Study tour proves printing excellence is truly ‘Made in Durst’.

PacPrint shines in Sydney

Top Six Apprentices

Blue Star ’s new Auckland site Fespa expands June

with 1987-2025

Study tour proves printing excellence is truly ‘Made in Durst’.

PacPrint shines in Sydney

Blue Star ’s new Auckland site Fespa expands June

with 1987-2025

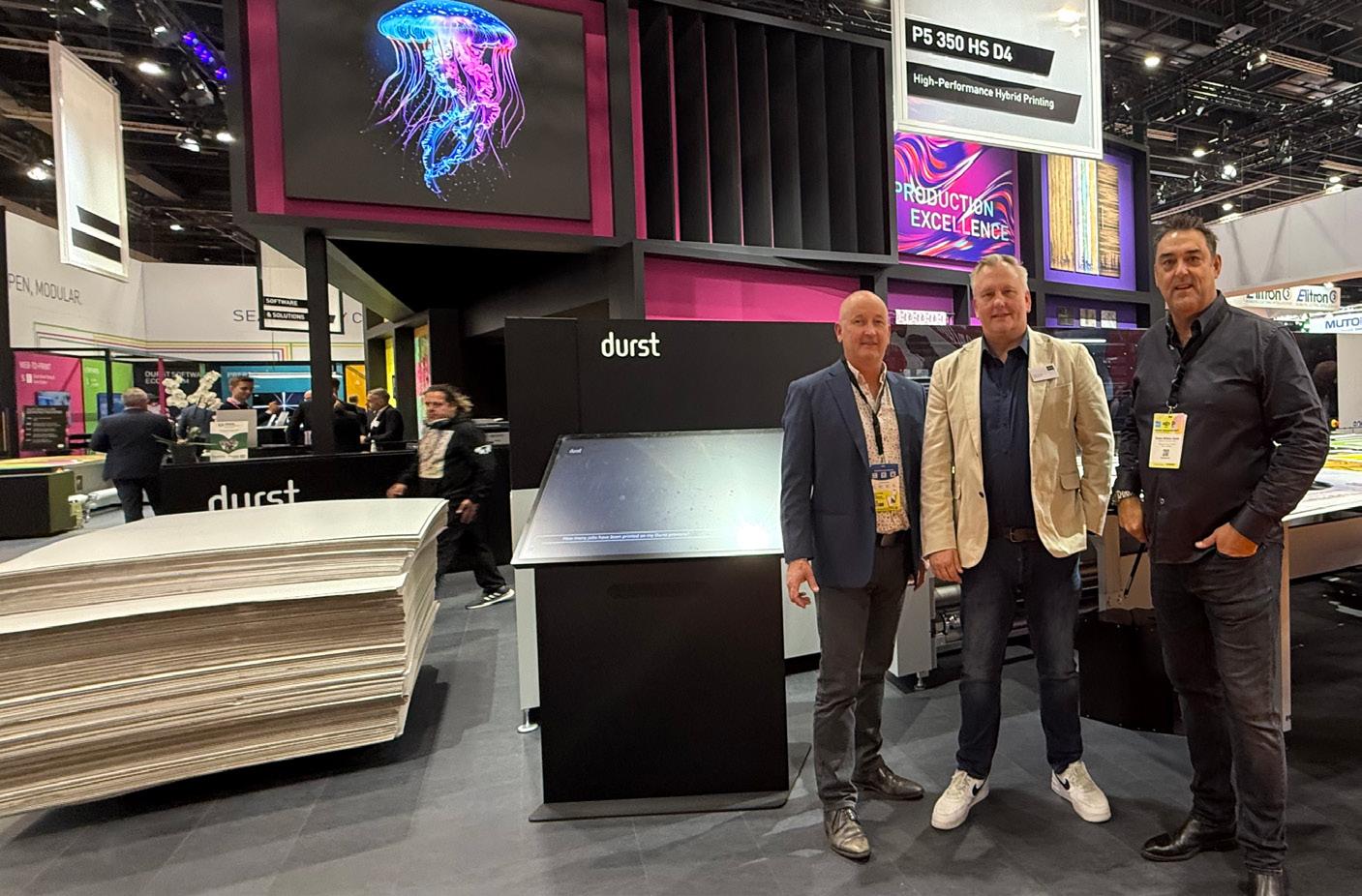

Durst Oceania recently concluded its fourth European tour – once again demonstrating that world class printing quality, ingenuity, and innovation is truly ‘Made in Durst’.

Durst, a global leader in digital printing and production technologies, recently hosted its fourth pre-Fespa European tour, a three-day event designed to foster networking, share industry insights, and offer an exclusive preview of the company’s latest printing solutions.

The tour, led by Matt Ashman, managing director of Durst Oceania, featured a visit

to Durst’s state of the art headquarters in Brixen in northern Italy, as well as a cultural stop in the picturesque town of Kufstein, Austria. The event brought together industry professionals across Asia Pacific for a blend of innovation, collaboration, and European heritage.

Durst Group, a third-generation family owned business co-owned by Harald Oberrauch and CEO Christoph Gamper, has

been a leader in digital printing technology since its founding in 1929. Today, the company employs more than 1,100 people globally – an increase of 10 per cent over the past year – and is renowned for the quality and reliability of its advanced solutions across the global graphics, ceramic tile, labels, packaging, and commercial corrugated packaging sectors.

The Durst P5 Platform – Powering the future of print

During a guided tour of Durst’s headquarters in Brixen, delegates were given a firsthand look at its technologies and heard more about the thinking behind the company’s flagship solutions.

At the heart of the showcase was Durst’s extensive P5 platform, a standout example of its commitment to innovation and customer-centric design.

“The word ‘game-changer’ is used too often, but the P5 platform truly earns the title,” said Ashman.

Ashman explained that the P5 platform was developed in response to customer feedback and built to be scalable, designed to evolve with both Durst and its customers’ needs. Combining advanced hardware, hybrid flexibility, and integrated software, service, and ink solutions, it delivers a true end to end offering.

“We set out to create a unified platform that could grow with us and our customers,” he said.

“The P5 has been incredibly successful in achieving that. Many of our innovations are not only available now but can also be retrofitted to existing machines.”

Ashman said the recently launched P5 X marks a new direction for Durst, but it builds on the proven strengths of the P5 platform.

The new PX 5 is a ‘true flatbed’ with roll to roll capability to fill a mid-market position in the company’s P5 large format printing portfolio.

The PX 5 is designed for ease of use, featuring ergonomic handling,

multifunctional LED status bars, intuitive media registration with a pin system, and automated safety functions for a smooth and secure workflow. Operators benefit from a smart interface and advanced job management, supporting up to 12 independent print queues for efficient multitasking and reduced downtime.

“The P5 X complements the other products in the P5 portfolio and is the true flatbed machine that everyone has been asking for from Durst for some time. The market needs a machine like this with the flexibility, reliability and functionality that Durst customers have come to expect,” Ashman said.

AI meets advanced automation in Durst’s latest print solutions

Another focus of the tour was Durst’s increasing emphasis on software. From automation to artificial intelligence, Durst’s expanding software portfolio is designed to deliver smarter, more connected workflows.

The company’s portfolio includes end to end workflow solutions for seamless automation and AI-powered applications to optimise production processes.

“Our software development, and our software team, has grown at an exponential rate,” Ashman told tour attendees.

Matthias Summerer, sales management software and solutions at Durst Group, told delegates the company is making significant investments in software development to optimise every stage of the production process.

“We recognise that software is the foundation of true automation,” he said.

“What sets Durst apart is that we’re the only print manufacturer offering a complete, end to end software ecosystem. Our solutions are designed to be as flexible, modular, and scalable as possible.

“Each module can be integrated not only with Durst systems but also with non Durst systems, making it adaptable to virtually any production environment.”

Durst Lift ERP is a cloud-based ERP/ MIS software which provides a single integrated platform to run every aspect of a print business. The process is automated and streamlined, from taking a customer’s order online, into preflight and manufacturing, and all the way though to customer delivery. Durst Workflow Plus is a fully featured RIP and pre-press software production suite.

New AI-powered tools developed by Durst are designed to enhance the processes

and make technologies more performant and accessible.

Notably, Durst’s Image Tracking Tool utilises a camera or smartphone to instantly capture and identify prints in real time, ensuring seamless job tracking and enhanced process reliability.

Durst’s new AI-based Upsampling feature intelligently reconstructs low resolution files to ensure crisp, high quality output, even when the original file provided by the customer lacks sufficient resolution.

Durst Group also recently acquired callas software, one of the leading providers of prepress automation and PDF technologies that plays an essential role in many print workflows, either directly or as an OEM component in prepress product.

In the coming months, the collaboration between callas software and Durst Group is expected to deepen, leveraging synergies and accelerating the development of an open, vendor independent software platform for the print industry.

Labels leading the way

Ashman said Durst is focused on delivering flexible solutions that help customers diversify into new markets – whether it’s wide-format, packaging, or labels – with labels standing out as a key area of growth.

“Labels has been massive growth for Durst and we have some of the most advanced label solutions,” said Ashman.

Among these solutions is the Tau 340 RSC. With print speeds of up to 80m/min for

the upgraded version, a native resolution of 1,200dpi by 1,200dpi and up to 8-colour stations, the Tau 340 RSC enables customers to achieve flexo like productivity in a 24/7 environment. It can be also equipped with the revolutionary Durst Hawk Eye technology to automate print quality. Applications for the machine include variable data and speciality packaging.

Further solidifying its commitment to the packaging and labels space is Durst’s partnership with fellow family-owned Italian company Omet to develop hybrid printing systems.

The jewel in the crown of the Durst and Omet partnership is the KJet, a new digital and flexo hybrid machine tailored for the label and flexible packaging market. It is the second joint development by the companies after the XJet.

The KJet combines the ‘cylinder-base dual-servo’ flexo technology from Omet with the robustness and reliability of Durst’s RSCi digital printing engine. The companies say it also offers operators a seamless experience with its user friendly interface and ultra-short web path. This design minimises waste and reduces setup times, showcasing the advantages of digital printing.

“This partnership brings together two industry leaders, combining their strengths to deliver much needed innovation to label converters across the Oceania region,” Ashman said.

Durst will host its next tour dedicated to label innovation ahead of Labelexpo, which takes place from 16-19 September 2025 in Barcelona.

3-5 Durst: The fourth Durst European tour demonstrated that world class printing quality, ingenuity, and innovation is truly ‘Made in Durst’.

PrintNZ p10-13

10-12 Iain MacIntyre learns about our Top Six Apprentices.

13 Ruth Cobb presents the PrintNZ report card for the 2024 calendar year.

Features p14-36

14-16 HP/Currie Group: Long Beach hosted this year’s Dscoop Edge.

18 Konica Minolta: The new AccurioPress 30000 3,000 sheets per hour.

32-35 Site unveiling: Blue Star officially opened its massive Auckland site recently.

36-38 Fujifilm Business Innovation: A Festival of Five Colours showed a raft of print technology.

50 Printerverse: Deb Corn explains her print-to-table concept.

52 PIDA: The AP has announced this year’s winners.

53 Consulting: Ex-industry specialists can play a role in your business.

54 High performance: Your business can buzz like a beehive.

56 Offset: Is offset still premium option for large scale print jobs?

20 Introduction: The pursuit of new revenue streams and operational efficiency drove conversations at PacPrint 2025.

21 Epson: The SureColor S9160 is Epson’s new eco-solvent flagship.

22 Fujifilm Business Innovation: The Acuity Triton uses new Aquafuze ink technology.

23 HP: Water-based HP Latex printers wowed the crowds.

24 Konica Minolta: New AccurioPress technology impressed visitors.

25 Graffica: Packaging and point of sale solutions were the focus for Graffica.

25 Mimaki: The UJV300DTF-75 is a new UV-curable Direct to Film printer.

26 Screen: Label interest and growth drove leads for Screen.

26 Ricoh: The company unveiled a new colour management tool.

26 printIQ: Enfigo and Cyanfix joined printIQ to automate print workflows.

27-30 Kiwis at PacPrint: We caught up with Kiwis who crossed the Tasman for the show.

40 Aarque: Durst continues to evolve its P5 platform.

42 Fujifilm Business innovation: The Acuity Ultra R2 has taken Benefitz to “a whole new ball game“.

44-47 Fespa: Visitors enjoyed new technology and new education programmes.

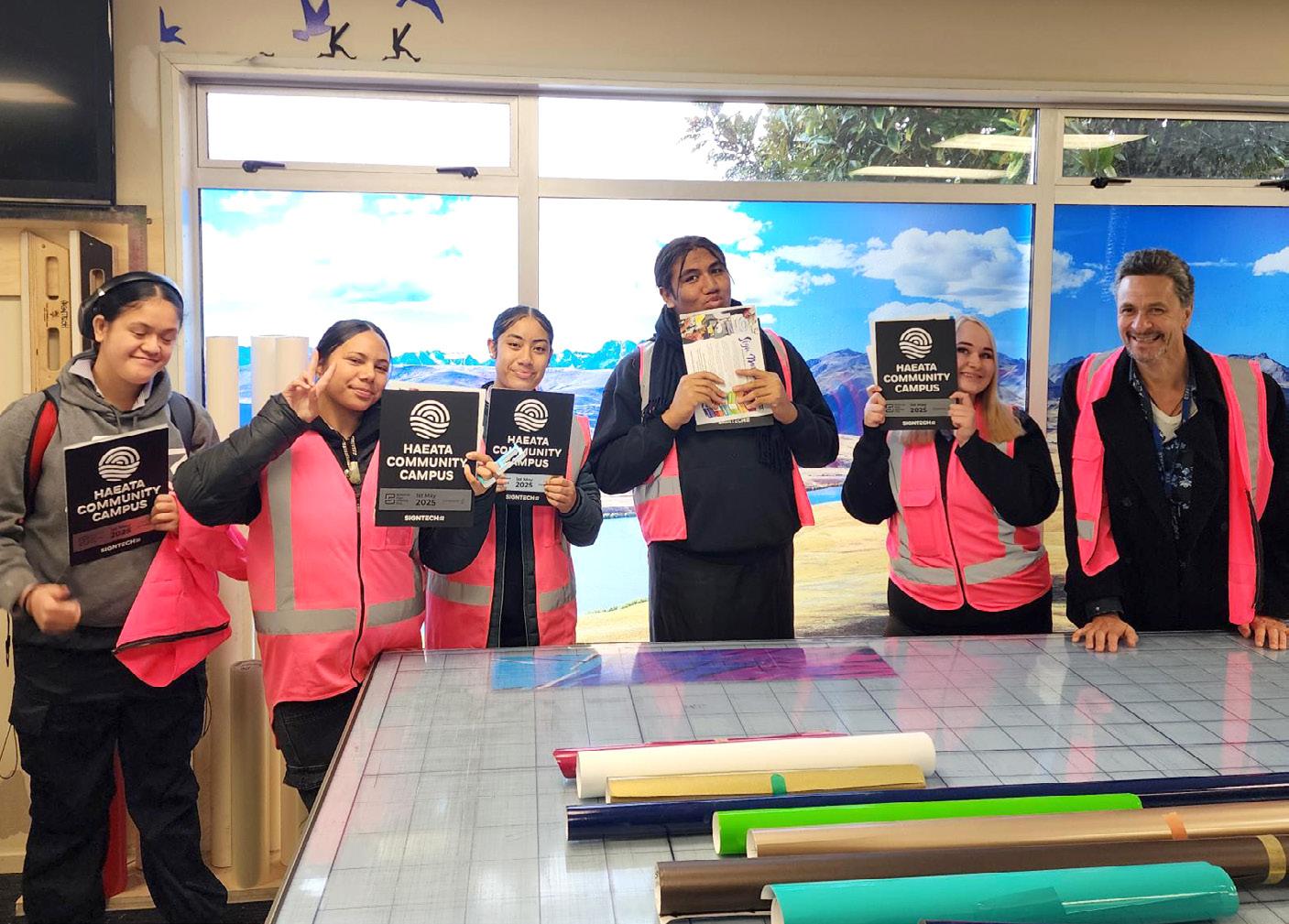

48 NZSDA Update: The inaugural National Sign Making Day was a hit with students..

49 NZSDA President: Shae Goom reflects on his time as NZSDA leader.

EDITORIAL: 021 631 559

Bruce Craig, Editor - bruce@newzealandprinter.co.nz

CONTRIBUTORS:

Andrew Ash, Ruth Cobb, Deb Corn, Peter Fotiadis, Shae Goom, Mikayla Hopkins, Iain MacIntyre

CIRCULATION: brian@newzealandprinter.co.nz

DISPLAY ADVERTISING SALES & SERVICE:

Brian Moore - brian@newzealandprinter.co.nz +61 410 578 876

CLASSIFIED ADVERTISING: Brian Moore - brian@newzealandprinter.co.nz

DESIGN & PRODUCTION: Sarah Vella - sarahvelladesigns@gmail.com

New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December.

New Zealand Printer is a member of the Printer Media Group

New Zealand: New Zealand Printer

Asia Pacific: ProPack.pro Australia: Australian Printer, ProPrint

MANAGING DIRECTOR: James Wells - james@intermedia.com.au

GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz

© Copyright 2025: Contents of this magazine are subject to copyright and cannot

COLOR-LOGIC has expanded its certification of print solutions to include the Revoria Press PC1120, due to its ability to print high quality metallic effects on paper with silver and CMYK toner, as well as on metallic stocks using white and CMYK toner. Mark Geeves. Color-Logic director of sales and marketing Mark Geeves said, “This certification builds on the previous Fujifilm success in achieving Color-Logic certification for its line of large format UV inkjet printers.”

PRINT EPS has acquired MIS provider Avanti Systems from Ricoh. Print ePS says the deal strengthens its position in the midmarket print segment and expands its global technology portfolio. The company says its delivery of software solutions that drive operational efficiency and business value enables Print ePS to serve print companies of all sizes worldwide. It adds that integrating Avanti into the Print ePS ecosystem enhances the company’s ability to continue delivering advanced MIS solutions tailored to midmarket commercial printers.

EPSON has received the highest rating in the MSCI ESG Ratings in 2025. The Morgan Stanley Capital International (MSCI) ratings measure a company’s long term commitment to socially responsible investments (SRI) and environmental, social, and governance (ESG) investment standards. MSCI says Epson received the AAA rating for the second consecutive year due to its commitment to meeting internationally recognised standards of corporate social responsibility (CSR) procurement and to the enhancement of transparency in raw material procurement and human capital development systems in 20231.

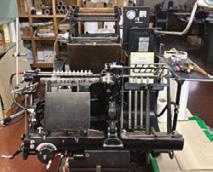

The Printing Museum (TPM) is appealing for funds to purchase a building to help preserve our print heritage and continue its work promoting print.

Dan Tait-Jamieson, secretary/treasurer of TPM, says, “The establishment of a National Printing Museum in an appropriate building will be an asset for both the region and the nation. I

“In addition, it will serve as a springboard for the long term plan of a National Centre for Book Arts.”

At China Print in Beijing, RMGT showed several of its latest technologies.

Cyber, which distributes RMGT’s products in New Zealand and Australia, also attended China Print 2025. Paul Cheong, sales director for Cyber, said, “We showcased the eight-colour plus double coater RMGT 1060LX hybrid press at China Print, equipped

Dan Tait-Jamieson, secretary/treasurer TPM

Comprising one of the largest collections of printing equipment and the only operating type foundry in the Southern Hemisphere, the Printing Museum currently operates from rented space in old army storage buildings in Mangaroa. Recently, it established a Book Arts Centre in Wellington for classes, demonstrations, and workshops.

It has reached an agreement to buy the Hopkirk Building, the former Wallaceville Animal Research Centre. Dan says,

with LED UV. RMGT has sold several 1060s at China Print. These machines are very popular. They come in a variety of configurations and can be tailored to cater to what the customers’ needs are.

“At this show, we also demonstrated how the RMGT 1060LX can be used for chemical emboss.

“Packaging is growing tremendously in China, and when it comes to trends in this space, customers are all looking to purchase at least a six-colour with coater, seven-colour, or eight-colour machine.

“The RMGT 1060LX also prides itself in its high

“The sale terms allow a period for TPM to fundraise for the minimum one million dollars needed to secure the building, which does not require earthquake strengthening.

“Our museum team is confident of again assembling its skilled volunteers for a building restoration and fit-out. The Museum has always been self-sustaining financially and this can continue with a partial lease of the premises.

“Without a permanent home, The Museum, its collection, and the skills and knowledge of its members will remain at risk. This is an opportunity for us to utilise TPM’s full potential and to save a significant piece of New Zealand’s heritage, both tangible and intangible.”

To learn more, please contact Dan Tait-Jamieson: Phone 0274 444-599, or email info@theprintingmuseum. co.nz

productivity rates and fast makeready times.”

The RMGT 1060LX press has application for packaging printing. It uses RMGT’s SimulChanger parallel automated plate changing system. It also has a new polygon-type vacuum wheel that provides a superior vacuum across the entire substrate sheet, and included are improved front-lay and side-lay detectors to accommodate thicker stock up to 1.00 mm.

It delivers fast speeds of 17,100 sheets per hour, plus Smart Assist Printing to further drive productivity to higher levels.

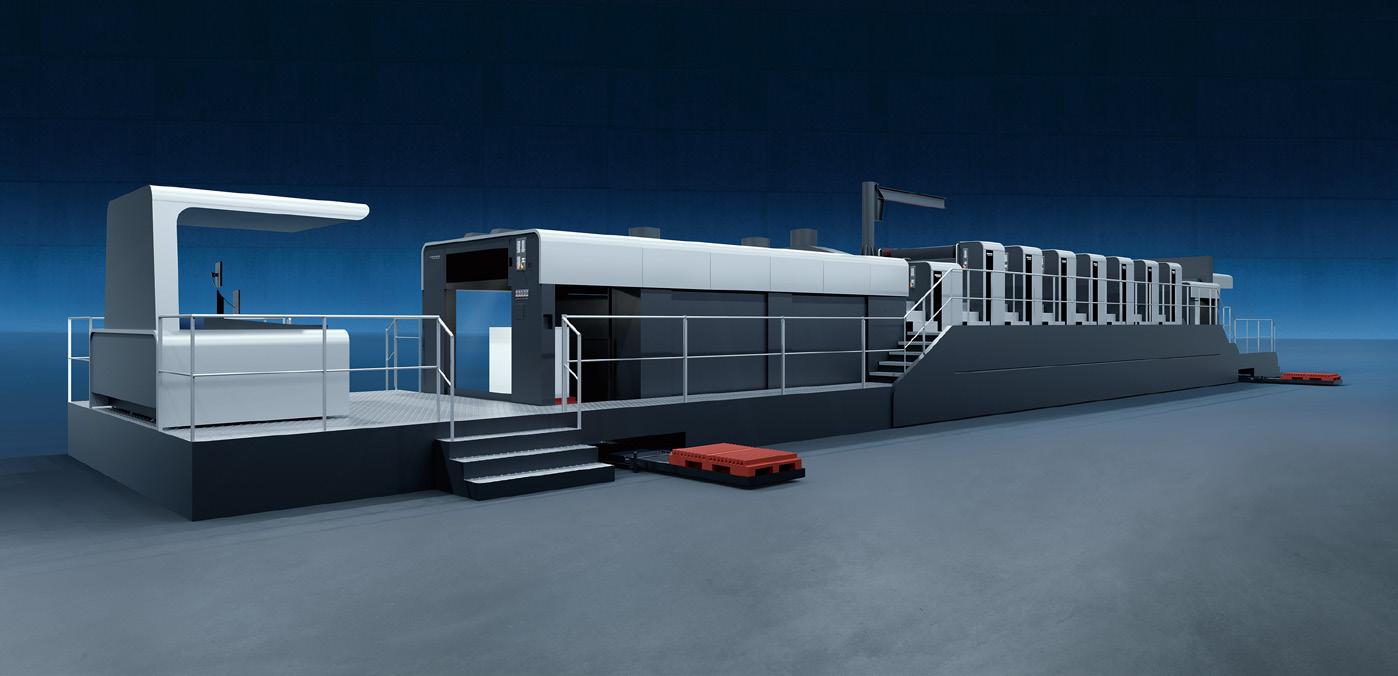

Offset press giant Heidelberg has expanded its packaging portfolio, adding the new Cartonmaster CX 145 in response to the continuing trend for packaging sector growth, in particular long run folding carton printing for food, beverage, and consumer packaging.

The company sees large format class 6 (105cm × 145cm) sheetfed offset presses playing a key role in the future of folding carton printing. Dr David Schmedding, chief technology and sales officer at Heidelberg, says, “Our new Cartonmaster CX 145 makes Heidelberg a full range provider for folding carton printing.

“As part of our growth strategy, we are expanding our range of solutions for the packaging sector and, at the same time, plugging a gap in our portfolio.”

Heidelberg has based the Cartonmaster CX 145 on the Roland Evolution 900 from manroland sheetfed. The press can be integrated into both the Prinect workflow and the workflow solutions of third-party suppliers. Customers can access performance data for their press in the Heidelberg customer portal.

Besides the actual press in the Heidelberg design, the package on offer also covers sales, installation,

training, and support, including service and consumables. Heidelberg sees maximum press availability, minimal complexity, and a professional, and well established service from the supplier as key investment criteria, especially for packaging producers in the high volume folding carton segment. It adds that the global Heidelberg service organisation offers added value for customers, who now have a more comprehensive portfolio in this market segment.

Schmedding adds, “Our performance promise for all Heidelberg machines includes local support for parts, the global presence of qualified service staff, and quick response times.”

Heidelberg plans the first Cartonmaster CX 145 customer installation for 2026 and a global rollout will follow. The company expects the biggest demand to come from North America, Europe, and China.

Jürgen Otto, chief executive officer of Heidelberg, says, “Adding the

Cartonmaster CX 145 to our portfolio is further proof of our credentials as a system integrator for the end to end production of folding cartons. Thanks to our excellent position in the folding carton segment, this new press, too, is expected to be highly popular with customers and generate increasing sales.”

Heidelberg says it now supplies a full range of products for folding carton printing and can provide the right solution for every need. For example, the company offers packaging customers Speedmaster presses in all kinds of configurations in the 50cm × 70cm and 70cm × 100cm formats, all the way through to the new Peak Performance generation of the Speedmaster XL 106. With its partner MK, Heidelberg also provides solutions for postpress applications, including robotics. The Boardmaster flexographic web printing system in the Heidelberg portfolio covers the top end of the productivity range in folding carton production.

Training advisers and managers share their insights into the country’s top apprentices.

PrintNZ has announced the Top Six apprentices in the 2024 Apprentice of the Year Award. Normally, PrintNZ names a Top Five but this year, judges could not whittle down the finalists any further.

On July 4, at the Cordis Hotel in Auckland, PrintNZ will name the 2024 Apprentice of the Year during the Pride In Print Awards gala dinner.

The top six apprentices are:

• Binding and Finishing – Jessia Moore of Imagine If Creative Studios

• Gravure Printing – Eligh Arthur

of Gravure Packaging

• Label Printing – Faamao (Paul) Müller of Wedderburn New Zealand

• Packaging – Toese Fauatea of Opal Packaging NZ, Cartons

• Reelfed Printing – Bradley Smith of Transcontinental NZ

• Sheetfed Printing – Tayla Jones of Logan Print

Bradley Smith

Steven Jack, training adviser at Competenz, says, “Brad demonstrates a real passion for the industry. This comes through with the way he speaks and is shown in the work produced

over his apprenticeship. His bookwork was a pleasure to read and mark.

“Brad faced his challenges well: being the father of two young children, shift work, and completing an apprenticeship. It is never easy with all this going on but due to his passion for the industry, he never failed to deliver.

“He would often turn up to work in his own time to learn as much as possible. This is a real credit to the man.

“Brad expresses a hunger for knowledge and is keen to succeed. I am 100 per cent sure that Brad will be a future

leader in the industry. With young people like him, the future of the industry is very bright.”

Involved in flexible packaging for most of his career, Brad joined Transcontinental in 2005 and evolved from blown film extrusion operator to shift supervisor in the print department.

Nick Ball, printing manager at Transcontinental, adds, “Brad is very thorough. All his assignments were done to such a high standard. He has set the bar very high for the next apprentices that come through here. After completing the plastics engineering apprenticeship and coming runner up in the Apprentice of the Year then, I had no surprise in hearing that he had been nominated again.

“Being able to juggle the apprenticeship, leading the team and having a young family; it has been great to see the personal and professional growth in Brad. It is great to see people coming through the apprentice programme to further their careers and open that door for a lot more possibilities.”

Eligh Arthur joined Gravure Packaging as a finisher in 2020 having previously been an electrician by trade. Andrew Young, managing director at Gravure Packaging, says, “Eligh has worked hard to understand and subsequently master a number of the machines. In doing so, he quickly established himself as a prospect for future development.

“He was rewarded for his hard work August of 2020 when the company offered Eligh the opportunity to start a Level 4 apprenticeship in reelfed printing under Malcolm Pearce’s tutelage.

“Eligh consistently displays a positive attitude and a strong work ethic. He is punctual, polite, reliable and willing to take on additional tasks when needed. Eligh’s enthusiasm for learning and improving his skills is commendable, and he actively seeks feedback to enhance his performance.”

In 2028, Tayla Jones left a background in childcare to join Logan Print as a print assistant in 2018. Colin Lean, technical manager at Logan Print, describes Tayla as “highly motivated”.

He says, “Tayla has trained on all three of our six-colour Heidelberg presses, so she has experienced changes in technology from 74 centimetres to 102 centimetres and from sheetfed to the latest Heidelberg CutStar reel to sheet infeed.

“I have been lucky enough to help mentor 14 apprentices, including Tayla, and we have never had someone with her bubbly personality, work ethic and self-motivation.

“For example, during Tayla’s apprenticeship she completed a module where she had to lead a team in a task. Tayla had four experienced printers in their 40s and 50s taking notes from her

plans and then offering feedback. At no stage was she uncomfortable, as she had made her plan and done her preparation and had respect from her colleagues.”

Advisor’s nomination criteria

Commenting collectively on Tayla Jones and Eligh Arthur, Competenz training advisor Malcolm Pearce emphasises that he only nominates for Apprentice of the Year when he “firmly believes” a candidate can win both the award in their field of work and overall.

He says, “Both my nominations have been consistent from the first day of their apprenticeships through to becoming fully qualified in their trade.

“Key factors I consider are assignments that are well documented, and questions answered in detail, often calling on personal experience from the trade, assignments completed by their due dates and apprenticeships completed on time.

“Factors for my nomination of these two apprentices include positive feedback from employers and what I observe from their peers.”

Other aspects Malcolm takes into consideration include:

• Being given more responsibilities during their apprenticeship – for example, are they in charge of a press or do they have an assistant reporting to them?

• Are there obstacles in their lives they

have managed such as sports or family commitments, disabilities or biases?

Jessia Moore

After previously working in administration for an electrician firm, Jessia Moore joined Imagine If Creative Studios as a print finisher.

Aly Cosson, senior graphic designer and owner of Imagine If Creative Studios, says, “Jessia has excelled in the apprenticeship and that comes as no surprise. From the beginning she said she wanted to go for Apprentice of the Year, I made the Top 5 back in 2013 and so her goal has been to beat me, and I really hope she does.

“She has put so much dedication into this, and her efforts are more impressive when you know she has dyslexia, something that she really struggled with at school. She was able to receive assistance through this process, and she has really blossomed and become prouder of herself. She knows now that she can do things. She doesn’t have to let the dyslexia stop her. We are so proud.”

Faamao (Paul) Müller

Coming from within the print industry to work at Wedderburn New Zealand as a print assistant in 2019, Faamao (Paul) Müller now operates an eight-colour press.

Tony Reid, labels production manager at Wedderburn, says, “Paul showed drive and commitment to his training.

I knew he would always do well in his print apprenticeship.

“Paul has excelled, consistently demonstrating a strong work ethic, eagerness to learn and the ability to adapt quickly to new challenges. He is also very good at trouble shooting technical printing issues.

“Paul is an asset to us as he brings fresh perspectives and innovation, helping to drive Wedderburn forward.”

Previously a school teacher in Samoa, Toese Fauatea has excelled since joining Opal Packaging NZ in 2020, initially as an assistant in the gluing department.

Dave Wilson, operations manager for Opal Packaging NZ, says, “We asked if he would go into the die-cutting department, because we were introducing some new equipment in gluing and knew some people would be affected by that restructure.

“It has turned out pretty well for him. A number of people in the gluing department had said to me, ‘Actually, this guy is quite good’. Obviously, you take what the people on the floor say, as they are working with him day in day out.

“He has an eagerness to obtain new knowledge, and he applies it. He says: ‘I actually tried what you showed me, and it is working’. and there is a smile on his face that he has achieved.”

Grant Alsop, training adviser at Competenz provides the following comments on Jessia, Paul, and Toese: the three “worthy” apprentices under his tutelage:

Grant says, “Jessia was very enthusiastic and conscientious throughout her binding and finishing apprenticeship. She completed her assignments on time which were always presented to a high standard.

“Putting a lot of effort into gathering the information for each unit, Jessia was proud of her achievements. Her commitment to producing quality work and her problem solving ability was impressive, and her manager always spoke highly of her.

Paul was engaged throughout the four-year reel fed print apprenticeship. He completed his assignments on time and to a good standard and was able to provide quality evidence of his work. He was well supported and is highly regarded by his manager.

“Paul was excited to get the opportunity to do a fibreboard packaging carton cut and crease apprenticeship. He always did his best to provide good work for each unit standard. He demonstrated good practical skills throughout and was able to provide quality evidence of his work. I always received positive feedback on his work and ability from his supervisor.”

Iain Macintyre

PrintNZ focuses on delivering services that provide value and relevance to its members.

As an industry organisation, we are owned by our members and it is only fitting that we provide feedback to our stakeholders about how we are doing, so here is our report card for the 2024 calendar year following our 117th Annual General Meeting held on Wednesday May 14.

The AGM saw the completion of Fred Soar’s four year term as president. Fred has contributed a substantial amount of time and expertise to the role, taking on the presidency in 2021 as we were coming out of Covid and through a busy period for his own business. The meeting acknowledged the sterling job he has done as he steps down into the newly created role of immediate past president.

Jill Cowling, chief executive officer of Blue Star Group, was duly elected to the vacated role of president. Jill has been on the Board since 2021 and we welcome the knowledge, experience and capability she brings to the position, particularly in these challenging times.

Matt Wilson (NZME) and Angela Nauck (Torque Digital) were both re-elected into their roles on the Board for a further two year term, and David Parsons (CQ) remains a standing member.

Penelope Savidan (B&F Papers) completed her two year term as the Supplier Representative and Daniel Telfer from B J Ball was elected by the Board to take that position for the next two years.

Our thanks go to both Fred and Penelope for the time they have given to the Board – these are voluntary roles, and they undertake them in addition to their already busy jobs.

The audited Accounts were presented to the AGM. PrintNZ made a pre-tax profit of $37,052 for the 12 months to December 31, 2024. This was down on pre-tax profit from the previous year, a similar story to many of our member businesses as we faced a challenging market and increasing inflationary pressures. The organisation has equity of $1.4m and an investment portfolio valued at $1.5m which generated dividend income of $63,103.

The Annual Report of the president and chief executive was presented to the meeting. This summarises the expansive activities undertaken during the year including lobbying; networking; training; direct to member services; related association activities; and membership statistics. On December 31, 2024, PrintNZ had 487 members.

PrintNZ currently sends annual invoices on 1 January each year in line with its financial year. A proposal was tabled and accepted to move the billing year to October 1-September 30, taking it away from the cashflow crunch-time of January. This will involve a stepped transition to the invoicing in 2026 to accommodate the new date for annual payers. All members continue to be encouraged to pay monthly to spread the load, and those doing so will not be impacted by the billing change.

In keeping with the new Incorporated Societies Act 2022, PrintNZ was required to present an updated Constitution at the meeting and have passed this by a vote of the members present. The rules were last reviewed in 2007, and the mandated change provided a timely opportunity to update the rules to reflect best practice and match the current legislated requirements of a constitution. Following this approval of the rules PrintNZ must now apply to be re-registered as an Incorporated Society under the new Act.

At the end of 2024, the Board committed a substantial sum of money to develop a marketing campaign to raise the awareness of print and create a broader understanding of its effectiveness, the role it plays in everyday life, its sustainable qualities, with the goal to ultimately improve engagement with the print industry. The first stages of the campaign are underway, and resources will be developed for both a targeted external market and for internal use by members to customers.

So, there it goes. Hopefully, our work is worthy of at least an A. We exist for our members and remain focused on delivering services that provide value and relevance, looking for opportunities to deliver further benefits and support, and continuing to look for prospects for growth for the organisation, both within the industry and across complementary groups.

But we are nothing without our members, our staff and our Board, and a huge thank you goes to all the businesses and individuals that recognise the value of having an industry organisation, in good times and in bad, and support PrintNZ accordingly through membership, sponsorship and participation.

Ruth Cobb

Nearly 1,300 members gathered at Dscoop Edge Long Beach for a three-day event spotlighting the power of connection, idea sharing and innovation.

Dscoop Edge Long Beach recently took place in California, bringing together nearly 1,300 members of the Dscoop global community, where they converged for three days of learning and connecting. This year, the flagship event, centred around powerful idea-sharing within the Dscoop global community, celebrated its 20th year.

Dscoop, one of the largest digital print communities in the world, now comprises about 22,000 HP Industrial and HP Large Format users and partners across 96 countries including New Zealand and Australia.

In Long Beach, as the event’s theme depicted, they confronted the industry’s next waves, major forces like AI and economic trends that will crash into businesses left unprepared, while uplifting others with incredible momentum.

At the event, Haim Levit, HP industrial print senior vice-president and division president, said, “For two decades, HP

and the Dscoop Edge community have been driving the transformation of digital print – raising the bar for quality, versatility, productivity, cost efficiency, and sustainability.

“This year at Dscoop we celebrate that legacy and embark on a new journey, one in which AI will revolutionise the world of print as we know it today, opening a new era where presses become autonomous and workflows are connected, automated, and orchestrated from creation to delivery.”

A cohort of 18 print professionals from Australia and New Zealand, including staff from HP Indigo A/NZ distributor Currie Group, attended Dscoop Edge Long Beach, joining like-minded innovators at the event.

The trip delivered more than just a conference experience. The group embarked on a curated programme of exclusive site visits to several high

performing Californian print businesses, gaining invaluable insights into the latest technologies, workflows, and business models shaping the future of print. These tours complemented the immersive Dscoop agenda.

The event also marked a proud milestone for the Australasian print community with industry leader and long time Dscoop advocate Kelvin Gage’s election as global chairman of the Dscoop Global Board.

The energy, collaboration, and inspiration that came from the Long Beach experience left a lasting impression on all who attended. The A/NZ delegates returned home with fresh ideas, strengthened global connections, and a renewed sense of momentum to help drive their businesses, and the broader regional print community, forward.

Mark Daws, Currie Group labels and packaging A/NZ director, said, “Dscoop Edge is always an inspiring experience, bringing together like-

minded professionals from across the globe. It was fantastic to see so many of our A/NZ customers making the journey, connecting with peers and learning from the best. The site visits to high-performing print businesses really reinforced how technology and collaboration are shaping the future of our industry.

“We should be proud of the level of quality and automation we are achieving here in Australia and New Zealand, as it truly stands out on the world stage.”

Among the Kiwis who attended, Craig Loveridge, chief commercial officer - Blue Star Group, said, “It was great to be part of the wider Dscoop community for a few days and get the latest industry insights from across the globe. We were really appreciative of the sites that opened their doors to us during the site visits.”

Also travelling to the event, New Zealand Dscoop country lead and managing director of innovative print company Fuzed, Matt Mills had time to reflect on Dscoop after the event. Matt said, “I have been involved with Dscoop for eight years now. It’s been a valuable space for connection, learning, and staying plugged into some of the latest innovations.

Initially, I became interested in Dscoop after hearing the rumours and wanted to find out for myself what Dscoop had to offer. It wasn’t till I experienced it for myself that I really understood it was the opportunity to connect with like minded professionals and learn from others facing the similar if not the same challenges. The community feel and practical value sets Dscoop apart from typical trade events.

“This year, like every time I go to a Dscoop event, I go to connect, and reconnect with other industry peers, explore existing and new technologies,

with the premise to gather ideas to bring back to Fuzed.

The three best parts for me from this year’s Dscoop were:

• The conversations: Both formal and informal, they sparked new thinking and helped validate some of our strategies along with create ideas to think about for the future.

• Technology demos: Seeing the latest in digital print tech in action, with opportunities to ask real-world questions and how they can apply directly to Fuzed.

• Breakout sessions: Especially those focused on business growth, customer experience, and market trends.

“We gained immense value from the strategic insights: hearing how other businesses are evolving, especially in customer engagement, workflow automation, and scalability. All with the focus of enhancing the offering at Fuzed.

“Compared with previous Dscoops, this year felt more focused and forwardthinking. The sessions were very engaging; the networking was fantastic the relationships built with regular attendees got even stronger and new relationships formed with first timers. AI was a major focus throughout the event, which added a layer of futurereadiness to many conversations, even if that wasn’t my main draw.

“Dscoop helps Fuzed by opening doors to ideas, to partners, and to practical solutions we might not come across otherwise. One of the most helpful parts is being surrounded by people who are solving similar challenges and willing to share their learnings.”

From Australia, Rawson Print & Packaging managing director Andrew Price said, “It has been eight years since

my last Dscoop in 2017. This was my third Dscoop, having previously attended in 2010 (Dallas), 2017 (Phoenix), and now Long Beach.

“Dscoop is a fantastic experience, not just for connecting with like-minded professionals from across the print industry, but for the opportunity to collaborate with peers globally. We’re often facing similar challenges, and it’s incredibly valuable to share ideas and solutions.

“I was eager to see what’s new in the industry and what opportunities we could leverage. I was also keen to explore the latest advancements in HP Indigo technology. My most valuable takeaway was the use of AI in the printing industry, particularly how it can help streamline and enhance both operational workflows and the sales and quoting process.”

Onpack managing director Michael Nankervis said, “This was my first Dscoop event. For anyone considering Dscoop for the first time, I’d describe it as a unique opportunity to gain practical insights, build meaningful relationships, and see what’s possible with new technology, all in one place.

“My motivation for attending this year was to stay ahead of industry trends and connect with peers and partners who are shaping the future of print and packaging. The most valuable takeaway from Dscoop Edge Long Beach was seeing firsthand the latest advancements in digital print technology, including AI for the industry, and how global operators are leveraging them to deliver more agile, efficient solutions for customers.”

The AI advancements that sparked attendees’ attention included:

HP Nio

Powered by HP’s PrintOS, HP Nio empowers businesses with data-driven intelligence to maximise printing resources, drive productivity, and unlock new avenues for growth.

HP Nio is a new chatbot that allows customers to ask questions about their print operations. It connects directly with HP PrintOS to deliver real-time data, production insights, and on-demand knowledge, all in one place.

By using tools like Print Beat and the Knowledge Zone, HP Nio provides expert, print-specific guidance. Soon, it will also integrate with other HP PrintOS apps like HP Site Flow to support workflow automation and suggest smart, actionable next steps. Ultimately, HP Nio will act as an intelligent co-creator, enhancing the PrintOS experience and helping

automate the entire print workflow from start to finish.

Introduced at drupa for HP Indigo presses, HP’s AI-enabled solutions including Automatic Alert Agent (AAA 2.0), Print Mode Preflight, and PQ Maestro, were showcased in an end-toend intelligent print workflow at Dscoop Edge Long Beach.

These innovations are estimated to be commercially available in July and are becoming core assets of HP Indigo’s AI technology, helping customers significantly increase print efficiency.

HP has further enhanced the HP PrintOS Creativity Power Pack with new features in HP SmartStream Designer, including support for Adobe CC2025, integration of Amazon Transparency codes, and the addition of Bria.ai capabilities for generating AI images within variable data projects, allowing for the creation of highly personalised and scalable campaigns.

HP Quality Power Pack is also available for HP Indigo 120K and HP Indigo 18K Digital Presses enabling printers and converters to achieve colour industry standards in minutes, fully automated, with zero human touch points to increase press uptime.

New features in HP Site Flow will also help printers and converters efficiently track orders, for a more agile workflow including the ability to:

• Get data on reprint jobs with flagged items table.

• Automate complex workflows with custom production plans.

• Connect 100+ carriers in a matter of days with ShipStation API Integration.

• Gain access to advanced intelligent picking and warehouse management capabilities by integrating with Mintsoft.

HP has improved HP Brand Centre, the platform designed to speed up onboarding and improve order tracking, by connecting brands to printers and converters efficiently.

The solution enhances the overall efficiency to manage and share the brand’s product catalogue, simplifying their onboarding process to a few days, and allowing users to manage invoicing,

production, and service agreements in one place.

At Dscoop Edge Long Beach, HP welcomed four new brands to the intelligent HP Brand Centre platform: Zazzle, Minted, Printerpix and Mixam.

HP also announced the launch of HP Business Centre, providing customers with enhanced finance management capabilities empowering customers to make informed decisions and to optimise their operations.

The new solution enhances the HP PrintOS ecosystem with features including online supplies lifespan score monitoring, impressions performance tracking and comprehensive invoice tracking – driving efficiency and automation for organisations to deliver smarter printer operations.

At Dscoop Edge Long Beach, HP also demonstrated full production lines powered by the HP Indigo 120K and HP Indigo 18K HD Digital Presses, showcasing the wide versatility and productivity. These presses, with their AI-based solutions, were released at drupa, and aim to redefine the shift from analogue to digital printing.

With the HP Indigo 200K Digital Press, HP celebrates its milestone of 10 years in the flexible packaging market and more than 400 flexible packaging presses installed worldwide. It also presented the add-on slitter showcasing how converters can seamlessly use their HP Indigo 200K press to print pressure-sensitive labels, flexible packaging, shrink sleeves, slit on press and then convert the slitted roll-on narrow web devices.

For the first time, HP put the spotlight on a live, large scale Web2Print experience

printed on the HP Indigo 18K Digital Press, in collaboration with Canva and Printbox, supported by finishing partners Nobelus, Duplo and Z360. Visitors saw the creation and personalisation of posters, greeting cards, sports trading cards, and even photo albums in real-time.

On the show floor, attendees also had the opportunity to learn more about the high speed of the HP PageWide Advantage 2200 and the newly introduced HP PageWide T4250 HDR and HP PageWide T500 HD presses. These two presses let users explore new markets and build new business models, delivering on performance across publishing, direct mail, and commercial print.

As for the HP Indigo V12 Digital Press, it brings digital value to mid-to-high volume label production.

HP said its co-innovation with customers has driven increased technology stability and repeat investments, proving the value of digital adoption with a record of about one million metres a month, adding that it is a “great achievement accomplished only three months after installation”.

HP’s commitment to sustainable print

In addition, HP announced its Sustainability Amplifier Programme is expanding with a new CO₂ calculator to help businesses measure and reduce their environmental impact.

Since its launch in November 2024, over 1,000 industrial print and large format customers have engaged with the programme and its tools.

The company said HP Indigo’s new CMYK+, and PIP+ consumables cut CO₂ emissions by up to 16 per cent while also reducing waste, saving time and space, and maintaining high print quality.

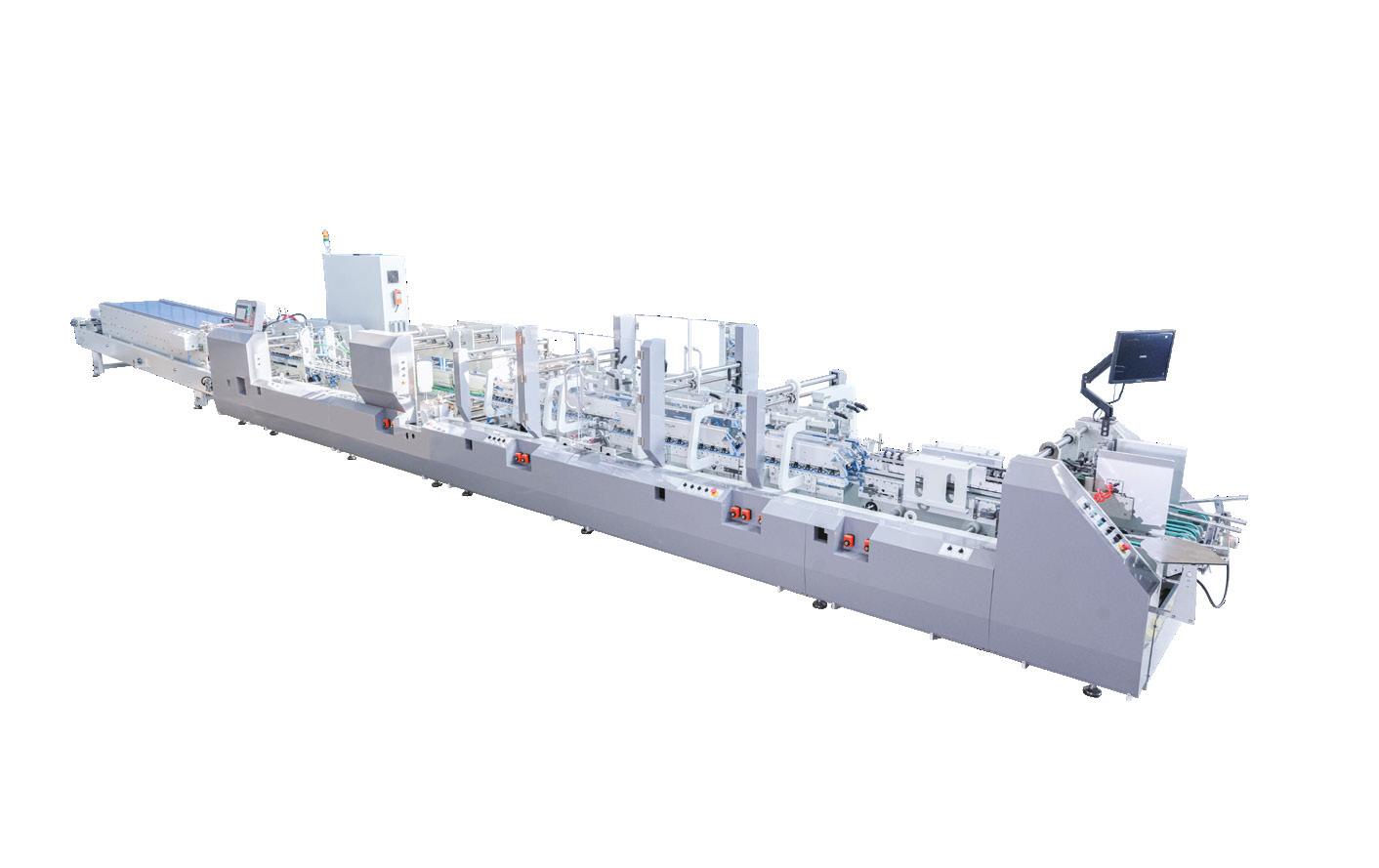

ADVANCED AUTOMATION FOR HIGH VOLUME PERFORMANCE.

The pursuit of new revenue streams and operational efficiency drove conversations at PacPrint 2025.

PacPrint 2025 concluded a successful run at the Sydney Showground last month, colocating with Visual Impact and Label & Packaging Expo.

PacPrint 2025 welcomed 3,847 attendees and 116 exhibiting companies. Organisers say PacPrint’s “dynamic environment underscored the print and signage industry’s resilience, innovation, and forward momentum”. Even daily train disruptions and an extremely wet week in Sydney didn’t discourage the strong crowd.

The show attracted a high quality audience of serious buyers, with numerous exhibitors reporting strong sales activity from Day One. The sentiment echoed across the show floor, with vendors highlighting the presence of decision makers intent on discovering innovations and making meaningful investments. Organisers commented that a significant contingent from New Zealand added depth to commercial conversations, reinforcing the show’s regional importance. They added that “multiple exhibitors reported strong sales and plenty of high-quality leads”.

Kirsten Taylor, chair of PacPrint 2025, set the tone during the opening ceremony. She said, “This year, our

theme ‘Innovation, Collaboration, and Transformation’ captures the very essence of what drives the industry forward. It’s inspiring to see the energy, creativity, and resilience gathered within these walls today as we come together to shape the future of print.”

She explained that PacPrint 2025 is designed not just to inform, but to ignite ideas, adding, “As we navigate a rapidly evolving landscape, it’s clear that our ability to adapt and innovate has never been more important. This event is your opportunity to explore breakthrough solutions, build new connections, and uncover possibilities that can redefine your business future.”

The show’s forums brought together some of the industry’s brightest minds and boldest thinkers. The sessions covered everything from industry trends in technology to what it really takes to navigate success in today’s print landscape.

Topics included emerging talent; strategic partnerships; mental health and employee well-being; sustainability; industry compliance; superannuation planning; industry associations and leadership.

Kirsten commented: “PacPrint is more than a trade show. It’s a space where bold ideas come to life. Where connections are made, and where we collectively reimagine the future of our industry.”

Across four days, this vision came to life through imaginative exhibits, informative panel sessions, and robust networking. She added, “The positive energy and commercial success reaffirm the essential role of PacPrint for our industry.”

Exhibitors say visitors came with purpose, looking for transformative solutions and innovation to drive business growth. While automation and sustainability featured prominently, the pursuit of new revenue streams and operational efficiency drove most conversations, according to exhibitors.

With post-event surveys underway, organisers expect to gather deeper insights to further enhance future editions. They add that early indicators point to resounding satisfaction: strong foot traffic, meaningful engagement, and business outcomes that reaffirm the essential value of trade shows, particularly those embracing hybrid strategies to extend their reach.

The organisers concluded, “We extend heartfelt thanks to all attendees, exhibitors, expert presenters and panellists, sponsors, and partners. Your passion, participation, and collaboration are what make PacPrint 2025 the premier event for the print, sign, labels and packaging, and visual media industry.”

printers deliver a range of possibilities.

Epson highlighted a range of solutions PacPrint 2025 with a focus on its recently announced eco-solvent flagship, the SureColor S9160.

The company says the 1.6m printer sets a new standard in signage printing by delivering exceptional image quality, an expanded colour gamut, unparalleled productivity, and a compact, user friendly design.

Equipped with Epson’s latest user replaceable 6.6cm PrecisionCore MicroTFP printhead, the printer uses an advanced 11-colour ink set, including red, orange and an all-new green, as well as opaque white ink.

This printer’s eco-friendly features include the fact that Epson uses recycled material to make around 30 per cent of the plastic used in its hardware. Epson says this reflects its ongoing commitment to reusing resources and reducing waste. The S9160 also offers the opportunity to install either 800ml or 1,500ml sizes of any of its low VOC UltraChrome GS3 eco-solvent inks which reduces environmental footprint and plastic waste.

Also, on show at PacPrint, the SureColor S8160 eco-solvent printer, featuring Epson’s latest 2.64-inch PrecisionCore MicroTFP printhead.

Epson says the printer ensures minimal downtime, while advanced technologies, including an integrated temperature sensor, nozzle verification and nozzle replacement system, work together to deliver consistent image quality, precise colour accuracy and improved workflow efficiency.

It also features a six-colour UltraChrome GS3 ink set, including light cyan and light magenta. It supports a wide range of materials, including vinyl, canvas, film, and wallpaper and roll media up to 1,626mm wide. The inks are GreenGuard Gold certified and low-VOC.

For uninterrupted high volume production, the SC S8160 printer features dual ink slots per colour, enabling hot swapping and allowing ink replacement without pausing print jobs. It allows for flexible ink configuration, enabling the installation of either 800ml or 1,500ml of any colour to optimise workflow efficiency while minimising plastic waste.

In line with its PacPrint theme of ‘Come Alive with Epson’, the company also had several other products on display, catering to the photo, signage, merchandise, and labels sectors. They included the SureColor G6060, Epson’s first wide format printer designed exclusively for direct to film (DTF) production featuring a compact design with all front loaded consumables; the SureColor P20560, designed for highquality poster, graphic, signage, and fine art printing; and two Australasian firsts: the SureColor S7160 eco solvent printer and the SureColor V2060.

Other innovative Epson technology at the show included the Epson SD10 Spectrophotometer and Auto Table, ColorWorks C8010, ColorWorks C6510, ColorWorks C4010A, SureColor P20560, SureColor T-Series T5760DM, the SureColor G6060, SureColor F9560, and SureColor F1060.

The SureColor S7160 builds on the success of the SC-S40600, which has achieved over 11,000 units in global sales. Epson says it designed the SC-S7160 to deliver outstanding image quality, productivity, ease of use and reliability at a minimal cost.

The Epson SureColor V2060, an A3 UV flatbed desktop printer, targets the growing demand for high quality, on demand customisation. Specifically designed for producing bespoke merchandise, promotional products, and small-format signage the SC-V2060 brings professional grade UV printing into compact spaces to a wide range of users with ease.

Avinash Patel, business development manager for Professional Print at Epson New Zealand, welcomed Kiwi visitors to the stand over the four days of the show.

Fujifilm Business Innovation team highlights a raft of innovations and solutions.

Fujifilm Business Innovation took to PacPrint to launch the Acuity Triton in the region at PacPrint 2025. The company also showed a raft of printing technology including two new Revoria presses.

The new roll fed printer uses the company’s new Aquafuze ink technology, meeting a multitude of market requirements as it combines the benefits of LED UV and water-based inkjet technologies.

The Acuity Triton brings together two titans of the wide format inkjet industry. Mutoh manufactures the hardware in Japan and Fujifilm developed and produced the Aquafuze technology, drawing on its track record of ink innovation.

Aquafuze technology combines UV LED and water-based inkjet, offering low energy, low temperature drying compared to traditional water-based print systems. It provides adhesion to a wide range of media without the need for a pre-coat primer or optimiser.

Prints have a thin scratch-resistant film and do not require a topcoat. Fujifilm says the technology offers excellent jetting stability through reduced nozzle blocking due to low temperature drying.

The Acuity Triton, Fujifilm’s first machine in the 1.6m market has a fourcolour process with UV water-based inks. Features include instant cure and minimal amounts of power consumption. Fujifilm can offer a professional print and cut solution for sign and display applications.

The company also showed the new Revoria Press SC285S and Revoria Press EC2100S.

With the help of Super EA-Eco toner used in high-end models, both the Revoria Press SC285S and Revoria Press EC2100S enable high-quality CMYK printing and achieve shiny metallic colour and gloss. The compact high quality LED print head can provide high-resolution output of up to 2,400dpi x 2,400dpi to achieve high-definition printing with clear lines and images.

The Revoria Press EC2100S is compatible with a variety of papers, has postprocessing functions, and is easy to operate. It features an automatic optimisation function using Revoria Flow, of neon pink toner to achieve a wider colour gamut.

It allows for high-speed printing of uncoated paper (52gsm to 400gsm) and coated paper (72gsm to 400gsm). It prints A4 at up to 100 pages per minute, while its A3 print productivity reaches 55 pages per minute.

The Revoria Press SC285S supports a wide range of paper types and sizes, including various paper sizes as small as 90mm ×146mm and as large as 330mm × 660 mm, and supports optional long paper printing (single-sided) up to 330mm × 1300mm.

From 52gsm thin paper to 400gsm thick paper, it can flexibly handle various gram weight media. In addition to printing a variety of exquisite materials, the machine also has various common business office functions such as copying and scanning. It achieves production efficiency for A4 of 85 pages per minute and as high as 47 pages per minute for A3 printing.

Other products on show included: the new Revoria Press PC1120 + Plockmatic Booklet Maker, the Acuity Prime Hybrid, and Revoria XMF PressReady integrated print workflow.

Fujifilm Business Innovation New Zealand (FBNZ) hosted visitors on the stand over the four days of the show. In a strong Kiwi representation, managing director David Jupe joined with Greg O’Shanassy, Paul Thomas, Cary Rawson, and Ryan Stevens to showcase the company’s latest innovations.

New printers target high impact print quality and enhanced productivity.

At PacPrint 2025, HP unveiled its latest generation of water-based HP Latex large format printing solutions: the HP Latex 730 and HP Latex 830 Printer Series at PacPrint 2025.

Following last month’s innovations announced at HP Amplify, including the all in one HP Latex R530 and HP PrintOS Production Hub, the unveiling of the new series reinforced HP’s ongoing commitment to innovation in large format printing, delivering an impressive portfolio of hardware, software solutions and services.

HP has designed the HP Latex 730 and HP Latex 830 printers to deliver high impact print quality, enhance productivity and costs for small and medium-sized print shops while continuing to differentiate with a sustainability edge.

Craig Hardman, A/NZ country manager large format printing at HP, said, “With the introduction of the HP Latex R530, L730 and L830 Printer Series, we are reaffirming HP’s commitment to empowering print service providers with cutting edge, sustainable technology.

“These next-gen solutions combine exceptional print quality, breakthrough productivity, and operational simplicity, designed to help our customers grow efficiently in a competitive market. Together with innovations like the HP PrintOS Production Hub, we are delivering an unmatched ecosystem that redefines what is possible in large-format printing.”

With the new colour pipeline, HP Pixel Control, the latest generation of inks and printhead architecture, HP says these advanced printers deliver elevated print quality with maximum consistency.

HP calls its Pixel Control the digital colour pipeline that enables print service providers to deliver a more robust and consistent image quality at a lower number of passes, allowing customers to print uniform solid colours and greater detail. Additionally, enhanced colour consistency and the ability to create colour profiles with the HP Embedded

allows print service providers to confidently repeat print jobs across various media types without compromising quality.

HP says these printers are a powerful tool for diverse printing needs. Equipped with HP Latex Ink to deliver vivid colours and universal user-replaceable HP Latex Printheads to deliver sharp four-point text, print service providers can print a wide range of including branded campaigns, décor, and titled graphics, benefiting now from automated doublesided printing.

HP has engineered the new HP Latex Series to simplify production and optimise printing processes. Rapid production speeds significantly reduce printing time, while instant drying prints eliminate waiting times so operators can complete more jobs in less time. When coupled with the recently introduced HP PrintOS Production Hub software, print service providers can further enhance their operations by simplifying print workflows, order management, and remote production from a centralised, real time platform.

HP has considered productivity and time saving innovations at every step of the printing process, from spindle-less front loading to facilitate quick and easy media loading, to the new output platen which minimises material waste by allowing

tighter media control of each print job. The company has enhanced the HP Latex 830 printer to further reduce running costs. It features three-litre HP ink cartridges that you can replace without halting operations,

HP says that each enhancement delivers a smoother, more efficient workflow that enables faster job turnaround and lower total cost of production, ideal for smaller teams when managing multiple jobs in high mix, fast paced large format print production.

Furthering HP’s commitment to operational efficiency and sustainability, the HP Latex 730 and 830 join the HP Latex 630 as EPEAT Climate+registered printers, the only printers in the signage industry with this certification.

HP adds that the HP Latex Series supports a more comfortable work environment while helping print service providers meet the growing demand for sustainable, high impact print applications with water-based, odourless, and UL ECologo-certified HP Latex inks, low emissions, and compatibility with fibre-based recyclable media.

Over the four days of PacPrint 2025, Wayne Shaw, business manager Sign & Display at HP New Zealand, showed Kiwi visitors around the stand demonstrating the new printers and their innovations.

The AccurioPress C14010S and C12010S print at speeds of 140ppm and 120ppm respectively

Konica Minolta debuted its next generation AccurioPress C14010S and AccurioPress C12010S production presses at PacPrint 2025.

Chris O’Hara, national production and industrial print manager for Konica Minolta New Zealand, said, “We were excited to see the new presses launch at PacPrint 2025. These innovative presses empower businesses with stunning print quality, exceptional speeds, and unmatched versatility, letting customers unlock more possibilities in digital print with CMYK + white toners.

“The AccurioPress C14010S and C12010S from Konica Minolta deliver exceptional performance, achieving print speeds of up to 140 pages per minute (ppm) and 120 ppm, respectively.

“The new five-colour print models add white as a new colour and let businesses explore new creative avenues, such as eye-catching print effects.

“The AccurioPress C14010S and C12010S feature six Intelligent Media Sensors. For automated print management, these identify paper type, weight, and size instantly for optimal print settings every time without additional operator input.”

The presses support a broad range of media, from 52gsm up to 450gsm paper including envelopes, embossed paper, polyester, and cut sheet labels, opening doors to diverse applications.

Chris added that the new CMYK + white toner is high opacity and achieves exceptional coverage in a single pass, making it ideal for premium applications, further expanding offerings for the new models, and helping businesses tap into new revenue streams.

For larger and more demanding projects, the systems accommodate long sheets up to 1,300mm simplex and 900mm in duplex, providing flexibility to meet customer demands.

Chris commented, “Whether it is for banners, book covers, or specialty items, the AccurioPress C14010s

and C12010S let customers rethink possibilities in production printing and explore additional opportunities for business growth.

“Konica Minolta has engineered the AccurioPress C14010S and C12010S for efficiency, streamlining operations with advanced smart innovative technology. These new print solutions help operators to work smarter, reduce manual adjustments for unattended, uninterrupted printing, and deliver flawless print results faster with reduced touchpoints and exciting new colour options with the addition of white in the new high-opacity CMYK + white toner.”

“Features such as the Intelligent Quality Optimiser Unit, IQ-601, including a new inline spectrophotometer for precise colour profile creation, and Intelligent Media Sensors (IM-104 and IM-105) support consistent, high-quality output with minimum user intervention.

“The IM-105 measures the paper size of the substrates and detects even the slightest variations in paper cutting size and, together with the Intelligent Quality Optimiser IQ-601, automatically adjusts image positioning to eliminate front/back alignment errors for professional quality and consistency with every print run.

Other key other benefits include automatic print quality adjustments with Automated Quality Adjustments (AQA)

and Automatic Inspection Technology (AIT), with an intelligent overall design to maximise press uptime.

Chris added, “The AccurioPress C14010S and C12010S models underpin Konica Minolta’s mission to support the digital transformation of our clients’ companies by sector and industry, predicting potential challenges and creating solutions together. This human-centric partnership approach lets customers streamline their businesses through fewer human touchpoints and higher productivity with tangible benefits including highquality output with less print waste.

“Konica Minolta is dedicated to fostering creativity and driving digital transformation for its customers. The new five-colour AccurioPress C14010S and C12010S print systems are built on 20 years of expertise, innovation, and leadership in digital printing, all backed by the trusted support Konica Minolta is renowned for.

“New operator assistance tools and fewer touchpoints, enables Konica Minolta customers to optimise workflows and minimize downtime. This empowers greater creativity, helping customers uncover new opportunities and identify profitable revenue streams.”

Konica Minolta New Zealand managing director Eric Holtsmark headed a strong Kiwi team at the show, joining Chris O’Hara, Rebecca Hughes, and Wade Marriner in escorting visitors around the stand.

Supplying premium equipment and services catering to the packaging and point of sale sectors, Graffica presented a range of folding box gluers, board slitters, creasing machines, auto loaders, and cutting tables.

The company represents several established global brands specialising in carton finishing, corrugated solutions, point of sale equipment, as well as ancillary machinery and pre-owned equipment. Neil Southerington, director of Graffica, said, “We have sold several cutting tables, and PacPrint has been a great opportunity not only to connect with new potential customers but also to catch up with existing ones who are now considering adding another machine.”

Among its broad portfolio of brands, which includes AOPACK, Wonder Digital, Century, and Fengchi, Graffica also represents Guowei. Graffica introduced Guowei’s latest range of guillotines, distributed in partnership with Robert Allan from Allan’s Graphic Engineers. Robert said, “There are plenty of cheaper brands on the market, but our focus has been on the mid-range, not the high end, because production volumes have shifted.

“Many businesses are not running full scale, all day cutting operations anymore;

Among the solutions on the busy Mimaki stand, the company introduced four new products:

The UJV300DTF-75 is Mimaki’s first UV-curable Direct to Film (UV-DTF) printer. It features a new pinch roller for improved precision and uses SVHCfree UV ink, aligning with strict EU environmental standards and setting a new benchmark for safe, high-quality DTF production.

The JV200-160 is an entry level printer powered by the same engine used in the 330 series. It delivers intuitive operation and consistently professional output, ideal for businesses seeking quality with simplicity.

3M MCS, Mimaki’s SS21 solvent ink, known for its rich colour and durability, is now officially certified by the 3M MCS Warranty. This first ever certification for Mimaki’s solvent range strengthens its value, particularly in vehicle wrap applications where the JV330/CJV330 and SS21 are already trusted by brands

they are doing shorter runs, and these machines are perfectly suited for that while remaining competitively priced. They are also strong on service and support, with fast turnaround on parts and real time assistance from China. We can get immediate answers for our customers and that is what they want.”

Graffica also reported strong interest in its new range of automatic box makers from AOPACK, along with WonderJet’s latest digital printer – reflecting a growing trend of commercial printers moving into packaging and custom box production. Neil added “The WonderJet brings some impressive new technology to the custom box market. We see more demand for short-run, personalised

packaging, and this machine is a great fit for that.”

Other key products on the Graffica stand included its range of Century range die cutters. The automatic flatbed diecutting machines target corrugated boxes and POP/POS displays. They can cut corrugated boards, laminated paperboards and carton boards used in the printing and packaging industry, with a maximum sheet size of 2500mm by 1620mm.

Other machines included the CartonFold Pro, a carton folding machine available in 650, 850, and 1100 models with auto-set and job recall; as well as the CorrFold range, a selection of corrugated folder gluers available in 1450, 1700, and 2300 formats.

such as Brad Jones Racing.

The Tx330-1800 is a next-generation textile printer that incorporates Mimaki’s latest 330-series engine and supports BlueSign-approved TP410 pigment ink, making it ideal for both educational

settings and industrial textile production. Mimaki also demonstrated a range of its printers at the show. Geoff Milliken, business manager at Mimaki’s New Zealand supplier Total Supply, welcomed Kiwi customers to the show.

Screen GP Australia managing director Peter Scott said PacPrint generated a strong pipeline of leads, reflecting growing interest from commercial printers in the expanding labels and packaging sector.

He said, “We saw a strong turnout with several high quality leads coming through. I have been pleasantly surprised by the level of engagement and truly appreciate the industry’s support for the event.”

Unlike previous PacPrint exhibitions, Screen chose not to display equipment on its stand this year, instead displaying samples and providing information on its full range of print on demand solutions. He explained, “At previous shows, we have had label presses that took four days to install and two days to decommission, so this time around, we didn’t think that would be necessary and I think we made the right choice.”

The print samples presented at PacPrint 2025 included labels – where

Ricoh showed its new colour management solution: the Ricoh Auto Color Adjuster. Henryk Kraszewski, Ricoh Australia production print senior product and marketing manager, said, “If you have a fleet of machines, a key concern is being able to produce the same colour on each of the devices; that is something we can simplify.”

With the Ricoh Auto Color Adjuster, you can print calibration sheets on each device, scan them in about 80 seconds, and within minutes standardise colour

At PacPrint 2025, printIQ sponsored Infigo and Cyanfix on its booth to demonstrate fully automated print workflows bringing together three solutions: printIQ’s cloud-based MIS system, Infigo’s web to print platform, and Cyanfix’s automated preflight and proofing technology.

The companies say the combined solution creates a seamless end to end system that maximises automation across the entire print production process, from initial online

Screen, through its partners Jet Technologies and Fujifilm New Zealand, has a major foothold in Australia and New Zealand with the Truepress L350UV series. Other samples came from packaging solutions such as the Truepress PAC 520. It produces recyclable, sustainable paper-based wraps and packs that replace micro-plastic producing hydrocarbon-sourced plastics. Screen also presented samples of production

output across all machines. Also, when a customer requests a previous job, the system makes it easy to reproduce it with consistent colour accuracy, ensuring

ordering through to final delivery.

By integrating web to print capabilities with sophisticated prepress automation, print businesses can eliminate manual

from its Truepress PAC830F. Peter added, “Strong interest across the board was really encouraging, connecting with several attendees who were not previously familiar with us and now have a clear understanding of what we can offer.

“The label press has been the most talked-about product at our stand, closely followed by our high-speed inkjet solutions.”

He said the event attracted interest from offset printers who currently outsource label work but are now looking to enter the label market in a more serious way.

He commented, “We listened to many offset printers who currently outsource their label printing but are now looking to bring that capability in-house.

“Additionally, with the strong presence of sign and display printers at the show –many of whom are producing small runs of stickers – we received interest from companies considering their next step. While we may not have a solution for them right now, they now know who we are and what we offer, which sets the stage for future conversations as they grow.

“The show generated a healthy pipeline of leads. There is clearly a strong and growing interest in labels and packaging because it is becoming such a growth area.”

reliable results every time.

Henryk added, “Without knowing the original stock or print conditions, the Ricoh Auto Color Adjuster can scan both the customer’s sample and your current output, helping quickly achieve a close colour match. Simply by scanning [the material] in this device, we can get a much closer match in just a few minutes with no colour skills required. Even though the print may not be what you normally deliver, what is most important is the customer is happy that it matches the original.”

Ricoh also showed samples where it transformed plastic-based gift cards into a more sustainable fibre-based alternative, using its Pro C9500 cutsheet printer to run 800-micron card stock.

intervention at critical workflow stages, dramatically reducing human error and operational costs.

This partnership enables print companies to streamline their operations, improve accuracy, and enhance customer experience while scaling their business efficiently. The automated workflow eliminates double data entry, reduces production bottlenecks, and ensures consistent quality throughout the production cycle.

The companies add that they change how print businesses operate, delivering intelligent automation that drives profitability and growth in today’s competitive marketplace.

Sydney show welcomed New Zealander industry members with open arms.

PacPrint 2025 enjoyed a strong representation from New Zealand’s print professionals.

New Zealand Printer caught up with members of the Kiwi contingent at PacPrint 2025; some at PrintNZ’s Kiwi Night at The Helm in Darling Harbour; some on the show floor; and some at both.

Tuesday, October 14 2025

Auckland

Industry leader shows off its 23,000 sqm printing and packaging facility to 300 guests

The Rt. Hon Christopher Luxon, prime minister, cut the ribbon to officially open Blue Star Group’s facility in Auckland.

Around 300 guests and members of the Blue Star team gathered to celebrate the occasion, marking Blue Star’s significant investment in New Zealand’s manufacturing sector.

The facility at 114 Swanson Road consolidates Blue Star’s Auckland operations into one purpose-designed site, bringing together advanced technology, new equipment and an additional 8,000 square metres of production space – totalling 23,000 square metres. For the rugby fans, that is almost three rugby fields.

Guests included customers, suppliers, and key partners. Jill Cowling, chief executive of Blue Star Group, said, “This world class facility represents not only a substantial investment in the future of Aotearoa New Zealand’s print, communications, and packaging industries, but in our people and diverse sectors we serve.

“We are focused on increasing productivity and setting new standards in capability and innovation, utilising AI and digital technologies to improve our efficiency and environmental performance while continuing to deliver the trusted products and service our clients expect.

“Today’s ribbon cutting moment is, importantly, the start of an exciting new chapter for our business, our people, and our industry. A moment to celebrate the ambition, collaboration, and the belief in what is possible with a 40 million dollar investment, not just in buildings or equipment, but in our team’s capability and innovation in local manufacturing.”

Jill continued: “This new facility will support our major customers across sectors including retail, financial services, education, insurance, publishing, and FMCG. As we open the doors today, we are also opening new opportunities to increase productivity through advanced automation; to embrace

AI for smarter data driven decision making; and to lift both efficiency and environmental performance across every part of our operation.

“The facility is future focused and customer-centric designed to help our clients deliver their stories, their brands and their products with more impact, precision, and speed than ever before. In a world increasingly shaped by digital threats, I want to emphasise that cyber security is something we take extremely seriously. We have made significant investments in that space in protecting our people, our systems and our clients.

“I am also very proud to say we are now ISO/IEC 27001:2022 certified, an internationally recognised benchmark that reflects our unwavering commitment to information security and data protection.

“We have also taken a logical and systematic approach to our environmental management systems and are proud to say that all of our sites are Toitū environment certified and Blue Star is Toitū CarbonReduce certified.”

“Officially opening this remarkable site today, would not have been possible without the support and leadership of the Blue Star shareholders and board. Your belief in our vision, helped turn the facility from a concept into a reality.

“We’re also particularly grateful to our long standing customers, to our future customers, and to our many partners who backed this project from the very beginning and share our long term commitment to New Zealand’s print and packaging sector.