EIC Inside

Sector analysis

Assessing the prospects of small modular reactors: global projects and challenges

Nuclear power provides roughly 10% of the world's electricity and a quarter of its low-carbon electricity, according to the World Nuclear Association. In the wake of growing worldwide energy insecurity, driven primarily by rising consumption rates, states have begun to pivot toward nuclear power once again in terms of policy discussions. However, despite recent narrative shifts and although the sector is a significant part of the energy mix in countries like France and South Korea, nuclear energy remains a highly controversial and costly industry that faces pressing challenges.

The tech industry has been one of the biggest boosters of nuclear power as its electricity needs rise alongside the demand for larger datacentres, driven primarily by AI and cloud computing. This growing demand has led major tech players to invest directly in nuclear solutions. Most prominently, Google has agreed to fund nuclear power sites for Elementl Power, has ordered power from Kairos Power's Hermés 2 developing plant and recently announced a partnership with Westinghouse to use AI in building advanced nuclear reactors. Similarly, Amazon has expanded its nuclear energy partnerships to better support its operations, while Microsoft has officially joined the World Nuclear Association as it doubles down on its nuclear plans.

This renewed interest from the tech sector has been a key driver in the revival of the nuclear conversation, with a new surge in startups and projects, especially for small modular reactors (SMRs).

Nuclear plans tend to run over budget, which is why a bigger focus has been given to the prospect of SMRs in recent years – a shrunken version of a larger reactor with a typical maximum capacity of 300MW, constructed in a modular fashion (in factories, instead of onsite), which, in theory, reduces upfront capital costs. Additionally, a SMR's reduced size contributes to the developer's ability to incorporate more passive safety measures that don't rely on external power –an approach deemed safer than more active safety models.

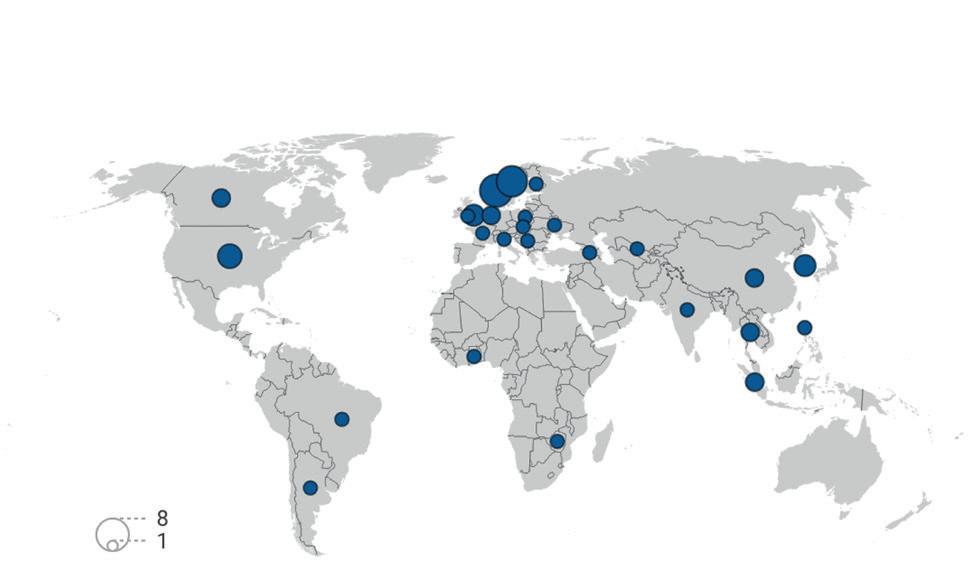

Despite the promising design and safety features, the operational reality of SMRs is still at the beginning of its development. Currently, of all announced SMR plants under various stages of development, none have begun operations. In fact, EICDataStream indicates that most remain in the early planning stages, with only 11 actively under construction in Bulgaria, Canada, China, India, Russia, Sweden and Uzbekistan.

This slow pace is further highlighted by recent project announcements. Since 2024, 51 new SMR projects have been announced globally – 29 of those in Europe alone.

So far, 47 remain in the early planning stages while four are indeed moving forward and have progressed to EPC, namely China's Gobi Desert TMSR-SF1 SMR prototype, Uzbekistan's Jizzakh small modular reactor, Sweden's Oskarshamn SEALER-D demonstration power plant (Blykalla) and India's Bharat small modular reactor (BSMR) project.

Recent small modular reactor announcements: Norway and Sweden lead (2024-2025)

Despite the optimistic narrative surrounding SMRs, the financial viability of such technologies remains a major hurdle. Smaller reactors promise faster construction and lower upfront costs than conventional large-scale nuclear developments, which can easily surpass US$10bn, but this theoretical cost advantage is failing to materialise. Due to notyet-established supply chains, novel or first-of-a-kind (FOAK) technologies and smaller efficiency compared to larger reactors, SMRs have not fared well in maintaining their initial CAPEX forecasts, especially in Europe and North America.

In this context, viewing SMRs as a strategic national investment is the approach taken by countries like China, India and Russia, where SMR projects are almost entirely state-run. Such state-controlled models ensure that regulatory burdens are avoided and guarantees the operator will be able to compete effectively within the market once the project comes online, assured of a reasonable rate of return for power sales downstream.

While the sector has talked about it for years, a true nuclear renaissance remains speculation beyond our current technological and market reality. The prospect of synergistic, fossil-free hybrid systems integrating nuclear and renewable energy is promising, but it is also undermined by opposing cost trends: nuclear expenses are escalating as the costs of renewables such as solar and battery storage (BESS) continue to fall. Ultimately, a lot will hinge on the commissioning of the world's first commercial land-based small modular reactor – China's LingLong One – scheduled to come online in 2026.

Gabriela Santos, Junior Energy Consultant gabriela.santos@the-eic.com

Inside this issue...

Welcome to another packed and highly information EIC Inside Energy members magazine. This month, I want to use this foreword to highlight two new services that EIC now offers to its members that we are really excited about.

Firstly, for the last few months, we have been building a powerful new podcast series, under the general header of EIC Podcasts. We have five podcast shows in the series, that provide unique opportunities for our members to promote the amazing work they are doing and to use this exciting and powerful new channel to reach your target audience.

We have two C-level podcast shows, namely EIC Clearly and EIC Energy Focus; we have two podcast shows for members to promote specific success stories and share best practises, namely EIC Survive & Thrive and EIC Inside Energy; and we have one podcast show that showcases the work EIC does, namely EIC Energy Insights. If you want to be featured in any of these platforms, please contact EIC CEO Stuart Broadley directly at stuart.broadley@the-eic.com

Secondly, after months of behind-the-scenes product development work, we are delighted to now announce that members can integrate EIC data from EICDataStream into their own internal systems via something called an EIC API, which stands for Application Programming Interface. Why would an API help you?

Are you looking to automate the distribution of project insights from EICDataStream throughout your business? Have you always wished EIC project insights from EICDataStream could be loaded directly into your business software or enterprise software, for example CRM or Salesforce, removing manual uploading of project information? The API also works with Power BI or other business analytics tools.

Please note that this new and very wonderful API feature is only available for EIC global members. If this sounds interesting, we recommend you involve your IT team or IT support company, for any development work that may be needed to integrate the EIC API into your systems. To find out more about how an EIC API could help your business, please go to www.the-eic.com/MarketIntelligence/EIC_API

DataStream

AUSTRALIA

Marinus Interconnector Project – Stage 1

Operator: Marinus Link Value: US$3bn

Stage 1 of the project has reached FID. Construction will begin in Q1 2026. The project has also received its environmental permit from the Australian government. Hitachi Energy has the contract to provide the converter stations and Prysmian will supply the HVDC cables.

For information on these and more than 16,000 other current and future projects we are tracking please visit EICDataStream

THAILAND

Arthit Offshore Gas Field – CCS Project

Operator: PTTEP

Value: US$328m

The project has reached FID and will see investment totalling up to US$328m. The project, which will capture 1 mtpa of CO2, will utilise existing infrastructure at the field while constructing additional facilities as needed and will not affect the natural gas production at the Arthit field.

Global opportunities

BRAZIL GasLub Refining Hub

Operator: Petrobras Value: US$2.4bn

The HIDW/HCC units tender has been awarded to the consortium formed by Tenenge, ECB and EGTC Infra. The contract is worth around US$795m (R$4.37bn).

SAUDI ARABIA

Al

Sadawi Solar PV IPP

Operator: Masdar Value: US$2bn

Masdar's consortium has successfully achieved financial close through US$1.1bn financing by eight regional and international lenders; Standard Chartered Bank, KEXIM, ADCB, BNP Paribas, ADIB, Bank of China, HSBC and Société Générale. The funds will be used to cover a major part of the total project costs.

TURKEY

Sakarya Gas Field – Phase 3

Operator: TPAO Value: US$5bn

The major EPC contracts have been awarded on the project. Saipem has been awarded an EPCI contract for eight rigid flowlines and a 24-inch diameter gas export pipeline around 183km long. Wison Energies has been awarded an EPCIC contract for the project's FPU. Subsea7 has the EPCI contract for the subsea umbilicals, risers and flowlines.

US

Rio Grande LNG Export Terminal (Train 4)

Operator: Next Decade Value: US$6.7bn

NextDecade has issued a positive FID for the Rio Grande LNG Train 4 project. A Full Notice to Proceed has been given to Bechtel and total CAPEX is US$6.7bn (including EPC costs, owner's costs, contingencies, financing fees/interest during construction and other costs). First commercial delivery under Train 4 is anticipated in 2H 2030.

THE VOICE OF THE ENERGY SUPPLY CHAIN

DataStream

Are you up to date on the latest project developments in the energy market? The EIC’s leading market intelligence database – EICDataStream – contains information on energy projects and associated contracting activity from the inception stage all the way through to construction and commissioning.

• Access details on over 16,000 CAPEX projects across all energy sectors

• Identify business opportunities and inform your business development strategies

• Explore a truly global database, updated daily by an international team of analysts

• Stay up to date with project developments, including information on tenders and awards

• Get insights into what your existing clients are doing and identify potential new clients

• Have a direct interface with analysts for local knowledge and insights

• Access insight and country reports with in-depth data on specific sectors and markets

NEW COUNTRIES ADDED

SupplyMap

EICSupplyMap maps the capabilities of supply chain companies that operate across all energy industries. These industries cover renewables, oil and gas, power, nuclear and energy transition technologies like energy storage, carbon capture and hydrogen.

• Identify the supply chain local to your region, giving you the opportunity to engage with potential new clients.

• Find the supply chain capability in 12 regions, now covering the UK, Germany, Spain, Italy, UAE, Oman, Saudi Arabia, Malaysia, Singapore, Indonesia, US and Brazil.

• An in-depth look at profiles of more than 10,000 energy sector supply chain companies.

• Make smarter decisions by targeting your offering to international developers/operators and contractors matching your capability with international energy projects.

RIO

DUBAI

KUALA LUMPUR

HOUSTON

BERLIN

One-to-one

with Will Fossey, International Development Director, NRL

Will Fossey has supported companies to manage their workforce needs to facilitate global growth for over 20 years. He’s overseen significant expansion of the company’s international capability, now servicing 70 countries and providing strategic labour management and global mobilisation support to high-profile engineering clients.

You've recently celebrated 10 years with NRL, how has the business changed over that time?

The evolution has been remarkable to see, and a testament to the people in our business who are always ready to embrace change. When I joined the company, we had a small international recruitment offering, primarily gained through business acquisition. My remit for international development was to grow that piece of business into a sustained vertical for the NRL Group, so we could truly proclaim to prospective clients that we are a global provider.

Initially this involved expanding our recruitment expertise into new sectors and geographical regions, having predominately supported oil, gas and petrochemical clients recruiting highly skilled expats into the Middle East. Five years into that plan we quickly had to rethink our strategy, as life-changing events such as the pandemic and Brexit threatened our international operations. The changes we have made have catapulted our capability to deliver a range of labour management, global mobilisation and recruitment solutions across the globe, which is exciting to have been involved with.

That sounds intriguing, can you tell us more?

When the world ground to a halt due to COVID 19 we went from a growing international operation which represented around 5% of our recruitment business, to just one single worker.

Our day-to-day operations relied on clients wanting to bring over expats and we did a good job of recruiting them compliantly.

With cross-country borders closed as the pandemic took hold and safety precautions rightly put in place, we quickly identified that our remote location in the UK hindered our ability to deliver global services and taking a local in-country approach would allow us to better service our clients.

The pandemic was quickly followed by the looming Brexit deadline, another indicator that we needed business entities within the countries we were strategically targeting, to grow at the scale we sought. In 2020 we set up our first business entity outside the UK in Ireland, providing us with an office based in the EU to manage our service delivery in Europe post-Brexit, which is still providing a number of advantages today.

It was followed by entities in Spain, Sweden, Poland, Germany and Saudi Arabia – in addition to Norway through a strategic business acquisition. Bringing on board seven business entities outside the UK in just five years, and with further growth plans, we're now able to work within our own operations and with our network of in-country partners to support clients in over 70 countries. The focus on setting up incountry entities and building relationships with in-country partners such as payroll and accountancy experts, allowed us to pivot our international

focused on recruitment, to begin creating labour management solutions for our clients. This includes Employer of Record services where we engage the workers on their behalf and manage the payroll and legal aspects of their employment, as well as statement of works and visa sponsorship.

We now play a much bigger role in solving our clients' global employment challenges and they come to us to ask for advice and compliant solutions, instead of just seeing us as a recruiter. These sizeable changes have allowed the international side of our operations to grow considerably and it now represents 24% of our group turnover.

In 2023 we were recognised by the Staffing Industry Analysts as one of the largest engineering staffing firms globally, which was a testament to our growth and we're now seeing companies approach us to work with them thanks to the respected industry reputation we've earned.

What challenges are businesses facing when planning global energy transition projects?

Across the globe there are significant factors which are impacting how our clients operate, from socioeconomic to changing immigration legislation and skills availability. Civil unrest is impacting large geographical areas, making it harder to mobilise workers safely and impeding the ability to deliver global projects.

AQWe're also seeing changes in some nations as to how receptive they are to expatriates entering the country for work, emphasising the need to recruit locally and through in-country business entities. Continuous changes to employment legislation, immigration and work permits also make it challenging for companies to stay compliant without a labour management partner with the expertise to advise them.

While the growing demand for new engineering innovation in key energy transition sectors such as wind, hydrogen, as well as pharmaceutical and data centres, are highlighting a chronic underinvestment in STEM learning which is driving skills shortages globally.

How is NRL supporting organisations with these challenges?

This is where our decision to diversify beyond traditional recruitment into full labour management solutions has really paid off. Today, we're not just providing workforce solutions, we're supporting clients with a range of complementary services such as purchasing, translations, language support and multicurrency payroll management. These additions make it easier for clients to operate globally without the friction of local complexities. When challenges arise, we don't just offer a service; we design bespoke solutions which remove barriers and keep projects moving.

One example is where we manage all in-country hires through our Employer of Record service, working with local partners and through our own legal entities to manage all the necessary employment legislation, work permits, payroll and taxation, so our clients can focus on the operational side of their global projects.

As a business we've always taken a partnership approach with our clients, regardless of how large or small their account is.

It's this approach that encourages our teams to understand the future challenges our clients are facing and look at how we can support these as a business. It's resulted in us opening new business entities in countries such as Saudi Arabia, investing locally so we can provide a better service.

We're able to do this because we've prioritised bringing on board a wide range of skills, languages and industry knowledge as we've grown our international operations. We've recruited people with experience of working in the countries we are targeting for growth, who have the language skills and local knowledge to be able to advise our clients, as well as ensuring we're hiring for compliance and financial acumen to expand our geographical capability.

AQHow does NRL stay up to date with the change in immigration rules from country to country?

Over the years we’ve built a robust network of in-country partners including payroll and accountancy experts. We work with those companies to ensure we have the latest information to advise our clients, while drawing on the expertise of our own colleagues.

Our international compliance team is well versed in managing complex labour solutions, to understand the finer details of immigration rules and employment legislation. To ensure we’re always one step ahead of upcoming changes, the NRL Group’s compliance panel, made up of subject matter experts from our payroll and labour operations, meet regularly to determine our business’s approach and proactively communicate with clients. In today’s world immigration and the documentation needed to work abroad is continually changing, so it's an area our clients are always looking for support with.

Like many businesses we’re also navigating how AI can drive efficiencies within our operations, including how it can help us stay on top of immigration and employment legislation changes from one country to another, always ensuring a human eye is verifying the finer details.

AQWhat's the current focus for NRL's international strategy?

It’s about expanding our geographical remit while strengthening our international service offering and ensuring we’re focused on what our clients need from us now and in the future. Many of them are looking to get involved with more energy transition projects across the globe, but don’t have the incountry operations to be able to hire workers or confidently manage local employment legislation.

We're able to offer a range of services to clients, from hiring and global mobility, to comprehensive labour management solutions which allow us to engage an entire workforce in a country on behalf of our clients. Solutions are built with 100% compliance in line with local employment laws and immigration rules and are always focused on creating a positive experience for the workers, understanding that it is crucial candidates feel supported when relocating abroad.

As a business our strategy has always been to work closely with our clients, understanding what their future challenges are, what they want to be able to achieve and the international barriers they’re currently facing. That's because we're able to offer practical solutions to address these and are happy to invest in strengthening our own operations in readiness to support them. It’s an approach which has proved successful since pivoting our business at the start of the pandemic and one we’re looking forward to continuing in the coming years.

Member’s news

Flexitallic welcomes global network to UK Channel Partner event in Manchester

Flexitallic, a global leader in static sealing solutions, has successfully hosted its UK Channel Partner event in Manchester.

The two-day gathering brought together representatives from more than 30 distributors worldwide, with partners travelling from countries including Spain, Korea, Angola, Nigeria, Poland, Sweden, Finland, Pakistan, Ireland, the UK, Iraq and the Netherlands.

Flexitallic's own teams also attended from Belgium, Germany, Italy, UAE, China, Türkiye, France and the US.

Held at Old Trafford Football Ground, the event combined strategic updates, technical insights and interactive sessions. Highlights included application insights delivered by Flexitallic engineers and an in-depth look at Flexlogics®, the company's digital joint integrity ecosystem that improves safety, reliability and efficiency by centralising flange data, gasket selection, bolt load calculations and joint integrity records.

Delegates also enjoyed networking opportunities, including a dinner at The Edwardian Manchester Hotel, as well as a tour of Flexitallic UK's manufacturing base at Cleckheaton, West Yorkshire, where they were introduced to the latest innovations in gaskets and sealing solutions.

The Flexitallic Group is a global leader in specialised sealing solutions and products serving the oil and gas, power generation, chemical and petrochemical industries in emerging and developed markets. Focused on the refining, petrochemical, chemical, power generation and upstream sectors, it has operations in the US, Canada, Mexico, the United Kingdom, France, Belgium, Germany, Italy, the United Arab Emirates, Thailand and China, plus a network of worldwide licensing partners and distributors.

This was an incredibly successful event that highlights both the strength and breadth of Flexitallic's global distribution network. To have so many of our partners travel from around the world demonstrates the value they place on working closely with us and the commitment we share to delivering excellence.

By working in close partnership with our distributors, we can ensure that high-quality products are consistently supported by outstanding service. This combination is what gives operators the confidence that their assets are being protected to the highest standards.

Most importantly, events like this allow us to listen, learn and collaborate. Together with our partners, we are not only meeting the needs of today's industrial operators but also preparing for future challenges – with innovation, digital tools such as Flexlogics® and a shared focus on safety, reliability and efficiency.

Sam Bradley, VP Sales for the UK, Middle East and Asia (UMEA)

Delegates attending Flexitallic's UK Channel Partner event tour its manufacturing hub in Cleckheaton, West Yorkshire

Spotlight on technology

When a tornado swept across the Midwest USA, it left a trail of destruction, damaging infrastructure, downing power lines and halting operations at a major refinery. With product lines solidified due to a total power loss, the facility urgently needed emergency onsite heat treatment support to evacuate material and resume operations.

That's when Superheat was called in for a rapid response. Within hours, its team mobilised to the site with 15 technicians and quickly scaled operations to over 65 heating machines running across the facility. However, the real game-changer was the use of the Superheat SmartCenter™, the proprietary remote control and monitoring hub.

Once the heat cycles were up and running, SmartCenter™ enabled Superheat to reduce onsite staffing from over 20 technicians per shift to just 5, saving the client numerous labour hours while continuing to monitor the equipment 24/7 without interruption.

By reducing manpower, Superheat not only lowered overall costs but also decreased safety exposure, helping the client recover operations more quickly and efficiently. The success of this project has already led to discussions for future planned work at the refinery for Superheat.

This is the Superheat SmartWay™ in action, combining advanced technology, experience and rapid deployment to solve complex heat treatment challenges under pressure.

Watch Episode 3 of Superheat’s Innovation in Action series to see how the company helped turn disaster recovery into an opportunity for smarter, safer, heat treatment execution.

Contact Superheat today for all your onsite heat treatment needs:

US 1.888.508.3226

UK +44 (0)1462 888003

Email sales@superheat.com

New EIC members

NEW PRIMARY MEMBER

AC Valves Alliance

Unit 6, Interlink Way South

Bardon Hill

Coalville LE67 1PH UK

Contact

Elissa Park, Marketing Manager

Telephone +44 (0)1530 834 270

Email elissap@acvalveallilance.com

Web www.acvalvealliance.com

The AC Valve Alliance Group provides end-to-end valve and automation solutions for its customers, across a broad range of industries and applications.

Operating out of custom facilities in the heart of the UK and the Netherlands, the company prides itself on both its technical knowledge and world-class customer service – AC Valve Alliance has built a reputation for flexibility, innovative solutions, fast-tracked stock and world-class support from its team of expert consultants.

NEW PRIMARY MEMBER

Add Value Consultancy (AVC)

Spaces, 1 Marischal Square Broad Street

Aberdeen AB10 1BL UK

Contact Hossam Aboegla, CEO

Telephone +44 77667 17516

Email hossam.aboegla@ addvalue-consultancy.com

Web

www.addvalue-consultancy.com

Add Value Consultancy (AVC) is a UK-headquartered consultancy with a strong presence in Abu Dhabi and Dubai, delivering technical services, project management consulting and AI-enabled solutions to the energy, industrial and public sectors.

The company's expertise covers asset integrity, maintenance and reliability, HSE, environmental and sustainability studies and digital transformation. Leveraging AI and data-driven solutions, it enables clients to enhance safety, reliability and performance while aligning with ESG and ISO 55000 standards.

Operating across EMEA and beyond, AVC partners with leading operators, EPCs, digital firms and government entities to deliver measurable value, innovation and sustainable growth.

Thursday 20 November 2025

• Manchester

NEW PRIMARY MEMBER

AISUS Offshore

Unit 21

Denmore Road

Aberdeen AB23 8JW UK

Contact

Barry Marshall, General Manager

Telephone +44 (0)1224 222 070

barry.marshall@aisus.co.uk

Web www.aisus.co.uk

AISUS is a leading provider of advanced inspection solutions, specialising in remote crawlers, robotics, visual and advanced nondestructive technologies for the energy sector.

Focused on asset integrity, AISUS delivers innovative, tailored services that maximise efficiency and minimise downtime. Operating worldwide, AISUS deploys in the most challenging environments, including areas such as the splash zone and behind guide frames to gather critical inspection data safely and effectively.

By leveraging AI and machine learning, AISUS transforms traditional reporting into immersive, animated models with precise defect sizing. With expert professionals and deep offshore knowledge, AISUS provides high-quality inspection services and trusted client support.

NEW BRAZIL NETWORKING MEMBER

BR2W Soluções Ltda

Rua José Eugênio 23A São Cristóvão Rio de Janeiro RJ 20941-140 Brazil

Contact Loreno Ribeiro do Val, Comercial

Telephone +55 21 3005 3320

Email loreno.ribeiro@br2w.com.br

Web www.br2w.com.br/show

To oil and gas operators the company performs mechanical automation of equipment aboard ships and platforms, i.e. the control of cranes or anchoring line.

To maintenance teams BR2W Soluções Ltda monitors the condition of moving equipment, i.e. generators, engines, gearboxes and axis.

NEW PRIMARY MEMBER

Divine Flame and Energy International Ltd

KM 20 Aba Port Harcourt Expressway By Timber Bus Stop Port Harcourt Rivers State Nigeria

Contact Billy Idoro, General Manager

Telephone +23491 6580 4495

Email b.idoro@dfande.com

Web https://dfande.com/

Divine Flame and Energy Int. Ltd is an ISO 9001/ISO14001/ISO 45001/NCDMB certified Nigerian oil and gas services company that is headquartered in Lagos with a full field service support operational base in Port Harcourt.

The company's key products/ services include engineering, procurement, installation, inspection, repairs, maintenance, precommissioning, commissioning and aftermarket support for wellhead equipment (surface and subsea), choke valves (surface and subsea), Xmas trees (surface and subsea), wellhead control panels, subsea equipment and ancillary services.

Divine Flame and Energy Int. Ltd is currently active with ExxonMobil, Chevron, Renaissance (formally SPDC), TotalEnergies, Seplat Energy, First E&P and Oriental Energy amongst others.

Tuesday 10 February 2026 Dammam

NEW

PRIMARY MEMBER

DLC

Avenida Nossa Senhora da Gloria 1109 Pecado

Macaé, Rio de Janeiro 27.923-215 Brazil

Contact Claudio Ramalho, Business Development Manager

Telephone +55 21 998305257

Email claudio.ramalho@dlcdiesel.com.br

Web

www.dlcdiesel.com.br

DLC Diesel was established in 1996 in Mogi das Cruzes/SP, Brazil. The company stands out for providing complete solutions for high and medium-speed engines, air compressors, gensets and filtration systems. It has significant competitive advantages, which is why DLC is an authorised distributor in Brazil for renowned international manufacturers. With dedicated branches, the company offers customised solutions to meet the needs of the energy, marine and oil and gas markets.

Sectors: oil and gas. Categories: operation and maintenance contractor, turbine installation, inspection services, Caterpillar and Perkins engines, Z-Pellers and Niigata engines, Cummins and MAN engines, Napier, Garrett, Holset and BorgWarner turbochargers, ABB and KBB turbochargers, Bosch fuel injection systems, generators, energy storage systems, air compressors, booster lighting towers from Atlas Copco, Fueltrax electronic fuel management system, Parker contaminant management and filtration systems, Motcom predictive failure.

NEW KUALA LUMPUR NETWORKING MEMBER

ENest Pte Ltd

151 Chin Swee Road

#02-04A Manhattan House Singapore 169876

Contact Ho Mun Choong, Co-Founder & Chief Executive Officer

Telephone +65 9146 5001

+6012 681 6960

Email munchoong.ho@enest.ai

Web www.enest.ai

ENest is an AI-powered platform designed to simplify and speed up complex engineering, procurement and construction (EPC) workflows.

The company helps energy, infrastructure and industrial companies cut through manual processes, reduce errors and make faster, smarter decisions.

With built-in AI agents and connectors to your existing systems, ENest automates tender reviews, improves bid accuracy and streamlines project planning.

ENest's approach saves time, reduces costs and increases win rates, while providing transparency across teams and stakeholders.

Backed by industry expertise and advanced technology, ENest delivers practical tools that are easy to adopt and built to scale with your business.

NEW PRIMARY MEMBER EXHEAT Ltd

Threxton Road Industrial Estate

Watton

Norfolk IP25 6NG UK

Contact

Martin King, Business Development Manager

Telephone +44 (0)1953 886 200

Email martin.king@exheat.com

Web

www.exheat.com

EXHEAT is a globally renowned designer and manufacturer of electric process heating and control systems. Its experience in the design of electric heaters for use in hazardous area locations is second to none. The company's complete range of custom-engineered process and immersion heaters, together with its standard product portfolio which incorporates immersion heaters, room heaters and thermostats have extensive IECEx, ATEX and CSA certification amongst others. The range of electric process heaters and standard industrial heaters are designed and manufactured in the UK, backed by more than 20 years of industry experience. EXHEAT's dedicated services company will assist you with all your after-sales needs.

EXHEAT has the knowledge and expertise to design and manufacture electric process heating equipment suitable for installation within the extreme environments commonly found in the oil, gas and petrochemical industries.

NEW BRAZIL NETWORKING MEMBER

L. Quintella Advogados Associados

Av Rio Branco 156, sala 1108

Centro, Rio de Janeiro - RJ Brazil

Contact

Leonardo Quintella, Managing Partner

Telephone +55 21 98867 0433 +55 21 2220 4076

Email lquintella@lq.adv.br

Web www.lquintella.adv.br

Founded in 2012, L. Quintella Advogados is a law firm specialising in litigation, consulting and legal support on:

• Labour and workers compensation disputes.

• Legalisation of foreigners and citizenships.

• Social security claims.

• Contracts.

• Sports law.

With a highly qualified technical team, the company always seeks the best legal solution for its clients in its areas of expertise.

NEW RENEWABLES MEMBER Mapei

Via Cafiero, 22 20158 Milano MI Italy

Contact Lee Parnaby, Corporate Business Development Manager

Telephone +39 0237 6731

Email l.parnaby@mapei.co.uk

Web www.mapei.com

Founded in 1937, Mapei is now among the world's leading manufacturers of chemical products for the building industry. Mapei offers long-lasting high-quality products that are mindful of both the planet and people.

The company draws on this same expertise to contribute to the most important architectural and infrastructural works globally, including projects in the housing industry, energy industry and renovation of historic buildings. Mapei's vision embraces the entire world, reaching all five continents. An internationalisation strategy that has resulted in responsible growth as the company responds to market and local demands and contributes to the development of local communities.

NEW PRIMARY MEMBER

Seven Seas Shipping and Logistics Services

Hatat Complex A-Wing 2nd Floor, Office No 218 Wadi Adai, Muscat Sultanate of Oman

Contact Chacko Jose, General Manager

Telephone +968 91992520

Email c.jose@sevenseasworld.com

Web

www.sevenseasworld.com

Part of the Seven Seas Group, Seven Seas Shipping and Logistics is a leading Omani provider of end-to-end freight and logistics solutions across sea, air and land. Backed by strong expertise in maritime and supply chain operations, the company offers freight forwarding, liner agency, customs clearance, warehousing and inland transportation. With a focus on reliability and efficiency, Seven Seas ensures seamless movement of cargo – from small parcels to large project shipments – across Oman and international markets.

NEW KUALA LUMPUR NETWORKING MEMBER

Verra Seals & Engineering Sdn Bhd

No 99 Ground Floor

Jalan Putra A/4

Taman Bandar Putra, KG Mak Lagam

24000 Kemaman

Terengganu

Contact

Raja Muhammad Al-Amin Bin Raja Zahri, Director

Telephone 09 8504697

Email raja.muhammad@ verraseals.com.my

Established in 2025, Verra Seals & Engineering Sdn Bhd is a private limited company incorporated in Malaysia under the Companies Act 2016. The company specialises in providing engineering services with a primary focus on supplying, servicing and repairing various types of mechanical seals.

In addition to mechanical seals, Verra Seals & Engineering is actively engaged in the wholesale, trade, import and export of industrial machinery, equipment and a variety of general goods, offering reliable solutions for multiple industries.

Member news

ABB expands IE5 SynRM motor range to enable ultrapremium efficiency in more applications

ABB has expanded its IE5 SynRM motor portfolio with three smaller frame sizes (90, 100, 112), now covering 0.75kW to 450kW. This gives customers the broadest range of magnet and rare earth-free motors to boost efficiency, reliability and sustainability across even more applications. With extended power and speed options up to 3,600 RPM, the motors are ideal for pumps, fans and compressors – perfectly paired with ABB variable speed drives for maximum performance.

ABB's IE5 SynRM motors cut energy losses by up to 40% compared to IE3 motors, resulting in significant savings. For example, a single 90kW motor can save €79,800 and reduce CO2 emissions by 95,760kg over 20 years. Industrial sites typically operate dozens or even hundreds of smaller motors alongside larger ones, multiplying these savings and environmental benefits – often delivering a payback in as little as five months.

ABB SynRM motors are included in the ABB EcoSolutions™ portfolio, empowering customers and partners to make more sustainable choices through increased transparency about each product's circularity and environmental impact. This supports informed, responsible decisionmaking. Products in this portfolio are backed by externally verified, third-party environmental product declarations (ISO 14025 Type III).

This expansion reinforces ABB's commitment to IE6 hyper-efficiency, already achieved by select SynRM models above 90kW. These futureready motors deliver up to 20% lower losses than IE5, setting a benchmark in energy efficiency for the industry.

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resourceefficient future. By connecting its engineering and digitalisation expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. The company has over 140 years of history and around 110,000 employees worldwide.

Amarinth awarded grant to develop next-generation multistage cryogenic pump

Amarinth, a world-leading, net zero designer and manufacturer of low lifecycle cost centrifugal pumps and associated equipment, primarily for the offshore and onshore oil and gas industries; nuclear and renewable energy generation; defence; desalination; process and industrial markets, has been awarded a £500,000 grant by Innovate UK to develop an advanced multistage centrifugal pump for cryogenic LNG applications.

This award builds on Amarinth's previous success in securing a £250,000 grant to refine its design and production processes for highly energy efficient pumps, which culminated in the launch of an industry leading molten sulphur pump.

Innovate UK's new funding underscores its confidence in Amarinth's engineering excellence and entrusts the company to meet the growing demand for modern, efficient pump technology in the low temperature fuel sector.

Leveraging its proven cryogenic expertise, including recent projects replacing obsolete single stage pumps, Amarinth will design and prototype a multistage pump capable of handling liquefied natural gas at approximately -162°C. Departing from legacy designs, the new pump will incorporate state of the art CFD designed hydraulics and bespoke impellers, ensuring each stage operates at its optimal duty point.

Atlas Copco's X-Air⁺ 750-25 portable air compressor powers reliable water well drilling in rural Spain

Reliable access to water is essential for agriculture, construction and development – and it often starts with efficient water well drilling. In the Spanish countryside near Zaragoza, a local drilling company is relying on Atlas Copco's compact, powerful and fuel-efficient X-Air⁺ 750-25 portable air compressor to carry out well drilling projects with ease and confidence.

Water well drilling in rural terrain is no easy task. Beneath the dry, gravelly soil of the Zaragoza countryside, operators often face compacted ground that resists even the toughest drilling equipment. Access roads are narrow and uneven, requiring equipment that's not only powerful but also highly mobile. The drilling process itself demands consistent high pressure and air flow to break through layers of stone and sediment – all while keeping fuel consumption low and productivity high in remote locations where downtime is costly.

Perforaciones y Sondeos Hermanos Rodríguez SL (Hermanos Rodríguez), based in Peñaflor de Gállego, Zaragoza, Spain, is a local drilling company that has built a reputation in water well drilling and geological soundings. For them, the ability to transport and deploy their compressor easily was essential but so was ensuring reliable performance and fuel efficiency in remote conditions. That's why they chose the Atlas Copco X-Air⁺ 750-25, a compact, high-performance portable air compressor specifically designed for demanding drilling jobs in rugged, hard-to-access environments.

In a recent project, the team faced the task of drilling wells and conducting soundings up to 40 metres deep in challenging gravel terrain. With site access limited to a dirt road, they needed a compressor that could be transported and deployed easily – without compromising on pressure or performance.

The Atlas Copco X-Air⁺ 750-25 portable air compressor was selected for its ability to meet the pressure and air flow demands of medium-depth water well drilling.

With a working pressure range from 16–25 bar (232-363 psi) and free air delivery between 20-19m³/min (701–678 cfm), the X-Air⁺ 750-25 provided the consistent performance needed to penetrate dense, rocky subsoil.

This level of power ensured that the drilling operation could proceed without interruptions, even in some of the toughest terrain found in rural Zaragoza.

The X-Air⁺ 750-25 was designed by listening closely to our customers, who need more power in a smaller, more efficient package. This case shows how the right balance of power, mobility and fuel efficiency can make a real difference in dayto-day operations, especially in remote, rugged conditions.

Raúl Roldán Quintana, Business Line Manager, Atlas Copco

Atlas Copco Group innovates to develop products, services and solutions that are key to customers' success. The Group's four business areas offer compressed air and vacuum solutions, energy solutions, dewatering and industrial pumps, industrial power tools and assembly and machine vision solutions.

The Atlas Copco X-Air⁺ 750-25 portable air compressor excels in water well drilling applications

Photo © Atlas Copco Ltd

Bureau Veritas confirms new Teesside location after being named key partner on East Coast Cluster projects

Bureau Veritas, a world leader in testing, inspection and certification, has expanded its UK presence with the opening of a new project office in Teesside. The new office will support local content amid the area's focus on growth and energy transition.

The development follows Bureau Veritas' appointment to a major framework contract to provide quality services for Net Zero Teesside Power (NZT Power) and the Northern Endurance Partnership (NEP), two projects within the East Coast Cluster, one of the UK's leading Track 1 carbon capture storage initiatives.

The development of NZT and NEP as part of the East Coast Cluster is a significant step towards a net zero future and the UK's transition. We're proud to be working with bp through our local UK and extensive global network, providing services and solutions and building on our own reputation and technical capabilities and understanding of the supply chain.

Darren Taylor, Market Lead for Energy Transition, Bureau Veritas

Bureau Veritas will provide independent quality, inspection and surveillance services, representing bp within a significant portion of the project supply chain.

NZT Power aims to be the world's first gas-fired power and carbon capture project and a key driving force behind plans to make Teesside the UK's first decarbonised industrial cluster.

Once operational, NZT Power's combined cycle gas turbine electricity generating station could produce up to 742MW of flexible, dispatchable, low-carbon power, equivalent to the average annual electricity requirements of more than 1m UK homes.

NEP is developing onshore and offshore infrastructure needed to transport CO₂ from carbon capture projects across Teesside and the Humber to secure storage under the North Sea. The NEP infrastructure includes a CO₂ gathering network and onshore compression facilities, as well as a 145km offshore pipeline and subsea injection and monitoring systems for the Endurance saline aquifer, located around 1,000 metres below the seabed. The infrastructure will transport and permanently store up to an initial 4m tonnes of CO₂ per year.

NEP is a joint venture between bp, Equinor and TotalEnergies. It was formed in 2020 as the East Coast Cluster CO₂ transportation and storage provider, which will transport and store CO₂ emissions from the Teesside and the Humber industrial clusters.

Bureau Veritas has a track record of more than 250GW in renewables and net zero projects, supporting major power companies globally. Its inspection team can act as a second party for developers and OEMs, acting as a representative of its client, or as an accredited or voluntary third party offering its independent technical consultancy to make recommendations and issue statements regarding product quality.

Bureau Veritas is a world leader in laboratory testing, inspection and certification services. Created in 1828, the Group has more than 84,000 employees located in more than 1,600 offices and laboratories around the globe. i

For more information: https://marine-offshore.bureauveritas.com/

ECITB: new welding qualification launched for engineering construction industry

The ECITB awarding organisation has launched a new Level 2 welding qualification and is inviting colleges and training providers to become approved centres to deliver this.

The regulated qualification – ECITB Level 2 Diploma in Introduction to Welding in Engineering Construction Operations – is now available for registrations in England.

With units covering safe working practices, communications and working relationships, interpreting documentation, preparing and reinstating work areas and welding techniques, the qualification prepares candidates for a welding career in the engineering construction industry (ECI).

To view the qualification including entry requirements and modules visit: www.ecitb.org.uk/qualifications/ ecitb-level-2-diploma-inintroduction-to-welding-inengineering-construction-operations/

The qualification is based on the National Occupational Standards (NOS) and Occupational (Apprenticeship) Standards for the trade, encompassing the required knowledge, skills and behaviours.

This ensures the qualifications are relevant and future proofed. Through extensive consultation with industry, they are tailored specifically to meet the needs of industry.

For more information on the qualifications, including entry requirements, structure and progression opportunities, visit: www.ecitb.org.uk/professionaldevelopment/ecitb-qualifications/

For more information on applying to be an approved centre visit: www.ecitb.org.uk/professionaldevelopment/ecitb-qualifications/ become-an-approved-centre/

iFor more information: www.ecitb.org.uk

Welding is one of those key trades that will be vital to build the infrastructure needed to deliver major projects. ECITB qualifications are the only ones designed specifically for engineering construction to meet the needs of our employers and the wider industry.

Kent joins FEED team to help deliver UK's hydrogen future

Kent, a global integrated energy services partner, is proud to announce its support to the front-end engineering design (FEED) delivery team for Project Union East Coast, a landmark initiative by National Gas to create a corehydrogen network across the UK.

Kent has joined the expert delivery team, contributing to the two-year FEED phase of Project Union East Coast, led by WSP, acting as FEED integrator. This multidisciplinary team will deliver the two-year FEED phase, including engineering design, environmental assessment, public consultation and route consenting, alongside National Gas's in-house experts and other appointed specialists.

As part of this team, Kent will contribute its extensive experience in end-to-end project delivery and engineering design, helping to shape the infrastructure required to support a hydrogen economy across the UK.

Project Union will initially connect key industrial clusters in the Humber and Teesside regions, eventually forming a 1,500-mile core hydrogen network capable of transporting 100% hydrogen. This network will be vital in reducing industrial emissions, supporting clean growth, protecting jobs and advancing the UK's net zero targets.

Kent brings to the programme over a century of engineering excellence and a track record of delivery in complex, regulated energy environments. Kent's involvement in Project Union East Coast reflects its ongoing commitment to enabling the energy transition by repurposing and building infrastructure that will fuel the UK's hydrogen future.

For more information: https://kentplc.com/

Global Recruiter Awards 2025 shortlist for NRL

Technical engineering specialist NRL is celebrating securing a spot on the shortlist for Global Recruiter Awards 2025's highly competitive Best Large Recruitment Business (annual turnover £100m+) category.

The prestigious accolade celebrates the achievements of recruitment organisations that demonstrate outstanding performance, innovation and impact across the industry. Held each year in November, the Global Recruiter Awards are widely recognised as a benchmark of excellence in the recruitment sector, showcasing the very best in the industry.

Being shortlisted in the Best Large Recruitment Business category for a second consecutive year is a significant honour, reflecting NRL's continued

growth, strategic client relationships and unwavering commitment to ethical and inclusive recruitment practices.

NRL's submission highlighted its 40+ years of experience supporting UK and global engineering organisations with tailored recruitment and workforce solutions. The company is trusted by clients to deliver the right people for complex projects and strategic hires, acting as a key supply chain partner and often working as an extension of internal talent acquisition teams. NRL's expertise spans both temporary and permanent recruitment, with a strong focus on compliance, industry knowledge and global reach. The company's longstanding relationships with clients, some dating back to its founding in 1983, are a testament to its industry reputation and service excellence.

The winners of the Global Recruiter Awards 2025 will be announced at the annual awards ceremony which takes place in London on Wednesday 19 November. i

For more information: www.nrl.co.uk

Andrew Hockey, CEO, Engineering Construction Industry Training Board

Gordon Matson promoted to director of Peterson Freight Management

A leading figure in the international freight forwarding industry has taken over the reins at Peterson Freight Management. Gordon Matson will now lead both LS Customs and Peterson Freight Management for Peterson Energy Logistics.

Gordon joined Peterson in 2022. In that time, his customer-connected focus has led to significant growth in contracts and service offering at LS Customs which has doubled its headcount.

Peterson Freight Management and LS Customs not only share a location, but an ethos. Their innovative approaches meant that Gordon was a natural choice to lead both businesses.

Andrew Ellis, Commercial Director, Peterson Energy Logistics

Gordon worked as national oil and gas manager at Keuhne & Nagel for more than 15 years. His focus as managing director of both businesses will be strategic customer engagement, business development, developing and delivering external training and internal business management.

Gordon is supported by a strong management team of Martin Scott, operations manager and Chris Carter, warehouse and transport manager, for Peterson Freight Management and Jane Waldie, customs hub manager, for LS Customs.

Peterson Freight Management has managed international transport solutions within the UK and overseas, ensuring all requirements in terms of documentation are addressed for more than 10 years.

i For more information: www.onepeterson.com

SGS elevates FPSO operations through innovation and insight

As global offshore energy projects become more complex, success depends on more than just meeting minimum standards – it demands proactive innovation, technical precision and deep sector insight. SGS goes beyond compliance to help FPSO operators drive safer, smarter and more sustainable performance across the full asset lifecycle.

From fabrication yards to offshore operations, SGS delivers integrated support built on decades of experience in the energy sector.

Its services encompass vendor inspection, commissioning support, crew well-being monitoring and real-time data insights through SGS managed and operated onsite modular laboratories. With each solution, the company focuses on improving operational efficiency, reducing risk and ensuring asset integrity – as well as considering how sustainability performance can be improved.

i For more information: www.sgs.com/FPSO

Today’s FPSO projects require partners who understand the technical, logistical and regulatory demands from day one. At SGS, we bring global expertise with local agility –helping operators achieve efficiency, compliance and competitive advantage.

Laura Wakeham, Global Head of Supply Chain and Technical Staffing Solutions, SGS

Compliance and engineering appointments strengthen STATS Group offering

STATS Group (STATS) has announced two key appointments which bolster its legal and compliance and engineering capabilities.

The pipeline technology company – a leading provider of pressurised pipeline isolation, hot tapping and plugging services to the global energy industry – has appointed Adam Morrice as legal and compliance director based in the company's Kintore headquarters in Aberdeenshire, Scotland.

Previously Adam held senior positions with Expro as legal and contracts manager and most recently he was head of legal at Trojan Energy. As a member of the executive committee, he leads the renewal of STATS' legal, contract, risk and compliance functions, working closely with global and regional leadership teams on contractual oversight, regulatory compliance, policy development and strategy.

Vince Kolbuck joins the company as global engineering manager based in Houston, US.

Vince will work closely with engineering teams across Canada, the US, the Middle East, Asia Pacific and UK, ensuring strategic alignment of regional and global engineering priorities with clients' needs.

A seasoned, results oriented leader, Vince joins the company with a diverse three-decade background in midstream pipeline operations, tank terminals, engineering and construction.

STATS, a wholly owned subsidiary of Mitsui & Co Ltd, provides specialist engineering services for the maintenance, integrity and repair of oil, gas and petrochemical installations and infrastructure.

STATS has gained an excellent reputation for providing a responsive, client-centred approach combined with expertise and innovative products which enhance safety and environmental performance, reduce system or plant downtime, improve asset performance and support decommissioning and abandonment.

The group operates from its headquarters in Kintore, Aberdeenshire in the UK.

Adam and Vince bring us a wealth of knowledge and experience as we move into the execution phase of our 3-year growth plan. Legal and compliance and engineering are important enablers of our success as we bring industry leading technology and customer service to more regions and customers around the world.

Stephen Rawlinson, CEO, STATS Group

SINI is now part of the WIKA Group

The WIKA Group has acquired AB Svenska Industri Instrument SINI as a wholly owned subsidiary. This move strengthens the global measurement technology manufacturer's presence in Sweden. Established in Gothenburg in 1948, SINI was originally founded as a service provider for the shipping industry. Since SINI became a distributor for WIKA measuring instruments in 1970, the partners have steadily expanded their joint business. Today, SINI enables Swedish companies to directly access a broad portfolio of instrumentation for pressure, temperature, level, flow and force. They also benefit from various services such as calibration, installation and warehousing.

The acquisition of SINI as a subsidiary marks a strategic milestone for WIKA in Northern Europe. Our local presence allows us to offer more tailored advice and enhanced support.

Sascha Niederhagen, Executive Vice President EMEA India, WIKA

i For more information: www.wika.co.uk

Vince Kolbuck, Global Engineering Manager and inset, Adam Morrice, Legal and Compliance Director

Photos Copyright © 2025 STATS Group

Wood and Equinor extend UK collaboration

Wood, a global leader in consulting and engineering, has secured a three-year contract extension to provide operations, maintenance, modifications and support services (OMMS) on Equinor's assets at the Mariner field, located on the UK Continental Shelf (UKCS).

With this extended contract, Wood will continue to support the delivery of Equinor strategic objectives through projects, upgrades and maintenance on the Mariner A platform and Mariner B floating storage unit.

The contract, which includes a further one-year contract extension option, will continue to be supported by more than 110 employees based at Wood's office in Aberdeen, as well as offshore on the Mariner assets.

Wood has a longstanding collaboration with Equinor, supporting global projects, including long-term contracts in Norway and Brazil as well as Equinor's renewable energy business in the UK.

Wood is a global leader in consulting and engineering, delivering solutions to critical challenges in energy and materials markets.

This contract extension reflects Equinor's continued confidence in Wood's ability to deliver safe, efficient and reliable performance on the Mariner assets – a responsibility we've upheld since 2020. The Mariner field plays a vital role in supporting the UK's energy security and we’re proud of Wood's part in its success.

Steve Nicol, Executive President of Operations, Wood

The company provides consulting, projects and operations solutions in 60 countries, employing around 35,000 people.

Worley's new Aberdeen headquarters

Worley has relocated to a new facility, 16 North Esplanade West, in central Aberdeen. The move signals a major milestone for the company - reaffirming its long-term commitment to the city, its people and the energy sector.

Wood will continue to support Equinor's assets at the Mariner field

The new workspace has been designed to encourage collaboration, innovation and sustainability, reflecting Worley's forward-looking approach and deep industry roots.

As a company with a rich heritage in Aberdeen, we’re proud to be investing in the region’s future. This symbolises our continued commitment to our customers and the wider energy community.

Chris Behan, Vice President of Operations – Scotland, Worley

The energy capital of Europe, Aberdeen has long been a hub for expertise and innovation. As a global professional services company, Worley's continued presence in Aberdeen strengthens its role in shaping the future of the energy industry, supporting customers through the energy transition and delivering solutions across oil and gas, renewables and emerging technologies.

The new facility provides space for expanding teams and new projects, ensuring Worley is well positioned for future opportunities.

i For more information: www.worley.com

Social media round up

We want to use every opportunity to connect with our members, so please follow us on LinkedIn –EIC (Energy Industries Council)

Below you’ll find a selection of some of the exciting EIC activities and useful industry information we’ve shared through our social media channels.

EIC (Energy Industries Council)

EIC CEO Stuart R Broadley speaks with Dr Michaela Kendall, co-founder and CEO of Adelan – one of the UK's leading voices in hydrogen and fuel cell innovation: https://lnkd.in/dATDebW3

EIC (Energy Industries Council)

The first in a new series jointly produced by the EIC and Decom Mission, this report provides an overview of end-of-life activity across the UK and Europe: https://lnkd.in/eTBksbGh

EIC (Energy Industries Council)

Discover how solar, wind and hydrogen initiatives are positioning Chile as a leader in South America's energy transition. Watch the full session on EICTV: https://lnkd.in/d9gmUWD2

Events calendar LIVE events

3 November Business Presentation

ADIPEC Business Breakfast

Pearl Rotana Capital Centre, Abu Dhabi

3-6 November Overseas Exhibition

ADIPEC

4 November Overseas Exhibition

World Nuclear Exhibition (WNE) 2025

Paris Nord Villepinte

5 November Business Presentation

Europe's Nuclear Future: SMRs & AMRs

Innovation Breakfast, Paris

5 November Regional Showcase

Cross Industry Decommissioning Mapping the Future, Edition One: Europe Webinar

November Business Presentation

Gas Market Opportunities

Minas Gerais Breakfast with TAG and Actemium

EIC

EIC CONNECT UK & Ireland Energy Hotel Football, Old Trafford

November Business Presentation

Breakfast in Houston: Project Opportunities Houston with Subsea7 and Guardian Decommissioning

EIC Regional Awards 2025 Asia Pacific

November Overseas Delegation Overseas Delegation to Mozambique

EIC Breakfast: Opportunities with SLB

Cannon West Houston

INTERNATIONAL TRADE

EVENT LISTING 2025 | 2026

UK & EIC PAVILIONS AND DELEGATIONS

World Nuclear Exhibition (WNE) | Paris, France | UK & EIC Pavilion 4-6 November 2025

Trade Delegation to Mozambique | Delegation 24-27 November 2025

World Future Energy Summit (WFES) | Abu Dhabi, UAE | UK & EIC Pavilion 13-15 January 2026

Hyvolution | Paris, France| UK & EIC Pavilion 27-29 January 2026

Trade Delegation to Angola | Delegation 23-27 February 2026

Wind Expo Japan | Tokyo, Japan | UK & EIC Pavilion 17-19 March 2026

Trade Delegation to Chile | Delegation 9-13 March 2026

Trade Delegation to Guyana & Suriname | Delegation 13-17 April 2026

Offshore Technology Conference (OTC) | Houston, USA | UK & EIC Pavilion 4-7 May 2026

Trade Delegation to Nigeria | Delegation 11-15 May 2026

Trade Delegation to Egypt | Delegation 24-28 May 2026

INTERNATIONAL TRADE

EVENT LISTING 2026

UK & EIC PAVILIONS AND DELEGATIONS

OPES | Muscat, Oman | UK & EIC Pavilion 18-20 May 2026

Trade Delegation to Denmark & Norway | Delegation 1-5 June 2026

Beijing Energy Congress| Beijing, China | UK & EIC Pavilion 24-26 June 2026

ONS | Stavanger, Norway | UK & EIC Pavilion 24-27 August 2026

Oil & Gas Asia (OGA) | Kuala Lumpur, Malaysia | UK & EIC Pavilion 2-4 September 2026

ROG e | Rio de Janeiro, Brazil | UK & EIC Pavilion 21-24 September 2026

WindEnergy Hamburg | Hamburg, Germany | UK & EIC Pavilion 22-25 September 2026

Trade Delegation to Spain & Portugal | Delegation 5-9 October 2026

Hydrogen Technology Expo Europe | Hamburg, Germany | UK & EIC Pavilion October 2026

Please note that the list is not final If you think there are any events we should attend, please contact the team

EIC National Dinner 2025

Welcoming over 430 guests to a sell-out event and hosted by Matt Lucas, the evening celebrated excellence across 17 categories, highlighting outstanding achievements from across the UK and Europe within the energy sector supply chain. The journey to winning a WESCA begins each January, when members share their stories through Survive & Thrive. 140 companies featured in the 9th edition, before their success strategies were rigorously reviewed by a global expert judging panel. On behalf of EIC I extend our congratulations to each and every finalist and of course our winners – you should all be incredibly proud of your businesses achievements! Kim Stephen, Regional Director, UK

Photographs by Photographer London Ltd

Continental Europe

Regional update

The Continental Europe team continues to grow. We welcome Tunde Sebok to the team. Tunde is a highly experienced event producer and will immediately dive into the creation of our first EIC Europe events. More events in this new series are scheduled to take place next year.

Tunde Sebok

In addition to the exhibitions listed in the events calendar of this magazine, where the EIC is present with a dedicated booth, the Continental Europe team is planning to attend the following exhibitions in November in Europe and is very much looking forward to meeting with members of the EIC. Please get in touch to schedule a short meeting:

Sara Castiglioni

Business Development Manager, Southern Europe sara.castiglioni@the-eic.com

Tunde Sebok

Events & Office Co-ordinator tunde.sebok@the-eic.com

wwwRegional news

What is Nordex's secret?

Vestas' share price has been trending downwards over the last five years, although there have been signs of a slight recovery over the last 12 months. The shockwaves from the Ørsted scandal, triggered by the externally imposed construction freeze on the almost completed offshore wind farm off New York, have spread this far. Ørsted itself has not really recovered from the share price loss at the end of August 2023 and the construction freeze off the coast of New York, combined with the increase in share capital to secure liquidity, led to a 25% drop in the share price in a single day. In a press release Ørsted states to have received the order to stop all work on the project from the US Department of the Interior's Bureau of Ocean Energy Management (BOEM) on 22 August 2025, after having received the final federal approval from BOEM last year. The project is 80% complete with all offshore foundations installed and 45 out of 65 wind turbines installed.

And Nordex? It seems as if Nordex has been operating in a different market segment since at least the beginning of 2024, a segment that appears to be constantly on the rise. We sincerely hope that the currently struggling players in the wind industry will also recover sustainably and that, in future, they and the entire supply chain will benefit even more from reliable, stable and futureoriented framework conditions for the industry.

Money talk

In her 2025 State of the Union Address, the President of the European Commission von der Leyen emphasised energy independency through clean homegrown energy, the new initiative called Energy Highway and the identification of eight critical bottlenecks in the European energy infrastructure.

We welcome the recognition of the importance of reliable, safe and affordable energy and energy infrastructure and are very excited to see how the energy-related aspects will be translated into real actions and projects and we will stay on the ball to enable the participation of the supply chain and thus our members.

Middle East news

Regional update

As the year draws to a close, it was a privilege to celebrate excellence across the energy supply chain at the recent EIC regional awards ceremony, where we honoured the winners of the World Energy Supply Chain Awards (WESCAs) across nine outstanding categories. This annual event continues to grow in stature and it is always an honour to recognise such a diverse group of companies, from innovative SMEs to global giants each striving for excellence in their respective fields. The energy sector's resilience, creativity and ambition were on full display and it was truly inspiring to see so many organisations committed to driving the industry forward. Thank you to everyone who attended and sincere congratulations to all 24 finalists, with special recognition to this year's winners for their remarkable achievements. Applications for Survive & Thrive X will open soon and are open to all EIC members.

Just five spaces remain, don't miss this chance to showcase your solutions to 40,000+ key industry stakeholders. As we enter the final stretch of the year, now is the time to make the most of upcoming opportunities. The EIC team is here to support you every step of the way, whether through events, insights, or connections, please don’t hesitate to reach out.

Ryan McPherson

Regional Director, Middle East, Africa, Russia & CIS ryan.mcpherson@the-eic.com

Regional news

Syria: first crude export in 14 years marks revitalisation

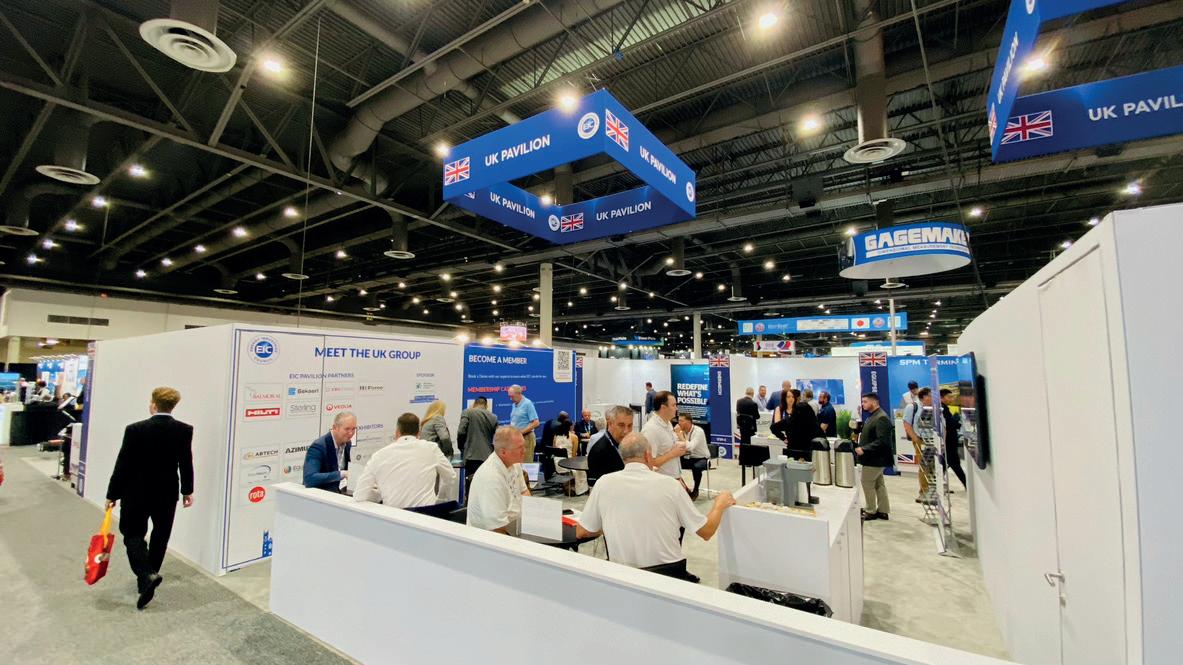

The beginning of this month will be marked by the return of ADIPEC 2025, the world's largest gathering for the energy sector. Once again, EIC is proud to host the UK pavilion, representing over 125 UK companies across Halls 8, 12, 15 and 17. The pavilion will serve as a platform for showcasing advanced technologies, forging strategic partnerships and facilitating high-level engagement across the entire energy sector. Our welcome breakfast, on 3 November, has reached full capacity for the second consecutive year which should prove to be a great way to kickstart the week. If you are attending the show please stop by and explore the UK pavilion, where exhibiting companies span the breadth of the sector, from engineering services and digital solutions to clean energy technologies and manufacturing.

Following the success of last month's sold-out Iraq business briefing with Wood, it's clear that interest in the Iraqi energy market is gaining real momentum. In response to this demand, we are actively exploring the opportunity to host a dedicated in-country event in 2026. If your company is interested in joining us on this exciting mission, we'd love to hear from you.

Our recent trade delegation to Namibia and South Africa was a resounding success, building strong foundations for companies in emerging markets. Building on this momentum, we will be leading follow-up delegations to Mozambique later this month and to Angola and Nigeria in 2026. For further details please contact: internationaltrade@the-eic.com

Looking ahead to the start of next year EIC is proud to lead the UK pavilion at WFES 2026 in Abu Dhabi, a global platform for clean energy and innovation.

Syria has resumed official crude exports for the first time in 14 years, signalling a potential return to the global energy stage. A shipment of 600,000 barrels of heavy crude departed from the port of Tartus under a new deal with B Serve Energy. This follows the lifting of US sanctions in mid-2025 and a shift in the country's diplomatic landscape after the removal of President Bashar al-Assad. With oil production and trade once again active, Syria is positioned to begin rebuilding its energy infrastructure.

KPC explores pipeline leasing to finance ambitious upgrade

Kuwait Petroleum Corporation (KPC) is considering leasing some of its existing pipelines as a means to raise capital for its US$65bn investment plan. The proposal is part of a broader strategy to unlock funding without raising additional debt, leveraging assets more efficiently. Lease arrangements could enable KPC to maintain ownership while securing long term income from such infrastructure. The plan is still under evaluation with details including lease terms, potential partners and regulatory frameworks expected to follow.

Forthcoming events

Please go to page 24 to see upcoming events around the world

Ryan McPherson

North and Central America news

Regional update

Reflecting on September, I had the opportunity to represent the EIC with my attendance at Gastech 2025. Held in Milan, Italy I had the honour of serving as a moderator for three sessions: The Future of Inclusion and Diversity Initiatives, Bridging the Green Talent and Digitalisation Gap to Prepare a New Skilled Workforce for Tomorrow, Reimagining Corporate Culture to Drive Inclusion in the Energy Workforce. During these sessions I was joined by fellow panellists: Stepanie Sirt, VP – Global Strategic Accounts, Scheider Electric; Tracy Lothian, Head – Asia Pacific & Global Low Carbon, MidOcean Energy; Patricia Lizarraga, Chief Investment Officer & Founder, Hypatia Women; Ilaria Catastini, Group Sustainability Head of Department & GM, Maire; Sandra Melki, VP –Sustainability, Technip Energies; Pablo Peris, Industry Advisor Manager – Energy Resources, Microsoft; Marco Sanchez, Chief Advisory Office & Board Member, Stellar Energy; Wendi Tao, Deputy Director – Natural Gas Trade Department, Shenzhen Energy Gas Investment Holding and Lameul Levels, Chief Diversity & Engagement Officer, Berkshire Hathaway Energy.

As the North and Central America region gathers to reflect on the season of gratitude, I want to extend our heartfelt thanks to you, our valued members and stakeholders, for your continued support over the last 30 years of the Houston office. This milestone is made possible by the incredible partnerships and trust our members have placed in us. I also want to thank the amazing EIC team for North and Central America, both past and present, as they have been instrumental in shaping our journey. Wishing you and your loved ones a joyful, restful and meaningful Thanksgiving.

Amanda Duhon

VP & Regional Director, North & Central America amanda.duhon@the-eic.com

Regional news

Canada introduces new biofuel production incentives

The prime minister has unveiled new measures to reinforce an industrial strategy aimed at countering US tariffs. Among these measures, the government plans to make targeted amendments to the clean fuel regulations (CFR) and introduce a two-year biofuel production incentive, providing more than CAD370m (US$270m) to support domestic renewable diesel and biodiesel producers and to help restructure their value chains.

The measure also seeks to offset China's 75.8% tariff on Canadian canola, a key feedstock for the sector. This incentive will be provided on a per-litre basis and will be available from January 2026 to December 2027 for up to 300m litres per facility.

AI boom leads to data centre state race for investment in US

The rapid expansion of cloud computing and artificial intelligence (AI) has triggered a surge in demand and investment for data centres across the US.

Successive announcements by tech giants Google, Microsoft, Amazon and Meta illustrate more intense competition among states of the federation, in that certain conditions – tax breaks, availability of renewable energy, reliable water supply, workforce readiness – are determinant to where money will be beyond Virginia. Research states data centres are projected to require US$6.7tn worldwide by 2030 to keep pace with the demand for compute power.

Forthcoming events

Please go to page 24 to see upcoming events around the world

Amanda Duhon

South America news

Regional update

EIC Rio is kicking off November in style with one of our most prestigious gatherings: the Gala Dinner – South America Regional Awards 2025. On 6 November, we'll come together to celebrate the remarkable accomplishments of industry leaders, with a special spotlight on the companies participating in Survive & Thrive 2025. Beyond an evening of recognition and celebration, the gala offers a prime opportunity to expand your network, connect with peers and explore fresh business possibilities – open to both EIC members and non-members alike.

The following week, on 13 November, our Breakfast in Rio series returns, featuring SBM Offshore and Baker Hughes, who will share insights into upcoming project opportunities. SBM Offshore has identified numerous opportunities in the near term in South America – especially Brazil, Guyana and Suriname. SBM Offshore has ordered its tenth MPF hull, guaranteeing the availability of two units for future tenders. Baker Hughes has recently secured another contract with Petrobras for the supply of around 77km of flexible pipes to be used in the Búzios, Mero, Berbigão, Sururu and Sépia fields, located in the Santos Basin.

Staatsolie offers flexible entry options in upcoming offshore bidding round

Suriname's state-owned energy company will launch an auction for open offshore blocks on 24 November 2025. Bidders will have the option of entering into a joint study agreement (JSA)/technical evaluation agreement (TEA), or a production sharing contract (PSC). Staatsolie has indicated that the final acreage boundaries may still be adjusted and will be confirmed at the launch.

This initiative forms part of a broader strategy to unlock further exploration and development opportunities while providing flexible entry options for international investors. Following the recent PSC signed with Petronas for Block 66, around 50% of Suriname's offshore acreage is now under contract.