Become

HP has unveiled the HP Latex 630 Printer Series, available now from Computaleta. Arlette Farland, director at Computaleta, says, “The new printer series consists of four separate models that open up exciting new opportunities for small to medium sign and print makers. They can help make your business unbeatable.

“The HP Latex 630 Printer and HP Latex 630 Print & Cut Plus offer fourth generation Latex ink at an entry-level price point for the first time, while the HP Latex 630W Printer and HP Latex 630W Print & Cut Plus add the stunning application versatility of white ink.

“Alongside HP’s fourth generation Latex 700W and Latex 800W printers launched in 2022, the Latex 630W uses the same auto recirculation system with minimal wastage and no manual maintenance, making the HP Latex 630W the easiest, most accessible and affordable white printers on the market, with a total cost below $35,000.”

With a competitive price point that includes SAi Flexi HP Edition RIP in the box, Arlette believes the Latex 630 series will allow signage and print companies to deliver a competitive and sustainable edge. She explains, “If you currently own a third generation HP Latex machine, like an HP Latex 315 printer, an HP Latex 335 printer, or an HP Latex 365 printer, the 630 is the ultimate upgrade. We believe print’s future is about fighting commoditisation to gain higher margins

by producing great work, and the HP Latex printers with white ink do just that.

“The HP white ink is distinctive for its lack of complexity to operate and maintain and has the same outdoor warranty as the Latex coloured inks. The HP Latex 630W prints on a wider range of media, including clear, coloured and metallic films, with minimal wastage.”

The HP Latex 630 Printer Series uses a new curing module architecture that enables printing from the leading edge of many media types, significantly saving media waste. Arlette says, “With lower curing temperatures of up to 30 per cent less heat than HP third generation models, the HP Latex 630 printer will expand sign and print makers’ versatility allowing easy printing on offset paper, outdoor paper and polypropylene, perforated vinyl and dot adhesives as well as coated papers. Paired with effortless media loading, the new HP Latex 630 series saves time with a front-loading system that is spindle-less with improved automatic skew correction.

“The Latex 832 ink used in the HP Latex 630 series, which uses the same cartridge as the HP Latex 700 series, has a greater pigment load and higher colour gamut than third generation Latex inks. This produces vibrant colours, sharper small text, and barcodes. With a new printhead architecture and non-circular nozzles, you get text sharpness at six pass, allowing for beautiful fine text labels which exceed the results of older models.

“The HP Pixel Control technology used in the Latex 630 series provides deeper colours, especially when used for contours and gradations. With colours defined and controlled at the pixel level it gives better transitions when colours are going from dark to light. This creates new possibilities for printing on clear, and I can see sign and print makers utilising this feature for stunning vehicle wraps on clear and glass like never before.”

Since becoming a distributor for HP in December 2020, family owned Computaleta has won the HP Partner of the Year Award for two years running, in 2021 and 2022.

Wayne Shaw, business manager for HP Large Format, says, “This is an exciting launch for HP. The success of our current third generation Latex printers in New Zealand demonstrates the many benefits of HP Latex. The new fourth generation HP Latex 630 Printer Series range bolsters an already strong portfolio.”

The Latex 630 Printer Series features:

• Affordable white ink without the complexity.

• Recyclable cartridges

• Productivity mode of 18 sqm per hour.

• Easy fast reprints from the front panel.

• Instant dry ink.

• Auto maintenance, no hassles.

• GreenGuard Gold certified.

• Monitor from anywhere with PrintOS.

• Fast and easy media loading.

Signage and large format printing continue to be largely profitable but the team at Computaleta say that many easier, more common core applications such as banners, corflute and posters, are becoming commoditised.

Arlette Farland, director at Computaleta, says, “Print service providers who concentrate on high-value jobs are those who are positioned to capture higher gross margins in the future. Using 3M graphic films can help you grow the value of your business.

“In July 2020 HP conducted a study that analysed 100 print service providers across the USA, Germany and India to evaluate the industry’s most profitable applications. The results showed some applications are simply worth more, both to customers and to the bottom line. They also discovered that many print service providers frequently end up outsourcing these in-demand high value applications.

“So how do we take that knowledge and apply it in the real world, for us here in New Zealand? As HP distributors at Computaleta, we have partnered with 3M to share four print jobs that can help you increase your margins and fight commoditisation. Read on and discover the print applications you can use to make your printing and signage operation grow in volume and in value.”

For contour-cut window displays, Arlette recommends 3M 8150 Clearview media. She says, “This is an easy to install transparent self-adhesive vinyl with white ink in spot white mode.

“There are two key insights worth knowing:

• Contour-cut window display was rated by print service providers as the highest value print job.

• Contour-cut window graphics garner much higher gross margins for print service providers, especially with HP White Ink on transparent selfadhesive vinyl. This application can drive increased profitability by up to 10 per cent.

“The benefits of printing with 3M 8150 Clearview on the HP Latex 700W printer

and HP Latex 800W printer include:

• A high opacity white that resists yellowing over time.

• Flexible ink enables easy application.

• Optically clear film allows for multiple images in a single graphic. This would essentially eliminate shape and contour cutting for faster installation, perfectly spaced images and much quicker removal.

• Creative design flexibility to produce effects, such as see-through, that simulate perforated film. Alternate image on reverse side of a single graphic, frosted crystal with white ink – for amazing results and infinite possibilities.

• HP’s white ink system with automatic recirculation and printhead cleaning helps avoid clogs and reduces manual purging.

• Produce safe odourless prints for indoor spaces.”

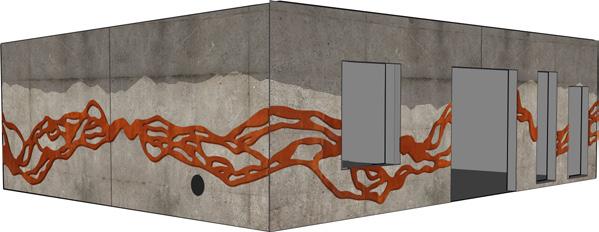

You can create indoor wall covering panels for retail or decoration using 3M 48C Envision media.

Arlette says, “3M 48C Envision is an easy to install, environmentally friendly self-adhesive vinyl. “Two points to note here are that it commands above-average margins and drives print volumes, and it is a high-demand application that is often outsourced.

“The advantages of printing with 3M IJ48C on the HP Latex 700W printer and HP Latex 800W printer are:

• Inks with high pigment load deliver vivid colours at speed.

• Colour consistency and length repeatability between tiles.

• Excellent grey neutrality.

• Use water-based HP Latex Inks for wallcoverings with the environmental certifications that matter to your customers.

• 3M 48C Envision is matched also with Green Guard Gold certification.

• Five-year performance life, non-PVC media.

• 3M Comply adhesive for easier bubble-free application.”

Computaleta advises using 3M 40C or 48C self-adhesive vinyl with slip resistant laminate for floor graphics. Arlette says, “Three key insights to consider are:

• Firstly, the solid above-average gross margins you can gain.

• Second, over the past few years, it is one of the most in-demand applications for health signage, retail and public spaces.

• Third, nearly one-fifth of floor applications are outsourced.

“The benefits of printing with 3M 40C and 48C on the HP Latex 700W printer and HP Latex 800W printer are:

• You can skip the overcoat when laminating.

• Help avoid short-term lamination with HP Latex overcoat.

• Excellent printability with slide, tack and snap-up.

• Multi-use film for floors, walls and more.

• Pair it with 3M 3645 overlaminate to provide slip and scuff resistance that is waxable and scrubbable.”

3M IJ280 print wrap film can help you deliver high quality vehicle wraps. Computaleta lists the benefits of printing with 3M IJ280 on the HP Latex 700W

printer and HP Latex 800W printer:

• Prints come out dry, ready for immediate lamination and application.

• A flexible HP Latex ink later helps facilitate installation.

• 3M MCS Warranty provides the greatest protection and performance guarantee.

• The IJ280 and 8428 combination is up to 20 per cent faster to install and proven to lift less; it conforms with less heat.

• New 3M Comply v4 Air Release for maximum air flow and smooth results.

• A new, proprietary adhesive on IJ280 offers optimised initial tack, slide and repositionability for smooth results.

• Removes cleanly at end of life with heat.

HP’s study found that nearly twice as many of the top high-margin print jobs were completed using HP Latex technology. Arlette says, “This reflects HP Latex technology’s specific advantages for printing signage and décor, as well as its excellent white ink capabilities.

“For more information about 3M Films and how they can benefit your business, contact us today for our ‘Signage in a Box’ presentation box at help@clgroup.co.nz.

“To find out more, you can download the ‘Six Print Jobs that can Help Grow Your Margins’ from the HP website.

It is based on research that HP commissioned and conducted during July 2020 with 100 print service providers across the USA, Germany and India.”

She concludes, “Paired with 3M’s Films that offer outstanding design and application benefits, backed by a solid MSC Warranty, it’s a match made in heaven.”

2 Computaleta: HP has released its latest Latex solutions: the HP Latex 630 Printers, comprising four models, which Computaleta believes can make your business unbeatable

4 Computaleta: Learn how a combination of HP technology and 3M film can add value to your wide format production

22 Fujifilm NZ: A new Fujifilm CTP system at Kale Print has boosted the company’s offset and environmental strategies

24 Fujifilm Business Innovation: Villa Maria owner Indevin has brought its marketing in-house with an ApeosPro C750 printer

26 Konica Minolta: The AccurioPress C14000 continues Caxton’s tradition of innovative and high quality printing

28 Think Laterally: Mick Rowan introduces us to digital humans as we cautiously open the gate to virtual reality

16-18 Currie Group: Wedderburn has taken its digital label production to the next level with an HP Indigo 6K Digital Press and an ABG

20 Trimatt: While enjoying awards success with its Colourstar AQV, Trimatt has also released a new coffee cup printer, the CupPro 600

NEW ZEALAND PRINTER

PO Box 32-395, Devonport, Auckland 0744

EDITORIAL: 021 631 559

Bruce Craig, Editor - bruce@newzealandprinter.co.nz

CONTRIBUTORS:

Ruth Cobb, Melissa Coutts, Shae Goom, Laura McConchie, Iain MacIntyre, Mick Rowan

CIRCULATION:

brian@newzealandprinter.co.nz

DISPLAY ADVERTISING SALES & SERVICE:

Brian Moore - brian@newzealandprinter.co.nz

+61 410 578 876

CLASSIFIED ADVERTISING:

Brian Moore - brian@newzealandprinter.co.nz

DESIGN & PRODUCTION:

Sarah Vella - sarahvelladesigns@gmail.com

New Zealand Printer is mailed to members of the printing,

12-14 Helping Hand: Iain MacIntyre reports on Paper Source, discussing its range of environmentally friendly products

15 Comment: Ignore Health and Safety guidelines at your own (and your staff’s) peril, says Ruth Cobb

Wide Format Plus p29-40

30 Aarque Group: Roland DG has released its latest VersaSTUDIO desktop printers, available from Aarque Group

32 Durst: Streamlining workflow and web to print is all in a day’s work for Durst Software & Solutions

34 NZSDA Awards: Piotr Wnuk checks out the winners at the NZSDA celebration of excellence in sign making

37 Wrap Challenge: Find out who took out the honours as the cream of Kiwi wrapping talent competed against each other

38-39 NZSDA Update: Melissa Coutts introduces this year’s Notable Awards winners and Laura McConchie reports back from SigneeNZ’s recent outings

40 NZSDA President: Shae Goom reflects on how sign makers enhanced our appreciation of the FIFA Women’s World Cup

Tony Reid, label production manager at Wedderburn, with the new HP Indigo 6K Digital Press

ISSN 1171 7912

packaging and graphic communications industry in New Zealand 11 times a year, February-December.

New Zealand Printer is a member of the Printer Media Group

New Zealand: New Zealand Printer

Asia Pacific: ProPack.pro

Australia: Australian Printer, ProPrint

MANAGING DIRECTOR: James Wells - james@intermedia.com.au

GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz

© Copyright 2023: Contents of this magazine are subject to copyright and cannot be reproduced without written permission of the publisher.

2021

Official Media Sponsor

or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher, its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication.

Copyright © 2023 — Charted Media Group Pty Ltd

FLINT GROUP has removed mineral oils and now offers the full range of K+E process series exclusively made from more sustainable formulations, under plans to increase the use of environmentally friendly raw materials and make packaging easier to recycle. From July, mineral oil will also be phased out as a raw material during Flint Group’s sheetfed bulk manufacturing processes, meaning Flint Group will eliminate the substance.

DOMINO PRINTING

SCIENCES has been developing a new digital retrofit module for integration or retrofitting into flexographic presses to offer hybrid printing. Domino said that hybrid presses are cutting costs for converters through just-in-time delivery, shortrun cost efficiency, and waste reduction – they also allow flexo print providers to stay current with market trends and meet the demands of their clients. Domino’s digital retrofit module is expected to provide a lower-cost shortcut process for customers looking to build hybrid flexibility into their flexographic presses.

HEIDELBERG has made an excellent start to its new financial year thanks to the recovery in Asia and growth in the packaging segment. The company has reported stable incoming orders and has registered strong growth in the digital label and packaging printing spaces. Heidelberg’s sales in the first three months of the year (April 1 to June 30, 2023) climbed year-on-year from €530 million ($885.9 million) to €544 million ($909.3 million).

enabling more efficient and streamlined workflows.

Moreover, the system improves product quality, ensuring consistent and precise winding processes. And because of better tension control through its servo technology, it helps to reduce material waste.

ABG global sales director Matt Burton said, “Key to ABG’s leadership in print finishing is our ability to create solutions for the market as it evolves. With the addition of ABG’s non-stop winding technology, label printers will be able to maximise the potential of the V12 press.”

A B Graphic International (ABG) has teamed up with HP Indigo to develop a nonstop winding technology that significantly enhances the automation capabilities for the V12 Digital Press, HP’s flagship narrow-web printer.

The new non-stop unwind and rewinding system has been designed with state-of-

the-art guarding measures, ensuring operator safety and offering operational speeds of up to 120 metres per minute.

According to AGB, the new technology delivers the best tension control in the market, making it highly reliable for various applications. It boosts the productivity of printing presses and converting lines

Total Supply NZ has appointed Gareth McGrail as its new general manager. He joined the company with a vast hospitality background and brought extensive experience in managing sales teams to the role.

McGrail worked across several verticals in New Zealand, focusing on managing teams in Reefton Distilling Co, Sacred Hill Family Vineyards, Johnson & Johnson, Lion and Pernod Ricard New Zealand. “My

background comes from the hospitality industry, which includes senior sales and marketing roles through Lion Breweries and Sacred Hill winery and, more recently, Johnson & Johnson on the consumer side,” said McGrail.

“My focus at Total Supply is to grow our portfolio and continue to expand our market penetration. I have been in hospitality for 20 years, and whilst I really enjoyed my run, getting into something completely new is

HP will demonstrate the HP Indigo V12 Digital Press with ABG’s non-stop winding technology at its stand at the upcoming Labelexpo Europe in Brussels.

Currie Group, the authorised HP and ABG distributor in Australia and New Zealand, is answering all regional enquiries.

a big reason to get out of bed and get energised each day,” concluded McGrail.

Trimatt’s ColourStar AQ V redefines sustainable printing for paper and cardboard packaging. According to the manufacturer, the machine places the profit in food and drink manufacturers’ hands by providing a versatile and economical solution for ecofriendly packaging needs. Its capabilities span various applications, from coffee bags to packing boxes and takeaway food packaging.

Australian equipment manufacturer Trimatt Systems has been awarded a coveted Product Innovation Award at the Melbourne International Coffee Expo (MICE) for its ColourStar AQ industrial digital colour print system.

MICE is Australia’s largest dedicated coffee event showcasing the latest coffee technology, products, and services.

It attracts over 15,000 attendees and connects café owners, roasters, equipment manufacturers, service suppliers and more.

During this year’s 10th expo edition, Trimatt Systems presented its cutting-edge colour digital packaging printing systems, with its ColourStar AQ V receiving the coveted Product Innovation Award for coffee accessories.

Wellington will host this year’s national Wayzgoose, which takes place from November 24-26.

With planning for the event well underway, the Association of Handcraft Printers (AHP), the Association of Bookcrafts (ABC), and the Wellington Print Museum look forward to welcoming participants. Some of the planned activities require pre-registrations. Graham Judd, Inkiana Press owner, says, “The Wayzgoose is open to all who have an interest in the printing.

The weekend’s events include a National Library visit, which offers the chance to view bookcraft treasures from the Alexander Turnbull library (places limited, preregistration required) on the Friday afternoon and Saturday morning. Workshop topics will cover bookbinding and letterpress printing.

A swap meet will take place at the Wellington Centre for Book Arts in Thorndon Quay on the Saturday afternoon, where participants will have the opportunity to buy, sell and swap all things relating to book crafts, letterpress printing and bookbinding and calligraphy. Site visits include a visit to the Type Foundry at Mangaroa and the annual Wayzgoose Dinner will be held on the Saturday night. The word Wayzgoose historically refers to an annual summer dinner or outing held by a printing house for its employees. Some bookbinders believe that the Wayzgoose was held on St Bartholomew’s Day because he was the patron saint of leather workers. The holiday, a break in printing, was traditionally also the day that papermakers took a break from making paper for the printers.”

Trimatt Systems CEO Matt Johnson said, “Securing this award and gaining industry-wide recognition is exhilarating. Our victory can be attributed to the value people place on innovation, coupled with the relatability of supporting a local equipment manufacturer.

“As pioneers in the engineering domain, we spot opportunities, invest considerable effort, channel resources into research and development, and subject our equipment to rigorous testing. It’s an intensive undertaking by the entire team, and the results are evidently remarkable.”

FUJIFILM BUSINESS INNOVATION ASIA PACIFIC has launched new Fiery print servers and workflow software for Revoria Press EC1100, Revoria Press SC180 / SC170 and the ApeosPro C Series, expanding the printers’ capabilities to meet various applications and workflow needs. Sales of the new Fiery print servers have already begun in the region, with customers able to choose between Revoria Flow or GP Controller, Fujifilm Business Innovation proprietary print server technologies, and the Fiery print servers.

EPSON has been selected for inclusion in the FTSE4Good Index Series, a responsible investment (RI) index of FTSE Russell, a London Stock Exchange Group company, in recognition of its ESG initiatives that contribute to social sustainability. Epson aspires to achieve sustainability and enrich communities over the long term. The company sees its inclusion in this index as objective evidence that its efforts to address environmental and social issues have been recognised and that it is a sustainable company.

Flexible Packaging and Label Manufacturers Association (FPLMA) has confirmed that this year’s Forum and Gala Dinner edition is scheduled for the end of August next year in Melbourne.

The association has already started accepting entries from label and packaging converters based in Australia and New Zealand for its awards.

Currie Group, one of the leading suppliers of innovative print and finishing solutions in Australia and New Zealand, has partnered with renowned Pennsylvaniabased post-press finishing industry pioneer B&R Moll.

“With great pride and enthusiasm, Currie Group is now the exclusive representative of B&R Moll, Inc. in Australia and New Zealand. This collaboration brings together two powerhouses in the industry, combining our expertise, passion, and commitment to delivering cutting-edge solutions to our valued customers,” Currie Group said, emphasising that this deal brings together

The annual FPLMA Print Awards, a culmination of FPLMA’s technical conference, recognises excellence in the packaging industry and is an

important way to showcase outstanding work in the field. It represents a celebration of creativity, innovation and technical skill.

FPLMA secretary and treasurer Tony Dalleore said, “The 2024 Print Awards brochure has been distributed, and this year we are pleased to announce that the awards will be carried out in collaboration with the Lithographic Institute of Australia (LIA).

“This approach will signify the start of further collaboration with the LIA and Visual Connections and show a unified approach to all activities held within the scope of both associations.”

The competition is open to all Australian and New Zealand converters for works produced between March 30, 2023 and April 30, 2024. The deadline for all entries is April 30, 2024.

cutting-edge technology and unparalleled service to deliver exceptional results and unlocks limitless possibilities in the world of printing and packaging.

The Moll family has had a rich legacy of innovation and a global reputation for its high-quality post-press finishing equipment for over 40 years. Headquartered in Pennsylvania, US, the company has a European full-service and sales facility in the UK.

B&R Moll’s extensive equipment, which ranges from digital registering, nick-less cutting FlexCut rotary die cutters, and versatile folder-gluers to advanced bindery systems, is designed to streamline operations and maximise productivity. With the company’s state-of-the-art technology, users can achieve precision and excellence in folding, glueing, die-cutting, and more.

Australian Institute of Packaging (AIP) has confirmed the details of the forthcoming Flexible Packaging: Now and Into the Future training course, which will run alongside the Foodtech PackTech expo on September 20 in Auckland.

The course will cover the fundamentals of flexible packaging,

its benefits, how to choose the specific structures to match the product, its performance, marketing challenges and packaging manufacturing.

Additionally, the course will look at

plans for flexible packaging and available recycling options to meet the 2025 National Packaging Targets.

Participants will be able to understand better the benefits of flexible packaging, the manufacturing process, the latest packaging trends and market drivers, as well as the future of flexible films and the changes ahead.

Joe Foster will present the course. As a chief executive officer of Close the Loop Group, he has been heavily involved in the flexible packaging industry for over 35 years with experience in engineering, production, technical, sales and marketing.

All AIP training courses are internationally recognised and approved to attain Certified Packaging Professional (CPP) points towards the global designation.

women in print & sign

Book cloths created from recycled denim jeans or ocean-bound plastics, and paper created from used coffee cups or seaweed number among the specialty stocks that Lower Hutt merchant Paper Source procures for the print, packaging, and design communities.

In 1999, Lyn Sayers established Paper Source in the suburb of Alicetown. Dawn and Tony Field took over the firm in 2011. After Tony passed away in 2018, Janine and Dawn continued to grow the boutique family business, which consists of four additional staff in Lower Hutt and one South Island-based sales consultant.

Janine, now general manager, says Paper Source strives to offer specialty premium stocks that are not readily available in the

country, and which are provided with a social and environmental focus whenever possible. She says, “We are dedicated to doing our bit as a business for the future; thinking big, but making continuous, small changes to improve our impact.”

In this vein, she highlights a rewarding attendance at the recent G.F Smith Global Conference in London. G.F Smith, Paper Source’s paper supplying partner, announced it had achieved B Corp-certification. She adds, “For over a century, G.F Smith has striven to build a business with purpose – one that looks after and listens to its people and its customers, has a positive effect on its community and takes responsibility for its impact on the environment.”

At that event, the host introduced Paper Source to G F Smith’s latest environmentally friendly paper products, provided through a partnership with all natural packaging solutions Notpla, whose mission is ‘to make packaging disappear’. Janine explains, “Notpla is also the name of the material the firm creates from seaweed and plants. It is non-chemically modified, polysaccharide

based, and classified as a natural, organic substance by European Union law. Just like a fruit peel, Notpla can claim to be biodegradable and home compostable.

Waste Free World. In addition to Notpla Ooho, an edible bubble designed to replace single-use plastic packaging for liquids, Notpla Seaweed Paper is also transforming a wasted resource. After extracting the gelatinous part of seaweed, what’s left behind are fibres and biomass that can be turned into paper, enabling a new circular way of using the entire seaweed. Notpla Seaweed Paper is visually distinct, tactile, fully printable and converts beautifully, meaning it is relevant to many secondary packaging applications.”

Representing suppliers from around the globe, including G.F Smith, Winter & Company and van Heek Textiles, Paper Source has built up a wide portfolio of stocks. Janine says, “This includes perhaps the largest range of coloured paper in New Zealand.

“In addition to the 55 colours of Colorplan that we carry in two weights, we stock Extract Paper in ten colours and two weights, which has been created from recycled, single-use coffee cups. All stocks are available with 25 embossed textures and in other weights up to 2100gsm by special order.

“We distribute a large range of stationery raw materials, bookbinding and print finishing products as well as offering a full range of services tailored to help our customers realise their creative ambitions.”

Other offerings include:

• Cut-to-size and exact sheet ordering.

• Duplexing to heavy card stocks.

• Wristbands.

• Envelopes and presentation folders.

• Archival papers.

• Wax coating for corrugated board.

To ensure Paper Source can provide the full range of book cloths available, the company brings stocks in specifically to order, including new products such as Ecojeans and Toile Ocean.

Janine says, “Ecojeans, made from eco-friendly viscose and lyocell, gets its distinctive look from recycled denim yarns. Worn out jeans, donated through the #hackyourjeans initiative, are shredded to create raw materials for the yarn.

“Clients love the randomly scattered flocks from recycled denim throughout the material, making every metre unique and embracing the beauty of imperfection.

“The combination of dope-dyed yarns with viscose creates a contemporary multi-tonal effect, perfect for modern books, stationery, and packaging. It also contributes to the reduction of ecological impact, lined with 90 per cent recycled, Forest Stewardship-Council certified paper, available in eight colours.”

Winter & Company has developed Toile Ocean, collaborating with Swiss startup #tide ocean SA. This the first book cloth

to contain yarns derived from what would have been ocean bound plastic. Janine adds, “With the assistance of local communities in Southeast Asia, this initiative collects plastic waste on islands, beaches along coastlines and uncontrolled landfills. The plastic is compressed into granules using a mechanical, awardwinning process and finally spun into yarn.

“Toile Ocean, woven from 100 per cent recycled plastic waste and coated with water-based acrylic offers high durability, and the naturally mottled book cover fabric has a very high-quality touch and feel. Available by special order in six natural colours, it can be offset printed and finished with screen printing and foil stamping. Applications include book

covers, premium packaging, or menu cards as well as hang tags, carrier bags or stationery items.”

Each year, humans dump eight million tonnes of plastic into the world’s oceans. She says, “In using this resource that already exists, #tide ocean and Winter & Company are closing the cycle of plastic production and saving on the use of fossil fuels. And the highlight: for every metre sold, one per cent of the turnover goes to clean water projects.”

As a strong supporter and ongoing sponsor of the Pride In Print Awards, Paper Source’s stocks have made their mark.

Two of the most notable successes were:

• The 2020 Supreme Award along with the Paper & Board Packaging Category Award. Logick Print & Graphics produced the Bee NZ Premium Packaging Manuka Honey using Extract Flint 380gsm Coltskin Emboss, Colorplan Racing Green Labels. and Extract Moon 130gsm stocks.

• The 2019 Letterpress Process Award.

Laserfoil Design and Print produced the Filigree Business Cards using Colorplan Racing Green 270gsm stock.

Despite targeting the procurement of premium, specialty stocks, Paper Source does not feel driven to pursue the latest in technology to facilitate its operations. Janine says, “We maintain a more traditional approach to processes and equipment, using a Heidelberg from the 1950s for our in-house die cutting. If it ain’t broke, we keep using it. While we do embrace new technologies and advances in printing and packaging, we are seeing a resurgence in traditional methods being used in some exciting ways.”

Looking at the wider New Zealand print and packaging industry, she adds, “I hope the trend continues for New Zealand companies to produce print and packaging here rather than overseas.”

She concludes, “Along with our suppliers, Paper Source’s aim is to incorporate both social and environmental goals to build a better world.”

Changes to Health and Safety need our attention.

could have debilitating side effects for both the employees and the business.

Our risk management assessments moved from machinery and processes to workplace setups and people and included things we had never dealt with before like social distancing, hygiene and vaccinations. This was new territory for everyone involved and there was no single correct conclusion, a fact that has been borne out by the many cases that have gone through the Employment Relations Authority in the last 12 months with employees challenging dismissals based on these risk assessments.

RUTH COBB

Every now and then I feel the need to write about this old chestnut and remind everyone of the importance of having a robust Health and Safety system operating in their business. I last wrote about it five years ago, so it is worthwhile having this discussion as there have been some quite significant shifts in this space.

The wellbeing of your employees, contractors and stakeholders is vital to the success of your business and requires regular focus. Employees spend a significant portion of their lives within the confines of the workplace so their physical and mental wellbeing will directly impact their performance and job satisfaction.

In 2015 when the Health and Safety at Work Act came into law, it moved health and safety to a risk-based platform which requires identifying the risk factors that have the potential to cause harm and determining appropriate ways to either

eliminate the hazard or control the risk to minimise harm.

Since then, we have worked with many of our members to help them create health and safety programmes inside their businesses and the work that has been done in this space by the industry is admirable and we see very few businesses hiding behind the ‘common sense’ defence now.

But one of the biggest changes we have seen in this space since the change of legislation is a move to focusing on Health and Safety as two individual strategies, not one. It is important that both are given the attention they need to ensure this function of the business is being properly fulfilled.

For many years the focus had been solely on the Safety part of the equation – taking steps to minimise the risks to employees via the places they work and the processes they follow. This is only half of the Health and Safety equation. Covid-19 and its after-effects have swung the Health part of the equation to the forefront.

The term wellness has gained momentum in relation to workplaces and for the first couple of years of Covid, this focused mainly on the physical aspects of health. This ensured there were steps in place to protect our workforce from a virus that

Following on from these initial, but still mainly physical, risk factors, the aspect that has come to light later in the piece is mental health. Until now this has largely been the domain of employee assistance programmes in the larger organisations and little to no assistance in the smaller ones, but the ability to push these issues to third parties without any involvement by the employer has been reduced as recognition of employee wellbeing has become more widely accepted.

As employers you are required to take a more active approach to Health and Wellbeing and be aware of issues that could require adjustments to how you operate. While it is difficult to run a risk assessment for mental wellbeing for every individual staff member, some of the more straightforward things you can put in place that will help both employers and employees are:

• Set clear, achievable tasks and goals

• Make sure employees have the skills to do their jobs properly

• Be aware of workloads and discuss challenges where they appear problematic

• Be aware of the signs of stress among workers

• Have clear policies and procedures to deal with unacceptable behaviour

As an employer, you can set expectations and actively manage these, but supporting your employee’s wellbeing will help create a culture of trust in the workplace that will produce better outcomes.

As always, PrintNZ is here to help our members understand and manage both parts of the Health and Safety equation.

Wedderburn has operated in New Zealand for 33 years and in Australia for more than 125 years. The family-owned group, collectively employing more than 300 people, has earned a reputation for quality and integrity in everything it does.

Tony Reid, label production manager at Wedderburn New Zealand, says, “With a foundation in metrology, Wedderburn has enjoyed a somewhat natural progression into weighing, labelling and automated packaging. Our label manufacturing capabilities have grown from strength to strength alongside that progression.

“We are in the fortunate position to offer both long and short run printing, which is ideal for the New Zealand market. For many years, our label customers were predominantly in the food sector but more recently we have expanded into a much broader client base that includes industrial

manufacturers and wholesalers, household and personal care producers, logistics and distribution, and horticulture.”

In April this year, Wedderburn installed a new HP Indigo 6K Digital Press and a new A B Graphic International (ABG) Digicon Series 3 finishing system. Tony says, “We are seeing real growth in craft and boutique markets and with that comes a growing demand for short runs, label personalisation and batching data being included in custom labels. The addition of our new HP Indigo 6K Digital Press will help us serve that market even better than we have been doing.

“This is an entirely new machine for Wedderburn Labels. As mentioned, we have seen a real uptake in requests for short run, high-end and personalised custom labels. The HP Indigo 6K Digital Press enables us to serve these customers at a whole new level. It gives us flexibility

to compete with the smaller and more boutique print runs.

“The print quality is impeccable and is much sharper than conventional flexo label printing. We have printed a lot of promo stuff to showcase the press to some of our clients. We have tried silver, fluorescents, and whites, and we have printed on all our range of substrates, from standard face stocks, DT stocks, Silver PP to Clear PP for different effects. Clients like something that is different from the rest.

“So far, we have not run any work that would suit Enhanced Productivity Mode, but we have earmarked a few jobs for that process.

“We use the ILP unit on every job we print to improve the transfer and adhesion of HP Indigo ElectroInks. The intelligent colour automation with inline spectrophotometer and a shorter colour

calibration makes it fast and easy to hit brand colours with extreme accuracy, consistency, and repeatability from the first print to the last.

“The HP Indigo One-Shot Color technology for colour registration feature means we have no registration issues as all the colour separations are transferred simultaneously to the blanket in one pass for accurate and repeatable registration.

“We use PrintOSX Production Pro all the time with the DFE (Digital Front End). It enables us to monitor and drive continuous operational improvements. We are starting to use the HP SmartStream feature that comes with the press; we have run a few VDP (variable data print) jobs; and we are also using a colour correction programme, HP Colour Pilot.”

Choosing its first ABG Digicon Series 3 as the finishing system to complement the HP Indigo 6K Digital Press made good sense to the Wedderburn team. Tony says, “We like the concept of the modular finishing unit. We can add more features to it in the future, especially if the market dictates. Plus, we know ABG as we have some of their gear already and it is good equipment.

“We use it for finishing all the work that comes off the HP Indigo 6K Digital Press. This is a very versatile machine, and it has finished all that work with ease, no matter how complex the job.

We take advantage of the automation features that we have on the ABG Digicon Series 3. These include a servo-driven full rotary quick change flexo print unit; a semi-rotary die cutting station; an over lamination unit; I- Score, which is an auto-set back scorer; and an upper web advance unit. It also offers super easy user-friendly software.”

“We have seen a real uptake in requests for short run, high-end and personalised custom labels. The HP Indigo 6K Digital Press enables us to serve these customers at a whole new level. It gives us flexibility to compete with the smaller and more boutique print runs.”

Tony Reid, label production manager at WedderburnWith 32 years’ industry experience, predominantly in commercial web offset and heatset, Tony is enjoying his more recent move to full on labels production.

He says, “I moved to New Zealand in 2005 to take up a shift supervisor position at APN in Manukau. After six years, I moved to Ovato, formerly PMP, as the print manager, where I stayed for 12 years until they closed the heatset

division of the business in April 2022. Looking for a new challenge but wanting to stay in the industry, I accepted this role at Wedderburn.”

Currie Group has supported Wedderburn for the last 10 years, since the company installed an eight-unit OMET X4 press. Tony says, “I have gotten to know Craig Paul, country manager - NZ Currie Group, and the team over the past year but Vernon Herbert, our NZ managing director, has known Craig for a long time.

“Currie Group has always been there for Wedderburn: for all our training needs, press upgrades and machine breakdown support. We have HP and ABG trained staff inhouse who perform all press maintenance.”

Mark Daws, director - Labels & Packaging ANZ Currie Group says, “We are honoured to be the partner of choice on this exciting journey for Wedderburn. Vernon, Tony and their team have embraced the digital mindset head-on and Currie Group have already rolled out local Business Development training to their Sales and Production teams.

He concludes, “The complementary tools Wedderburn now has to offer its customer base will give them not only production gains but also a competitive edge. We wish them all the success as they grow on this journey.”

The latest model iteration in the 6000 series of presses, the HP Indigo 6K Digital Press, seven-colour machine delivers up to 97 per cent of the Pantone spectrum. Among its key inks, the new premium high opacity white ink offers numerous new applications such as print sleeve applications. The powerful RIP is five times faster than the previous model.

Offering a range of modes, it prints at speeds of up to 30 metres per minute

in four-colour mode; up to 40 metres per minute in Enhanced Productivity Mode; and up to 60 metres per minute in one or two-colour mode. Special inks available for use include Premium White for Sleeves, Spot Colours, Silver, Fluorescent Pink, Green, Yellow and Orange, Transparent, Digital Matte, Invisible Yellow and Red, plus two White ink cans on press.

Its advanced features include Enhanced Productivity Mode, Inline Priming

Unit, Intelligent colour automation (media fingerprint with new inline spectrophotometer), HP Indigo OneShot Color technology for perfect colour registration, and PrintOSX Production Pro, the world’s first cloud integrated Digital Front End.

Mark Daws adds, “With the HP Indigo 6K, any colour can be reached consistently through its unmatched versatility of media, inks, and applications. Its combination of tools, support, technical breakthroughs, and continuous improvement add up to a proven formula of long-term success, with an installed base of thousands of presses worldwide.”

ABG’s flagship Digicon Series 3 offers a modular design so you can tailor this finishing system to suit your requirements.

It offers a choice of web widths 330mm and 430mm. You can use it roll-to-roll or roll-to-sheet. Incorporating intuitive controls and low-cost maintenance, the Digicon Series 3 keeps pace, inline, with the latest digital print engines.

Innovations and options include:

• Full automation enables quick job changeovers and simple prepress setups.

• Reliability using high quality components, intelligently designed for consistent production.

• Intelligence: Digicon Series 3 integrates with any Management Information System (MIS)

• Multiple web widths available at two different web widths: 330mm and 430mm

• Modularity simple to configure modules and options to allow you to have the machine you need.

• Flexibility working across a range of print applications, from roll to roll and

roll to sheet, foil, embossing to screen varnish; its screen module runs at twice the speed of its predecessor.

• Foil and embossing the Big Foot 50 Tonne Hot Foil & Embossing features applies 50 tonnes of pressure allowing foil stamping across and along the web.

• Fast track die a semi-rotary die that runs up to 180 metres per minute.

• Automatic die plate mounting and removal every time you change jobs, flexible dies are mounted accurately and precisely using high resolution cameras.

Mel says, “The Trimatt Systems cup printer empowers packaging companies of all sizes to expand their offerings and meet the growing demand for personalised cups. Whether for cafes, restaurants, or corporate events, customised paper cups have become a powerful marketing tool, allowing businesses to enhance brand visibility and engage with their target audience effectively.

Recently, Trimatt Systems took the opportunity to present its cutting edge colour digital packaging printing systems at the 10th Melbourne International Coffee Expo (MICE).

Held at the Melbourne Convention and Exhibition Centre, the show attracted more than 10, 200 visitors. First-time exhibitor Trimatt scored a major success with its ColourStar AQ V receiving a Product Innovation Award for coffee accessories.

The company says its Trimatt ColourStar AQ V redefines sustainable printing for paper and cardboard packaging, placing the profit in food and drink manufacturers’ hands by providing a versatile and economic solution for eco-friendly packaging needs. Its capabilities span various applications, from coffee bags to packing boxes, to take away food packaging.

Matt Johnson, chief executive officer Trimatt, says, “Securing this award and gaining industry-wide recognition is an exhilarating feat. Our victory can be attributed to the value people place on innovation, coupled with the relatability of supporting a local equipment manufacturer.

“As pioneers in the engineering domain, we spot opportunities, invest considerable effort, channel resources into research and development, and subject our equipment to rigorous testing. It is an intensive undertaking by the entire team, and the results are evidently remarkable.”

Trimatt’s success at the exhibition reflects its team’s hard work and smart strategy. Mel McFarlane, marketing coordinator at Trimatt, adds, “Participation in the event

has been an overwhelming triumph for Trimatt, with substantial market interest. This recognition stands as a testament to the team's alignment with the right course of action.”

Among the growing number of companies installing the Trimatt ColourStar AQ is MJ Goods located in Perth, Australia. Owners Matt and Julie Marchese say the addition of the eco-friendly and economic packaging print system means they can support the expanding requests of their customers.

MJ Goods provides a broad range of products and services, including food packaging, coffee cups, bags, bottles, shop suppliers and catering boxes. Matt Marchese says, “We have a range of clients in varied fields that would definitely like to customise products they use.

“With the capabilities the Trimatt ColourStar AQ gives us, we are expanding what we do for our clients. I’m almost certainly looking at adding another system because I know the demand is there.”

Trimatt also exhibited at this year’s foodpro, Australia’s largest, and longest running, trade event dedicated to food production, manufacturing and distribution.

At foodpro, Trimatt unveiled the Trimatt CupPro 600, aimed at the cup customisation market. The new printer enables takeaway, coffee, and packaging companies to enter the short run, on demand market, the opportunity at an entry level price point.

“With its compact one square metre footprint, the CupPro 600 offers packaging companies a cost-effective and efficient solution for custom branding on biodegradable paper cups. Utilising 300DPI digital imaging technology, two spot colour print heads are adopted for the printing of words, QR codes and simple logos with a throughput of 1500 cups per hour printed and stacked.”

Matt Marchese also commissioned Trimatt, in close consultation, to create the CupPro 600. He expects to serve a substantial short run custom printing market in Perth with his new machine. Expressing his eagerness to witness the new machine in action, he flew to Melbourne from Perth for its debut appearance.

Matt Johnson is excited for the possibilities the new printer offers the industry and the environment. He says, “Our new biodegradable cup printer represents a significant leap forward in cup customisation technology.

“We take pride in providing packaging companies with an efficient and eco-friendly solution that meets the increasing consumer demand for sustainable packaging options at an accessible price point. By enabling packaging companies to offer custom branding on biodegradable paper cups, we assist them in attracting and retaining customers, unlocking new revenue streams, and contributing to a greener Australia and New Zealand.”

Peter adds, “The Screen PlateRite

PTR8600NII-S helps us to create capacity for future growth. We have seen significant year on year sales growth in the A2 and A1 offset print category. Clients love the print quality and fast turnarounds produced by the Komori and Ryobi presses that both have HUV instant drying. One of the fastest growing sectors is our print for other trade partners.”

Screen has worked to make its latest CTP solutions gentler on the environment, assessing the environmental impact of all its products as a form of design review. The company says it has developed the PlateRite 8600N series with the goals of minimising energy use and environmental impact while maximising safety. It offers these features:

Tauranga-based Kale Print offers a comprehensive range of printing products and services. The Bay of Plenty’s largest commercial print company has a well-deserved reputation for producing quality print on time.

Part of its success lies in its willingness to invest in the best technology available to help Kale Print in delivering to its broad customer base.

Recently, Kale Print installed a Screen PlateRite PTR8600NII-S eight-page thermal CTP, supplied through Fujifilm New Zealand.

Peter Lloyd, general manager at Kale Print sees the Screen PlateRite PTR8600NII-S helping the company with its production. He says, “The Screen PlateRite PTR8600NII-S will provide improved reliability, quality, and productivity with its capacity to process up to 32 plates per hour.”

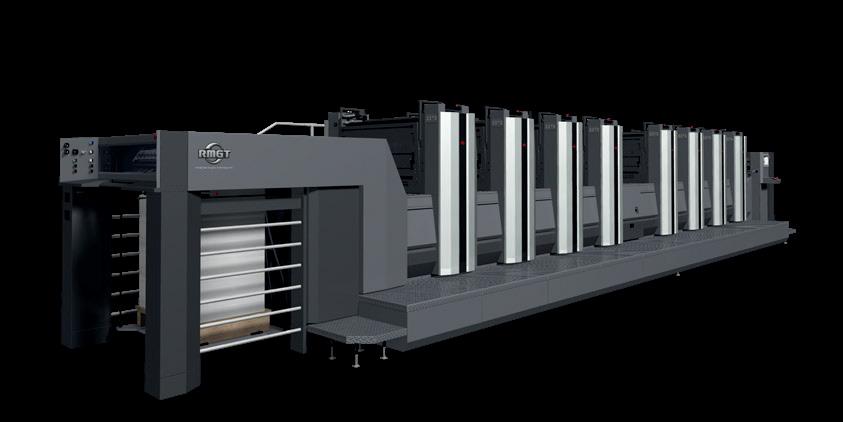

Kale Print’s investment demonstrates the ongoing profitability of offset printing for companies prepared to roll up their sleeves and get stuck in. With a fivecolour Komori press and the country’s first RMGT 920ST-4 LED-UV press, Kale Print needed a versatile CTP that could keep these presses fed.

Part of the equation is its ability to handle 32 plates per hour speed. It is equipped with high-output fibre laser diode exposure heads. These heads work with proprietary clamp technologies and an auto-balance mechanism to enable stable, high-speed exposure.

Another factor is the Screen PlateRite PTR8600NII-S’s capability to handle diverse plate sizes on any press. Plate sizes range from a minimum of 304mm x 370mm up to 1,160mm x 940mm.

Screen offers two options for automatic plate loading. The MA-L8900 multicassette autoloader comes standard with three plate cassettes (up to five as an option) and full automation of both plate supply and cassette switching. Each cassette holds up to 120 plates for a maximum of 600 plates stored in the autoloader. Even if different plate sizes are loaded into separate cassettes, the autoloader flexibly switches between the cassettes as required.

The SA-L8900 single-cassette autoloader features a single cassette that holds up to 120 plates, as well as automatic detection and removal of interleaf paper. Its transport system only contacts the rear side of a plate, preventing damage to the sensitive emulsion side.

• Energy use during operation reduced by up to 60 per cent.

• A power-saving mode allows energy savings during idling.

• Energy use during standby reduced by up to 73 per cent, when using power-saving mode.

• All models are compatible with chemical-less plates from a range of manufacturers.

• The use of a registration punch-less system cuts running costs.

In addition, Fujifilm’s new Superia ZX processless plate offers fast on press development, higher durability, robust scratch-resistance and better visibility thanks to several new and innovative technologies. Fujifilm calls it “strong, robust with excellent image visibility”.

Peter adds, “This supports our carbon reduction goals, especially our Toitū carbon reduce programme through lower energy use. In addition, the Screen PlateRite PTR8600NII-S uses no chemicals in plate production. It is better for the environment and our operators.”

Stephen Hodson, director and general manager of Fujifilm New Zealand, says, “We are pleased to partner with Kale Print in bringing the new Screen PlateRite PTR8600NII-S to the market. Its speed, quality, and environmental features mark it as a vital tool in today’s offset press rooms.”

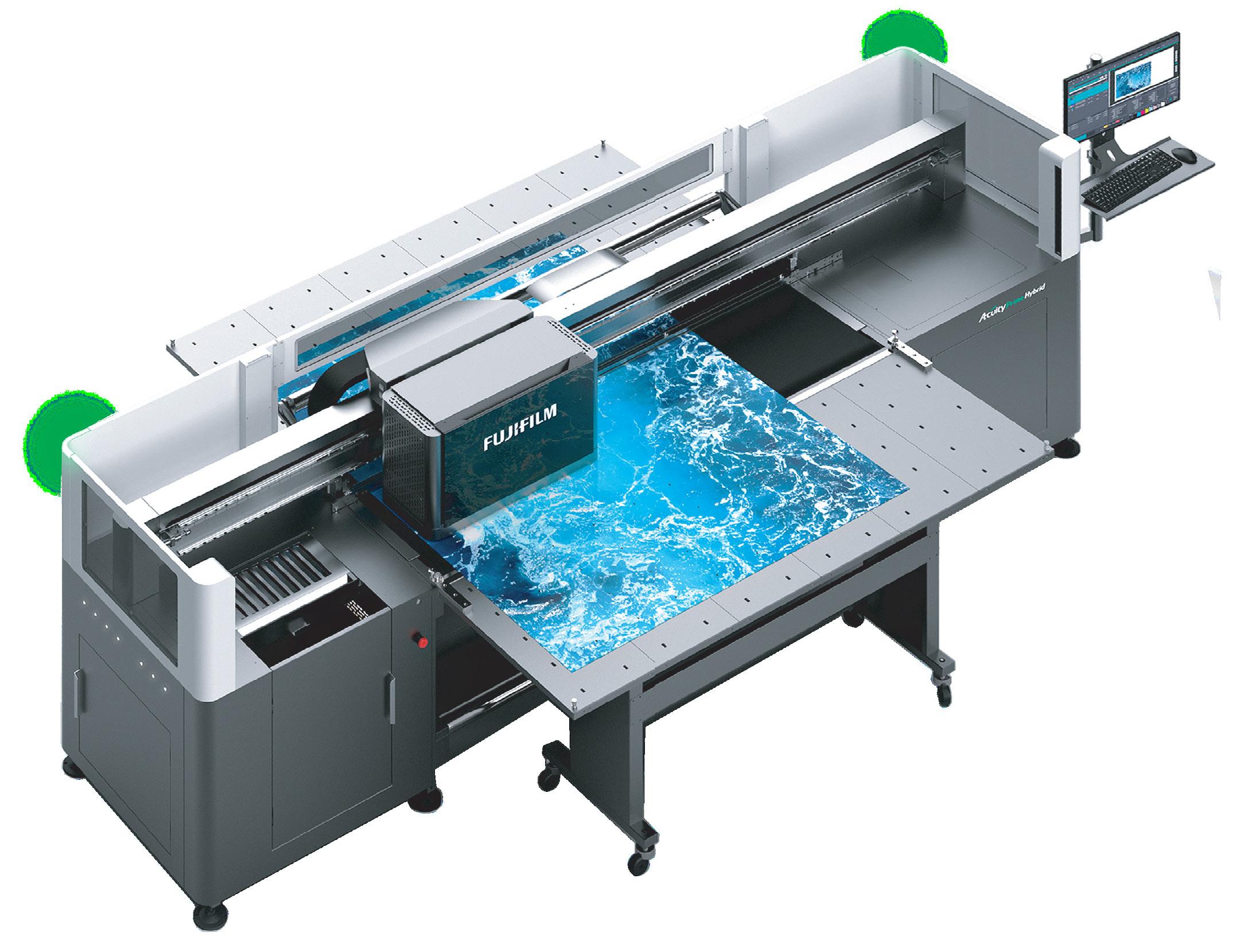

Introducing the new Acuity Prime Hybrid printer from Fujifilm – embodying their innovative 'blueprint for wide format'. The Acuity Prime Hybrid is a mid-range LED UV wide format hybrid printer capable of printing on both rigid and roll media. The design of the printer is based on the award-winning Acuity Prime.

As a flatbed, the Acuity Prime Hybrid handles up to 2m-wide substrates, up to 51mm thick. Along with a 4 zone vacuum system, automatic registrations pins it can produce print at speeds up to 141 m2/hr. The roll-fed can be setup as single or multi-roll options.

The Acuity Prime Hybrid can be configured with up to 7 channels, with CMYK as standard, and optional White, Clear and Primer, and produces stunning quality print. The ink is Greenguard Gold certified for eco-friendly wallpaper and more. Media variety meets versatility, satisfying printers working across a wide range of applications like Dibond, acrylic, and beyond. The Acuity Prime Hybrid echoes the success of Acuity Prime, upholding exceptional quality without compromise.

For more information contact one of the team: Cary Rawson - cary.rawson@fujifilm.com – 021 240 7547

Scotty Martin - scotty.martin@fujifilm.com – 021 645 096

• Craig Hutchinson - craig.hutchinson@fujifilm.com – 021 335 986

• Todd Powell - todd.powell@fujifilm.com – 021 244 8661

design systems. Anita says, “We wanted to replicate what we were outsourcing and really own the process from design to print.”

The ApeosPro C750 copies, prints, and faxes with up to 75 pages per minute in 2400 x 2400 dpi colour. It handles stock from 52 to 350 grams per square metre, and up to 330 x 1300mm in size and is suitable for creating a wide range of marketing outputs rapidly and efficiently with full colour management and imposition. The machine’s a finisher offers three-knife trim.

Anita says, “It’s a great machine. The print quality is second to none, and it only took a few hours to learn how to drive it. We are reaping positive feedback from customers and operating at a level truly in line with Indevin Group’s industry leadership.”

The busy marketing department responsible for producing promotional items for wine brand Villa Maria has welcomed a new team member on board, brightening things up, accelerating productivity, adding a dash of colour, and even improving office morale.

The Fujifilm ApeosPro C750 production printer has quickly proven a reliable and popular performer, taking on a variety of tasks without hesitation or hassle. Bringing small-run print jobs in-house has seen the marketing department increase its efficiency, save costs, and reduce time-to-market for a multitude of custom outputs including trade support material like table cards, tasting mats, beverage lists, and more.

Indevin Group, a leading producer of high-quality wines, owns the Villa Maria brand, which began over 60 years ago. Indevin’s marketing team supports multiple channels and activity across a broad portfolio covering global markets, with activities including design, brand, digital, communications, activation, and customer marketing.

Anita Niven, Indevin Group Design Studio manager, explains, “We create

efficiencies and streamline processes tailored for each market. The design team works on all collateral including photoshoots, new product development, and activations from a full design studio.

“We also partner directly with our domestic New Zealand sales team, and we are integral to Indevin’s corporate and internal functions. There is never a dull moment, particularly when design briefs regularly come in from across the world.”

The marketing department has substantial print and document production requirements. Anita says, “We produce on-premises trade support material including table cards, tasting mats, table talkers, beverage lists and wine of the month promotions. We also create corporate stationery, including business cards, compliments slips and training manuals.”

With a move to modern offices, the marketing team had its eye on bringing print in-house. It needed an easily controlled complete document management solution which would readily integrate with existing technology and

As the prints have rolled out from the ApeosPro C750, the wider team recognised a transformation in the design operations. Anita says, “As design collateral arrives in key markets, we’ve received positive feedback on fast turnaround times, while enjoying lower costs, and improved efficiency. So far, it’s been glowing feedback, and we hope to increase our in-house printing capabilities.

“Instead of sinking time into briefing suppliers, partners and doubling up on communication, we’re designing or focusing on quality control. Printing in house makes so much business sense, not just from a brand point of view, but managing our brand guidelines, by consistently sensor checking our brand colours are printing accurately, not to mention the cost savings over the year that can now be better spent throughout the entire business.”

Anita points out that the Fujifilm ApeosPro C750 allows the team to be flexible, pragmatic and provide a real advantage for all its customers.

It holds promise for great things to come. She adds, “Watch this space as my team learns more of the device’s capabilities, including on a new campaign in September. Keep your eyes peeled for a beautiful new creative from Villa Maria across multiple printed touchpoints, all done on our ApeosPro C750.”

High performance multifunction printers that are perfect for creating beautiful, professional output quality in-house promotional material.

Find out how to accelerate your business at: www.fujifilm.com.fbnz

The new banner feed tray with improved registration also facilitates in-line stapling of A4 landscape brochures.

“We have a large variable data merge job that requires double perforation, with the need to maintain accurate address postcodes. Previously, this job would traverse three departments. With the AccurioPress, we inputted the addresses, printed, performed double perforation, and trimmed to A4 seamlessly.

In 1935, one of New Zealand’s most influential literary figures, Denis Glover, established Caxton Press with his business partner John Drew, seeking to publish the works of New Zealand authors. In its time as the most important publisher of creative writing in New Zealand, Glover lavished special care on the typography and printing.

Since then, Caxton has evolved into a key player in Aotearoa’s commercial print industry, retaining Glover’s dedication to quality printing. Rooted in a steadfast dedication to its skilled, professional, and innovative team, the company upholds its ethos of “Design and Print Excellence”.

Mindful of its 88-year legacy, Caxton has transformed into a modern commercial printer that takes pride in eco-friendly practices and cutting-edge technology to enhance its print solutions and service quality.

In its pursuit of maintaining the quality of print and services that its clients expect, Caxton continuously explores emerging technologies. Among its recent investments, the Konica Minolta AccurioPress C14000 caught the attention of Janice Page, Caxton’s general manager, right from the outset.

She recalls, “After witnessing a demonstration of the AccurioPress

C14000 at a print expo, we were greatly impressed by several innovative features. Coincidentally, this was during our search for a new production printer.”

The installation process went smoothly, with Caxton’s team swiftly returning to full production following a brief learning phase. This seamless transition can be attributed to the expertise of Konica’s knowledgeable team, making the entire process effortless.

The new equipment significantly enhances the company’s digital print production efficiency, featuring builtin automated print technologies that reduce turnaround times. It offers a print resolution of up to 3,600dpi x 2,400 dpi and speeds of up to 140 pages per minute. However, Janice highlights that the print quality truly stood out for Caxton.

“Many of our clients are professional photographers and artists who are highly discerning about print quality. The auto inspection and IQ technology instil added confidence in our ability to achieve consistent colour matching across print runs and reprints in the future.”

Beyond quality and speed, the Konica Minolta AccurioPress C14000’s inline creaser, perforation unit, and trimmer mark a significant step towards automating Caxton’s digital department.

“This advancement in automation reduces manual steps, the potential for errors, and overall processing time. The same applies to various items such as business cards, DLE sizes, and folded greeting cards, from printing to delivery.”

She also expresses her admiration for the Flux software, which encompasses imposition, user-friendly variable data merging, and the capability to export high-resolution vector PDFs.

The new press also resolves a crucial challenge for Caxton. Digital toner can appear glossier on coated stocks because it rests atop the sheet. However, Caxton has clients seeking a more matte finish.

Janice explains, “Specific jobs call for a matte appearance. The AccurioPress has fulfilled this requirement for us. We can easily adjust settings to enhance or reduce the overall glossy finish of the print, a feat that was not as easily achievable in the past.”

She praises the support staff at Konica Minolta, with a special mention of Rebecca and Steve, who provide consistent expertise, advice, and creative solutions, regardless of the complexity. Their friendly and helpful approach exemplifies a strong team effort.

She concludes, “Considering all the benefits, it’s no surprise that we were captivated by this machine upon witnessing it in action. Yet, I have confidence that we will continue to uncover even more features that address challenges we’ve encountered in the past.”

Caxtonstrengthens its commitment to design and printing excellence, investing in a Konica Minolta AccurioPress C14000. Janice Page, general manager at Caxton with Scott Williams, digital print manager at Caxton

The digital revolution continues with the highly evolved AccurioPress C14000 series, designed to ensure you never stop printing. These high speed digital colour presses offer next level automation for ultra-efficient, high volume colour printing. Packed with an array of impressive features, powerful inline finishing options for high pr oductivity and with in-built technology, they offer unparalleled quality and consistency print after print.

To rethink efficiency, simply visit: konicaminolta.co.nz/AccurioPressC14000series

Addressing the challenge of securing important information is a constant struggle. As we work alongside a virtual team, we must implement strong protections to safeguard customer data. Additionally, we know that even digital beings require regular maintenance and improvements. Neglecting to stay updated with the latest advancements could render them obsolete and less effective.

In a world defined by lightning-fast technological progress and everchanging business environments, companies worldwide constantly seek new methods to boost productivity and slash expenses.

Enter the potential life changing trend of digital humans – the intelligent, cost-effective alternative to conventional staff. As enterprises strive to maintain seamless operations, these lifelike virtual beings offer a blend of cuttingedge technology and financial savvy. But should you trust the future and embrace the power of a virtual workforce to revolutionise your business?

Digital humans, often powered by artificial intelligence (AI) and natural language processing (NLP), are sophisticated virtual entities designed to replicate human interactions and behaviours. They can engage in conversations, understand emotions (to a degree), and perform tasks traditionally assigned to human employees. With the ability to operate around the clock without breaks, digital humans hold the promise of uninterrupted service delivery, a critical advantage in today’s global business landscape.

One of the key factors driving the adoption of digital humans is their unparalleled reliability. These virtual entities are immune to human limitations, such as fatigue, mood swings, or personal biases. As a result, businesses can ensure consistent and standardised customer interactions, potentially improving customer satisfaction. For instance, in customer support roles, digital humans can provide accurate and uniform responses to frequently asked questions, ensuring a high level of service consistency that human agents might struggle to maintain.

As anyone who employs staff knows, the financial implications of maintaining a workforce are substantial. Businesses must consider salaries, benefits, training, and infrastructure expenses. Digital humans offer an appealing alternative by significantly reducing these costs. Once developed and deployed, the operational expenses associated with virtual employees are comparatively lower than their human counterparts. Additionally, the scalability of digital humans enables businesses to handle increased workloads without proportionally increasing expenses, making them an attractive proposition for companies of all sizes.

Businesses can design virtual beings to embody specific brand identities and personas, tailoring them to match the company’s values and culture. This level of customisation enables organisations to provide distinctive experiences to their customers, fostering a stronger emotional connection.

While digital humans offer cost savings and reliability advantages, it is only fair to shed light on the other side of the coin. As with any innovation, there are hurdles and drawbacks that businesses must carefully analyse before showing their human workforce the exit.

Although digital humans may be costefficient in the long term, the initial setup expenses could be a significant roadblock. Anyone who has integrated multiple systems will cringe at the thought of incorporating virtual humans into current systems, undeniably a complex and potentially pricey endeavour. Cracking the code of human emotion and empathy also poses a formidable challenge as virtual entities aim to grasp the intricacies of nuanced interactions.

As we integrate digital entities, ethical considerations will arise, especially regarding sincere and transparent customer interactions. It will be crucial for businesses to proactively establish the true identity of virtual entities, preventing any misunderstandings that may make customers think they are engaging with real people.

Regardless of the hurdles, numerous industries have already embraced digital humans. In sectors such as healthcare, digital humans act as personalised health assistants, monitoring patients’ conditions, providing medication reminders, and even offering emotional support. In financial services, they facilitate self-service banking and provide investment advice. Retail businesses employ digital humans to assist customers in making purchase decisions and navigating online stores. With each successful implementation, the value of digital humans as reliable and cost-effective assets becomes increasingly evident.

The rise of digital humans represents a pivotal moment in the evolution of the workforce, but we must enter cautiously and thoughtfully. Our technological advances have enabled us to create remarkable digital solutions that drive our businesses’ efficiency, reliability, and growth. However, should we fail to implement these technologies responsibly, then any gains made may quickly dissipate.

Let’s strive to ensure that any decisions we make in this space are made with careful consideration and measured planning for success, enabling us to reap the full benefits of this exciting evolution. Let’s start planning – cautiously!

Mick has spent the past decade building printIQ into one of the most recognised software brands in the printing industry, and with over four decades of experience, Mick truly has ink in his veins.

Warranty – a comprehensive manufacturer’s warranty is standard.

New features on the printers include LED with multiple colours, ethernet, storage space, 1.8 litre waste ink cartridge, sheet cut function, detachable media clamps, new media holder, new front-loading lever, front media loading, and an automatic suction fan.

Roland DG has launched the BN2-20 and BN2-20A desktop inkjet printer cutters, growing the VersaSTUDIO product range to four desktop models.

Aarque supplies Roland DG solutions in New Zealand.

Since launching the VersaSTUDIO BN series in 2011, Roland DG has sold more than 25,000 units worldwide. The new printers build on the success of the original models as compact, easy-to-use, affordable desktop products.

With broad applications including startups, shifting outsourced production in-house, and educational settings, the new BN2 series offers the choice of two powerful eco-solvent desktop devices that use the same high definition print heads, eco-solvent inks, and cutting technology as its wide format printers for outstanding print quality and precision contour cutting.

Customers can choose from two 51cm (20inch) models, the CMYK plus White five-colour BN2-20 and the CMYK fourcolour BN2-20A.

In addition to their compact size, the new BN2 series models offer printing speeds approximately four times faster than previous BN models. Roland DG says this allows operators to produce a wide variety of high value-added items, from original t-shirts, posters, stickers and labels, to displays.

Roland DG lists the key features:

Faster print speed – BN2 print speed in standard mode is approximately four times faster than existing BN models through the adoption of an LM guide, dryer, and new, advanced system controller.

Improved precision – banding is less likely, even during bi-directional printing.

Improved cutting quality and speed – the adoption of new solenoid drive technology and a ZEC-U5032 blade make cutting a breeze.

Sheet Cut Function – this enables you to neatly and automatically cut straight without manual assistance.

Ease of operation – enjoy excellent usability through the innovative frontal access structure; multi-colour LED lights indicate printer status at a glance; detachable media clamps improve media setup and are user replaceable.

Small footprint – the new printers offer a 20 per cent smaller installation space than BN models.

Cloud – you can download all necessary software from Roland DG Connect.

Software – Roland DG Connect software allows control over production and simple design and output app, FlexiDesigner VersaSTUDIO Edition.

Scan here

Ideal for companies looking to expand their product o ering by supplying apparel decoration, stickers, decals and small signage.

Ideal for companies looking to expand their product o ering by supplying apparel decoration, stickers, decals and small signage.

The new design includes an intuitive user interface for simple operation, e cient print and cut function and small footprint products.

The new design includes an intuitive user interface for simple operation, e cient print and cut function and small footprint products.

Its compact size makes it suitable for work areas with limited space, such as a small shop, o ce or in home use.

Its compact size makes it suitable for work areas with limited space, such as a small shop, o ce or in home use.

Scan here to learn more

to learn more

FlexiDESIGNER VersaSTUDIO simple and easy design and print software, allows you to e ortlessly produce professional quality designs at a ordable prices.

FlexiDESIGNER VersaSTUDIO simple and easy design and print software, allows you to e ortlessly produce professional quality designs at a ordable prices.

Contact us for your individual consultation

Contact us for your individual consultation

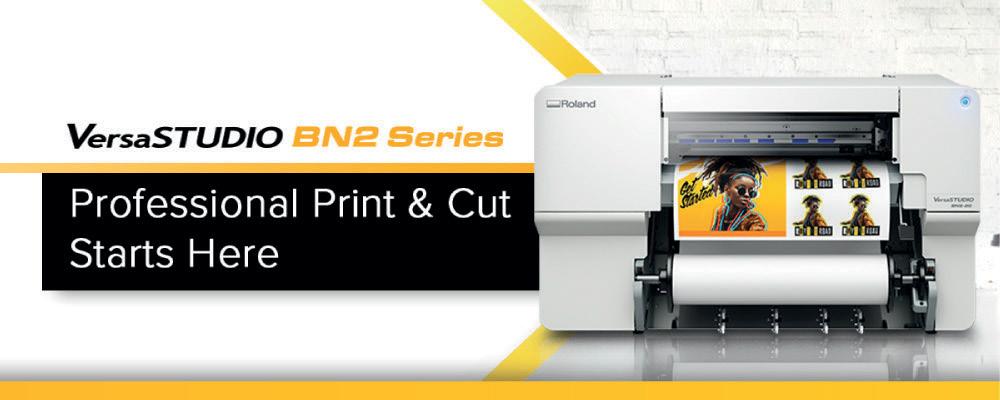

graphics, labels and packaging market. The solution includes an online graphic editor to ensure the complete handling of custom print orders and sale of customisable products and services.

BY DURST OCEANIA MANAGING DIRECTOR MATT ASHMAN

Simply adopting a technology on the shop floor is no longer enough – it is critical to invest in the right software tools to ensure greater costeffectiveness of the printing business.

The digital printing landscape is constantly evolving. Today, digital printers have reached very high levels of productivity and quality.

In securing profitability, the greatest opportunities very often lie in improving the efficiency of production as well as sales processes.

Durst Software & Solutions provides smart and simple software solutions to streamline the process from ‘Pixel to Output’ and to maximise the print buying experience.

The solutions are especially tailored for digital printing, and come with accompanying consulting and training services, helping print service providers to improve printing and simplifying business.

Our portfolio includes:

• ERP/MIS software to streamline and automate every aspect of the print business, starting from receiving the quote until the product delivery

• Web-to-Print solutions designed to support print service providers in attracting leads, engaging customers and successfully selling products online

• Pre-press and production software

Durst

for the simplified and automated management of pre-press and production tasks

• Analytic software that is designed exclusively for Durst printers to ensure complete handling of production data and increase the equipment efficiency.

Durst’s software is modular and adapts flexibly to any print service provider’s needs – from a stand-alone solution to a fully integrated and revolutionary software eco-system that covers all relevant aspects of their printing businesses.

Specifically, Web-to-Print is one of the areas that is on a growth trajectory. Research shows that the global Webto-Print software market size was US$1.187 billion ($1.8 billion) in 2021, and this market is expected to reach US$1.968 billion ($2.99 billion) in 2028, exhibiting a CAGR of 7.4 per cent during the forecast period.

As such, print service providers need to boost their businesses with Web-to-Print by introducing product personalisation capabilities to their online store fronts or any other web applications and streamline their order management processes.

To meet their needs, Durst has been building on its Smart Shop solution that enables them to see success with Webto-Print through individual solutions. Durst provides a comprehensive, premium solution for customisable print products. This allows print service providers the ability to give their customers the opportunity to construct a wide variety of products directly from their browsers and to view them in real-time – with the Durst Smart Shop in combination with the Durst Smart Editor.