MUELA

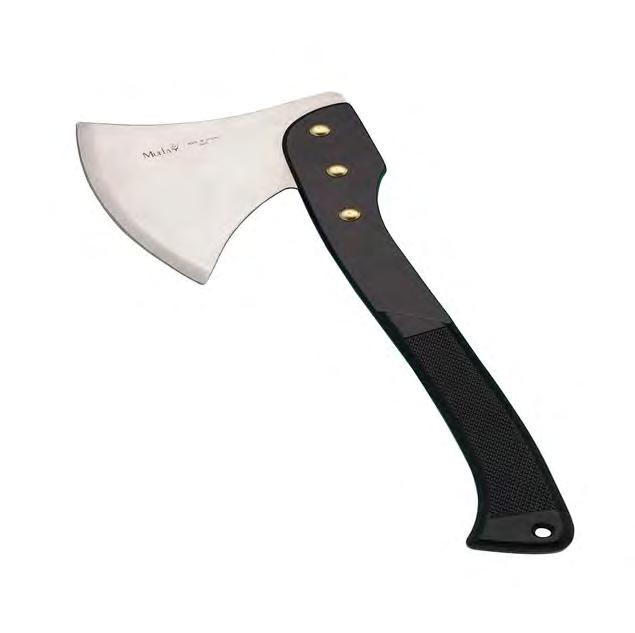

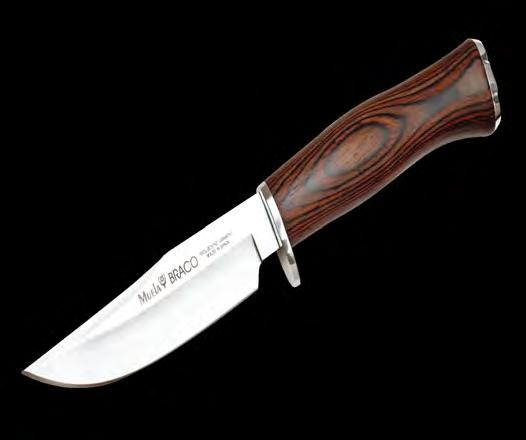

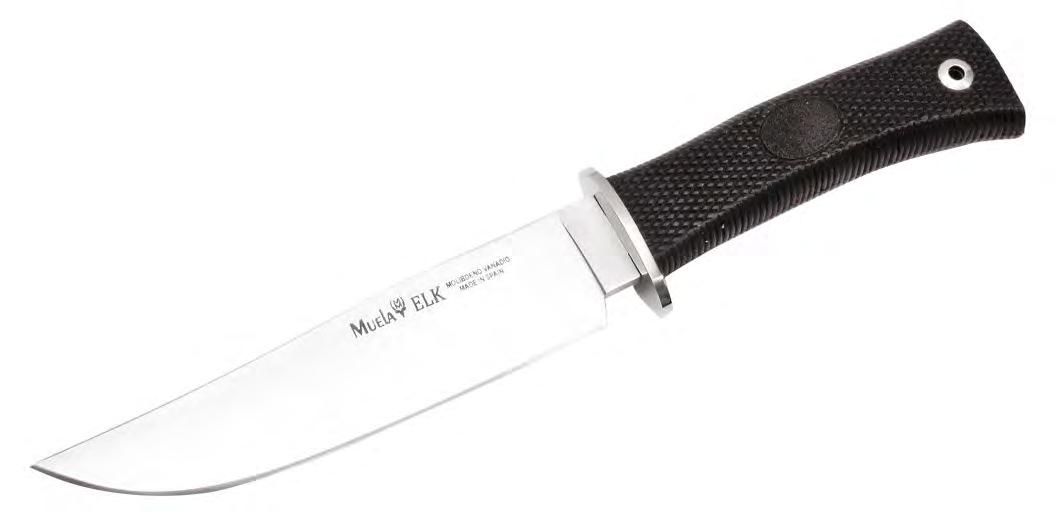

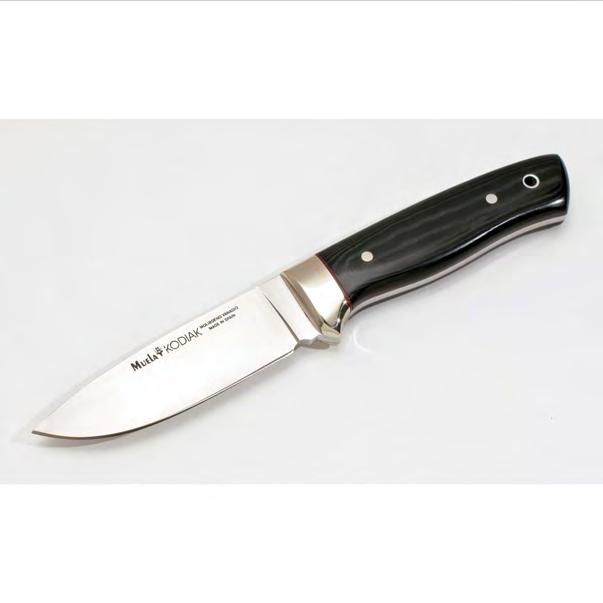

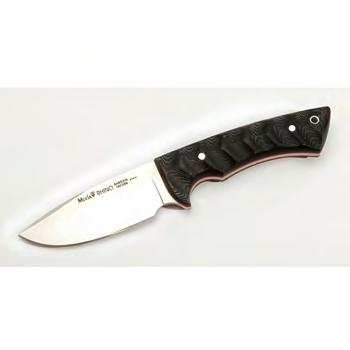

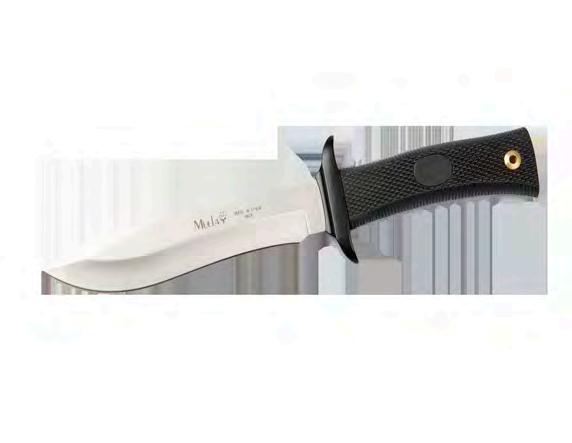

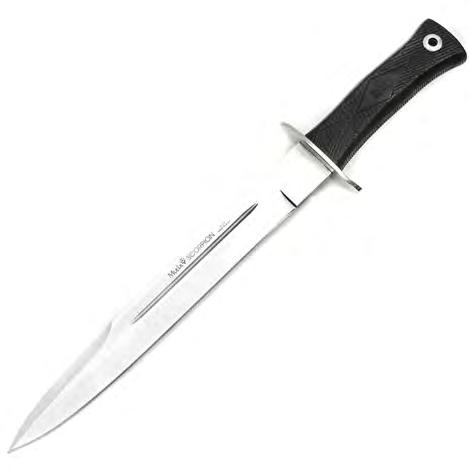

Combining old world craftsmanship with modern production technologies, Muela knives are beautifully crafted with quality and functionality in mind. Blades are produced primarily from high-quality martensitic steel alloyed with chrome, vanadium and molybdenum. Handles feature stag, wood, micarta and rubber. Each knife comes with a one year warranty.

Introduction

More than 50 years ago Eladio Muela handcrafted his first knife - a fine piece of work that began the Muela company’s proud history of knifemaking in the Spanish tradition. From its beginnings in a small workshop, Muela now produces around 350,000 pieces a year in its modern factory, located in Ciudad Real, Castile-La Mancha, Spain.

ith the uarantee and su ort of over half a century manufacturin s ortin knives

Manufacturers Muela offers a ide selection in its ne catalo ue here you are ound to find the most suita le model hatever your o tion

rom the most classic desi ns in huntin and eneral knives com ined ith fine natural materials such as horn and ood to the most modern and inaltera le com ounds and s ecial coatin s on tactical models and the traditional or exem lary functional and ractical sha es of our knives

Combining old world craftsmanship with modern production technologies, Muela knives are meant to last, and are exceptionally beautiful and functional. Blades are produced primarily from high-quality martensitic steel alloyed with chrome, vanadium and molybdenum. Handles feature stag, wood, micarta and rubber. Each knife comes with a one year warranty.

Production

Manufacturers Muela produces over 300,000 knives and folding knives a year. We count on the latest industrial techniques, including mechanized computer controlled centres and ovens working continuously, which is ideal for thermal treatment of the different types of steel employed for the specific models.

In our factory our artisanal experts are capable of achieving the best results using their expertise which is essential when working with natural materials such as the antler handles or wood, and whose genuine mastery cannot be equaled even with the most sophisticated machines, resulting in a distinctive, highly valued features of our products since the inception of the Muela brand over many years.

In our main factory, located in Argamasilla de Calatrava (in addition we have complementary workshops also in the province of Ciudad Real), we manufacture all the components of the Muela knives and folding knives, as well as carrying out the decoration work, the quality control processes and the packaging for their distribution across the five continents.

Steel Types

420H (High Carbon content)

420 steel with high Carbon content. Very stain resistant and tough. Easy to re-sharpen.

MOVA 1.4116 (X50CrMoV15)

It's a classic steel used in our knives. An excellent combination of Molybdenum and Vanadium that is highly stain resistant and corrosion resistant.

MOVA 60 (X60CrMoV15)

More content in Carbon than MOVA (1.4116)

SANDVIK 14C28N

Sandvik 14C28N ® is a martensitic stainless chromium steel with a chemistry optimized for high quality professional knife applications. The chemical composition provides a unique combination of properties including: Excellent edge performance; Very high hardness; Good corrosion resistance

DAMASCO (CARBON STEEL)

Damascus steel of 576 layers forged by hand following ancient techniques.

DAMASCO INOXIDABLE

The “Stainless Damascus Steel” is a compound of about 130 layers although it can range between 90 and 130 depending on the thickness and production using two kinds of rapidly solidified powder steels. (RWL34PMC27) welded at a temperature of 1150ºC and at a gas pressure of about 1000 atmospheres, we produce a material that is hard, durable, heat resistant while increasing the fracture strength radically

Handle Materials

MICARTA®

A composite of linen, canvas that is impregnated with epoxy resin and formed into sheets or blocks. Extremely resistant to water, wear, heat, etc…

PAKKAWOOD

This is a natural wood composite (cocobolo, coral, birch...) soaked with resin, and at times dyed. When subjected to pressure and temperature, it obtains better properties than the wood itself that makes it up, such as greater hardness and water resistance.

PBT + FIBRE GLASS

PBT is an engineering polymer with excellent thermal, mechanical, electrical and chemical properties. Its fibre glass reinforcement bequeaths it with greater hardness and tenacity, and therefore greater wear resistance. In addition to excellent chemical resistance, which makes it practically indifferent to weather and light, it also has good thermal properties, withstanding temperatures greater than 200ºC. It is non-toxic and totally recyclable.

ANODIZED ALUMINUM 5083

Anodizing makes aluminum stronger and anodic films are much longer lasting than other surface colorations.

Anodized aluminum knife handles are highly scratch resistant and fade resistant.

NICKEL SILVER

This is a ternary alloy with Copper, Zinc and Nickel, with a colour and shine similar to silver. With a greater proportion of Nickel, the quality and resistance to corrosive elements increase.

BRASS

This is a Copper and Zinc alloy made in furnaces at a smelting temperature of 980º C.

ZAMAK

A family of alloys with a base metal of zinc and alloying elements of aluminium, magnesium, and copper.

Sheaths

All fixed blade knives ship with sheaths. Images may not be available in some cases.