MATT NICHOLLS Editor, Helicopters Magazine

MATT NICHOLLS Editor, Helicopters Magazine

hen it comes to innovation in the rotary MRO space, Canadian companies lead the way in developing processes, techniques and products that are enhancing safety and adding value for their customers.

And for firms such as Vector Aerospace, Heli-One, Airbus Helicopters Canada, Bell Helicopter Textron Canada and more, refinements in product development and process comes at every level – from technological enhancements, to the implementation of new technologies such as 3D printing, the harnessing of big data, introducing new customer service options, digitizing work spaces for more efficiencies and more.

“The MRO industry is in for a major

change in the next 10 years,” notes Tom Cooper, vice-president of Cavok, a division of Oliver Wyman, an industry MRO watchdog.

“Technological changes, geographic shifts, the development of new fixed and rotary wing aircraft . . . companies must find new ways to cut costs and improve the servicing of aircraft.”

With a shortfall in the number of adequately trained mechanics and engineers on the horizon, it’s imperative now more than ever for companies to continue to find new and intriguing ways to do business and service customers – all so operators can continue to exceed all safety requirements and keep aircraft in the air. Solving the talent crunch with an influx of retiring MRO professionals on the horizon is also an issue

that needs to be considered.

This special digital edition for Helicopters Innovation in Rotary MRO week highlights unique ways Canadian and other international firms are meeting some of these objectives. Sponsored by Vector Aerospace, a global independent provider of aviation maintenance, repair and overhaul (MRO) services, this edition highlights news and features that highlight how Canadian and global firms are adapting in the new MRO frontier.

From overhauling the MRO service and support department at Airbus Helicopters Canada to Safran’s new ways to present its MRO directories, advancements big and small are changing the MRO landscape, all with the intent of enhancing value and keeping the blades turning.

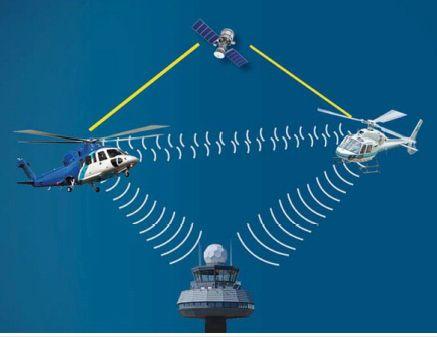

Vector Aerospace, a global independent provider of aviation maintenance, repair and overhaul (MRO) services, has developed a new FAAcertified ADS-B Out solution for the popular Leonardo Helicopters AW139 medium twin rotorcraft.

Vector’s ADS-B Out solution utilizes an L-3 Avionics Systems Lynx 1090 MHz Mode S ES transponder, installed either via a new centre console control panel or on the aircraft’s existing instrument panel. This ADS-B Out solution received supplemental type certification (STC) from the U.S. FAA and Brazilian ANAC airworthiness authorities last

year, and will provide air traffic controllers with accurate, realtime aircraft position information, enhancing operational safety in congested airspace.

“This STC development is an example of our expertise and flexibility when it comes to developing avionics solutions to meet our customer’s unique needs,” said Craig Pluim, vice president rotary-wing sales at Vector Aerospace. “Vector is

pleased to offer this product to the marketplace to meet demand from operators for lower cost solutions, especially in today’s challenging economic conditions.”

Vector Aerospace’s worldrenowned avionics capabilities utilize the latest technology to provide quality rewires, new installations, STC installations, refits and avionics upgrades.

The company’s platform

capabilities include the Airbus Helicopters H125/AS350, AS355, H130/EC130 and H215/AS332 Super Puma series, Bell Helicopter models including the Bell 205, 206, 212 and 407, and the Sikorsky S-61 and S-76. Specialist avionics technicians support a wide range of operators across the private, commercial and military sectors, and are available to provide worldwide field support 24/7.

Vector Aerospace Corporation, a global independent provider of aviation maintenance, repair and overhaul (MRO) services, and its partner Robertson Fuel Systems (RFS), a HEICO Company, have announced that their CrashResistant Fuel Tank (CRFT) for the Airbus AS350 light single helicopter family has successfully completed its first flight.

This second major milestone toward Federal Aviation Administration (FAA) certification of the CRFT comes shortly after the successful completion

of an FAA-certified 50-foot drop test that demonstrated the tank’s ability to withstand impact without any leakage, thereby helping to prevent post-crash fires.

The new CRFT has since been installed on two flight test aircraft, an AS350 B2 and an AS350 B3, with both undergoing extensive ground-testing as the program progresses steadily forward.

“This milestone is a testament to the team here at Vector, which has been working hard to bring this product to market for our customers,” noted Jeff

Booker, CRFT program manager at Vector. “As soon as the drop testing was complete we began the process of installation to move us into this new test phase. It’s a great feeling to see this tank flying.”

Company flight testing will continue on both aircraft is ongoing, as Vector and RFS work towards a late 2017 FAA supplemental type certificate (STC) target date.

The CRFT is being developed by RFS and Vector as a direct replacement for all AS350 models, including the H125 (AS350

B3e), as well as for the EC130 B4. The unique design features a robust crash-resistant fuel bladder, and uses several innovations including a magneto-resistive fuel quality transmitter to keep the tank from being compromised in the event of an accident.

Vector is also working closely with Onboard Systems to incorporate their industry proven cargo swing solutions as a compatible option which can be used with the new crash-resistant fuel tank. The AS350 CRFT can be ordered from either RFS or Vector.

Sikorsky’s Commercial Overhaul and Repair division in Trumbull, Conn. has has earned a FAA Diamond Certificate of Excellence award for its 10th consecutive year. It’s the highest training award of its kind. This recognition is given to employers with 100 per cent employee participation in a FAA-approved aviation maintenance training program.

To achieve this, nearly 50 employees completed 1,967 hours of training in productspecific helicopter instruction,

Sikorsky continues to lead the way in rotary MRO excellence.

safety and FAA regulatory compliance training last year.

“This accomplishment reinforces our commitment to quality and improved customer support,” said Sikorsky vice president, Product Centers, George Mitchell. “We are proud of our service technicians and the

exceptional work performed here at Sikorsky Trumbull O&R.”

The FAA also recognizes individuals for their personal achievements. In 2016, 21 technicians received personal silver awards while 26 received bronze awards.

“Training is a critical component to ensuring efficient processes and improvements, and also in developing our workforce, enabling teams to react effectively to market demands,” added Mitchell.

Overhaul and Repair Trumbull is Sikorsky’s premier maintenance, repair and overhaul (MRO) facility. This facility is an industry leader in providing complete factory authorized services for Sikorsky S-61, S-70, S-92 and S-76 helicopters.

Trumbull O&R is an authorized service center to several rotorcraft Original Equipment Manufacturers with Federal Aviation Administration (FAA) and European Aviation Safety Agency (EASA) certificates.

Vector Aerospace a global independent provider of aviation maintenance, repair and overhaul (MRO) services, has recently received approval from the European and United States airworthiness authorities for its ADS-B solutions offered for Part 27 and Part 29 rotorcraft.

In December 2016, Vector received European Aviation Safety Agency (EASA) supplemental type certificate (STC) approval for its Part 29 rotorcraft ADS-B solution for the Airbus Helicopters AS332 UL 1 Super Puma, Leonardo Helicopters AW139 and Sikorsky S-76.

Simultaneously, Vector received Federal Aviation Administration (FAA) STC approval to extend the approved model list (AML) its Part 27

ADS-B solutions to include the Airbus Helicopters H120/ EC120, H125/AS350 and H130/ EC130 light helicopter families.

Vector’s Part 29 ADS-B retrofit upgrade has already received STC approval from the national airworthiness authorities of the U.S. (FAA), Brazil (ANAC) and Mexico (DGAC). This STC –which utilizes the L3 Lynx NGT-9000 transponder – allows for a panel mount or remote mount transceiver, if cockpit space is a challenge.

The company’s ADS-B In/ Out solution for the Airbus light helicopter family offers customers a choice between using the L3 Lynx NGT-9000 transponder or Garmin’s GTX-345 unit.

Vector’s ADS-B In/Out retrofits include a 1090 MHz extended squitter and UAT ADS-B In,

and the upgrade also features Wi-Fi enabling for use with portable electronic devices (PEDs) via apps such as ForeFlight or Garmin Pilot. Installation of this ADS-B retrofit can be undertaken easily, with the associated aircraft downtime ranging from one day for simple configurations to a maximum of three days for more complex work.

“Receipt of EASA certification and the new AML STC for the ADS-B retrofit upgrade broadens our ability to offer this unique solution to customers across the globe,” said Elvis Moniz, vice president, business development - Airframe & Avionics Solutions at Vector Aerospace. “This upgrade has generated significant customer interest in recent months, and we are actively supplying ADS-B

kits and installation support to operators globally as the ADS-B regulatory compliance mandate date draws closer. Vector has installed nearly 500 ADS-B systems in a variety of aircraft types, and it is continuing to work on new ways to offer customers cost-effective solutions that are technically sound, well documented and well supported.”

Heli-One, a leading global provider of helicopter maintenance, repair, and overhaul (MRO) services, recently completed Airbus AS332 dynamic component exchanges with a customer in Puerto Rico. The aircraft’s main gearbox and main rotorhead were also recently overhauled at Heli-One’s facilities.

The availability of the components allowed the customer to continue to provide services for their utility-based missions with minimal interruption.

The customer operates a fleet of Airbus AS332L1 and AS350B2 aircraft for mixed use, with utility their primary mission type. This exchange was facilitated by Heli-One’s

large pool of rotable assets, with freshly overhauled and serviceable part numbers being added regularly.

Heli-One’s Build to Spec exchange program has a dedicated team to ensure that new part numbers are being sourced to meet current and anticipated customer demands. The exchange program also empowers operators to customize their requests to meet both budget and planning requirements.

“We are happy to provide this customer with these indemand dynamic components to ensure their aircraft continue to maintain their service levels,” said Eddie Lane, president, Heli-One. “The AS332 is a durable and flexible aircraft

that meets many of their rotor wing operational demands and we are happy to support their fleet. We have an extensive Super Puma component exchange pool and through our global network, we were able to quickly procure the right asset to meet their requirements.”

Heli-One has extensive support experience for the AS332 helicopter type with three global facilities having capability. The company provides full nose-to-tail MRO services including all levels of inspections, major and minor component overhaul, engine support, testing, avionics, and modifications (including more than 60 proprietary repairs).

As operational environments and maintenance business practices change, maintenance professionals need new ways to maintain their competitive edge and sustain their future.

In this atmosphere of change and evolution, Cloud computing represents a significant technology that has the potential to transform the world of aviation MRO and usher in a new era of innovation and advancement. The advent of the Cloud and a shared IT infrastructure, offers the possibility where:

• Original Equipment Manufacturers (OEMs) will benefit from returnon-experience information, which will feed back

into improved products for all.

• Fleet managers will have infrastructure and information to make forecast plans, budgets, and cost lines for bidding work, leading to improved control, visibility and better decision making.

• Airline and helicopter operators will benefit from reduced barriers to implementation since traditional architectural burdens required for software-as-a-service are now offset to other parties.

• MRO service providers will now have easier access to all the data

HELICOPTERS MAGAZINE P.O. Box 530 105 Donly Drive South Simcoe ON N3Y 4N5 Tel.: 519-428-3471 Fax: 519-429-3094

Toll Free: 1-888-599-2228

Website: www.helicoptersmagazine.com

EDITOR MATT NICHOLLS email: mnicholls@annexweb.com 416-725-5637

MEDIA DESIGNER JAIME RATCLIFFE

CONTRIBUTING WRITERS

RICK ADAMS, DAVID CARR, BRIAN DUNN, PAUL DIXON, WALTER HENEGHAN, FRED JONES, CARROLL MCCORMICK, COREY TAYLOR

NATIONAL ADVERTISING MANAGER

MENA MIU email: mmiu@annexweb.com 416-510-6749

ACCOUNT MANAGER KORY PEARN email: kpearn@annexweb.com 519-902-8574

ACCOUNT COORDINATOR

STEPHANIE DEFIELDS email: sdefields@annexweb.com 1-888-599-2228 ext. 257

GROUP PUBLISHER MARTIN MCANULTY email: mmcanulty@annexweb.com

COO TED MARKLE

EMAIL: tmarkle@annexweb.com

PRESIDENT & CEO Mike Fredericks RETURN UNDELIVERABLE CANADIAN ADDRESSES TO ANNEX PUBLISHING & PRINTING INC., P.O. BOX 530, SIMCOE, ON N3Y 4N5 CANADA. email: subscribe@helicoptersmagazine.com

Published five times a year by Annex Publishing & Printing Inc.

Printed in Canada ISSN 0227-3161

CIRCULATION Email:apotal@annexbizmedia.com Tel: 416-510-5113

Mail: c/o Circulation, 80 Valleybrook Dr. Toronto, ON M3B 2S9

being generated by aircraft and the corresponding work that needs to be done.

With an its commitment to excellence and innovation, Mxi Technologies continues to explore meaningful ways of improving maintenance planning and execution for our customer community and the aviation market as a whole.

Cloud computing is no exception. Mxi Technologies is actively working with our customers and partners to explore the development of the MRO Cloud as a major step forward in realizing the measurable efficiency gains being asked for by the industry.

SUBSCRIPTION RATES Canada - 1 year $29.95 USA- 1 year $54.50 Foreign - 1 year 60.00 plus applicable taxes www.helicoptersmagzine.com/ subscribe

Occasionally, Helicopters magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2017 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Helicopters Magazine is a corporate member of the Helicopters Magazine is an associate member of the following Canadian aviation associations:

As part of Airbus Helicopters Canada’s international maintenance, repair and overhaul success, the company has expanded its support and services department at its main facility in Fort Erie, Ont.

The 5,000 square foot space represents an increase of 65 per cent for the company’s repair and overhaul department.

“It is our main priority to keep our customers‘ aircraft operating at peak performance. With this expansion, we will increase the efficiency of our repair and overhaul capabilities, resulting in faster turnaround-time when an aircraft requires service,” said Romain Trapp, president of Airbus Helicopters Canada. “An operator’s competiveness is directly linked to the amount of time their aircraft is flying. We are committed to taking the steps necessary to ensure we support our customers’ ability to

succeed, as their success will ultimately become a reflection of our own.”

The expansion of Airbus Helicopters Canada’s maintenance, repair and overhaul department is a direct result of the high demand for service from customers both domestically and internationally.

Five years ago there was a dramatic increase in AS350/ H125 aircraft sales worldwide. With 300-600 flight hours per year, many of these aircraft are coming due for overhaul. Today, there are currently 522 AS350/H125’s flying in Canada.

Part of the newly expanded facility is the creation of

additional repair and overhaul workstations as well as, the hiring of new full-time employees to assist with the high demand. Airbus Helicopters Canada is considered an International Centre of Excellence for light aircraft, including; H120, EC130/H130, AS350/H125 and AS355.

Heli-One has developed an upgrade for the Sikorsky S-92 to enhance safety and situational awareness.

The company’s new economical solution features two tail boom-mounted cameras that monitor the engine and cargo door operations in real-time. Two additional cameras can be mounted to focus on hoist and cargo hook operations. This solution provides pilots live video feed of critical external views that impact crew and passenger safety while inflight.

The new solution was developed inhouse using 3D printing technology. The small physical size of this modification made it a perfect candidate to trial out 3D printing in the prototyping phase of the design. By printing in plastic, engineers were able to make adjustments for fit quickly and economically. This efficient design iteration

loop allowed for the overall turnaround time to be reduced and the modification to be deployed sooner.

The same technology was used to create a ventilation duct transition prototype for the Sikorsky S-76. Engineers had to design a transition piece that would link two ends –one square and one round. A prototype was designed and printed and to their delight – it fit immediately. A metal transition piece was commissioned to be created based on this design.

A more complex project was undertaken at Heli-One Norway in Stavanger, Norway where the design and engineering team prototyped a SAR cabin interior in plastic to trial before manufacturing. A short project deadline had the design team think outside the box on how to prototype the design quickly.

Oliver Wyman’s 17th annual Fleet & MRO Forecast released earlier this year notes rapidly changing technological developments will drastically alter the global MRO landscape in the next 10 years, both on the rotary- and fixedwing sides of the coin.

The 10-year outlook focuses on the airline and rotary fleet growth and notes how technology will also impact maintenance costs and volumes, including 3D printing applications, the harnessing of big data and much more.

• The in-service commercial airline fleet is forecast to grow from nearly 25,000 aircraft at the beginning of 2017 to more than 35,000 by 2027. Aircraft deliveries to airlines – and rotary operators – will total about 20,000 over the period, so retirements of older technology will accelerate to about 10,000 during that time.

• The accelerated rate of new aircraft deliveries will result in a massive technology shift over this period. By 2027, 58 per cent of the fleet will be new-generation aircraft.

“The MRO industry will need to evolve significantly over the next 10 years to meet changing demand driven by growth, geographic shifts, fleet mix trends, and new technology,” said Tom Cooper, vice president, Cavok, a division of Oliver Wyman.

• Major net fleet growth will occur in Asia, especially China and India, which will become the largest region, nearly doubling in in-service fleet and related MRO demand. By contrast, North America will experience little absolute growth, although there will be a significant upgrading of the fleet over the period. North America will slip to the third-largest region, behind Asia and Europe.

• The retirement of aircraft will remain brisk. Having fallen out of favour in recent years, small regional jets and narrow-bodies have been the predominant source of aircraft retirements, resulting in a

surprisingly young retirement age of about 18 years. Helicopter operators will explore new ways to improve aircraft and keep them in the air, opening up plenty of opportunities for global and Canadian MRO providers.

• However, with many of these smaller-capacity aircraft now purged from the fleet, the industry can expect retirement ages to climb again as retirement selections will naturally revert to older, largercapacity aircraft. The report also explores the big data and new-generation aircrafts, the changing fleet mix, and the used serviceable material market.

LORD Corporation has announced the addition of fly-by-wire (FbW) aftermarket repair capabilities at its Cambridge Springs, Pa. facility in an effort to expand aftermarket support for long-time client Airbus.

LORD has supported Airbus since 1984 out of their repair centre in Saint-Vallier, France. The addition of this new repair station will ensure faster service, reducing an average return from 40 to approximately 15 days.

“Having LORD FbW products repaired at a LORD repair station allows us to provide the turnaround times that customers expect because we are the original component manufacturers,” said Mike Penfield, Cambridge Springs manufacturing engineer. “This enables us the control to ultimately

improve customer satisfaction.”

The repair station, ready to operate, is equipped to handle cockpit equipment used on the Airbus fleet. Starting with three part numbers, the station will expand to support more than 50 part numbers in 2019.

According to Penfield, the Cambridge Springs facility was ideal to meet this market need because of its history of both producing and repairing LORD Electromechanical Systems.

“The Cambridge Springs team is well-suited with its skillset, experience and enthusiasm,” said Patty Foote, manager of LORD Aerospace and Defense Product Support Engineering.

“The team has a proven track record during the last 10 years of using in-house technical capabilities to deliver on complicated and

important initiatives.”

Frederic Ponchon, LORD Flyby-Wire sales director, noted that “the addition of a LORD FbW repair station in the U.S will improve LORD Corporation’s service to airline and MRO customers for repair of cockpit control parts used in Airbus aircraft.”

In addition, SATAIR, a leading global provider of aftermarket services and solutions for the civil aerospace industry, has been selected to provide Airbus AOG support services for LORD FbW parts.

LORD Cockpit Control solutions provide functional and ergonomic interfaces between pilots and various aircraft systems.

The flight control inceptors are compact and lightweight, seamlessly integrated into cockpit designs, and can be tailored to

sidestick or yoke based cockpit layouts.

LORD Corporation’s Cambridge Springs facility was established in 1966 with just 60,000 square feet.

The plant is comprised of 190,000-square-feet of space on 17 acres.

With a staff of nearly 90, the plant serves industrial, aerospace as well as oil and gas markets. Products manufactured at the plant include: Active Vibration Control Systems (AVCS), semiactive MR suspensions, Tactile Feedback Devices (TFD), Active Balancing Systems, monitoring products, as well as other general aviation, rail transportation, civil engineering, packaging and sealing products.

New positions are being created to support the FbW operation.

COURTESY OF AIRBUS

n applying digital technologies that are bringing major transformation across all of its operations, Airbus increasingly is asking: “What if?

“What if” the company could digitally connect every tool in each of its factories?

“What if” substantially more data could be accessed aboard aircraft in service around the world on a more regular basis than today? “What if” most instances of component failure could be predicted on its jetliners, helicopters and spacecraft?

The answers, according to Airbus digital transformation officer Marc Fontaine, lead to what he terms “360-degree aerospace data:” a way of using emergent technology in improving nearly every aspect of Airbus operations, including MRO.

Fontaine sketches out a future in which additive manufacturing, augmented reality

glasses, robotics that amplify human users’ capabilities, and the intelligent use of advanced data analytics are the norm.

Using an A320 Family jetliner from Airbus Commercial Aircraft as an example, he noted that the aircraft’s onboard systems typically track approximately 400 parameters for the pilots and maintenance crews – less than two per cent of all the data available. Ubiquitous connectivity, and the processing power to manage this data, would enable some 24,000 parametres to be tracked.

Such improvements in data acquisition and analysis are reflected in Airbus’ new open digital aviation data platform called Skywise – powered by Palantir Technologies, a pioneer in big-data integration and advanced analytics.

With Skywise, Airbus operators can

leverage the power of 20,000 Airbus engineers in following the performance of each aircraft throughout its entire operational life. Until now, this deep reservoir of information was accessible only during the few years of development, flight tests and certification prior to an aircraft’s entry-into-service.

The new digital aviation platform was unveiled at the Paris Air Show earlier this year, and details were provided on how seven “early adopter” airlines are working to harness the power of Skywise – positioning it as “the beating heart of aviation.” These carriers are AirAsia, Hong Kong Airlines and Peach in Asia; Delta Air Lines and jetBlue in the United States; Emirates in the Middle East, and easyJet in Europe.

They are benefitting from Skywise through multiple developments, including integrating data for large-scale fleet analyses and maintenance capabilities, developing

advanced predictive digital solutions to boost and deliver airline efficiency and implementing real-time health monitoring and predictive maintenance.

Other steps include developing a new data analytics tool that helps airlines avoid fuel overconsumption on descent and approach flight phases; evolving new capabilities encompassing engineering investigations, component reliability analyses, and enhancing maintenance operations; as well as automating quality monitoring and interactively visualizing flight paths.

As Airbus’ Digital Transformation Officer, Fontaine also is interested in providing powerful digital tools to everyone from the company’s production workers to airline customers.

“For example, augmented reality is giving our employees on the assembly line the power of a computer without limiting their mobility or dexterity,” he says.

Left: Airbus Helicopters’ H160 has been built on a 100-per cent digital shop floor.

Below: Airbus Helicopters is seeking to apply digital technology to all levels of its developmental and service processes.

Fontaine also imagines airline customers for Airbus jetliners being able to “walk through” as-yet-unbuilt passenger cabins by using immersive virtual reality headsets to see how their interior design choices come together.

Beyond commercial aircraft, the future Fontaine sketches out is one with the potential to touch every aspect of Airbus operations.

Guillaume Faury, the chief executive officer of Airbus Helicopters, for example, speaks of the “digital continuity from design to production to support” that infuses his division today. “Until now, the way helicopters are produced had not changed much over the past 50 years,” he says.

The newest Airbus rotorcraft – the H160 helicopter – is built “on a 100-per cent digital shop floor.

There are no paperwork inspections,” Faury says. “Every worker has their own tablet connected in real time to a manufacturing execution system. Everyone on the shop floor can see in real time the progress of each aircraft in production. This is the digital world we live in.”

Airbus’ Defence and Space Division are similarly embracing digital systems and technologies, says Nicolas Chamussy, the executive vice president of Space Systems. “We use 3D digital models along the entire value chain,” he says, including “computer aided design modelling on the shop floor to support the integration of the equipment and systems.”

“Thanks to 3D technology and automatic design,” continues Chamussy, “we are reducing the lead time for designing the connectivity of a satellite payload –which is becoming increasingly complicated – by a factor of more than one thousand.”

BY WILSON J. BOYNTON, CET, CCT-I

Irecently received an e-mail from a friend overseas who is a fellow AME and former trainee of my company, and who has just completed his training courses in advanced composite aircraft structural repair.

He related a near-miss story that could have had a dreadful ending had it not been for his eagle eye professionalism and excellent composites training. The helicopter company at which he is employed operates a large fleet of new “significantly composite” helicopters equipped with all-composite main rotor blades. Preparing to depart with the rest of the crew for their mission, he noticed on his pre-flight walk-around that one of the main rotor blades had a very noticeable gouge in the camber of the leading edge inboard of the tip.

Inspecting the area a little closer he was surprised to find that the area appeared to have been “dressed,” not unlike an aluminum propeller blade with a stone chip would be dressed-out by a technician with a series of files.

My friend decided to ask questions and, to his horror, discovered that the chief mechanic had noticed a small cut in this area of the blade with carbon fibers poking up around it, so he had decided to smooth things out by filing down the fibers.

The helicopter manufacturer’s technical representative was contacted to give an opinion as to the airworthiness of such a (minor) dressing. One look and he immediately grounded the machine!

Good thing he did: composites are NOT metals. The structures of a helicopter (including rotors) that are manufactured from advanced composite materials do not perform, do not react, and do not sustain damage

like metal structures; nor can they be repaired by any method common to a metal structure.

In a composite, all of the load-carrying capability is borne by the fibers within the laminates (layers/plies) of the structure. These fibers are held in place by means of a polymer matrix called the “resin.” If the fibers become damaged and severed or “cut,” they no longer have any strength and cannot transfer loads as they were designed to do.

If you were to “dress out” a nick or cut in the surface of a carbon- or glassfiber rotor blade, you would actually be causing an exponentially greater amount of damage to the blade with every stroke of your file.

Whenever a composite is damaged, be it a primary-, secondary- or tertiary-loadbearing structure, restoring the strength and airworthiness of the part means restoring the load-transfer ability of the fiber across the entire area in which it was “cut.”

A patch consisting of a like fiber with the individual layers of material oriented in the same direction as the original laminate is the normal method of repair.

Was my friend justified in his reaction to the “dressed out” area of damage on the main rotor blade? Absolutely! The discontinuity of the fibers in the laminate plies that were filed away would have severely weakened the structure in that area.

Under flight loads, it is entirely possible that the blade could have failed in that area with the loss of the blade tip. Then, the sudden mass imbalance and altered aerodynamics of the rotor could have resulted in a departure from controlled flight.

Today’s generation of helicopters use a large amount of advanced composite materials throughout their structure. We now have helicopters which have the entire primary loadbearing structure of the fuselage and rotors made entirely of composite materials. Exceptionally light weight (Aramid fiber or Kevlar) combined with rigidity (carbon and glass fiber) and the very high tensile and compressive strength of composite materials, make them ideal for helicopter structures.

The disadvantage of composites is that they are easily damaged by impact and can be damaged by some fluids that would have no effect on a similar metal structure. Glass-fiber and Aramid-fiber composites do not conduct electrical current; instead, they have what is called a high “dielectric strength,” Unlike aluminum airframes, composite structures cannot be used as an electrical “ground” to transmit current. Various means are used to

provide a current path for both electrical devices and the dissipation of static and lightningstrike energies.

Lightning-strike protection and the ability to shed static electricity from the airframe and rotors is critically important with composites. The heat generated by a lightning strike or static discharge can severely burn the resin (matrix) that holds the fibers of a composite together. Expanded aluminum or copper foil mesh is a material used on the external surfaces of composites in order to dissipate this energy without damaging the composite substructure.

Unlike solid metal structures, “sandwich” metal structures (two thin sheets of aluminum separated by an aluminum honeycomb core) do not always reveal damage in the form of a “dent” on the surface. A deflection of the surface which exceeds the honeycomb

Left: Composite stabilizers and rotor fairings. When working with composite materials, AMEs must remember they are not dealing with metal – new advanced carbon helicopters need a special touch and techniques.

Below: Carbon fiber engine and transmission cowlings.

core compressive load-bearing ability, can crush the core and destroy the strength of the bonded metal structure entirely. But no external evidence of the crushed core may be visible.

Carbon, glass or Aramid fiber sandwich structures may be damaged in exactly the same way, showing little or no external evidence that the damage exists. Additional problems may occur with fiber laminate structures if the fibers are exposed to moisture or fluids (such as hydraulic fluid, engine oil, etc.) and absorb these fluids into the fiber skins and core, chemically destroying the resin matrix.

Simple water absorption will cause the most damage through freeze-thaw cycles if the helicopter is operated in cold climates. The expansion of the water as it freezes causes the delamination or disbonding of the structure, a process that will continue until the structure fails, often without warning.

Repairs to most composites involve the removal of the damaged skin and core materials in the affected area. The core is replaced or “potted” with an epoxy-based filler compound, and the damaged skin (bonded metal structure) or fiber laminate plies are replaced by a bonded patch.

It may look simple, but composite repairs involve a complex array of processes that are not required in a mechanically fastened metalstructure repair. The composite structures of helicopters must be maintained to exceptionally high standards, as the dynamics of rotarywing flight leave little margin for error in repairs. A helicopter technician should obtain a solid foundation of knowledge regarding composite materials and repair processes though expert training and OJT before ever performing a repair on a primary-load-bearing structure.

ell Helicopter, a Textron Inc. company, has experienced significant progress with its MRO customer service – continuing to provide the best customer support in the industry.

“Last year we launched a brand new support solution, our Customer Advantage Plans (CAP), and strengthened our support network, adding four new service centres across the globe,” said Glenn Isbell, executive vice president, Customer Support and Services for Bell Helicopter. “We will continue to enhance our customer support capabilities, and I am excited to carry this momentum throughout 2017.

Bell Helicopter’s CAP provides customers with comprehensive coverage solutions for its daily global operations. Since its launch, the innovative support solution has gained traction across the globe – with current customers represented in regions including North America, Latin America, Asia Pacific and Europe.

The plans have additionally been adopted by customers in mission segments ranging

from emergency medical, corporate/VIP to oil and gas operators. Multiple large fleets have also adopted the plans, including the most recent announced customer, Heliservicio, signing its large fleet of 20 Bell 412EPs.

“We will continue to support our customers’ success with products and services that provide the most value, responsiveness and cost competiveness for their operations,” added Isbell.

Recently, Bell Helicopter signed its first CAP customer in India. The corporate customer operates a Bell 429 and was signed through Dubai-based aircraft management company, Titan Aviation Group.

“With predictable maintenance costs, priority access to parts and assemblies and increased aircraft availability, Bell Helicopter’s Customer Advantage Plan provides peace of mind, knowing my investment is protected,” said Sakeer Sheik, a Bell 429 customer.

In addition to the support plans, Bell Helicopter continues to strengthen its support network, adding four newly authorized Customer Service Facilities:

• Zhenjiang Aerochine Aviation Limited, Zhenjiang City, Jiangsu Province, PRC

• Eagle Copters Australasia, Coffs Harbour, NSW, Australia

• Genel Havacilik A.S. Turkey, Istanbul

• Petroleum Air Services, Nasr City, Cairo, Egypt

“The addition of our newly authorized Customer Service Facilities reinforces our commitment to enhancing the regional support customers need to continue their operations,” said Mike Reagan, director, Global Services at Bell Helicopter.

Bell Helicopter’s Customer Service Facilities aim to enhance customer satisfaction by providing a personal link between Bell Helicopter and its customers. With services ranging from aircraft refurbishment and accessory options to maintenance, repair and overhaul solutions, combined with personalized service offerings, Bell Helicopter’s service facilities provides complete and seamless support – offering Bell Helicopter customers the advantages of a one-stop service experience worldwide.

Bell Helicopter as the largest support network in the industry with more than 100 Authorized Customer Service Facilities in 34 countries.