14

TREENA HEIN

by Brett Ruffell

14

TREENA HEIN

by Brett Ruffell

Poultry groups have called it a giveaway, failure and deeply concerning. The reviews are in for the latest version of the Trans-Pacific Partnership (TPP) trade agreement. They aren’t good.

President Donald Trump pulled the U.S. out of the deal shortly after taking office. When that happened, Canadian poultry leaders hoped negotiators would rescind concessions granting countries increased access to Canada’s supply managed sectors.

After all, they were only put in place to appease our neighbours to the south in hopes of some reciprocal benefit. “That was negotiated almost solely at the behest of the U.S.,” says Bruce Muirhead, research chair in public policy at the University of Waterloo.

To the poultry industry’s dismay, when the remaining 11 countries announced in late January that they’d reached an agreement in principle on the newly named Comprehensive and Progressive Trans-Pacific Partnership (CPTPP) trade pact, the concessions were still intact.

Making things worse, Canada’s poultry sectors got nothing new in return. Organizations were quick to slam the agreement. “We believe this deal will harm the turkey sector,” Turkey Farmers of Canada (TFC) chair Mark Davies says. “There was no need to maintain the market access levels of

the original TPP.”

On the turkey side, TFC says the agreement will result in $270 million in lost cash receipts for producers over the next 19 years and a farm output loss of at least 4.5 per cent. It foresees total economic activity losses in the order of $111 million per year occurring through the value-chain as a result of CPTPP.

From what he’s heard about partner countries’ interests, Muirhead says turkey producers are right to be concerned. “The Chileans are salivating at the possibility of shipping turkey breasts to Canada,” he says. “So their market share

“There was no need to maintain the market access levels of the original TPP.”

will absolutely be eroded,” he continues, noting that the Canadian turkey market is already stagnant.

On the other hand, Muirhead is unsure about the trade pact’s impact on Canada’s table egg sector. “The market would’ve been a lucrative one for U.S. producers,” he notes.

“But I’m not entirely sure who’s going to supply that market share for eggs now.”

One possibility he suggests is that some countries might supply industrial egg products or dried eggs.

But Egg Farmers of Canada

(EFC) expects the trade deal to take its toll. It says Canadian egg farmers will lose the right to produce close to 291 million dozen eggs when the pact is implemented. That will be followed by an additional 19 million dozen eggs added each year. The deal represents close to $1 billion in lost farm family income, according to EFC.

With so much at stake, poultry groups are urging the government to expedite work on measures to mitigate the impacts of the deal.

The feds previously announced several support programs aimed at offsetting the concessions made in signing the original TPP pact.

Perhaps most importantly, poultry leaders say Canada must stand firm during other trade discussions – namely, ongoing NAFTA talks.

“If the U.S. wants access to our market, for example, they are welcome to rejoin the CPTPP,” states Benoît Fontaine, Chicken Farmers of Canada chair.

President Trump shows no signs of wanting to rejoin that fold. And with U.S. negotiators openly seeking to dismantle Canada’s supply management system, Muirhead believes the Americans will at a minimum demand a significant increase in market access in any new NAFTA agreement.

The trade expert forsees the U.S. seeking at least the same new market share Canada gave up for CPTPP.

With so much uncertainty, one thing’s for certain – interesting times lay ahead.

canadianpoultrymag.com

Editor Brett Ruffell bruffell@annexweb.com 226-971-2133

Associate Editor Jennifer Paige jpaige@annexweb.com 416-305-4840

National Account Manager Catherine Connolly cconnolly@annexweb.com 888-599-2228 ext 231 Cell: 289-921-6520

Account Coordinator

Alice Chen achen@annexweb.com 416-510-5217

Media Designer Alison Keba

Circulation Manager

Anita Madden amadden@annexbusinessmedia.com 416-442-5600 ext 3596

VP Production/Group Publisher Diane Kleer dkleer@annexbusinessmedia.com

COO

Ted Markle - tmarkle@annexbusinessmedia.com

President/CEO Mike Fredericks

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Circulation

email: rthava@annexbusinessmedia.com

Tel: 416-442-5600 ext 3555 Fax: 416-510-6875 or 416-442-2191 Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Subscription Rates

Canada – 1 Year $32.00 (plus applicable taxes)

USA – 1 Year $69.00 USD Foreign – 1 Year $78.00 USD

GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2018 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Perch system on plastic slats

Perch system on wire mesh

Easy to install on new systems or retrofit in cages

LUBING’s Comfort Perch System is a unique product that offers noticeable results. Our Perch System is ergonomically designed to offer the most pad contact and comfort to the birds while perching. The mushroom perch design fits the contour of the birds’ paws and allows the birds to grip the perch without working to keep their balance as they do on round perches. This design has been proven to significantly reduce bird stress and result in higher production with lower mortality.

Our Comfort Perch Systems can be installed on plastic slats or wire mesh and can also be easily retrofitted onto any existing system. Installation is simple and does not require the use of nuts, bolts, rings or clips.

Contact us to find out more about this product. Free samples are available upon request.

The Business Development Centre at the University of Guelph Ridgetown Campus is offering up a suite of free agri-food online courses through the Agriculture and Food Education website. Industry members can log on to agandfoodeducation.ca and gain skills and knowledge in farm business practices. Curriculum topics include: food safety foundations; traceability; recall; sanitation; personnel; water use; worker practices; maximizing your traceability investment; profiting from traceability; and growing your profits.

In a new initiative, the College of Veterinarians of Ontario (CVO) is launching a new public advisory panel. The college is currently seeking applications from members of the non-veterinary public to fill 10 positions on a panel. CVO says this is an opportunity for those who own animals or are involved in the animal sector to contribute to the development of veterinary policy and support the College’s mandate in serving the public interest in Ontario. For more information, visit: http://cvo.informz. ca/z/cjUucD9taT05MjY0MzEmcD0xJnU9OTIwODc2MDkxJmxpPTEwMDY4NzIz/index.html

Canadian Poultry magazine’s Who’s Who issue is released every July with the goal of shining a light on stand-out members of the Canadian poultry industry. The theme for the 2018 Who’s Who issue is up-and-comers and we want your help in finding the best candidates. Nominate rising stars today to potentially have them recognized in our Who’s Who issue. For details, visit: canadianpoultrymag.com/whoswho

30,678 poultry, meat and feed industry leaders from all over the world attended IPPE 2018

America represented the largest international region at IPPE with 2,759 visitors

The International Production & Processing Expo (IPPE) recently showed off an impressive event with representation from the entire chain of protein production and processing. The event’s trade show was focused on innovation – bringing together buyers and sellers of the latest technology of products and services to make your business successful. As well as education – learning from the experts in free- and fee-based world-class programs on topics that cross industry interests.

IPPE 2018 was held in Atlanta, Ga. on Jan. 30 to Feb. 2, and had 30,678 poultry, meat and feed industry leaders from all over the world in attendance. A total of 1,218 exhibitors showcased the latest technology on more than 521,000 square feet of exhibit space. The Expo is the world’s largest annual feed, meat and poultry industry event of its kind and is one of the 30 largest trade shows in the U.S.

“The turnout for the 2018 IPPE was excellent. With three halls and more networking opportunities, we expect the 2019 IPPE to provide economic value for attendees and exhibitors alike,” said a representative from the event sponsor, the American Feed Industry Association.

There were 7,093 international visitors from 124 countries in attendance.

Canada represented the largest group from a single country outside the U.S. with 1,132 visitors. Latin America represented the largest region with 2,759 visitors.

This year’s educational line-up featured 140-plus hours of sessions, ranging from a conference on preventing and responding to foreign material contamination incidents, to a program on feed production education, to a program on biosecurity for poultry and egg producers and live operations.

poultry-related news, stories, blogs and analysis from across Canada.

Tim Nelson is CEO of the Livestock Research Innovation Corporation. Throughout his career, Nelson has developed many ag-related businesses and initiatives and won awards from around the globe. His biosecurity technology platform Be Seen, Be Safe was recognized for novel use of geospatial technologies from the South Australian government. We asked him five questions.

Tell us about yourself

Except for being a fencing contractor, which was my first business in Australia, I’ve always worked directly with farmers and with farmer-owned organizations to develop new things to benefit them. I am a business developer at heart. Rather than managing something, I prefer to take something that’s in trouble or new and build it up, or to take an idea and make it a reality.

Why does the challenge of business development excite you? It’s creative. If you actually manage to create something or take it to a new level, it’s very exciting. Growing a business by increasing efficiencies and productivity is one thing, but the energy that is generated from the ideas and enthusiasm of people doing something new and exciting together that is potentially game changing is a real buzz.

How did the ideas for Be Seen, Be Safe and Farm Health Monitor come about?

Be Seen Be Safe fills a huge gap in livestock disease outbreak management that we’ve tried to fill with paper visitor logs, but we’re always playing catch-up with those. So, the idea was to

find a system that provides real-time monitoring and warnings. Farm Health Monitor bridges another gap in the time taken between observing clinical signs of disease and getting a confirmed diagnosis. This takes time during which the disease (serious or otherwise) gets a hold and spreads. Both platforms are about speeding up reaction time, observe-and-prevent instead of diagnose-and-treat. It’s becoming more important with the reduction in the use of antimicrobials.

What are your future plans?

We’ve planted some seeds in the animal health and welfare protection space that are starting to grow. I also want to see Hypereye (the hyperspectral imaging process for determining gender and fertility of eggs developed by Egg Farmers of Ontario) really take off. I also want to ensure that the livestock protein industry is ready for the challenges ahead of it from alternative protein products. Livestock is an essential element in good land stewardship but we don’t sell that point – we should and must. I would like to help to ensure that we protect our livestock farming heritage here in Ontario and elsewhere in any way I can. There’s always plenty to do!

Any interesting hobbies? How do you unwind?

Our hostel in Newfoundland is my hobby. I enjoy building, renovating and working with my hands. My wife Sioban and I like to hike when we get the chance. I also have grandparent responsibilities now. My real hobby is what I do for a living – it’s great fun. I’m very lucky to do what I do.

APRIL 2018

APRIL 4 - 5

National Poultry Show (Formerly London Poultry Show), London, Ont. westernfairdistrict.com poultryindustrycouncil.ca

APRIL 8 - 10

IEC Business Conference, London, England internationalegg.com

APRIL 12

PIC Ag Lenders Day, Guelph, Ont. poultryindustrycouncil.ca

APRIL 16 - 18

Western Poultry Disease Conference, Salt Lake City, Utah cevs.ucdavis.edu/confreg

MAY 2018

MAY 2

PIC Research Day, Stratford, Ont. poultryindustrycouncil.ca

MAY 15

WestVet

Abbotsford, B.C. westvet.com

MAY 16

B.C. Poultry Symposium, Abbotsford, B.C. bcpoultrysymposium.com

PIC Human Resource Day

Guelph, Ont. poultryindustrycouncil.ca

JUNE 2018

JUNE 20

PIC Health Day

Stratford, Ont. poultryindustrycouncil.ca

Throughout the winter months a number of industry members have taken the time to share their stories through community events. Late last year the Saskatchewan Egg Producers took part in the interactive portion of the Canadian Western Agribition held in Regina, Sask., in November.

For the second year in a row the attending Saskatchewan Egg Producers displayed an enriched housing system, which was donated by Hellman Poultry Equipment.

“We of course have producers in each type of housing system and our board supports whatever approved system a producer uses,” says Cam Broten, executive director of the Saskatchewan Egg Producers.

“We chose to showcase the enriched system because it is an effective way to communicate with the public about advancements being made in housing systems.”

Over the course of the week-long event a number of volunteer farmers manned the booth, discussing the process of egg farming and bird care to attendees.

“Our farmers took the time to point out the features of the enriched system and the visitors were genuinely impressed. The response was overwhelmingly positive,” Broten says.

Along with a number of well-established local farmers like Peter Kleinsasser and Philip Wipf of Springfield Farming Company, Stan Fehr of Hague, Sask., and Ben Entz of Huron Colony, the organization also involved a number of next generations farmers including Tyler Wiens of Hague, Sask.

Wiens is a participant in the Egg Farmers of Canada’s (EFC) Young Farmer Program. The organization founded the young farmer program as an opportunity to bring together young farmers to learn and exchange knowledge, experience and expertise.

The volunteer farmers shared their stories with thousands of local school-aged children, as well as a number of international guests, as the Canadian Western Agribition is an international hub, hosting over 1,200 international guests from over 75 countries.

Sarget Farms is investing $10 million to retrofit its halal chicken processing facility in Milton, Ont. The upgrade project is scheduled to begin this spring. It will be carried out over three years with the plant continuing to operate through the upgrades. The plant’s physical footprint will remain the same with all the changes occurring on the interior. All processing equipment being replaced with the latest technology.

Enterra Feed Corporation has received new approvals to sell its insect-based feed ingredients in the U.S., Canada and the European Union. Enterra received approval from the Canadian Food Inspection Agency to sell Enterra whole dried larvae in Canada as a feed ingredient for tilapia and poultry, including chickens, ducks, geese and turkey. This builds on previous approvals for the same product in salmon feed in 2017 and broiler chicken feed in 2016.

In June 2018, five agricultural leaders will be inducted into Ontario Agricultural Hall of Fame including the late William Beaty, who was responsible for creating thousands of jobs in Ontario and innovating in the fields of product development, poultry and swine genetics and production quality. Beaty was involved with many agricultural organizations including the Ontario Federation of Agriculture, Ontario Poultry Council, Poultry Industry Conference and Exhibition, Ontario Egg Producers’ Marketing Board and others.

By Crystal Mackay

Irecently went back to school to join an ethical food choice discussion at a high school in our nation’s capital. Although it jarred me on some levels, it inspired me on many more. I’m sharing this experience as just one example of thousands like it that are happening online, in boardrooms and conversations about food across Canada every single day.

A representative from The Ethical Choices Program had been in the school for two days to speak with science classes with the mandate to “educate students about the impact of their food choices, inspiring them to make decisions that are consistent with their own values as related to human health, the environment and animals.” The presentations emphasized impacts on the environment and included disturbing videos of farm animal abuse.

One teacher felt that her students needed some answers from someone with a practical, Canadian farm perspective. I have spoken about the need to join these conversations about food for years as a base for earning trust – how could I say no? So I prepared to speak to the most daunting group – a room full of upset teenagers.

My goal was to put the Canadian Centre for Food Integrity (CCFI) public trust research insights into action. Could I connect with these students with shared values?

Walking the walk, I aimed to hear their concerns first. I went in for a conversation on food, not a lecture, with intentionally no PowerPoint or videos.

I only spoke for about five minutes upfront to introduce myself and my purpose, which was to address their concerns and help equip them to make informed food choices. I told them briefly about my farm experience, animal science education and unique work experience with all types of farmers and food system partners across Canada.

Secondly, I shared the concept of the spectrum of opinions – some people are extremely against, others extremely for and most Canadians are in the middle. It sounded like the presentations they watched focused on one end of the spectrum. I was there to genuinely answer any question they had that I could, with the offer to find out more.

A bright young lady started the discussion by asking, “Is it true that if we all became vegetarians we would have enough food to feed the world?” I disagreed, providing a simple principle and visual to explain why.

Approximately two-thirds of the world’s farmland can only support grazing animals – it’s unsuitable for growing crops. Thus, if we stopped using it for livestock we’d be feeding far fewer people.

The next young gentleman wanted to know exactly how animals are killed in processing plants. He also asked about specific things he saw in the videos on farms that didn’t seem right and about male layer chicks. These are all sensitive topics that we need to approach with care, acknowledging where improvements have been made and promising more to come.

After a few more specific questions, they started

inquiring about my personal experiences. One student asked about the toughest time I ever had working with farmers. I chose to share a bit about an awful incident when a farmer who was dealing with several issues left many animals to die. It was horrible for the animals and heart wrenching for people.

The farm community stepped up to help and created the Farm Animal Care Helpline in Ontario. While it was upsetting, the silver lining of this story is the students could see a real-life example of how farmers care for animals and take real action to do so. They then asked about my funniest experiences. We connected.

This led to good discussion with a very engaged teacher about the need to acknowledge problems and work together on solutions. The students were clearly looking for actions – what could they do to help the environment, the animals and our food supply? Every petition they sign is against something. What could we ask them to be for?

The CCFI public trust research shows Canadians expect transparency from the entire food system. This is just one small example of a conversation about food based upon the principles of shared values, listening and transparency that truly worked. Everyone passionate about the poultry industry can do more to share credible information about ethical food choices with the public.

By Tom Inglis

Tom Inglis is managing partner and founder of Poultry Health Services, which provides diagnostic and flock health consulting for producers and allied industry. Please send questions for the Ask the Vet column to poultry@annexweb.com.

What does the change in the use of medically important antimicrobials in poultry production mean to producers?

Antibiotic resistance is real. In Canada and around the world, fewer antimicrobials remain effective in controlling infection as more microbes become resistant in both human and veterinary medicine.

In its 2015 report on nationwide antibiotic use and drug resistance rates, Health Canada stated that ‘Superbugs’ (bacteria with multidrug resistance) have already cost Canada one billion dollars in medical care. The report noted a 14-fold increase in the use of last-resort antibiotics to treat difficult infections since 2002. Already, more than 18,000 patients in Canada acquire multi-drug resistance strains of bacteria each year. In the E.U. and U.S., hospital acquired infections kill a total of 50,000 people each year. The World Health Organization has called it a global emergency.

Due to the complex nature of antimicrobial resistance, its multi-factorial and concern to human and animal health, many players globally and in Canada (including poultry producers and their veterinarians) are acting to stop and if possible reverse the danger of antimicrobial resistance.

The Government of Canada has introduced Antimicrobial Resistance and Use in Canada: A Federal Framework for Action. The focus is on surveillance, stewardship and innovation. Additionally, Health Canada has introduced and will implement new policies and regulations. The use of Medically Important Antibiotics (MIAs) for growth promotion (rate of gain, feed efficiency) has been eliminated. As of

December 2018, MIAs currently available over-the-counter will be rescheduled as prescription and will require a valid prescription before they can be dispensed. Only pharmacists and veterinarians can dispense non-feed use MIAs, water soluble medications for examples. Feed manufacturers can sell feed containing MIAs pursuant to a prescription. Prescriptions can only be written within the confines of a valid Veterinarian-Client-Patient-Relationship (VCPR).

Many countries have already taken action. Here, the Canadian Veterinary Medical Association has introduced Veterinary Oversight of Antimicrobial Use-A Pan-Canadian Framework for Professional Standards for Veterinarians”. Veterinarians are best positioned to assess the benefits and risks of antimicrobial use in poultry and must explain to their clients the importance of judicious use of antimicrobials. Namely, the right drug for the right bug at the right dosage for the appropriate time interval.

MIAs will only be used in poultry operations under veterinary oversight and pursuant to a prescription generated by a veterinarian, who has established medical need and appropriateness within the confines of a valid VCPR. In addition to their role in antimicrobial stewardship, bird welfare is paramount and birds that are deemed responsive to treatment must be treated.

Globally, there are two trends in the use of MIAs in animal production, namely the use of antibiotics for treatment but not for the prevention

A post-antibiotic era where common infections and minor injuries are once again deadly is a real possibility for the 21st century.

of disease. The World Health Organization on Nov. 7, 2017, released the press release, Stop giving antibiotics to healthy animals. The World Health Organization is recommending that livestock and poultry producers stop using antibiotics to promote growth and prevent disease in healthy animals. This opens up the conversation of what is meant by prevention and treatment?

1. Prevention is described as the use of a MIAs in healthy birds to prevent the occurrence of a disease caused by bacteria. For example, an antibiotic is used because there is risk of disease.

2. Treatment is detailed as the use of a MIAs to treat a clinical or subclinical disease (metaphylaxis/ control) in poultry, including the mass medication of flocks in which a subset of birds are identified with a clinical or subclinical disease that will respond to administration of a specific antibiotic.

MIAs will only be used in poultry operations under veterinary oversight and pursuant to a prescription generated by a veterinarian.

Where possible, without sacrificing bird welfare, use an MIAs for treatment that is categorized by Health Canada as medium importance (Category III) rather than one that is high importance (Category II) or very high importance (Category I). It is important to use the right antibiotic for the disease at hand rather than necessarily one of less importance but has limited efficacy and could promote the development of antimicrobial resistance. Health Canada’s categorization is based on the options available to treat disease in human medicine. There are very few drugs in Category I and if resistance would develop to these antibiotics, there could be no other options available for patients with particular diseases.

3. Examples of Category I, II, and III used in poultry production:

• Category I: Third and fourth generation cephalosporins and fluoroquinolones

• Category II: Tylosin, lincomycin,

Infrared sensors promote full pans and healthy birds

Automatic start/stop feed dispersion

No moving parts or sensitivity adjustments

Optional LED light for 360° coverage

gentamicin, neomycin, virginiamycin

• Category III: Bacitracin, tetracyclines and sulphonamides

• Category IV: This category is deemed low importance by Health Canada because these drugs do not have a counterpart in human medicine. Examples: ionophore anticoccidials (antibiotics but not MIAs); non-ionophore anticoccidials (not antibiotics); and bambermycins.

Poultry producers have led with the following strategies:

• Eliminated the preventive use of Category I in commercial chickens and turkeys and breeders by May 2014.

• Withdrew the preventive use of Category I in parent stock by May 2015.

• The Canadian Hatchery Federation developed a turkey hatchery-specific AMU reduction strategy to eliminate the preventive use of Category II antibiotics by October 1, 2017.

• Chicken Farmers of Canada (CFC) have embarked on an antimicrobial use reduction strategy to eliminate the preventive use of Category II MIAs by the end of 2018, and pending reassessment, elimination of Category III MIAs for preventive use by the end of 2020.

• Turkey Farmers of Canada (TFC) also have an antimicrobial use reduction strategy to eliminate the preventive use of Category II antibiotics by the end of 2018 and the preventive use of category III antibiotics by the end of 2019.

Note: the AMU strategies of CFC and TFC are not raised without antibiotics programs, considering ionophores and non-ionophores (chemical) anticoccidials can be used. Additionally, MIAs can be used for therapeutic purposes to maintain the health and welfare of birds.

How will results of the MIA-use reduction strategies be measured?

A mandatory requirement to not preventively use Category II and III (depending on timeframe) will be included in On-Farm Food Safety Programs and audited. Additionally, surveillance will be performed through poultry industry use surveys, as well as government surveys via the Canadian Integrated Program for Antimicrobial

Resistance Surveillance (CIPARS) of the Public Health Agency of Canada.

What does the elimination of the use of Category II and III for prevention mean for my birds?

As far as treatment is concerned, there will be no change, as all MIAs are still available for treatment. Birds with treatable bacterial infections will be treated according to the strategies of CFC and TFC. With regards to no longer using antibiotics for prevention, this includes not using drugs such as virginiamycin and bacitracin. Both these antibiotics have been used for over 20 years to prevent Necrotic enteritis and have considerable benefits that contribute to better feed utilization, and litter management. When these products are not used in a preventative manner the producer must control coccidiosis and avoid immune-suppression. This checklist may be of value. All points are important and inter-connected:

1. Flock-to-flock biosecurity: Correct use of cleaners, disinfectants and pest control products.

2. Water quality: Remove biofilms and manage sulphates and sodium levels.

3. Manage coccidiosis: Coccidiosis predisposes to necrotic enteritis, which can lead to wet litter conditions predisposing the flock to higher ammonia and increased risk of E. coli infections.

4. Prevent immunosuppression: Monitoring and evaluation of vaccination programs and procedures.

5. Litter management: Attention to pen temperature, ventilation rate and drinker management.

6. Early detection of disease: Watch for changes in water intake, litter condition and bird behavior.

7. Alternative products in grow-out: Evaluate products to learn how to use them so birds can handle challenges.

8. Monitor antimicrobial sensitivity and use: We can’t manage what we can’t measure.

9. Enhance the Veterinarian-Client-Patient-Relationship: A renewed opportunity to work together.

10. Communication: Network, provide feedback and share observations.

You’re a grower – raising them healthy and strong from day one. With feeders designed for every stage, you can be sure of the well-being of your flock. So, you can concentrate on growing your business as strong as you grow your birds.

Ready for your custom solution? Contact your Cumberland dealer for an expert who stands with you and behind the products we manufacture.

By Treena Hein

How time flies – it’s been a year since two major fast food chains introduced all-day breakfast (ADB) in Canada.

Both McDonald’s Canada and A&W say they began offering breakfast items throughout the day because of strong customer demand. McDonald’s Canada spokesperson Kristen Hunter explains that, “In 2016, ADB was one of the top requests we heard from our guests, with thousands of people tweeting us. After testing the concept in several restaurants, we launched ADB nationwide in February 2017. We’re proud that ADB is still going strong and offered in the majority of [our] restaurants across the country.”

If McDonald’s experience is any indication, the all-day trend has been a boon for egg producers. The company says since introducing ADB it sources 25 per cent more eggs from Canadian farmers.

The restaurant’s ADB menu includes four McMuffin breakfast sandwiches, three of which contain eggs: Egg, Bacon ‘N Egg and Sausage ‘N Egg.

A&W’s story is similar. The firm’s senior director of marketing Tom Newitt says, “We take pride in not only listening to our customers but

following through with their requests. We introduced our ADB menu a year ago and the response from millennials in particular has been incredible.”

The menu has remained three breakfast sandwiches, all with eggs: Bacon & Eggers, Sausage & Eggers and Cheese & Eggers.

There are many major U.S. chains that offer ADB, including McDonald’s USA, White Castle, Sonic, Starbucks, Jack in the Box, Dunkin’ Donuts, Golden Corral, Denny’s, IHOP, Cracker Barrel and Bob Evans. There are also thousands of independent restaurants and regional chains that offer it in North America and beyond. Indeed, Google search ‘all day breakfast near me’ and you’ll get a staggering nine million results.

Although other Canadian chains like Burger King and Tim Horton’s show no interest in serving breakfast outside morning hours, Quebec-based Cora’s went the other way from the start. The franchise empire was started in May 1987, when Cora Mussely Tsouflidou bought a small diner in Montreal. Within a few months, she decided to make breakfasts her specialty.

Breakfast and lunch dishes are served at Cora’s during all operating hours, from morning until mid-afternoon.

Today, there are over 130 Cora’s across Canada serving a million guests a month. The ‘Eggquis’ restaurant chain, which started in 1995, has followed a similar strategy. It currently has approximately 40 locations in Quebec (mostly) and Ontario.

Why do consumers want breakfast items all day and night? According to a recent survey by Technomic mentioned on the website of the American Egg Board (AEB), one reason is a simple fondness for breakfast foods.

Approximately 54 per cent of consumers surveyed enjoyed eating breakfast foods at non-traditional times, a 12.5 per cent increase over 2013. “We also love our eggs,” states the AEB. “To our moods and taste buds, they’re warm, satisfying and have great flavour and a silky mouthfeel.

“Combine that with decreasing numbers of consumers living traditional nine-to-five lifestyles and the impact of millennials’ whatever/whenever approach to eating has had on many of our habits, and you’ve got a teeming mass of humanity looking for breakfast at non-traditional times.”

For her part, Margaret Hudson, president of Burnbrae Farms (the sole egg supplier for McDonald’s Canada), believes part of the reason people enjoy eggs in ADB meals is that they are seeking healthy protein more often.

“Eggs provide complete protein in the most convenient and affordable format,” Hudson says.

“People enjoy breakfast offerings with eggs, but often don’t take the time to eat them in the morning, so they are now seeking them at other times of the day.”

To address this trend, Burnbrae Farms now offers snack packs of two hardboiled eggs in their EGGS2go! product, which come in

54% of

omega-3 and a variety of flavours like dill and hot sauce.

To make a quick anytime meal with eggs, they also offer Egg Creations, flavoured omelette mixes and EGG Bakes! pre-cooked crustless quiches, which take only 90 seconds in the microwave. EGG Bakes! Flavours include spinach, ricotta & caramelized onion and cheddar, mushroom & bacon.

AEB points to new uses for eggs as another factor in egg consumption outside breakfast hours. For example, many restaurants now top burgers with eggs, such as Appleby’s All-day Brunch Burger, which is topped with a fried egg, bacon, onion, hash browns and cheese. Egg are also showing up on menus and in countless recipes as a pizza

topping, the star ingredient in bowls and much more. On its website, Egg Farmers of Canada now features many beyond-breakfast recipe categories such as salads and BBQ (think eggs grilled in sweet peppers, portobello mushroom caps and avocado shells, on their own or in a mixture).

Also, in its recently-released Egg-Centric Culinary Trends for 2018, Egg Farmers of Canada lists many new global food trends in which eggs shine. One features a growing interest in Japanese dishes. Eggs are found, for example, in the small omelettes that form part of a traditional Japanese small-dish breakfast meal.

Other ethnic dishes continue to be another hot trend, with one popular example being shakshuka, poached eggs in a tomato sauce

with onions, peppers and cumin.

Another trend is cloud eggs, where egg whites are whipped until stiff and used in a variety of ways, such as placing them on bread or another food base and baking them briefly with the yolk nestled in the centre.

One more hot culinary trend for 2018 is the concept of the late-night fourth meal, this is increasingly popular with busy and active families, and one in which eggs often star as a convenient and healthy ingredient.

Indeed, the numbers show ADB was a hit for McDonald’s and for egg production. Who contributed most to the restaurant’s demand for 35 million more eggs? That would be an outlet in Regina.

February 21st marked the one year anniversary of all-day breakfast at McDonald’s Canada. To celebrate, it shared some fun facts:

McMuffin Lovin’ Canada’s favourite McDonald’s all-day breakfast selection is the Sausage ‘N Egg McMuffin.

Egg Demand Since launching, McDonald’s has sourced 25 per cent or 35 million more eggs from Canadian farmers.

Breakfast Capital Regina,, is McDonald’s Canada’s all-day breakfast capital with more items sold than any other outlet in the country.

Time of Day

Other than in the morning, the restaurant’s breakfast items are most popular during lunchtime.

The Egg McMuffin

1976.

McDonald’s also looking to boost chicken consumption McDonald’s also has big plans for it’s other poultry offering – chicken. The restaurant is rolling out more chicken menu items all the time – including items similar to those offered by Chick-Fil-A, a chicken-centred U.S. fast food chain. According to Bloomberg News, Chick-fil-A generated US$4.41 million per U.S. restaurant location in 2016, compared to US$2.55 million for each McDonald’s outlet, so it’s clear why McDonald’s is going this route.

McDonald’s now offers three Southern-style chicken menu items that sport a breading similar to that used by Chickfil-A – its Buttermilk Crispy Chicken sandwich, Sweet BBQ Bacon with Buttermilk Crispy Chicken sandwich and Buttermilk Crispy Tenders. Business Insider reports that after the Buttermilk Crispy

Tenders were introduced last October in the U.S., they were so popular that some locations ran out by December.

Other McDonald’s chicken menu items stateside currently include McNuggets, five salads (Southwest, Caesar and more) and many sandwiches (Chicken Mexicano, Grand Chicken Special, Grand Chicken Deluxe, Grand Chicken Spicy, Grand Chicken Classic, McArabia [two Halal patties with toppings and a garlic sauce on Arabic bread], Chicken Mac [with two patties and three bun parts, similar to a Big Mac], McChicken, Spicy McChicken, Chicken Burger, Chicken Burger Deluxe, Sweet BBQ Bacon with Artisan Grilled Chicken, Artisan Grilled Chicken and Pico Guacamole with Artisan Grilled Chicken).

However, Bloomberg News believes that McDonald’s may be preparing to produce chicken items even more like Chick-Fil-A, using some kind of pressure-frying preparation method. The move was mentioned in a recent three-year chicken product growth plan that Bloomberg News obtained, presented by the company to franchisees (who operate about 90 percent of McDonald’s U.S. locations). Several media outlets have asked McDonald’s to confirm these plans, but so far, no comments are forthcoming.

Other fast food chains such as Burger King are also trying to liven up their chicken items. Burger King updated its chicken sandwich last year and the company says it’s been well-received. However, Burger-centred Shake Shack recently tried out a new Chick’N Club Sandwich, but reviewers have panned it.

By Nora Wolske

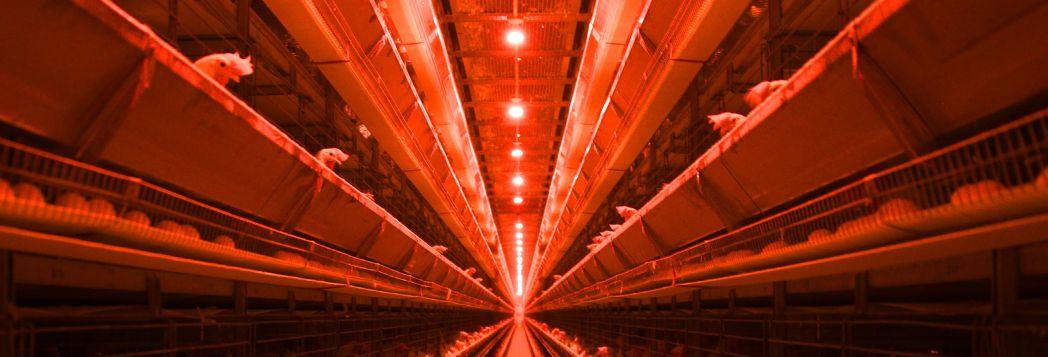

Today’s poultry farmers are faced with the necessity of maintaining a profitable balance in managing their livestock facilities. This ongoing challenge, coupled with keeping up with new regulations and animal welfare concerns, add to the complexity of managing a healthy and well-performing flock.

Historically, farmers monitored and observed their production by being physically present in the barn several times per day. Nowadays, most barns have some kind of automation that decreases the need of the farmer to be onsite more than once or twice a day. This presents the freedom to hire farm labour to do the day-to-day chores, so producers can now focus on making management decisions.

In most cases, finding skilled labour, or finding time to be in the houses several times per day, is proving to be increasingly

difficult. Having high-end, Internetenabled controllers can compensate somewhat for that. However, since these monitoring tools only report on what has happened, they therefore give only a snapshot of the current state of the flock.

If a parameter, such as temperature, has strongly deviated from the norm, the farmer will be alerted and given the chance to fix it. If the anomaly has not yet developed into a full-blown issue, there is a high chance the producer won’t be able to act on it until it is too late.

Having the ability to detect performance deviation early is key to success. The onset of a problem might be so slim it may not have registered yet in the current state of the flock. Farmers need solutions that will bring this information to their attention in real-time so they will be able to act on it much sooner. We all know that prevention saves money over remediation.

Today’s livestock barns and production

buildings are equipped with a lot more sensors than 10 years ago. On top of the common temperature, water and feed monitoring, farmers are now measuring carbon dioxide, ammonia, static pressure, humidity and much more, to ensure that they maintain a good balance between animal health, welfare and profitability. It is not an easy task.

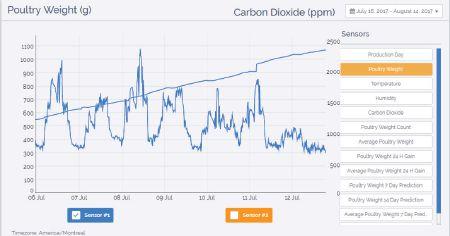

The advent of livestock production data analytics platforms aims at helping farmers manage this delicate balance. The data coming from the house sensors is fed on a continuous basis to these platforms to be read, stored in servers and analyzed to give the producer insights on bird health and expected performance.

Data analytics can be classified in four levels, based on the depth of analysis and process that is applied to the raw data received from the sensors.

At the most basic level, the platforms provide historical data in aggregated

form. Some provide a way for the producer to visualize this data in chart form. Others are able to graph this data. This is helpful to identify trends, evaluate retrospectively such things as the impact of a new feed type and decide on the future conduct of subsequent flocks. Any adjustment made will be “after the fact”.

Taking the data processing a step further, one will find the web-enabled controllers and their proprietary platforms allow farmers to see the current state registered by all connected sensors, as well as alarms that report that a parameter is higher or lower than a user-defined limit. It is helpful to assess how the flock is doing in real time. This also allows the farmer to take action immediately if something is wrong and, thus, limit the consequences on the production performance.

The next level of analytics has the ability to increase the value of the data currently available.

These platforms are able to cross reference graphs and data from multiple sensors in real time to provide the producer with more defined cues in order to make timelier, more effective management decisions. These platforms even predict future performance based on current events.

The final level, which could come sooner than we think, involves a level of automation where one could see the platforms suggesting corrective actions that need to be taken to prevent any deviation identified at the predictive level. The best analytic solutions do not provide more data, but a clearer picture. How does this translate in real life for Canadian poultry farmers?

Let’s use air quality as an example. By cross-referencing the birds’ weight and the carbon dioxide levels provided in real time by the analytical tools, a producer will realize that the dip that is visible in the growth curve may be linked to the abnormal level of carbon dioxide in the air. Why? With analytical tools, the producer gets a better representation of

On Monday morning at Forest Farm, broiler producer Stephan Forest enters one of his poultry barns. His chickens arrived five days ago from the hatchery. After walking through the barn to ensure that these newcomers are doing well, the producer takes out his cellphone and consults his flock’s weight prediction on his data analysis platform. He wants to make sure that his chickens will meet the crucial 10-day weight target.

“It’s amazing. I cannot only see what my average bird weight will be at day 10 but what it will be over the next 14 days,” he says. “This kind of data is crucial to us. It helps us make the right decision, when and where needed, to ensure we will meet our performance goals.”

Moreover, by using the previous production data, the platform Forest uses enables him to compare his current growth with his personal best.

Once Forest returns to his farm office, after his daily flock inspection, he finally sits down for breakfast. While enjoying his morning coffee, he navigates through his platform from his laptop and accesses several production metrics.

He can see in real time the average weight of the birds, the average daily gain and the deviation from the target weight for each connected house.

“The uniformity data is very useful,” Forest says. “It helps me assess if the birds are growing optimally or if I need to make corrections to my lighting management for instance. And, if I’m not satisfied by something, I can investigate, using the data from other sensors, like ammonia or CO2, to identify the probable cause. It orients my actions for the day.”

On day 10, he walks through his poultry house and observes his birds’ growth curve on the data analysis platform, with a very satisfied look on his face. Thanks to the latest technology, he was able to adjust his production parameters and his birds are right at their target weight. This flock is off to a great start.

what is actually happening in the barn, instead of just viewing random raw data.

With better visibility, in real time, the producer can respond immediately by adjusting the ventilation or taking other actions that will restore the growth curve to its expected progress.

Given the high cost of the feed, delivery expenses and storage, it’s imperative to accurately estimate the quantity of feed each flock consumed.

Analytical tools help the producer better estimate feed consumption based on actual rate of consumption and will aid in creating a more efficient

delivery schedule to reduce waste and feed outages. Feed outages negatively affect the health of birds.

This affects their value and losses can even occur. The insights provided by analytical tools are invaluable in preventing these feed outages, and the resulting value losses. Add to that the higher costs of overtime or weekend deliveries and the savings can be very significant.

The best data analytics solutions allow for the monitoring of various parameters pertaining to bird health in real-time. These timely adjustments can make

a big difference in achieving weight targets, reducing condemnation and improving the quality of each flock.

The real-time capture, analysis and interpretation of data generated by livestock production activities is the next step in profitability optimization for the livestock industry.

Farmers need tools to help them manage the delicate balance between animal

health, welfare and rising production costs. Real-time data analytics are decision-support systems that will bring insight on the performance of the flocks. By taking timely actions, they will uncover all the savings that are hidden in their production data.

This is the next revolution in poultry production and it is happening right now.

hybridturkeys.com

What has been accomplished, how and what comes next.

By Treena Hein

As it did for most live stock species, substan tial genetic improve ment in turkeys started in the 21st century. In the 1960s, hybridiza tion of turkey varieties began, followed by the development of pedigree programs for large white turkeys in the 1970s. In the 1980s, feed conversion testing came in, and selection index methodologies (simultaneous selection for several traits) were put in place. In the 1990’s, breeding moved forward again with the use of ‘mixed model equations’, which take both phenotype (observable traits such as body weight) and family genetic information into account.

The year 2016, however, marked a large step forward in turkey breeding with the use of genomics – sequencing and analysis of an organism’s genome (DNA). By combining genomic data with phenotypic data, more accurate selec tions of desirable traits can be achieved, resulting in faster rates of trait improve ment.

“What used to be dubbed as a future possibility has become an integrated enhancement to turkey breeding programs around the world,” explains Dr. Owen Willems, a geneticist at Hybrid Turkeys, a leading primary turkey breeder with locations in Canada, U.S., France, Poland, Hungary and the Netherlands. “With the inclusion of genomic breeding

values, the industry moved from a statistical method of breeding called Best Linear Unbiased Prediction (BLUP) to Genomic-BLUP (GBLUP),” he says. “It involves the inclusion of information on 65,000 DNA markers distributed over the total turkey genome and has increased the accuracy of breeding values

so that a yearly average of 15 per cent improvement in genetic gain could be achieved over previous levels.”

Another benefit of implementing genomic selection, albeit in the short term, is better control and accuracy of pedigree systems. “Through the analysis of genomic information, the processes of

• More efficient breeder

• Tested globally for 3 years (Asia, Africa, Middle East, North America and South America)

• Performs well in all environments and nutritional programs

• More efficient broiler

• Better FCR at lighter weights (advantage increases as broiler reaches heavier weights)

• Better livability for life of flock

insemination, egg collection and hatching can be easily validated,” Willems explains. “In the near-term, this added information could lead to identifying birds that are ‘carriers’ of certain genes that have a negative impact (but tend to stick around at low frequency) and then filter these birds out of the population. This information could also lead to genetic improvements in lowly heritable traits (traits where genetic improvement is more difficult) such as fertility.”

Today, Willems explains that turkey breeders around the world focus on balanced breeding, selecting turkeys based on a variety of traits that meet the needs of the market, while maintaining the overall welfare of the animal. He notes that the importance of each trait in a given breeding program depends in part on customer expectations in various market segments. In general, he says most markets are looking for a turkey that offers production efficiencies, physical soundness (animal welfare) and strains that can be sustained well into the future.

The traits that are commonly included in breeding programs are weight, breast meat yield, egg production, feed conversion and leg strength. Willems notes that before genomic selection came into the picture, the turkey industry realized average yearly improvements of approximately two per cent in body weight, one to 1.5 per cent in feed conversion and one per cent in breast meat yield.

The year 2016 marked a large step forward in turkey breeding with the use of genomics – sequencing and analysis of an organism’s genome (DNA).

To further boost production efficiency, and to improve industry environmental sustainability as well, a new project kicked off in May 2017, where Hybrid Turkeys received $6 million in funding from Genome Canada. This genomic selection research project is being led by Hybrid Turkey geneticist Dr. Ben Wood in collaboration with University of Guelph professor Dr. Christine Baes. Besides providing better economic gains through the entire turkey value chain, the research aims to provide environmental benefits through improved feed efficiency, reduced manure production and lower greenhouse gas emissions.

Beyond traits related to production and sustainability, global turkey breeding programs include evaluation of walking scores to ensure physical soundness of the birds. Willems says walking scores are closely related to turkey health and survival, and including them in breeding programs ensures that, as the size of the bird increases, the overall stability and strength of the legs that support the bird are also improved.

Willems notes that although genomic selection is an integrated part of today’s turkey breeding programs, the extent of the possibilities that genomics might provide are still being evaluated. However, in addition to applying new advancements such as genomics, another important factor in achieving breeding gains is the safeguarding of sources of genetic variation.

One source of variation is the global turkey populations owned by breeding companies and backyard farmers alike, which contain diverse genetic lines.

“The genetic variation in the non-commercial lines can be used as a source to be crossed into commercial populations,” Willems explains. “A source of genetic variation is also contained within current commercial populations, with a range of body weights, behaviours, feed conversion, yields and other traits. Lastly, genetic variation can also arise from natural spontaneous mutation of DNA as it undergoes its constant cycle of replication, recombination and repair.”

Willems reiterates that turkey breeding programs depend, in part, on what is needed by each market. “As grower, processor or even consumer preferences change, the breeding program will be adapted,” he notes. “Variation in all important traits is largely available. It is up to the industry to provide direction to animal breeding companies on what is needed. Though 10 or 20 years seem to be the distant future, in terms of genetic development, it is really not that far away.”

Flavio Henrique Araujo Silva

Raising broilers is much like building a house. A good deal of effort goes into planning and constructing the structure, but one also needs to be a bit of an artist to create the ideal end result. Experienced and knowledgeable growers are similar in that they follow recommended procedures while also being proactive in identifying issues before they can cause a problem. They are able to read the bird and relate aspects of bird behavior and performance to react quickly and ensure good end results. That’s where the artistry comes in.

To maximize broiler performance, it is important to consider multiple aspects of genetics, chick quality, nutrition, health and environment. Being knowledgeable about the five elements of poultry handling and husbandry - food, water, light, temperature and air quality - is also essential for success.

Downtime between flocks is very important if litter is re-used. Some countries use this technique because of high litter material and litter disposal costs while other countries replace litter with every single flock.

The disinfection system used is very important. If litter is replaced with every flock, correct cleaning methods and disinfection are essential to the next flock’s success. If litter is re-used, at least seven days of downtime is necessary between flocks, with the best results varying according to the disease or contamination challenge in the region. Some countries or regions may need 15 to 20 days to get a good disinfection. A recent study by Vaz et al, published in Poultry Science in March 2017 (https://doi.org/10.3382/ps/pex063), showed the differences between the use of quicklime, windrowing and shallow fermentation against the control method of not doing anything.

The results of the study showed the fermentative treatments were superior to the others in terms of reducing the bacterial load, with shallow fermentation standing out with the highest reduction of enterobacteria.

A good or bad flock starts in the hatchery. If you watch chicks after placement, you can easily tell the quality of your chicks and how good the brooding area is. The chicks should be active, looking for water and food, making sounds and be well distributed throughout the brooding house. If we receive excellent quality chicks into a poor brooding area, we lose a fantastic opportunity to do well. The chicks can be ready to go, but without proper house conditions they will not be successful. Additionally, if you receive sleepy, closed eyes, dehydrated, “tired” birds, it’s time to check things at the hatchery because this is not an acceptable condition.

The Konavi® Feeding System is a breakthrough in global broiler feeding. It features an angled cone with anti-rake fins that helps keep birds out of the feeder to maintain fresh, clean feed. With its low pan height and patented scalloped edge, the Konavi Feeder invites chicks to eat from the pan from day one and gives birds

comfortable, easy access to feed throughout their growth cycle. Plus, the streamlined design permits more complete cleaning between flocks for better bird health. The new Konavi Feeder lets beaks in, and helps keep feet out.

Learn more about clean, openstyle feeding at choretime.com/KONAVI

It is an art to apply our knowledge in an effective way to maximize genetic potential

Water needs to be fresh, clean and free of pathogens. Chlorine (three to five ppm) with a good pH (six to seven) will help to achieve the Oxidation-Reduction Potential (ORP) of 550-750, which will kill most of pathogens that could cause a problem for a day-old chick or during the life of the flock.

Feed and nutrition deserve much attention, with establishing feed consistency being a top priority. Birds get used to the quality of the feed, so avoiding a lot of change (from mash, crumble, and pellet) every time a truck arrives to the farm will help the birds to perform their best with the nutrition designed to get the highest results.

Follow the feed schedule designed by nutritionists for your birds. Many times, feeding more or less of a prescribed feed will cause detrimental effects, or in other words, reduce the potential for maximum broiler performance.

Floor and litter temperature is vital in brooding and maximizing performance. Experts are often called to visits where poor initial performance is directly linked to low temperature in the brooding area. The chicks are cold and therefore do not eat or drink. This also causes them to form big chick circles in the warmest areas.

The relation between temperature and air quality is a key environmental factor in performance. Dealing with these two factors properly is key to achieving superb results. Usually the seven-day weights show if this was done correctly from the beginning. Also, when chicks are adults, look to their behaviour inside the house to tell if they are hot. This can be seen in bird activity such as open wings, breathing hard and open beaks. Birds will also display if they are or too cold by all laying down, without going to water or feed lines. The minimum ventilation concept with correct equipment and house control is important to maintaining good condition, saving costs and using the house more effectively.

Worldwide, the season of the year plays an important role in performance, as does the construction of and the environment in the houses. Solid houses have certain requirements, and open houses have their

own recommendations. For example, minimum ventilation for a solid wall house with a correct inlet system needs a good control that will work correctly 24-hours a day if maintained properly. In an open house, a successful grower knows the expectation is the same and equipment must be checked daily and work properly in order to be effective.

Examples of tunnel ventilation and correct ambient management are also a good thing to reflect on these days – even with the sweltering summer in the southern hemisphere or the coldest weather in northern hemisphere. The relationship between the building, equipment and the manpower required to manage it are key points to maximizing performance.

Another critical element is proper house maintenance. A new house stops being new when the first flock is placed

To maximize broiler performance we need to give flocks the best conditions we can while utilizing all the theory and understanding available to us.

and later goes to the processing plant. Maximizing results requires an ongoing scheduled house maintenance program.

Don’t forget to check on water consuption and feed consumption – this tells a lot about a flock and can even give clues about diseases, behavior, management and environmental issues.

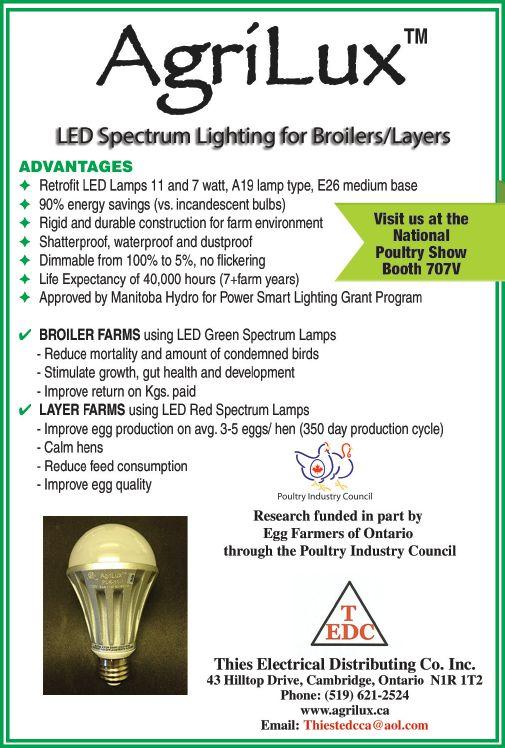

To optimize broiler performance, we must think about lighting programs, light systems and all the options we have available today in the marketplace. A recent study published by Morrissey et al in July 2017 in the Journal of Applied Poultry Science (https://doi.org/10.3382/japr/pfx029), showed many variances between dimmer styles and types of lamps (LED, incandescent and fluorescent). Be aware of what equipment you’re working with when determining the correct lighting program. Different styles and types of lighting equipment often produce varying results.

In conclusion, to maximize broiler performance we need to give flocks the best conditions we can while utilizing all the theory and understanding available to us. It is an art to apply our knowledge in an effective way to maximize genetic potential.

In growout after growout, results prove that Ziggity Systems with Max3 drinkers consistently produce not just great but exceptional performance in every category. That’s because Max3 delivers all the hygienic water birds need to thrive and stay healthy without oversupply that causes wet litter and all of its related problems.

More ways to improve performance

Reduce management time and make correct pressure adjustment easy with PressurePro.

Visit www.ziggity.com www.ziggity.com/pressurepro

Conventional cage laying barns have always been dusty, notes Harry Huffman, an agricultural engineer based in London, Ont. “Thus, I would assume the new floor and aviary style of housing systems will continue to be dusty as well.” Huffman notes that the more important ventilation design parameters in a layer barn hinge around the number and size of birds being housed, and how airflow should occur through the airspace to accommodate the building specs. These parameters include the width, length and height of the building, as well as installed equipment, including feeders, waterers and so on.

“Ventilation is based off air exchanges per animal,” Jonathan Kasa, partner at Nor-Ag in Red Deer, Alta., says. “Then we get specific, based on temperature, humidity, CO2, drafts, air flow, etc. These free-run layer barns have a much higher number of birds per cubic foot than broiler barns, so every aspect of proper ventilation is magnified and it’s far more important to design a proper system.”

Dr. Hongwei Xin, assistant dean for research in the College of Agriculture and Life Sciences at Iowa State University, also agrees that compared to enriched colony and conventional cage housing, ventilation is more of a challenge in freerun layer barns. “One factor is manure accumulating and possible caking on the

floor, which leads to some ammonia issues, and another is the higher dust levels from bird activities on the litter floor,” Xin says.

“Egg producers with free-run housing systems have to increase minimum ventilation to control indoor ammonia, especially in the wintertime. And,

supplemental heat is needed in areas in the northern U.S. and Canada where the climate is colder.” He adds that in a freerun layer barn, there are fewer birds in the same amount of space compared to conventional cages or enriched colony housing. “Fewer birds means less body heat for warming the room air in

Jarvis Power Actuated Stunner (PAS) Model Type C Non-Penetrating Concussion Jarvis No. 4144080

Renders stunned poultry insensible to pain, without penetrating the skull. Unique design euthanizes poultry, and renders them insensible to pain.

World Leader in Meat Processing Equipment View Jarvis tools on our website

E-mail: info@jarviscanada.com Website: www.jarviscanada.com

wintertime,” he notes. “How to distribute the supplemental heat uniformly throughout the barn is a challenge, and producers must make sure air ducts flow freely and don’t get plugged with feathers. Overall, free-run barn ventilation system requires more maintenance and cost.”

Xin points to the large study completed by the Coalition for Sustainable Egg Supply, which involved a team of scientists evaluating three laying hen housing systems – coventional cage, enriched colony and aviary cage-free or free-run. The study authors

found cost of production for free-run barn eggs was 36 per cent higher compared to the conventional cage, but Xin says that number takes much more than ventilation and supplemental heat costs into account. “There are fewer eggs on average per hen due to higher mortality caused by feather pecking, cannibalism, smothering and injuries in the free-run barn,” he notes. “As well as higher initial cost and higher labour costs from picking up floor eggs and de-dusting equipment for example, less efficiency in feed conversion and so on.”

The updated Canadian code of practice for laying hens requires that “environmental control systems must be designed, constructed and maintained in a manner that allows for fresh air and hygienic conditions that promote health and welfare for birds,” and that “action must be taken to manage ammonia levels if they reach a harmful range (e.g., 20 to 25 ppm).”

There are no specific requirements for dust, but Xin is not surprised. He notes that farm workers always wear dust masks in layer barns. “We’ve measured much higher dust levels in layer barns than the guideline values for workers by the U.S. Occupational Safety

and Health Administration. Much more fresh air flows through the barns in mild to warm weather for temperature control, which lowers the dust concentrations, but in cold weather – winter and early spring –masks are definitely needed.”

Xin says that ventilation is only one factor of many that farmers must consider when deciding whether to go with enriched colony or free-run barn housing. “On a bird welfare basis, the hens have more room to move around in free-run barns, but smothering and injurious feather pecking can be worse, for example, than in enriched housing,” he notes. “From an air quality standpoint, there is half the ammonia and about eight times less dust in enriched colony housing compared to barn production.”

In terms of manure management, Bill Snow, aviary specialist for Big Dutchman, says if the quality of the litter is higher, hens will be more engaged to act out natural desires of foraging, dust bathing and scratching. However, he notes that “the better the quality of the litter, the more dust you are likely to have. Poor manure quality means higher levels of ammonia and good quality means more dust. The way we try to manage the dust levels in the house is to continually scrape litter out of the aisles.” The scraper is placed underneath the system row, Snow explains, and a path of litter is scraped from the front of the laying house to the rear. “The hens will go in and move the litter around and fill the bare areas back in,” Snow adds. “Each time the scraper system is run, litter is removed off the floor, and this keeps the height of the litter down to a workable level. This also helps to reduce miss laid eggs on the floor and reduces the dust levels in the house.”

Housing design certainly affects air quality, and Snow notes that the more litter space in a laying facility, the dryer the litter will be and the better the ventilation system will be able to function. “The benefit of upwards of 30 per cent litter space ensures that system rows are far enough apart from one another,” he explains, “so that fresh litter that falls into the aisle has a chance to dry out.”

Also, if perches are not placed over a manure belt, litter that is excreted falls

directly onto the floor below and builds up quickly. The hens will then scratch through it and spread it around. “If the system rows are too close together, the build-up of manure from the perch will fall very close and does not have an

opportunity to dry out because of the density of hens that are on the floor,” Snow explains. “The hens will be closely grouped together and ventilation will not reach the litter level as easily. The litter will not get the opportunity to dry.”

The H3N2 canine influenza virus was detected in dogs in Ontario this past December.

Some producers might be wondering if the outbreak poses a threat to poultry. While the strain is of avian origin, experts Canadian Poultry consulted say the chances of it being transmitted to poultry now that it has switched to a canine-adapted virus are small. Thus, they consider any related disease threat to the poultry industry in Canada to be very low. That said, the situation remains a good reminder that poultry biosecurity risks can present themselves at any time and potentially from unexpected sources.

The story began in late December 2017, when two dogs had been flown in from Asia for pet adoption by an Essex County resident. The animals began to show signs of respiratory disease. The cause was determined to be H3N2 influenza, the first known detection of the virus in Canada.

It is one of two canine influenza strains, the other being H3N8. According to the American Veterinary Medicine Association (AVMA), influenza in canines (the H3N8 strain) was detected for the first time worldwide in 2004 among greyhounds at a racetrack in Florida. The viral strain is closely related to and believed to be a mutation of the strain that causes influenza in horses. Later in 2004 and the year after, outbreaks occurred in dogs across many states. The disease has currently been reported in 40 states.

In 2015, the H3N2 strain of canine influenza, which was first detected in 2007 in South Korea, was found in the U.S. for the first time. Now, according to the AVMA, “thousands of dogs have been confirmed positive for H3N2 canine influenza across the U.S.”

This strain of influenza is highly transmissible between dogs, particularly in areas such as Canada where dogs do not have natural immunity from previous

infection and where canine influenza vaccination is rare, explains Dr. J. Scott Weese, a professor at the Ontario Veterinary College, University of Guelph, chief of infection control at the Ontario Veterinary College Teaching Hospital and the Canada Research Chair in zoonotic diseases. Weese says most dogs that develop influenza do not get seriously ill, and that the recent H3N2 infection cluster in Ontario is hopefully still contained.

H3N2 is an ‘A’ strain of influenza. These strains can infect a range of birds and mammals, including humans, pigs, whales, horses and seals. The ‘H’ in the classification refers to the type of hemagglutinin present (a surface glycoprotein involved with binding the virus to host cells) and the ‘N’ to the type of neuraminidase the virus has (a surface enzyme involved when the virus releases from host cells).

“The highly-pathogenic types of this

Meller offers a wide variety of Poultry equipment to meet today’s standards and needs. The Meller Aviary meets all EU standards as well as providing an exceptional living space where the welfare and production of the flock are able to flourish.

Starting from day old chicks to 19 week layers Meller has it all. CP_Meller_April17_CSA.indd 1

Now representing Official Dealer for all Jansen Poultry Equipment products in Ontario and Manitoba 519-587-2667 • www.meller.ca • meller@optionsdsl.ca

Providing a wealth of background knowledge on poultry anatomy, physiology, and immunology, this comprehensive reference explores poultry diseases that are directly related to or influenced by the gastrointestinal tract.

Filled with useful images, this informative record discusses the impact of human pathogens harbored by poultry and offers alternatives to antibiotics in the treatment of intestinal disorders in poultry.

virus are H5 and H7, which are reportable to Canadian Food Inspection Agency,” notes Dr. Grant Maxie, co-executive director of the Laboratory Services Division and director of the Animal Health Laboratory at the University of Guelph.

The concern with any influenza virus, explains Maxie, is that different variants of the virus present within a host (particularly pigs) and can exchange bits of DNA (called re-assorting).

“Similarly, with the canine infection, should the dogs come into contact with another flu virus, the combination might re-assort and become more pathogenic, but this is highly unlikely,” he says. “Also, similarly, the H3N2 in dogs is of little concern to poultry in Canada, primarily because the dogs, and we assume their owners, have no contact with poultry.”

Weese echoes the sentiment. “Overall, the risk here to poultry is negligible for a few reasons, including lack of evidence that this strain is avian-adapted anymore – while it has an avian origin, it’s now a canine type – the rarity of it in Canada in

dogs and the hopefully low incidence of direct contact between dogs and poultry.”

Weese is unaware of any studies looking at whether canine H3N2 could be transmitted to poultry. However, researchers from the United States Department of Agriculture in Athens, Ga., looked at whether the H3N8 strain could be transmitted to birds in 2010, specifically to chickens, turkeys and Pekin ducks.

For the study, birds were inoculated with infectious doses of the virus. The researchers then observed the birds for any clinical signs or gross lesions. They saw neither. Thus, they concluded that chickens, turkeys and Pekin ducks were not susceptible to infection.

The other way changes can happen in influenza viruses (all RNA viruses) is through spontaneous mutation, which is common occurrence. “However, spontaneous mutation to a highly pathogenic form is very unlikely,” Maxie says. “More likely is re-assortment with a virus from wild waterfowl, which carry a range of influenza viruses asymptomatically [display no symptoms].”

Whichever influenza viruses or other disease agents are or are not present in Canada at this point, Maxie stresses that strict biosecurity is important for poultry operations at all times. He reminds us that on a farm, “exclusion of air-borne viruses such as influenza is even more onerous than exclusion of pathogens that are carried on fomites – vehicles, equipment, personnel, clothing.”

Broiler Signals follows the life cycle of these fast growing animals and points out issues specific to each developmental stage.

Broilers are fast growing animals that need constant care. There is no time for correcting mistakes; mistakes mean high costs. The prevention of mistakes is therefore crucial.

Proper management starts with recognizing signals in practice. For broiler-keepers, this means being alert when in the poultry house, watching and listening to the animals, paying attention to their environment and their behaviour as individuals and as a group. This usually provides important information about their animals’ health, well-being and production. This information helps poultry-keepers to improve their economic results, the well-being of their animals and their own.

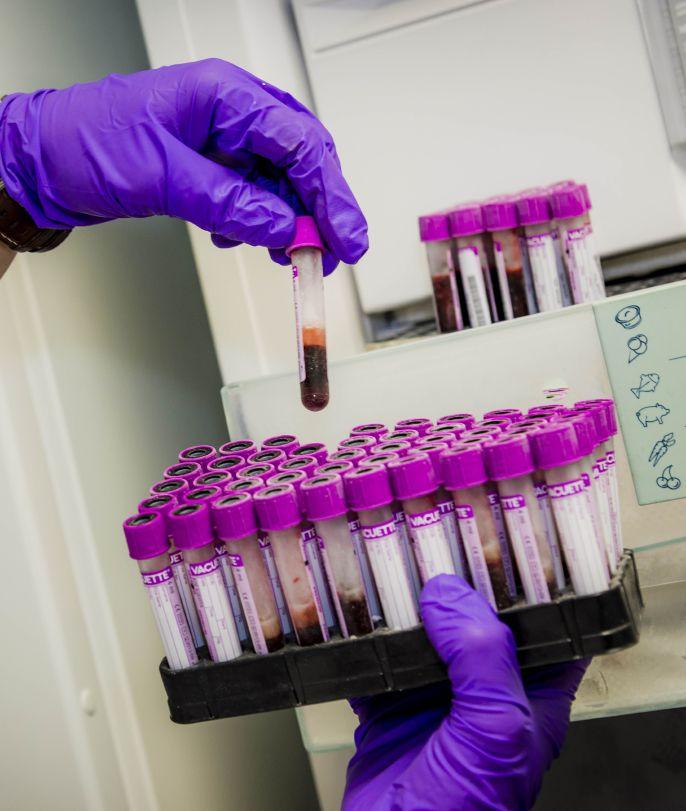

The latest on the use of eggs in drug manufacture, disease treatment and more.

By Treena Hein

The idea of using a biological system to produce products for human use is not new. Since civilization began, humans have harnessed bacteria, yeast and more to produce alcoholic drinks, fermented foods and, later on, things like silk and insulin.

Modern-day scientists are taking biological systems engineering to the next level. Indeed, it’s now a university degree program offered at major institutions around the world. Experts are applying fundamental principles of engineering to living systems to produce everything from drugs to organic computers.

For some time, bacteria, yeast and some types of mammalian cells have been used to produce a group of pharmaceuticals called pharmaceutical proteins. Using an egg to produce these protein drug treatments is a relatively new idea, but one that makes a lot of sense. Eggs provide a sterile, closed environment and the capability of large-scale production at relatively low cost, all allowing mass manufacture of a given compound that would otherwise be unfeasible.

It turns out that eggs are suitable to produce a particular cell-signalling protein called interferon beta (some biological systems are better suited than others to produce particular proteins). Interferon beta can not only disarm viruses like the one that causes hepatitis, but can also control some cancers as well as auto-immune diseases like multiple sclerosis. In short, it’s in hot demand.

Enter researchers at Japan’s National Institute of Advanced Industrial Science and Technology, who have genetically engineered hens to produce eggs with large amounts of interferon beta in the whites. Their first step is to edit genes found in chicken sperm. They then use these modified sperm to fertilize eggs. The resulting male chicks are then crossbred, with interferon beta produced in the eggs of the hen offspring. The research was jointly conducted with scientists from Japan’s