Works

INNOVATING INFRASTRUCTURE WITH PRECISION

How ECI is shaping the future of trenchless construction in the Midwest

Gecko E Lateral & Gecko E Power: Electrically powered, precise cutters.

PUBLISHER

Paul Harwood pharwood@westrade.co.uk

EDITOR

Austen Lees editorial@trenchless-works.com

MANAGING EDITOR

Leigh Abbott labbott@westrade.co.uk

SALES DIRECTOR

Trevor Dorrell tdorrell@westrade.co.uk

DESIGN & PRODUCTION

Ioan Lucian Sculeac lucian@westrade.co.uk

CHINESE AGENT

Lexi Di lexi.di@bestexpo.cn

COPYRIGHT

Trenchless Works is published 12 times a year by Westrade Group Ltd I Carotino House| Bury Lane I Rickmansworth I WD3 1ED I UK

Contributions: Contributions are invited and articles should be emailed to editorial@trenchless-works.com. No responsibility can be taken for drawings, photographs or written contributions during delivery, transmission or when with the magazine. In the absence of an agreement, the copyright of all contributions, regardless of format, belongs to the publisher. The publishers accept no responsibility in respect of advertisements appearing in the magazine and the opinions expressed in editorial material or otherwise do not necessarily represent the views of the publishers. The publishers accept no responsibility for actions taken on the basis of any information contained within this magazine. The publishers cannot accept liability for any loss arising from the late appearance or non-publication of any advertisement for any reason whatsoever. ISSN 2049-3401

Editor’s Welcome

Austen Lees

As we move into the final quarter of 2025, the trenchless technology sector shows no sign of slowing down. Across every discipline, from rehabilitation and microtunnelling to HDD and asset management, innovation, collaboration, and sustainability continue to define the direction of our industry.

This issue captures that progress from multiple angles. We look back on a record-breaking No-Dig Down Under 2025 in Melbourne, where the global trenchless community gathered to share insights and celebrate new achievements, and ahead to International No-Dig Auckland 2026, which promises to build on that energy. Closer to home, the UKSTT Annual Dinner and Awards once again brought the industry together to recognise excellence and raise funds for an important cause.

Technical innovation remains front and centre, from energyefficient curing technologies and automated microtunnelling control systems, to bespoke GRP rehabilitation and precision HDD solutions. We also spotlight the ongoing importance of health and safety, training, and knowledge exchange, with UK utilities and suppliers continuing to lead the way in developing smarter, safer practices.

What’s clear is that trenchless technology is not standing still. It’s expanding its reach, driving sustainability, and redefining how we deliver essential infrastructure beneath our cities, rivers, and communities.

Thank you, as always, to our contributors, advertisers, and readers for your continued support and engagement.

Enjoy the issue, and we look forward to seeing many of you at Trenchless Middle East in Jeddah this November, where the conversation continues.

Austen

To submit editorial for Trenchless Works next issue please email copy and images to: editorial@trenchless-works.com by the 12th of the month. Submissions arriving after this date cannot be guaranteed inclusion in that month’s issue. For Trenchless Works sponsorship and advertising rates please email: tdorrell@westrade.co.uk

ARTICLE

Editor’s Welcome

INDUSTRY INSIGHT

Optimised energy efficiency in CIPP lining: Innovative approaches

Coil pipe safety: Raising the bar for operational health and safety standards

NEWS

Elios 3 Drone enables safe 150-Metre culvert inspection

BRAWO® Remote LC simplifies main-to-house pipe rehabilitation

Upstream resilience: WCSEE technology supports network performance and infiltration management

Thriplow Infiltration Scheme: Claret Engineering adopts Bluelight technology

Affinity Water selects Barhale as AMP8 and AMP9 capital delivery partner

MICROTUNNELLING

Innovating infrastructure with precision

VMT advances Microtunnelling precision with automated control measurement

PIPEBURSTING

Pipebursting enjoys a resurgence in the light of AMP8

HDD

A New ‘Rockstar’ in HDD

HDD and the water industry: Solving installation challenges under rivers and roads

SMART INFRASTRUCTURE

Smart Leak detection strengthens global network resilience

EVENTS

2025 No-Dig Roadshow series finishes in style

FOCUS ON TRENCHLESS TRAINING

Trenchless Training and the Middle East

UKSTT SOCIETY NEWS

A message from the Chair

UKSTT Annual Dinner celebrates industry excellence and raises £3,440 for charity

UKSTT concludes Annual General Meeting with leadership appointments and strategic council expansion

Wessex Water hosts industry learning event

ISTT SOCIETY NEWS

No-Dig Down under 2025 wraps with record numbers

ISTT announces 2025 Albert Shou student scholarship winners

ISTT supports Trenchless Middle East

NASTT SOCIETY NEWS

EVENTS AND MEETINGS

Optimised energy efficiency in CIPP lining: Innovative approaches

By Dipl.-Ing. Niklas Ernst, Bluelight GmbH, Stuttgart

Defining energy efficiency

Energy efficiency can be broadly defined as the ratio between energy input and the resulting output, or, more simply, how effectively energy is used to deliver a given service or outcome. As outlined by Wikipedia: “Energy efficiency is the rational use of energy. Through optimised processes, the quantitative and qualitative losses that occur during the conversion, transport, and storage of energy should be minimised in order to achieve a given benefit while reducing primary and final energy consumption.”

In trenchless rehabilitation, the central question is: Can the same output be achieved with less input through more efficient technology?

Key motivators include:

• Reducing CO2 emissions

• Improving economic performance

• Conserving limited resources

• Meeting sustainability and legal requirements, such as the Energy Efficiency Act

Environmental product declarations and their limits

At Per Aarsleff A/S, Environmental Product Declarations (EPDs) have been developed for the company’s most common CIPP liner types, verified according to ISO 14025 and EN 15804.

While valuable, EPDs present challenges due to the complexity of global supply chains and variable production inputs such as electricity mix, resins, fibres, and coatings. They offer a static snapshot rather than a dynamic reflection of real-world variations.

A comparison of Bluelight GmbH CIPP liners shows that, even with transport distances up to 500 km, the CO2 impact from transport remains

negligible compared to total liner production. Interestingly, switching from a styrenecontaining resin to a styrene-free alternative can nearly double CO2 emissions due to more energy-intensive manufacturing, raising the question of how sustainability should be holistically assessed beyond carbon metrics alone.

Energy use in CIPP lining

Energy consumption in CIPP lining spans production, transport, installation, and curing.While curing and installation consume more energy than transport, the greatest potential for improvement lies in production processes, including:

• Use of recycled or bio-based fibres

• Cleaner electricity mix

• Process optimisation

• Development of bio-resins

Ultimately, final product quality and service life determine the true environmental value. A product that is less energyefficient during manufacture may still be more sustainable overall if it performs reliably for decades. In CIPP lining, planning quality, correct product selection, and proper curing are critical to ensuring full design life.

Modern curing technologies

Electrically powered trucks and hydrogen-fuelled steam generators, as demonstrated by Aarsleff’s Norwegian subsidiary Olimb, represent the next step in sustainable curing. However, the capital cost of such systems is currently around 50% higher than conventional setups, and widespread access to green hydrogen remains limited across Europe, with Norway an exception due to its renewable energy base.

UV light curing

UV curing has become a proven, high-performance method for pipe diameters up to DN 2000 mm and lengths up to 350 m. A 100 kVA generator operating at full capacity (36 kW total lamp output) produces approximately 55 kg CO2 per hour using conventional diesel, or 11 kg CO2 per hour with HVO100, an 80% reduction.

LED light curing

Bluelight GmbH’s LED technology represents a lightweight, flexible, and highly efficient alternative for smaller diameters up to DN 600 mm and lengths up to 125 m. Operating at just 1.5 kW, it requires only a 6 kVA generator (5 kg CO2 per hour on diesel; 1 kg on HVO100), or can draw from a renewable grid supply. Mounted in vehicles under 3.5 tonnes, LED systems minimise site setup and emissions while maintaining curing quality. Demonstrations

are regularly held at trade fairs and live job sites.

Conclusion

Energy efficiency in CIPP lining must be viewed through a holistic lens, encompassing manufacturing, curing technology, and service life. While EPDs and CO2 accounting are valuable tools, they tell only part of the story. True sustainability combines efficient production, durable materials, and professional installation to ensure long-term performance and minimal environmental impact.

As technology advances, integrating electric, hydrogen, UV, and LED curing systems will further improve the energy profile of trenchless rehabilitation ensuring that efficiency and performance go hand in hand.

www.bluelight-gmbh.de

Coil pipe safety: Raising the bar for operational health and safety standards

By Steve Bradshaw, Managing Director, Towmate Trailers

Bradshaw, Managing Director, Towmate Trailers

Understanding the challenges and risks associated with laying coiled pipe is essential for ensuring safety, efficiency and long-term performance, not only for the installation itself, but for the teams behind it. Yet despite increasing awareness, regulatory gaps and inconsistent industry standards continue to pose serious challenges across the utilities and construction sectors.

The importance of precautions

Coiled piping has become a preferred choice for gas and water installations due to its speed, flexibility and costeffectiveness. However, when handled incorrectly, it presents significant health and safety risks, particularly during the unwinding process, when the release of stored energy can cause sudden, uncontrolled pipe movement. Such incidents can result in major, even life-changing injuries.

The construction industry remains one of the UK’s most hazardous sectors, with around 47,000 workers sustaining non-fatal injuries last year alone, and one-third of those leading to absences exceeding seven days.

Fatalities, though less frequent, remain a persistent concern, often the result of falls or being struck by moving objects.

A stark reminder came in April 2023, when a HS2 worker tragically lost his life after being struck by an unsecured coiled pipe during installation in Solihull. The incident prompted widespread calls for enhanced safety protocols, especially around drilling and pipe dispensing practices. It also underscored the importance of thorough pre-operation checks and comprehensive safety measures before, during and after coil pipe installation.

Challenges faced by industry professionals

Safety starts well before the first length of pipe is uncoiled. Comprehensive risk assessments, correct PPE, and clear training on handling and emergency procedures form the foundation of safe operations. However, a number of factors continue to impact on-site safety, from inadequate training and outdated practices to sluggish approval processes. Effective planning, robust procedures and the right tools are crucial. The use of mechanical lifting, pipe restraints, and uncoiling devices can dramatically reduce hazards, preventing the kind of catastrophic failures seen in past incidents.

While some have proposed banning coiled pipe in favour of straight length “stick” installations, the drawbacks are significant: higher costs, longer

installation times, greater labour demands, and increased risk of joint failure due to multiple connections. Instead, the focus must shift to engineering safer handling solutions.

Innovation in safety solutions

To drive safer practices and support the utilities industry, we developed LaySafe®, a patented safety mechanism fitted to our Raptor Pipe Trailer. Designed for water, gas and electrical sectors, LaySafe® prevents injury and fatality by controlling stored energy during pipe laying. Already adopted by several leading utilities, including Severn Trent Water, the innovation allows coiled pipe to be safely fed through to the rear of the trailer while maintaining the pipe in a stable, inert state. Its integrated chute design and central retaining disc enhance control and prevent uncontrolled release, saving both time and cost while protecting workers.

Why safety innovation matters

The physical demands of field work, combined with changing site conditions, make worker safety a critical factor in operational efficiency. Prioritising robust health and safety practices not only protects people, but also mitigates reputational, legal and financial risks for organisations. The HS2 incident demonstrated how quickly public and regulatory scrutiny can follow preventable accidents. Negative press and legal ramifications can severely damage a company’s reputation and hinder future

business opportunities. Although tight project deadlines can tempt shortcuts, health and safety is never an area for compromise. With modern industry standards increasingly focused on safety, sustainability, and productivity, innovations like LaySafe® represent the way forward, delivering efficiency without sacrificing protection.

The road to safer practices

Workplace safety has advanced significantly in recent decades, yet gaps remain. By combining product innovation, training, and industry-wide collaboration, the utilities and construction sectors can further reduce preventable incidents. Change can be daunting in traditional industries, but events such as the HS2 tragedy serve as a sobering reminder: prioritising safety today protects both lives and reputations tomorrow.

Towmate Trailers are proud to introduce the Raptor 125 LaySAFE Pipe Trailer, a more compact version of our game-changing LaySAFE system.

Eliminates stored energy

More than 10x faster Saves up to £4600 per 100m

AT120

Loaded with 120,000 lbs (533.8 kN) of pullback/thrust and 15,500 ft·lbs (21015 N·m) of rotational only opens you up to new types of jobs but moves through long bores and large diameter installs All Terrain technology and a 280-hp (209 kW) Stage V Cummins® engine reduce environmental impact power. 3,000 ft·lbs (4067 N·m) of inner rotational torque—a 50% increase over its predecessor— additional power to drill through the toughest terrain around.

THE BEST SELLING ROCK THE

DRILL

IN AND

UK IRELAND.

rotational torque, the AT120 not installs with eye-popping power. impact without losing any predecessor— allows the AT120

Elios 3 Drone enables safe 150-Metre culvert inspection

As part of a complex underground survey programme, the inspection team was tasked with delivering a safe, detailed structural assessment of a culvert that could not be accessed using conventional techniques. The structure’s confined geometry and restricted access presented significant health and safety challenges, ruling out both manual entry and standard CCTV inspection methods. A solution was required that could provide accurate visual and spatial data while ensuring complete operator safety.

The challenge

The culvert’s layout and distance from entry points prevented the use of a traditional mainline camera. Manual entry was deemed unsafe due to limited space, poor ventilation, and potential instability within the structure. With the upstream and downstream sections both requiring inspection, an alternative non-entry approach was essential to capture the required structural data.

resulting 3D point cloud and video outputs produced a precise and measurable digital model of the culvert, providing engineers with a clear, data-rich visualisation of its internal condition.

The outcome

The solution

To overcome these constraints, the team deployed the Elios 3 Drone, a collision-tolerant UAV equipped with LiDARbased 3D mapping technology and high-definition visual inspection cameras. To maintain communication underground, the drone’s range extender was connected to the mainline camera system, which was positioned further inside the culvert ahead of the drone. This setup ensured stable data transmission and control throughout the survey. Over two separate flights, the Elios 3 successfully surveyed more than 150 metres in each direction, capturing thousands of LiDAR data points per second. The

The project demonstrated how integrating drone and LiDAR technology can transform confined-space inspections, delivering comprehensive structural insights without human entry. The approach significantly reduced safety risks, shortened inspection time, and provided high-quality data for future maintenance and rehabilitation planning.

CELEBRATING EXCELLENCE IN TRENCHLESS TECHNOLOGY

APPRENTICES LEADING THE WAY IN INNOVATION

At S1E, we’re proud to recognise the success of our apprentices, Katie and Ebony, who have both achieved distinctions in their Level 3 qualifications

Katie, part of our Marketing team, has excelled in her apprenticeship and is already progressing to Level 4 Ebony, in Procurement , has demonstrated outstanding skill and commitment in suppor ting our fast-moving supply chain

Their achievements reflect the dedication, talent , and fresh perspective that continue to strengthen the trenchless sector.

To recognise their achievements, S1E’s CEO, Chris Cooper, presented Katie and Ebony with flowers and a card to congratulate them on their hard work and success. It was a thoughtful gesture that highlighted the company ’s appreciation for their dedication and commitment to their apprenticeships.

BRAWO® Remote LC simplifies main-to-house pipe rehabilitation

BRAWO® SYSTEMS has unveiled BRAWO® Remote LC, a new light-curing solution for the rehabilitation of connection pipes directly from the main sewer. Designed for efficiency, practicality, and cost-effectiveness, the system enables contractors to rehabilitate previously hard-to-access connection lines with greater independence and reliability.

Meeting market demand

While the concept of connection pipe rehabilitation from the main sewer has existed for some time, adoption has been limited by high costs and complex, failure-prone technology. Recognising the urgent need for a simpler, more robust approach,

BRAWO® SYSTEMS developed a modular system that integrates seamlessly with existing equipment while reducing process risk and setup time.

Proven components with a key innovation

BRAWO® Remote LC builds on BRAWO® SYSTEMS’ established technology, including the BRAWO® Drum 4.0 with side lock for the light-curing unit and the BRAWO® Magnavity sx lightcuring system.

The innovation lies in the patented deflection elbow, which enables liner inversion directly into the connection pipe from within the main line, eliminating the need for property access and streamlining site operations.

Technical features and benefits

BRAWO® Remote LC allows rehabilitation of connection pipes DN 100–DN 150 with bends of up to 90°, from main sewers DN 200–DN 300, and over lengths up to 50 metres.

Key advantages include:

• No access to private property required

• Shorter installation times

• Rehabilitation entirely within the sewer network

• Simple, safe, and reproducible process

Required equipment:

BRAWO® RLC, BRAWO® Magnavity sx, BRAWO® Drum 4.0, sewer camera (Ø 23 mm), compressed air push rod system with stone connector, and long inversion pipe.

Compatible materials:

BRAWOLINER®, BRAWO® UVPox51 or LR, and the reusable AIRBAGLINER.

Developed and proven in practice

Development was carried out in close collaboration with Lobbe Kanaltechnik, whose

“ We are delighted to now be able to offer our customers an economically attractive solution

operational experience helped refine the system.

“We are delighted to now be able to offer our customers an economically attractive solution,” said Dusty Weineck of Lobbe.

Field trials conducted in RhedaWiedenbrück in August confirmed the system’s performance, with successful rehabilitation of various pipe diameters and outlet angles. Dirk Mumm, Head of Sewer Operations at Eigenbetrieb Abwasser Rheda-Wiedenbrück, described the new technology as having “great potential for future use.”

Conclusion

With the launch of BRAWO® Remote LC, BRAWO® SYSTEMS has introduced an innovative, efficient, and economical solution that elevates connection rehabilitation from the main sewer to a new level. For network operators and contractors alike, it offers greater flexibility, faster processes, and significantly reduced operational effort.

www.brawosystems.com

Upstream resilience: WCSEE

technology supports network performance and infiltration management

Anglian Water has completed the installation of specialist wastewater treatment equipment from WCS Environmental Engineering (WCSEE) as part of a major upgrade to the Horning Knackers Wood Water Recycling Centre (WRC) in north Norfolk.

The project aims to improve network performance, manage infiltration, and ensure dry weather flow compliance, key factors that also support effective long-term trenchless rehabilitation planning.

The upgrade included the installation of ten WCSEE Hybrid modular biological treatment units and two Flocell XFM systems for tertiary solids removal. The WRC serves a riverside catchment in Horning, where changing ground conditions and high groundwater levels had led to infiltration issues and greater treatment demands.

Working with contractor Kier, WCSEE supplied and commissioned the modular systems to deliver a flexible,

“Our Hybrid and Flocell XFM technologies give utilities greater flexibility in meeting environmental standards under challenging conditions. he modular format allows rapid deployment while minimising operational disruption.

energy-efficient solution suited to local hydrological challenges. The company coordinated closely with Anglian Water’s engineering and logistics teams to align installation with Environment Agency permit requirements.

The new treatment configuration provides capacity for flows up to 25 l/s and ensures compliance with key discharge parameters, including 20mg/l TSS, 10mg/l ammonia, and 10mg/l BOD, with a retention time exceeding two hours.

James Greenwood, Head of Sales at WCSEE, commented:

“Our Hybrid and Flocell XFM technologies give utilities greater flexibility in meeting environmental standards under challenging conditions. The modular format allows rapid deployment while minimising operational disruption.”

The Hybrid system combines submerged moving-bed and fixed-film processes within a compact footprint, offering strong performance under variable flows typical of infiltration-affected networks.

The Flocell XFM units, originally developed for precision filtration applications, deliver reliable tertiary solids removal, enhancing treatment efficiency.

By strengthening upstream capacity and reducing infiltration-related loading, the Horning Knackers Wood upgrade contributes to wider network resilience, a critical factor in optimising downstream trenchless rehabilitation and asset management strategies across the Anglian Water region.

PEARPOINT systems are designed to excel in harsh environments, delivering unmatched reliability and adaptability for sewer inspection professionals.

From rugged terrains to urban settings, PEARPOINT’S innovative designs ensure seamless performance, minimizing downtime and maximizing efficiency.

With modular components that are easy to swap or upgrade, our equipment evolves with your needs, making it the ultimate partner in the field. When the job gets tough, PEARPOINT gets tougher. BUILT FOR

When we say our Bluelight LED light curing CIPP lining system is paired to perfection, we mean it. With its equipment and materials sourced from just one place, you can be sure that everything has been engineered to work in unison – the first time and with minimal fuss. Choose a Partner,

Thriplow Infiltration Scheme: Claret Engineering adopts Bluelight technology

Claret Engineering Ltd, a long-standing partner on the Anglian Water IMR framework, has recently expanded its in-house trenchless lining division to deliver infiltration works under the new AMP8 period. With several schemes scheduled early in the cycle, the contractor has prioritised faster, more reliable rehabilitation methods to meet programme demands and sustainability goals.

Driving trenchless innovation in AMP8

As part of the Anglian Water framework, partners are encouraged to advance trenchless practices that minimise disruption, improve efficiency, and reduce carbon emissions. Infiltration remediation is a key focus, and Claret Engineering has embraced new technologies to raise productivity while delivering environmental benefits.

Bluelight integration

With two framework partners already utilising the Bluelight LED curing system, Claret Engineering saw clear value in adopting the technology. Bluelight, introduced to the UK in 2018, is fully WRc-certified for both its curing system and materials, and also carries DIBt certification in Germany. These approvals underline the quality and consistency of the system.

Unlike traditional UV curing, Bluelight operates at a

450 nm blue light wavelength, curing resins faster and more efficiently. Dedicated liners and resins are designed specifically for compatibility, including:

• PAA-F felt inversion liners

• PAA-GF glass reinforced liners

• Diameter range from DN70–DN600, in lengths of 125m+

The liners use styrene-free, odour-free vinyl ester resin, with the option of polyester resin for PAA-GF where required. Standardised products, long shelf life, and the ability to ship pre-impregnated liners in a single delivery further reduce carbon impact.

System capability

With more than 19 years of development, Bluelight’s current generation includes five curing heads and four curing baskets, offering flexibility across site conditions. The system can negotiate multiple 90° bends, accommodate diameter changes, and install from a single access point where needed. It is suitable for infiltration, fractures, holes, and other common pipe defects across a range of depths.

Trial and adoption

Claret Engineering initially approached Bluelight Lining Ltd about hiring a system short-term before committing to purchase. This aligned with Bluelight’s plans to enter the hire market, creating the ideal opportunity to trial the technology in the field. Early results confirmed the efficiency and reliability of the system, paving the way for longerterm adoption within Claret’s trenchless division.

Affinity Water selects Barhale as AMP8 and AMP9 capital delivery partner

Civil engineering, infrastructure and tunnelling specialist Barhale has been appointed by Affinity Water to its capital delivery framework for both its Capital Enhancement and Capital Maintenance Schemes for AMP8 and AMP9.

The estimated total value of the framework is £900M, with around £450M earmarked for each regulatory period.

Barhale will be responsible for works comprising mains renewals, network reinforcements, street works, commissioning, developer services including new connections and water mains diversions, network modelling and network data management, network calming and MEICA for distribution assets.

The framework also covers: the design, build and commissioning of water treatment processes - including civils, MEICA and process design, the design, build and commissioning of booster pumping stations, service reservoirs and similar structures such as clean water tanks, and the integration of assets –including automation/control of the strategic network.

The programme is designed to ensure efficient, cost-effective improvements to Affinity Water’s infrastructure to benefit customers while safeguarding vital water resources.

“We are pleased to have awarded five contracts and to be working with our delivery partners, Barhale, Galliford Try, United Infrastructure, J Browne and Enisca over the next five years and beyond.

Daniel Meadowcroft, Projects Director – South Region at Barhale said: “We are very proud to be extending our relationship with Affinity Water and it is a fantastic result for us to have been appointed to both schemes.

“We are looking forward to working alongside Affinity Water to complete a very exciting capital delivery programme over the next two regulatory periods. It will deliver important benefits in terms of network resilience, improved environmental performance

and better services to its growing number of customers.”

Ben Hayward, Head of Capital Delivery at Affinity Water, added: “We are pleased to have awarded five contracts and to be working with our delivery partners, Barhale, Galliford Try, United Infrastructure, J Browne and Enisca over the next five years and beyond.

“Together, we face a huge challenge to deliver for our customers, but by working collaboratively with our trusted partners, we will ensure we meet those expectations and deliver on our commitments to our customers.”

The framework partners are, for Capital Enhancement Schemes: Barhale; J Browne; and Galliford Try, and for Capital Maintenance Schemes: Barhale; J Browne; Stonbury; and United Living.

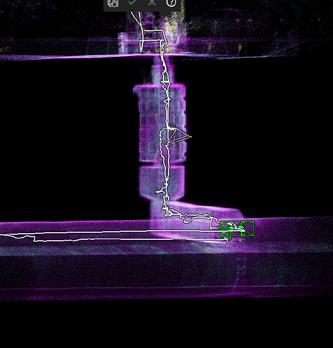

Innovating infrastructure with precision

How ECI is shaping the future of trenchless construction in the Midwest

By Jason Holden, Akkerman Inc.

For more than 25 years, Engineering & Construction Innovations, Inc. (ECI) has combined deep engineering expertise with practical field experience to tackle complex infrastructure challenges across the Midwest. Founded and led by CEO Shane McFadden and President Robb Johnson, the Oakdale, Minnesota–based company now employs over 80 professionals specialising in dam and hydropower, geotechnical construction, pipeline rehabilitation, and trenchless technology.

At Akkerman, we’ve been privileged to partner with ECI for more than two decades on a wide range of trenchless installations. Their reputation for innovation, precision, and self-performance continues to raise the bar for what’s possible in underground construction. Together, our teams have delivered some of the region’s most technically demanding tunnelling projects, from deep river crossings to long-distance water transmission lines.

10th Avenue Bridge Microtunnel, Minneapolis, MN

When the City of Minneapolis needed to replace a critical 54-inch water main beneath the Mississippi River, the engineering challenge was clear: complete the crossing safely, with zero disruption to the bridge or the waterway.

ECI deployed the Akkerman SL60P Microtunnel Boring Machine (MTBM) to install a 900-foot pipeline at a depth of approximately 30 feet below the riverbed. Leveraging precision guidance systems and experienced crews, the drive was completed in under two weeks, a remarkable feat for a river crossing of that scale. The project restored a vital component of the city’s water infrastructure, ensuring secure service for decades to come.

Lake Elmo West sewer expansion, Twin Cities East Metro, MN

To accommodate rapid residential and commercial growth in the Twin Cities’ east metro area, ECI undertook a major expansion of the Lake Elmo West Sewer System. The project required installing nearly one mile (5,200 feet) of 74-inch steel casing beneath Interstate 94, one of the region’s busiest transportation corridors.

For this challenging alignment, ECI used an Akkerman SL74P MTBM in combination with a 240A Guided Boring Machine to establish a precise pilot bore before upsizing. This hybrid approach significantly mitigated risk by maintaining line and grade accuracy through variable soils and high groundwater conditions. >

The project exemplified ECI’s ability to combine technical innovation with disciplined execution to deliver large-scale infrastructure safely and efficiently.

Aurora Raw Water intake - Northern Minnesota

In the city of Aurora, ECI faced another first-of-its-kind challenge: constructing a new raw water intake tunnel 120 feet beneath a lake to connect a regional water treatment plant. Working in saturated soils under a hydrostatic head,

ECI selected the Akkerman SL44C MTBM, adapting it with a custom-engineered caisson, pit seal, and dual bulkhead retrieval system to ensure safe underwater recovery.

This inventive configuration enabled controlled dewatering and retrieval without diver intervention, marking a regional milestone for safe underwater Microtunnelling. The Aurora project highlighted ECI’s culture of problem-solving and its commitment to advancing trenchless capabilities in the Upper Midwest.

Engineering the future of trenchless construction

From urban river crossings to deep-lake tunnels, ECI’s partnership with Akkerman demonstrates how collaboration, precision engineering, and on-site ingenuity continue to redefine the boundaries of trenchless construction.

By investing in technology, training, and innovation, ECI consistently delivers infrastructure that meets the dual demands of performance

“

By investing in technology, training, and innovation, ECI consistently delivers infrastructure that meets the dual demands of performance and sustainability

and sustainability. Their work exemplifies a future where underground construction is not only more efficient but also safer, smarter, and more environmentally responsible. As ECI and Akkerman continue to push technological and operational frontiers, one thing remains constant, the belief that the most significant innovations in infrastructure often happen below the surface.

VMT advances Microtunnelling precision with automated control measurement

For decades, achieving both accuracy and efficiency in Microtunnelling have been a balancing act. Manual gyro calibration, especially on longer or curved drives, has often slowed progress and increased project complexity. Where tunnel access is restricted, such as in small diameters, these challenges become even more acute.

Now, with its latest suite of automated control measurement technologies, VMT GmbH is ushering in a new era in Microtunnelling planning and execution, combining automation, digital precision, and efficiency to redefine industry standards.

Improving quality and efficiency in pipe jacking

One of VMT’s key innovations, MultiStation, is a fully automated control measurement system designed for complex pipe jacking projects. Traditionally, survey teams have relied on manual measurements that can be time-consuming and prone to cumulative error. MultiStation eliminates these inefficiencies through a smart, automated approach.

The system employs a chain of total stations installed inside the pipeline at defined intervals.

Beginning from a fixed base station in the launch shaft, the network automatically performs a traverse, with the endpoint referencing a point on the tunnelling machine itself.

This setup enables frequent, high-accuracy control measurements without manual intervention, improving precision across the entire alignment. The result is faster surveying, reduced human error, and greater assurance of line and level accuracy, especially vital for longer drives or when working in tight tolerances.

Expanding possibilities in direct pipe projects

VMT’s second innovation, TUnIS.pipelight, represents a breakthrough for both pipe jacking and direct pipe operations, particularly where access to the tunnel is impossible during excavation.

This advanced automated control survey system allows for non-entry control measurement in curved drives, an achievement that opens entirely new design possibilities for complex alignments. Compact camera sensors inside the pipeline track LED light points, which are used to determine angles and continuously calibrate the gyro

navigation system in real time.

This optical approach ensures navigation accuracy even in non-accessible sections, eliminating the need for manual calibration and minimising downtime. Beyond flexibility, TUnIS.pipelight also delivers significant operational advantages, including simplified logistics, enhanced safety, and improved overall quality control. By removing the need for personnel entry into confined or high-risk zones, the system supports safer, faster, and more sustainable tunnelling practices.

A new standard in automated surveying

Together, MultiStation and TUnIS.pipelight mark a significant leap forward in microtunnelling control measurement. VMT’s automation-led approach allows contractors and engineers to maintain high precision while reducing survey effort, downtime, and risk. As project demands grow more complex and alignments more ambitious, these innovations demonstrate how digital automation can directly improve construction efficiency and accuracy, setting a new benchmark for the next generation of trenchless tunnelling projects.

Enter a new era for pipe jacking and direct pipe projects with small and even non-accessible diameter: new planning possibilities, reduction in cost and construction time, increased daily output, maximum safety, ... ... and much more that TUnIS.pipelight, our new assistance system for automated control measurement has to offer. Find out!

www.vmt.global

Visit our presentation on 11. November at 02:40 PM:

„Pushing the limits of Pipe Jacking and Direct Pipe with automated control surveying“ Trenchless Middle East

Pipebursting enjoys a resurgence in the light of AMP8

Ttechnology of Pipebursting was popularised in the late 1970’s and early 1980’s when TRACTO developed a machine, the pneumatic GRUNDOCRACK, at the request of then nationally owned utility British Gas and Severn Trent Water. The objective was to facilitate the installation of replacement water pipes using trenchless methods to minimise disturbance to the surroundings and to save money by working more quickly and efficiently with less disturbance to the customer. The process was further developed to include the hydraulic GRUNDOBURST ladder rod system which can burst pipes from 2” to 32” and install up to 900mm HDPE pipe.

The GRUNDOBURST was designed to break – mainly old, brittle cast iron - pipes underground and pull through new HDPE pipes ready for connection to the water supply. The beauty of the technology was that like for like diameter pipe could be replaced, or if capacity necessitated, a larger pipe could be installed in the same manner and space, dramatically reducing the need to open cut the ground and the associated disruption this causes.

The introduction of AMP8 in April of 2025 and the guidance from Ofwat to prioritise trenchless techniques, has resulted in a resurgence of interest in pipe bursting and subsequently an increase in sales of TRACTO’s purpose-designed GRUNDOBURST.

AMP8 recognises the public frustration of the disruptions caused from perpetual civil

engineering works and has prioritised the use of trenchless techniques during the next 5 years of the funding cycle from 2025 to 2031; mandating contractors to use pipe bursting on mains replacement projects wherever possible.

Requiring minimal surface excavations – just two small pits from which to launch the burster – new pipe can be pulled back through the underground hole left by the displaced former pipe by the bursting process. It is not only quicker, but more environmentally friendly. A reduction in spoil waste, noise and dust pollution combined with quicker reinstatement ensures impact on businesses and residents, road closures and traffic disruption are minimised as much as possible.

The TRACTO GRUNDOBURST is a purpose-designed machine that offers the ultimate flexibility in pipe bursting. There are 6

models in the range from the 400G to the 2500G offering 40 to 250 ton pulls and the ability to install pipe sizes up to 900m. The specialised range of accessories and bursting tooling available only from TRACTO ensure each job can be completed with ease.

The GRUNDOBURST offers a unique ladder rod system of hooking rods together which allows some lateral flexibility enabling pipes to be installed, even on a slight curve. The ladder rod and hook mechanism removes the need to screw the rods together, which is not only quicker, but also removes many of the manual handling elements. Another inbuilt innovation is the red safety guard that prevents anybody standing directly behind the machine in the burst rod exit area.

Full product information is available on the TRACTO website www.tracto.com/uk/products/ grundoburst

A New ‘Rockstar’ in HDD

TRACTO introduces the state-of-the-art 20-tonne GRUNDODRILL 20ACS rock drilling rig German manufacturer TRACTO is globally recognised for its innovative, premium-quality trenchless equipment. Over the decades, the company has consistently advanced No-Dig

technology, particularly in the field of horizontal directional drilling (HDD). Its latest breakthrough in HDD rock drilling, the GRUNDODRILL 20ACS, was unveiled at bauma 2025 and is already attracting strong interest across the industry.

Evolution of rock drilling at Tracto

HDD is one of the most versatile trenchless construction methods, but also among the most technically demanding. TRACTO was the first German manufacturer to explore steerable underground

drilling in the 1970s, launching its first controllable rigs in the late 1980s. These early systems already featured a percussion mechanism that would later become a trademark element of the GRUNDODRILL range.

Decades of continuous innovation have followed,

each generation becoming more powerful, efficient and operator-friendly. A major milestone came with the 18ACS “All Condition System”, which combined jet and rock drilling capabilities in a single rig – a first for the industry. The main challenge in HDD rock drilling lies in complex ground formations where soil hardness changes frequently. TRACTO’s answer was the GRUNDODRILL 18ACS and its flexible ELICON twin-tube rod system. Here, the inner tube drives the rock drill head while the outer tube provides steering, eliminating wear and maintaining effective rinsing over long drilling distances. This design minimises bentonite consumption, reduces operating costs and maximises service life. Fully automatic rod handling and stepless torque control made the 18ACS the “King of Rock,” now operating successfully in demanding geologies worldwide. The same scalable rod concept has since been integrated into TRACTO’s latest JCS/ACS generation, including the 13-tonne ACS130 and the 30-tonne ACS300.

Masters any terrain: The Grundodrill 20acs

Responding to the sector’s growing project requirements, TRACTO developed the GRUNDODRILL 20ACS as an evolution of the 18ACS, offering greater power, higher efficiency, and enhanced operator comfort. Like its predecessor, it can perform both rock and jet drilling but now includes a host of automation and digitalsupport systems that simplify operation and improve flexibility on site. At its core, the 20ACS delivers 200 kN of thrust and pullback force with a loss-

free torque of 9,000 Nm on the outer rods and 2,500 Nm on the inner rods. Power comes from a 123 kW diesel engine driving a 400 l/min bentonite pump with stepless torque adjustment, ensuring maximum performance across varied ground conditions. An automatic drilling, rodchange and lubrication system streamlines operations, while the rig can be readily converted for cable-guided bores using ELICON rods when working at depth or in difficult terrain.

The optimised rod concept provides exceptional versatility, accommodating 144 metres of ELICON DL101 or 210 metres of ELICON DL80 twin-tube rods for rock drilling. For jet bores, the magazine can hold up to 225 metres of TD73 or 210 metres of TD82 rods. Operators can select rod types, EL D80, EL D101, TD73 or TD82, directly from the control menu, allowing quick changeover without external technical assistance. Jet drilling can also be performed using the inner rods without any system modification, further improving productivity.

Safety and user comfort were central to the redesign. A reinforced undercarriage provides stability even in critical ground conditions, while an optional anchor drilling system with an improved auger profile offers additional security during pilot and reaming operations under full load. A steep inclination angle allows the rig to work with minimal setback in confined spaces, and integrated lubrication strips simplify maintenance tasks.

From a usability standpoint, the rig can be driven and operated by radio remote >

“TRACTO developed the GRUNDODRILL 20ACS as an evolution of the 18ACS, offering greater power, higher efficiency, and enhanced operator comfort. Like its predecessor, it can perform both rock and jet drilling but now includes a host of automation and digital-support systems that simplify operation and improve flexibility on site.

control, and the swivel comfort cabin offers an ergonomically optimised working environment complete with air conditioning, tinted windows, a heated Grammer seat, USB ports, and increased storage space. Drilling data are automatically logged through the BORE DATA app and can be retrieved via USB or cloud connection. Integration with TRACTO’s COMMANDER fleet-management system provides contractors with real-time visibility of rig location, performance and consumption data across their entire fleet. Combining these advances, the GRUNDODRILL 20ACS stands as one of the most powerful and technically refined HDD rigs in its class, delivering strength, precision and intelligent automation for efficient operations in

The GRUNDODRILL 20ACS at work in Thuringia, Germany, where mixed rock and sediment formations test its full capabilities.

the most challenging geological conditions.

Contractors rely on customised solutions

Beyond supplying premiumgrade machinery, TRACTO supports customers through personalised consultation on rig configuration and tooling, tailored financing, and comprehensive operator training. The strong market response to the new “Rockstar” underscores industry confidence in TRACTO’s engineering leadership and customersupport ethos. Since its launch in April 2025, the GRUNDODRILL 20ACS has already entered service with contractors across Germany and internationally.

More flexibility, productivity, safety and operator comfort for your drilling projects. That’s the GRUNDODRILL 20ACS from TRACTO.

Combining the proven ‘All Condition System’ concept with the latest in automation and top-of-the-range ergonomics, this 200 kN drilling rig can handle even the most complex drilling projects in changing ground conditions, including rock.

To find out more about the 20ACS and our customised service solutions, please get in touch: info@tracto.com T +49 2723 8080

HDD and the water industry: Solving installation challenges under rivers and roads

Vermeer UK supports utilities and contractors with precision trenchless drilling solutions for complex crossings.

For the UK water industry, infrastructure projects are rarely straightforward, particularly when new or replacement pipelines must cross rivers, roads, or densely populated areas. Traditional open-cut methods are often unfeasible due to disruption, environmental sensitivity, or high reinstatement costs. That’s where horizontal directional drilling (HDD) provides a smarter, more sustainable solution.

Trenchless precision for critical crossings

Vermeer UK works alongside contractors, utilities, and engineering consultants nationwide to support trenchless installations with precision HDD equipment. From long river crossings to short road bores, Vermeer’s rigs enable faster, cleaner, and more controlled pipeline installations, minimising disruption and environmental impact.

HDD technology allows utilities to drill below surface obstacles with minimal disturbance to communities and habitats. For water projects, this means new mains can be installed under rivers, canals, highways, or

flood-prone areas without the need for large-scale excavation or surface reinstatement.

Tackling trenchless challenges with confidence

While HDD offers significant advantages, it also requires careful control and experience, especially when working in variable or difficult ground conditions. Unpredictable geology, fluctuating water tables, or long-distance bores can increase the risk of frac-outs, bore collapse, or steering inaccuracies if not properly managed. To meet these challenges, Vermeer UK’s HDD systems are engineered for maximum precision and performance across a wide range of ground types, from soft clay to fractured chalk or rock. The rigs combine high torque and thrust capabilities with intelligent fluid management, automated rod handling, and advanced bore-path monitoring, ensuring accuracy, efficiency, and environmental compliance on every project.

HDD in UK water projects

Across the UK, HDD continues to demonstrate its value in water infrastructure delivery.

In one recent high-profile project, trenchless installation enabled a new water main to be laid beneath both a major A-road and a chalk riverbed, avoiding surface disruption and protecting the fragile river ecosystem. Such projects highlight how HDD can overcome the logistical and environmental challenges faced by the water industry, achieving essential upgrades without the need for open-cut works.

Partnering for success

Vermeer UK does more than supply high-performance drilling rigs. The company partners with customers at every stage, offering operator training, technical support, and service expertise to ensure each HDD crew can deliver safely and efficiently, regardless of ground conditions or project complexity.

Whether working for a water authority, tier-one contractor, or specialist utility installer, Vermeer UK provides the experience, technology, and after-sales support needed to achieve trenchless success. Their solutions help contractors drill with precision, minimise disruption, and meet the latest standards for sustainable pipeline installation across the UK.

STILL IN A LEAGUE OF ITS OWN

THE D100X140 S3 NAVIGATOR®

HORIZONTAL DIRECTIONAL DRILL

The D100x140 S3 is a unique machine in the HDD market. It’s not only used for oil, gas or other large pipeline projects — but utility projects as well due to the machine’s small footprint.

TRENCHLESS ASIA 2026

Your gateway to Asia’s fastest-growing infrastructure markets

Trenchless Asia is where deals are made, and technologies transform cities.

As Thailand accelerates investment in smart cities, water resilience, and utility upgrades, Trenchless Asia 2026 connects you directly with the people delivering critical underground infrastructure.

Building on the success of 2025

Trenchless Asia 2025 brought together thousands of trenchless professionals, industry leaders, and key buyers from across the region, with a sold-out exhibition floor and record-breaking international attendance.

In 2026, the event returns to Bangkok, Thailand with even greater momentum, new project drivers, and increased demand for innovative underground infrastructure solutions.

Secure your space early to benefit from maximum exposure and priority stand positioning

For more details regarding exhibiting and sponsorship opportunities please

Smart Leak detection strengthens global network resilience

As droughts intensify and water scarcity becomes a critical global concern, utilities are turning to data-driven solutions to manage losses and protect supply. Smart leak detection is emerging as one of the fastest, most cost-effective ways to bolster water security, and to support proactive asset management ahead of trenchless rehabilitation.

According to the OECD Global Drought Outlook (June 2025), 40% of the world’s land area now faces increased drought stress, with economic losses projected to rise by 35% over the next decade. Tackling leakage, which averages around 30% of global water supply, offers immediate, measurable results.

Ben Crabtree, Product Line Director at Ovarro, says that modern, data-powered leak detection technologies are transforming how utilities manage underground networks:

“Today’s systems don’t just detect leaks, they identify high-risk areas before they occur, inform maintenance programmes, and optimise pressure management. That intelligence is vital for longterm resilience and efficient trenchless planning.”

Ovarro’s Enigma, EnigmaREACH, and LeakNavigator systems combine acoustic correlation, telemetry, and AI analytics to provide real-time insight across extensive water networks. The technology allows field teams to locate and verify leaks

rapidly, reducing both water loss and the operational impact of unplanned excavations.

Global impact

• Philippines: Enigma loggers detected a major leak within days of installation in Davao City, saving enough water to postpone construction of a new production well.

• Panama City: EnigmaREACH identified 12 points of interest in a dense urban district - five verified leaks were confirmed within hours of deployment.

• UK: Southern Water’s partnership with Ovarro on the LeakNavigator service achieved an 80% conversion rate, detecting over 1,100 leaks and saving 204 Ml/d monthly.

• France: In Paris, EnigmaREACH identified 10 confirmed leaks across 8 km of network during its first four weeks of operation.

Supporting trenchless strategies

By pinpointing network weaknesses before visible failure, smart leak detection enables utilities to target trenchless rehabilitation precisely where it’s needed, reducing disruption, optimising budgets, and extending asset life.

Ovarro’s global deployments demonstrate how the integration of digital intelligence, proactive maintenance, and trenchless intervention can deliver lasting resilience and water security worldwide.

Technology Snapshot: Ovarro Smart Leak Detection

Systems Featured

• Enigma / EnigmaREACH – Acoustic leak loggers and correlating sensors providing 24/7 remote monitoring and highaccuracy leak location, even in challenging urban environments.

• LeakNavigator – Fully managed leak detection service combining AI analytics with field verification and performance reporting.

• Applications

• Pre-rehabilitation leak detection to inform trenchless planning

• Continuous monitoring of critical water distribution assets

• Pressure optimisation and proactive maintenance scheduling

• Rapid leak identification to minimise non-revenue water

Key Benefits

• Reduces time from leak occurrence to repair

• Enables targeted trenchless interventions

• Improves operational efficiency and asset longevity

• Supports drought resilience and water security

Global Reach Deployed in 65+ countries, including the UK, France, Panama, and the Philippines.

Supplier Contact www.ovarro.com info@ovarro.com

2025 No-Dig Roadshow series finishes in style

By Paul Harwood, Managing Director, Westrade

We are delighted to reflect on another fantastic event at the stunning De Vere Tortworth Court, which, with approaching 300 visitors perfectly marked the end of our 2025 No-Dig Roadshow series. This year’s series has been a tremendous success, building on the popularity of events in Belfast and Sheffield earlier in the year. As always, it’s thanks to the incredible support from highly regarded and innovative organisations such as Wessex Water, UKSTT, the British Drilling Association, and DCA that these events continue to thrive.

As always, our roadshow series provides a vital platform for delegates from across the underground utilities sector to deepen their knowledge and share experiences. The conference programme, curated by Iain Naismith and the UKSTT team, was once again packed with insightful presentations. I was pleased to attend and hear from industry leaders at Wessex Water, Sutton and East Surrey Water, South West Water, and Paul Horton from the Future Water Association, who discussed the key points and next steps from the Cunliffe Report. A heartfelt thank you to all our speakers for taking the time to share their experience and expertise. It is this collaborative spirit and knowledge exchange that continues to drive the impressive visitor numbers we see at our events. Alongside the conference was a bustling exhibition area, with

over 35 exhibitors showcasing the latest products and services, demonstrating the ongoing innovation within our industry.

In addition to the main event, we were thrilled to offer supporters of Westrade and Trenchless Works an exclusive sneak peek of our new Trenchless Connect product. This innovative platform will provide partners with a dedicated portal to the underground utilities sector, enabling them to share news, case studies, and company updates with an engaged and relevant audience.

A big shout-out to the UKSTT Awards, which took place at Tortworth following the roadshow. It was inspiring to celebrate the innovation and success happening across our sector.

Congratulations to the winners and you all looked fantastic in your dinner suits and fabulous dresses!

Finally, a big thank you to our event sponsors, ProKasaro, Lateral Repairs, and Quick Pig as well as our Roadshow Series Premium Partners: Bluelight Lining, Channeline, IMS Robotics, Picote, PLS, Reline, RSM, S1E, Tracto, UIS and Vermeer.

As you know, our roadshows are always highly popular, so if you want to get involved, keep an eye out for our upcoming events in Ireland and London in 2026. Thank you all for your support throughout 2025. The Westrade team and I look forward to another successful year ahead!

TRENCHLESS MIDDLE EAST 2025

11-12 November 2025

Jeddah Hilton, Jeddah, Kingdom of Saudi Arabia www.trenchlessmiddleeast.com

TRENCHLESS MOROCCO 2026

11-12 February 2026

Rabat Marriott Hotel, Rabat, Morocco www.trenchlessmorocco.com

TRENCHLESS ASIA 2026

10 -11 June 2026

Queen Sirikit National Convention Centre Bangkok, Thailand www.trenchlessasia.com

NO-DIG LIVE 2026

29 September – 1 October 2026

NAEC Stoneleigh Park, Warwickshire www.nodiglive.co.uk

TRENCHLESS MIDDLE EAST 2026

www.trenchlessmiddleeast.com

NO-DIG ROADSHOW SERIES 2026

Dublin | London | Glasgow www.nodigroadshows.co.uk

MALAYSIA | SOUTH AFRICA | VIETNAM

Trenchless Training and the Middle East

Frank Reilly Director JBP’s Trenchless, Training Programme

Trenchless Middle East 2025 you will once again see JBP delivering its programme of Applied Trenchless Technologies workshops, together with experts drawn from across the sector, over the two days of the event in Jeddah. These workshops have become a cornerstone of the regional event calendar, offering contractors, consultants, and utility engineers the opportunity

to gain direct exposure to equipment, installation procedures, and international best practices under expert guidance.

A focus on applied learning

As with all of the Workshops programmes we have run in the past, as well as with the courses included in JBP’s Trenchless Training programme, the emphasis is on the practical considerations of working with Trenchless methods and Technologies.

We have had the privilege, other the last five years of training cohorts of operations and projects managers, engineers and technicians from many of the leading contracting and consulting companies across the Middle East, in inspection, condition and risk assessment of water and wastewater pipe infrastructures, and other key aspects of assets management.

Closing the skills gap

As the Middle East continues its rapid urban expansion, utilities face a mounting challenge: how to maintain and rehabilitate critical water and wastewater networks while minimising disruption to cities that never stop growing. From Riyadh to Dubai, the region’s utilities have invested heavily in infrastructure and technology — but the greatest challenge may now be human capability. Skilled people are the key to making advanced trenchless systems work safely, efficiently, and to international standards.

National academies such as the Saudi Water Academy and DEWA Academy in Dubai provide excellent general courses in water operations, and regional associations like ACWUA deliver management and policy-oriented capacity building. However, few programmes focus exclusively on trenchless technologies.

An industry-led Response

That is where JBP’s approach in focusing on trenchless training with an applied approach can play a vital role. With more than three decades of field experience and working with experts drawn from across the Trenchless sector, JBP has developed a comprehensive programme of Applied Trenchless Training designed specifically for the water and wastewater sector. Delivered

through short, intensive modules, each course combines the insights and experience of current practitioners with a hands-on practical focus –ensuring that participants leave not just informed, but confident to apply their newly gained knowledge.

This structured approach directly addresses a longrecognised gap in the regional training landscape. Trenchless methods and technologies, essential for modern, low-disruption rehabilitation, demand very specific technical understanding and hands-on practice that cannot be acquired from general O&M training alone.

Training for the future

The Middle East’s water and wastewater infrastructure ambitions will rely on skilled local teams, technicians, engineers, and manager, who can operate to regional and global trenchless standards. Bridging that skills gap requires structured, applied, and continuous professional

training. Practical, industryled programmes and strong partnerships across the region will help to build that capability from the ground up, one workshop, one course, and one skilled professional at a time.

P.S. Don’t forget to have your say in our monthly Training poll on LinkedIn!

Next issue – Practice, Theory and the Impact of AI

A message from the Chair

As we move into the final quarter of the year, October has proven to be a month of energy and achievement across the trenchless sector. From the success of the Autumn Roadshow to the inspiring UKSTT Awards Dinner, and the continued discussion of a significant new industry standard CP655, our community continues to lead the way in innovation and collaboration.

The Autumn Roadshow once again highlighted the strength and enthusiasm of our trenchless community. Held at Tortworth Court near Bristol, the event provided an invaluable opportunity for professionals from utilities, local authorities, consultancies, and contractors and suppliers to exchange insights and explore new technologies.

Presentations covered a wide range of topics including rehabilitation, resources available from UKSTT & ISTT, trenchless options for Coventry Very Light Railway, completion of SRM Part 2 and the Cunliffe report, all of which drew strong engagement from attendees.

I would like to extend my sincere thanks to our sponsors, speakers, and the UKSTT Technical and Education Committee for delivering another outstanding programme that continues to educate and inspire across the industry.

Another standout moment this month was the UKSTT’s Annual Dinner & Awards Ceremony, held after the No-Dig Roadshow. This prestigious event celebrated the exceptional achievements and innovations of individuals and organisations advancing the field of trenchless technology. Sincere congratulations to Russell Fairhurst who received The UKSTT Lifetime Achievement Award and Shauna Herron who was awarded the Trenchless Woman of the year award.

The Reverend Canon Kate Bottley did an excellent job of hosting and entertaining us and I must thank Liam Powell at Andy’s Man Club for his heartfelt presentation, which led to over £3,500 being raised for the Charity. Thank you for all your kind donations.

The quality of this year’s submissions reflected the remarkable creativity, professionalism, and technical excellence present across our sector. Congratulations to all winners and nominees, your work exemplifies the values of innovation and excellence that UKSTT stands for.

A special thank you goes to all our sponsors and partners for their continued support, and to everyone who attended for making the evening such a memorable celebration of our shared success.

“UKSTT has actively supported discussions surrounding CP655 and is committed to helping members understand and adopt the new requirements through technical briefings, training sessions, and guidance materials to be released in due course.

This is an important milestone for our industry, one that will enhance quality assurance and align with the UK’s broader sustainability and regulatory goals.

A key talking point at the event has been the publication of CP655, the Water Industry Specification for the Infiltration resistance testing of CIPP liners.

Preventing infiltration into our sewer network is a major challenge for the UK Water industry in AMP8 to help reduce flows and help prevent CSO spills and so to help with this challenge WRc Group have worked collaboratively with Thames Water, Southern Water, Wessex Water, Dŵr Cymru Welsh Water, Severn Trent, Anglian Water Services and the Government of Jersey to develop a new specification of testing Cured-In-Place-Pipe liners for their resistance to infiltration.

However, there are still challenges for the installers and the manufacturers/suppliers when using two independently tested products which have passed the requirements. They will still need to be tested again as a system when used in conjunction with each other. for example, a CP655 tested CIPP liner is installed followed by the installation CP655 tested connection collar.

UKSTT has actively supported discussions surrounding CP655 and is committed to helping members understand and adopt the new requirements through technical briefings, training sessions, and guidance materials to be released in due course.

This is an important milestone for our industry, one that will enhance quality assurance and align with the UK’s broader sustainability and regulatory goals.

As we look towards the end of 2025, the Society is already planning an exciting programme for 2026. Members can look forward to the continuation of our Technical Masterclass Series, expanded regional engagement events, and further opportunities to share knowledge and celebrate innovation.

Preparations are also underway for the 2026 UKSTT Annual Awards, and I encourage members to begin considering projects and individuals worthy of nomination. Recognising excellence is not just a celebration — it is a catalyst for continued progress across our field.

The next date for your diary is 12th of November when there will be not one but two exciting events; The UKSTT Masterclass tackling infiltration and inflow held at the Woodland Grange, Leamington Spa and the ISTT Educational webinar covering Thermoplastic lining for potable and wastewater applications.

For more details please contact lynn@ukstt.org.uk or visit https://www.ukstt.org.uk/

On behalf of the UKSTT Council, I would like to thank the UKSTT team Lynn, Linda and Tammy, all members, partners, and industry colleagues for your ongoing support and engagement. Together, we continue to strengthen the UK’s leadership in trenchless technology, promoting safer, smarter, and more sustainable solutions for the future of our infrastructure.

Kind regards

Graham

UKSTT Annual Dinner celebrates industry excellence and raises £3,440 for charity

“

Beyond celebrating technical excellence, this evening showcased our industry’s compassion and community spirit

Trenchless sector unites for a sold-out awards evening recognising innovation, leadership, and community impact

The United Kingdom Society for Trenchless Technology (UKSTT) hosted its Annual Dinner and Awards Ceremony on 2 October 2025 at De Vere Tortworth Court Hotel, celebrating outstanding achievements across the UK trenchless sector and raising £3,440 for men’s mental health charity Andy’s Man Club.

Following the successful NoDig Roadshow in Bristol, the prestigious event welcomed a sold-out audience of 256 guests. Ten industry awards were presented, recognising innovation, collaboration, and technical excellence in underground infrastructure and trenchless construction.

Special guest Reverend Canon Kate Bottley joined UKSTT Chair Graham Howard to host the evening, delighting guests with

her humour and warmth. A highlight of the night came from Liam Powell, representing Andy’s Man Club, whose heartfelt address on mental health resonated deeply, inspiring the record fundraising total.

“Beyond celebrating technical excellence, this evening showcased our industry’s compassion and community spirit,” said UKSTT Chair Graham Howard.

The event, regarded as the UK’s premier trenchless networking occasion, was made possible through the support of award sponsors including Bluelight Lining, Impreg, IMS Robotics UK, Lateral Repairs, Picote, Pro Lining Solutions, Prokasro, RSM Lining Supplies, RSP, Tracto, and Vortex. Special thanks were extended to

Westrade Group for outstanding event management.

About the Charity

Andy’s Man Club provides free mental health support groups for men across the UK, operating on the principle that “It’s OK to talk.” The organisation offers safe, non-judgmental spaces for open conversation and peer support.

About UKSTT

The United Kingdom Society for Trenchless Technology is the leading professional body advancing no-dig and trenchless solutions across the UK. Through education, collaboration, and industry recognition, UKSTT promotes innovation and best practice in underground infrastructure delivery.

Winners

Innovative Technology: OCU Group / United Utilities

200-ton Multi-Diameter Pipe Pusher

Detection, Location & Inspection:

Glanville Environmental The Pant Sinkhole

New Installation (Large): CPC Civils / Severn Trent Ambergate to Crich HDD Project

New Installation (Small): McBreen Enviro UK / SAERTEX UV-CIPP Airport Project

Renovation (Large): MGroup Water / Thames Water Millennium Main

Renovation (Small): Picote UK Ltd River Beaulieu Rehabilitation

Small Scheme: Glanville Environmental / Network Rail Eggesford Station Project

Young Professional: Jack Fuller McAllister Group

Trenchless Woman of the Year: Shauna Herron Environmental Techniques

Lifetime Achievement: Russell Fairhurst MTS Suction Systems UK Ltd

UKSTT concludes Annual General Meeting with leadership appointments and strategic council expansion

Trenchless technology society strengthens governance and outlines growth priorities for 2026

The UK Society for Trenchless Technology (UKSTT) successfully held its Annual General Meeting at Camden House, Kenilworth, marking another important milestone in the society’s ongoing growth and leadership within the UK trenchless industry. Chair Graham Howard welcomed members and guests before presenting a comprehensive review of 2025, which included a series of successful technical events, training initiatives, and collaborative industry programmes. He also outlined an ambitious agenda for 2026, featuring the 3rd Annual Trenchless Conference, to be held at the Manufacturing Technology Centre (MTC) in Coventry.

Confirmed leadership appointments

The AGM confirmed several key leadership positions, with Graham Howard entering his second term as Chair. The following honorary officers were appointed for a further one-year term:

• Tim Sargent – Vice Chair

• Claire Gowdy – Secretary

• Leon Woods – Treasurer

Tim Sargent delivered the Treasurer’s Report on behalf of the Finance Committee, with audited 2024 accounts made available for member review.

Strategic council expansion

Reflecting the society’s increased activity and membership engagement, the council voted to expand its maximum size from 20 to 25 members.

The following council members were re-elected after completing their terms: Dawn Greig, Leon Woods, Iain Naismith, Jim Albarella, and Andy Gundry. Additionally, Fran Thums, who was co-opted earlier in the year, was formally elected to council.

Further nominations from Richard Swan, Andrew Sapnik, Paul Cleaver, and Dean Morgan will be finalised following approval of amended articles currently under review by solicitors and awaiting Charity Commission consent. An Extraordinary General Meeting will be convened once this process is complete.

Commitment to good governance

“This AGM represents another important step forward for

UKSTT as we strengthen our governance structure to support our expanding activities,” said Chair Graham Howard. “The continued dedication of our council members and officers ensures we can deliver tangible value to our members while promoting trenchless technology adoption across the UK.”

The meeting also acknowledged the contributions of outgoing members. Special thanks were extended to Jo Parker, who stepped down from her role as Special Advisor after many years of service, and to Jill Tickle for her valuable support to the society.

About UKSTT

The UK Society for Trenchless Technology is the leading professional body dedicated to advancing trenchless solutions across the United Kingdom. Working in collaboration with industry patrons, utilities, and academic partners, UKSTT promotes innovation, technical excellence, and professional development through conferences, training programmes, and sector engagement.

Wessex Water hosts industry learning event

UKSTT and New to Trenchless Technology Network members gain valuable insight into sewer sealing strategies and AMP8 innovation

Wessex Water hosted a focused industry learning event at its Claverton Down Operations Centre in Bath, welcoming members of the UK Society for Trenchless Technology (UKSTT), the New to Trenchless Technology Network, and Wessex Water’s internal teams. The session took place ahead of the highly anticipated No-Dig Roadshow in Bristol, providing a timely platform for collaboration and technical exchange.

The event offered a rare opportunity for trenchless professionals to explore Wessex Water’s innovative approach to AMP8 objectives and its strategies for addressing groundwater infiltration through large-scale sewer sealing. Presentations were delivered by Eddie Rant, Director of Engineering and Asset Management; Daniel Humphrey, Networks Delivery Director; and Francieli Thums,

Sewer Rehabilitation Programme Manager and UKSTT Council Member. The expert-led programme covered Wessex Water’s strategic planning, stakeholder engagement, and practical methodologies for implementing sewer sealing at catchment scale.

“This event provided a unique opportunity for our industry colleagues to see firsthand how we’re addressing one of the sector’s most pressing challenges,” said Eddie Rant, Director of Engineering and Asset Management at Wessex Water. “The collaborative exchange of knowledge and expertise will undoubtedly benefit the wider trenchless community as we work together to deliver innovative solutions for AMP8.”

Tim Sargent, Vice Chair of UKSTT, who opened the session, praised the event’s educational value: “Attendees gained a comprehensive understanding

of how trenchless sewer rehabilitation can be deployed to tackle infiltration challenges. The detailed insights into Wessex Water’s planning methodologies, stakeholder engagement, and delivery frameworks offered significant practical value.”

The late-morning and afternoon event concluded in time for delegates to travel to De Vere Tortworth Court for networking ahead of the Bristol No-Dig Roadshow the following day, reinforcing industry collaboration across utilities, contractors, and suppliers.

About Wessex Water

Wessex Water is a leading UK water and sewerage company serving the South West of England. The company is committed to delivering sustainable water management solutions, with a strong emphasis on innovation and trenchless technologies for infrastructure rehabilitation and maintenance.

No-Dig Down under 2025 wraps with record numbers

Amonth may have passed since No-Dig Down Under 2025 took place in Melbourne (17–18 September), but the momentum and enthusiasm from this landmark event continue to resonate across the global trenchless community.

Hosted by the Australasian Society for Trenchless Technology (ASTT) and organised by Prime Creative Media, this year’s edition delivered record-breaking participation, a sold-out exhibition, and a high-calibre conference program that set new standards for innovation and knowledge exchange within the sector.

The two-day event drew in a truly international audience, highlighting both the strength and the expanding reach of trenchless technology across the Asia-Pacific region and beyond. Day 2 featured the highly anticipated International Trends Panel, which brought together industry leaders from around

the world to share insights on emerging technologies, project case studies, and policy developments shaping the future of underground infrastructure.

Event Highlights

• 2,000 attendees across the exhibition and conference