The voice of the trenchless community

-Gecko E Lateral & Gecko E Power: Electrically powered, precise cutters.

-Sewertronics Speedylight+ Cable Upgrade: Improved usability for the engineer, increasing efficiency on site. -Manhole Spray Lining System: Durable, leak-proof solution for manhole rehabilitation.

PUBLISHER

Paul Harwood pharwood@westrade.co.uk

EDITOR

Austen Lees editorial@trenchless-works.com

MANAGING EDITOR

Leigh Abbott labbott@westrade.co.uk

SALES DIRECTOR

Trevor Dorrell tdorrell@westrade.co.uk

DESIGN & PRODUCTION

Ioan Lucian Sculeac lucian@westrade.co.uk

CHINESE AGENT

Lexi Di lexi.di@bestexpo.cn

COPYRIGHT

Trenchless Works is published 12 times a year by Westrade Group Ltd I Carotino House| Bury Lane I Rickmansworth I WD3 1ED I UK

Contributions: Contributions are invited and articles should be emailed to editorial@trenchless-works.com. No responsibility can be taken for drawings, photographs or written contributions during delivery, transmission or when with the magazine. In the absence of an agreement, the copyright of all contributions, regardless of format, belongs to the publisher. The publishers accept no responsibility in respect of advertisements appearing in the magazine and the opinions expressed in editorial material or otherwise do not necessarily represent the views of the publishers. The publishers accept no responsibility for actions taken on the basis of any information contained within this magazine. The publishers cannot accept liability for any loss arising from the late appearance or non-publication of any advertisement for any reason whatsoever. ISSN 2049-3401

Austen Lees

As the trenchless sector continues to adapt to new challenges, one theme comes through clearly in this issue: innovation with purpose. From the Independent Water Commission’s “Great Stink” moment, calling for bold reform in the UK water sector, to the global roll-out of smarter rehabilitation and drilling solutions, our industry is shaping the future of infrastructure with resilience and vision.

In this edition, we bring you coverage of RSM’s 2025 Open Day, where systems, services, and partnerships took centre stage. We also explore new technical insights from Vermeer and TRACTO, showing how trenchless technologies are tackling everything from difficult ground conditions to offshore wind connections. Meanwhile, our profile of Bluelight Lining highlights how LED curing has evolved from pioneering concept to mainstream technology.

Looking ahead, preparations are already underway for NoDig Live 2026, the UK’s flagship trenchless event. As always, it promises to deliver unrivalled opportunities for business growth, technical learning, and industry recognition.

We also continue to see the value of collaboration across the supply chain. From suppliers investing in training and support to contractors trialling new rehabilitation techniques, progress is happening on every front. The strong turnout at industry open days, together with the appetite for knowledge sharing through ISTT webinars and upcoming events worldwide, shows that trenchless is not only innovating, it is also building a stronger, more connected global community.

Across these pages, you’ll see that same message echoed. Trenchless is no longer just an alternative method; it is a driving force in sustainable, cost-effective infrastructure delivery.

I hope you enjoy this issue and, as ever, welcome your feedback.

Austen

To submit editorial for Trenchless Works next issue please email copy and images to: editorial@trenchless-works.com by the 12th of the month.

Submissions arriving after this date cannot be guaranteed inclusion in that month’s issue. For Trenchless Works sponsorship and advertising rates please email: tdorrell@westrade.co.uk

ARTICLE

Editor’s Welcome

INDUSTRY INSIGHT

A new perspective on water: Cunliffe Report calls for a “Great Stink” moment

FEATURED NEWS

RSM Open Day 2025: Advancing pipeline rehabilitation solutions

NEWS

How new trenchless technology cuts costs and enhanced safety at Severn Trent Major upgrade to ageing water mains in Partridge Green Queens Quay essential sewer improvements progressing well Click into CIPP! Explore RSM’s brand-new website

TECHNOLOGY FOCUS

Bluelight Lining: Illuminating a trenchless pioneer

PIPELINE REHABILITATION

Working with IPA Products: From the garage to the underground Bespoke GRP liner brings new life to Scottish culvert Setting a new benchmark in rail infrastructure

HDD

No-Dig brings wind energy ashore at Norderney Drilling through tough ground conditions: Rock, clay and everything in between

TUNNELLING

TBM breaks through on Bangkok water supply tunnel

DRILLING

Ground Investigation – Specifying for sustainability

EVENTS

No-Dig Live 2026: The essential event for trenchless business growth

Trenchless Morocco 2026: Your gateway to a burgeoning underground infrastructure market

FOCUS ON

and the value of short courses

A

ISTT SOCIETY NEWS

A message from the Chair

Technical program announced International ISTT educational webinar

NASTT SOCIETY NEWS

EVENTS AND MEETINGS

By Paul Horton - CEO Future Water Association

The final report from the Independent Water Commission, chaired by Sir Jon Cunliffe, is being widely hailed as the most ambitious attempt to reform the UK water sector since privatisation. With 88 detailed recommendations, the report calls for a fundamental reset to how water services are governed, regulated, and delivered.

Framed by Cunliffe himself as a modern-day “Great Stink” moment, the report sets out to address the environmental, public health, and structural challenges facing the sector with urgency and vision.

Much like the infamous 1858 pollution crisis on the Thames that spurred Victorian engineering reforms, today’s water issues, pollution, public dissatisfaction, and fragmented oversight have created a crisis of confidence. In Cunliffe’s view, this moment demands equally bold and systemic action.

At the heart of the report are five transformational proposals, which Sir Jon reinforced in his speech at the launch:

Perhaps the most high-profile recommendation is the abolition of Ofwat, with its economic regulation role merged with the water-related functions of the Environment Agency, Drinking Water Inspectorate, and Natural England. This new integrated body would offer a “wholefirm” view of water companies, moving away from fragmented oversight and towards joined-up accountability. The Government has already indicated support for this change, suggesting rapid progress may follow.

The report criticises government for failing to provide clear long-term planning for the sector. To correct this, it recommends a National Water Strategy supported by independent regional planning bodies in England and a single national planner in Wales. These authorities would be empowered to align investments with climate, environmental, and customer priorities.

To rebuild public trust, the report recommends that regulatory powers be expanded to block changes in water company ownership that are not in the public interest. New

“public benefit” duties would be inserted into company licences, and a more rigorous framework introduced for senior executive accountability.

consumer and environmental protection

A series of recommendations target pollution, fairness, and water efficiency. These include accelerating the rollout of smart metering, strengthening sludge and drinking water standards, promoting water reuse, and creating a national social tariff for low-income households. The Consumer Council for Water would be upgraded to an ombudsman service to enhance complaint resolution.

The Commission recommends creating a Water Infrastructure Company within the new National Infrastructure and Skills Transformation Authority (NISTA). This body would oversee long-term infrastructure delivery, standardise procurement, and help bring innovation to scale. It would play a coordinating role across complex, multi-stakeholder water investment projects.

The report has sparked a wave of reflection across the sector. It recognises the dedication of frontline workers but makes clear that the current governance model is not fit for purpose. It also presents a call to action: to redesign systems around resilience, sustainability, and trust.

Organisations such as Future Water, which represents a crosssection of the supply chain, from utilities and equipment providers to consultants, technologists, and academics, have found strong alignment between the Commission’s recommendations and their own policy positions.

Future Water’s submissions to the Call for Evidence and Interim Report repeatedly called for:

• Integrated regulation to streamline accountability.

• Clearer long-term investment signals.

• A joined-up approach to standards and innovation.

• A proactive strategy to address digital resilience and cybersecurity.

• The introduction of a national water skills plan.

The Commission’s final proposals reflect many of these themes. In particular, Future Water’s work on standards mapping, which models the relationships between utilities, regulators, and supply chain actors, could serve as a practical foundation for shaping the structure of the new single regulator.

While the report has been widely praised for its scope and clarity, it has not been without criticism. Sir Jon Cunliffe himself acknowledged that implementation would take time, requiring primary legislation and sector-wide consultation. He estimated that establishing the new regulatory model could take two years, referencing previous largescale regulatory mergers such as the creation of Ofcom.

There are also voices arguing that the reforms do not go far enough. Various campaign groups have criticised the

report for staying within the boundaries of the current privatised model. They argue that the report fails to address what they see as the root cause of underperformance: a system that places profit above public interest. While the Commission did consider stronger public benefit duties and tighter governance, it was not permitted to examine public ownership as a structural alternative, a limitation some view as a missed opportunity.

Despite the complexities, the report presents significant opportunities, particularly for the supply chain. The call for smart metering, digitalisation, and standardisation of delivery models offers a clearer entry point for suppliers and innovators. The proposed Water Infrastructure Company could help derisk procurement and drive consistency across regions.

Future Water’s working groups, including those focused on metering, digital resilience, emerging talent, and innovation, are well positioned to support delivery. Their experience developing maturity

frameworks, advising on data interoperability, and building sector-wide collaboration will be invaluable as the sector transitions into this new model.

Framing this as the water sector’s “Great Stink” moment is no empty metaphor. Just as the 1858 crisis catalysed the creation of London’s sewers, today’s challenges, pollution, mistrust, and fragmentation, are prompting a longoverdue systemic shift.

As Sir Jon Cunliffe put it, “there is no single, simple change” that will fix the sector, but the breadth and depth of the Commission’s recommendations offer a genuine opportunity to rebuild the system on firmer, more transparent foundations.

The next step lies with the Government, which is expected to respond later this year. The sector, meanwhile, must prepare for transformational change. Future Waters voice has clearly resonated throughout the Commission’s process and will be central in turning vision into reality.

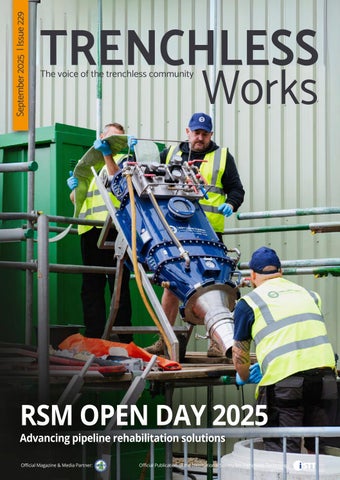

Innovation, collaboration, and new product launches mark a successful industry showcase

RSM Lining Supplies hosted its sixth biennial Open Day on 4th September 2025, welcoming customers, partners, and exhibitors to its headquarters despite challenging weather conditions. The event once again confirmed its status as a key fixture in the sewer rehabilitation industry calendar.

The Open Day combined technical presentations, live demonstrations, and new product launches with valuable opportunities for networking and hospitality. Beyond the serious business of trenchless technology, guests also enjoyed RSM’s trademark entertainment, including evening performances from BBC Radio One’s James Cusack and the legendary Judge Jules. This blend of industry insight and customer appreciation reflects the company’s ethos: combining technical excellence with strong, long-term partnerships.

The event also served as a platform to reflect on RSM’s achievements since the last Open Day in 2023. In just two years, the company has processed more than 80 kilometres of liner through its impregnation service, manufactured and dispatched over 93,500 Pipe Aid Kits, and supplied more than 42 kilometres of UV liner. Training has also been a major focus, with 370 engineers completing RSM’s certified course.

In the past 12 months alone, the business has provided products and services to 736 customers in 27 countries, a measure of its growth and reputation as a global solutions provider in pipeline rehabilitation.

Visitors to the 2025 Open Day had the opportunity to see several major new products first-hand. Among them was an enhanced UV LED curing cable for the Sewertronics SpeedyLight+ system, designed to reduce kinking and improve usability, particularly in demanding site conditions.

The launch of the Gecko E Lateral and Gecko E Power Cutters also attracted attention. Compact and electrically powered, these cutters are tailored to the increasing demand for low-emission, batterycapable equipment in urban projects where access, noise, and environmental restrictions are critical.

Finally, RSM introduced its WRc-approved Manhole Spray Lining System, which applies the GeoKrete Geopolymer to create a long-lasting, corrosionresistant barrier for manhole rehabilitation. Together, these launches underscored RSM’s commitment to delivering complete, integrated systems that address the real challenges faced by contractors. >

One of the highlights of the day was a comprehensive live rehabilitation sequence, showing how RSM’s technologies perform when used in combination. The process began with the inversion of a liner preimpregnated with CP655 Class 1 Epoxy Resin, installed using a KrasoTech Sluice 300. Curing was then carried out with the KrasoTherm Hybrid Boiler, with progress monitored in real time via the VeriCure system.

Attendees watched as the Gecko E Lateral Cutter reinstated laterals with speed and precision, before connections were sealed using a Top Hat System to ensure watertight joints. The sequence continued with UV LED curing of the lateral liner using the upgraded

Sewertronics SpeedyLight+, and concluded with manhole rehabilitation, where the Spray Lining System applied GeoKrete Geopolymer for durable, long-term protection.

This step-by-step demonstration highlighted the efficiency, reliability, and environmental benefits of RSM’s integrated solutions, leaving visitors with a clear impression of how the systems can perform together on site.

The Open Day also celebrated collaboration across the trenchless supply chain. RSM partners — including Applied Felts, BKP Berolina, Dancutter, KrasoTech, Picote Solutions, Sewertronics, UKSTT, Vortex, VP Polymers, Westrade

Group, and WRc Group — supported the event, sharing insights and innovations.

This collective presence underlined the importance of partnerships in advancing trenchless technologies, from developing new materials and systems to ensuring contractors have the training and technical support they need on site.

Managing Director Richard Davis reflected on the event’s success:

“The Open Day was a true reflection of the teamwork, innovation, and commitment that drives RSM. I could not be prouder of how far we’ve come, and I want to thank our customers for their loyalty and support. Without them, none of this would be possible.”

“

The Open Day was a massive success and a true reflection of the teamwork, innovation, and commitment that drives RSM. I could not be prouder of how far we’ve come, and I want to thank our customers for their loyalty and support. Without them, none of this would be possible.

Looking forward, RSM will continue to drive innovation in pipeline rehabilitation, invest in training and support, and build partnerships across the sector. With the next Open Day already confirmed for 2027, the company remains committed to leading through innovation and collaboration in trenchless technology.

Contact: sales@rsm-web.com

Loaded with 120,000 lbs (533.8 kN) of pullback/thrust and 15,500 ft·lbs (21015 N·m) of rotational only opens you up to new types of jobs but moves through long bores and large diameter installs All Terrain technology and a 280-hp (209 kW) Stage V Cummins® engine reduce environmental impact power. 3,000 ft·lbs (4067 N·m) of inner rotational torque—a 50% increase over its predecessor— additional power to drill through the toughest terrain around.

rotational torque, the AT120 not installs with eye-popping power. impact without losing any predecessor— allows the AT120

Jeddah Hilton, Jeddah, Kingdom of Saudi Arabia

11-12 November 2025

The 14th event in this outstanding series will be hosted in Jeddah, Kingdom of Saudi Arabia

• Sewerage and utility investment: Discover how trenchless is impacting dense urban centres, mega-project zones, infrastructure rehabilitation and environmentally sensitive areas in KSA

• Infrastructure Trends: Uncover market intelligence from case studies and insights shared by industry experts and trenchless thought leaders at the two-day conference

• JBP Training Sessions: Learn from the world’s leading trenchless training organisation hosting a two-day training programme

• Live exhibition showcase: Explore cutting-edge products and services from top exhibitors, providing solutions to your underground infrastructure challenges

• Networking Reception: Meet and network with innovators, future partners and thought leaders

• See trenchless technology in action: Watch live demonstrations of state-of-theart equipment and discover how they can install, repair, or replace underground infrastructure with minimal surface disruption

• Receive a free 3-month ATTME membership

The Severn Trent water treatment works near the village of Cropston lie on the edge of Bradgate Park in the Charnwood Forest in Leicestershire. Here the rising main undulates, with the ultimate discharge location at an elevation lower than the pump station.

Engineers working at the site suspect airlocks caused by this uneven environment, in addition to wastewater arising from the processes on site, may have been the reason for the varying flow rate of the pipeline. Every two years or so, a team would tanker flows and would ice pig the pipeline. Following the operation, the flow rate would improve. But within months they were back to square one, with disruption once again returning restricting the disposal of wastewater from the site.

Not only was this frustrating for the team at Severn Trent, but it could also prove costly long-term too, with no obvious solution to overcoming the recurrent disruption to the flow rate. An alternative method of servicing the main was explored.

Network Operability Specialist, Andrew Warren, from Severn Trent had first been introduced to Quick-Pig for rising mains in 2022 by Nico Hindriks of Reinert-Ritz at No-Dig Live.

Unlike traditional pigging methods, the Quick-Pig uses a compact station that can be operated from the ground surface. No entry via a sewer shaft is necessary, and there is

no need to worry about slippery steps or fermentation gases.

Pigs can be quickly inserted via a launcher and received with another station using the Quick- Pig receiving accessory unit made of PE 100 and V4A stainless steel. This can be inserted in the station without disrupting the operation. Quick- Pig already has a strong pedigree in Germany, where it has been used in over 1,500 installations and is now considered for all new rising main pipeline installations.

Here in the UK, the Severn Trent team decided to trial the technology on a 2km, 80mm MDPE rising main pipeline. Two Quick-Pig stations were planned for the first test clean. These were completely installed in one day at a cost estimated at around £20,000. The team planned the Quick- Pig access points to ensure the pipeline could be cleaned and inspected without the need to enter a manhole at any point along the line.

Quick-Pig stations are designed for 90 mm PE100 pipelines,

with dome heights of 900 mm or 1,200 mm. Access is through a dome cover at road level, leading to an insert locked into the pipeline with a pressure-tight bayonet and quick coupling for easy flushing. A trial in January 2025 showed the system could replace a full ice-pigging team: two operators can now service the entire rising main in under three hours. This has cut costs at Cropston, simplified maintenance, and boosted flow rates from about 11.5 m³/hr to 17 m³/hr.

The Quick-Pig station provided a convenient and safe solution for servicing the rising main, but it also delivered substantial cost savings. During a 5-year AMP period, regular ice-pigging every 12 months would cost an estimated £19,000. By installing two Quick-Pig units on one 2km rising main at roughly the same price, the annual servicing cost dropped to only £2,000 with more regular maintenance intervals. This investment will lead to significant long-term savings, making Quick-Pig a highly cost-effective alternative.

Amajor upgrade to the water network is set to get underway.Southern Water will replace 4.5km of ageing water mains in Partridge Green, West Sussex, using ‘no dig’ technology to minimise disruption.

The project aims to address frequent bursts and discoloured water issues by upgrading infrastructure that is up to 80 years old.

Jonathan Poll, project manager at Southern Water, said: “Some of the water mains are made of cast iron and other materials. They have been in the ground for around 80 years and despite regular maintenance they are beginning to show their age.

“

Some of the water mains are made of cast iron and other materials. They have been in the ground for around 80 years and despite regular maintenance they are beginning to show their age

This replacement project will reduce the risk of discoloured water coming through customers’ taps and will also reduce the risk of bursts, leaks and interruptions to the water supply.”

The scheme began in August 2025 and is scheduled for completion in October 2026.

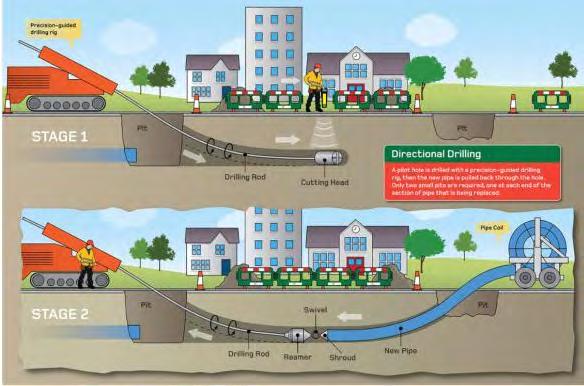

To reduce the impact on residents and businesses, Southern Water will use trenchless technology, including directional drilling to tunnel beneath roads and pavements. However, in areas where tunnelling is not possible, excavation will be required.

The project will be carried out in eight phases, with a combination of traffic lights and road closures in place throughout the works.

Southern Water serves 2.7 million water customers and provides wastewater services to 4.7 million people across Kent, Sussex, Hampshire and the Isle of Wight.

PEARPOINT systems are designed to excel in harsh environments, delivering unmatched reliability and adaptability for sewer inspection professionals.

From rugged terrains to urban settings, PEARPOINT’S innovative designs ensure seamless performance, minimizing downtime and maximizing efficiency.

With modular components that are easy to swap or upgrade, our equipment evolves with your needs, making it the ultimate partner in the field. When the job gets tough, PEARPOINT gets tougher.

NI Water is pleased to confirm that Phase 2 of essential Sewer Improvement Work at Queens Quay, between Harbour Square Roundabout and Strand Road Roundabout is nearing completion. All pipelaying and associated civil engineering works, carried out by our contractor GRAHAM, are scheduled for completion by the end of this week, and we anticipate that the road will be reopened - subject to favourable weather conditions. Final reinstatement work will be completed under an off-peak localised lane closure after the full reopening of the road.

This major programme of improvements is part of a wider programme of investment to upgrade the wastewater network serving the city and has already seen over 1,100 metres of the Culmore Trunk Sewer relined between Foyle Road and Queens Quay to strengthen the sewerage network and help protect against sewer collapses, blockages and reduce the risk of out-of-sewer flooding.

Kieran Grant NI Water Project Manager said:

“NI Water is pleased to announce that this essential work is progressing well and is scheduled to be completed by the end of this week, with the reopening of the A2 Queens Quay Road by Friday 19th September.

“The project team engaged a specialist crew to carry out major relining works across the majority of the scheme,

utilising underground trenchless techniques to minimise disruption throughout the city. This approach allowed us to avoid major road closures and significantly reduced inconvenience for residents, businesses, and visitors. In fact, it shortened the overall project timeline by up to nine months.

“Crews used trenchless (underground) methods to accelerate progress, eliminating the need for large open-cut trenches and further reducing disruption. Our contractor also facilitated the temporary reopening of Queens Quay to accommodate key city events such as the Foyle Cup and the Apprentice Boys March. Additionally, work was completed in sections during night time hours between Harbour Square Roundabout and Strand Road, as well as between Queens Quay Roundabout and Lower Clarendon Street to expedite delivery.

“This essential work will improve the efficiency of the network, helping to accommodate future development and economic growth in the city for many years to come.”

NI Water and our contractor GRAHAM appreciate work of this nature is disruptive and thank the public for their continued patience and cooperation as we complete the final stages of the improvements. The city will benefit from this scheme for many years to come.

The project team appreciates the co-operation of the wider public in ensuring that children do not play in or around any site or machinery. Working areas will have warning signs in place to protect the public from any hazards. The public are advised to stay out of these working areas for their own safety as we work to complete the scheme.

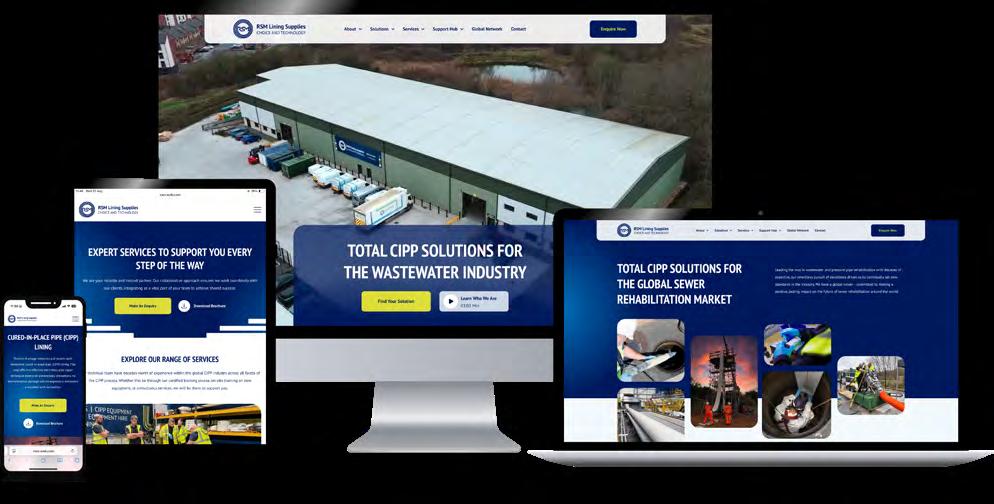

RSM Lining Supplies are thrilled to announce the launch of their redesigned website!

RSM are proud to present a sleek, user-friendly platform designed to better serve customers and showcase the very latest in CIPP technology. With a focus on accessibility and ease of use, the new site offers a modern, responsive design that works seamlessly across all devices, making it simpler than ever to explore RSM’s products and services.

More than just a visual upgrade, the new site represents an evolution in how RSM connects with its valued customers and reflects the company’s continued growth within the global trenchless sector.

As a leading supplier of trenchless technology worldwide, RSM wanted the new site to serve as a comprehensive resource for engineers, contractors, and industry professionals. Visitors can now explore everything from

small diameter point repair systems to the latest UV LED curing technologies, with each product and service presented on its own dedicated landing page. Detailed specifications, technical information, and data sheets are readily available for download, helping customers make informed decisions quickly and efficiently.

Users can stay up to date with the latest news and announcements from RSM on their exciting new blog page, filled with the latest company updates, new product announcements, and specialised industry insights.

The user experience has been a key priority throughout the redesign. Faster load times, streamlined navigation, and a clean, intuitive layout ensures visitors can find what they need with ease, whether browsing on mobile, tablet, or desktop.

In addition, dynamic tracking forms have been integrated across the site, making it easier than ever to contact the team & request support.

Commenting on the launch, RSM’s Sales Director, Phil Steele, said: “The new site clearly communicates our expertise and the range of services that we offer. We hope that the improved content, design, and usability will make it easier for customers to connect, explore our offerings, and see why RSM Lining Supplies is a trusted name in the industry.”

The launch of the website marks an exciting new chapter for RSM, but it is only the beginning. The company is committed to continuing to enhance the site with new features and updates to ensure it remains a valuable resource for customers across the globe. Visit www.rsm-web. com to explore the site today!

NO-DIG ROADSHOW SERIES 2025

With the UKSTT Annual Awards Ceremony

2 October 2025

Tortworth Court, Bristol www.nodigroadshows.co.uk

TRENCHLESS MIDDLE EAST 2025

11-12 November 2025

Jeddah Hilton, Jeddah, Kingdom of Saudi Arabia www.trenchlessmiddleeast.com

TRENCHLESS MOROCCO 2026

11-12 February 2026

Rabat Marriott Hotel, Rabat, Morocco www.trenchlessmorocco.com

TRENCHLESS ASIA 2026

10 -11 June 2026

Queen Sirikit National Convention Centre Bangkok, Thailand www.trenchlessasia.com

NO-DIG LIVE 2026

29 September – 1 October 2026

NAEC Stoneleigh Park, Warwickshire www.nodiglive.co.uk

TRENCHLESS MIDDLE EAST 2026

www.trenchlessmiddleeast.com

NO-DIG ROADSHOW SERIES 2026

Dublin | London | Glasgow www.nodigroadshows.co.uk

MALAYSIA | SOUTH AFRICA | VIETNAM

By Austen Lees, Editor, Trenchless Works

“ Even a small difference in light penetration can significantly affect cure quality. That’s why compatibility and control are essential

Earlier this summer I visited Bluelight Lining’s Northampton facility to meet Director James Stern. His history with the company reveals how quickly he recognised the potential of LED curing technology.

James first encountered Bluelight as a customer, working on contracts including the Anglian Water frameworks. When Bluelight gmbh (part of Denmark-based Aarsleff A/S) considered launching in the UK, his strong working relationship with the German and Danish teams placed him at the front of the queue. In 2018 he placed the first UK order, rigorously testing the solution for 12 months before becoming the official sole UK supplier in 2019.

As demand grew, James saw that relying on pre-impregnated liners from Denmark would be too restrictive, especially with Brexit approaching. Investment followed in a Northampton impregnation line, capable of processing up to 10,000m per month, giving Bluelight the capacity to scale in the UK.

The efficiency of Bluelight’s LED curing system has been a major driver of growth. James notes that installations are often two to five times faster than other systems. Today, Bluelight systems are used by contractors including ARM Pipetek, Blue House Services, Drain Lining Solutions, FM Conway, Pipeline Drain Solutions, and ESH Glanville Trenchless.

The solution is distinctive:

• Revolutionary LEDs operating at 450 nm wavelength.

• Flexible felt carrier with PU coating and high-

strength glass liners.

• Styrene-free vinyl ester resins using a patented photo-initiator that reacts only to the LED wavelength.

This technology has now been used in more than 90,000 installations, with success rates of 95–99% compared to around 45% for standard UV curing. Approvals include WRc (UK), DIBt (Germany), and CSTB (France), underlining Bluelight’s focus on quality and certification.

James stresses that the system is most effective when used as a fully integrated package: “Even a small difference in light penetration can significantly affect cure quality. That’s why compatibility and control are essential.”

Bluelight also incorporates a significant proportion of

recycled PET materials in its liners. James acknowledges challenges around cost and availability but believes those already adopting recycled content will be best placed as regulation and customer expectations tighten.

The wider issue, he argues, is that while water companies face pressure to use greener technologies, the sheer scale of work and pressure on budgets makes it difficult to adopt solutions with higher upfront costs. “Everyone wants to be greener, but no one really wants to pay for it. In the end, consumers will need to accept a more realistic cost for water and sewerage services.”

Certification remains a live debate. >

Bluelight has drinking water liners certified in multiple countries, New Zealand, Australia, Germany, Denmark, Norway, Canada, yet these cannot be used in the UK without Reg 41 approval.

James also questions the partial certification of systems: “What’s the point of certifying a liner and then curing it with an uncertified system? That creates a ticking time bomb of poorly cured liners.”

For him, the solution lies in tighter monitoring, certified installers, and full adherence to Water Industry Specifications (WIS). Bluelight’s system, with pre-set curing parameters for each liner size and thickness, is designed to prevent corner-cutting. Their 12-year partnership with Anglian Water, without a single failed liner, demonstrates the value of rigorous standards.

Bluelight continues to innovate. Recent developments include a dual-core light-head and new tools to extend system capability for thicker, longer liners. A non-entry measuring device for pipe diameters will deliver safety benefits by reducing the need for confined space access.

The company is also expanding its Northampton site, targeting 20% revenue growth this year.

A new impregnation plant is planned, doubling capacity to 20,000m per month and adding redundancy to safeguard production.

“Our commitment to customer satisfaction and quality is built into everything we do,” James says. “That philosophy is carried through every stage by the Bluelight Lining team.”

Spending time with James underlined Bluelight’s mix of technical innovation, integrity, and long-term investment. With sustainability, certification, and new product launches high on the agenda, the company looks set to remain a pioneering force in trenchless rehabilitation.

The products of IPA Bauchemie have established themselves as reliable solutions in both private households and professional environments. Their unique combination of durability, ease of use, and technical performance makes them suitable for a wide range of applications, from small-scale DIY projects to large industrial operations. In private households, IPA materials are often chosen for flooring and basement renovations. Homeowners benefit from products that are not only functional but also straightforward to apply, even without professional experience.

Andreas N., homeowner from Hesse (Germany) and in-house employee in the trenchless sewer rehabilitation sector, talks about his experiences with IPA products:

‘‘When people hear about construction materials, they often think of something complicated and reserved for professionals.

My own experience with IPA products taught me that this is not necessarily the case. What started as a small project in my garage showed me how these materials can be applied both at home and in much larger professional contexts.’’

Andreas continued: ‘‘I began with a fresh concrete floor that needed a protective coating. At first, I tried spreading the material with a roller rake, but soon realized that a water squeegee gave me a smoother finish. Like many first attempts, there were small mistakes, some uneven areas, a darker spot where I used leftover material, and the question of how thick the layer should be. But the process itself was straightforward: grinding the floor, cleaning it thoroughly, priming, sanding with quartz, and finally applying the coating. The result was not perfect in appearance, but it was solid, watertight, and exactly what I needed for a functional garage.

What struck me most was how approachable the products were. I am not a professional

“ When

people hear about construction materials, they often think of something complicated and reserved for professionals. My own experience with IPA products taught me that this is not necessarily the case. What started as a small project in my garage showed me how these materials can be applied both at home and in much larger professional contexts.

installer, yet I managed to complete the project with simple tools and a bit of patience. Friends and neighbors who stopped by were curious, often surprised that such a clean and durable result could come from a DIY effort.’’

On the other end of the spectrum, these very same IPA products are used by professionals in business-tobusiness projects. Instead of a single garage floor, entire warehouses, production areas, or infrastructure elements are coated and protected. The principles remain the same, careful preparation, the right materials, and methodical application by the experts.

A striking example is trenchless pipe rehabilitation. Here, IPA supplies products that allow entire sewer lines to be renewed without digging up streets.

The concept reminded me of my own project: preparing the surface, applying the material, and sealing it for long-term durability. Only the scale is different, instead of protecting a floor, the aim is to restore pipelines underground, efficiently and without major disruption.

What becomes clear is that IPA products are designed to perform under a wide variety of loads, from the light wear of everyday household use to the heavy demands of industrial machinery and municipal infrastructure. Their adaptability across such different scales makes them a practical choice for individuals as well as professionals.

The versatility of IPA products in private and professional applications

IPA products have established themselves as reliable solutions in both private households and professional environments. Their unique combination of durability, ease of use, and technical performance makes them suitable for a wide range of applications from small-scale DIY projects to large industrial operations.

In private households, IPA materials are often chosen for flooring and basement renovations. Homeowners benefit from products that are not only functional but also straightforward to apply, even without professional experience. A freshly coated garage or cellar floor demonstrates how IPA coatings create resilient, watertight, and easy-to-clean surfaces. Proper surface preparation, such as grinding, cleaning, and priming ensures long-lasting adhesion and results in a finish that withstands everyday use.

Many homeowners appreciate how these systems transform functional spaces into clean, bright, and durable areas, adding value and comfort to their property.

At the same time, IPA products are widely trusted in business-to-business contexts. Professional contractors and industrial clients rely on the same core product qualities but on a larger scale. Whether in warehouse facilities, production halls, or infrastructure projects, the consistent performance of IPA materials ensures safety, reliability, and long service life. Professionals particularly value the efficiency of these solutions, as they allow for predictable workflows and reduced downtime.

A special field of application in which IPA has developed a strong reputation is trenchless pipe rehabilitation. In this sector, the company provides advanced products that enable efficient, non-invasive

restoration of underground infrastructure. The principle is similar to surface renovation in private projects: preparation, application, and curing lead to a sealed, durable result. The difference lies in scale and complexity — instead of a garage floor, entire pipelines are restored without the need for excavation. This innovative approach saves time, minimizes disruption, and significantly reduces costs for municipalities and businesses alike.

The broad applicability of IPA materials shows how seamlessly private and professional worlds intersect. From the homeowner who wants a durable basement floor to the contractor responsible for rehabilitating a city’s sewer network, IPA provides solutions that deliver quality, longevity, and trust.

For further information and detailed insights into the full range of applications, visit: www.ipa-bauchemie.com.

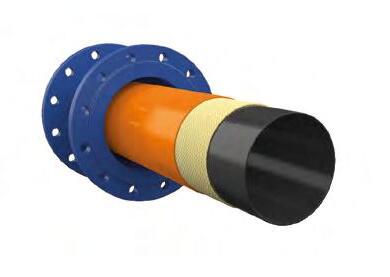

When it comes to rehabilitating buried infrastructure, there’s rarely such a thing as a standard job. Every structure is unique in age, condition, environment, and geometry, which means that rehabilitation demands solutions as unique as the challenges themselves.

That philosophy was put into practice in Scotland where a corroding ARMCO culvert beneath a busy highway required urgent attention. The project became a showcase for Channeline’s ability to design and manufacture tailor-made glass reinforced plastic (GRP) liners to precise specifications, delivering a structural solution that avoided the disruption of road excavation and eliminated the need for costly over-pumping.

A culvert at risk

The 45-meter culvert, measuring 1.2m in diameter and sitting 3m beneath a busy highway, was showing clear signs of rust and structural deterioration. The situation demanded swift action to prevent further decline and to safeguard the highway above.

At first glance, a CIPP UV lining solution might have seemed the obvious route. But closer examination revealed the complications: achieving a dry environment would have required overpumping, bringing delays, disruption, and spiralling costs. A more flexible, less invasive approach was needed.

The Channeline advantage

Channeline has built its reputation on a simple but powerful USP: the ability to manufacture liners to any shape and any size for a precise fit within the host structure.

This design freedom enables engineers to overcome complex rehabilitation challenges where other methods struggle.

For this project, Channeline manufactured a GRP liner to match the exact profile of the deteriorating culvert. Because the system can be installed in flow, the project team avoided the costly and disruptive over-pumping operations that CIPP would have required. The result was a faster, smoother project with minimal impact on road users.

Once the liner was manufactured to Channeline’s exacting standards, it was delivered to site for installation. iLine Technologies, specialists in trenchless rehabilitation, undertook the installation. Thanks to detailed planning and precision engineering, the works were completed efficiently and on schedule.

Within weeks, the failing culvert had been transformed into a structurally sound, corrosionresistant asset with a service life measured in generations.

This project was more than just a repair; it was a demonstration of how innovative trenchless technology can solve complex problems with minimal disruption. For iLine and Channeline, it was yet another example of how collaboration and custom engineering can overcome the limitations of traditional methods.

For municipalities and contractors worldwide, the message is clear: when every structure is unique, only a bespoke solution will do. For more information about custom GRP liners, visit channeline.com

PARTNERS

Alphaliner RL brings trenchless pipeline rehabilitation to railways.

Pipelines underneath trackbeds are among the most complex places for trenchless rehabilitation, with vibrations caused by the trains above and the impact of heavy pressure making them uniquely challenging.

With the Alphaliner RL, however, RELINE has devised a new solution that is designed precisely for these conditions – it is the first-ever UV-cured liner to be granted product-specific authorization from Deutsche Bahn.

Obtaining approval from Deutsche Bahn AG, the Alphaliner RL was specifically designed over a multi-year process to meet the unique product requirements within the railway track structure and underwent extensive material testing.

Among other things, the material quality and resistance to vibration loads (proof of longterm vibration durability) were tested. “Our goal was to develop a product that reliably meets the special conditions within the railway track structure while also overcoming all regulatory hurdles,” explains Philipp Bergmann, Head of Sales at RELINE. “The product-specific approval by Deutsche Bahn AG for use within the railway track is a milestone that offers planners and operators of both railway-owned and third-party crossing infrastructure new trenchless rehabilitation options and regulatory certainty.”

Regulatory reliability for use under railway traffic loads

The use of construction products and the application of construction methods under railway traffic loads are governed by relevant regulations and administrative provisions and monitored by the Federal Railway Authority (EBA).

The criteria for the use of CIPP liners have been defined in coordination with the EBA and are described in the “Planning Guide for Pipeline Rehabilitation” issued by DB InfraGO AG (formerly DB Netz AG; December 2022).

Construction products may be used without specific approval from the EBA, without case-bycase approval (ZiE), and without internal company approval (UiG), provided they are suitable for the intended use and have

“ Our goal was to develop a product that reliably meets the

special conditions within the railway track structure while also overcoming all regulatory hurdles

a general technical approval (abZ) issued by the DIBt.

With nominal widths between DN 200 and DN 800 and lengths of up to 280 meters, the Alphaliner RL already covers a broad range of uses and, what is more, it will also be available for diameters up to DN 1200 from 2026 onward. This is complemented by a full set of standard structural calculations and a successful long-term fatigue test, both of which prove the liner’s durability under cyclical vibration and pressure loads.

The new Alphaliner RL maintains the established structural integrity and material standards of its product

family, including high strength, consistent UV curing, and a smooth interior surface that ensures sustained hydraulic performance. Additionally, it incorporates all advantages of RELINE’s trenchless Alphaliner technology, such as reduced construction periods, minimal cross-sectional loss, lower environmental impact, and limited disruption to the surrounding community.

The Alphaliner RL is already raring to go, with the first few invitations to tender already drawn up and published in partnership with the project management teams at Deutsche Bahn.

This is making planning and implementation much easier and laying clear foundations for future projects.

The Alphaliner RL, like other RELINE solutions, is part of a complete system—not just a standalone product.

Along with manufacturing and delivery, RELINE provides support for tenders, sizing, and installation. “We accompany our partners throughout the whole project so that rehabilitation work inside the trackbed can be done efficiently, safely, and predictably,” says Christian Pfaff, Area Sales Manager Germany.

Tested in long-term vibration tests and with complete structural verification

ON A NEW TRACK

THE ALPHALINER RL FROM RELINE BRINGS TRENCHLESS PIPE REHABILITATION BENEATH THE TRACKS.

A strong signal for safety and future viability: With the new Alphaliner RL, a UV-curing liner with product-specific approval from Deutsche Bahn AG is now available for the first time. This makes trenchless pipe rehabilitation possible even for wastewater pipes and culverts beneath railway tracks –where vibrations and pressure loads place the highest demands.

Up to 280 m in length. Applicable from DN 200 to DN 800, and from 2026 up to DN 1200

Short construction times, minimal interventions, high environmental compatibility

Dynamic loads caused by rail traffic

High pressure resistance (proven long-term vibration durability)

Contact us for tailored advice!

RelineEurope GmbH Große Ahlmühle 31 76865 Rohrbach | Germany

Tel.: +49 6349 93934-0 info@relineeurope.com www.relineeurope.com

Trenchless technology in action for Germany’s offshore grid connection, with HDD casing support from TRACTO’s GRUNDORAM TAURUS.

One of the defining challenges of the energy transition is how to bring renewable offshore power to land without damaging sensitive coastal environments. Germany’s BalWin1 and BalWin2 offshore grid connection systems are a case in point: designed to transport 2,000 megawatts of electricity each, enough to supply around four million people, from North Sea wind farms to the mainland grid.

The route passes beneath the island of Norderney in the Lower Saxony Wadden Sea National Park, a UNESCO World Heritage site. Here, trenchless technology is being deployed to minimise impact on the protected dune and mudflat landscapes.

on a massive scale

Transmission system operator Amprion has commissioned contractor LMR Drilling to deliver 18 horizontal directional drilling (HDD) installations for protective pipes that will later house the submarine cables.

Work is being delivered in three phases:

• 2025: six HDD bores from the island towards the southern mudflats and mainland.

• 2026: HDDs northwards towards the offshore converter platforms.

• 2027: crossing of the mainland dyke.

Each bore exceeds one kilometre in length, drilled by maxi rigs with thrust and pull forces of up to 450 tonnes. The project site “At the lighthouse” covers 14,000 m², with cranes, storage, and a 10-metrehigh noise barrier shielding neighbouring campsites. Pontoons anchored in the mudflats provide logistical support for pipe and material transport.

Stabilising the ground with casing pipes

The sandy soils at the entry points posed a particular challenge. To create stable conditions for the HDD rigs, TRACTO’s GRUNDORAM

TAURUS rammer was used to drive 800 mm diameter, 24 m long steel casings into the drillable layers.

Dynamic pipe ramming transfers impact energy directly to the pipe, pushing it forward while soil collects inside. For HDD applications this “conductor barrel” method ensures precise casing installation at the correct angle, in this case, exactly 14° to match the bore path.

Although often associated with pipeline installation, ramming machines are increasingly used as HDD Assist tools: to drive conductor casings, free stuck drill rods, or support pipe pulls. >

On Norderney, the TAURUS enabled LMR to install one casing per day, with each active ramming sequence lasting only around three hours.

Protecting a sensitive environment

Environmental stewardship was at the heart of the project design. Construction on Norderney can only take place between July and September each year to avoid disturbing breeding bird species in spring and to minimise the risk of autumn storm surges.

Strict “zero discharge” rules apply, no substances may escape into the mudflats or dunes. HDD was selected because it requires only limited surface works and significantly reduces disruption compared with open-cut methods.

Noise management was also essential. Norderney is a popular holiday island, and the project site lies close to busy campsites. To reduce disturbance, ramming was restricted to set working windows between 8:30 a.m. and 7:00 p.m. The combination of careful scheduling and the noise barrier helped keep disruption to residents and visitors to a minimum.

Each casing consisted of two 12 m sections welded together during installation. Heavyduty cranes placed the pipes into custom-built guide rails, with the TAURUS rammer aligned to the bore path to within centimetres. Once the first segment was driven deep enough, the second was welded on and installation continued until the full 24 m length was in position.

This was the first time LMR undertook the ramming operations themselves using their own TAURUS unit. To ensure success, TRACTO specialists provided on-site training and support during the start-up phase. The team quickly mastered the method, achieving a consistent output of one casing per day, a crucial factor given the limited seasonal window for works.

While the ramming operations were still underway, preparation began for the HDD rigs that will drill the pilot bores along the specified cable routes. Once these are complete, protection pipes will be installed from the mudflats, with the steel casings reused for subsequent phases.

The two systems are scheduled for commissioning in 2030 (BalWin1) and 2031 (BalWin2), bringing the projects online one and two years earlier than originally planned.

context: trenchless in the energy transition

The Norderney project illustrates the growing role of trenchless technology in Europe’s energy transition. Offshore wind expansion

targets are ambitious: Germany alone plans for 30 GW offshore capacity by 2030, while the UK is aiming for 50 GW. To deliver this, new offshore grid connections and land-based distribution upgrades are essential.

For contractors and technology providers, this creates significant opportunities. HDD and HDD Assist techniques, including conductor casing rams, rescue methods, and precision guidance systems, are increasingly recognised as vital tools for minimising environmental impact and enabling power projects to proceed in sensitive locations.

BalWin1 and BalWin2 show how HDD and associated trenchless techniques can support largescale energy projects while balancing environmental protection and community sensitivities. With Amprion leading the transmission scheme, LMR executing the HDDs, and TRACTO technology providing essential casing installation support, the project demonstrates the adaptability of trenchless methods in one of Europe’s most challenging natural and cultural settings.

With TRACTO’s GRUNDORAM pipe rammers, you can install steel pipes up to 4,000 mm 0 with an impact energy of up to 40,500 J in any type of soil. The powerful rammers can also solve problems that arise during complex drilling projects using HDD Assist & Rescue methods. NEED SUPPORT WITH YOUR PIPELINE PROJECT? We can provide equipment, expert advice and hands-on training! For details, check online or get in touch : T +49 2723 808-0 M info@tracto.com

Insights from Vermeer UK on adapting HDD techniques to different

“ Effective fluid management is the best defence against clay, keeping tools free from adhesion and the bore stable.

Horizontal directional drilling (HDD) has transformed how utilities and pipelines are installed, but no two projects are the same. Soil conditions can vary dramatically even within a single bore, creating very different technical challenges for crews on the ground.

From abrasive rock to sticky clay or rapidly changing mixed soils, difficult ground conditions can slow progress, damage tooling, or compromise bore stability if not managed effectively.

Drawing on decades of experience, Vermeer UK shares practical guidance on how to prepare for, and successfully drill through, the most common tough ground scenarios.

Rock: slow progress, steady control

Solid rock presents one of the toughest environments for HDD. Its high abrasion and resistance require tooling designed specifically for these conditions. Carbide-tipped drill heads, rock reamers, and downhole hammers are standard solutions that withstand the punishment of rock formations.

In rock, progress will inevitably be slower, but patience and precision are vital. Applying steady thrust while avoiding excessive force prevents unnecessary wear or breakage.

High-viscosity drilling fluids also play a key role by cooling tooling, suspending cuttings, and transporting them effectively out of the bore.

Clay: sticky, swelling, and unpredictable

Clay may appear softer than rock, but it brings its own set

of complications. Sticky clays can adhere to tooling, causing blockages or even stalling progress. In reactive clays, swelling can constrict the bore and increase torque on the drill string.

The best defence is effective fluid management. Low viscosity, lubricating muds reduce adhesion, while maintaining consistent circulation prevents build-up.

In highly reactive conditions, stabilising additives can be introduced to improve flow, reduce swelling, and keep the borehole stable.

Few HDD projects progress through a single soil type from entry to exit. More often, drillers encounter transitions, for example, clay to rock, sand to gravel, or mixtures of cobbles and fines. These variations can disrupt steering, fluid returns, and tooling performance.

A versatile approach is essential. Crews need to anticipate changes in advance, keep contingency plans for switching tooling mid-bore, and adjust drilling fluid properties in real time. Continuous monitoring of torque, thrust, and returns helps operators detect shifts early and respond before problems escalate.

While every site is unique, a handful of best practices apply across conditions:

• Carry out a geotechnical survey before drilling to understand soil profiles and likely transitions.

• Select the right tooling for the ground and keep spares on hand to minimise downtime.

• Optimise drilling fluid mix for lubrication, stability, and cuttings transport.

• Monitor torque, thrust, and fluid returns continuously to identify changes quickly.

• Train crews in adaptive techniques so they can respond effectively when conditions shift.

Following these steps gives contractors the best chance of maintaining productivity and completing bores successfully, even in challenging ground.

The value of preparation and partnership

Tough conditions don’t have to derail HDD projects. With the right planning, tooling, and drilling fluid management, contractors can achieve reliable results across rock, clay, and everything in between.

Vermeer UK works alongside HDD professionals nationwide, providing equipment, tooling solutions, and industry expertise.

From planning guidance to on-site support, the company helps contractors adapt their approach and deliver successful outcomes in every soil condition.

The Vermeer D40x55DR S3 horizontal directional drill (HDD) delivers excellent productivity in a broad range of ground conditions, from hard, medium and soft rock to loam, dirt and clay. This rock drill features dual rod technology that uses an inner rod to provide torque to the drill bit, while the outer rod offers steering capability and rotational torque for reaming. The combination provides powerful downhole cutting action and the flexibility to select the appropriate tooling to best match the ground conditions, which can allow the entire install to be completed with one machine.

A4.39m-diameter Terratec EPBM has broken through on the Ninth Bangkok Water Supply Project in Thailand.

The breakthrough was achieved June 23 and marks completion of a challenging 3.76km tunnel drive under a major highway – delivered with surface settlement maintained within controlled limits despite complex geological conditions.

EPB TBM S105 was customengineered to tackle the geotechnical challenges of the project alignment. Featuring

a soft ground cutterhead with a spoke-type arrangement, injected tungsten carbide cutting tools, and a maximum cutterhead rotation of 2.4RPM, the machine was tailored to manage Bangkok’s notoriously variable soil conditions, including fine sand, clay, and high groundwater pressure.

Terratec S105 is one of three EPBMs supplied for the Ninth Bangkok Water Supply Project. The Metropolitan Waterworks Authority project is designed to expand and upgrade the city’s potable water distribution network.

The project, managed by contractor Italian-Thai Development PCL, includes more than 9km of tunnelling in total.

Designed to work within the constraints of densely populated urban areas, TBM S105 was equipped with active articulation, tail skin grouting, and automated bentonite and foam injection systems to ensure minimal surface impact. The project involves a total 9km of tunnelling.

By Lee Healey, Chair of the British Drilling Association T&S Sub-Committee

There is a growing imperative in our industry to undertake Ground Investigation (GI) in a more sustainable manner. Whilst the responsibility for reducing carbon emissions and improving environmental performance has often been placed on contractors, the reality is that those specifying and designing the investigation have a central role. To achieve tangible benefits, it is time to think creatively and holistically about how we specify, plan and execute GIs.

Innovations such as rig idle limiters; timers and the consideration of alternative fuel types all contribute to reducing overall emissions.

However, whilst these incremental steps are valuable, they alone will not help us meet stringent Net Zero targets. Some clients, whose budgets permit, may well consider

introducing electric vehicles and drill rigs. Current experience suggests that limited working time, hefty battery packs and additional transport costs remain challenging, yet as technology advances, we can hope to see improvements. The key is to remain aware that no single technological fix will be a panacea; instead, success lies in addressing the fundamental reasons for conducting GI and how it is planned in the first instance.

Arguably the most practical way to deliver a genuinely sustainable GI is to reflect on why the works are specified in the first place. Too often, Principal Designers and their clients over specify investigations to allow for multiple “options” or to mitigate perceived risks. Whilst caution is understandable, there can be a tendency to proceed without reevaluating the GI scope during the execution phase.

By creating a clear feedback loop between the field team and designers, we can continually assess whether we are doing the right amount of work in the right places. In some cases, scaling the investigation down might save time, energy and resources; in other cases, it may be more sustainable to increase the scope to avoid multiple remobilisations at a later date. Getting it right first time not only reduces cost and frustration but also minimises the unnecessary carbon footprint of repeated site visits.

Beyond specification, there is scope for more proactive resource management. A consolidated, coherent approach to GI across adjacent sites or related projects can make a significant difference. Grouping GIs allows for:

• Efficient Logistics: Better planning of drilling rig movements, the use of

shared haulage and the potential for lodging personnel locally rather than commuting daily.

• Local Labour: Engaging local teams reduces travel distances and supports regional economies.

• Lower Carbon Footprint: Fewer, more organised journeys to and from site decrease emissions substantially.

Such an approach requires open communication and collaboration amongst clients, consultants, contractors and all other stakeholders. Framework agreements often provide a suitable structure to facilitate this alignment, ensuring resources are shared effectively over a series of projects.

Post-fieldwork monitoring offers another opportunity to integrate sustainable thinking. Remote monitoring technology can reduce site visits, saving on fuel and travel time. However,

the initial outlay for equipment is not insignificant, and the technology may not always be the best fit for certain site conditions. For projects where remote monitoring is impractical or cost-prohibitive, simple measures such as travelling by train or bus for manual checks remain a valuable way to cut carbon emissions without sacrificing quality.

Making GI more sustainable does not mean compromising on safety or reliability. We need a balanced view of cost versus carbon savings to make informed decisions. One potential avenue is to collaborate with a consultant organisation within the BDA that has access to a carbon calculator. By modelling an “options GI” against a “targeted GI,” it becomes clearer where efficiency and carbon savings can be made, and whether any additional expenditure would be justified by the reduced environmental impact.

Though the transition to genuinely sustainable Ground Investigation is complex, it presents an exciting opportunity for innovation. From rethinking our materials to refining how we specify, plan and monitor site works, every project phase offers scope to reduce our environmental impact. Achieving Net Zero demands a collective mindset shift— where designers, clients and contractors work together, reviewing and adapting specifications in real time, and making optimum use of resources.

As we in the BDA continue to encourage sustainable practices, it is heartening to see an increasing appetite for change across the industry. There will undoubtedly be challenges, but by embedding sustainability at the very heart of Ground Investigation, we can meet both our environmental obligations and the operational objectives of our clients.

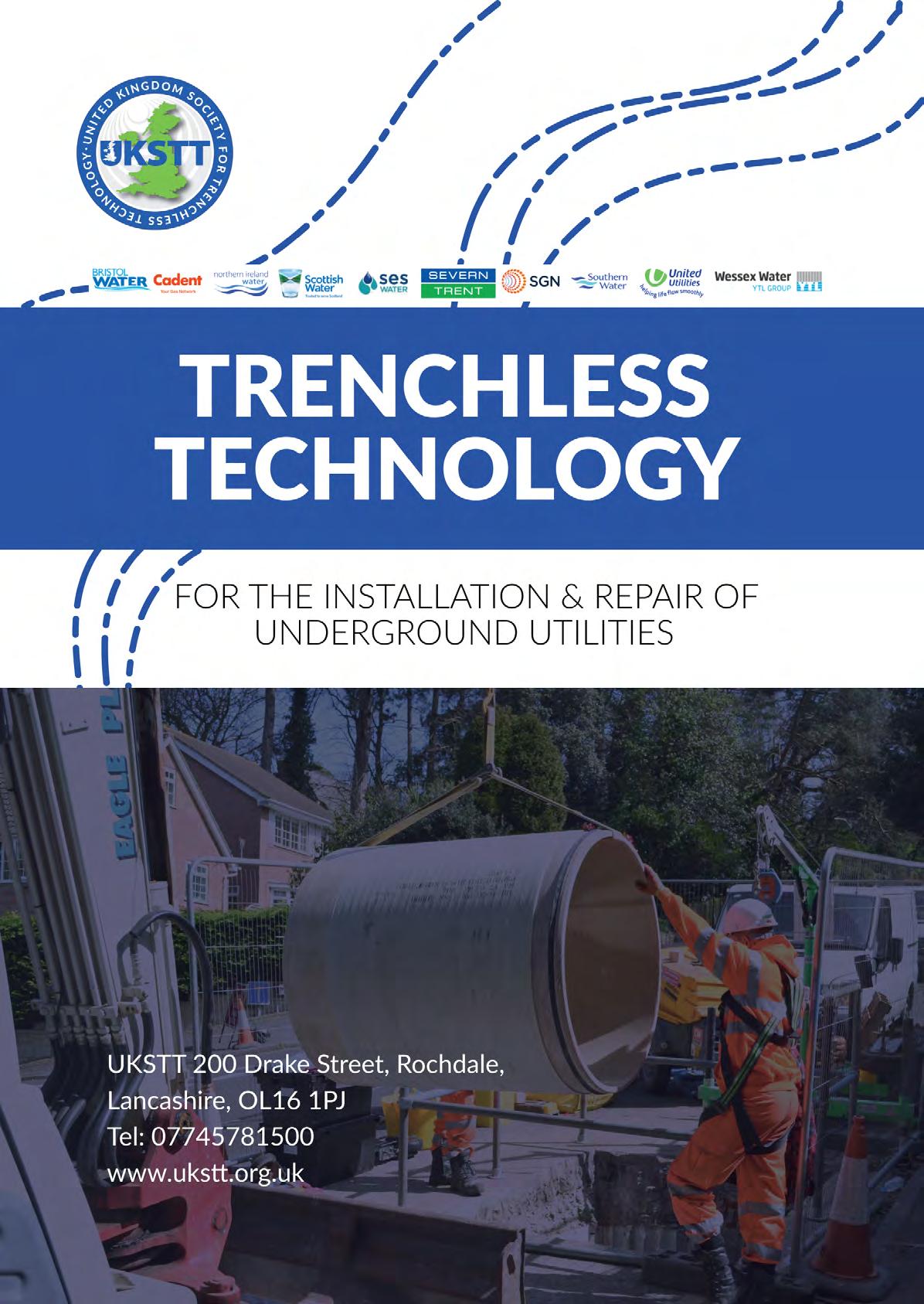

Book now to secure your place at the UK’s flagship trenchless exhibition

Exhibition and sponsorship sales for No-Dig Live 2026 are moving at record speed following its official launch, with demand already surpassing expectations.

Taking place from 29 September–1 October 2026 at NAEC Stoneleigh, the UKs only dedicated trenchless technology exhibition is set to deliver unrivalled opportunities for sales generation, brand visibility, and industry networking.

Building on the record-breaking success of the 2024 edition, anticipation for 2026 is already soaring. Exhibitors who secure space early will benefit from maximum visibility in the runup to the show, positioning themselves at the heart of the global trenchless community.

No-Dig Live is not just another exhibition; it is the flagship event for trenchless technology in the UK and one of the largest dedicated underground utilities shows in Europe.

With a track record of generating thousands of sales leads and forging new partnerships, it provides the single most effective platform for companies to launch products, showcase solutions, and grow their business.

The event attracts over 3,000 visitors from more than 30 countries and hosts more than 100 exhibiting companies spanning every area of trenchless technology.

Crucially, it is supported at the highest level by the UK water sector, with leading utilities represented. Across the threeday programme, the exhibition floor and demonstration areas create a vibrant working environment where suppliers can present equipment in action, giving delegates the opportunity to compare solutions side by side.

For suppliers, manufacturers, and service providers, this means direct access to project owners, engineers, contractors, and decision-makers who are actively seeking new technologies and partners delivering a proven return on investment.

The timing of No-Dig Live 2026 could not be more significant.

The UK water sector is in a period of transformation, with AMP8 investment cycles driving unprecedented levels of activity. The John Cunliffe Report has also set out major reforms across the sector, creating both challenges and opportunities for contractors and suppliers.

Being visible at No-Dig Live means demonstrating leadership in a rapidly evolving market, meeting customers the moment they are making procurement decisions, and building alliances that will shape the next phase of trenchless technology adoption.

The power of live demonstration

What sets No-Dig Live apart is its working exhibition environment. Indoor and outdoor space is available, with live demonstration areas giving companies the chance to show equipment in action. Visitors consistently report that the ability to see systems working side by side is one of the event’s greatest strengths, and for exhibitors, it is the most direct route to winning business.

Whether you are launching a new product, strengthening your market position, or highlighting the performance of proven solutions, No-Dig Live provides the platform to do so in front of a highly targeted audience.

Training, learning, and industry recognition

Alongside the exhibition itself, NoDig Live delivers a comprehensive programme of training and professional development.

Working in partnership with JBP, the show offers free masterclasses designed both for newcomers to trenchless technology and for experienced professionals looking to advance their knowledge. A series of technical seminars runs throughout the event, sharing the latest innovations, best practices, and case studies from around the world.

The week also includes the UKSTT Gala Dinner and Awards Ceremony, a highlight of the trenchless calendar. This prestigious evening not only celebrates excellence and achievement across the industry but also provides delegates with unrivalled networking opportunities in a relaxed, highprofile setting.

Supported by the United Kingdom Society for Trenchless Technology (UKSTT) and backed by national trenchless societies worldwide, No-Dig Live 2026 will once again be the focal point for global innovation in sustainable underground infrastructure.

Supported by the United Kingdom Society for Trenchless Technology (UKSTT) and backed by national trenchless societies worldwide, No-Dig Live 2026 will once again be the focal point for global innovation in sustainable underground infrastructure.

For companies seeking maximum exposure, No-Dig Live 2026 offers a range of sponsorship and partnership packages designed to deliver measurable impact. Sponsors enjoy enhanced brand visibility across all event marketing and media channels, ensuring their profile reaches delegates long before the doors open.

On site, sponsorship provides premium positioning that places brands at the centre of activity, while association with thought leadership sessions and high-profile networking events further strengthens credibility and industry influence.

Demand for exhibition and sponsorship packages is already exceeding expectations, with prime positions filling fast.

Exhibitors who confirm early will gain priority placement and extended pre-show marketing benefits.

Contact: Trevor Dorrell, Sales Director, Westrade Group tdorrell@westrade.co.uk Spaces are limited; early booking is highly recommended.

North Africa’s underground infrastructure market is experiencing unprecedented growth, driven by rapid urbanisation, modernisation initiatives, and a pressing need for sustainable solutions. At the heart of this transformation lies Morocco, a nation embracing trenchless technology as a vital tool for development. Don’t miss your chance to capitalise on this highgrowth market at Trenchless Morocco 2026, taking place February 11-12, 2026, at the Rabat Marriott Hotel in Rabat.

This event offers an unparalleled opportunity to connect with key stakeholders, showcase your expertise, and secure your position in this dynamic region.

Morocco: Huge potential for trenchless innovation

Morocco is undergoing a significant transformation, investing heavily in infrastructure upgrades across its major cities. Rabat, in particular, is experiencing rapid urban development, with substantial investments in water, sewage, telecommunications, and other vital utility networks. This growth fuels a rising demand for efficient, costeffective and environmentally conscious solutions.

Trenchless Morocco 2026 plays a critical role in facilitating this transition. The event brings together national government representatives, municipalities, contractors, utilities providers, consultants and other key decision-makers, creating a platform for collaboration and knowledge sharing.

Why attend Trenchless Morocco 2026?

Tap into a rapidly expanding market: Morocco ‘s underground infrastructure market is ripe with opportunity. Trenchless Morocco 2026 provides direct access to this rapidly developing region, allowing you to establish a foothold and cultivate valuable business relationships.

Showcase your expertise: The event features a tabletop exhibition, offering a unique opportunity to present your products, services and innovations to a highly targeted audience. Engage with potential customers, share industry insights, and build valuable connections that can drive your business forward.

Stay ahead of the curve: The high-quality conference programme features insightful presentations from leading experts, addressing key challenges and opportunities in the Moroccan market and beyond. Discover the latest technical developments in pipe installation, rehabilitation, inspection and cleaning, as well as the application of trenchless technology in gas, electricity, telecoms, and fibre optic installations. Also explore topical discussions such as the potential for the increased use of drone technology.

Network with industry leaders: Connect with key decisionmakers, industry experts and potential partners in a professional and collaborative environment. Benefit from high-quality networking opportunities that can lead to new opportunities and business ventures.

Limited opportunities available – act now!

The popularity of Trenchless Morocco has led to high demand for exhibition and sponsorship opportunities. Limited spaces remain for the tabletop exhibition showcase, so don’t delay in securing your spot. This cost-effective format provides an exceptional platform to expand your reach, promote your brand, and generate valuable leads.

In addition, very limited sponsorship opportunities remain, offering an exclusive chance to elevate your brand visibility and demonstrate your commitment to the North African market. For details on sponsorship packages and availability, contact Trevor Dorrell at tdorrell@westrade.co.uk

Supported by leading industry associations

Trenchless Morocco 2026 is supported by prominent industry associations, including ISTT, FSTT, GATT, IATT, and UKSTT, further solidifying its position as the premier event for the region.

Don’t miss out!

Trenchless Morocco 2026 is the ultimate opportunity for companies looking to capitalise on this high-growth market. Visit www.trenchlessmorocco.com for more information, registration details and to secure your place at this must-attend event.

We look forward to seeing you in Rabat!

Frank Reilly Director JBP’s Trenchless, Training Programme

Here at JBP we are continuously reviewing both the content and the approach of our trenchless training programmes.

As the water and wastewater sectors continue to undergo rapid transformation and development to meet the challenges of ageing infrastructure, increasing urbanisation, climate pressures, and the need for more sustainable solutions, it has never been more important to have a workforce that is not only technically competent but also adaptive and forwardthinking.

For those working with trenchless technologies, a field defined by innovation and the application of specialised methods, keeping skills and knowledge up-to-date is critical.

Engineers, contractors, consultants, utility managers, and site technicians alike are constantly balancing

demanding workloads and project deadlines. The luxury of taking extended time out of the office or being off a job site to undertake extended training may simply not be possible, no matter how necessary the training is. Short courses, whether delivered online, in person, or in blended formats, can be scheduled around professional responsibilities. This flexibility means individuals can target specific learning areas without committing to lengthy study programs, making CPD more achievable across all stages of a career.

Increasingly, short courses are designed to reach participants wherever they are. Digital platforms have complemented, and in many cases replaced, traditional classroom learning. Live webinars, recorded sessions, and interactive e-learning modules provide the opportunity for workers in remote regions or those operating on site to access the same quality training as their

colleagues who have access to physical training centres. In trenchless technologies, where expertise is spread across global networks, this accessibility ensures that lessons learnt in one part of the world can quickly be transferred to another.

The CPD approach is very effective, as it embraces a cumulative approach. Short courses allow professionals to build their knowledge in manageable steps, creating a strong foundation of understanding that can be applied almost immediately and expanded over time. A contractor may begin with an introductory course on pipeline rehabilitation, progress to a workshop on condition assessment, and then advance to specialist modules on UV-CIPP or HDD design. This modular learning approach encourages longterm engagement while steadily raising the competency level across the industry.

CPD’s value extends beyond technical knowledge. Short courses also foster broader professional growth. Participants develop transferable skills such as problem-solving, critical thinking, and communication, all essential in multidisciplinary trenchless projects. For individuals, the result means increased confidence and greater career advancement. For employers, it means more effective teams, improved project outcomes, and stronger organisational resilience.

Short courses serve as vital channels for disseminating the latest research, innovations, and international best practices. With trenchless technology evolving rapidly, professionals cannot rely solely on their original training. CPD ensures that the workforce remains up to date with advances in materials, equipment, and standards, helping to safeguard quality, safety, and environmental performance across projects.