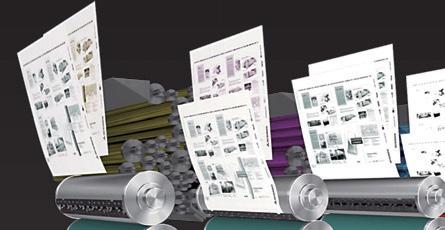

1987-2022 years in print New Zealand Printer October 2022 Print is also art Drupa global trends Deal with price increases Retaining staff WIDE FORMAT +Plus with Fujifilm expands the possibilities for printing More performance. More quality. More versatility.

Offset Printing | Digital Printing | Wide Format | High Speed Inkjet Chat with us today 0800 289 774, or order online www.wholesaleprint.co.nz We can do it all, Our A1 Offset Press and in-house bindery gear is perfect for your publishing and magazine printing needs. Get in touch with us today!

Cover Story p14-16

14-16 Fujifilm: Bringing the latest technology and solutions to the industry, Fujifilm is helping industry professionals exceed their goals by expanding the possibilities in printing

PrintNZ p8-12

8-11 Helping Hand: Printing is art. Iain MacIntyre hears from printers taking the craft to the next level

12 Comment: Ruth Cobb discusses our ongoing price increases and what we can do about them

Labels & Packaging p18-38

18-22 Labelexpo Americas: All eyes turned to the USA for the big Labelexpo Americas show, the first for some time. All the latest technology was on display for visitors from over 70 countries, including New Zealand.

34-35 Durst: Aarque has paired the Durst Tau RSC platform printers with GM label converters for an end to end labels solution

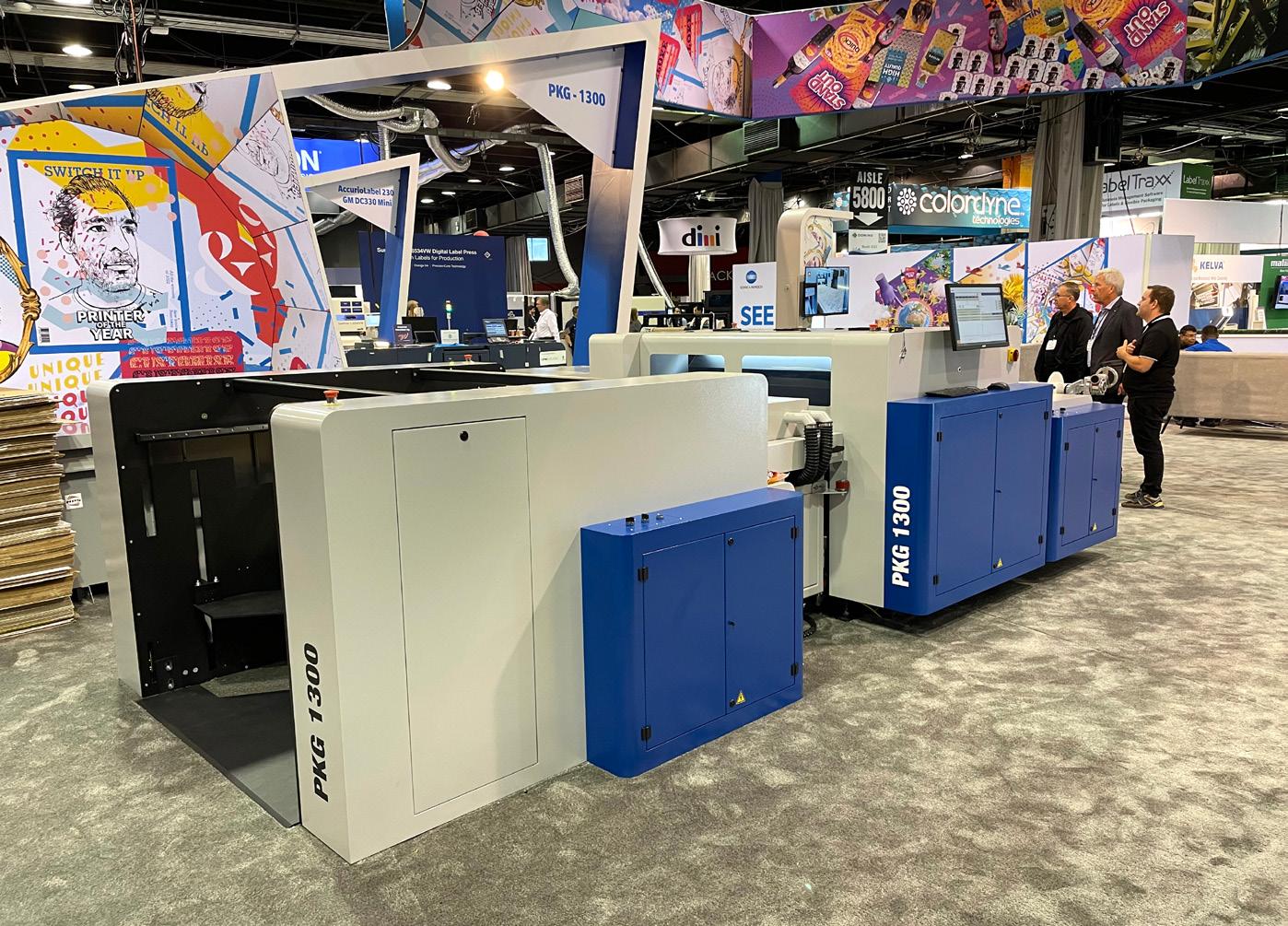

36 & 38 Konica Minolta: Wade Marriner, production print specialist at Konica Minolta New Zealand talks about the company’s new printers on display at Labelexpo Americas

Features p6

6 Think Laterally: Mick Rowan offers some great ideas for retaining staff in these trying times

Wide Format Plus p39-49

40 Epson: The latest dye sublimation printers from Epson offer versatility and a wide range of applications

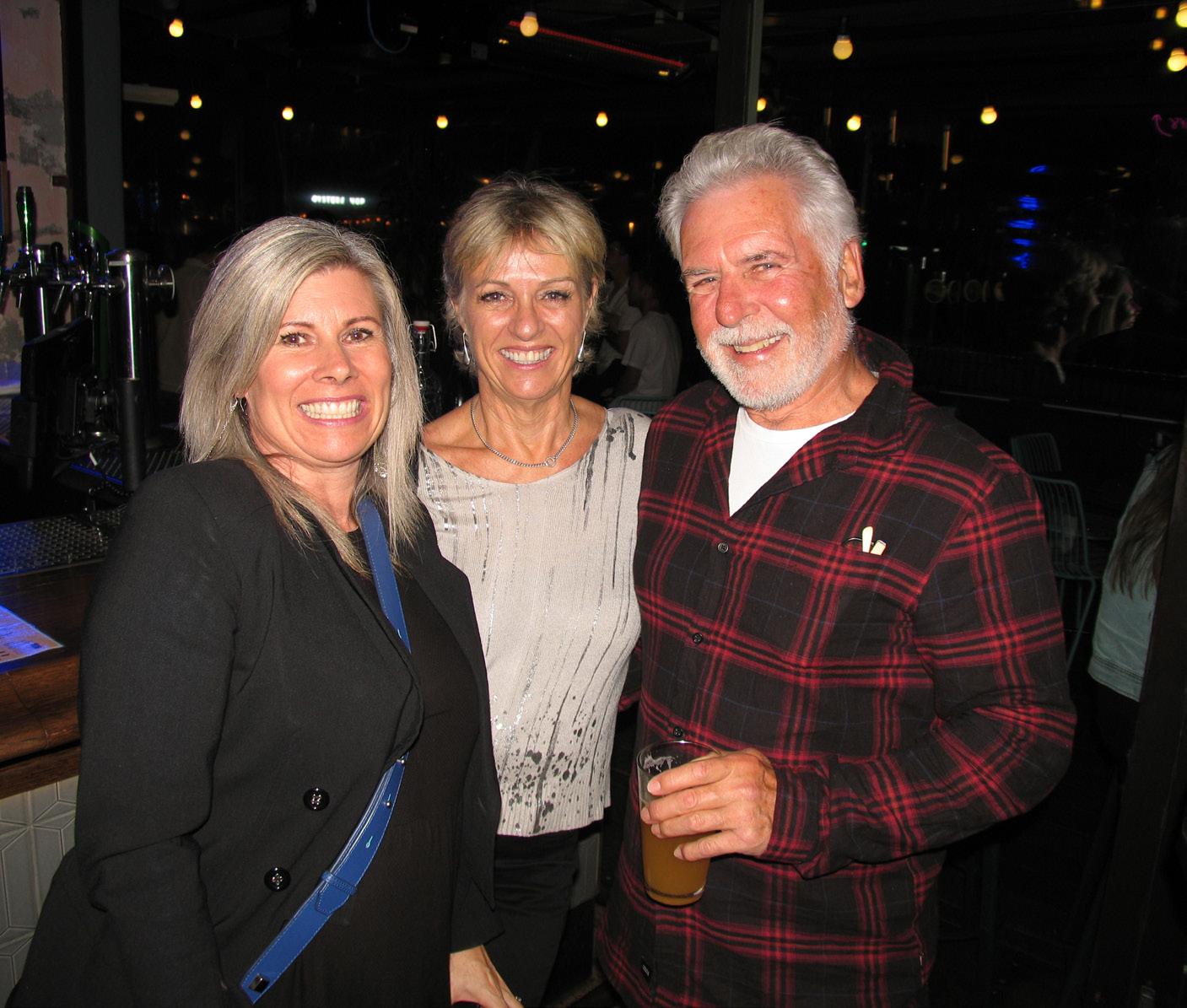

42-45 Total Supply: To celebrate 60 years serving the industry, Total Supply held a party at the viaduct for customers, suppliers, staff and friends

46 NZSDA Update: New initiatives for 2023 will see a focus on health and safety as well as signee opportunities

48-49 NZSDA President and Secretary: Andy Lowe has some ideas on how you can future proof your sign business. Meanwhile, Melissa Coutts has exciting news about events coming next year

Advertiser’s Index

brian@newzealandprinter.co.nz

its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication.

Copyright © 2022 — Charted Media Group Pty Ltd

3 newzealandprinter.co.nz October 2022 October

2022

EPSON

GLC

47 Pride In Print 51 Print NZ

Think Laterally

VPR

Wholesale Print

CONTENTS EDITORIAL: 021 631 559 Bruce Craig, Editor - bruce@newzealandprinter.co.nz CONTRIBUTORS: Ruth Cobb, Deborah Corn, Melissa Coutts, Iain MacIntyre, Mick Rowan CIRCULATION: brian@newzealandprinter.co.nz DISPLAY ADVERTISING SALES & SERVICE: Brian Moore - brian@newzealandprinter.co.nz +61 410 578 876 CLASSIFIED ADVERTISING: Brian Moore - brian@newzealandprinter.co.nz DESIGN & PRODUCTION: Sarah Vella - sarahvelladesigns@gmail.com New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December. New Zealand Printer is a member of the Printer Media Group New Zealand: New Zealand Printer Asia Pacific: ProPack.pro Australia: Australian Printer, ProPrint MANAGING DIRECTOR: James Wells - james@intermedia.com.au GROUP

DISCLAIMER This publication is published by The Intermedia Group Pty Ltd (the “Publisher”). Materials in this publication have been created by a variety of different entities and, to the extent permitted by law, the Publisher accepts no liability for materials created by others. All materials should be considered protected by Australian and international intellectual property laws. Unless you are authorised by law or the copyright owner to do so, you may not copy any of the materials. The mention of a product or service, person or company in this publication does not indicate the Publisher’s endorsement. The views expressed in this publication do not necessarily represent the opinion of the Publisher, its agents, company officers or employees. Any use of the information contained in this publication is at the sole risk of the person using that information. The user should make independent enquiries as to the accuracy of the information

relying on that information. All express or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher,

Aarque Group Ltd 32,33 APM 32 Cardy 7 Contact Labels 32 Currie Group 32 Cyber OBC Eamar Plastics 50

41 FUJIFILM 1, 17

5 Graphic Machinery 32 Konica Minolta 37 NZSDA

13

50

50

2

PUBLISHER: Brian Moore -

© Copyright 2022: Contents of this magazine are subject to copyright and cannot be reproduced without written permission of the publisher. ISSN 1171 7912

before

Official Media Sponsor 2021 NEW ZEALAND PRINTER PO Box 32-395, Devonport, Auckland 0744

Dan Mantel (l), Durst Oceania and Steve Sheppard, PrintLounge at Labelexpo Americas, p16

IN BRIEF

AVERY DENNISON has opened a new distribution centre in Moorabbin, Victoria. Jordan Leach, business director, graphics solutions, Australia and New Zealand and ASEAN, Avery Dennison, says the building will meet the growing needs of graphics converters and installers in the Australia and New Zealand region. He says, “This facility empowers us to be more responsive to changing customer needs. It is purpose-built for sustainability. As we grow, we shall continue to be a force for good to our industry, stakeholders, and local communities.”

DOMINO has announced a new UV-based laser coder, the U510, for high speed precision coding on recyclable, mono-material, coloured plastics, including flexible food packaging films in horizontal and vertical form fill seal applications. Domino says the U510 codes directly onto white and coloured mono-material plastics and films without the need for additional additives or laseractivated fields on the substrate. A photochemical reaction on the top of the plastic, creates an indelible mark without compromising the product packaging.

BOBST has received the Best of the Best prize in the Technical Innovation category of the 2022 Golden Cylinder Awards for its advanced register control for precision printing in Gravure. Bobst says a press operator using the register control can make a correction immediately after the colour is printed, without having to wait for the images to be displayed on the web viewer. The company adds that it also reduces downtime for press setup and print companies will generate less waste during the process.

Brother joins PTAS panel

The government has appointed Brother New Zealand as a panel member in the All of Government Print Technology and Associated Services (PTAS).

Warwick Beban, managing director of Brother New Zealand, says the appointment marks a momentous step forward for the business. He says, “It is a validation of our experience and capabilities, and this new opportunity will enable us to extend our services formally into New Zealand’s public sector as an official PTAS panel member.

“As the manufacturer of Brother products and authorised distributor for Konica Minolta A3 office equipment in Aotearoa, Brother brings two specialist brands into a single solution.”

With access to A4 and

A3 print hardware, and partnerships with document management solutions providers, Brother says it can assist agencies to move away from the heavy reliance on A3 print fleets to more flexible, hybrid, fit for purpose document solutions. All solutions centre on sustainable business practices which Brother has integrated into its PTAS offering.

Beban says, “Our All of Government print solutions are based on our industry leading approach to analysis, fleet right-sizing, ongoing quality improvement and cost management. This methodology has been

Software tool measures carbon footprint

Tharstern has launched a carbon footprint tool which instantly adds the certified carbon footprint of each print job to a quote.

The MIS specialist has collaborated print carbon measurement experts CarbonQuota for the venture. The tool delivers instant carbon footprints on every quote and invoice that Tharstern MIS produces, along with carbon offsetting costs or carbon neutral

certification that the end client can.

Dominic Harris, cofounder of CarbonQuota, says, “Carbon accounting is becoming as mainstream as cost accounting. We are now entering an era when it’s as normal to ask about the environmental footprint of goods or services as it is price.

“Historically, print businesses often only looked at the carbon footprint of paper, so we were determined

successfully refined in the New Zealand market for more than 13 years meeting the changing needs of our diverse customer base throughout the SME, corporate, education and healthcare sectors.”

He adds the business plans to work with a selected group of synergistic key channel partners to engage with eligible agencies. It will support customers through its extensive nationwide technical service and support network.

He concludes, “Our vision is to bring genuine change and choice to agencies by challenging the status quo through our unique approach.”

that our calculations not only measured paper, but also included production, consumables, transport, postage, outwork, fulfilment and end of life, as that truly reflects the total lifecycle environmental impact of a job.”

Lee Ward, chief executive at Tharstern, says, “The carbon impact of the manufacturing sector is under enormous scrutiny right now and the print industry has a rare opportunity to demonstrate leadership in sustainability and show the wider sectors how it should be done. This solution ticks all the boxes.”

4 newzealandprinter.co.nz October 2022 NEWS

NEWS for New Zealand – all the latest print industry news from home and overseas, delivered to your inbox Go to the news website newzealandprinter.co.nz Join the rest of the local print industry and sign up for your free newsletter

Warwick Beban, managing director of Brother New Zealand

PageWide Advantage 2200 series press announced

HP has announced the new PageWide Advantage 2200 series press.

Annette Friskopp, global head and general manager at HP PageWide, says, “HP has listened to our customers, and we realise ease of use and uptime are critical success factors. This new press offers configurations to enable customers to optimise the press for their quality, productivity, versatility, and economics to grow their digital production businesses.”

The HP PageWide Advantage 2200 can print at speeds up to 150 metres per minute colour and 244 metres per minute mono. HP says that, with the ability to print using HP Brilliant Ink and 2400 native nozzle per

PageWide Advantage 2200 series press.

inch printheads, the new press delivers top quality and addresses a range of higher value applications. These include colourful trade and educational books and high coverage, impactful direct mail pieces that differentiate clients in the market.

The press handles a range of media weights from 40gsm up to 300gsm. For reliability and ease of use, the HP PageWide Advantage 2200 includes a single print arch design. HP says that because the new press’s paper path has fewer components, it reduces the number of parts to manage as well as overall maintenance and servicing time.

The company adds that a modular design enables customers to start with a

Kale Print buys Endeavour Print

Bay of Plenty print company Kale Print has purchased Whitianga-based Endeavour Print.

Kevin Coughey, former owner of Endeavour Print, says, “Endeavour Print and Kale Print are iconic family businesses. Merging the technologies and talent of both teams will result in more products and services for our clients.”

The companies point out that it will be business as usual for Endeavour Print customers. Peter Lloyd, general manager of Kale Print, says, “We are thrilled to be able to continue serving Endeavour’s customers locally and through the region.”

Coughey continues, “Kale Print has an outstanding reputation in the print industry, the highest level of professionalism and of

course a passion for print. Endeavour Print has been a leading print provider for clients both local and across the region for more than 13 years, providing high quality digital printing.

“It has been an absolute privilege to be part of and contribute to the vibrant Coromandel community over the years. Now it is the right time for a change for me personally, and I am very excited to see what the future holds.

“Kale Print’s values align directly with Endeavour Print. Coupled with our long-standing working relationship, made Kale Print the perfect fit to best support our customers into the future.”

This deal follows Kale Print’s acquisition of Advocate Print last November.

lower capacity machine and enhance it as their business grows or their application mix shifts. Customers can select one, two or three dryer modules along with passive or active web cooling modules to fit their needs.

The HP PageWide Advantage 2200 also features a compact single engine duplex design. HP says this provides high quality and productivity while saving floor space for customers. It comes equipped with HP’s High Efficiency Drying system. This minimises power usage at higher print speeds by recirculating up to 80 per cent of the air heated during the drying process.

IN BRIEF

MÜLLER MARTINI has named Ian Sampson to replace Roman Beeler, who is stepping aside as Australia country manager. He will remain with the company on a part-time basis. Sven Olsen, Müller Martini Asia Pacific regional managing director, says, “The fact that Roman and Ian have known each other for 15 years and that Roman remains in the organisation in a different role, is extremely helpful for us and our customers.”

INTERGRAF , Europe’s printing association, has called for government support. It says the printing industry is experiencing the skyrocketing raw material costs combined with rising energy costs. Because of their SME-based structure, this is a situation that many printing companies will not be able to sustain for much longer. As well as the many printed products that are vital to democracy and Europe’s knowledge society, like books, newspapers, and magazines, the printing industry with its manifold products serves citizens and businesses every day.

5 newzealandprinter.co.nz October 2022 NEWS THERMAL LAMINATING • MATT & GLOSS • SPECIALTY FILMS • ADHESIVE LAMINATING • HOT FOIL STAMPING & EMBOSSING • ENCAPSULATION & WIDE FORMAT • METALLISED FILMS • SCRATCH OFF INKS SPOT & OVERALL UV FINISHES • SPECIALISED COATINGS • INDEX TABBING • NEW LAMINATES • SCRATCH RESISTANT MATT • VELVET FEEL • SLURPEX SOFT CLOTH & CHAMOIS PRODUCTS Unit 3, 343 Church St, PO BOX 12797, Penrose Auckland 1642, New Zealand, +64 9 636 8354 reception@glc.co.nz www.glc.co.nz ALBANY • PENROSE • PETONE

The

There’s a labour shortage, so how do I retain my

mid-level employee is 20 per cent of the departing employee’s wage.

When there’s cost pressure from all sides, it’s no wonder that many companies struggle with maintaining margins. So, the last thing we want is to be burdened with the search for new employees to cover the loss of existing staff. Perhaps the first step we implement is to ensure we find ways of retaining our already established staff.

The high cost of disengaged staff is clear to see. The lack of productivity and engagement can lead to higher absenteeism rates, greater human error, and potential safety incidents. Whereas engaged employees are more likely to make positive contributions and take better care of the company, they work for. But the benefits are more than just a better bottom line. Engaged teams also experience less turnover than their disengaged counterparts, which means you’ll have happier staff and longer careers in your organisation!

It’s no longer enough to have a great company culture; you need one that encourages growth. The best way of doing this is by aligning your employees with the goals and objectives outlined in their job descriptions. Hence, they feel valued for who they are while also achieving together what no single individual can accomplish alone. It takes everyone working towards something!

According to John J. Murphy, author of ‘Pulling Together: 10 Rules for HighPerformance Teamwork’: “Each individual has unique gifts, talents, and skills. When we bring them to the table and share them for a common purpose, it can give companies a real competitive advantage.”

A recent survey of over 1000 Atlassian employees demonstrated that most successful teams engage in honest feedback and take ownership of learning from their mistakes. Likewise, feeling respected is one of the biggest drivers of emotional health.

With relatively small, isolated populations, New Zealand and Australia fared well in the pandemic compared to the rest of the world. We shared an ability to keep the virus at bay; however, it came at the cost of a massive hit to our economies. And we now face a significant labour shortage due to the reduction of our immigrant workforce by Covid-related health and travel restrictions.

It probably won’t come as a surprise, but the cost of hiring staff has skyrocketed (along with electricity, gas, petrol, food, interest rates, alas, the list seems endless). According to a new survey by the Australian HR Institute in partnership with Elmo Software, it takes 50 days to make a new hire in New Zealand and 40 days in Australia. While the Society for Human Resource Management has estimated the replacement cost of a

Motivating employees today might seem a little more involved than what was once considered the norm. And it takes more than just remuneration and staff perks. Like Maslow’s hierarchy of needs, employees have an order of engagement. It spans from the bottom, where employees are disengaged and work for a salary and nothing more, to the top, where they are engaged, motivated and ambitious.

Essentially, at the bottom are the basic needs of pay and benefits, followed by development opportunities and the potential for promotion. Next comes respect, or more specifically, do they feel respected in their role. At the top and above all else, people desire a shared sense of connection and meaning at work.

Social belonging is hardwired into our DNA, a fundamental human need. And yet, according to the Harvard Business Review’s ‘The Value of Belonging at Work’, 40 per cent of people say they feel isolated at work. The result of this is lower organisational commitment.

Having happy employees is a worthwhile goal, but the company benefits, too. Research from the University of Warwick in England suggests happy employees are up to 20 per cent more productive than unhappy employees.

So, a combination of; good leadership, development opportunities, and the chance to contribute to a meaningful vision is essential when motivating employees. If your staff feel like they belong, there’ll be fewer sick days, better performance, and lower turnover.

Your staff are your most important asset; without them, your business would not be where it is today. Make sure to treat them well, show them appreciation and give them a sense of belonging within the company. If you take this small step, you’ll have a happy, loyal, and productive team. And who doesn’t want that?

Mick has spent the past decade building printIQ into one of the most recognised software brands in the printing industry, and with over four decades of experience, Mick truly has ink in his veins.

6 newzealandprinter.co.nz October 2022 THINK LATERALLY

already-established staff?

Keeping staff engaged is key to retaining them

MICK ROWAN

Demand for short-run packaging has never been higher and continues to grow. With excellent print quality, and ability to print on flexible materials this easy to use equipment will be an asset in any print business. The FP-230 press is an economic, low waste setup press which when compared to traditional production methods such as Flexo and Roto, it significantly reduces plastic waste by using only 2.5m (8.2') of film for job setup In-house production of flexible packaging has never before been easier.

Introducing Afinia FP-230 Label and Flexible Packaging Press

The new Afinia FP-230 Flex Pack Press has revolutionised label & packaging roll production. Impressively compact and easy to operate, the FP-230 lets you create high-quality, full-color flexible packaging with ease.

Ideal for small to medium runs and high levels of varying data or design, the FP-230 is a ground-breaking solution that opens the door to endless opportunities.

All on-site, all on-demand.

High Margin Short Run Business

Capture

Hardware - Consumables - Media - Laminates - Installation - Service Contact us for a demonstation or Free Sample Pack Steve Monkhouse | 027 257 9806 | steve@cardy.nz 0800 866 377 | 9G Airborne Road, Albany, Auckland. Create New Revenue Opportunities With Label & Flexible Packaging Key Fe a ture s Exceptional 1600dpi resolution EU & FDA food compliant Production speed up to 18m/min Easy variable data No minimum order quantities STEP INTO LABELS.

Print as art shines brightly

work

An impressive array of artistic, specialty print is being created in the New Zealand marketplace that might surprise those who naturally associate the sector with every day, transactional production.

Ruth Cobb, chief executive at PrintNZ, says some exquisite artistic work is being produced locally, even to the calibre of being shown in gallery exhibitions, with the specialist aspect also proving an attractive career path for individuals with artistic and tactile appreciation.

Guardians of Lenticular

One such example is Fuzed, a dynamic print company based in Kingsland, Auckland. Fuzed has progressively added to its portfolio of traditional print services to now provide numerous specialties.

Matt Mills, director at Fuzed, says, “This work is truly specific to us at Fuzed. For example, our lenticular print ranges from business cards to bus shelters as well as international and domestic curated art.

We have recently collaborated with New Zealand-based international artist Jane Mason, to produce a first series of incredible art pieces. Jane has painted

8 newzealandprinter.co.nz October 2022 helping hand

“The industry produces such a wide array of products and we need to showcase these specialist areas to highlight to both customers and potential employees the extraordinary uniqueness of what we do.”

Customers return to print for artisanal

Truly stunning: Fuzed’s production of the Guardians of the Galaxy movie premiere tickets

IAIN MACINTYRE

Matt Mills, director at Fuzed

them and Fuzed has then turned them into lenticular art.

“Then we also have our Scodix machine with which we produce 3D digital overglossing. It is like spot UV on steroids.”

He describes a wide range of customers attracted to such speciality services, including print brokers, other print companies as well as both small and large advertising agencies.

He says, “We are talking about the small company working out of the home garage all the way through to big corporates. We also supply to art galleries here in New Zealand and some around the world. The work we print for these companies matches the customer and their needs. Several printers here in New Zealand and abroad would have some similar equipment but would not be able to match all of our capabilities.

“You could argue that this sounds like Fuzed is a jack of all trades, but our record at the Pride in Print Awards would show otherwise.”

He feels most proud of the firm’s production of the Guardians of the Galaxy movie premiere tickets. He explains, “This job came in for a simple bit of overglossing but when it left, it was truly stunning and something you wouldn’t want to throw away.”

He adds that working in such a specialist area provides considerable personal satisfaction. He says, “The ability to come to work and produce something really special; something that makes our peers and clients stand back, take a minute and appreciate the job well done, or even have them wonder how is amazing.”

He contends that the sector should hold considerable attraction to the creatively minded. He says, “Most people who do a design degree would be encouraged to go towards designing for online and, while we need good web designers, good graphic designers for print are worth their weight in gold. There are a lot of specialities that print can offer visually, tactilely and interactively that other forms of marketing don’t give you.

“I get a real buzz when I see a really nice printed piece, whether that be lenticular artwork or a booklet or a business card with 3D digital overgloss, metallic finishes or embossed effects. Knowing we have produced this is really something special.

“If that’s what you want to achieve in life, something to be proud of, get into printing. There are heaps of different types of printing. If you try one and it’s

Janice Page, general manager Caxton Design & Print Excellence

the form of business print, brochures, reports, posters and so on, as well as having a strong reputation in publishing. With the addition of our other brands like Microfilm Digital Print, The Production House, Printabook and Jamjar, we cater to a much larger client base and now produce work for small business, selfpublishers, artists and photographers.

“There are many other printers in the market but Caxton stands out for our wide range of services offered. Many clients that have toured our factory are amazed at what we have to offer, from traditional large run offset print at one end of the building to the delicate, fine art scanning and print production at the other end.

“Having an in house design team, self-publishing experts and a team of knowledgeable people covering all areas is the cherry on top.”

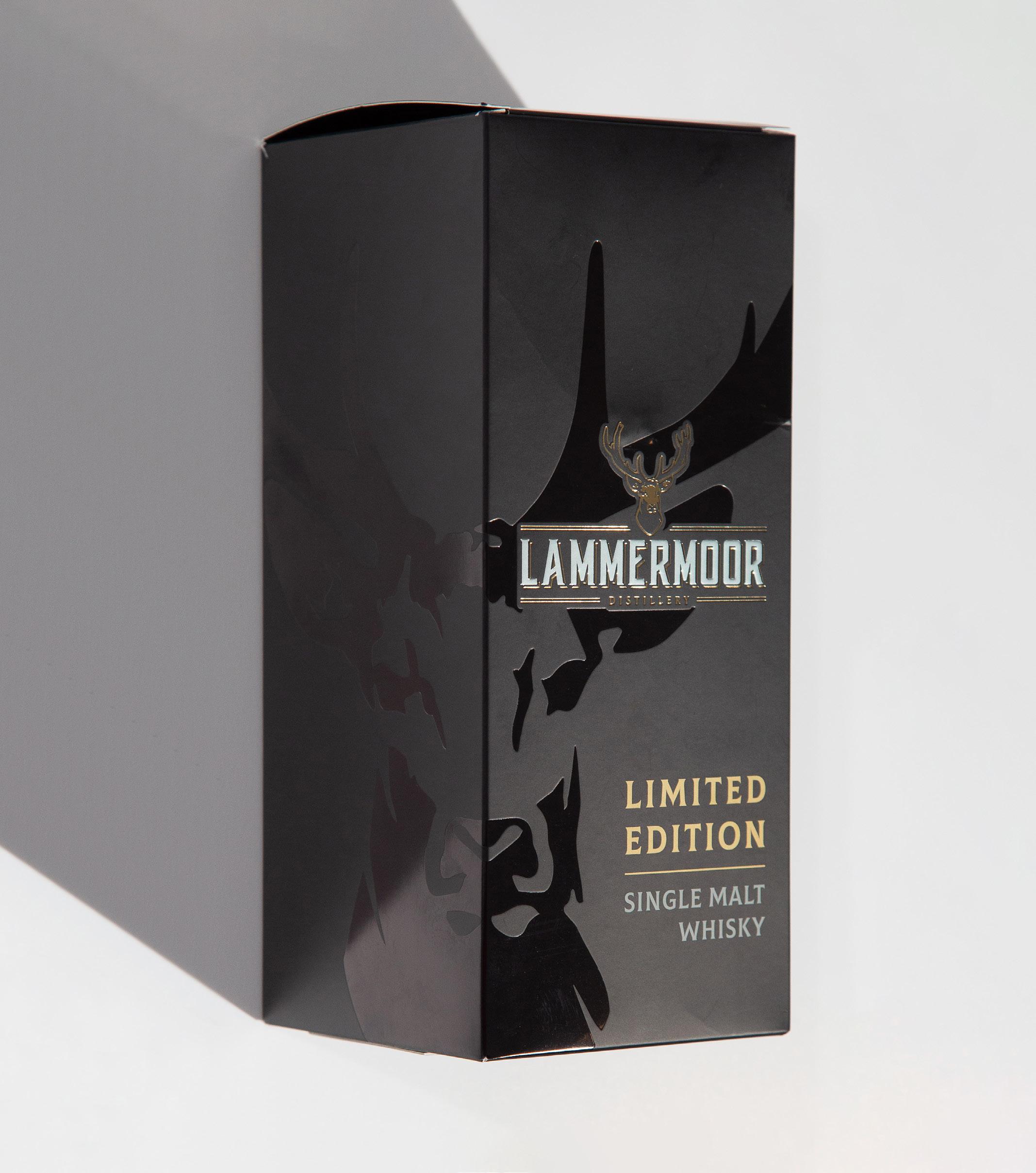

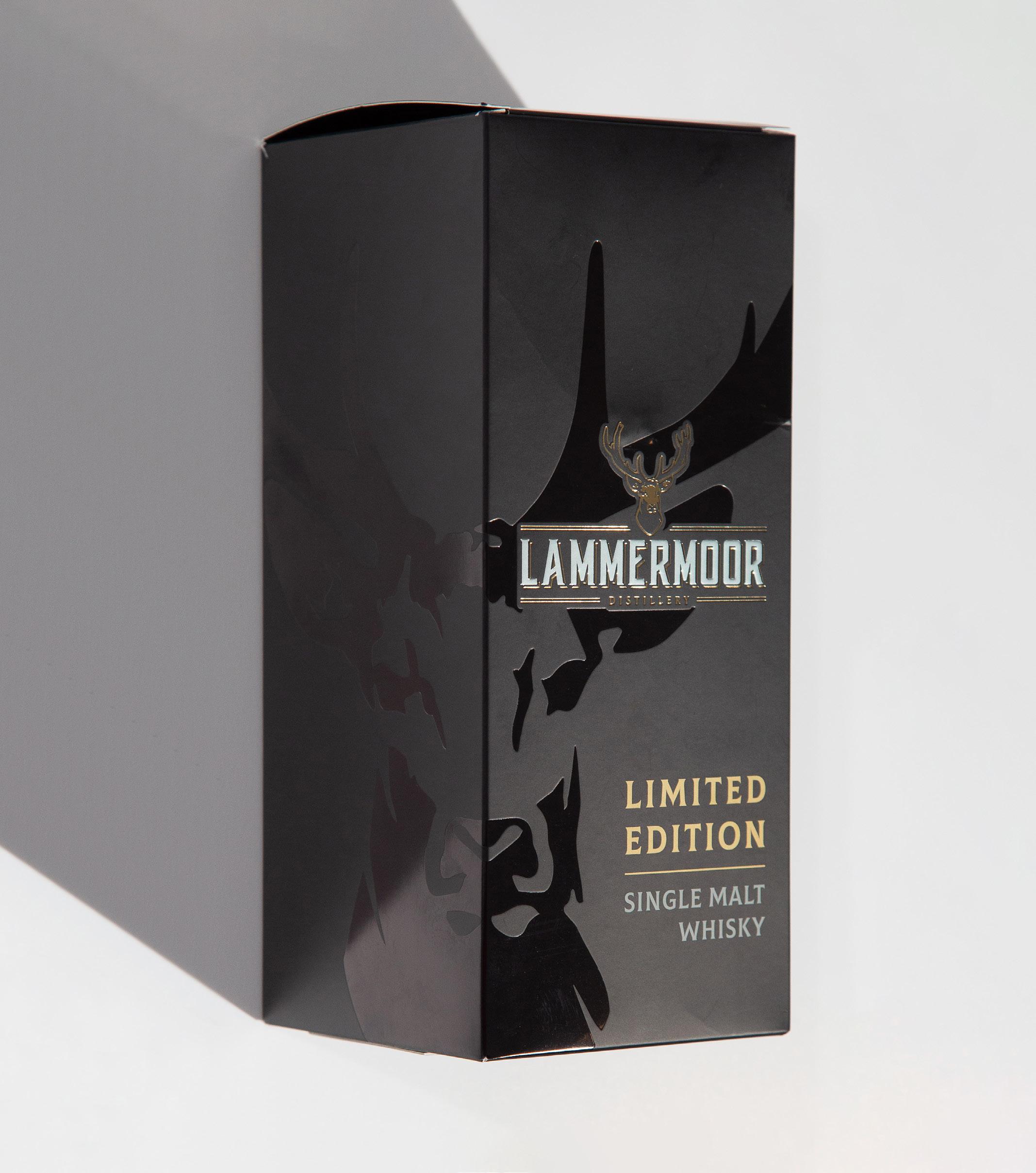

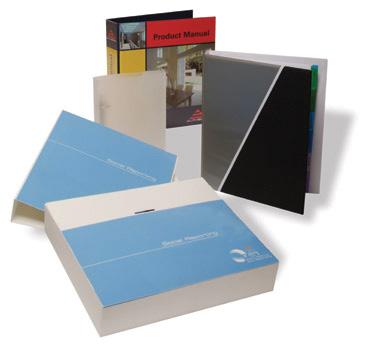

She feels particularly proud of the firm’s recent successes in the packaging realm. She says, “We have traditionally not been a big player in the packaging industry but with an eagerness to impress and create beautiful boxes, we won the Packaging Category Award at the Pride in Print Awards 2021 for the Lammermoor Whisky Box Packaging. We have also taken great pleasure in producing candle boxes for a successful New Zealand candle maker.

“The other area that we take immense pride in, is our Fine Art Reproduction Department which, year after year, wins awards at Pride in Print. Our in house specialist is well known amongst artists in New Zealand to be one of the best in the industry.

not for you try another one. There will be one.”

Print versus digital screens

Caxton Design & Print Excellence, the longstanding Christchurch, family-owned design and print firm, has also broadened from its bread and butter base of work over the past decade.

Janice Page, general manager at Caxton, says, “We have diversified significantly. With the addition of new equipment and software, we offer wide format print and signage; packaging and mail merge; photobooks and calendars; online ordering and logistics; and last but certainly not least, a very successful, award-winning fine art reproduction service.

“Previously, Caxton catered most prominently to corporate clients in

“Print and design is always changing, improving and advancing. The industry, and particularly the specialist areas, are extremely attractive career options.

“It is not just about putting ink on paper. It’s about creativity, coming up with new ways to achieve an idea, pushing boundaries and creating something beautiful like an amazing piece of packaging, a coffee table book, elaborate function invite with cut-outs and embellishments. There is no limit and if there is, we find a way around it.

“Print is a craft and a very exciting field to be in. The pure variety is fantastic. Never a day goes by without unusual requests that we are always eager to create and achieve.”

Over the past decade, many in the industry have felt concern that print would have less demand and many of Caxton’s, and other print companies’, current clients experimented with purely online

9 newzealandprinter.co.nz October 2022 helping hand

“There is no denying that print and marketing has changed and will continue to evolve but those companies that moved exclusively to online marketing have all returned to print as a medium which is still very much in demand.”

– Janice Page, general manager Caxton Design & Print Excellence

marketing. However, the industry continues to strongly demonstrate its relevance.

She adds, “There is no denying that print and marketing has changed and will continue to evolve but those companies that moved exclusively to online marketing have all returned to print as a medium which is still very much in demand.

“There is something to be said about the beauty of print and picking up a printed

piece to admire the design, photography and quality which cannot be appreciated on a screen.”

A place for fine art

Hamilton-based Reaction Print won this year’s Pride In Print Screenprint Category Award for its production of the ‘Wanaka Island’ fine art print.

Peter Grant, director of Reaction Print,

takes great pride in skill demonstrated in the production of that job, particularly given the complexities presented by the inks and stock, and other challenges involved.

He explains, “We produce work inside with print room conditions that vary as much the weather conditions do on the outside. Not being able to control any, but still being able to control the finished product was quite a remarkable achievement that can only be put down to

10 newzealandprinter.co.nz October 2022

Caxton won the Paper & Board Packaging Category at the Pride In Print Awards 2021 with the Lammermoor Single Malt Whisky Display Box

helping hand

our printer Cyril Southan’s expertise.”

For the Wanaka Island job, client Fran Shaw from White Light Studio, comments, “We wanted these to be special, something that had been lovingly crafted for our buyers to hang on their wall and admire. But we also soon realised what a dying art form screenprint is.”

After making the connection with Reaction Screenprint, she says, “They were passionate, knowledgeable and very open minded about doing something a little out of their comfort zone. We soon created a close working relationship which allowed us to work through many of the hurdles that were unexpectedly thrown at us, the classic Christmas deadline and the lack of paper within the country due to Covid.

“The outcome was bright and impactful, with the beautiful tactile feel of the ink on the textured paper. We are so happy that we went down the screenprinting route, the process might be a lot more involved than shooting off some digital prints, but in our eyes totally worth it. We hope that our customers will feel the same.”

Reaction Print also specialises in motor vehicle number plate frames and associated products that are used in the automotive industry and produces many polypropylene/corflute signs.

Peter says, “There are fewer specialist screen shops around now as the digital world has taken over. But still, there are works that are best done by the screenprint process, for varying reasons.”

Embracing his continued involvement in the industry, he encourages people who show an interest in embarking on a career in the sector, which still remains enticing and fulfilling for him.

He enthuses, “I particularly enjoy the interaction with our client base. I have been dealing with some clients for over 30 years and now, their sons are dealing with me. I love being able to offer advice on product usage, outdoor life, along with many other things.”

Despite continuous advancements in technology making automation the norm in the industry, print as a craft has survived and thrived. He believes artisans will continue to prosper. He concludes, “There will always be a need for a qualified screenprint person. The satisfaction of laying down one colour at a time, getting it right, getting the job in registration, achieving the result that everyone wants and remembering this is not a machine or a computer doing this work; it is you!”

11 newzealandprinter.co.nz October 2022

Cyril Southan (l) and Peter Grant from Reaction Print

Reaction Print won the Screenprint Process Award at this year’s Pride In Print Awards with the Wanaka Island fine art work

helping hand

Price increases – here, there and everywhere for everyone

How do you deal with rising costs?

RUTH COBB

Unsurprisingly, inflation ranks in the top three issues we are hearing from the industry over the last couple of months. While work levels are busy, cost pressures are coming from all directions and I wanted to take this opportunity to remind you that you can’t be the end of that chain. You have to pass some, if not all, of them on.

It is important for the success of your businesses and our industry that you look closely at the impact of price increases on your business and that you make any necessary adjustments to your own pricing.

We do often get asked for info to help support communications to customers so I have provided a few pieces of data that may be useful to help you explain why an increase is being applied, although in this current climate that almost shouldn’t be necessary.

The item that has had the biggest impact over the last two years has of course been shipping costs. While these are starting to fall, they are not expected to return to the levels they were in 2019. At its peak, a 12m container reached US$10,377 ($18,706) in September last year. While it is now down to US$3689 ($6650), it is still 160 per cent higher than the average pre-pandemic rates and not likely to move much lower. For a country that is isolated geographically, this has impacted heavily on the cost of both imported goods.

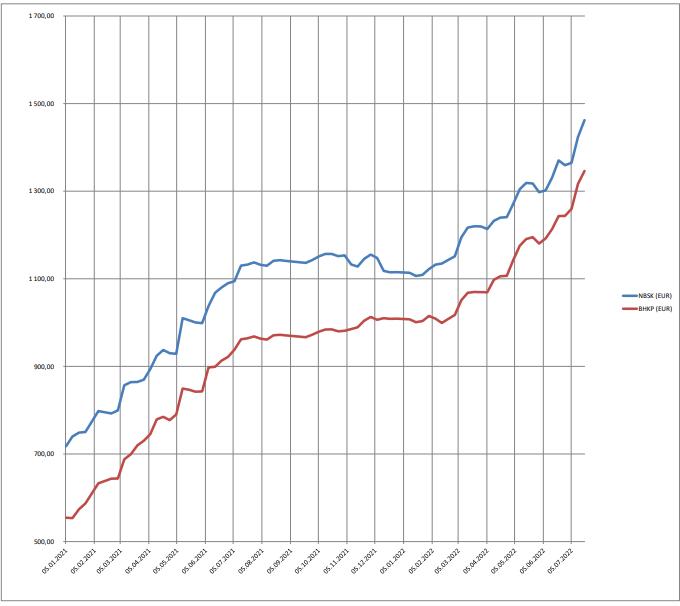

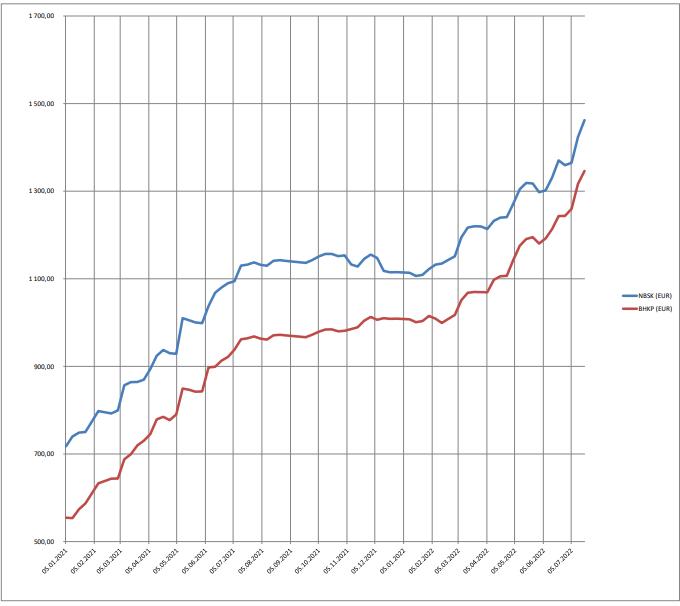

Another vital component for our industry obviously is paper. Pulp prices have followed a similar trajectory to shipping over the last 12 months and are also unlikely to see a fall back to pre-pandemic prices. This, combined with the increased shipping costs, has made it necessary for paper suppliers to increase their prices to printers as these costs have progressively risen. The same can be applied to the many consumables that our industry uses such as inks, chemicals and toners.

Just as the shipping and pulp prices were starting to show signs of settling, our New Zealand dollar has lost value against the USD and this now creates an added consideration to the pricing of any imported products. While a drop in value of the New Zealand dollar has made our exports more competitive, it puts price pressure on imports which subsequently convert to price increases for our industry.

On top of shipping, pulp prices and the exchange rate, general inflationary pressures continue to come from other sources, and some are continuing to escalate.

• Food price growth accelerated to 8.3 per cent per annum in the August month, the fastest rate in 13 years. Imported food price growth is at its highest since 1985.

• The Infometrics Foodstuffs NZ Grocery Supplier Cost Index rose 8.7 per cent per annum in August, a further acceleration from the 7.9 per cent recorded in July.

• Recent producer prices and capital goods prices rose at an accelerated rate.

• Stats NZ’s farm expenses price index rose at its fastest pace on record, going back to 1993.

• International energy prices continue to affect global manufacturing output and manufacturing costs, limiting supply and pushing up production costs.

And the final factor that can’t go without mention is pressure on wages. A shortage of available labour, a much tightened immigration policy and the impacts of inflation on employees is putting pressure on wages that we have not seen for many years. Increased wages equate

to increased costs and again these need to be passed on.

While it is not easy to deliver price increases to your customers, it has to be done. And if everyone does it, the playing field remains in the same position it was. For those that don’t it may be tilted, but with the potential to slide off the side if they don’t recover those increases.

Make sure you can stay in the game. And stand your ground. If your customers, both existing and prospective query your price, don’t automatically offer a discount. Explain why your product and service is worth the price and work with them to find a solution that works for you both.

12 newzealandprinter.co.nz October 2022

PRINTNZ COMMENT

0 2000 4000 6000 8000 10000 12000 Jan-20Mar-20May20 Jul-20Sep20Nov-20Jan-21Mar-21May21 Jul-21Sep21Nov-21Jan-22Mar-22May22 Jul-22Sep22 World Shipping Index Shipping rates are not likely to fall in the near future Northern Bleached Softwood Kraft (NBSK) and Bleached Hardwood Kraft Pulp BHKP continue to rise in price 0.52 0.53 0.54 0.55 0.56 0.57 0.58 0.59 0.6 0.61 0.62 11-Sep13-Sep15-Sep17-Sep19-Sep21-Sep23-Sep25-Sep27-Sep29-Sep 1-Oct 3-Oct 5-Oct 7-Oct 9-Oct 11-Oct New Zealand Dollar to United States Dollar The New Zealand dollar has fallen sharply against the greenmack

Keeping it local, let the world know

455 PNZORG 0000 WORKING FOR OUR INDUSTRY AND OUR MEMBERS EVERY DAY

Keeping print in New Zealand is more important than ever. Use this logo so both you and your customers can demonstrate the part you are playing. Apply to PrintNZ on info@printnz.co.nz or phone 0800 654

Fujifilm expands the possibilities for printing

With a raft of solutions, Fujifilm helps customers push the boundaries

Supporting the print industry with a diverse and comprehensive range of digital solutions, Fujifilm has a focus on continually improving its technology through listening to its customers as well as constant research and development.

As a result, the company’s portfolio provides customers with all the tools they need to progress in their business. We look at some of the company’s solutions that will help drive your business forward…

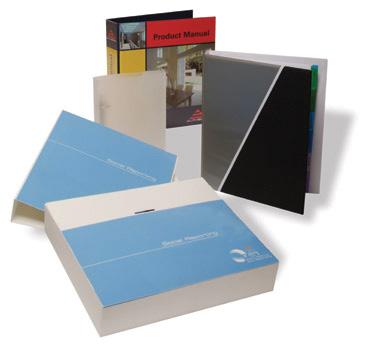

ACUITY PRIME

A true flatbed with an exceptional design and high value, the Acuity Prime offers high quality printing on a range of rigid and flexible media, supported by its five dedicated vacuum zones and jettable primer.

This range is available at a cost effective price point and offers an excellent return on investment.

Acuity Prime Features:

• Dedicated flatbed design

• High resolution greyscale printheads

• Standard (2.54 m x 1.27 m)

• Up to 150 square metres per hour throughput

• Registration pins

• Five dedicated vacuum zones to minimise masking

• Powerful instant curing LED UV system

• Fujifilm Uvijet LED UV curing inks

• Standard four colour plus white with clear and optional jettable primer

14 newzealandprinter.co.nz October 2022 COVER STORY

The Acuity Prime

The Revoria Press PC1120

• Automatic Printhead Maintenance System (APMS)

ACUITY ULTRA

The Acuity Ultra reaches new levels of quality and speed previously unattainable in the superwide arena.

It offers an unrivalled combination of speed and quality to give you a competitive advantage in the high-end and luxury brand interior graphics market, where near-photographic quality is critical. It also gives you the flexibility to produce superwide prints for the out of home (OOH) market segment or improve productivity by producing multiple, highquality prints from one machine.

Acuity Ultra Features:

• Native 3.5 picolitre, three-level greyscale printhead

• Linear driven printhead carriage

• Water cooled vacuum table

• Accurate and reliable media transport system

• 3.2 metre and 5 metre options

• 1,000+ hours of lamp life

• Fujifilm Uvijet GS inks

• Versatile, ultra-high quality 6 channel with white option

• Highly productive dual CMYK 8 channel model

• Up to 400 square metres per hour

• 0.1mm to 2.0mm media thickness

• Multi-roll printing

• Prints on heat-sensitive materials

REVORIA PRESS PC1120

Superior productivity with high-speed printing of 120 ppm even when printing in six colours

Revoria Press PC1120 Features:

• High definition expression with high output resolution at 2400dpi x 2400dpi

• High performance print server that maximises print engine productivity

• Supports a broad range of stocks: 52gsm lightweight paper, 400gsm heavyweight paper, minimum 98mm x 148mm and up to 330mm x 1200mm

• Various feeding and finishing options to streamline workflow from print to post-press

REVORIA MONO (E SERIES)

The Revoria Press E1136, E1125, E1110 and E1100 printers use a special feeder for enhanced paper handling capabilities.

The newly developed air suction feeder uses a shuttle head to draw up the paper strongly, using a small amount of air. It easily separates and delivers each sheet efficiently. This even improves feed performance of paper with a lot of paper dust, pre-printed paper using powder, paper with uneven texture, and coated paper that is prone to sticking. Stable and high speed feed is achieved for various paper types, from lightweight to heavyweight, small sized paper and long paper.

Revoria Mono (E Series) Features:

• Outstanding print speed of 136 ppm

• High Capacity Feeders and High Capacity Stacker make continuous mass printing possible

• Offering the latest finisher line up. Cover insertion, three-sided trim, and Saddle stapled booklet with Square Back supported

15 newzealandprinter.co.nz October 2022

COVER STORY

The Acuity Ultra

• Simple Image Quality Adjustment (SIQA) makes alignment adjustment easy

• Equipped with various copy and scan functions useful for office operation

JET PRESS 720S

The Jet Press 720S is a second generation ultra-high quality, four-colour B2 sheetfed digital inkjet press with a production speed of up to 2,700 B2 sheets per hour. With benchmark reliability and uptime, the Jet Press 720S sets new standards for digital print production

Jet Press 720S Features:

• Ultra-high image quality

• B2 sheet size

• Single pass inkjet technology

• Wide gamut water-based inks

• Industry leading 1200dpi x 1200dpi Samba printheads

• Automatic Nozzle Control

• Offset paper handling system

• Colour managed workflow and screening technologies

• Double sided variable data handling

• Exceptional environmental performance

APEOS PRO C810/C750

The Apeos Pro C810 and C750 have been designed to work in the corporate and CRD space as well in print for pay organisations. It will work both as a high end office multi-function printer MFP as well as an entry level colour printer.

Apeos

Pro Features:

• LED Printhead provides 2400dpi x 2400dpi resolution

• 270 ppm colour scanning (two-sided)

• Advanced office functions (support for DMP 20)

• Uses the same Super EA-Eco toner found in the Iridesse

• Plus or minus 0.5mm font to back registration

• Media support from 52gsm to 350gsm (duplex up to 300gsm)

• Paper sizes ranging from 100mm x 148mm to 330mm x 1300 mm (duplex up to 762mm)

• Supports the Primelink feeding and finishing from both Green controller and GP RIP

• The optional GP Print Controller is equipped with a variety of image

The Apeos Pro C810

quality control functions including 1200dpi x 1200dpi native resolution, 10-bit gradation, i3 calibration, the latest stochastic and dot screens and Iridesse-level colour management

UCHIDA CUTTER AND CREASER AEROCUT X PRO

The AeroCut X Pro is a top end slitter/ cutter/creaser featuring technology and knowledge stored since the launch of original AeroCut in 2009. Designed, built and calibrated with Japanese engineering and craftsmanship at its best.

The robust full metal machine body keeps a top level of accuracy and finishing quality every time. It has the capability to perforate stocks both across and along feeding direction by adding on optional perforating units. An ideal solution for finishing especially short run digitally printed applications, such as business cards, postcards, invitations, greeting cards, leaflets, tickets and more. The AeroCut X Pro saves times and costs for any print shops, in house printers and commercial printers.

16 newzealandprinter.co.nz October 2022

COVER STORY

Unleash the clarity of White Dry Ink

Unleash the clarity of White Dry Ink

A powerful way to earn your stripes.

A powerful way to earn your stripes.

Create bright, distinctive prints on dark stock with White Dry Ink using the next-generation Revoria Press PC1120. Explore the dynamic White underlay capabilities on film and transparent media that animate Metallic Colour, Pink, and other Specialty Inks with sparkling detail.

Create bright, distinctive prints on dark stock with White Dry Ink using the next-generation IridesseTM Production Press. Explore the dynamic White underlay capabilities that animate Metallicolour, Pink, and other Specialty Inks with sparkling detail.

Discover a wondrous realm of possibilites. www.fujifilm.com/fbnz

Discover a wondrous realm of possibilites. www.fujifilm/fbnz.com

Labelexpo Americas shows latest industry trends

Organisers have hailed Labelexpo Americas 2022 an outstanding success with 13,569 visitors flocking to the Donald E Stevens Convention Centre in Rosemont, Illinois.

Visitors from 77 countries witnessed the latest developments in digital printing and digital embellishment, along with sustainability and workflow automation. Hardly surprising as the show’s key theme was the digital transformation of the labels industry.

Global digital press debuts at the show included HP Indigo’s V12 digital press, the Durst Tau RSCi and the Dantex Pico Jet 1200S. On the converting side, automation and digital replacement of analogue processes featured with new machine lines from a range of companies.

Several Australian and New Zealand companies attended the show including Currie Group, Konica Minolta, Nekkorb, PrintLounge, Wedderburn and Wrapt.

Manufacturers and suppliers showcased some amazing solutions, which we have summarised here.

A B Graphic International (ABG)

Currie Group supplies solutions from print finishing specialist A B Graphic International (ABG) in Australia and New Zealand. Staff from Currie Group

supported ABG and were on the stand demonstrating the technology to visitors.

With its biggest booth at the event, ABG showcased more finishing machines than ever, demonstrating

18 newzealandprinter.co.nz October 2022

LABELS & PACKAGING

Digital transformation of the labels industry on display at US label event.

Currie Group and friends at Labelexpo, from left: Jon Murray, Currie Group, Lindsay Nutley and Jesper Noisen, QLM; Mark Daws, Currie Group, Simon Pugh, QLM, Craig Walmsley, HP; and Wayne Quayle, Currie Group

Steve Matthews (l) and Chris Wise from Wrapt

LABELS & PACKAGING

including Non Stop Winding Technology and a range of shrink sleeve product.

Matt Burton, global sales director, A B Graphic International, says, “Labelexpo Americas was an overwhelming success for ABG. The level of interest we received across a whole range of finishing lines was really gratifying after a few years of no exhibitions. On a personal level, it was great to be back at Labelexpo meeting customers and partners in person. It’s these moments that make the label industry a great place to work.”

HP Indigo

The new HP Indigo V12 Digital Press proved hugely popular at the show with visitors three and four deep across the 15-metre face of the machine for most of the first day of Labelexpo Americas.

Using the new LEPX technology, the HP Indigo V12 Digital Press prints at 120 linear metres per minute with 12 HP ElectroInk stations and 1600dpi image resolution.

The LEPX multi-imaging architecture incorporates six imaging engines – each making its own colour separation on the blanket belt simultaneously. The new LEPX writing heads feature thousands of LEDs to compose an image as an electrostatic field at 1600 dpi.

Designed from the ground up, the new press spent several years in development and the wait has proved worthwhile as it runs narrow-web at a speed of four times faster than anything seen before with the traditional HP Indigo Electroinks. It can run 12 colours simultaneously.

the company’s constant innovating to improve efficiencies and workflow for its customers.

Machines on display included: ABG’s flagship Digicon Series 3 beverage specification, including Big Foot, Flat Bed Screen and even more retrofittable modules; ABG’s new SRI3 incorporating enhanced functionality and ease of use for operators, while being fully retrofittable; DigiLite; DigiLase with a new decal option for roll to roll, individual pieces and A4 sheets; Vectra ECTR, for efficiency in turret rewinders; and an RTS sheeter.

Designed for any digital printing application, the Digicon Series 3 can be used roll to roll or roll to sheet. Key features include die plate loading and un-loading; fast track die-cutting with the world’s fastest semi-rotary die cutting

system, which can run at 180 metres per minute to work in-line with the world’s fastest digital print engines; gap sensing and knife setting; the Big Foot 50-ton capacity hot foil and embossing module with multiple foil feeding across and along the web; a flatbed screen printing module; a crossover module; a lamination in register module so you can laminate pre-printed web to the main web in register; and DigiJet, ABG’s digital embellishment module to create high quality digital embellishments.

ABG also showed the first Actega Ecoleaf unit in North America, a standalone unit highlighting the machine’s innovative technology.

Members of Enprom, ABG’s latest acquisition were also available to talk about the latest additions to the ABG portfolio,

Key features of the HP Indigo V12 Digital Press include: using six inline imaging engines running simultaneously; new high definition imaging; up to 12 colours on press capabilities; and one-pass, high speed finishing capabilities provided by ABG.

The Indigo V12 also meets sustainability targets with up to 90 per cent saving in media waste as there are no plates to discard and requires no hazardous cleaning fluids.

Dantex

Nekkorb Solutions supplies Dantex in New Zealand.

The new Dantex PicoJet 1200S reel to reel press, the latest version of the PicoJet 330S, impressed visitors with its print width of 330mm and print speed of 75 metres per minute. You can custom configure the press as CMYK or CMYK plus

19 newzealandprinter.co.nz October 2022

The ABG Digicon Lite 3

Natasha Brokken, from Nekkorb, flanked by Jed Hardcastle (l) and Benjamin Danon from Dantex

white and/or additional colours stations.

The PicoJet 1200S uses energy-efficient LED final cure with temperaturecontrolled backup roller for temperaturesensitive substrates. It incorporates static control, web cleaning and corona treatment for wide choice substrate printing capability.

Durst Durst has announced major upgrades to its Tau RSCi label printer.

The company has added a ninth white channel as well as two integrated flexo stations to the RSCi.

Matt Ashman, managing director Durst Oceania and Dan Mantel, technical sales manager Durst Oceania, were at the show. Mantel says, “The Tau RSCi label printer now has the option to fit another print bar to add another row of white print heads to the arrays. You can put down the same amount of ink but at a much higher speed. It will take the RSCi from 52 linear metres per minute to 80 linear metres per minute with the fastest white in the market without using any more ink.

“The Tau RSCi also has the option to be equipped with two flexo stations. One is before and one is after the digital print unit. This allows us to enter into some of the more technical markets like shrink sleeves and in-mold labels at 510mm wide and at a maximum speed of 100 linear metres per minute.”

Martin Leitner, labels product manager at Durst, says, “With these improvements, we can now produce in-mold labels for very big buckets, for example, 25 litre paint buckets. IML labels for this

application are 90cm or 100cm long and also wide. So we now have the perfect solution for the customer with a 51cm wide press and we don’t have a limitation in the repeat length. So when it comes to large IML labels, there is now a digital solution on the market today, and it’s ours.”

Epson

Making their Labelexpo debuts were Epson’s new UV inkjet digital label press, the SurePress L-6534VW with orange ink, and the new L-4733AW water-based resin ink digital label press.

Epson says the highly automated SurePress L-6534VW enables reliable and repeatable high-speed printing adding that the SurePress L-4733AW delivers accurate spot colours and gradients required for brand-quality colour prime labels and packaging. The new SurePress line offers high levels of print quality, expanded colour gamut, consistency, flexibility, and value for label converters, according to Epson. All SurePress models are Pantone certified.

The company also demonstrated a range of its other printers including its SureColor R5070 roll to roll printer; the 10-colour SureColor S80600 with white and metallic silver inks; and the SureColor P5000 printer, which includes a violet ink.

Esko

After its recent acquisition of Canadian AI software company Tilia Labs, Esko intends to address the need of brand owners and converters to connect and integrate the entire value chain through upstream digitalisation.Mattias Byström, vice president at Esko owner Danaher

Corporation, says, “Converters are coming under increasing pressure to deliver more volume with shorter print runs to bring versatility to the market, while the adoption of digital printing continues to grow. This acquisition demonstrates our ongoing commitment to providing integrated software and hardware solutions that accelerate the go-to-market process for consumerpackaged goods.”

“This underlines our commitment to delivering the tools that serve to connect brands and converters upstream. For all our customers continuing their digital transformation journey, the integration of these next generation tools means businesses will be able to digitise, automate and connect more efficiently to drive significant workflow and operational advantages, as well as sustainability benefits.”

Konica Minolta

Unveiling the new AccurioLabel 400 five-colour label press, Konica Minolta cemented its position in the burgeoning digital label printing space.

The AccurioLabel 400 allows customers to expand their businesses in digital label production and packaging. It incorporates Konica Minolta’s innovative technology, including the Intelligent Quality Optimiser (IQ-520) colour management functionality for real-time colour stability and registration control.

Offering a fifth well for white toner to expand creative label applications, the AccurioLabel 400 delivers resolution equivalent to 3600dpi x 2400dpi. It also uses numerous automated control features for highly productive output.

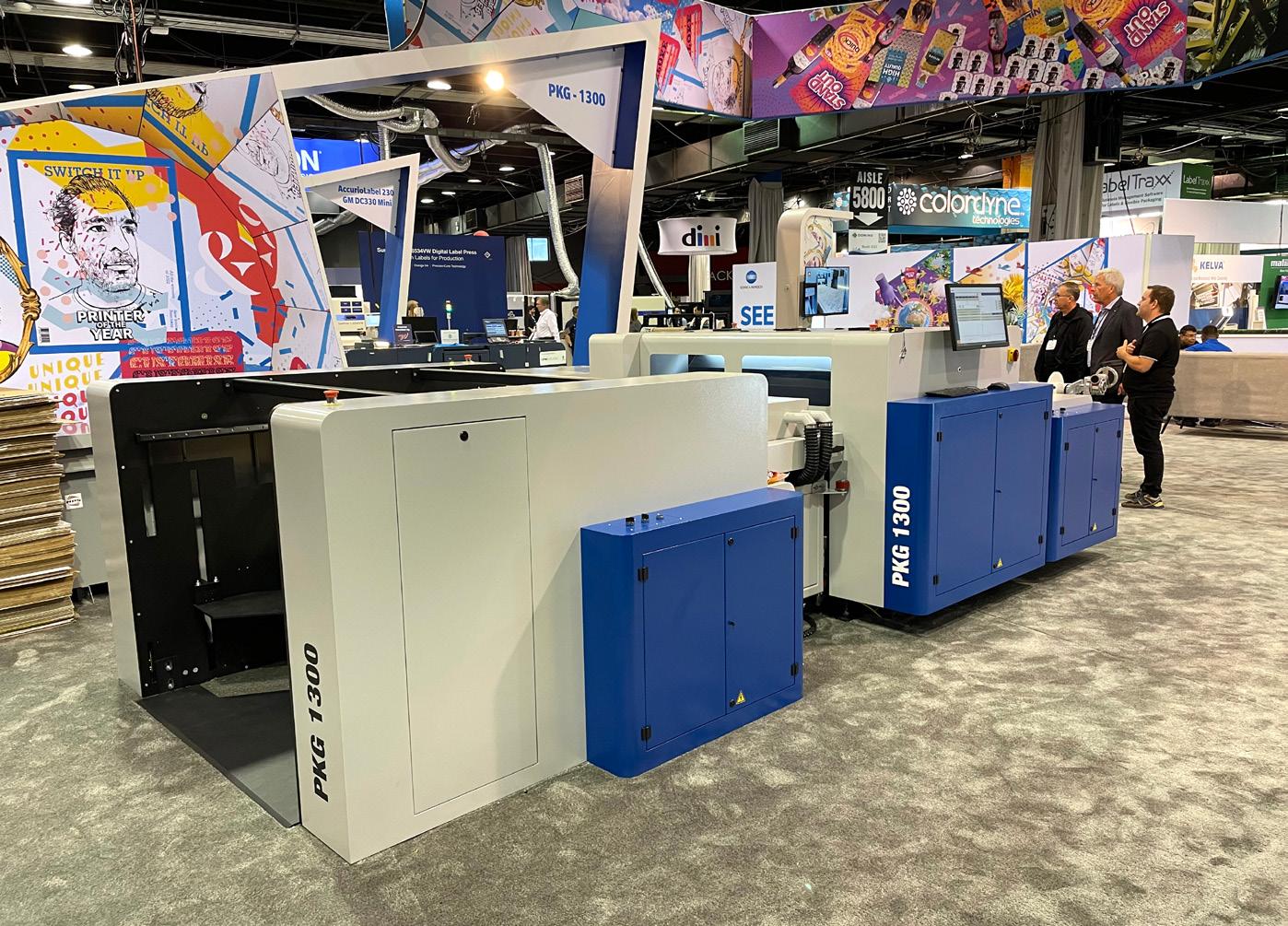

Konica Minolta also showed its new PKG 1300 packaging press for boxed material. Essentially an upgrade to Konica Minolta’s PKG line, the PKG 1300 includesan automatic feeder and stacker. Konica Minolta describes it as a high-quality inkjet printer for printing short runs of custom corrugated and folding cartons, flat or pre-cut, quickly and economically. For packaging manufacturers, it also offers a solution for quickly creating mock-ups of packaging designs, helping to improve time to market and reduce waste.

The company also showcased the AccurioLabel 230 digital label press running with the GM DC330 Mini for a compact digital label print and finishing solution. This label finisher allows users to add UV varnish with options for spot UV varnish, laminate, super-gloss and cold foil. It can also die-cut, slit and rewind to provide finished labels.

20 newzealandprinter.co.nz October 2022

LABELS & PACKAGING

Dan Mantel (l) from Durst with Steve Sheppard from PrintLounge

Flint Group Narrow Web

With new waste and cost-saving ink and coating products, Flint Group Narrow Web had plenty to talk about with visitors to the show.

Flint Group’s Evolution series of UVflexo coatings allows recycling of the substrates and their containers without contamination. The process of applying Evolution deinking primer to shrink sleeves allows the release of the ink during the recycling process, without contaminating the valuable bottle flake. The materials are then rinsed and pelletized into recycled polyester (rPET) for reuse.

The Evolution Caustic Resistant Over Print Varnish facilitates the recycling of PET bottles utilising pressure-

LABELS & PACKAGING

Gallus

With their first fully-digital label press, the Gallus One, scheduled for release in 2023, Gallus and Heidelberg had much to talk about at the show.

Based on the Gallus Labelmaster press platform, the Gallus One targets costefficient and sustainable production of high-quality labels.

The reel to reel UV inkjet digital inline label press has a width of 340 mm; a resolution of 1,200 dpi; four colours plus white; and a print speed of up to 70 metres per minute. It also fully integrates into Heidelberg’s Prinect workflow. The companies say the new system combines the digital printing and software know how of Heidelberg with the extensive expertise of Gallus in label printing.

Gallus will open a new experience centre in April 2023 at St Gallen in Switzerland. Dario Urbinati, chief sales and service director at Gallus, says, “The Gallus One is not just a new printing machine, but the start of a new era for Gallus and Heidelberg.”

Kurz

The DM-Uniliner 2D digital embellishment machine is Kurz’s standalone metallisation unit for brilliant 2D effects on labels.

Designed for the narrow-web sector, this digital embellishment unit works independently from printing systems and is equipped with inkjet technology. With this machine, operators can apply metallisation in preprint or post print processes. Overprinting of the metallised designs or holographic structures creates a variety of iridescent colour and light effects.

sensitive labels. The varnish prevents contamination of the wash-water and bottle flake in the initial recycling process by keeping the ink secured to the label substrate. When immersed in the floatsink bath, the intact label floats to the surface where it is separated from the bottle recycling stream.

Flint Group Narrow Web also presented its expanded range of Dual Cure UV-flexo inks that are curable under LED lamps as well as mercury lamps. The company’s new Dual Cure products focus on ultraclear non-yellowing performance and food contact materials (FCM) applications.

Dual Cure Ultra Clear is a UV-flexo clear overprinted coating, that does not yellow over time. Free of benzophenone, it offers long-term brand integrity and product safety.

The DM-Uniliner 2D transfer machine targets flexibility in terms of finishing time for smooth, fast processes with low amounts of waste. Its performance and process reliability are specifically tailored to industrial requirements, so that finishing, even of the shortest runs, always remains profitable.

Depending on the substrate, the DMUniliner 2D can process up to 75 roll metres per minute. Roll diameters up to 800 mm enable long running times without roll changes. The designs to be finished can be metallised either before the overprinting process or afterwards.

The company says the DM-Uniliner 2D is ideal for finishing web labels. In addition, the Kurz multi-use function is also available in the DM-Uniliner 2D, as up to three transfer runs are possible

21 newzealandprinter.co.nz October 2022

First glimpse: the HP Indigo V12 Digital Press

Felix Mueller, president Heidelberg America; Dario Urbinati, chief sales and service director at Gallus Group; and Dan Maurer, vice president digital print Heidelberg USA

LABELS & PACKAGING

depending on the design for maximum usage of the metallisation layer and increased sustainability of the product.

Xeikon

A division of the Flint Group, Xeikon displayed several of its latest solutions and applications including its hybrid printing machines, Cheetah 2.0 portfolio and Panther 2.0 technology.

Xeikon Cheetah 2.0 dry toner technology is now cloud-connected with man to machine and machine to machine

interfaces where the machines are in constant communication with each other, driving and monitoring print jobs with full automation.

Earlier last year, Xeikon introduced two new models: the CX30 and the CX50 entry level dry-toner presses. With each cloud-connected solution, operators can monitor print manufacturing from anywhere on the shop floor by viewing the interfaces/dashboards 24/7 on a smartphone or any other device. At the show, Xeikon introduced new application capabilities for Cheetah 2.0, including

gold and silver toners. Xeikon also provided more information about Titon toner technology, its new heat-resistant, food safe and dry toner formulation offering the benefits of UV inks without the disadvantages.

The company aims to meet industry needs for sustainable printing methods and environmentally friendly paper-based flexible packaging production. Its Panther 2.0 technology for UV inkjet targets durable labels as well as those for health and beauty,

DuPont

Demonstrating the latest Cyrel technologies and solutions, DuPont focused on high performing innovative technologies to address label converters’ challenges to achieve their sustainability, productivity, and quality goals.

Cyrel Fast, a thermal plate making system, comprises a thermal processor and a variety of photopolymer printing plates for flexible packaging, labels and other applications. DuPont says it offers superior productivity and performance while helping to reduce processing costs, time, and environmental impact compared to the existing solvent method.

The system eliminates the use of solvents, including water, from the platemaking process and needs no drying time.

Tucker Norton, general manager for DuPont Cyrel, says, “The system is an achievement of more than 20 years of continuous evolution and investment into this platform and has resulted in more than 1500 installations globally.

“We consider the show a great opportunity to get closer to the label converters, and reinforce our solutions for a more sustainable printing in flexo.”

Actega

Manufacturing specialty coatings, inks, adhesives and sealing compounds, Actega showed a new line of inks as well as some of the company’s most innovative inks and coatings for the food, cosmetics and pharma industries.

Applications on display included labels and narrow web pouches highlighting Actega’s LED-UV and water-based flexo inks and coatings. The company also showed samples of haptic and visual effect coatings for shrink.

These coatings are applied on the outside of the shrink sleeve to give extra impact on the shelf. Effects achievable include soft touch, matte and raised image. Actega experts explained the functional benefits of these coatings to visitors.

22 newzealandprinter.co.nz October 2022

Wade Marriner, from Konica Minolta, with the AccurioLabel 400

From left: David Reece, Jet Technologies; David Morris, Kocher+Beck; with Tony Reid and Vernon Herbert, Wedderburn New Zealand

8th drupa Global Trends Report 2022 –Executive Summary

Welcome to the 8th drupa Global trends Report Executive Summary. A lot has happened since the last one was drafted in Spring 2020! Covid pandemic, global supply chain difficulties, regional wars, trade wars, rising inflation, climate change - the list goes on. But so does

life and the print industry is remarkably resilient. So strikingly, printers globally were on average slightly more confident about their companies than they were in 2019 and have strong expectations for 2023.

drupa Printer Barometer of economic confidence

2022 by region drupa Printer Barometer economic confidence 2022 by region

Globally in 2022 34% of the printer panel stated their company current economic condition to be ‘good’ and 16% described it as ‘poor’, a net positive balance of +18%. It is this net balance, positive or negative that is used in many of the charts. The detailed breakdown of printers and suppliers by market and region is given in the full report’s Appendix, but the data sets for Australia/ Oceania and the Middle East were too small to use separately, though they are included in the global data. The same applies to Functional

Actual 2022 Forecast 2023 Africa

Chart A: How do you rate your company’s current economic situation? What are your expectations for the next 12 months?

data set

printers. Where small data sets have been included e.g. North America and Africa, attention is drawn to this limitation in both the text and the charts.1

1. Column gaps in any chart indicate a nil result.

23 newzealandprinter.co.nz October 2022 drupa Global Trends 1

drupa Global Trends September 2022

S/CAmerica

NAmerica Asia Europe

Drupa Global Trends

Actual 2019 -40 -20 0 20 40 60 80 Small

% net balance positive v negative 100 -40 -20 0 20 40 60 80 100 Global % net balance positive v negative

We can see striking variations in optimism e.g. between Europe – cautious and South/Central America or Asia - optimistic. Looking at the data by market, Packaging printers show increasing confidence, Publishing printers show a recovery from a poor result in 2019 while Commercial printers reported a small decline in confidence this year but have expectations of recovery in 2023.

“Raw materials availability, rising inflation rates and rising product prices, declining margins, ruinous price wars between competitors [combine to be the biggest threat over the next 12 months].“ Commercial printer, Germany

“Take advantage of economy growth after pandemic times. Communicate our innovation and sell our added value products to new customers and markets.” Packaging printer, Costa Rica

Suppliers were more confident, a global net positive of +34% for 2022 and notably more

positive for Europe for 2023. Whilst they were a little more cautious for the Commercial and Publishing markets for 2022 - down 4 or 5% on 2019, they have strong positive forecasts for all market sectors for 2023 (net positive balances for Publishing +36%, Commercial +38%, Packaging +48%, Functional +51%).

Between 2013 and 2019, more printers dropped prices than raised them by an average of -12% despite ever increasing paper/substrate prices. Then suddenly in 2022 there is an unprecedented positive net balance of +61% in favour of those raising rather than lowering prices. Yes, there were heavy paper/substrate price increases, but those never prompted such price increases to end customers in the past. What is going on? What is more, this pattern is global, applying to most regions and markets. It should be noted that margins remain under pressure for almost everybody – so some things stay the same.

over time

24 newzealandprinter.co.nz October 2022 drupa Global Trends

2 drupa Global Trends September 2022

negative

How have your company’s revenues/prices/margins/utilisation/ substrate prices changed over the last 12 months?

time % net balance positive v negative Prices Margins Revenues 2018 2019 2022 100 -80 -60 -40 -20 0 20 40 60 80 Utilisation Paper/Substrate prices Drupa Global Trends

Global printer financial performance

% net balance positive v

Chart B:

Global printer financial performance over

It is a similar story for Suppliers with a +60% net increase in pricing – previously the highest was +18% in 2018. Clearly emerging from Covid, pricing behaviour has changed radically and this has implications for inflation if repeated across other industries.

Turning to printer operational measures, one key metric that has been tracked since 2014 is the volume of print produced by the huge variety of print technology. The Appendix of the main

report provides this in full, but Chart C gives the headlines, shown as net positive or negative net balances in volume of printed material. A large drop in Sheetfed offset in Commercial was almost matched by an increase in Packaging. It is worth remembering that the first negative net balance in Commercial was only in 2018 and then only very small. The other standout features are the huge growth in Flexo for Packaging and substantial gains in Digital toner cutsheet colour and Digital inkjet rollfed colour.

Print volume 2022 by technology

% net balance positive v negative

Print volume 2022 by technology

% net balance positive v negative

Commercial

Chart

One trend we would expect to have seen sustained through the pandemic is the growth of digital print as a % of total turnover. Yet this appears to have stalled globally between 2019 and 2022 – except in Commercial print which grew modestly.

Next, we must report a real puzzle. There has been a steady decline in the % of printers reporting they operate a Web-to-Print/Digital storefront from a peak of only 27% in 2017 to

23% in 2019 and 20% in 2022. For Commercial printers this has dropped from 38% in 2017 to 26% in 2022, while Publishing grew to 33% this year, but Packaging fell from 15% in 2019 to 7% in 2022. We acknowledge the reduction in sample size, but the numbers are still good globally. We will just have to see if next year shows a recovery.

25 newzealandprinter.co.nz October 2022 drupa Global Trends

3 drupa Global Trends September 2022

C: How would you assess your printing volume in the following technologies over the last 12 months?

Drupa Global Trends

Publishing Flexo Digitaltoner cutsheetcolour Digitalinkjetrollfedcolour Sheetfedoffset Total -40 -20 -10 0 10 20 30 40 Packaging

% of those with web-to-print with > 25% of turnover W2P

% of those with web-to-print with > 25% of turnover W2P

Chart

However, for those with Web-to-Print installations, the Covid period saw a substantial increase in turnover via that channel (Chart D). Pre Covid this growth had stalled with no significant growth globally across all markets

between 2014 and 2019 (just 17% of the panel with Web-to-Print reporting that more than 25% of turnover came that way in both years). But since then, it has shot up to 26% and the increase is across all markets.

Chart E: How has capital investment changed over the last 12 months? Over the next 12 months will your company‘s capital investment ?

26 newzealandprinter.co.nz October 2022 drupa Global Trends 4 drupa Global Trends September 2022

Total

0 5 10 15 20 25 30 35

% 2019 2022 Commercial Publishing Packaging

2014

Cap Ex Printers 2022 Global and by market % net balance positive v negative Commercial Publishing Packaging 0 10 20 30 40 50 Actual 2019 Actual 2022 Actual 2018 Forecast 2023 0 10 20 30 40 50 Global Cap Ex Printers 2022 Global and by market % net balance positive v negative

D: What % of total turnover by value was handled by Web-to-Print over the last 12 months?

Drupa Global Trends

Not surprisingly Capital expenditure has fallen back since 2019 both globally and in all markets, but the prospects for 2023 and beyond are good. Regionally all regions forecast growth next year, except Europe with a flatline forecast. Finishing equipment and print technology were by far the most popular targets.

Regarding print technology, the clear winner in 2023 will be Sheetfed offset (31%), followed by Digital toner cutsheet colour at 18% and Digital inkjet wide format and Flexo both at 17%. It is very striking that Sheetfed offset remains the favourite target in 2023, despite a clear decline in volume

of print by that means in some markets. For some it is to consolidate, reduce labour and wastage, for others it is to grow capacity. What is more the popularity of Sheetfed Offset remains for all three markets - see table 1.

Strikingly when asked about long term (5 year) investment plans, top came Digital Print at 62% then Automation at 52%. Conventional print was still listed as the third most important likely investment 32%, this is not to overlook the fact that the Digital technologies are growing fast if we collate the various technologies together.

1st choice

Sheetfed offset 31%

Sheetfed offset 30%

Sheetfed offset & Digital toner cutsheet colour 27%

2nd choice

Digital toner cutsheet colour 18%

3rd choice

Flexo & Digital inkjet wide format 17%

Digital toner cutsheet colour 26%

Digital inkjet wide format 25%

Coldset offset 24%

Flexo 39%

Sheetfed offset 34%

Gravure, Digital inkjet rollfed colour and hybrid offset/flexo/ digital 14%

Table 1: In which of the following print technologies do you plan to invest in the next 12 months?

As for suppliers, they reported a net positive balance +15% for Cap Ex in 2022 and a net positive of +31% in 2023. Investment forecasts for 2023 were more muted in Commercial and Publishing but strong in Packaging and Functional.

Looking at the emerging strategic challenges, both printers and suppliers have been struggling with supply chain difficulties (paper/substrates and consumables for printers and raw materials for suppliers) and they expect these to continue into 2023.

41% of printers and 33% of suppliers also reported labour shortages. Wage/salary rises have been and/or will be the result.

Environmental, Social and Governance issues are increasingly important across the globe for both printers, suppliers and their customers.

Considering short term constraints on the Print Market globally, the traditional issues dominate: Strong competition and Lack of sales/Demand – the former highlighted more by Packaging

27 newzealandprinter.co.nz October 2022 5

drupa Global Trends September 2022 drupa Global Trends

2023 Print technology investment targets - Global and by market Global Commercial Publishing Packaging

Drupa

Trends

Global

printers, the latter more by Commercial printers. Looking to the next 5 years, the impact of Digital media is highlighted by both printers and suppliers followed almost equally by Lack of specialist skills and Overcapacity in the industry.

When we started the Trends Report series, we paid only modest attention to broader socioeconomic issues. However, given the increasing impact these were having on the print market, we introduced questions on this in 2019. Given Covid and the other challenges that have come fast and furious since, this was a wise move. Globally 52% highlighted the impact of pandemics either directly or on the economy and 42% chose Economic recession in their country or region. But there were some noticeable regional variations. For example, 62% of Asian printers chose pandemic impact versus 52% globally; 58% of South/Central American printers chose Economic recession versus 42% globally; and 32% of European printers chose regional physical wars versus 21% globally. And there was a clear majority (59%) that thought socio-economic pressures were either more important than or of equal importance to market pressures.

In conclusion we were encouraged by the broadly positive outlook that printers and suppliers had both of trading in 2022 and the prospects for 2023. Indeed, perhaps the single most striking result of the survey was that globally the Barometer of Economic Confidence was slightly higher in 2022 than in 2019 before Covid struck. Then again, most regions and markets forecast better trading in 2023. This was not universal and there are strong headwinds to make things more difficult – some global, some regional.

Clearly investment fell during the Covid pandemic and companies have taken time to recover. Nevertheless, printers and suppliers report a determination to grow their businesses, investing as necessary, starting in 2023. As there are few signs that market and broader economic pressures will lessen, this is just as well. For only those companies who invest wisely, bring their costs down by raising productivity, diversify and innovate and invest in their team, will prosper. This is well summarised in a quote from a printer in Portugal.

“Looking for the biggest opportunity, my company must be alert, be patient and look for new demands... The Covid pandemic, and the Russia/ Ukraine war will bring new disruptions in market, but equally may create new opportunities. [These] could be found in markets where innovation and rehabilitation [reform] could happen. For that, my company will look essentially for digital operations... (labelling, digital printing - wide format and medium format).” Commercial, Packaging and Functional printer, Portugal

28 newzealandprinter.co.nz October 2022 6

drupa Global Trends September 2022 drupa Global Trends Drupa Global Trends