by replacing the original Rolls Royce C47 engine with a Honeywell HST900D-2. The result is a significant increase in horsepower, improved payload and generally increasing the capabilities of the aircraft over a wider operating spectrum, especially in “high and hot”

Bell and Honeywell worked together to develop what is now known as the 407HP. “We had already demonstrated what we could do with the Eagle Single,” O’Reilly said. “There might have been other companies they could have gone with, but the opportunity was there and we were at the right place at the right time. It was quite a challenge.”

The 407HP program has transformed a good helicopter, the Bell 407, into a really good helicopter – the Bell 407HP. (Photo by Torrie Chartier, Elbow River Helicopters)

Kohler was at Bell back then, on the other side of the looking glass, and he remembers being part of the discussions. “I was a little skeptical Mike could pull this off, because I knew what it took to do something this complex from the OEM standpoint,” Kohler said. “But I ended up being very impressed with the engineering capabilities of the people here and the ability to do things without the vast intellectual horsepower of a huge OEM. It speaks to the unique engineering capability and the unique overall capability of Eagle.” It took five years for Eagle to make the 407HP a reality, with Transport Canada and Federal Aviation Administration approval received in December 2014.

The 407HP conversion is not an inexpensive proposition, much more than simply swapping engines. Eagle currently projects the job at about 1,000 hours, which translates to a month of downtime. It is an exacting process, but with a big payoff as Kohler explains. The 407HP “will have far better productivity and carrying capacity than anything else in its class because of the HST900D-2 engine and the capabilities it will provide.”

Honeywell quantifies the improvement in performance by stating that the 407HP was able to make 32 per cent more bucket lifts in an hour while fighting a fire, with 42 per cent more time on station, though they do not qualify those numbers by total hours or number of aircraft. Calgary’s Elbow River Helicopters took delivery of one of the first 407HPs and company owner and chief pilot Bruce Holloway had the opportunity to fly both the HP and the stock 407 over the summer. His assessment is the 407HP clearly outperforms the stock aircraft when flying under the same conditions.

The realization that clients are becoming increasingly cost-conscious is a key driver in spurring Eagle’s product development. O’Reilly cites the U.S. Forest Service and that agency’s work in assessing various aircraft types in terms of identifying those that are the most cost-effective. “We are attempting to deliver a product, whether it’s a Super 205 or a 407HP, which will have such a competitive advantage that they will have no other choice.” There are more than 1,000 407s in operation around the world and if even a small percentage of operators opt for the conversion, it will keep Eagle busy for years to come.

A MILITARY PERSPECTIVE

Looking ahead at new business opportunities, Kohler has his eyes firmly set on the upcoming Canadian Forces Griffon Limited Life Extension Program. Projected to cost

as much as $1.5 billion over a decade, with the first steps in 2016 and RFP in 2018, Kohler is most emphatic in saying “this project is right in our wheelhouse based on what we’ve done with the Eagle Single and now the 407HP.” He also references the work Eagle has done with the National Research Council on its fly-by-wire 412, upgrading it with the Pratt and Whitney electronically controlled T9 engines in combination with the new Genesis glass cockpit.

O’Reilly can be very self-effacing and it is true that luck does play a role in one’s

success. However, it takes more than just being lucky – and more than simply being good at what you do – to succeed. The key is to evolve with the times and not just meet market demands, but also be able to sense a need before it becomes widely accepted. You must also attract (and retain) a team of people who have the ingenuity and creativity to get where you want to be – and this is a talent in its own right. It’s the people that make the difference and it’s the people that make Eagle Copter what it is today – confidently steadily growing in a challenging, ever changing economy.

FEATURE

Sikorsky Changes Corporate Horses

Lockheed-Owned Sikorsky Helicopters: The Canadian Perspective

BY RICK ADAMS

Lockheed Martin’s intended acquisition of Sikorsky Helicopters will likely have little impact on Canadian aviation, civil or defence, in the long term. In the short run, it could mean further delays for the Royal Canadian Air Force’s aptly named Cyclone program’s twisted path just when deliveries of the CH-148 are beginning.

Sikorsky had already announced a workforce reduction scheme before United Technologies Corporation put the U.S. rotorcraft manufacturer up for auction. A Polish military contract, which failed to come through, triggered layoffs of nearly 10 per cent of its employees. And when the U.S.$9 billion ($11.6 billion Canadian) sale was announced in July, Lockheed Martin officials indicated they expected about $150 million in “synergies,” or code for further job cuts from duplication. So no surprise that Sikorsky’s 18,000 employees are going to be nervous for a while about takeover integration on top of restructure, and may not perform at peak production.

Few of those workers are in Canada. Sikorsky-owned Composite Technology has a small team in Winnipeg, Man., doing repair and modification of rotor blades, and Wisconsin-headquartered Derco Aerospace performs maintenance services for some Canadian military equipment in Abbotsford, B.C. Lockheed Martin Canada, which claims a business presence in the country since 1937, has more than 800 people supporting military combat systems and government information technology, including the Statistics Canada online census.

Marillyn Hewson, Lockheed Chairman, CEO and president, explained they’re buying at a time when Sikorsky’s financials have dropped due to lower revenue from commercial oil and gas customers. Chief financial officer Bruce Tanner added, “This is a longterm business. We’re not buying this business for the next three

years. We’re buying for the next three decades.”

Bethesda, Md.-headquartered Lockheed (112,000 employees worldwide) hopes to wrap up the Sikorsky deal by the end of 2015 or early 2016 at the latest. First, it must pass muster with U.S. Department of Defense and Department of Justice antitrust regulators, which is not necessarily automatic. As recently as this spring, for example, the DOJ was reportedly prepared to block the merger of cable television giants Comcast and Time Warner (which the two companies subsequently called off). In 1998, Lockheed Martin abandoned its planned $8.3 billion acquisition of Northrop Grumman when the government opposed it. In effect, the DOD has unofficially ruled out mergers among the top five American defence contractors (Lockheed, Boeing, General Dynamics, Raytheon, Northrop Grumman).

Indeed, prior to his confirmation as U.S. Secretary of Defense, Ashton Carter told the Senate Armed Services Committee: “I believe the government must be alert for consolidations that eliminate competition.”

“I think this Pentagon is going to take a real and serious look at this,” said Jeff Bialos, a partner in the American law firm of Sutherland Asbill & Brennan who previously served as the U.S. Deputy Under Secretary of Defense for Industrial Affairs. “I don’t ascribe to the view that it’s ‘green-lighted.’ Antitrust is an area where the facts matter. You can’t get the answer to this deal until you delve into the facts at length.”

Sikorsky accounts for two-thirds of the Pentagon’s helicopter spending, and could lead the U.S. to examine its reliance on Lockheed, which is also responsible for the troubled, expensive F-35, aka the Joint Strike Fighter. The F-35 Lightning II is also Canada’s most significant fixed-wing procurement; for the moment, the intent to purchase 65 of the fifth-generation fighters at a cost

ABOVE: The RCAF’s 27 CH-124 Sikorsky Sea Kings have been in service since 1963. (Photo courtesy of RCAF)

RIGHT: Igor Sikorsky’s vision for the company will live on under the Lockheed Martin banner. (Photo courtesy of Sikorsky)

segment of the domestic defense market.”

“If you read between the lines, it’s not that they make helicopters. It’s that they make military helicopters,” said Mike Blades, an analyst with Frost & Sullivan. “Sikorsky may have steady sales; it won’t show huge growth.” According to the Teal Group consulting firm, military rotorcraft saw a 7.9 per cent compound annual growth rate between 2004 and 2013, with an unheard of 66 per cent jump from 2008-2012. That unsustainable growth has slowed and is projected to continue to decline. The commercial helicopter market had been on an upswing, but has stalled recently with plummeting oil prices.

A significant factor in the appeal of Sikorsky to Lockheed Martin is its post-production support of fielded helicopters, especially thousands of H-60 Black Hawk variants. The aftermarket business generates a continuous stream of revenues for spare parts, mission equipment, overhauls, and maintenance.

Canada’s CH-148 Cyclone program may be affected in the short-term by the Lockheed Martin/Sikorsky merger. (Photo courtesy of the RCAF)

of about $16 billion is on hold until after the October federal elections.

Dr. Loren Thompson, chief operating officer of the non-profit (but defense contractor-funded) Lexington Institute think tank, stated, “The Sikorsky transaction is probably the biggest domestic defense acquisition that Lockheed Martin could have accomplished without running afoul of regulators. Because Lockheed Martin does not currently assemble rotorcraft, adding Sikorsky to its holdings would not materially increase concentration in any particular

After Lockheed completes the Sikorsky acquisition, “they’ll be the biggest fighter prime in the world, the biggest helicopter prime in the world, and the U.S.’ biggest military transport maker,” noted Richard Aboulafia, an industry analyst at Teal. “But there is still competition in each of these segments.”

Lockheed plans to align Sikorsky under its Mission Systems and Training business segment.

CYCLONE – NOT SIKORSKY’S FLAGSHIP

Canadian defence officials certainly hope the Lockheed-Sikorsky integration won’t negatively impact the long-suffering Maritime Helicopter Project. After all, the RCAF just took delivery of the first six of 28 planned CH-148 aircraft. It only took 11 years to get those – the original contract was awarded to Sikorsky in 2004.