Cedar Organics recreates live extracts

Left to right: operations manager Rob Mason, master grower Alex McKay, and CEO Greg Kasting

COLUMNS

08 | Business

CCX CEO explains the need to expand into international markets

10 | Cultivation

Producing sun-grown B.C. bud at scale with Pure Sunfarms

12 | Vantage Point

Why Low-Risk Drinking Guidelines should matter to cannabis users

14 | Legal Matters

The enforceability of liquidated damages provisions in contracts

DEPARTMENTS

COVER STORY

Cedar Organics recreates live extracts

Take a tour of Cedar B.C.’s unique trichome farm and extraction facility BY HALEY NAGASAKI

20

The art and science of cannabis extraction

Borna Zlamalik and Abi Roach disclose product innovation, industry setbacks, and pleasing concentrate connoisseurs BY ASHLEY KEENAN

Cannabis and aquaculture: a perfect match?

East Coast LPs Aqualitas and Stewart Farms share why they have paired cannabis production with fish farming BY MATT JONES 28

Outlook for LPs cloudy amid shifting financial conditions

Questioning the sustainability of the industry as companies contract due to rising debt BY JAKE

HRIBLJAN

By Haley Nagasaki

East to West and back again

What a privilege it was composing this issue with a top-notch band of sources, contributors, and guest writers. This is the fifth magazine I’ve sent to print as the editor of Grow Opportunity, and I’d say it’s my most distinguished yet. Maybe it’s due to the length, richness and breadth of issues covered, or perhaps it’s in relation to the rapport I’ve been busy building over the past year. The sincerity of those eager to share their life’s work with me while keeping an open line for queries, regardless of the size or restrictions on time, I can assure you, has not gone unnoticed. I thank each of you dearly. While the facets of this industry in its current state make up these pages, there are nuggets of my own experience embedded within.

March 2022, I packed my car – rallying my grow gear, apothecary trunk, and my precious pup Isla – and left Vancouver Island traveling eastbound back to Georgian Bay, Ont. I’d been living on a rural property in Cedar, working on a nearby hemp farm and growing a sacred garden of my own. I’d heard of the cannabis farm around the corner, even drove by it a couple times, marveling at the location and size of the acreage.

Fast forward to March 2023 when I made a reunion trip out west, this time as the editor of a cannabis magazine seeking a cover story.

Cedar Organics checks the boxes for me – a West Coast operation grown under the sun, boldly exposed to the elements, rooted in living soil. It may not be the easiest way to grow bud, but it’s certainly the most romantic. I recall my own excitement, lopping down those trees and bringing them in off the field, covered in aromatic resins and dew. I wanted to draw attention to that experience, be it in cannabis or in hemp, and the underlying joys of farming.

While the facets of this industry in its current state make up these pages, there are nuggets of my own experience embedded within.

Bonus: when I arrived on site at the LP, I learned their crop is made entirely into extracts, which just so happened to be the theme of the issue.

Beyond Cedar, thank you to all the producers who contributed to this edition, offering up their own tales of differentiation. From the sustainable and highly effective aquaculture endeavours of Maritime LPs Stewart Farms and Aqualitas, to the extraction moguls at Organigram and Mera Cannabis – journalist and patient advocate Ashley Keenan captured the extraction landscape in this story, regulatory complications and all. Shoutout to the crew at Pure Sunfarms for crafting the cultivation column

during the peak of their highyield season, and a big congratulations on entering the German market.

On that note, this issue our scope reaches into the broader international market with a stat-heavy and visually descriptive business column on the importance of going global. Thanks to Steve Clark for sharing this vital data imperative to LP expansion. And to Jake Hribljan, renegade writer and new freelancer for the magazine, thank you for your synopsis on the Canadian financial side of things – a space in need of consistent and high-level coverage. As always, to the columnists who anchor our magazine, we are pillared by your expert remarks.

With that, I will wrap up by drawing your attention to a new department in the magazine by request: a “Behind the Counter” budtender segment that shifts the lens from producer to retailer, divulging instore occurrences that LPs might be curious to glean.

With budding trees abound, it can be hard not to get carried away at this time of year. And while impossible to forget the entanglement of penalties, hurdles, and lawsuits, it’s important to recall that perhaps the most inspired and productive people are those who have successfully merged their titillating truths of work and of play. So, if you’re not having any fun, maybe ask yourself what might bring about more joy to each day.

May/June 2023

Vol. 7, No. 2 growopportunity.ca

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Services Administrator Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

Haley Nagasaki hnagasaki@annexbusinessmedia.com 519-410-0600

PUBLISHER

Adam Szpakowski aszpakowski@annexbusinessmedia.com 289-221-6605

NATIONAL ADVERTISING MANAGER Nashelle Barsky nbarsky@annexbusinessmedia.com 905-431-8892

ACCOUNT COORDINATOR

Mary Burnie mburnie@annexbusinessmedia.com 519-429-5175

MEDIA DESIGNER

Curtis Martin

AUDIENCE DEVELOPMENT MANAGER

Shawn Arul sarul@annexbusinessmedia.com

GROUP PUBLISHER

Paul Grossinger pgrossinger@annexbusinessmedia.com

PRESIDENT/COO

Scott Jamieson sjamieson@annexbusinessmedia.com

MAILING ADDRESS

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

1 year subscription (6 issues: Jan/Feb, Mar/Apr, May/Jun, Jul/Aug, Sep/Oct, Nov/Dec):

1 year offers: Canada $25.50 + Tax USA $47.00 CDN FGN $53.50 CDN GST # 867172652RT0001

ANNEX PRIVACY OFFICE privacy@annexbusinessmedia.com

Tel: 800.668.2374

ISSN: 2561-3987 (Print) ISSN: 2561-3995 (Digital) PM 40065710

Occasionally, Grow Opportunity will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Made possible with the support of

Mississauga, Ont., votes to allow legal retail cannabis stores

Ontario’s legal cannabis market is poised to grow significantly larger, with the province’s largest city that had banned retail pot stores voting to opt in.

Mississauga, Ont., was one of dozens of municipalities to bar retail cannabis stores from their communities when legalization came into effect in 2018. But, four and a half years later, a city report highlighted that Mississauga residents are “disproportionately'” served by the illegal market in the absence of legal stores.

Mayor Bonnie Crombie also spoke in favour, saying she had supported opting out in 2018, hoping the province would give municipalities greater control over location of stores.

The Alcohol and Gaming Commission of Ontario is responsible for issuing licences and in municipalities that have opted in, one of the only restrictions on location is that stores must be at least 150 metres away from a school.

– Allison Jones, The Canadian Press

Supreme Court says Quebec’s ban on homegrown cannabis plants is constitutional

Canada’s high court says Quebec’s ban on possessing and cultivating cannabis plants for personal purposes is constitutional.

The Supreme Court of Canada says the province has jurisdiction to pursue public health and security objectives by prohibiting homegrown marijuana plants.

It says Quebec’s rules don’t frustrate the purpose of the 2018 federal Cannabis Act... and Chief Justice Richard Wagner says Quebec’s ban has the same objective as the federal law, which is to reduce the presence of criminal organizations and restrict growing marijuana at home.

– The Canadian Press

4/20

Stewart Farms opened “Stewart’s Herbal Dispensary” on April 20 “It is a space where we can interact directly with our local community, while teaching our team how to better support Canadian dispensaries that carry our product. ” –Tanner Stewart

Twitter shifts advertising policy in favour of legal cannabis

Organigram files for judicial review of Health Canada’s decision to end sale of “Jolts” edible extracts

Organigram is the first LP to undertake such an action against a Health Canada ‘ruling.’ They believe the decision that Edison Jolts lozenges should be classified as cannabis edibles rather than ingestible extracts is factually incorrect and inconsistent with the Act and Regulations.

In a huge win for the cannabis industry, as of February, Twitter permits the marketing and advertising of cannabis products and other cannabis related information. As more states in the U.S. and countries around the world begin to legalize cannabis for recreational and medical use, Twitter’s decision is another example of positive momentum for this industry.

As of now, the countries exempt from the prohibition of cannabis advertising on the platform are Canada, the United States, and Thailand. Twitter makes clear that companies hoping to advertise in Canada must be licensed by Health Canada and pre-authorized by Twitter. Furthermore, advertisers “may only promote informational or brand-preference content…may only target jurisdictions in which they are licensed to promote these products…are responsible for complying with all laws and regulations.” – Twitter

Once companies pass Twitter’s pre-approval process, they will have access to Twitter’s 500 million users and all of the platform’s advertising products such as, promoted tweets, video sponsorships and partner publication features. Cannabis companies will retain responsibility for complying with the various location specific governmental regulations, but Twitter’s decision could be the first domino to fall, as other social media platforms may now look to follow suit. – Jake Hribljan

Though as of April 26, “Facebook parent Meta, Google and other major tech companies all prohibit cannabis ads. [In the U.S.,] Google does allow ads for FDA-approved CBD products and topical, hemp-derived CBD products with THC content of 0.3 per cent or less in California, Colorado, and Puerto Rico, but not for marijuana even in states where it is legal.” – Barbara Ortutay, The Associated Press

One less thing to worry about.

EASY-TO-USE | CLEAN & QUALITY INPUTS

TRACEABILITY OF ALL PRODUCTS | TECHNICAL GROWING SUPPORT

CANNA is the pioneer and global market leader of plant nutrients and growing mediums for the cultivation of fast growing crops. All CANNA products are manufactured from the highest quality materials, as a known partner of the Green Market. We understand the importance of clean, consistent, traceable inputs, as well as keeping it simple!

By Steve Clark Business

Beyond borders: why Canadian LPs must enter international markets

As I stepped into the Canadian cannabis industry in early 2018 as a seasoned commodity professional, it didn’t take me long to realize that this was not an industry for the faint of heart.

Regulated cannabis is a market that demands financial prudence, lean operations, and a hyper-focus on executing corporate strategies. The uncertainty of a new emerging market was expected, but I don’t think anyone foresaw that the Canadian market would get stuck in second gear while the world caught up and eroded our first mover advantage.

Canadian industry experts such as Dan Sutton, Myrna Gillis, George Smitherman, Nathan Mison, and many others continue to advocate for regulatory changes required for a sustainable domestic cannabis industry. Despite these challenges, caused by numerous factors, there are still select licensed producers/processors (LPs) that have been able to succeed in domestic and international markets.

With the global cannabis landscape rapidly evolving, LPs must broaden their global reach to tap into higher-priced markets to ensure their survival.

Now, as Canada’s cannabis industry approaches its fifth year of legalization, there is a growing urgency to expand internationally and capture new markets. The good news is that many Canadian LPs are already exploring international opportunities and helping to develop this emerging market.

According to a recent survey conducted by the Canadian Cannabis Exchange (CCX), 10 per cent of Canadian LPs are exporting cannabis products to other countries and 40 per cent plan to make exporting part of their marketing mix. Germany, Australia, Israel, and the

2021

$669,955

$19,968,654

With the global cannabis landscape rapidly evolving, LPs must broaden their global reach to tap into higher-priced markets to ensure their survival. Steve

$25,021,484

$47,216,004

United Kingdom are the top destinations from the survey. The development of new supply channels to international markets

led by LPs, consultants, and brokers/exchanges is a significant boost to the cannabis industry.

What is required to advance?

Canadian LPs face regulatory hurdles when expanding into international markets. They must comply with the regulatory frameworks in the target markets, including obtaining import and export permits, and meeting international standards such as GPP, GMP, EU-GMP, GACP, and CUMCS-G.A.P., IMC-G.A.P.

These licensing standards are stringent and cover all aspects of cannabis cultivation, processing, packaging, and distribution. There are many Canadian LPs holding these types of licenses and even more who are nearing a range of certifications. However, obtaining certification is not easy and involves significant costs, reporting, inspections, third-party audits, and recertifications. Given that the global cannabis market is projected to grow to $73.6 billion by 2027, with medical cannabis driving the majority of growth, entering this channel is crucial for producers.

Germany

In Germany, strict quality standards for the production, import, and distribution of medical cannabis are enforced by the Federal Institute for Drugs and Medical Devices (BfArM). To deliver medical cannabis to this country, Canadian LPs must meet the BfArM’s standards, have a valid Health Canada issued export permit,

Steve's innovative drive is the force behind CCX's success, where he currently serves as founder and CEO.

Figure 2: Flower, volume (kg) exported from Canada, by destination country (2021)

Figure 1: Flower, $CAD value exported from Canada, by destination country (2021)

an EU-GMP certified product, as well as a corresponding German import permit.

Announcements of the recreational cannabis framework are still pending but reports in early April 2023 indicate the delay of nationwide adult-use sales in Germany’s reported two-phase approach to legalization. This may impact Canadian cannabis companies looking to export into Germany. The companies that were preparing for a free-market model, with increased national distribution, may have to wait until the second phase to see the expected market growth. However, the first phase, including home cultivation and non-commercial cannabis clubs, still presents opportunities for Canadian companies to establish themselves in the medical German market as they achieve EU-GMP certification.

Given that the global cannabis market is projected to grow to $73.6 billion by 2027, with medical cannabis driving the majority of growth, entering this channel is crucial for producers.

In 2022, Germany witnessed a significant increase in the importation of medical cannabis, and Canada accounted for 8,966 kilograms of dried flower imports. Overall, according to recent statistics published by the BfArM, nearly 25,000 kilograms (27.6 tons) of cannabis was imported, which represents a 19 per cent increase compared to the 20,769 kilograms imported in 2021. This was the slowest growth since 2018 and doesn’t account for a re-export of product to other medical European markets.

According to pharmaceutical data provider Insight Health, cannabis extracts witnessed the most rapid growth among all categories in the German market, constituting roughly 26 per cent of the market share in October 2022 – a marked increase of 21 per cent from the preceding year. These values underscore the importance of developing medical distribution channels, exploring other European countries, and fulfilling multiple product categories.

Israel

The Israeli cannabis regulator IMCA was formed in 2013 in response to the first government resolution to control the cannabis industry, which was passed in 2011. The Israeli cannabis industry has been rapidly

To import cannabis into Israel, companies must hold an IMC-GMP or equivalent CUMCS certification issued by the Israeli Ministry of Health’s Medical Cannabis Unit. This certification ensures that the cannabis meets strict quality and safety standards, including testing for heavy metals, pesticides, and other contaminants.

According to pharmaceutical data provider Insight Health, cannabis extracts witnessed the most rapid growth among all categories in the German market.

To date, Canada has seen limited price compression for cannabis exporting into Israel as the market has grown in similar size compared to the newly licensed CUMCS production. Expect to see, in early 2024, the global supply of Israeli certified product catch up with the growth in the Israeli market. And similar to Germany, re-export to neighboring countries could also be a viable opportunity for the country.

Germany and Israel are just two of the international export opportunities present today for Canadian cultivators. Growing demand for cannabis worldwide presents a significant opportunity for Canadian LPs to expand into international markets. Tapping CCX’s connections, industry consultants, or the newly formed Global Cannabis Trade Association (GCTA), can substantially open doors to new distribution and revenue channels.

evolving in recent years, with the country becoming a leading option for Canadian cannabis exports (18,045 kg in 2022).

I also believe the government should provide financial support to Canadian cannabis LPs in obtaining these international certifications. Canadian companies are competing together against lowcost supply from countries such as Colombia, South Africa, and many other emerging markets. Government assistance would not only promote Canada’s reputation, once again highlighting Canadian cannabis on the world stage, but it would also benefit all those involved.

Figure 4: Flower, volume (kg) exported from Canada, by destination country (2022)

Figure 3: Flower, $CAD value exported from Canada, bydDestination country (2022)

Cultivation

By Rob Baldwin

Cultivating sun-grown B.C. bud at scale

As many people know, B.C. bud has quite a reputation, not just in Canada, but around the world.

That’s something we’ve always taken seriously at Pure Sunfarms. Since legalization, we’ve had the incredible opportunity of transforming our greenhouse from vegetable growing into a large-scale cannabis operation for the cultivation of sun-grown B.C. bud.

There’s a few things that have really been important to our success as a Canadian LP, and most of it is in the way we do things here in our greenhouse.

I’ve been working in this same greenhouse for over 20 years, long before we were cultivating cannabis; I know this environment and this greenhouse inside and out. Unlike vegetables, cultivating cannabis requires a whole different set of expertise, which is why our team consists of greenhouse experts and legacy cannabis growers who work alongside each other, informing every step of the process.

To us, cannabis cultivation is not about reinventing the wheel or doing something first, it’s about understanding the plant we grow and adapting our operations in a way that produces quality cannabis at our scale all year long.

Right now, we operate within 1.65 million square feet of greenhouse space and have been recognized as one of the largest recreational cannabis cultivators in the world. How are we successfully growing at this scale? Through thoughtful innovation of both our practices and our product offerings.

An example of this is our recent transition to the hang drying method: a legacy practice that flips the whole plant upside down (leaves and all).

Hanging our plants to dry protects the

integrity of the bud, its trichomes and terpenes, and the natural structure of the bud. This transition took us many months to roll out because we wanted to do it right. Since the switch, we’ve heard great feedback from both consumers and retailers.

At this time of year, we are in our peak cultivation period, which usually falls between April and June. Now we’re usually able to yield about 40 per cent more than the fall and winter months as the temperature in the greenhouse is naturally optimal for our plants. This is because we’ve optimized our cultivation practices to harness the power of the sun.

Our greenhouse is situated within B.C.’s sunny Fraser Valley, which allows us to grow using primarily natural, full spectrum sunlight for about 298 days, or 40 per cent of the year. All this solar power also dramatically reduces our electricity use at the farm. And to further conserve energy, we use innovative energy screens that help to capture the sun’s warmth and prevent heat loss year-round.

At any given moment, our flower rooms, each approximately the size of a football field, are filled wall-to-wall with plants. Each room features state-of-the-art lighting, irrigation, and temperature control systems.

We carefully tend to each batch and constantly monitor each room through our 24-hour app-based monitoring system, ensuring the plants get exactly what they need when they need it. We’re consistently cultivating tried and true B.C. strains, like our top-selling Pink Kush, now being sold in Germany, while also trialing new genetics to see what grows best in our greenhouse. Not everything makes it into our packs. It is only the strains we know consumers want, and that thrive in our environment.

At the end of the day, we know what is expected of B.C. bud and we take that seriously in everything we do. It’s humbling to see what we’ve created in such a short time, and how Canadians love our products. It’s an exciting legacy to be a part of, and we’re only just getting started.

As VP of cultivation and operations, Rob Baldwin grows high quality plants with a passionate team of growers. He is responsible for Pure Sunfarms’ cultivation and greenhouse operations and continues to deliver quality cannabis to the Canadian market.

Pure Sunfarms diagram detailing their cannabis production cycle.

By Denis Gertler

Why Canada’s new Low-Risk Drinking Guidelines should matter to cannabis users

On January 17, Canada’s Guidance on Alcohol and Health’s Final Report was released following two years of research. The Health Canada funded report is based on the analysis of 6,000 peer-reviewed studies and replaces the 2011 Low-Risk Alcohol Drinking Guideline

The previous guidelines identified 15 drinks per week for men and 10 drinks per week for women as low risk. The new guidance recommends no more than oneto-two drinks a week and says that as few as seven drinks per week brings elevated risk of stroke, heart disease and several cancers. The Canadian Centre on Substance Use and Addiction (CCSA), the organization which conducted the research, insists it’s not trying to promote abstinence but provide Canadians “...with the information they need to make well-informed and responsible decisions about their alcohol consumption.”

The guidelines have certainly sparked a debate, much of it unfavourable to the research conducted and the conclusions drawn from it. Pundits and academics alike have pointed out that of those thousands of research papers considered, only 16 were selected for modeling purposes.

The CCSA admits that its evidence base is weak – “the overall quality score of most of the retained reviews was low” – but decided to gut the previous guidelines anyway. Writing in the National Post , Sabrina Maddeaux noted that of the 25 papers on risks related to pregnancy or breastfeeding (one of three areas targeted for analysis), none qualified for risk assessment.

Dan Malleck, Professor of Health Sciences at Brock University, has

The CCSA’s new guidance document trumpets its advice as though it was based on conclusive evidence in a bid to shift public behaviour without drawing attention to the shortcomings of its research.

questioned the CCSA’s exclusive focus on harms without including the benefits of low to moderate drinking found by other studies. Malleck also maintains that singling out impacts of alcohol consumption alone disregards contributing lifestyle behaviours, such as drinking

in bars filled with tobacco smoke, exposure to toxic chemicals and other relevant factors. Former federal Opposition Leader Tom Mulcair waded in with his opinion column in Journal de Montréal , relaying allegations of CCSA bias by eminent alcohol researchers, cardiologist Dr. Martin Juneau and Dr. R. Curtis Ellison, professor of medicine at Boston University and chairman of the International Scientific Research Forum on Alcohol Research. According to CCSA’s critics, the influence of Tim Stockwell, neo temperance advocate, has been detected in a further effort to disprove

Denis Gertler is a regulatory consultant, board member,

“J Curve” effects, which show that mortality risk decreases with moderate consumption before rising with heavy drinking.

Like the University of Ottawa cannabis study I discussed in my last column, the CCSA’s new guidance document trumpets its advice as though it was based on conclusive evidence in a bid to shift public behaviour without drawing attention to the shortcomings of its research. As Maddeaux notes, CCSA acknowledges the limitations of its evidence in the final report, but “…somehow, they weren’t highlighted in media interviews or the summary with colourful graphics most people will see.”

How does this relate to cannabis?

What do the new Low-Risk Guidelines have to do with cannabis, you may ask? Although known mainly for its drinking guidelines, the CCSA’s mandate covers more than alcohol. It addresses a range of substances and behaviours including opioids, cocaine, gambling, methamphetamine, prescription drugs, and cannabis.

A look at CCSA’s website reveals that one-third of its staff offered for interviews, speaking engagements and research projects are identified as cannabis experts. The body has a privileged, long-standing relationship with Canada’s federal cannabis regulator. It’s not a stretch to imagine the organization pitching Health Canada on a similar guidance document to address the harms of cannabis use. I think it’s fair to say that human health has not typically topped the industry’s agenda, except, perhaps with respect to clamping down on contaminated products in the illegal market. Dealings with the Industry Expert Panel currently reporting to the federal ministers of Health, and Mental Health & Addictions further illustrate this point.

Much has been made of the lack of business representation on the panel: and clearly, we need a business champion inside government. But apart from looking at the progress of legalization in deterring criminal activity and displacing illicit use, the Panel was not asked to address industry competitiveness. Its mandate and recommendations will instead consider the impacts of cannabis on marginalized and racialized communities, medical patients, indigenous peoples, youth, and the public at large. Economic concerns are only mentioned within the context of social and environmental impacts, and workplace equity for women and racialized groups.

It is an axiom of change management practitioners that those seeking change should start where the system is, not where they think it should be. And where the system is, broadly speaking, is its concern with Canadians’ health. This is where advocacy should also be focused, to position cannabis as good for Canadians’ overall well-being, and where the news is mixed, to promote balanced advice on managing the risks.

We can start by learning the lamentable lessons of Canada’s Low-Risk Alcohol Drinking Guidelines, by pressing for a credible research agenda and the funding to support it.

Legal Matters

By Matt Maurer

Penalty or damages? The enforceability of liquidated damages provisions

When one party to a contract commits a breach, the innocent party may elect to sue for ‘damages,’ which is a fancy legal term for monetary losses.

In some instances, the damages that have been suffered are fairly straight forward and easy to establish. However, in many instances, ascertaining what damages have been sustained is more difficult.

For example, if I grant you an exclusivity agreement to sell my products in a given territory and I breach that agreement by allowing someone else to sell my products within the same territory, what are the losses that are properly attributable to my conduct?

One could argue that your decrease in sales may be a good indicator of your losses. However, who is to say that market conditions did not happen to coincidentally also contribute to your decrease in sales? One could also argue that the sales of the other vendor may be representative of the sales that you in turn lost. Possibly, but who is to say that some of those sales occurred on account of the new vendor’s efforts and therefore they were sales that you would have not been able to generate even if I had not breached our arrangement?

These are fairly straightforward examples of a problem that can in real life become quite complicated.

The cannabis industry may demonstrate similar cases for a number of reasons, including the fact that the industry itself is still relatively nascent. For example, if a party breaches a contractual obligation to manufacture products for another party thereby depriving the innocent party of the revenue from the sales of those products, how can we accurately calculate

There is a fine line between stipulating what the liquidated damages would be in the event of a breach and inserting what is effectively a penalty provision in the event of a breach.

those lost revenues? If there are no meaningful historical sales figures, how do we know what the revenues would have been? While there are different ways to go about attempting to quantify those losses, often times parties will attempt to get out in front of the issue in advance and set out the damages within the contract itself. These types of clauses are known as liquidated damages provisions.

Liquidated damages provisions explained

A liquidated damage provision is a clause in a contract that stipulates an amount that the breaching party must pay to the innocent party if a breach of the agreement occurs. These types of provisions can be highly useful as they allow the parties to understand precisely what the consequences will be in the event of a breach, and also to simplify the resulting legal process since the issue of attempting to determine what damages are payable is effectively eliminated. However, these clauses can also be dangerous because courts are sometimes not prepared to enforce them.

There is a fine line between stipulating what the liquidated damages would be in the event of a breach and inserting what is effectively a penalty provision in the event of a breach. The courts have repeatedly stated that its power to strike down a penalty clause is a blatant interference with freedom of contract and is designed for the sole purpose of providing relief against oppression for the party having to pay the stipulated sum. The court’s power to strike down a clause has no place where there is no oppression.

Generally, liquidated damages clauses will be enforced so long as they represent a genuine attempt to pre-estimate the loss arising from the breach. Where, however, such a clause is not based on an estimate of damages and represents a sum that is “extravagant and unconscionable in amount in comparison with the greatest loss that could conceivably be proved to have followed from the breach,” the clause will be considered an unenforceable “penalty clause.”

The takeaway is that liquidated damages clauses are useful tools that can be inserted into commercial agreements to give the parties more certainty as to their rights and obligations in the event of a breach. This is especially useful in the cannabis industry where attempting to establish actual losses at trial can be difficult and costly.

However, care should be taken when the clause is drafted to ensure that thought is given to the nexus between what sort of losses may be incurred and the amount provided for in the contract.

As mentioned above, if the amount stipulated is found to be “extravagant and unconscionable” in comparison with the greatest loss that could conceivably be proved to have followed the breach, the court will not hesitate to strike down the clause and decline to enforce it.

Matt Maurer is a partner and co-chair of the Cannabis Law Group at Torkin Manes LLP in Toronto, Ont.

Cedar Organics recreates extracts

Vancouver Island trichome farm hones in on live extracts using fresh-frozen flower, Synthite partnership, and floodplain cultivation technique

By Haley Nagasaki

Cedar Organics holds a distinctive place in Canada’s cannabis industry as an organic, sun grown trichome farm. That is, they practice outdoor organic cultivation in fields that spend six months of the year submerged under water to produce flower entirely for the purposes of live extracts. The LP then performs white labeling of their products, in addition to the external biomass they process, package, and label for other B.C. cannabis companies.

Cedar Organics is a 42-acre farm located in picturesque rural Vancouver Island, 15 minutes south of Nanaimo, B.C., where the neighbouring Quennell Lake swells over the fall and winter months, flooding the acreage. Fish, frogs, and other residual biotic life die and decompose once the fields drain, adding rich organic matter to the soil composition while encouraging a feast for droves of circling eagles overhead.

Once British Columbia’s regulations changed, producers were permitted to grow cannabis on the Agricultural Land Reserve (ALR), though counterintuitively, the province’s ministry of finance still does

not consider cannabis cultivation to be a farming activity. The implications of which include hefty tax bills for B.C. growers that producers of other crops, like barley or alfalfa, will never see – a forthcoming issue to be addressed.

Once a potato farm, the property was later purchased by Cedar Organics’ founder Greg Kasting with investment from family and a couple friends, and was licensed in 2020. Of the 42 acres, approximately 28-acres are under cultivation. Outside, the property also exhibits year-round greenhouses for mother stock and clone production, and a covered harvest or staging area where plants are potted-up, prepped for planting, or brought in off the field for bucking.

A joint office-extraction building with additions under construction is the spoke of the operation, while 11 generator-powered freezer shipping containers that hold up to 40,000 kilos of fresh-frozen cannabis flower keeps product secure as it awaits processing. The LP has also acquired a 25-acre neighboring property to minimize contamination risks from non-compatible farming uses, as well as to serve as an expansion cultivation area when the time is right.

“It’s been a journey to find what we’re now focusing on,” says the CEO, Greg Kasting. “Trying to figure out what the market wants, what we’re good at, and what we’re capable of,” adds operations manager Rob Mason; “it’s been quite a year.”

Cedar Organics is an outdoor cannabis farm located on Vancouver Island, dedicated to the production and extraction of live cannabis concentrates.

Growing cannabis on a floodplain

The trichome farm, as it’s described, specializes in extracts. Now in partnership with Common Roots Extracts, the Canadian subsidiary of India’s Synthite Industries Ltd. and the world's largest producer of value-added spices and botanical extracts, a new hydrocarbon extraction lab is being built on the property. The farm produces both solvent and solventless concentrates where 100 per cent of their product is live.

The cultivation team led by master grower Alex McKay is currently building up their mother stock as well to produce 40,000 clones of which 25-to-30-thousand plants will take root in the field. “It’s a 10-day turnaround from when they are removed from the cloning chamber as a fully rooted tray of clones,” says the Saskatchewan-born grower. Clones come out and populate the field mid-June beneath Cedar’s unique cultivation technique and they “start harvesting the lowest lying area around third of September and continue into October,” he says.

The harvest or staging area also stores nutrients and soil amendments for the mother plants. “There’s going to be a lot of potting,” says Kasting, “and as they harvest, they have hand bucking stations as well as an automated bucking system from Germany.”

Six months of the year the main field remains under water. “Last year we experienced a rain or flood event that inundated the fields like we hadn’t seen in 25 years,” he says, looking out over the land. “The plants are going into a very clean growing media once the water goes,” he says; “they thrive in it.”

Beneath the fields are 12 kilometers of drainage tiles one meter beneath the earth that gets pumped out to control the level. The irrigation system includes the tiles, risers, and two settling ponds connected to Quennell Lake, located on the other side of the fence that discerns property limits. Nearby, two sea cans house the filtration system, dosing it with natural fertilizers typically kelp-based.

McKay compares organic outdoor cultivation to hydroponic systems, which are “sterilizing.” Whereas here, the beneficial microbes nurture plants and bolster the resilience of their immune systems.

Typically, Cedar Organics is pulling 1,000 kilos of fresh flower off the field daily, with a target harvest yield of 30 to 40,000 kilograms of fresh flower. The flower is immediately frozen, and in another building, the extraction takes place. Ice water extraction works very well. About 150 kilos of frozen flower is washed daily, producing up to three-to-five kilos of bubble hash.

“We should be able to process our entire crop into live extracts in about six months, and then we’ll have the remaining six months for working with other peoples’ biomass to process for them as well,” says Kasting.

Taking root in the greenhouse

Cedar Organics pulls 1,000 kilos of flower off the field daily, with a target harvest yield of 40,000 kilos of fresh flower that is immediately frozen and prepped for extraction.

While touring Cedar’s greenhouses, master grower McKay describes growing experiences from previous years, including best performing cultivars and lessons learned along the way. Walking between rows of healthy mother plants, eggplant trap plants, and flower tents along the walls, a humidifier runs tirelessly and supplemental lighting powers the two 3,200 square foot greenhouses.

In 2020, their first year, they planted 84 cultivars in the field. “One plant sprung up next to the irrigation pond by itself,” says McKay. “We never fed it; it just wanted to survive.” So, they tested the cultivar, and its results were actually quite high.

This year they’ll commercially cultivate six varieties and test about 20 newly created cultivars from their ongoing breeding program, determined using several grow tents housing two of each pheno. McKay allows the plants to flower and die on the stalk. “And as soon as I can go in and find a bud 20-30 per cent high, then that allows for the transferable elements,” he says. “We trial everything in the tents.”

McKay describes ideal node spacing on the outdoor plants for commercial growing and discusses the ways in which they stagger them so that certain cultivars finish earlier. “We had a year where the whole field was done at the same time,” he says. “So how do you pull 15-20 thousand kilos off the field at once? The answer is you don’t!”

Operations manager Rob Mason reveals live organic extracts in a refridgeration unit.

One of their fan favourite strains, Orange Crush (California Orange x True Blueberry), is a hardy, photo period sativa they’ve worked with for over three years of careful selection and breeding. The crew has now identified an optimal genetic expression for their unique micro-climate, which happens to be Canada’s only Mediterranean climatic zone.

Touring the extraction facility

Currently, Cedar Organics sells bulk B2B products that end up on shelves primarily in Ontario, B.C., Alberta, and the Maritimes. They’re also moving into white labelling and contract manufacturing. The company intends to focus on working with B.C.-based brands and getting the CPGs as close to their final state as possible. “In about a month from now we will be able to do a full turnkey solution whereby our products are being end-packaged, labeled and excised on the

farm, and shipped out,” says Kasting.

Inside the facility, operations manager Mason describes the various products they offer, in the new environment where they’re “tapering variables and getting a little bit more automated,” he says.

At the moment, processing includes ice water agitation of fresh-frozen flower into wet bubble hash, which is then freeze dried into dry, granular bubble hash, and pressed into live hash rosin, of which a large portion is then reformulated for use

YOUR FULL-SERVICE LAB WITH INDUSTRY LEADING TURNAROUND TIMES

Serving the cannabis industry with complete testing and agronomic support.

Comprehensive testing and production services including Health Canada lot release, plant disease diagnostics, DNA testing, plant nutrient leaf analysis, fertilizer nutrient solutions, and media/soil testing.

in vapes, infused pre-rolls and edibles. Cedar is now putting into immediate packaging bubble hash temple balls, live rosin dabs and vape carts. Infused pre-rolls are being manufactured through a partnership with ANC Solutions.

Kasting underlines the sea of data in need of organization. “Part of what we’re constantly struggling with is the sea of data that ensures compliancy. A large focus is now on how to simplify, streamline data, and improve operational efficiencies. One

Aerial view of Cedar Organics’ 42-acre farm next to Quennell Lake, which swells over the winter months.

of the most important factors to our success has actually been the close down of Tilray’s facility in Duke Point,” he confides.

Mason is a former Tilray production manager who transferred to Cedar Organics when the Island’s Duke Point facility closed. Members of the quality assurance, inventory control and logistics teams as well as key production supervisors all came over from Tilray, leveling up the company’s operational excellence.

They now have eight staff who each have worked at least five years for Tilray and brought a different level of compliance and understanding to the company. This, coupled with the partnership with Common Roots (Synthite), their proprietary extraction processes, R&D abilities and full analytical testing lab on site speaks to the company’s new direction.

Common Roots will enable the delivery of organic live resin, diamonds, and terp

sauces to the market, crafted by a low temperature extraction approach inspired by Synthite’s perfumery ingredients work.

Praveen Padmanabhan, director of Common Roots Extracts, considers the partnership with the LP to be a “white labeling powerhouse.” He advocates for sun-grown cannabis and the full spectrum of extracts it offers, stating: “there is a lack of high-quality outdoor cannabis products in Canada. We are focused on breeding for full-spectrum extracts with unique terpenes and effects.”

And still with the diligence that Cedar Organics barrels ahead, obstacles arise to meet them stemming from a B.C. government cabinet order in 2018, which specifically excludes cannabis cultivation as farming activity and is thus not eligible for many governmental support programs.

The company has seen their property tax bill increase eight times, and they must pay

Always maintain your company’s high standards

IMSM can help you use ISO standards to...

• Cut energy bills and increase your bottom-line savings (ISO 50001)

• Increase sustainability by reducing waste and environmental impact (ISO 14001)

• Safer cultivation/processing and accomplish more in less time (ISO 9001)

• Maintain regulated testing and calibration (ISO 17025)

Scan the QR Code to the right to find out how we can help:

a $93,000 provincial tax bill. They are out on the forefront of this issue, calling out the injustice that is both hypocritical, coming from one of the only entities currently profiting from the sale of B.C. bud, and ironic, in that cannabis processing is considered a farming activity by the B.C. government.

“Unfortunately, we are now in appeals process and are trying to have this charge changed,” says Kasting. “We’re working together with the B.C. Craft Farmers Co-op where we’re seeing a whole range of unfair practices and stigmas related to the industry.”

The major regulatory issues proliferating Canada’s cannabis market must continue to be addressed, as only through public awareness and push back will there be change. In the meantime, the team at Cedar Organics preps the mothers and clones, the field for planting, and the new extraction facilities for processing, with an optimistic outlook on sunny days ahead.

The art and science of cannabis extraction

Organigram’s Borna Zlamalik and Abi Roach of Mera Cannabis disclose product innovation, industry setbacks, and the importance of pleasing concentrate connoisseurs

By Ashley Keenan

Cannabis extracts, or concentrates, are a unique and robust product category. One that blends science and art to create cannabinoid-rich products like shatter, budder, rosin, live resin, hash and more. The concentrate market in Canada is growing steadily, though it remains a relatively small part of legal cannabis sales.

Concentrates are the third best-selling ‘cannabis 2.0’ category behind vape pens and edibles. Their market share has increased from 2.9 per cent to 3.8 per cent of total cannabis sales, according to Headset data. Despite recent growth and ever-improving extract products, there are numerous barriers unique to this category.

Product innovation meets popularity in shatter, hash and infused pre-rolls

New product formulations and growing sales make the cannabis extracts product category alluring to many licensed producers. Mera Cannabis and Organigram have both seen success in their cannabis concentrate offerings as the format’s popularity grows.

Organigram’s most successful concentrate is hash, especially from their brands Edison, Tremblant, and Shred. “Our Cherry Limelight Bubble Hash Joints is one of our popular extract products,” writes Borna Zlamalik, Organigram’s senior vice president of R&D and innovation. The bubble hash and the dried flower are the same cultivar, which was specifically pheno-hunted for its unique aroma.

The mix of Black Cherry Punch and Limelight produces a pungent cherry and lime scent reminiscent of convenience store slushies. “When you open the pack, it’s like a slushy hitting you in the face,” he says. “It is so aromatic that people believe we add [terpenes]; which is absolutely not true.”

While Tremblant is the company’s OG hash brand, Organigram also released a new spin on an old classic with ‘rip-strip’ hash through Shred, a brand that is known for its milled flower and pre-roll products. Instead of the more traditional brick or ball-shaped hash, this product is pressed into perforated strips for easy tearing.

“Hash has traditionally had a difficult adoption curve among new cannabis consumers. Our Rip Strips were

Organigram’s extraction equipment is an essential part of the LPs’ operations, enabling the production of a variety of popular cannabis concentrates.

designed with the new consumer in mind – this is a product that is super convenient, designed to fit in any pre-roll, and with the ability to easily be portioned.”

This one-of-a-kind product was created by considering the best way to reinvent the hash experience.

“Given its millennia of history, hash has very loyal and very passionate legacy consumers, so we made sure that whatever we created would live in a distinctly different space so that we don’t alienate our connoisseurs,” shares Zlamalik, innovater for Canada’s No. 1 player in hash and concentrate markets.

Mera Cannabis is also well-known for creating cannabis concentrates geared towards legacy consumers, at scale, which can be tricky for aspiring extractors. Mera products are formulated by an “awesome mix of legacy cannabis extractors, enthusiasts and scientists,” says Abi Roach, head of marketing and merchandising at Mera Cannabis.

“One of the first brands we launched in the concentrate space was through our partners, Shatterizer,” shares Roach. “The Shatterizer portfolio is all about shatter and shatter-based infusions, from the ‘pull-and-snap’ classic shatter texture to shatter-infused pre-rolls and vapes. This portfolio has been a huge hit in Ontario and is building momentum in western Canada.”

Mera is also behind bringing a legacy market extract into the legal space. Under their medical brand Ellevia, they launched the first legal RSO to market. “It is a beautiful full-spectrum phoenix tears; a multi-use extract focused on wellness that can be inhaled or ingested.

“Although the industry has been slow to ramp up, and has historically lacked appealing offerings for the consumer, the category is now growing quickly,” writes Roach.

Extract products among the hardest to transition to the legal market

The burgeoning cannabis industry isn’t without its difficulties, of course. And the concentrate category in particular has seen its fair share of challenges. The steep learning curve, regulatory challenges and burdensome excise taxes are significant barriers for extract producers.

“The concentrate category was the toughest to transition to the legal market. Many legacy extractors were resistant to sharing their knowledge or converting their operations,” says Roach. “We are lucky at Mera to have such a great group of legacy extractors with a wealth of knowledge who we have been able to build our business around.”

In addition to finding the right growers and extractors, Roach explains how excise taxes are particularly burdensome for concentrate products. “While concentrates are already a costly product to produce, particularly in the legal market, excise tax and provincial markups make legal

concentrates a hard category to compete against illegal sellers.”

However, Roach notes that these barriers will ease as consumers’ understanding of the category deepens and the government addresses regulatory and tax burdens.

Recently, Health Canada sent out a letter that changed the game for certain extract products, stating they had been incorrectly categorized as concentrates when they were, in fact, edible cannabis products. Organigram was one of many companies affected, their popular product Edison Jolts has been for sale in retail stores as an ingestible extract.

Health Canada didn’t ask these products to be pulled from retail stores but has given companies the deadline of May 31, 2023, to cease manufacturing and distributing products like Jolts. However, Organigram maintains that these products aren’t edibles but ingestible extracts correctly labelled.

Jolts by Edison were created intentionally and strategically, using ingredients that they assert satisfy the strict requirements for extracts

Organigram personnel walks down a hall to which their grow rooms may be accessed.

under the Cannabis Act and Regulations, says Zlamalik. While the company will be complying with the Health Canada notice, Organigram isn’t ready to give up on the popular product. “We are rooted in our strong scientific process and at the core, our extreme dedication to creating compliant products with no shortcuts,” writes Zlamalik. “We disagree with Health Canada’s determination that Jolts are improperly classified as an extract, and we are pursuing a Judicial Review to challenge their decision.”

The future of cannabis concentrates is a blend of art and science

The next big thing in the extracts category has yet to be discovered, but whatever product or trend it might be will likely be highly influenced by the consumer, according to our experts.

“Concentrates are a really amazing yet underdeveloped space in Canada,” says Zlamalik. “The way we will re-invent this category is to really listen to consumers – why they use concentrates,” as well as what makes them apprehensive about the product category.

“The next big thing in concentrates is going to be about hitting the right potency and cannabinoid profile. I am bullish on having concentrates deliver a full spectrum stack of cannabinoids as this category is used not just for recreation but also heavily for therapy/medical needs,” writes Zlamalik.

“I believe by striking the balance between art and science we can change the trajectory and prominence of this category.

It’s about simple consumer unmet needs – both emotional and functional. And most of all the love of how concentrates can highlight the best characteristics of great flower.”

Concentrate lovers are notoriously hard to please. Connoisseurs often come from the legacy space and expect the same quality and potency from pre-legalization, and new consumers are hard to capture as the format can be daunting due to its complexity of use and vast range of products.

“I see the potential for growth in two sub-categories: ready-touse formats like vapes and infused pre-rolls, as well as high-quality cannabinoid-rich extractions,” writes Roach. She notes that newer consumers, as well as younger consumers, are all about easy and effective – propelling the popularity of disposables vapes, pre-rolls, beverages, and edibles.

“The cannabis connoisseur will always look for aesthetics and effect, and as we perfect the ancient art of hash making, you will see evolutions to classic techniques with incredible results full of rich flavours and beautiful colours that will entice a small but enthusiastic segment of the market,” she concludes.

&Education Consultation

Organigram personnel inspects cannabis plants in a three-tiered grow room.

Ashley Keenan is a journalist, consultant, and patient advocate who uses reporting and storytelling to educate, entertain, and empower folks curious about cannabis.

Cannabis and aquaculture: a perfect match?

East Coast LPs Aqualitas and Stewart Farms share why they paired cannabis production with fish farming

By Matt Jones

As in the famous pairings of chocolate and peanut butter or Cheech and Chong, some things just go well together. That appears to be the case with cannabis production and aquaculture.

Several Canadian LPs have paired their cannabis production with fish farming efforts, with significant benefits to the product and the bottom line. While aquaculture can be an incredibly difficult business in which to make a living, these producers say that farming fish, not as a primary product but as a support to their cannabis production, has been very effective.

Definition: For readers who may not be familiar, aquaculture is the general catchall name for all types of aquatic farming. Aquaponics is a type of aquaculture where fish and crops are grown in a mutually beneficial way. As opposed to the similar hydroponics – where the optimal conditions for a crop are simulated – an aquaponics system will typically attempt to create an ecosystem where the fish can feed off the crops that are grown and the crops are nourished by the fish waste.

When the crops, fish, and assorted bacteria are in perfect balance with each other, these systems can be self-sustaining, even cleaning their own water. Cannabis producers have typically been using what is called a ‘decoupled’ aquaponics system, where the fish and crops are kept separately, but the fish waste is collected and used as a fertilizer, either on their own or in tandem with other nutrient inputs.

AQUALITAS ’ KOI FISH

Based out of a facility in Brooklyn, Nova Scotia, Aqualitas was founded by Myrna Gillis, a disability lawyer who saw the benefits of medical cannabis for her clients.

Aqualitas director of science and cultivation technology Danielle Maitland says that while looking at different methods of growing, she came across aquaponics,

Brooklyn, N.S. LP Aqualitas farms koi fish in their decoupled aquaponics system.

which had a reputation for being environmentally sustainable.

“[Gillis] spoke with several experts,” says Maitland, “and was told ‘it grows the best cannabis we’ve ever seen, but it’s really hard to do.’ But that wasn’t a deterrent. Aquaponics has traditionally been used for leafy greens, like lettuce and spinach, that have a very simple lifecycle. They’re only growing leaves, whereas cannabis is a flowering plant and has a bit more complex lifecycle and has different nutrient requirements over the course of that lifecycle, which does make it difficult to do aquaponically.”

The company had little experience with the cultivation method, so they conducted a variety of research trials to figure out the technique. In the end, the cannabis that was produced through aquaponics received better feedback from customers than cannabis produced through other means. But they don’t know exactly why.

“We have theories,” says Maitland. “We don’t know the exact mechanism of why it translates to such good product, and we are looking at some research projects to try and figure that out. But our working theory is twofold: one, the nutrients that come from the aquaponics system are very available to the plants – they’re in an ionic form dissolved in the water, so the plant can really easily uptake them.

“And the second part is that the system is very microbially active. The water that we use is filled with beneficial microbials. The soil that we use is filled with beneficial microbials. And when the plant has a really healthy microbiome at the roots, it’s also better able to uptake nutrients, anything that isn’t immediately in an available form will be broken down into an available form by those microbes in that soil food web around the plant roots.”

There have also been some theories that THC and terpenes are an immune response with the plant, so microbial life at the roots would tell the plants that they should protect themselves in case some of them are bad. All of that is theoretical currently, but it lines up with Maitland’s observations.

“We live in Canada, and the incoming water can go from four degrees up to 25, and koi can live anywhere in that range. If our heating and cooling equipment ever broke down, the koi would be fine.” – Danielle Maitland

“And in terms of the bumps that we see in yield and bud size, I believe that would be a combination of the very available nutrients and the microbes being present to solubilize any nutrients that aren’t immediately available so the plant can pick them up,” says Maitland.

The biggest challenge, Maitland says, is that both cannabis and aquaponics are fairly new commercial scale products. There isn’t a huge amount of research and trade knowledge that the company can rely on and thus are largely left to blaze their own trail. Even more so with the fish which they produce in their system – koi, a fish which is seldom raised in recirculating aquaculture systems. Maitland muses that she’s asked, ‘why koi?’ almost every time she gives a presentation on behalf of the company.

“Koi do very well at the water temperature we want to use for irrigating the cannabis,” says Maitland. “They also have very wide environmental tolerances. We live in Canada, and the incoming water can go from four degree Celsius up to 25, and koi can live anywhere in that range. So, if our water heating or cooling equipment broke down, the koi would always be fine. They’re very tolerant to the high nutrient density in the water. They’re fine at lower pH and can handle lower oxygen than some other species.”

The company raises the koi in a 60,000-liter system with seven

Grow Opportunity the Podcast, featuring conversations with Canadian cannabis industry experts.

grow tanks. As of right now, they sell a few koi here and there, but it’s not a significant source of income for the business. Mostly, the koi are there to support the cannabis, not as a product in their own right. However, that may change in the future. With their current knowledge of the systems, Aqualitas could be producing 3000 baby koi every three months if they so desired.

STEWART FARMS ’ TILAPIA

New Brunswick-based Stewart Farms, on the other hand, was grown out of an aquaponics background. Founder Tanner Stewart started out aquaponically farming leafy greens and herbs in Alberta almost a decade ago. Stewart says that he became enamoured with aquaponics as soon as he was introduced to the concept while working at a tech startup.

“It just made complete sense to me,” says Stewart. “It’s ecosystem-based farming, or another way to look at it is waste stream recovery farming, where you’re taking a protein source – farmed fish – and you’re capturing what would normally just be a waste stream, that is extremely high-quality manure, which is nutrient rich, microbial rich fish effluent, and you’re taking that waste stream and using it to grow higher quality plants. From that moment forward, I said that’s what I’m interested in.”

Stewart Farms is a largely research-focused company, and most of their current research is looking at the microbiome living in their soil and analyzing it, and the microbial cultures and comparing them to the microbial cultures and the microbiome in their fish water, as well as the intermingling of the soil and the water.

The tilapia raised in Stewart Farms’ system will be donated to culinary courses, local restaurants or in some

cases will simply be eaten by staff.

Once the company hosted a dinner party in Toronto and had a top chef cook their tilapia as one of the courses, as well as incorporating some of their cannabis flower into the dishes. It was hoped by some proponents of aquaponics that the technique would revolutionize the aquaculture sector due to its sustainability benefits. But, while there are companies

that have done well with aquaponics, that has not happened as of yet, most likely due to how much capital it requires to develop a fully functioning system and business. In Stewart’s experience, it is much easier to run an aquaponics system in support of your cash crop, rather than trying to make the fish and crop equal parts of the business.

“It’s two completely different busi-

“My version of aquaponics is a fish farm beside a plant farm. You don’t want to have to sacrifice two things at once; you want them optimized beside each other.” – Tanner Stewart

A cleanly, LED lit two-tier vegetation room at Aqualitas. PHOTO: AQUALITAS

nesses,” says Stewart, of trying to monetize both the fish and the crops in an aquaponics system. “They have completely different distribution mechanisms, different price bases and different cost bases, and they each have their own breakeven point. It needs to be approached from a standpoint of running two very different businesses.”

Stewart says that his first system in Alberta was a closed loop – with water cycling back and forth between the plants and the fish at all times. But there were sacrifices that had to be made on both sides. In his experience, it is much easier and more effective to grow fish and plants separately.

“So, the biggest lesson I took from that is don’t do that,” says Stewart, with a laugh.

“Build your fish farm and pull the water out of your fish farm into a secondary holding tank and get that water to where you need it to be the fish effluent. We run a decoupled system now, so then you optimize your fish farm, and you optimize your plant production. So my version of aquaponics is a fish farm beside a plant farm. You just need to be able to access the fish effluent and take it over to the plant farm. You don’t want to have to sacrifice two things at once; you want them to be able to be optimized beside each other.”

All of the decisions about how those systems are designed are crucial and interconnected Stewart advises. Whether you’re raising a warm or cold-water fish, for example, will determine whether you need to heat or cool the water before it is used on the plants.

Cannabis plants like water about 22 degrees, he says, so Stewart Farms chose tilapia over salmon, as the ideal temperature for tilapia is a little closer to that. The nutritional value of the effluent will also vary from species-to-species due diet variations as well. As such, and with all types of farming, the most important thing is to understand the techniques you are employing, the crops you are growing, and how all the parts of the system will work together.

“Today, Stewart Farms’ goal is to drive research and innovation on the microbiome,” says Stewart. “That’s the purpose of our fish farm today. Does Stewart Farms plan or have the intention at least, to potentially build a larger scale, fully profitable

fish farm? The answer is yes. Will we do that with tilapia? I’m uncertain at this point because we’re not focused on that right now. I’m focused on research and plant growth and promoting bacteria and microbes.”

Danielle Maitland, director of science and cultivation technology, Aqualitas, takes a gander at the koi they raise alongside their cannabis in an aquaponics system.

Matt Jones is a freelance writer and journalist who specializes in trade publications. He lives with a cat named Bowie in Frederiction, New Brunswick.

Outlook for LPs cloudy amid shifting conditions

Questioning the financial sustainability of Canada’s overregulated market

By Jake Hribljan

As Canada’s economy barrels closer to recession territory, cannabis industry players continue bracing for layoffs and restructuring amidst a sector already navigating high excise duties and increasing debt obligations.

Canada’s third largest LP Canopy Growth announced in February that they would be laying off roughly 60 per cent of their workforce as they work towards profitability, 40 per cent of which took place immediately with the layoff of 800 employees and the closure of their Smiths Falls Ont., 1 Hershey Dr. facility. Aleafia Health also laid off 36 per cent of their full-time equivalent workforce in 2022, and Canada’s second largest producer by market cap, SNDL, made additional February layoff announcements. The effects of mounting debt have reverberated across the industry, and now rising interest rates will be another factor of concern.

After legalization in 2018, many LPs took on massive debts to fund growth and capture market share. A report by the Canadian Imperial Bank of Commerce found that Canadian cannabis companies had accumulated more than $3 billion in debt by the end

of 2019. These debts were also attributed to significant upfront costs to meet the standards of new regulations. In 2021, Aurora Cannabis, Canopy Growth, and Tilray all announced new debt offerings. 2023 was predicted by some in the cannabis industry to be a big year for mergers and acquisitions, as companies consolidated in a tighter lending environment.

Last year MNA volume was down 80 per cent, representing only USD$4.87 billion. However, if smaller companies fail to keep up with their debt payments required to fund their operations, or are forced to sell off assets, it could foreseeably rise. Consolidation creates the opportunity for larger, more resilient companies that have more resources to weather the uncertain conditions.

Now, as banking sector concerns and rising interest rates impact the emerging American cannabis market, Canadian producers are also finding themselves looking for solutions.

Canopy Growth has been navigating the

balance between managing debt loads and increasing market share for years, and on April 14, announced they reached an agreement to refinance $100 million in unsecured notes due in 2023. After finishing 2022 with a debt of $1.21 billion, Canopy’s interest expense jumped by 1128 per cent to $103.94 million, up from $8.46m the year prior.

Meanwhile, industry leaders find themselves struggling under the weight of excise duty tax. In fiscal year 2020-2021, the federal government collected just over $514 million in total cannabis duties.

“Because of price compression, excise tax has become a larger percentage of each sale and is exasperating the cost of excise tax,” said Tilray Brands CEO, Irwin Simon, in his company’s most recent earnings call. “Tilray has paid approximately $120 million in excise tax and corporate income tax in the last 12 months [to] the Canadian government… No question that [the] Canadian government has been the most profitable cannabis business in our industry.”

C3 noted in a statement: “In the 2021/22 fiscal year, governments earned $1.6 billion dollars in revenues from legal cannabis sales. With legal retail sales totaling $4 billion per year, 40 per cent of all revenues from the sale of legal cannabis are going to governments.” Meanwhile, excise duty tax debt owed by LPs is at an all-time high, sitting at $97.5 million halfway through the 2022-23 fiscal year, according to CRA data.

This comes as an unregulated and untaxed illicit cannabis market represents roughly 40 per cent of the total Canadian cannabis industry. “There are two very different cannabis markets in Canada: one that’s legal, highly taxed, and regulated; and one that’s thriving and illicit. The unregulated illicit market is generating billions of dollars of revenue, with a 40 per cent market share and faces virtually no

risk of enforcement,” David Klein, CEO of Canopy Growth, told investors during Canopy’s Q3 2023 call.

“The competition with the illicit market, compounded by an overbuilt legal cannabis industry, has caused price compression across the board. We expect the sector challenges to remain for years to come,” he continues. “And as a result, the sustainability of this legal sector is in question.”

These growing concerns are repeatedly being brought to politicians and regulators and are slowly gaining attention. The OCS announced it would be reducing its markup rates in a bid to help the financial viability of the legal market and combat the illicit.

“We appreciate and applaud the OCS’ commitment to transparent mark-ups and the reduction in its mark-up rates,” said George Smitherman, CEO of C3.

Despite these challenges, the Canadian

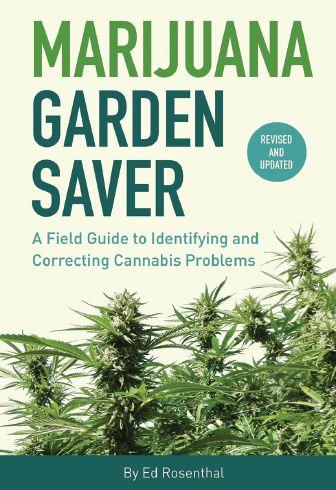

MARIJUANA GARDEN SAVER

cannabis industry is still growing. According to a Deloitte Canada report, legalized recreational cannabis has added $43.5 billion to Canada’s GDP. The industry has created almost 100,000 new jobs and continues to beat yearly revenue estimates.

Still, there is continued investment interest from alcohol and tobacco companies, and the expansion of an international cannabis marketplace. As the Bank of Canada weighs further interest rate increases to combat inflation, which inevitably impacts the ability of LPs to service interest on debt and raise further capital, industry players will be forced to consider consolidations and cost reduction methods until the financial landscape becomes more clear.

Jake Hribljan is a Canadian freelance writer with a background in economics currently residing in the E.U. Twitter: @JakeHCE

Bud-ucation: my experience budtending on Vancouver Island

Most days were the same.

Open up the doors to have three or four of the same regulars saunter in, casually browsing before making roughly the same purchase they had made the day before. At that hour, you’re guaranteed to have your chronic customers – the window shoppers and dabblers don’t show up until around 3pm.

Half of my job was getting people in and out the door as fast as we could, and the other half was education. It never occurred to me that when applying for this job, it would lead to feeling so fulfilled in a retail setting. The ability to educate about cannabis and its benefits for a wide variety of ailments, while being careful not to give any medical advice, took up most of my time with prospective users.

Rarely did a customer ever discuss trichomes or genetics unless they came in to show off their knowledge, of which I would cherry pick the gems and pass them onto other clientele.

Our elderly customers would come in for a sleep aid or for pain management, and a consistent story began appearing with these folks: “I've got this terrible pain and I'm on (two or three prescriptions). Do you have anything you can recommend that won’t make me high?”

I’ve got to say, compared to working at the liquor store when I was younger, it’s neat being a legal drug dealer and interacting with much happier customers. At a liquor store, pointing out who’s the alcoholic is pretty evident. As for the chronic

weed smokers, they are much more upbeat, and their physicality appears to be in better shape.

As for the store I worked at, I will say it was certainly not an... inspired experience. But I loved my customers and co-workers. It was our job to sling bud and build an engaging atmosphere for people when they came in, which we were consistent with, seeing as how we needed to install a bench for our customers to sit down and chat (upon which many a chat was had!)

That being said, the management and corporate management of our company was run by people who you could tell didn’t have as much compassion for people. From a business perspective, I understand the need to be profit-oriented, but it should never come at the cost of the cool atmosphere created and maintained in the pot shop; that is why the people came.

Staff were pleasant, the layout was beautiful without being busy or overcrowded, and our prices were comparable if not better than our competition across the street. If the opportunity arose to educate someone on the benefits of cannabis, it was almost always met with a “thank you” and subsequent purchase.

The cannabis industry is relatively simple on the retail side when it comes to customers. I mean if they are walking in the door, chances are the purchase has already been made in their head and you just have to close the deal. But be on the lookout for the not-so-confident person who wanders in out of curiosity. With kind words and earnest listening, as many are interested in being heard, they’re sure to become a repeat customer.

Honestly, it’s Vancouver Island, where everyone and their dog is selling weed. So, the best method I saw for capturing the sale, and future sales, is consistency. Consistency of product, but most importantly, I feel, is consistency from the budtenders in terms of knowledge and attitude towards the public.

Questions to consider:

Maybe as an industry we should be collectively asking ourselves this: Does securing this kind of talent require a raise in pay grade? Should more samples and perks be afforded to those behind the counter? Would better rapport between growers and retail be effective for the purposes of tackling the legacy market?

How many budtenders become brand ambassadors for the products they’re partial to? As an extension of that, how many producers are mining their pool of local tenders before posting ads directed at the marketing graduates? I think we can all agree that passion for cannabis isn’t taught, but is inherit in the personalities of enthusiasts.

My takeaways from working in this industry have been positive. Establishing those relationships with growers and seeing their products flourish in retail is rewarding – you can tell whose heart and soul goes into what’s brought to market. I work in oil and gas now, and I tell you: I miss the industry and the Island, and will likely return to both.

Canadian bud will always have high global status, from coast-tocoast, because the people here really know how to deliver on some of the finest smoke around – it’s just part of our culture.

The cannabis industry is relatively simple on the retail side when it comes to customers. I mean if they are walking in the door, chances are the purchase has already been made in their head and you just have to close the deal.

Uhrius Hartwell hails from Calgary and intends on advancing his work in the Canadian cannabis industry.