REASONS WHY HERO IS AUSTRALIA’S BEST TRADE PRINTER

Redefine Commercial Printing Standards and elevate production with Next-Gen High-Speed Inkjet

PRODUCTIVITY

•High productivity

•560mm paper width

•High machine uptime

QUALITY

•New Inkjet 1200dpi PHs

•New saturated ink SC2

•Enhanced image quality

USABILITY

• Energy-efficient drying

•Easy operation

•Offset-coated papers

AGILITY

•Optimised integration

•Precision paper sensing

•Complete New Platform

We’ve just wrapped up events season, having attended and hosted some of the printing and packaging’s most prestigious events locally and internationally.

The biggest takeaway from these events, for us, is the speed at which the industry is evolving – it’s safe to say that challenges that were faced just 12 months ago have shifted elsewhere very rapidly.

Technology is also moving at unprecedented rates, with newer and faster versions of machines making their debuts. One must keep up with all of this change or be left behind.

This issue of AP reviews the recent Printing United 2025 Expo, detailing the new launches at the show (from page 18).

We also explore LEP Colour Printers’ purchase of three new RMGT 9 Series machines from Cyber (from page 14), and deep dive into how the business has improved processes since the machines were installed.

We hope you enjoy reading our last AP issue of the year.

Starleaton launches new, updated website

Starleaton has launched a new website weeks after damning findings from the liquidators of the former company Starleaton Holdings and the re-emergence of the brand and business under a new entity Starleaton Pty Ltd.

The company recently recommenced trading under Starleaton Pty Ltd, operating with the same website address and branding as the former business that entered liquidation in June.

The relaunch has been made possible through the ownership of the Starleaton brand, company name, and intellectual property – all of which have always been held by the company’s original founder, Peter Eaton.

Peter Eaton, father of Ben Eaton, Melissa Spooner (née Eaton), and Josh Eaton, retained ownership of these key assets through is entity, Starleaton Pty Ltd.

The previous entity, Starleaton Holdings Pty Ltd (along with SDS Bidco), which was owned and operated by the three siblings under a license agreement for the brand, initially entered administration.

Despite a last-minute Deed of Company Arrangement (DOCA), the business was ultimately placed into liquidation.

On the home page of the new website are brands previously represented by Starleaton including Zünd, Bret Martin, Hahnemühle and Neschen.

However, Zünd is now a fully owned subsidiary in Australia with former Starleaton employee Dale Hawkins appointed as managing director in March 2024. Spicers was appointed distributors for Neschen in January 2024 and named the exclusive distributor of Hahnemühle in June 2024.

The launch of the new website also comes within weeks of Starleaton Holdings liquidators, Andrew Blundell and Simon Cathro of Cathro & Partners, claiming the business was insolvent from at least 1 July 2022 – and potentially even earlier.

Managing Director

James Wells / 0414 995 104 james@intermedia.com.au

Subscriptions / (02) 9660 2113 subscriptions@intermedia.com.au

Subscription rate (5 issues) Australia $79

Editor

Hafizah Osman / 0431 466 140 hosman@intermedia.com.au

Printed by Hero Print Alexandria, NSW, 2015

National Sales Manager

Carmen Ciappara / 0410 582 450 carmen@proprint.com.au

Mailed by D&D Mailing Services Wetherill Park, NSW,

Design and Production Manager

Sarah Vella / 0406 967 559 svella@intermedia.com.au

Kwik Kopy Australia joins Fortidia in global acquisition

Fortidia, a leading global commerce enabler, has acquired Kwik Kopy Australia. Fortidia (formerly MBE Worldwide) supports micro, small, and medium-sized enterprises (MSMEs) and consumers with a range of services including ecommerce, fulfilment, shipping, marketing and print solutions. The company operates with multiple brands across 57 countries.

Kwik Kopy’s move to the group further strengths Fortidia’s presence in the A/NZ business solutions sector, complementing its existing operations through Pack & Send (directly operated), the Mail Boxes Etc. and World Options brands (operated via Master Licensees).

Under Fortidia, Kwik Kopy Australia will retain its brand, leadership, and franchise teams. Founded in 1982 by the Penfold family, Kwik Kopy Australia is a recognised leader in design, print, and marketing services with a network of more than 85 centres nationwide.

Gawk Outdoor ends oOh!media partnership

Gawk Outdoor and oOh!media have officially ended their partnership after eight years.

For activity after 12 January 2026, agencies and advertisers will no longer be able to book Gawk’s 422+ static and 64 digital billboard faces through oOh!media.

The decision marks a strategic shift for Gawk, which is bringing its agency sales in-house. The company says the move will allow it to directly share its growth story and better connect with the market as it continues to expand.

To support the move, Gawk has created a dedicated agency sales team. Tim Stevenson has been appointed to the newly created role of group agency director, while Heidi Lawrie will continue to lead Victoria as agency sales director.

Joining the team are Mitchell Madeley, Khayam Jeffrey (Sydney) and Sam Liistro (Melbourne) as group sales managers,

Kwik Kopy Australia founder Stephen Penfold has been instrumental to the development of franchising in Australia since the early 1980s. Since then, it’s been a family affair with several family members still actively involved in the organisation in varying capacities – from sitting on the board to being centre owners.

The Penfold family will retain a minority stake in Kwik Kopy Australia and remain actively involved in contributing to the brand’s next phase of growth alongside Fortidia.

“We are proud of the legacy we have built with Kwik Kopy Australia and

excited about the opportunities this new partnership will bring,” said Annalise Penfold, representing the Penfold family. Fortidia shares our passion for creating customers for life and together we can scale our capabilities in design and technology to world class solutions.”

Paolo Fiorelli, chairman and CEO of Fortidia said, “We are delighted to welcome Kwik Kopy Australia to the Fortidia Group. Together, we will strengthen Kwik Kopy’s market position, accelerate growth, deliver innovative solutions and create greater customer value”.

Under the new structure, Kwik Kopy Australia CEO Sonia Shwabsky has been promoted and will also head Pack & Send.

Shwabsky, now managing director of Kwik Kopy Australia and Pack & Send A/NZ, said, “I am incredibly excited about the opportunities ahead. With Fortidia as the global enabler of our franchise system, entrepreneurs can tap into globally leading expertise.

“Every Kwik Kopy Australia and Pack & Send business remains proudly Australian and locally owned. This combination gives us global strength and local ownership, empowering people to power business and make their mark on the world”.

alongside Inese White and Akansha Sharma who have both been appointed as agency sales coordinators.

Gawk’s director, Luke Course said, “We could not thank oOh!media enough for their support over the last eight years. It has allowed us to grow our business rapidly and we recognise their important contribution. We are confident we will look back on them as our first serious girlfriend, but now it is time to play the field ourselves and have some fun”.

Tim Stevenson, group agency director said, “We’ve been the best-kept secret

in regional out-of-home. oOh! was our first love, but we’ve built a talented team, the momentum, and a large-scale communications platform to flirt with the whole industry”.

In regional Victoria, Gawk holds 80 per cent share of roadside OOH. In South Australia, Gawk operates the largest digital billboard footprint of any provider. In regional NSW, Gawk is now the second-biggest operator, sitting just behind oOh! Media.

In July, Gawk opened its first New South Wales office in Erina, with a new Sydney office set to launch soon.

A Gawk Outdoor billboard

Sonia Shwabsky (Kwik Kopy Australia)

Rawson Print and Packaging acquires NSW-based IntoPrint

Rawson Print and Packaging has successfully acquired NSWbased IntoPrint, marking a significant milestone in its continued growth and commitment to delivering world-class print solutions.

The company said this strategic acquisition follows its integration of Megacolour earlier this year and reflects on its unwavering dedication to expanding capabilities, enhancing customer service, and investing in the future of Australian print manufacturing.

Intoprint is a known commercial print company on the northern beaches of Sydney operating since 2001. Throughout the last 20 years, it has grown from being a small A2 printer to a medium sized A1 printer.

The company has prided its success on acquiring the latest in pre-press, press, and finishing technology, and energetic approach to servicing its clients.

“We have known [IntoPrint directors] Grant Regan and Tony Perini for a long time and have often discussed the advantages of joining forces, so the timing was right to consolidate these two great businesses for the benefit of both business’ customers,” Rawson Print and Packaging director Lachlan Finch said.

“For decades, both Rawson Print and IntoPrint have built reputations for quality, reliability, and innovation. With IntoPrint now part of the Rawson family, we are excited to build on this legacy – bringing together expertise, technology, and customercentric values to deliver even more advanced and efficient printing solutions. It is the right fit for our business strategy,” Rawson Print and Packaging added, in a statement.

As part of the acquisition, Rawson Print and Packaging is welcoming the majority (10) of IntoPrint’s staff into its operations, as well as Regan and Perini, saying their extensive industry experience will be instrumental in ensuring a smooth transition and continued excellence for clients.

Finch confirmed IntoPrint will be absorbed into the Rawson brand, with Regan and Perini servicing IntoPrint customers as usual, with the added benefit of an expanded service offering.

Finch said all IntoPrint employees were offered employment with Rawson and almost all of them have accepted positions. A change in location was the main reason a couple did not come across.

In addition, the acquisition has enabled Rawson Print and Packaging to expand to a six-day, 24-hour operational model, significantly increasing its production capacity and enabling faster turnaround times without compromising on quality, Finch said.

ROLAND

The widely acclaimed ROLAND 700 EVOLUTION litho press deploys an array of innovative technologies to give unprecedented levels of efficiency, productivity and print quality.

(l-r) Lachlan Finch and Andrew Price from Rawson Print and Packaging

FIMI finalises acquisition of Landa Digital Printing

FIMI, Israel’s largest private equity fund, has taken full ownership of Landa Digital Printing (LDP), following the completion of its acquisition.

As part of the transition, FIMI has appointed Richard Klapholz as active chairman, alongside a newly established board.

“This is a defining milestone for LDP,” said Gil Oron, CEO of Landa Digital Printing.

“With FIMI’s ownership, we have the stability, focus, and disciplined operating approach to deliver our plan: strengthening product performance in the field, ensuring reliable service and supply, and reenergising our go-to-market with a sharp customer focus. Our teams are already moving, and our priorities are clear.”

“We are excited and are here to build

1800 Projects wins Champion Sign Maker Award

Sydney-based 1800 Projects has been recognised with the Champion Sign Maker Award at the Australian Trades Small Business Champion Awards.

Founded in 2006 by Ben Browning and Brent Nassibian, 1800 Projects was initially created to produce branding solutions for action sports events.

It has since grown to become a multiple award-winning company that produces premium branding solutions specialising in major venues, events, and corporate branding.

“The Australian Trades Small Business Champion Awards is a nationally recognised event showcasing small businesses and trades from all walks of life,” Browning said.

“Brent and I work hard day in and day out to keep the wheels in motion. We understand the challenges faced by small business owners, and we truly appreciate accolades like this one.

“This recognition is a solid pat on the back! It’s a national competition and there

a strong, enduring industrial company,” said Klapholz.

“Our approach is pragmatic and long-term: focused investments, operational excellence, and steady, measurable progress.

“The printing industry needs LDP’s breakthrough technology; our mission is to realise its great potential.”

In a statement, Benny Landa, the company’s founder, welcomed and expressed his support for the acquisition by FIMI, noting he is pleased the company he founded and the technology he invented will continue to grow.

were people in the room from all over the country, so it was nice to hear our name get called out and share it with the team.”

The award win comes off the back of a standout year for the company. Speaking to Australian Printer as part of the 2025 Leaders Forum earlier this year, Browning said 1800 Projects “experienced another remarkable year of growth” in 2024, particularly within its print division.

Among the year’s standout achievements were major national rollouts for Australian designer Camilla, and the production of Nine’s Paris Olympics merchandise.

However, one of the most significant projects of the year was the design,

The takeover follows LDP’s filing for court protection in July amid a reported “cash flow crisis”, where it was reported that “the geopolitical situation, as a result of the long war in Israel and regional instability, as well as commercial reasons, have made it difficult for the company, and the shareholders who have financed the company throughout its years and they informed the company’s management that they intend to stop financing the company immediately”.

“As a result, the company has found itself in a cash flow crisis. In response, the company has carried out a reorganisation process as part of which significant cuts were also made to deal with the situation and enable the continued realisation of its potential,” it reported previously.

At the time, the company disclosed debts totalling NIS 1.75 billion (approximately A$790 million), with around NIS 1.4 billion (A$632 million) owed to secured creditors.

The development came just weeks after local media reported that the company was also planning to lay off more than 100 employees – more than 20 per cent of its workforce.

production, and installation of more than 400m of printed signage for the new Stan offices in North Sydney.

Browning said the company also made strategic investments in advanced print technology. This included the Canon Colorado M5W for high-speed, high-quality printing, a Summa flatbed cutter for precision finishing, and a Mimaki DTF printer to boost its uniform branding capabilities.

“These additions have not only increased our production capacity but also enabled us to offer a wider range of services to our clients, ensuring we remain at the forefront of the print industry,” Browning said at that time.

“Our commitment to innovation extends beyond just hardware. We also focused on enhancing our internal processes and workflows to improve efficiency and deliver better results for our clients. By continuously evaluating and refining our operations, we ensure that we are always providing the best possible service.”

Browning also said the company’s strategic direction in 2025 continues to be grounded in quality, team culture, and sustainability.

“In 2025, our primary focus will remain on delivering the highest quality across every project we undertake. Quality has always been the cornerstone of our success, and it will continue to be our top priority,” he added.

Ben Browning (1800 Projects)

Benny Landa, founder of Landa Digital Printing

A life dedicated towards print

Rawson Print & Packaging account manager Lani Draheim has spent her entire 23-year career in the print industry and doesn’t plan on stopping any time soon

Amulti-disciplinary print professional, Rawson Print & Packaging account manager Lani Draheim has shown dedication to print throughout her entire 23-year career in the industry. Over the past eight years, she has settled into her role at the company, working with clients and her team to offer bespoke and tailored print solutions.

Rawson is just one of two workplaces Draheim has been a part of since she entered the industry, saying she counts herself very lucky to be in this world of print and that she doesn’t plan on leaving it.

Draheim’s career in print began in June 2002, when she started work at Burwood Press. Draheim said the small familyowned company took the time and care to teach her the skills required for her graphic pre-press role.

Six months after she started, she embarked on her apprenticeship for a Certificate III in graphic pre-press, which she completed with flying colours in 2007.

Throughout this time, she was encouraged to get involved in all the steps and services the company offered, helping her have a fuller understanding of print processes and capabilities.

Following the acquisition of Burwood Press, she transitioned to Rawson Print & Packaging, where she has been able to continue her passion for delivering innovative, sustainable, and high-quality Australian-produced print solutions for local brands.

“I’ve only worked with two companies, and this is something I take great pride in. I started in print back in the days of film setting and was part of the early shift into computer-to-plate technology – an exciting leap into the digital era,” she said.

“I began in pre-press, gaining a deep understanding of every stage of the print process from the ground up before transitioning into client-facing and account management roles.

“Since then, I’ve seen print evolve into a fast, creative, and sustainable industry. At Rawson, we continue that evolution, driving innovation, greener practices, and premium Australian-crafted solutions that keep brands connected and beautifully consistent.”

A standout moment in Draheim’s career was when she was named a finalist in the 2025 National Print Awards for Women in Industry and her nomination for the 2025 ProPrint Awards’ Printer 50 – recognising her ongoing contribution to innovation, sustainability, and the future of print.

“Print is endlessly dynamic – a blend of art, technology, and precision. What excites me most is helping Australian businesses bring their stories to life through high-quality, homegrown print and packaging,” she said.

“I take great pride in ensuring brand continuity across every touchpoint, making sure each piece reflects the same level of care and consistency. I love creating tailored solutions that not only look beautiful but also deliver real brand impact.”

While print has traditionally been a male-dominated industry, Draheim finds it inspiring to see more diverse voices and perspectives shaping its future.

“I’m motivated by people who lead with authenticity, creativity, and collaboration –those who challenge outdated norms and make space for others to thrive. I also draw inspiration from individuals across creative and community spaces who show that visibility, courage, and compassion can drive meaningful change,” she said.

“My mentors have taught me resilience, attention to detail, and the value of genuine connection. They have also encouraged me to be adaptable, solution-focused, and to never lose sight of the human side of business. Their guidance helped me build both technical knowledge and emotional intelligence – the foundation for lasting success in an industry that’s as much about people as it is about print.”

Draheim aims to give back to the industry by sharing knowledge, fostering connections, and championing the strength of Australian-made print, adding that she believes in encouraging people –especially women – to work and grow within the industry with confidence and curiosity, knowing their contributions matter.

“By supporting others to develop their skills and embrace their individuality, we build a stronger, more inclusive print community that continues to evolve, innovate, and thrive together,” she said.

“I promote change by leading through collaboration, care, and authenticity –embracing my femininity as a strength rather than something to downplay. It shapes how I communicate, connect, and build trust – both within the team and with clients.

“I champion sustainability and Australian manufacturing, helping brands make smarter, more eco-conscious print choices while contributing to a culture of innovation, integrity, and genuine connection at Rawson.”

Looking ahead, Draheim’s goal is to keep evolving – exploring new technologies, creative applications, and smarter ways to connect people through print.

“I’m driven to push boundaries while keeping craftsmanship and care at the heart of what we do. For me, it’s about continuing to grow, inspire confidence in the value of print, and help shape an industry that remains proudly Australian, innovative, and full of possibility,” she added.

Lani Draheim (Rawson Print & Packaging)

Scan to view

or contact your Ball & Doggett Sales Executive to request a copy.

Discover our latest Print & Packaging Consumables Catalogue, your complete resource for inks, coatings, blankets, rollers, adhesives and more, all in one convenient place.

What’s Inside:

• Pressroom Consumables – press chemistry, rollers and blankets for o set and packaging applications

• Packaging Tools & Adhesives – for corrugated, folding carton and label markets

Finishing & Converting Supplies – aqueous coatings, varnishes and o set inks

Each section includes technical details, compatibility notes, and QR codes linking directly to safety data sheets for easy access.

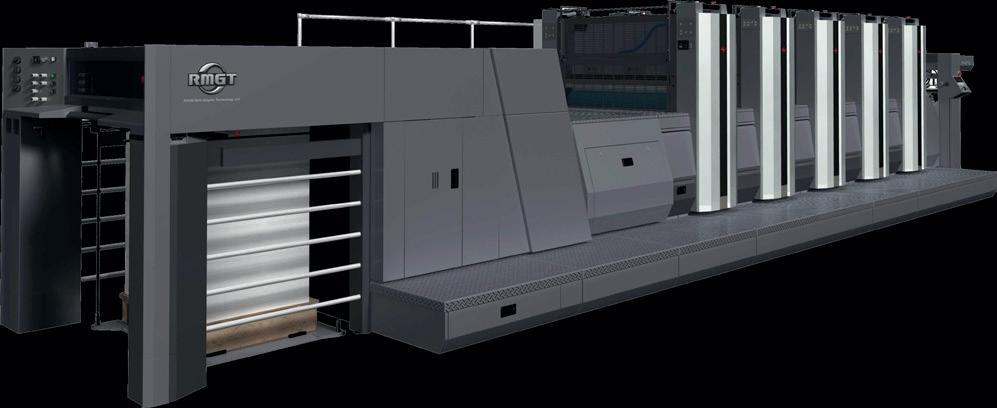

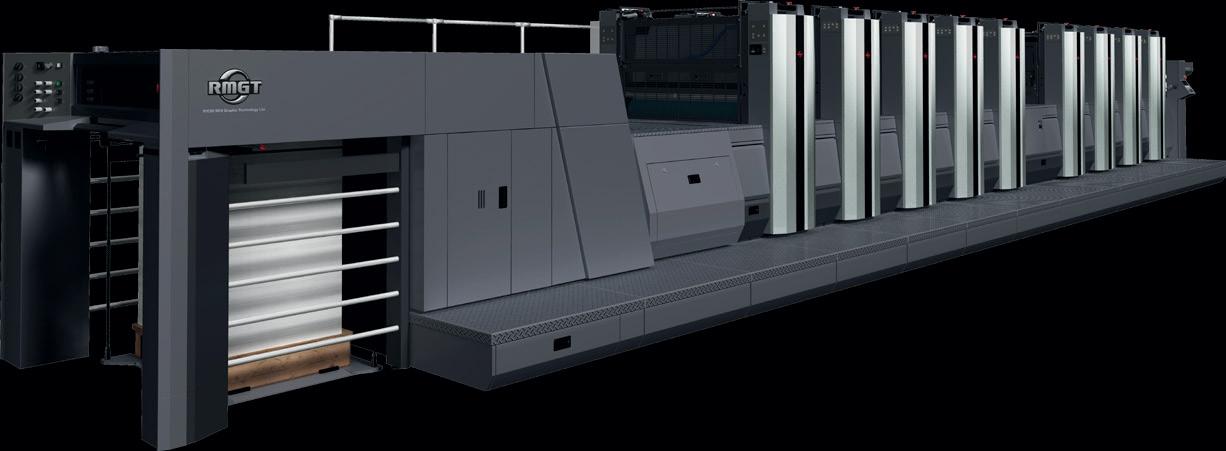

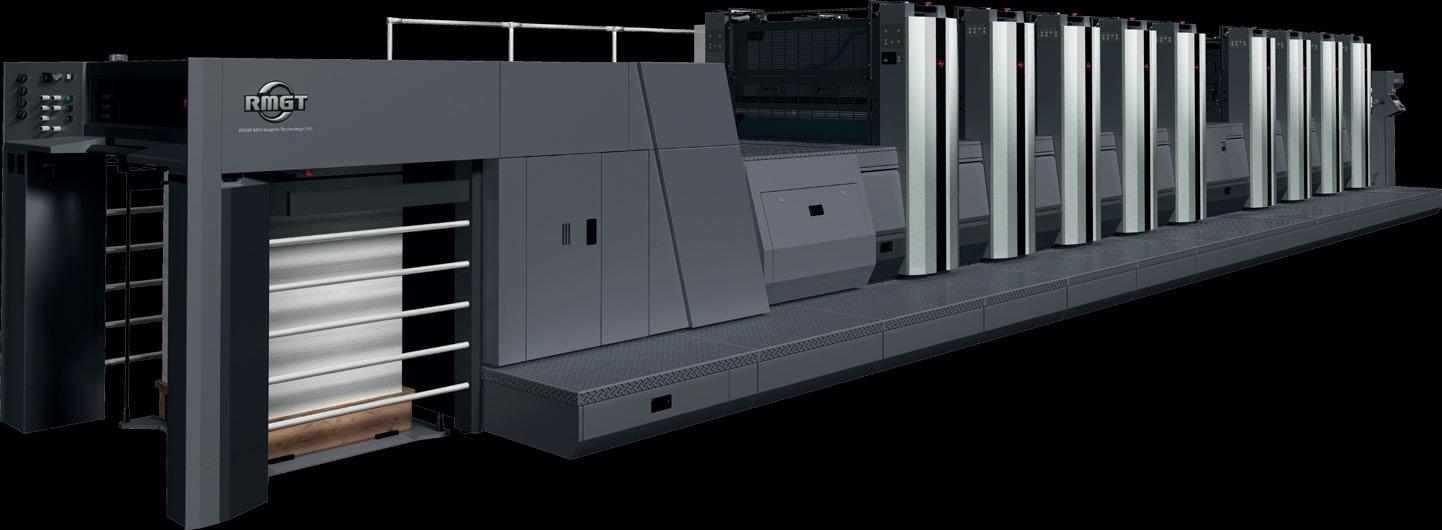

LEP and Cyber strengthen relationship with new RMGT 9 Series installs

LEP Colour Printers has invested in three new RMGT 9 Series presses from Cyber Australia to improve processes at its facilities in Queensland and Victoria

Acompany that prides itself on being a fast, reliable, and dependable dedicated trade printing partner, LEP Colour Printers knew it needed some of the best machines in the market to remain competitive, whilst providing fast turnarounds and without compromising on quality.

To deliver on these needs, LEP Colour Printers recently turned to its long-time technology partner Cyber Australia to purchase and install not just one but three RMGT 9 Series machines for its premises in Queensland and Victoria, boosting its output, improving its speed to market in multi-folds, and fully transforming its production capabilities.

This strategic investment has marked a significant milestone in LEP’s journey to deliver faster, higher-quality, and more sustainable print solutions to its clients nationwide, highlighting its innovation and commitment to serving the evolving needs of the Australian print market.

Established in 2001, LEP Colour Printers is headquartered in Forest Glen in Southeast Queensland and expanded its operations

in 2013 with the addition of a facility in Port Melbourne, Victoria. Its range of products includes business cards, brochures and flyers, DL flyers and cards, stationery, presentation folders, posters, postcards, magazines, calendars, and more.

LEP Colour Printers CEO John Bromfield said, “Our production facility in Port Melbourne was something we invested heavily in. The way our business model works is that with both our production facilities, we’re able to produce jobs in either place, then deliver across the eastern seaboard of Australia either on the same day, the next day, or within a couple of days.

“We specialise in wholesale printing, focusing solely on delivering high-quality results without altering customer artwork. Our lean manufacturing approach ensures timely delivery and cost-effective solutions that help our clients save both time and money. That model has supported our growth and business model, and all through that journey, Cyber Australia has been a business partner.”

Cyber Australia and LEP’s relationship began in 2005 when the former owner of LEP Mike Brooks bought an exhibited Ryobi 755 from Cyber Australia at PacPrint. Through the years, the companies built on this partnership, acquiring the very first RMGT 9 Series press – sight unseen – in Australia when it was first launched and followed it with two more presses shortly after – until now.

With the new purchases, a 920PF-8 LED Smart-FPC and 920ST-4 LED presses have been installed at LEP’s Queensland site, while another 920PF-8 LED SmartFPC press is making its way into its Port Melbourne facility.

Having had the two machines for about 12 months now, Bromfield said buying the same 920PF-8 LED Smart-FPC press for both of LEP’s sites will allow for colour and quality consistency between factories.

“Because we’re running the same platform on two different sites, from a customer assurance perspective, the result of a job, from a print quality point of view, is going to be the same whether it’s produced in Victoria or in Queensland,” he said.

LEP Colour Printers’ John Bromfield in the company’s Forest Glen facility in Queensland with one of the new RMGT 9 Series printers

“Also, back in the day, 75 per cent of our print runs were less than 1,500 sheets and our premises were taking 24 minutes to do a setup or make ready. So, we worked on our Theory of Constraints – which is removing bottlenecks in our business – adopted lean manufacturing and installed these machines to deliver on a ‘Formula 1’ mentality of make ready around five minutes.”

Building on company strengths

According to Bromfield, having been predominantly a short-run, four-colour gang printer, these new presses add to the strengths of the company’s business model of gaining efficiencies on full-colour work.

“Looking at what our business is, what we’re good at, who our customers are, and what we’re trying to achieve, the 8-colour 920PF-8 LED Smart-FPCs and 4-colour 920ST-4 LED presses are the perfect fit for our business needs,” he said.

“Our business is dedicated to supporting small and mid-sized clients rather than large-scale print corporations. We have a clear understanding of our core strengths and remain focused on delivering excellence within those areas. Expanding into fields outside our established expertise is not part of our strategic direction or business philosophy. So, these new investments lend themselves well to the kind of work we do and what our customers require from us – which is speed to market, quick turnaround times, and quality jobs created at an affordable price point.

“With the 8-colour recipe, and with the efficiencies that come from the added features that it offers, we have hit productivity levels that are two and a half to three times more than what’s possible on a conventional press.”

All three sheet-fed offset machines are SRA1 size, which is what LEP has built a business on, with the added benefits of LED UV and convertible perfecting, so that all the jobs get done in one-pass rather than two.

“The perfecting capabilities of these presses is not just about having state-of-the-art technology, but also about speed – printing in one pass with instant curing. For example, we’ve printed magazines on these presses that have been done from start to finish in a couple of hours. The customer was over the moon. In the past, this process would have required several days to complete, as it involved waiting for the ink to dry and managing issues such as markings, scuffing, and bruising. With the latest machines, these challenges have been eliminated, enabling significantly faster turnaround times and an exceptional ability to meet market demand,” Bromfield said.

“The impact on our business has been tremendous, delivering significant gains in both quality and capacity. The presses have effectively given us more time, allowing us to increase production and efficiency. Overall, they have enhanced our operations and established a new benchmark for what it means to remain competitive and relevant in today’s market.”

Advantages of the presses

Handling sheet widths of up to 920mm (900mm printing area), the 920PF-8 LED Smart-FPC and 920ST-4 LED presses enable printing of international A1-size posters as well as 8-up printing in both international A4-size and letter-size. They can also print on paper from 0.04mm in thickness up to 0.6mm, enabling flexible handling of a wide range of jobs, and can print up to 13,000 sheets per hour.

The machines are also highly automated, improving the work efficiency of each printing process. With their SmartFPC (Smart-Fully automatic Plate Changer) functionality, plate changing is simultaneous. Automatic blanket cleaning and ink roller cleaning also mean fewer manual touchpoints is required.

In addition, with a press information display that enables operations to be monitored at the delivery section and the PDS-E system for managing printing quality, work efficiency is improved by the centralisation of operations at the delivery end.

According to Cyber Australia managing director Bernard Cheong, the LED UV machines also have the added benefit of a 28.5 per cent cost saving on plates and a 43 per cent cost saving on electrical consumption per month when compared against B1-size presses – a plus on the sustainability front.

This is also supported by a newly developed predictive ink density control system that quickly achieves and maintains the target density with minimum wasted sheets.

“In business, there are so many variables. So, if we can remove some of these variables, it is a big plus. In this case, there’s no variable as to how long we need to wait before we can convert the sheet – when it’s out of the press, we can convert straight away, eliminating one of the big variables in printing,” Cheong said.

“These versatile RMGT 9 Series presses offer the latest automation and laboursaving systems, including a large-screen press information display for confirming printing status at a glance, together with the same maintenance functions, sheetfed air presets, and smart make-ready functions as our flagship RMGT 10 Series.

The RMGT 9 Series has allowed LEP to deliver faster, higher-quality, and more sustainable print solutions

A close up of the inks used in the RMGT 9 Series

The RMGT 9 Series sheet-fed offset machines are SRA1 size

The versatile RMGT 9 Series presses offer the latest automation and labour-saving systems

LEP has gained efficiencies on full-colour work following the install of the RMGT 9 Series

“Faster job changeovers boost printshop productivity, and the new Smart Assist Printing automatic printing function reduces operator workload significantly, creating new potential for business.”

Futureproofing LEP

With the speed and advantages of LED UV technology now part of LEP’s capabilities, Bromfield noted that the new machines integrate seamlessly with the company’s existing equipment. This alignment is expected to create new opportunities across several of LEP’s key target markets.

“We run a very well organised and lean production operation at both our sites. The new presses sit alongside – physically and systematically – our other machines and this system fits very well with our business in terms of integration,” Bromfield said.

“We’ve already seen additional work coming through various channels since we installed the presses. Some existing customers that used to send their slightly more higher end quality work elsewhere have been sending them to us as soon as they heard about us moving into the LED UV space. The fact that they are already well received by the market is reassuring and encouraging for us. That gives us a lot of confidence in some of the other things we’re looking to do going forward.

“We’ve got a few things in the pipeline, which we want to keep a little closer to our chest until it comes to fruition, but we’re very confident that the machines will be an enabler of these new business opportunities.

“To stand head and shoulders ahead in today’s environment, you’ve got to be contemporary; you’ve got to keep up – not just ahead of the curve in terms of what the market wants.”

He added that the press also suits an environment where it’s very difficult to get skilled trades people – a common challenge faced by many in the printing industry in Australia.

“It’s evident that hiring skilled staff is a challenge for many businesses. The RMGT 9 Series is a future press in the sense that you’re not relying on having a huge workforce. So, you’re automatically reducing your labour costs and your dependency on skilled personnel,” Bromfield said.

“Everybody is working towards what is called ‘dark room manufacturing’, so this series supports the move in that direction. You still need staff, but they don’t need to be as hands-on with the machines as before.”

Building on a strong foundation

Bromfield and Cheong expect LEP and Cyber Australia’s relationship to only strengthen over time.

“We have a personal interest in the LEP business, so we always look at the best of what we can do and offer. We like to think that we are in this together and the relationship goes well beyond just the sale of a press. We like to work together with our clients to get the best outcome that’s mutually beneficial,” Cheong said.

Bromfield said Cyber Australia has always exceeded LEP’s expectations in delivery, installation, and service, unwavering on its market offerings.

“Cyber Australia has worked with LEP for so many years, and they’ve done installations for us many times,” he said.

“Cyber knows our business very well and we work very closely with their engineers. So, from an implementation perspective, the installs were very smooth, just as always, as Cyber knew what our requirements were from the start.

“Cyber has also been very supportive, working with our business to minimise disruption downtime. As businesses, I believe we work very well together. It’s not just about selling a piece of machinery; there’s an added level of care in ensuring things go as smooth as possible with minimal business disruption. That’s how you strengthen a business relationship.

“We’re very grateful to Cyber and RMGT for their continued investment in this industry and what they enable businesses like us to do. There has been a lot of consolidation in this industry and ongoing challenges for small commercial printers, including significantly rising input costs; the decline in demand for printed materials as electronic mediums continue to penetrate our lives; and the ever increasing shortage of skilled print trades people.

“This partnership between RMGT, Cyber Australia, and LEP shows these printers how our investment in new machinery and producing quality work can give them the confidence to transition from a high cost, high risk printing operation to a low cost, sales focussed business where margins and profitability are higher by outsourcing work to LEP.”

Bromfield added Cyber Australia has also always gone out of its way to support LEP in its endeavours.

“With Cyber, we’ve always had the faith that they’ve got our back. There has always been a depth of specialist mechanical and electrical engineers available to support us in unlikely times. It’s hard to put a value on that loyalty,” he said.

Benefits of LED UV technology

The adoption of LED UV technology will allow LEP to:

• Provide sharper print quality and consistency across all jobs

• Deliver faster turnaround times with “dry-to-dry” efficiency

• Offer more competitive pricing and enhanced value to clients

• Expand into new markets with the ability to print on a wider variety of substrates

• Reduce environmental impact through lower energy usage and eco-friendly processes.

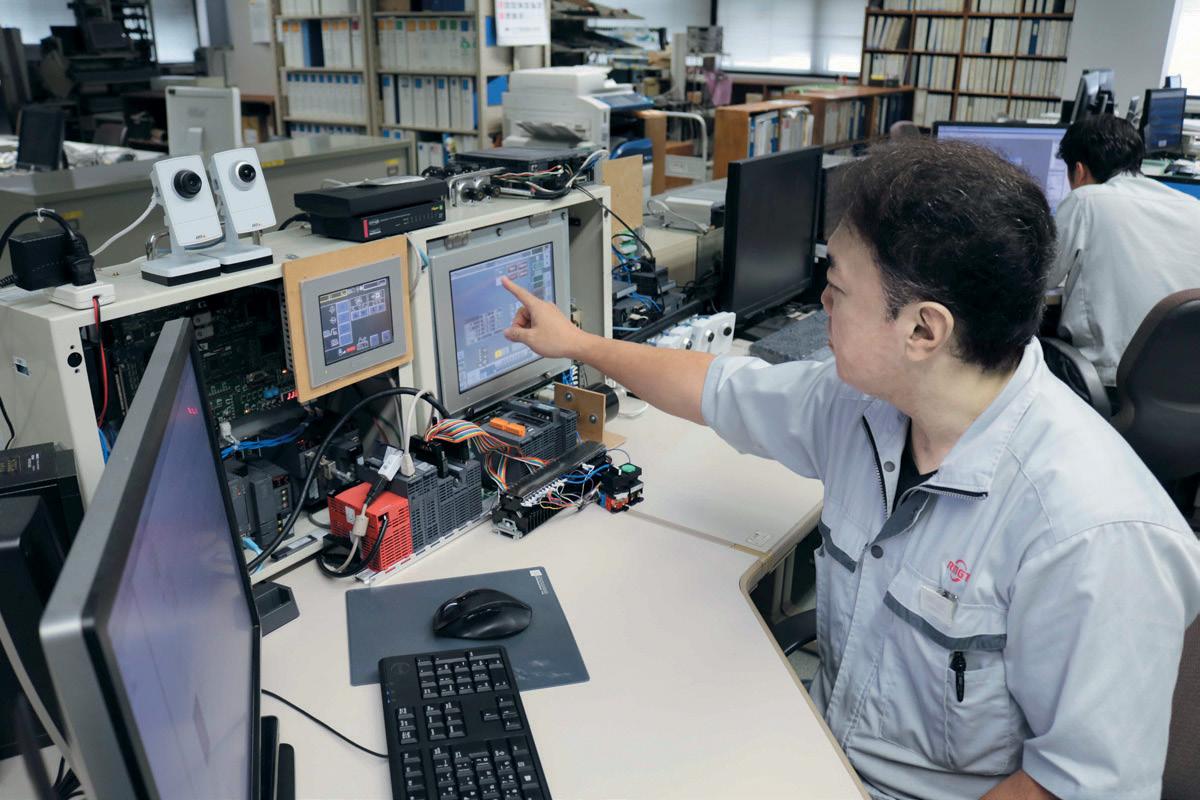

The RMGT 9 Series features press information display that enables operations to be monitored

Cyber Australia’s Bernard Cheong

Invitation to a RMGT Factory that Builds In Reliability

Witness with your own eyes a fully integrated system from design and development to parts machining, assembly, and pre-shipping inspection.

RMGT’s Head Office Factory in Fuchu City, Hiroshima Prefecture, manufactures large and mid-size offset presses and is the company’s main facility. As printing presses require exacting precision, the Head Office Factory utilizes a fully integrated system from design and development to parts machining, assembly, and pre-shipping inspection. We invite you to visit the Head Office Factory, where you can see the technological expertise and creativity behind the manufacturing that builds in reliability to produce offset presses with proven functions and exceptional printing quality. We are constantly refining and improving our production lines, so even customers who have previously visited our factory are sure to discover something new.

Everyone at the Head Office Factory is ready to extend a warm welcome. An online video offers more detailed information about RMGT and our operations. The video can be accessed via the QR code at right. If you are unable to use the QR code, the video can also be accessed at the URL below. https://youtu.be/3FQfsABk-tk

Innovation and technology galore at Printing United Expo 2025

A spectacular display of innovation and technology was on show at the recent Printing United Expo in Orlando USA, with 838 exhibitors in attendance

Printing United Expo 2025 recently concluded in Orlando USA, showcasing a variety of innovations. The event attracted 838 exhibitors and more than 30,000 attendees, with organisers calling it a “record high”. Momentum is expected to be carried forward to next year’s event in Las Vegas.

Here’s what some leading exhibitors had on show this year:

Agfa

Agfa showcased its full inkjet portfolio, putting on display its Jeti Tauro H3300

XUHS, Jeti Bronco H3300 HS, Onset Panthera FB3216, and Anapurna Ciervo H2500 machines.

The Jeti Tauro H3300 XUHS showcased speed and automation, featuring the Flex RTR system for seamless roll-to-roll printing and the MAX Bot stacker for advanced media handling. As the boldest member of the Tauro family, it is designed for 24/7 hybrid productivity.

The Jeti Bronco H3300 HS is a wide-format hybrid printer designed for sign shops and digital printers looking for a combination of versatility, productivity, and excellent print quality. With a 3.3m print width, UV LED curing, and a six-colour plus white ink set, this print engine is suitable for a wide range of indoor and outdoor print applications.

The Onset Panthera FB3216 is a true flatbed equipped with an autoloader that maximises throughput while maintaining precision and energy efficiency. The machine is ideal for high-volume POS, retail graphics, and packaging applications.

Completing the line-up, the Anapurna Ciervo H2500 brings agility and versatility

in a compact format. This model appeared in a limited-edition wrap by street artist DZIA, marking 20 years of Anapurna innovation.

Smartech Business Systems is the distributor for Agfa in the A/NZ region.

Canon

Canon unveiled the Colorado XL-series, a new 3.4m printer platform that extends the proven benefits of its UVgel technology to the 3.2m graphics segment.

Available in hybrid and roll-to-roll configurations, the modular, field upgradable platform powered by

The Agfa Jeti Tauro H3300 XUHS

The Canon stand at Printing United 2025, showcasing the Colorado XL-series

More than 30,000 attendees and 838 exhibitors were at Printing United Expo 2025

UVgel technology delivers versatility and productivity for both flexible and rigid media applications.

The Colorado XL-series comprises two models: the Colorado XL7 roll-to-roll printer and Colorado XL7 hybrid printer. The new series brings the benefits of UVgel to a new market segment with exceptional application versatility across a comprehensive range of media, providing the flexibility to tackle diverse customer requirements.

With print speeds of 70m²/23 boards per hour in quality mode, 106m²/35 boards per hour in production mode, and up to 211m²/70 boards per hour in express mode, the system delivers the productivity needed for demanding production environments while accommodating substrates up to 52mm thick for rigid applications.

Optional features for the Colorado XLseries include UVgel White, FLXfinish+ for creative effects using matte or gloss or mixed matte and gloss on the same print without additional varnish, and FLXture for textured finishes.

The Colorado XL-series will be available in the Oceania region by mid-2026 and will be available from Canon Production Printing.

DigiTech

DigiTech featured its TruFire LT3/X2 and TruFire LT3/X3 flatbed printers with conveyors and cutters.

The TruFire LT3/X3 builds on the impressive features of its predecessor, the TruFire LT3/X2, with more added capabilities. It was launched in 2024 with three rows of printheads and a speed increase of up to 150 boards per hour printed and cut. Like the LT3/X2, it is ideal for large capacity jobs.

It is also a true flatbed and is available in various configurations.

As for the TruFire LT3/X2, it is ideal for large capacity jobs. The auto unloader operator can change sheets of media in under 10 seconds. This printer is designed for large print shops as it is capable of

running all day at more than 60 sheets per hour printed and cut (including unloading and reloading time). The machine also uses advanced UV technology to deliver bold, vibrant prints that are built to last.

In Australia, DigiTech’s local distributor is Celmac.

Durst

Durst placed its newly launched XT Concept at the heart of its showcase at this year’s Printing United. The XT Concept represents the next evolution of Durst’s successful P5 platform, integrating expanded capabilities, enhanced productivity, and advanced automation.

At the show, the P5 350 HS with D4 technology embodied this XT philosophy – a high-performance hybrid printer that redefines productivity standards while maintaining Durst’s hallmark of uncompromising print quality.

Durst also spotlighted its Open Software Initiative in a dedicated booth. The new platform gives customers the freedom and flexibility to connect software and solutions with third-party platforms.

The Smart Factory Portfolio further empowers print providers to establish open, scalable, and fully integrated digital ecosystems tailored to their specific business needs and further demonstrates how Durst’s integrated solutions drive operational excellence and unlock new business potential.

Four key systems featured prominently in the booth, underscoring Durst’s ongoing commitment to performance, sustainability, and workflow efficiency.

Making its North American debut, the Durst P5 500 TEX iSUB is an extension of the multiple award-winning P5 TEX iSUB printer. The 500 takes the platform superwide, combining 5m-wide sublimation printing with fully integrated inline fixation. Offering excellent colour consistency with sharp details in images and text, the P5 500 TEX iSUB produces beautiful prints in the most sustainable and efficient way.

Appearing for the first time at the show was the Durst P5 X. The Durst P5 X brings

the benefits of the Durst P5 platform into a smaller footprint workhorse. This true flatbed offers optional roll-to-roll print production and ergonomic handling for ease of use. With up to 10 channels that can include white ink, varnish for special effects and Fluo Glow neon inks, the P5 X offers astonishing versatility.

Returning to this year’s Printing United was the Durst P5 350 HS. This printer offers speeds up to 930 sqm/h and maximised productivity through the implementation of a double CMYK (D4) colour configuration.

Also making a return this year was the Durst Tau 340 RSC E label printer, which offers a real print speed of 170 ft/min (upgradeable to 262 ft/min) and native resolution of 1,200dpi by 1,200dpi, setting the benchmark for digital label printers.

EFI

EFI showcased multiple productivity and automation enhancements designed to increase the value and versatility of its broad portfolio of production-level digital inkjet printers.

Visitors saw:

• The EFI VUTEk Q3h XP high-speed hybrid flatbed/roll-fed LED printer that combines image quality, flexible production-level throughput, and advanced media handling and automation options. New at the show was the printer featuring software that delivers faster RIP times and improved smoothing levels.

• The 3.2m EFI VUTEk M3h hybrid flatbed/roll-fed LED printer designed for PSPs moving into higher-volume production and looking for new capabilities to lower costs, increase margins, accelerate turnarounds, and enable printing on a broader range of flexible and rigid applications. New options available for the VUTEk M3h printer were demonstrated at the show.

• The 3.5m EFI VUTEk X3r roll-to-roll LED printer engineered for high-volume production of indoor and outdoor sign and display graphics. The VUTEk X3r printer integrates automation,

The DigiTech TruFire LT3/X3 on the Printing United 2025 floor

The Durst P5 350 HS with D4 technology showcased at Printing United

The EFI VUTEk Q3h XP on display at Printing United

software, and hardware to support minimal operator supervision of print job and an efficient print-to-finishedgraphic workflow system.

EFI also previewed several new automation and control innovations to boost throughput, including two new inline finishing options available for the VUTEk X3r and X5r printers.

A preview of EFInsight, a cloud-based intelligence for sign and display graphics printing, was also provided.

EFI machines are available locally through Currie Group.

Epson

printhead with Nozzle Verification Technology and an integrated temperature sensor control, it also produces highquality prints and consistent colour.

Fujifilm

Continuing the evolution of its SureColor S-Series line, Epson launched its latest SureColor S8160 solvent printer, calling it its “fastest 64-inch solvent printer”.

The company said with more than 20 per cent faster print speeds and improved print quality compared to the previous generation, the new SureColor S8160 is one of the most productive sign printers it has ever developed.

Touting a compact and efficient design, it features the latest generation print head and a 6-colour ink set to deliver outstanding image quality and productivity for medium to large shops producing signs, banners, stickers, vehicle wraps and more.

Built to maximise production capabilities, the SureColor S8160 delivers the highest productivity of the SureColor S-Series product lineup, according to Epson.

Its 6-colour UltraChrome GS3 ink set includes Light Cyan and Light Magenta, to help minimise banding, even at the fastest production speeds. The versatile, fast-drying ink set allows for same day lamination, and the ability to mix and match ink packs, available in either 800ml or 1,500ml, with hot swap technology that automatically switches from an empty ink pack to a new pack mid-print.

Featuring the latest generation, userreplaceable, PrecisionCore Micro TFP

Fujifilm showcased its platform of innovations including the Acuity TR and three Revoria presses.

The Acuity TR, powered by Fujifilm’s AQUAFUZE water-based UV ink and hardware, helps PSPs make more stunning prints with less complexity and greater sustainability. With low-energy curing, exceptional media versatility, and scratchresistant, low-odour finishes, Acuity TR lets users deliver more high-quality jobs, faster and smarter.

The Revoria Press PC1120, a highperformance 6-colour print machine that maximises print engine productivity by printing 120 pages per minute, was also on show, boasting high-output resolution at 2,400dpi by 2,400dpi and supporting a broad range of stocks.

The Revoria Press EC2100S, a new midrange production press that is equipped with a specialty CMYK+ toner station in addition to the four-colour toners, was also on display, enabling five-colour printing in one pass. It prints at a high speed of 100 pages per minute and is primarily utilised for commercial and quick printing.

In addition, the Revoria Press SC285S, a newly launched mid-range production press that also enables five-colour printing in one pass thanks to a specialty toner station in addition to the four-colour toners, was on display. It can print speeds of 85 pages per minute and is utilised for quick printing and in-house printing.

Heidelberg

Heidelberg presented a dynamic digital showcase, highlighting its full Prinect Suite workflow – including Prinect Touch Free, Jetfire 50, Versafire LP, Stahfolder TH 66 Fireline, and Heidelberg Customer Portal.

Prinect Touch Free is an AI-driven central control system that enables PSPs to

harmonise digital and offset print jobs into one workflow. It automatically optimises production processes, adapting to changes in real-time across three stages to ensure the most efficient method from PDF to finished product.

The Jetfire 50 is a future-proof production machine for commercial printing. Boasting high productivity with a print speed of up to 4,560 ARS3 sheers per hour duplex and an enormous application media flexibility and reliability, this machine enables fast, profitable production.

As for the Versafire LP, it is a highperformance four-colour digital printing system tailored for the commercial sector. With a productivity of up to 2.6 million A4 pages per month, it excels in handling high volumes.

The recently launched Stahfolder TH 66 Fireline is tailored to the needs of digital finishing by directly going from the digitally printed sheet to the finished cut and/or folded product in a single operation. This solution enables the automated production of short and very short runs with variable cut and folded products.

Finally, the Heidelberg Customer Portal is an all-in-one digital portal that provides easy access to production and workflow apps, analytics, service and maintenance, shopping, and administration tools. It simplifies operations with a single interface to streamline print shop responsibilities.

HP

HP Large Format celebrated an unprecedented year of innovation and customer success at Printing United 2025.

The new Epson SureColor S8160

The Fujifilm Acuity TR

The Heidelberg team at Printing United 2025

HP’s stand at Printing United 2025

With more than 80 per cent of HP’s booth showcasing new products, HP said it marked its most transformative portfolio launch to date, setting a bold new standard for productivity, automation, and sustainability in print.

This year’s lineup included the HP Latex R530, HP Latex 730 and 830, HP Latex FS70 W, HP Latex Productivity Kit, and the HP PrintOS Production Hub, each designed to push the boundaries of what’s possible in large-format printing.

Highlights included:

• Driving the next era of automation: HP is setting itself apart by leading the way in connected AI-enhanced solutions through the new HP PrintOS Production Hub. This platform represents HP’s commitment to integrating artificial intelligence into real-world print workflows helping customers achieve smarter, more efficient production.

• Performance on display: The HP Latex FS70 W made its global debut and ran at full production capacity throughout the event, printing a total of 2,000sqm in three days.

• Collaboration that drive growth: HP announced a new agreement with Wallquest Inc., showcasing how the HP Latex FS platform enables scalable, high-quality growth for interior décor applications. The company purchased four new HP Latex FS Series, underscoring the strategic value of HP technology in powering long-term, sustainable partnerships.

HP also spotlighted its collaborations with Neolt Factory and the Summa F Series Cutter for the HP Latex R530, expanding its ecosystem of cutting and finishing solutions that empower end-to-end productivity.

Kongsberg PCS

Kongsberg Precision Cutting Systems (PCS), together with its subsidiary MultiCam, showcased their Kongsberg Ultimate, Kongsberg Entro, and MultiCam Apex3R Evo solutions.

Making its global exhibition debut, the Kongsberg Entro is an entry-level cutting solution designed to deliver precision, quality and durability for small volume outfits, while combating more rigid applications such as corrugated plastic, acrylic panels and plywood.

The Entro 24 delivers enhanced performance and maintains the userfriendly operation and reliability that Kongsberg PCS’ signage, graphics and packaging customers expect.

The Kongsberg Ultimate is an awardwinning cutting table that has been carefully engineered to answer the unique needs of display and corrugated producers. From its material selection –encased in more durable and sustainable aluminium – to its simplified and intuitive design and increased safety features.

The Kongsberg Ultimate is designed for continuous high-volume multi-batch production, enhanced productivity and optimised maintenance and intervals across a variety of materials, including vinyl and oppboga.

As for the MultiCam Apex3R Evo, it is a high-performance CNC router designed to deliver exceptional cut quality and superior edge finishes with its specifically designed condensed knife system and upgraded tapping features to simplify and streamline production.

Compatible with a wide range of applications, the Apex3R Evo offers highquality routing capabilities across a variety of dense substrates, such as wood and aluminium, as well as precision capable of a mirror-edge finish on thick acrylic.

Konica Minolta

Konica Minolta unveiled a new collaboration with Color-Logic and Unifoil at Printing United, demonstrating the advanced capabilities of its AccurioPress C14010S.

This partnership was highlighted through an exclusive, limited-edition print series featuring artwork by world-renowned comic book cover artist Greg Horn. The series, which debuted at Printing United, showcased the exceptional precision,

colour range, and metallic embellishment possible with the AccurioPress C14010S.

Each day of the show, attendees had the opportunity to collect a different Greg Horn design, produced live on the show floor using Unifoil’s new UnilustreD metallic stock and CMYK plus white toner for an embellished look.

These effects were made possible by the advanced capabilities of the AccurioPress C14010S, which brought Horn’s dynamic artwork and Color-Logic’s dazzling enhancements to life with unmatched clarity and vibrancy.

Konica Minolta’s AccurioPress C14010S streamlines operations, boosts productivity with automation and opens new revenue streams with the introduction of fifth colour, white toner printing. This collaboration showcased the powerful features and cutting-edge performance of this highvolume, toner-based production press.

Mimaki

Mimaki took to Printing United 2025 to launch its new UJF-7151plus II e nextgeneration flatbed UV printer that aims to set a new benchmark for direct-toobject and industrial printing.

The UJF-7151plus II e builds on the reliability of its predecessor while solving three key challenges that have long affected the market: maintaining consistent precision at high printing speeds, printing on curved or uneven surfaces, and reproducing sophisticated threedimensional textures.

The new model achieves resolutions of up to 1,800dpi, made possible by its robust structure and high-precision position control. It also supports light cyan and light magenta inks, alongside CMYK, enabling smooth and natural reproduction of delicate gradations such as skin tones and landscapes.

In practical mode, the printer can print 19 sheets per hour (710mm by 510mm), offering a fast and flexible digital alternative to screen printing for ondemand, short-run production. It also enables emboss printing up to 5mm,

The MultiCam Apex3R Evo CNC router on the Printing United floor

The Konica Minolta stand at Printing United

The Mimaki UJF-7151plus II e next-generation flatbed UV printer

allowing richly textured surfaces and three-dimensional effects.

With its new LD Mode, the printer maintains the same level of precision during direct printing on substrates with height differences of up to 10mm, ensuring stable results on curved, stepped, or moulded parts.

Equipped with Mimaki’s printable primer, when printing two colour layers plus primer and white, the process is approximately 3.7 times faster than with previous models. The Ink Saving Function cuts ink use by up to 40 per cent, maintaining colour accuracy and image quality while lowering operational costs.

In addition to the new features, the UJF7151plus II e integrates Mimaki’s core technologies, including the Nozzle Check Unit (NCU) and Nozzle Recovery System (NRS) for uninterrupted printing, the Colour Gloss function for achieving glossy or matte finishes without clear ink, and RasterLink 7 RIP software, which supports variable data printing and efficient workflow automation.

Müller Martini

Müller Martini presented the Antaro Digital perfect binder and the GEN8 EVO roll-to-stack solution from Hunkeler.

The Antaro Digital perfect binder is a compact, extremely flexible machine. In the OnDemand mode, it achieves an output of 2,000 cycles per hour.

The Antaro Digital features a continuously running swivel clamp system. The book blocks are transported in horizontally, standing on their spines and are reliably retained by the six clamps, which are always fully open.

Furthermore, the large clamp pitch of 610mm ensures the continuous production of brochures with a block thickness variance of up to 20mm. The thicknesses are always changed over fully automatically.

The newly developed Antaro Digital can be used as a nearline or inline system, thereby covering a broad range of customer requirements. Thanks to its

compact design, it realises a unique output rate over a comparatively small area.

As for the GEN8 EVO roll-to-stack solution from Hunkeler, it aims to set new standards in production efficiency. Its debut follows Müller Martini’s acquisition of Hunkeler in December 2023.

With its robust design and increased speeds, it maximises the availability and performance of production. The efficient mode of operation ensures consistently high-end product quality, not only guaranteeing optimised productivity, but also a reduction in operating costs due to less waste and downtime.

Summa made its North American debut of the new F1625 flatbed cutter at Printing United, while also showcasing its comprehensive range of solutions for signage, display, packaging, and textile professionals.

Specifically engineered for wide-format printing professionals, the F1625 is a 160cm by 250cm flatbed cutting solution that combines ease-of-use, precision, and modular versatility. It handles both rigid and roll media including vinyl, PVC, acrylics, foam board, and ACM, empowering users to expand their production capabilities with confidence.

It offers all the hallmark features of the F Series, including its powerful, easyto-use GoProduce software, over 15 interchangeable tools, and the ability to cut more than 100 materials with precision and speed.

Like all models in the F Series, the F1625’s modular design can handle three tools at the same time. Its swappable tool system allows for kiss-cutting, creasing, routing, and more – all supported by Summa’s extensive range of professional-grade tools and accessories.

In addition to the F1625, Summa presented a full line-up of cutting solutions including its S1 vinyl cutter, S3 TC vinyl cutter, S3 DTF cutter, Optima flatbed cutter, Omnia Evo flatbed cutter, and the L1810 laser cutter.

Summa is available locally from Pozitive sign & graphic supplies.

Vanguard Digital Printing Systems

Vanguard Digital Printing Systems, a Durst Group company, launched a new powerhouse printer – Natchez – at Printing United. The latest printer in its productivity redefined line, this UVLED flatbed printer delivers the speed, precision and performance that print service providers need.

Natchez was engineered with the most challenging substrates in mind, from wood to corrugated boards. With the ability to add up to three rows of Kyocera 4pl variabledrop printheads, Natchez offers remarkable speeds and resolutions up to 1,800dpi.

Combined with an enhanced vacuum table, machined to a flatness of ±50 microns, Natchez delivers precise dot placement and perfect registration from print to print.

Some key features of Natchez include:

• Enhanced vacuum table with 127,000 1/8th-inch holes for superior media stability

• Turbo 5-horsepower blower motor for maximum substrate hold-down

• Dual-zone vacuum system for simultaneous setup and printing

• Magnetic linear drive control for precise drop placement for sharper lines and text

• Optional White + Varnish ink channels in addition to CMYK channels for expanded application versatility

• Eco-friendly LED curing system for energy savings and reduced consumables

• Available in two models, the Natchez 300 and Natchez 3220

The VIPA inks used in the Natchez printer are UL GREENGUARD Gold certified and meet stringent low chemical and VOC emission standards. Products with this certification are proven to contribute to healthier indoor air quality by emitting extremely low levels of thousands of chemicals, making them ideal for printed materials in sensitive environments like nurseries, schools, and healthcare facilities.

Summa

The GEN8 EVO roll-to-stack solution on display at Printing United

The Natchez was launched at Printing United

The Summa team at Printing United

VANGUARD

Hilton Laminating installs HPL SADF laminating system at Chase Print

The installation of the HPL SADF 540 Fully Automatic Laminating System has enabled Chase Print to process jobs more efficiently and with greater reliability

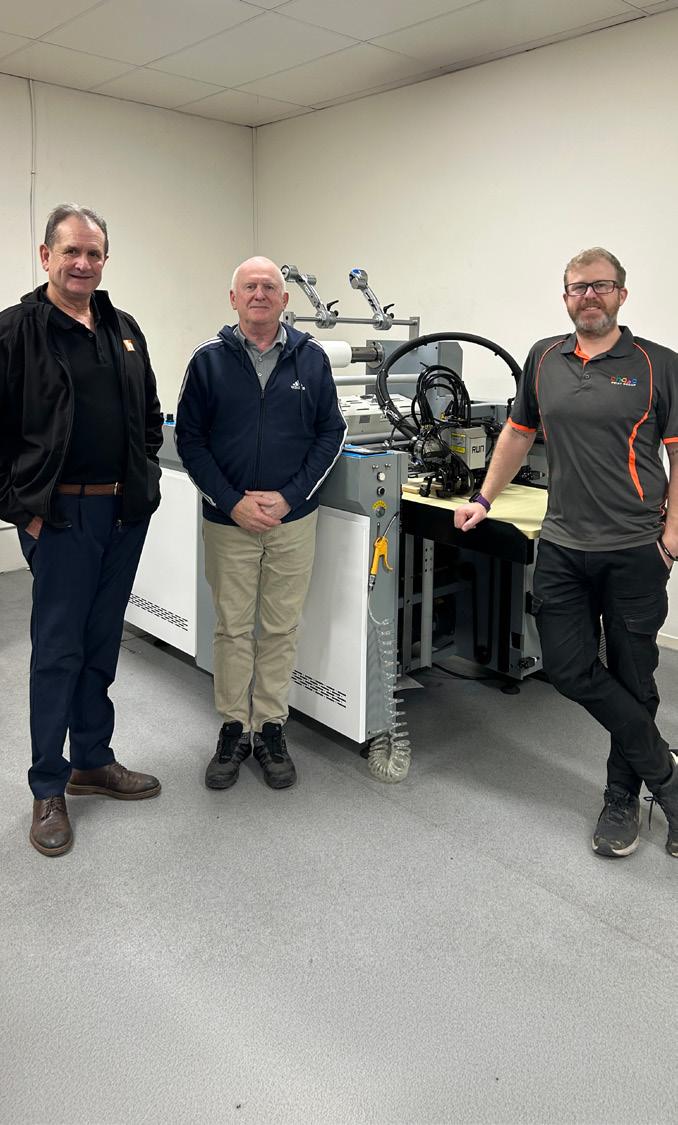

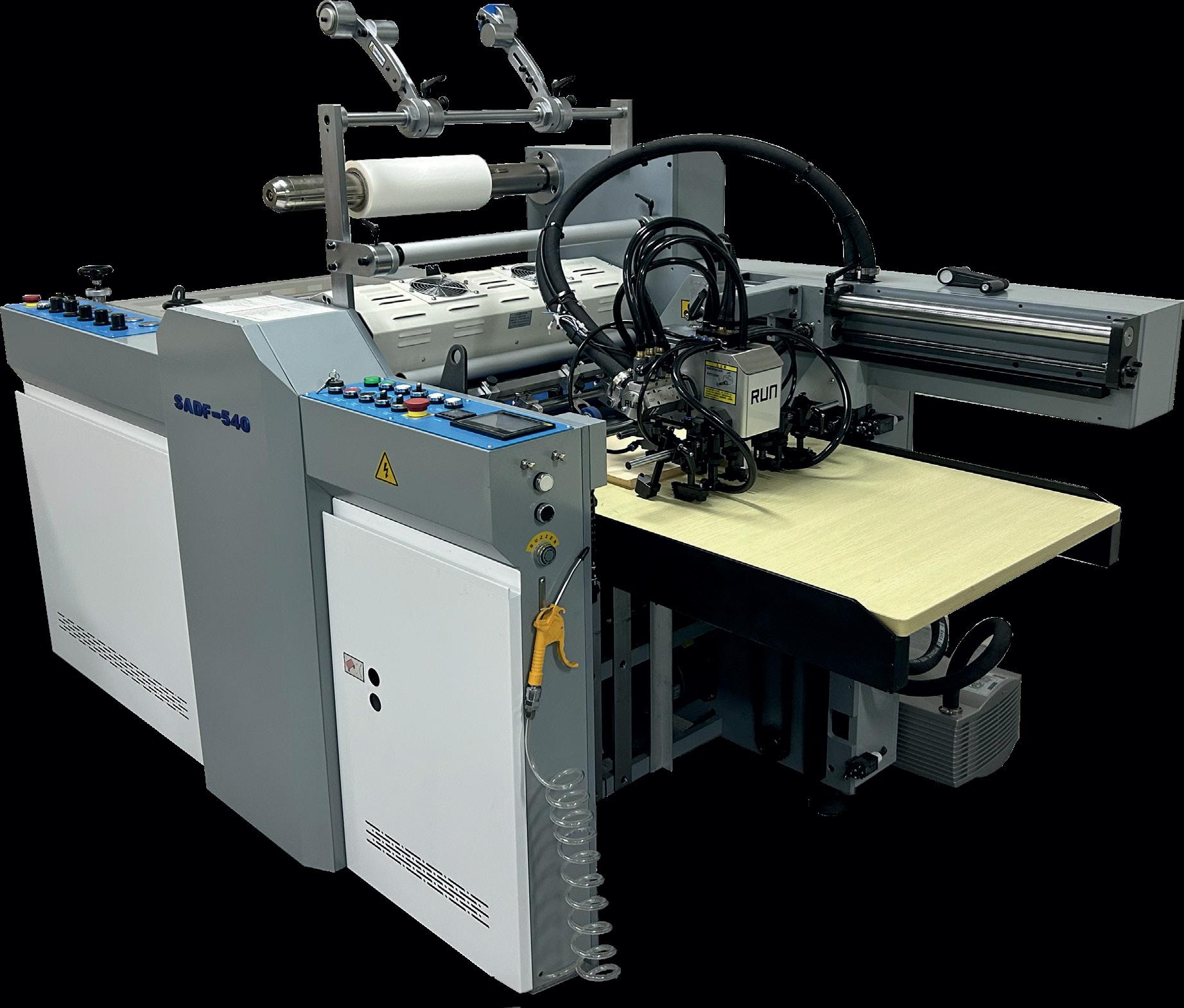

Chase Print Group has purchased an HPL SADF 540 Fully Automatic Laminating System from Hilton Laminating, which was recently installed at Chase Print’s Yarraville premises in Victoria.

Chase Print is a proud family-owned business that has been in operation since 1989 and is one of Melbourne’s leading providers of digital, offset, and large format printing today.

Chase Print co-owner Daniel Shadbolt said prior to having the fully automatic laminating system, the company was relying on an old, second-hand machine that lacked consistency and reliability, which often led to high levels of material wastage.

For smaller jobs, it previously used a desktop laminator that was entirely manual and significantly slower – resulting in an inefficient use of staff time.

Larger runs also had to be outsourced because Chase Print’s existing equipment simply couldn’t handle the volume or duration required, limiting its capacity and impacting turnaround times.

As such, after evaluating the business’ needs, Chase Print purchased the HPL SADF 540 Fully Automatic Laminating System from Hilton Laminating – a business dedicated to delivering cutting-edge, automated solutions that transform the laminating process.

The machine was installed early September, with full production commencing shortly after installation and training.

The decision to go back to Hilton Laminating was an easy one for Chase Print, having worked with Hilton on its finishing needs over several years.

“Chase Print has been a valued Hilton Laminating customer for the last couple of years. It initially purchased smaller binding equipment and binding and laminating consumables. The company also had an existing laminating machine which was proving inadequate for its growing business needs,” Hilton Laminating business development manager Rob Gazet du Chattelier said.

“Chase Print then reached out, looking for a way to streamline its laminating and to

improve turnaround times, which naturally led to a discussion about upgrading to a fully automatic system. After reviewing their production requirements, the HPL SADF 540 was the perfect fit.”

The HPL SADF 540 Fully Automatic Laminating System is designed for highspeed, precision laminating with minimal operator input.

Featuring fully automatic feeding and stacking, it ensures a smooth, continuous workflow, while the servo-controlled feeder with a photoelectric sensor provides consistent and accurate sheet feeding.

Its advanced electromagnetic heating system delivers rapid warm-up times and exceptional energy efficiency, and the intuitive touchscreen interface allows for simple operation and quick setup.

The built-in de-curler guarantees perfectly flat finished sheets, even at production speeds of up to 30m/min.

With three tonnes of pneumatic pressure, the system produces a flawless, high-quality finish, and because the laminating film only makes contact at the nip, make-ready and

roll changeovers are fast and effortless maximising uptime and productivity.

According to Shadbolt, since the install, Chase Print has been able to process jobs more quickly and with greater reliability.

“The machine delivers consistent, highquality results from the first sheet to the last, with minimal to no spoilage. Additionally, film changeovers can be done while the machine is still hot, virtually eliminating downtime between jobs and allowing for a more efficient workflow,” Shadbolt said.

“Jobs are being turned around much faster, which our clients have certainly noticed and appreciated.

“By eliminating the need to send work to a trade house, or tying up staff to wrestle with our old machine, we’ve been able to streamline production and reduce lead times by up to two business days. This has allowed us to deliver faster, more reliable service without compromising on quality.

“Its faster processing speed has also allowed us to take on more work and boost throughput without compromising on quality.

“Additionally, its capacity to handle larger sheet sizes aligns perfectly with our longterm growth plans, ensuring we won’t need to invest in another laminator when we transition to A2 printing.”

Gazet du Chattelier said Hilton Laminating prides itself on its fully automatic laminating systems as they streamline production, providing flawless results faster, allowing teams to focus on their core priorities.

“With intuitive controls and custom settings, every job becomes effortless and precise,” Gazet du Chattelier said.

“This deal with Chase Print reinforces Hilton Laminating’s reputation as a trusted partner for quality print finishing solutions.

“Every successful installation highlights our commitment to helping Australian print businesses stay competitive through smart technology, dependable service, and tailored advice. We are thrilled to see this system supporting Chase print’s high-quality print production.”

(l-r) Rob Gazet du Chattelier (Hilton Laminating), with Daniel and Geoff Shadbolt (Chase Print Group) and the HPL SADF 540 Fully Automatic Laminating System

FUTURE-READY

AUTOMATION THAT WORKS AS HARD AS YOU

Power through production with the HPL-SADF 540. A fully automatic laminator built for speed, precision, and strength. Running up to 30 metres per minute with three tonnes of pneumatic pressure, it delivers a perfect finish at an industrial pace.

Pegasus replaces legacy equipment with new Agfa Jeti Tauro from SMARTECH

Pegasus Media & Logistics has chosen a Jeti Tauro 3300 UHS from Agfa for its automation, speed, and exceptional print quality with robust analytics and cost-effective consumables

Pegasus Media & Logistics has installed a new Agfa Jeti Tauro 3300 UHS with full automation from SMARTECH Business Systems, following a comprehensive review of leading suppliers of large-format printing technology.

The system’s automation, speed, and exceptional print quality, combined with robust analytics and cost-effective consumables were key factors in Pegasus’ decision. CEO Michael Sherlock described the printer as the “ideal replacement” for its legacy equipment.

“By investing in this state-of-the-art technology, we are not only enhancing efficiency and precision within our operations but also expanding our capacity to take on more complex and higher-volume projects,” Sherlock said.

“The Jeti Tauro 3300 UHS is an advanced system that delivers a high-gloss varnish finish. Coupled with reliable service and technical support, we can ensure that we consistently uphold the high standards our clients expect.

“This investment positions us to deliver greater value to our existing clients while opening new opportunities for growth and collaboration across a wider range of industries.”

Agfa’s Jeti Tauro 3300 UHS offers 24/7 productivity and award-winning quality on a wide range of rigid and flexible materials, while maintaining the lowest ink consumption in its class. The UHS models can also be configured with an optional second gantry for maximum throughput.

With print speeds up to 905m²/h and eight rows of print heads, the Jeti Tauro 3300 UHS is available in four-, six- or seven-colour configurations. It also supports Varnish, Primer, and White options for maximum versatility and premium finishing effects.

Now fully operational at Pegasus’ Blacktown site in NSW, the printer has already begun producing a diverse range of work, elevating the company’s output particularly in the point-of-sale (POS) and large-format market segments.

“With the Jeti Tauro 3300 UHS, we’re expanding what’s possible,” Sherlock said.

“From high-impact POS displays to bespoke projects across entertainment, food, agriculture, and pharmaceuticals, we now deliver greater capacity, faster turnarounds, and premium finishes on every sheet – whether flat or pre-mounted.”

Sherlock praised the installation process managed by SMARTECH, noting the team’s professionalism and communication throughout.

“The SMARTECH team demonstrated a high level of engagement, professionalism, and support throughout the installation. Their timely communication and consistent updates ensured our team remained well-informed at every stage,” he said.

“I would gladly recommend SMARTECH to others. Their attention to detail and customer focus made this an exceptional overall experience.”

Encouraged by the success of the project, Sherlock added that Pegasus remains open to future investments.

“Our business is committed to continuous development and innovation. As new technologies emerge, we will actively evaluate and adopt advanced machinery that enhances our capabilities,” he said.

“By embracing these advancements, we ensure our operations evolve with industry progress – delivering greater efficiency, quality, and value to our clients.”

Brett Wark, SMARTECH’s NSW Sales Manager and National Product Manager for Sign & Display, described the Jeti Tauro 3300 UHS as the perfect solution for large print service providers like Pegasus.

“This installation represents a major milestone for SMARTECH, our partnership with Agfa, and our relationship with Pegasus,” Wark said.

“We’re incredibly proud of this achievement and look forward to supporting Pegasus in meeting customer needs with world-class technology.”

(l-r) Brett Wark (Smartech) and Michael Sherlock (Pegasus Media & Logistics) with the Agfa Jeti Tauro 3300 UHS with full automation

Universal Approach expands fleet with new Konica Minolta AccurioPress C14000

Universal Approach, in its 20th year of operations, has not only doubled its productivity since the install of a new Konica Minolta AccurioPress C14000 with a Fiery digital front end (DFE) server, but has also cut its turnaround times considerably

Victoria-based commercial printer Universal Approach recently invested in a new Konica Minolta AccurioPress C14000 with a Fiery digital front end (DFE) server in January, boosting its productivity and cutting its turnaround times.

Located in Dandenong, Universal Approach is a one-stop-shop for all print, finishing, mailing, and packing needs. The business hit its 20-year milestone this year, growing from a home-based office in its early days to quickly becoming an industrial facility servicing a wide range of industries with affordable pricing, quick turnarounds, and professional expertise.

Early last year, Universal Approach realised it was facing increasing pressures to keep up with customer demand in a time-critical industry.

The business’ role as a mailing house makes it the last step in the production chain, meaning deadlines are tight and turnaround times are short. Larger jobs, such as half a million sheets, placed enormous strain on the production floor and often required operators to stay back after hours to meet commitments.

Universal Approach managing director Amit Gupta said, “Productivity was the real issue for us. We were struggling with time, especially for bigger jobs. As the last link in the chain, we get the least turnaround time, so we needed to be highly productive”.

The team also faced ongoing challenges with ensuring consistent quality across devices and keeping jobs moving without jams or delays.

“Quality is primary for us. We would not send anything out the door which is low quality. Whether it’s time critical or not, we need to be happy with the work before we expect others to be happy with our work,” Gupta said.

“Outsourcing some work was an option, though this would have meant reduced control, lower margins, and less confidence for customers. Universal Approach needed a way to scale output

speed, reduce operator intervention, and continue delivering on quality-critical jobs to protect its reputation and maintain competitiveness.”

As such, Universal Approach reviewed its business’ growth trajectory and increasing job volumes before deciding to invest in additional production capability, rather than rely on outsourcing.

The company had already tried other production houses; however, chose to purchase a press from Konica Minolta Australia following a six-year relationship, quality equipment, and reliable technicians.

Universal Approach chose to expand its fleet with the AccurioPress C14000 with Fiery digital front end (DFE) server, getting it installed in January alongside its existing AccurioPress C4070 and C3080 machines.

The AccurioPress C14000 provided Universal Approach with the speed and throughput it required to halve turnaround times for jobs of up to 500,000 sheets, while larger stackers and improved reliability reduced the need for afterhours operator time.

The addition of the Intelligent Quality Optimiser (IQ-501) with Auto Quality Adjustment (AQA) further automated colour calibration and consistency checks, saving valuable production hours and removing the need for constant manual intervention.

“It saved a lot of headaches for the production team. The machine can check it and match automatically, which saves a lot of time and effort. It was a smooth implementation; I don’t think we faced any hiccups. We were very comfortable using it, and the support from the technicians has always been excellent,” Gupta said.

“Investing in such a big piece of equipment shows our clients we’re serious about the business and our future. It’s helped us increase productivity, deliver consistently, and build trust. We’re very happy with Konica Minolta, otherwise we wouldn’t be buying our third machine from them.”

The Konica Minolta AccurioPress C14000 with a Fiery digital front end (DFE) server at Universal Approach’s premises

The warehouse section of Universal Approach

Amit Gupta (Universal Approach)

The outside of Universal Approach’s site

Universal Appproach is a commercial printer based in Dandenong, Victoria

AMBITION

INTELLIGENT AUTOMATION

Intelligent Quality Optimiser and Auto Quality Adjustments

Scan to find out more

SUPERB COLOUR REPRODUCTION

Deliver quality, accuracy and consistency on deadline

HIGH-SPEED OUTPUT

Up to 90/100ppm colour

WIDE MEDIA FLEXIBILITY

Up to 400gsm, specialty and long sheet/banner

INLINE FINISHING

Large range of finished applications

RELIABLE PERFORMANCE

Built for heavy-duty use and compact efficiency at speed

IVE Group, Koenig & Bauer, and LIA Victoria band together for technical tour in Melbourne

Attendees were given an exclusive inside look at IVE Group’s world class facility, spanning more than 40,000sqm in Braeside and its latest Koenig & Bauer Rapida presses

IVE Group, Koenig & Bauer, and LIA Victoria joined forces for a technical tour in Melbourne, showcasing the very latest offset print technology.

IVE Group opened the doors of its state-of-the-art printing facility in Braeside for the LIA technical event featuring live demonstrations of its new Koenig & Bauer Rapida presses – a Rapida 106X 10-colour commercial press with in-line coater, and a Rapida 106X 7-colour packaging press with two in-line coating devices – and a presentation by product specialists.

The event was attended by the IVE team including CEO Matt Aitken, executive general manager – print and Jacpak Shane Britten, and head of operations (print VIC/CX and data) Shaun Hodge.