New solutions deliver automation, sustainability, and enhanced production capabilities.

HP has unveiled a suite of innovations designed to drive significant advancements in the print and sign industry.

The company’s latest announcements include the launch of HP PrintOS Production Hub; the new HP Latex R530 all in one printer; and, most recently, the debut of the HP Latex 730 and 830 Series printers at the International Sign Expo (ISA) in Las Vegas.

Recently, HP’s Corporate Reseller, Computaleta launched the new innovations in New Zealand. Arlette Farland, director at Computaleta, sees them “transforming the print service provider experience through cutting edge technology focused on automation, sustainability, and enhanced production capabilities”.

HP PrintOS Production Hub

Throw away your job sheets. The new HP PrintOS Production Hub is the industry’s

first large format software platform to combine order management and remote production control into a single, integrated interface.

While the experts at HP have designed it specifically for print service providers using HP Latex and Stitch printers, the cloud-based platform will support non-HP printers as well, and offers a robust solution for streamlining production workflows, from order intake to final delivery.

This highly intuitive platform simplifies operations by offering a centralised view of job status, allowing users to track and manage production in real-time. Additionally, PrintOS Production Hub helps to minimise downtime by offering remote queue control, allowing print service providers to adjust schedules, prioritise jobs, and make real-time decisions from any device, anywhere.

Key Features of PrintOS Production Hub include:

• Centralised order management: Track jobs across all stages, from creation to delivery, within one organized interface, reducing time spent on administrative tasks.

• Remote production control: Manage production queues, adjust schedules, and monitor job progress remotely from any device.

• Configuration Center: Access device settings, make adjustments, and receive real-time

recommendations on maintenance and workflow optimization.

• Print Beat Analytics: Gain actionable insights through data driven reports to help make informed decisions that improve operational efficiency.

• Mobile App Access: Monitor production processes on the go, providing flexibility and remote management capabilities.

• Jobs API Integration: Integrate PrintOS data with existing ERP/MIS systems, enabling seamless business oversight and supporting non-HP devices.

HP developed this system to address common challenges faced by small to mid-sized print service providers, including inefficiencies from manual workflows and lack of real-time visibility. By digitising and automating these tasks, the Production Hub helps reduce errors, increase productivity, and provide scalability to growing businesses.

Wayne Shaw, HP New Zealand business manager for Large Format Production, says that it’s not just about having a great printer or group of printers. He explains, “It is how you run that printer and all that goes with it. Print Production Hub being one platform means you can talk to your printers and check on how your business is doing, with simplified production control.”

HP has scheduled the global rollout of PrintOS Production Hub for May 2025

and the company will make it available by subscription as part of HP’s Professional Print Service Plans.

HP Latex R530 printer

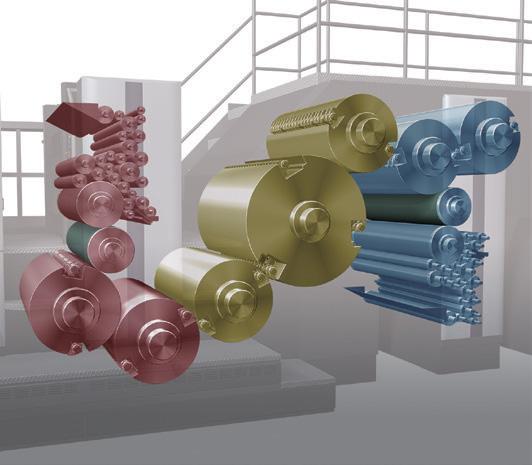

In tandem with the software announcement, HP introduced the HP Latex R530 printer, a versatile 162cm (64-inch) hybrid printer that seamlessly handles both rigid and flexible substrates.

The HP Latex R530 printer represents a significant step in expanding HP’s R Series portfolio. The company says it provides print service providers and sign shops with the flexibility they need to diversify their applications across various materials without needing multiple machines.

Key Features of the HP Latex R530 printer:

• Flatbed and roll to roll printing: Supports rigid media up to 1.6 metres wide and up to 50mm thick, accommodating a wide range of substrates. Spindleless media loading and fast transitions between rigid and flexible media.

• High control belt system and 16 zone vacuum system. These hold substrates secure. Load up to 8 boards simultaneously across the belt.

• Ink system: Utilises three-litre ink cartridges for both colours and white, ensuring extended printing sessions with fewer interruptions.

• Pixel control technology: For

grain-free output and crisp text down to a 4pt size and 30 per cent larger colour gamut.

• Printing speed: Capable of reaching speeds up to 31 square metres per hour (in draft mode) translating to approximately eight (1.2mx2.4m) boards per hour.

• Sustainable printing: The printer uses HP’s fourth-generation water based Latex inks, which are odourless and meet international environmental standards such as UL Ecologo and Greenguard Gold certifications.

• Enhanced efficiency: With automated maintenance routines, high-speed performance, and robust media handling, HP has built the Latex R530 printer to meet the demands of medium to high productivity environments.

• PrintOS integration: The printer integrates with HP’s new PrintOS Production Hub, enabling print service providers to manage production and monitor job progress remotely, improving uptime and operational control.

• Compact design: The HP Latex R530 printer’s compact footprint makes it a perfect solution for smaller production spaces, offering performance without sacrificing space.

Arlette believes its ability to print on both rigid and roll media makes it an ideal solution for many customers. She says, “The HP Latex R530 printer will be a game changer because not only is it compact, it’s also versatile. It will enable many of our customers to offer direct-to-substrate printing for the first time and we’re excited to help them expand their capabilities without a major capital investment.”

New HP Latex 730 and 830 Series printers

Unveiled at ISA 2025 in Las Vegas, the HP Latex 730 and 830 Series are the latest additions to HP’s renowned Latex printer portfolio. These printers bring significant upgrades in both performance and sustainability, ensuring high-quality results with faster printing speeds up to 36 square metres per hour and greater colour accuracy.

Performance Enhancements and Key Features:

• White Ink Innovation: The 730 and 830 Series continue HP’s leadership in white ink technology by providing the whitest white ink in their class. With an upgraded curing system and an additional 2 fans, the white ink dries 30 per cent faster, which is critical for applications involving multiple layers

or underflood printing.

• New printhead design: This features non-circular nozzles and micro-recirculation technology, ensuring sharp text reproduction down to four-point size and enhanced colour accuracy thanks to HP Pixel Control Technology as well as an embedded HP Spectrophotometer ensuring reliable and consistent colour output.

• Media handling and precision: A new output platen reduces media friction, while new pinch rollers improve media traction and alignment. The redesigned left hub improves skew correction and media stability, allowing for more precise print jobs, particularly on long runs and large panels making tiling easier.

• Expanded media versatility: This includes heat sensitive materials and automated double sided printing on a variety of media.

• Sustainability: Both printers use 40 per cent recycled plastics and are the only signage printers registered as EPEAT Gold, reflecting HP’s commitment to eco-friendly practices. Additionally, the new maintenance cartridge lasts 50 per cent longer than previous versions and is recyclable through HP’s Planet Partners Programme. It is also backwards compatible to the 630, 700 and 800 series printers.

• Sustainability in Design: These printers reflect HP’s ongoing commitment to reducing environmental impact. The use of recycled plastics, longer-lasting cartridges, and energy-efficient drying systems makes the 730 and

830 Series more sustainable options for businesses seeking to reduce their ecological footprint.

A unified vision for print efficiency

Together, the PrintOS Production Hub and the new HP Latex printers create a unified ecosystem that enhances visibility, streamlines workflows, and improves productivity. This combination of hardware and software offers print service providers and sign shops a seamless solution for managing print jobs, reducing waste, and improving overall operational efficiency.

With the combination of powerful new hardware and a state of the art software platform, HP remains at the forefront of the large format printing industry, offering solutions that meet the diverse needs of print service providers worldwide.

Are you ready to experience the latest in wide format printing?

For hands-on demonstrations, expert advice, or to learn more about HP’s innovative wide-format printers, including the new HP PrintOS Production Hub, Latex R530, 730, and 830 Series printers, contact Computaleta today. As HP’s trusted corporate partner in New Zealand, we offer personalised support to help you elevate your business.

Contact Computaleta now to schedule a demo or request more information:

• Phone: 0800 505 600

• Email: hardware@clgroup.co.nz

• Website: www.clgroup.co.nz

3-5 Computaleta: HP has launched Print Production Hub and expanded its wide format portfolio with a new Latex line-up including the HP. We get the details from Computaleta director Arlette Farland.

18 Fujifilm Business Innovation: Virtual Print has boosted its capabilities with an upgrade to a Revoria Press PC1120

20-21 Currie Group: Recently, HP, Dscoop and Currie Group hosted the Print for the Planet Forum in Auckland.

22 & 24: PacPrint 2025: The region’s big show for the year is ready to go with the latest technology and industry trends.

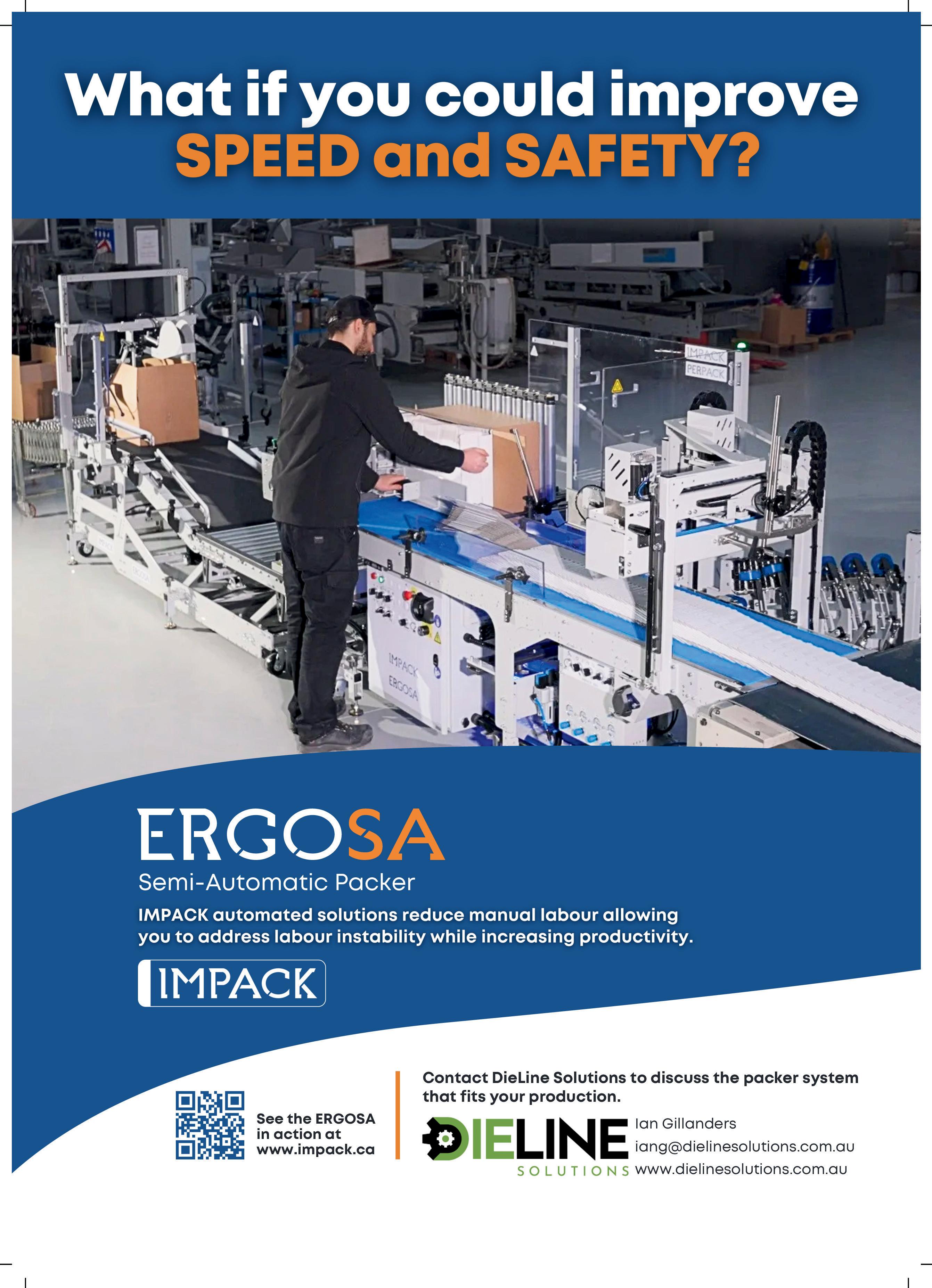

26 DieLine Solutions: DieLine Solutions MD Ian Gillanders discusses how smarter automation ensures a safer and more productive workplace.

28 Konica Minolta: In May, PacPrint will see the regional debut for the new AccurioPress C14010S and C12010S.

48 Think Laterally: Mick Rowan outlines strategies to keep your business on track as tariffs disrupt the global economy.

10-11 PrintNZ Helping Hand: Iain MacIntyre meets Tainui Press Apprentice of the Year winners: Jackie O’Reilly and Vanessa Hooton.

12-17 PrintNZ Comment: PrintNZ Golf Days provided industry professionals the chance to have some fun and network.

32 & 34 Aarque Group: Steve WiltonJones says Aarque Group’s media provides numerous opportunities for expanding your business.

36-37 Currie Group/Epson: Partnering for wide format with Epson expands Currie Group’s already impressive portfolio of solutions.

38 Durst: Acquiring callas software has given Durst a chance to “actively shape the future of printing”.

40-43 Fespa: We preview Fespa global Print Expo, which runs from May 6-9 in Berlin.

44 Durst: Out of the Box thinking gives Durst and edge and it will take that attitude to Fespa next month.

46 NZSDA Update: Mikayla Hopkins brings us the latest news from NZSDA including details of the upcoming awards event.

47 NZSDA Feature: Leon Guerin is one of the first to achieve Master Sign Maker accreditation under the new certification process.

EDITORIAL: 021 631 559

Bruce Craig, Editor - bruce@newzealandprinter.co.nz

CONTRIBUTORS: Ruth Cobb, Mikayla Hopkins, Iain MacIntyre, Mick Rowan, Steve Wilton-Jones

CIRCULATION: brian@newzealandprinter.co.nz

DISPLAY ADVERTISING SALES & SERVICE:

Brian Moore - brian@newzealandprinter.co.nz +61 410 578 876

CLASSIFIED ADVERTISING: Brian Moore - brian@newzealandprinter.co.nz

DESIGN & PRODUCTION: Sarah Vella - sarahvelladesigns@gmail.com

New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December.

New Zealand Printer is a member of the Printer Media Group

New Zealand: New Zealand Printer Asia Pacific: ProPack.pro Australia: Australian Printer, ProPrint

MANAGING DIRECTOR: James Wells - james@intermedia.com.au

GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz

© Copyright 2025: Contents of this magazine are subject to copyright and cannot be reproduced without written permission of the

Heidelberg subsidiary Gallus has announced the global commercial availability of its new matte finishing technology for the Gallus One, Gallus MatteJet. The company says the new technology allows converters to produce profitable digital labels inline with a high end matte finish at the touch of a button.

Gallus unveiled the technology as a research breakthrough at Labelexpo Americas 2024 and says that strong market demand led it to fast track Gallus MatteJet’s development.

The company says that achieving a premium look by removing the traditional digitally printed gloss finish, historically one of the foremost barriers to digital label adoption, Gallus MatteJet paves the way for broader use in labels and packaging, particularly in high-end segments like wine and spirits where brands demand a sophisticated, premium matte finish.

With the value of the global wine label market estimated at over US$3.5bn ($6.1bn) and on a steady growth trajectory, projected to reach US$5.8bn by 2033, Gallus says the new technology delivers a significant opportunity for converters to tap into a lucrative new revenue stream.

Dario Urbinati, chief executive of Gallus Group says, “Gallus and Heidelberg are delighted to announce the commercial launch of Gallus MatteJet technology as well as the opportunity it represents.

“Until now, matte finishing for digital inkjet has only been achievable through

the addition of integrated flexo units or post-processing equipment to utilise matte coatings, adding time, complexity and cost.

“Now, by eliminating the need for these types of varnishes, customers can unlock various efficiencies whilst retaining the surface texture of their desired substrate. This also in hand eliminates any required tooling and cleaning of coating machinery, adding up to a significant overall benefit.

“Three years ago, with the launch of the Gallus One, we addressed the total cost of ownership barrier to profitable digital labels. With MatteJet, we’ve taken this concept further, bringing all the advantages of digitally printed matte labels to premium brands – including short runs, reduced inventory, enhanced sustainability, personalization, and ondemand printing.

“These strategic developments demonstrate our commitment to closing the gap between the vast promise of digital technologies and the current reality for businesses across our industry. Making the embrace of digital solutions an accessible and profitable path for more converters and further supporting the drive towards ‘smart, connected, printing’, this innovation effectively completes the circle for premium digital labels.”

The company has designed the Gallus MatteJet to integrate with the Gallus One, the company’s flagship digital label press. Converters can now incorporate it into the 340mm printing width and the newlyexpanded 430mm web width. Gallus says this enhances the System to Compose concept and boosts performance and flexibility for businesses.

XSYS has completed the acquisition of the MacDermid Graphics Solutions business from Element Solutions. The flexographic, letterpress and prepress market provider says the deal will create one of the leading companies in the sector worldwide. Dr Alexander Unterschuetz, Group chief executive at XSYS, says, “This transaction creates significant value and opportunities because of the complementarity of both businesses’ product portfolio, services, and employees, thus making us a more complete solution provider for our customers.”

REPROFLEX3 has partnered with Hybrid Software UK, bringing together Reproflex3’s flexographic printing with Hybrid Software’s technology solutions. The collaboration leverages a cloud-based platform to provide secure access across all six Reproflex3 sites worldwide, including New Zealand, so tasks can be executed seamlessly, delivering optimised results. Andrew Hewitson, chief executive officer at Reproflex3, says, “This partnership further positions us as a serious contender in the global flexo prepress industry.”

HP large format senior vice president Michael Boyle has been appointed as HP senior vice-president and managing director of the Central and Eastern European market. With HP for almost 10 years, he began as its vice-president of Asia Pacific and Japan, based in Singapore, before taking up the role of vice-president and managing director in A/NZ and relocating to Sydney. He then moved on to the large format senior vice president role in August 2022.

Soar Communications Group (SCG) has implemented HP Site Flow, aiming to improve its digital printing operations.

HP says SCG’s strategic investment enables the company to automate digital workflows, eliminate prepress bottlenecks, and reduce manual touchpoints in job processing. With over 150 jobs processed daily, HP Site Flow allows SCG to batch process jobs, automating everything from file uploads to press preparation.

Benefits include faster turnaround times, reduced staffing costs, and minimised wastage, which align with

Epson’s SurePress digital label press line, the SurePress L-4733AW and SurePress L-6534VW, have received Idealliance Digital Press System Certification.

Idealliance’s Digital Press Certification programme involves testing and certification in areas of colour, print properties and

SCG’s sustainability goals. Fred Soar, joint managing director of SCG, says, “HP Site Flow removes the repetitive and time consuming tasks from prepress, empowering our team to focus on more value driven activities. Having no prepress time means each job can go straight to print. Jobs can move straight to print without operator intervention.

print production. For inkjet systems, it certifies the capabilities of commercial production inkjet, high speed, cut sheet, and web devices to meet specific print standards.

Epson says the certification demonstrates its entire press system, including the digital front-end, print engine, and paper, meets or exceeds established industry tolerances for excellence in the areas of colorimetric accuracy, uniformity, repeatability, durability, and registration.

Jordan Gorski, executive director of Idealliance, says, “The SurePress certification underscores its commitment to excellence and dedication to print accuracy.

“Once set up, Site Flow runs automatically, ensuring seamless job processing. This efficiency enables our team to shift focus toward more complex, high value projects, fostering a culture of innovation within the company.”

In December 2024, SCG automated 38 per cent of its digital orders through Site Flow, underscoring its ability to deliver at scale during peak periods, according to HP.

Enda Kavanagh, HP Software & Solutions sales lead in APAC, says, “SCG’s adoption of HP Site Flow showcases the transformative potential of automation software in the print industry. By leveraging our technology, SCG is achieving greater efficiency, sustainability, and market competitiveness, setting a benchmark for digital print service providers in the region.”

“As the demand for consistent and high-quality print grows, Idealliance’s standards across print production such as G7 continue to serve as the foundation of industry standards for colour, print quality and alignment of workflows and supply chains.”

Epson says it has designed the SurePress digital label presses for colour accuracy, ease of use and to be complementary with other presses used in a print shop. Whether using a four, five, or six colour SurePress, the press intelligently manages the file in a four-colour workflow and calculates the remaining colours to ease operations.

Former Apprentices of the Year Jackie O’Reilly and Vanessa Hooton talk about their print journeys, starting their time at Tainui Press Design and Print.

Matamata-based Tainui Press Design and Print has produced two Apprentice of the Year winners: Jackie O’Reilly in 2001 and Vanessa Hooton in 2019.

Jackie, the sole graphic designer at Tainui Press at the time of her win, recalls her wide and varied workload and having to teach to develop her own skills and knowledge. She says, “This made it quite challenging to complete my apprenticeship assignments at times.

“I often joked that I did the world’s longest apprenticeship. The length of time increased by doing some papers in typography before we realised that I needed to change to graphic prepress as

it was more in line with the work I was doing at Tainui Press.

“I would like to think that this was all a great character building exercise which taught me plenty of valuable things like resilience, motivation, and self-reliance.”

She had ambitions of undertaking a Diploma in Print Management but headed to England for a year after her apprenticeship. She says, “I was based in a smaller town, so did some freelance graphic design work among other things.

“The prize money from winning Apprentice of the Year allowed me to purchase a single-lens reflex camera and a couple of lenses, giving me a great

new hobby which I still enjoy when I have spare time, albeit with an upgraded camera from the one I bought 20-odd years ago.”

Returning to Tainui Press as a graphic designer/production planner, she welcomed the opportunity to assist firm’s next graphic prepress apprentice to study. In time, she opted to join her partner in share milking on a dairy farm and to also start their family.

She says, “I had previously helped on the farm before and after work at Tainui Press. Since leaving Tainui Press, I have continued with graphic design as a self-employed freelancer. I feel grateful to have had a career that I could work around having our three children and farm responsibilities. It has allowed me to contribute to our business and family financially while also continuing to do something I love.

“I have spent many years doing volunteer graphic design work for our local rugby club and various local charities. I am currently designing promotional and marketing material for the charitable trust that is raising funds to build a stadium in our local town of Matamata. It is rewarding to be able to contribute to our local community in a small way.

“Being self-employed, I have all the tasks and responsibilities. While I don’t love doing the accounts and boring things like that, I do enjoy having my downtime to design collateral of all different types for clients.”

Reflecting on the commitment that led to her Apprentice of the Year success, Jackie’s advice to future apprentices is simply to “study hard, work hard”.

She says, “I encourage you to diversify in your knowledge and learning. Keep upskilling so that if you feel you would like to branch out into a different part of what is a rapidly-changing and developing industry in terms of technology, then you have armed yourself with the right tools to do so.”

Her future ambitions include growing the farming business and paying the

mortgage, while also continuing to dabble with graphic design and photography. She adds, “I feel content with design being a bit of an escape from real life as such; a bit of light relief. I have a few exciting design projects lined up for 2025 which I look forward to. I have also started an online photography course for when I have a spare moment, but it is taking a lot longer than planned.”

Dale Ertel, managing director of Tainui Press, praises Jackie for effectively completing two apprenticeships. He says, “Because we took her with us from the Matamata Chronicle when we bought Tainui Press commercial print, she had started a typography apprenticeship on the newspaper side. But we changed that when we realised that apprenticeship was not suitable in the commercial print arena.”

Pandemic disruptions

Vanessa Hooton recalls the Covid-19 pandemic lockdown taking place on the same day she made the Apprentice of the Year final five. With the 2020 Pride In Print Awards evening taking place virtually, Vanessa celebrated with her employers, colleagues, and family in the staff room.

She says, “I felt immense pride sharing that moment with those close to me. However, it did feel like a smaller achievement due to the lockdown and limited celebration. So, I am especially grateful to PrintNZ chief executive Ruth Cobb for inviting me to the 2021 Pride In Print Awards where I had the honour of having the awards represented on stage. I like to joke that one positive aspect of the virtual event was that I didn’t have to present a speech.

“The achievement was absolutely life impacting. While I have always focused on continuous self-improvement and striving for excellence, receiving a respected industry accolade certainly boosted my confidence.

“It opened new opportunities and avenues I had not previously considered, helping me clarify my direction and aim higher in my career. It has been a valuable milestone in shaping my professional growth.

“I took some time off from studying after completing my apprenticeship, but I am now over halfway through my Diploma in Print Management. I am excited to continue developing my skills and knowledge in the industry as I continue to advance in my career.”

At the time of receiving the Apprentice of the Year Award, Vanessa’s role at Tainui Press covered graphic design, prepress and digital print element. She says, “Working in a small business meant wearing many hats, so I was also involved in wide format printing and signage installation alongside my co-worker.

“In 2022, I moved to Kale Print, starting a new role as account manager/ administrative support, and in 2023 I progressed to the senior account management team. I have found this transition incredibly rewarding.

“I feel grateful for the diverse background I have had, as the broad skillset I developed in my previous role has proven to be a tremendous asset in my current position. It has helped me effectively manage accounts, collaborate with clients, and contribute to the team’s success.”

As account manager, her main responsibilities include being the primary point of contact for assigned clients.

She says, “This involves creating quotes, solving problems, and finding the best solutions for each client. I also collaborate with various internal teams to deliver the highest-quality service and ensure that projects are completed on time.

“While I was initially apprehensive about transitioning from a graphic design and digital print-focused role, I have enjoyed the shift to account management. I enjoy building relationships and collaborating with clients to find the best solutions for their needs, as well as organising and overseeing projects.

“I particularly enjoy the estimating and problem-solving aspects of my role, as I get to establish solutions that not only meet but often exceed client expectations.”

She implores apprentices to “follow your passion”.

She says, “If you are enjoying what you are doing and are passionate about print, you are already on the right track. One of the things I love most about this industry is that it is filled with passionate people who love what they do. There are so many different avenues to explore within the print industry, and when you love what you do, you can’t go wrong.”

Dale adds, “Vanessa secured her job interview after a discussion of our previous apprenticeship successes. Rather than being intimidated, she claimed right then: ‘That’s what I want to achieve’ and she did exactly that.”

Iain Macintyre

Mainland Golf goes from strength to strength, while Auckland Golf makes a welcome return to Huapai after an 11 year hiatus.

PrintNZ kicked off its calendar of events for 2025 with the Mainland and Auckland Golf Days held in February.

The Christchurch event saw 80 players from the print and sign industries take to the greens at Waitikiri Golf Club on a perfect Canterbury day to raise funds for the Full Colour Trust. This was the fullest field we have had for some time, and it is great to be able to pass the profits from the day on to the Full Colour Trust who support people in the industry that need financial assistance around medical events.

Two weeks later in Auckland, we reintroduced the Auckland Golf Day at Huapai Golf Club. After a hiatus of 11 years, the field of 112 were keen to be back on the greens and the spectacular day made for perfect playing conditions, with a record eighteen 2s scored on the day.

These events were a great way to kick off the year, and a good opportunity to spend some valuable time with others in the industry.

A huge thank you to everyone that contributed to the day; in particular, the players, and most importantly, our sponsors across the two events:

Aarque Group, Advantage Business Group, B & F Papers, B J Ball, Blue Star Group, Canprint & Design, Competenz, Computaleta, Coural, Dash Engineering, Durst Oceania, Epson, Fujifilm, Hammerking Rollers, Heidelberg, Hubergroup, Kale Print, Kurz, Nekkorb, Point Paper, PSP, Ricoh, Rothfield,

Servicom, Spicers, T S Wilson Jnr, and Total Supply.

MAINLAND GOLF WINNERS:

Best Gross

• 1st Coural – David Farrant, Juls Voykavic, Mark Kelly, Darren Bywell

• 2nd Ricoh – Ryan O’Driscoll, Tim Rowe, Steve McLeod, Alex McDuff

• 3rd BJ Ball #1 – Richard Cooke, Guy Noble, Matt Costello, Andrew Carver

Best Nett

• 1st Servicom – Johnny Main, Tom Sevier, Gary Eyre, Paul Webb

• 2nd BJ Ball #2 – Chris Thomas, Dan Bushby, Mark Richardson, Andrew Thompson

• 3rd Mulford Plastics – Agi Tolo, Scott Walkin, Ross Nicholson, Jason Evans

• Longest Drive Men: Alex McDuff, Ricoh

• Longest Drive Women: Juls Voykavic, Coural

• Closest to the Pin: Adam Dunn, Autographics

AUCKLAND GOLF WINNERS

Best Gross

• 1st Kurz/T S Wilson Jnr/Leach Bindery – Darren Gallot, Mike Graham, Steve Wilson, Brian Kidston

• 2nd Ricoh – Michael Laursen, Jeff Aris, Scott Prouse, Sean Hawkins

• 3rd Fujifilm Business Innovation – Greg O’Shannassay, Paul Thomas, Cody O’Shannassay, Matt Thomas

Best Nett

• 1st Flint – Martin Hitchmough, Wayne Romminger, Andrew Brook, Paul Hopkirk

• 2nd BJ Ball #2 – Richard Cooke, Sean Cloete, Grant Young, Taine Douglas

• 3rd Rothfield – Ruhan Snyders, Ping Huang, Jerry Stancil, Jayshree Nayee

• Longest Drive Men: Chris Thomas, BJ Ball

• Longest Drive Women: Tracy Turner, PSP

• Closest to the Pin: Michael Schofield, Point Paper

Ruth Cobb

Starting from a garage in the heart of the Waikato, Virtual Print, now Virtual Print, Design and Branding has established a reputation for delivering top quality branding and exceptional service for its customers, nationally and internationally.

Sales manager Kara Seddon says, “We provide everything from business cards to uniforms, car decals to building signage. If your name is on it, we can brand it for you. We work with the SME market as well as monthly retail dispatches for a number of multinational companies.”

Recently, Fujifilm Business Innovation (FBNZ) installed a Revoria Press PC1120 at Virtual Print, Design and Branding. Kara says, “Our new Riv, which we call ‘Rosie’ delivers premium printing. It is a huge upgrade in technology after nine years with our last Fuji machine.

“The installation from the FBNZ team was seamless; not once was it too much of a hassle. We received two days of one on one training with an experienced FBNZ technician which was communicated well and easy to work through.

“FBNZ has been beside Virtual from its creation. FBNZ’s Jeffrey Loye provides our team with by far the best service and support. This factor, and the international

standard print quality that Rosie delivers, are two of the main reasons we chose the Revoria Press PC1120. These standards align with Virtual’s values: providing top quality branding with top quality service.

“The innovations featured in the Revoria Press PC1120 allow Virtual to compete in the market with top quality digital print options that compare pricewise for short runs and stand out marketing material. Its benefits include:

• Exceptional colour and colour management. It also gives us the option to add white and special colours.

• A Raster image viewer that allows live and easy colour comparison when adjusting any colours by CMYK curve.

• Improved automation with streamlined job imposition features.

• The ability to add short cuts on the main properties tab that helps us to create our ideal workflow

• New technology and great innovation speed up productivity with less errors to navigate.”

Last August, Virtual Print, Design and Branding owner Gael Mackenzie and her team of nine employees celebrated the company’s 15th birthday.

Kara says, “Our staff members are our greatest asset, and we make their safety and security our first priority. Of course, Rosie is now a staff member too.”

“We specialise in business branding, which will always have a place in the market. These include tangible products, whether they are DLE Flyers, uniforms or signage, Virtual offers sales and marketing for any and all companies. We say, ‘Let your branding sell your product. Let us make your branding your best sales representative’.”

The company faces some specific challenges. She adds, “We know that, in a tight market, it is better to pay a little more and receive the quality and service your company needs. However, in a flat economic environment, we need to work closely with our valued customers to justify that philosophy.”

Wish you could print a stunning white ink underlay on occasion?

Explore the potential of new White Dry Ink made possible by Revoria PC1120 – our new industry leading six station colour press.

Revoria is unique in that it can print a vivid white underlay in a single pass. No more registration issues. Printing CMYK plus two specials inline (white, gold, silver and clear) allows you to expand into new higher value markets producing higher quality with greater flexibility and profitability.

Presenters share their insights on how to improve sustainability and the benefits of belonging to the global Dscoop community.

Currie Group recently partnered with HP and Dscoop to present the Print for the Planet Forum at Currie Group’s Demonstration Centre in Auckland.

Attendees enjoyed presentations from Olivia West, HP sustainability customer services manager for the Americas and Asia Pacific Japan; Daniel Blau, solutions manager for HP Indigo; Kelvin Gage, Dscoop global board member and global supply chain manager – hyble; and Matt Mills, director at Fuzed and New Zealand Dscoop chairman.

In his role as event Emcee, Kelvin engaged the audience from the start and kept proceedings bubbling along with a solid blend of humour and a deep knowledge of his subject. He introduced each speaker and discussed the benefits of belonging to Dscoop. He said, “Dscoop began 20 years ago when the Indigo machines first arrived. A group of Indigo

owners began to share ideas about how to keep their machines going and how to sell print more effectively.

“From those small beginnings, Dscoop has grown into a global community that comprises some 4,000 print organisations and 20,000 members. The Dscoop community builds contents and helps businesses develop. Its events welcome people from all over the world with similar goals.

“The next Dscoop Edge event takes place from May 14-17 in Long Beach, California, USA.”

Kelvin asked New Zealand Dscoop chairman Matt Mills what he liked about Dscoop. Matt said, “It’s about sharing and learning. When I first attended Dscoop, I met other HP Indigo owners, and I realised that I could lean on those people when I needed advice. Everyone wants to keep their secrets but with these events,

everyone wants to share their great ideas, and those ideas are really helpful.”

Olivia West discussed sustainability and the part that HP is playing locally, regionally, and globally to help preserve the environment. She said, “HP has been around for a long time and sustainability has always been a part of what we do. Sustainability is becoming highly regulated with compliance increasing in Europe and Australia, where we see our customers moving in the direction of sustainability reporting.

“Customers are demanding sustainability and investors are increasingly looking at it. We also see a young workforce is coming through that wants to work for companies that have solid sustainable credentials.

“HP has several sustainable goals including achieving net zero by 2040,

10 years before the Paris agreement goal. In terms of our HP Indigo Digital Presses, we consider our HP sustainability practices. For example, we ship them carbon neutral. All emissions and other factors are calculated in there. Our HP team has a fabulous recycling programme.

“Collaboration and partnership from across the Tasman mean we have access to some great programmes.”

HP tools make your business more sustainable

In his presentation, Daniel Blau shared how HP Indigo owners can take advantage of HP’s many tools to make their business more sustainable. He said, “The tools you can use in the HP Indigo world are excellent and they are easy to use.

“One of the new tools is the HP Sustainability Amplifier. One of the things it enables you to do is to complete a self

assessment, a company assessment, on your sustainability journey. It enables you to generate a report and to be recognised in the HP community about how you are going in your sustainability journey.

“This free programme is a part of PrintOS. You can access a range of HP resources.”

Following a Q&A session, the discussion returned to Dscoop and the upcoming Dscoop Edge event that followed. Kelvin said, “This year, we will have some big keynotes including skateboard legend Tony Hawk. Dscoop’s education tracks are designed to innovate, inspire, and optimise your ability to sell print.

“Dscoop Edge will also have site tours and will wrap up with a fun party.”

The Print for the Planet Forum also gave away a door prize of an entry ticket to this year’s Dscoop Edge, which went to Christy Esterhuyse, business unit director at Rothfield.”

Industry professionals are looking forward to a bumper four days in May.

From May 20-23, at Sydney Showground, Sydney Olympic Park, industry leaders, suppliers, manufacturers, innovators, and technology pioneers will gather to showcase the latest advancements in printing, packaging, signage, workflow automation, and sustainability.

As the pace increases enroute to the region’s leading show for 2025, Kiwi industry professionals have numerous reasons to cross the Tasman in May. Organisers believe the combination of a packed exhibition floor, live demonstrations, industry forums, and networking opportunities make PacPrint 2025 an irresistible proposition.

PacPrint 2025 will co-locate with the Visual Impact Expo and the Label & Packaging Expo. These three events will provide a comprehensive showcase for all sectors of the print, sign, graphics, packaging, and wider visual communications sector, with more than 16,000 square metres of equipment and technology on display, industry leading education and networking

programs and an audience of thousands of industry professionals.

With a focus on digital transformation, sustainability, and the latest industry trends, the event will feature:

• New technology: Exhibitors will showcase their latest tools, from manufacturing automation, cloudbased workflows, energy-efficient solutions and more.

• Thought leadership: Seminars and panels led by industry experts will explore topics including sharing of business knowledge, innovation, sustainable practices, and strategies for thriving in a competitive landscape.

• Networking opportunities: Attendees can connect with peers, partners, and potential clients, fostering collaborations that drive growth and innovation.

Kirsten Taylor, PacPrint 2025 chair, says, “2024 was a remarkable year of innovation and growth for the

print industry. Businesses embraced change, leveraged new technologies, and demonstrated that sustainability and profitability can go hand in hand. PacPrint25 will provide a platform to celebrate these achievements while looking ahead to the opportunities and challenges of the future.”

Leading brands including Epson, HP, Fujifilm, Konica Minolta, Mimaki, Mutoh, Roland DG, Screen GP, Spicers, Trimatt, and Zünd will unveil their latest solutions aimed at redefining efficiency, enhancing creativity, and driving sustainability in print and graphic communications.

The PacPrint 2025 Industry Forum Series will feature an impressive lineup of expert speakers, panels, and leadership discussions. Kirsten says, “We are curating a dynamic programme that not only highlights industry trends but also prioritises the human side of business: collaboration, leadership, and employee wellbeing.”

Our in-house A1 offset press and full bindery setup make us the go-to for publishers and trade printers needing high-quality, high-volume production. Whether it’s books, magazines, catalogues or more— we’ve got the capacity, speed, and reliability to deliver. If you’re not already one of our thousands of trade partners, let’s fix that. Phone 0800 289 774 or visit us online at www.wholesaleprint.co.nz Do you need magazines or books printed & bound?

Topics will include:

• Business planning for the future: Expert advice on financial resilience, digital transformation, and operational excellence.

• Sustainability in print and packaging: Addressing eco-friendly printing, biodegradable materials, and energy-efficient technologies.

• Diversity and emerging talent: Exploring pathways for new industry talent, mentorship programs, and inclusive hiring practices.

• Signage innovation and best practices: Insights into emerging trends and sustainable solutions in signage.

The show has announced two keynote speakers: Steven Gamble, founder of Anchor Health and David Ferraz, principal of Argus Business Brokers.

Taking the stage on Wednesday May 21, Steven will lead an exploration of the role of employers across mental health and wellbeing in the workplace. He will share actionable strategies to support employee wellbeing and compliance with increasing legislative requirements.

With workplace mental health becoming an increasing priority across the print, signage, and graphic communications industries, his experience and knowledge of the industry will deliver a relevant and essential discussion on fostering resilience, productivity, and a supportive work culture.

As the founder of Anchor Health, a leading mental health and wellbeing organisation, Steven has spent years educating workplaces, communities and our industry on the importance of early intervention and structured mental health support.

He says, “We know that a healthy workforce leads to a healthier business. By integrating mental health support into workplace culture, companies can create a thriving, resilient team while positively impacting their bottom line.”

David Ferraz will take the stage on May 23 to deliver a session on ‘Mergers and acquisitions: A solution to the talent shortage’.

An expert in business sales and valuations, David has facilitated mergers and acquisitions across diverse industries, including manufacturing, printing, wholesale, distribution, franchises, trades, accommodation, e-commerce, and retail. With firsthand experience in helping businesses navigate growth through acquisition, he brings a wealth of knowledge to the print and visual media sectors.

With 86.25 per cent of businesses in the print industry being owner-operated small businesses, many business leaders find themselves consumed by day-to-day operations, leaving little time for strategic planning. Ferraz’s session will highlight the importance of stepping back to work on the business, not just in it, providing creative thinking across merger and

acquisition strategies with specific to labour supply.

Attendees will gain valuable insights into how acquisitions can be leveraged not only to expand capabilities but also to secure specialised talent, strengthen their competitive edge, and improve overall business resilience.

Kirsten adds, “Collaboration and knowledge-sharing are essential for the future of our industry. PacPrint25 will bring together the brightest minds to explore how we can harness technology, improve sustainability, and build a stronger future for print.”

Another PacPrint 2025 highlight will see an exclusive hands-on channel lettering workshop, presented in collaboration with LetterTech Australia and Bounce LED.

PacPrint visitors will have the chance to gain practical skills and insider techniques in a live 3D channel lettering experience, running across all four days of the event.

New fabrication technologies and illuminated displays are playing a part in the ongoing evolution of our industry and this workshop responds to a growing industry need for practical education and innovation.

Open to professionals of all levels, the workshop promises to equip attendees with the tools and techniques to enhance signage production efficiency and creativity.

Kirsten says, “PacPrint 2025 is about offering experiences to apply in our businesses. This workshop with LetterTech exemplifies our mission: empowering professionals with hands-on learning that can drive immediate results.”

The channel lettering workshop will offer:

• Live demonstrations of state-ofthe-art channel letter fabrication, including precision bending and 3D LED integration;

• Guided hands-on sessions where participants will create and take home their own fully fabricated, illuminated channel letter;

• Expert instruction from leading technicians offering insights on how to reduce production times, boost efficiency, and maintain exceptional build quality; and

• Access to cutting-edge tools and techniques used by top professionals in the signage industry.

The sessions will run from 10:30am daily on the show floor.

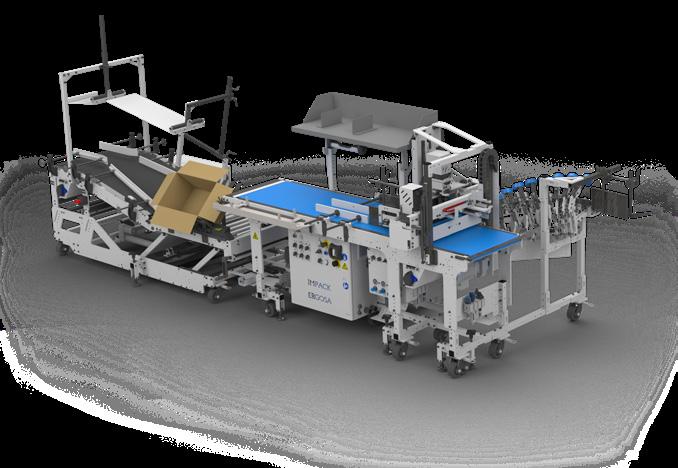

Ian Gillanders of DieLine Solutions says smarter automation ensures a safer and more productive workplace.

New Zealand’s packaging producers face a tough challenge. Labour is expensive, and repetitive manual tasks – like lifting heavy boxes all day – make jobs at the end of the folder-gluer line difficult to fill. Did you know that a single worker can lift and pack up to nine tonnes in a single day? That’s a massive strain on the body. But what if we could make these jobs more attractive, safer, and more productive?

Automation is key. It doesn’t just lighten the load, it removes the most physically demanding tasks, making jobs more ergonomic and engaging. Instead of lifting cartons all day, workers operate and oversee automated systems.

And the benefits go beyond individual wellbeing: staffing shortages and absenteeism due to injury are real concerns, and hand-packing with a skeleton crew means slower speeds and lost efficiency. When automation steps in to do the heavy lifting, finishing lines can maintain peak output –even with fewer people on the floor.

In the folding carton and tray-forming sector, speed limitations at the packing stage have long been a bottleneck. While full automation works for some, other producers need the flexibility to do many box types on a single finishing line. Recognising these issues, IMPACK has developed innovative semi-automatic solutions such as the ERGOSA.

These systems bridge the gap between full automation and manual labour, providing flexibility, fast changeovers, and ergonomic benefits.

The impact of these solutions is remarkable. One local packaging producer installed an ERGOSA and, after a short training session, put it to work. On its first run, a single worker packed 40,000 boxes per hour of a specific box type. I suggested they test its full potential, and after increasing the speed of their folder-gluer, they hit 60,000 boxes per hour without breaking a sweat. Before the ERGOSA, two workers packing manually could only manage 20,000 per hour of this box type. This isn’t a one-off case – facilities worldwide are seeing similar gains after implementing IMPACK solutions.

Automation isn’t just about improving working conditions – it’s about boosting profitability. With production numbers and labor costs, it’s easy to calculate

the payback period on automation, and in the case of IMPACK solutions, it’s a matter of months before the machine starts delivering pure profit.

Innovation meets the tray forming line

I’m always on the lookout for cutting-edge solutions that give my clients an edge. For years, I’ve supplied Gietz Tray Formers and until recently, there weren’t any solutions to help with end of line tray packing. But this year, IMPACK is introducing the TRAYVA, a semi-automatic packing system designed for tray formers, unlocking higher productivity and improved labour utilisation. It’s so efficient that a single operator can pack for two tray-forming machines.

Value through superior solutions

My commitment has always been to provide packaging producers with high-quality solutions that address industry challenges and maximise longterm investment value. I also represent MARBACH flatbed/rotary die-cutting tooling in the A/NZ market – a premium, German-engineered product renowned for its performance and durability.

Another standout innovation is Policart Anvils, which significantly extends the lifespan of cutting tools while enhancing precision for the fibre/corrugated converting market. By improving cutting accuracy and lasting longer, these Anvils help businesses reduce costs and increase efficiency, delivering tangible benefits in a highly competitive market.

Innovation is the driving force behind industry advancement. The right automation does more than boost output; it revolutionises operations, making packaging producers more resilient, efficient, and profitable.

New Intelligent Media Sensor (IM-104/IM-105)

Automatically detects paper characteristics before printing Integrated purge tray

New Intelligent Quality Optimizer (IQ-601)

Detection and inspection on the fly

Automated engine linearization

Automated duplex registration

Real-time adjustments

AccurioPress C14010/S

Duty Cycle 2.5 million prints

Up to 140 A4 pages per minute

Up to 80 A3 pages per minute

5-color 'S' version for printing in white

AccurioPress C12010/S

Duty Cycle 2.2 million prints

Up to 120 A4 pages per minute

Up to 69 A3 pages per minute

5-color 'S' version for printing in white

Long-life platform, long-lasting parts and consumables

Accurate front to back registration

Fusing-rolling mechanism

Remote monitoring and diagnostics

Responsive maintenance and repair

S.E.A.D. X Image Processing

2,400 x 3,600 equiv. dpi x 8bit

Advanced color reproduction at high speed

Image density control

White printing with C14010S and C12010S

Purge Tray Integration

50-sheet booklet making with front trimming and optional creasing, slitting and spine corner forming

100-sheet stapling with cutting mechanism

102-sheet auto ring binding

Flexible choice of controller technology: EFI®, CREO® or proprietary Konica Minolta controller

Advanced media recognition and purging

Vacuum feeding technology

Up to 14,140 sheets paper input capacity

Up to 10 paper input trays

Up to 2,300 sheets paper input for long sheets (up to 900 mm)

Simple paper catalogue settings

Simitri® V Toner offering gloss and matte finishes

Lower fusing temperature

Clean Planet Program

Cost-free recycling

Operator replaceable parts

Integration into hybrid workflows

Auto Inspection Technology

Automated color calibration, profile and validation

Intelligent Color Control

Konica Minolta has announced its next-generation AccurioPress C14010S and C12010S production presses.

Chris O’Hara, national production print manager at Konica Minolta, says, “These innovative presses empower businesses with stunning print quality, exceptional speeds, and unmatched versatility, letting customers unlock more possibilities in digital print with CMYK + white toners.

“The AccurioPress C14010S and C12010S from Konica Minolta deliver exceptional performance, achieving print speeds of up to 140 pages per minute (ppm) and 120 ppm, respectively.

“The new five-colour print models add white as a new colour and let businesses explore new creative avenues, such as eye-catching print effects.

“The AccurioPress C14010S and C12010S feature six cutting-edge Intelligent Media Sensors. For automated print management, these identify paper type, weight, and size instantly for optimal print settings every time without additional operator input.”

The presses support a broad range of media, from 52gsm up to 450gsm paper including envelopes, embossed paper, polyester, and cut-sheet labels, opening doors to diverse applications.

Chris adds that the new CMYK + white toner is high opacity and achieves exceptional coverage in a single pass, making it ideal for premium applications, further expanding offerings for the new models and helping businesses tap into new revenue streams.

Flexibility and smart technology

For larger and more demanding projects, the systems accommodate long sheets

up to 1,300mm simplex and 900mm in duplex, providing flexibility to meet customer demands.

Chris says, “Whether it’s for banners, book covers, or specialty items, the AccurioPress C14010s and C12010S let customers rethink possibilities in production printing and explore additional opportunities for business growth.

“Konica Minolta has engineered the AccurioPress C14010S and C12010S for efficiency, streamlining operations with advanced smart innovative technology. These new print solutions help operators to work smarter, reduce manual adjustments for unattended, uninterrupted printing, and deliver flawless print results faster with reduced touchpoints and exciting new colour options with the addition of white in the new high-opacity CMYK + white toner.”

“Features such as the Intelligent Quality Optimiser Unit, IQ-601, including a new inline spectrophotometer for precise colour profile creation, and Intelligent Media Sensors (IM-104 and IM-105) support consistent, high-quality output with minimum user intervention.

“The IM-105 measures the paper size of the substrates and detects even the slightest variations in paper cutting size and, together with the Intelligent Quality Optimiser IQ-601, automatically adjusts image positioning to eliminate front/back alignment errors for professional quality and consistency with every print run.

Other key other benefits include automatic print quality adjustments with Automated Quality Adjustments (AQA) and Automatic Inspection Technology (AIT), with an intelligent overall design to maximise press uptime.

Chris says, “The AccurioPress C14010S and C12010S models underpin Konica Minolta’s mission to support the digital transformation of our clients’ companies by sector and industry, predicting potential challenges and creating solutions together. This human-centric partnership approach lets customers streamline their businesses through fewer human touchpoints and higher productivity with tangible benefits including high-quality output with less print waste.

“Konica Minolta is dedicated to fostering creativity and driving digital transformation for its customers. The new five-colour AccurioPress C14010S and C12010S print systems are built on 20 years of expertise, innovation, and leadership in digital printing, all backed by the trusted support Konica Minolta is renowned for.

“New operator assistance tools and fewer touchpoints, enables Konica Minolta customers to optimise workflows and minimize downtime. This empowers greater creativity, helping customers uncover new opportunities and identify profitable revenue streams.”

The official New Zealand launch of the AccurioPress C14010S and C12010S will take place on Tuesday May 20 at 10:30am AEST on the first day of PacPrint at the Sydney Showground, Sydney Olympic Park.

Chris says, “We invite all PacPrint visitors to come to our stand for an exclusive first look at these groundbreaking digital print solutions in action. Our Konica Minolta New Zealand production print specialists look forward to discussing the many ways we can help your business.”

Steve Wilton-Jones discusses the benefits of combining Aarque Group’s rigid and roll print media with the new HP Latex R530 printer.

The global packaging and display graphics market continues to grow as business owners seek ways create new revenue streams in rigid and roll print applications. Thanks to HP’s new all in one HP Latex R530 printer you can now have the advantage.

It is super important to have the right product to support your production requirements. Aarque Group provides a huge catalogue of media, available on demand from its warehouses in Auckland, Wellington, and Christchurch. Our team has the R530 up and running in our show room and it is evident this printer is ideal for these media.

Aarque Group is offering a special launch package of the Rigid Media to give your business a head-start when you purchase the HP Latex R530 printer!

Based on our experience, the following medias will support sales growth and give you the scope to create for customers. Use this package for customer samples, sellable production work or decorate your shop, either way you will be delivering outstanding prints with this package!

Our PP flute is PVC free which means you can recycle this through our return programme. Simply register, agree to terms and conditions and we will provide the bag and arrange the collection service for this all important environmentally conscious process.

This corrugated twin wall polypropylene sheeting is designed for signage, displays, packaging and protection applications. It combines lightweight with high strength, durability, and impact resistance. It is also nontoxic, UV stabilised as well as water and chemical resistant, making it weatherproof for any environment.

Because it is UV stabilised, you can expect an outdoor life of 24 months, and as our product is mechanically extruded, it has a straight leading edge, which is ideal for print production.

This lightweight panel material consists of a polyethylene core sandwiched between two thin aluminium panels making it ideal for producing durable signs, which last up to five years outdoors.

Aarque Group supplies both 3mm and 4mm with options in 0.25mm or 0.3mm skin thickness, Primarily, we supply gloss/matt specially developed digital grade coating ACM to our market while we also support steel and coloured products like red and black ACM.

Aarque Group also offers a bespoke cut programme. Simply let us know the size and we will manage the best yield for you from the sheet requested*

This premium core board has print grade surfaces in either kraft, white or kraft white finishes. The hexagonal (honeycomb) cellular structure provides good load capacity, making it ideal in the construction of exhibition furniture or creative displays.

You can V-cut it, while the hexagonal (honeycomb) cellular structure provides good load capacity, making it ideal in the construction of exhibition furniture.

Among our growing list of environmentally friendly offerings, Honeycomb Board is 100 per cent recyclable carton board. Lightweight for ease of handling and moisture-resistant, it offers an excellent solution for both heat and sound isolation.

Excelfoam Board:

A range of lightweight, bright white fine cell foam panels with double-sided smooth printable surfaces, Excelfoam PVC Board premium panels are extremely versatile, easy to fabricate, and produce excellent prints. This makes them ideal for visual merchandising applications, high quality POP displays, store fixtures and digitally printed signage.

Other features include excellent impact strength, chemical and moisture resistant, low flammability, non-corrosive and non-toxic. Easy to fabricate with standard tools, they offer outstanding printability and double-sided printing. They are single-sided lined with a fine cell structure and excellent impact strength.

Non-corrosive and non-toxic, this chemical and moisture resistant board is also a better insulator than wood.

POP Foam Board:

A lightweight, brilliant white panel with a hard flat, smooth surface and an expanded closed structure foam core, POP Foam Board is ideal for post print cutting of 3D letters and shapes with an outdoor life expectancy of 12 months.

Our POP Foam Board Specialty comes with various finishes to produce distinctive prints. These strong, versatile, easy to cut boards are used in interior applications and in digital printing, especially when printing white, again, ideal for the new HP Latex R530.

Katz Display Board

A premium substrate with a glazed high white double-sided surface, Katz Display Board is designed for digital printing, providing excellent printing results and dimensional stability.

Safe for food packaging, it is doublesided printable with a mechanical pulp core that ensures it stays flat. Made in Germany and PEFC certified, it is 100 per cent recyclable, biodegradable, and it will break down over one year in landfill.

For indoor use, it provides a great alternative to foam PVC, producing brilliant colours with good contrasts and saturation as well as offering fast ink curing. It also offers good cutting and folding properties (a processing guide

is available) and it has no electrostatic charge or discharge when handling.

For outdoor use, its life expectancy is 12 weeks and makes a great alternative to Corflute for short term outdoor applications.

Katz Board makes an ideal match with HP Latex water-based inks, which are odourless and meet UL Ecologo and Greenguard Gold certifications.

Ultra Display Board

Ultra Display Board is a two-sided coated display board with a white centre. It has a wide variety of uses, particularly for high end flatbed digital printing. With a distinctive clean-white surface that delivers crisp colours and sharp contrasts while maintaining optimal colour fidelity, Ultra Display Board is ideal for printing with the HP Latex R530, making high end point of sale, photo albums, display cards, packaging, and signage.

Roll to roll

The possibilities for the HP Latex R530 don’t end with rigid media. Being a true hybrid, it offers you the flexibility to print our range of roll to roll media as well. Notably, the following:

Durapro solvent backlit film

This 275gsm translucent polyester coated

backlit film has a semi-matte coating that reduces glare and provides high quality image density. Its rigidity and flatness make it easy to install and it is scratch resistant.

Applications include lightbox graphics, backlit trade show displays, department store display, luminous advertising, bus shelters, and transport illuminated signage.

Durapro metallic self-adhesive film

This 195gsm metallic self-adhesive dual sided coloured film features a smooth and glossy, almost mirror, effect that prints, cuts and weeds with ease. You can apply this film dry or wet. The film and liner are PVC free making it an environmentally friendlier solution.

Applied to perfectly smooth substrates like glass, the films shiny metallic print material has a mirror look finish. A short term application gives displays a sleek and modern look. It is ideally suited for indoor and outdoor signage and lettering on glass and any smooth substrate; as a metallic digital printable film for retail decoration; as a reflective wall covering solution; for 3D labels and doming; for lamination boards and rigid substrates; and for pre-production packaging mock-ups.

This clear PET film is a removable, recyclable and environmentally friendly. Designed for window and smooth surface application, this premium printing media has innovative cling technology for graphics, printing, and sign markets. It doesn’t rely on chemical adhesion, magnetic force or static. It can cling onto glass, and other smooth surface easily by using vacuum force. So, it is low-tack and will not leave adhesive on applying surface.

Suitable for perfectly smooth substrates like window glass, this easy to remove film ensures no residue at all, even after a long application period as well as no damage to the application surface.

Our Aarque Group team love helping our customers find ways to transform their business. We can discuss your media requirements and the exciting new HP Latex R530 printer, which we have ready to demonstrate in our showroom. Please contact us on freephone 0508 22 77 83 or email customerservice@ aarque.co.nz.

Steve Wilton-Jones, National Equipment Sales, Aarque Group

Epson and Currie Group have announced a new partnership which will see Currie Group add Epson solutions to its product range for the sign, graphics and wide-format print sector providing expanded market coverage for Epson and further strengthening Currie Group’s sign & display product portfolio.

The new partnership, which commenced on April 1, 2025, will see Currie Group add Epson’s range to its already extensive portfolio. This will include the Epson SureColor eco-solvent models in the 162cm (64inch) size range, as well as resin and dye-sublimation solutions, providing productive solutions for a diverse range of market requirements.

Epson says it has seen consistent growth and has developed a strong customer base since launching its Epson branded printers in both sign and graphics as well as fabric markets.

To help meet increasing demand and drive growth, the company has looked to expand its network of dedicated and capable partners. This coincided with Currie Group’s desire to expand into the more traditional signage market and round out their existing offerings with eco-solvent, resin, and dye-sub technologies.

Craig Heckenberg, managing director for Epson A/NZ, explains, “The sign and display and textile markets are key to Epson’s global strategy, making our partnership with Currie Group a natural fit. With a strong reputation for delivering advanced digital printing and finishing solutions, supported by a nationwide service team, Currie Group is an ideal partner for us.

“From our first conversations, it was clear that we share common values and a deep commitment to exceptional customer service and support. Strong partnerships are essential to achieving our long-term goals, driving the growth of print, and bringing innovative solutions

“With a strong reputation for delivering advanced digital printing and finishing solutions, supported by a nationwide service team, Currie Group is an ideal partner for us.”

Craig Heckenberg, managing director of Epson A/NZ

to businesses of all sizes across Australia and New Zealand.

“We look forward to a successful collaboration with the Currie Group team for many years to come.”

Rob Mesaros, chief executive officer at Currie Group, says, the agreement is an extension of his company’s well established partnership approach. He says, “As a company, our growth has always been driven by the needs of our customers, and we are delighted to be

“Epson really stood out during the evaluation process because of their strong commitment to customer-led innovation, high quality manufacturing, and sustainable, responsible operations.”

– Rob Mesaros, chief executive officer of Currie Group

partnering with Epson to extend our range of solutions for this important market sector.

“As with all our partnerships, decisions are made very carefully and after lengthy discussions to ensure that we not only add the best products to our portfolio, but that we build strong and positive relationships with partners whose values and philosophies align with those of Currie Group and our customers.

“Epson really stood out during the evaluation process because of their strong commitment to customer-led innovation, high quality manufacturing, and sustainable, responsible operations. We very much look forward to working with the Epson team.”

Epson says it boasts the broadest range of products offered by any manufacturer in the sign & display and fabric markets, including the recently launched SureColor S9160 flagship signage printer. The company says its advanced printing technologies cater to diverse applications, from wallpaper and signage to textiles and décor.

For high-quality signage, Epson says its eco-solvent printers provide durable results on uncoated materials costeffectively, using biodegradable inks that are virtually odourless and resistant to water, scratches, and UV exposure, whilst

the resin printer range offers vibrant colour, precise imaging, and fast-drying prints with low VOC output, making operation easy and hassle-free.

The company adds that it meets the growing demand for soft signage, furnishings, and custom garments with its dye-sublimation printers, engineered for exceptional imaging quality, speed, and reliability.

Commenting on how the new partnership will benefit the market, Romano Bacci, business manager – Professional Print Solutions at Epson, says, “Epson focuses on quality, reliability and delivering a positive experience for our customers.

“When we looked to expand our network, Currie Group was not only a perfect fit in terms of business strategy, but a natural choice given their reputation for outstanding customer service and a shared commitment to customer satisfaction.”

Paul Whitehead, business unit manager – Sign & Display for Currie Group, says the strategic partnership enhances Currie Group’s ability to provide complete, end to end solutions for the sign and display market.

He says, “We have worked to understand exactly what our customers need and carefully assessed the available technologies and manufacturers to find the perfect fit to complement our existing offerings. That is exactly what Epson provides.”

Durst Group has acquired callas software, a prepress automation and PDF technologies provider.

According to Durst, the purchase strengthens its software strategy and focus on openness and connectivity within the printing industry as it aims for an objective: intelligent, seamless automation between machines, software, and print processes. At the same time, callas software will remain autonomous in its management and product development.

The companies say that, for callas customers and OEM partners, the acquisition brings maximum stability and new technological opportunities:

• Long-term security: callas continues to operate as an independent company.

• Guaranteed advancement: With the resources of the Durst Group, callas can continuously improve its technology.

• Unchanged OEM contracts: Existing customer relationships remain unaffected.

• New opportunities: Expanded integration options through access to Durst Group’s software technologies.

Dietrich von Seggern, chief executive officer of callas software, says, “Maintaining independence for callas was a central requirement for joining the Durst Group. Our customers must be able to trust that callas will continue as a reliable partner, while also gaining a new foundation for long-term innovation.”

Durst Group says the acquisition intensifies its strategy to build an open and connected software platform for the printing industry. callas will play a key role in connecting isolated solutions and enabling print service providers worldwide to achieve greater efficiency, scalability, and flexibility.

In the coming months, the collaboration between callas software and the Durst

Group will deepen. The goal is to leverage synergies and accelerate the development of an open, vendor-independent software platform for the print industry.

Christoph Gamper, chief executive officer and co-owner of the Durst Group, says, “This is not just another step towards digitalisation. We are actively shaping the future of digital printing. With callas at

our side, we are making print software smarter, more connected, and more powerful. The best solutions arise when strong partners work together toward a shared vision.”

Durst and Omet collaboration

Durst and Omet, who have been in a partnership for eight years, and strengthened their partnership in 2023, have announced their collaboration has seen the sale of more than 20 machines in 2024.

The jewel in the crown of the Durst and Omet partnership is the KJet, a digital and flexo hybrid machine tailored for the label and flexible packaging market. It is the second joint development by the companies after the XJet.

The KJet combines the ‘cylinder-base dual-servo’ flexo technology from Omet with the robustness and reliability of Durst’s RSCi Digital printing engine. The companies say it also offers operators a seamless experience with its user-friendly interface and ultra-short web path. This design minimises waste and reduces setup times, showcasing the advantages of digital printing.

In response to the announcement of the 20 machines sold, Durst Oceania managing director Matt Ashman said, “It is great to see the strengthening of the collaboration between two giants of the label printing industry.

“As the saying goes, we can achieve great things by standing on the shoulders of giants. This partnership leverages the strengths of both businesses to bring much-needed innovation to the label converters in the Oceania region.”

Omet added, “When innovation and mutual trust meet, great projects come into being. As a result of a long-lasting collaboration between Omet and Durst, 2024 saw the sale of over 20 hybrid machines, an incredible result, which celebrates not only our technology, but also a shared vision of two cutting edge realities.”

Tuesday, October 14 2025

Auckland

From May 6-9, 2025, at the Messe Berlin, Germany, Fespa Global Print Expo along with its co-located events, European Sign Expo and Personalisation Experience, will set the stage for print professionals to discover a wealth of products and solutions in speciality print, signage, and personalisation.

Fespa Global Print Expo, European Sign Expo, and Personalisation Experience is set to welcome more than 550 new and returning exhibitors from more than 36 countries, already surpassing exhibitor numbers from last year’s events.

Returning to Berlin for the first time in three years, visitors will have the opportunity to see the latest products and innovations from a rich line-up of international players in the speciality print space including the latest trends in sustainability, print on demand, and intelligent automation.

Michael Ryan, head of Fespa Global Print Expo, says, “This year’s events are set to be a pivotal platform in 2025 for our global community.

“Eight halls full of innovation await professionals from the speciality print market, where they can discover a plethora of on-demand technologies for

specialist print applications. With over 550 exhibitors, Fespa Global Print Expo and its co-located events will be the meeting point for visionaries in 2025.”

Agfa to feature new inkjet “power beasts”

Agfa is set to continue its innovation momentum at Fespa 2025, where it will unveil its latest high-performance inkjet printing solutions.

Over the past year, Agfa has significantly expanded and modernised its inkjet portfolio, introducing four new inkjet printing solutions: the hybrid Anapurna Ciervo H3200 and Jeti Bronco S printers, the roll-to-roll Jeti Condor, and the SpeedSet Orca inkjet press.

Additionally, Agfa has enhanced automation features, such as robotics and a new autoloader, for the Jeti Tauro hybrid printer and Onset Grizzly flatbed printer. These innovations have been widely

accepted by the market, demonstrating their alignment with industry demands.

Arnaud Calleja, Agfa’s vice president of digital printing solutions, says, “At Agfa, innovation moves faster than anywhere else in the inkjet printing realm.

“In just over a year, we have nearly completely renewed our inkjet printing portfolio. Every solution is designed in close collaboration with our customers, addressing their challenges and opportunities.”

Agfa’s advancements are brought together under the ‘Powerful by Nature’ theme, reflecting the strength, versatility, and performance of its products. At Fespa, Agfa will unveil three new powerful additions to further help print service providers take on emerging challenges.

Agfa’s booth will also showcase inspiring print applications and highlight how its solutions cater to diverse markets while contributing to a more sustainable printing industry.

Arnaud adds, “Agfa empowers businesses to meet growing demands for sustainable prints while offering long term reliability.”

Visit Agfa at Fespa Berlin (Hall 27, Booths D70 and D60) to explore the latest in inkjet printing innovation and sustainability.

Canon Production Printing to showcase ‘The Power to Move’

Canon Production Printing will be showcasing ‘The Power to Move’ where bold, high impact print creates emotional connections, delivers real business momentum, and transforms spaces into unforgettable brand experiences.

Under the theme ‘The Power to Move’, Canon Production Printing will demonstrate how its combination of technology innovations, expert teams, support services, and collaboration empowers print service providers to transform their businesses. Attendees will get insights into the industry’s trends and opportunities and be inspired by show stopping applications and new technologies.