Works

BEYOND THE MACHINE

Customer-centricity drives IMS Robotics

PUBLISHER

Paul Harwood pharwood@westrade.co.uk

EDITOR

Austen Lees editorial@trenchless-works.com

MANAGING EDITOR

Leigh Abbott labbott@westrade.co.uk

SALES DIRECTOR

Trevor Dorrell tdorrell@westrade.co.uk

DESIGN & PRODUCTION

Ioan Lucian Sculeac lucian@westrade.co.uk

CHINESE AGENT

Lexi Di lexi.di@bestexpo.cn

COPYRIGHT

Trenchless Works is published 12 times a year by Westrade Group Ltd I Carotino House| Bury Lane I Rickmansworth I WD3 1ED I UK

Contributions: Contributions are invited and articles should be emailed to editorial@ trenchless-works.com. No responsibility can be taken for drawings, photographs or written contributions during delivery, transmission or when with the magazine. In the absence of an agreement, the copyright of all contributions, regardless of format, belongs to the publisher. The publishers accept no responsibility in respect of advertisements appearing in the magazine and the opinions expressed in editorial material or otherwise do not necessarily represent the views of the publishers. The publishers accept no responsibility for actions taken on the basis of any information contained within this magazine. The publishers cannot accept liability for any loss arising from the late appearance or non-publication of any advertisement for any reason whatsoever. ISSN 2049-3401 Subscribe

www.trenchless-works.com

Editor’s Welcome

Austen Lees

As we wrap up 2025, this final issue of the year reflects just how far the trenchless community has travelled over the past twelve months. It has been a year defined by innovation, new partnerships, and a growing global momentum behind smarter, more sustainable infrastructure delivery.

In this edition, we explore some of the standout developments shaping our industry—from advances in HDD technology and connected microtunnelling, to award-winning rehabilitation projects and the evolving landscape of trenchless training. We also take a closer look at customer-first service models, product launches, and the increasingly critical role of digital tools across design, diagnostics and delivery.

Our global community continues to expand, with major milestones from ISTT, UKSTT, NASTT and affiliated societies around the world. The success of Trenchless Middle East in Jeddah, and the extraordinary demand for Trenchless Morocco 2026, with the exhibition now sold out and new sponsors stepping forward, highlight just how strong the appetite is for trenchless solutions on the international stage.

This issue also celebrates the people behind the progress: the engineers, innovators, trainers, and industry leaders who continue to push boundaries, share knowledge, and raise standards across every corner of the sector.

Thank you to everyone who has contributed to Trenchless Works throughout 2025, our authors, partners, advertisers, and the dedicated community who read, share, and support the magazine. Your insight and enthusiasm remain at the heart of what we do.

On behalf of the whole team, I wish you a restful Christmas period and a successful start to the new year. We look forward to bringing you even more stories, breakthroughs and industry highlights in 2026.

Austen

To submit editorial for Trenchless Works next issue please email copy and images to: editorial@trenchless-works.com by the 12th of the month.

Submissions arriving after this date cannot be guaranteed inclusion in that month’s issue. For Trenchless Works sponsorship and advertising rates please email: tdorrell@westrade.co.uk

ARTICLE

Editor’s Welcome

SPECIAL FEATURE

Celebrating an historic milestone of UV Light-Cured CIPP technology

NEWS

RENSET: The future of clean, portable power

Ipsum expands proven No-Dig capability into Scotland

Picote Open House 2025: Innovation, community and global collaboration in Porvoo, Finland

INSPECTION EQUIPMENT

Beyond the machine: Customer-centricity drives IMS Robotics UK growth

HDD

Long-term solutions for intact infrastructure

Vermeer highlights key HDD trends for 2026

TUNNEL BORING

Breakthrough for Herrenknecht TBMs beneath the Alps

PIPELINE REHABILITATION

Primus Line® marks 20 years of gas pipeline performance in Leipzig RELINE introduces liner integrated temperature measurement for real time curing control Where engineering meets ecology

SUPPORT EQUIPMENT

API completes first pilot project in Belgium using Pipa flowrider™ Technology

EVENTS

Trenchless Morocco 2026: Registration now open as exhibition sells out and new sponsors join

FOCUS ON TRENCHLESS TRAINING

2025 – that’s a wrap!

UKSTT SOCIETY NEWS

A message from the Chair

ISTT SOCIETY NEWS

No-Dig Turkiye 2025: A great success

ISTT and NASSCO announce global training partnership

Introduction to Trenchless: Free ISTT–IWA Webinar

ISTT Educational Webinar: Prediction of the deviation of the horizontal directional drilling line in sedimentary soils

ISTT opens call for 2026 committee members

NASTT SOCIETY NEWS

Meet, mix, connect. networking shines in Palm Springs at the NASTT 2026 No-Dig show

EVENTS AND MEETINGS

AT120

Loaded with 120,000 lbs (533.8 kN) of pullback/thrust and 15,500 ft·lbs (21015 N·m) of rotational only opens you up to new types of jobs but moves through long bores and large diameter installs All Terrain technology and a 280-hp (209 kW) Stage V Cummins® engine reduce environmental impact power. 3,000 ft·lbs (4067 N·m) of inner rotational torque—a 50% increase over its predecessor— additional power to drill through the toughest terrain around.

THE BEST SELLING ROCK THE

DRILL

IN AND

UK IRELAND.

rotational torque, the AT120 not installs with eye-popping power. impact without losing any predecessor— allows the AT120

Celebrating an historic milestone in UV Light-Cured CIPP technology

Cured in Place Pipes (CIPP) technology has been pivotal in pipeline rehabilitation worldwide since its inception in the 1970s. This year, we celebrate the 40th anniversary of the first commercial installation of UV Light-cured CIPP, a groundbreaking advancement in trenchless technology.

Historic installation

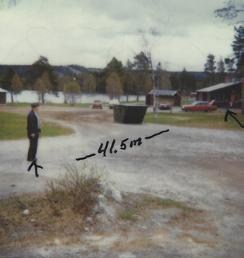

This historic installation took place in September 1985 at a campsite in Vilhelmina, a quaint village located 300 km south of the Arctic Circle in northern Sweden. It marked the

debut of the first commercially sold Inpipe liner, installed into 42 meters of DN 150 mm gravity concrete host pipe. This feat was made possible through bespoke installation equipment designed by Jan Borje Persson, who many readers will recognise as the Managing Director of JBP Composites S.L. Reflecting on this installation, Borje recalls the close collaboration with his former boss, friend, and trenchless pioneer Mr. Vollmar Jonasson, who invented the UV light-cured “Plast Strumpan” or “Plastic Stocking.” Jonasson’s patents date back to 1977, paving the way for this innovative technology.

It’s remarkable to reflect on how this invention, which meant liner could be produced and impregnated in a factory, stored, and transported to the site without risk of “pre-curing”, only requiring protection from sunlight, has evolved into one of the fastestgrowing trenchless rehabilitation techniques for pipeline networks worldwide.

During the installation, the factoryimpregnated glass fibre sleeve, which was shielded both inside and outside by tubular thermoplastic foils, was inverted using air. The light trolley (yes, only one trolley)

was installed and pulled to the receiving manhole manually. It was later retrieved using an electrically driven cable winch.

Evolution of liner materials

Returning to materials and liner design, the earliest CIPP systems introduced to the market utilised synthetic fibers as the resin carrier. In these designs, strength and ring stiffness were derived primarily from the resin’s wall thickness and its degree of cure. With the introduction of fiberglass, the liner gained a true structural reinforcement layer, enabling a dramatic increase in the cured pipe’s mechanical performance while reducing overall wall thickness, an approach commonly referred to as unisotropic design. Thus, the breakthrough lay not only in the curing technology but also in the evolution of liner materials and structural design.

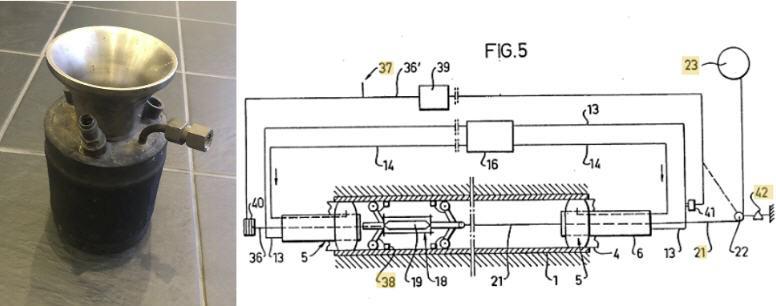

The patented reinforcement concept developed in 1977–78 featured a unique fiberglass architecture consisting of 96 individually woven fiberglass tapes, each 5 mm wide, braided into a flexible tubular structure. As the liner expanded during installation,

the orientation of the braided “sock” shifted, and the fibers adopted a more circumferential alignment. This transformation substantially increased the ring stiffness of the cured pipe without requiring additional wall thickness. It was, by any standard, an elegantly engineered solution.

One early drawback, however, was that the liner shortened as its diameter increased, which caused creasing in the inner layer. This issue was later resolved by adjusting the thermoplastic components and the internal reinforcement layer, while retaining the use of pure fiberglass.

Innovative installation technologies

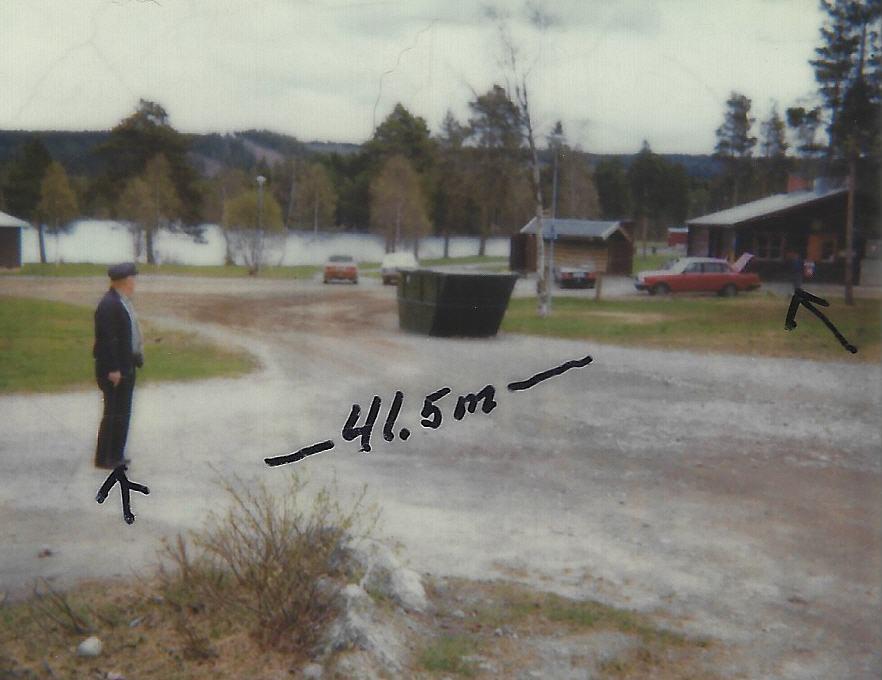

The installation utilised a coneshaped tool anchored at the inversion side manhole with a “rubber packer.” Remarkably, the rubber packer was placed inside the liner itself, leaving the first 20-30 cm uncured. This required separate curing after the light train completed its work. The liner was then pushed through the cone and secured with a leather membrane tightened by a rubber band to prevent any internal pressure from

leaking out. Once inverted over the rubber packer, the liner was locked in place using compressed air, similar to a packer for short lining or pipe stoppers.

This technology necessitated the presence of a technician in the manhole throughout the entire inversion process, which could last for several hours. Keeping the liner and the inner tubing lubricated with talcum powder was essential for smooth operation. Soon after the initial installation, the original tool was upgraded: the “invrängnings dorn” was replaced by a 90-degree elbow, allowing for top-fed lining while maintaining the secure locking mechanism.

The first commercial installation of a DN 150 glass fibre liner, comprised of a braided structure of 96 woven glass fibre bands, was a significant achievement for Vollmar, Borje and prospective investors, drawing keen interest from other major industry players. Companies, such as Insituform, soon announced that they would be commencing their own projects to develop UV curing systems as a replacement for traditional hot water curing methods. >

1983 Patent (ESO 0 122 246) Method and Design diagram

Research, development and cooperation

As previously noted, the first UVcuring method patent was granted with priority from 6 April 1983. Insituform had monitored the Swedish inventor’s work since the 1970s, following his public announcement of the research initiative, and consequently launched its own development program focused on UV-cured liners. Insituform received its first UV method patent shortly after Mr. Vollmar, with priority established in autumn 1983.

Insituform’s UV-curing patent was subsequently granted across Europe; however, their design placed the light source underwater. At Inpipe, we did not consider this configuration competitively viable at the time due to the inherent challenges of operating a highvoltage light source in a waterfilled pipeline. Furthermore, water absorbs a notable share of UV radiation, significantly reducing

curing efficiency.

During the first field installation, the resin used had been developed in collaboration between the inventor and the Swedish company ASEA in Piteå (now ABB). This styrene-based polyester resin was initially formulated to be thixotropic and was later modified using magnesium oxide to further increase viscosity and enhance storage and transport stability, ensuring consistent wall

thickness in the final cured pipe. The difference between relying on thixotropy versus deliberate thickening is substantial in terms of viscosity control and processing consistency.

In 1988, senior management elected to accelerate resin development and entered a joint venture with the German chemical company BASF. Comprehensive laboratory and testing programs

began immediately at BASF’s Ludwigshafen facility which, at that time, employed over 55,000 people. This unique environment enabled nearly a year of direct collaboration with BASF’s resin and composite R&D division.

This phase marked the refinement of the light-curing isophthalicacid-based resin “A 400,” an unsaturated polyester resin modified with isophthalic acid to improve reactivity and stiffness upon curing. Palatal P 92 later emerged as an improved version of A400; its “I” variant incorporated isophthalic acid and neopentyl glycol, compliant with DIN 18820/1 Group 3, still one of the most widely used resin systems for CIPP relining today.

The development and optimization of the curing and installation equipment were carried out in close cooperation with international technical experts, establishing the foundation for modern UV-cured CIPP technology.

Key markets, major players and competition

Between 1986 and 1987, Inpipe AB was established, acquiring the assets of VJ System AB (the inventor’s company) and building a factory in Vilhelmina, which evolved into a centre for research, development, and production. Through licensed installers in Sweden, Norway, Denmark, and Germany, extensive development efforts for the Inpipe Liner gained momentum.

Simultaneously, Insituform initiated its venture into the UV-cured CIPP market, aiming to improve speed and reduce water use, key selling points at the time. By mid1988, Insituform sold its first set of ultraviolet curing equipment

to its Danish partner, Per Aarsleff. The technology was promoted as a “special application alternative” to their traditional Insituform solutions, igniting competition that resembled a classic David versus Goliath scenario.

The early rivalry between Inpipe and Insituform catalysed significant advancements, shaping the market we see today. Light-cured CIPP now represents approximately 30% of the global CIPP market, exceeding 50% in Europe and China. The annual installation length is estimated at close to 8,000 km, with a liner material value in excess of €400 million and an installed value of between €1.25 and €1.4 billion –and still growing strongly, globally

Revisiting a UV-CIPP milestone

On the occasion of the 40th anniversary of the first commercial installation of UV Light-cured CIPP, I was able to revisit the original site in Vilhelmina and meet again

with former colleagues who were involved in the project and early development of the UV Light-cured CIPP method and materials. It was a great opportunity to reflect on some of those early challenges and recall the perseverance to overcome them.

Special thanks go to Dr. Dec Downey, Prof. Henrik Lindberg, Thomas Lundmark, Roland Lindberg and Tom Sangster for their contributions and support in providing their reflections, recollections and important information in the revisiting this important milestone, and thanks also to the many other trenchless colleagues who have shared this journey. As we reflect on the origins of UV light-cured CIPP technology and this 40th anniversary, we recognise the collaborative spirit and innovation of those early pioneers and that their contributions continue to drive the industry forward.

Add Atlas to your project and save time, money, and effort. We stock an extensive range of cable and pipe pulling winches suitable for all trenchless operations.

Add Atlas Winch and Hoist Services to your project. Give us a call today to discuss your requirements.

RENSET: The future of clean, portable power

As industries come under increasing pressure to reduce their environmental impact, the journey to net zero has become a business imperative. RENSET is helping to lead that transition with a new generation of clean, portable power, delivering high performance, zero-emission energy wherever it is needed. Whether deployed in congested urban areas or on remote and demanding worksites, RENSET is built for modern operations.

Its lightweight and rugged design allows it to handle harsh conditions with ease, while the interchangeable LiFePO4 battery system ensures there is no downtime. When one module is depleted, it can be swapped for a fully charged unit in seconds, allowing operations to continue uninterrupted and enabling capacity to scale as required.

Designed specifically to support net-zero ambitions, RENSET provides companies with a practical way to eliminate emissions on site while also reducing long-term operational costs. The patent-pending doublewalled housing gives the unit exceptional weather resistance, protecting internal electronics from rain, cold and harsh site environments. This makes RENSET particularly well suited to

unpredictable conditions common in construction and utility works.

Despite its compact footprint, RENSET delivers serious power. With a peak output of up to 10 kW, it is capable of running handheld tools, site cabins and even small forklifts, making it one of the most versatile portable energy solutions available today.

Steve Vick International, the sole UK distributor, is proud to partner with RENSET in developing this technology and supporting the shared mission of a greener, more sustainable future. Through this collaboration, UK companies can adopt a reliable, clean and cost-effective power source that supports their netzero goals with confidence.

Ipsum expands proven No-Dig capability into Scotland

Leading engineering solutions provider Ipsum has expanded its No-Dig services into Scotland, bringing advanced, low-disruption infrastructure solutions to a new region of the UK.

The move supports Ipsum’s strategy to deliver cleaner, more efficient and sustainable services, and responds to increasing demand for smarter approaches to sewer rehabilitation and pollution prevention. With Scotland facing ageing assets, complex environmental conditions and rising regulatory pressure, the need for cost-effective trenchless technology is accelerating. By reducing excavation, Ipsum aims to protect ecosystems, minimise community disruption and deliver faster, more economical repairs.

Mark Kaney, Managing Director for Water & Infrastructure at Ipsum, said: “Following the publication of The Cunliffe Review, it is obvious that the sector is in need of methods that meet sustainability requirements but also put customers at the very centre. No-Dig provides the reassurance

“Ageing infrastructure is a big issue faced by the UK, but Scotland presents unique complexities, such as a mix of remote rural networks, densely builtup urban areas and stricter environmental and planning constraints

of extended asset life and a highly controlled programme of works, as well as a bonus of reduced disruption to local communities. From a sustainability perspective, it also reduces programme emissions compared to those seen with traditional excavations.

Our expansion of the Trenchless Technologies team into Scotland is a crucial move to help address ageing infrastructure and showcases Ipsum’s commitment to providing better, faster and greener ways of working.”

Mark McCallum, Operations Director (Scotland) at Ipsum, added: “Ageing infrastructure is a big issue faced by the UK, but Scotland presents unique complexities, such as a mix of remote rural networks, densely built-up urban areas and stricter environmental and planning constraints. No-Dig methods are a real game changer when it comes to programme predictability, cost efficiency and community impact.

We’re proud to be expanding our capabilities into Scotland and supporting the country’s commitment to preventing the pollution of its waterways.”

Ipsum already delivers a well-established Trenchless Technologies service across England, working with major Water Companies. At the 2025 UKSTT Awards, the company’s Dale Road Spills Scheme was ranked in the top three in the Renovation – Small Projects category, recognised for delivering a long-term solution to a significant pollution risk.

The expansion follows substantial CAPEX investment in Ipsum’s trenchless division, enabling the purchase of state-of-the-art equipment and further upskilling of its engineering teams.

More information about Ipsum’s No-Dig offering is available, you can download its brochure here

No one will NOTICE…

& that’s the beauty!

Because the best infrastructure isn’t the loudest, it’s the one you never have to think about

Why Inpipe sets a new global standard:

UV-cured GRP liners engineered for extreme durability

Flexliner adapts to 50% pipe changes, seals tight, and lasts 100 years

Faster installation with minimal disruption

Up to 80% CO₂ savings compared to full replacement

• Sliplining

• Guided Boring Systems

• Microtunneling

• Pipe Jacking

• Tunneling

• Earth Pressure Balance

Picote Open House 2025: Innovation, community and global collaboration in Porvoo, Finland

Picote’s Open House 2025 in Porvoo, Finland brought together more than 200 guests from across its global reseller network for two days of innovation, handson learning and Finnish hospitality. From live demonstrations and panel discussions to local food and a sauna evening, the event showcased not only Picote’s latest technologies but also the collaborative spirit driving the trenchless industry forward.

The programme opened with introductions to the Picote team and discussions around why innovation remains central to Picote Solutions’ development strategy. Delegates were given an exclusive preview of new products scheduled for launch in Winter 2025 and Spring 2026, followed by an in-depth look at Picote’s manufacturing and R&D operations in Porvoo.

A key highlight was the launch of the new Picote ProLITE, a powerful and portable addition to the Miller range. Live demonstrations illustrated how the system streamlines on-site work and offers contractors greater flexibility in day-to-day operations. This was followed by demonstrations of the Mini Multi-Cutter, focusing on concrete removal and failed liner removal capabilities.

Across both days, guests rotated through a series of product stations, including overviews of the Xpress Coating System, Connection Collar solutions, CIPP lining equipment and the new Picote inversion drums for CIPP. Practical sessions encouraged visitors to test the equipment themselves and discuss real-world requirements directly with members of Picote’s R&D and technical support teams.

Global collaboration and technical support were recurring themes throughout the event. Panel discussions brought together experts from different regions to explore topics such as facility management in trenchless applications and the value of strong support services in emerging markets. A notable contribution came from Loctech in Malaysia, whose case study on trenchless rehabilitation for offshore oil rigs highlighted how partnershipled approaches and shared learning can raise standards internationally.

The technical content was complemented by a strong social programme. Delegates made good use of the Picote Bar, complete with its signature “Picotini” cocktail, and enjoyed hearty Finnish meals. A dedicated Picote sauna experience was introduced as a new

Open House feature, while daily competitions, including challenges featuring the Mini Multi-Cutter, helped keep energy levels high through to the closing happy hour and traditional BBQ on day two.

Picote’s 2025 Open House ultimately served as both a technology showcase and a celebration of the growing global trenchless community around the brand.

Those interested in attending future events can register interest for next year’s Open House in Finland, or for the UK Open House in Sandhurst (10–11 June 2026), by emailing steph@picotesolutions.com

Beyond the machine: Customer-centricity drives IMS Robotics UK growth

By Austen Lees, Editor, Trenchless Works

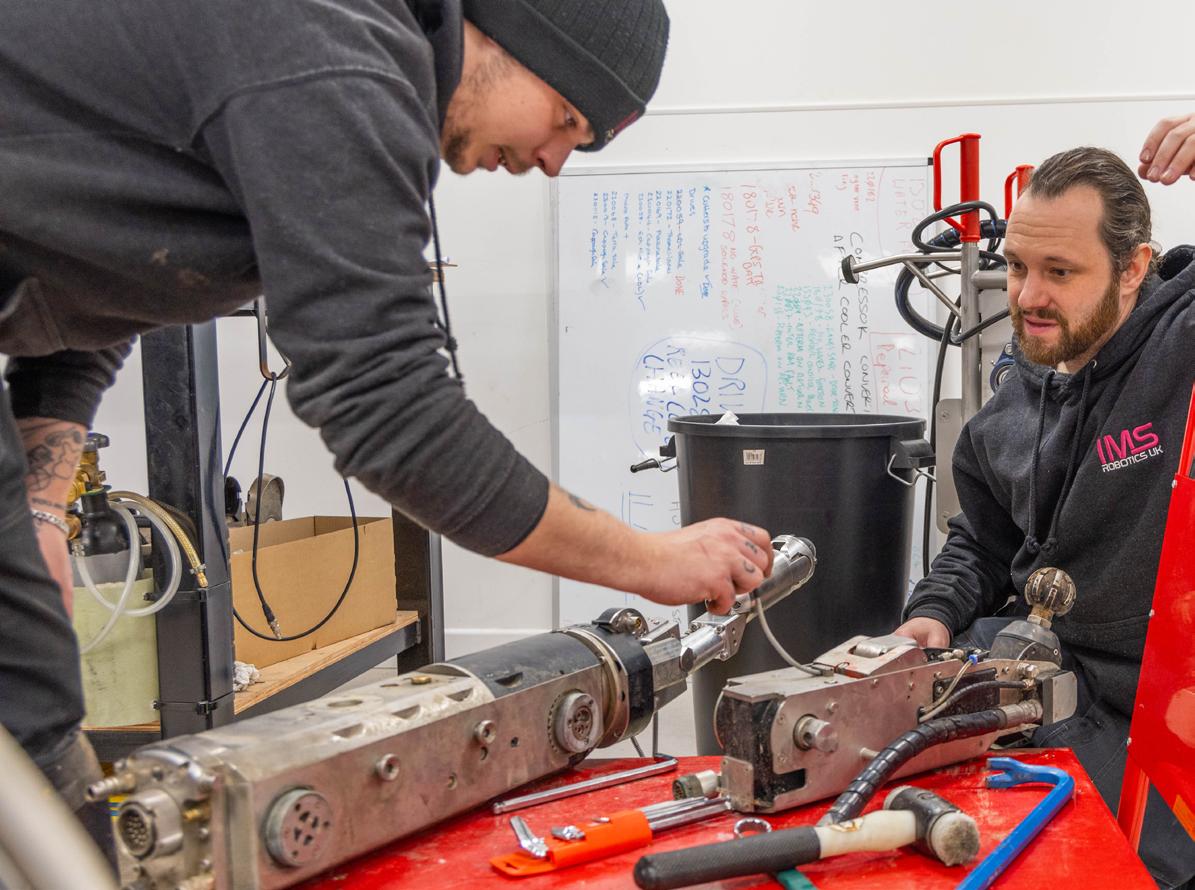

Arecent visit to IMS Robotics UK and Pro Lining Solutions Ltd (PLS) provided an excellent opportunity to meet with Mark Douglas, Simon Tucker, John Rose, and Garrick Daykin. The discussion offered valuable insights into the companies’ impressive growth and their ambitious plans for the future.

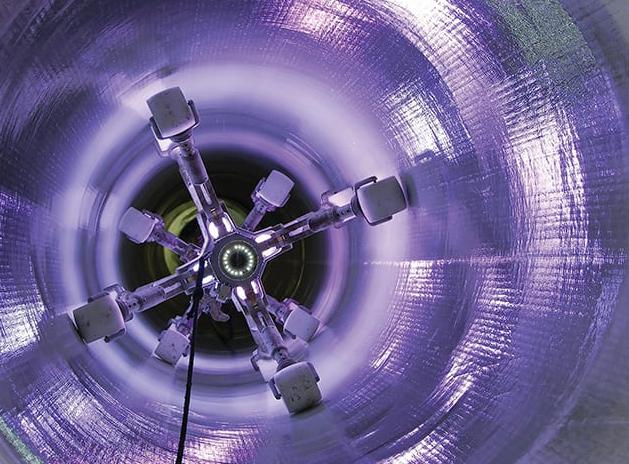

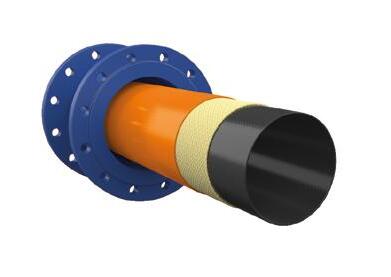

IMS Robotics UK was founded in March 2022 by John, Mark, and Simon, operating as a subsidiary of IMS Group. Initially, the company began with just seven machines in its hire fleet, delivered to customers in a second-hand transit. However, the team quickly expanded their offering to fill a gap in the UK market. This initial expansion included a large mainline cutter, which significantly differentiated their offering and quickly built brand awareness across the sector. This commitment to a diverse and comprehensive offering has been maintained, resulting in a hire fleet of over 70 high-spec machines and more than 200 IMS machines operating across the UK within just three years. In fact, IMS Robotics UK has become one of IMS Group’s largest retailers of cutters anywhere in the world.

From day one, the team recognised their opportunity lay in a truly customercentric approach, founded on delivering outstanding service. They emphasise that a machine out of service, even for a short period, can cost contractors tens of thousands of pounds. Their commitment to minimising these losses for customers remains as strong as ever, extending beyond significant financial investment in service infrastructure. The entire team still dedicates weekends, early mornings, and late evenings when necessary. This work ethic was exemplified by a recent late-night delivery of a hire machine to a customer on the M62! This dedication is further underpinned by significant investment, including four fully trained engineers and a comprehensive stock of spare parts readily available in the UK.

The IMS team also quickly recognised the vital importance of education and training for their customers. In fact, training is mandatory for all firsttime hires of their equipment. Mark emphasises that even if a customer has prior experience with cutters, or even an IMS machine, specific training on the exact tool being used is crucial. Beyond obvious safety aspects, this training ensures customers can perform tasks as effectively and efficiently as possible. It also minimises the risk of damage or unnecessary wear, preventing costly downtime and associated expenses. Crucially, this commitment to training and cutting delays has been instrumental in building IMS’s enviable reputation for delivering high-spec, high-quality machines. The team reflects on their ability to often identify when new users join a customer’s team, indicated by an uptick in maintenance requirements. At this point, they proactively offer additional training to ensure everyone is fully up to speed. >

The team discussed the dynamic between their sales and hire divisions, a relationship one might initially assume to be in conflict. Simon notes that expanding the hire fleet, now including cutters up to 800mm and technologies like pneumatic, electric, and UHP (ultrahigh pressure), ensures customers have access to the right technology for their specific applications. Once customers become comfortable with these tools and have sufficient ongoing work, they often choose to invest in and add the products to their own fleet. A similar customer journey is observed within PLS’s lining division, where clients can seamlessly transition from traditional UV curing systems to LED technology, benefiting from a highly familiar interface for data entry and operations.

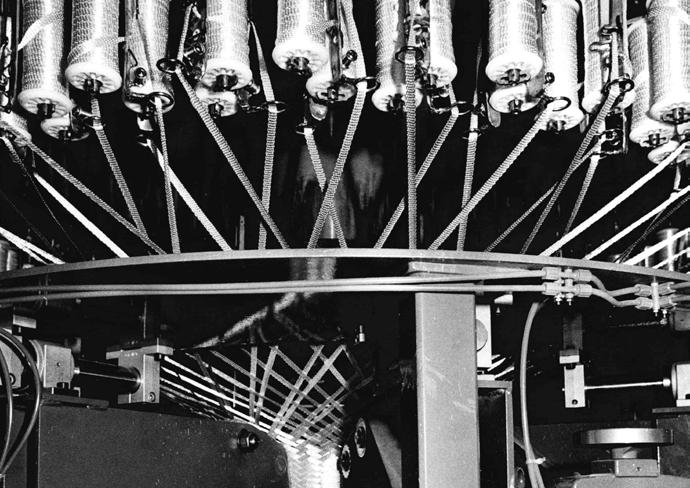

This naturally led to a discussion about Pro Lining Solutions Ltd (PLS), which recently celebrated its second anniversary. Garrick explained that PLS originated from the IMS team receiving numerous lining inquiries. They saw an opportunity to leverage the products and expertise of Hurricane Trenchless Technologie GmbH, which IMS Group acquired in 2024. This offering includes inversion vessels, steam boilers, wet-out tables, and UV rigs that, while part of the company’s European offering for some time, were relatively untouched in the UK market.

Garrick further explained that PLS’s mantra is to provide highquality products not sourced from “regular suppliers,” thereby offering the market greater choice and ensuring customers have the

right product when they need it. The company demonstrates a clear commitment to business expansion, exemplified by the installation of a new wet-out table in July this year. Exciting plans are also underway for a new range of liners and resins, currently undergoing testing, and a new training facility featuring underground pipes to closely mirror real-world job site conditions. Garrick and the PLS team appear genuinely motivated to improve the UK network. This involves developing legacy products designed to stand the test of time and endure as long as the original Victorian sewer network, ultimately benefiting UK taxpayers.

However, future growth is certainly not limited to PLS, with IMS Group’s 29-person R&D team in Germany continuously developing products

perfectly suited to applications and conditions worldwide. When asked about future growth areas, Mark highlighted the potential for UHP (Ultra High Pressure) systems, which are highly effective in removing concrete and other deposits. Indeed, a job that might take six months with a traditional cutter could be completed in just one-sixth of that time using UHP. He also understands that these systems require specialist training and operation, which is why the company has introduced them into their hire fleet, allowing customers to understand their capabilities before considering a purchase.

Another exciting development and recent portfolio addition is the IMS UV Stand Alone system. Designed for curing UV top hats and performing UV short-liner

rehabilitations, it is mobile, with all necessary equipment integrated into the cable drum, and can be used in a nominal diameter range of DN 150 - DN 300.

To conclude, I asked the team what they considered the biggest opportunity or challenge for the UK trenchless sector. The unanimous answer was the need to increase the amount of skilled labour. Simon emphasised that the network is decaying faster than it can be repaired, fundamentally due to a shortage of individuals skilled in effective maintenance and rehabilitation. Given the absence of formal college courses, the sector must establish a training and development system that meets future needs and protects employers who invest in their staff from immediate turnover.

The reality is that a really good living can be made in installing, maintaining, and rehabilitating our underground utilities, but the necessary educational pathway is simply not in place.

It was a pleasure to spend time with the team, and one cannot help but be impressed by their work ethic and unwavering commitment to providing customers with everything they need to remain productive. This consistent focus on delivering high-quality, high-specification equipment, perfectly suited for the task at hand, will undoubtedly ensure both businesses continue their impressive growth.

LONG-TERM SOLUTIONS FOR INTACT INFRASTRUCTURE

A comprehensive approach trengthens the global pipe rehabilitation market

“Bursting technology has incredible potential. The global rehabilitation market is estimated at around €5 billion. With more people living in cities and heavy rainfall events increasing due to climate change, the need to expand the capacity of existing infrastructure is enormous. Complete pipe replacement offers a long-term solution for all of these challenges.

Space-saving: The GRUNDOBURST system renews pipes from a compact trench

The renewal of underground infrastructure has become an urgent priority worldwide. Ageing water, gas and wastewater networks are increasingly prone to leaks, blockages and structural failures, wasting resources, threatening the security of supply and forcing operators to make major investments in emergency repairs.

While open-cut excavation is often unfeasible and many repair techniques offer only short-lived results, complete pipeline renewal using the pipe bursting method provides a long-term, sustainable and economically sound alternative. As a co-inventor of the bursting technique, TRACTO delivers a full portfolio of safe, proven systems supported by a comprehensive service and training offering.

Proven pipe bursting technology – made in Germany

TRACTO’s solutions cover both dynamic and static bursting methods for replacing ageing pipelines along their existing alignment.

The dynamic GRUNDOCRACK system combines percussive bursting with the pulling force of a winch, allowing fast and effective renewal of gas or wastewater pipes made from brittle materials.

The static GRUNDOBURST range is capable of renewing defective pipes from ND 50 to 1,200 in both brittle and ductile materials. With pulling forces from 400 to 2,500 kN, these rigs are ideal for projects in dense urban environments, operating from compact pits or manholes and working horizontally in both directions even manhole to manhole.

TRACTO’s QuickLock bursting rods, which lock via a ratchet mechanism rather than threaded connections, significantly reduce installation time and labour requirements. New pipes either likefor-like or upsized—can be pulled in during the bursting process, enabling operators to increase hydraulic capacity where required. With additional accessories, contractors can also carry out calibre bursting, relining and the TIP method.

Tailored support for contractors

TRACTO provides specialist companies with much more than equipment. Through its dedicated Pipe Bursting Centre (PBC), the company offers hands-on technical guidance, demonstrations, training sessions and advice on optimal machine selection for specific applications.

Contractors also benefit from flexible financing options, rental solutions and a broad accessory portfolio, ensuring that even highly bespoke rehabilitation projects can be delivered safely and efficiently. >

A growing global market

The team at the Pipe Bursting Centre is not only focused on supporting contractors but also on advancing the wider market.

They continue to enhance equipment capabilities, raise industry awareness and prepare for future challenges.

Thorsten Schulte, responsible for PBC’s international customers, sees substantial growth ahead:

“Bursting technology has incredible potential. The global rehabilitation market is estimated at around €5 billion. With more people living in cities and heavy rainfall events increasing due to climate change, the need to expand the capacity of existing infrastructure

is enormous. Complete pipe replacement offers a long-term solution for all of these challenges.

“With our comprehensive services, we can support civil engineering companies already active in rehabilitation—or those looking to enter the market—so they can benefit sustainably from this growth sector.”

GRUNDOBURST systems are used to replace defective pipes up to ND 1,200 quickly and gently underground, without reducing hydraulic capacity.

The result is a new, loadbearing pipeline in the existing route. In addition, complete renewal allows

even more hydraulic capacity to be created by pulling in larger diameters.

Pipe rehabilitation could not be more sustainable.

Find out more online or get in touch with our experts: T + 49 2723 808-0

E info@tracto.com

VERMEER HIGHLIGHTS KEY HDD TRENDS FOR 2026

As the infrastructure and utilities sectors face growing pressure to deliver faster, cleaner, and more accurate underground installations, the world of horizontal directional drilling (HDD) continues to evolve. In 2026, contractors can expect the next generation of equipment designed to improve efficiency, meet tougher environmental standards, and adapt to increasingly complex ground conditions.

According to Vermeer UK, a long-standing supplier of HDD systems and trenchless solutions, several key developments are set to define the year ahead. One major shift is the move towards hybrid and fully electric HDD rigs, as contractors seek to reduce fuel consumption, lower emissions, and comply with urban air-quality targets. The added benefit of quieter

operation is particularly valuable in residential and noise-sensitive environments.

Automation and smarter guidance are also transforming the sector. Modern rigs feature advanced steering sensors, automated alignment systems, and real-time bore path monitoring, helping operators achieve greater accuracy with less manual input. These innovations improve consistency, reduce fatigue, and enhance productivity across longer or more intricate bores.

Meanwhile, the rise of telematics and connected fleet management is changing how contractors plan and monitor operations. Data-driven insights into rig performance, tooling wear, service requirements, and jobsite conditions are allowing companies to reduce

downtime and optimise resource allocation across multiple projects.

Equipment design is evolving too, with faster setup and modular tooling now standard features on many new rigs. Simplified assembly and interchangeable tool systems enable crews to switch tasks more efficiently, a major advantage on smaller jobs or those requiring rapid turnaround.

Sustainability remains a strong focus for manufacturers. New HDD models are incorporating recyclable materials, cleaner engines, and reduced fluid consumption, alongside lifecycle support programmes that help contractors minimise waste and extend machine life.

Finally, the latest rigs are delivering more power, torque, and cooling capacity to handle increasingly complex drilling environments, from deep rock formations to long-distance urban installations, without compromising stability or precision.

Vermeer UK continues to invest in innovation, training, and aftersales support to help contractors meet these evolving demands. Whether upgrading existing fleets or preparing for future projects, the next generation of HDD systems promises higher performance, smarter operation, and a more sustainable approach to trenchless installation.

For more information, visit www.vermeeruk.co.uk

BREAKTHROUGH FOR HERRENKNECHT TBM BENEATH THE ALPS

Eight tunnel boring machines manufactured by Herrenknecht have now excavated approximately 83.4 km of tunnel for the Brenner Base Tunnel, marking one of the most significant phases of progress on this landmark European project. On November 11, 2025, representatives of the project owner, the construction companies and key partners gathered deep beneath the Alps to celebrate the breakthrough of the TBMs “Lilia” and “Ida” in the H41 Sill Gorge–Pfons construction section south of Innsbruck.

Despite their gentle names, both machines are among the most powerful units deployed on the project. Each Single Shield TBM weighs more than 2,400 tonnes, stretches roughly 160 meters in length, and operates with a diameter of 10.25 meters. Their cutterheads are driven by 4,550 kW of installed power, enabling sustained excavation of hard alpine rock. Since tunnelling began in May and June 2023, the construction consortium Implenia, Webuild and CSC has advanced more than eight kilometers with the two machines, installing precast concrete segments throughout the drive. >

“Lilia” completed its excavation of the eastern main tube in early October, while “Ida” achieved breakthrough in the western tube at the end of August. Two additional Double Shield TBMs continue to advance further south in the H53 Pfons–Brenner section. Once all drives are complete, Herrenknecht machines will have excavated around 90 kilometers across the Brenner Base Tunnel, including main tubes and exploratory tunnels.

At the ceremony, BBT CEOs Umberto Lebruto and Martin Gradnitzer highlighted the exceptional progress made in 2025, noting that “not only the two TBMs in this construction lot, Ida and Lilia, but also the TBM Flavia in the Mauls construction lot have achieved major milestones this year.” Dr.Ing. E.h. Martin Herrenknecht, founder and CEO of Herrenknecht AG, described the project as “a tough challenge and a top reference in the history of tunnel construction,” praising the determination and

technical excellence of all teams involved. Project manager Bernhard Wienhold echoed this sentiment, emphasising the expertise and dedication of both Herrenknecht service staff and the construction crews working daily underground.

Herrenknecht’s role on the Brenner Base Tunnel extends far beyond the supply of eight TBMs. The company is also providing complete systems for segment production, navigation and ring sequencing technology, as well as multikilometer conveyor belt systems that support excavation and logistics. These integrated technologies and services ensure consistent progress in one of the most demanding tunnelling environments in Europe.

The Brenner Base Tunnel is part of a broader strategic effort to overcome the natural barrier of the Alps for modern transEuropean rail transport. High gradients on historic routes have long restricted capacity

and slowed travel across the region. The Swiss Gotthard Base Tunnel, inaugurated in 2016, was a major step forward, and its 57-kilometer length was excavated using four Herrenknecht Gripper TBMs between 2003 and 2011. The next major Alpine rail project is the Mont Cenis Base Tunnel, forming the core of a new fast rail link between Lyon and Turin. For this project, the client TELT has already ordered six Herrenknecht TBMs for more than 70 km of tunnel, along with extensive auxiliary equipment.

The breakthrough achievements of “Lilia” and “Ida” mark another decisive step toward completing the Brenner Base Tunnel and improving Europe’s north–south rail corridor. Their success underscores the engineering capabilities of Herrenknecht and the ongoing commitment of all partners involved in delivering this transformative infrastructure project.

STILL IN A LEAGUE OF ITS OWN

THE D100X140 S3 NAVIGATOR® HORIZONTAL DIRECTIONAL DRILL

The D100x140 S3 is a unique machine in the HDD market. It’s not only used for oil, gas or other large pipeline projects — but utility projects as well due to the machine’s small footprint.

Primus Line® marks 20 years of gas pipeline performance in Leipzig

In the autumn of 2003, Rädlinger Primus Line GmbH carried out one of its earliest gas pipeline rehabilitation projects at the South Cemetery in Leipzig, using what was then the newly developed Primus Line® inliner system. More than twenty years later, the question arises: what has become of this rehabilitated pipeline? Is it still in operation? And how does the network operator evaluate the trenchless method today?

Covering 72 hectares, Leipzig’s South Cemetery is one of Germany’s largest park-like cemeteries, and both the site and its tree stock are protected as historical monuments. This posed a major challenge for the municipal utility company Leipzig Stadtwerke in 2003, as a DN 300 gas pipeline running beneath the cemetery required rehabilitation. Open-cut construction was ruled out due to the protected status, leaving trenchless renovation as the only viable option. Netz Leipzig GmbH, a subsidiary of Leipzig Stadtwerke, was open to new methods and became one of the first network operators in Germany to use an inliner system for gas. >

Founded only two years earlier, Rädlinger Primus Line GmbH had developed a liner specifically designed for gas transport; applications for other media would follow later. After extensive testing, the system, Primus Line® was approved for live use. Netz Leipzig classified it as a “viable method” and used it to rehabilitate the steel pipeline beneath the cemetery.

According to Holger Thieme, then and now Head of Gas Network Operations at Netz Leipzig, the method was chosen because it was “fast, uncomplicated and lowcost.” Only a few small excavation pits were needed, the existing pipe could remain in place, and the long, relatively branch-free

alignment made the project ideal for an inliner approach.

The steel pipe, installed in the 1950s, had previously carried town gas — a mixture from lignite processing with hydrogen content of up to 30 percent. The gas mixture had created heavy deposits inside the pipe, requiring intensive cleaning before liner insertion.

“Back then we didn’t have the milling robots we use today,” recalls Christian Pollak, who oversaw construction management for Primus Line in 2003 and still does today. “The cleaning device looked a bit like a handheld angle grinder.”

Despite the limitations of the time, the cleaning succeeded and the Primus Line® liner was installed.

The rehabilitation was divided into five sections and ultimately required seven excavation pits rather than the six originally planned. During insertion, the pulling forces generated by the winch proved higher than anticipated. To prevent any potential impact on liner stability, the longest section was split into two, necessitating an additional pit. The pre-cleaning camera inspection also revealed an undocumented concrete slab at a water pipe crossing, which the utility replaced using open-cut construction.

Despite these challenges, the project was completed to the full satisfaction of the network operator in 2003, and the pipeline

continues to perform reliably today. “The rehabilitated gas pipeline is still in operation at 3 bar pressure,” reports Holger Thieme. “There has been no damage in more than 20 years. We inspect the pipeline twice a year in accordance with DVGW guidelines. We have detected no leaks and virtually no permeation.”

What Primus Line Learned from the Project

The installation in Leipzig provided essential insights that contributed to the system’s further development:

Reducing insertion forces

To minimise pulling forces and protect the liner, Primus Line

now delivers the liner folded in a U-shape rather than flat. Deflection rollers reduce friction, and twist arresters prevent rotation of the winch cable and liner during insertion. An optimised insertion angle further reduces forces.

Improved cleaning technology

Today’s milling robots are significantly more advanced, allowing sharp-edged weld roots and heavy incrustations to be removed safely and precisely.

Achieving a clean, consistently dimensioned inner diameter is crucial to protecting the liner during installation.

Conclusion

The rehabilitated gas pipeline in Leipzig has now surpassed almost half of its 50-year design life without issues, confirming long-term test results in real-world operation.

The challenges encountered in this early project provided valuable knowledge that helped Rädlinger Primus Line refine and optimise its installation process. Today, Primus Line® technology is a mature, highly reliable system that requires only standard equipment and is particularly well suited for sensitive or protected environments just like the South Cemetery.

RELINE introduces liner integrated temperature measurement for real time curing control

“

The temperature cable is integrated between the resin-impregnated glass fibre layer and the outer film layers of the liner, recording values every five seconds

RELINE has introduced a major advancement in GRP liner curing technology, liner-integrated temperature measurement, a system that captures real-time temperature data along the full length of the liner, enabling consistently high and uniform curing quality.

Until now, even with modern monitoring tools, temperature variation along the pipe has been difficult to measure—despite being one of the most critical factors influencing the curing of resin-impregnated liners. RELINE’s new system directly addresses this gap. “The temperature cable is integrated between the resin-impregnated glass fibre layer and the outer film layers of the liner, recording values every five seconds,” explains Dr. Rainer Wendel, Head of Research & Development at RELINE. “This provides precise temperature readings taken from the exterior of the laminate inside the host pipe.”

More precise data for optimised curing

Compared to conventional methods such as dielectric analysis (DEA), which require complex interpretation of molecular mobility, liner-integrated temperature measurement provides clear, direct temperature values that the installation team can interpret instantly and use to make informed decisions on site. Instead of isolated measurement points, the system records continuous temperature data along the entire liner, enabling dynamic adjustment of UV curing parameters according to the surrounding temperature conditions. “This ensures the liner achieves its best possible mechanical characteristics throughout its entire length,” says Dr. Wendel. “In turn, this improves quality, structural performance and long-term service life.”

The next development stage is already underway. Future RELINE curing systems will use the integrated temperature data automatically, providing even more precise process control without manual intervention.

Field tests and next steps

Following a successful first field trial, verified against standard measurement technology, RELINE is now collecting extensive data from additional projects. “Our goal is to install at least 30 kilometres of liner with integrated temperature measurement by the end of Q1 2026,” says Dr. Wendel. Data will be collected across a wide range of pipe diameters, profiles, wall thicknesses and temperature conditions. Material samples from each project will undergo further mechanical and chemical testing. The aim is to build a comprehensive dataset that supports the development of optimised processing windows for maximum curing quality.

“Liner-integrated temperature measurement represents a decisive step forward in quality assurance,” Dr. Wendel emphasises. “We look forward to working closely with our customers and industry partners as we refine and expand this technology.”

The system is already available across all variants of RELINE’s Alphaliner 500G and 1800H product lines.

WHERE ENGINEERING MEETS ECOLOGY

Channeline’s custom GRP lining systems deliver new infrastructure life and wildlife protection

When it comes to infrastructure rehabilitation, one size never fits all: from unique shapes and profiles to site-specific conditions and, now more than ever, the need to protect the environment and local wildlife.

The answer? A truly bespoke approach to lining solutions. Renowned worldwide for their ability to be manufactured in any shape and any size, Channeline’s fully structural glass-reinforced plastic (GRP) lining systems offer a 150-year design life and complete flexibility in design. These custom solutions allow environmental and hydraulic requirements to be engineered in from the outset, ensuring infrastructure renewal works hand in hand with nature.

Designed for animal movement

In one UK project involving a large brick arch culvert suffering from significant deterioration, environmental assessments identified regular use of the structure by otters, badgers and other mammals. This meant that any rehabilitation works would need to maintain a safe route for animals during both low and high flows.

iLine Technologies brought on Channeline to design and manufacture a bespoke GRP segmental liner with an integrated 500mm-wide mammal ledge running along one side of the structure. This provides a dry passage for wildlife even when the channel is active.

To further support aquatic species, a stone invert was added to slow flow velocities and improve conditions for fish movement and spawning.

This tailored design demonstrates how the bespoke nature of Channeline’s manufacture can be used not only to address structural deficiencies but also to meet increasingly complex environmental objectives.

Adapting to hydraulic constraints

Another iLine Technologies culvert project faced a different set of challenges. Initial proposals for a built-in mammal ledge within a new GRP liner proved

unworkable due to reduced flow capacity. To resolve this, the project team developed a detachable GRP shelf system, supported on GRP brackets chemically anchored into the liner walls.

The final solution, incorporating a 500mm-wide antislip coated ledge, met all hydraulic and environmental requirements without compromising the culvert’s operational performance. The success of this approach highlights the versatility of GRP segmental systems in accommodating project-specific constraints. >

Preserving bat roosts during rehabilitation

In another UK culvert renewal, the existing brick arch structure was in poor condition and required full structural rehabilitation. A wildlife survey revealed the presence of bats roosting within the existing fabric, prompting a collaborative approach between engineers, environmental specialists, and regulatory bodies.

A segmental GRP liner was selected as the most suitable method to restore strength and extend the service life of the culvert. To protect the bat population, sections of the new GRP crown were cut away after installation, exposing areas of the old brickwork and rough grouting to recreate

familiar roosting conditions. The result: a structurally renewed waterway that remains home to its original nocturnal residents.

Improving aquatic habitats

In Maine, United States, improving aquatic life passage was a key requirement of the rehabilitation of a culvert. DLVEWS brought on Channeline to tackle this problem.

Channeline’s bespoke rectangular GRP liner not only fit the culvert shape and size precisely, it also incorporated angular internal weir panels arranged in alternating slopes. These, combined with rock weirs, allowed the water to behave like a naturalised stream channel.

Shaping a sustainable future

These projects highlight a new era in trenchless rehabilitation; one where structural performance and environmental sensitivity are designed together from the outset. With Channeline’s bespoke approach to lining solutions, ecological features can be fully integrated into the design and manufacture process, ensuring that environmental obligations are met alongside long-term structural performance. This proactive, design-led philosophy redefines what sustainable rehabilitation looks like: stronger structures, longer infrastructure lifespans, and thriving habitats.

For more information visit channeline.com

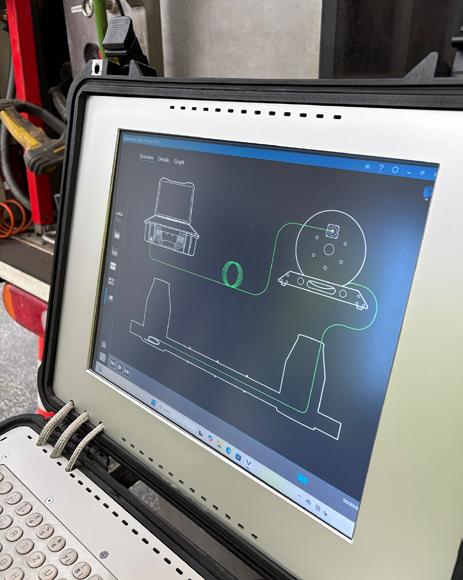

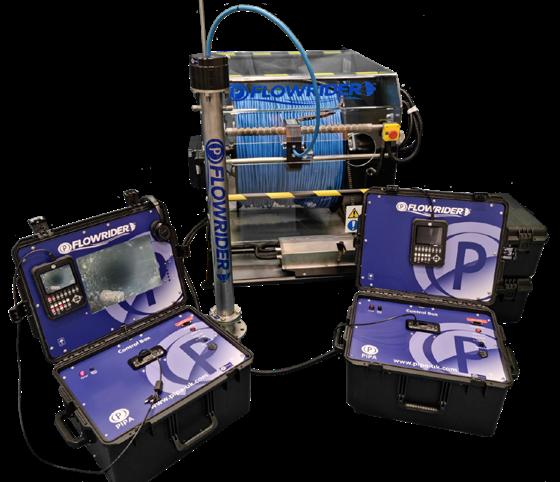

API completes first pilot project in Belgium using Pipa flowrider™ Technology

API has successfully completed its first pilot project in Belgium, working alongside partner Evodis to deliver advanced trunk main inspection trials using the PIPA Flowrider™ system. The trial marks another step in API’s growing portfolio of UK and international inspection work.

The Flowrider™ was deployed to assess the internal condition and configuration of a pressurised 800mm water main estimated to be over 100 years old. As an industryapproved floating camera platform, Flowrider™ combines HD visual

assessment with an ultra-responsive hydrophone for precise leak detection, plus a cable-trace feature for accurate location tracking.

For long-range surveys, the system uses PIPA-designed Hydrochutes, enabling inspections of up to 1,000 metres using the natural water flow. The Hydrochutes also incorporate a remote-collapse mechanism, ensuring safe and controlled system retrieval. All PIPA equipment includes a chlorination housing and is fully approved for potable water network use.

Each inspection location in Belgium provided valuable structural and operational data. API is now analysing these datasets, with final condition reports to be issued to the water utility as part of API’s comprehensive under-pressure pipe survey service. PIPA representative Fabio Orlandi commented:

“We are receiving significant international interest in our Hydrocam™ and Flowrider™ systems, and we are delighted to see API successfully operating our technology in Belgium.

Further projects are already being planned, including long-range 1km Flowrider™ deployments in Norway.”

PIPA continues to develop the world’s widest range of commercially available pressurised pipe inspection systems, working with the majority of UK water utilities and an expanding list of international clients.

Applications of Flowrider™ Technology

• Pressurised potable water main condition assessment

• Visual and acoustic surveys via push or float deployment

• Pipe material and

lining validation

• Identification of defects, blockages, buried valves and illegal connections

• Tracing and mapping of mains

• Investigation of discolouration sources prior to customer complaints

• Accurate leak location on all pipe materials

• Budget validation and asset management support

For more information about Hydrocam™, Flowrider™ or any PIPA technology, please contact: sales@pipa-uk.com

Trenchless Morocco 2026: Registration now open as exhibition sells out and new sponsors join

With just two months to go, momentum is building rapidly for Trenchless Morocco 2026, taking place 11–12 February 2026 at the Rabat Marriott Hotel. Following strong industry interest across North Africa and Europe, the exhibition is now fully sold out, and event registration is officially open.

The surge in demand highlights the importance of trenchless solutions in Morocco, where rapid urbanisation, major utility upgrades and sustainability goals are driving investment in underground infrastructure.

The event continues to attract organisations looking to engage directly with decision-makers from government, municipalities, utilities and contracting sectors in one of the region’s fastest-growing markets. Eurohinça and JBP join as Event Sponsors.

Trenchless Morocco 2026 is pleased to welcome Eurohinça and JBP as event sponsors. Their involvement further strengthens the conference and exhibition programme, reflecting the increasing commitment of global suppliers and technology providers to support Morocco’s developing trenchless sector.

Sponsors will be featured throughout the two-day programme, which includes technical presentations, case studies and insights into the latest innovations across installation, rehabilitation, inspection, cleaning and digital technologies.

A premier platform for industry engagement

While the tabletop exhibition has reached full capacity, delegates can still register to attend the conference and networking sessions, which offer valuable opportunities to understand Morocco’s infrastructure priorities

and explore potential collaborations. The programme will cover trenchless solutions for water, wastewater, telecoms, gas and electricity networks, alongside emerging topics such as drone technology, advanced diagnostics and sustainable urban development.

Supported by leading associations

Trenchless Morocco 2026 is supported by ISTT, FSTT, GATT, IATT and UKSTT, underscoring its position as the region’s leading trenchless event.

Register Now

Delegate registration is now open at www.trenchlessmorocco.com.

For sponsorship enquiries, contact: Trevor Dorrell –tdorrell@westrade.co.uk

We look forward to welcoming the international trenchless community to Rabat in February.

www.vmt.global

2025 – that’s a wrap!

Frank Reilly Director JBP’s Trenchless, Training Programme

As 2025 comes to a close, we can look back on a year marked by growth, collaboration, and a renewed commitment to raising standards in trenchless training and skills development across the globe. For JBP, this has been a year of strengthening partnerships, expanding applied training initiatives, and contributing thought-leadership through monthly articles in Trenchless Works.

We began the year with “Learning from the Experts, focussing on the value of practitioner-led knowledge transfer and how industry experience remains the backbone of effective training. February’s article, “Small Question: What Impact AI?”, explored the rapid rise of artificial intelligence in condition assessment and planning—an early signal of a theme revisited later in the year.

In March, “Educating the Next Trenchless Generation” highlighted the importance of structured learning pathways, apprenticeships, and professional development programs that will shape tomorrow’s engineers and technicians.

April saw the publication of “New Approaches at Trenchless Asia 2024”, which set the tone for one of JBP’s major milestones of 2025: participation in Trenchless Asia 2025 in Kuala Lumpur. Our Applied Trenchless Technologies Workshops there attracted strong attendance and reinforced the importance of hands-on, scenario-based learning. Feedback from attendees showed that practical demonstrations are one of the best ways to improve understanding of CIPP, robotics, inspection, and rehabilitation techniques.

In May, “Questions, Questions, Questions” encouraged the industry to embrace critical thinking and curiosity, reminding us that innovation begins by asking better questions. June’s “Applied in Applied Trenchless Workshops” showcased the continued refinement of our training model, shaped by real-world case studies. July followed with “New Markets and the Importance of Training”, examining the skills required as trenchless technologies expand into emerging regions.

August’s “Business and Academia – A Win-Win Combination” highlighted the value of research partnerships, while September’s “CPD and the Value of Short Courses” emphasised the critical role of ongoing professional education. In October, “Trenchless Training and the Middle East” reflected JBP’s growing footprint in the region—strengthened further this year by our participation in “Trenchless Middle East 2025” in Jeddah, where our Applied Trenchless Technologies Workshops once again took centre stage.

“Practice, Theory and the Impact of AI” allowed us to return to the evolving intersection of digital tools, engineering experience, and future skills in the November issue.

Across all of the above articles, workshops, and events, 2025 has reaffirmed one message for us: training, collaboration, and continuous learning are central to the future of trenchless technologies.

In 2026, we look forward to drilling down in greater detail to explore and discuss the challenges facing the trenchless sector, with a particular focus on how training can help meet many of these challenges.

JBP have some exciting plans, together with our team of experts and partnering organisations, for 2026 to continue to deliver targeted, impactful and easily accessible training courses and programmes for trenchless professionals wanting to enhance their knowledge and skills.

Thank you to everyone who has supported, attended, contributed, and engaged with us throughout the year. And a special thanks to Paul, Austen, Leigh, and the entire team at Trenchless Works! Here’s to an even stronger 2026!

Next Issue – And now for something completely different.

P.S. No LinkedIn Poll this month, look out for all feedback in 2026.

When we say our Bluelight LED light curing CIPP lining system is paired to perfection, we mean it. With its equipment and materials sourced from just one place, you can be sure that everything has been engineered to work in unison – the first time and with minimal fuss. Choose a Partner, Not a Product

TRENCHLESS MOROCCO 2026

11-12 February 2026

Rabat Marriott Hotel, Rabat, Morocco www.trenchlessmorocco.com

TRENCHLESS ASIA 2026

10 -11 June 2026

Queen Sirikit National Convention Centre Bangkok, Thailand www.trenchlessasia.com

NO-DIG LIVE 2026

29 September – 1 October 2026

NAEC Stoneleigh Park, Warwickshire www.nodiglive.co.uk

TRENCHLESS MIDDLE EAST 2026

www.trenchlessmiddleeast.com

NO-DIG ROADSHOW SERIES 2026

Dublin | London | Glasgow www.nodigroadshows.co.uk

Graham Howard, Chair, UKSTT

A message from the Chair

As we reach the end of another busy and challenging year, I would like to take this opportunity to extend my sincere thanks to everyone who has contributed to our work and progress over the past twelve months.

To our Trenchless community, thank you for your continued engagement, expertise, and commitment. Your participation is the foundation of everything we do, and your willingness to share knowledge and collaborate ensures that our community remains strong and forward-looking.

To all the Council members, I am deeply grateful for the time, energy, and thoughtful leadership you freely give throughout the year. Your guidance, professionalism, and dedication enable us to navigate both opportunities and difficulties with confidence and clarity.

Our heartfelt thanks also go to our Patrons and Members, whose encouragement and contributions, both practical and financial, are invaluable. Your support allows us to deliver events, develop initiatives, and provide resources that benefit the entire Trenchless sector.

I would also like to express our appreciation to Westrade, whose partnership and support continue to play an essential role in our activities and events. Their professionalism and commitment have again been evident throughout the year.

While we have much to celebrate, it is also important to acknowledge the challenges we have faced. Regulation 31 remains a significant area of concern, particularly the ongoing difficulties in securing timely approval of materials and products. This situation poses real risks as we work to meet the demanding delivery requirements for AMP 8, and the sector continues to express frustration at the pace and practicality of the approval process. We will continue to raise these issues, champion clarity, and push for more efficient pathways to ensure innovation and supply are not held back at a critical time.

Despite these pressures, the strength of our community, its expertise, collaboration, and collective determination, gives me confidence as we head into the new year. Together, we will continue to advocate for sensible regulation, support our members, and work to ensure the sector is equipped for the challenges ahead.

Finally, a special thanks to our UKSTT permanent team -Lynn, Linda and Tammy - whose dedication, passion, enthusiasm and hard work continue to grow the society from strength to strength.

Thank you all once again for your unwavering support as we look forward to another year of fantastic Trenchless events I wish you and your families a very Merry Christmas and a happy, healthy, and prosperous New Year.

Kind regards

Graham

No-Dig Turkiye 2025: A great success

Delegates at the Opening Ceremony

TSITT (Turkish Society for Infrastructure and Trenchless Technology) hosted No-Dig Turkiye 2025 Conference on 5-6 November in Istanbul together with 9th Water Loss Forum and 2nd Waste Water Forum under the umbrella of 2nd Eurasia Water Expo.

1262 national and 264 international delegates attended the show; 33 exhibitors from 6 countries demonstrated their latest products and solutions in the show.

TSITT Chairman Yasin Torun, SYGM Founding General Manager Prof. Dr. Cumali Kinaci, SASKI General Manager Seyit Sakallioglu, DESKI General Manager Egemen Emre Besli, KASKI General Manager Yavuz Cagan, GASKI General Manager Huseyin Sonmezler, KOSKI

General Manager Ahmet Demir, DSI Deputy General Manager Goktug Ilter and Pamukkale University Rector Prof. Dr. Mahmud Gungor made the opening speeches. Following the opening ceremony, 32 speakers made their presentations during five sessions in two days.

TSITT Deputy Chairman

Abdulkadir Aydin moderated a session focused on the trenchless solutions for green cities. BORTEK General Manager Seyhan Doner, LK2 Business Development Manager Clara Calvi, Assoc. Prof. Dr. Mucahit Namli of Istanbul Medeniyet University, PIPE DOCTOR General Manager Mustafa Inal, APROTEK General Manager Stephane DELHEUR and UHRIG Sales and Business Development Manager Michael Kersting made their presentations in this wonderful session.

Several water and waste water utilities, municipalities, ministries, executives, engineers, economists, consultants, academicians and contractors visited the show. They were highly interested in the trenchless, water loss control and waste water recycling solutions.

As Turkish trenchless, water and waste water markets grow every year; more utilities and municipalities visit the show to follow the innovations and new products.

TSITT is going to host No-Dig Turkiye 2026 Conference on 4-5 November in Istanbul together with 10th Water Loss Forum and 3rd Waste Water Forum under the umbrella of 3rd Eurasia Water Expo. For details, please visit www.nodigturkey.com

ISTT and NASSCO announce global training partnership

The International Society for Trenchless Technology (ISTT) has entered into a landmark agreement with the National Association of Sewer Service Companies (NASSCO) that will significantly expand the worldwide availability of trenchless training and certification.

The agreement was signed on 31 October during the International No-Dig Vancouver / No-Dig North 2025 Conference and Exhibition by ISTT Executive Director Trevor Gosatti and NASSCO Executive Director Sheila Joy.

Under the partnership, ISTT will support NASSCO in taking its respected Inspector Training Certification Program (ITCP™) to a global audience, leveraging ISTT’s international network to help promote and introduce the training in key regions.

The collaboration focuses particularly on two established NASSCO programmes: the Inspector Training and Certification Program for Cured-in-Place Pipe (ITCPCIPP) and the Inspector Training and Certification Program for Manhole Rehabilitation (ITCP-MR).

Both provide structured, professionally recognised training and certification for field construction personnel, equipping them with the knowledge and tools required to understand and inspect critical trenchless rehabilitation works. Each programme includes licensed training materials and comprehensive technical manuals.

“ISTT is extremely pleased to partner with NASSCO and help bring their excellent training products to many regions of the world

- Trevor Gosatti

ISTT Executive Director Trevor Gosatti welcomed the partnership, emphasising the shared commitment to raising professional standards across the industry.

“ISTT is extremely pleased to partner with NASSCO and help bring their excellent training products

to many regions of the world,” he said. “We are grateful to Sheila Joy for her support in enabling this important agreement.”

The new partnership underscores a joint dedication to strengthening global skills, competence and technical excellence within the trenchless sector. ISTT looks forward to working with NASSCO to introduce these programmes into priority markets where structured training is needed and will make a meaningful impact.

Introduction to Trenchless: Free ISTT–IWA Webinar

Following the recent partnership between the International Society for Trenchless Technology (ISTT) and the International Water Association (IWA), the organisations will deliver their first collaborative webinar in January 2026.

The session, “Introduction to NoDig Technologies and the ISTT,” is designed for newcomers who may have heard the terms trenchless or No-Dig but are unsure how these methods work in practice.

The webinar will introduce the fundamental concepts behind installing or rehabilitating

underground utilities without surface excavation, and will outline how trenchless approaches reduce disruption, lower carbon impacts and improve project efficiency.

Participants will gain an overview of the main trenchless techniques, where they are used, and the resources ISTT provides to support learning and industry awareness.

Webinar Details

Date: 28 January 2026

Time: 14:00 GMT (60 minutes)

Speaker: Iain Naismith (ISTT Technology & Education Committee Member; UKSTT

T&E Committee Chair)

Cost: Free and open to all — no prior experience required

Register here:

https://www.iwa-network.org/ learn/introduction-to-no-digtechnologies-and-the-istt

This inaugural webinar marks the beginning of a growing programme of shared learning between ISTT and IWA, aimed at increasing global understanding of trenchless solutions and modern infrastructure management.

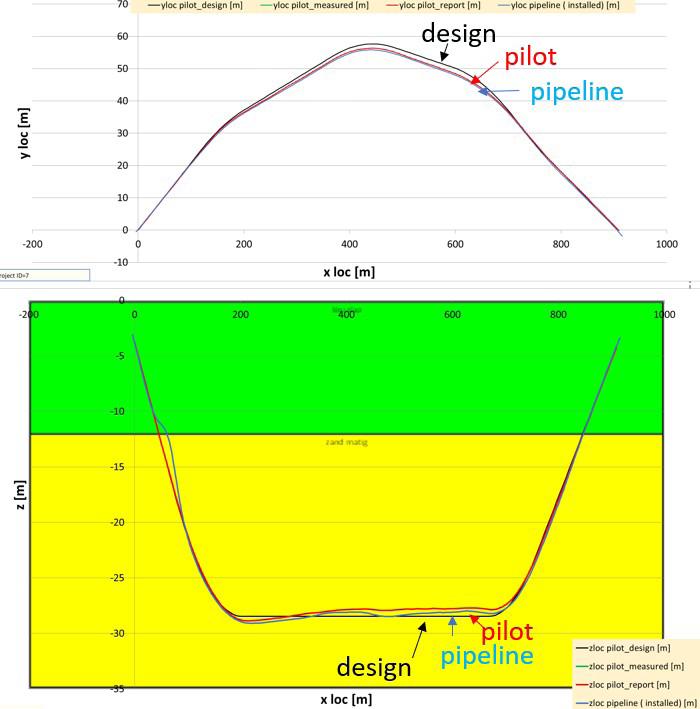

ISTT Educational Webinar: Prediction of the deviation of the horizontal directional drilling line in sedimentary soils

ISTT EDUCATIONAL WEBINAR

DATE: 25th February 2026

TIME: 14:00 GMT (15:00 CET, 09:00 US EST)

Horizontal Directional

Drilling (HDD) is the most used technique for trenchless installation of cables and pipelines. The HDD technique minimizes the impact of installation activities in densely populated and economically sensitive areas. Due to the presence of other underground infrastructure in the urban and industrial areas, it is necessary to ensure that HDD projects are carried out without damage to underground infrastructure. The available underground space for HDD projects is limited.

Therefore, the design drilling lines for the installation of cables and pipelines are often optimized on the design drawings, and during the execution of the horizontal

directional drilling, high accuracy demands are prescribed. Although the measurement systems that locate the position of the drill bit have improved considerably over the last decades, deviations from the design drilling line are still common.

The deviations are part of the drilling process and depend upon the interaction of the drilling tools and the soil conditions. In sedimentary soils, a deviation analysis on performed HDD projects was carried out. The analysis resulted in an overview of measured deviations and a reconstruction of the processes that caused the deviations.

The results of the analysis were used to build a drilling

process-based deviation model. The modelling of the deviation processes makes it possible to make a prediction of the expected deviations when a drilling line in certain soil conditions with selected drilling equipment is designed.

The deviations can be visualized as a zone around the drilling line in which the probability of damage to adjacent underground infrastructure is present due to deviations from the design drilling line.

About Dr. Henk Kruse

Dr. Henk Kruse is an expert in the field of underground infrastructure. In addition to tunnelling, he spends his time on pipeline installation and maintenance/ asset management of pipelines. He has an in-depth knowledge of and experience in soil mechanics, especially in the behaviour of soft soils and pipeline modelling.

Since 2002, he has been working for Deltares, the national knowledge institute in the

Netherlands for water and soil. Deltares works on solutions for the increasing demand for sustainable energy and the use of underground space under changing climate conditions. The underground infrastructure of the future requires well-considered decisions and sustainable.

Note: This webinar is open to everyone, but only members will have access to the recording.

Register Now!

ISTT opens call for 2026 committee members

The International Society for Trenchless Technology (ISTT) has opened its annual call for committee members for 2026. Each year, ISTT refreshes its committees to ensure diverse expertise and representation from across the global trenchless community.

For 2026, the committee structure has been updated to better reflect the evolving needs of the industry. Seven standing committees will operate next year, including a newly formed Young Trenchless Professionals Committee.

2026

ISTT standing committees

International No-Dig Committee (INDC)

Chair: Ian Ramsay

The INDC provides guidance and direction for the ISTT International No-Dig Conferences and Exhibitions. The committee

continually reviews current practices, develops best-practice guidelines for hosting No-Dig events, and prepares the criteria used to select host countries.

Affiliated Societies Committee (ASC) (formerly Membership and Regional Support)

Chair: Thorsten Schulte

The ASC supports the growth and stability of ISTT’s Affiliated Societies. It assists existing societies, reviews applications from new societies, and manages ISTT’s strategic partnerships with aligned organisations.

Technology and Education Committee (TEC)

Chair: John Matthews

This committee provides strategic and policy guidance on trenchless technology issues.

It promotes education through webinars, seminars and certified training, and is responsible for ISTT’s professional recognition programmes, including the ISTT Fellows Program.

Outreach and Marketing Committee (OMC)

Chair: Carlos Munera

The OMC leads ISTT’s global outreach efforts, including marketing, communications, and strategic partnerships designed to strengthen the ISTT brand and raise awareness of trenchless solutions worldwide.

Finance Committee (FC)

Chair: Borje Persson (New)

The Finance Committee oversees ISTT’s financial planning and operations. It prepares annual budgets, reviews financial

statements, and reports regularly to the Board of Directors.

Governance Committee (GC)

Chair: Sam Efrat

The Governance Committee reviews ISTT’s bylaws, operating procedures and core documents, ensuring that the organisation remains compliant, transparent and effectively governed.

Young Trenchless Professionals Committee (YTPC) (New)

Chair: Pertti Leppänen

Created for members aged 18–35 working in any role across the trenchless field, the YTPC offers younger professionals a platform to contribute to ISTT’s development. Supported by an ISTT Board member, the committee aims to inspire and engage the next generation of No-Dig talent.

Note on structural changes