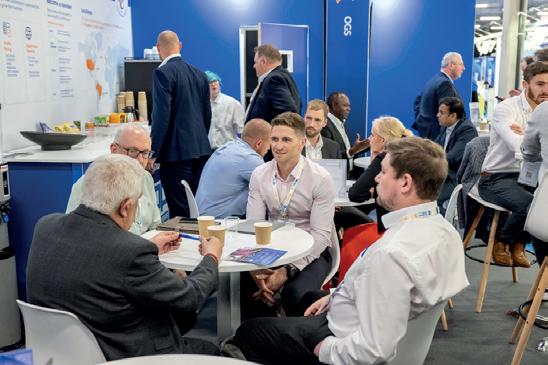

Under the theme Energy. Intelligence. Impact., ADIPEC 2025 returns to unite industries, investors, innovators and technologists to transform dialogue into delivery. It serves as a platform where solutions are showcased, strategic decisions are made and collaborations are catalysed to drive systemwide transformation and unlock long-term value.

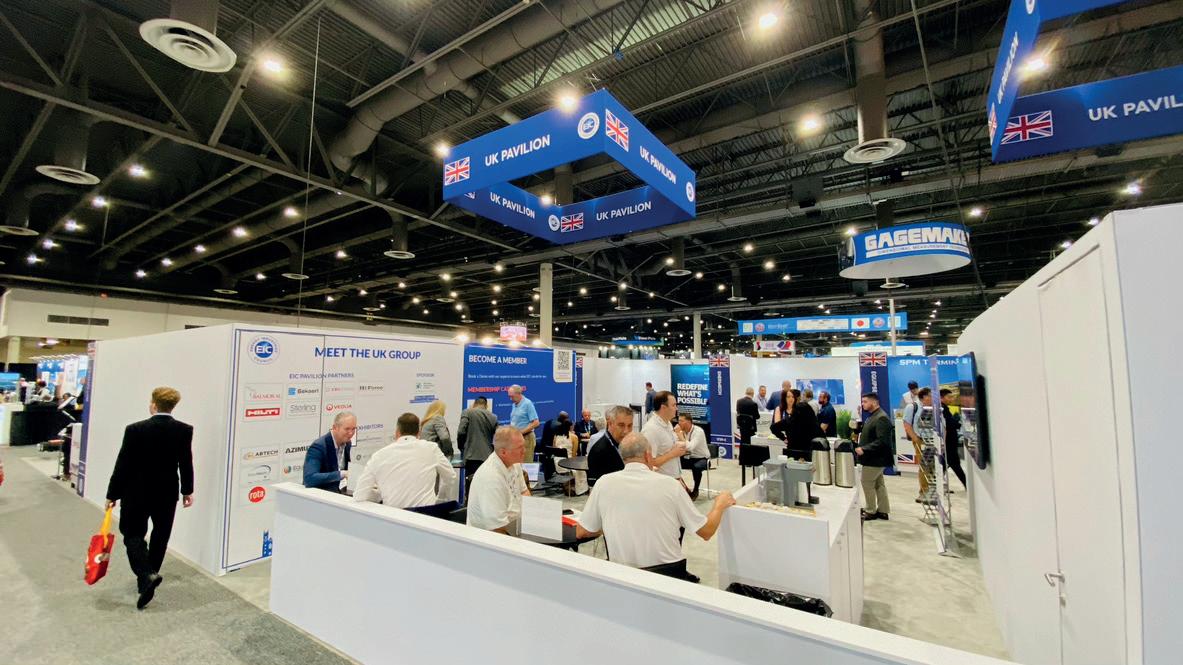

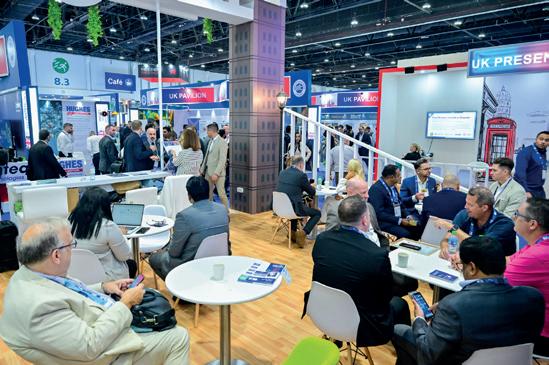

Once again, the Energy Industries Council (EIC) is proud to manage the UK pavilion at what is recognised as one of the world's largest and most prestigious energy events.

Over the course of four days, ADIPEC will welcome more than 205,000 attendees from across the globe, including leading energy producers, government representatives, major contractors and critical supply chain stakeholders. This unparalleled gathering offers extensive opportunities for collaboration, knowledge exchange and innovation.

Spanning multiple exhibition halls, the ADIPEC exhibition will host over 2,250 exhibitors representing the entire global energy ecosystem. This includes 54 NOCs, IOCs and IECs, 30 dedicated country pavilions, four specialised industry zones focused on decarbonisation, digitalisation, maritime and logistics and artificial intelligence.

Since 2000, the EIC's international trade team has proudly supported UK companies at ADIPEC, helping businesses showcase their capabilities and secure tangible returns on investment. What began as a biennial showcase has evolved into our largest international pavilion and this year promises to be no exception.

The UK pavilion will occupy Halls 8, 12, 15 and 17, hosting 125+ innovative companies alongside dedicated pavilions from Scottish Development International (SDI) and Wales Cymru. In addition, nine leading contractors will be providing exclusive one-to-one meetings throughout the week, ensuring the UK pavilion remains a hub of business activity and opportunity.

This is an exciting and pivotal moment for the energy sector, particularly in the Middle East. Insights from the recent EIC Survive & Thrive IX report revealed that companies operating in the region achieved an average growth rate of 68%, significantly outperforming the global average of 10-20%.

As the global energy transition continues to accelerate, opportunities are expanding across AI, decarbonisation and other transformative technologies. ADIPEC 2025 offers a unique platform to explore these innovations, forge strategic partnerships and contribute to shaping the future of energy.

Whether this is your first time at ADIPEC or you're a returning delegate, we invite you to explore the UK pavilion, connect with our exhibitors and meet the EIC team. We look forward to welcoming you and supporting your growth in one of the world's most dynamic energy markets.

Ryan McPherson, Regional Director, Middle East, Africa & CIS ryan.mcpherson@the-eic.com

The International Trade team is proud to once again be hosting the UK pavilion at ADIPEC, taking place on 3-6 November in Abu Dhabi

The EIC has been managing UK pavilions at ADIPEC for over 20 years, which has enabled us to witness its growth into one of the world’s most influential energy events as well as seeing how UK companies are leading the way by offering innovative products and services renowned worldwide for adding real value to projects and the local supply chain.

There are over 983 energy projects across all sectors under development in the Middle East region from 20252030 with an estimated CAPEX worth over US$1,367bn; ensuring that the Middle East continues to be a key area of focus for companies as they seek to maintain the UK supply chain’s position as a trusted and proven partner in the Gulf region.

In 2024, the EIC announced the expansion of the UK pavilion within three halls. We are delighted to announce that this year, the UK pavilion will be spread across four halls: Hall 8, 12, 15 and the newly created Hall 17.

The addition of this purpose-built hall, dubbed the ‘Future of Energy Hall’ reflects the growing need for diverse solutions to deliver a high-growth, lower-carbon future and we are thrilled to support UK companies in exhibiting within this exciting new development at the show.

An astonishing 125 companies will exhibit within the UK pavilion this year, making 2025 our largest pavilion to date.

The Scotland pavilion and Wales pavilion will once again join the UK pavilion in Hall 8 – hosting 26 and 12 co-exhibitors, respectively.

Located in a prime position at the centre of the exhibition halls, the pavilion is a constant hive of activity. The EIC invites its extensive network of contacts to the pavilion to develop bi-lateral trade through the following opportunities:

SPONSORS

• VIP pavilion tours with NOCs and IOCs, in previous years these have included ADNOC, ARAMCO, SABIC and PDO.

• One-to-one meetings between exhibitors and EPC contractors such as Kent, McDermott, Petrofac, Saipem, TechnipEnergies, Wood and Worley.

• An exclusive networking reception at the ALOFT Hotel, ensuring industry influencers and buyers from across the GCC can network with the UK pavilion exhibitors in an informal setting.

• An EIC ADIPEC Business Breakfast at Pearl Rotana Hotel on the morning of Day 1, providing a unique opportunity to hear from industry experts and participate in dynamic discussions.

We look forward to meeting many EIC members, UK companies, colleagues, friends and guests at ADIPEC 2025 and we wish those that are attending an exciting and productive event.

With thanks to all our sponsors:

• EIC Platinum Global Partner: Lloyd’s Register

• Platinum Lounge & Platinum Networking Reception Sponsor: Penta Global

• Gold Lounge Sponsor: Sensoteq

• Silver Lounge Sponsor: Fulkrum

• Silver Lounge Sponsor: Speedcast

• Bronze Lounge Sponsor: Airpac Rentals

• Bronze Lounge Sponsor: Woodcock & Wilson Ltd

• Silver Networking Reception Sponsor: Holyhead Towing

• Silver Networking Reception Sponsor: Mammoet

• Bronze Networking Reception Sponsor: AEG

• Bronze Networking Reception Sponsor: OEG

• UK Pavilion Media Partner: OGV

ABL Group 8539

Abtech 8338

Acteon 8450Scotland Pavilion

Advanced Sensors 8256

AGR 8450Scotland Pavilion

Airpac Rentals 8415

AISUS 8450Scotland Pavilion

AJT Engineering Limited 8450Scotland Pavilion

Alba Gaskets 8355

Alfa Laval 8550

Amnitec 8650Wales Pavilion

ASCO Engineering & Surface Technology 8438

Beamex 8554

BiSN 8616

Bodycote 8254

Brannan Instrumentation 15546

Brimmond 8635

Marine consulting and engineering, asset integrity management, marine survey, inspections and audits, marine warranty surveys (MWS), infrastructure and vessel design, geoscience consultancy, reservoir audits and subsurface consultancy, pre-FEED and FEED, EPC, risk and loss management, auction support, owner’s engineering, decommissioning, drilling and well engineering, recruitment and staffing, training, Software, decarbonisation, energy transition and environmental impact engineering

Electrical & Instrumentation, E&I junction boxes in stainless steel and GRP, medium and high voltage enclosures up to 72.5kV, hazardous area lighting, and local control stations, with selected products available with global certifications including ATEX, IECEx, and ECAS Ex.

Foundation Installation, Geotechnical surveys, Mooring Equipment, Scour and structural surveys and repairs, Decommissioning, Digital Services and Data Monitoring, Drilling, grouting and lifting, Engineering consultants, Foundation design, engineering and installation, Geotechnical surveys, Project design and feasibility, Seabed Survey

Advance Global Recruitment (AGR) is a trusted partner to energy companies worldwide, delivering agile recruitment solutions across the full energy lifecycle—from oil and gas to renewables. AGR ensures personnel are globally deployed, trained, and certified to meet industry standards. Through tailored recruitment strategies and training support, AGR helps clients maintain operational continuity and drive sustainable growth

Equipment Rental, Air Compressors, Steam Generators, Nitrogen Production Units

Inspection Services, Subsea and vessel inspection services

Mooring Equipment, Marine/Subsea equipment (Umbilicals, Risers, Manifolds), Steel fabrication, Drilling and well equipment design and manufacture, site services, specialist welding, assembly and high-pressure hydro testing to 22,500psi

Reverse Integrity Testing system, Equipment manufacture, Subsea design and manufacture, Flange Reverse Integrity Testing System, Hydraulic and Nitrogen leak test equipment

Antifouling Technology & Deposit Protection Technology

Thermal Spray Coating, Laser Cladding, CNC Manufacture and Precision Finishing

Calibration solutions, Calibrators, Calibration Hardware, Calibration Software, Calibration Management, Field Calibrators, Workshop Calibrators, Expert Services

Innovative sealing solutions using bismuth alloy technology

Heat Treatment, Coatings, Thermal spray coatings (HVOF, plasma spray)

Temperature & pressure instrumentation and associated accessories, Electrical & Instrumentation, Equipment manufacture

Equipment Rental, Decommissioning, Equipment manufacture, Marine/ Subsea equipment (Umbilicals, Risers, Manifolds), Marine Cranes

BS&B Safety Systems (UK) Ltd 8520

CR Encapsulation Ltd 8450Scotland Pavilion

Cable Solutions Worldwide Ltd 8450Scotland Pavilion

Calder Ltd 12119

Cargostore Containers LLC 8620

Central Wire Industries UK LTd. 8556

Chemostrat 8650Wales Pavilion

Clarksons Research 8356

CMP Products 8434

Cokebusters 8538

Concrete Canvas 8650Wales Pavilion

Crescent Engineering FZE 12250

Crowcon Detection Instruments Ltd. 8535

Cutting & Wear 8339

Cylinders Holding 15542

DALY MIDDLE EAST LLC 8350

Danum Well Services Ltd. 8556

Equipment manufacture, Pressure Safety Management, Safety Equipment, Safety Systems: Rupture Disk Devices, Safety Heads, Custom Engineered Products, Industrial Explosion Protection, Safety Relief Valves, Flame Arresters, Emergency Relief, Breather Vents, Buckling Pin Relief Valves

Subsea design and manufacture, Electrical & Instrumentation, Marine/Subsea equipment (Umbilicals, Risers, Manifolds)Electrical and Fibre Optic Subsea Connectivity

Cable Protection, Power, Instrumentation, Fibre and data cables for many industry sectors, Specialists in the supply, design and distribution of Offshore, Marine, Subsea Cables & Top Drive Service Loops to support the global energy industry.

Decommissioning, Drilling and well equipment design and manufacture, Equipment manufacture, Machinery/plant design and manufacture, Design, assembly and test of high pressure and hazardous area pump packages, vacuum systems, compressors for every industry

Equipment Rental/Supply, Equipment Rental, Safety Equipment, Bespoke DNV 2.7-1 Offshore CCUs

Well services contractors, Drilling and well equipment design and manufacture, Equipment manufacture, Access, Central Wire Industries manufactures wire, SUPA Slicklines, profiled wire, knitted mesh and welding wire for the Oil & Gas industry

Geoscience Consultancies, Laboratory Services

Market intelligence, covering Maritime and Offshore Energy, Fleet & Orderbook data and analysis, Online Digital platforms (Offshore Intelligence Network & Renewables Intelligence Network), Publications & Reports

Cable Protection

Inspection Services, Engineering Consultants, Technology Licensor Operation and Maintenance contractor, Mechanical Cleaning of Tubes and Pipelines

Civil engineering, Soil Erosion Control Solutions

Engineering Contractors (pre-FEED/FEED), Engineered Process Packages, Project Design & Feasibility, Water Treatment, Crescent Engineering specialises in the design and delivery of custom oil & gas processing plants and advanced produced water and wastewater treatment solutions. Providing end-toend engineering and construction services, combining technical expertise with proven project execution capabilities to support clients from early-stage feasibility through to full project delivery

Fixed Gas Detection, Portable Gas Detection, Flame Detection

Drilling and well equipment design and manufacture, Engineering support, Equipment manufacture

Marine/Subsea Equipment (Umbilicals, Risers, Manifolds), Business Development, Cylinders

Electrical & Instrumentation, Safety Equipment

Provision of Supa slicklines, Dyform well service strands, and ORB sheaves for slickline and wireline. Specialists in well intervention

Decom Engineering Ltd 8450Scotland Pavilion

Digital Edge Subsea 8514

Digitising Reality 8450Scotland Pavilion

E2S Warning Signals 8630

Enhydra 8552 •

EPIC 8450Scotland Pavilion

ESI Technology Limited 8650Wales Pavilion

Fibron BX Ltd 8534

Fifth Ring 8450Scotland Pavilion

Flexitallic 8511

Fulkrum Technical Resources 8415

Decommissioning contractor, Equipment Rental/Supply, Engineering support, Equipment manufacture, Subsea Cutting

IT Hardware/Software, Equipment manufacture, Equipment Rental/Supply, Inspection Services, Digital Video Recording and Remote Inspection Services

Digital modelling, digital twins, asset integrity, emissions monitoring, predictive maintenance, AI-powered data analysis of assets providing real time reporting and actionable insights

We specialise in safety equipment, safety systems, and equipment manufacturing, delivering high-performance notification signals, initiation and detection devices for fire alarm and mass notification use. Our products are approved for NEC and CEC Class/Division and Zone applications, rigorously tested to UL38, UL1480, UL1638, and UL1971 standards. Designed for reliability in critical conditions, our solutions provide the highest level of life safety across marine, industrial, hazardous location, and explosion-proof environments, ensuring compliance, durability, and protection where safety is paramount

Safety Systems, IT Hardware/Software, Digital Services / Data monitoring, Safety Equipment, Access Control Systems

Equipment Rental/Supply, Engineering Consultants, Water Treatment, Main Process Units, Produced Water Treatment: Deoiling Hydrocyclones, Desanding Hydrocyclones, Induced Gas Flotation, Compact Flotation Units, Micro-Bubble Flotation, Degassers, Nutshell Filters, Media Filters, Cartridge Filters, Coalescing Filters, Absorption Filters. Sand Management: Wellhead Desanders, Sand Transportation, Sand Wash Hydrocyclones, Online Sand Jetting zzles and Manifolds. Water Injection Systems: Coarse Strainers, Desanding Hydrocyclones, Multi-Media Filters, Vacuum Deaeration. Environmental & Industrial Water Treatment: Corrugated and Tilted Plate Separators (TPI/CPI), Coalescing Oil Separators, Lamella Settlers Services: Feasibility and FEED Studies, Third Party Design Reviews, Pilot Trials and Equipment profiling, Operator Training, Full packaged plant, Spare parts and the supply of all vessel Internals

Electrical & Instrumentation, Electrical & Instrumentation, Electrical & Instrumentation, Electrical & Instrumentation, Pressure transmitters and pressure sensors

Components Supplier, Cable Protection, Array Cables, Export & array cables and components, Design and manufacture of bespoke cables and umbilicals and the associated terminations

Business Development, Marketing and Communications

Gaskets and Seals, Sealing Solutions, Engineering support, Training, Joint Integrity, Services, Integra Technologies; Controlled Bolting, On-Site Machining, Flexlogics Software; Torque Calculator, Gasket, Selector, Flange Management

Inspection Services, Staffing, HS&E Services, Safety and environmental regulatory compliance, Auditing & Expediting Greene Tweed 8432

Halton Wales (MEI) 8650Wales Pavilion

HCS Control Systems 8450Scotland Pavilion

n-metallic materials (elastomers, plastics, composites)

Electro-Mechanical Equipment, Equipment manufacture, Safety Systems, Safety Equipment, Fire Dampers, Isolation Dampers, Blast Dampers, Moisture/Salt Eliminators, Volume Control Dampers, Pressure Relief Dampers, n Return Dampers, Bespoke Dampers

Subsea Trees, Decommissioning, Equipment Rental/Supply, Equipment manufacture, IWOCS Rental, Manpower services, Design & Manufacturing, Subsea tooling rental, Subsea equipment refurbishment, Topside Services

Company Name

Hi-Force Limited 8330

HMS Networks 15540

HMT 8631

Holyhead Towing Company 8650Wales Pavilion

HRH Geology 8638

Hubbell 8617

Imtex Controls 8650Wales Pavilion

Innospec Inc. 8238 •

Inov8 Systems Ltd 8512

J&S Subsea Limited 8450Scotland Pavilion

James Walker 8611

Kent 8230

Monaco Engineering Services 17119

Norco Al Yaseah Energy Services LLC 8558

NOVOSOUND LTD 8450Scotland Pavilion

OEG 12115

Orga bv 8430

Equipment manufacture, Heavy Lift, Equipment Rental/Supply, Training, A wide range of hydraulic tools and bolting equipment are available to cater to the client's project and application requirements. Our services include tool rental, repair and calibration, onsite services, and Hi-Force product training as well as the ECITB approved Mechanical Joint Integrity (MJI) training courses

Access, IT Hardware/Software, Waste management, Cyber Security, Industrial Automation

Tank Design and Manufacture, Chemicals, Safety and environmental regulatory compliance

Specialist Vessels, Vessel Supply, Workboats and Helicopter Services, Shallow-draft Tug Operator

Hardware/Software

Cable Protection, Castings, Array Cables, Beacons/Strobe warning lights, cable glands, cable management, conduit fittings, controls AC/ DC components, drag chains/festoons, driller’s intercom, electrical connectors & tools, electrical enclosures, fire pump controls, grounding & bonding, HV arresters & insulators, lighting (egress), lighting (LED), medium voltage connectors, motor controls/meter starters, plugs & receptacles, power distribution, public address/general alarm, resistors, braking & chopping, transformers/power quality

Equipment manufacture, Equipment manufacture

Provides a wide range of Fuel Additives, Marine Additives, and Oilfield Solutions & Services

Equipment manufacture, Electrical & InstrumentationOil in Water Analyzer, Analyzers

J+S Subsea is a specialist provider of engineering, operational support, and maintenance services for subsea equipment, with a strong focus on the Subsea Production Control market. Key services are: Bespoke subsea engineering solutions, Reverse engineering of obsolete equipment, Technical fault finding and restoring functionality of faulty equipment, Engineering design for small scale greenfield and brownfield projects, Supply of goods and service for small scale greenfield and brownfield projects, Cable and control system monitoring and fault finding, Electrical and hydraulic intervention work, General electrical and electronic control system support, Critical spares reviews, Supporting waste management and reducing customer carbon footprint, ESG and advisory services

Non-metallic materials (elastomers, plastics, composites), tension control fasteners, flange management services, metallic gaskets

Engineering Consultants

Process Safety, Risk Assessment, Environmental and Asset Integrity Management providing solutions across all phases of design, commissioning, operations and decommissioning

Electrical & Instrumentation, Engineering support, Equipment Rental/Supply, Engineering Consultants, Uninterruptible Power Supplies, Battery Chargers, Batteries

Cable/Pipeline Route, Inspection Services, Testing, Certifications & Documentation

Cargo handling, well completion solutions, chemicals and tanks, custom engineered solutions, waste handling, and wider energy services

Safety and environmental regulatory compliance, Electro-Mechanical Equipment, Safety Systems, Aids to Navigation, Helideck Lighting, Remote power supply, obstruction Lighting solutions

OsecoElfab 8435

PD&MS Group 8450Scotland Pavilion

Penspen 8358

Penta Global Engineering Company LLC 8530

Petrasco Energy Logistics 8450Scotland Pavilion

Petrostat 8650Wales Pavilion

Pharos Marine Automatic Power Limited 8639

Pioneer Safety Group 8258

PJ Pipe and Valve Co Ltd 8634

Poole Process Equipment 8335

Premaberg Manufacturing Ltd 15541

Premier Corex 8450Scotland Pavilion

Premier Ship Models Ltd 8334

Protectoseal 8614

Radiodetection 8515

Raytec Ltd 12117

Reid Lifting 8650Wales Pavilion

Rhino Hysafe 8650Wales Pavilion

ROVOP 8450Scotland Pavilion

Rupture discs, explosion vents, burst sensors, and pressure relief design, engineering, training and support services

EPC, Engineering contractors (pre-FEED/FEED), Engineering Consultants, Decommissioning contractor,

Engineering Consultants, (Pre-FEED, FEED), Asset Integrity, Project Management Consultancy, Asset Management, Infrastructure repurposing for hydrogen / CO2 / green ammonia

EPC Contractor. General Construction Contractor for major EPC Projects. Specialised piping and steel fabrication services provider, including testing and painting

Logistics

Geoscience Consultancies, Laboratory Services

Electrical & Instrumentation, Port and Logistics, Remote Power Solutions, Aids to Navigation Equipment, Helideck Lighting Equipment

Safety Systems, Safety Equipment, Safety and environmental regulatory compliance, Equipment manufacture,

Design, manufacturing and supply of Industrial valves for oil & gas applications

Equipment manufacture, Steel Fabrication, Tank Design and Manufacture, Boilers, Shell & Tube Heat Exchangers, Air Cooled Heat Exchangers, Pressure Vessels

Equipment manufacture

Laboratory Services, Geoscience Consultancies, Project Management, Well Services Contractors

Premier Ship Models crafts precision scale models for the energy industry and beyond. From offshore vessels to tankers / FPSOs to nuclear power stations, we combine traditional craftsmanship with modern technology to deliver accurate, bespoke models trusted by global worldwide corporations over the last 20 years. Pls visit our corporate website https://www.premiershipmodels. com/ae/ for more information

Safety Equipment, Equipment manufacture, Ancillary equipment

Cable Protection, Cable/Pipeline Route, Environmental surveys, Safety Equipment, Cable avoidance tools

Safety Equipment, Equipment manufacture, Electrical & Instrumentation, Safety Lighting for Hazardous Areas

Heavy Lift, Climbing and safety equipment, Access, Water Treatment, Lifting of materials and personnel upt0 5000Kg

Safety and Environmental Regulatory Compliance, Safety Systems, Security Systems, Compressor Design and Manufacture

Subsea and vessel inspection services, Inspection Services

RXHK 15544 • STATCOM, BESS, VSC - HVDC, Large electrical drives

Safelift Offshore 8610

Access, Decommissioning, Safety Equipment, Equipment Rental

Company Name

SAS Environmental Services Ltd 8450Scotland Pavilion

Scottish Development International 8450

Sensoteq 8415

SGS 8250

Sonardyne 17120

Speedcast 8415

SPP Pumps 8439

Sterling Thermal Techlogy 17117

Sureclean 8450Scotland Pavilion •

Synectics 15548

THREE60 Energy 8555

Tomoe Valve Ltd 8650Wales Pavilion

TPS WeldTech Ltd 8450Scotland Pavilion

Trelleborg Marine and Infrastructure 8431

Trident IES 8450Scotland Pavilion

TWMA 8410

Victaulic 12110

Chemicals, Decommissioning, Environmental services, Environmental surveys

Remote Condition Monitoring for Predictive Maintenance - ATEX Certified Wireless Sensors and Machine Health Analytics Platform

Testing, Certifications & Documentation, Inspection Services, Environmental services, Safety and environmental regulatory compliance, Discipline labs, Consumer Product Certification, ISO Certification, Food Safety

Subsea design and manufacture, Equipment manufacture, DP Positioning

IT Hardware/Software, VSAT, Telecommunications, System Integration, Professional IT Services

Equipment manufacture, Engineering Consultants, Engineering support, Ancillary equipment, Fire protection

Equipment Rental, Equipment manufacture, Ancillary equipment, Aftermarket-MRO

Industrial Services, NORM Decontamination & Management, Oil Spill Prevention and Response

Security Systems, Safety Systems, Synergy security and surveillance software, COEX Cameras (hazardous-area and safearea)

Decommissioning, Digital Services / Data monitoring, Drilling Contractor, Engineering contractors (pre-FEED/FEED), Engineering, Procurement, Construction & Commissioning, Operations & Maintenance, Topside Management, Subsea Engineering, Subsea Techlogies

Equipment manufacture, Butterfly Valves

Welding automation systems, Equipment manufacture, Equipment Rental/Supply

Equipment manufacture, transfer systems, transfer hoses, filtration, strainer equipment, safety link systems

Trident IES is a leading provider of HVAC, refrigeration, & modular door maintenance & engineering solutions. We specialise in the design, installation, repair & maintenance of HVAC & Door applications across critical energy infrastructure, including onshore refineries to offshore installations, FPSOs, and windfarm substations. As an ISO accredited organisation, our expert on & offshore teams are focused on delivering the highest quality, environmental, & safety standards in every project we undertake

Waste management, Drilling Waste Management

Cable/Pipeline Route, Engineering support, Pipeline design, Project design & feasibility, Couplings, Valves, Fittings, Sprinklers Wales Cymru 8650 Business Development

Wall Colmonoy 8650Wales Pavilion

Walter Frank 8513

Castings, Heat Treatment, Turbine Blades, Coatings, Air & Vacuum Casting, Finish Machining, Additive Manufacture, Metallic Powders, Brazing, HVOF

Equipment manufacture, Safety Equipment, Project management

WeConnect Energy 8450Scotland Pavilion

Weidmuller Middle East (FZE) 8252

Westerton Access 8450Scotland Pavilion

William Hackett 8336

Wolf Safety 8510

Woodcock & Wilson Ltd 8415

Wozair Limited 8518

Xodus Group

8450Scotland Pavilion

Xylem 8650Wales Pavilion

Zelim 8450Scotland Pavilion

Recruitment

Electrical & Instrumentation,Electrical & Electronic products

Providing offshore structural inspections and Subsea services to the offshore energy sector, ROV Services, Equipment Rental/Supply

Heavy Lift, Equipment manufacture, Safety Equipment, Marine/ Subsea equipment (Umbilicals, Risers, Manifolds)

ATEX and IECEx safety lighting for potentially explosive atmospheres

Electro-Mechanical Equipment, Equipment manufacture, Machinery/Plant Design & Manufacture, Equipment Rental/ Supply, Woodcock & Wilson design and manufacture highperformance industrial fans for a wide range of applications, including HVAC, power generation, offshore, marine, tunnelling, and hazardous areas. Our product range includes axial flow fans, centrifugal fans, and ATEX/IECEx-certified explosion-proof fans. In addition to fan manufacture, we offer a comprehensive suite of services including fan testing, balancing, performance upgrades, on-site servicing, installation support, condition monitoring, and repairs. We also provide tailored engineering solutions, acoustic enclosures, fan control systems, and expert advice to help customers meet complex ventilation and safety requirements.

Machinery/plant design and manufacture, HVAC Design & Manufacture

Global energy consultancy helping clients deliver sustainable, low-carbon and high-value projects through integrated strategic, technical and environmental expertise

Water Treatment

Safety Systems, Safety and environmental regulatory compliance, Security Systems

Corpay Cross-Border Solutions is a global leader in Global Payments and FX Risk Management solutions, helping companies protect their bottom line whilst managing their FX exposure.

Corpay can help you:

• Make your payment processes more efficient

• Reduce expenses associated with errors on international business payments

• Give you greater visibility and control over your international business payments

To find out how Corpay can help your company navigate the complexities of the Global Payments marketplace, get in touch with the Corpay Team here: https://cross-border.corpay.com/ energy-industries-council/

by Aisyah Sarjuni EIC Energy Analyst – MENA

Over 1,100 projects are tracked on EICDataStream in the Middle East and North Africa (MENA) region as of August 2025

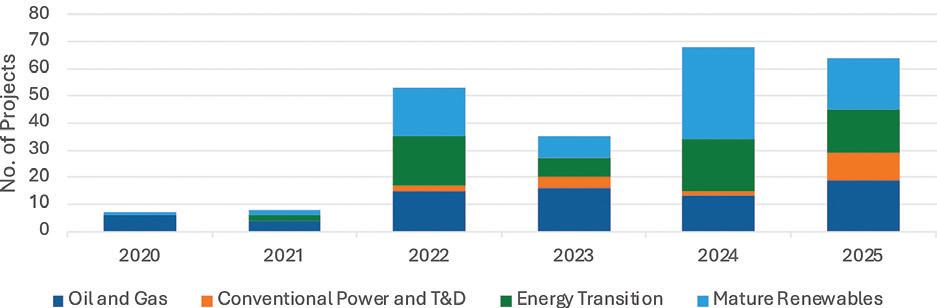

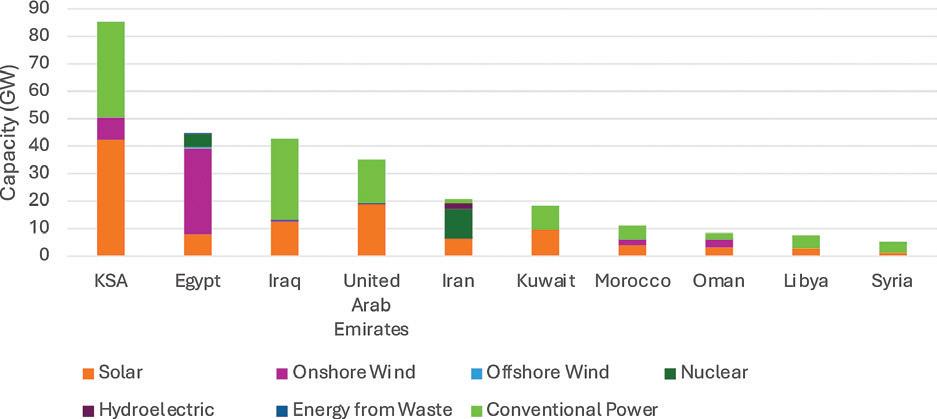

Figure 1: Project announcements in MENA since 2020 by energy sector. Source: EICDataStream

Over 1,100 projects are tracked on EICDataStream in the Middle East and North Africa (MENA) region as of August 2025. In the last five years, tides have changed in the region with the progressive diversification of its energy mix. Based on Figure 1, projects announced within the renewables and energy transition (hydrogen, carbon capture, energy storage and biofuel/SAF) sectors reached its peak in 2024 with a combined total of 53 projects. The steady recovery of the oil and gas sector proved a foundation for economic stability and ensuring supply chain security. This has allowed the establishment of new policies and funding which support the global decarbonisation targets.

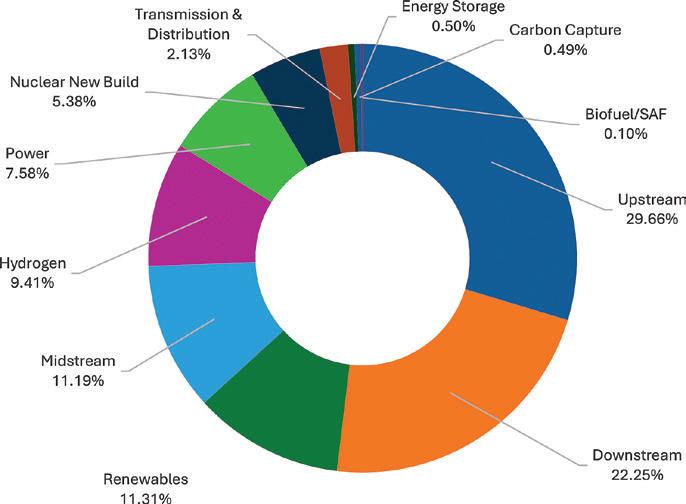

MENA records a total of US$1,372bn in potential investments across all energy sectors by 2031. In Figure 2, the oil and gas sector dominates the market share with an estimated CAPEX of US$843.7bn. The power sector holds 13.2% of the total CAPEX as more gas-fired power plants are being built to ensure sufficient and stable baseload power. Investments for renewables and hydrogen projects are catching up with 21.6% of the total market share, as the region leverages its solar and wind power advantages for green hydrogen and ammonia production. While this supports its own decarbonisation goals, demand and funding from the European market also plays an equally instrumental role for export opportunities. Hydrogen’s rapid expansion contrasts with the development of remaining energy transition sub-sectors, which currently hold only about 1.6% of the total market share.

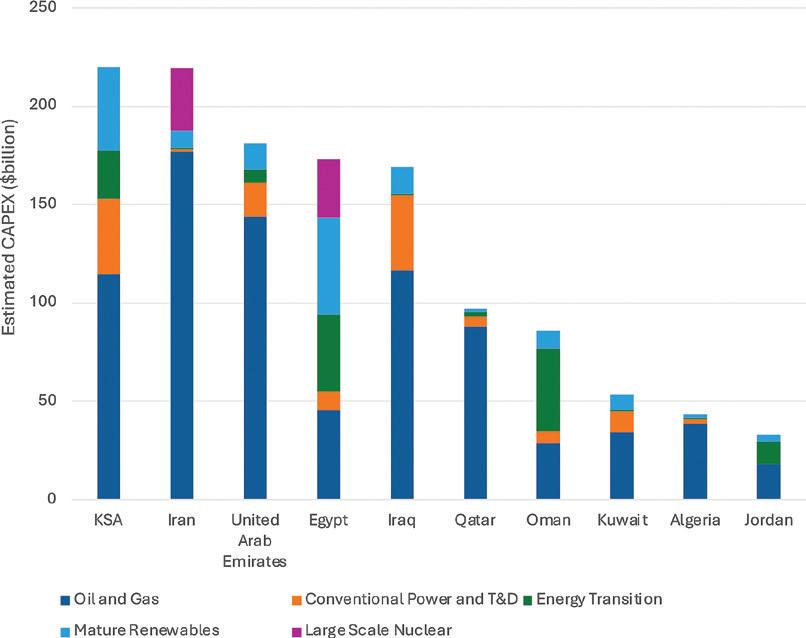

The top 10 countries in Figure 3 represent a combined estimated CAPEX of US$1,308.4bn, mainly driven by upstream developments in the Middle East. KSA, Iran and UAE top the chart as major oil and gas investors, with the estimated CAPEX in each country reaching US$219.9bn, US$219.5bn and US$181.1bn respectively. Egypt comes in fourth with the most diverse investment portfolio across all energy sectors with approximately US$181.1bn on the line. Although the oil and gas sector is still a key driver for the top 10 markets, mature renewables and energy transition projects are contributing significantly to the CAPEX pipelines, especially in Egypt, Oman and KSA.

Figure 4: Oil and gas opportunities by project stage in MENA by 2031. Source: EICDataStream

The MENA oil and gas sector records estimated investments of US$398.8bn for upstream, US$309.7bn for midstream and US$133.5bn for downstream. Based on Figure 4, approximately US$96.7bn worth of projects are still in the feasibility and field exploration phase.

Most of the projects are coming from exploration fields in KSA, upcoming chemical plants in Egypt and planned pipeline constructions across the region. Over half of the projects in the engineering phase are downstream projects with upcoming refineries and petrochemical complexes across the Middle East. Projects that have advanced through EPC account for US$611.3bn of the total CAPEX where 46% of the total investments are from the upstream sector. Approximately US$88bn constitute for projects that are still in the tendering and bidding process.

With a focus on energy security and trade, the region continues to boost its production rates. Saudi Aramco leads the GCC region with 11 new exploration projects in 2025. Multiple onshore blocks were recently awarded in North Africa, where QatarEnergy announced its debut in the region after winning the Ahara Block in Algeria’s 2024 bid round.

Egypt awarded 13 exploration wells in June 2025 while the winners for Libya’s 2025 bid round will be announced by end of 2025. The downstream sector is catching up with significant demand from Asia. Saudi Aramco reported in mid-2025 that the company is halfway through its target of converting 4MMbpd crude oil to chemicals by 2030 where China is a major exporter. The midstream sector observes more pipeline construction to support the oil and gas transport network within MENA and hydrogen transport to EU countries.

5: Projects of interest for the oil and gas sector in MENA. Source: EICDataStream

Ratawi Field Development:

The Ratawi oil and gas field is developed in Iraq under TotalEnergies’ Associated Gas Upstream Development (AGUP). The field holds an estimated 1.75Tcf of gas and 10bn barrels of oil. TotalEnergies has awarded Wood plc with a three-year term engineering and procurement contract for Phases 1 and 2 of the project.

Kirkuk to Ceyhan (Iraq to Turkey) Oil Pipeline – Rehabilitation and Reopening Project:

Two 970km oil pipelines from Kirkuk, Iraq to Ceyhan, Turkey, will be modernised to transport 1.6MMbbl/d of oil. A new 350km pipeline length will be added with 1.0 MMbbl/d transport capacity. Iraq’s Ministry of Oil is currently reviewing a proposal to renew the old Turkey-Iraq crude oil pipeline agreement.

TA’ZIZ – Ruwais Derivatives Park:

Seven chemical production facilities to be built in the TA’ZIZ Industrial Chemicals Zone, Ruwais, UAE. The production capacities will cover 0.94mtpa of chlor-alkali, 1.1mtpa of ethylene dichloride and 0.36mtpa of PVC, maleic anhydride, methanol, ammonia, isopropyle alcohol and elastomers. Two contracts were awarded in 2025 for the methanol production facility; with Samsung E&A securing a US$1.7bn EPC contract and Wood a project management consultancy (PMC) contract.

Renewables and Power:

Although oil and gas remains a key sector for MENA, the region is seeing positive progress towards a greener energy grid. US$173.9bn investment is estimated for the addition of 171.3GW renewable power capacity. In contrast, US$196.1bn is needed for 128.1GW of conventional power capacity, reflecting the low costs associated with developing renewable technologies. The renewables sector is further supported financially by the EU. The European Investment Bank (EIB) launched the Blue Mediterranean Partnership (MBP) which aims to support a sustainable blue economy in the southern Mediterranean and Red Sea. MBP recently funded the feasibility study and technical support for Morocco’s first offshore wind farm in Essaouira, totalling 1GW.

Planned power capacity (GW) additions by country and industry sector

Figure 6: Planned power capacity additions across MENA for developing projects up to 2031. Source: EICDataStream

Based on Figure 6, KSA continues to dominate 30% of the region’s total upcoming power capacity additions of 280.9GW. KSA has 42.7GW of upcoming solar capacity, driven by its target of reaching 130GW of renewable capacity by 2030. ACWA Power remains a key player, holding 50% of the total developing solar projects up to 2031. Onshore wind power is mainly concentrated within Egypt where it holds approximately 31GW out of its total 44.5GW planned power capacity. In line with Egypt’s national strategy to localise its renewables supply chain, the addition of upcoming solar component manufacturing plants may grow its solar power capacities in the upcoming years.

Estimated CAPEX ($ million) for energy transition sector by country

Figure 8: Estimated CAPEX for developing energy transition projects across MENA up to 2031. Source: EICDataStream

The energy transition sector constitutes US$166bn of the region’s overall CAPEX share, with 86% from green hydrogen. Commercial viability remains a key hurdle with over 55% of the total developing projects still in the planning stage. Oman continues to lead the hydrogen market with investments reaching US$41.7bn, followed closely by Egypt with US$39.2bn. Infrastructure development and government support are key drivers in moving the sector forward. For instance, MENA records 14.7GWh of potential energy storage capacity which will bridge the gap between green hydrogen and renewable energy intermittency.

Figure 7: Projects of interest for power and renewables sectors in MENA. Source: EICDataStream

Onshore Wind Farm – ACWA Power & Hassan Allam Holding: Two phases of an onshore wind farm with 550MW capacity each to be built in Egypt’s Gulf of Suez. A financial investment decision (FID) was reached in January 2025 after securing a US$703.6m debt facility out of the total US$1.2bn estimated CAPEX.

Al Sadawi PV Solar IPP – NTP Round 5: The 2.3GW project was tendered under the fifth round of the National Renewable Energy Programme (NREP). It is developed under a build-own-operate (BOO) basis in the KSA by Masdar, GD Power Development Co Ltd and Korea Electric Power Corporation (KEPCO). FID was received in August 2025 through a US$1.1bn financing by eight regional and international lenders.

Az Zour North IWPP – Phase II and Phase III: The US$4bn project is expected to produce 2.7GW power and 120MIGD of desalinated water. It will be built in Kuwait’s Al-Zour region, under a 25-year BOT model.

Figure 9: Projects of interest for the energy transition sector in MENA. Source: EICDataStream

Yanbu Green Hydrogen Project Phase I: ACWA Power and EnBW are developing a green hydrogen hub in KSA’s Yanbu region, which utilises a 4GW electrolyser to generate up to 400,000tpa of green ammonia. Técnicas Reunidas and Sinopec were appointed to perform FEED for the project.

Ras Laffan Industrial City (RLIC) Carbon Capture Project: This project is part of QatarEnergy LNG’s LNG train expansion project at Ras Laffan, Qatar. It is expected to capture 4.3mtpa of CO2 from QatarEnergy LNG North 7 trains and QatarEnergy LNG South 3 trains. The captured CO2 will then be compressed and injected into newly developed injection wells, requiring the installation of additional compression trains and pipelines.

Jubail e-SAF Plant: Nordic Electrofuel signed a MoU with the Jubail Royal Commission to develop an e-SAF plant. The project will produce 280,000tpa of e-SAF using solar energy from existing assets in the region.

World Nuclear Exhibition (WNE) | Paris, France | UK & EIC Pavilion 4-6 November 2025

Trade Delegation to Mozambique | Delegation 24-27 November 2025

World Future Energy Summit (WFES) | Abu Dhabi, UAE | UK & EIC Pavilion 13-15 January 2026

Hyvolution | Paris, France| UK & EIC Pavilion 27-29 January 2026

Trade Delegation to Angola | Delegation 23-27 February 2026

Wind Expo Japan | Tokyo, Japan | UK & EIC Pavilion 17-19 March 2026

Trade Delegation to Chile | Delegation 9-13 March 2026

Trade Delegation to Guyana & Suriname | Delegation 13-17 April 2026

Offshore Technology Conference (OTC) | Houston, USA | UK & EIC Pavilion 4-7 May 2026

Trade Delegation to Nigeria | Delegation 11-15 May 2026

Trade Delegation to Egypt | Delegation 24-28 May 2026

OPES | Muscat, Oman | UK & EIC Pavilion 18-20 May 2026

Trade Delegation to Denmark & Norway | Delegation 1-5 June 2026

Beijing Energy Congress| Beijing, China | UK & EIC Pavilion 24-26 June 2026

ONS | Stavanger, Norway | UK & EIC Pavilion 24-27 August 2026

Oil & Gas Asia (OGA) | Kuala Lumpur, Malaysia | UK & EIC Pavilion 2-4 September 2026

ROG.e | Rio de Janeiro, Brazil | UK & EIC Pavilion 21-24 September 2026

WindEnergy Hamburg | Hamburg, Germany | UK & EIC Pavilion 22-25 September 2026

Trade Delegation to Spain & Portugal | Delegation 5-9 October 2026

Hydrogen Technology Expo Europe | Hamburg, Germany | UK & EIC Pavilion October 2026

Please note that the list is not final If you think there are any events we should attend, please contact the team

Floating production, storage and offloading (FPSO) units play a critical role in supporting energy security by enabling the exploration and production of hydrocarbons from remote and challenging offshore reserves. The first FPSO was used in 1977 on Shell's Castellon field in the Spanish Mediterranean. Since then, FPSOs have become key to offshore oil and gas production, especially in remote areas or where the sea is too deep for fixed platforms.

According to EICDataStream, the FPSO market is growing significantly, with 105 new FPSOs expected to begin operations globally between 2025 and 2034. South America leads the count, with 39 FPSOs expected to come online during that period. Among the countries in the region, Brazil emerges as the top market, with 30 FPSOs planned and Brazil's national oil company, Petrobras as the leading FPSO operator in the country. This growth in FPSO deployment reflects the increasing importance of offshore production in meeting global energy needs.

The FPSO market is expanding globally as offshore explorations increase in deepwater and ultra-deepwater segments. In Brazil, operators are using FPSOs to develop discoveries in the pre-salt region, such as the FPSO Marechal Duque de Caxias, which serves the Mero field at a water depth of 2,000m. In Angola, the FPSO Agogo, operated by Yinson Production, is a low-carbon vessel that operates at a depth of 1,700m and serves the Agogo and Ndungu fields. These advanced floating production assets are key to meeting the growing global energy demand. Meanwhile, operators favour floating solutions like FPSOs, as the cost of fixed platforms has increased. For example, the number of fixed platforms in Brazil is declining, while the number of FPSOs is growing, with many already in operation and more being planned.

Based on the graph, the country with the highest number of FPSOs in the Asia Pacific region is Australia, with 24 vessels, followed by Malaysia with 14. This figure reflects that FPSOs are now one of the preferred solutions for operators to develop oil and gas fields.

The top two countries in Asia Pacific have attracted major players in the FPSO market due to active governmental support. Global operators such as SBM Offshore, BW Offshore and Bumi Armada have invested in these regions, drawn by stable policy frameworks and favourable tax regimes.

Malaysia's government has introduced incentives for marginal and deepwater fields under production sharing contracts (PSCs), which provide companies with lower taxes and accelerated tax deductions. Similarly, Australia's Petroleum Resources Rent Tax (PRRT) benefits FPSO projects by allowing companies to pay tax only after they generate profits, while the Offshore Petroleum and Greenhouse Gas Storage Act 2006 reduces the regulatory burden by having one national regulator, NOPSEMA, which makes the approval process more efficient. This makes FPSOs a more financially attractive solution for field development.

The flexibility and mobility of FPSOs make them ideal for marginal and remote fields and aligns with national energy goals of enhancing domestic energy production. Their mobility allows operators to maximise the lifespan of FPSOs by relocating them to different fields, which also contributes to faster deployment and a quicker response to growing energy demands. Advances in digital monitoring, modular topside systems and subsea tiebacks have also further improved operational efficiency.

On top of the FPSO benefits, the FPSO market also faces several operational challenges, especially in offshore environments where they are exposed to extreme weather conditions such as storms, high waves and strong winds. To manage these risks, modern FPSOs use advanced mooring and dynamic positioning systems to maintain stability and keep the vessel securely anchored, even in rough conditions. FPSOs can also face financial challenges, including high capital expenditure that can exceed billions of dollars, depending on project complexity and location. To overcome these challenges, operators and contractors should work together and leverage their expertise to ensure smooth FPSO development.

Corrosion is another major concern, as constant exposure to seawater can weaken the vessel's structure over time, so FPSOs are built with corrosion-resistant materials and undergo regular maintenance. Subsea inspections and repairs have also improved with the use of remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs). Operating in remote offshore locations presents logistical difficulties, especially when transporting maintenance equipment and skilled personnel. However, advances in remote technologies and automation help to manage these challenges, allowing FPSOs to be maintained more effectively in isolated areas.

The current offshore development landscape is shifting towards deepwater and ultra-deepwater segments, making FPSOs an effective solution for operators. The flexibility and fast deployment of FPSOs can overcome the challenges of marginal and remote fields. Despite the challenges, FPSOs can be a game-changer for future energy security.

Layla Zinnirah Energy Researcher – Operational Assets & Decommissioning layla.nasir@the-eic.com

Operator: Atmos Renewables Value: US$144m

Atmos Renewables has achieved financial investment decision (FID) for 100MW/400MWh Merredin battery project. The construction is expected to begin in 2025. The EPC contract has been awarded to GenusPlus, while Tesla will supply the batteries.

For information on these and more than 16,000 other current and future projects we are tracking please visit EICDataStream

Operator: ACWA Power Value: US$4bn

ACWA Power and Gulf Investment Corporation (GIC) signed an agreement with KAPP and MEWRE to develop the power plant which will have a capacity of 2.7GW. The project will be developed under a 25-year build-operate-transfer (BOT) model.

Operator: BP Value: US$500m

BP has announced details of its largest oil and gas find in 25 years. BP will conduct laboratory tests to further characterise the reservoir and fluids, with additional appraisal activities planned, pending regulatory approval.

Operator: Terna SPA Value: US$1.8bn

The European Investment Bank (EIB), Terna, Intesa Sanpaolo (IMI Corporate and Investment Banking Division) and SACE have signed agreements totalling €1.5bn to back the development and construction of the project by Terna.

Operator: Equis Funds Group Value: US$860m

Taihan Cable & Solution has secured a turnkey contract worth KRW181.6bn (US$131.4m) to supply and install over 100km of submarine cables for phase's 1 and 2 of the offshore wind farm. The scope of work includes the design, manufacturing, transportation and installation of inter-array cables.

Operator: Venture Global LNG Value: US$16bn

Venture Global has announced a positive FID for the first phase of the CP2 LNG export complex. Worley has been given full notice to proceed with work under its reimbursable EPC contract with Venture Global. The assignment is being led by its teams in Houston (TX) and Reading (PA).

Are you up to date on the latest project developments in the energy market? The EIC’s leading market intelligence database – EICDataStream – contains information on energy projects and associated contracting activity from the inception stage all the way through to construction and commissioning.

• Access details on over 16,000 CAPEX projects across all energy sectors

• Identify business opportunities and inform your business development strategies

• Explore a truly global database, updated daily by an international team of analysts

• Stay up to date with project developments, including information on tenders and awards

• Get insights into what your existing clients are doing and identify potential new clients

• Have a direct interface with analysts for local knowledge and insights

• Access insight and country reports with in-depth data on specific sectors and markets

EICSupplyMap maps the capabilities of supply chain companies that operate across all energy industries. These industries cover renewables, oil and gas, power, nuclear and energy transition technologies like energy storage, carbon capture and hydrogen.

• Identify the supply chain local to your region, giving you the opportunity to engage with potential new clients.

• Find the supply chain capability in 12 regions, now covering the UK, Germany, Spain, Italy, UAE, Oman, Saudi Arabia, Malaysia, Singapore, Indonesia, US and Brazil.

• An in-depth look at profiles of more than 10,000 energy sector supply chain companies.

• Make smarter decisions by targeting your offering to international developers/operators and contractors matching your capability with international energy projects.

Proeon Systems, a leading systems integrator provider within the global energy sector, is proud to announce that as a result of its growing operations and expansion, it is relocating to a new, larger premises within the Norwich area. This strategic move underscores the company's sustained growth and commitment to better serving its clients and employees.

This provides Proeon Systems with an expanded space and state-of-the-art facilities, doubling the footprint of the current operating base. Providing the company with larger manufacturing/engineering/office space and improved infrastructure to support the company's increasing workforce and business operations, the building is situated 3 miles to the east of Norwich city centre, providing easy access to the A47 and the A11, as well as local infrastructure and services.

Proeon has experienced unparalleled growth in recent years, solidifying its position as a key player in the control and automations systems sector. As a result of winning several multi-million pound projects with clients across Europe in renewable energy, in particular the offshore wind sector and experiencing a strong market demand for its services providing bespoke control solutions for highly regulated and demanding applications across the globe, including oil and gas, nuclear, utility/national infrastructure and defence, this has led to Proeon's need to secure a larger purpose-built facility.

The new headquarters provides enhanced resources to support the company's mission and long- term vision. Proeon is excited about this new chapter and looks forward to welcoming employees, partners and clients to the new location.

Proeon is a specialist systems integrator supplying control and safety solutions for complex and critical applications. It provides complete turnkey systems, a combination of hardware, software, control and functional safety engineering coupled with service and support to its clients.

With 70+ skilled and talented staff, Proeon operates internationally providing bespoke solutions for complex and critical applications. Based in Norwich, Proeon operates across the global energy sector, ensuring development of robust and sustainable solutions to meet its client's specific requirements operating within challenging and hostile environments. In 2022 Proeon was acquired by RSK Group, becoming part of a family of 200+ environmental, engineering and technical services businesses.

The relocation reflects Proeon's dedication to innovation, excellence, efficiency and a dynamic work environment for its people.

In response to our rapid growth and increasing client demand, moving to a larger facility was a natural next step. This transition marks an exciting milestone in our journey and positions us for further expansion and success.

Richard Miller, Managing Director, Proeon Systems

The new premises is located at: 35A Barnard Road, Bowthorpe, Norwich, Norfolk NR5 9JB, UK

HMSWeb, developed by Forship, is a 100% paperless and cloud-based platform designed to transform the way industrial assets are commissioned, from mechanical completion to final handover. It provides full visibility and control over every stage of the commissioning process.

More than just a software tool, HMSWeb is a strategic enabler for project decision-makers, ensuring compliance with quality standards and significantly supporting the safe and efficient delivery of complex industrial projects.

Its modular and customisable structure allows workflows to be configured by discipline, area, subsystem, or schedule, making it adaptable to different project types and implementation phases. HMSWeb also focuses on data centralisation, process standardisation and complete asset traceability with speed and accuracy.

Whether in industrial plants, infrastructure projects, or oil and gas entrepreneurships, HMSWeb delivers innovation, control and reliability throughout the commissioning lifecycle.

A global reference, its main features and highlights are:

• Full traceability and precise control over all project activities.

• Real-time monitoring of productivity, such as physical progress, S-curves, dashboards and KPIs.

• Comprehensive punch list management module that streamlines each item tracking and resolution.

• Centralised access to critical operational procedures and activity plans for field execution.

• Automated generation of records, ITRs, checksheets, certificates and commissioning reports.

• A secure digital project library for document storage and retrieval.

• ISO 27001, 27017, 27018 and 27701 certified.

• Available in Android and iOS mobile apps.

• User-friendly.

To learn more about HMSWeb and how it can support your projects, please contact Forship's team at: comercial@forship.com.br or visit: https://forship.site/en-hmsweb/

NEW

Unit 3a, Brindley Way Rotherham South Yorkshire S60 5FS UK

Contact James Hinchliffe, Sales Director

Telephone +44 (0)114 492 0198

Email james.hinchliffe@colson.co.uk

Web www.colson.co.uk

Established in 1991, Colson X-Cel Ltd designs and manufactures a range of double block & bleed and instrument valves. Colson X-Cel designs, machines, assembles, tests and QA's all products in-house.

Colson X-Cel is approved with major global operators and holds an extensive worldwide reference list for supplying valves into critical and severe applications. Colson X-Cel's extensive and innovative valve knowledge ensures it's a world leader in valve technology for safe and reliable products.

Avenida de Pirineos 7, Local 10C San Sebastián de los Reyes Madrid 28703 Spain

Contact Nelson A Pineda, Operations Director Alessandro Carmo, Commercial Director

Telephone +34 916625770

Email npineda@dapin.es alessandroc@dapin.es

Web https://dapin.es/

Design and Projects International Iberia (DAPIN Iberia) is a specialised engineering company providing technical consultancy and project development services for the energy, oil and gas, petrochemical and industrial sectors.

The company delivers multidisciplinary engineering solutions across all phases of a project – from feasibility studies and design to implementation and commissioning. DAPIN Iberia supports clients in both local and international markets, with a strong focus on operational excellence, safety and innovation.

The company's team combines in-depth technical knowledge with hands-on experience to deliver cost-effective, sustainable solutions tailored to the evolving needs of the energy sector.

Thursday 20 November 2025 • Manchester

Unit 29-13B, Q Sentral 2A

Jalan Stesen Sentral 2 Kuala Lumpur Sentral 50470 Kuala Lumpur Federal Territory of Kuala Lumpur

Contact Gary Cross, Business Manager, ASEAN Region

Telephone +60 199 76 1903

Email gary.cross@gqsgroup.com

Web www.gqsgroup.com

Global Quality Services (GQS) is a global QA/QC inspection and quality services partner to operators and tier one contractors.

Headquartered in Perth, Australia, with offices across Asia, Europe and the Americas, the company delivers second and third party inspections, expediting, technical audits and various other quality services across the energy industry.

The GQS integrated management system, Connect, provides real time visibility, compliance and reporting. With 20 years of experience across oil and gas, offshore wind, hydrogen and wider energy, GQS reduces risk and delivers for its clients.

Rua Conceição de Monte Alegre 107 Conj 101 Cidade Monções

São Paulo 04563-060

Brazil

Contact Bianca Bazzoli, Institutional Relations –Executive Secretary

Telephone +55 71991850279

Email bianca.bazzoli@guofuhee.com.br

Web www.guofuhee.com.br

Guofuhee is a company specialising in the development and manufacture of integrated solutions for the hydrogen energy industry.

Founded in 2016, the company is a global reference in the supply of essential equipment for the production, storage, transportation, supply and use of hydrogen, operating throughout the sector's value chain.

With cutting-edge technology and continuous innovation, Guofuhee stands out for its quality, efficiency and commitment to the advancement of sustainable energy.

Workland Maakri St 19/2 Tallinn 10145

Estonia

Contact Erko Elblaus, Business Development Manager

Telephone +372 5650 0195

Email erko@instaglobe.eu

Web www.instaglobe.eu

Headquartered in Tallinn, Estonia, Insta Globe delivers electrical installation and commissioning for energy, industry, marine and offshore.

With 100+ in-house specialists in industrial electrification, process instrumentation, low-current systems and commissioning, the company mobilises globally and scales teams to project needs.

Insta Globe's track record includes gigafactories, battery manufacturing, semiconductor facilities, waste-to-energy plants, cruise ships and FPSOs.

Insta Globe is defined by experienced crews, a safety-first mindset, disciplined execution and well-maintained equipment. Clear goals and tight teamwork keep plans aligned with site realities, while continuous improvement keeps quality consistent.

Completed projects span Europe, North America, Asia, North Africa and the Middle East.

Rua Lauro Müller 116, sala 4304

Botafogo

Rio de Janeiro RJ, CEP 22290-160 Brazil

Contact Daniele de Oliveira Nunes, Partner

Telephone +55 21 3550 8080

Email dnunes@lealcotrim.com.br

Web http://lealcotrim.com.br/

LealCotrim is a law firm specialising in providing legal advice to national and multinational companies involved in strategic projects and litigation in the energy, infrastructure and oil and gas industries, among others.

The firm is comprised of experienced lawyers qualified in Brazil and abroad, who are routinely recognised in many of the most prestigious legal rankings.

LealCotrim is marked by the multidisciplinary education of its lawyers, which enables them to combine knowledge in public and private law to provide services in a fast, comprehensive and adequate manner to its clients' needs. Its areas of expertise include corporate law, contracts, tax law, public law, bidding and regulatory.

Lot 6757 (1235)

Ground & 1st Floor

Bandar Baru Permyjaya

Desa Pujut Shophouse

98000 Miri Sarawak

Contact

Alvin Dian Imang, Director

Telephone +6016 753 0598

Email alvin@lusanpeju.com

Web www.lusanpeju.com

Lusan Peju Sdn Bhd, founded in December 2017, has quickly established itself as a leading provider of construction, building maintenance and engineering services in Malaysia.

Specialising in civil and structural engineering, fire and gas detection systems and integrated medical services (IMS) and buildings, facilities infrastructure management, the company delivers comprehensive, multi-industry solutions tailored to the marine, industrial and commercial sectors.

Marina Plaza

Dubai Marina United Arab Emirates

Contact

Alexander Beck, Head of Business Development

Telephone +971 58 594 1144

alexander.beck@mde-group.com

Web

www.mde-group.com/mena

MDE MENA (part of MDE Group) is a global recruitment company specialising in placing talent and providing the highest skilled project personnel around the world. The company attracts the best international candidates, delivering industry-leading solutions for any stage of the project lifecycle.

MDE MENA prides itself in nurturing business relationships by balancing the needs of clients and consultants and delivering a highly professional and personalised service to all stakeholders.

Thanks to its unique business model, the company is lean and flexible, giving it the edge its competitors may often lack. By pro-actively delivering highquality and cost-efficient solutions, MDE MENA aims to become market leaders in the fields of recruitment and consultancy.

With an office in Dubai and Group offices across Norway, the UK, Asia, Africa, North America and South America, MDE MENA's services extend as it offers integrated project support, procurement and logistics and global mobility assistance to clients worldwide.

NEW PRIMARY MEMBER mselect

825 Town and Country Ln

Houston Texas 77024

US

Contact

Sam Erickson, Business Development Director

Telephone +1 832 288 1979

Email sam.e@mselect.com

Web www.mselect.com

mselect delivers agile staffing solutions for the US energy industry, combining global expertise with local market knowledge.

The company's services, from contract staffing and direct hire to statement of work and payroll management, give energy companies the talent, flexibility and compliance they need to keep complex projects on track and on budget.

mselect is a boutique partner with international reach, built to serve the unique needs of companies in the energy market.

The Offices 1, One Central Sheikh Zayed Road PO Box 115580

Dubai

United Arab Emirates

Contact Rosie Butler, Business Development Manager

Telephone +971 4 373 9700

Email rosie.butler@pinsentmasons.com

Web www.pinsentmasons.com

Pinsent Masons is a purpose-led professional services business with law at its core. With a global turnover of £650m (2024), the firm operates from 29 offices across four continents, employing over 3,800 people, including 2,200+ partners and lawyers.

Established in 1769, Pinsent Masons is recognised for its innovative approach and deep sector expertise, particularly in energy, infrastructure, financial services and technology.

The firm delivers first-class legal services, combining international reach with local insight and is committed to helping clients achieve their global strategies while navigating complex commercial, regulatory and cultural landscapes.

5325 S Moorland Rd New Berlin WI 53151 US

Contact

Raveenthan Thambirajah, Business Development Director

Telephone +1 416 450 8797

Email raveenthan.thambirajah@ renewable-d.com

Web https:// renewableenergyanddrives.com/

Renewable Energy & Drives is a UK and US based clean energy engineering and consultancy firm specialising in the supply and servicing of global power quality solutions, including MV and LV uninterruptible power supply systems, D-Statcom and advanced energy storage systems, with a state-of-the-art 30,000 sq ft manufacturing facility in Wisconsin, US. Originally founded in 2010 to support wind farms across the UK and Ireland, the company has expanded under the Critchley Engineering Group to support much wider critical infrastructure facilities worldwide.

Transwater API Sdn Bhd

35, Jalan Pengacara U1/48 Kawasan Perindustrian Temasya 40150 Shah Alam Selangor

Contact

Syed Afisol Bin Syed Sofi, Assistant General Manager (Sales)

Telephone +603 5569 1155

Email afisol.sofi@transwater.com.my

Web www.transwater.com.my

Established in 1981, Transwater began as an engineering company dedicated to advancing solutions within the water sector. It has more than 40 years of experience in integrating products and systems from global manufacturers with best-in-class application engineering and project management expertise tailored to local requirements.

Transwater is a leader and respected provider of control, relief and isolation valves and regulators, shutdown and turnaround service support and environmental monitoring for the oil and gas, power and general industries.

Transwater is committed to leveraging its experience and expertise to consistently deliver value-added solutions that meet the highest standards of safety, reliability, sustainability and environmental responsibility every single day.

The final electrical substation for Dogger Bank C has been floated out to sea for installation, marking a major milestone in ABB's electrical infrastructure delivery for the world's largest offshore wind farm, which is supporting efforts to decarbonise the UK grid.

Located over 130km off the coast of Yorkshire, UK, the three-phase Dogger Bank offshore wind development will deliver clean electricity to approximately 6m homes when fully operational. ABB's advanced electrification and digital solutions enable the reliable transmission of offshore renewable power at large scale.

Working in collaboration with Norwegian contractor Aibel, ABB delivered the complete electrical system for Dogger Bank C's offshore substation, having been selected in 2019 to supply electrical substations for all three phases, Dogger Bank A, B and C.

The scope for this project includes auxiliary control systems, overall OT security, IT infrastructure, condition monitoring, telecoms, low voltage power distribution and bus ducts. Combined with digital technologies, these systems enhance availability, safety and efficiency while enabling remote operations and predictive maintenance to reduce offshore staffing and extend asset life.

ABB's technology and engineering solutions act as a central gateway that unlocks the offshore wind process, allowing the electricity generated by wind turbines to flow through to the national grid and into peoples' homes. When the turbines at Dogger Bank produce power, offshore substations allow the alternating current (AC) to be converted to direct current (DC) so the electricity can be transported to onshore substations, where it is inverted back to AC.

ABB has been involved in commercialising wind power projects for over four decades, working with partners to maximise energy output, ensure grid stability and keep operations running smoothly through automation, electrification and digital solutions built to adapt to tough conditions.

Today, over 40,000 wind turbines around the world use ABB components, making ABB the largest supplier of electrical components to the wind industry with an installed base in many countries.

ABB is supporting 14 offshore wind projects worldwide which collectively represent 20GW of power capacity. Across the UK alone, ABB is contributing to nine key offshore wind projects, collectively representing close to 12GW of power capacity.

For more information: www.abb.com

Every single year in the past two decades, the energy industry has hit a new record in renewables installations. Yet every year the industry moves further away from keeping global temperature rises within 1.5°C. The reason is clear: the need to act on a far bigger scale.

To accelerate the energy transition, industry needs a global scale-up. Investment in clean energy remains concentrated in wealthy countries, with much of the rest of the world left behind. Redressing the balance by unlocking the deployment of renewables in the global south is essential if we are to decarbonise the world's energy systems and meet the goals of the Paris Agreement. The global south, home to two-thirds of the world's population, remains dramatically underserved, today receiving only 15% of clean energy investment.

From March to May 2025, Bureau Veritas collected insights and opinions from over 1,100 market experts and industry leaders from all continents and corners of the energy sector. By highlighting pragmatic solutions and best practices from around the world, the report aims to show what can be achieved – and how these successes could be replicated to meet the world's growing energy needs in a sustainable manner.

i Download the full report here: https://news.bureauveritas.net/ l/591681/2025-07-01/3t8znd3

We'll use our engineering expertise and long record of predictable best-in-class delivery to optimise the performance of Kinneil Terminal. This is critical national infrastructure and our work will build vital resilience into the UK's energy system with a safer, more efficient and more reliable terminal. With our strong and growing presence in the region this contract marks the next chapter in our productive and collaborative relationship with INEOS FPS.

Sean Close, Energy Resilience Director, Costain

Costain, the infrastructure solutions company, has secured a multi-million pound engineering services contract with INEOS FPS.

The contract, covering a minimum of three years, will see Costain deploy its extensive engineering expertise to support the optimisation and utilisation of operations at the Kinneil Terminal – a critical piece of the UK's energy infrastructure.

Costain has already been providing end-to-end engineering services at the Kinneil Terminal for more than ten years, having delivered multidisciplinary front-end studies through to detailed design engineering and procurement services for both onshore and offshore assets since 2014.

Costain will service the contract from its new Aberdeen office where it continues to serve a growing customer base in the energy sector in Scotland and across the UK.

Costain's energy sector delivers innovation, engineering and construction excellence to solve complex problems facing the UK's energy infrastructure. It has a long track record of delivering infrastructure solutions in Scotland, including front end studies, asset maintenance and engineering, procurement and construction (EPC) contracts. Costain has also provided technical consultancy services to Storegga (formerly Pale Blue Dot Energy) in support of the Acorn carbon capture and storage project.

Crondall Energy has announced that its SafeMoor technology has been selected the Offshore Renewable Energy (ORE) Catapult and Flotation Energy as the solution provider for the Innovation Exchange challenge:

Solutions for Anchor Monitoring, with a Focus on Anchor Slippage, supported by Innovate UK.

Floating offshore wind represents the next evolution for the offshore wind industry. However, with innovation comes risk. To address these challenges, Crondall Energy has developed SafeMoor – a comprehensive mooring integrity management (MIM) solution designed to mitigate risks associated with deploying mooring systems, which can involve hundreds of lines in a floating wind farm.

The challenge, proposed by Offshore Renewable Energy Catapult's Floating Offshore Wind Centre of Excellence (FLOWC), in partnership with offshore wind farm developer Flotation Energy, was supported by Innovate UK's Innovation Exchange programme. Innovate UK Innovation Exchange, ORE Catapult and Flotation Energy will provide support to Crondall Energy as they continue to develop SafeMoor.

i For more information: www.crondall-energy.com

The HIMA Group has appointed Carl Ramsden as CEO of Sella Controls – A HIMA Company – effective 1 October 2025. This newly created position represents an important milestone in the further integration of the British company into the HIMA Group.

Carl Ramsden brings more than 20 years of international leadership and financial expertise from the industrial and technology sectors. He has worked on both the manufacturing and end-customer fronts, giving him a comprehensive understanding of the industrial value chain.

With his expertise and clear value-driven leadership style, Carl Ramsden will further accelerate growth in the process and rail industries in the UK and Ireland and help us to further expand our global position as a solutions provider.

CEO, HIMA Group

As CEO of Sella Controls, Carl Ramsden will assume overall responsibility of the company and will lead it alongside Chris Parr (CTO) and Eddy Turnock (CSO). Carl will also take on the responsibilities previously held by John Blackwell, who will retire as chief financial officer (CFO) on 31 October 2025.

Sella Controls was acquired by the HIMA Group in February 2023 following a long-standing partnership. The integration went smoothly, with central IT and management systems harmonised within a short period of time. Sella Controls now serves as the regional centre for the UK and Ireland and as the HIMA Group's global centre of excellence for railway activities, currently employing over 130 people.

Kent

Kent, a global leader in integrated energy services, has been appointed by ACWA Power as owner's engineer for the Yanbu green hydrogen hub, a major green hydrogen and ammonia export facility being developed in the Kingdom of Saudi Arabia. The project is set to become one of the largest of its kind globally, forming a centrepiece of the country's clean energy transition strategy and aligning closely with Vision 2030.

As owner's engineer, Kent will act as ACWA Power's technical representative throughout the front-end engineering design (FEED) phase being delivered through a joint venture between Técnicas Reunidas and Sinopec. The Kent team will provide independent oversight and assurance to support safe, efficient and technically robust project delivery. Kent's responsibilities include ensuring engineering design compliance with international standards, reviewing safety and constructability, managing technical interfaces and integration across the various workstreams and advising on risk and design optimisation. The team will also support ACWA Power in planning the transition into the engineering, procurement and construction (EPC) phase.

Situated in the port city of Yanbu on the Red Sea, the project will feature full integration across the green hydrogen value chain. This includes its own dedicated renewable power generation, desalination plants, ammonia production lines and an export terminal. At full scale, the facility will deliver up to 400,000 tonnes of renewable hydrogen per year, converted into over 2.2m tonnes of green ammonia for international markets. With more than 4GW of electrolysis capacity planned, the Yanbu hub is expected to be nearly twice the size of the NEOM green hydrogen project. Kent's appointment builds on its growing portfolio of energy transition work in the Middle East, reflecting the company's commitment to advancing decarbonised energy systems worldwide.

Kent is a privately owned international integrated energy services partner backed by Nesma & Partners. Founded in 1919 as a small family business in Ireland, Kent is a 13,000-person strong, client-centric team and a US$1.7bn revenue global business. It delivers sustainable and innovative engineering services and project delivery solutions for the oil and gas, chemicals, renewables and low-carbon industries. It has a roster of blue-chip clients, including international energy companies, national energy companies, renewable energy companies and global petrochemical companies.

Nidec Conversion has always positioned itself as a facilitator of the energy transition. Being able to unveil our first sustainability plan this year is a reason for us to be proud and a demonstration of the tangibility of the path we started several years ago.

Dominique Llonch, CEO and President, Nidec Conversion

Nidec Conversion unveils its first ESG Improvement Plan for the three-year period 2025-2028

Nidec Conversion, among the largest international players in power solutions, industrial automation, power quality and BESS (battery energy storage system), as well as a market leader in technologies using renewable energy, has announced its first Environmental, Social & Governance (ESG) Improvement Plan summarised in the project claim Powering the Change, Driving Sustainability.

Nidec Conversion, with manufacturing plants in Europe, China, India and the US, confirms its commitment to promoting a sustainable energy transition of its production processes, supply chain and product innovation, providing advanced technologies to support the industry and actively contributing to the fight against climate change.

Nidec Conversion is based in Milan, Italy and has more than 2,200 employees and 11 global production sites to support growth in industries including BESS, drives and electric vehicle (EV) charging. The company takes an integrated approach to environmental sustainability, focusing on responsible resource management, energy efficiency and waste reduction through the implementation of innovative solutions.

This way, Powering the Change, Driving Sustainability outlines the company's comprehensive approach to environmental management, social responsibility and sustainability.

As part of Nidec Corporation (Nidec Group), a global leader in electric motors and drives, Nidec Conversion offers products oriented towards optimising consumption. Nidec Conversion's products position the Nidec Group at the forefront of the energy storage industry, including projects in hydrogen technology, projects for the electrification of port docks and electric vehicle charging station installations to accelerate the global energy transition.

Nidec Conversion continues to grow as an industry leader because of its ability to successfully navigate sensitive market dynamics, ensuring that clients receive not only the highquality products but also the strategic support needed to actualise shared sustainability goals.