Pride In Print Awards

Tuapeka is gold

Support local print

So long Andy Lowe

with 1987-2023

Pride In Print Awards

Tuapeka is gold

Support local print

So long Andy Lowe

with 1987-2023

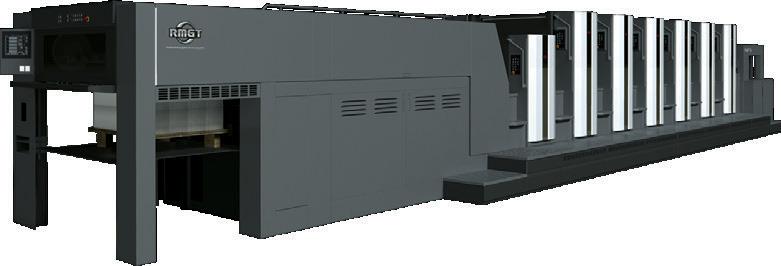

Heidelberg has equipped its solutions with the most intelligent systems to enable print shops to optimise every aspect of their production

Heidelberg’s Prinect workflow allows its customers to stay ahead and benefit from a digitised world

Today’s printshops are facing increasing challenges, such as shorter run lengths, faster turnaround times, increasing costs, competition for talent and declining print prices. Therefore, it’s important now, more than ever, that print shops are optimise every aspect of their production to stay competitive and profitable.

To help print shops alleviate these challenges, Heidelberg has fitted its solutions with intelligent systems that control the harmonious interaction of six key factors:

1. The integration of customers Web portals simplify communication and automate workflows. The result that print shops get is more efficiency, more customer service and in turn, more turnover.

2. The reduction of touchpoints

Fewer touchpoints and more automation unleash unrealised potential. This results in visible throughput increases.

3. The increase in productivity and operating time

Efficient planning and automatic data availability increase the operating time and productivity. This means profits for print shops increase.

4. The reduction of paper waste and warehousing

The use of optimal materials ensure reproducible production. When this occurs, paper waste decreases.

5. The optimisation of consistency and reproducibility

Standardisation provides certainty

and consistency. As a result, production becomes more predictable.

6. Having business intelligence

Having insight into business intelligence delivers sound information for print shops to utilise. This means they can make decisions based on real facts.

Digitisation offers the printing industry a great many opportunities. But anyone looking to harness these opportunities need to actively shape this process of change.

As such, Heidelberg’s Prinect Production solution reorganises the production workflow, ensuring the basis for increased cost-effectiveness, consistently

high performance, and outstanding quality. Many processes are completely automated, thus providing a smart boost to the success of a print shop.

In addition, Heidelberg’s Prinect workflow allows customers to stay ahead and benefit from a digitised world.

Two leading Australian print companies provide their comments on how they have benefitted from using Heidelberg’s digitisation solutions:

Southern Impact managing director Rod Dawson said, “Prinect gives us a lean production workflow, a consistent quality outcome, accurate repeatability, and transparency across the entire production – which in turn helps to identify any bottlenecks and uncover potential areas for further improvements”.

NEO general manager Clinton Daley said, “A print company’s workflow is the beating heart of its manufacturing process that has enormous ramifications on output – both in speed and quality.

“When it came to aligning ourselves with a business, we felt that Heidelberg was the natural fit. My family’s relationship with Heidelberg would be getting close to a hundred years. The choice of Prinect was simply a natural evolution of this long-standing relationship and we knew in Heidelberg that it was a company that would help us grow and share the same industry-leading mentality that we as a company strive to have.”

Prinect Production offers enhanced performance thanks to intelligent processes. It digitises a print shop. In addition, it automates production and colour and quality management while also providing key data for analyses and reporting. It keeps customers coming back and maximises performance with a smart workflow.

The new Heidelberg philosophy

Push to Stop is Heidelberg’s idea of a smart print production. It is based on networked processes and intelligent machines that organises and works

through print jobs independently with full autonomy. The operator only has to intervene if necessary. Print shops can increase the overall effectiveness of their machines and can almost double their net productivity, enabling them to become a Smart Print Shop.

For Push to Stop to become reality, new and improved processes are required that provide all the necessary production data. Prinect is the tailored solution for successfully implementing this philosophy of the Smart Print Shop with Push to Stop. Prinect Business supports printers in the automation of their commercial processes and production. Prinect Production covers the actual production workflow – from the pre-press modules through to offset and digital press to post-press.

Whether a company is small or large, or whether it is a commercial or packaging printer, Prinect reduces all touchpoints.

In other words, the process steps and manual interventions involved in order acceptance, data transfer, or postprocessing is kept to a minimum. Users always have an overview – of the workflows, the utilisation, and the economic efficiency of their print shops – and can react directly.

The perfect solution for the Smart Print Shop Prinect Production transforms a print shop’s workflows. Manually controlled operations involving a wide range of touchpoints are replaced by intelligent networking and automated processes. Touchpoints are reduced and flexibility increased.

With Prinect Production, printers are closer to their customers and integrate them directly into the workflow. Data entered online controls processes throughout production and quality management. Digital approvals speed up production times and increase productivity. Moreover, as efficiency increases, so too does the satisfaction and loyalty of their customers.

It also lets printers reduce waste and storage through standardised quotations, perfectly coordinated consumables, and defined processes. This means printers can use their time, machines and materials more efficiently, while simultaneously optimising consistency and repeatability. Pave the way for Push to Stop by using intelligent machines that organise and work through the production process independently. With Prinect Production, most operations can be carried out based on navigated or autonomous control.

Prinect Production also makes it possible to unlock the full potential of a print shop. Integrated business intelligence functions can be used to produce reports for corporate management and production that are intuitive to understand.

Accurate data and sound analyses reveal error sources before damage occurs. Real-time data capture and evaluation ensure you are always up to date on current processes.

Printing was never so easy.

How Prinect Production increases your productivity

• Offers portal functionalities to optimise selling and communication process

• Enables powerful job setup, planning and presetting, eliminating manual intervention that keeps presses up and running

• Includes fully-automated plate production including pre-flighting, imposition and more

• Has press room and finishing integration, delivering best data to drive Push to Stop production philosophy

• Provides significant analysis and reports, changing the way printers make their business decisions

• Offers maximum freedom with one workflow, whether a printer produces with toner, inkjet or printing plate

• Provides everything needed and much more – no matter where a print shop wants to extend its business, Prinect Production is ready for commercial, packaging and labelling.

Prinect Production Manager provides a full suite of software productivity tools that help printers attain the highest levels of productivity in their print shops through an easy monthly subscription fee. Some of the benefits include:

• Low initial startup costs that lets users take advantage of Prinect Production Manager solutions without the big upfront capex or the need for financing

• Simple subscription model: Complex, expensive license models are a thing of the past with an easy and transparent monthly usage fee that follows a printer’s production volume.

• All the latest upgrades and new technology from Prinect Production Manager with the monthly subscription. This is safety that a print business deserves.

• Scalability of workflows and introduce new Prinect solutions into a print shop at a printer’s own pace.

• Return on investments from productivity and efficiency gains with powerful workflow tools like presetting, multi-colour, gang printing, smart automation and more.

Printshops are rapidly adopting Prinect Production Manager on the road to building a Smart Printshop. Currently, Heidelberg has more than 2,000 Production Manager subscribers worldwide, with 65 of them based in Australia and New Zealand. Heidelberg continues this growth by adding 400 new systems globally every year.

Prinect Production Manager provides a full suite of software productivity tools that helps printers attain the highest levels of productivity

2-4 Heidelberg: By equipping its solutions with the most intelligent systems, Heidelberg enables print shops to optimise every aspect of their production

14 Fujifilm and Jet Technologies: Unimax has installed New Zealand’s first Screen Truepress Jet L350UV SAI S digital label press, supplied through Jet Technologies and Fujifilm New Zealand

16 Konica Minolta: Matamata-based Tainui Press has taken a significant step towards future-proofing its operations with the acquisition of a Konica Minolta AccurioPress C7100

18 Inkwise: The only print company in New Zealand that offers coldset, heatset, sheetfed and digital under one roof has expanded the options for trade printing locally

32 Think Laterally: Mick Rowan discusses how deglobalisation can help local manufacturers and foster a healthier vision for the future

34 Aarque: A new Format 4 beam saw enables Aarque to process a wider variety of materials for customers

36 Durst: The digital manufacturer celebrated Fespa with a slew of wide format innovations

38 NZSDA Update: Melissa Coutts reviews the recent NZSDA events, which attracted industry professionals from around the country to Auckland

40 NZSDA President: Andy Lowe delivers his final President Post and Laura McConchie has the latest Signee NZ news

41 NZSDA Signee Profile: Aaron Joines has had a varied and interesting journey through the world of sign making

Pride In Print Awards p20-29

22 Supreme Award: Te Henga Sunset, a “genuine labour of love”, has taken out the major prize in the 30th annual Pride In Print Awards

23-29 Category and Process Winners: The standards achieved this year reflect the commitment to excellence that all entries demonstrated

ISSN 1171 7912

PO

EDITORIAL: 021 631 559

Bruce Craig, Editor - bruce@newzealandprinter.co.nz

CONTRIBUTORS:

Ruth Cobb, Melissa Coutts, Andy Lowe, Laura McConchie, Iain MacIntyre, Mick Rowan

CIRCULATION: brian@newzealandprinter.co.nz

DISPLAY ADVERTISING SALES & SERVICE:

Brian Moore - brian@newzealandprinter.co.nz

+61 410 578 876

CLASSIFIED ADVERTISING:

Brian Moore - brian@newzealandprinter.co.nz

DESIGN & PRODUCTION: Sarah Vella - sarahvelladesigns@gmail.com

New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December.

New Zealand Printer is a member of the Printer Media Group

New Zealand: New Zealand Printer Asia Pacific: ProPack.pro

Australia: Australian Printer, ProPrint

MANAGING DIRECTOR: James Wells - james@intermedia.com.au

GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz

© Copyright 2023: Contents of this magazine are subject to copyright and cannot be reproduced without written permission of the publisher.

2023

The

expressed

its agents, company officers or employees. Any use of

information contained

at

sole risk of

person using

accuracy

All express or implied

before relying

conditions, warranties, statements, assurances and representations in relation to the

its

and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication.

Copyright © 2023 — Charted Media Group Pty Ltd

September 11-12, 2023

September 13-15, 2022

Brussels, Belgium

Chicago, USA

Apart from the latest technology and solutions, Labelexpo Americas this year features a full two-day conference programme and two masterclasses organised by the Label Academy on digital embellishment and self-adhesive materials. www.labelexpo-americas.com

This will be the first Labelexpo show in Europe since 2019. Along with demonstrations of the latest printing and converting equipment will be masterclasses and special events focused on automation and flexible packaging. New equipment at Labelexpo Europe will include the new HP Indigo 200K press, the Xeikon CX500t Titon toner press and the Screen Truepress PAC520P water-based packaging press.

www.labelexpo-europe.com

September 17, 2022

Napier

September 29 – October 1, 2023

Christchurch

The Association of Handcraft Printers has a full day programme including visits to Imprimo in Havelock North and Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

Foodtech Packtech

September 20-22, 2022

Auckland

This year’s event, hosted by Anne McDonald of Signs of Art, will feature a series of demonstrations and workshops with industry experts such as Dean Evenson, Clinton Potter, Alan Clarke, Alex Burnett, Louisa Jessop and Ross Probert. Experts will be on hand to show both apprentices and those experienced in the industry “How to” with a variety of different old-school techniques. www.letterheads.co.nz

November 3, 2023

Sydney

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise. www.foodtech.packtech.co.nz

October 11-15, 2022

Shanghai

Celebrate and acknowledge the achievements of the people in print across Australia at the ProPrint Awards 2023. What started as the Power 50 eleven years ago has evolved into a comprehensive annual awards evening recognising the industry leaders, rising stars, suppliers, and industry veterans. www.proprintawards.com.au

October 18 - October 20, 2023

Atlanta, Georgia

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”. www.allinprint.com

Letterheads

October 21-23, 2022

Sign Foundry, Welling

This global printing event serves markets across all printing segments. With over a million square feet of equipment, technology and trends on display, attendees will live product of the industry’s latest products and innovations across apparel, commercial, wide-format, industrial, promotional, label and packaging, mailing, shipping and fulfilment and more. www.printingunited.com

drupa

May 28 – June 7, 2024

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke. www.letterheads.co.nz

Düsseldorf, Germany

Interpack

May 4-10, 2023

Düsseldorf, Germany

One of the world’s biggest trade fairs for print and cross-media solutions is returning following its postponement in June 2020 due to the pandemic.

Key themes in Düsseldorf will include industrial printing, workflows and Industry 4.0. The growth of the packaging and labelling sector means packaging production will be at the centre of things, as will 3D and functional printing. www.drupa.com

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors. www.interpack.com

A B GRAPHIC INTERNATIONAL (ABG) has launched ABG Connect, a new workflow solution developed in cooperation with UK-based Mercian Labels and Cerm, aiming to increase automation by connecting all stages of the print and finishing processes. ABG says that one of the main advantages of ABG Connect is the dramatic increase in productivity and operator efficiency it can provide. It adds that Beta testing achieved efficiency savings of up to 75 per cent on a single machine, compared to multiple passes on multiple devices from other finishing solutions.

After decades of presenting the label and packaging markets innovations in Brussels, Tarsus Group, the organiser of LABELEXPO EUROPE, has decided to move the trade show to Barcelona from the 2025 edition. Labelexpo Europe 2023 will go ahead as planned in Belgium in September 2023. Tarsus Group said the move to Barcelona comes after extensive consultation with label industry stakeholders and is set to take advantage of the facilities at the Fira venue and in the city of Barcelona.

MARK ANDY has introduced

Pro Series, a new class of fully servo-driven presses designed to optimise single-pass pressure sensitive label printing. According to the manufacturer, the Pro Series delivers low operating costs with a proven design, a built-in sMArt link production monitoring system, and distinct features that reduce operating costs and improve profit margins. Pro Series will be offered in 330mm and 430mm web width versions achieving a maximum speed of 120 metres per minute and handling substrates between 50 and 305 microns.

The introduction of an unmanned robotic system on the Durst stand stole the show in terms of visitor engagement and interest at the Fespa 2023 exhibition in Munich.

According to Durst, the decision to introduce the P5 Robotics concept was the logical next step following the introduction of the P5 Automat – the company’s automated feeder/stacker system for flatbed printing.

Durst said it is “igniting the next stage of automation with P5 Robotics for flexible and continuous production cycles with long run times”. The robots, modified and

programmed by Durst, can pick up media from different pallets with a height of up to 180cm, feed them and then stack them again separately. In the process, it can also

turn the printed media 180-degrees for reverse-side printing and feed it into a second printing system.

Matt Ashman, managing director Durst Oceania, said, “This is a game-changing technology. What is required is high speed robotics and precision robotics. Just like a Durst P5 350 HS D4 – we need high speed robotics to keep up with a machine that delivers high productivity.

“When you are printing at 700 square metres an hour, most normal robotics don’t keep up but ours do. We are already talking to cutter suppliers to make the robots feed directly into cutting solutions and then you will end up with a finished cut stack. This is the holy grail: lights out.”

New Zealand (FBNZ) has launched a Growth Partners programme, aiming to identify and onboard channel partners, to further expand the company’s business across the country.

Growth Partners will exclusively sell and support Fujifilm print technology in

specific geographic regions. This is a continuation of the company’s strategy to streamline operations for local businesses while maintaining robust support for national customers.

David Jupe, managing director FBNZ, says, “We believe our Growth Partners will help us further grow our

product and service offerings in regional New Zealand with greater pace, flexibility, and autonomy – the essence of being local.

“This represents a great opportunity for our people, our customers, and the right partners. We see current FBNZ branch staff being a critical part of our Growth Partner programme.”

FBNZ is in the early stages of identifying potential Growth Partners. Jupe adds, “Our mission is to never stop finding ways to help Kiwis work smarter, and we are excited to be on the way to finding partners who are keen to be part of this journey with us.”

FBNZ will continue direct sales and support in areas not covered by a Growth Partner.

Christchurch-based Hi-Tec Ink has commenced sale of the Amethyst A50-RIG inks by Nutec Digital Ink, which has recently received Gold status from independent environmental orgaisation Greenguard.

Nutec has attained Greenguard Gold status for its Amethyst A50-RIG range of UV-curable inks, adding to its growing list of accredited inks and further demonstrating the company’s commitment to the environment.

Ink supplies

Greenguard Gold certified Nutec UV inks

Greenguard certified products need to meet some of the world’s most demanding chemical emissions standards for interior use.

The Gold certification standard is the highest level achievable and ensures that products are acceptable for use in sensitive environments such as hospitals and schools.

According to Nutec, the Amethyst A50-RIG UV-curable inks range, designed for rigid substrates, offers excellent media adhesion and is suitable

for use without primer, on a large variety of materials, including polycarbonate, melamine, glass, wood, acrylic and ceramics.

Offered in various packaging configurations and developed for conventional and LED UV lamp curing, the new range provides compatibility across a broad range of print head types. As well as the new Amethyst A50-RIG inks, Hi-Tec Ink offers other Nutec products in CMYK, lights, white and varnish options for a superior colour gamut, bright, vivid images and eye-catching prints.

Les Kin, managing director for Hi-Tec Ink, says, “This Greenguard Gold Status has given our New Zealand print operators something to talk about. We now have total confidence that we are involved not only in saving the environment by choosing safer environmental inks, but also inks that are user friendly for a vast lot of applications such as hospitals, childcare, schools, where only the best will do.”

EFI has taken to Fespa Munich to launch its latest next-generation, modular and scalable Nozomi 14000 SD printer. According to EFI vicepresident of sales and marketing Ken Hanulec, the new printer beefs up its award-winning, highly versatile, super-highspeed and high-quality Nozomi single-pass UV LED printing range. Available later this year, the modular, base-model and four-colour EFI Nozomi 14000 SD prints paper, synthetic media and board at speeds up to 30 linear metres per minute.

CANON has launched two new models in the Arizona 1300 flatbed printer series, the GTF and XTF and PrismaElevate XL, which creates textured effects and raised lettering up to 2mm. The Arizona 1300 series with Flow technology serves the growing mid-volume segment, enabling large format graphics printers and other print service providers to offer their customers an extensive range of applications for retail, interior décor, packaging, and industrial markets.

To further its environmental commitment, Epson has transitioned to fully renewable energy for its Australian and New Zealand offices and company sites. All facilities have received certification under the Australian GreenPower and the New Zealand Energy Certificate System (NZECS).

Craig Heckenberg, managing director for Epson Australia, explains, “In our renewed Environmental Vision established in 2021,

Epson committed to achieve negative carbon status and be underground resource free by 2050. We have set targets to reduce greenhouse gas emissions in our operations and value chain, aligning with the 1.5°C scenario of the Paris Agreement and the criteria of the Science Based Targets initiative (SBTi).

“By 2025, our aim is to reduce scope 1 and 2 greenhouse gas emissions by 34 per cent compared to FY2017 levels.

Aconstant drive for innovation backed by a strong team culture and solid business principles have seen Fairfield (Dunedin)headquartered Tuapeka grow into the largest supplier of branded promotional products in Australasia.

Jim Robertson founded the company in 1987 as Tuapeka Gold Print. From initially printing gold foil business cards from his kitchen bench in Lawrence,

the business made a notable change in shareholding two decades later.

Greg Jolly, current Tuapeka chief executive, explains, “Brad Houghton was brought into the company as an equal shareholder in 2007. His experience in international business and engineering skill set, combined with Jim’s industry knowledge and ambition, has since seen the company grow exponentially.

“We now have over 500 staff members, and we are constantly looking for new talent.”

Operating a vast number of machines that offer its customers a wide range of branding processes in Australasia, Tuapeka’s offering covers pad print, engraving, sublimation print, screen print, embroidery, Colourflex transfers

and several digital print processes, all completed in-house.

Tuapeka takes pride in having developed industry-leading recognition. Greg says, “The size and scale of our operation gives us the ability to offer over 6000 SKUs (stock keeping units) to our customers, supported by 15 branding techniques.

“We introduced our silicone digital print branding process back in 2020, a world first, offering flexible, washable fullcolour prints on silicone.

“Our distributors work with a number of large companies and clientele, so it is quite common for us to see our jobs used as part of larger campaigns or out in the media. While we do several large scale print runs, a lot of our jobs are smaller components of a much larger project.

“The volume and variety of products we offer are what set us apart.”

However, he emphasises that Tuapeka continually explores creative innovation to ensure it “stays ahead of the curve”.

He says, “While we use many traditional print methods, we constantly look to improve and innovate. Our research and development team work hard to push the boundaries of our printing capabilities, and our product development team stays abreast of worldwide trends to ensure we offer our customers a diverse range of quality products.

“We focus on opportunities that allow us to disrupt the market when executed correctly. By continuously improving and innovating our systems, we are able to provide seamless functionality for our distributors to deliver our services to their customers in an efficient manner.

“We are customer-centric and strive to create efficiencies in branding processes that allow us to provide and achieve highend branding at competitive prices.”

Tuapeka launched over 400 new products last year alone. Greg says, “Earlier this year we went live with our in-house sublimated poly-cotton towels. Before this, customers would need to order these via indent, which could take up to eight weeks. Being able to offer this in-house is a massive improvement in service offering.

“We have some great new developments coming soon, including custom packaging and new branding processes.”

Tuapeka’s mission of ‘We create customised product solutions through an outstanding customer experience’ guides the company. In addition, Greg points out that the business has founded its success

on an underlying strength of culture. He says, “Our culture is key to our performance, and we uphold an ‘above the line’ attitude and work ethic, encouraging staff to take ownership and responsibility in their roles.

“Training is just one component of our overall approach to fostering a ‘make it happen’ mindset towards project completion, and we celebrate successes as a team.

“As a family company, we prioritise mutual respect and promote family values as we grow. We are a very supportive and inclusive company.”

While also growing in other export markets, such as the Pacific Islands, Tuapeka continues to primarily supply within Australia and New Zealand. He adds, “The New Zealand market has proven to be consistent over the last decade, with the exception of some

disruptions due to Covid-19. We have experienced significant growth in Australia since entering the market in 2014.

“Being in two markets has proved extremely beneficial, as the scale of the Australian economy has supported us in upscaling to improve our offerings to customers in New Zealand and Australia through investment in people, stock and systems, including the development of our industry-leading website, trends.nz.”

As well as recently celebrating the major milestone of 35 years in business, Tuapeka also achieved the significant strategic objective of moving from an eight-digit to nine-digit turnover. Greg says, “This accomplishment is particularly significant given the disruptions caused by the Covid-19 pandemic in recent years.

“It was essential for us to celebrate these milestones with our staff, and we were fortunate enough to do so during

March and April with gatherings in Dunedin and the Philippines, recognising that none of this would be possible without their contribution.

“Over the past decade, our business has prioritised growth and scaling up, achieving a tenfold increase in turnover in just nine years is a source of great pride for us. We attribute this success to being focused with a robust strategy, clear goals and having dedicated, hard-working people behind us.

“We are a great team that has evolved to grow and adapt to conquer any challenges we face.”

While emphasising that his primary recent focus has been on the Tuapeka business rather than considering wider print industry issues, he nonetheless observes those challenges will have largely remain unchanged. He says,

“The low unemployment rate and associated increases in wages either via the government minimum wage or for retention reasons, along with the cost of compliance, freight, and the government lockdown on immigration, have all been key issues our industry is struggling with.

“On the upside, it’s great to have containers back down to competitive rates and sailing frequency back to pre-Covid levels.

“I have concerns about the economy being pushed into a recession due to the Reserve Bank’s actions, but it is difficult to predict how severe and long-lasting the effects will be. Our capital plan is significant this year, so it is a worry, although sometimes you have to commit and have the courage to keep growing.

“We are very fortunate to have two entrepreneurial owners that are not riskaverse, striving for continued innovation

and growth without losing sight of the end goal.”

In regard to advice to other operators in the industry, he unequivocally urges “identify your strengths and focus on them”.

He advises, “Develop a thorough plan and surround yourself with competent and dedicated individuals who will stick to the plan and see it through. Be careful not to become a ‘busy fool’, trying to do everything with low margins, and focus on doing what you need to do at appropriate margins.

“Whatever you do, business is about being smart.”

Looking ahead, he sees Tuapeka facing the future positively, including through significant expansion of its facilities. He says, “We are bursting at the seams in our current location, so I am thrilled that our new warehouse build is nearly complete. It is 8000 square metres and has the capacity to house 11,500 pallets.

“This new warehouse is being built on our Fairfield site, which will be Tuapeka Business Park, where we will also host our new production facility in coming years.

“Despite the past decade being challenging, we have learned the value of staying focused and maintaining a positive and supportive attitude, which has led to significant accomplishments.

“We are very excited about our future prospects and have no intention of slowing down.”

We are proud to be part of an industry that celebrates achievement and recognises excellence

service we receive from both Fujifilm New Zealand and Jet Technologies.

The range of substrates available to Unimax has increased substantially with the new model, enabling the company to print on thinner synthetic stocks, as well as a thicker range of paper and hybrid products.

From its base in Avondale, Auckland, labels, and packaging printer Unimax works with a diverse group of clients across the agriculture, transportation, health, food, and beverage sectors.

Recently, Unimax installed Screen’s most productive label inkjet press – the L350UV SAI S digital label press, supplied and supported by Jet Technologies and Fujifilm New Zealand. With an eye to the future, Unimax looked for a solution to support its growth and competitiveness with the capability to provide a broader variety of printing options for its customers.

Dinesh Kumar, director at Unimax, says, “We were looking for a digital printing press that offered the highest quality print product and consistency. The solution we chose has those two qualities and was the most cost-effective of the options we considered.

“We feel particularly pleased to bring the first L350UV SAI S into the country. We have always been huge fans of inkjet and what it can do. In fact, we were the first to bring the L350UV into New Zealand and can proudly say that we are now the first with the new SAI model.”

Increasingly, industry sectors such as liquor, cosmetics, food, and beverage employ UV inkjet-based digital printing as a substitute for silk-screen printing. Digital printing provides these industry customers with several benefits, including shorter turnaround times, lower costs and reduced environmental impact. Demand for quality label and packaging printing continues to

grow. Unimax recognised this trend five years ago when it invested in its first Screen Truepress, which helped take the business “from letterpress to the digital age”.

Dinesh says, “Our original press was extremely reliable over its five years with us. It helped us to diversify our client base and grow our business in higher-value markets. Upgrading to the L350UV SAI S was an easy decision, especially with the

Dinesh adds, “Productivity has increased on all jobs and particularly for the work containing Screen’s high opacity white. The Truepress Jet L350UV SAI S digital label press has impressed everyone, and we are thrilled with the results, which are next level in quality and productivity. Another benefit is the addition of orange and blue, which has increased the colour gamut.”

Stephen Hodson, director Fujifilm New Zealand, says, “We are proud to partner with Screen and Jet Technologies to deliver this solution to Unimax and we look forward to continuing our support.”

Introduced in 2020, the Screen Truepress Jet L350UV SAI S digital label press builds on the success of the popular Plus (+) range, as a highproductivity, high-quality and versatile UV inkjet label press.

Screen developed the SAI series to help printers produce a wider range of spot colours to meet brand owners’ challenging demands. The machine prints on media widths of up to 350mm wide, with a print speed of up to 60 metres per minute. Using white ink, it can still achieve 50 metres per minute.

As a compact and configurable platform, the SAI series can accommodate the full range of label printing requirements. For example, the four-colour CMYK standard ink set and can easily upgrade to seven colours, as Unimax has done. to include white, orange, and a vivid blue.

Another option for the Truepress Jet L350UV SAI S digital label press is the recently introduced high opacity white mode. When used with clear film or similar labels, this new printing mode provides more opaque white, preventing the colour of bottles or package contents, from showing through. This helps to maintain rich colour saturation, ensuring highquality labels with eye-catching visual appeal, even when applied to translucent base materials.

The printer has already taken out the EDP (European Digital Press) Best Label Printer Award for its “its ease-of-use, thanks to its advanced software, as well as for its improved colour quality and increased speed”. It is the third time Screen’s digital inkjet label press technology has an EDP award for its digital inkjet technology.

The Acuity Prime L is a true flatbed with exceptional design and high production. The Acuity Prime offers high-quality triple-head printing on a range of rigid and flexible media, supported by its six dedicated vacuum zones and jettable primer. PLUS get $20,000 Cash Back* for a limited time.

PRODUCE A WIDE RANGE OF APPLICATIONS

With outstanding image quality and excellent adhesion to a broad range of rigid and flexible media, materials and objects, the Acuity Prime can produce an amazing variety of printed products for distance and close viewing at ultra high speeds. The vacuum table can handle almost any sheet material. It secures rigid and flexible media and holds it perfectly flat for high quality print across every sheet.

EXPAND YOUR CREATIVE OPTIONS

The option to print with white and clear inks, and to print directly to almost any material, up to 51mm thick, in perfect registration, along with its 16 pneumatic media location pins (front and back),enables the Acuity Prime to produce high value, creative work that could offer opportunities for new revenue. With the jettable primer option, the Acuity Prime can adhere to a wide variety of industrial media.

DESIGNED WITH THE OPERATOR IN MIND

At Fujifilm we understand the value of production time and usability, so we designed the Acuity Prime with the operator in mind. With a new and user-friendly GUI, the Automatic Printhead Maintenance System, easy clean printhead maintenance and visible status lights for the ink tanks, operators are able to spend less time maintaining the machine.

LOWER COST OF OWNERSHIP AND EXCELLENT ROI

With variable drop-size printheads and highly pigmented inks, Acuity prime in conjunction with Fujifilm’s in-house ink formulation, enables less ink to be laid down, which minimizes production costs, and in combination with a competitive system price, support an excellent ROI.

talk about this offer call the Wide-Format Team on 0800 242 646. Finance avaiable though

Matamata-based print company takes a significant step towards future-proofing its operations with the acquisition of a Konica Minolta AccurioPress C7100.

Established in 1934 on Tainui Street, Matamata, the company derived its name from its original location. Over the years, it has moved to various premises and currently operates from modern facilities at 7 Short Street.

With over five decades of industry experience, husband and wife team Dale and Sheryl Ertel helm the business, offering a diverse range of printed products. Dale embarked on his career as a lithographic offset machinist apprentice at Goldfields Print in Paeroa immediately after finishing high school. In 1979, he joined Tainui Press Design & Print and in September 1998, he and Sheryl acquired the commercial printing segment of the company.

As the printing industry has undergone significant changes in recent years, Tainui Press Design & Print has proactively diversified its production floor, incorporating digital printing equipment, signwriting, and upgrading its on-site technology arsenal.

Initially sceptical about the claims made by a Konica Minolta sales representative who introduced new digital print equipment a year ago, Dale gradually became intrigued. He explains, “At first, the equipment seemed almost too good to be true. However, when the need arose to replace our old two-colour press with a perforation function, which had become increasingly challenging due to the manufacturer’s discontinuation and unavailability of spare parts, I revisited the proposal.”

He travelled to the Konica Minolta site in Auckland, with a member of his team, to witness the AccurioPress C7100 in action and ascertain the veracity of the earlier sales pitch. Dale recalls, “I was captivated by the capabilities of this machine. On the journey back, I contemplated how to convince Sheryl that this was the way forward.”

After several discussions, the couple requested Konica Minolta to produce

samples of docket books. Dale adds, “To our amazement, the AccurioPress C7100 could handle printing, numbering, perforating in two different directions, collating, and depositing the finished products into a bin – all in one machine. Previously, we needed three different machines to accomplish the same tasks.”

Konica Minolta has designed the AccurioPress C7100 to meet the rigorous demands of commercial printing through its advanced automation features. This advanced digital printing press offers exceptional performance, delivering high-resolution output of up to 3,600dpi (equivalent) x 2,400dpi.

With the ability to accommodate a wide range of coated, uncoated, and textured media ranging from 52gsm to 400gsm, and the capability to print long sheets up to 1300mm, the AccurioPress C7100 provides in-line four-sided trimming for full bleed applications, creasing, perforation, and much more.

The intelligent quality optimiser, IQ501, ensures automatic management of registration and colour adjustments, diagnoses images, and creates printer

profiles. It also streamlines prepress adjustments, increasing uptime without the need for highly skilled operators.

Dale’s office overlooks the production floor, where he can keep a close eye on the AccurioPress C7100 producing up to 100 pages per minute for A4 sheets. He shares, “One day, as I glanced down, I saw a job running on the new press. I could not believe my eyes, so I hurried downstairs to witness the AccurioPress C7100 printing and then perfectly trimming fullcolour, double-sided rack cards.

“Although I knew the machine was capable of such feats, I was amazed by its speed. I immediately called Sheryl to witness the remarkable performance, and while she had been supportive of our digital evolution, she was truly impressed and convinced by what she saw.”

Dale and Sheryl emphasise that through the recent investment, they have not only enhanced the company’s capabilities and significantly increased production capacity, but also fortified their business to withstand future uncertainties, a crucial aspect in today’s volatile economic climate.

More profitable business through a press that works smarter, not harder, with the AccurioPress C7100 series. You serve more customers and complete more jobs with innovative technologies that power your success.

Inkwise supports over 60 families in the local community, as well as support for local sports clubs and charities. Brent says, “When you buy local from a locally owned and shareholder operated business, you are dealing with real people who have skin in the game. We care; our team cares; and we stand by our work. Buying offshore does not have any benefit for the towns our print partners do business in. Any profits we make stay here for the benefit of our communities. You might save a few hundred dollars buying offshore, but is this the right thing to do by your community?”

Privately owned and operated, Inkwise has transformed from a mainly coldset printer into a company that offers one of the country’s most diverse trade print offerings.

Born out of the Ashburton Guardian Print Works, Inkwise owners Steve Gallop and Bruce Bell have grown the enterprise into the only print company in New Zealand that offers coldset, heatset, sheetfed and digital under one roof. Operating as Inkwise since its 2014 move to Rolleston in Christchurch, the company’s team of 60 staff keep the presses running 24/7, six days a week.

Brent Goldsmid, general manager at Inkwise, says, “In the Guardian Print days we were mainly coldset, printing newspapers. Our first heatset press moved us into retail catalogues. Our newer technology Goss M600 now sees us in the magazine and catalogue market with a range of clients from Toolshed and Mitre 10 Mega to Stoney Creek and NZV8 magazine.”

One of only two heatset web printers in the country after the closure of Ovato last year, Inkwise provides print services to a range of businesses such as print shops, graphic design houses, and agencies.

Brent says, “As a trade printer we provide the opportunity for traditional sheetfed and digital printers to offer their clients a competitive alternative for larger publication runs that they may have previously not considered. They can keep their client with them across the full spectrum of their work.

This keeps that client close and avoids them looking elsewhere.

“Traditionally, web print does not have the rapid turnaround times of sheetfed work due to the number of publications booked well in advance. However, at Inkwise we can be a lot more flexible due to the nature of our business and our willingness to work with our print partners.

“Our ability to offer both web options, coldset and heatset, under one roof means we can do a greater variety of jobs, such as a newsprint text with a gloss art cover. No one else can offer that.

Inkwise’s management team clocks up around 130 years in the business and many of the company’s production team members have worked there since the Guardian days. There is not much they haven’t seen or done. Brent says, “We offer plenty of experience to help our partners come up with the right offering for their client.

“Right now, we see several New Zealand companies are ‘onshoring’ their catalogue work. Over the period of Covid-19, and with increased transport costs, printing offshore was not as attractive. Many of these companies have remained with us having seen the quality, turnaround, and cost benefits we provide. As run sizes have declined, the benefits of offshore printing have declined with them. Printing locally is a much better option now.”

With solid commitments to the environment and print in general, PEFC and FSC approved Inkwise takes sustainability seriously, recycling plates, paper and chemicals. Brent says, “We firmly believe there will always be a place for print and we are seeing more and more research about people wanting the tactile feel, smell and look of a printed object. There is pushback on digital mediums and an inherent mistrust developing around social media and online scamming; it is hard to scam someone with a catalogue.

“While rising costs around shipping, distribution and raw materials make this a tough market, we work closely with our partners to ensure we have the right stock option, distribution channel and cost model to make it work. Again, skin in the game matters and where companies such as Inkwise thrive, it ensures clients have alternatives to the large entities out there that reduce the options available.

“We also value our mill direct relationships with mills all over the world. It is a horses for courses scenario meaning we can supply numerous options to suit the job and client. Inkwise has always bought reel stock direct from the mills, but we are now also securing palleted sheets from those same mills.”

He concludes, “As a New Zealand owned and operated business, we are not part of a large group that competes across all market sectors nationally. Doing trade work is a great way to increase your business without increasing your costs. We offer security and we work with our partners on a trust basis.”

All under one roof.

Heatset and coldset web, sheetfed offset and digital print, for covers and inserts.

• Work on trust and mutual respect.

• No competing associate entities.

• Locally owned and operated since forever.

• Owners work in the business.

• Lasting partnerships.

Here’s what one of our trade customers had to say:

“The team at Inkwise are great to work with and we have always found them professional and completely trustworthy. Have no problem recommending them as a trade print supplier.”

brent.g@inkwise.co.nz

Proudly kiwi owned and independent

– Brightprint Ltd

Genuine “labour of love” wins Supreme Award.

Onehunga-based Artrite claimed the Supreme Award at the 30th annual Pride In Print Awards, held at the Cordis in Auckland.

Judges described the screen print creation called Te Henga Sunset as a “genuine labour of love” and awarded it the Specialty Products/Limited Edition & Fine Art Prints Category as well as the Screen Process Award.

Accepting the award on the night, Glenn Taylor, managing director at Artrite, said, “This is overwhelming. I have been in the industry a long time; started as a 16-year-old, coming straight from school to Artrite. So, to get this now is special.”

He described how Artrite had made a strategic decision to “stick with the knitting” in screen print versus other modes. He explained, “An artist will come up to us with an original work, and our job is to break down that job into single layers and try to recreate that job exactly as the painting.

“Art is a big thing, and we are having to compete against a digital market. We’re always evolving and learning new things. We are still finding better inks, better machinery, better techniques to achieve what digital can’t do. Really, we are trying to achieve a painting look, so that people will say, ‘How is this done?’”

He added that artist Matt Payne had expressed a “mind blowing response” to the work. He said, “Matt was with us for most of the process too, so it was a real collaboration of him and us.

“We are privileged to work with so many talented artists from New Zealand and overseas and it is just really opened up a well of good will for us. We love what we do and we have a passion for our craft. It never feels like a job.”

Pride In Print judges said, “The work is an incredible example of true print craftsmanship and artistic collaboration. It required the hand-mixing of 33 colours and production of film layers, which the

artist needed to sign off each time. With colours prone to change during repeated screen pulls, they could only complete 30 at a time before it required a clean up. They then needed to remix colours, reproduce film layers, and obtain artist sign off again.

“Taking three weeks and about 2000 hand pulls to complete, the result was an original screen print, produced with great detail and wonderful colour consistency over all areas. So many things can go wrong in all those processes, yet it was so beautiful. We were blown away. This screenprint was a genuine labour of love.”

The Pride In Print Awards celebrated its 30th anniversary in style.

Lisa Hegh, Pride In Print Awards chair, took the opportunity to thank everyone involved in making the awards such a huge success, from the patron and sponsors to the awards committee and

the judges, and of course, the team at PrintNZ.

The Pride In Print Awards could not take place without support from the industry and its suppliers. Fujifilm New Zealand is the patron of the awards. The awards sponsors are Avery Dennison, B&F Papers, BJ Ball, Currie Group New Zealand, DIC New Zealand, Kurz New Zealand, Nekkorb, Reproflex3, Paper Source, Ricoh New Zealand, Spicers, UPM Raflatac, and WML. The Friends of the Awards are Blue Star Group (New Zealand), Contact Labels & Print Finishers, PhilStic Labels, SCG, Sealed Air (Hamilton), and Wholesale Print. The media sponsor is New Zealand Printer Magazine.

Fittingly, two legends of Pride In Print, Fraser Gardyne and Grant Letfus, were present on the night. As 2023 convenor of judges, Fraser spoke briefly to the audience. He said, “It is quite special being here after 30 years. The first awards were held just down the road at the Civic Theatre.

“The wonderful thing about the judging process at the Pride In Print Awards is that, while we are part of one of the most competitive industries, the companies who enable the awards to happen by letting their staff do the judging; they all give us their time generously. All the judges work to get the best possible result through consensus and the positive spirit that everyone brings to the table is extraordinary.

“Tonight, we are celebrating the competitive nature of the industry, which brings the improvement in the quality of the work. The judging process is incredibly tough now. In the early days, people did not check their work as carefully and the judging was easier.”

In 1993, the Pride In Print Awards gave out 16 gold medals. At this year’s awards, that number is 202. Speaking to the audience, Ruth Cobb, chief executive at PrintNZ, explained, “It is about the fact that judges have seen an exponential lift in the quality of work that our industry produces, and this is something that everyone should feel incredibly proud of.

“One of the great things about print is that every job is bespoke, which allows you to approach each one differently. These entries certainly show that the creativity genes flow strongly through our industry. New technology, and sometimes old technology, gives you the ability to try new things for your customers; all done with requirements for the work to be more sustainable and more cost-effective,

and you must find your customers that special point of difference. Our industry delivers all that. The reason that we can produce this work is the people in this industry and it is always such a pleasure to present the training awards.

“There has never been a more important time to train people. In these times, if you want to have more and effective staff, then you have to train your own. Print is a craft. This is proved in the way our apprentices talk in such technical terms about the work they show us.

“Listening to the apprentices assures us that print has a solid future. I must thank BJ Ball Papers for its ongoing support over many years. Through thick and thin, BJ Ball has supported our training programmes. We also thank our other

training awards sponsors: Heidelberg, Competenz, Te Pūkenga, Trust4Skills, and the Graphic Arts Prepress Federation.”

The training awards winners are:

Trainer of the Year – Wade Collins from Seal Air Hamilton.

The Training Company of the Year – Blue Star Jackson.

Apprentice of the Year – Catriona Mellows from Display Associates.

The 30th Pride In Print Awards received 475 entries from 71 companies. The 202 gold medals were up 40 from the 2022 awards and the 78 highly commended medals were down nine from last year.

New

Judges appreciated this work as a great demonstration of the quality achievable when all the correct technical attributes are utilised to produce work as good as any other printed media.

The same job has been also recognized with the award in the flexographic process.

According to the judges Kāpiti Caramel and Almonds flexible packaging is an outstanding example of technical excellence from a demanding print process.

Auckland-based brand display and packaging solutions business, APC Innovate has been praised by Pride In Print judges for producing a “standout example of excellence in point of sale” in taking out this year’s Structural Design Packaging Category award.

Judges described this work as a standout example of excellence in point of sale, which, “Won out in a closely contested category. The job features functionality, good attention to detail, good print work and robustness, executed at large size.

“Instead of resorting to the ‘same old, same old’, it is obvious they’ve had a hard think about the modular design structure – the shelving is well made, everything fits as it should, and all components are removable to assist transportation to stores around the country. Additionally, they’ve demonstrated significant attention to detail – for example, printing inside the taco element. It’s all there.”

Judges described this work as a standout example of excellence in point of sale

Multi-embellished, colourful Chemistry Gin label brough a win for the East Tāmaki-based Multi-Color New Zealand in the label category.

Chemistry is a modern London-Dry gin infused with Sichuan peppercorns, sage and seaweed. Born from a love of science and nature, the company explored botanicals at a molecular level to bring out the best of each flavour for a perfectly balanced New Zealand gin.

Judges thought it was a great example of a creative concept combined with high-quality digital print and finishing.

“This label has expertly drawn together a silver foil, high-build varnish and beautiful colours to deliver an amazing effect,” said the judging panel.

Magnets NZ claimed its win in the Sign & Display category for its Log Cabin concept.

Don’t be fooled, this custom 6x6 Patrol isn’t towing a giant log… it’s a caravan… home built in the Far North by Joe. Magnets fully wrapped it on site in high resolution 3M Films paired with 3M’s 8520 matte laminate for a more realistic finish.

Wood rings were added to the window recesses and log ends, and a chunky bark was laid over the outer surface, the finishing touch was the bark edge around the front and rear to blend the two together.

This piece was described by judges as the clever concept that has been executed perfectly with incredible attention to detail across every aspect of the job.

The same concept has grabbed the award in the Digital Print category leaving the judging panel impressed with a fantastic design concept, realised by the highest attention to detail and application capabilities.

“Magnets NZ has produced a caravan wrap that conveys real wood cut-out effects and has been hailed as a very, very difficult piece of work,” commented the judges.

Rapid Labels entered the competition with a concept utilising a mini turntable with playable sleeved records

One of the largest commercial printers in the central North Island, Brebner Print, scored the award in the Business Print category for its Ross Dependency: Science on Ice stamp series.

The images featured in this series of Ross Dependency stamps represent the work of New Zealand’s leading Antarctic Sea ice scientists. Along with their teams, they are conducting ground-breaking research in McMurdo Sound, investigating better ways to predict the future and, in turn, how the changing climate may impact the fragile sea ice balance in Antarctica.

Judges appreciated the amazing detail captured in this 300-line-screen job and enhanced through the subtle application of spot UV. For example, when viewing through a magnifying glass, you can see the shadow of a tiny little man and other detailed features.

La Montée Champagne label and packaging printed by Rapid Labels has been names the winner of the Industry Development and Creativity category.

Designed to be re-gifted, La Montée Champagne, which translates as “The Rise” is a beautifully designed comment on the soaring cost of living and a little something to help ease the pain.

Judges commented, “As well as being a beautifully printed job, featuring fantastic foiling and other enhancements, this double-acting label has been innovatively devised to enable the printer’s customers to seamlessly regift their bottles of wine, if so desired.”

The second entry by Rapid Labels, Rapid Remix, has also grabbed the award in the Print Industry Promotion category with its concept utilising a mini turntable with “playable” sleeved records demonstrating a wide range of print processes.

Rapid Remix was appreciated by the judges as an amazing concept utilising a mini turntable with “playable” sleeved records to demonstrate a wide range of printing processes and techniques has delivered an outstanding piece of selfpromotion for the printer.

“It was produced on a hand-registered machine, where three passes were made to each to print specific aspects of the stamp and then one final pass was completed over the full work. Solid ink coverage was achieved in a nice, clean print, and excellence in registration ensured all of the perforation holes lined up perfectly,” added judges.

Judges appreciated incredible detail in this series of Ross Dependency stamps

Each year, winners of WOW Awards are added to the incredible collection of garments. This year, Blue Star Wellington, which produced the WOW Art Show Program has added a double win in the Promotional Print and Sheetfed offset categories.

The judging panel described the programme as a fabulous publication that was every bit as amazing as the event it was showcasing.

“A beautifully produced book whereby great design and eye-catching imagery was brought to life by excellent colour reproduction, subtle application of foil, matt laminate and spot UV, as well as perfect registration and binding,” said the judges.

New Zealand Media and Entertainment (NZME), an integrated media company offering market-leading newspapers, radio stations and digital platforms, has been awarded double win for the New Zealand Herald - November 1, 2022, in the Newspapers and Web Offset Coldset categories.

The judging panel described this print job as an outstanding piece of work produced at high speed in a tight timeframe.

Judges commented, “This work is outstanding in terms of print quality, colour, registration and marking – the overall quality is exceptional. This copy is 48 pages, the press would have run at 60,000 copies per hour, and this would have been one of a hundred thousand printed that night, completed in one pass.

“With newspaper printing we are talking about deadlines measured in hours and minutes. It is a run on the press –there are very little electronics to assist the printer – it is the essence of print. A deserved winner among a batch of very good entries.”

“A labour of love” Te Henga Sunset by Matt Payne, an Auckland based landscape painter who specialises in capturing the New Zealand coastline with breath-taking realism, and produced by Onehunga-based Artrite Screen Printing, was successful twice in the Specialty Products and Screen Printing categories.

Judges appreciated Te Henga Sunset as an incredible example of true print craftsmanship and artistic collaboration resulting in a screen print of great detail.

Described by the judges as a “genuine labour of love”, this beautiful fine art print involved the hand-mixing of 33 colours each requiring artist sign-off. A flawless example of screen printing.

The second edition of Aotearoa Graffiti Magazine Fresh Press printed by SCG secured the win in the Publications – Magazine category.

Following the success of the premier edition of Fresh Press, Fuego and Berst headed to SCG offices to produce Issue Two of this seminal documentation of the Aotearoa graffiti scene on 226 pages of exclusive interviews and image showcase.

According to the judging panel technical challenges producing vibrant images on an offset stock and putting the job through the press multiple times have been mastered superbly in this publication that has literally been described as flawless.

Judges commented, “We poured through the magazine, but couldn’t find anything wrong with it. It is an extremely nice job and there are some great images, produced superbly.

For example, it is very difficult to achieve vibrancy when laying colours onto an offset stock, but they delivered in spades. And this job has been through the press multiple times – which increases the chance for errors – and we couldn’t find anything wrong with it.”

The range produced for Tiny Table Co. brand delivered a win to Inkiana Press in the Paper and Board category.

Tiny Table Co. creates quality feeding essentials and toys designed to encourage developmental growth and independence. The company loves the practical design and celebrating simplicity.

Inkiana was tasked with producing packaging for this innovating brand.

Judges commented, “A fantastic combination of stock choice and the letterpress technique, it is very elegant and has lots of different parts to it which each perform their roles perfectly.”

Excel Digital, one of New Zealand’s leading digital printing companies and a Toitū carbonzero certified organisation, impressed judges receiving three gold medals, three highly recommended recognitions and won the Sustainability and Wellness Category.

“Excel has lived up to its name and shown leadership in the areas of wellness and sustainability with a range of initiatives to support staff and to reduce their impact on the environment,” said the judges.

The company is particularly delighted about taking out the Wellness and Sustainability honour as it cements that it is on the right track regarding how it treats its staff and the decisions it made regarding the environment.

“We have a long-running aim to be the most sustainable digital printing brand in New Zealand and have been unwavering in our dedication to this goal. For us, sustainability is a journey, and we are committed to continuously improving our sustainability practices,” said the company.

Sustainability has been part of Excel Digital’s DNA for many years. It has been a member of the Toitū Enviromark programme since 2013, being Gold-certified since 2017. Additionally, it is a Toitū net carbonzero company, FSC-certified, and recently became a certified Living Wage Company.

Excel Digital’s managing director Guy Phillips, said “It’s the small things that matter to us. We live by a set of values; we care about human connection and believe this is at the heart of the relationship we build with each other and our client base. By understanding and truly caring about what matters to them, we can continue to deliver what they need and more.”

Judges appreciated impressive colour consistency and spoton registration

Gravure Packaging, a privately owned flexible packaging and shrink sleeve manufacturer, head-quartered in Wellington, scored gold in the Gravure category with its Ajax Hospital Disinfectant job.

Gravure Packaging technical director Grant Amelung enthuses that being bestowed with the Pride In Print Gravure Process award “enshrines the competitiveness and relevancy of rotogravure”.

Judges commented, “This job has been very well printed with crisp and vibrant graphic elements. The background vignette is very clean and effective. There has also been clever use of software to distort the image to ensure perfect reproduction when applied to the final product. A very well-designed and well-executed example of gravure print work.”

Masterton-based division of Webstar has been recognised for its work for the Countdown supermarkets chain with the Bricks Farm promotional material in the Web Offset Heatset category.

Judges said that despite being printed on a challenging newsprint stock – which is prone to linting due to its fibrous nature – this catalogue was extremely clean and crisp, with impressive colour consistency achieved throughout.

“As well as being perfectly trim and square and folded precisely, registration was spot on, and overall, it was sharp and punchy, and simply nice to look at. Additionally, given the constraints and challenges presented by the age of the press and some of its design features, it was an extremely well-done job,” added judges.

Rachel & Maxx Wedding Invite Suite printed by a boutique design and print shop based in Albany, Laserfoil Design & Print has scored the win in the Letterpress category.

Judges thought that from concept to execution, this job stands out as an ambassador for the print industry’s relevance in the digital era and is one of the finest examples of letterpress work.

Incredible attention to detail and mastery of print capabilities has earned the Pride In Print Inkjet Process award for Picaflor Fine Art Printing.

Judges commented, “This particular fine art print stood out to the judges. Whilst the subject matter wasn’t to everyone’s taste, the incredible quality of the print certainly was. The printer’s efforts within the prepress stages – to bring together a multitude of photographs and then the retouching to get a clarity of image and detail – is to be thoroughly commended. It was this that made the entry stand above its rivals.”

According to the judging panel using the best photographic inkjet printer helped and whilst this can be a bone of contention within the judges’ ranks, this is also all about the content. The final result is only as good as what you put in. Often overlooked, the choice of media also enhanced the perception and viewing of this entry.

Having ticked all these boxes, this was a standout contender for best inkjet print.

at the Aotea Centre and Jim Hopkins was the host. We then moved into the largest room at the Aotea Centre where we hosted almost 1000 people for dinner across two levels. It was a night to remember, and the industry was hooked.

In 2023, the industry was just as enthralled as Paul Ego and Jacqui Brown hosted the event in an upmarket dinner setting. Animations and LED lighting set the scene. Presenting the 202 Gold medals in groups allowed the presentation to take the same time it took to present just 58 Awards in 1993.

Of course, the reason we can produce this incredible work is the people. Without the skill, creativity, and continuous innovation of those that work in our industry, none of this would happen.

The Pride In Print Awards celebrated its Pearl anniversary a couple of weeks ago with a spectacular event at the Cordis Hotel. I have had the absolute privilege of attending every one of these events and the growth of the industry over that time has been nothing short of spectacular.

Milestones present an opportunity to look back and reflect on what was then and what is now.

Of the 16 categories in the 1993 awards, 13 of them described how the work was produced, for example colour sheetfed printing and three were products: specialty products, self-promotion, and annual reports. We received a staggering 989 entries. A team of only 10 judges had one day to achieve a result, emerging just prior to midnight with 16 gold medals and 42 highly commended awards.

In 2023, the score is 202 gold medals, 13 category awards and 9 process awards from 485 entries and not because the judges have become more generous. In fact, over 30 years, the requirements to achieve a gold medal have become stricter. Instead, we have seen an

exponential lift in the quality of the work produced and entrants are much more discerning with what and how many jobs they enter.

Spend a day at awards judging and you will see how difficult it is to get gold, with jobs declined for the tiniest of imperfections and those winning category and process awards needing to be nigh on perfect. Every year, the judges are impressed with clever new concepts, clever use of technology and clever use of substrates, all developed to create pieces of work that are simply stunning.

From those original 16 categories, we have moved to 14 overarching categories with 70 sub-categories, meaning every business that produces print can enter their work, no matter what it is.

Now more market facing, the categories focus on products our customers will understand such as magazines, newspapers, labels, packaging, signs, business print and art prints. Customers don’t care what type of oven you bake their cake in as long as it tastes great, looks great and fits their budget. Giving your customer a certificate that says you printed the “Best Label” has so much more meaning to them and is immensely more marketable for you.

In 1993, we put on a show with laser lights and smoke, the likes of which we had never seen before as every one of the winners came up on stage to receive their medals and certificates. The first half of the show was held in the theatre

In 2000, the Apprentice of the Year Award moved to being announced on stage at the Pride In Print Awards. This huge step forward acknowledged the important role that training, and our apprentices play in the future of the industry. In 2020, the awards further expanded, developing a platform to recognise the businesses driving the future of the industry with a commitment to wellness, sustainability, and innovation.

In 1993, the supreme award went to McCollam Printers for a four colour offset sheetfed publication called DesignWorks Credentials.

In 2023, the Supreme Award went to Artrite Screen Printing for the reproduction of Te Henga Sunset, a 33 colour screen print.

Finally, I must give a special mention to the companies that have spanned the 30 years of the awards. Admark Visual Imaging is the only company that won gold in 1993 and again 30 years later in 2023, with 58 more in between; a special achievement. And to our Patrons and Sponsors who were there at the beginning and are still here today: Fujifilm, Spicers, B & F Papers, and BJ Ball – thank you for 30 years of support.

What hasn’t changed? The Pride In Print Awards continue to recognise excellence in craft and people and validate the world class work that is produced by our industry every day.

Pride In Print has adapted and changed to serve the industryRUTH COBB That was then: Ruth Cobb as part of the first Pride In Print organising committee in 1993 (apparently an after school job)

aim to provide a level of protection to domestic industries by making imported products relatively more expensive. It has also implemented procurement policies that prioritise local suppliers for government contracts. This helps support local manufacturing by giving domestic businesses an advantage when competing for government tenders.

The season’s buzzword is Deglobalisation: the art of reclaiming economic, political, and cultural sovereignty from global entanglements. Consider it a fierce, yet necessary, shift towards putting your backyard first.

It gained traction after the 2008 financial calamity and the ensuing recession, where its proponents questioned the benefits of relinquishing control over their economies to foreign forces. Covid-19 accelerated and exacerbated the process of deglobalisation, highlighting the vulnerability of complex, globalised supply networks.

The deglobalisation movement provides an opportunity for nations to revive their dormant local industries, foster self sufficiency, and help restore public faith in their government’s economic policies.

Governments across the globe have implemented various protectionist measures to safeguard their domestic economies and address supply chain vulnerabilities. These measures include export restrictions and prioritising domestic production for critical items. Such actions have been driven by the desire to ensure access to necessary goods and protect national interests, contributing to a more protectionist environment.

This shift to localisation has been particularly pronounced in the manufacturing sector, where companies

seek to regionalise their operations and build strategic alliances. These strategies often involve relocating production facilities closer to consumers, forming collaborations with local suppliers, and investing in new infrastructure. While this will help reduce supply chain complexity and increase responsiveness, it will likely lead to higher costs as firms pay for relocation, training, and additional resources. Localisation could result in reduced economies of scale and higher consumer prices.

In response to this, governments and businesses alike have been investing in new technologies, processes, and resources that can help local manufacturers meet the changing needs of consumers. This includes digitisation projects and investments in AI-driven automation and robotics solutions. These efforts will likely result in a more efficient production process that will provide a competitive edge to local companies.

At the same time, local governments are investing in initiatives to help businesses operate sustainably and provide better working conditions. This includes incentivising companies that use renewable energy sources or invest in environmental conservation projects. In addition, there is a focus on creating a more diverse workforce, which could create new opportunities for small businesses and entrepreneurs.

In Australia and New Zealand, these efforts have included targeted support for specific industries, financial assistance for investments in new technologies, and initiatives to enhance the competitiveness and profitability of local manufacturers.

New Zealand currently maintains a tariff schedule that imposes import duties on certain goods, including those in the manufacturing sector. These tariffs