TRENCHLESS Works

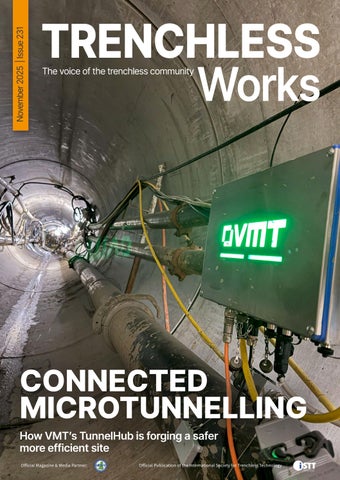

CONNECTED MICROTUNNELLING

How VMT’s TunnelHub is forging a safer more efficient site

PUBLISHER

Paul Harwood pharwood@westrade.co.uk

EDITOR

Austen Lees editorial@trenchless-works.com

MANAGING EDITOR

Leigh Abbott labbott@westrade.co.uk

SALES DIRECTOR

Trevor Dorrell tdorrell@westrade.co.uk

DESIGN & PRODUCTION

Ioan Lucian Sculeac lucian@westrade.co.uk

CHINESE AGENT

Lexi Di lexi.di@bestexpo.cn

COPYRIGHT

Trenchless Works is published 12 times a year by Westrade Group Ltd I Carotino House| Bury Lane I Rickmansworth I WD3 1ED I UK

Contributions: Contributions are invited and articles should be emailed to editorial@ trenchless-works.com. No responsibility can be taken for drawings, photographs or written contributions during delivery, transmission or when with the magazine. In the absence of an agreement, the copyright of all contributions, regardless of format, belongs to the publisher. The publishers accept no responsibility in respect of advertisements appearing in the magazine and the opinions expressed in editorial material or otherwise do not necessarily represent the views of the publishers. The publishers accept no responsibility for actions taken on the basis of any information contained within this magazine. The publishers cannot accept liability for any loss arising from the late appearance or non-publication of any advertisement for any reason whatsoever. ISSN 2049-3401

Subscribe

www.trenchless-works.com

Editor’s Welcome

Austen Lees

As we head into the final stretch of 2025, the trenchless sector shows no sign of slowing. From major infrastructure investment to rapid technical innovation, it’s been a year defined by momentum, and this issue reflects that energy across every page.

Leading the edition is our cover feature with VMT, exploring how the company continues to set new standards in guidance systems, navigation and digital control. Their latest advancements underline how far precision technology has come, and how indispensable it has become for delivering complex trenchless projects safely and efficiently.

This month’s Industry Insight takes us in an equally important direction with A conversation with Shauna Herron: Championing the next generation of women in trenchless. Shauna offers a candid and inspiring perspective on representation, mentorship, and the steps needed to attract and retain more women across technical and leadership roles. Her voice is one shaping the future culture of this industry.

We also spotlight a major milestone for the global trenchless community: Trenchless Middle East 2025 in Saudi Arabia. Its debut in the Kingdom marks a landmark moment, one that reflects both the scale of regional infrastructure ambitions and the growing influence of trenchless technologies in supporting sustainable development.

Alongside these features, November brings a wide range of project stories, technology updates, award-winning innovations and global news, from advanced rehabilitation techniques and HDD breakthroughs to asset management insights and training initiatives shaping tomorrow’s workforce.

As always, we welcome your feedback, project updates and ideas. If your organisation is driving innovation or delivering work that deserves to be seen, please get in touch, we’d love to share your story in a future issue.

Thank you, as always, for reading Trenchless Works. It’s a privilege to showcase the people, companies and ideas driving our industry forward.

Austen

To

ARTICLE

Editor’s Welcome

INDUSTRY INSIGHT

A conversation with Shauna Herron: Championing the next generation of women in trenchless

NEWS

Openreach trial trenchless drilling robot to boost UK FTTP broadband build

Consultation launched on major Suffolk water infrastructure plan

Introducing Trenchless Connect: A new digital hub for the trenchless industry

MICROTUNNELLING

Connected microtunnelling

PIPELINE REHABILITATION

Two records and a major project in bruges

Inside Channeline’s bespoke GRP rehabilitation process

Pump station rehabilitation using Hermes Technologie m-coat system

HDD

EAS opts for compact PS60 for underground works

The benefits of remote diagnostics and fleet monitoring for HDD contractors

SUPPORT EQUIPMENT

The Hydrocam™ System

Building carbon-conscious supply chains in utilities and industrial transport

EVENTS

Saudi debut heralds a new era for Trenchless Middle East

FOCUS ON TRENCHLESS TRAINING

Practice, theory and the impact of AI

UKSTT SOCIETY NEWS

A message from the Chair

UKSTT infiltration & inflow masterclass delivers expert insights to record attendance

ISTT SOCIETY NEWS

Strength in diversity: Mark André Haebler outlines his plans for ISTT’s continued growth

ISTT announces 2025 No-Dig Award winners

Announcing the ISTT Lifetime Service Award winners 2025

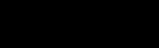

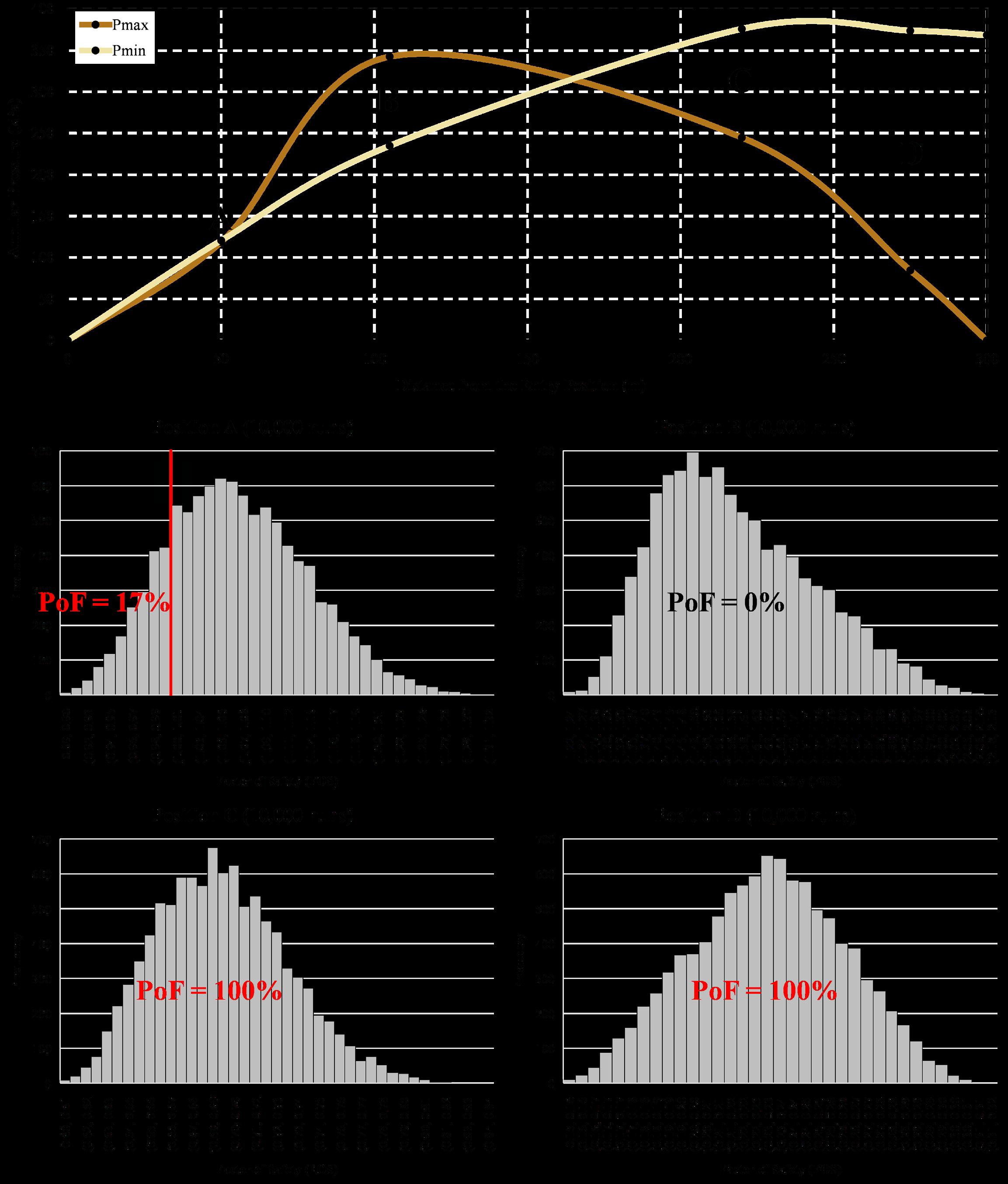

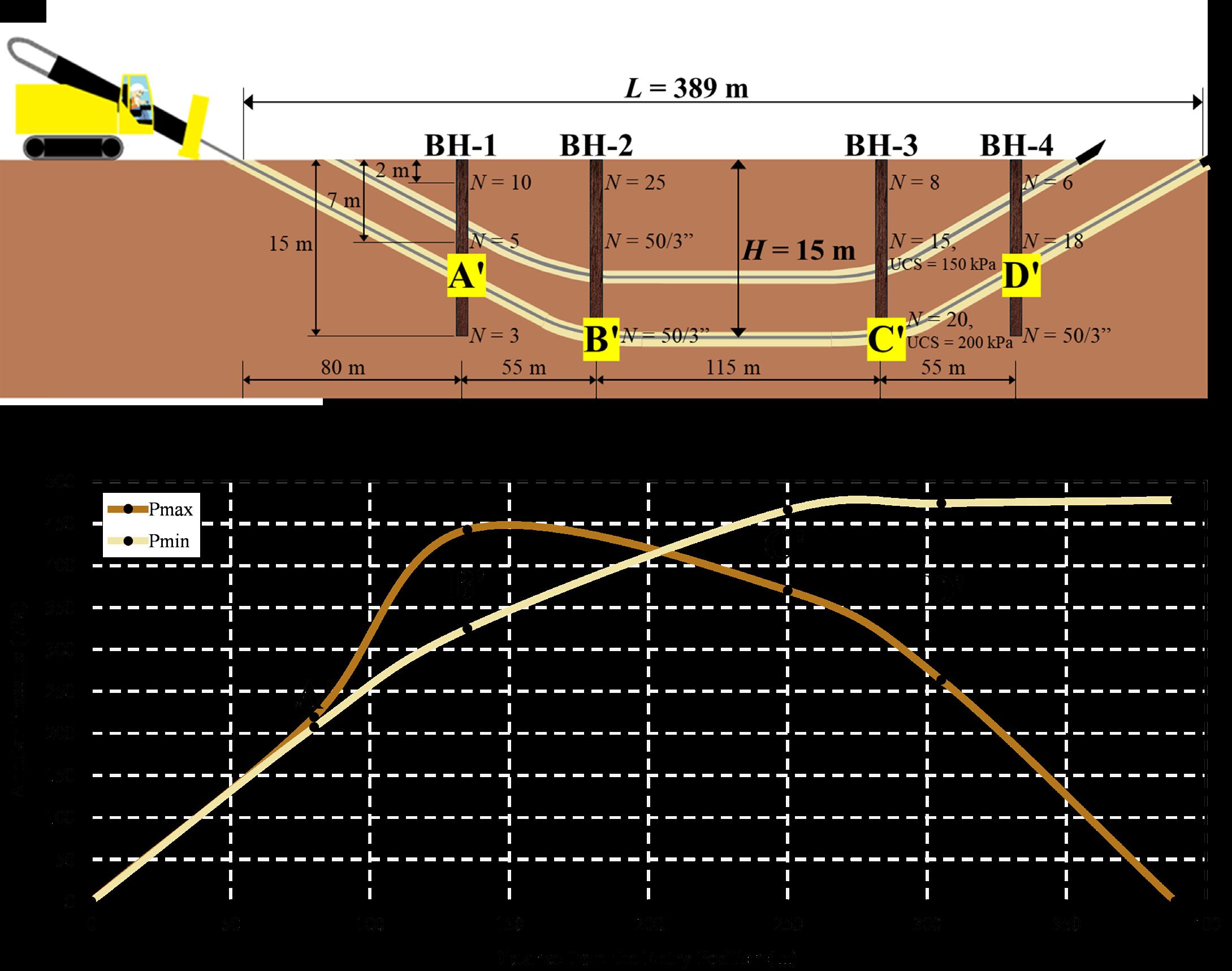

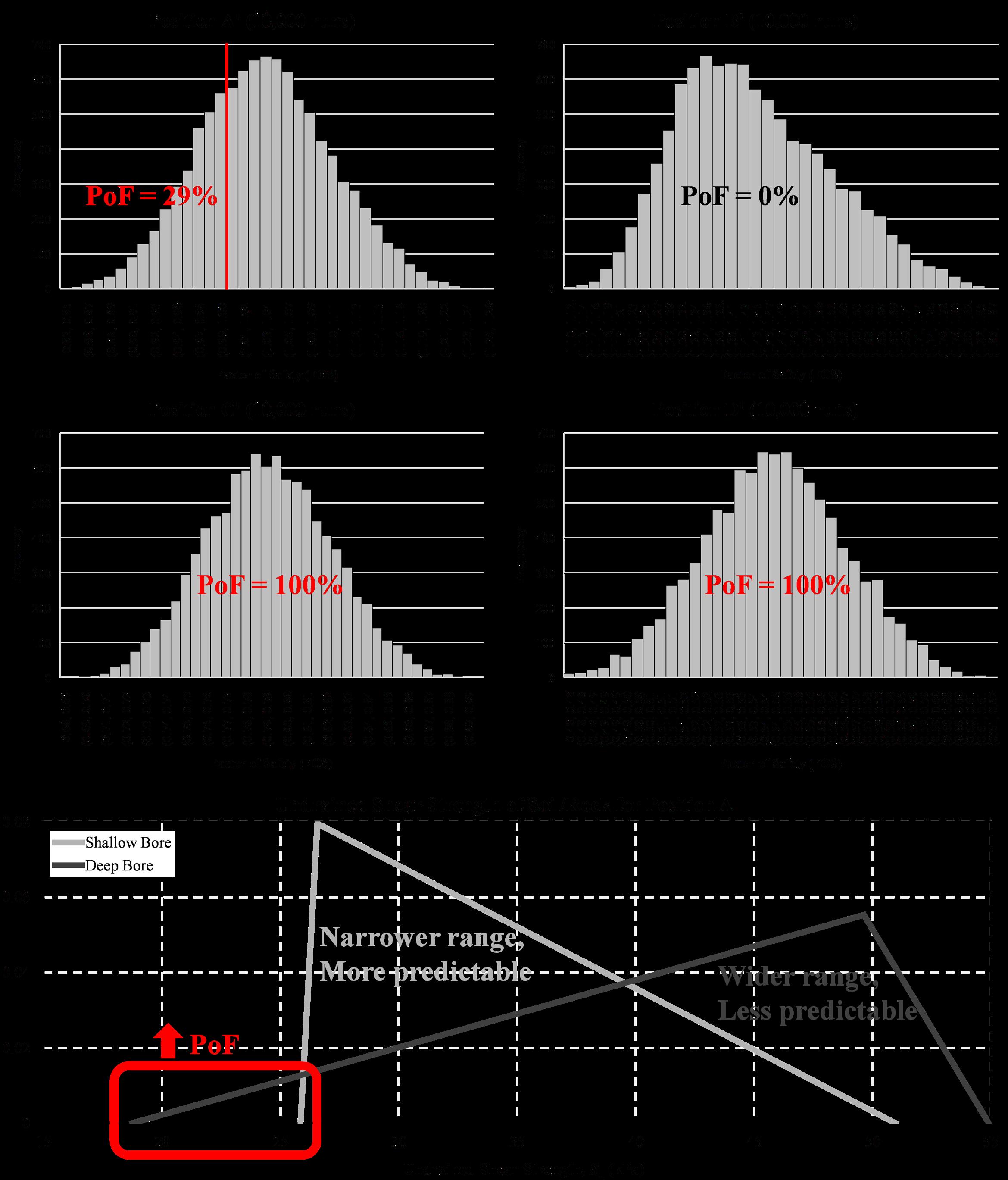

Probabilistic Hydraulic Fracture Analysis in HDD

Michels: An international leader in trenchless construction

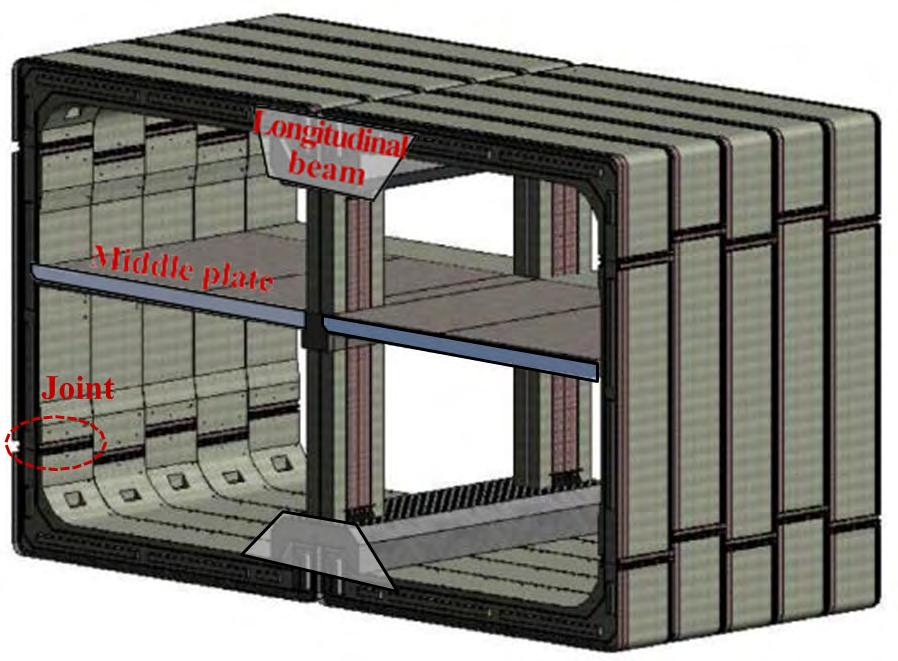

Close-fit twin tunnel pipe jacking technology for subway station construction

NASTT SOCIETY NEWS

NASTT’s good practices courses & publications featuring newly revised CIPP

North American Society for Trenchless Technology announces leadership transition

EVENTS AND MEETINGS

A conversation with Shauna Herron: Championing the next generation of women in trenchless

By Austen Lees, Editor, Trenchless Works

The No-Dig Roadshow in Bristol, always a valuable platform for showcasing innovation and exchanging expertise within the trenchless sector, also provided an ideal opportunity to engage in discussions that extended well beyond technological advances and project delivery. Sitting down with Shauna Herron, CEO of Environmental Techniques and the UKSTT Trenchless Woman of the Year 2025, it quickly became evident that her recognition wasn’t merely a personal accomplishment; rather, she is determined to use it as a powerful catalyst to advocate for the next generation of professionals, with a particular focus on encouraging young women to pursue careers in civil engineering and the water industry.

“It’s certainly rewarding to be recognised by one’s peers,” Shauna began, “but the true measure of success lies in my ability to use this award to inspire

more young women to consider this sector as an exciting and fulfilling career path. That, for me, is the ultimate objective.” Shauna speaks with a measured determination about the need to actively address the outdated perceptions that continue to linger within some corners of the industry and the notion that in 2025, young women might still encounter discouragement when considering a career in what remains a predominantly male field.

Shauna’s own personal journey serves as an important illustration of the importance of individual resolve and strength of mind to overcome ingrained societal biases. Growing up in Zambia, her early and enduring interest in toys like Lego and Meccano was not simply a fleeting childhood pastime; it was, in retrospect, a clear indication of a passion for engineering and construction. This early inclination led her to pursue a degree in civil engineering at Queen’s University Belfast, a path that she consciously chose despite the best efforts of others. She recalled a careers advisor at her school, suggesting that careers such as nursing or teaching might be “better suited for a girl” - advice that she thankfully chose to ignore.

“It’s not, of course, that those alternative career paths aren’t inherently valuable or fulfilling,” she clarified, “but it’s fundamentally about ensuring that everyone has the freedom

to make informed choices about their future based on genuine interests and aptitudes, without feeling constrained or unduly influenced by preconceived notions of what is deemed ‘suitable’ or ‘appropriate’ based on gender or any other arbitrary characteristic.” Shauna’s firm decision to respectfully disregard that piece of advice was a pivotal moment that shaped her future trajectory and paved the way for her to become a respected and influential figure within the ever-evolving water industry.

Shauna is deeply committed to actively cultivating a more inclusive, equitable, and supportive environment for women in all fields of engineering. To that end, she readily and gratefully acknowledges the invaluable support and encouragement she received from organisations such as the UKSTT and from pioneering figures such as Dr Dec Downey, particularly during her formative years within the industry.

She consistently emphasises the critical importance of mentorship programs and the cultivation of a robust culture of shared knowledge as essential ingredients for fostering the success of future generations of engineers. “In those early days, readily accessible online resources were far more limited than they are today,” she explained. “As a result, much of the practical learning and valuable insights came from simply spending time with those

who had already accumulated significant experience in the field. That kind of direct mentorship proved to be extremely valuable, offering a much-needed source of guidance and perspective precisely when it was needed most.”

She also notes the significant and demonstrable impact of trenchless technology, not only in modernising critical infrastructure, but also in directly contributing to the increasingly urgent global effort to achieve net-zero and how aligning with these big-ticket issues which will help get us a seat at the top table with government. “We need to be more proactive and effective in highlighting the environmental benefits of trenchless technologies,” she stated, advocating for a concerted effort to highlight the significant potential for reducing waste, resources, and the use of heavy plant and machinery to substantially lower emissions.

There are signs that we are achieving this recognition, with Environmental Techniques recently presenting at Stormont on the work they had undertaken using drones and CIPP to rehabilitate two siphons in Belfast harbour, which saved £16m and around 90% of carbon emissions compared to traditional methods. “Ultimately, it’s about us reframing the core narrative surrounding trenchless technology,” she explained.

“It’s not simply about efficiently repairing underground pipes; it’s about actively contributing improved safety, and the creation of environmental, social and financial value.”

For young people who are currently navigating the complex process of considering their future career options, Shauna offers a straightforward and easily accessible piece of advice: “Take a serious look at it. Do some research. >

Don’t automatically allow preconceived stereotypes or outmoded assumptions to unduly influence or limit your decisionmaking process.” She readily acknowledges that “the world of underground pipes and utilities might not immediately strike everyone as the most glamorous or exciting career path,” but she is quick to stress the increasingly vital importance of these essential services in supporting our modern way of life and the enormous potential for contributing to meaningful progress.

She also encourages young people to actively embrace the wide range of diverse roles that are readily available within the industry. “It’s definitely not just limited to traditional engineering positions,” she points out. “There are so many unique and exciting opportunities in cutting-edge research and the development of technologies such as AI and robotics which are really improving safety standards by removing people for unsafe and unpleasant working environments.”

Looking ahead, Shauna underscored the value of continuous professional development and highlighted the need to foster a workplace culture that actively encourages and rewards lifelong learning throughout the trenchless industry. She also emphasised the ongoing importance of well-designed mentorship programs that effectively connect experienced professionals with the next generation of engineers.

Talking with Shauna Herron served as a valuable reminder of the continued importance of promoting inclusivity, supporting learning, and embracing innovative thinking within our sector. She is an inspiring role model committed to breaking down long-standing barriers and establishing a more equitable future for all.

AT120

Loaded with 120,000 lbs (533.8 kN) of pullback/thrust and 15,500 ft·lbs (21015 N·m) of rotational only opens you up to new types of jobs but moves through long bores and large diameter installs All Terrain technology and a 280-hp (209 kW) Stage V Cummins® engine reduce environmental impact power. 3,000 ft·lbs (4067 N·m) of inner rotational torque—a 50% increase over its predecessor— additional power to drill through the toughest terrain around.

THE BEST SELLING ROCK THE

DRILL

IN AND

UK IRELAND.

rotational torque, the AT120 not installs with eye-popping power. impact without losing any predecessor— allows the AT120

Openreach trial trenchless drilling robot to boost UK FTTP broadband build

Network operator Openreach (BT) has revealed that they’re conducting trials of a new “advanced robotic … space-age” trenchless drilling technology, known as MicroBORE, to help accelerate their ongoing rollout of Fibre-to-the-Premises (FTTP) based broadband ISP lines across the United Kingdom. It could also cut civil engineer costs and reduce disruption.

The system, which is claimed to have originally been “designed for lunar and Martian exploration“, was developed through a 5-year collaboration between BT Group, UK-based engineer firm Synthotech and the University of Surrey to translate space research into realworld infrastructure innovation.

The robotic MicroBORE is designed to bore narrow channels beneath pavements and driveways, allowing fibre optic cables to be laid from the main duct to residential premises “without the need for traditional open trenching “, which is of course the most expensive and disruptive part of underground street works. But preciously how much “faster” and more costeffective this is than traditional methods remains unclear (that’s what the trials are for).

There is also potential for longterm savings from reduced restoration and traffic management costs. In dense urban areas, where traditional methods would require road closures and extensive digging, MicroBORE can drill from one small access point to another, threading fibre cables beneath roads and pavements. By avoiding large-scale excavation, MicroBORE

also helps preserve green spaces and reduce carbon emissions.

Violeta Novakovic, BT Research Manager, said:

“Through our partnership with Synthotech, we’re taking cuttingedge engineering and applying it to one of the UK’s biggest infrastructure challenges. The MicroBORE could be a gamechanger for Openreach by enabling faster, greener, and less disruptive fibre installations that benefit customers and communities nationwide.”

Simon Langdale, Engineering Director at Synthotech, said:

“The new drilling technology will significantly reduce the cost and accelerate the execution of key civil engineering tasks. This is a hugely exciting application of advanced robotics that will

completely transform how underground fibre connectivity is managed and delivered.”

The scale of civil engineering required in areas lacking existing duct infrastructure is substantial and Openreach, alongside the developers of this new technology, are currently seeing if they can prove that the new technology can be made to work at scale. Testing at BT’s R&D centre in Suffolk is said to have already confirmed the system’s “operational viability“.

Assuming all goes well, then we could also see MicroBORE being adopted to support other sectors that require low-impact underground access, such as for the deployment of electric vehicle (EV) charging and utility connections. At present, we don’t have any other pictures or videos of the new robot, but we are trying to locate some.

• Sliplining

• Guided Boring Systems

• Microtunneling

• Pipe Jacking

• Tunneling

• Earth Pressure Balance

Add Atlas to your project and save time, money, and effort. We stock an extensive range of cable and pipe pulling winches suitable for all trenchless operations.

Add Atlas Winch and Hoist Services to your project. Give us a call today to discuss your requirements.

Consultation launched on major Suffolk water infrastructure plan

Essex & Suffolk Water has launched a six-week public consultation for one of the region’s most ambitious infrastructure programmes, a multi-million-pound scheme to strengthen water supply resilience across Suffolk, which the Environment Agency has classified as “seriously water-stressed.”

Reported by New Civil Engineer, the Suffolk Water Recycling, Transfer and Storage Project forms part of Essex & Suffolk Water’s £1.5 billion regional investment plan aimed at securing long-term water resources in response to climate pressures, population growth, and rising demand.

At the heart of the project is an advanced water recycling facility near Lowestoft, which will treat and reuse effluent from Anglian Water’s Lowestoft Water Recycling Centre. The purified recycled water

will be discharged into the River Waveney, from where it can reenter the wider supply network.

Two new service reservoirs are also proposed, one near Lodgewood Water Tower close to Sibton and another at Eye Airfield. These reservoirs will provide strategic storage during hot, dry periods and improve supply reliability across Suffolk’s Hartismere and Blyth Water Resource Zones.

Supporting this infrastructure will be approximately 80 km of new pipelines, transferring both treated wastewater to the recycling facility and purified recycled water back into the supply system. Pipe diameters will range from 180 mm to 560 mm, with materials selected to optimise durability and capacity across changing ground conditions. While route options are still being considered, trenchless installation methods

are likely to be assessed for several sections to minimise environmental and community disruption.

The scheme will directly address constraints in the Hartismere zone, where a moratorium on new nondomestic connections remains in place due to supply pressures.

Public consultation runs until 10 December 2025, with eight drop-in sessions scheduled near proposed sites to allow residents, businesses, and stakeholders to view plans and engage with the project team.

Preferred pipeline routes and final infrastructure locations are expected to be confirmed toward the end of 2026, followed by further consultation in 2027.

Source: New Civil Engineer

When we say our Bluelight LED light curing CIPP lining system is paired to perfection, we mean it. With its equipment and materials sourced from just one place, you can be sure that everything has been engineered to work in unison – the first time and with minimal fuss. Choose a Partner,

Introducing Trenchless Connect: A new digital hub for the trenchless industry

Westrade Group is set to launch a major new digital platform designed to strengthen connections, visibility, and industry knowledge across the UK and Ireland’s trenchless sector. Trenchless Connect, powered by Trenchless Works, will bring suppliers, contractors, utilities, engineers and consultants together in one central, search-driven environment, creating a new digital home for trenchless engagement.

Launching publicly in January 2026, Trenchless Connect has been developed to meet a clear industry need, a dedicated, continuously updated platform where trenchless organisations can showcase expertise, publish knowledge, and reach audiences well beyond traditional channels. The platform forms part of Westrade’s ongoing commitment to supporting best practice and raising the profile of trenchless technology as the preferred method of underground installation and rehabilitation.

Central to Trenchless Connect is the opportunity for suppliers to own

their web space within the wider Trenchless Works ecosystem. This dedicated, controlled publishing environment allows organisations to post news, case studies, technical insights and videos directly to the industry audience. With all content indexed via Google News under Trenchless Works’ verified publisher status, Connect clients gain an SEO advantage and build long-term visibility for relevant trenchless search terms.

The platform will also offer buyers and specifiers a central place to filter, compare and connect with solution providers across all major trenchless technologies, including HDD, microtunnelling, lining, robotics, condition assessment, and more. With thousands of trenchless professionals already engaging with Trenchless Works each month, Trenchless Connect will expand this reach even further.

A tiered annual membership structure ensures suppliers of all sizes can participate, from essential presence through to enhanced visibility, lead generation, and

high-impact digital sponsorship. Early adopters joining as Founding Partners will receive priority placement at launch and the opportunity to help shape the platform’s evolution.

The Trenchless Connect soft reveal took place at the No-Dig Roadshow in Bristol on 1 October, where the industry was given an early glimpse of the new identity and direction. The response was overwhelmingly positive, with strong appetite from organisations seeking greater digital visibility and more meaningful ways to connect with decision-makers.

As the trenchless industry continues to grow, Trenchless Connect marks the next step in Westrade Group’s long-standing support of the global No-Dig community, providing a modern, scalable digital space built by the industry, for the industry.

To learn more about Trenchless Connect or to enquire about Founding Partner opportunities, contact tdorrell@westrade.co.uk.

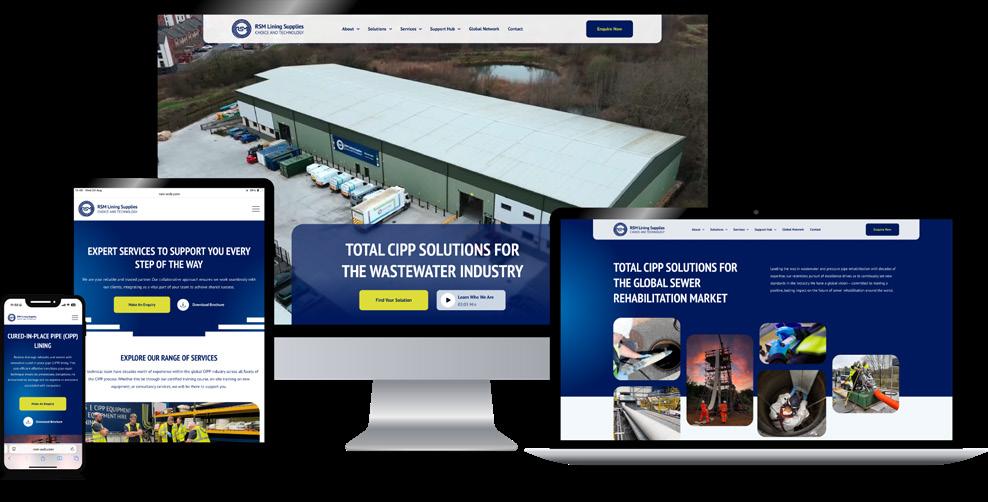

CONNECTED MICROTUNNELLING

How VMT’s TunnelHub is forging a safer, more efficient site

By Austen Lees, Editor, Trenchless Works

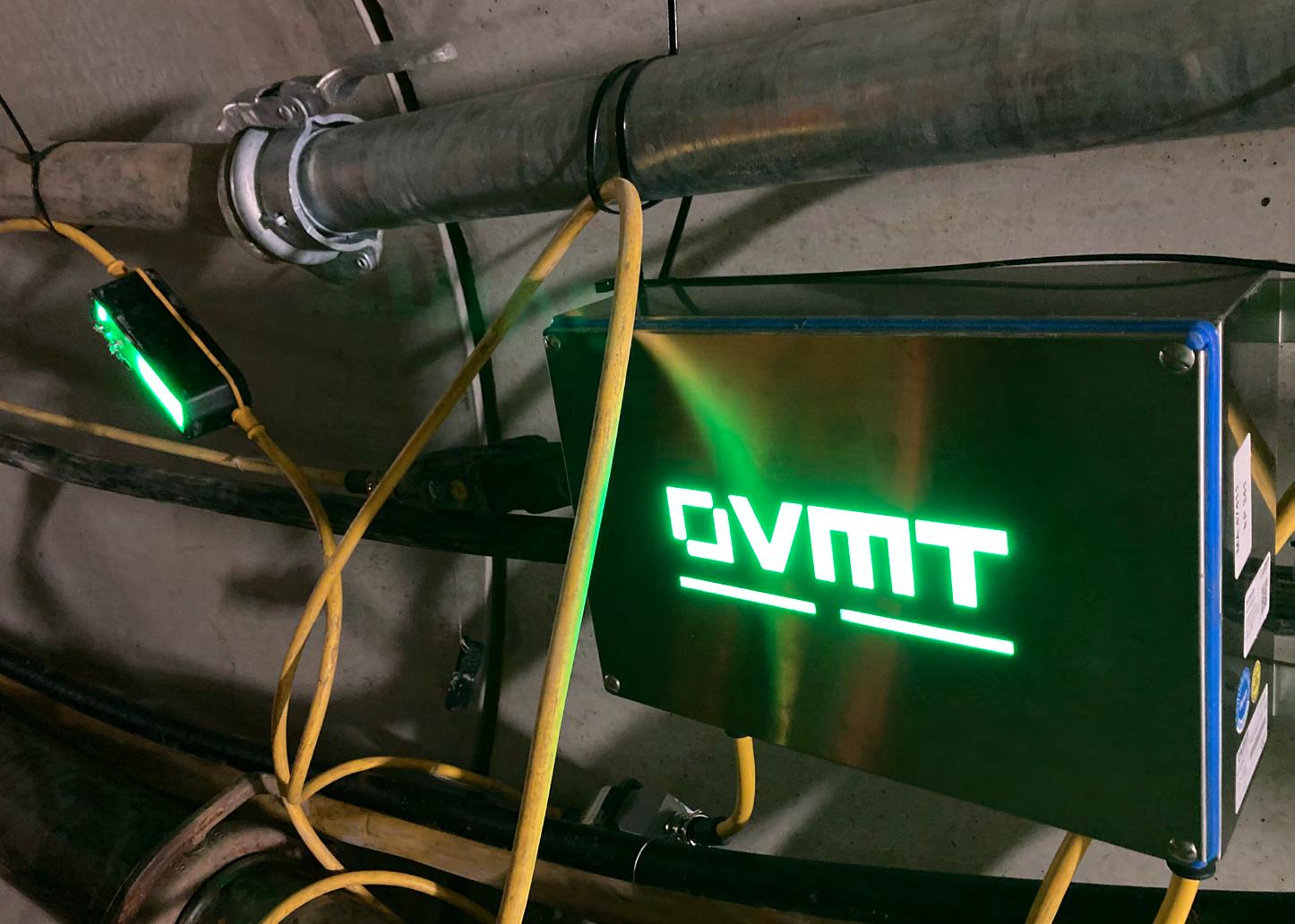

When it comes to trenchless technology, innovation isn’t solely about pushing the boundaries of what’s possible; it’s about making underground operations more efficient and safer for the teams working on site. VMT has consistently been at the forefront of this drive, and their latest offering, TunnelHub, is a prime example of this philosophy in action. This sophisticated Ethernet-based infrastructure promises to transform microtunnelling and direct pipe operations, connecting teams and equipment in ways we’ve not seen before, and ultimately, changing the very nature of how projects around the world are delivered.

Tunnel Control Unit for integration of navigation sensors

To better understand the vision behind TunnelHub and the impact it’s set to make, I spoke with Jürgen Göckel, Business Development Manager for Microtunnelling at VMT. “The inspiration for TunnelHub,” he explained, “was to give jobsite teams the ability to seamlessly communicate with each other anytime and anywhere on the construction site, including inside the tunnel.” He elaborated that despite advancements in the automation and remote control of tunnelling processes, the reality remains that personnel still need to enter pipelines for maintenance, critical repairs, and essential surveys. Recognising the inherent risks associated with these confined spaces, VMT sought to develop a solution that would fundamentally prioritise both safety and efficiency.

TunnelHub’s core innovation lies in its Smart System Cable. Far more than just a cable, this is a central data line, a digital backbone equipped with integrated repeaters and WLAN access points. This ingenious design creates seamless Wi-Fi coverage, effectively blanketing the entire tunnel and stretching from the control cabin all the way to the Tunnel Boring Machine (TBM). This uninterrupted connectivity is a cornerstone of the system’s capabilities. Strategically placed connection points every 50 metres support a network of cameras for real-time monitoring, enabling constant communication and personnel tracking with impressive accuracy. This provides a level of situational awareness that is seen by those using the system as a genuine game-changer.

But TunnelHub’s commitment to safety extends far beyond simple location tracking. The system also boasts dedicated interfaces for sophisticated gas monitoring systems and alarm functions, enabling rapid and coordinated tunnel evacuation through strategically placed optical and acoustic warning signals. To further enhance safety and visibility, optional LED modules with battery backup provide optimal tunnel illumination, including emergency lighting that helps support a safe exit in the event of a power outage or other unforeseen incidents.

In addition to its multi-faceted safety features, TunnelHub is meticulously engineered to streamline operations and dramatically enhance efficiency. By cleverly integrating all essential components into the Smart System Cable, VMT has eliminated the need for cumbersome and space-consuming additional boxes within the tunnel itself. This seemingly simple design feature translates to a greatly simplified and accelerated installation process, freeing up valuable time and resources and reducing the potential for errors. The central data line acts as a single point of control, managing a multitude of essential functions, including seamless audio communication, highdefinition video monitoring, accurate personnel tracking, comprehensive tunnel lighting, and rapid alarming, thereby optimising the entire pipe jacking process from start to finish. >

The system’s integrated WLAN capabilities also unlock exciting new possibilities for enhanced remote collaboration and real-time support. Project teams can now leverage standard communication apps, like WhatsApp, for instant messaging and rapid information sharing, or conduct high-quality video calls to remotely troubleshoot complex issues and provide expert guidance for maintenance operations from afar, minimising downtime and maximising productivity.

Implementation is designed to be as intuitive and straightforward as possible. VMT takes a hands-on approach, delivering the system directly to the construction site and collaborating closely with the

customer’s team on the initial basic installation. Thanks to TunnelHub’s intelligent and user-friendly design, it automatically recognises newly installed components, minimising the need for complex and timeconsuming configurations and enabling teams to get up and running quickly and efficiently.

“TunnelHub is fundamental for us,” emphasised Jürgen, “because our portfolio of navigation solutions for all types of microtunnelling machines and tunnel alignments is now based on the same uniform hardware infrastructure. An example of this is our assistance systems for automating control measurements, even in small diameters where men-entry is not possible.”

This strategic alignment creates tremendous synergies across VMT’s entire ecosystem, allowing them to seamlessly bundle a wide range of functionalities within a single, unified data line. Moreover, VMT’s long-standing and trusted partner, Jackcontrol AG in Switzerland, which actively participated in the development of TunnelHub, utilises the same robust hardware platform. This enables effortless and seamless integration of their specialised systems, such as the Microtunnelling Support System, advanced pipe load management solutions, and precise pipe joint observation technologies.

The initial response from customers and pilot programmes has been overwhelmingly positive, with early

adopters consistently praising TunnelHub’s comprehensive and reliable Wi-Fi coverage, crystal-clear video call capabilities, and highly accurate people tracking features. In fact, this invaluable customer feedback has played a direct role in shaping the system’s ongoing evolution, leading to the recent development of the advanced alarm module and the highly sensitive gas monitoring interface.

Looking ahead, VMT envisions TunnelHub as a dynamic and open system that will continue to adapt and evolve in direct response to the

ever-changing needs of the industry. While the system primarily serves as an indispensable assistance tool, it significantly enhances the user’s ability to maintain a complete and comprehensive overview of the entire construction site, paving the way for more sophisticated autonomous and remote operations in the years to come.

By connecting teams, equipment, and critical data in real-time, VMT is empowering the sector to build a safer, more productive, and more connected future, one tunnel at a time.

TWO RECORDS AND A MAJOR PROJECT IN BRUGES

Most people remain unaware of what goes on underground. It’s only when problems arise that society takes notice, yet functioning sewers are vital for both infrastructure integrity and public health.

In the Belgian city of Bruges, IMPREG GmbH has once again demonstrated its position as a pioneer and specialist in largeprofile rehabilitation. Working alongside long-term partners Kumpen Renovatietechnieken and Smet Group, the company successfully rehabilitated several DN 1400 – DN 2000 sewers for client Aquafin NV in an exceptionally complex large-scale project.

Consulting expertise from start to finish

A team of experts from IMPREG GmbH supported the project throughout its entire lifecycle, from planning to final acceptance, ensuring feasibility was assessed early and implementation could be planned and executed at the highest professional level.

High complexity requires precise preparation

Over many years, high levels of biogenic sulphuric acid and aggressive wastewater had corroded the concrete pipes to such an extent that the steel

“

The success of this measure is the result of cooperation between all parties involved at the highest level from start to finish. Everything fell into place in all areas, this fills me and the entire IMPREG GmbH team with great pride

reinforcement was exposed in places. Immediate action was required. Aquafin NV opted for GRP liner rehabilitation using UV technology.

Given the soft, partially sandy subsoil, a construction road several hundred metres long was laid using steel plates to allow access for heavy trucks and construction machinery. Extensive wastewater diversion was also required, designed to handle both dry-weather flow and rainy-weather events for Bruges’ 120,000 residents.

To access the sewers, located 7–9 metres below ground, castin-place concrete shafts with pile

foundations were constructed, as groundwater levels could not be lowered. The rehabilitation was divided into several sections, covering diameters from DN 1400 to DN 2000 and lengths up to 200m.

A record-setting achievement: The first dn 2000 in Belgium

The project set two records for IMPREG GmbH. The largest and heaviest IMPREGLiner DN 2000, weighing 45.2 tonnes, measured 159 m in length with a wall thickness of 22.1 mm, making it the heaviest GRP pipe liner ever produced in IMPREG’s history. Including its specially manufactured reusable transport crate and

temperature-controlled cooling system, the total transport weight reached an impressive 56 tonnes. The project also marked the first-ever installation of a DN 2000 GRP liner in Belgium.

Power

and precision: Pulling and curing a 45-tonne GRP liner

Both personnel and equipment were pushed to their limits. Around 30 workers were on site to install the record-breaking UV liner. The liner was pulled from its crate using a custom installation aid with a folding device. A specially designed pulling packer was attached and used to guide the liner into place. >

Thanks to precisely coordinated scheduling, all works were completed within the planned timeframe.

Curing GRP CIPP liners of this magnitude demands significant UV power. A ProKASRO Power UV system with three jumbo cores delivering 3 x 6 x 2,000 watts was deployed. Because a 22.1 mm wall thickness cannot be cured by UV radiation alone, peroxide was added to the resin mixture as a reaction accelerator. The resulting exothermic reaction ensured complete curing through the full wall thickness.

Collaboration and innovation

“The combination of different perspectives, the highest level of expertise in theory and practice, and the creativity of the manufacturer IMPREG GmbH for temperature-controlled

transport, all characterised by mutual trust and the utmost respect, has led to this success,” said Gert-Jan Merkx, CEO of Kumpen Renovatietechnieken.

IMPREG – your supplier of choice

Several factors were decisive in selecting IMPREG GmbH and the IMPREGLiner for this project:

• Global references and extensive expertise in rehabilitating profiles larger than DN 1200

• Proven competence in planning and technical implementation, supported by long-standing partnerships and open, transparent communication

• IMPREGLiner properties that ensure safe handling on site and long-term durability in operation

• Lean production processes and just-in-time delivery to site

Looking ahead

“The success of this measure is the result of cooperation between all parties involved at the highest level from start to finish. Everything fell into place in all areas, this fills me and the entire IMPREG GmbH team with great pride. Further projects of this magnitude are already in the planning stage, both in Europe and in the USA,” said Guido Wey, General Manager of IMPREG GmbH.

Connected

www.vmt.global

INSIDE CHANNELINE’S BESPOKE GRP REHABILITATION PROCESS

Precision-engineered lining systems built to fit every unique structure

Every underground structure tells its own story, shaped by age, geometry, condition, and location and that’s why Channeline has never believed in a one-size-fits-all approach. For more than four decades, the company has specialised in designing and manufacturing fully structural, bespoke GRP lining systems that are engineered to fit each unique host structure precisely.

“

Quality is fundamental to Channeline,” says Nick Walters, Director. “Our goal is simple to produce the best GRP rehabilitation liners in the world. Every liner that leaves our facility has been tested, verified, and signed off with complete traceability.”

The Channeline process begins with understanding. Before a single drawing is produced, the technical team collaborates closely with contractors and asset owners to define the project’s exact requirements. This may involve reviewing CCTV or laser survey data or visiting the site to capture details that can’t be seen on screen, such as irregular profiles, access limitations, or flow management considerations.

Once the data is gathered, Channeline’s in-house engineers translate it into a custom structural solution. Each liner is designed to meet both hydraulic and load-bearing requirements and is frequently validated through finite element analysis (FEA) to confirm performance under all anticipated conditions. The result combines decades of trenchless expertise with advanced modelling and materials science, creating solutions that restore ageing infrastructure to better-than-new condition without excavation.

For contractors, that precision translates to confidence. Whether rehabilitating a non-circular brick sewer beneath a city street or a stormwater culvert running under a motorway, Channeline liners arrive ready to install. Every unit is individually manufactured to order from highspecification glass-reinforced plastic (GRP), ensuring a perfect fit and consistent performance.

Quality lies at the heart of Channeline’s philosophy. Rigorous inspection and validation occur at every stage of production. Daily batch testing verifies compliance in key parameters including wall thickness, flexural strength, compression, and ring stiffness. Each shipment includes a comprehensive test report and

certificate of conformity, and independent third-party inspection is available where required.

“Quality is fundamental to Channeline,” says Nick Walters, Director. “Our goal is simple — to produce the best GRP rehabilitation liners in the world. Every liner that leaves our facility has been tested, verified, and signed off with complete traceability.”

When manufacturing is complete, Channeline’s logistics specialists coordinate global shipment and delivery. The company’s modular design system ensures even the largest or most irregular segments can be transported and handled easily, supported by end-to-end logistics planning.

On-site, Channeline provides installation training and supervision, offering contractors practical support to ensure every liner performs exactly as designed. Recently, Dr Dev Chelot, Channeline’s Quality Assurance and Control Manager,

travelled to Los Angeles to conduct a mock installation of a multi-segmental GRP system.

“We replicated the Channeline training on-site,” explains Dr Chelot. “We guided the team through the process, adapting to local conditions, and shared key installation practices to ensure everything was perfect.”

Channeline’s commitment extends far beyond installation. Every system is backed by a ten-year standard guarantee and designed for a 150-year service life, giving asset owners and contractors complete long-term confidence.

From initial site assessment to final installation, Channeline’s approach is defined by collaboration, precision, and uncompromising quality, delivering not just a liner, but a customengineered partnership built to perform for generations.

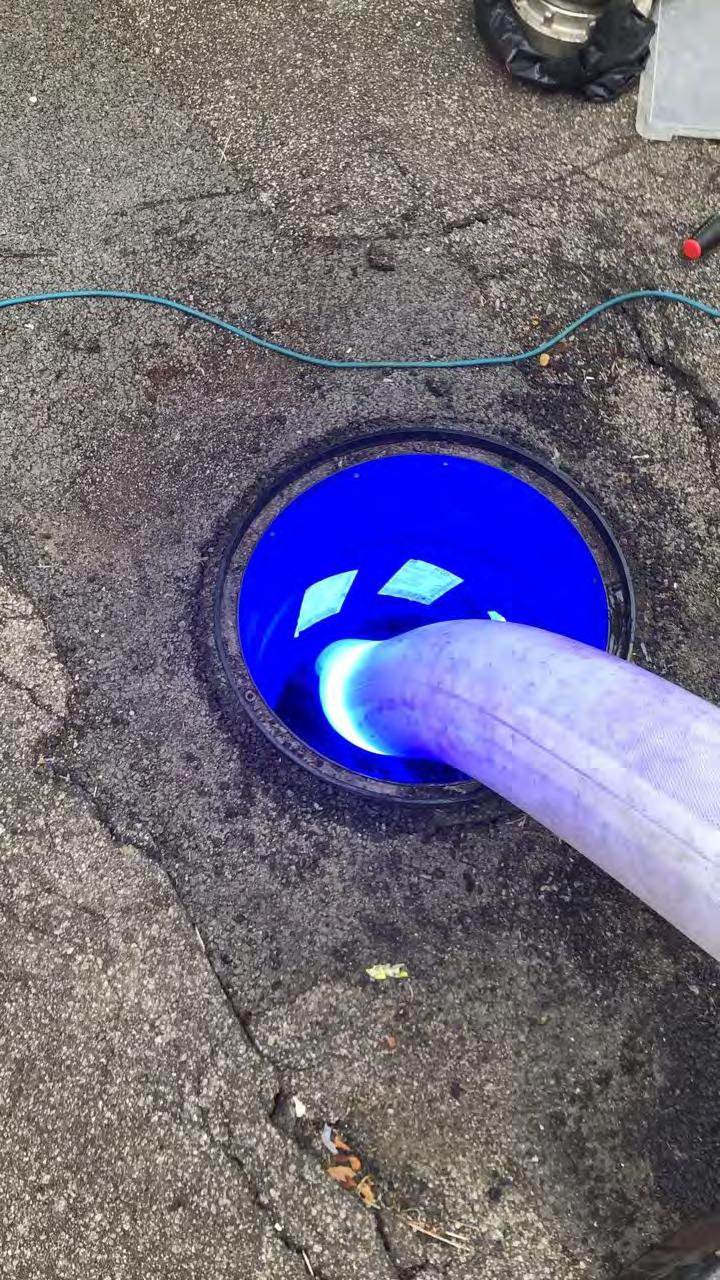

Pump station rehabilitation using Hermes Technologie m-coat system

McBreen Enviro UK was contracted to restore a pump station suffering from groundwater ingress through the joints of its concrete chamber rings. The client required a permanent solution to eliminate leakage, protect the structure, and minimise downtime.

The problem

Groundwater was entering the pump station through failed joints between the concrete chamber rings, allowing external water to infiltrate the system. The resulting inflow increased pumping demand and operational costs while accelerating the structure’s deterioration.

Access was further complicated by the confined layout of the shaft, which required strict adherence to confined-space safety protocols.

Because the system remained live throughout the works, robust flow and waste management controls were essential to maintain compliance and site safety.

The McBreen Enviro UK solution

A team of seven qualified rehabilitation engineers delivered a five-day programme using Hermes Technologie’s M-Coat system, a high-performance method that combines precision sealing and automated lining to deliver durable, watertight protection.

The rehabilitation involved a twostage process. First, dual-compound polyurethane resin was injected at 300 mm intervals around the 7.5 m circumference to seal joints and stop active leakage, forming a watertight barrier. The internal surfaces were then lined using M-Coat’s centrifugal spray technology, achieving

consistent coverage, a high-strength finish, and minimal manual entry.

Surface reprofiling and cleaning

Following the precision sealing stage, all internal surfaces were thoroughly cleaned and reprofiled using a TSSR ultra-high-pressure (UHP) cleaning unit. This process removed residual deposits and ensured a sound, even substrate, the ideal surface for the subsequent relining works.

Automated structural lining

Once preparation was complete, the internal surfaces were lined using M-Coat’s centrifugal sprayapplication technology. This fully automated system ensured even mortar distribution and structural integrity, eliminating weak points and significantly reducing the need for manual entry.

Waste and flow management

To manage waste safely, McBreen Enviro UK supplied two 20,000-litre waste tankers and a KOKS mobile storage container with an additional 90,000-litre capacity. Certified operatives implemented traffic management, deploying “Stop & Go” controls when required to maintain safe site access.

Safety, collaboration and compliance

All works were carried out under current health and safety regulations, including confined-space procedures. McBreen Enviro UK maintained continuous communication with the client to manage access, weather impacts, and operational constraints efficiently, ensuring full transparency at every stage.

Outcome

McBreen Enviro UK successfully eliminated groundwater ingress, reinstated the structural integrity of the pump station, and extended the service life of the asset. The application of Hermes Technologie’s M-Coat system delivered a durable, watertight lining while the automated process enhanced safety, accuracy, and overall project efficiency.

This project demonstrates McBreen Enviro UK’s capability to deliver complex rehabilitation works with precision, innovation, and full compliance, protecting critical wastewater infrastructure for the long term.

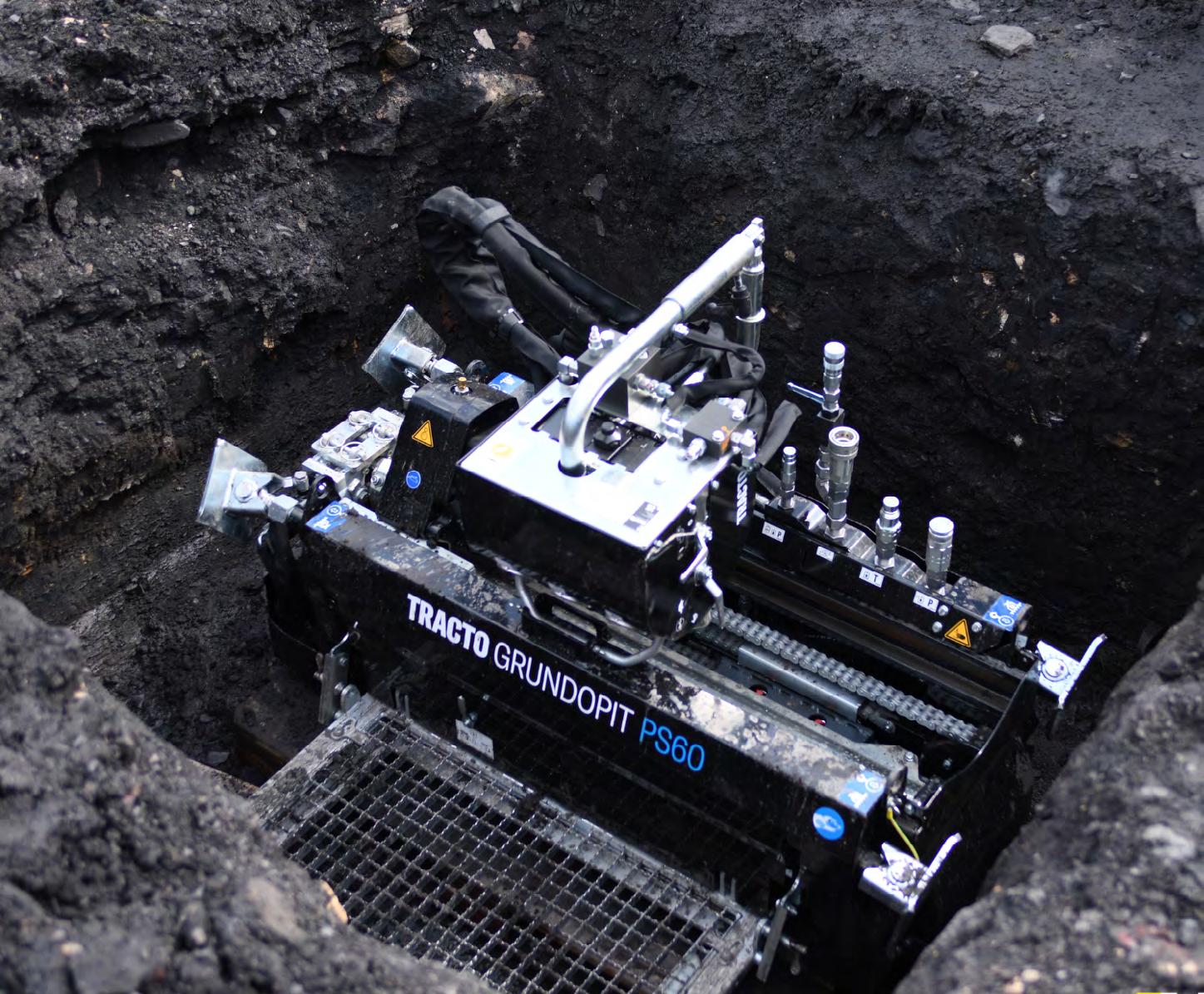

EAS opts for compact PS60 for underground works

Scottish-based Electricity Asset Services specialises in high and low voltage underground electricity networks and works on behalf of major framework contractors and Distribution Network Operators (DNO’s). With over 60 years of combined experience, the company designs, manages and executes electricity works throughout Scotland and has built a reputation for exceptional work and service.

In summer 2025, the company took delivery of a TRACTO UK GRUNDPIT PS60 Horizontal Directional Drilling (HDD) rig, which marked the company’s official move into the world of trenchless technology. The compact, lightweight rig allows the company to install up to 100 metres of cable without disturbing the surface of the local environment, which is a real gamechanger for the company. Jack Brown is Business Development Lead for EAS and was involved in the procurement of the unit:

“

This unit is ideal for more complex sites where we are faced with road crossings, tight or restricted spaces, sloped terrain, or areas with heavy soil. It is easy to transport which was appealing to us as a company as we work hard to restrict transport movements when out on projects

“This unit is ideal for more complex sites where we are faced with road crossings, tight or restricted spaces, sloped terrain, or areas with heavy soil. It is easy to transport which was appealing to us as a company as we work hard to restrict transport movements when out on projects.”

The EAS team initially saw the unit at No Dig Live and then attended demonstrations at TRACTO’s Bedford HQ, as well as a trip to the HQ in Germany. To finalise the deal, the two businesses worked closely together further putting the unit through its paces at EAS’s Lochgelly HQ. Nothing was too much trouble for the TRACTO team and Jack is impressed with the service both before and after the deal was made;

“We had to make sure the PS60 was up to the challenging terrains and locations that we typically work in

and the TRACTO team worked very hard to demonstrate its capabilities to us. After the machine was bought and delivered, they even offered to help us on the first job – and subsequent jobs if required. The on-going support from the company is very impressive.”

The company recently completed its first project using the PS60 trenchless drilling rig. The job site included a newly resurfaced road, meaning traditional excavation was not an option. To overcome this, they carried out a 20-metre guided mole shot which then enabled the installation of 114 metres of mains cable without disturbing the surface. The scope also included the installation of a new threephase service and the successful transfer of an existing supply. With the first job under their belt, EAS are now ready to offer the unit out on more projects going forward.

More flexibility, productivity, safety and operator comfort for your drilling projects. That’s the GRUNDODRILL 20ACS from TRACTO.

Combining the proven ‘All Condition System’ concept with the latest in automation and top-of-the-range ergonomics, this 200 kN drilling rig can handle even the most complex drilling projects in changing ground conditions, including rock.

To find out more about the 20ACS and our customised service solutions, please get in touch: info@tracto.com T +49 2723 8080

For horizontal directional drilling (HDD) contractors, productivity and uptime are everything. Whether boring beneath a busy roadway or installing utilities under a riverbed, a delayed drill or breakdown can quickly lead to missed deadlines, rising costs, and frustrated clients.

To meet these challenges, remote diagnostics and fleet monitoring technologies are transforming how trenchless contractors operate, offering greater visibility, faster troubleshooting, and smarter equipment management.

At Vermeer UK, we’ve seen first-hand how connected equipment and digital platforms are helping HDD contractors maximise uptime and performance across multiple sites. >

Reducing downtime with remote diagnostics

Remote diagnostics systems allow service teams or equipment dealers to monitor HDD rigs in real time, tracking data such as engine temperature, hydraulic pressure, and performance trends. When an issue arises, alerts can be sent instantly to the relevant technicians.

Instead of waiting for a fault to escalate or dispatching engineers for manual inspection, the machine itself communicates diagnostic data back to a central platform. In many cases, issues can be identified and resolved remotely, or, if site attendance is required, technicians can arrive with the right parts and tools on the first visit. The result is faster response times, reduced labour, and significantly less downtime.

Smarter decision-making through fleet monitoring

Modern HDD fleets now rely on telematics platforms that record detailed information on machine utilisation, idle time, fuel consumption, and service

intervals. By analysing this data, contractors can identify underused assets, redeploy machines more effectively, and make evidence-based decisions about maintenance, upgrades, or replacement.

Fleet monitoring also helps benchmark performance across different rigs and crews, revealing opportunities for operator training or workflow optimisation. Over time, this creates a feedback loop that improves productivity, equipment longevity, and cost control across the fleet.

Supporting compliance and maintenance

Digital service logs and automated maintenance scheduling don’t just improve efficiency, they also support compliance with UK regulations such as PUWER (Provision and Use of Work Equipment Regulations 1998). Fleet monitoring platforms can issue reminders for upcoming inspections, service intervals, or certification renewals, ensuring that no critical checks are overlooked.

This data-driven approach provides a transparent maintenance history for every asset, helping contractors demonstrate compliance, manage risk, and maintain consistent safety standards across their operations.

The Vermeer UK approach

Vermeer UK provides HDD contractors with connected equipment solutions, training, and tailored service packages that make fleet management smarter, safer, and more efficient. From diagnostics and telematics support to fully integrated drilling systems, Vermeer helps operators stay productive and compliant, on every job, every time.

To learn more about Vermeer’s connected HDD solutions, visit vermeeruk.co.uk/ new-equipment/horizontaldirectional-drilling.

STILL IN A LEAGUE OF ITS OWN

THE D100X140 S3 NAVIGATOR® HORIZONTAL DIRECTIONAL DRILL

The D100x140 S3 is a unique machine in the HDD market. It’s not only used for oil, gas or other large pipeline projects — but utility projects as well due to the machine’s small footprint.

The Hydrocam™ System

Developed by UK manufacturer PIPA, the Hydrocam™ is an industryapproved, pressurised push-rod camera system purpose-designed for live inspection of potable water pipelines. It allows utilities to carry out detailed surveys of DMA-sized mains under standard operating pressure, with no interruption to supply.

The fully sanitised, WRASapproved system integrates an HD camera with ultra-bright COB lighting, an ultra-responsive hydrophone for pinpoint leak detection, and a cable tracing function to accurately locate buried assets. A dedicated chlorination housing ensures complete hygiene compliance for safe use in drinking-water applications.

Training and field demonstration

Over a five-day programme, API provided both classroom and on-site training to Maynilad Water engineers. The sessions included system familiarisation, leak verification, locating buried bends, and identifying inline assets such as water meters.

Training culminated in a successful night-shift deployment, where several live surveys were

“ We are receiving growing interest from international clients in our Hydrocam™ and Flowrider™ systems and are delighted to see API delivering highquality training in Manila

carried out under operating conditions. The project was supported by PIPA’s local agent, Waterkonsult, with additional meetings held with Manila Water and MWSS during the visit.

Safe and adaptable technology

PIPA’s pressurised inspection systems are designed for safe use on potable pipelines via fire hydrants, valves, and pressure fittings. The Manila configuration required only minor adjustments from UK specifications, demonstrating the system’s adaptability to a wide range of network types.

Global collaboration and expansion

“We are receiving growing interest from international clients in our Hydrocam™ and Flowrider™ systems and are delighted to see API delivering high-quality training in Manila,” said Fabio Orlandi,

PIPA Representative. “Further projects are already planned in Belgium, Finland, and Spain.”

The longer-range Flowrider™ system, capable of inspecting up to 1 km of pipe, will form part of future collaboration in the Philippines.

PIPA - global leaders in pressurised inspection

PIPA has developed one of the world’s most comprehensive ranges of pressurised pipe inspection systems, working with the majority of UK water utilities and an expanding list of international clients. Its Hydrocam™ and Flowrider™ systems offer reliable, easy-to-deploy inspection and leak detection tools suitable for potable water networks of varying sizes and configurations.

For more information, visit www.pipa-uk.com

Building carbon-conscious supply chains in utilities and industrial transport

Reducing emissions across utility and industrial supply chains has become a non-negotiable. As the UK moves toward net zero, businesses are under pressure to cut operational carbon not only in energy generation and enduse, but across the logistics networks that support core infrastructure.

Towmate Trailers, a UK-based manufacturer of modular trailer systems, is helping the utilities and construction sectors tackle one of the most carbon-intensive yet often overlooked aspects of operations: the movement of heavy plant and equipment. From transporting pipe coils and diggers to moving reinstatement materials between sites, machinery logistics still rely heavily on diesel fleets, inefficient routing, and outdated trailer designs.

Identifying the Carbon Hotspots

Transport is the UK’s single largest source of greenhouse gas emissions, accounting for 28% of the total in 2022. The true carbon cost of moving machinery extends beyond tailpipe output to include loading, idling, poor route planning, and underused return journeys, all of which drive up costs and waste energy.

Driven by regulation and rising environmental expectations, contractors are re-evaluating fleet operations. Reducing vehicle miles, minimising trailer weight, and consolidating loads are now key priorities. Lightweight, modular trailer innovation from manufacturers such as Towmate Trailers is helping offset the additional mass of electric vans and diggers, enabling crews to carry more equipment per journey while remaining within legal weight limits.

Designing with net zero in mind

A carbon-neutral manufacturer, Towmate Trailers has demonstrated how embedding sustainability into design and engineering can deliver compound benefits. Its modular trailer systems allow operators to transport multiple load types with fewer trailers, reducing fleet size and promoting circular, lower-impact operations.

In collaboration with Kier Group, Towmate designed a modular solution that enabled excavation and reinstatement work to be completed using a single crew and trailer rather than multiple vehicles. The result was improved efficiency, lower emissions, and streamlined project delivery.

A similar partnership with Clancy led to the development of a hotbox trailer based on a Ram General Duty chassis, allowing two operatives and one vehicle to carry enough asphalt for two days’ work, cutting return trips and increasing daily output.

Regulation and digital accountability

Carbon accountability is now embedded within procurement and compliance frameworks. Under the UK’s Procurement Policy Note (PPN) 06/21), suppliers bidding for major government contracts must commit to net zero and provide detailed emissions disclosures.

For logistics and plant operators, this means demonstrating both operational safety and measurable carbon performance. Digital tracking, load monitoring, and route optimisation are increasingly critical for accurate reporting and continuous improvement. Combining these digital insights with physical engineering advancements is essential for achieving real carbon reductions.

Retrofitting for resilience

Rather than replacing entire fleets, many contractors are retrofitting existing trailers with modern safety and emissions-reducing systems such as LaySafe, developed by Towmate. Modular upgrades extend the life of existing assets, reduce waste, and help operators comply with evolving legislation, offering a practical path toward long-term decarbonisation.

A shift in mindset

Building a carbon-conscious supply chain is less about radical overhauls and more about continuous, datadriven improvement. Route by route and component by component, efficiency gains are achievable. For utilities and industrial contractors navigating the road to net zero, transport logistics must now sit at the heart of decarbonisation strategy, not as an afterthought, but as a core enabler of sustainable progress.

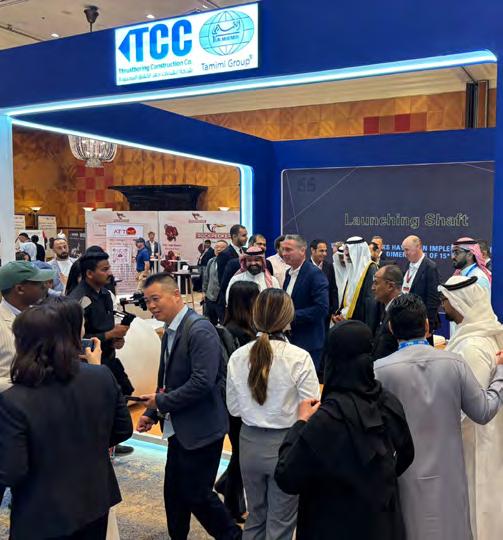

SAUDI DEBUT HERALDS A NEW ERA FOR TRENCHLESS MIDDLE EAST

A landmark moment for the region’s utilities sector, and the realisation of a long-term industry vision

“ Bringing Trenchless Middle East to the Kingdom has been a long-term vision. We are incredibly proud of what was achieved in Jeddah and deeply grateful to TCC, CEPCO, our partners, exhibitors, speakers, and visitors. The trust they placed in us made this exceptional event possible. The success here has laid a powerful foundation for the future

-Paul Harwood, Managing Director, Westrade Group, Event Organiser

Trenchless Middle East 2025 has been hailed as a breakthrough moment for the region’s infrastructure community, marking the first time in its 20-year history that the event has been held in the Kingdom of Saudi Arabia. Hosted at the Jeddah Hilton on 11–12 November, the exhibition and conference drew exceptional attendance and firmly established itself as the region’s leading platform for trenchless innovation.

For Westrade Group, this moment was the culmination of a multi-year strategic vision to bring the trenchless industry’s flagship Middle Eastern event into Saudi Arabia, and the results spoke for themselves. After two decades of anticipation, Trenchless Middle East finally arrived in the Kingdom and delivered an event the region can genuinely be proud of.

Unprecedented support from Saudi Arabia’s trenchless leaders

A defining factor in the event’s success was the backing of two of the Kingdom’s most influential utilities contractors, Thrustboring Construction Company (TCC) and CEPCO, who supported the event from inception. As Platinum Partners their involvement gave the show immediate legitimacy, signalling strong confidence from the region’s major players and ensuring that senior representatives from utilities, government bodies, and specialist contractors attended in force.

This level of local investment was particularly significant for a first-time event. It highlighted Saudi Arabia’s commitment to adopting trenchless methods that support sustainable, minimally disruptive infrastructure delivery, priorities at the heart of the Kingdom’s development strategy.

A world-class programme and outstanding engagement

With over 70 leading suppliers exhibiting and a high-profile international conference, Trenchless Middle East 2025 exceeded expectations across every metric. Delegates from utilities, municipalities, contractors, and global technology innovators explored solutions in HDD, pipeline rehabilitation, underground utilities management, robotics, and sustainable construction.

Speakers and exhibitors praised the high quality of engagement. The warm hospitality extended by partners and hosts also contributed to the show’s exceptional atmosphere, something repeatedly noted by both regional and international attendees.

Supported once again by the ATTME (Association of Trenchless Technologies Middle East) and ISTT, Trenchless Middle East 2025 exemplified the region’s commitment to advancing trenchless solutions as a cornerstone of efficient, sustainable infrastructure growth.

David Henderson, Regional Head of the Department at Applus and Chair of the Association of Trenchless Technology in the Middle East (ATTME), reflected on the event’s significance: “This is a milestone for the Middle East industry. The conversations and connections made here reflect the substantial progress we’re witnessing across the region. >

Trenchless Middle East isn’t just an exhibition; it’s a vital gathering for our community to discuss, innovate, and drive the future of trenchless technology.”

The realisation of a long-term vision

For Westrade Group, the debut of Trenchless Middle East in Saudi Arabia represents the fulfilment of a strategic ambition many years in the making. Paul Harwood, Managing Director, reflected on the achievement:

“Bringing Trenchless Middle East to the Kingdom has been a long-term vision.

We are incredibly proud of what was achieved in Jeddah and deeply grateful to TCC, CEPCO, our partners, exhibitors, speakers, and visitors. The trust they placed in us made this exceptional event possible. The success here has laid a powerful foundation for the future”.

This first edition in Saudi Arabia proved far more than a new location, it established a new regional benchmark for trenchless events and demonstrated the Kingdom’s central role in advancing sustainable utilities infrastructure across the Middle East.

“ This is a milestone for the Middle East industry. The conversations and connections made here reflect the substantial progress we’re witnessing across the region. Trenchless Middle East isn’t just an exhibition; it’s a vital gathering for our community to discuss, innovate, and drive the future of trenchless technology

Riyadh 2026: Building on a powerful foundation

Buoyed by the tremendous success of the Jeddah debut, preparations are already underway for the next edition, this time in Riyadh, the Kingdom’s capital. Interest from sponsors, exhibitors, and utilities is already strong, reflecting the momentum and credibility forged by the 2025 event.

With Saudi Arabia accelerating infrastructure investment on an unprecedented scale, Trenchless Middle East is now positioned exactly where the industry needs it to be. The 2025 edition was more than an event, it was the start of a new chapter for trenchless technology in the region.

Practice, theory and the impact of AI

“Knowledge guides us, but experience shapes us; through practice, skill becomes wisdom.”

Frank Reilly Director JBP’s Trenchless, Training Programme

The above quote is a synopsis of the ancient Greek philosopher Heraclitus’s thinking on education. For me it summarises, better than I ever could, the relationship between practice and theory, and interestingly includes the word wisdom, not a word often found in technical training courses or theoretical textbooks (if such things still exist!). It’s interesting to note that the word ‘wisdom’ is a compound of old English ‘wis’ –knowing – and ‘dom’ – judgement. But enough of lessons in Greek philosophy and the etymological roots of words.

A balance of practical and theory

If we accept, from the above, there is a self-evident relationship between practice and theory, and I assume most of us do, then the only question that arises is where does the balance lie, and how best do we achieve that optimal balance? Okay, that was two questions.

Well, the obvious answer is: it depends. It depends on the focus of any training and its objectives

and desired outcomes for those undertaking the training. There are plenty of good reasons and examples of courses where the weighting is heavily focused on imparting information, aiming to deepen the technical knowledge of course participants – for example, CIPP liner design.

Equally, for a CCTV camera operator, practical, hands-on skills are perhaps paramount for a successful outcome to a good pipeline inspection.

Better outcomes

I would still argue that all good courses should give space for both the practical and the theoretical, appropriately balanced. This, I believe, provides both context and more secure knowledge, ultimately resulting in a better outcome.

At trenchless events, such as the recent Trenchless Middle East and Trenchless Asia conferences, JBP’s Applied Trenchless Technology Workshops aim to provide practical insights delivered by industry professionals, complementing the more technically focused

papers included in the conference programs.

What role for AI?

So where does AI fit into this training equation? We all know AI is everywhere and rapidly revolutionising the way we do things in almost every sphere. As one side of the training equation is knowledge, it is hardly surprising that AI is already having a significant impact in training.

Two news headlines caught my attention recently.

The first was an interview on the BBC with Sundar Pichai, the head of Google’s parent company, Alphabet. He said, “People should not blindly trust everything AI tools tell them”, as it is prone to errors, and it is engineered to deliver answers that please us. This sentiment, coming from the head of Alphabet, should serve as a cautionary note! He went on to highlight the importance of having a rich information ecosystem, rather than solely relying on AI technology. Sage advice indeed!

The second item that caught my attention was a headline on one of the inner pages of a leading U.K. newspaper – “What AI doesn’t know: we could be creating a global knowledge collapse.” At a glance this could be dismissed as the rantings of an AI sceptic, but the article deserved closer inspection. Here are a few quick takeaways from the article that I think are relevant to this topic.

LLMs – a cautionary note

The depth of the LLMs (large language models), foundation of AI’s knowledge base, are relatively shallow. They have an incredible breadth of data sets they can and do access for us at the touch of a button, but they do not necessarily include the accumulated depth of the knowledge we might assume.

Over 80% of the data included in LLM’s knowledge databases are based on English language resources. This results in the exclusion of significant contributions and sources from other languages.

These large language models tend to amplify “knowledge hierarchies” - simply put, they give great importance to reproducing the most statistically prevalent ideas

and theories. In the trade this is known as “mode amplification.” The risk here is that this can lead to a loop of amplification that ignores and suppresses valuable accumulated areas of knowledge. This phenomenon can be particularly true, not only because of language imbalances already referred to above, but also in niche areas – something for our sector to consider.

Before I go down a rabbit hole of inspecting the architecture of AI in too much detail, way above my pay grade, or sound like a Luddite seeking to smash up my nearest data centre, let me clearly state, I think AI has an important and valuable role to play. It should be included in both the content and delivery of any and all of our training, not least because it already does and will continue to impact every aspect of what we do going forward.

Curiosity didn’t kill the cat!

To return to a bit of etymology, in an earlier article I pulled apart the word ‘expertise’ – from the Latin, and meaning ‘to know by experience’.

Add to this wisdom – learnt experience and judgement –and we have the benefits of the practical and the theoretical coming together. AI can help us fast track our access to and processing of an incredible wealth of information and data. But maintain a healthy degree of scepticism and always be curious!

“I know that I am intelligent, because I know that I know nothing.” – Socrates

P.S. Your have say in our final monthly Training poll for 2025, on LinkedIn!

Next issue: Looking forward, Looking back.

Which of these options most closely reflects your motivation to sign up for a course in 2026?

TRENCHLESS MOROCCO 2026

11-12 February 2026

Rabat Marriott Hotel, Rabat, Morocco www.trenchlessmorocco.com

TRENCHLESS ASIA 2026

10 -11 June 2026

Queen Sirikit National Convention Centre Bangkok, Thailand www.trenchlessasia.com

NO-DIG LIVE 2026

29 September – 1 October 2026

NAEC Stoneleigh Park, Warwickshire www.nodiglive.co.uk

TRENCHLESS MIDDLE EAST 2026

www.trenchlessmiddleeast.com

NO-DIG ROADSHOW SERIES 2026

Dublin | London | Glasgow www.nodigroadshows.co.uk

Graham Howard, Chair, UKSTT

A message from the Chair

UKSTT was delighted to participate in the NASTT No-Dig North Exhibition this month, joining international colleagues to share insights and explore the latest developments in trenchless technology.

It was an honour to represent UKSTT along with Ian Ramsay of ISTT to collect three awards for outstanding contributions to the trenchless industry on behalf of three legends in our industry- Dec Downey, Norman Howell and Russell Fairhurst . Congratulations to them for all they have done and continue to do.

The event highlighted major advancements in condition assessment, asset management, and innovative rehabilitation techniques. Our presence helped strengthen collaborative ties and ensured UK perspectives remain well represented in global conversations.

Infiltration & Inflow Masterclass Success

We were pleased to host a fully attended Infiltration & Inflow Masterclass at Woodland Grange. Delegates from across the water, consulting, and contracting sectors took part in a day of practical guidance, case studies, and open discussion focused on diagnosing and mitigating I&I issues. Feedback has been excellent, with many requesting further sessions—an encouraging sign of the industry’s appetite for deeper technical learning in this area. A special thanks has to go to Iain Naismith our Technical and Educational Subcommittee chair for not only organising this event but also for hosting it with his usual aplomb.

Thank you to all the speakers and delegates for making this such a successful event.

Rising Use of HDD and Pipe Bursting in the UK

Across the UK, we are seeing a clear increase in the use of Horizontal Directional Drilling (HDD) and pipe bursting techniques. This shift reflects:

• The need to minimise surface disruption in busy and sensitive environments

• Accelerated delivery pressures under AMP8

• Improved equipment and contractor capability

• Growing client confidence in trenchless solutions

HDD continues to gain traction for complex crossings, while pipe bursting is proving its value for upsizing and replacing pipelines efficiently and with less environmental impact.

As always, a big thank you to Lynn, Linda and Tammy who work tirelessly behind the scenes to ensure the continued success of UKSTT in promoting Trenchless Technologie for the public benefit.

Email: admin@ukstt.org.uk

Kind regards Graham

UKSTT infiltration & inflow masterclass delivers expert insights to record attendance

Industry professionals gather at the Woodland Grange Hotel for comprehensive one-day programme addressing critical wastewater and surface water infrastructure challenges

The United Kingdom Society for Trenchless Technology (UKSTT) successfully concluded its Infiltration & Inflow Masterclass at the Woodland Grange Hotel in Leamington Spa, drawing exceptional attendance from water industry professionals seeking practical solutions to persistent infrastructure challenges.

Whilst infiltration to sewers has been on the agenda for decades, the unprecedented investment in the current AMP for reducing Storm Sewer Overflow (SSO) discharges has brought the issue of sealing against infiltration into sharp focus. However, achieving reduction at the scale required is a challenge and so we invited Water and Sewerage Companies (WaSCs) to come and share their experiences and plans. Alongside infiltration reduction, WaSCs are also beginning to focus on the reduction of inflow of surface water to combined sewers to reduce SSO discharges. This involves both the

identification and disconnection of illegal inflows and the identification of legal inflows that can be redirected away from the sewer.

The one-day interactive masterclass focused specifically on water companies’ real-world experiences with tackling infiltration and inflow issues, providing attendees with invaluable insights into what strategies have proven effective and which approaches have fallen short in practical applications. The event’s record-breaking registration numbers demonstrated the urgent industry need for collaborative knowledge sharing on these critical water management topics.

Expert speakers from Severn Trent Water, South West Water, Wessex Water and Anglian Water delivered comprehensive coverage of current industry challenges, sharing detailed case studies and proven methodologies for addressing infiltration and inflow problems that continue to impact water

infrastructure across the UK. They were supported by contributions from Thames Water, Irish Water and United Utilities who were in the audience. The masterclass format encouraged active participation and facilitated extensive networking opportunities between the sector including water company representatives, consultants, and technology providers.

Recent developments in standards and regulation were also highlighted with speakers from WRc on the updated Sewer Rehabilitation Manual and new UK Water Industry Specification on infiltration resistance testing of liners, and from IKT on the UK Industry Guidance Notes on CIPP rehabilitation and water industry regulation.

The programme’s success reflects the exceptional quality of speakers and their direct relevance to the pressing issues facing the water sector today.

Industry professionals praised the practical focus of presentations, which moved beyond theoretical discussions to examine real implementation experiences and measurable outcomes.

“This masterclass represents exactly the kind of collaborative approach our industry needs,” said Iain Naismith, Chair of UKSTT’s Technical & Education Subcommittee. “The exceptional attendance and engagement we witnessed demonstrates how critical these infiltration and inflow challenges have become for water companies nationwide. The quality of discussion and knowledge sharing exceeded our expectations.”

The infiltration and inflow issues addressed during the masterclass have gained increasing prominence within the water management sector due to their significant impact on system efficiency, environmental compliance, and operational costs. Water companies are under mounting pressure to develop effective strategies for managing these challenges while maintaining service quality and meeting regulatory requirements.

UKSTT’s Technical & Education Subcommittee has been instrumental in organising educational programmes that

address the industry’s most pressing technical challenges. The masterclass builds upon the Society’s commitment to facilitating knowledge transfer between water companies and promoting best practices across the sector.

Based on the overwhelming positive response and continued industry demand for practical guidance on infiltration and inflow management, plans are currently being discussed for a follow-up event that will further explore emerging solutions and advanced case studies in this critical area.

A huge thank you to everyone who attended and supported the event!

About UKSTT

The United Kingdom Society for Trenchless Technology (UKSTT)

is the leading professional organisation dedicated to promoting trenchless technology solutions across the UK. Through its Technical & Education Subcommittee and various specialist working groups, UKSTT facilitates knowledge sharing, develops industry standards, and provides educational programmes for professionals working in underground infrastructure.

The organisation serves water companies, consultants, contractors, and technology providers committed to advancing sustainable underground infrastructure solutions.

Media Contact: UKSTT Communications Email: admin@ukstt.org.uk

Strength in diversity: Mark André Haebler outlines his plans for ISTT’s continued growth

By Austen Lees, Editor, Trenchless Works

It was a pleasure to catch up with the new ISTT chair, Mark André Haebler, during the recent NoDig Middle East event in Jeddah, and to discuss his aspirations and priorities for his time in the role.

Mark began by reflecting that, at the start of his career, he never envisioned becoming an active member of any professional society and that is involvement has been more of a “pleasant and positive accident.” Just a year after entering the trenchless sector, he joined the Austrian Association Trenchless Technology (AATT) taking on the voluntary role of auditor. His dedication soon led to broader responsibilities, and by 2016, he was representing the association at an ISTT Council meeting in Beijing.

It was at the ISTT conference in Washington the following year, that the idea of Mark running for the Board of Directors (BoD) first arose. Ultimately, he did so at the International Council meeting in Cape Town. In Helsinki, he was

then elected Vice Chair, and initial considerations were made about him becoming the next Chair. At first, he hesitated, fearing that his commitments at UHRIG and his lack of university activity might prevent him from fulfilling the duties and expectations of the office. However, his peers, including past chairs, did not share these concerns. It was ultimately the confidence and trust shown to him by the affiliated societies and their members that inspired him to take on the role. Mark also emphasised that he is fortunate to have the support of numerous outstanding individuals, most notably his two vice chairs, Sam Efrat of SASTT and Carlos A. Munera of LAMSTT.

Mark is quick to recognise that no single person can be all things to all people. Different regions and affiliated societies are at various stages in their trenchless journeys, and understanding these differences will be key to his effective leadership. Mark also brings a political background, having served on a council and as vice mayor. This will no doubt serve him well in navigating the complex challenges and opportunities associated with the role of chair.

I then asked Mark about his objectives and ambitions for his three-year tenure as ISTT chair. It was encouraging to hear that his first point was on an issue I’d been keen to discuss - diversity. Mark pointed out that the society will be stronger and more dynamic when it better reflects the makeup of society at large. He believes enhanced diversity will bring increased creativity, innovation,

better problem-solving, and more effective decision-making.

“I would love to be able to say that during my time as chair, I was able to motivate more women and young people to become visible and take on key roles within the ISTT and its Board of Directors,” Mark said. “We need to appear more welcoming and less like a boys’ club.” To support this vision, a new initiative has been announced, a dedicated committee aimed at attracting young trenchless professionals into the industry, supported by funding. This Young Professionals Committee will be chaired by Pertti Leppänen, a Board of Directors member from Finland, whom Mark describes as “the perfect person with his experience of running the Finnish society.”

Another key focus is raising awareness of trenchless technology and ISTT. Mark emphasised the importance of ISTT’s online presence and his desire to create the primary resource and knowledge bank for the sector. This will include the largest library of conference papers, presentations, and white papers, together with an online marketplace where affiliate societies can showcase their members work. The aim isn’t to develop a commercial website but a global resource for exchanging knowledge and experiences. While many societies already have dedicated pages, awareness among members and the broader industry needs to improve. Mark envisions a platform that encourages societies to contribute and, in turn, motivates their members to engage. Access to this knowledge is a crucial

member benefit, though it requires a reciprocal relationship, with members needing to contribute to really make it flourish.