Nearly 80-year-old founder still has big plans

BY ERICH LUENING

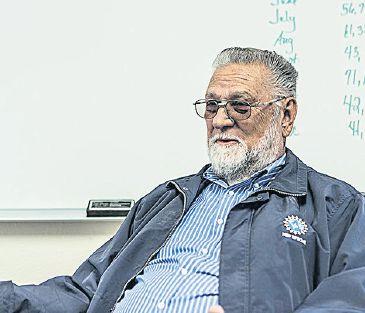

Family businesses are sometimes vulnerable to inertia, but not the Fish Breeders of Idaho. Ask founder Leo Ray where he imagines his catfish, trout, tilapia, and sturgeon farm will be in a decade and he’ll tell you the freshwater aquaculture business will be adding to its species list and still be run by his family.

“The biggest change in my life is witnessing the decline of small business,” Ray, who will be 80 years old in December, told Aquaculture North America (ANA). “My son works with me now and some grandchildren plan to come back and run the business after college.”

Fish Breeders of Idaho initially got its start in the Golden State of California in 1968 under the name Fish Breeders. Leo and his wife Judith started with catfish but by 1973, they had moved to Idaho where the artesian geothermal spring waters and abundant cold water springs offered the catfish farmers the opportunity to diversify their production to other species. The new company became Fish Breeders of Idaho.

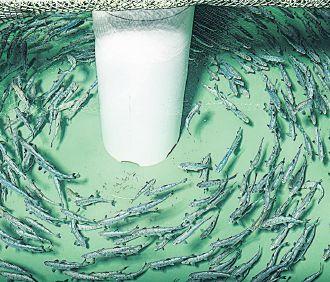

By 1975, after tweaking his catfish farming to include warm geothermal water flowing through concrete raceways that enabled high-density

continued on page 6

‘Stress-prone’ Atlantic salmon identified as good candidate after trials show fish fed with the supplement dealt with stressors better

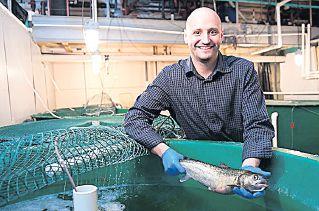

Anew research effort out of the University of Wisconsin-Madison is examining the benefits of using preen oil extracted from chickens in aquaculture. Dr Jake Olson, an assistant scientist working with Dr Mark Cook at the Department of Animal Sciences, says the oil has benefits as an antiinflammatory and as a health and growth booster, and is particularly effective when administered to smaller fish.

Preen oil is a plentiful resource as the preen glands of chickens are not used for any productive purpose. “They’re basically garbage,” says Olson, so they can be obtained extremely cheaply. After conducting trials on mice to determine the oil’s potential anti-inflammatory benefits, the researchers tested it on two dominant fish species in Wisconsin – yellow perch and walleye – and

Scientists

BY MATT JONES

Maryland’s oyster industry has rebounded, with industry players reporting robust oyster production and increased employment in the sector that has seen hard times.

Sources attribute the growth to the state’s restructured leasing laws implemented in 2010. Prior to that, shellfish aquaculture production and leasing was stagnant; over 600 leases were in existence but the majority of them were not being used.

State’s “use it or lose it” lease laws catalyzed rebound

there’s been success stories of traditional watermen becoming oyster farmers but ‘it’s a completely different business strategy and outlook’

“Maryland’s lease laws now contain a strict ‘use or lose’ criteria requiring leaseholders to use their leases or return them to the state so this acreage could be made available for leasing to new shellfish aquaculture businesses. In response to this requirement, many inactive leases have reverted back to the state and this acreage is now either in production or available for lease,” said Karl Roscher, Acting Manager and Aquaculture Coordinator for the Maryland Department of Natural Resources.

Today, Maryland has 436 active lease sites covering more than 9,000 total acres. The state has also has attracted some of its traditional watermen to take up oyster aquaculture. “These fishermen faced cutback after cutback to quotas of what they can land, and the collapse of various fisheries,” said Bob Rheault, executive director of the East Coast Shellfish Growers Association. He noted that 535 permit holders have created over 1,500 jobs. “It’s a wonderful story for a sector of rural America that has seen hard times.”

continued on page 8

Aquaflor® is now approved for use in all freshwater-reared finfish at dose rates of up to 15 mg/kg*. I t ’s cleared for use in recirculating aquaculture systems, too.

For the full stor y, call our fish-health specialist, K asha Cox, at 662.907.0692 or visit our new website at Aquaflor-USA.com. Dep enda ble

S o whether you raise trout, tilapia, bass, c atfish or even baitfish or ornamentals, you can turn to Aquaflor for managing the toughest bac terial diseases of farm-raised fish.*

It just keeps getting better

A Q U AF L O R ®

* In the USA, Aquaflor is approved for use at 10-15 mg/kg in freshwater-reared salmonids for the control of mor tality due to furunculosis associated with Aeromonas salmonicida and coldwater disease associated with Flavobacterium psychrophilum; in catfish for the control of mor tality due to enteric septicemia of catfish associated with Edwardsiella ictaluri; and in all freshwater-reared finfish for the control of mor tality due to columnaris disease associated with Flavobacterium columnare At 15 mg/kg Aquaflor is also approved in freshwater-reared warmwater finfish for the control of mor tality due to streptococcal septicemia associated with Streptococcus iniae. LABEL CLAIMS NOT APPROVED IN CANADA.

CAUTION: Federal law restricts medicated feed containing this veterinary feed directive (VFD) drug to use by or on the order of a licensed veterinarian.

© 2015 Inter vet Inc., doing business as Merck Animal Health, a subsidiar y of Merck & Co Inc All rights reser ved MAH-AQF-38 ( or fenicol) T YP E A MEDI C A TE D A R TICL E

quAdvantage Salmon, the genetically engineered salmon from biotech company AquaBounty Technologies, has made its market debut in Canada.

The company said it sold approximately five tons of fresh AquAdvantage Salmon fillets at market price to customers in Canada, earning it $53,000 in revenue on the sales.

The announcement came along with AquaBounty’s August 4 reporting of its financial results for the second quarter ended June 30, 2017.

Ronald Stotish, CEO of AquaBounty, called the very first sales of AquAdvantage Salmon a milestone for the company. “The sale and discussions with

Senator Lisa Murkowski (R-Alaska) is pushing a bill mandating the clear labeling of genetically modified (GM) salmon and other GM finfish so consumers know what they are buying.

Congressman Dave Reichert cut the ribbon dedicating the completion and use of Troutlodge’s newly remodeled trout egg incubation facility in Bonney Lake, Washington. With him are Senator Phil Fortunato (wearing cap) and State Rep Morgan Irwin

ashington State’s Troutlodge has upgraded its trout egg incubation facility, allowing it to hold and incubate as many as 100 million trout eggs at a time.

The remodeled facility, located in Bonney Lake, Washington, was officially opened in July.

“Our new incubation hatchery is very likely the largest privately owned trout egg incubation facility in the world,” said Keith Drynan, general manager. “Troutlodge can now incubate eggs at several different temperatures to facilitate customer requirements, as well as sterilizing and reusing the incubation water several times.”

Drynan added that support from parent company, Hendrix Genetics, enables Troutlodge to supply quality, disease-free rainbow trout eggs selected for high survival and growth to customers in 50 countries around the world.

Washington Congressman Reichert, who cut the ceremonial ribbon at the facility’s opening, noted the role of Troutlodge in the state’s economy. “The new Troutlodge incubation facility is of critical importance to retaining jobs in the 8th Congressional District. Troutlodge prides itself on being the largest and leading supplier of live trout eggs. Each year their 60 employees work hard to produce about 500 million trout eggs, of which the vast majority is exported. This is a great example of how exports help drive business and support jobs. It is also one of the reasons I am a committed advocate for trade and will continue fighting to open new markets for American businesses and workers.”

potential buyers clearly demonstrate that customers want our fish, and we look forward to increasing our production capacity to meet demand,” he said.

In the United States, the issue of genetically enhanced fish remains contentious (see box). The US Food and Drug Administration (FDA) has banned its import and sale until it issues product-labeling guidelines.

The Genetically Engineered Salmon Labeling Act, or HR 204, requires the market name of genetically modified salmon to include “Genetically Engineered” or “GE” in front of the existing market name.

The bill also calls on the Department of Health and Human Services to ensure that “an independent scientific organization reviews and reports on the Food and Drug Administration’s (FDA) environmental assessment of AquAdvantage Salmon,” the trade name of AquaBounty’s genetically modified salmon.

Another lawmaker from Alaska, Chris Tuck (D), has earlier filed a bill calling for the ban on the sale off GM fish altogether.

In-Situ Ad – Aquaculture North America Size: 6.84” x 5” print: 4-color / CMYK SCD# 17INST212 / Date: January 2017

Local consumer advocates have expressed shock at the news that genetically modified (GM) salmon has entered the Canadian marketplace.

GM salmon producer AquaBounty revealed on August 4 that it has sold approximately five tonnes of GM Atlantic salmon fillets in Canada (see main story).

“This is the world’s first sale of GM fish for human consumption and has occurred without GM product labeling for Canadian consumers,” said the Canadian Biotechnology Action Network (CBAN).

Without mandatory labeling for GM foods in Canada, consumers are shopping blind, says watchdog

“No one except AquaBounty knows where the GM salmon are,” said Lucy Sharratt of CBAN. “The company did not disclose where the GM salmon fillets were sold or for what purpose, and we’re shocked to discover that they’ve entered the market at this time.”

Without mandatory labeling in Canada, CBAN says it works to track GM foods to keep Canadians informed. Canada “requires labeling for food products, including genetically modified foods, where clear, scientifically established health risks or significant nutritional changes have been identified that can be mitigated through labeling.” In the case of AquaBounty’s GM salmon, “the decision of whether or not to proceed with voluntary labeling is that of AquaBounty,” says Health Canada.

“The immediate remedy is for grocery stores to commit to keeping GM salmon out,” said Sharratt. So far, two grocery companies in Canada have published statements online responding to consumer concerns over GM salmon: IGA Quebec states that it only orders non-GM salmon, and Costco’s website states that it does not intend to sell it, said the group.

“We clearly need mandatory labeling of all GM foods,” said Thibault Rehn of the Quebec network Vigilance OGM, a member group of CBAN.

“When it comes to GM foods, Canadian consumers are shopping blind,” added Sharratt.

in

Reduce operational costs and gain better visibility into changing conditions with the Aqua TROLL® 400 Multiparameter Probe and the Con TROLL® PRO Process Controller. Accurate and reliable sensors let you optimize pond conditions to protect your investment and increase your ROI.

• Measure salinity, pH, ORP, optical dissolved oxygen, temperature, level, and more

• Low-maintenance and compact probe

• Integrate with Con TROLL PRO, PLC, or wireless options to automatically run aerators and pumps only when needed, reducing energy costs

Improve feed-conversion ratios, minimize sh stress, and reduce sh disease and mortality with consistent water quality monitoring.

Learn more at in-situ.com/aqua-na

We o er:

• Extensive technical support with access to juveniles and seed

• Academic partnerships with the University of Maine

• Entrepreneurial training & business counseling

• RAS and ow-thru culture facilities from 50-1000 sq meters

• State-of-the-art culture systems

• Business support facilities and networking opportunities

We provide entrepreneurs and business startups professional support and excellent facilities to develop their aquaculture ideas.

• Assistance in grant writing and identifying funding opportunities

• Plus exceptionally high quality sources of water!

For more information, contact: Chris Davis, Maine Aquaculture Innovation Center 193 Clarks Cove Road, Walpole, ME 04573 Phone: (207) 832-1075, cdavis@midcoast.com

Credit: University of Valparaiso

Atreatment developed in Chile that could replace the use of antibiotics in the salmon industry has been granted a patent in the United States.

The solution, obtained from an indigenous marine bacteria, was developed by a team of scientists led by Dr Alejandro Dinamarca at the University of Valparaiso.

The highlight of the solution is its ability to be blended into fish feed. Dinamarca said the food additive does not generate resistance, is non-toxic to fish farming, and poses no harm to the environment. It is thus seen as a better alternative to antibiotics in controlling infections in salmon.

Dr Alejandro Dinamarca and his team developed the potential alternative for antibiotics for salmon treatment

The use of large quantities of antibiotics in aquaculture is a concern because it has the potential to be detrimental to other wildlife, the environment and humans. In 2016, Chilean salmon producers revealed they used 557 tons of antibiotics during the previous year, the highest level in at least eight years.

British Columbia has allocated $200,000 to a project that would address issues affecting the shellfish industry, including food supply security and climate change.

The project, called Ocean Acidification Shellfish Industry Seed Supply (OASISS), has the BC Shellfish Growers Association (BCSGA), Vancouver Island University (VIU) and the Hakai Institute (HI) behind it.

VIU is receiving $50,000 to expand its oyster seed production capacity within the Deep Bay Marine Station, which will supply producers with seed that is better adapted to local growing conditions.

BCSGA is receiving $75,000 for new equipment for ocean monitoring and to continue to work with HI to develop baseline data to better understand the local impacts of climate change.

BCSGA will receive an additional $75,000 to work with their members to develop a business case and plan for further investments in food safety improvements, research to better understand foodborne illness in shellfish, business risk management strategies, and economic development opportunities.

Editor Liza Mayer

Tel: 778.828.6867 liza.mayer@capamara.com

Advertising Sales Jeremy Thain Tel: (250) 474.3982 Fax: (250) 478-3979 Toll free in N.A. 1.877.936.2266 jthain@annexweb.com

Art Department James Lewis Tel: (709) 754-5059 james@capamara.com

ADDRESSES TO:

Regular Contributors: Quentin Dodd, Ruby Gonzalez, Erich Luening, John Nickum, Matt Jones, Tom Walker

Group Publisher - Scott Jamieson sjamieson@annexweb.com

COO – Ted Markle, tmarkle@annexweb.com

President & CEO – Mike Fredericks

North America. CIRCULATION DEPT. 80 Valleybrook Dr., Toronto, ON M3B 2S9 Subscriptions – Malkit Chana – mchana@annexbizmedia.com • Tel. 416-442-5600, ext. 3539 1-800-668-2374 (CDN) • 1-800-387-0273

But the absence of big players in animal nutrition indicates segment is still in ‘risky phase,’ observes an industry player

BY MATT JONES

he insect protein market has grown steadily over the past 10 years as producers continue to seek solutions to feed problems in a variety of markets. One of the most interesting markets for the protein source is aquaculture, due to efforts to reduce the amounts of fishmeal used in the industry’s processes. Aquaculture North America (ANA) spoke with some of the companies breaking ground in this sector.

“We saw the demand for a replacement for fishmeal,” says Andrew Vickerson, chief technology officer for British Columbia-based Enterra Feed Corporation. “We know there are only so many sardines and anchovies in the ocean to catch and the catch has been the same since the 1970s. Meanwhile aquaculture has grown by about 10 percent per year. We’ve seen demand growing. And the sustainability aspect of using fish to feed fish needs some attention. So those two things combined make it an ideal market for us.”

Enterra was founded a decade ago with a focus on the black soldier fly. After a few years of research and development, a demonstration plant was built in Vancouver, which ran for about a year. In 2014, the company built a facility in Langley, BC. Victoria Leung, Enterra’s manager of marketing and operations, says the company initially targeted the aquaculture market, but has since expanded to other sectors.

“As we’ve grown, we’ve discovered new markets,” says Leung. “Any animal that eats insects, which is most of them, is a market for us. So our target markets today are the aquaculture industry, the poultry industry, the pet food industry and we’ve got some niche markets like backyard chickens.”

Black soldier fly larvae are an ideal feed ingredient because they are about 40-percent protein and 40-percent fat, and contain essential omega fatty acids.

“We’re able to replace at least 50 percent of fishmeal without any reduction in performance,” says Vickerson. “And the fish taste the same as they would as if they had fishmeal. The amino acid profile is quite good as well and the digestibility is high. It’s a fantastic ingredient.”

AGRIPROTEIN

AgriProtein is another insect larvae company targeting the animal feed sector. With a full-scale insect rendering facility in Cape Town, South Africa, AgriProtein’s production is bigger than many of the companies in this sector,” says Mark Williams, chief operating officer.

“In the past five to six years, several companies have

tried to develop ways to take advantage of this protein,” says Williams. “From what I’ve heard and seen, Agriprotein are the only ones who’ve been able to do it in a massive way.”

‘None of the big boys have turned up yet,’ observes Taplow Feeds partner Brad Hicks

AgriProtein offers a line of insect-based products such as MagMeal, an insect based protein; MagOil, an extracted fat; and MagSoil, a residual soil conditioner.

Some companies have not yet begun targeting aquaculture, but it is in their long-term plans. Georgia’s Grubbly Farms is beginning to ramp up production of insect-based feed products. Company co-founder and CEO, Sean Warner, says they initially wanted to focus on insect protein for human consumption but admits that would be a hard sell, even if they have perfected their process.

“We did make a burger patty,” says Warner with a laugh. “We mixed it with black beans and it was not the most appetizing thing in the world.”

While still convinced that insect protein will play an important role in human nutrition in the future, the company decided to focus on animal feeds. Its only product is called “Grublies,” is dried black soldier fly larvae sold as chicken feed. The company plans to enter the aquaculture sector in the long term, but the challenge will be meeting the scale of the industry, adds Warner.

Brad Hicks, a partner at Taplow Feeds and has worked with Enterra, says the larval feed sector is indeed growing rapidly but it is still in its infancy. While some players are beginning to scale up their production, he says there is one clear indication that the market is not quite exploding just yet — the absence of big names in animal nutrition.

“None of the big boys have turned up yet,” says Hicks. “That always tells you. None of the big agriculture or protein and fat commodity characters have turned up to the table yet. They’re still watching, so that tells you it’s still in a risky phase. When the Cargills and ADMs of the world decide that they’re going to purchase one of these companies, that’s because they have an analysis that says they know how to make this commercially viable. They’re pretty cautious.”

Pranger Enterprises specializes in land-based, indoor aquaculture facilities utilizing recirculating aquaculture systems (RAS). The field of RAS is incredibly promising because it is sustainable, energy efficient and eco-friendly. Fish have an excellent feed-toprotein production rate of approximately 1-to-1.2. When paired with energy-efficient RAS methods, fish become the ultimate sustainable food source. Contact Pranger Enterprises to learn more about how RAS can benefit your facility.

Credit: Wikimedia

handful of dried larvae of the

The company has expanded

beyond aquaculture

Sacks of MagMeal, an insect based protein, from Agriprotein of Cape Town, South Africa. The company is dubbed ‘the world’s largest fly farm’

Credit: f6s.com

production and temperature control, he expanded into tilapia farming.

“I started raising trout in 1980,” he said. “I got white sturgeon spawned here in 1989.”

Ray claims the best thing he did was to use his fisheries degree from the University of Oregon and continue to use the national university system for research and technology transfer to expand his species production.

Ever since he was a kid, he said he always worked with wildlife. After college he thought he would work with fish in the government fisheries area. As a grad student, he focused heavily on catfish hormone reproduction. There’s no surprise that he went ahead and started with catfish.

half of the sturgeon feed is natural organisms growing in the system, the company explains on its website.

Today Fish Breeders of Idaho includes subsidiaries Big Bend Trout and Fish Processors. Obviously, Ray knew early on it was a good business model to control his own supply chain from production to processing.

“The catfish industry is a model of how aquaculture species production is supposed to work, from researchers, government, to farmers,” he explained.

It also requires clean sources of water.

When he discovered and then moved to the Thousand Springs Area in Idaho near the town of Hagerman, he was attracted to the natural flowing coldwater springs and warm geothermal artesian springs. With an eye toward sustainable farming techniques, he knew using pumps wouldn’t be necessary, saving costs, protecting natural aquifers and limiting air pollution.

Farming his fish in concrete raceways uses water but doesn’t consume water, he claims. After the fish farm uses the water it is available for other purposes, including irrigation, organic fertilizer and, during the winter, duck resting areas.

The company’s white sturgeon use the same water delivery system as the trout and help clean the raceways by eating accumulating vegetation. Approximately

In 2003, the company was chosen to produce rainbow trout according to sustainable food production standards required for sale in the Whole Foods Market national store chain. Under the Whole Foods Quality Standards, trout farming operations operate under inspection and certification protocols, according to Whole Foods and Fish Breeders. The farm staff controls the entire process from egg through growout. Orders for the trout, either as dressed, boned, or filleted, come from Canada and the United States. In 2004, the family fish farm debuted Idaho Caviar, which is prized in the region by local chefs and media foodies. And this year, as ANA reported, the fish farmer announced it is converting raw fish guts into fish feed, a move that not only makes use of what is deemed as a “worthless waste product,” but also save him roughly 30 percent in feed costs.

Ray obviously is one not to rest on his laurels. He and his son Tod, who is Vice President of sales, are now looking to expanding their offerings to include aquarium species and minnows.

“I look forward to working on the fish farm as long as I can and then handing it off and getting out of the way of my grandchildren,” he said.

Company president and founder Leo Ray. ‘I look forward to working on the fish farm as long as I can and then handing it off and getting out of the way of my grandchildren,’ he says

continued from cover

on fathead minnow to look at the oil’s potential in feed applications. They soon discovered the oil had beneficial properties, but was particularly effective in smaller fish.

“We can’t feed five-kilogram fish, we can’t feed adult salmon, as that would be their market size,” says Olson. “It has to be a smaller fish who will benefit from this — fish that we don’t have to feed throughout their entire lifetime, otherwise the product doesn’t make any sense.”

In the trials with walleye and perch, the growth effect was hit or miss. However, the effect as it related to stress factors was unmistakeable. Throughout the testing process, whenever an accidental stressor occurred (such as problems with water temperatures and filtering equipment failures) the fish that had been fed preen oil always dealt with the stressors better than those without.

A GOOD CANDIDATE

“That’s when we started to pin it down,” says Olson. “If we’re going to feed a small fish, let’s feed a small stressed fish. So what is a small stress-prone fish? It turns out that Atlantic salmon, at a certain stage of their development, are an incredibly stress-prone fish.”

Inspired, Olson says, they began looking into Atlantic salmon operations and discovered that when salmon reach the age to be transferred from freshwater to sea water, about 10 percent will die annually due to stress-related opportunistic infections. That works out to over $400 million in lost revenue globally. As Norway is the number one Atlantic salmon producing country in the world (shouldering roughly $250 million of those worldwide losses), that market has become the immediate target of their research.

{When salmon reach the age when they need to be transferred from freshwater to sea water, about 10 percent will die annually due to stress-related opportunistic infections, making them good candidate for the supplement.

“They make up a pretty good chunk of the global Atlantic salmon production,” says Dr Olson. “We think they have the largest share of a large problem. And we know right now that we have the material to meet at least their need. What we’re hoping to do is make an impact where it seems to be hitting hardest, which is Norway.” They call the oil product itself Cosajaba oil – a combination of the names of the scientists Mark Cook, Jordan Sand, Jake Olson and Terrance Barry. The researchers will continue to work with industry partners, such as Wisconsin’s Superior Fresh Fish, to advance the product’s development. Olson says the company is now at a point where they have to make a decision – whether to develop their own company producing Cosajaba oil for various markets, or to licence their process for others to use.

“Right now, we’re at a really good place for this project to go either way,” says Olson. “Timeline wise, in about a year, we’ll probably be talking to customers at that point. We’re not that far away. I’m hoping in about a year we already have something to offering.”

— Matt Jones

Healthy fish is our shared commitment. With one small dose of FORTE VII®, you can help protect your fish against six naturally occurring bacterial, and one viral salmon pathogen.

-Non-Corrosive schedule 80 PVC reactor bodies are stronger and handle higher internal pressures compared to HDPE and Polypropylene. Schedule 80 reactor bodies are seawater safe and will not corrode in harsh environments, unlike stainles ssteel

-Single end glassware access makes for easy maintenance when replacing lamps and quartz sleeves

-Thermoplastic or Fiberglass NEMA 12 Power supply enclosures with Standard HMI control package or optional HMI Pro Series control package.

-Electronic ballasts matched to the performance of the specific lamp for optimal UV-C output and longest useful lamp life

-Standard Over Temperature Safety Cutoff Switch thermally protects reactor when water temperature reaches 120 Degrees F

-American made low pressure amalgam (ALH/

- AUH models) and high output (HLH/HUH models) lamps. These lamps are rated 80% efficient at the end of 12,000 hours.

Johnny Shockley is a third-generation Maryland waterman. In the early 90s, he began to see some major problems starting to surface in the seafood industry in the Chesapeake Bay and recognized the possibilities of a new, sustainable oyster industry that could help the entire seafood industry in the bay and the bay’s ecology. The result was Hooper’s Island Oyster Company. Shockley says the industry’s growth has been palpable since the state government got behind it.

“We’re consistently holding application numbers of 100 plus and have been for the last several years,” says Shockley. “A couple of million dollars in funding has been used and part of that has been paid back under some new funding programs from Marbidco (the Maryland Agricultural & Resource-Based Industry Development Corporation) that came in around the same time. Since that came along, we’ve grown very quickly compared to prior years.”

Honga Oyster Company was incorporated in 2011 and put their first live oysters in the water in the spring of 2012. The company was formed by two former watermen, Don Simmons and David Tippett, and former computer program manager, Bill Cox. Cox says that many in the local community were questioning their sanity when they started their venture, but they started to understand once the product started to be pulled out of the water.

“It took a while for the community to buy in,” says Cox. “But the ones who were calling us crazy, they started going, ‘looks like you guys figured out what you’re doing! You’ve got something going here!’”

However, as some of the local producers told Aquaculture North America (ANA), any industry expanding at this rate will have some growing pains.

Kevin McClarren saw the growth of the industry from its infancy. As general manager of the Choptank Oyster Company, McClarren began working in aquaculture in Maryland a full decade

Rheault, executive director for the East Coast Shellfish Growers Association, is optimistic oyster farmers will overcome the industry’s growing pains

before the state turned it around. While McClarren is happy to see the industry grow, he has reservations about hailing the industry as the region’s “savior.”

“It’s not the silver bullet that some people are trying to portray it as,” says McClarren. “The state wants to say, ‘this is a great thing, this is creating jobs!’ But, these are very small, little farms and you’re not employing that many people. I don’t know that it really has that big of an impact here on the shore. And I don’t know that it will.”

McClarren has concerns about the local markets becoming saturated given the industry’s rapid expansion. As he sees it, distributors now have an overabundance of boutique-style oysters to choose from the local market, which could touch off a price war amongst the producers. “There’s not enough space in the local market to handle all the boutique oysters,” says McClarren.

Roscher, the Department of Natural Resources executive, however, says that they haven’t seen any evidence of that. “It’s been the opposite,” he says. “The markets in our state have been strong. Prices have been steady. The volumes that the markets are interested in buying have been steady as well.”

Roscher adds that while oyster aquaculture is still quite small, it is increasing its share in the state’s total aquaculture production. “It’s changing the way that Maryland oysters are viewed in the market,” he said.

One of the crucial issues small farms face is marketing – how to position one’s company and access markets. Brian Russell is part of the four-man team behind Shore Thing Shellfish. He says marketing has been one of the key issues they have struggled with.

“Somebody who’s energetic and has the time, I think they could sell themselves much better than we can,” says Russell. “Marketing is almost one person’s full-time job. It could be.”

Rheault, the East Coast Shellfish Growers Association official, can sympathize with such notions. Speaking as an oyster farmer himself, he says that he sought other markets because local price wars were “a race to the bottom.”

He believes, however, that ultimately, the market will work itself out. But he

says it’s up to the producers to figure out what they need to do to appeal to different markets, in particular higher paying markets such as oyster bars in New York. One of the key things producers can do is to tailor their products to their target markets. With different regions having their own preferred tastes, oyster producers can take steps to make them appeal to larger markets. Consumers in the lucrative North East markets prefer saltier oysters, for example, so Rheault suggests salting up oysters by leaving them in tanks with saltier water for 24 hours. Giving the customer what they want is perhaps the most important lesson he learned about marketing.

In the meantime, he says the challenges are just natural growing pains that come with a rapidly expanding industry. “This is a pretty young industry. Are there going to be growing pains in a 30-year-old industry? Absolutely. Are we going to conquer them? I’m optimistic,” he says.

For over 30 years oyster growers worldwide have trusted our S1000 Oyster Tray and S4000 nursery tray, to produce the highest quality half-shell oyster for today's demanding consumers. Featuring our 6061 T-6 aluminum suspender pole which stands up to the harshest of salt water environments.

Phone: 604-926-1050 Fax: 604-926-1055

BY JOHN G. NICKUM

f representatives in Michigan are successful with their legislative efforts, aquaculture in the Great Lakes region will be regulated as a source of pollution, perhaps even banned. Other representatives in the Great Lakes region meanwhile want to support expansion of aquaculture development. Which will it be? Given my career in both aquaculture and environmental conservation, will I choose one side over the other? Before I answer that question, I want to examine some of the issues involved and provide some insights, from my perspective.

First, I am opposed to pollution. I frequently add the following statement to letters I send to my Congressional representatives: “No one has a right to pollute.” I also include that statement in Letters to the Editor sent to my local newspapers. I am an activist when it comes to combating pollution. Toxic wastes must not be dumped into our air, water, or soil by corporations or individuals who do not want to clean up discharges from their operations. People who want to “externalize” the costs of pollution control and hope that no one will notice the damage they are causing to our air, water, and land are the reason we have regulatory agencies and environmental regulations.

“In spite of such polarized points of view, there may be acceptable compromises in the Great Lakes argument.”

When the world’s population was small, waste discharges were considered to be minor inconveniences. Our waters, atmosphere, and soils could accept contaminants without major detrimental effects. Almost all forms of exploitation and development were perceived as “good” and even essential for the economy of new nations. In those times many polluters were given a “free pass” to do

Credit: S. Beaulieu/GLEAM

Net pen aquaculture in Ontario. The Great Lakes are five large lakes in eastern North America, which hold 21 percent of the world’s surface fresh water

whatever helped their bottom line. The natural resilience of the ecosystems was thought to be strong enough to handle the wastes humans create without dangerous effects. Things are different now. The amount and the toxicity of waste discharges are much greater and many people challenge the need for additional exploitation of natural resources. Controlling and eliminating the toxic forms of pollution produced by a growing world population has become essential.

Where does aquaculture fit in this discussion? Aquaculture is primarily a food-production activity, an aquatic form of agriculture. However, 50 years ago American aquaculture was used to support recreational fisheries management. What has changed? Why would anyone consider aquaculture to be a source of pollutants, so harmful to the Great Lakes region that it should be

Great Lakes watershed? H.R. 961, which was introduced recently by Representative Dan Kildee from Michigan, would do exactly that, ban aquaculture in the Great Lakes region. A similar action, Senate Bill 526, which was introduced recently in Michigan by State Senator Rick Jones, actually has bipartisan support, as well as support from environmental advocacy groups.

These legislators and their supporters acknowledge that aquaculture is a valuable activity; it is sustainable, produces “nutritious local food,” and is important for economic development. However, they claim that aquaculture operations contribute waste food, fecal material, fish disease agents, alien species, and genetically modified native fish to the waters of the Great Lakes. They go on to state that “the Great Lakes belong to everyone and no private interest should transfer the risks of their business venture to the citizens of this state and the future generations who will inherit our natural resources.” I agree strongly with this statement, I just do not agree that aquaculture poses the environmental risks that they claim. Aquaculture is not the evil activity that they imagine it to be. Should aquaculture be banned in some areas, or at least severely regulated? I say no. It should be, and can be, managed to minimize environmental conflicts.

Individual opinions about regulation usually depend on how the regulation affects them. If it is “others” that are affected, the regulations are good; but if it affects them personally, the regulations are bad. In spite of such polarized points of view, there may be acceptable compromises in the Great Lakes argument. Effective biosecurity procedures that reduce fish escapement, the release of wastes, and the introduction of exotic disease agents will satisfy most of the demands of the legislators and their environmental constituents. In return, these activists must accept the fact that aquaculture operations do not create disease agents; these agents originate in wild populations, not aquaculture facilities. Perhaps closed-loop recirculation facilities are the answer, if they can be financially feasible.

As long as aquaculture operations involve public waters and the aquatic animals in them, there will be conflicts between competing users of those waters. I suggest that banning aquaculture by way of regulations is not the way to resolve these conflicts. Best Management Practices on the part of fish farmers and real, evidence-based understanding of environmental issues on the part of environmental activists can resolve the problems. Do these opponents have the will to seek such solutions? We can hope and try to inform both sides.

enetic modification of animals for human consumption is a hotbutton topic for many consumers but a recent innovation from Israel shows promise in accelerating fish growth without resorting to such method.

The innovation, which accelerates growth rate in fish by inhibiting reproduction, was developed by researchers at the Hebrew University of Jerusalem (HUJI) and touted as an “important breakthrough for the aquaculture industry worldwide.”

“The value proposition for fish growers is shorter time to market and reduction of production costs and risks associated with the growth period. The technology provides a non-GM, non-hormonal solution for accelerating fish growth,” said Israelbased AquiNovo, which has the exclusive worldwide license to the technology.

Prof Berta Levavi-Sivan and her team at Hebrew University zeroed into the fact that reproduction is an energy-intensive endeavor that slows down fish growth. She identified neuropeptides — named neurokinin B (NBK) and neurokinin F (NKF) — that are secreted by the brains of fish and play a crucial role in their reproduction, HUJI said.

Levavi-Sivan worked with Prof Chaim Gilon, a world-renowned chemist

The Trendlines Group

Young tilapia fed the inhibitors gained 40% more weight at four months than those that weren’t given the feed supplement

at HUJI, to develop short peptides to make NBK and NKF ineffective. “The molecules inhibited fish reproduction and, consequently, led to increased growth rates. These inhibitors can now be included in fish feed to ensure better growth rates,” HUJI said.

At the time the announcement was made in June, experiments had been conducted on tilapia and salmon. Two months into being fed with inhibitors in their feed, the young tilapia gained 25 percent more weight compared to fish that did not receive the supplement.

With NBK being found in 20 different species of fish, there are indications that the technology could be effective in a wide variety of species.

-Ruby Gonzalez

ermaq will launch in 2018 a new salmon processing facility in Norway with features that will make it the “the most innovative and efficient processing facility for salmon ever created,” according to the company.

Located in Storskjæret, Norway, the facility will be equipped with “intelligent software” from Oslo firm CodeIT AS that will connect and integrate all surrounding machines in the production environment. Cermaq said it will be one of the first in the seafood industry to have this feature.

Cermaq says its new facility will feature game-changing ‘intelligent software’ that integrates all machines in the production environment

Explaining the tangible benefits such software provides to a salmon producer, CodeIT CEO Bjørnar Torsnes said: “A modern salmon facility takes in the fish, evaluates quality, weight, grading etc and during all processes automatically determines which department the fish should go to. Once we introduce truly interconnected intelligence to these processes we can create efficiency at several orders of magnitude higher than was previously capable. For example, calculating the appropriate ice dosing for different geographical locations of shipments.”

Atle Kvist, project leader at Cermaq commented: “We as an industry are being more and more challenged on documentation and traceability, our green footprint is important to all our future planning and this is why we have chosen CodeIT AS to deliver a solution that fits our requirements very well. They specialize in intelligent and flexible software that gives us the control and visibility we need.”

Cermaq expects the 8,000-square meter factory to be finished by the second quarter of 2018.

BY ERICH LUENING

ver the last five years, Pacifico Aquaculture has morphed from a tuna ranching operation to a smallscale striped bass startup to one of the largest farmed fish producers in Mexico, say industry observers in the Latin American country.

Permitted to grow several types of species on their farm site in waters near Ensenada, located on the Baja Peninsula coast, the company has found its niche market in the “true” striped bass (nonhybrid) — Morone saxitallis — for markets in the United States and the Americas, Pacifico executives said.

“Presently we are focusing solely on the commercial production of the striped bass,” Pacifico co-founder Rex Ito told Aquaculture North America (ANA). “The full species list that are permitted to grow in our concession are the striped bass, yellowtail (Hiramasa), white seabass, and Pacific halibut.”

The farm, located 70 miles from the border with the US, is in a prime location for exporting to northern markets, including the Whole Foods Market store chain, Ito explained.

In 2010, Ito and his business partner Eric Pedersen converted the farm and site to a sustainable finfish farm after originally running a bluefin tuna ranch from 2004 until 2009. In 2013, MBAs Omar Alfi and Dan Farag brought an investment plan and management team together to back the project. Alfi is now a partner and the general manager of the company and Farag is a partner and chief financial officer (CFO).

“With their strong financial help and commitment to the concept, plus drawing

from aquaculture and seafood experts that have worked in Latin America, Pacifico has cut learning curves in commercial aquaculture on establishing this new species,” Ito explained.

Supported by their freshwater recirculation system hatchery on the mainland, Pacifico’s farming operation is actually located in waters around Todos Santos Island just eight miles off the coast of Ensenada.

“Broodstock are from our own production, from five separate strains of striped bass grown from fingerlings from different regions in the US, as well as a seventh-generation domesticated true striped-bass,” Ito said.

Three different vintages of striped bass are farmed in 33 cages in waters around the island, according to Pacifico Aquaculture.

The company currently produces nearly 1,000 tons of striped bass annually, and plans to double that total in 2018.

Striped bass has always been a favorite of American consumers for centuries. It was introduced to the Pacific in the late 19th century though the traditional wild fishery is in the Atlantic coastal waters and the Gulf of Mexico. By the 1970s, tight regulations on commercial and sportfishing industries were put in place to protect the wild populations from overfishing.

Striped bass are grown in many aquaculture operations around the United States, according to the National Oceans and Atmospheric Agency (NOAA). In 2005, almost 60 percent of all striped bass sold in the US were farmed. Aquaculture for hybrid striped bass (a cross between white bass and striped bass) began in 1986, and production peaked in the early 2000s.

Canadian project aimed at improving the health and welfare of cultured Atlantic salmon using genomics and other biotechnologies has received funding.

The project, led by Memorial University faculty of science professor Kurt Gamperl and Dr Mark Fast of the University of Prince Edward Island’s Atlantic Veterinary College, will mitigate the impact of climate-related challenges on salmon aquaculture.

Dr Mark Fast, associate professor at UPEI’s Atlantic Veterinary College, is part of the project that aims to improve the health and welfare of cultured Atlantic salmon

The project will focus on the predicted effects of warming coastal waters and improve methods for protecting salmon from pathogens that can lead to diseases, which can have significant negative economic impacts on the industry, said the Memorial University.

As a result of the project, Atlantic Canadian fish farmers will be able to expand their workforce and revenue and have more disease-resistant broodstock as well as new scientific tools to improve fish health.

The total project cost is $4.4 million, with approximately $900,000 of the funding coming from industry and national academic partners, and $500,00 and over $2.9 million respectively from the provincial and federal governments.

The practice of catching juvenile eels from the wild and raising them in farms to adulthood has provided Asian markets with supply of this slippery delicacy, but most eels raised are male, which does not yield enough product to be worthwhile.

An innovation from Nova Scotia, Canada could make this type of eel aquaculture a commercially viable operation by turning male eels into fastergrowing and heavier females.

New aquaculture company NovaEel said it has succeeded in turning glass eels into females, and have them stay female in crowded conditions.

The company, founded by a group of licensed eel fishers and companies from Nova Scotia and Maine, worked with scientists at Dalhousie Medical School to perfect the eel-feminization method.

“We’ve validated a method of feminizing the eels using a form of estrogen known as estradiol, and can confirm this feminization even before the eels develop any visible sexual characteristics,” Dr James Fawcett, a professor in the departments of Pharmacology and Surgery told Dalhousie University’s school paper, Dal News. “Most importantly for human health, we’ve found that the eels’ estradiol levels return to normal in a matter of days, leaving no residue behind in the tissue.”

Eel, or unagi in Japanese, is a delicacy in many Asian countries, especially Japan

NovaEel CEO Paul Smith expects to begin raising eels as early as 2020, assuming all goes well with regulatory approvals

With the main challenge in eel farming now addressed, the next step for NovaEel is to seek FDA and Health Canada approval for the process and the medication, and then move on to practical matters of raising the female eels, said the university.

NovaEel plans to harvest baby eels in the wild and farm in low-impact, landbased production facilities. It expects to begin raising eels as early as 2020, assuming all goes well with regulatory approvals, said Dal News

The company believes the eel-farming industry has the potential to generate $250 million in annual sales for the regional economy.

“Why continue to literally ship our industry’s growth potential to China?” asks “We want to capture the potential value of this industry for the Maritime economy by raising the eels for market here. Thanks to our partners at Dalhousie, we expect to be able to do that.”

Ensuring accountability in the seafood supply chain is a critical aspect of

SeaChoice says it is shifting its focus to reforming unsustainable seafood production rather than ranking seafood products, after it realized that consumer-level promotion is not enough to improve fishing and aquaculture practices “still badly needed.”

The Vancouver-based organization said its new mandate is to reform unsustainable seafood production and become Canada’s leading sustainable seafood watchdog. Its new goals include improving seafood-labeling regulations, eco-certification standards, fisheries and aquaculture management, and making information more transparent throughout the supply chain, it said.

“We’re proud that our retail partners have made great strides in their commitment to sustainable seafood,” Kurtis Hayne of SeaChoice said. “Now we’ll be working towards solutions for persistent challenges that keep sustainable fisheries and aquaculture from further improvement in Canada. Our transition will benefit seafood retailers as well.”

Ewos

rendering facility collects byproducts from over half of aquaculture businesses in

BY LIZA MAYER

hen two million pounds of farmed fish perished in British Columbia because of a toxic algal bloom in 2015, crew from West Coast Reduction Ltd (WCR) moved the volume to the company’s Nanaimo facility. But the work that WCR professionals perform is clearly no ordinary cleanup. It is a delicate job involving microbes and pathogens from dead animals that could seep into the environment if not handled well.

“We have all the logistics and a Canadian Food Inspection Agency (CFIA)-certified facility in place that we can take those volumes, render them, sterilize them and make a value-added product, with no fear of getting those pathogens out in the open. It is similar to the services we provide to the livestock processing industries,” Ridley Bestwick, WCR’s chief financial officer, tells Aquaculture North America (ANA).

The vital work that rendering facilities such as WCR perform often goes unnoticed, but their services are critical to helping sustain the agriculture/aquaculture industry, the food services sector, and the environment.

WCR is Western Canada’s largest independent rendering facility. It recycles about 450,000 tonnes of food byproducts, including beef, pork, poultry and fish, in Western Canada annually. Of this volume, aquaculture

byproducts — heads, fins, tails and guts — account for between 5,000 to 10,000 tonnes a year.

Marine Harvest Canada (MHC) accounts for a large part of WCR’s aquaculture volume along with Brown’s Bay Packing Company, which is its longest standing aquaculture supplier. WCR also services Cermaq and others on the BC coast. MHC produces three to four trailers of fish waste from its Port Hardy processing plant each week and that waste is trucked down to WCR’s Vancouver plant daily or every second day, depending on the volume.

Bestwick tells ANA that rendering is a lower-cost solution for fish farmers and processors dealing with aquaculture byproducts than industrial composting, and also a more environment-friendly option.

“Our plant here in the Port of Vancouver takes the equivalent of 150,000 cars off the road each year in

green-house gas reduction. In BC, there is no enclosed composting facility where the gases from composting are captured, so those materials, if they went to compost, would create gases. Composting facilities have a negative carbon footprint, we have a positive carbon footprint,” he says.

Rendering is also “the best way to clean the product,” adds Doug Davidson, WCR’s operations manager. “Animal byproducts are cooked at high temperature during rendering so microbes and pathogens, or any viral-type issues, are sterilized in the process,” he says.

Bestwick and Davidson see aquaculture’s share in WCR’s business growing alongside aquaculture. Today, the company provides collection services to 50-60 percent of aquaculture businesses in British Columbia.

The supply of fresh raw product and how quickly it is rendered is crucial in producing quality fish oils and

Operations manager Doug Davidson shows fishmeal from a box of samples. Customers can buy the fishmeal in bulk, in one-metric tonne bags or 25kg paper bags

protein meals. “For some of the businesses that are far away and have small volumes of byproducts, composting is the closest and easiest fix because WCR can’t collect those volumes fresh enough to get to rendering,” says Davidson.

He explains that fish byproducts produce fishmeal with a protein content of between 64 to 70 percent, and the fresher byproducts are when rendered, the more of that protein is retained. “So if something is left for two days (because of travel time) before it is rendered, it will lose 1 or 2 percent of those proteins.”

But Davidson sees the share of those small farms in WCR’s business growing as the aquaculture industry grows. “As their business and volumes grow, our service to them becomes more economical,” he says.

Bestwick adds: “We are supporting the biggest players of aquaculture and we hope to support the small players as well. In the near future we hope to provide options to supply the service to the more remote locations.”

WCR not only serves the industry in terms of helping dispose its byproducts but also in recycling that waste into valuable feed ingredients.

The aquaculture industry is the company’s biggest customer for proteins produced from rendering poultry byproducts. “We sell our finished products to the likes of Skretting and EWOS, who blend those proteins into feeds,” says Bestwick.

The biggest customer for the fish meals produced out of rendered fish waste is the pet food industry.

Since the company’s start in 1964, Bestwick says the rendering industry has become more regulated, customers’ demands have become more specialized, and competition for animal byproducts has increased because of the growing movement toward composting and other green energy initiatives.

“In the last 50 years, scrutiny over the process and products in our industry has increased; biosecurity and food safety have become top priorities,” says Bestwick, who noted that CFIA audits and issues industry permits.

Davidson says the basics of rendering have also become much more refined

over the years; centrifuge technology and polishing are now the norm, along with raw materials segregation to produce higher quality ingredients. “When I started in 1978, everything was boiled in one pot,” he recalls. Clearly, specialization helps answer the customers’ increasing demand for single-ingredient feed ingredients.

Over the last 10 years, Bestwick says the company has seen its supply of raw materials decline because they are being diverted into other recycling initiatives— for example, composting and biogas — that he believes is not as sustainable as rendering. The organic landfill ban in Greater Vancouver has also contributed to the decline in the supply of byproducts for rendering, he says.

“Organics (food scraps) cannot go into landfill anymore in Greater Vancouver. We don’t render green vegetable material — it’s better for that to go to composting or biogas or landfill — but the organic landfill ban created an opportunity for waste haulers to also take fish and meat material from our suppliers. I would say we’ve seen a 5- to 10-percent drop in volumes of byproducts that we pick up from butchers and supermarkets,” he adds.

Bestwick acknowledges that while disposing waste via composting is well intentioned, he says rendering is the most sustainable solution for recycling meat and fish byproducts. “Compared to composting, rendering reduces greenhouse gas emissions by 90 percent and adds five times more value to the local economy,” says Bestwickhe.

He regrets that this fact is lost on most consumers because “the fact is, in past years we did not market what we were doing,” he says. But now, the company is increasing its visibility in the media and the community to promote a better understanding of the company’s work.

“We are communicating our role, we meet with government officials, we go to conferences and trade shows, we advertise, sponsor events, communicate with the media, talk to consumers and regulators. We get the message out about the contribution we make to the sustainability of aquaculture and agriculture.”

In 2016, the BC Food Producers Association awarded WCR with the Sustainability Award, a proof that finally, the company is succeeding in getting the word out, and its contribution to the environment, economy and people of BC is recognized.

quaponics’ green credentials and sustainability is attracting Winconsin’s young generation into farming, says Chris Hartleb, professor of Fisheries Biology at the University of Wisconsin-Stevens Point (UWSP).

Hartleb, who follows the state’s aquaculture industry, says an influx of newer, younger fish farm owners and the rapid rise of aquaponic farms is spurring industry growth. “Generally, the growth of Wisconsin’s aquaculture industry has been stagnant for the past 10 years with as many new businesses opening as others closing,” he tells Aquaculture North America (ANA)

He says younger people are especially intrigued by aquaponics’ sustainability as a method for food production; the concept of raising both a protein and vegetable crop together; and the farm-to-table concept. “Growers and consumers alike want to know where their food is coming from and to be able to purchase fresh produce right around the corner,” says Hartleb.

The steady rise in the number of students enrolled in University of Wisconsin-Stevens Point’s aquaculture and aquaponic programs points to the trend that more people are interested in sustainable and locally grown food. For UWSP aquaponic courses, the school says over 320 undergraduates and 17 graduates have taken the courses since their inception in 2012. In collaboration with aquaponics industry leader Nelson and Pade Inc, the Aquaponics Master Class has now educated over 1,400 students from over 101 countries and all 50 states since the course began in 1997.

Hartleb sees the state’s aquaculture industry growing further with the signing of the “Fishing for Our Future Act” by Wisconsin Governor Scott Walker on June 23, 2017. “It helps relax some of the burdensome regulations and squarely puts Wisconsin aquaculture in the category of agriculture. So now Wisconsin fish farms are not at a competitive disadvantage to neighbouring states,” says Hartleb.

— Liza Mayer

UWSP students take a break for a photo op. An influx of newer, younger fish farm owners and the rapid rise of aquaponic farms is spurring the growth of Wisconsin’s aquaculture industry

he Canadian province of Prince Edward Island has for the first time secured the services of a provincial veterinarian.

Dr Carolyn Sanford is focused initially on establishing and utilizing the Certificate of Health for Transfer, a policy developed with all the Atlantic Provinces in order to enact consistent disease surveillance and general fish health management.

“That’s been the biggest part of my aquaculture role to date, working on this policy and actually seeing it through to implementation,” says Dr Sanford. While her work will revolve around the transfer policy initially, finding avenues for her to work in other aspects of the aquaculture industry is in the scope of the long term plan.

“I think it’s going to streamline some of our moving processes for export. To have one main person who’s speaking with the other provincial vets, it’s a win-win,” says Shawna Taylor, site manager with Ocean Trout Farms.

Matt Sullivan, executive director of the PEI Aquaculture Alliance, added: “It’s something that the other provinces have and it’s something PEI didn’t until now. Its great that the province is able to provide that investment to help industry here.”

Interest in sea urchin aquaculture is trending up but an expert suggests caution because the venture could prove very expensive and “tricky.”

Robert Steneck, who at one time also served as a scientific advisor on Maine’s Sea Urchin Zone Council, says while the technology exists to farm sea urchins, it’s hard to find a balance between the volumes required to make a profit and the need to give the animals the space they must have to stay healthy and keep oxygen levels in the tanks from falling, reported CBC News

“They’ll have to be very clever to figure out a way to do it and to be able to sustain the operation, especially a land-based operation. Those are always expensive,” Steneck, was quoted as saying.

He says there have been five attempts to create sea urchin aquaculture industries in Maine and not one, so far, has been sustainable.

• Alloyed polyethylene

• UV stabilized

• Resist puncture and tears for a more secure system

• Lightweight and easy to handle

• Cold crack tested to -60°F for continuous performance

• Custom engineered fabrication and sizes up to an acre

WMT’s Gas Management Tower (GMT) o ers degassing, aeration, and oxygen/ozone injection in a compact integrated design.

GMT Bene ts Include:

Multiple water treatment processes in a single, compact footprint.

Fiberglass construction for fresh or saltwater use. Sectional bolt together design for cost e ective shipping and ease of installation.

Accessible internals to permit cleaning and maintenance.

State’s farmed oyster market is relatively new and smaller than other states, but growing

etbacks did not slow Alabama’s oyster aquaculture industry as it continued to flourish despite the segment’s challenges in 2016. A report that tracked the segment is forecasting continued growth this year.

The state’s farmed oyster market is relatively new and smaller than other states, but is growing. Last year production from Alabama oyster aquaculture operations totalled 2.7 million oysters and sold for a reported value of $2.7 million.

“In 2017, Alabama oyster aquaculture likely will grow in number of operations and permitted acres for farming. Additionally, there is growing interest in commercial aquaculture under existing piers, which has an easier permitting process,” said the study Alabama Shellfish Aquaculture Situation and Outlook Report: Production Year 2016.

Oyster parks in Alabama use both floating and Australian long line systems. In 2016, Alabama oyster farmers produced and sold 2.7 million oysters in the half-shell market

Indications that the segment continues to thrive despite challenges are two new oyster farms that have begun operations, two new oyster parks in development — Grand Bay Oyster Park and Bayou Sullivan Oyster Park — and a strong demand for seeds and eyed larvae.

The Grand Bay Oyster Park has over 40 acres available for off-bottom oyster farming and is managed by Alma Bryant High School. The Bayou Sullivan

Oyster Park will have 20 acres available for commercial off-bottom aquaculture with some additional area to be used for research by the Auburn University Shellfish Laboratory.

The uptick in the number of students enrolled in Auburn University’s third Oyster Farming Fundamentals class also points to the segment’s growth. The course provides training in all aspects of starting and operating an oyster farm.

Further pointing to the brighter outlook is the increase in the volume of orders for seeds and eyed larvae. The Auburn University Shellfish Lab alone

reported sales of 13 million seeds and 4 million eyed larvae in 2016, while three hatcheries reported combined sales of approximately 8 million seed and 6.2 million eyed larvae. Eleven of the 14 oyster aquaculture operations certified by the Alabama Department of Public Health participated anonymously in the study last year. They said the prolonged closures of oyster farms due to harmful algal blooms and rainfall, larval production problems that impacted seed supply, and farms experiencing a higherthan-normal summer mortality rate in the grow-out crop affected the industry’s profitability and sustainability. They also said the non-renewal by the landowners of the lease for the Auburn University oyster park in Portersville Bay at the mouth of West Fowl River also had an impact.

The report was prepared by Russell Grice and Bill Walton, both of the Mississippi-Alabama Sea Grant Consortium, the Alabama Cooperative Extension System, and the Auburn University Marine Extension and Research Center.

“We are planning to do this every year to help the industry and resource managers understand the changes in the industry and its importance to our coastal communities,” Grice said.

Walton added the segment’s resilience is “really a tribute to the hard work of the men and women who are working these oyster farms that they weathered the challenges of 2016 and are pushing forward to increase Alabama’s production.”

— Ruby Gonzalez

British Columbia’s new geoduck management framework seeks to develop new aquaculture operations while maintaining an active wild harvest

isheries and Oceans Canada (DFO) has finalized its Integrated Geoduck Management Framework, which provides guidance on developing new geoduck aquaculture sites along the BC coastline. Though it has taken over 10 years to develop, industry groups feel that it will help advance BC’s geoduck aquaculture industry.

“It is a promising start,” says Darlene Winterburn, executive director of the BC Shellfish Growers Association. “The framework is a means to grow aquaculture and there is opportunity within the guidelines.”

DFO describes wild geoduck harvesting as a “prosperous and environmentally sustainable fishery.”

The Underwater Harvesters Association (UHA) says it sees roughly $8-$12 (C$10-$15) per pound at the boat. Quotas are restricted to less than 2 percent of the observed geoduck biomass on a bed-by-bed basis. The clams are harvested by directing a high-powered water nozzle, called “stinger,” into the substrate to uncover the geoduck and harvest it alive.

BC growers, and particularly First Nations groups, are interested in expanding aquaculture opportunities.

“It’s positive we can now expand outside of the Strait of Georgia,” says Richard Harry, executive director of the Aboriginal Aquaculture Association (AAA). “The waters between Vancouver Island and the mainland of British Columbia were previously the only areas where geoduck aquaculture tenures were granted.”

“Geoduck aquaculture really fits with traditional First Nations values,” adds Harry. “It’s just a big clam. We have been tending clam gardens on our traditional territories for thousands of years.”

The challenge of managing geoduck fishery and aquaculture together is how to develop new culture sites,

BC’s geoduck aquaculture production in 2016 was around 35 tonnes, valued at roughly $588,000 (C$738,593), according to Fisheries and Oceans Canada

while maintaining access to current wild harvest beds.

DFO has divided the province’s coast into three zones: “red” zones are locations where there have been active commercial geoduck landings each year for the last four years. “Yellow” zones have seen a wild harvest one to three times in the last four years, and “green” zones are not part of the current wild harvest.

Red areas will remain wild harvest sites and will not be open to aquaculture, except for small 10-hectare applications by First Nations grower companies. The First Nations can only apply for red-zone tenure on a site directly adjacent to reserve lands. They must actively farm the tenure and the license will be non-transferrable.

“There are opportunities here to move forward,” says Harry. “We are not happy with the 10-hectare size, but that’s what we are dealing with now. We will be discussing this further with DFO.”

Applications for new tenures will be accepted in yellow zones with a pre-harvest allocated to the wild fishery.

Prior to the licensee occupying the site, the UHA may harvest 20 percent of the assessed wild biomass. A similar pre-harvest condition applies to the new First Nations tenures within red zones. Remaining stock is owned by the licensee and is considered by-catch to the aquaculture operation. The rest of the province is considered “green” and applications are unrestricted.

Daniel Rabu, a business and technical expert with the AAA, encourages growers to look for new sites. “I don’t think folks should just be looking at those red and yellow zones,” says Rabu. “They should be looking for ground that is suitable based on mapping, local knowledge and historical harvest. They should be putting divers in the water and checking the substrate, its depth, how it is for digging and how they can place predator protection.”

“It is a promising start. The framework is a means to grow aquaculture and there is opportunity within the guidelines.”

Darlene

Winterburn, Executive Director, BC Shellfish Growers Association

And while DFO currently has a seven-year wait time from seed until harvest, growers hope to access stock earlier to provide working capital for their business and “cocktail ducks,” a smaller product, which has received good market feedback. “We’re seeing a 25-percent higher value for farmed product due to its uniform consistency, size and color,” says Rabu. —

Tom Walker

Arecent court decision to subject Grieg Seafood’s massive salmon aquaculture project in Canada to an environmental assessment will not jeopardize the project, said the company.

The planned aquaculture project in Placentia Bay in the province of Newfoundland will feature a large landbased facility for smolt and small salmon (post-smolt) up to 1.5 kg, and 11 sea sites for production of up to 30,000 tons of harvested salmon.

On July 21 a judge has ordered a full environmental impact statement (EIS) for the project, overturning an earlier decision by then-environment minister Perry Trimper to free it from such assessment. The Atlantic Salmon Federation (ASF) went to court seeking a judicial review of the decision, and won.

“The minister lacked jurisdiction to release the project,” Butler wrote in her decision. “The only possible conclusion he could reach from the Record was that the Project had both ‘significant public concerns’ and the potential for ‘significant negative environmental effects.’”

But Grieg says in a statement on July 23 that it understands that the Province is “contesting the verdict strongly, and will most probably appeal the court ruling.” The company added that it considers the court ruling to be of “low risk to our project, and will continue business as usual.”

Grieg added that it got an assurance from “both Federal and Provincial governments that our project has strong public support and public interest by creating jobs and supporting substantial value creation on the Burin peninsula, and that they see no change to their support for the project.”

The Van Gaalen Fish Egg Sorter uses the most current technology to bring you an egg sorter that offers: variable egg sizes, speed, accuracy, egg counts, safety and versatility.

VMG Industries Inc.

2972 Bellmeade Way Longmont, CO 80503 USA

T: 303.682.8890 F: 303.682.8892 www.vmgindustries.com

Globally Trusted UV Experience

Proven bio-security; over 35 years, 380 installations, more than 740 million gallons per day

Lifetime Disinfection Performance Guarantee Aquafine Genuine parts program provides this peace of mind

Long-term Industry Commitment

Collaboratively advancing UV research in aquaculture

aquafineuv.com

The purple-hinged rock scallop (Crassadoma gigantean) could be a viable species for aquaculture but the industry hasn’t caught on because of some drawbacks.

The Pacific Shellfish Institute (PSI) said one “unresolved issue” in the way of rock-scallop aquaculture is the species’ tendency to ingest and retain toxins that can cause poisoning in humans. The lack of information on the rock scallops’ biotoxin and detoxification is considered as a drawback.

“The native purple-hinged rock scallop shows promise for aquaculture production, yet information on scallop biotoxin retention and detoxification is lacking. This is critical because toxins associated with potentially deadly paralytic shellfish poisoning (PSP) are widely reported in bivalves along the North American west coast,” said the Washington Sea Grant (WSG), which funded an ongoing project by PSI.

The project will examine the commonly occurring dinoflagellate, Alexandrium catenella, which is a cause of red tide. The study will also determine the microorganism’s potential impacts on efforts to farm the species.

The Washington State-based organization said results of the research will directly support production of rock scallop by facilitating public health certification to allow sales in domestic and international markets. It will also enable public health labs in Washington and Alaska to evaluate the most appropriate biotoxin detection methods for this species, it added.

• Scallop aquaculture could exist from Baja California to southeastern Alaska due to the native species expansive range

• Rock scallops grow rapidly in the first several years, achieving market size in two-four years

• Live rock scallops have high market value, priced $5$8/lb in California, and a potentially high value in the sushi market

• Scallop farming has the potential to provide significant employment opportunities

• Scallop farming has the potential to produce a highquality shellfish product for both domestic and export markets

Source: Pacific Shellfish Institute

• Our tanks are available in many colors, shapes and sizes from 25 to 3000 gallons

• Smooth inside surfaces prevent damage to your fish

• Edge lips provide wall strength & minimize deformation

• Custom installation of optional drain fittings • FDA and UV sterilized

We also offer Vertical Storage , Horizontal, Cone bottom, and General Purpose tanks- see our website for details.

The maker of AlgaPrime DHA has filed for bankruptcy

Algae nutrient producer TerraVia (NASDAQ: TVIA) filed for bankruptcy on August 1 and announced that it has made a “stalking horse” stock and asset purchase agreement with Dutch food ingredients company Corbion N.V. to acquire substantially all of TerraVia’s assets in a sale process.

TerraVia, whose AlgaPrime DHA is starting to get noticed in the aquaculture market, asked its lenders in June to allow it to delay debt payments while it seeks “strategic alternatives” that will chart its future course.

The bankruptcy filing and the sale process “should have no material impact on TerraVia’s ability to fulfill its obligations to its customers and employees going forward,” it said.

AquaBounty Technologies says it has entered into a deal to acquire the operator of Indiana’s largest recirculating aquaculture systems (RAS), and plans to use the facility to grow its genetically modified (GM) salmon.

The company acquired Bell Fish Company, located in Albany, Indiana for $14 million in cash. It will be AquaBounty’s first commercial-scale facility in the US for growing GM AquAdvantage salmon.

“This site will enable production of healthy Atlantic salmon, which will not require vaccines or antibiotics, in a sustainable and responsible manner close to domestic consumers,” said AquaBounty CEO Ronald Stotish.

The facility’s first harvest is expected to come as soon as the third quarter of 2019, if anticipated timelines are achieved, the company said. This is significantly faster than other land-based facilities due to the quicker time to market for AquAdvantage Salmon, it added.

AquaBounty says it will grow its genetically modified salmon in a facility in Indiana it is acquiring

Credit: Alexi Hobbs/AquaBounty

Once fully operational, the current facility will have an expected annual capacity of 1,200 metric tons, which at current Atlantic salmon prices represents over $10 million a year in potential sales, with the possibility for future expansion.

AquaBounty added that it continues to evaluate additional opportunities for larger production facilities in both the United States and Canada.

Meanwhile, the company announced that it posted net loss of $2.1 million in the second quarter, similar to Q1 2017. The company did not explain the losses.

A former banker in Florida has embarked on an aquaculture project with a target of producing 10,000 pounds of farm-raised pompano per month by next year.

Entrepreneur Joe Cardenas started Aquaco Farms in 2015 at the Florida Atlantic University (FAU) Tech Runway, a public-private partnership that helps incubate startups.

“Aquaco Farms is designed to be one of the largest saltwater grow-out facilities in Florida and will provide a sustainable, highly sought after commodity in the seafood industry. An industry where consumers are demanding a change in the way seafood is sourced and purchased today,” said the company on its website.