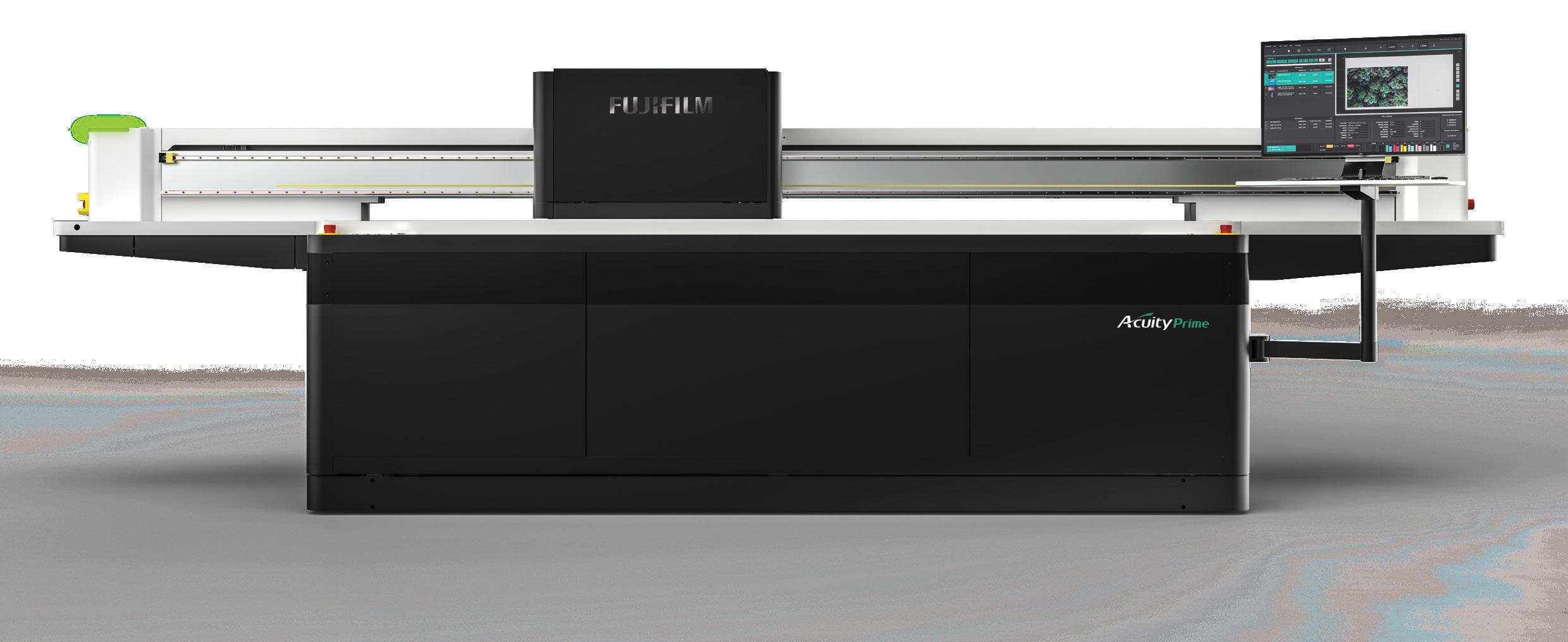

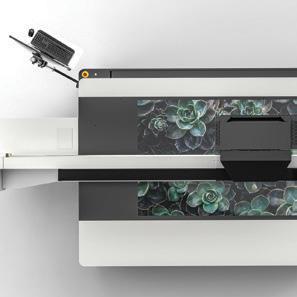

The new Acuity Prime FB30 and FB20 flatbeds offer high quality printing on a range of medias, supported by its five dedicated vacuum zones and optional jettable primer. This range is available at a cost effective price point and offers an excellent return on investment, and once you’ve had it installed, FUJIFILM’s nationwide service network will keep it printing!

With outstanding image quality and excellent adhesion to a broad range of rigid and flexible media, materials and objects, the Acuity Prime can produce an amazing variety of printed products for distance and close viewing. The vacuum table can handle almost any sheet material. It secures rigid and flexible media and holds it perfectly flat for high quality print across every sheet.

The option to print with white and clear inks, and to print directly to almost any material in perfect registration, enables the Acuity Prime to produce high value, creative work that could offer opportunities for new revenue. With the jettable primer option, the Acuity Prime can adhere to a wide variety of industrial media.

At Fujifilm we understand the value of production time and usability, so we designed the Acuity Prime with the operator in mind. With a new and user-friendly GUI, easy clean printhead maintenance and visible status lights for the ink tanks, operators are able to spend less time maintaining the machine and more time printing.

With variable drop-size printheads and highly pigmented inks, Acuity Prime printers lay down a thin ink film, which minimizes production costs, and in combination with a competitive system price, support an excellent ROI.

For more information contact the Wide-Format Team on 0800 242 646.

Finance avaiable though

12-15 Aarque Group: For over six decades Aarque Group has been one of the leading providers of digital printing solutions, offering Kiwi businesses the very best in printing technology, including the latest software, materials, machinery and finishing equipment — all under one roof

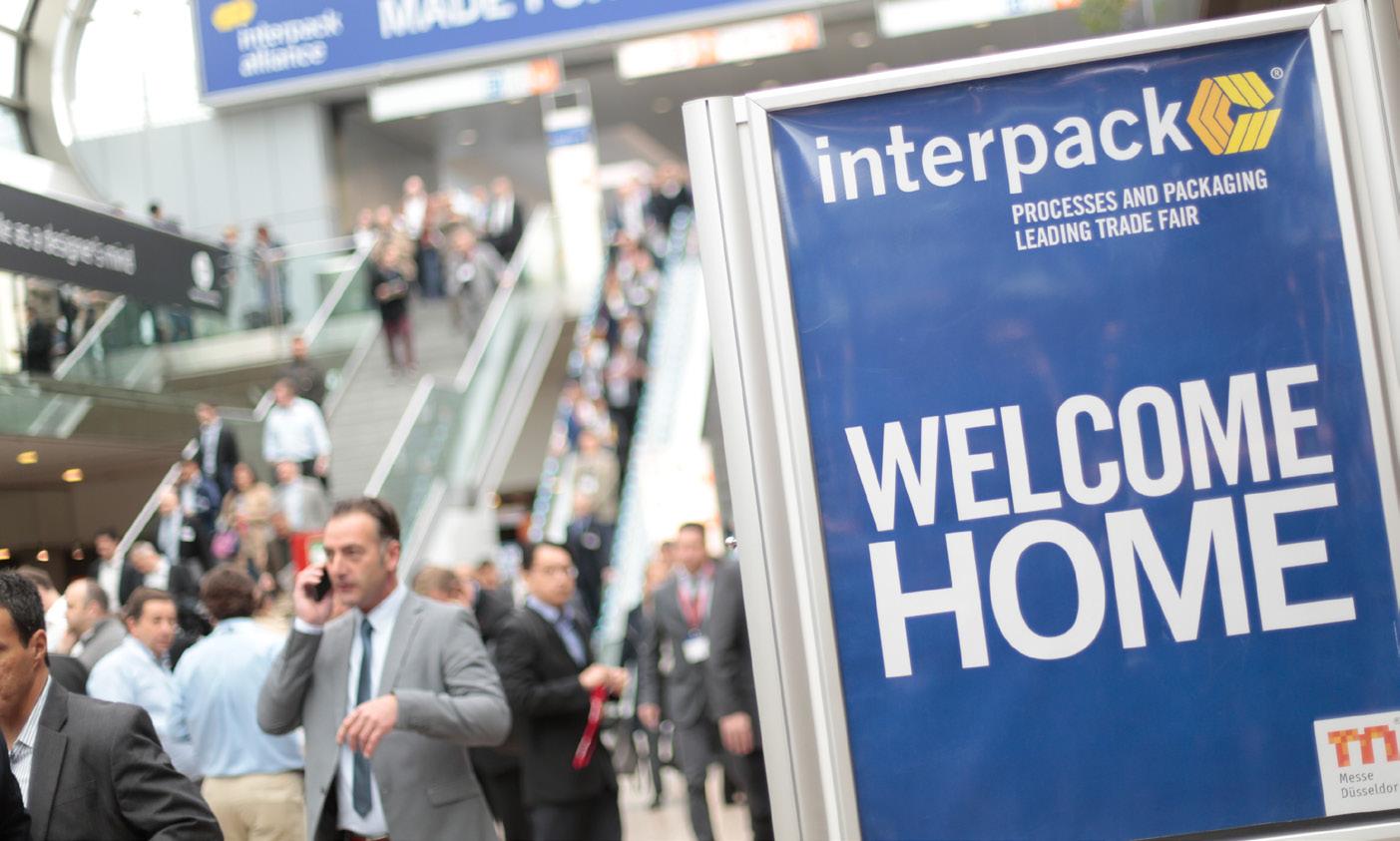

32-34 Interpack: After a two-year absence, Interpack will return in May

Wide Format Plus p45-52

46 NZSDA Update: Melissa Coutts discusses how planning for change can help your sign business

48 NZSDA Signee Insight: Raising industry standards is just one of the aims for Signee New Zealand this year

54-55 Increasing energy efficiency forms part of MBO’s investment in climate and environmental protection

56 Sustainability: Jo Pearson offers five ways to create value from your sustainability initiatives

57 Think Laterally: Mick Rowan discovers that his journey in print continues, despite changing his career direction

16-17 Introduction: Piotr Wnuk discusses how digital is making headway into this sector, with short-run costeffectiveness and print personalisation

18 BJ Ball: Short run label solutions from BJ Ball are proving popular with companies across the country

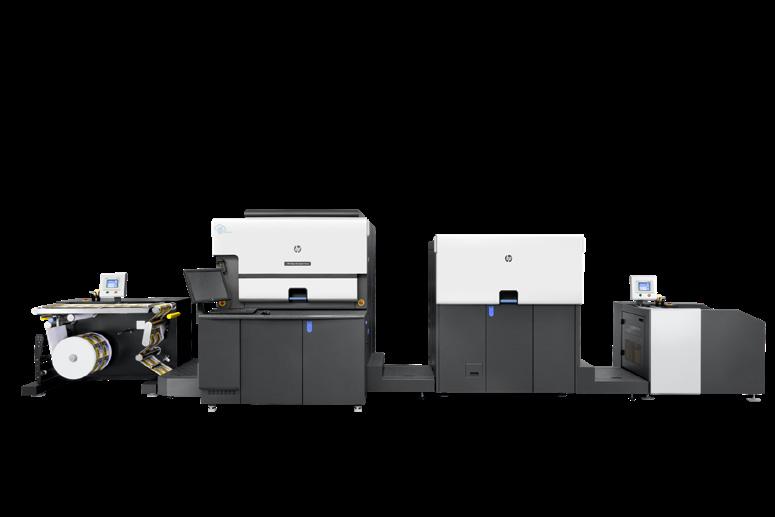

20 Currie Group: SSCG is forging ahead in labels with its new HP Indigo 6k Digital Press, supplied through Currie Group

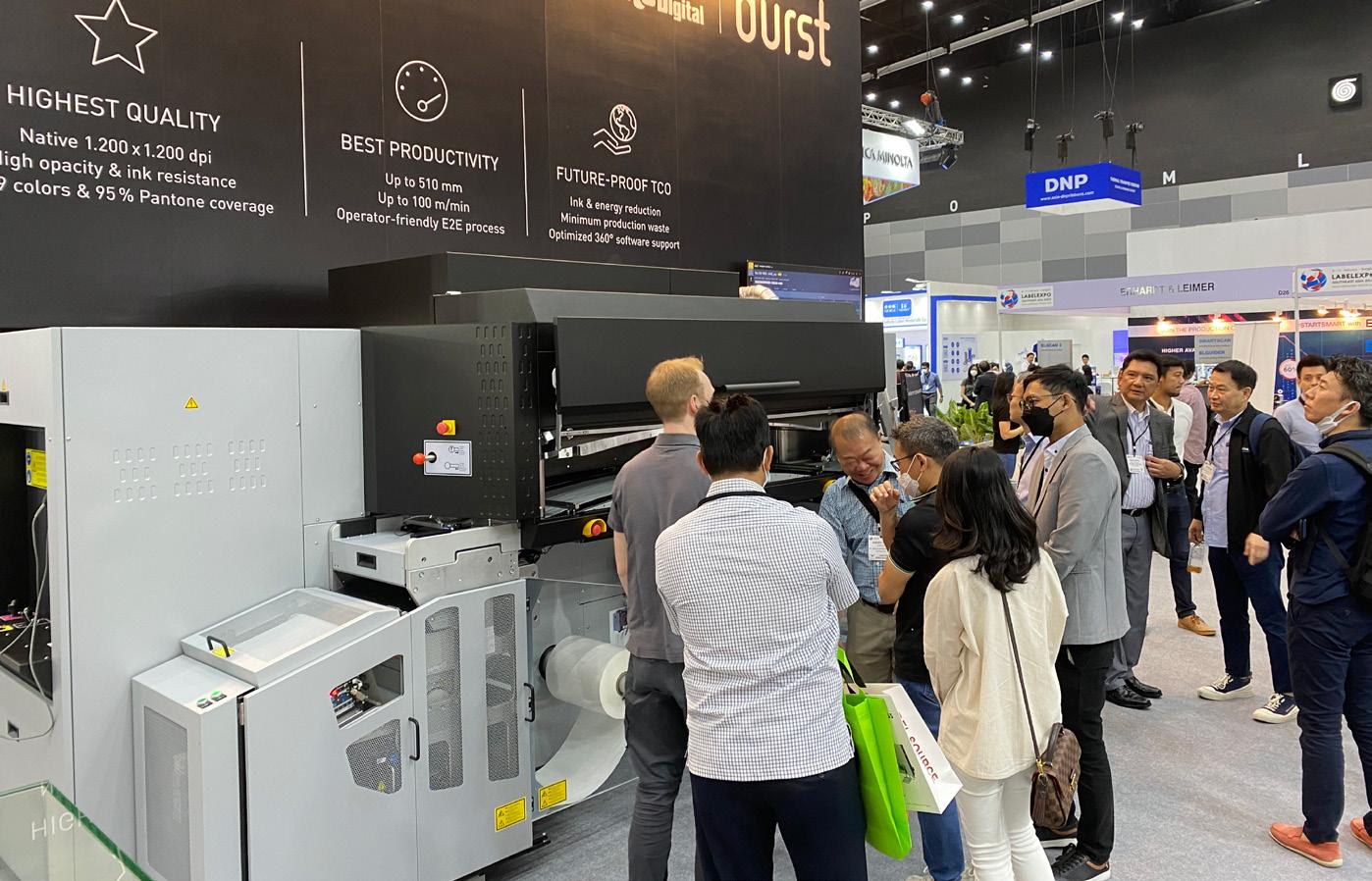

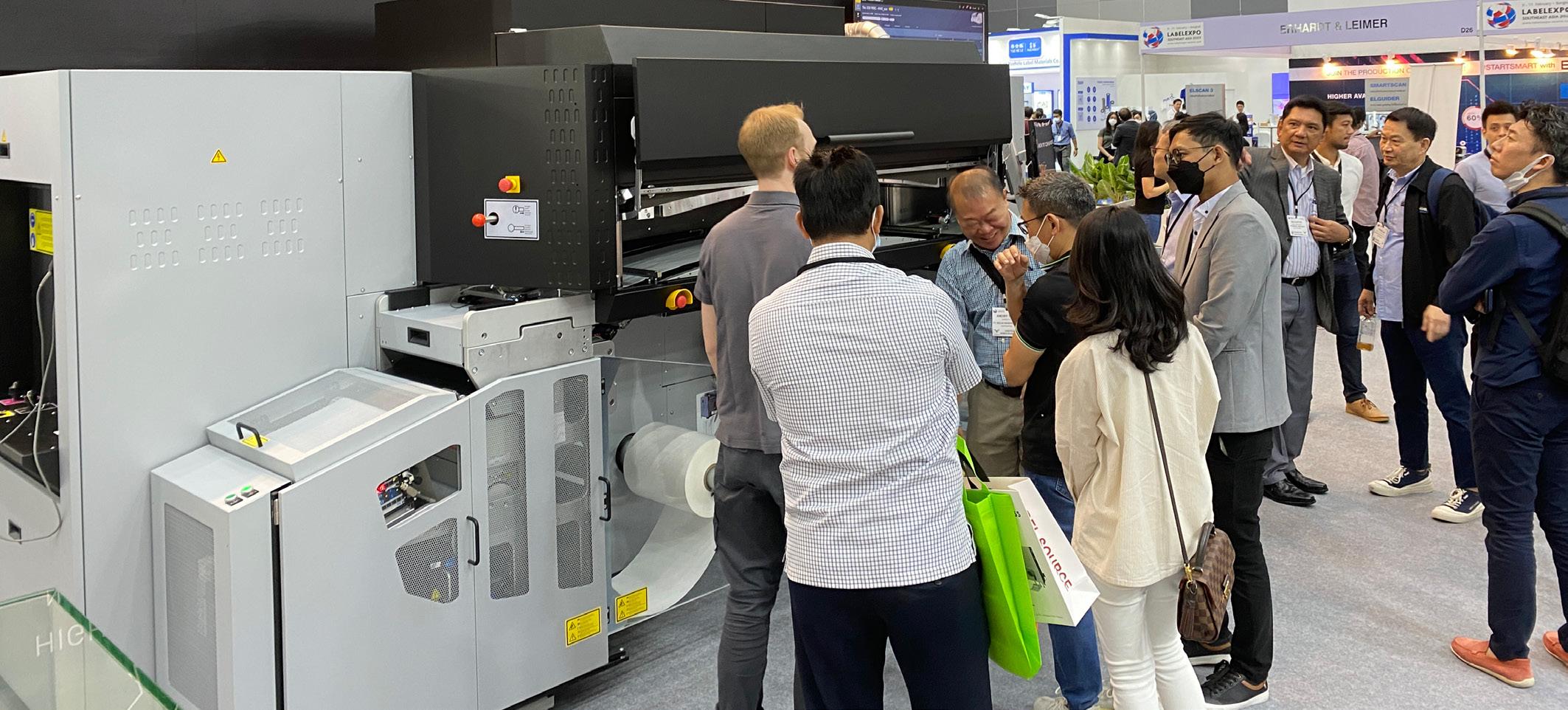

22 Durst: At Labelexpo Southeast Asia, Durst showcased the capabilities of its Tau RSC E 330 5c press

24 Jet Technologies: Labelexpo Asia gave Jet Technologies a chance to join its industry partners and meet visitors from across the region

26 Spicers New Zealand: Ecofoil Digital and Gorilla Board are the latest solutions from Spicers

28-30 Labelexpo: Returning to Bangkok, Labelexpo Southeast Asia showed the latest technology and solutions

PO Box 32-395, Devonport, Auckland 0744

EDITORIAL:

Bruce Craig, Editor - bruce@newzealandprinter.co.nz

021 631 559

CONTRIBUTORS:

Ruth Cobb, Melissa Coutts, Andy Lowe, Iain MacIntyre, Jo Pearson, Kevin Ptak, Mick Rowan, Piotr Wnuk

CIRCULATION: brian@newzealandprinter.co.nz

DISPLAY ADVERTISING SALES & SERVICE:

Brian Moore - brian@newzealandprinter.co.nz

+61 410 578 876

CLASSIFIED ADVERTISING:

Brian Moore - brian@newzealandprinter.co.nz

DESIGN & PRODUCTION:

Sarah Vella - sarahvelladesigns@gmail.com

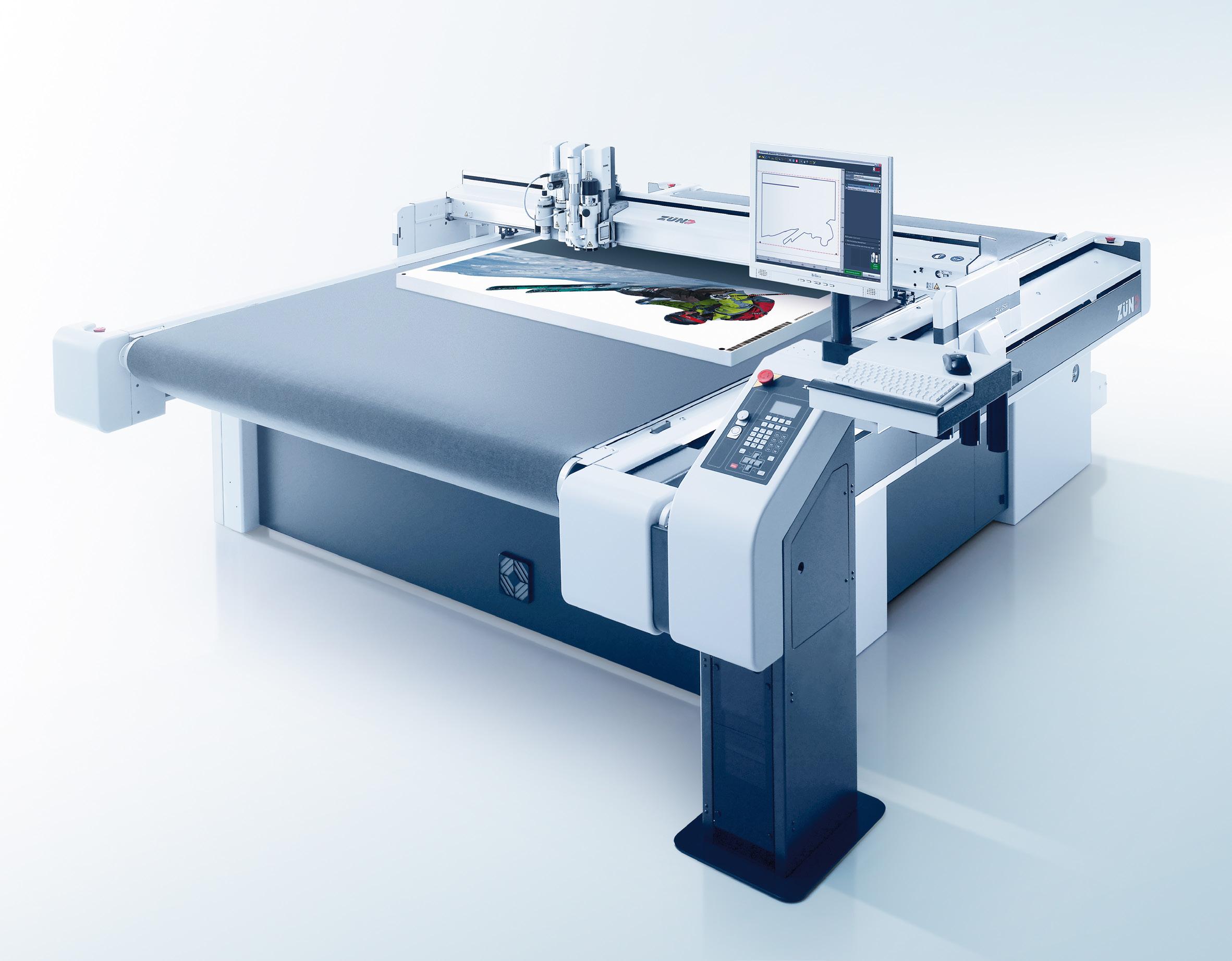

50 Starleaton: Mirage Visual is looking forward to installing a new Zünd G3 cutting table

PrintNZ p8-11

8-10 Helping Hand: Getting a handle on business insurance is vital right now, reports Iain MacIntyre

11 Comment: Ruth Cobb has the winners from the recent Mainland Region Charity Golf Day

36-37 Fujifilm Business Innovation: The company’s global president and chief executive officer Naoki Hama recently visited New Zealand

38-40 Fujifilm Business Innovation: Two Iridesse Production Presses are delivering quality and productivity to Gallagher Group

42 & 44 Konica Minolta: Inline finishing is a growing strength for Konica Minolta customers

ISSN 1171 7912

New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December.

New Zealand Printer is a member of the Printer Media Group

New Zealand: New Zealand Printer

Asia Pacific: ProPack.pro

Australia: Australian Printer, ProPrint

MANAGING DIRECTOR: James Wells - james@intermedia.com.au

GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz

© Copyright 2023: Contents of this magazine are subject to copyright and cannot be reproduced without written permission of the publisher.

MIRACLON has expanded its leadership team in the AsiaPacific region with the recent appointment of Andy Yarrow as regional commercial director and Joerg Kullwitz as commercial lead to drive optimisation of customers’ gravure-to-flexo conversions. Based in Singapore, Yarrow will head up Miraclon’s APR sales, service and business management teams. He has over 23 years of printing industry experience across a wide range of markets and applications, including commercial print, sign and display, corrugated, ceramics and textile. Originally from the UK, for the last eight years, he has worked in the Asia-Pacific region in a variety of sales and leadership roles for Xerox, EFI, Océ and Kornit Digital, where he served as APR President. In his most recent position, he was responsible for kickstarting the operations of an innovative Israeli start-up, Twine Solutions.

EPSON has partnered with a Japanese fashion designer Yuima Nakazato at Paris Haute Couture Fashion Week Spring/ Summer 2023. In addition to utilising Epson’s digital textile printing to reproduce his unique designs, Nakazato developed a part of his collection using a more sustainable textile production process. Epson’s dry fibre technology, which is used commercially to recycle office paper, and which requires virtually no water, has been adopted by the designer to produce printable non-woven fabric from used garments. The new fabric production process was revealed in Paris as part of a three-year collaboration between Epson and the designer and was used in the creation of items for the first time, showcased during his runway show.

Durst Oceania has confirmed it will be conducting a global search for new sales executives as the geographical reach of the business expands.

“Due to the ongoing success of Durst Oceania, we are now looking to grow the team and sales in the region as we broaden our reach into new markets,” Ashman said. “The two new sales roles will be for a label sales manager as well as for a wide format and textiles sales manager,’ Durst Oceania managing director Matt Ashman said.

“Candidates with global experience in sales as well as complementary cultural and language skills will be at an advantage as we embark into

new territories.

“We are also recruiting for an inside sales role responsible for pre-sales and after sales care and support. Along with this expansion, we will be recruiting additional field service engineers in New South Wales and the greater Brisbane area. All of these new team members will join our existing

dynamic and hard-working ‘Durst’ler’ family.”

Durst offers a friendly and flexible working environment with ample training provided.

The successful candidates with receive a competitive remuneration package aligned with experience and relevant skills for the role.

“We encourage applications from people looking to upskill and challenge themselves with a new career opportunity within our great industry. Durst is an equal opportunity employer and encourages applicants from all sectors of community,” Ashman said.

Contact Matt Ashman from Durst Oceania at matt. ashman@durst-group.com.

A B Graphic International (ABG), one of the global leaders in innovative labels and packaging solutions, has introduced laser perforation to its Shrink Sleeve SR –ABG’s seaming offering designed to meet the high productivity demands of the modern labelling market.

The laser perforation adds to and builds on ABG’s recent rebrand of the shrink sleeve range, including seaming (SR), doctoring (DR) and cutting machines (IC).

According to the company, by using a unique solvent application system with

The laser perforation adds to and builds on ABG’s recent rebrand of the shrink sleeve range

a motorised roller system (smartwheel), the SR creates a robust and reliable weld, ensuring that the web will not break when heat is applied. The application of the adhesive creates a flat,

clean weld that improves productivity, boosts product quality and helps reduce operating costs and waste.

The addition of laser perforation, which can be retrofitted to existing seaming machines, will provide quicker turnaround times and increased efficiency. Moreover, it does not require additional tooling as it uses the laser to make perforations.

All enquiries should be directed to Currie Group, the authorised distributor for A B Graphic International solutions in Australia and New Zealand.

Fiery, a provider of leading Digital Front End (DFE) technology for production and industrial printing, has separated from Electronics For Imaging (EFI). It will operate independently as a separate company while remaining owned by EFI’s owner, Siris Capital Group.

EFI and Fiery will have distinct areas of strategic focus that will enable them to serve their customers better and grow over the long term, with EFI as an industrial inkjet specialist and Fiery as one of the leading digital front-end (DFE) providers.

Jeff Jacobson, who led EFI as CEO following its 2019 takeprivate by Siris, will remain executive chairman of each business. Toby Weiss, longtime chief operating officer and general manager of Fiery, will continue to lead the business as CEO of Fiery. EFI has also appointed Frank Pennisi, a

veteran of the industrial and technology sectors, as chief executive officer.

“This realignment positions both EFI, now solely focused on digital inkjet for industrial applications, and Fiery, the leading global DFE provider, to win in their independent markets while maintaining the close partnership that has contributed to the success of each business,” commented Jacobson. “Digital imaging would not be where it is today without Fiery. Operating as a standalone company will only further strengthen Fiery’s market-leading position in providing innovative DFE solutions. Similarly, no company in the industry can match the depth and breadth of EFI’s industrial inkjet portfolio and I am looking forward to this next chapter of growth under Frank’s leadership.”

EFI will be solely focused

UK-headquartered KM Packaging has established an official business entity in Australia in Sydney.

KM Packaging has been exporting to Australasia since 1996, and outside of the US, it is the company’s second biggest export market. As a result of continued growth, the KM business is now at a scale that can support its further international development, which is a key part of the company’s long-term strategic growth plans.

John Shipley, KM’s business unit director for the Australian and European markets, said: “This expansion has been two years in the planning, and we are excited to build even stronger relationships with our partners and customers in the region. The move will allow us to explore new opportunities right across the chilled, frozen

Industry supplier

and ambient ready meal, convenience and fresh produce, and protein sectors.”

Tammy Spencer was appointed business unit manager (ANZ) based on the Gold Coast.

She has a wealth of industry experience and was most recently business manager for packaging and polymers with TCL Hofmann and previously with Multivac.

Spencer said: “KM has always had a strong reputation in the ANZ market. Customers spoke highly of its service and quality, so I knew it was a business with a strong customer focus and core values.”

on driving the analogue-todigital transition across the packaging and corrugated, display graphics, textile, and building materials/décor endmarkets for industrial inkjet. As an independent company, Fiery business will continue to provide DFE technology for digital production and industrial printing.

“Fiery solutions have always been about enabling digital print and making print engines better, and this is a milestone in furthering that mission,” added Weiss.

COMPUTALETA will host a Hardware Expo in Wellington in March. The two-day show, over March 15-16, will take place at the Southern Cross in Abel Smith Street. Arlette Farland, director at Computaleta, said: “The Hardware expo provides industry professionals with the opportunity to see the latest in signage and print-specific hardware technology from HP and Samsung. We will have live demonstrations with these solutions running throughout the show.

ESKO has launched Mox, a software package combining project management, digital proofing, and DAM in a single cloud-based product content tool developed to help growing brands bring quality products to market consistently, quickly, and sustainably. Mox delivers a host of benefits to businesses, including a Collaboration tool, bringing internal and external contributors together with the correct information to create and review before product launch.

Epson has expanded its range of PrecisionCore printheads with two new models, I3200(8)-S1HD and S800-S1, compatible with various inks used for industrial applications. The new products will be available from April 2023.

In addition to aqueous, UV-cured, and eco-solvent inks, the new printheads are compatible with oil-based, solvent, and other types of inks for digital printing applications in production printing.

Screen has announced it will introduce Truepress PAC520P, a high-speed, waterbased inkjet digital press for paperbased packaging substrates developed in response to the trend of reducing plastic material in packaging.

Screen showcased a prototype model of its new Truepress PAC520P at FachPack 2022 in Germany in September. It has been developed specifically for printing onto paper-based substrates, using waterbased, food-compliant inks for sustainable,

Fujifilm has expanded its series of highperformance RxD pigment dispersions for water-based inkjet ink formulation to include Orange PO71, Green PG7, and Violet PV23 pigments.

OGV colours are typically used to formulate ink sets that extend the gamut of a print system beyond the colour space achievable with CMYK, which is particularly important for achieving higher vibrancy, colour accuracy and matching brand spot colours in

Epson has expanded PrecisionCore rage with two printheads for industrial applications

The I3200(8)-S1HD is compatible with solvents with high solubility, giving this printhead the ability to meet the requirements for handling displays and photovoltaic cells. It prints with up to eight different colours of ink. Liquids of different types can also be jetted, enabling this printhead to adapt flexibly

to industrial printing applications. It delivers 1,200 DPI high-definition image quality, suitable for high-speed singlepass and multi-pass printing.

The S800-S1 is compatible with the same inks as the I3200(8)-S1HD, but the single-chip design enables it to print where space is limited and close to substrates with a 3D surface.

New printheads expand Epson’s offerings in the PrecisionCore series and enable the company to support a broader range of industrial and other digital printing environments for applications such as marking/coding, signage, and printed electronics.

The two new products are expected to increase the implementation of inkjet printing technology in new fields, particularly in industrial printing applications.

more environmentally friendly and easyto-recycle format for the products they buy. Meanwhile, brand owners demand shorter turnaround times with higher product diversification.

In response to these market trends, Screen has moved forward with product planning for its Truepress PAC 520P, offering lower environmental impact than conventional printing processes due to a drastic reduction in energy and material waste.

New inkjet press has been developed especially for paper-based packaging susbtrates

flexible packaging applications.

According to the company, one rapidly growing trend is reducing plastic material used in packaging. Many market research studies have shown that consumers perceive paper-based packaging as a

Building on almost two decades of experience in inkjet printing, the Truepress PAC 520P uses newly developed proprietary water-based pigment inks that comply with appropriate food-safety regulations for sustainable flexiblepackaging applications.

The system is expected to provide outstanding print quality and safety while maintaining exceptional throughput.

RxD pigment dispersions are used in Fujifilm’s aqueous ink developments for OEMs and are available to other ink formulators.

packaging, textile and commercial print applications.

Grant Murney, product manager of RxD inkjet pigment dispersions, said: “In developing the new RxD Orange, Green and Violet dispersions, we’ve carefully selected the best polymers and processing conditions to ensure optimum stability and print performance for our customers in line with the standard CMYK products already in the RxD product range.”

According to Fujifilm, RxD dispersions are highly stable and suitable for ink formulation across a wide range of applications. They are engineered with Fujifilm’s proprietary reactive dispersant technology, which uses a cross-linked polymer to create a secure cage around the pigment. This provides a stable dispersion that is compatible with a wide range of components used in inkjet ink formulation, enabling the design of stable ink formulations that meet demanding performance requirements.

Last year, Fujifilm announced a further expansion with a USD 47 million investment in its global RxD inkjet dispersion manufacturing capabilities, part of its commitment to meet the growing demand for new applications with aqueous inkjet inks.

September 13-15, 2022

March 24, 2023

Chicago, USA

Wellington PrintNZ’s annual Golf Days will welcome players of all skill levels to a social and fun day on the course. The Ambrose competition will make it an even playing field with great prizes, including best gross, best nett, nearest to the pin and best-dressed team.

Apart from the latest technology and solutions, Labelexpo Americas this year features a full two-day conference programme and two masterclasses organised by the Label Academy on digital embellishment and self-adhesive materials. www.labelexpo-americas.com

www.printnz.co.nz

September 17, 2022

Napier

March 28-29, 2023

Crown Promenade, Melbourne

The Association of Handcraft Printers has a full day programme including visits to Imprimo in Havelock North and Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

The AIP Australasian Packaging Conference and the Australasian Packaging Innovation & Design (PIDA) Awards will be held in person for the first time since the pandemic. This year AIP also celebrates its 60th anniversary. www.aipack.com.au

September 20-22, 2022

April 26-28, 2023

Auckland

World Trade Center Mexico

Following on from record attendance at Mexican label summits, Labelexpo Mexico is the newest addition to the series and has been created to service the rapidly growing Mexican market.

www.labelexpo-mexico.com

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise. www.foodtech.packtech.co.nz

October 11-15, 2022

May 3-5, 2023

Shanghai

Brixen, Italy

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”. www.allinprint.com

Following the success of the past few years, Durst is once again organising an Open House in 2023, the biggest to date. This is an exclusive event where customers from around the world will meet at the company’s headquarters in Brixen, South Tyrol, and get the chance to look beyond the surface and into the future of the digital label printing world. www.durst-group.com

Letterheads

October 21-23, 2022

Sign Foundry, Welling

May 3-5, 2023

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke. www.letterheads.co.nz

Sydney Olympic Park

It’s been four years since the show was able to bring the very latest innovations for the print, sign, display, engraving and wider graphics sector to Sydney. Industry leaders will be showcasing latest products, innovations, and services. www.visualimpact.org.au

Interpack

May 4-10, 2023

May 4-10, 2023

Düsseldorf, Germany

Düsseldorf, Germany

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors.

www.interpack.com

Interpack is a meeting point for the global packaging industry, where innovations along the entire value chain are presented, and the top trends are discussed. The focus is on packaging materials, packaging machines and related process technology. www.interpack.com

Floods and disasters bring planning into focus.

Unprecedented rain and subsequent flooding that particularly struck Auckland and the upper North Island, quickly followed by Cyclone Gabrielle bringing a National State of Emergency, has brought a renewed and heightened focus on business insurance considerations.

As the latest devastating events unfold, PrintNZ chief executive Ruth Cobb emphasises her and the association’s thoughts were with everyone affected. She says, “As well as the physical effects, this will be a very stressful time for many and I know that businesses will be doing their best to support their staff as they

work through this, while at the same time having their own issues and families to support.

“Everyone has different needs and different ways of coping and we have recently published some contact numbers and websites that may be of help during this time. The list can be accessed from the PrintNZ website and includes assistance for both material and emotional issues.

“Remember too that the PrintNZ team is here to help. Please reach out to us if we can assist you in any way.”

In light of these unprecedented developments, PrintNZ invited Marsh business development manager Mike Sanders to partake in a question and answer session for this special edition of Helping Hand. Sanders outlines his firm’s insurance partnership with PrintNZ and provides key considerations for members

whose businesses may have been badly affected by events as well as other general insurance advice.

PrintNZ: As the recent terrible weather events have graphically

illustrated, ensuring appropriate business insurance is imperative. What sort of policies would you recommend to New Zealand printers in this regard?

MS: The severity of weather events has highlighted the need for business owners to evaluate material damage and business interruption exposure, which is considerable for commercial printers. Even if there is partial damage, particularly to the building and printing presses, it may well stop the operations at the premises for a considerable period. As most printing presses are foreign made, a total loss or even a partial loss of printing facilities could stop production.

Marsh is seeing more insurers becoming averse to clients who do not have a strong valuation and risk management programme in place. New Zealand is seen as a country exposed to many natural disasters and this can mean that, without accurate information on assets, some clients may be deemed an unacceptable risk. To prepare for renewal, business owners can benefit from having an insurance review which can be provided to an insurer to demonstrate they have the right material damage values for their policy.

PrintNZ: The business threat from cyber attack appears to be another ever-growing concern. Are there specific policies on offer in this area?

MS: One of the findings in the 2022 Marsh and Microsoft Cyber Risk Survey was that the toll of almost three years of unrelenting workplace disruption, digital transformation and ransomware attacks means most leaders are no more confident in their ability to manage cyber risk than they were two years ago.

Cyber risk is pervasive at most organisations. An employee or vendor firing up their laptop from home brings risk. A user connecting a new product to the Internet of Things introduces risk. Deciding not to launch a new product, fearing cyber threats, is a risk.

Traditionally, the focus of print technology has been on performance and safety, not security. Therefore, businesses may have legacy print systems with unsecured and unpatched operational technology. As computers regulate the machinery and processes to produce products, any failure of such machinery following a cyber incident could result in a partial or total shutdown of the manufacturing process and serious business interruption.

PrintNZ: Is ‘key person insurance/ still relevant?

MS: A key person is any person in your business whose sudden loss would have an impact on your company’s wellbeing. Without this person, your business could suffer significant disruption.

The loss of a key person through death or disablement can have a significant impact on your business, resulting in significant damage to your bottom line, operations and reputation.

In a recent Mercer Marsh Benefits Five Pillars of People Risk Report, 67% of respondents deemed it likely that a key person risk would affect their business within the next three years and 55% stated that the loss of a key person would have a high impact on their business.

Our team of personal risk advisers can partner with you to find the right solutions to protect your business. We can help you:

• assess the key person and human capital risks for your business, providing insights and recommendations

• determine the best insurance solutions and negotiate competitive rates

• work with you to navigate the unexpected so you can focus on growing your business

PrintNZ: In the wake of these recent weather events, the insurance industry will no doubt be reviewing the extent and terms of coverage being offered. Do you have any thoughts on what print businesses should expect and/ or look for in their policies as a consequence?

MS: Business owners need to engage with their insurance brokers at least two months before their renewals so that they can get an understanding of what changes they will be expecting. This will allow businesses to re-evaluate their risk and implement controls within the organisation to mitigate any gaps.

The Marsh advisory team are specialists in assessing the critical risks that threaten business and the creation of risk management policies and procedures.

PrintNZ: What are some of the general to-dos you would highlight

for print industry businesses when attempting to recover from a catastrophic event while needing to file an insurance claim?

MS: With regard to flood and cyclone damage claims particularly, we recommend people take the following steps:

• stay safe

• do not return to properties or evacuated areas until it is safe to do so

• check buildings for structural damage and ensure gas, water and electricity are working

• check appliances are working

• try not to start flooded cars or electronic/electrical equipment until inspected by someone qualified to do so

• take reasonable steps to preserve property and, if possible, store it for later inspection by the insurer before disposal

• take photos or videos to document all damage

• take photos that show tide levels and if “black” (sewerage) or “grey” water was involved

• you can’t take too many photos!

• send an E-mail to yourself making a note of what happened and listing damaged items/loss

• if you have to dispose of stock or furniture and fittings, take careful notes and photos of what was damaged and in what way – insurers require proof of loss

• look out for the development of mold in hot and humid weather which can be harmful to health

• keep records of your expenses and set up a cost code

PrintNZ: How can Marsh assist with claims?

MS: The vast majority of policies will cover claims preparation costs, including the services of an independent claims

consultant. As independent claims consultants, we can:

• advise on strategy/policy response

• quantify the financial impact

• prepare detailed and documented submissions

• seek to maximise the settlement outcome and reduce delays

PrintNZ: Lastly, can you please provide an overview of the partnership between Marsh and PrintNZ?

MS: Marsh is proud to have been the insurance broking partner to PrintNZ for over six years. We provide members with a tailored package to cover the variety of risks and exposures that the print industry faces most often.

The industry is facing uneven demand and continued uncertainty, making budgeting and financial planning more challenging. Long-term recovery for print operators will require the adoption of new operating models, technologies and data-driven planning to forecast emerging trends, including enhanced safety considerations and rising consumer concerns.

At Marsh, we have designed a ‘print package’ specifically for the insurance and risk management needs of the industry. Our specialist team can assist business owners with creating a loss control programme that helps anticipate and manage risks.

Cobb emphasises to PrintNZ members: “One thing that has been highlighted following the recent floods is the number of businesses that are either uninsured or under-insured and this is a timely reminder of why we need the safety net that insurance provides.”

Russell Taylor Memorial Cup

For the closest to the pin shot –Jeff Packman, Industrial Solutions

Closest to the Pin Ladies Lisa Tamaki, Industrial Solutions

PrintNZ has a full calendar of events planned for 2023, and the first of the ‘sporting’ events took place on Friday 24 February when 64 players took to the greens at Waitikiri Golf Club for the Mainland region Charity Golf Day.

The day provided participants with a bit of sunshine, a bit of rain and a chunk of exercise. At the same time, they raised funds for the Full Colour Trust.

The Full Colour Trust is a charitable organisation serving the print and graphics industries in the South Island by providing funding to individuals and families who may not qualify for assistance through the usual channels, and can’t afford to pay for the help they need. The Trust has been going for 15 years, and has assisted many in their time of need in a variety of ways. Over the past 12 months alone it has generously gifted approximately $10,000 to families in the industry.

This year the Dale Hopkins Memorial Cup for Longest Drive was introduced. Dale, owner of Dunedin Print, sadly passed away in 2022. He was an avid supporter of the Canterbury Golf Day and made

the trip up each year to participate so it was fitting to be able to recognise his commitment to the event and the industry with this trophy. Simon Gallop from Inkwise was the inaugural winner.

Thank you to everyone that contributed to the funds raised – the players, and in particular the sponsors: BJ Ball Papers, Currie Group, Custom Cutting Formes, Fujifilm, Heidelberg, Inkwise, Leading Label Company, Servicom, Spicers Paper and Total Supply.

Best Gross:

1st: Custom Cutting Formes – Glen Mearns, Fraser Mearns, Duncan Mearns, Bill James

2nd: Servicom – Colin Dawson, Gary Eyre, Paul Webb, Johnny Main

3rd: BJ Ball #2 – Richard Cooke, Guy Noble, Dan Bushby, Mark Richardson

Best Nett:

1st: All Print – Steve Tansey, Simon Hay, Jeremy Booth, Bruce Chapman

2nd: Spicers #2 – David White, Nigel Williams, Brent Libeau, Bryce Coulbeck

3rd: Inkwise – Brent Goldsmid, Simon Gallop, Steve Gallop, Karl Stanbra

Dale Hopkins Memorial Cup

For the longest drive – Simon Gallop, Inkwise

For over six decades Aarque Group has been one of the leading providers of digital printing solutions, offering Kiwi businesses the very best in printing technology, including the latest software, materials, machinery and finishing equipment — all under one roof.

Aarque has a solid history of growth and adaptation to new and changing markets with roots reaching back to 1948, when a British firm, Harding & Hallden, was established in New Zealand, mainly as a coater and converter of sensitised media for the architecture, engineering, construction and survey industries. In 1968 it was renamed GAF Corporation, and in 1982 it was acquired by US-based Richard Quintus Anderson, who changed the name to Aarque.

The company underwent a series of NZ ownership changes in 1988 at the peak of the share market. Two years later, listed Australian Investment group Hancock Gore Ltd created a merger with Office Graphics, Smileys Wholesale, Littlejohns, Ace Drawing Office Supplies and Aarque Systems to form Aarque Graphics NZ Limited.

In 1992, 50 per cent of Aarque Graphics NZ was acquired by New Zealand shareholders, the Monte Carlo Group, to become the only Aarque name remaining worldwide, retaining a brand held in high regard in New Zealand.

In 2007 Aarque bought Frontline Technologies Ltd to continue its strategic focus in New Zealand. Three years later, it was rebranded as Aarque Group Ltd, creating dedicated industry task groups to meet the challenges of rapid, diverse growth in the digital print industry.

Tuscany Enterprises acquired 50 per cent shareholding formerly held by Australia’s Anitech and became 100 per cent New Zealand owned and operated.

In March 2014 Aarque Group acquired Alpha GMP Prographics, one of the leading suppliers of print finishing equipment and consumables in the NZ market. A few months later, the company appointed Leo Bult and Jason Bult as joint CEOs, succeeding Peter Bult.

Aarque Group joined forces with BJ Ball NZ in 2018 as part of the Ball & Doggett and a year later, the company acquired competitor business Jenrite to increase its offering to wide-format customers.

In 2021 Aarque Group’s head office in Auckland moved to a state-of-art office and warehouse facility in Henderson, Auckland.

The Aarque Group is uniquely positioned to offer New Zealand businesses specialist advice and digital print solutions across many industries.

The company prides itself on not just selling packages but bespoke solutions designed to improve profitability and speed to market while decreasing waste and adding new levels of automation to production floors across the country.

Being entirely independent, Aarque Group’s specialists can mix and match technology to suit the exact requirements

of each customer and develop a bespoke solution, including software, materials, rentals, services and consumables. Therefore, the team focuses on the customer’s needs first to understand printing volumes, target markets, production schedules, timings and other essential factors.

Once Aarque specialists understand the customer’s need, they create a customised package and an implementation plan before it is shipped. Each project is different, and it needs to synchronise with the customers’ plans and expectations — stringent processes are put in place at the installation of any equipment to ensure everything is up and running as it should be, leaving the team comfortable, safe, fully trained and supported.

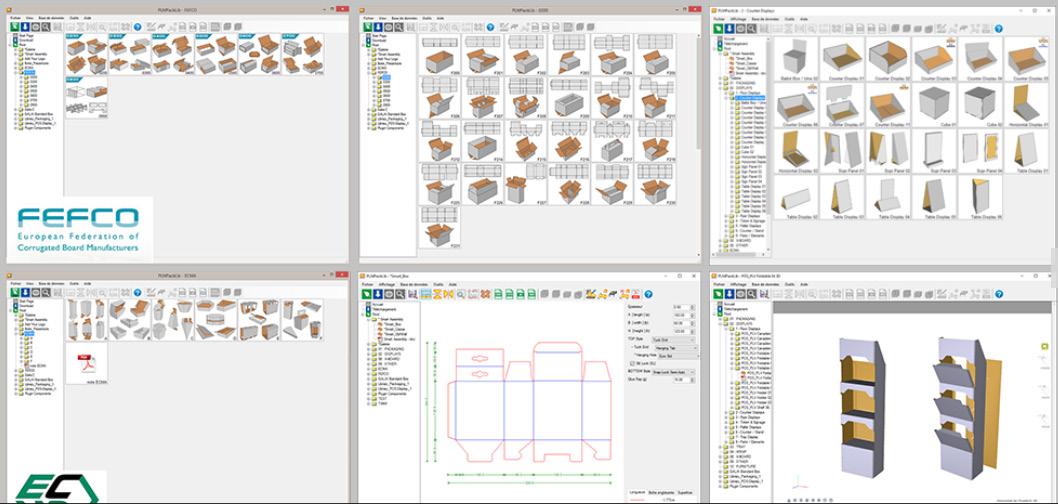

EngView Packaging Suite, also offered by Aarque, is a CAD/CAM solution for structural design and preproduction of boxes (FEFCO & ECMA Standards) and POP/POS displays. It provides a wide range of tools that speed up and automate the day-to-day jobs of structural designers, graphic designers, diemakers and salespeople involved in creating, communicating, and producing packaging. It is integrated with Adobe Illustrator and helps professionals visualise the 3D model of the packaging with the product inside and apply graphics to the structure. The new Step and Repeat functionality directly

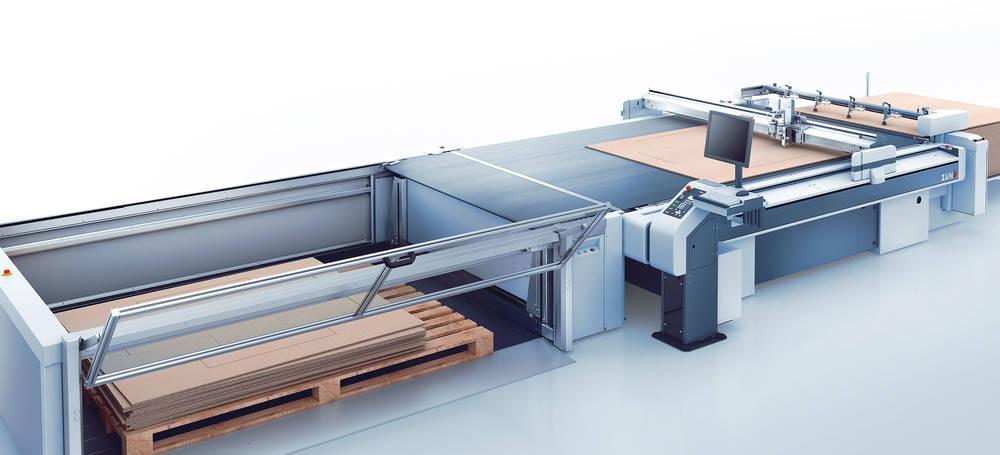

Zünd plug-in creates one-piece and multi-part packaging and threedimensional displays

multiplies the one-up design over the layout in Illustrator.

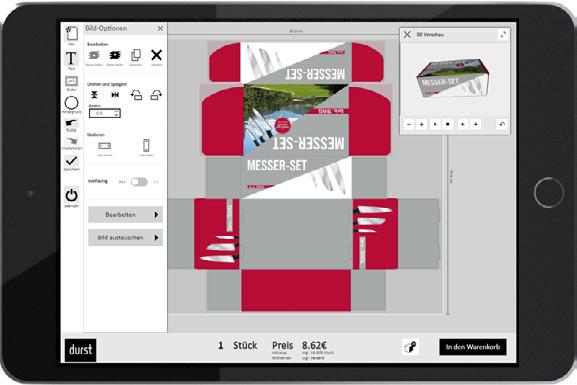

One of the supplier packages available at Aarque Group is Durst Corrugated Smart Shop, a web-to-print software designed to implement the right sales scenario for your specific clientele and shop type. It enables customers to select their desired packaging type, enter the required size and choose their print image. Variable designs for different languages or special promotions are generated with a click and placed in the shopping cart.

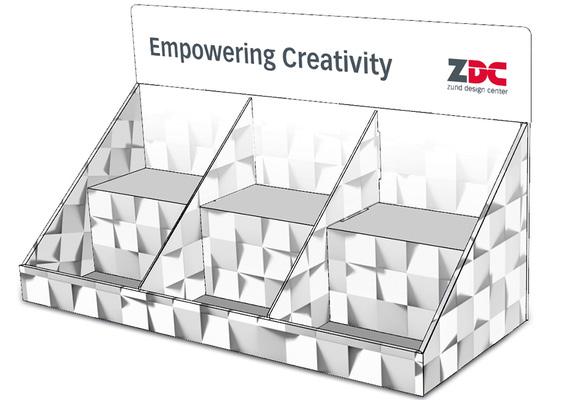

Zünd Design Centre (ZDC) is an Adobe Illustrator plug-in for creating one-piece and multi-part packaging and three-dimensional POP/POS displays. At its core is an extensive library of parametric designs. Customers can choose a template from this collection, enter their dimensions, and complete their design with logos, patterns, text, and other elements. The 3D preview function makes checking designs easy and enables exporting from ZDC for presentations or proposals. In the next step, ZDC generates a printable PDF from the finished design.

Lastly, PackLib is a module software integrated into the PLMpack platform, allowing the management and the use of 2D, 3D and parametric libraries of packaging and POS/Display. It is designed to optimise the packaging system and includes graphic navigation, standards libraries, an intra-company exchange platform, animated 3D visualisations, parametric resizing and downloading models. PackLib comes as a free add-on with Summa F-Series cutters.

Regarding print job performance, the media materials used are crucial. Print providers must distinguish which substrate

will give the best outcome when dealing with digitally printed applications. When deciding the optimal substrate for a specific print task, the essential factor is the customer’s end use. Here, Aarque specialists are happy to share their knowledge and experience to ensure optimal results.

The company offers a wide variety of materials. One of them is Koru Corrugated Board, a lightweight, versatile, eco-friendly substrate which maintains rigidity whilst offering the flexibility of cutting and creasing. It is ideal for printing direct or mounting and offers clay-coated products a smooth white surface for superior printing results. The company also stocks Onyx Flut corrugated twin-wall polypropylene sheeting designed for signage, displays, packaging, protection of surfaces and many other industrial applications. It combines light weight with high strength, durability and impact resistance. It is nontoxic, UV stabilised, water- and chemical resistant, making it weatherproof for any

environment. Furthermore, Onyx Flute is food-grade approved.

Moving onto polypropylene, Aarque has a wide range of ViPrint Polypropylene products, including Polypropylene, designed to meet the creative demands of the graphic arts industry. Sheets have been corona treated on both sides, making them suitable for UV offset, screen, UV digital and latex flatbed printing. The entire line has exceptional finishes that are flexible, durable, light and resistant to water and many chemicals. It is ideal for many innovative designs as it can be folded, creased, cut, welded, riveted, perforated and embossed. It offers some of the best chemical and moisture resistance in class. Where sustainability is essential, Aarque specialists suggest the ViPrint Eco line with sheets made from 50 per cent postindustrial recycled material and 50 per cent virgin material.

The printer is more than just a machine. It is the powerhouse that helps achieve flawless work. It can command the speed, volume and final quality of each project. Because it’s such a critical component, you need the Aarque specialists to ensure you are making a wise choice with confidence. With no lack of options to choose from, each type of printer has different merits.

The HP Latex R Printer series can help to expand product packaging services to include high-value speciality boxes for retail applications, short-run decals, packaging labels, and packaging prototypes. HP Latex inks deliver the glossiest white and the most vibrant colours - and HP Latex ink flexibility enables better folding and bending

HP Latex R Printer series can help to expand product packaging services to include high-value speciality boxes for retail applications

without cracking compared to some UV printer ink-based technologies.

The HP Latex R1000 Plus Printer is designed for various hybrid applications, including signage and displays; the growing portfolio offers choice, value, and versatility while featuring innovative technologies. Its larger brother HP Latex R2000 Plus, can handle boards of up to 2.5 metres wide and rolls up to 100kg.

Roland TrueVis AP-640 is a premium 4-colour Resin printer with fast drying inks, excellent durability and optimum usability designed to build and expand any sign and graphics business with a wide range of applications, low running costs, and quick drying benefits.

For the perfect finishing touch Aarque specialists offer Roland Camm-1 GR2 professional wide format cutter built to fit seamlessly with a print-then-cut workflow and deliver a fast, flawless results.

Canon Arizona 135 GT is designed as a true flatbed printer with professional quality, providing unparalleled, sellable print quality at speeds of up to 34.2 sqm/ hr on almost any rigid or flexible media. It features exceptional print quality thanks to the VariaDot greyscale printing technology. It uses advanced drop-size selection techniques offering greater uniformity for flawless photo-realistic images with great colours and white.

Canon Arizona 6100 Mark II Series sets the standard for speed, reliability, ease of use, rigid media application versatility and high-quality productivity. It offers repeatable registration with

platform to make the increasing complexity of large-format printing much more manageable. The P5 350 is the hybrid solution for roll and board printing up to 11.5ft (3.5m) and reaches in the high-speed version productivity of up to 7,000 sqft/h (650 sqm/h). Fast media change, easy maintenance handling and full safety make printing more efficient. The P5 platform provides optimum performance from Pixel to Output.

thermal overprinting: no more delays, disruption, waste or inconvenience. No more pre-printed label inventory, production downtime, lost orders or late shipments.

The Epson ColorWorks CSC4010 features an Epson-engineered PrecisionCore TFP printhead delivering ultra-sharp text and precise barcodes. It also produces varying droplet sizes that, coupled with a 1,200 x 1,200 DPI resolution, can produce a vast gamut of vibrant, accurate colours, smooth gradations and fine image details. The CWC4010 uses highly durable pigment-based inks with gloss or matte versions available to best suit the labelling application.

A slightly larger version, the Epson ColorWorks CS-6510 is a highly dependable 8-in commercial inkjet label printer covering the full spectrum of label sizes for enhanced productivity and versatility.

If durability is a factor, then the Epson ColorWorks C7500 can be the perfect solution as it uses the DURABrite Ultra ink, which is ideal for customers who want durable prints and who primarily want to print onto matte or GHSapproved BS 5609 media.

excellent corrugated substrate hold-down utilising the HF-High Flow Vacuum. It is an easy-to-integrate, high-volume true flatbed flagship printer purpose-built for a wide range of rigid media applications.

If you are looking for a solution for flexible production in every printing environment, then Durst P5 is the answer. It is a fully integrated technology

The Epson ColorWorks series has been designed to simplify the print of highquality, customised colour labels, tickets and tags in-house, as and when needed –from print to product in minutes. Epson’s on-demand inkjet colour label printers eliminate the traditional problems of

For longer runs, printing presses are the most suitable option. Aarque offers Epson SurePress L-4533 Digital Label Press, which incorporates Epson’s acclaimed MicroPiezo inkjet printhead technology with multiple heads combined in an array that moves laterally over a fixed platen. Each head contains hundreds of micro-fine nozzles that are precision engineered to ensure ultra-precise drop formation and

placement. This press offers excellent colour with a quality finish – 6 colour pigment aqueous ink set with an enhanced gamut + white, selectable black ink for coated and uncoated stocks, selectable over-print, and optional integrated colour management.

For high productivity, Durst Tau 330 RSC is the choice and the benchmark in productivity and flexibility with an actual print speed of 80 m/min, a native resolution of 1,200 x 1,200 DPI and up to 8 colour stations. Customers can achieve flexo-like productivity in a 24/7 environment, where even challenging label designs with small negative text or skin tones are produced with competitive TCO. It is available in standard colour configuration CMYK, orange, violet, green, and white optional.

As digital label printing grows, labelprinting houses realise the need for all-inclusive digital printing systems that provide value-adding features for producing fully finished labels. Further processing of printed labels and packaging can significantly impact and be a decisive factor in a customer purchasing decision and differentiation on the shop shelf. Aarque group specialists can also help in the final packaging and labelling production aspect.

The company offers a wide range of commercial laminators developed by Bagel Systems, a Spanish equipment manufacturer focused on developing and

manufacturing added-value laminating equipment for graphic arts and packaging. The Aarque Group offers the entire range of laminators starting from entry models and ending on highly automated Falcon B1, featuring a touch screen, user-friendly interface, quick fast film reel loading, secure high-speed performance system, automatic balance heat temperature and pressure or intuitive device adjustments.

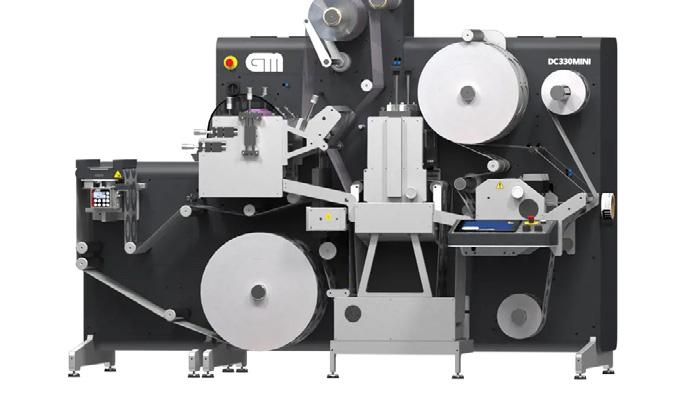

If space is at a premium, Aarque can also offer a compact design of Grafisk Maschinfabrik (GM) machinery. The equipment is developed in Denmark, where for over 40 years, the company has engineered best-in-class solutions for the self-adhesive label converting, finishing and flexible packaging industry. GM DC330Mini is the latest generation of digital label finishing machines. It features new electronics, a newly-designed control panel and an updated user interface. Based on the DC330 platform designed and improved over eight generations – the

DC330Mini has a strong and highly proven background. Its smaller brother, the GM DC350 Nano, is an ultra-compact, costeffective unit for self-adhesive lamination, semi-rotary die-cutting and length slitting of label web widths up to 350mm.

Regarding digital cutting at an industrial level, Aarque offers unbeatable Swiss technology from Zünd. Its cutting systems and automation solutions sustainably increase the profitability of packaging production. A wide range of product offerings includes anything from automatic tool changers to collaborative robotics and fully integrated production lines with total material-handling automation for lights-out production.

Digital print technology offers nearly endless personalisation capabilities. It is also true for Summa flatbed plotters and cutting systems from the F Series. They are used to finish packaging that is usually made of printed cardboard. A flatbed plotter from Summa is ideal for making customised packaging. Because the multifunctional head holds up to three modules, it can perform different techniques on the material in one simple job, such as cutting and making folding lines.

In short, Aarque Group not only supplies equipment designed for every need but also offers unrivalled after-sales service and support nationwide. When it comes to printing, downtime is not an option, and the group does everything it can to ensure the printers are always fully functional.

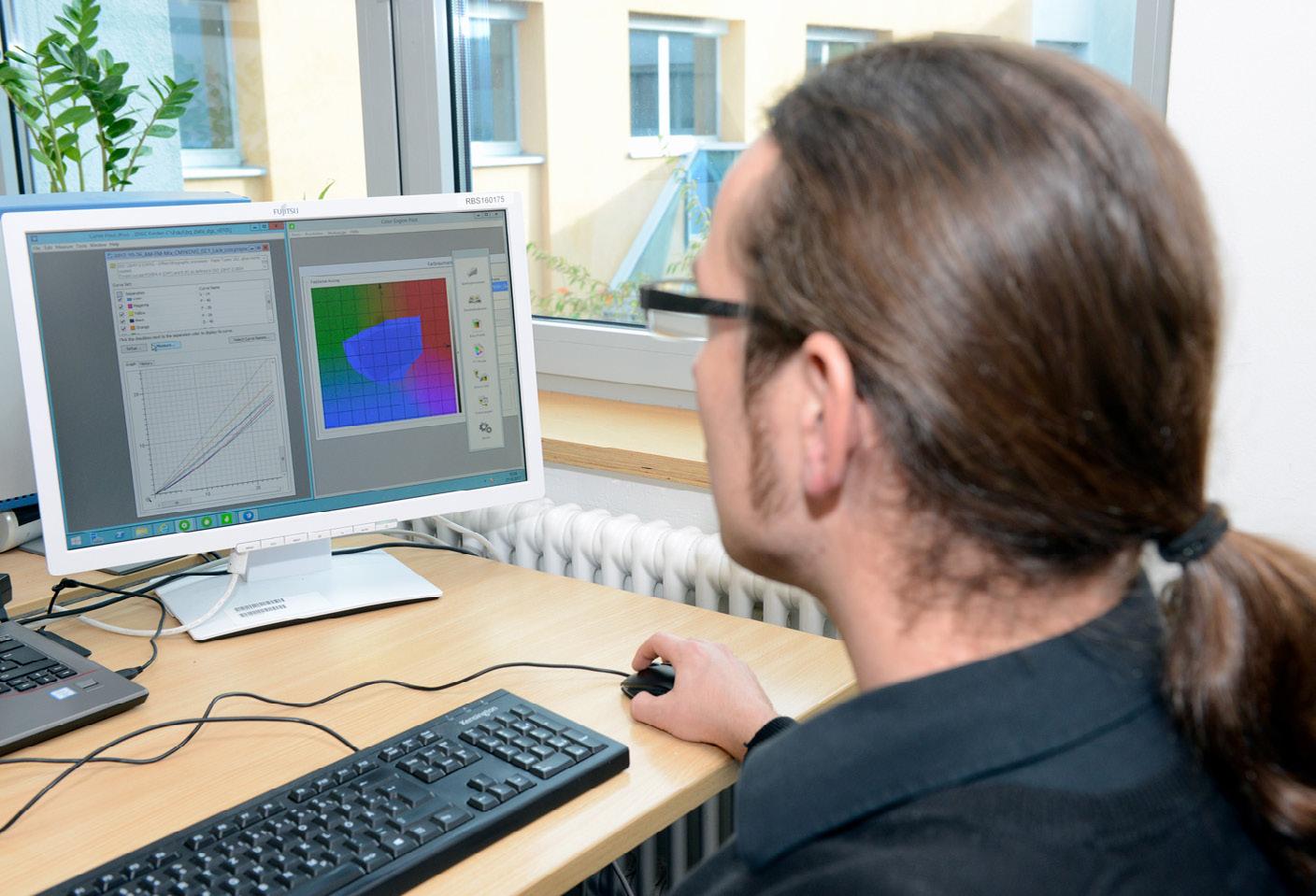

Aarque Group has engineers right around the country to maintain and service machines. It also offers comprehensive colour management and profiling services, workflow optimisation and customised training.

If you would like to partner with Aarque and learn more about Aarque’s extensive product range and support services please see www.aarque.co.nz

Durst says it is challenging 4-colour flexography with its Tau RSCi inkjet press, shown for the first time also at the Labelexpo Americas 2022, printing at 1,200 x 1,200 DPI resolution at 100m/min on a 20in web in four colours, with flexo units both before and after the digital engine.

Global consultancy Smithers, has released a new study, “The Future of Package Printing to 2027”, forecasting that the labels and printed packaging markets will continue to increase in demand.

Data charts show that a global market worth of USD 456.3 billion in 2021 will increase to USD 473.7 billion and then grow at a CAGR of 3.1 per cent to reach USD 551.3 billion in 2027.

While flexo will remain the most widely used print process, the greatest expansion will come from digital print for packaging – with a CAGR of over 10 per cent forecast through 2027.

Print service providers are poised to reap the benefits of significant R&D investment by digital OEMs.

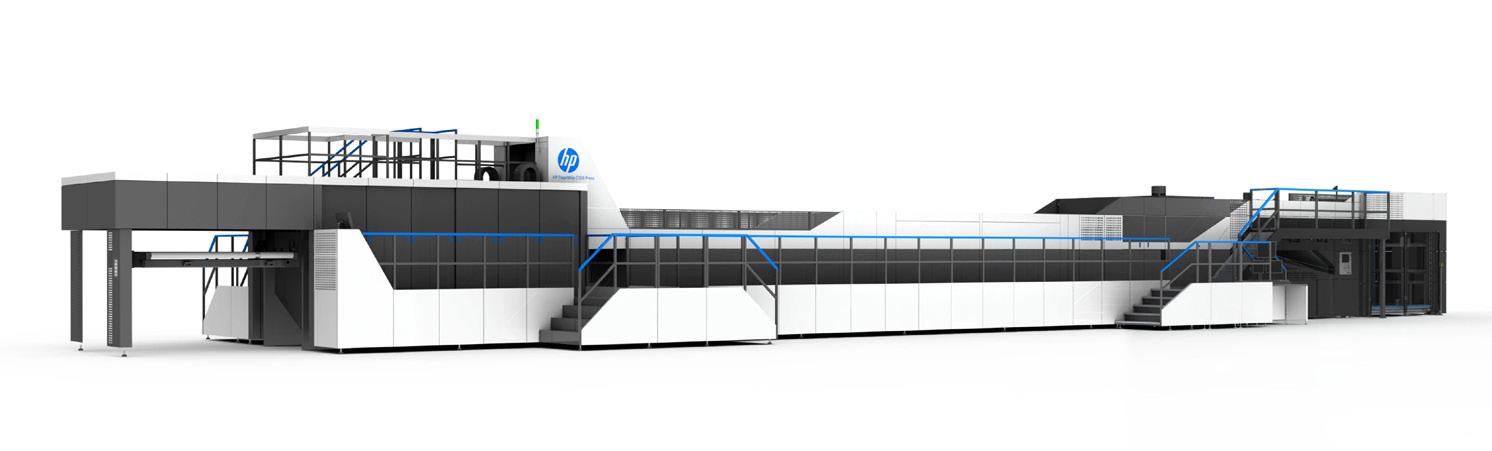

For a long time, digital was slightly behind analogue methods. Still, with the latest developments on the market, this speed barrier is slowly diminishing as machines such as the HP Indigo V12 Digital Press.

It is the first Indigo press built on nextgeneration HP Indigo LEPX architecture. It prints up to six colours at 120 linear metres per minute, using six in-line imaging engines running simultaneously; new high-definition imaging; up to 12 colours on press capabilities; and onepass, high-speed finishing capabilities provided by AB Graphic.

“The V12 is our Series 6 press, and it is completely redesigned from the ground

up. The V12 is a press that has been in development for several years. It runs narrow-web at a speed of four times faster than anything we’ve seen before, powered by HP Indigo Liquid Electro Photography technology (LEP),” said Craig Walmsley, HP Indigo A/NZ country manager. “We call it a V12 as we’re able to run 12 colours on it simultaneously. The V12 Press has the power of multiple flexo presses, in the one system. The speed of the press is only matched by its versatility, technical capabilities, and print quality, all of which sets a new benchmark for performance. For label manufacturers, this press will lead to new business opportunities including brand protection, smart packaging, sustainable packaging, and diversification into flexible packaging. The HP Indigo V12 Digital Press is tomorrow’s print technology, today.”

HP Indigo and AB Graphic equipment is supplied and supported by Currie Group in ANZ.

Inkjet doesn’t typically require frequent parts replacements and offers several advantages, including zero waste, higher robustness, and expanded colour gamut with fewer inks when compared to the traditional and current toner-based digital print technologies. According to Durst, printers can achieve 98 per cent of Pantone colours with just eight inks. Inkjet is also approaching production cost closer to flexo, without its click charge or print tax, and considering media and time saving.

“We see first-hand the digital print and finishing space continue to evolve. This combination is going to play a huge part in the way labels and packaging are produced,” commented Graham Blackall, national equipment sales consultant, Aarque Group Limited and a distributor of various brands, including Durst, Epson and GM in New Zealand. “As manufacturers broaden their product offerings, marketers need to react quickly, which drives adaptable just-in-time fulfilment at the packaging and label production end –digital meets these needs.”

Screen, which has been at the forefront of inkjet printing for many years, develops

While flexo is still widely used across labels and packaging markets, digital is making headway with short-run cost-effectiveness and print personalisation.The HP Indigo V12 can print as fast as analogue with greater production agility, redefining digital label printing Screen’s press is available in a low migration option to meet food packaging-compliant regulations

presses for labels and paper packaging in various formats from 330mm to 830mm. The company sees the future growth of digital coming in one-pass digital/hybrid presses, where printers are able to both print and finish labels efficiently.

2023 will be a year with numerous announcements as Screen continues its growth in the ANZ market with Jet Technologies.

“Whilst we are still strong believers in flexo, ultimately, as technology continues to improve and commercialise, the ability of digital will keep on improving, and the cost will continue to fall until it is the dominant print technology,” said Jack Malki, director of Jet Technologies, offering Screen equipment in the region. “That said, there are and will be more varying digital technologies, so, for example, inkjet is on the ascendancy now over toner, but who knows what the future holds?”

From the printer’s perspective, in the long run, digital printing is likely to be the direction that perhaps all print is heading.

“It won’t happen tomorrow, but it definitely feels like it’s edging that way,” said Alex Straight, technical director at Auckland-based Rapid Labels. “In saying that, though, when I started my apprenticeship, there was always talk about conventional machines becoming obsolete in the very near future with digital presses being developed.

“That was over 30 years ago, and flexo is still going strong, as is offset. Letterpress, however, was the first to wind down. Its demise occurred when digital machines were still running at relatively slow speeds.

If we take this as a learning of what the future holds for flexo, then surely, with the increased running speeds of digital, flexo could be the next print process in its sight.”

As with every printing technique, digital has its long list of pros and cons. It offers incredible quality and low costs at low volumes compared to traditional printing. It introduces variable data printing flexibility and short lead times.

According to Alex Straight, the biggest advantage of digital print is its ability to print unique images and data. “No two printed images need to be the same. It opens a whole new world of print. Unique QR codes, numbering and the option to make changes to any job without the cost of making more plates. These are some of the digital print’s greatest advantages that conventional machines can’t do,” he said.

“Our customers see the flexibility of the digital press as a key feature in our multifaceted print market,” added Aarque Group’s Blackall. “Our customers want to cater to a broad range of market demands; volumes vary — so having a printer that can create a sign-off proof or prototype on demand without wasting metres of media and time — results in a payoff for the customer and the manufacturer.”

Jack Malki thinks that the benefits are many, and it is difficult to focus on just one, but the one he appreciates the most is being able to print right now exactly what’s needed, no matter if it is one SKU, many SKUs, personalisation or whatever else. “Here and now is always a powerful tool,” said Malki.

All these factors explain why digital print is poised for such considerable growth. So, what are the disadvantages?

“Cost and productivity are still the major disadvantages,” agreed Jack Malki. “If the digital print was as economical and productive as flexo, then there would be no place for flexo (or other print technologies), but right now, that is not the case.”

On the other hand, Aarque’s Graham Blackall is convinced that digital production has no disadvantage when printers have defined their supply requirements. “Digital Print caters to demand between alternative production methods; it delivers flexibility across media types, volumes and high quality. Ultimately the customer benefits from a production base that can cater to their requirements, big or small.”

Printers in the digital space see more highly embellished labels. Regarding digital printing, it’s not unusual for the customer to reallocate the money they have saved on plate costs, smaller dies and add something special to their label.

“Perhaps a sculpted emboss or textured foil, a micro embossed security feature or a floating foil. Anything that can give them a point of difference and a greater shelf presence compared to their competitors,” confirmed Alex Straight.

For carton packaging, it is the on-demand fulfilment, managing volumes, storage requirements vs product going to market. “Customers want to remain relevant and compete in the store aisle, so it’s vital they have a supplier that can respond to these demands with efficient print and finishing solutions,’ said Blackall. “Labels are not dissimilar; there are more and more boutique products coming to market, and large brands are diversifying with variants – you only need to look at the beer market to see the evidence of change there.”

Jack Malki added that hybrid, in-line presses is where he sees the customer’s interest just now. “Clients are asking how they can print and finish in one pass, with one operator, and that is very much possible today,” he said.

In the next issue of our magazine, we will be analysing all things offset. Contact Piotr Wnuk (pwnuk@intermedianz.co.nz) if you want to participate and share your market view.

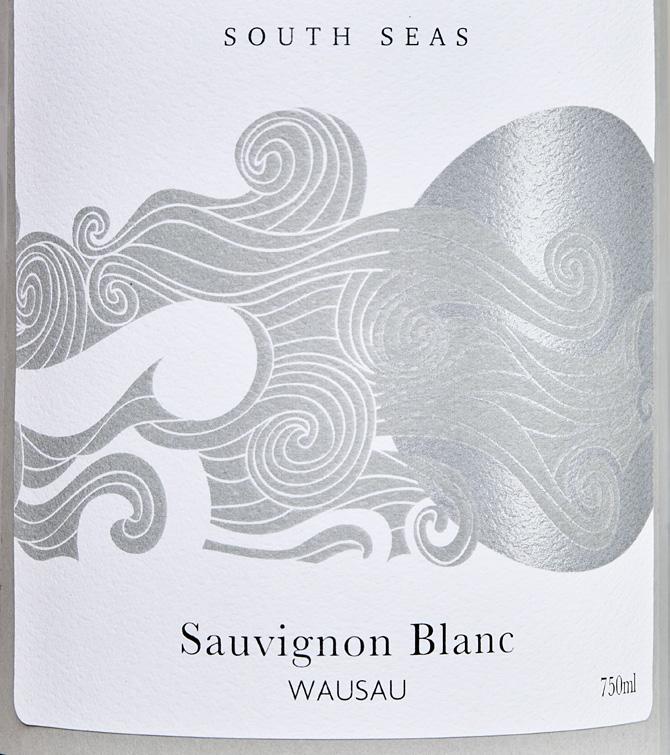

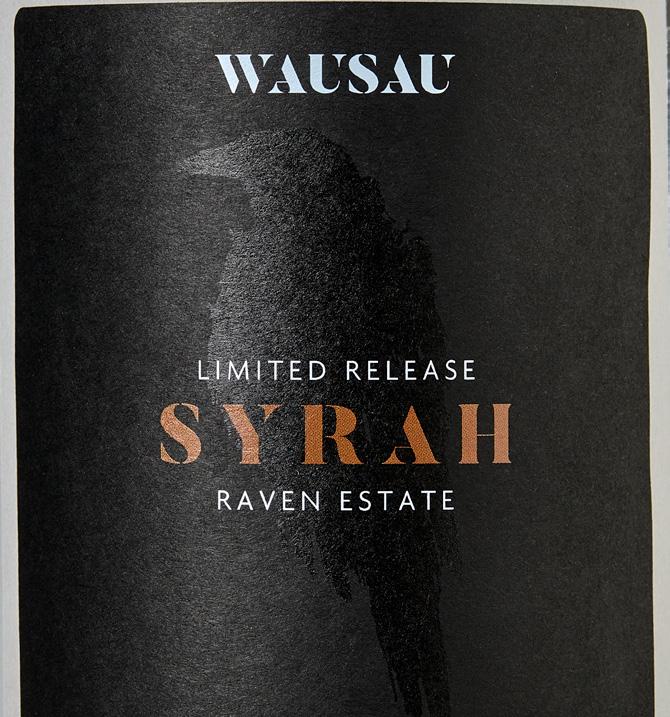

New Zealand has a reputation for producing great wine, healthy honey, boutique soaps, and any number of wonderful consumer goods.

Rachel Foye, marketing manager for BJ Ball, says, “Many of our great Kiwi companies start out small, often hand applying labels at first, and then growing to machine applications. The challenge for printers becomes: How do you help support that growth while giving them a distinctive label stock that makes their product stand out?”

Wausau Coated is a boutique label products manufacturer based in Wisconsin, USA. The representative for Wausau Coated New Zealand likes to remind us that their company does 80 per cent custom products. They are constantly asked to do weird stuff, new stuff and innovative stuff. The ones they like become stock lines, giving the rest of the world access to some amazing label face stocks.”

A few years ago, BJ Ball launched a few of the Wausau label products in roll formats. As the orders grew, the company received comments from customers that they wanted a way to trial them, or to use them for limited edition runs, for example, 200 high-end whisky bottle labels. Rachel says, “Wausau Coated has taken this feedback on board and has moved into the sheet fed market.

“Those shorter run jobs needed to be digital, so we were relieved when the spec sheets listed them as HP Indigo and dry toner suitable. We wanted to put the stocks through their paces in New Zealand, so that we had some samples to give to customers. However, it was a tricky time to try and launch a new product: the stock got delayed and Auckland went in and out of lockdowns, owing to the Covid-19 pandemic.

“At BJ Ball, we persevere when we know we have a product that can improve our customers’ business. When we were finally able show the product to printers, they all loved it. In fact, we ran out of stock of four SKUs within a week. The promo had to go on pause until more stock arrived. We know no one likes to be shown samples of something they can’t have. We chose four face stocks from the range to highlight with its printed samples. Although there were wood veneers and

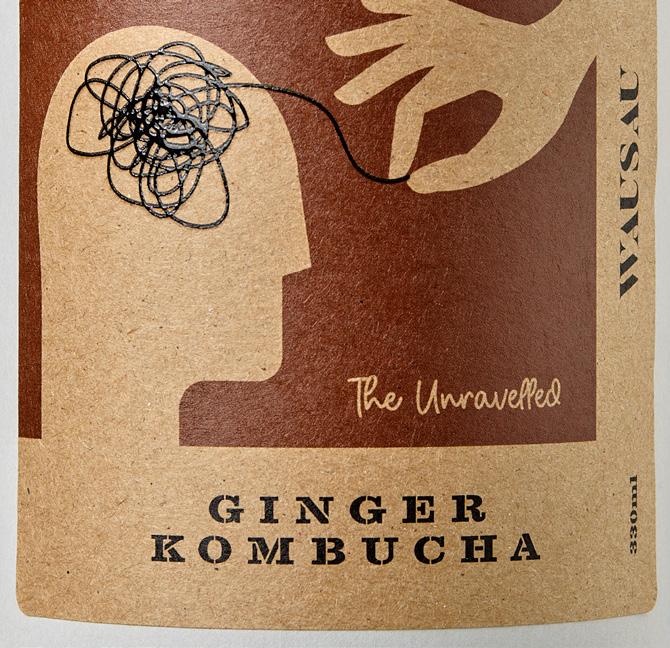

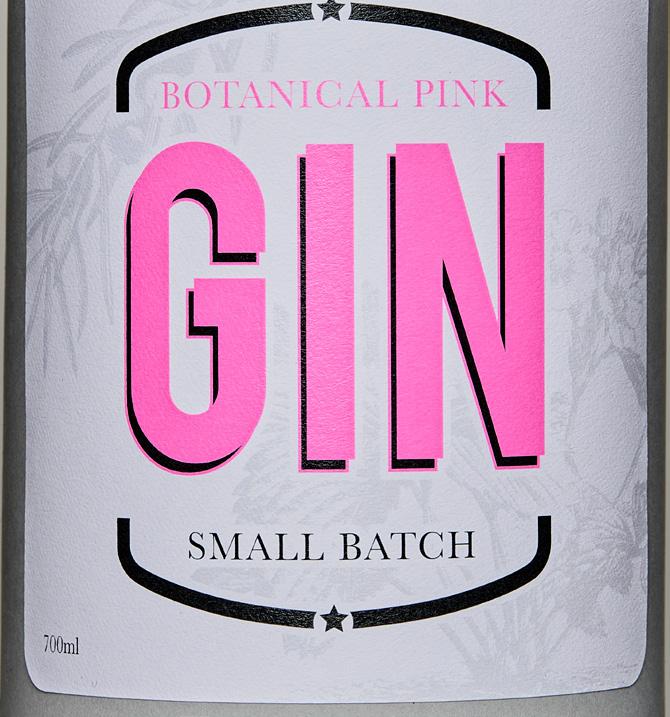

crimson flocked options, we started with the more budget friendly SKUs as they will be more popular. Bryce Carleton has photographed the four labels shown on this page showing the value of the Wausau solutions:

Recycled Natural Kraft Permanent Adhesive (Kombucha label). Digitally printed on an HP Indigo with a clear Scodix enhancement over the string to give a raised effect without needing to emboss. The brown solid shows good ink adhesion and a consistent coverage. This label’s face stock is made with 100 per cent recycled fibre which is also FSC certified C102086.

FSC certified. There is also an Eggshell Felt option available which is cream in colour.

Estate #8 Permanent Adhesive (Gin label). Digitally printed on a Fujifilm Iridesse incorporating a show stopping fluoro pink toner. The florals in the background are a subtle grey (CMYK) topped with a clear toner. This face stock contains wet strength properties and is FSC certified.

Bright White Felt Permanent Adhesive (Sauvignon Blanc) – Digitally printed on a Fujifilm Iridesse incorporating a silver toner moon which contrasts nicely with the grey (CMYK) waves. This face stock contains wet strength properties and is

Black Vellum Permanent Adhesive (Syrah label). Digitally printed on an HP Indigo with a few hits of white ink. The black raven watermark is just black ink creating a wonderful contrast of the matt stock with a gloss hint in the ink. This face stock contains wet strength properties.

She concludes, “We look forward to discussing how BJ Ball can help printers use the Wausau label products, and our other label solutions.”

2022 was a milestone year for an Auckland printer Soar Communications Group (SCG).

for shrink sleeves, new inks including metallics, fluorescents, invisible red and green for brand protection applications and new varnishes from leading partners for higher durability.

“When Currie Group offered us a deal on the HP Indigo 6K, I knew we were just about to get more control and be able to do even more things. We have done some cool products already, but we are still in a trial mode, in my opinion. All the software HP developed makes a huge difference. We have done an interesting project for a product containing milk and or cream, so it perishable very quickly. Thanks to the new press, I created a shrink sleeve using the new silver that blocks the light and the packaging itself, adding shiny metallisation to the label.”

Wshaking off the Covid misery, SCG pressed through with its ambitions by combining two successful companies and expanding its machine park.

SCG brought two companies together, coalesced two groups of talented people into one, moved headquarters and installed new equipment to expand its capabilities even further. These achievements are magnified by the fact that the new business, combining 80 Soar Print staff and 100 ICG staff, remains independently owned.

Soar Print brought print, logistics, mailing and packaging expertise. The Image Centre Group (ICG) complemented this offer with its deep knowledge and expertise in the creative/content side of print, publishing and large format.

While servicing different clients, Soar and ICG have had an open and strong working relationship for over a decade. In the same way, as both businesses were built on the family-led values of each of the company’s founding fathers, also their CEOs at the time, Fred Soar and David Atkins, decided to manage the company side-by-side.

This merger strengthened the overall offering of both businesses and created more significant opportunities for their clients and teams. It paved the way for an exciting future and allowed operating as an independent Kiwi-owned business.

It was clear from the outset that the consolidation would command bigger premises. In February 2022, ICG kicked

off the rebrand by moving into a new 5,000 sqm headquarters in Mount Wellington, with the Soar team picking up any printing slack during the transition. By May, all operations were established at the new site, which ensured a seamless transition for clients, staff, and key suppliers.

“It was quite an incredible time,” Brian Landry, general manager of SCG, recalls. “A lot of staff from both sides came together on weekends to help move stuff and break walls down. We pulled all the electrical cables, big, thick, fat cables, out of the walls and reused them in the new building.”

People are undoubtedly the core of the business, but they could not succeed without quality equipment.

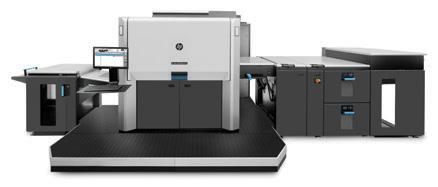

The company runs a Heidelberg CX 102 and an eight-colour B1 Komori long perfector among the other production equipment that it has at its disposal. There is also a brandnew racing stud in its stables, an HP Indigo 6K Digital Press, which, a few months after the installation, still impresses Brian Landy, general manager at SCG.

“The automation ability, with its new frontend side, is what excites me,” said Landry. “And we’ve only touched on that because we’re still in the training stage with the prepress guys and recreating die templates; we have around 4,000 to go through.”

The new HP Indigo powers the Rocket division of the company specialising in labels, which was also using the HP Indigo 6800 press to produce shrink sleeves.

The HP Indigo 6K can deliver more applications using higher opacity white

Engineered for higher productivity and faster colour, the HP Indigo 6K Digital Press is the new model of the highversatility HP Indigo 6000 series. The press introduces Spot Master, HP Indigo’s next-generation colour automation technology. It uses a patented algorithm for fast and accurate colour matching, enabling converters to reach brand colours within minutes with high colour consistency and uniformity across the entire print frame, ensuring every package looks the same no matter when or where it was printed.

“Digital is the future; it’s not going away. What is really amazing is the quality we get from the HP Indigo 6K. It enables us to keep offering our personal attention to each client, work with start-ups, introduce our customers to Mosaic and Collage and expand their design abilities. Last year was one hell of a year for us. And it was right the way to the end. This year is all about consolidations, streamlining and automation. And we’re very excited,” concluded Landry.

“The long-standing relationship with SCG is exactly what Currie Group stands for,” said Mark Daws, director of labels and packaging ANZ at Currie Group. “We continue to work with local printers to sell quality equipment and create relationships built on trust and full understanding of customers’ needs. I am delighted that we were able to find the best solution for SCG by working closely with Brian and listening to every technical need he mentioned. I am certain our cooperation will not end here, and I look forward to seeing future success and growth in SCG’s business. We are proud to be a partner on their digital journey.”

on the stand included Thomas Bodner, a service engineer who travelled from the company headquarters in Brixen, Italy, to showcase Durst’s holistic approach to print and automation by presenting the Durst Workflow and Durst Analytics software working with the Tau RSC E 330 press. (video walkthrough is available on the New Zealand Printer website).

Durst Workflow is a tailor-made solution for the printing industry to prepare customer data for printing and finishing. Data preparation typically requires recurring tasks that can now be automated, freeing up valuable time for other tasks. This software combines automation and product-specific data preparation to decrease production costs.

Durst Group has gathered tremendous interest from regional audiences hungry for innovations and the latest technology developments in the labels and packaging space during the recent Labelexpo Southeast Asia 2023 show in Bangkok, Thailand.

The company showcased its Tau RSC E 330 5c press working in unison with the Durst printer-software ecosystem and providing visitors access to experienced industry experts.

“We are people, and we like to interact with each other that’s why we have shows like this one. It was the first time I was at the show, and I think it went very well. We have seen a significant amount of people,” commented Thomas Macina, global sales director for labels and flexible packaging at Durst.

“I heard some statistics that only on the first day we had more people coming through the doors than for the entire duration of the last edition in 2018. What surprised me was that we have seen printers not only from Thailand but also from surrounding regions. So, we met people from Australia, Japan, Taiwan, Malaysia, Indonesia and Uzbekistan,” added Macina. “Converters from all

surrounding regions are flocking here, and most were stopping by our booth.

“I think we were the only digital inkjet manufacturer at the show with a 1,200 DPI machine. I believe all visitors can see the difference in print quality between Durst and the other inkjet players. I have spoken to several visitors who have seen this machine for the first time and have questions. Some customers know us, already have an older version of our presses, and are considering an upgrade.”

The RSC E has been designed by Durst to evolve and grow with the business and is equipped with native 1,200 DPI resolution. It offers converters an economically attractive entry into successful Tau RSC technology. The press comes fully equipped with Durst Workflow and Durst Analytics software and optional Durst Smart Shop software, enabling web-to-print technology.

According to Macina, some of the most prevalent trends and most often requested functionalities by the Labelexpo visitors were workflow and automation options.

This is precisely what Durst has set out to showcase during the show. The team

On the other hand, Durst Analytics is a web-based software that leverages printer’s data to provide easily accessible and interpretable dashboards, all available on a single screen.

All software packages are individually expandable and can be used for label, corrugated, textile and large-format printing.

Durst is gearing up for an open house event to dive deeper into automation, workflow, and other functionalities offering printers time savings and reduced production costs. The event –Beyond Label Open House – is scheduled for 3 to 5 May in Brixen, Italy.

For the full Labelexpo Southeast Asia review, please turn to the next page

Durst was one of the few European manufacturers arriving at the Labelexpo show with an impressive equipment lineup.Durst showcased its Tau RSC E 330 5c press working in unison with the Durst software Thomas Bodner, a service engineer from Brixen, Italy, presented Durst’s holistic approach to print and automation

P5 350/HS

The hybrid printer that elevates the efficiency in your production cycle.

For more information, please visit durst-group.com/p5350

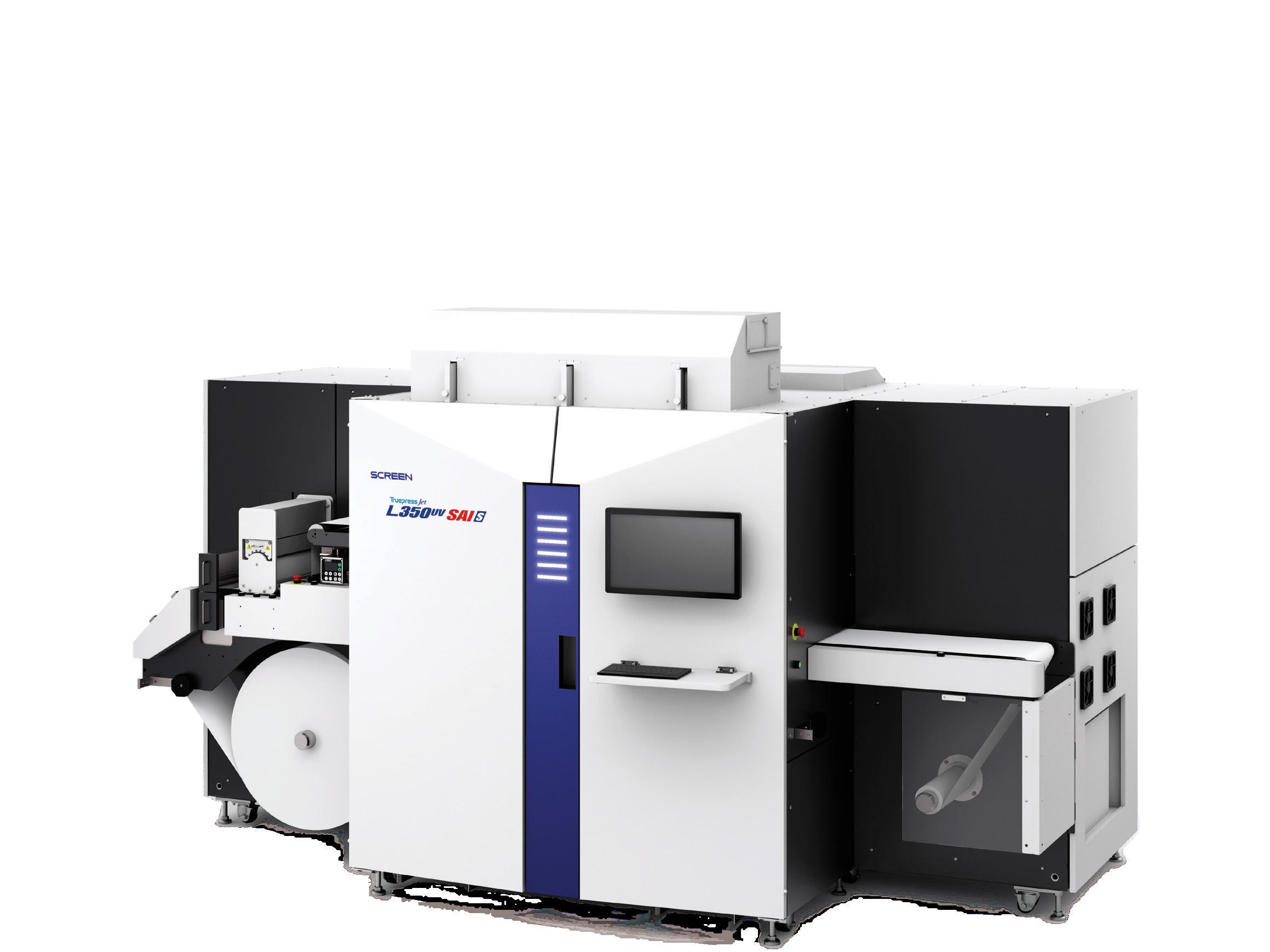

Screen L350UV SAI series deliver:

• NEW High opacity white

• Industry-leading productivity (up to 60m/min)

• Highest reliability (>93% Uptime)

• Ability to upgrade on site

• Chiller for thin and heat-sensitive substrates

• Reverse feed (material saving)

For more information, please contact us here:

David Reece• Expanded colour gamut

• Up to 7 colours including blue, orange & white

• Hybrid integration ready

• Fully supported by local factory-trained technicians

• User-friendly EQUIOS workflow integrates with MIS

P: +61 2 8399 4999 M: +61 488 190 290 dreece@jet-ap.com / 19 Rosebery Ave. Rosebery, NSW, 2018

Gorilla Board

A premium GC1 hi-bulk board with a high white shade, premium double coated surface, Gorilla Board is suitable for freezer applications and is direct food contact safe.

This recyclable solution is also biodegradable. It has PEFC and ISO 14001 certifications.

Marco Smolcic, Packaging Category manager at Spicers New Zealand, says, “This range offers a great value paperbased packaging solution that fits with our sustainability strategy.

“Samples are available now with stock available in 295 and 325 gsm in 720 x 1020 LG and 1020 x 720 SG. Also, available upon request in 215, 235, 250, 270, 295, 325, 350, 380 gsm.

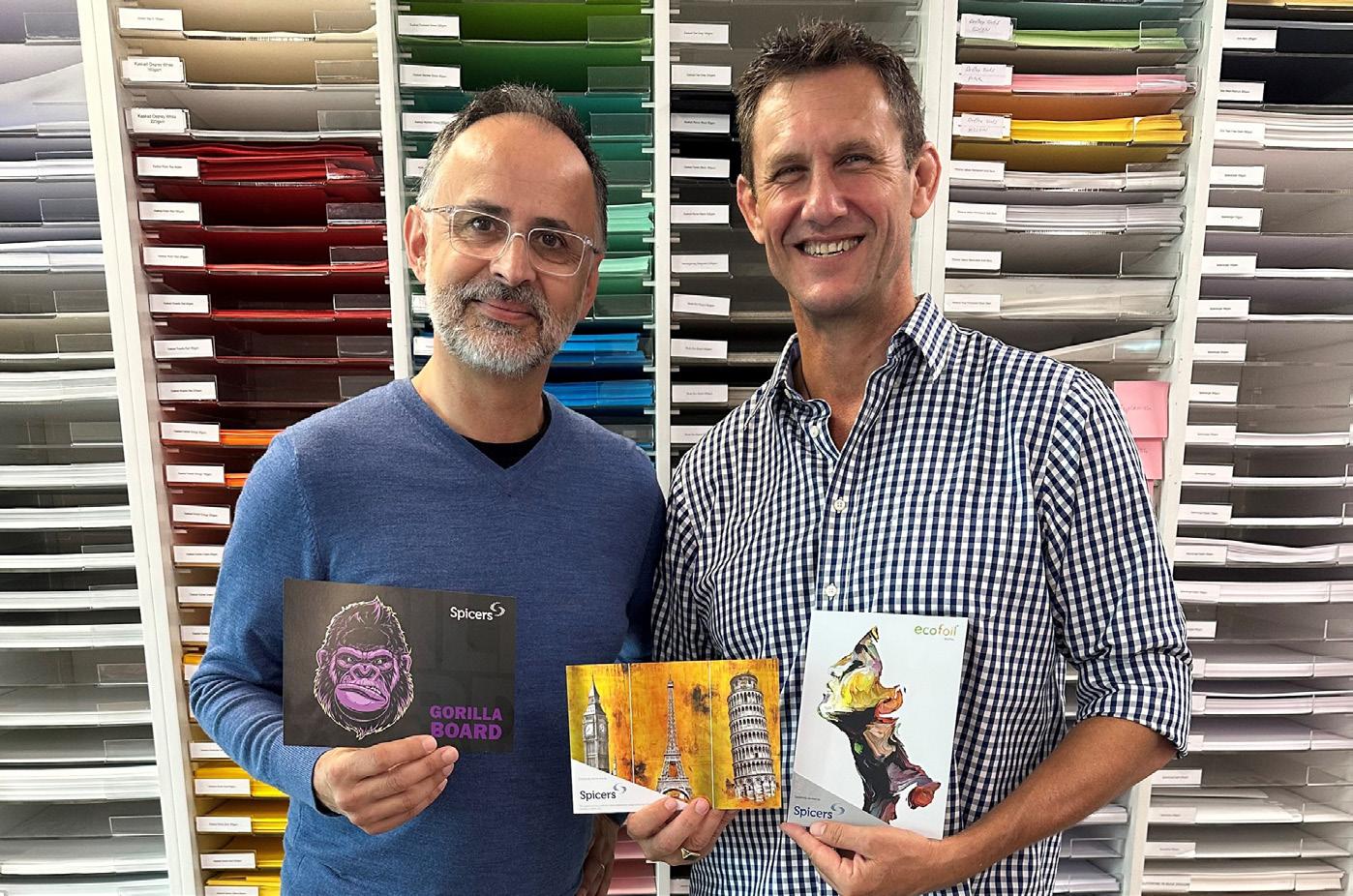

Spicers New Zealand has increased the number of environmentally friendly solutions for the local market by expanding its portfolio of digital printer paper with Ecofoil Digital and its range of packaging products with Gorilla Board.

The company has serviced the industry’s paper needs in New Zealand for over 100 years, whilst maintaining a strong international identity with operations in Australia and Asia.

In recent years the business has expanded its product portfolio with diversified products, including sign and display substrates, via Total Supply, as well as industrial packaging consumables, via Universal Packaging, and this expansion continues with exciting and innovative new products such as Ecofoil Digital and Gorilla Board.

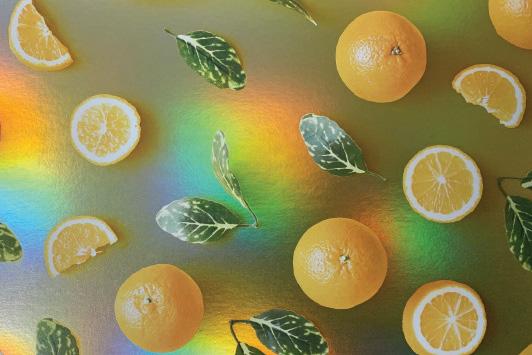

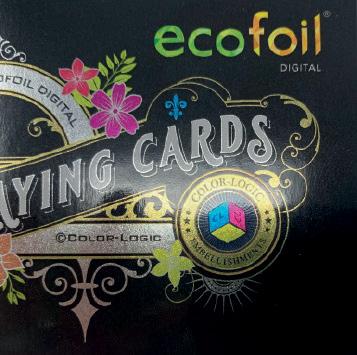

Specifically developed for the HP Indigo, dry toner and UV inkjet digital print markets, the Ecofoil Digital range of silver metallised foil board enables you to create foil embellishment inline, using your existing digital press, without the need for any additional capex investment.

Brooke Painter, Digital Papers Category manager at Spicers New Zealand, says, “This exciting new range enables

customers to create and reproduce foilembellished designs that are simply not possible via any other process. With its added sustainability benefits, we believe this offering is unique in the global marketplace. Samples are now available.

“As the only sustainable and commercially viable foil board range on the digital market, Ecofoil offers all the creative benefits of a metallised polyester but with three huge differences: it is certified plastic free, recyclable, and has FSC certification. Ecofoil Digital is proven to run at commercial speeds with no buildup of static. A true one-sided foil-board substrate, it delivers significantly higher gloss levels comparable to metallic inks or metallic substrates.”

Brooke points out that Ecofoil Digital is a foil-board substrate rather than a selective foil embellishment such as hot foil or digital foil, so there are no limitations in the amount, size, complexity, or number of foil colours that can be created in a single pass. He adds, “Ecofoil Digital is compatible with all known post-press processes, including folding, bookbinding, embossing, debossing, foiling, UV varnishing and laminating.”

Ecofoil Digital stock is available in 162gsm self-adhesive label; 260gsm / 405µm GC1 Board; and 300gsm / 330µm Satin card.

“Ideal applications include packaging for the pharmaceutical and healthcare sectors; chocolate and confectionery; FMCG packaging, greeting cards, point of sale, swing tags and posters.”

Brooke adds, “Spicers New Zealand believes in leading by example. In everything we do, the impact on our environment is always taken into consideration. Our FSC, PEFC, Enviromark and Environmental Choice certifications and Zero Waste programme are examples that we continue to manage environmental initiatives that impact our operational footprint.”

The second edition of Labelexpo Southeast Asia returned to Bangkok in February 2023 to host printers and converters from the region.

Regional printers and converters flocked to Bangkok, intrigued to see the latest developments available in the label and packaging printing space and preview trends which will potentially drive the market this year.

Regional printers long awaited this year’s edition of the show after events planned in 2020 and 2022 were postponed in the wake of the pandemic. Tarsus Group, the organizer of Labelexpo Global Series, was impressed with the multi-national attendees flocking to Bangkok to see the latest labels and packaging technologies developments.

“Labelexpo Southeast Asia launched in 2018 in May was the most successful launch event our company has ever had,” Tarsus Group event manager for Labelexpo Southeast Asia Richard Quirk said.

According to Tarsus, the first edition of Labelexpo Southeast Asia was the

region’s biggest label and package printing event, attracting 7,934 attendees from 62 countries.

“We were due to have the second edition in 2020, and we were forced to cancel and then postpone. So, this is the first time we’ve been back here for nearly five years,” added Quirk.

This year the exhibition featured more than 170 exhibitors across the label and packaging supply chain and 7,448 delegates from 84 countries, including Thailand, Malaysia, China, Indonesia, India, Singapore and Vietnam.